Thermally Modified Hem-Fir

Western Forest Products’ Thermally Modified Hem-Fir is coming in 2026.

With the rich, warm look of Western Red Cedar and lasting durability, Western Forest Products’ Thermally Modified Hem-Fir is crafted for resilience while redefining modern wood design.

The future of wood products is here.

• Exceptional stability

• Engineered durability

• Natural beauty evolved

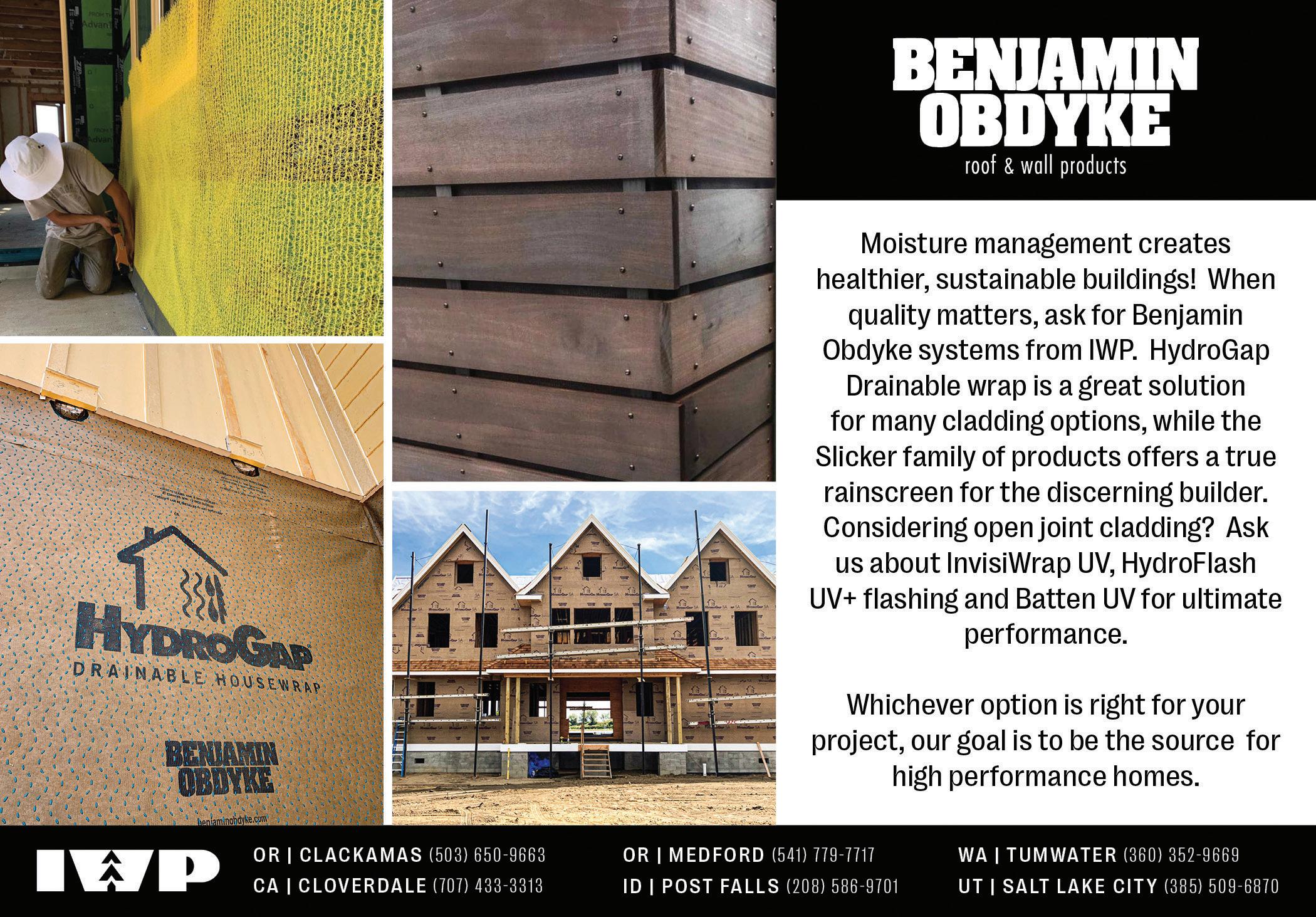

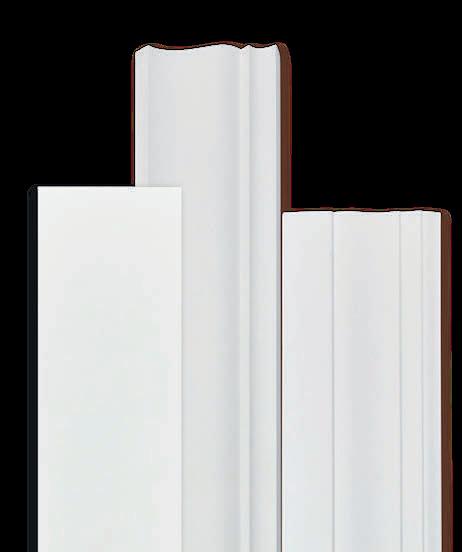

With its durability against the elements, low maintenance and wide range of styles, vinyl siding has been a picture-perfect fi xture with homeowners for decades.

Today, vinyl selections from Gentek US provide fresh takes on this reliable option, with a mix of traditional and contemporary looks, distinctive textures and striking colors to fit the wide-ranging needs of your customers, all designed to help streamline projects and minimize callbacks.

• Signature Supreme® and Sequoia Select ® deliver premium, design-forward options.

• Aurora™ II and Concord ® offer beauty on a budget without sacrificing longevity.

• Centennial™ Beaded is timeless with a twist, where historic looks match modern performance.

PRESIDENT/PUBLISHER

Patrick Adams padams@526mediagroup.com

VICE PRESIDENT

Shelly Smith Adams sadams@526mediagroup.com

PUBLISHER EMERITUS

Alan Oakes

MANAGING EDITOR

David Koenig dkoenig@526mediagroup.com

SENIOR EDITOR

Sara Graves • sgraves@526mediagroup.com

COLUMNISTS

James Olsen, Claudia St. John, Dave Kahle

CONTRIBUTORS

Jenna Ernst, Paige McAllister, Kendall Reynolds

ADVERTISING SALES (714) 486-2735

Chuck Casey • ccasey@526mediagroup.com

John Haugh • jhaugh@526mediagroup.com

Nick Kosan • nkosan@526mediagroup.com

DIGITAL SUPPORT

Katherine Williams kwilliams@526mediagroup.com

CIRCULATION/SUPPORT info@526mediagroup.com

A PUBLICATION OF 526 MEDIA GROUP, INC.

151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626

Phone (714) 486-2735

CHANGE OF ADDRESS Send address label from recent issue, new address, and 9-digit zip to address below.

POSTMASTER Send address changes to The Merchant Magazine, 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626. The Merchant Magazine (ISSN 7399723) (USPS 796-560) is published monthly at 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Santa Ana, CA, and additional post offices. It is an independently-owned publication for the retail, wholesale and distribution levels of the lumber and building products markets in 13 western states. Copyright®2025 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

Volume 104 • Number 10

Your Premier Supplier of Building Materials

2,600 dedicated employees, and one of the most extensive product offerings of value-added treated lumber, we can deliver in ways few others can.

A PRECIOUS GIFT WE CAN’T AFFORD TO SQUANDER

------------ BY PATRICK ADAMS

AS I SIT HERE writing this, flying home across the country from an industry event, I can’t shake the thought: should I even write this? Would it be easier to stay with safe topics—family, business, gratitude for this industry I love? Probably. But silence feels dishonest.

This week, a tragedy claimed the life of a young man, leaving his wife and children behind. On flights like this years ago, I’ve often wondered if I would make it home myself. That sobering thought makes me grateful for the freedoms I enjoy—freedoms made possible because others before us stood for ideals greater than themselves, sometimes at the cost of never coming home. That is the very essence of this experiment called the United States of America: imperfect people willing to sacrifice for something better.

And yet, what I see today doesn’t always resemble that America. We’re letting ourselves be divided by the loudest voices with the biggest megaphones. We’re told we’re enemies of one another, when in truth the things we’d truly die for—the things that unite us—are the same. Family. Safety. Opportunity. Hope. The noise convinces us otherwise, but we are not at war with each other unless we choose to be. Those who have not been to war should not ask for it.

When I’ve traveled beyond the well-marketed destinations, I’ve seen children playing in the dirt with joy that mirrors my own kids—yet with less food, less comfort, and far less certainty about tomorrow. I’ve seen parents looking at them with the same love I feel, but carrying a heavier burden of stress and doubt. That perspective reinforces how extraordinary this country really is, not just for us but for the world, as proof of what’s possible.

The America I know and love is still here, in the quiet strength of citizens who don’t make the headlines. It is in

the perseverance of people who build businesses, raise families, and do their best in tough conditions. It is in the belief that, even when we stumble, we are capable of more. Like my own children when they throw a tantrum, our country may act out of character at times, but the values underneath remain. I love my kids no less in those moments, and I believe we should love this country no less, even when it disappoints us.

It’s up to each of us to protect this gift. Not with louder arguments or deeper divisions, but with patience, humility and courage. Be kind, for everyone you meet is fighting a battle you know nothing about. Those words ring truer than ever. We cannot know the burdens others carry, but we can choose to ease them rather than add to them.

I know this industry is full of some of the most remarkable people I’ve ever met—people who have proven again and again that perseverance, grit and values make the impossible possible. If we can embody those same qualities in how we treat one another, then the America I love will not just endure—it will thrive.

I am grateful for the honor of serving you through these words, and grateful in advance for the grace of reading this with an open heart. May we remember that this country is a precious gift, bought with sacrifice, and best honored by how we live each day—with kindness, patience and gratitude not only for what we have, but for each other.

Thank you for the gift and honor of allowing me to be a part of this great industry, and for serving each of you in our own pursuit of something better.

PATRICK S. ADAMS, Publisher/President padams@526mediagroup.com

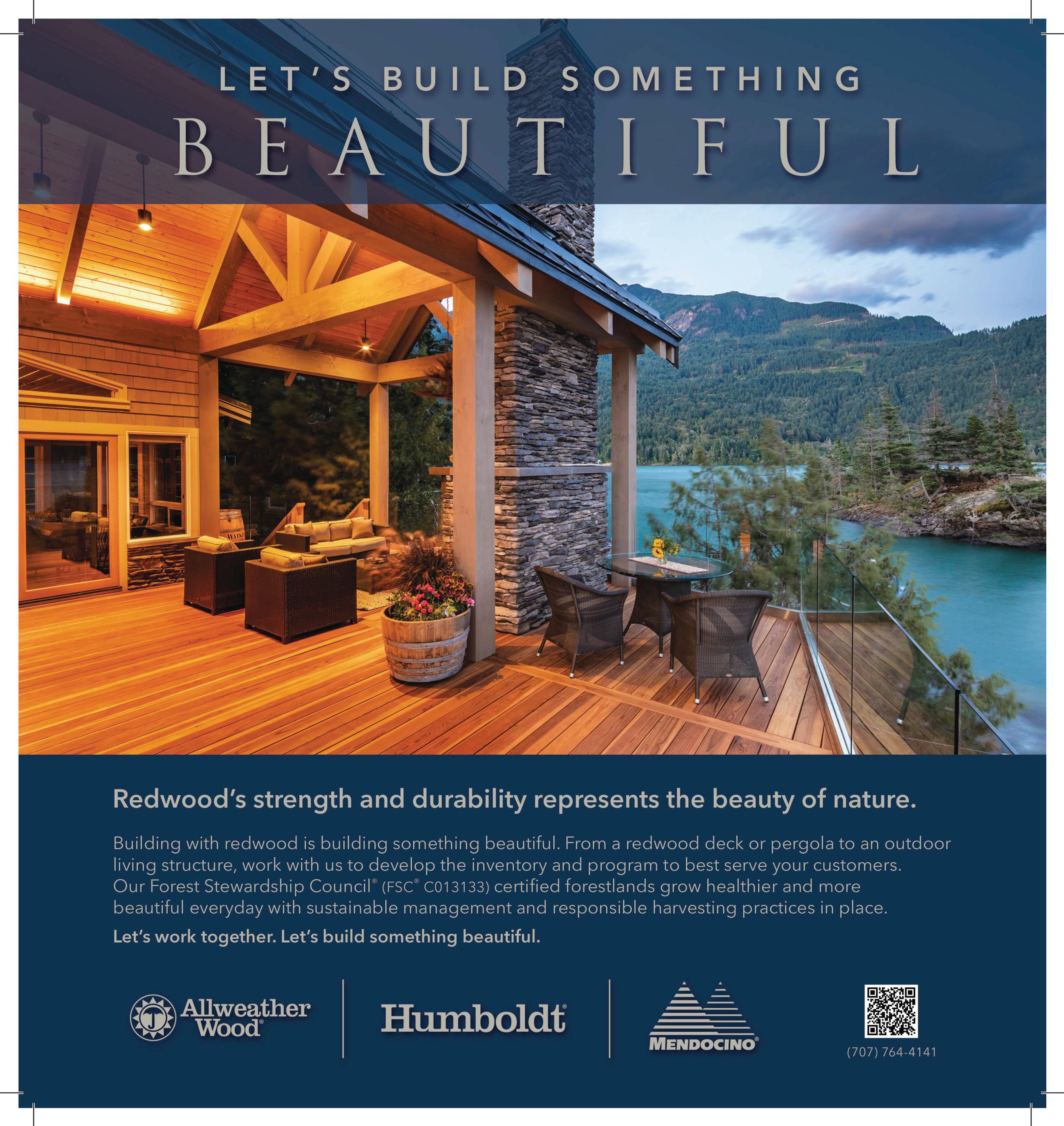

Like the foods we buy, when it comes to decking, we want natural and real. Redwood is always available in abundance of options. So stock the shelves! Unlike mass-produced and inferior products, Redwood is strong, reliable and possesses many qualities not found in artificial products. They maintain temperatures that are comfortable in all climates.

Redwood Empire stocks several grades and sizing options of Redwood.

HOT TOPICS IN HARDWOODS

BY DAVID KOENIG

THOUGH STEEPED in tradition, the hardwood lumber industry is in the midst of rapid change—driven by fluctuating tariffs, shifting markets, and new technologies.

Here are the issues that are top of mind for hardwood professionals:

1. Trade. Recent increases in tariffs on imports haven’t just led to higher prices. They’ve also thrown a monkey wrench into many longtime trading relationships. Domestic producers that sell primarily within the U.S. are the beneficiaries. But importers—as well as domestic producers that are dependent on export markets—are now feeling the brunt retaliatory tariffs instituted by other countries.

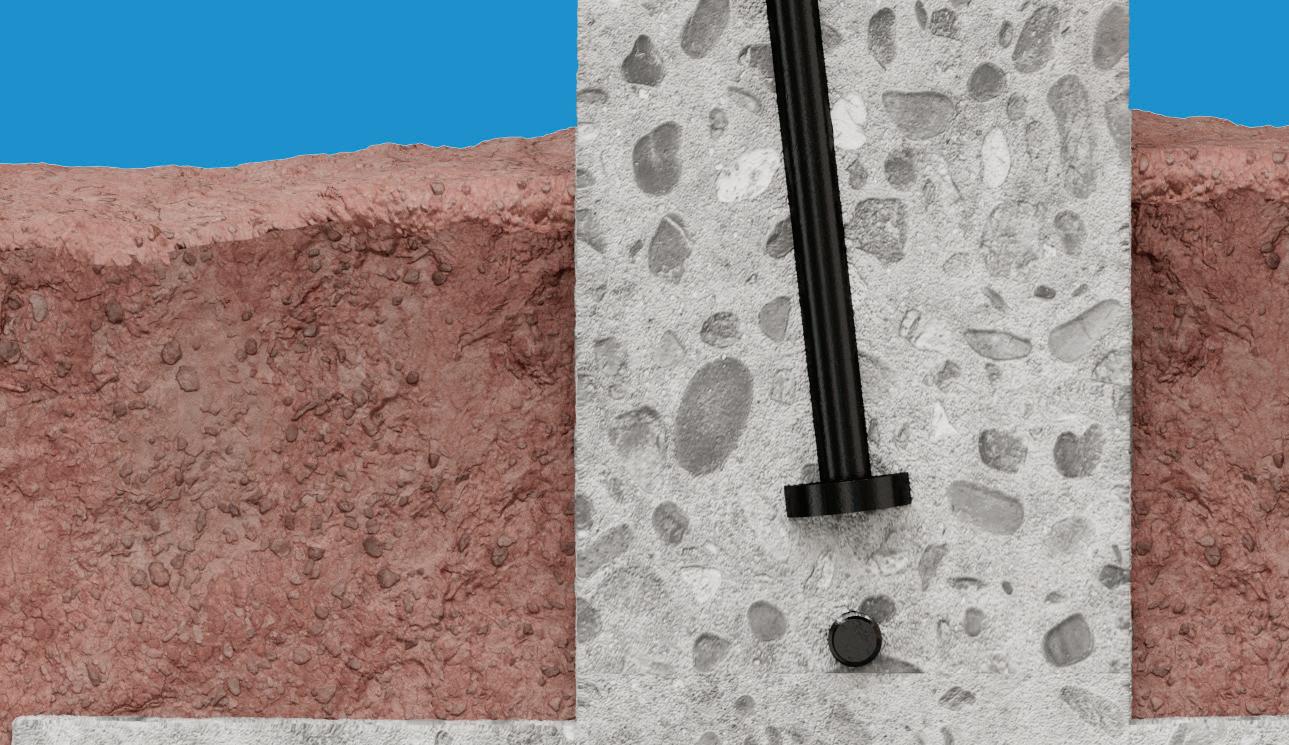

2. Thermal modification. Thermal modification is opening up a host of new markets for hardwoods, particularly in siding and decking. The process removes moisture from the wood, making it more dimensionally stable (meaning less warping, shrinking and expanding), more durable (adding rot, decay and insect resistance), aesthetically appealing—without the use of chemicals.

“Thermal modification has opened new markets for several types of hardwoods, namely ash, red oak, and poplar,” says Matt Pryor, director of specialty product sales, including Americana thermally modified wood, for Bingaman & Son Lumber. “These three hardwoods seem to take the process best.”

He points out that, as in most other areas of the wood world, hardwoods maintain a higher-end, boutique position compared with softwoods, with knot-free, clean boards, high dimensional stability, and unique grain patterns all contributing to their appeal. “Decking is the harshest environment for any wood type, but hardwoods have an edge thanks to their inherent strength, durability and weathering characteristics. Siding is a much gentler application allowing for a broader playbook when it comes to finishes, textures and milling patterns.

“Just a few years ago, it was unthinkable to put hardwoods outside, but with thermal modification, hardwoods bring uncommon beauty to a project’s exterior. No mechanical, repeating patterns, no plastic or chemical infusions—just nature’s artistry, every board as unique as a fingerprint. Nothing else quite captures it.”

AMERICANA thermally modified red oak decking greets visitors to the National Hardwood Lumber Association’s headquarters in Memphis.

3. Eco-friendliness. Hardwood companies have been promoting their green credentials for decades, yet even tighter environmental laws, like the U.S. Lacey Act and the EUDR (European Union Deforestation-free Regulation) and changes—including overseas—are transforming how. We’re seeing stricter traceability, higher compliance costs, and evolving sourcing and certification strategies.

“Sustainability and certifications are becoming more and more concerning as the EUDR and others try to get away from risk-based models that FSC, SFI, CSA and PEFC use,” notes Dallin Brooks, executive director of the National Hardwood Lumber Association. “They are moving to more stringent GPS maps, and blockchain that show the deforestation and forest degradation in real time, but have other major shortcomings. This will come to play in the USA if manufacturers and wholesalers distribute overseas.”

4. New technology. In an effort to increase efficiency in production and distribution, hardwood companies are investing in a host of new tech tools, including AI, IoT and predictive analytics.

Perhaps most noteworthy, AI grading is finally coming on stream for the hardwood industry, promising increased speed, accuracy, consistency and yields. However, since there’s less human involvement, lumber buyers should make sure they get what they ordered. (See related story on next page.)

5. Mass timber. While the vast majority of mass timber utilizes softwood lumber, an increasing number of hardwoods are finding use in “niche” applications, including recent multi-story, high-profile projects build of red

oak, white oak, and tulipwood.

According to the American Hardwood Export Council, using higher-strength hardwoods would require significantly less wood to produce a cross-laminated timber than with traditional softwoods. CLT comprised of softwood would require seven layers to achieve the strength of just five layers of hardwoods such as tulipwood.

The same holds true for other types of engineered wood products, including glulams and laminated veneer lumber. MM

Let us become your pole partner!

From the treating plant at our mill in Montana, we provide treated and white Hop poles, Vineyard poles, Apple poles, Props, Drilled fence, and jump rails.

HARDWOODS are a viable alternative for engineered wood products, such as these white oak glulams overhanging the stands at the Marylebone Cricket Club in London. (Photo by Jon Cardwell)

DO IT BEST MARKS FIRST FALL MARKET WITH TRUE VALUE

DO IT BEST and True Value opened the doors to their first fully integrated Fall Market in Indianapolis, In., drawing record-breaking attendance. Thousands of independent dealers gathered for four days of buying, learning and networking—making it the largest independent event in the industry.

“This market is proof of what independents can achieve when two industry leaders come together with a shared vision,” said Dan Starr, CEO of Do it Best and True Value. “Our investments in branding, merchandising, and vendor partnerships are designed to help independent dealers grow bigger, stronger and faster in their communities.”

The show, held Sept. 5-8 at the Indiana Convention Center, showcased the combined strength of Do it Best and True Value. Dealers experienced firsthand the significant investments being made in branding, marketing and merchandising across both banners. New brand initiatives included expanded consumer marketing programs from Do it Best and the unveiling of the 2026 True Value national brand awareness campaign featuring the chain’s new celebrity spokesperson, actor Nick Offerman (Parks and Recreation).

“This market showcases our continued investment in building strong in-store experiences,” True Value president Dent Johnson said. “An exciting highlight is

the return of Destination True Value, a revitalized and reimagined store design featuring modern layouts, updated signage, and curated assortments. Dealers can walk through the refreshed concept in Assortment City on the market floor, gaining inspiration on how to elevate customer experiences, strengthen brand visibility and drive sales.”

Alongside True Value’s brand enhancements, Do it Best featured its award-winning store design solutions in Solutions in Action, together reinforcing a shared commitment to equipping independents with powerful branding tools that preserve their local identity while amplifying their market presence.

Outdoor living took center stage with the expansion of Broil King and Napoleon to the Do it Best and True Value assortments. The premium grilling brands bolster a “good, better, best” strategy, creating grilling destinations in each store. At the high-energy Power Preview, dealers saw these products in action—complete with live cooking, exclusive dating terms, and deep discounts.

“Our Fall Market also puts a big spotlight on lumber and building materials, a cornerstone of independent growth,” said Do it Best president Nick Talarico. “Our Do it Best and True Value dealers are exploring all the can’t-miss LBM VIP Deals. These are exclusive in-person

LBM PREVIEW: Do it Best president Nick Talarico and True Value president Dent Johnson shared the stage to brief members of the wonders ahead at the coop’s first fully integrated Fall Market in Indianapolis.

savings on core building categories. And our expanded Studio 695 showroom features complete room concepts— from laundry and garage solutions to master baths and outdoor patios—providing inspiration to position stores as full-service destinations.”

LBM Learning Sessions delivered actionable strategies on topics ranging from AI applications for profitability to futures market insights and operational playbooks that boost productivity and margins.

During the market, Talarico and Johnson shared ways that True Value and Do it Best members were continuing to gain additional benefits from last year’s merger. Citing examples, Johnson said, “We’ve implemented 10,000 price reductions over a very short period to ensure our retailers are competitive. We swiftly adapted to a major change in the grilling category. We complemented strong offerings with brands like Stanley Black-Decker by adding Milwaukee and Freud/Diablo to True Value stores. Drop ship through True Value has returned. We expanded our partnerships with Broil King and Napoleon, and we’re

2025 Vendors of the Year

Do it Best and True Value recognized their topperforming vendor partners over the last year, including:

Overall Sales Growth Milwaukee Tool

Supply Chain Excellence Charlotte Pipe

Outstanding Products/Services First Alert/Resideo

LBM Excellence The Hillman Group

Building Materials Simpson Strong-Tie Co.

Building Materials (Direct) Georgia-Pacific

Cleaning Supplies & Storage Bissell

Decorative Plumbing Fluidmaster

Electrical Alliance Consumer Group

Farm & Ranch, Pet Supplies, Apparel & Sporting Goods Dare Products

Flooring AHF Products

Hand Tools Mayhew Steel Products, Inc.

Hardware 3M Company

Heating & Automotive WD-40 Company

Housewares, Food & Snacks Midwest Distribution

International JJA SAS

Kitchen & Bath Whirlpool Corporation

Lawn & Garden, Green Goods Jonathan Green

Lumber Distribution Partners Dealers Choice

Lumber & Engineered Wood Georgia-Pacific

Marketing Laughlin Constable

Millwork Speciality Building Products

Outdoor Living & Holiday Kingsford

Outdoor Power Equipment/Garden Tools Husqvarna

Outdoor Power, Farm & Ranch VP Racing Fuels

Paint Sunnyside Corp

Paint Supplies Gorilla Glue

Power Tools & Accessories DeWalt

Rental Bobcat

Rough Plumbing Sharkbite

Structural Panels West Fraser

WITHIN ASSORTMENT CITY, True Value retailers could view full planogram displays of new and existing product lines across various categories to help them decide on inventory and secure deals from suppliers. Do it Best members could visit a Solutions in Action model storefront at the show.

strengthening private label brands like Easy Care, Green Thumb, Best Look and more.”

Talarico continued, “In addition to products… over the next few years, our back-end systems, teams, catalogs and pricing strategies will come together as one to give you better buying power, better tools, and more consistency across the board.”

Do it Best is also rolling out three new marketing “easy buttons,” designed to help members quickly drive awareness, traffic and sales:

(1) The easy promo plan, allowing retailers to enroll in promo pricing and marketing for monthly promos all at one time.

(2) An ecommerce ignition kit—a total package solution including marketing vehicles, and store operations instructions to really get the ecommerce program off to a great start.

(3) The postcard power pack, which will send out two postcards a month on behalf of enrolled stores to their local communities. The program offers multiple options for postcards, so retailers can pick and choose which ones they think will work best for their audience.

In addition, True Value is getting a national ecommerce engine that can show member retailers’ inventory and pricing, provide the opportunity for it to be bought online, and allow customers to either pick up their purchases in store or have them shipped directly to them.

The market floor was packed with immersive displays, vendor showcases, and new product launches. From the Solutions in Action and Assortment City storefronts, and pro-focused planograms in Contractor Solutions, to over 800 Market-only VIP Deals, the event highlighted the breadth of opportunities available across both brands.

“With record-breaking attendance, a unified market floor, and an expanded lineup of vendor partnerships and programs, the first integrated Fall Market sets a powerful tone for the future of Do it Best and True Value,” Starr said. “As independent dealers explore new products, strategies and solutions, the message is clear: The combined strength of the company is fueling a new era of growth.” MM

Hood Lumber is an industry-leading supplier known for strength, durability, treatability and fastener holding capabilities.

Made from strong Southern Yellow Pine, Hood Lumber is a preferred choice among architects, builders and homeowners.

Hood Industries supports responsible forest management and is certified to the Sustainable Forestry Initiative® (SFI) Fiber Sourcing Standard at all of our manufacturing facilities. www.forests.org

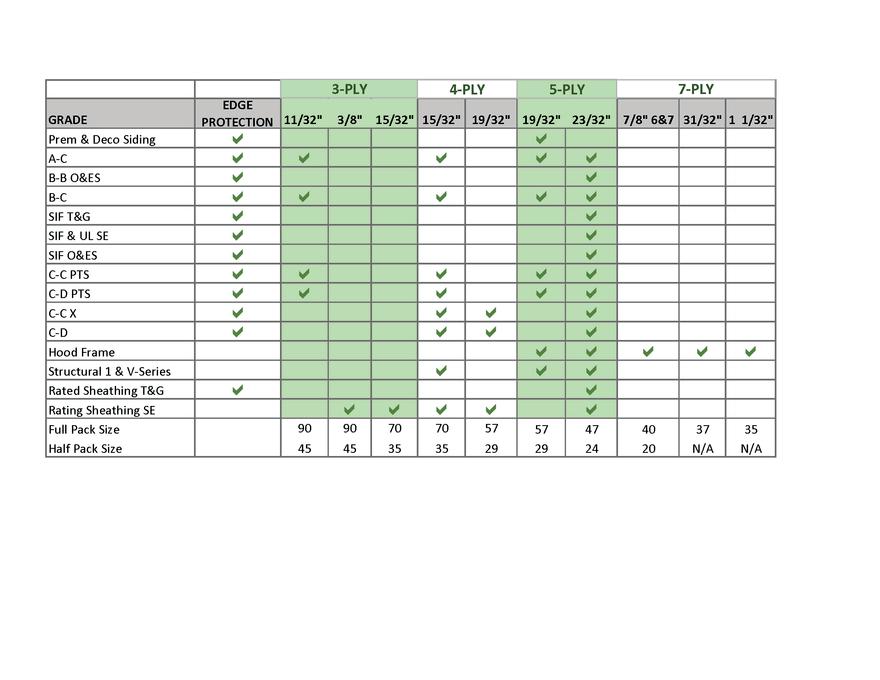

Hood Plywood is also a leading supplier in the industry offering customers a variety of quality and reliable products made from sturdy Southern Yellow Pine. Product applications range from structural sheathing, preservative and fire-retardant treatment, underlayment and subfloor, siding, concrete forming and industrial applications.

WHEN SHOULD WE GIVE THE PRICE?

WE GIVE OUR PRICE to our customers when they ask for it. We must structure our calls so that the customer does ask for our price.

Many sellers enter conversations with customers giving them every detail of their (the seller’s) proposal, including price, leaving the customer with nothing left to ask. The customer then says, “Thanks, I’ll get back to you.” We, as sellers, are left frustrated.

When we discuss the positives of our proposal, leaving price out, the customer who is interested is compelled to ask, “What’s your price?” From here, we are in a selling conversation. We are in a dialogue. Isn’t dialogue what we want with our customers?

As sellers we are not information dispensers. We are information sharers. We share information with customers who are willing to share their interest or desire with us. (I’ll share my price if you share some interest in my offering.)

In competitive markets, often the price we give is only used to keep our competition honest. We should only give prices to customers who are thinking of buying from us, not to customers who are “shopping our number.” We have nothing to hide, but we don’t need to advertise our price to non-customers who are going to take our price to our competitors and use it against us. We give price after building value

Seller: “John, I’ve got a great deal on sheathing today. We are selling it well and the market is moving in our favor. We feel the market is strong and have many customers who are buying.”

Buyer: “That sounds good. What is your price?”

------------ BY JAMES OLSEN

We give price after establishing customer need

Seller: “John, we’ve got a great deal on sheathing. Are you needing any sheathing right now?”

Customer: “I may, what’s your price?”

Seller: “John, the price is the icing on the cake, but before we go into that, how much are you going to need in the next week or two?”

If the customer is king, then what are we?

Many sellers have the attitude that the customer is king. This attitude is fine. This tells us what the customer means to us. But what do we mean to the customer? What is our role in their mind? Are we just someone they are using to keep their favorite supplier honest? Is that the position we want to be in?

Absolutely not. We want to be an equal with our customers. We want to be their trusted advisors. We want to be kings also. We are in competitive markets. Holding price gives us the opportunity to compete. Holding price creates a “vital tension” that is good for a sales call. Giving price before interest has been shown eliminates the possibility of us even competing for the order.

Giving price to customer’s before they show interest makes selling a oneway street. It is our responsibility as sellers to make selling a two-way street. Holding price will help us do that.

When we are in the middle of building value or trying to establish need, many customers will interrupt and ask, “What’s your price?” Here are a few responses we can use to hold the

customer off until we have built value/ established need with our customers:

“That’s the good part, John, but let’s discuss the other points of this item first. You’re going to love the price.”

“That’s the icing on the cake.”

“You’re going to love the price, but let me tell you the details first and see if this item will work for you.”

“Do you need it?”

“The price might vary depending on when you need it to ship or how many you need. When do you need it to ship? How many do you need to buy?”

Some customers will become irritated when we don’t give them a price immediately. Holding the price can be a delicate move. But it is necessary. We need to deal with our customer’s irritation in a positive, confident way. Won’t we be irritated if we give a price and the customer says, “Thanks, I’ll let you know”?

The structure of a sales call is important. Holding price until our customer shows interest creates a structure that is more advantageous to us as sellers. It doesn’t guarantee victory, but it does guarantee we will be in more sales calls and fewer “thanks for the information” calls. MM

JAMES OLSEN

MAKING EMPLOYEE DECISIONS

BY PAIGE McALLISTER

I SPEAK WITH clients every day who want to terminate an employee for poor performance, unacceptable attendance, or personality clashes. They are concerned, rightfully so, about the impacts on their business by either keeping an employee who is not meeting expectations or by letting them go in this litigious time. It can seem like a no-win situation, which can paralyze employers, leading to problems such as low productivity or sales and increased turnover of valuable employees.

I often hear, “It’s employment-at-will, right? Doesn’t that mean I can fire someone at any time for any reason?” While this is technically accurate, I remind them that it must be a non-discriminatory reason and that anyone can “sue-at-will” claiming to have been discriminated against, despite the facts of the case. If a claim is filed, the employer must be able to prove why they took the action and that it had nothing to do with the individual having a characteristic (such as race, color, religion, sex [including pregnancy, sexual orientation, and gender identity], national origin, age, disability, genetic information, and military or veteran status) protected under federal, state, or local law.

Making these employment decisions even more challenging is the heightened political debate and disagreement around discrimination and protected status, including:

Diversity, Equity, and Inclusion (DEI): President Trump’s executive orders rescinding DEI programs in the federal government, along with the ongoing culture clash between DEI and “anti-woke” philosophies, have created distinct “sides” to each situation. Often, complex decisions are (fairly or unfairly) reduced to one characteristic, such as race or sex. The potential heightened sensitivity on either side of an adverse employment situation increases the likelihood that a terminated employee will sue for discrimination, even with legitimate factors behind the decision.

Reverse discrimination claims are increasingly being filed, pursued, and won by employees who argue that they were discriminated against based on a non-protected characteristic, claiming that they were adversely impacted or held to a higher standard because they do not claim a protected status. The recent unanimous United States Supreme Court decision in Ames v. Ohio Department of Youth Services clarified that Title VII does not impose a higher standard for people in majority groups and negated the additional requirement of “background circumstances” many lower courts have imposed upon reverse discrimination claims to succeed. Instead, Title VII focuses on individuals, not groups, so every case should be judged based on the individual circumstances.

At the end of the day, there is no guaranteed way to prevent an employee or applicant from filing a discrimination claim or lawsuit, regardless of the reason behind adverse employment action, nor how frivolous a claim might appear. The best thing an employer can do is build and gather evidence to support their defense throughout the process, in the hope of defending their decision if needed. This includes:

Developing accurate and comprehensive job descriptions, customized for every position, to define what is truly required in that position. Good job descriptions should not only include required job duties, experience, and/or education but should also include the essential requirements of the job such as the physical (i.e., weight to be lifted, standing, sitting, using hands or fingers, etc.), mental (i.e., ability to read, speak, or comprehend instructions in a specific language; perform math computations; or make analytical decisions), and environmental (i.e., outside, non-climate-controlled, hot, humid, cold, etc.) factors along with the specific expectations and frequency of each. These must be critical to the job duties of each

position and not just a wish list to make things easier for the company. Occasionally, certain jobs may also require that an employee possess a particular characteristic that is usually protected by law. These bona fide occupational qualifications (BFOQ) are permitted but only when necessary. For example, the requirement for only a male to be placed to serve as an attendant in a men’s locker room could be acceptable, as would requiring only a female to be placed in a women’s lounge. These situations are extremely limited, so they should be reviewed carefully and defined accurately.

Hiring well by using a practical and unbiased hiring process and training interviewers and selectors on compliant practices. Know who you are hiring by conducting thorough background checks, including criminal history checks, credit checks, and reference checks. Follow employment law to determine what information can be used to exclude a candidate from further consideration. Expand your insight into potential employees through valid behavioral assessments to ensure they have the profile ideal for success.

Documenting every employment action, positive or negative, minor or severe, first incident or last chance. While not needed to take an employment action, this documentation may be required as part of your defense if faced with a lawsuit and cannot be created after the fact. Whether using an evaluation as part of your regular performance review process or using warnings through your progressive discipline process, each document should show the ongoing conversation to define expectations,

Q. We have a remote workforce. One of our employees just moved to a different state. It does not impact their job performance or schedule, but is there anything we need to do?

A . Having remote employees does not negate an employer’s obligation to follow the laws of the state and city where their employees work. This means that not only do companies need to comply with regulations in the state where their corporate office is located, but they also need to follow those wherever an employee works, including from a home office and, in some cases, where they will be working for an extended period.

Since your employee has moved, you will need to enroll with their new state of residence to ensure that proper payroll taxes are withheld and unemployment records are maintained. You will also need to ensure your Workers’ Comp coverage is valid for that state. Since all states and some cities have unique employment laws, you also need to research applicable employment laws, such as breaks, paid and protected time off, leaves of absence, and wage-and-hour laws. If you do not have the capacity to expand into other states or do not want to be obligated to follow the more restrictive or beneficial laws of certain states, you can restrict where an employee is permitted to work from, either for a short or extended period of time. You can require them to get permission before working in a new location and reserve the right to deny such requests.

assess an employee compared to those expectations, explain how they need to improve while offering resources to help them do so, and detail the repercussions for their failure to improve. It should be detailed in writing and signed off by both the supervisor and the employee (or by a manager serving as a witness if the employee refuses to sign). Allowing the employee to add their comments is also a strong practice to prove the conversation took place.

Being consistent is critical. You always need to adjust your expectations or actions based on each situation. That said, you should also set the same or similar expectations for each person within the same or similar position. You need to treat all employees the same whether they are your favorite person or someone who drains your enthusiasm and patience. Be as consistent as possible but do not be so rigid as to not provide employees with the variation needed for them to accomplish their jobs given their circumstance.

While my general advice—consistency, documentation, and focusing on essential job requirements—has been the same over my 25 years as an HR consultant, current factors such as recent legal decisions, executive orders, government agency guidance, and our contentious and litigious society in general have made that advice even more critical for every company to follow every day for every employee. MM

– Paige McAllister, SPHR, SHRM-SCP, is vice president for compliance with The Workplace Advisors, Inc. Reach her at (877) 660-6400 or paige@theworkplaceadvisors.com.

MITCHELL LUMBER ACQUIRES JUNEAU DEALERS

Breezy and Andy Mitchell of Mitchell Lumber Co., Belfair, Wa., have acquired Don Abel Building Supply and Valley Lumber Co., both in Juneau, Ak., from Bruce Abel.

The stores will retain their existing names, while operating under the newly-formed Mitchell Northern Acquisitions, LLC.

Don Abel Building Supply was founded in 1936, and Valley Lumber in 1965. Bruce Abel purchased Valley Lumber from previous owner, Dan Graves, in 2018.

Mitchell Lumber was established in 1971 with Jim Mitchell’s purchase of CK Lumber in Silverdale, Wa. His son, Jeff, took over in 1984 and relocated the business to Belfair in

1992. Jeff’s son, Andy, and his wife, Breezy, took over when Jeff passed away in 2014.

Valley Lumber operates a contractor/pro yard with a kitchen & bath design center that offers cabinets, flooring, window treatments, appliances and more.

Don Abel Building Supply is Southeast Alaska’s largest lumber, building material, and hardware dealer. Its five-acre facility features a lumberyard, 20,000-sq. ft. home center, kitchen & bath design center, tool and equipment rental center, full-scale garden center, and small engine parts and repair service. Its boom truck allows jobsite deliveries of drywall and roofing products.

U.S. Department of Commerce set countervailing duties for most Canadian softwood imports at 14.63%, weeks after establishing an anti-dumping duty rate of 20.56%, bringing the total rate to more than 35%.

Home Depot opened a new location Oct. 1 in Caldwell, Id.

Ridgefield Hardware, Ridgefield, Wa., closed its doors on Sept. 30 after 111 years, to allow owner Scott Hughes to focus on his wife's health.

Ganahl Lumber, Anaheim, Ca., is now carrying Euro Pratick USA decorative wall panels.

Restoration Forest Products, Bellemont, Az., reportedly shipped the first rail car of ponderosa pine lumber out of Northern Arizona in over 30 years. The car was headed south to Mexico.

Weyerhaeuser completed the $60-million sale of its Princeton, B.C., sawmill to Gorman Group BPWood, in partnership with SaferWood Thermex- FR, announced its ThermoWood Ayous and Thermo-Wood Nordic Pine successfully passed independent third-party testing to achieve Class A ignition-resistant status per ASTM E2768 (E84 30-minutes) after ASTM D2898 accelerated weathering—the first available in North America.

Misura Group completely redesigned its website to better aid LBM companies in their executive searches.

Humboldt Sawmill signed on as the title sponsor of the West Coast LBMA annual convention Oct. 28-30 in San Diego.

Eugene True Value Hardware, Eugene, Or., celebrated its 100th anniversary with a special event Oct. 3–5.

South Coast Lumber Co., Brookings, Or., held a family BBQ, cornhole tournament, raffle and carnival to mark its 75th anniversary.

Patrick Lumber Company

Combilift recently produced its 100,000th multi-directional forklift and is celebrating the milestone by raffling it off, with all proceeds donated to UNICEF Ireland’s Children’s Emergency Fund.

TruWood leads the way in beautiful, long-lasting engineered wood siding and trim. And thanks to EcoGuard® – a naturally occurring additive – our products resist fungal decay and termite damage decade after decade. So you can protect your family, as well as your investment. TruWood. Engineered to perform. Designed to protect. Contact Visit TruWoodSiding.com and discover what’s Tru to you. Get Tru.

WASHINGTON DEALER BAYVIEW REBRANDS

Bayview Building Materials, Elma, Wa., has officially changed its name to Elma Building Center as part of an exciting new chapter in its growth. The name change was made to avoid confusion with a similarly named store in Olympia, Wa., and reflects the branch’s commitment to celebrating the Elma community it proudly serves.

Since 1964, Bayview Building Materials has been a cornerstone of the Elma community, providing quality products and exceptional customer service. As part of TAL Building Centers, a family-owned company with 30 building material centers across the Pacific Northwest, Elma Building Center has grown to become the area’s goto destination for contractors, DIYers, and homeowners. With this new identity, the store is reaffirming its commitment to the Elma community and to helping people build better lives and spaces.

“Our new name reflects our deep connection to the Elma community, and we’re excited to showcase our newly enhanced store,” said Brian Christensen, branch manager of Elma Building Center. “With an expanded range of products, a dedicated garden center, and our recent major store reset, we are more than ready to serve our customers, both big and small, with an exceptional selection and outstanding service.”

Over the last few months, the Elma Building Center team has refreshed the store from top to bottom. Shoppers will now find a wider selection across every hardware category. The store is also now the area’s destination for Stihl outdoor power equipment, and later this fall it will unveil a brand-new Design Center with windows, doors, decking, and cabinets to inspire customers with their projects.

“We are excited to offer our customers not just products, but a full-service experience, from expert advice to a welcoming atmosphere where they can explore, design, and make their building and renovation ideas come to life,” added Christensen. “Our mission remains the same: to help build better communities by providing great products and exceptional customer service.”

To celebrate the new name and all the updates, Elma Building Center hosted a Customer Appreciation Day on Sept. 23. Customers enjoyed free lunch, vendor displays, prizes, and special discounts while exploring the refreshed store.

Based in Vancouver, Wa., TAL Building Centers is a fam-

ily-owned company helping to build better communities. At its 30 building material centers located throughout the Pacific Northwest, TAL creates a positive experience for its customers—pros and homeowners alike—by providing guidance for innovative, smart building solutions.

TAL’s family of brands include Badger Building Center, Beaverhead Building Center, Best Built Builders Supply, Browne’s Home Center, Elma Building Center, Ennis Building Center, Gerretsen Building Supply, Harbor Rental and Saw Shop, Lake Chelan Building Supply, Marson & Marson Lumber, Midway Building Supply, Miller’s Home Center, Mount Vernon Building Center, and Tum-A-Lum Lumber.

UFP EDGE SHUTTERS MONTANA PLANT

UFP Industries closed its UFP Edge plant in Bonner, Mt., on Sept. 27, laying off about 100 employees.

UFP, which has more than 200 locations worldwide, had manufactured siding, trim and interior accents at the facility.

HALL DISTRIBUTING DUXXBAK DECKING IN PACIFIC NORTHWEST

DuxxBak Composite Decking has forged a new strategic distribution partnership with Hall Forest Products, a respected supplier of building materials throughout Washington State. This collaboration will significantly improve regional availability of DuxxBak’s advanced decking solutions, including DuxxBak Dekk, by offering localized inventory, quicker fulfillment, and enhanced support for contractors, dealers, and specifiers.

Based in Puyallup, Wa., Hall Forest Products is a distributor of premium building materials serving Washington, Oregon, Alaska, and Hawaii. With extensive industry expertise and a commitment to service, Hall Forest is a trusted partner for lumberyards and dealers throughout its markets.

This relationship is intended to strengthen DuxxBak’s footprint in the Pacific Northwest market by leveraging Hall Forest Products’ established lumberyard connections and AmeriLux International’s expertise in supply chain logistics. Customers will now benefit from:

• Faster local delivery and stock availability of DuxxBak’s premium decking profiles

• Access to comprehensive training programs, including hands-on installation workshops and product knowledge sessions

• Tailored support from a distributor dedicated to delivering the highest standards of service across the industry

“By working with Hall Forest Products, we’re able to place DuxxBak directly into the hands of builders, specifiers, and homeowners across the Pacific Northwest,” said Eddie Holzem, vice president of sales & marketing, DuxxBak Composite Decking. “Hall Forest’s proven reputation for dependability and outstanding service makes them an ideal partner as we continue building momentum in this important region.”

Leading this launch is DuxxBak Dekk, the company’s flagship water-shedding system engineered to keep the area beneath elevated decks completely dry without the need for secondary drainage. Its mineral-based composite formulation resists moisture, rot and fading for long-lasting performance.

NEW LOOK: Bayview Building Materials, Elma, Wa., has been renamed Elma Building Center in conjunction with a top-to-bottom store refresh.

GOLDEN STATE BUYS SACRAMENTO SHOWROOM

Golden State Lumber, Petaluma, Ca., has acquired The Window and Door Shop, Sacramento, Ca., from Warren and Gaby Sizemore.

The business rebranded as a Golden State Lumber showroom on Oct. 1.

The Window and Door Shop has been supplying quality products from brands such as Marvin, Western Window Systems, Milgard, Weather Shield, and Trustile throughout Northern California since 2009.

The location becomes Golden State’s fourth door and window showroom, in addition to its six lumberyards throughout the Bay Area. The other three showrooms (Santa Rosa, Brisbane and Newark) are in cities that Golden State also has a lumberyard. Its nearest lumberyard to Sacramento is in Stockton, Ca.

TRUSSWORKS OPENING IN COLORADO

Trussworks Operations will open a new manufacturing plant in Pueblo, Co.

With plans to be up and running by the end of the year, the facility will produce roof, floor and timber trusses, wall panels, and LVL beams for large-scale multi-family, commercial and production builder projects. The 17,000-sq. ft., rail-served facility is located near the Pueblo Memorial Airport.

Trussworks expects to immediately outgrow the 40-year-old building, so it will begin making trusses there in the fourth quarter of 2025, then start construction on a larger building behind it. The hope is to be up to 65

total workers within two to three years.

According to Travis Anderson, operations manager for the Pueblo facility, the company is looking to expand its operations into Mountain West states to support demand in Colorado, New Mexico, Wyoming, and Utah.

Andy Dunham will serve as sales manager.

Based in Texas, Trussworks currently operates plants in Kingman, Az.; Caldwell and Mabank, Tx.; Durant, Ok.; Lincoln, Ar.; Jackson, Mo.; and—opening later this year— Wauchula, Fl.

COLLINS FINALIZES TRUWOOD SALE TO SWISS KRONO

Collins Pine Co., Wilsonville, Or., has completed the sale of its particleboard and engineered wood siding manufacturing facilities in Klamath Falls, Or., to Swiss Krono Group, effective Aug. 25. The sale included the TruWood Siding & Trim brand name.

This closing marks the final step in the transaction announced on May 30 and represents a significant milestone for both companies. The facilities and their operations are now officially part of the Swiss Krono Group, strengthening its North American presence and expanding its footprint into the western United States.

Chad Turner, formerly regional director of operations with Alliance Door Products, is the new general manager of the Klamath Falls operation.

Among Collins employees moving to Swiss Krono USA are marketing manager Cameron Waner, TruWood sales manager Brett Bleichrodt, salesman Dominic Mattos Jr.,

and shipping supervisor Tracy Sullivan.

Swiss Krono Group is one of the world’s leading manufacturers of wood-based materials and stands for sustainable and innovative solutions in the business areas of flooring, interiors, and building materials. Swiss Krono focuses on recyclable materials for living and working environments. Founded in 1966 as a family business, the group now employs around 4,800 people at 12 production sites in eight countries around the globe. The corporate office is based in Lucerne, Switzerland.

Founded in 1855, Collins is family-owned and produces softwood and hardwood products at their facilities in Chester, Ca.; Lakeview, Or.; and Kane, Pa. Collins is highly respected for their sustainable forest management, practiced across their over 370,000 acres of FSC-certified lands in California, Oregon and Pennsylvania.

INTERFOR CUTS BACK ACROSS ALL REGIONS

Interfor Corp., Burnaby, B.C., plans to reduce its lumber production by approximately 145 million bd. ft. between September and December of 2025, representing approximately 12% of its normal operating stance.

The temporary curtailments will be through a combination of reduced operating hours, prolonged holiday breaks, reconfigured shifting schedules and extended maintenance shutdowns. The curtailments are expected to impact all of Interfor’s operating regions, with both the Canadian and U.S. operations expected to reduce their production levels by approximately 12% each.

The curtailments are in response to persistently weak market conditions and ongoing economic uncertainty.

The company will continue to monitor market conditions across all of its operations and adjust its production plans accordingly.

MONTANA’S EMPIRE PICKS UP THERMALLY MODIFIED KLAASWOOD

Empire Building Materials, Bozeman, Mt., is now distributing KLAASWOOD thermally modified wood.

The strategic alliance combines KLAASWOOD’s innovative approach to thermally modified wood processing and product development with Empire Building Materials’ extensive experience and reach in the forest products industry.

Empire Building Materials, established in 1954, maintains its corporate headquarters in Bozeman, with distribution facilities in Butte, Missoula and Laurel, Mt.

KLAASWOOD leverages advanced hydrolysis technology to revolutionize thermally modified wood. Its unique process subjects wood siding, decking, and trim to high temperatures and pressure, enhancing stability, durability, and resistance to decay and moisture without chemicals or biocides.

Its chemical-free wood offers unmatched stability and durability, minimal maintenance, and enhanced moisture resistance. Available in four colors with customization options, KLAASWOOD combines the natural look of wood with the benefits of alternative materials like vinyl or fiber cement siding. The brand is said to boast reduced lead times, a lower CO2 footprint, and high-performing, beautiful wood.

HARDWOODS OPENS DOORS TO NORTHERN CALIFORNIA “SUPER DISTRIBUTION CENTER”

Hardwoods has officially opened its newest and largest distribution center in Stockton, Ca. The new 150,000-sq. ft. facility is a state-ofthe-art hub designed to serve customers better than ever by merging operations from the former Livermore, Modesto and Rancho Cordova, Ca., locations.

“We’re very excited to open this new regional hub in Stockton,” said Nick Smith, regional vice president of Hardwoods West. “This new location will allow us to serve our existing customers with greater efficiency, expand our product offering, provide an enhanced will call experience, and explore new material handling technology. It represents our continued commitment to the Northern California market and is another piece of our long-term growth strategy across the west.”

The new regional hub will feature an impressive 10,000-sq. ft. Will Call area meticulously designed for customer comfort and convenience. The climate-controlled space offers refreshments and washrooms, along with a streamlined process where customers can easily select their own material. Soon, the area will also feature product displays and TV monitors showcasing current promotions and new arrivals.

The new Stockton facility also offers access to the convenient ShopHardwoods.com e-commerce platform, a 2,000-sq. ft. showroom, and a specialized sample room—an important resource for supporting architects and designers with a wide assortment of samples and comparative information to simplify product selection. The showroom will be designed for collaborative meetings, allowing specifiers and their clients a relaxing place to meet and choose materials together.

The new distribution center will significantly improve operational efficiency with its prime location, expanded operating hours, and new material handling technology. The larger size means the Stockton location can maintain a deeper and more diverse inventory for the Northern California market. With 27-ft.-high ceilings, 16 loading docks, and five all-weather loading doors, the facility is built to provide superior customer service.

There is also plenty of room available to accommodate future expansion.

From its headquarters in Langley, B.C., Hardwoods operates 30 regional customer service centers throughout the United States and Canada. Hardwoods has evolved into one of the

largest architectural and decorative material suppliers in North America. Products include hardwood lumber, hardwood plywood, engineered/modified wood, synthetics, prefinished wood panels, high gloss and matte panels, decorative veneers, TFL, HPL, and outdoor living products for residential and commercial interiors/ exteriors.

It is a division of ADENTRA Inc., one of North America’s largest distributors of architectural materials to fabricators, home centers and professional dealers servicing the new residential, repair and remodel, and commercial construction-end markets. The company currently operates 83 regional customer service centers across the U.S. and Canada under six brands—Hardwoods, Rugby Architectural Building Products, Paxton Lumber, Novo Building Products, Mid-Am Supply, and Woolf Distributing—DesignOneSource, its Specification Division, which represents products from Hardwoods, Rugby and Paxton for the A&D community.

U.S. PRODUCERS HAIL CANADA DROPPING ANTIDUMPING APPEAL

The U.S. Lumber Coalition supports Canada’s decision to drop its appeal of the second administrative review of the antidumping order in the trade case against softwood lumber imports from Canada. This step finalizes the total antidumping liability for Canadian softwood producers that shipped product into the U.S. market in 2019.

“With the conclusion of this appeal, Canadian lumber producers will now owe U.S. taxpayers an additional estimated $236 million. That liability reflects the high level of dumping that occurred in 2019 and sets the stage for a total estimated payment of $760 million to U.S. taxpayers once the anti-subsidy portion of that review is completed,” said Zoltan van Heyningen, executive director of the U.S. Lumber Coalition.

To date, Canadian softwood lumber producers have paid an estimated $7.2 billion in duties.

“Strong trade law enforcement is exactly what must continue for the United States to sustain its progress to self-reliance in softwood lumber milled by American workers to build American homes,” concluded van Heyningen.

HARDWOODS’ massive new distribution center in Stockton, Ca. , combines its Livermore, Modesto and Rancho Cordova, Ca., operations into a single, powerful hub, designed to serve customers faster and more effectively.

Re Reddwwood i ood is

thrives in some of the most productive timberlands in the world. Redwood is known for its timeless durability without the use of chemicals. Due to its flawless formation, there has never been a Redwood recall. There is a grade of Redwood for every application, every budget, and every customer.

“Growing beyond measure.”

Call or visit us today. Our family of Redwood timberland owners will continue to be your reputable and reliable source of Redwood.

SPECIALTY BUILDING PRODUCTS BUYING OREPAC

Specialty Building Products, LLC, a leading multi-brand distributor of specialty building products, has signed a definitive agreement to acquire western distributor OrePac Building Products, Wilsonville, Or.

Financial terms of the deal were not disclosed.

OrePac will become SBP’s newest operating brand, joining U.S. Lumber, DW Distribution, REEB, Millwork Sales, Amerhart and Alexandria Moulding.

Combined, SBP’s six current brands operate more than 40 locations that serve 43 states in the U.S. and eight provinces in Canada—but the only one facility—an Alexandria Moulding distribution center in Moxee, Wa.—is in the western U.S.

Founded in 1977, OrePac is a second-generation, family-run distributor of high-quality building materials serving customers from 13 locations across Oregon, Washington, Idaho, Montana, Utah, Colorado, Arizona and California.

“We are excited to welcome one of North America’s leading specialty distributors to the SBP family,” said Jeff McLendon, president and CEO of Specialty Building Products. “OrePac and its team share our unrelenting focus on customer success, building and maintaining strong relationships, and sustaining operational excellence. OrePac’s legacy of leadership and service aligns seamlessly with SBP’s vision of championing customer success from the core of the specialty building products value chain.”

“After nearly 50 years as a family business, this moment is both emotional and exciting for OrePac,” said Brad Hart, president and CEO of OrePac. “We are proud to join forces with SBP, whose scale and expertise will help carry forward our legacy while honoring the values our family has built since 1977.”

“This partnership ensures that our employees, customers, and communities will continue to benefit from OrePac’s exceptional dedication

and support, while also opening the door to new opportunities for growth and success,” added Glenn Hart, founder and chairman of OrePac.

The acquisition is expected to close in the fourth quarter of 2025. Following the transaction, OrePac will continue operating under its current brand name, with its geographic locations, management team, and employees remaining in place, led by senior VPs Darin Coder and Kris Schroeder.

Specialty Building Products is at

the core of the value chain for high value specialty building materials. SBP provides sales, marketing, manufacturing, assembly, customization, finishing and logistics solutions that bring a range of high value, SKU-intensive, and logistically complicated specialty building products to dealers serving the repair & remodel and new construction marketplaces. Its best-in-class operations supply top building product brands to local, regional and national building material dealers, national one-step distributors, national retail chains, and industrial and OEM manufacturers.

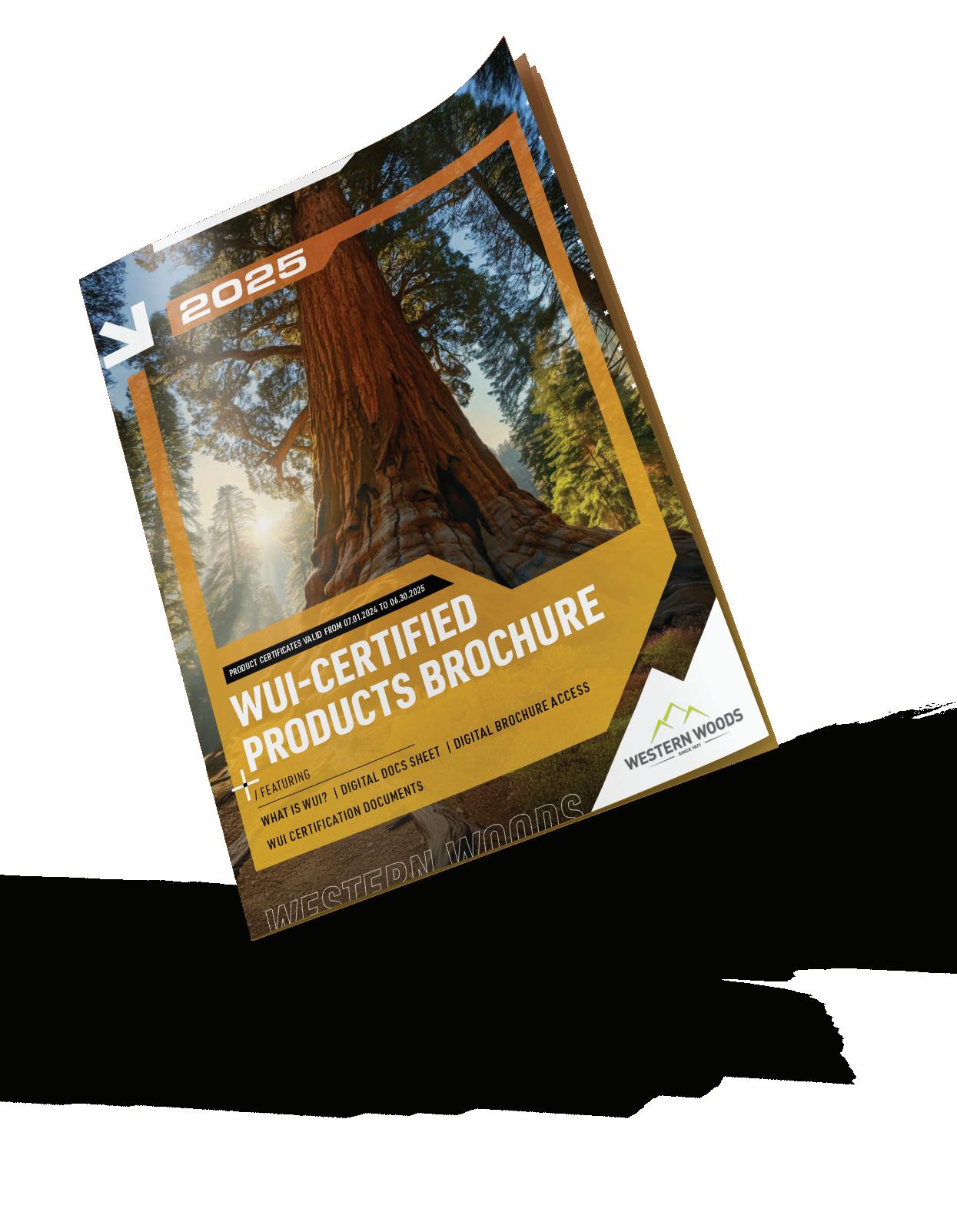

PUSHBACK FORMS TO FORTHCOMING COLORADO WILDFIRE CODE

Led by the efforts from the American Wood Council (AWC), the lumber industry is pushing for reasonable exceptions to the 2025 Colorado Wildfire Resiliency Code recently adopted by the Colorado State Legislature.

The code, as written, currently bans the use of natural wood products for exterior uses such as siding and decking. Long-standing options for builders and homeowners such as cedar and redwood, which carries a natural Class B flame spread rating, would not

2025 COLORADO WILDFIRE RESILIENCY CODE WHAT IT MEANS FOR EXTERIOR WOOD CONSTRUCTION

In recent years, Colorado has experienced multiple devastating wildfires in what has been termed the Wildland-Urban Interface or WUI. WUI is defined as areas where structures and other human development meet or intermingle with undeveloped wildlands or vegetative fuels. Population growth and expansion of urban development into traditionally non-urban areas have increasingly brought people into contact with wildfires. WUI is the fastest-growing land use type in the contiguous U.S.

2023,

stemmed from a joint effort between the Colorado State Legislature and firefighting professionals. On July 1, 2025, the 2025 Colorado Wildfire Resiliency Code (CWRC) was adopted.

The CWRC, as written, currently bans the use of natural wood products for exterior uses such as siding and decking. Long standing options for builders and homeowners such as Redwood, which carries a natural Class B flame spread rating, and Cedar, would not be allowed. This and other provisions of the CWRC will likely lead to higher housing costs and exacerbate housing shortages

Articles discussing concerns around higher housing costs and potential housing shortages can be read here:

• The Durango Herald

• Colorado Community Media

INFORMATIVE FLYER is being distributed by the Mendocino Family of Companies to rally support for making reasonable exceptions in the coming Colorado Wildfire Resiliency Code to accommodate certain naturally fire-resistant wood products

be allowed. As is, the code would likely lead to higher housing costs, likely lead to fewer material options and higher home construction costs, possibly exacerbating housing shortages.

In recent years, Colorado has experienced multiple devastating wildfires in what has been termed the Wildland-Urban Interface or WUI. WUI is defined as areas where structures and other human development meet or intermingle with undeveloped wildlands or vegetative fuels. Population growth and expansion of urban development into traditionally non-urban areas have increasingly brought people into contact with wildfires. WUI is the fastest-growing land use type in the contiguous U.S.

Additionally, there are concerns that the Wildfire Resiliency Code Board failed to adequately incorporate comments from stakeholders—including AWC—throughout the code development process. Having had previous success in California, AWC’s team of technical experts engaged the Wildfire Resiliency Code Board via public comment to recommend these effective provisions.

In 2008, California adopted California Building Code Chapter 7A, Materials and Construction Methods for Exterior Wildfire Exposure. Under this code, Redwood siding and decking are approved for use in California’s WUI fire hazard severity zones. Now approaching two decades in effect, this code has proven itself by reducing wildfire losses of new construction in California. In fact, the Chapter 7A provisions have proven so effective that they have been incorporated into California’s new 2025 California Wildland-Urban Interface Code.

As of press time, the Colorado Wildfire Resiliency Code Board had not responded to letters of recommendation from the wood products industry to incorporate California’s successful WUI provisions. Despite AWC’s recommendations to utilize these proven methods, the board proceeded with finalization of the CWRC without integration. As such, the future for the use of natural wood decking and siding such as redwood and cedar remains in limbo.

Mendocino Family of Companies, including Humboldt Sawmill Co., Allweather Wood, and Mendocino Forest Products, are distributing a flyer breaking down the issue and encouraging wood products industry members, as well as builders, designers and homeowners in Colorado, to get involved by contacting their local state Senator and Representative in the Colorado State Legislature, and their local building department officials.

C&E LUMBER COMPANY

1 1/2” to 12” Diameter in Stock.

CWRC ADOPTION

In May

Colorado introduced Senate Bill 23-166, leading to the formation of a Wildfire Resiliency Code Board under the Division of Fire Prevention and Control. The goal of this Board is to improve safety and resilience against wildfires across communities in Colorado by promoting the adoption of relevant codes and standards. The initiative

Traders Market 2025: An opportunity for connection

By Kyle Little

We’re just months away from gathering in Kansas City, Mo., for Traders Market 2025, and the excitement is building. Since its start in 1996, Traders Market has established itself as one of the premier events in the lumber and building materials industry—and this year will be no exception.

Traders Market isn’t just a meeting point—it’s where our industry advances. In a time of both opportunity and challenge, it’s more important than ever that we lean into what defines NAWLA: uniting the industry, not only during times of growth, but when it matters most.

Whether it’s your first Traders Market or your 20th, you can expect a week filled with innovation, networking and meaningful conversations. Building on feedback from members and past attendees, we’ve made important enhancements to the 2025 experience, with even more improvements already planned for 2026 and 2027. This year’s event features 12 hours of networking time on the tradeshow floor—that’s four extra hours to get business done—and new engaging activities including a biergarten and golf simulator.

Our commitment to continuous improvement means every year Traders Market delivers greater ROI: stronger connections

that translate into partnerships, richer content that fuels smarter strategies and a tradeshow floor designed to drive opportunities well beyond your time in Kansas City.

One of the highlights we’re looking forward to is Thursday’s featured educational session, “Innovating the Business: RealWorld Tools, Smarter Operations and Leading Through Change.” With insights from industry leaders Sarah Smith of Roseburg Forest Products, Carl Lamb of Snavely Forest Products and Henry German of DMSi, this session promises to deliver practical strategies for navigating today’s evolving business environment.

We’re also extending tradeshow floor hours this year—giving you more time to connect, explore and do business. With more than 200 exhibitors and 12 hours of floor time, you’ll have the chance to discover new products, share ideas with suppliers and customers and strengthen partnerships that drive our industry forward.

And let’s not forget the excitement of being in Kansas City—a city rich in culture, music and legendary food. Between sessions, you’ll have the chance to explore world-class jazz, vibrant neighborhoods and some of the best BBQ and breweries in the country. It’s in these moments—whether over coffee, at dinner or

while taking in the local flavor—that the most meaningful connections often happen. These informal conversations often spark the most valuable ideas and collaborations.

Contents NAWLA TRADERS

2025

As our industry continues to face shifting markets, regulatory changes and broader economic pressures, Traders Market is a timely opportunity to share insights, support one another and plan for the future. You’ll also have the chance to connect directly with NAWLA’s leadership team—our board, volunteers and staff—and share your feedback to help strengthen both this event and the value you receive as a member yearround.

Let’s make the most of the days ahead as we gather to celebrate successes, tackle shared challenges and invest in the

relationships that keep our industry strong.

I look forward to seeing you in Kansas City. If you have any questions before the event, please reach out to the NAWLA team at info@nawla.org.

Sincerely, Kyle Little Sherwood Lumber Corp.

NAWLA Chair

NAWLA chair Kyle Little extends an invitation for LBM wholesalers and manufacturers to attend the 2025 Traders Market in Kansas City

Plan your trip to the industry’s most effective show

Who’s who on the NAWLA Executive Committee, Board of Directors, and staff

This year’s Traders Market will be even better than previous editions thanks to a number of improvements

Meet the exhibitors who will fill the marketplace

Your guide to the products and services provided by Traders Market exhibitors

in 2026: T-100

Your first look at a brand new event for top LBM industry owners and executives, scheduled for March 2026 in Southern California

Schedule of Events

(Times subject to change. All activities will take place at the Kansas City Convention Center)

Wednesday, November 5

7:30 - 9 a.m. – Executive Committee Meeting

8 a.m. - 5 p.m. – Exhibitor Set-up

9:15 a.m. - 12 p.m. – Board Meeting

11 a.m. - 7 p.m. – Registration Open

1 - 2:30 p.m. – Committee Meetings

2:30 - 4 p.m. – 10 Group Meetings

4 - 4:30 p.m. – YELP Mixer

4:30 - 5:30 p.m. – Chair’s Reception

5:30 - 7 p.m. – NEW! Welcome Party

Thursday, November 6

7:30 a.m. - 6 p.m. – Registration Open

8 - 9 a.m. – Education Session: “Innovating the Business: Real-World Tools, Smarter Operations, and Leading through Change”

9:15 - 10 a.m. – NEW! Business Meeting Breakfast

10 a.m. - 6 p.m. – NEW! Tradeshow Open All Day

12 - 1 p.m. – NEW! Lunch on the Tradeshow Floor

5 - 6 p.m. – Show Floor Reception

Friday, November 7

8 - 11:30 a.m. – Registration Open

8 a.m. - 12 p.m. – Tradeshow Open (Brunch on the Show Floor)

8 a.m. - 12 p.m. – Student Program

12 - 6 p.m. – Exhibitor Move-out

NAWLA Executive Committee

Kyle Little, Sherwood Lumber Corp. –Chair

Judy Haney, Boise Cascade Building Materials Distribution –First Vice Chair

Warren Reeves, Wholesale Wood Products –Second Vice Chair

Derek Cone, Capital Lumber –Secretary/Treasurer

Thomas Mende, Binderholz Timber –At-Large

Clark Spitzer, Snavely Forest Products –Immediate Past Chair

NAWLA Board of Directors

Kent Beveridge, Skana Forest Products

Brian Boyd, Manufacturers Reserve Supply

Lori Byrd, RoyOMartin

Harris Gant, Claymark USA

Gavy Gosal, Western Forest Products

Kaycee Hallstrom, Zip-O-Log Mills

Carl Lamb, Snavely Forest Products

Paul Odomirok, Great Lakes Forest Products & Lamination

Grant Phillips, Wildwood Trading Group

Alden Robbins, Robbins Lumber Co.

Curt Stuckey, Wholesale Wood Products

Morgan Wellens, Nicholson & Cates Ltd.

Steven Rustja, Cedar Mills Investments (Honorary Director)

2025 Traders Market Committee

Brandon Desyatnik, Weston Forest Products Inc. (Chair)

Taissa Achar-Winkels, Alpinewest Resources

Mauricio Bravo, Weston Wood Solutions

Lori Byrd, RoyOMartin

Adam Cooley, Madera Trading International, LLC

Judy Haney, Boise Cascade Building Materials Distribution

Trent Johnson, 526 Media Group

Aly Kingsley, Wildwood Trading Group

Chase Morrison, Sunset Moulding Co.

Patrick Price, All Star Forest Products

Casey Pierce, Castle Building Products

Phil Schumock, Stella-Jones

Warren Reeves, Wholesale Wood Products (Board Liaison)

Kelsey Kwasniak, NAWLA (Staff Liaison)

Sustainable Wood Solutions

Delivered Across North America

With operations and a commercial office in the U.S., we provide:

ʃ Reliable supply, delivered with speed and precision.

ʃ Certified sustainable forestry and biodiversity conservationcore to our operations.

ʃ Innovative wood-based materials, driving the future of construction and manufacturing.

ʃ Strong partnerships with leading distributors and wholesalers locally and globally

Plywood

Mass Timber

Moulding & Boards

Sawn Timber

What’s new? Traders Market keeps getting better

Youʼve heard the old saying? “If it ain’t broke, make it even better?” That’s the plan for NAWLA Traders Market—the premier event for professionals in the forest products industry, set for Nov. 5-7 in Kansas City, Mo. Offering even more opportunities to connect with leading buyers and suppliers, there is no other event like it.

Connect with top-level lumber and building material professionals from every link in the distribution chain at Traders Market. Whether you're looking to build new relationships, strengthen existing partnerships, or make deals that drive your business forward. NAWLA Traders Market brings the decision-makers together in one place to get it done.

Forge high-value relationships with over 1,200 leading buyers, suppliers and key decision-makers representing every facet of the lumber industry. Whether you’re a seasoned professional or just starting out, Traders Market is the place to grow your network and expand your company’s bottom line.

Meet face-to-face with top suppliers, discover the latest products and innovations and build

relationships that go beyond what a phone call or email can offer. With over 200 exhibitors in one place, it’s your chance to grow your network, find new solutions and build your company’s book of business—all under one roof.

What’s New This Year

This year’s Traders Market will provide fresh features, more floor time, and bigger impact with updates designed to enhance your experience and maximize your ROI.

• Expanded Tradeshow Hours

This year’s Traders Market provides 12 hours dedicated to networking on the tradeshow floor. Engage in strategic conversations that drive deals and build lasting partnerships in a business-first environment. More time to meet, network and close deals.

• New Activations on the Show Floor

These interactive stations will provide more touchpoints to elevate engagement with potential partners.

• Fresh Networking Opportunities

Curated events to help you make meaningful connections faster.

Among the new events are an opening night Welcome Party, Business Meeting Breakfast, and enlightening panel discussion examining the surge of innovation that is transforming the wood products industry. The session, “Innovating the Business: Real-World Tools, Smarter Operations, and Leading Through Change,” speakers Carl Lamb, Snavely Forest Products; Henry German, DMSi; and Sarah Smith, Roseburg Forest Products, will share how to successfully navigate change by adopting new technologies and forward-thinking strategies. It’s not just about adding new tools. Leading through change requires vision, adaptability and the ability to inspire teams.

Get ready for a reimagined experience that puts connection, innovation and business at the center of it all! See you next month in Kansas City!

When it comes to Class A, Ignition Resistant, Appearance Grade, Exterior FRTW, nobody does it better than The Watkins Group.

International WUI Code Compliant

ASTM E84 Extended 30 Minutes

ASTM D2898 Accelerated Weathering

ASTM E108 Class A Roof Assembly

Listed: OSFM #2520-1450:0502

Listed: Cool Roof Rating Council Meets Title 24

2025 NAWLA Traders Market

Exhibitor Directory

526 Media Group 630 padams@526mediagroup.com; (714) 4862735; www.building-products.com

Publisher of a range of print and digital offerings for the world’s hardest working market segment, the American Bedrock Infrastructure Industries. Its flagship LBM supply-chain offerings are the official publications of NAWLA: BPD-Building Products Digest (in the South, Midwest and Northeast) and The Merchant Magazine (in the West). We also offer a host of digital marketing tools, including the website Building-Products.com and weekly email newsletters.

aMerican Wood TechnoloGy, llc 1016 cstaalner@awtech-llc.com; (404) 5200239; www.americanwoodtechnology.com

We offer the latest in Thermo modification equipment and lumber preservation/treating plants.

arauco 1001 (800) 261-4890; www.arauco-na.com

ArAuco North America offers sustainable forest product solutions for the construction, casework/fixture fabrication, and architectural design industries. These include a comprehensive selection of composite panels such as TFL, particleboard, MDF and HDF, along with premium plywood, millwork and lumber.

arroW reload SySTeMS inc. 714 (503) 735-1100; www.arrowreload.ca

Arrow has been providing transportation, distribution, logistics and materials handling services across Canada and the United States since 1919.

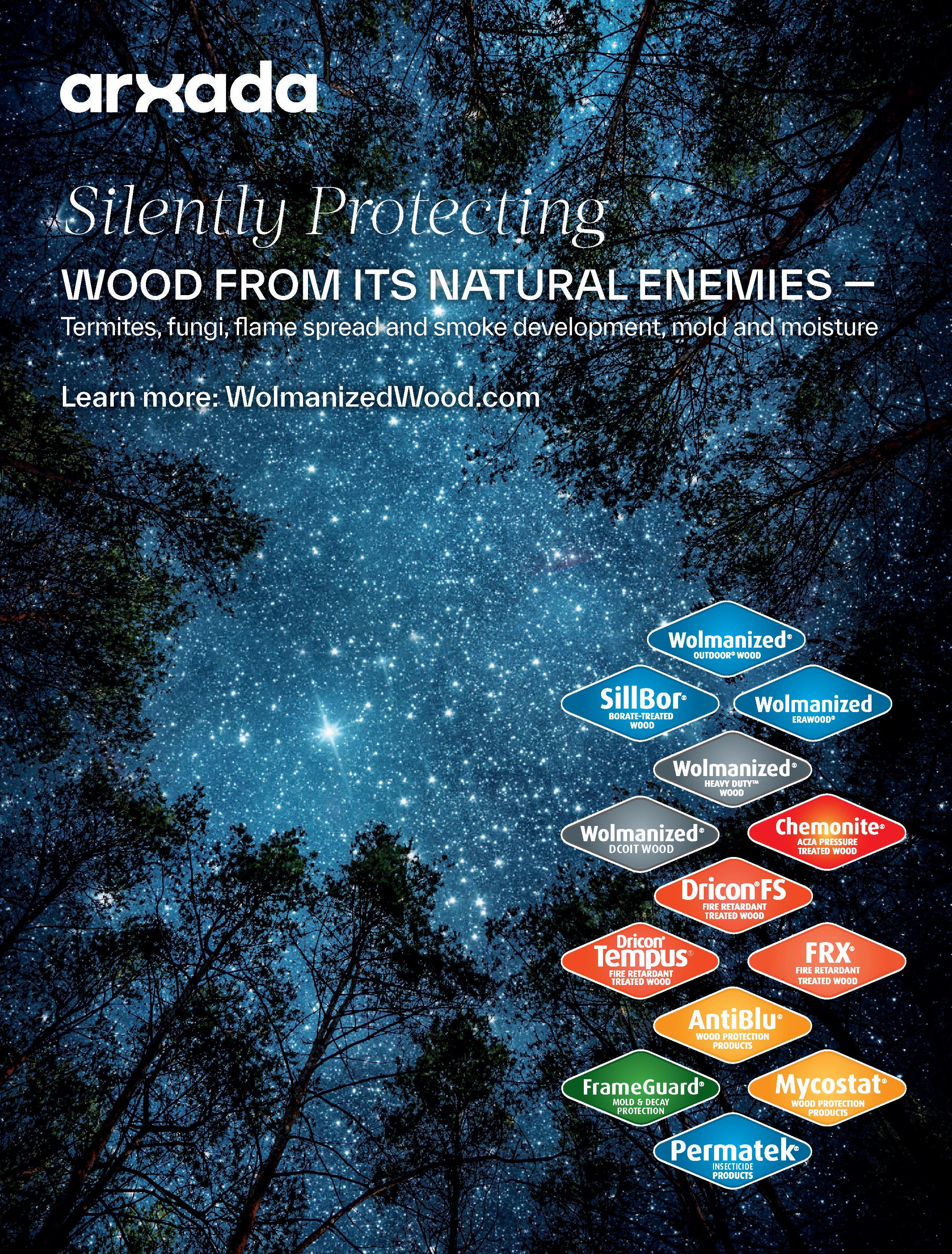

arxada 1000 chris.leslie@arxada.com; (470) 297-9215; www.wolmanizedwood.com

Arxada is a global leader providing innovative technologies that improve the performance of wood, making it resistant to termites, fungi, flame spread and smoke development, mold and moisture

avenex coaTinG TechnoloGieS 912 mnielly@avenex.com; (678) 575-9513; www.avenguard.com

AvenEx Coating Technologies is the global leader in manufacturing and distribution of our high quality AvenGuard branded wood packaging wrap and fitted covers.

avon plaSTicS 327 sara.tschida@avonplastics.com; (320) 2437318; www.avonplastics.com

Avon Plastics Inc. designs and manufactures sustainable outdoor products, including Armadillo composite decking and accessories, combining innovation, quality and eco-friendly solutions for residential and commercial projects.

Baillie luMBer – rippinG diviSion 1019 rbrunner@baillie.com; www.baillie.com

Resource-based company providing S4S, profile mouldings, and ripped-to-width products backed by the country’s largest inventory of hardwood lumber ensuring supply through any market condition.

BarreTTe STruTural diSTriBuTion 429 (TriForce)

triforce-sales-can@ebarrette.com; ( 800) 263-7265; www.openjoisttriforce.com

Barrette Structural Distribution Inc. manufactures the TRIFORCE open joist, distributed across the U.S. and Canada.

BauMann uSa 907 rob@sideloaders.com; (855) 334-2909; www.baumannusa.com

For over 50 years, Baumann has been a global leader in the manufacture of highquality diesel and electric two-way sideloaders.

BenneTT luMBer producTS, inc. 607 jim@blpi.com; (208) 874-2104; blpi.com

Family owned and operated with mills in Idaho and Washington producing all species manufactured in the Inland Empire. Quality products by quality people!

BieWer SaWMillS 931 pturner@biewerlumber.com; (800) 4825717; www.biewerlumber.com

Biewer is a fourth-generation, familyowned company with advanced sawmills across the Midwest and Mississippi. We are committed to the environment and sound forest practices.

Binderholz TiMBer inc.

705 marketing@binderholz.com; 0043-5288 601; www.binderholz.com

Binderholz produces sophisticated solutions in wood. Dealing responsibly with this wonderful raw material and the environment guarantees quality products.

BoiSe caScade – GlulaM BeaMS 923 tylercook@bc.com; (208) 337-4717; www. bc.com/ewp/boise-glulam

From extra-long spans and curved beams to headers and dramatic columns, Boise Glulam gives you the rich, natural beauty of wood with engineered performance.

BoiSe caScade diSTriBuTion 925 (541) 213-1337; www.bc.com

Boozer laMinaTed BeaM co. 903 eruss@boozerbeam.com; (256) 237-2875; www.boozerbeam.com

BoozerBeam is a premier SYP glulam manufacturer located in Anniston, Al. Products include 2.1E, 1.9E, 1.8E, 1.6E Beams, Combination #50 columns, and Outsider pressure treated beams and columns.

Border BrokerS 631 info@borderbrokers.com; (855) 236-2566; www.borderbrokers.com

Border Brokers streamlines Canadian and U.S. customs clearance with expert, personalized service. We are problem solvers ensuring smooth, compliant cross-border operations.

BoWerS ForeST producTS 732 cbowers@bowersfp.com; (503) 631-4408; www.bowersforestproducts.com

Family-owned and operated lumber remanufacturer and wholesaler located in Beavercreek, Or. Specializing in industrial, home and garden products. First class customer service with integrity

BpWood lTd. 412 (250) 493-9339; www.bpwood.com

Based in Penticton, B.C., BPWood’s expanding team excels in diverse wood solutions for evolving customer demands. We solve problems, cultivate partnerships, and create value globally.

BriGhT Wood corp. 914 scotthi@brightwood.com; (541) 475-2234; www.brightwood.com

We manufacture fingerjoint dimension lumber in 2x3 through 2x12 up to 60'. Fingerjoint studs in 2x3, 2x4 and 2x6 up to 12'. WWPA stamped.

Brunner hildeBrand luMBer dry kiln 933 info@brunner-hildebrand.com; (615) 4690745; www.bhl-drykilns.com

Brunner Hilderband is a leading kiln manufacturer based in Nashville, Tn. For decades, Brunner Hildebrand has introduced innovations, including global advances in drying technology to the global market.

BuilderWire, inc.

323 jmcnamara@builderwire.com; (781) 2147119; www.builderwire.com

BuilderWire, Inc. integrates the latest Internet technologies to help improve your company’s operational efficiencies and the way you sell and service customers on the web.

BWT TiMBer 804 zanda@bwt.lv; 371-2830-1574; www.bwt.lv

Located in Latvia, BWT Timber operates three planing lines, focusing on the production of CLS, roofing battens, as well C24 treated carcassing, decking, fencing and more. Working with spruce and pine. Products are FSC or PEFC certified.

canFor

522

michael.almond@canfor.com; (604) 2646291; www.canfor.com

Canfor is a global leader in the manufacturing of low-carbon forest products, delivering sustainable, high-quality wood solutions to markets worldwide.

cedar valley ManuFacTurinG inc. 902 info@cedar-valley.com; (800) 521-9523; www.cedar-valley.com

Western red cedar shingle siding panels & accessories. WUI rire rating, factory finishing, extended warranties, 180-mph hurricane rating. Easy-to-use 8' stackable panel. R&R or combed.