2 minute read

Gare and handling of hardwood

by Jack Millikan Lane Stanton Vance Lumber Co. City of Industry, Ca.

n S HARDWOOD lumber becomes Au rote and more common sight in retail lumber operations, knowledge of its care and handling becomes more important.

While its handling is similar to shop and moulding softwoods in many ways, different handling methods are imperative to ensure minimal loss and downgrade. Awareness of the problems discussed below might assist in better hardwood merchandising.

Storage in lift loads - Kiln dried hardwood should be packed in random width layers, reasonably close together, oriented with one end stacked even and solid. Most lifts are random length, but care should be taken that single unsupported pieces on the random length end of the lift should be as few as possible.

Storage of lifts left to air dryOrientation is less important than sticking. Sticking with stickers of equal thickness is mandatory. Sticking every 12 to 18 inches is recommended for most hardwoods so it remains flat.

Storage stand-up bins While stand-up storage is nol recommended for hardwood, some retail stores must use their racks as they are. Three measures can be taken to care for the hardwood.

(l) If the floor of the rack is bare cement, cover the floor with plywood or some barrier to ensure no moisture transfers to the board end.

Story at a Glance

Tips on the care and handling of hardwood . . . storage in lift loads, stand-up bins, water damage possibilities, shipping, thickness factors . . . handling cost considerations.

(2) If ends are not square, square the boards or stack so that they stand up straight.

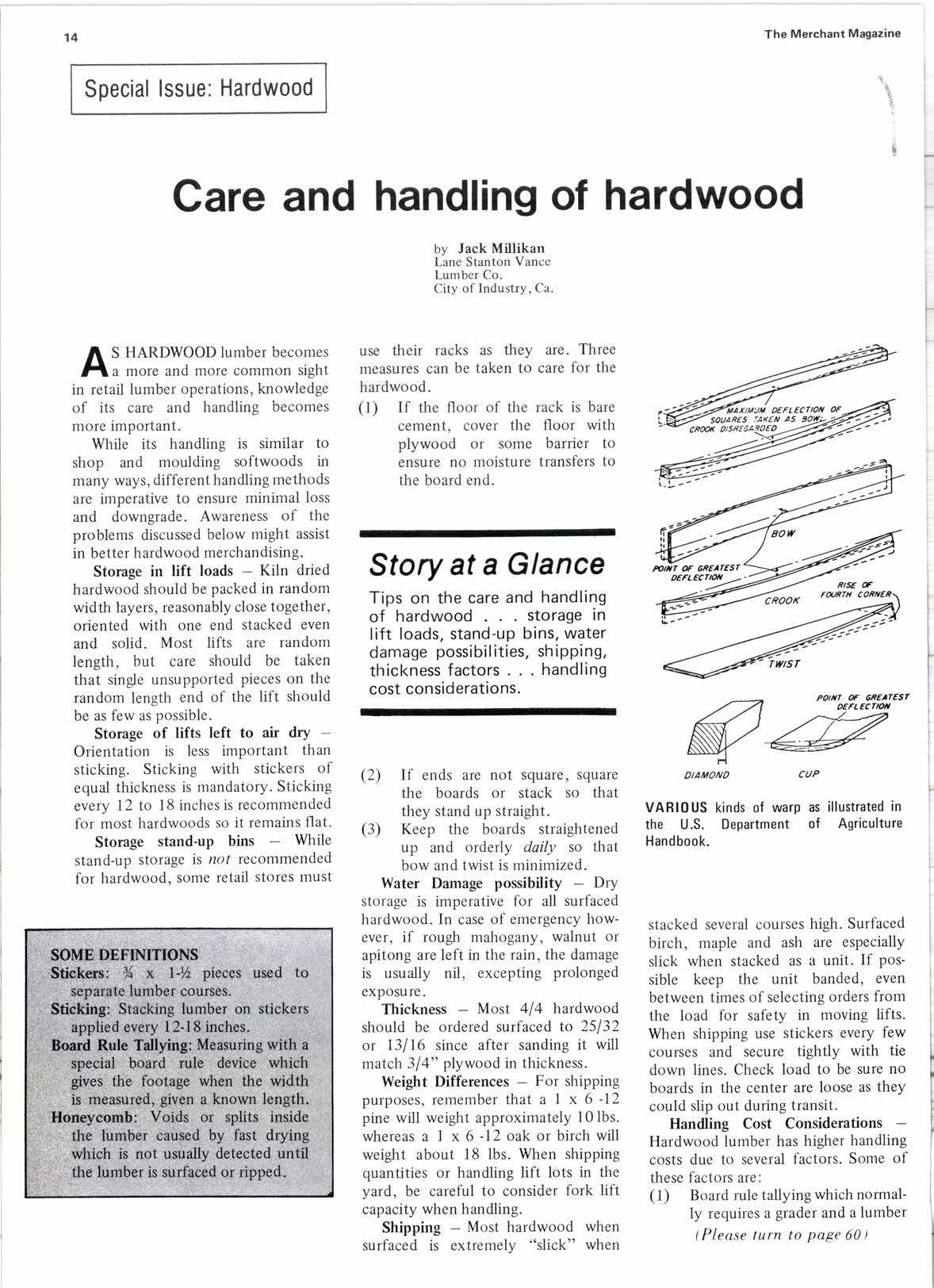

(3) Keep the boards straightened up and orderly daily so Ihat bow and twist is minimized.

Water Damage possibility - Dry storage is imperative for all surfaced hardwood. In case of emergency however, if rough mahogany, walnut or apitong are left in the rain, the damage is usually nil, excepting prolonged exposure.

Thickness - Most 4/4 hardwood should be ordered surfaced to 25132 or 13116 since after sanding it will match 314" plywood in thickness.

Weight DifferencesFor shipping purposes, remember that a 1 x 6 -12 pine will weight approximately l0lbs. whereas a I x 6 -12 oak or birch will weight about 18 lbs. When shipping quantities or handling lift lots in the yard, be careful to consider fork lift capacity when handling.

ShippingMost hardwood when surfaced is extremely "slick" when

VARI0US kinds of warp as illustrated in the U.S. Department of Agriculture Handbook. stacked several courses high. Surfaced birch, maple and ash are especiallY slick when stacked as a unit. If possible keep the unit banded, even between times of selecting orders from the load for safety in moving lifts. When shipping use stickers every few courses and secure tightly with tie down lines. Check load to be sure no boards in the center are loose as they could slip out during transit.

Handling Cost Considerations

Hardwood lumber has higher handling costs due to several factors. Some of these factors are:

(l) Board rule tallying which normally requires a grader and a lumber

(Please turn to page 60 )