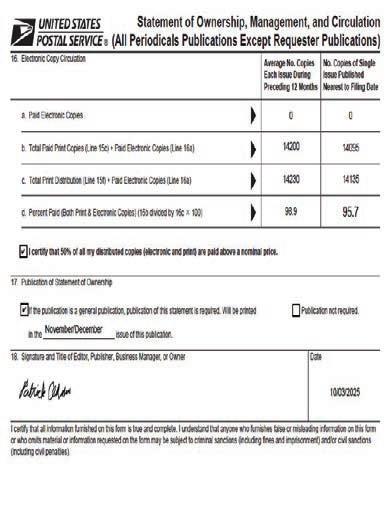

A publication of 526 Media Group, Inc. 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 Phone (714) 486-2735

President/Publisher Patrick Adams padams@526mediagroup.com

Vice President Shelly Smith Adams sadams@526mediagroup.com

Managing Editor Sara Graves sgraves@526mediagroup.com

Editorial Director David Koenig dkoenig@526mediagroup.com

Columnists

Brendan Casey, April Edwards, Andy Henley, Mike Mitchell, Bobby Parks

The ultimate publication for qualified industry decision makers!

•

• Update your subscription

•Sign up key colleagues

• Sign

• Enroll

•Enroll multiple locations T for qualified industry decision makers!

Advertising Sales (714) 486-2735

Chuck Casey ccasey@526mediagroup.com

John Haugh jhaugh@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

Digital Support

Katherine Williams kwilliams@526mediagroup.com

Circulation/Support info@526mediagroup.com

Change of Address Send address label from recent issue, new address, and 9-digit zip to address below.

POSTMASTER Send address changes to Deck Specialist, 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626. Deck Specialist (USPS 224) is published six times a year at 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Santa Ana, CA, and additional post offices. It is an independently-owned publication for U.S.-based builders and contractors that specialize in decking and other outdoor living projects. Copyright®2025 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

Nov./Dec. 2025 • Volume 9 • Number 6

& Strategies

From the Ground Up

Strong decks start with solid footings and framing

Hidden Fasteners

The quiet heroes of deck construction

Sturdy Substructures

ProWood strategist Grace Bilbrough discusses deck safety

The Wish List

Decks Elevated makes its homeowners’ wish list come true

A Ramp and a Miracle

Builders and manufacturers join forces to help a family in need

Lessons for the Future

The Solid Ground crew learns new lessons from a rotten wood deck

Stress-Free Service

Houston Deck and Shade have mastered the art of stress-free service

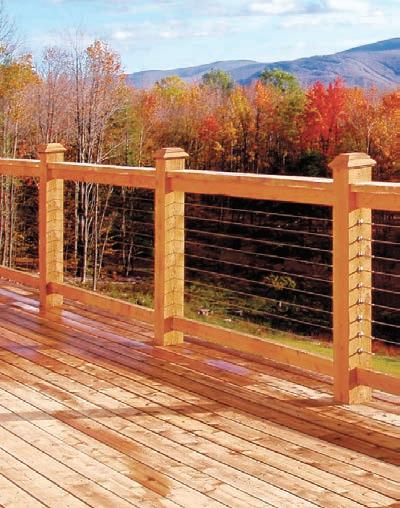

ON THE COVER: From rain-ready comfort to a hidden living space below, Decks Elevated turned a homeowner’s wish list into reality, and proved that true craftsmanship thrives both above and under the deck. Photo by Decks Elevated.

ALSO INSIDE

Editor’s Note

Industry News

Parks & Deck Creation with Bobby Parks

Set the Standard with Brendan Casey

Tool Reviews with Andy Henley and Mike Mitchell

Market Yourself with April Edwards

New Products

Date Planner

Ad Index

NADRA So. Cal. Event

In a world of “good enough,” real craftsmanship stands out. When you build with Deckorators®, you get materials that last longer and perform in every season. Backed by industry-leading warranties, our products ensure your work is built to last and built to be noticed. Learn more at deckorators.com.

ve always believed that most contractors want to do right by their customers. They want to build something solid, something they can stand behind. But a few weeks ago, my husband and I had an experience that reminded me that sometimes the real work isn’t in what a contractor builds, but in how they treat the people who hire them.

We signed a contract with a company for a bathroom project. We’ll call them Contractor123. At first, everything seemed routine. They introduced themselves, took photos, explained the process, and promised to send someone in three days to take measurements.

But later that night, off a hunch, we did an even-deeper dive into their reputation online. They had changed their company name to hide from their previous reviews.

I saw the same pattern in their older reviews: customers saying the company didn’t respond once contracts were signed, left projects undone, and questions unanswered.

The next morning, we cancelled the contract within our three-day window. We did everything by the book— emailed, called, faxed, but they never answered their phone or responded to our messages. Their fax machine and website were both supposedly “down” that day.

Contractor123 still sent a third person to take measurements two days later. They even tried to say they had ordered supplies for the job, yet no money was exchanged, and it was over the weekend.

The next day, a fourth representative came to the door. He seemed to be an owner of the company. He stood in our doorway, pressed us with questions about why we cancelled, and asked to reenter our home so he could give us a new estimate. When we refused, he asked to see our copy of their contract. He crossed out the contract details in pen, ripped the contract in fourths, and handed it back to us in pieces. He told us we weren’t acting “professional.”

How you handle your customers— even when they walk away—speaks louder than any portfolio ever could. Projects may not materialize, but your reputation follows you everywhere.

Sadly, it proved that the old reviews weren’t exaggerations. The company had lived up to its reputation. After he left, we were quick to post a “Buyer Beware” review on Yelp as a warning to other homeowners.

Here’s the truth: reputation is everything in this industry. Every interaction, every phone call returned (or not), every moment of respect or disrespect becomes part of the story people tell about you online and in their communities. That story can mean the difference between securing the next job or losing it before you even have the chance to bid.

Homeowners today have options. They do their research. They talk, they post, they share. And if they see a pattern of poor communication, corner-cutting, or pressure tactics, they’ll walk away.

Let this be a lesson. How you handle your customers— even when they walk away—speaks louder than any portfolio ever could. Projects may not materialize, but your reputation follows you everywhere.

Sara Graves is the managing editor of Deck Specialist. Reach her at sgraves@526mediagroup.com

Install Cortex screws with the FastenMaster PAMFast TM AutoFeed Tool for a faster #PerfectPlugInstall.

3X Faster Installation of Cortex screws with PAMFast

Stand-Up Application of Cortex screws without bending over No Predrilling Required in PVC or capped composite decking

Buy a PAMFast AutoFeed Tool & get FREE Cortex screws & plugs!

Advantage Lumber LLC has been designated the first certified cooperative partner of the International ThermoWood Association (ITWA) in the United States. This landmark achievement solidifies Advantage Lumber’s position as a leader in bringing innovative, sustainable, and high-performance wood products to the American market.

The ITWA officially welcomed Advantage Lumber LLC, stating: “The International ThermoWood Association (ITWA) welcomes Advantage Lumber LLC as a cooperative partner of the association. At the same time, Advantage Lumber LLC has become the first certified cooperative partner in the U.S. ITWA has now certified ThermoWood producers and cooperative partners in nine countries.”

Envision Outdoor Living Products, manufacturer of Envision composite decking and Fairway Railing collection, has a new distributor, Evansville, IN.–based Lensing Building Specialties. Lensing will sell the complete line of Envision composite decking as well as skirting and fasteners.

Envision also partnered with Genesee Reserve Supply who will sell Envision’s Distinction and Ridge Premium capped composite decking and vinyl railings through both of its locations in Rochester and Buffalo, N.Y.

New Castle Steel has expanded its strategic partnership with BlueLinx Corp. to bring New Castle’s American-made steel deck framing solutions to the Pacific Northwest and Midwest regions.

The new distribution partnership will serve customers through two strategic locations: Spokane, WA., covering Idaho, Western Montana, Washington, and Oregon; and Indianapolis, IN., covering Kentucky, Ohio, and Illinois.

BY SARA GRAVES

EVERY SOLID DECK BEGINS beneath the surface. For today’s builders, what happens under the deck—how it’s framed, supported, and waterproofed—can make or break the finished product. Across the country, pros are finding that the foundation work below the boards is where efficiency, strength, and creativity meet.

In Fredericksburg, MD., Brendan Casey builds in an area he calls “Fredrock,” where hard bluestone makes traditional footing work nearly impossible. “We can’t use helicals. What works for one area doesn’t work for another guy in a different area,” he says. Instead, he relies on critically treated posts designed to resist moisture for decades. “We dig the hole about 30” deep, add 12” of concrete, and set our posts on top of that concrete, then fill the hole halfway back up. We’re not worried about them getting wet or rotted out. We’re using a post designed to sit in fresh water for 25 years.”

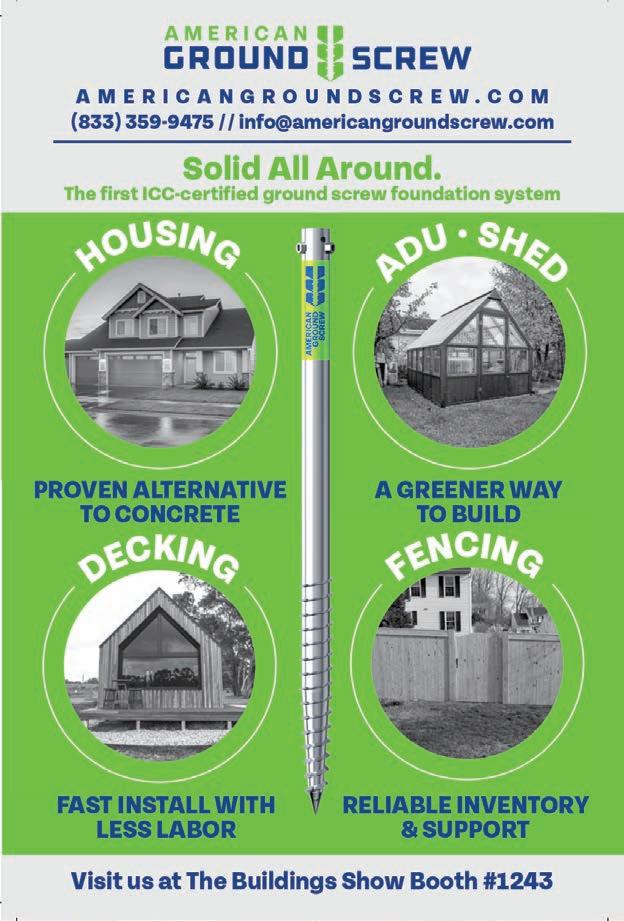

Levi Tippetts of TC Decks, Saratoga Springs, UT., takes a different approach, one that skips concrete altogether. “I’ve been using ground screws exclusively on all my decks for nearly five years now,” he says.

The rocky soil once made digging footings Tippetts’ least favorite task. Now, ground screws, notably those from American Ground Screw, have been a game changer for his workflow. “Ground screws are structurally solid, minimally invasive, and far less disruptive to the jobsite. I don’t have to worry about hitting sprinkler lines or buried cables, and in most cases the screws simply pass between or break through rocks.”

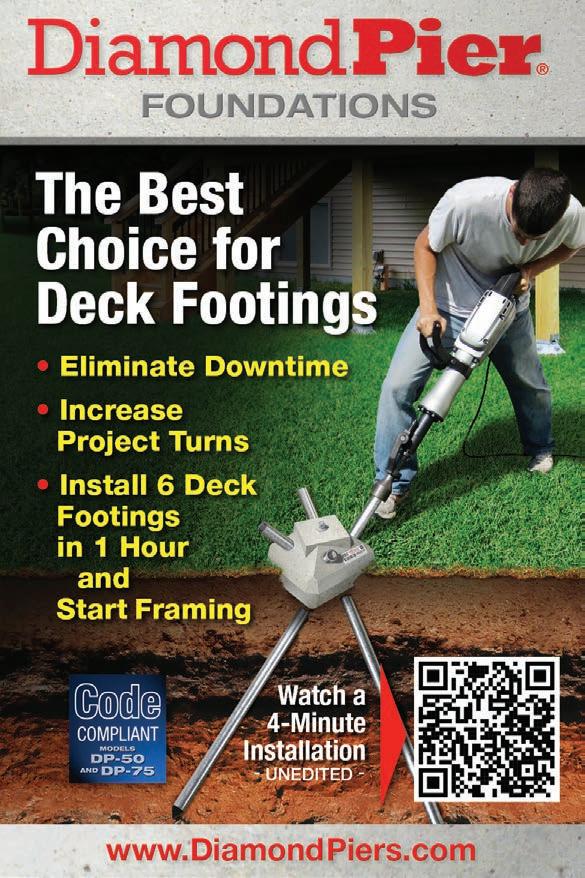

Diamond Pier Foundations deck footings are another popular choice among builders who are looking to save time when installing decks. Each pre-cast concrete head installs with four galvanized steel pins that transfer loads deep into surrounding soil. The system is ICC code compliant and lets builders install and start framing the same day.

In South Windsor, CT., Rob Pichette, owner of Deck Experts LLC, turns to helical piers to tackle challenging damp, sandy conditions. He prefers a 3” pipe with a 10” galvanized steel helical. “Our average pier depth is 6–7 ft., typically hitting hard rock. The more torque we apply, the stronger the helical pier. It’s a stronger, better pier than concrete.”

In areas prone to moisture, Pichette’s crew also regrades and installs crushed stone under the deck to improve drainage and avoid standing water. “You don’t want pools forming under a deck attracting mosquitoes,” he adds.

Precision framing starts long before the first board is laid. In Canada, Phillip Andrews, Andrews Decking Co., uses a custom-made steel triangle to ensure every deck begins perfectly square. “I took a bunch of angle iron and cut it to perfect 3-ft., 4-ft., and 5-ft. lengths and welded them together to make a giant triangle,” he says. The tool lets him hook one length along the ledger and the adjacent length along a joist to square up frames quickly. “It’s also very helpful in footing locations because I can lay it tight to the foundation of the home and run a string line out from it, or a long, straight edge, and get my footing locations squared as well,” he explains.

Speed and accuracy of framing are also important to Clint Webb of Webb Decks, Godfrey, IL. He uses what he calls “ghost framing” to temporarily assemble the entire deck frame before pouring the concrete piers. “With ghost framing, the inspector can check the entire frame, including hangers, fasteners, and connections, at the same time they inspect pier depth,” Webb says. The result is fewer delays and faster project turnaround.

While framing and footing innovations take center stage for many builders, waterproofing plays an equally critical role, notes Kevin Choquette of Ravin Builders, Wood River Junction, R.I. He relies on a layered Nichigo G-Tape and EPDM double-sided tape-layering system that “creates a continuous, flexible, and serviceable barrier that works with, not against, the structure.” The double-sided tape provides the primary adhesion that enables Choquette’s crew to shingle the EPDM rubber so water is always directed in the right path. The G-Tape finish seals and protects the edges, preventing uplift or creep over time.

Together, these techniques reveal a shared truth among builders: what lies under a deck defines what lasts above it. From Fredrock’s bluestone to Utah’s bedrock, today’s deck builders are rethinking every inch of the deck from the ground up. DS

BY SARA GRAVES

THE STABILITY OF ANY DECK begins below the surface. While boards, railings, and lighting capture attention, the integrity of the structure depends on how it’s fastened together. For builders focused on longevity and clean craftsmanship, hidden fasteners have become the quiet heroes of modern deck construction.

Tana Mallory, president and owner of Three 60 Decks, which serves Southwest Washington and the Portland metro area, says hidden systems are no longer optional. “From a professional standpoint, hidden fasteners are considered an integral component of quality composite decking installations. They offer a more refined and seamless appearance compared to visible screws on the surface of each board.”

She points out that hidden fasteners benefit the frame below and can save builders upwards of 30% in installation time. “Attaching screws through the top face of the wrapped board is more challenging due to drilling requirements,” explains Mallory. “This method also requires careful attention to screw placement for alignment.” In contrast, she says, clips are attached to the side of the board above the joist, making installation straightforward and efficient.

Beyond performance, Mallory says hidden fasteners also convey value to clients and show expertise in composite installation. “We highlight the smooth surface for bare feet, the protection from water intrusion coming from multiple holes on the deck surface, and the overall aesthetic look.”

In Northern Utah, Levi Koehler, founder and CEO of B & B Customs, sees similar advantages in using hidden fasteners. “Hidden fasteners have become an essential part of modern deck building because they create a cleaner look, improve safety, and help extend the life of the deck,” he says.

Koehler estimates he saves about 20–30% on installation time compared to face-screwing. He recalls one project where installing clips made all the difference. “The clips slid right into place and locked down without us having to stop and measure or pre-drill every board. It sped things up so much that we finished the decking almost a full day earlier than planned.”

There are structural advantages as well, Koehler notes. “It keeps every deck board evenly spaced, adds to the overall longevity of the deck, and leaves very little room for error during installation,” he says. “Over time, this not only improves the appearance but also helps the structure hold up better against wear and weather.”

For Clint Webb, Webb Decks, Godfrey, IL., using a combination of the CAMO Universal Deck Clips with the ClipDRIVE stand-up drive gun, and the deck clamp adapters manufactured by Jeremy Wilkins (Deck Master J) in Greenville, S.C., has been “one of the biggest advances in deck building.”

Webb’s experience underscores how the right tools and hardware can improve efficiency on the job. That same attention to detail, says Roderick Kabel of DeckWise, is just as critical when choosing which fasteners to use. “Every decking material, whether exotic hardwood, thermally modified wood, composite, or projects built on wood versus steel joists, demands hardware engineered for performance. Cheap may be tempting, but it never lasts,” he says.

For Koehler, the takeaway is simple: “If your goal is to save time, reduce costs, and deliver high-quality, professional-looking decks, switching to hidden fasteners is an obvious choice.” DS

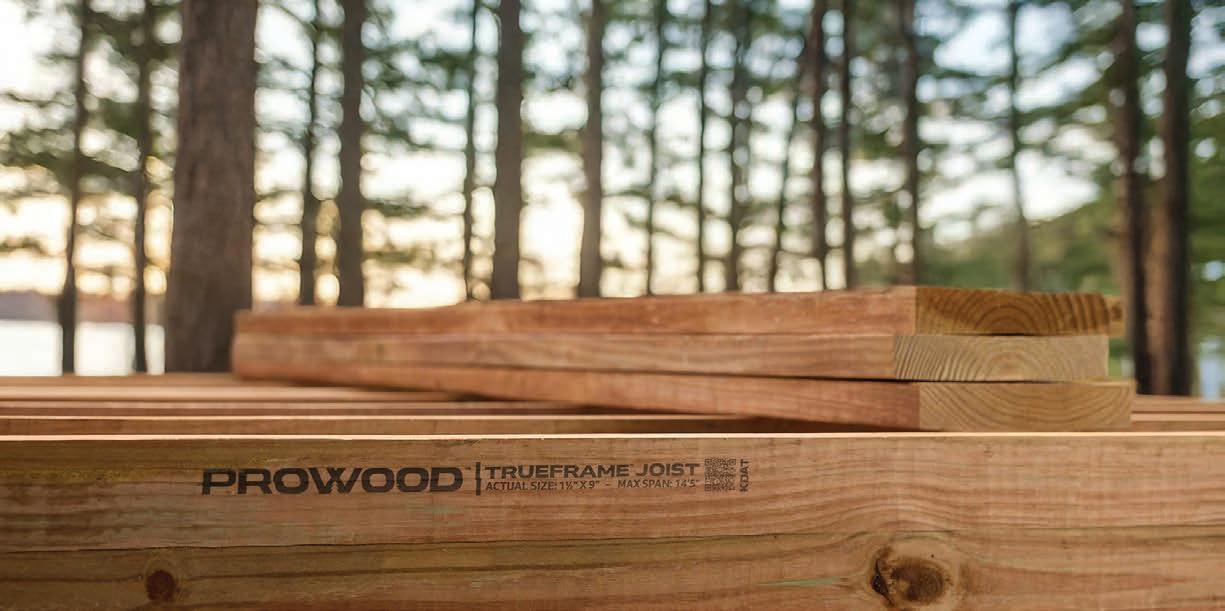

BY GRACE BILBROUGH, PROWOOD

DECK SAFETY STARTS with building a strong structure underneath, ensuring that the components hidden under the deck boards are durable and stand up to outside threats like rot, infestation, and moisture. If any of these pieces are compromised, it can lead to a structural failure that makes the entire deck unsafe. To avoid such issues, trade professionals need to be armed with the knowledge of what goes into creating a sturdy substructure and how each part works together to support a long-lasting deck.

Pressure-treated wood is a leading material choice for substructure, offering dependable performance for a wide range of regional conditions while remaining cost-effective. At ProWood, we utilize micronized copper azole treatment, which helps extend the wood’s life span by decades without the use of toxic metals like arsenic and chromium. It’s equally important to select treated lumber that meets the correct standards for its intended use. Failing to do so could void the warranty and undermine performance.

For most projects, ground contact wood is the go-to option for anything situated under the deck, as it’s required by the AWPA to retain a higher content of the preservative

than above ground products, protecting better against wear and erosion. For builds exposed to extreme temperatures, elevated moisture levels, or bodies of water, critical structure/heavy-duty lumber provides an even greater preservative content to protect the wood. Don’t forget to factor lumber grades into your decision-making. #1 Grade, which provides the best appearance and strength with fewer and smaller knots, is the recommended choice for substructure.

Most residential decks sit on either footings or pier blocks set at or below ground level. These bases create the deck’s foundation and are commonly made from concrete, though highly durable plastics and composites are also options. For elevated decks, footings buried below the frost line are the

way to go. For freestanding projects that are relatively low to the ground, pier blocks are an effective choice.

Above the foundation is where framing components, such as posts, beams, and joists, come into play. These products form the “skeleton” that keeps the deck structurally sound. It’s important to cut materials accurately, space them to code, and choose products built and treated for long-term exposure. Joists act as the top level of the frame, carrying the weight of the deck boards and anything that sits above them. To enhance stability and ensure even weight distribution, builders should include proper joist blocking and spacing during installation. Beams sit under the joists, running perpendicular to transfer the deck’s weight down to the posts and ground level.

If a deck is being built next to the property, the ledger board plays the critical role of attaching the deck to the

resistance with copper-based preservatives.

Having built a strong frame and foundation for the deck, additional accessories and protective measures can also serve to improve its longevity. Applying joist/ deck tape is an easy and affordable way to add further defense to the substructure, as it protects the wood with a waterproof membrane. Butyl tape is widely considered the best material for this, as it offers high performance and excellent adhesion. Drainage systems are another way to protect these structures from moisture by employing a network of troughs and gutters to divert water away from the deck.

Mastering this ecosystem of components empowers builders to assemble dependable substructures, which is key to delivering safe projects that instill homeowner confidence and result in fewer callbacks. Contractors are

with Decks Elevated owner Nick Rukamp, they came prepared with a wish list. It wasn’t just about building a deck; it was about creating a retreat that felt like a true extension of their home. Each request, from wide-open spans to a quiet reading nook, became a line item to be checked off.

At the top of the list was protection from the elements: the ability to sit outside during a rainstorm. Next was openness, with unobstructed views that made the room feel large and welcoming. Then came entertainment—a surround sound system for movies and sporting events, with music to fill the space when friends gathered. The homeowners also wished for a cozy daybed nook to escape with a book and the privacy to enjoy it without distraction.

Within a week of the initial design consultation, Rukamp presented 3-D renderings showing how their wish list would look when built. After minor revisions to meet city restrictions and final permit approvals, the project went onto the production calendar. Construction began in July, and just three weeks later—in early August—the finished retreat stood ready for use.

Rukamp says how the details came together is what made this project stand out. “I’ve had the privilege of working on some incredible projects over the last 16 years, but a few key points that made this project special included the size and clear spans between supports,” said Rukamp.

The 16-ft.-deep by 24-ft.-wide room, supported with LVL beams and only two posts, delivered a vaulted ceiling that felt “open and grandiose,” he says. That, and the standard TV wall that was elevated with custom trim, transforming it into a focal point. “We were able to take a very standard TV wall and give it visual interest to complement the rest of the space,” he adds.

Every product was chosen to match the clients’ low-maintenance lifestyle and withstand Minnesota’s dramatic climate shifts. Techno Metal Post helical piers anchored the foundation. The 528 sq. ft. of Trex Enhance decking paired with Trex RainEscape, ensures the space below stays dry and usable. Palram PVC trim wraps the porch in clean, durable lines.

BY SARA GRAVES

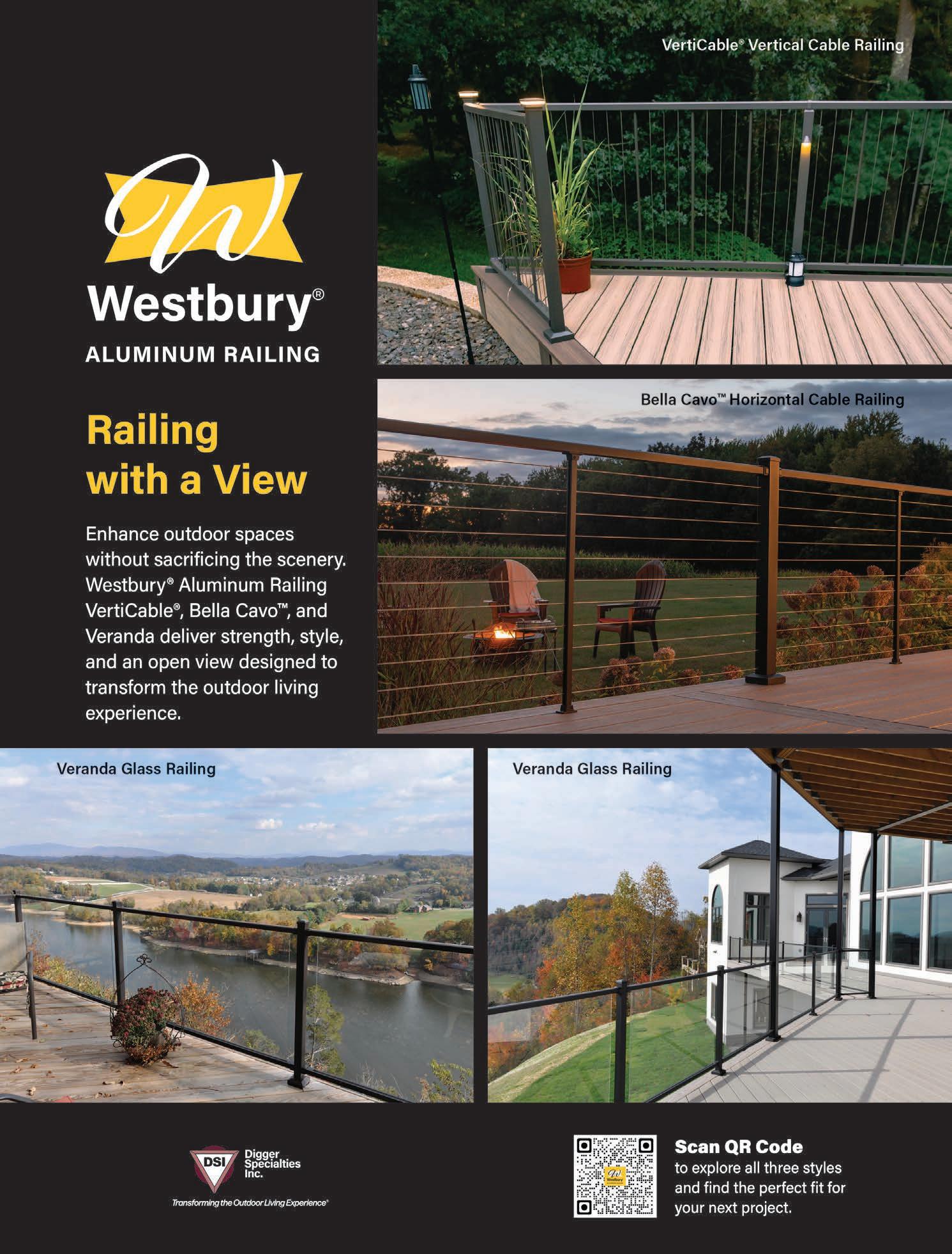

To preserve views, 118 linear ft. of Westbury Veranda aluminum railing with glass panels opens sightlines into the yard and lake. Rustic cedar beams across the vaulted ceiling bring warmth and character, while Sonance outdoor speakers and an outdoor-rated television checked off the entertainment portion of the list.

Decks Elevated collaborated with other contractors to install the electricity for the 12 can lights, nine outlets, 22 low voltage lights, and eight Sonance outdoor speakers. They also coordinated with a concrete company installing the color stamped concrete patio and drain tile to carry water away from the house.

Near the end, one wish nearly proved too big: installing 12-ft.-wide by 5-ft.-tall glass panels 22 ft. above ground in the gable wall. The panels were massive, heavy, and fragile, hard to maneuver into place, and nearly impossible to set without perfect alignment.

Scaffolding was built, and the Wayzata, MN.based crew carefully choreographed each step. With steady planning and six sets of hands working in sync, the glass was raised, balanced, and inched into position. Only when the final panel clicked into place could the crew check off that last, hardest box.

By the time the Twins Cities Metro retreat was finished, every item on the homeowners’ wish list had been fulfilled. From vaulted ceilings to custom trim, from surround sound to private corners, nothing had been overlooked.

The clients expressed their satisfaction in unmistakable terms: “Our family couldn’t be happier with the professionalism, communication and expertise that Decks Elevated provided us. If I could give this company 25 stars, I would!”

For Rukamp, that kind of praise is the ultimate box to check. Sixteen years of experience, a clear process, and a focused four-person crew had once again turned a handwritten list of hopes into a living reality.

“I believe the secret to creating an incredible outdoor space is making it feel like an extension of your home, inviting and comfortable, yet designed with purpose and function,” he adds. “This means weighing trends against timelessness and pairing distinctive materials with expert craftsmanship.” DS

BY DAN PETTIT, NORTHERN OUTDOOR LIVING

ON FRIDAY, JULY 11, MY PHONE RANG with a call that would reshape the meaning of community for me. The voice on the other end was a father-in-law, desperate yet determined. His 28-year-old son-inlaw, Baylor, a young husband and father of two small children, had been paralyzed from the chest down after a devastating work accident. Doctors were preparing to send him home after a nearly two-month stay in the hospital, but there was one enormous obstacle— without a wheelchair ramp, he couldn’t even get inside his house. There was no time to plan, no time to hesitate. Just a call to action—and an overwhelming feeling that I was meant to help.

Answering the Call Summer is the busiest me of year in construction, but I knew there was no other choice. I committed on the

spot, even though my wife knew the family, but I had never met them.

What happened next restored my faith in human goodness and the power of trade professionals rallying around one cause.

Within hours, I started calling every manufacturer, contact, and supplier I knew. “Would you partner with me on a charity ramp build?” I asked. The responses were immediate—and humbling.

In the four days leading up to the build, NCP Industries stepped up first, donating nine Handi Pier footings without hesitation. Deckorators joined in, supplying aluminum railings. In-lite offered to crown the deck with custom garden and deck lighting, a symbolic gesture that seemed to say: there’s still light ahead.

Then came the call that truly floored me. Casey Ingle from OC Lumber assured me that all the framing and

decking materials could and would be taken care of! “We’ve got you!” he said— and he meant it.

But Casey didn’t stop there. He sent a blast email to his nationwide OC Pro Build team, calling for volunteers. And within hours, two professional crews— Built Right Inc., a construction company from Fargo, N.D., and Deck Van Gogh, a decking company from Greenville, S.C., committed to traveling to help the cause for this family they didn’t even know.

The build began Friday night after my regular workday. Tim (Baylor’s father inlaw) and Chad (Baylor’s father) and I stayed late, setting all the deck footings. By Saturday morning, layout and ledger prep were underway when a truck, that had been hand loaded by Casey himself the day before, rolled up to the site. We all got to work unloading the framing and decking from OC.

Deck Van Gogh landed and got to the site around 3 p.m. We worked together until nearly 10:30 p.m. Our headlamps and jobsite flashlights gave us an extra hour from sundown.

The next morning we were greeted by an Uber Eats drop off that contained hot breakfast sandwiches, a growler of cold brew coffee, two cartons of hot coffee, some Monsters, Gatorades, and plenty of water. What a morning kickoff!

Around midday, Built Right arrived, and the productivity doubled. By nightfall, flashlights were being held up by one team while the other made final cuts by lamplight. No one complained. No one quit. We were all racing toward the finish line of our mission: getting this young man into his home.

By Monday and Tuesday, the railings were installed, and a feathered, seamless concrete taper from the deck to the driveway was created. My family even came in to help plug the screw holes.

Wednesday finally arrived... and so did Baylor.

Even after he got home, I found others who wanted to give what they could. Elegant Landscapes, a local contractor, donated mulch, edging, and plants to turn the ramp’s surroundings into a peaceful garden space. Even Done Right Dumpsters provided waste management free of charge, ensuring this family wouldn’t shoulder a single burden from the build.

What began as one desperate phone call, became a symphony of generosity. Every person who picked up a hammer, shipped a product, or simply showed up brought something intangible: human decency in its purest form.

Many times during and after this experience, I have spoken to the people involved in this effort and reminisce on how amazing and incredibly it was to come together as it did. This campaign brought Fargo and South Carolina and a little corner of Minnesota together. It is proof that in a world that can feel divided, there are still countless hands ready to lift someone up. DS

BY SARA GRAVES

FOR TOMMY HOLSTEIN AND THE CREW of Solid Ground, their recent O’Fallon, MO., project wasn’t just about replacing what was lost. It was about learning from the process at every stage, from uncovering oversized piers beneath the slab to experimenting with new steel stair stringers. It all began with a rotted wood deck.

“The homeowner had a failing wood deck with rot that was causing significant rot to the home,” says Holstein, chief development officer for Wentzille, MO.based Solid Ground.

“The old deck was a massive piece of the very secluded yard,” adds crew leader Griffin Rock, noting the rarity of two-story decks in the area. “It was incredibly clear they needed a replacement space to safely enjoy the privacy of living in the woods surrounded by nature.

The team had to use the existing deck’s piers to avoid damaging the patio area. They first obtained the original plans for the home and deck, which showed oversized concrete piers, even by today’s code. After examining the plans closely, the engineering proved that they were able to reuse the existing piers.

Post placement demanded extra care. Rather than

setting them on the concrete slab, Rock painstakingly cut perfect circles to gain access to the original piers below grade. “Griff could have cut square blocks out, but instead carved out a perfect footprint for our 10”-diameter base plates to set in,” Holstein says.

Holstein adds that the detail ensured the deck’s longterm integrity. “Should the clients ever need or want to replace the patio, the structural integrity of their deck will remain intact. It’s a detail that many might overlook, and some may not think is worth the extra effort. It was the right move.”

Even with solid piers beneath, elevation added another challenge. The greatest, Holstein says, was overcoming the spans and loads. The original deck was built back in the ’90s “when wood was strong and spans were much greater than what can be spanned with today’s lumber.”

Setting the upper-level beams was no easy task. There’s nearly 20’ to the second-story frame, so staging was crucial, Rock says. The three-man crew built one frame at a time, creating a path to the next level. They set the posts, “stopped looking down,” and

climbed the ladders with a couple of 20’ New Castle Steel double beams—a task Rock called the project’s “biggest workout.”

To ensure longevity, the crew opted for New Castle Steel deck framing. “In our market we are lucky to see a wood-framed composite deck last 10 years,” Holstein explains. With steel framing, the crew could carry heavier loads and maintain an open flow. That allowed them to eliminate several posts from the original design and expand the decks. They also cantilevered one side by 4’, widened the upper and lower decks by 2’, and corrected inefficiencies in the original build and design, Holstein notes.

For the finish, the steel frame was wrapped in Deckorators Voyage Sedona 5.5” deck boards, with a 7.25” Sedona picture frame encasing the space. A Sedona fascia was cut down to create a stepped fascia look.

The crew used the CAMO ClipDrive hidden fastener system paired with the Lever tool, aligning deck boards in half the usual time, Holstein says.

“While the multiple levels are fun,” Rock says, “the stairs are what always feel the most satisfying, especially when there’s what feels like a million ladder rungs to the top.”

The finished stairs featured New Castle pre-fabricated stair stringers wrapped in a mitered 5.5” Deckorators

Sedona picture frame on the treads, Sedona 7.25” risers, custom-cut Sedona fascia, and continuous textured black Westbury aluminum rail.

The project gave the crew a chance to test details they’ll carry into future builds, notably the stepped-style fascia and pre-fabricated stair stringers. Rock says the stringers alone saved at least a day of build time on a staircase that size.

“Every build is completely custom, which means that every build has something new to teach us,” Rock reflects. DS

BY SARA GRAVES

LOREN GOODRICH STARTED Houston Deck and Shade at 19 years old with a beat-up pickup truck and some ragged-out tools, his vision was never solely about finished decks. From the beginning, his goal has been to restore dignity to the trades by creating a company culture where both customers and employees feel valued. More than 15 years later, Houston Deck and Shade has become known throughout the Houston metro area for doing exactly that—delivering stress-free projects for clients while building a workplace where people want to stay.

The company builds more than 150 projects annually, ranging from backyard decks to commercial boardwalks, supported by three crews and roughly 20 employees. Houston Deck and Shade does not hire subcontractors and has less than a 4% tardy/no show rate. Goodrich explains. “I’m building my business for generations. I don’t want to be a flash in the pan.”

Houston Deck and Shade’s hiring, training, and—very rarely—firing are driven by three core values: show up, play hard, and win together. Crews are known for arriving on time, respecting client properties, and maintaining job sites with care. This enables the company to accomplish its purpose of protecting its customers from misinformed, uneducated, and downright unscrupulous contractors with the guarantee to make it right. Goodrich

adds, “Every nail, every board that goes down has my name attached to it (figuratively).”

To help its employees be successful, Houston Deck and Shade offers its employees retirement plans with company matching and encourages financial literacy for its employees. Goodrich says they make sure the employees have a stable home life so if they need to be at that opening day for their kids’ kindergarten class, “they make it happen for them.”

Goodrich emphasizes that quality craftsmanship is only part of the equation. He stresses that contractors can build a beautiful deck, but if they don’t respect the property and its occupants, they won’t receive referrals. “A lot of craftsmen are great craftsmen, but they don’t understand that when I take my shirt off and I wear tattered old pants in somebody’s backyard, and I drive my beat up pickup truck, leak oil all over the driveway and I put ‘donkey trails’ (trails left on grass when you walk repeatedly in the same path) all through the backyard that what you left behind was a bad taste.”

To prevent this, his teams take extra steps to create a stress-free experience with superior service: laying temporary walkways across lawns, cleaning up daily, and ensuring vehicles aren’t parked in the driveway blocking the homeowner from leaving.

While Houston Deck and Shade is best known for residential decks, pergolas, and pavilions, commercial projects have become a growing focus. In the past, the company has worked with high-end landscape architects and taken on neighborhood amenity packages, college installations, and large-scale walkways.

More recently, the company is in the process of building a 5,333-sq.-ft. boardwalk at NASA’s Johnson Space Center. As a Trex Platinum builder, Goodrich opted for curved Trex picture-frame borders, premium Trex Select boards in Malted Barley and Millstone, chosen specifically for Trex’s Sun Comfortable technology. The decking was installed over 250 footings. The company bought a Toro TRX 427 Dingo compact utility loader at auction to help the crews dig the 16” holes 48” deep holes to hold the 6x6 wood posts that were embedded into concrete.

Goodrich recalls the surprise of receiving the initial call. “It almost felt like a prank,” he admits. But Houston Deck and Shade landed the contract because “it was the only local contractor (in the area) with employees who could pass the federal background checks required for a government facility,” he says.

The NASA build is not only the company’s largest project by square footage to date, but also a milestone in proving its ability to handle complex, high-profile commercial jobs.

In 2021, Houston Deck and Shade expanded further by opening Loren’s Lumber LLC, its own retail lumberyard and supply house next door. The idea came during the COVID-19 pandemic, when skyrocketing material prices and delays created chaos for builders. Goodrich began ordering materials as soon as jobs were booked and storing them on-site. Before long, he realized he was doing the work of a supplier without the benefit of wholesale pricing.

The solution was to launch a full-service yard. Today, Loren’s Lumber supplies Houston Deck and Shade and retail customers, providing a steady flow of materials and additional revenue stream. The dual operation reflects Goodrich’s long-term strategy: “to weather huge financial downturns and come out the other side.”

Goodrich has intentionally stepped away from dayto-day building to focus on sales, leadership, and vision. “I haven’t built a deck myself in about eight years,” he says. Instead, he relies on his team, including James Fitzgerald, who has been with the company for 10 years as operations and project manager; Bonnie Hambrick, office manager, who has been with the company for eight years; Aaron Millican, junior sales rep; and James “J.D.” Choate, a versatile team player who splits his time between maintenance work and commercial deliveries.

OWNER: Loren Goodrich

SERVICE AREA: Houston metro and outside the city

SPECIALTY: High-end residential and commercial with Trex decking

FOUNDED: 2009

FACEBOOK: Houston Deck and Shade

INSTAGRAM: Loren Allen Goodrich

WEBSITE: houstondeckandshade.com

His leadership advice for others in the trade is straightforward: Be a reader. He says a lot of tradesmen are too busy working on their businesses and not in their businesses. “Get off your tools and work on your business,” he advises. He also encourages contractors to invest in professionalism. “Keep your beard tamed, tuck in your shirt, and comb your hair. It goes a long way.” And for those contractors who want to “get off their tools,” he says they’ve got to learn to be a good salesman, businessman and lead people. “Most contractors are in their own way,” Goodrich says.

With ambitions to grow the company significantly in the years to come, Houston Deck and Shade is pursuing a bold vision. Yet Goodrich insists growth will remain rooted in integrity and values. “I want my resources and blessings to flow through me like a river and be used of God for the glory of God to give these men and women opportunity that they may not have had anywhere else,” he says.

For customers, that means VIP-level service and peace of mind. For employees, it means stability and a future. And for Houston Deck and Shade, it means continuing to build not only beautiful outdoor living spaces, but also a legacy of professionalism, dignity, and purpose in the industry.

“(Speaker) Zig Ziglar said you can get everything in life you want if you just help enough other people get what they want,” Goodrich says. DS

IN TODAY’S FAST-MOVING construction environment, carving out time for professional development is no small task, especially during peak building season. Yet, when the opportunity is worthwhile, contractors are willing to step away from busy job sites. That was exactly the case this summer in Portola Valley, CA.

Following the success of the National Master Class Expo on steel deck framing in 2024, Fortress Building Products expanded its program regionally, bringing hands-on training directly to job sites across the U.S. and Canada. In July 2025, more than 35 builders gathered for a Regional Master Class Workshop to learn how to frame a deck with steel from seasoned industry expert Joe Frith, owner of Mountain Deck (location), and Mike Fredy of Fortress Building Products.

With more than two decades of experience building large-scale outdoor living spaces in the San Francisco Bay Area, Frith shared practical lessons learned on the job, from framing techniques to marketing strategies. His message was clear: “Steel deck framing offers strength, durability and long-term value unmatched by traditional

wood.” Unlike pressure-treated lumber, which can split, warp and deteriorate after exposure to the elements, steel deck framing stands up to the damaging effects of moisture and extreme weather conditions.

Frith also addresses lingering misconceptions about working with steel (see sidebar). “Evolution steel deck framing by Fortress Building Products is a comprehensive system, which is easy to learn,” Frith said. “Outside of simple cutting, you just screw the parts together. That cuts down labor costs, improves construction efficiency and leaves you with a deck substructure that’s going to last forever.”

Most importantly, Frith spoke about steel deck framing’s fire-resistance properties that add significant value for contractors and homeowners today, especially those in California. “Burning embers are one of the leading ways wildfire spreads,” Frith explained. “If that structure is an old, dried-out wooden deck bolted to a home, it’s basically like having a bonfire fastened to your house.” To mitigate loss in events of wildfire, local codes in the state now prohibit combustible building materials within 5 ft.

the idea of switching to steel deck framing still brings to mind heavy I-beams, specialized equipment and steep learning curves. But the reality is very different. Advanced comprehensive systems, such as Evolution steel deck framing, are helping to dispel outdated misconceptions.

with.”

Unlike raw structural steel, leading steel deck framing systems available today are ready-to-assemble and arrive on-site with all the required parts for a straightforward installation. No specialized tools are required. In fact, some deck builders like Frith argue that building a steel frame deck is actually easier than a traditional wood frame deck.

“Steel

While the upfront cost may be slightly higher than pressure-treated lumber, the long-term value is significantly greater and clients gain peace of mind knowing they’ll never have to worry about it again. For contractors, installing a steel frame that will not warp or move means fewer callbacks.

“Steel

Many leading contractors have heard client praise the clean, modern aesthetic of a steel deck frame. In fact, some homeowners even opt to not clad the framing and showcase the exposed steel look.

of a home. “Steel deck framing is noncombustible, fireresistant and ignition resistant, which means contractors can meet compliance and build a safer, more resilient outdoor living space for their clients,” Frith added.

For attendees, the experience was more than just a workshop, it was a chance to connect with peers and gain confidence about a new way of deck framing. “Your first deck with any new system and material will always feel intimidating, whether it’s 5,000 sq. ft. or 400,” Frith said. “The way to overcome that is to attend one of these Master Classes. Here you see how it’s done, you try it yourself and you realize framing with steel may actually be easier than building with wood.”

That peer-led, collaborative approach is what makes the Master Class series so impactful. Beyond product education, the workshops foster stronger professional networks and create a ripple effect of knowledge-sharing across the industry. According to Frith, “Contractors who attended these workshops walk away not only with practical skills but also the ability to position themselves as experts in fire-safe, long-lasting building practices—an advantage that can translate directly into business growth.” DS

BY ROBERT TICHY, PH.D.

MODIFIED WOOD IS SHOWING UP more often in decking projects. Thermally modified, acetylated, and furfurylated products promise longer life, better resistance to decay, and a smaller environmental footprint.

All of that is good, but if you are going to trust it to hold people up, you need proof that it can.

That proof comes in the form of a valid code listing.

Why a Code Listing Matters.

A code listing is not just another piece of paperwork. It is the evidence that a product has been tested, verified, and approved for the structural job you are about to give it.

For decking and rails it protects both the people using the structure and the person who specified, installed, and sold it.

The primary agency issuing these Code Listing Reports is the International Code Council Evaluation Service (ICCES). For modified wood decking and rail system, these Reports are the result of testing and evaluation according to the ICC’s Acceptance Criteria 47 (AC47).

Three Ways Wood Gets “Modified.”

AC47 recognizes three types:

• Thermally Modified – Heat-treated in a high-temperature dry kiln to reduce hemicellulose, the sugars that attract decay organisms.

• Acetylated – Treated with acetic anhydride to stabilize the wood’s cell walls.

• Furfurylated – Treated with furfuryl alcohol, which polymerizes inside the wood.

These treatments change the wood at a structural level. While they can improve durability, some types dramatically increase brittleness. In addition, it has

been shown that reductions in flexural strength can be more than 50%, according to a 2014 ACS study by H. Militz and M. Altgen.

Not All Modified Wood Is the Same.

At this time, only the manufacturer of furfurylated wood currently has a code listing according to AC47.

Thermally modified wood does not follow a consistent, standardized process. AC47 simply states it must be treated in an “advanced dry kiln,” which leaves room for variation between manufacturers. Without a verified listing, there is no guarantee of performance or code compliance.

Why You Should Care.

If a non-listed product fails after installation, the person who approved or installed it could be held liable, as could the person/entity that sold it as well as the manufacturer.

The rule is simple. If a modified wood product does not have an ICC-ESR that references AC47, it is not approved for structural use, including decking or railing.

1. Ask for the ICC-ESR report.

2. Confirm it covers deck boards and/or guardrails.

3. Check allowable spans and labeling requirements.

Bottom Line.

Modified wood has a place in modern decking and railing, but only when the product comes with the proper documentation. If it is not listed, it should not be installed. DS

From 1992 until his retirement in 2017, Robert J. Tichy, PhD, held the position of Research Engineer | Composite Materials and Engineering Center, Washington State University, Pullman, WA. His focus was product and market development of wood-based products in engineered applications. He holds a Ph.D. in Materials Science and Engineering from Washington State University, an M.S. in Wood Engineering from Colorado State University, and a B.S. in Wood Science from University of Illinois.

Introducing the Quik Drive ® Project Pro screw driving tool from Simpson Strong-Tie. Project Pro makes it easy to drive screws up to four times faster than traditional drivers alone. It’s perfect for repetitive fastening on deck boards and railing, fences, flooring and other home improvement projects. Lightweight and simple to attach, Project Pro works with almost any cordless drill or driver motor. It installs collated fasteners that are 1 5/8" to 2 ½" inches long. For outdoor projects, use Deck-Drive™ DSV Wood screws. Indoors, use Strong-Drive® WSV Subfloor screws. Project Pro is widely available at building supply centers and backed by our expert service and support. Learn more at go.strongtie.com/projectpro or call (800) 999-5099.

IN A MARKET DEFINED by shifting costs and rising uncertainty, stability has become the new measure of success. Deckorators Executive VP Ryan Kemp discusses how the company is helping contractors navigate economic pressures, streamline operations, and stay competitive through reliable systems, innovative tools, and forwardthinking support.

Q: With inflation, interest rates, and tariffs influencing demand and material costs, how is Deckorators helping contractors stay competitive and profitable in 2025 and beyond?

A: Over the past 20 years in this industry, I’ve seen markets cycle through booms, recessions, and everything in between. One truth has remained consistent: contractors succeed when they have a reliable foundation to lean on. When pricing and demand shift quickly, uncertainty puts pressure on margins and schedules, and I’ve watched many pros adapt by focusing on what they can control: consistency, efficiency, and strategic partnerships.

That’s why I think about contractor support in terms of systems, not just products. Steady supply, streamlined tools, and responsive support all contribute to keeping projects moving, even when the market doesn’t cooperate. Our Certified Pro program reflects that philosophy. It was created to give builders more stability in an unpredictable market. Things like clear rebate processes, timely payouts, and tools that save time on estimating and scheduling all make an impact. Small efficiencies like these really do add up, and in my experience, they often make the difference between simply getting by and building a business that can keep growing in challenging times.

Q: Installers continue to struggle with labor shortages. How is Deckorators optimizing products (like board design or kits) to speed up installs or reduce callbacks?

A: My background in operations has taught me that jobsite efficiency often comes down to respecting the crew’s time and energy. Labor has always been tight in this industry, and when crews are stretched thin, the last thing they need is a system that slows them down or creates more callbacks.

What they need is solutions that make the work more manageable: lighter boards that reduce strain, fastening systems that minimize errors, and designs that don’t require constant troubleshooting. Recently, we introduced Glass Rail Post Kits with that exact mindset. They’re engineered to install smoothly and give homeowners the elevated design they want. In practice, that means fewer headaches for the crew and more time to focus on craftsmanship. Over the years, I’ve seen how these kinds of efficiencies can mean the difference between hitting a deadline and missing it, and those moments are what both contractors and homeowners remember.

Q: The $250 million investment and New York production campus in New York is a big move. How will this improve regional availability, shorten lead times, or offer new SKUs for East Coast builders?

A: Nothing erodes trust faster than delays. On the East Coast especially, builders are working in competitive environments with short timelines, and shipping products long distances often means they’re operating at the mercy of bottlenecks. This is what makes the Buffalo, N.Y., campus so important. With production and distribution closer to where the work is happening, contractors can shorten lead times, reduce disruptions, and have more control over their schedules. In an unpredictable economy, reliability is one of the greatest advantages we can offer. I’ve seen firsthand how confidence in supply helps pros plan better and build stronger relationships with homeowners.

Q: With more brands and private labels entering the market, how does Deckorators plan to deepen loyalty and value for the pro builder?

A: Loyalty doesn’t come from pushing product. It comes from proving you understand what contractors deal with on a daily basis and then doing something about it. In conversations I’ve had over the years, contractors consistently bring up the same pain points: managing time, protecting margins, and keeping the homeowner experience positive.

The key is to approach loyalty by providing support that has a tangible impact on a builder’s business. For

us, this means developing innovative resources and practical, viable solutions that reflect how outdoor living projects actually operate. That includes clear processes for ordering and delivery, tools that make estimating and job tracking more manageable, and training informed by real-world experience. When contractors can rely on that kind of forward-thinking support, they can focus on what matters most: building quality projects, maintaining strong client relationships, and running a sustainable business.

Q: What, if any, digital tools or AI-powered resources are you exploring to help the contractor in their business?

A: I’m a firm believer that tools should make the contractor’s job easier, not more complicated. If a platform or app takes more time than it saves, it’s a step in the wrong direction. That’s why it’s best to focus on solutions that reduce friction. Our new Deck Visualizer is a good example. It’s an intuitive, mobile-friendly tool that helps contractors and homeowners align design decisions early. It makes it easier to customize layouts, railings, and colors, which speeds up approvals and reduces miscommunication before anyone even steps on the jobsite.

Beyond visualization, we’re also exploring tools that streamline estimating, scheduling, and product tracking. The goal isn’t to digitize for the sake of it. It’s to give contractors more control, fewer surprises, and better efficiency where it matters most.

Q: What does the path to 2026 look like for Deckorators in terms of innovation, channel partnerships, and market expansion? Are you betting on new categories or doubling down on decking?

A: The outdoor living category is becoming more integrated, more design-forward, and more purposedriven. Contractors are being asked to build complete environments, not just decks. Over the years, I’ve watched how this shift has changed the role of the contractor, and it’s clear they need systems that support the whole project, not just one piece of it, which is why we are building a system that supports the full spectrum of outdoor living. Looking ahead, the opportunity lies in creating cohesive solutions that feel tailored, not transactional. That could mean new materials, smarter platforms, or expanded partnerships. But the principle stays the same: everything we bring to the market should help contractors build better spaces more effectively. DS

Ryan Kemp has over 20 years of industry experience in sales, marketing, operations, and product development. He currently serves as the Executive VP for Deckorators. www.deckorators.com.

IF A THIRD PARTY ASKED your employees or subs if they like working with you, what would their answer be? Yes, no, or only until I find something else? Their response may be an indicator of your future employee and subcontractor turnover rate, your production capacity, and ability to deliver quality projects consistently. If they are unmotivated, they are probably not giving you their best effort. If they are unhappy, they are prime poaching targets for other competitors in your market.

Depending on the skill level and position, most hires require an investment of time and money to become productive, efficient, and familiar with what you do. Your return on the investment can take weeks or months to occur. To lose people after that investment time is costly and creates a negative repetitive cycle.

Low turnover rates begin with vetting and making good hires upfront. But in the long run it comes down to your leadership, culture you create, and benefits you provide.

When I first started subcontracting, I didn’t even know what work culture meant. I simply wanted to create a good work environment so I could keep a good team of people on the job. Later when I started running multiple crews, I became better at managing and motivating multiple personality types.

Through the years, I had two crew leaders who worked with me for 22-24 years, and other crew leaders and members for 10-12 years. They did not stay with me because I made them rich. They stayed because they were well paid, shown appreciation, treated with respect, and had upside growth and financial opportunities. It required creating and managing a blend of personal and business relationships.

If you lead a solo crew, you lead by example every day and you stay connected. Your team members have a constant exposure to you. Your leadership style, attitude,

moods, and people skills will determine whether your employee retention level increases or decreases.

When you run multiple crews, the same aspects apply. But it is easy to become detached from team members if you are not around. If neglected, when they think about their job, it only includes the immediate environment and people that they spend the day with.

I visited job sites at least every other morning both to keep an eye on the jobs and to maintain that personal contact. I made it a point to communicate with everyone on the job during each site visit. I wanted everyone to feel like they were part of something bigger than the crew they were on and not just hired guns.

Once a month I arranged for the crews, key sub leads, and office staff to meet for lunch in as centralized location as possible to where the ongoing jobs were. Sometimes I invited a building product rep to join us. I would cover everyone for an extra hour so they would not stress over being off the job. If anyone had a birthday that month, we had a birthday cake for that occasion. It was an opportunity to connect and talk about other things besides work.

If you are working in your crew and already do lunch daily with your team, consider taking the crew members

and their spouses or girlfriends to dinner periodically. Invest in activities outside of work that promotes team building. Do not let the once-a-year Christmas gathering be the only time you pull your teams together. It is an investment cost that will provide long term returns.

I had several subs that I used for years that were shown appreciation and paid a premium. Although we had agreed rates, in some instances I paid more than they asked on miscellaneous items when I did not think they asked for enough, or I just wanted to show appreciation. This gesture went a long way with creating loyalty and made my jobs a priority. I never tried to beat them down on price, and they were always responsive when needed.

For example: One Christmas Eve at 4 p.m., we hit a copper waterline to the kitchen while the customer was preparing dinner for Christmas Eve guests. It was a case where we had loaded up tools and were done with the job, but the crew leader realized at the last minute that they had missed two bolts on the house ledger. They hit dead center on the waterline with the drill bit on the very last hole, causing the blowout.

I had several subs that I used for years that were shown appreciation and paid a premium ... This gesture went a long way with creating loyalty and made my jobs a priority.

I called my plumber, praying he would answer. He did, and he was like an emergency responder, and made the repair right away. He could have just let my call go to voicemail. But he took it and responded because of the relationship. I had similar instances involving my roofer when we were doing porch roof tie-ins and we knew we had weather moving in. He was always flexible and fit us in no matter what else he had going on.

Salaries and benefits are obvious factors, but retaining a strong workforce requires more. It requires a solid culture and healthy relationships. Positive attitudes are always more productive than bad ones.

As important as it is to keep good people, it is equally important to root out the bad ones. Do not allow underminers or employees with bad attitudes to poison the well. Find a way to fix the problem or a way to remove them from the lineup.

Do a self-assessment of your company practices. Ask successful contractors on social media what they

do to retain help. Research what keeps people loyal to a company, and what programs support that.

Strengthen your local presence and reputation so you can charge a premium for your work. Healthy margins make it possible to offer competitive pay, insurance, and other benefits. The better you run your business, the more likely you can afford to keep good people.

At a minimum, pay well, treat your team with respect, and recognize their contributions. Motivate them by providing clear paths for growth within your company. And do not shy away from giving credit where it is due. Everyone needs to feel valued for what they do. DS

Bobby Parks is a well-known contractor who has delivered more than $40 million in outdoor living projects. He is now a partner with IG Railing, focusing on business development.

WHETHER WE REALIZE IT OR NOT, every one of us travels in another man’s footprints. There has always been someone else who came before us and blazed a portion of the path we choose to follow. They tore down some of the barriers, set earlier standards, saved us from a lot of trial and error, and even suffered our pains without us ever realizing their hardships.

Though we may see ourselves as groundbreakers in our own right, the reality is we stand in the shadow of another man’s greatness. We view our shtick as influential or unique when in actuality we are just the next level of a pyramid where generations before us had already set the foundational blocks.

As we follow those footprints, they lead us to many forks in the road that, in turn, carry us down a trail we perceive to be the pathway to our success. Ironically enough, the end of that road already has someone else’s footprints because we got there walking in another man’s shoes.

The products we use may have changed over the years. With the advent of composites, the evolution of PVC, vinyl, aluminum, stone, or glass, we have infinite possibilities at our fingertips. Artificial Intelligence has put us into hyperdrive, but we didn’t get to this stage without the history behind us.

Experts have been crafting curves and spirals for centuries and blending materials for millennia. Heat forming, bending, and thermally modifying workpieces isn’t a new concept. In an effort to preserve wood, Japan has been practicing Shou Sugi Ban since the 18th century and some of those early pieces are still around. Before that, the ancient Vikings used fire to char the wood of their ships in a successful effort to protect their hulls against the elements. The ancient Egyptians did it to preserve their wood in outdoor construction. Those old shoes go back hundreds, if not thousands, of years.

P.T. Barnum is credited with saying, “There’s a sucker born every minute.” Truer words have seldom been spoken.

We are so hungry to jump on board with the next greatest fad, big idea, or crazy technique being displayed by a hired mouthpiece to create buzz, that we lose all semblance of common sense. We will disregard our reputations, core values, and manufacturer warranty requirements in an effort to be seen as someone on the ground floor of a questionable idea or practice.

That new and exciting trick, technique, or philosophy that is captivating everyone’s attention is pulling you out of the proven footprints of success with its “shiny

new toy syndrome.” They are distracting your attention from your trusted goals and results, and eventually they will fade and tarnish over time.

Yet, the footprints made by those old work boots will always be there.

Hard work, dedication, common sense, integrity, education, and craftsmanship are shoes that made the footprints we are walking in today. A willingness to start at the bottom and learn from the ground up is the first rung on the ladder to success, not going on social media and asking others to answer elementary questions that a first-year helper should have already mastered.

Paying your dues and respecting the process is the second rung.

I see far too many people thinking it’s OK for a novice to sell themselves as a master while taking an

unsuspecting client’s hard-earned money. It’s up to the “Brotherhood” to call these guys out and protect the footprints, not let them get blown away by the winds of ignorance.

The generations that came before us knew there were no shortcuts to success—it came from the grind. From the hard-worn leather gloves and boots that protected us from the harsh realities of 12- and 14-hour workdays in brutal conditions. The rain, snow, extreme heat or freezing temps that came with treacherous terrain and awkward site conditions were enough to make the casual worker quit, but the seasoned veteran refused to tap. They went toe to toe with the worst of it and came out victorious. They persevered because they knew their families, reputations, and futures depended on a backbone of granite and a soul of steel. CONTINUED >>

Unfortunately, just as Icarus challenged tradition in Greek mythology, a great many people today are flying too close to the sun, seeking out the fast track superhighway to success. They are indoctrinating themselves with the KoolAid of industry pressure to fit in with tactical psychology that systematically moves them away from the work boots of tradition and into the sneakers of pleasure. With it comes a fear of failure and disappointment to others, instead of the knowledge of a honed craft, and the realization that the footprints have led you to the table of victory.

Our forebears laced up their hard-worn, weather-beaten boots and set out as the pathfinders of a burgeoning new industry, forging their way into the brave new emerging field of deck building. They were shaping the direction and future of an innovative trade that also gave rise to a Brotherhood of outdoor artisans. Like-minded men and women believed in the traditions of the past and the spirit of the future.

Knowing that those footprints were left behind by men of grit and gristle makes me proud to feel like a member of this Brotherhood of blood, sawdust, and sweat.

Unfortunately, that tide has been changing. It appears that a wedge is being driven into the family. Builders from all over are telling me they are sensing seismic shifts in the industry. They sense the Brotherhood we arduously brought to life is systematically being dismantled. We are being led astray from our mentors’ rugged boots to shiny, new shoes. We are allowing others to influence a path where the footprints guide us to a destination of someone else’s choosing, and we are not the true beneficiaries of our destiny.

al experience. He and his wife, Dianna, started their business 25 years ago and immediately gained a reputation for high quality and a unique approach when it comes to delivering exceptional value for your outdoor living investment.

FROM AUGUST 20 TO 22, we had the incredible opportunity to attend Milwaukee Tool’s exclusive Pipeline 2025 event at their global headquarters in Milwaukee, WI. This invitation-only experience gave us a rare inside look at the company’s culture, innovation process, and upcoming lineup of new and upgraded tools designed specifically for our trades.

What follows isn’t just a rundown of what was announced. It’s our take on what stood out, what it means for the trades, and why some of these tools could make a real difference in the field.

MIKE: Before getting into the tools, I have to talk about the people behind them. After this experience, I walked away with a whole new respect for what it really takes to bring these products to life.

ANDY: My experience at Pipeline was very similar to Mike’s. The passion and pride that every Milwaukee employee showed made a lasting impact. It changed the way I see this company, not only as one of the most innovative tool brands but also as one that truly values relationships.

The Unsung Hero: Nitrus Sawzall Blades

MIKE: I might not be the only one with a “just-in-case” stash of old saw blades, but man, those things pile up fast. Every time I see a Sawzall bag packed full of used blades, I see dollar signs spinning like a cartoon knockout.

That’s why one of the standouts for me was Milwaukee’s new Nitrus Sawzall Blade lineup. They’re not flashy like a new drill or driver, but these blades mean business. Their special carbide blend makes them tougher, sharper, and built to last. We ran them through hundreds of screws and nails in thick framing, and they chewed through it like nothing. Where a typical demolition blade would’ve been cooked and tossed, these just kept cutting.

For deck builders, that’s less downtime, cleaner cuts, and more productivity with fewer blade swaps. Sometimes, it’s the quiet upgrades that make the loudest impact.

The Quiet Powerhouse: New Impact Surge

ANDY: One of my favorite tools I got to demo at the show was the new M18 Impact Surge. Anyone who’s used an impact knows how loud they can get when driving lags into deck framing. When we’re trying to film video content, that noise can definitely throw things off. The upgraded Impact Surge, though, hits the sweet spot, it has the power of an impact with the quietness of a Surge.

The Jobsite MVP: M18 PACKOUT Radio + Charger

MIKE: In my opinion, there’s one tool that comes out on every single deck build, the radio. That’s why I got excited about the new Milwaukee M18 PackOut Radio + Charger. It locks right onto your PackOut stack and rolls with you from the trailer to the job site. Beyond sound, it doubles as an M18 battery charger, which is a huge win when you’re trying to keep tools powered up. A cool new feature is Audio Link, which lets you sync multiple radios together to create a consistent sound system across the entire job site. Add in an auxiliary port, Bluetooth, and USB charging, and this radio easily doubles as both a power hub and a jobsite sound system.

ANDY: Another addition that grabbed my attention was Milwaukee’s new heated gloves. They are offering two versions using their innovative heated gear technology:

• A base-layer glove that fits comfortably under standard work gloves. It is perfect for staying warm without bulk while still getting full dexterity.

• A heavier, insulated version that I call the “Boss’s Glove” would be ideal for site visits and inspections when you’re not swinging a hammer, but still braving the cold.

Both models are powered by Milwaukee’s proven battery tech, and I’m looking forward to testing them through this upcoming Ohio winter.

A Surprising Standout: Battery-Powered Snowblower

MIKE: This one might not be glamorous, but it sure caught my attention. Milwaukee’s new battery-powered snowblower is the real deal. At the demo, they used thick sawdust instead of snow—and it ate through it like nothing. The power matched (and even outperformed) several gas models I’ve used in the past. Honestly, I never thought I’d say this, but I’m actually excited for the first big snowfall in Ohio just to put this thing to the test.

Built for the Builders

ANDY: Milwaukee’s Pipeline event wasn’t just about tools, it was about people, innovation, and pride. From the engineers and testers to the pros in the field, everyone shares the same goal: to push the trades forward. For deck builders like us, that kind of support means everything. DS

The CAMO Drive and CAMO Wedge clips are my go-to specialty tools because they make deck building fast and smart. The Drive lets me stay standing while fastening boards, cutting install time and saving my knees and back. Its guided design keeps spacing tight and screws precise, pure efficiency with a flawless finish.

For productivity, nothing beats the Wedge system. Once you get rolling, it is clip, set, drive, repeat. The clips hold boards securely while allowing natural movement, meaning fewer callbacks and smoother installs. Paired with the Drive, it keeps the workflow seamless and fast. Every board sits even, every screw lines up, and the result looks dialed in.

Djay Thompson, Owner Nova Interior Custom Exteriors LLC

Novacustomsllc@gmail.com

TikTok: @djay.nice

YouTube: @djay_nice

Facebook: Nova Interior Custom Exteriors LLC

Andy Henley is the owner of Hen-House Decks, Uniontown, OH. Mike Mitchell is the owner of Mitchell Construction in the Chicagoland market. Andy and Mike can be reached in the DeckingTNT Facebook group.

THREE YEARS AGO, you could build great decks, post a few photos, and stay busy off referrals. That world doesn’t exist anymore.

Homeowners aren’t just searching for “deck builder near me” anymore. They’re talking to AI tools like ChatGPT, Gemini, and Google’s new generative search.

They’ll say things like: “I want to make our backyard the place where everyone wants to hang out. What kind of deck or setup would work best?”

Then AI starts showing them ideas, price ranges, and even a list of local deck builders that look like the best fit. They’re getting ideas and narrowing their list long before they ever reach out.

The Post-COVID Boom Is Over

During COVID, demand was automatic. You didn’t have to compete for work because homeowners were lined up and ready to build. But that overflow of easy work is gone. Homeowners are comparing more bids, and more builders are fighting for the same projects. You can’t rely on being good at what you do anymore. You have to be the one they trust first.

Andy Henley from Hen-House Decks, Uniontown, OH., said, “We used to rely on referrals and repeat customers, and that worked for years. But now, if you’re not staying in front of people online, you disappear.”

You’re not getting found because someone saw your

truck in the neighborhood. You’re getting found because a homeowner saw your name online and liked what they saw.

You can’t hide behind your work anymore. People want to know who you are, how you operate, and why they should trust you.

Whether it’s Google or ChatGPT, the web rewards builders who are real. The clearer and more honest you are about what you do and how you do it, the easier it is for homeowners—and even AI—to find and trust you. AI is a good tool to research other deck builders in your area so you can vet their businesses.

Sean Collinsgru of Premier Outdoor Living, Palmyra, N.J., said, “Every builder has great work. What separates us is who’s showing up when homeowners are researching.”

That means being upfront about how you do things differently and why it matters. Talk about timelines, materials, permitting, and delays. Be open about your process and what someone can expect when they work with you. When you do that, you stand out. When you don’t, you blend in with everyone else.

Most builders think marketing is just about getting found, but that’s only the beginning. Marketing is where the relationship starts. It’s where homeowners get their first

real impression of what it’s like to work with you.

Brendan Casey of Casey Fence & Deck, Frederick, MD., said, “A properly run website, social media, SEO, etc., serves not only as many layers of the sales process but is in actuality the first impression and sets the precedence for the entire experience.”

If your website only has a basic contact form, you’re making the homeowner do the work. They fill it out, and then you chase them for details. Ask better questions up front—type of project, materials, size, timeline, and budget. Even better, use an online scheduler so they can book a consultation right on your calendar.

Speed to lead matters more than ever. If a homeowner fills out two forms and your competitor replies first, they’re probably getting the job.

Tony McKlem of Hollywood Decks, Fernandina Beach, FL., said that to be first to lead means you must have systems in place. “Systems sell. If you can’t explain your process clearly, people assume you don’t have one.”

That’s as true for your communication as it is for your builds.

A lot of builders think posting tons of project photos will sell jobs. But when every site looks the same, homeowners stop paying attention.

If your website doesn’t show your personality or walk homeowners through your process, it just feels like noise. Show what makes you different. Explain what working with you is actually like. Pick your best projects—the ones you’re proud of—and tell the story behind them.

If you’re not being intentional and selective, your site feels messy, and homeowners can’t tell you apart from anyone else.

When updating your site, don’t forget reviews. It’s not enough to have them—you need more and better reviews than your competition. If you’re not asking for them on every job, you’re falling behind.

Marketing Isn’t Optional. It’s Operational.

Marketing isn’t extra. It’s not something you do when you have time or when leads slow down. It’s an equal part of your business, right alongside operations, finance, and leadership.

- Operations build and deliver the work.

- Finance keeps it profitable.

- Leadership builds the team.

- Marketing keeps the pipeline full and the reputation strong.

If one of those pieces is weak, the whole business wobbles.

Look, marketing isn’t the cherry on top. It’s the system that keeps everything moving. The builders who understand that never really slow down.

Luan Nguyen, Deck Bros, Omaha, NE., said it best: “When

things slow down, that’s when people disappear. The ones who keep showing up, keep marketing, keep pushing— they’re the ones still standing when it picks back up.”

He’s right. Marketing isn’t a reaction. It’s how you stay in the game. The ones who treat it like a core part of their business stay steady no matter what the market does. The ones who don’t? They’re always playing catch-up.

This isn’t a short-term change. It’s a full behavioral shift. Homeowners expect transparency, clarity, and speed. They want to work with professionals who guide them, not chase them.