6 minute read

Air dried redwood

I AST year. The Pacific Lumber

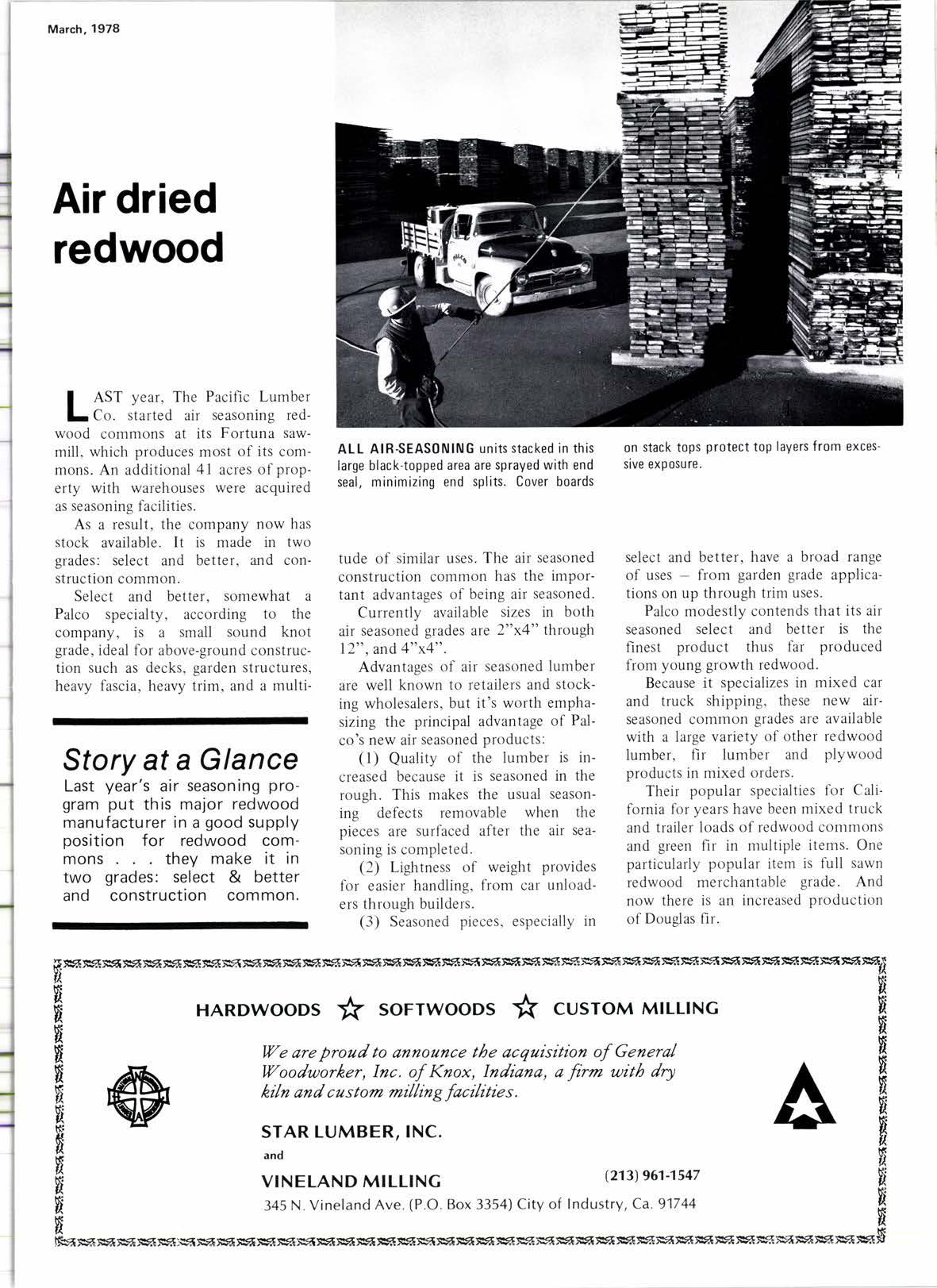

L Co. started air seasoning redwood commons at its Fortuna sawmill, which produces most of its commons. An additional 4l acres of property with warehouses were acquired as seasoning facilities.

As a result, the company now has stock available. It is made in two grades: select and better, and construction common.

Select and better, somewhat a Palco specialty, according to the company, is a small sound knot grade, ideal for above-ground construction such as decks, garden structures, heavy fascia, heavy trim, and a multi-

Story at a Glance

Last year's air seasoning program put this major redwood manufacturer in a good supply position for redwood commons they make it in two grades: select & better and construction common.

ALL tude of similar uses. The air seasoned construction common has the important advantages of being air seasoned.

Currently avallable sizes in both air seasoned grades are 2"x4" through 12", and 4"x4".

Advantages of air seasoned lumber are well known to retailers and stocking wholesalers, but it's worth emphasizing the principal advantage of Palco's new air seasoned products:

(1) Quality of the lumber is increased because it is seasoned in the rough. This makes the usual seasoning defects removable when the pieces are surfaced after the air seasoning is completed.

(2) Lightness of weight provides for easier handling, from car unloaders through builders.

(3) Seasoned pieces, especially in on stack tops protect top layers from excessive exposure. select and better, have a broad range of uses - from garden grade applications on up through trim uses.

Palco modestly contends that its air seasoned select and better is the finest product thus far produced from young growth redwood.

Because it specializes in mixed car and truck shipping, these new airseasoned common grades are available with a large variety of other redwood lumber, fir lumber and plywood products in mixed orders.

Their popular specialties for California for years have been mixed truck and trailer loads of redwood commons and green fir in multiple items. One particularly popular item is full sawn redwood merchantable grade. And now there is an increased production of Douelas fir.

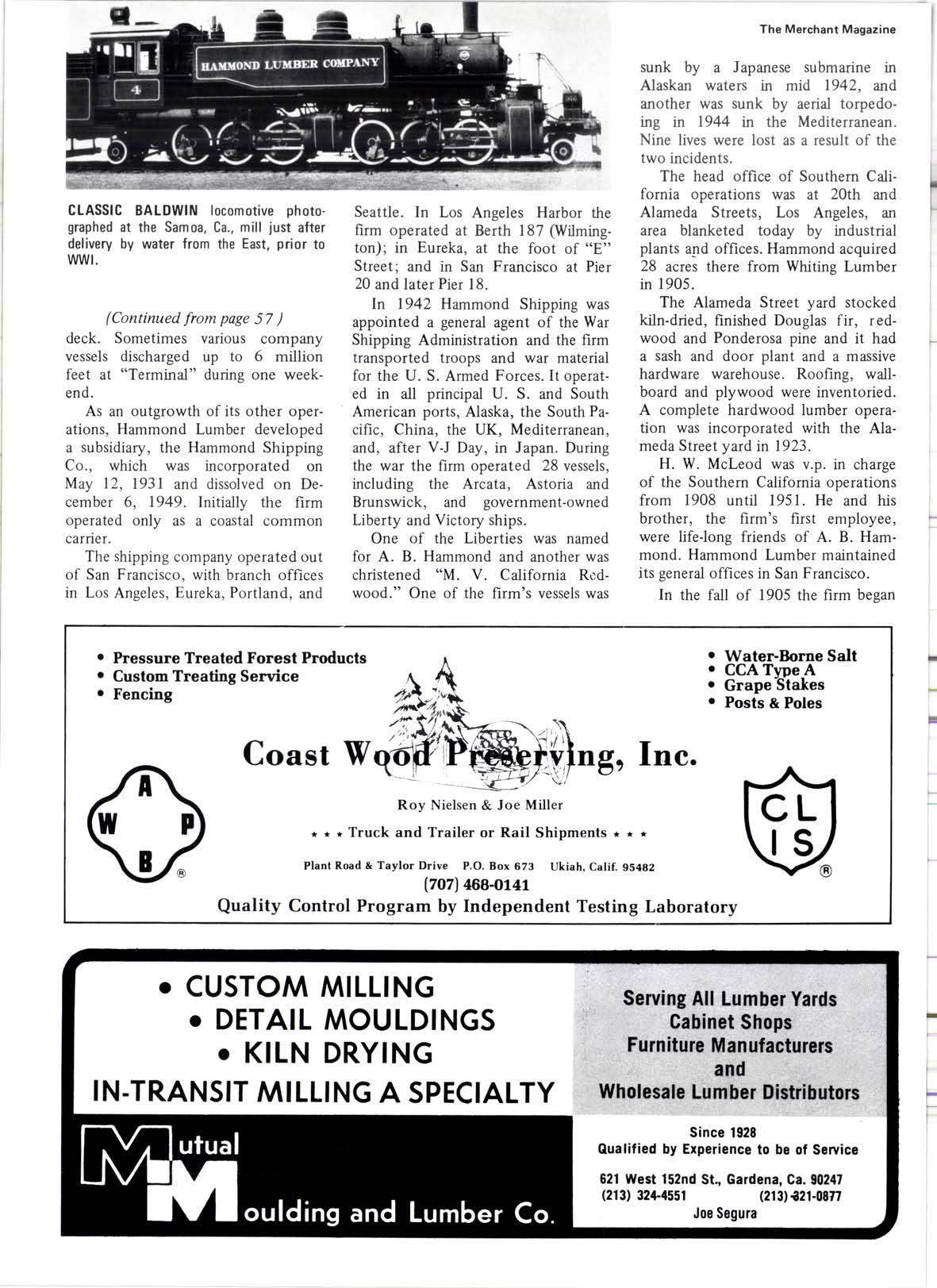

CtASSIC BAtDWIN locomotive photographed at the Samoa, Ca., mill iust after delivery by water from the East. prior to WWI.

(Continued from page 57 ) deck. Sometimes various company vessels discharged up to 6 million feet at "Terminal" during one weekend.

As an outgrowth of its other operations, Hammond Lumber developed a subsidiary, the Hammond Shipping Co., which was incorporated on May 12, 193 1 and dissolved on December 6, 1949. Initially the firm operated only as a coastal common carrier.

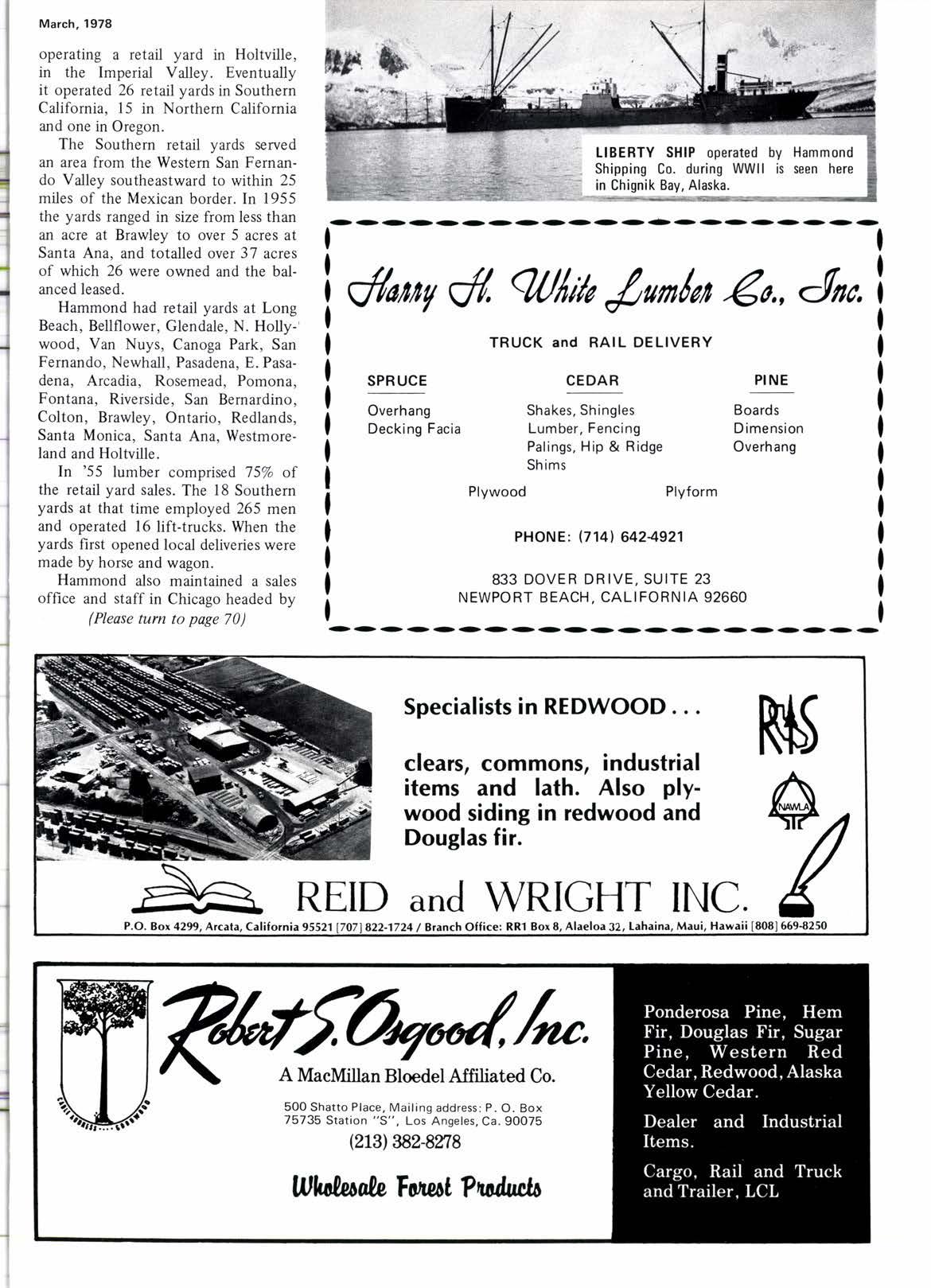

The shipping company operated out of San Francisco, with branch offices in Los Angeles, Eureka, Portland, and ln 1942 Hammond Shipping was appointed a general agent of the War Shipping Administration and the firm transported troops and war material for the U. S. Armed Forces. It operated in all principal U. S. and South American ports, Alaska, the South Pacific, China, the UK, Mediterranean, and, after V-J Day, in Japan. During the war the firm operated 28 vessels, including the Arcata, Astoria and Brunswick, and government-owned Liberty and Victory ships.

Seattle. In Los Angeles Harbor the firm operated at Berth 187 (Wilmington); in Eureka, at the foot of "E" Street: and in San Francisco at Pier 20 and later Pier 18.

One of the Liberties was named for A. B. Hammond and another was christened *M. V. California Rt:dwood." One of the firm's vessels was sunk by a Japanese submarine in Alaskan waters in mid 1942, and another was sunk by aerial torpedoing in 1944 n the Mediterranean. Nine lives were lost as a result of the two incidents.

The head office of Southern California operations was at 20th and Alameda Streets, Los Angeles, an area blanketed today by industrial plants and offices. Hammond acquired 28 acres there from Whiting Lumber in 1905.

The Alameda Street yard stocked kiln-dried, finished Douglas fir, redwood and Ponderosa pine and it had a sash and door plant and a massive hardware warehouse. Roofing, wallboard and plywood were inventoried. A complete hardwood lumber operation was incorporated with the Alameda Street yardin 1923.

H. W. Mcleod was v.p. in charge of the Southern California operations from 1908 until 1951. He and his brother, the firm's first employee, were lifelong friends of A. B. Hammond. Hammond Lumber maintained its general offices in San Francisco.

In the fall of 1905 the firm beean r operating a retail yard in Holtville, in the Imperial Valley. Eventually it operated 26 retall yards in Southern California. 15 in Northern California and one in Oregon.

The Southern retail yards sewed an area from the Western San Fernando Valley southeastward to within 25 miles of the Mexican border. In 1955 the yards ranged in size from less than an acre at Brawley to over 5 acres at Santa Ana, and totalled over 37 acres of which 26 were owned and the balanced leased.

Hammond had retail yards at Long Beach, Bellflower, Glendale, N. Hollywood, Van Nuys, Canoga Park, San Fernando, Newhall, Pasadena, E. Pasadena, Arcadia, Rosemead, Pomona, Fontana, Riverside, San Bernardino, Colton, Brawley, Ontario, Redlands, Santa Monica, Santa Ana, Westmoreland and Holtville.

In '55 lumber comprised 75% of the retail yard sales. The 18 Southern yards at that time employed 265 men and operated 16 lift-trucks. When the yards first opened local deliveries were made by horse and wagon.

Hammond also maintained a sales ofhce and staff in Chicago headed by (Please turn to page 70)

PHONE:

HAMMOND LUMBER

(Continued from page 69) was sales

John Klopfenstein. This office re.sponsible for promotion and East of The Rockies.

Naturally, Hammond Lumber Co. outlived its founder. A. B. Hammond died January 15, 1934 in San Francisco at the age of 85. As an old man he had piercing grey eyes and a white goatee that bobbed up and down as he o Poles and PostsSupports for every conceivable purpose. lf we don't have it, we'll make it. o Custom Pre-fabricationWe'll help you meet special proiect require' ments. Nearly any format, size or design, including drilling and cutting. o Custom TreatingWhether it's our lumber or yours, we use For spoke. His mind was strong until his hnal days.

From a simple business in stakes and poles over 40 years ago, we've become one of the West's most extensive treating sources. Today we're treating lumber for nearly any use that lumber is called for.

Despite his many and varied activities, Hammond found time to develop the cultural side of his life. He loved to commune in his library with the great masters of literature. One of his obituaries said. "Simple were his habits of life; his office door was never closed."

In 1936 his son, Leonard C. Hammond, became president of the firm.

He assured stock holders at that time cently described A. B. Hammond as that the company was again in the "self-reliant and courageous" and a hands of associates of his father. man "acquainted with physical labor and the value of a hard-earned dollar."

L. C. Hammond had served in the He was the last of a type and the sale Harjes Ambulance Corps., a volun- of his firm marked the end of an epoch. teer American unit attached to the Today a group of former Hammond French army, during World War I. employees still gathers twice a year for When the U.S. entered the war he be- lunch and a chance to socialize and came one of America's ace fighter reminisce over old times. As many as pilots. He was decorated with the 30 former Hammond men have been Distinguished Service Cross, Silver known to attend the informal lunchStar and the French Croix de Guerre eons in Southern California. Frank with two palms. He was educated at Bergstrom, of Plywood Los Angeles, Stanford University. is the unofficial leader of the group.

The younger Hammond died at 61 on December 2O, 1945. On May 5, 1956 a majority of the stockholders, including A. B. Hammond's four daughters, approved a plan for complete liquidation. On October 17, Georgia-Pacific Corp. paid $86 million for Hammond Lumber. G-P immediately liquidated the retail yards. The Alameda Street and Terminal Island yards closed the following spring. ln 1973 the Samoa mill became part of Louisiana-Pacific when L-P was spun-off from Georgia-Paciflc.

Dan Strite, a lumberman who worked nearly 40 years for Hammond, re-

CLEAR & CLEAR ALL.HEART

(Continued from page 12)

For more and more consumers, redwood lumber paneling is an investment in lasting quality, beauty and insulation unmatched by other paneling materials, including all other woods, according to the CRA. Outstanding dimensional stability, weatherability and redwood heartwood decayresistance ensure top perforrnance for the life of any building to which redwood lurnber is applied.

According to industrY studies, a third of all 1976 horne lerrtodclirrg projects involved wall paneling. Development of tough rtew polyurethane and alkyd resin coatillgs llow ensures redwood lurnber will pcItbrnr well even in kitchens artd bathroonts. Also r-ecottltttcllded arc l.l()llcorrosive hot-dipped galvanized, stairlless steel or alutuinuttt alloy rtails arld fastenings.

Besides renrodeling. new single alld multi-t'arnily builder ltorttcs ltc plirttc redwood markets; ntore atld lllore rrrodel homes use redwood lurttber paneling and siding to project quality with contenrporary style. A Class II flamespread rating lbr I -inch redwood lunrber (Uniforrn Building Code) also nrakes utrtreated redwood lutttber practical fbr institutional structures.

Redwood lunrber is also in demand for "garden" office contplexes. apartnlents. entertalnnlent centcrs, and fbr urban redevelopnrent and rehabs to break up city "ccrnent-scapes."

Redwood lurtrber dealers' paneling pronrotion that reflects nroderrl do-ityourself trends can be a ltlng-terrtt irtvestnrent in custonter loyalty und strong steady sales Ycar-rourtd.