Deadlines. High expectations. Tough conditions.

Deadlines. High expectations. Tough conditions.

You don’t just handle the pressure - you thrive in it. You show up, put in the work, and build something that lasts. ProWood® pressure-treated lumber is built the same way - treated under pressure to stand strong against the elements, so your work stands the test of time.

When the pressure’s on, real pros rise to the occasion.

TREATED LUMBER, DECKING, RAILING, AND

A publication of 526 Media Group, Inc. 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 Phone (714) 486-2735

President/Publisher Patrick Adams padams@526mediagroup.com

Vice President Shelly Smith Adams sadams@526mediagroup.com

Managing Editor Sara Graves sgraves@526mediagroup.com

Editorial Director David Koenig dkoenig@526mediagroup.com

Columnists

Brendan Casey, April Edwards, Andy Henley, Mike Mitchell, Bobby Parks

The ultimate publication for qualified industry decision makers!

•

• Update your subscription

•Sign up key colleagues

• Sign

• Enroll

•Enroll multiple locations T for qualified industry decision makers!

Advertising Sales (714) 486-2735

Chuck Casey ccasey@526mediagroup.com

John Haugh jhaugh@526mediagroup.com

Nick Kosan nkosan@526mediagroup.com

Digital Support

Katherine Williams kwilliams@526mediagroup.com

Circulation/Support info@526mediagroup.com

Change of Address Send address label from recent issue, new address, and 9-digit zip to address below.

POSTMASTER Send address changes to Deck Specialist, 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626. Deck Specialist (USPS 224) is published six times a year at 151 Kalmus Dr., Ste. J3, Costa Mesa, CA 92626 by 526 Media Group, Inc. Periodicals Postage paid at Santa Ana, CA, and additional post offices. It is an independently-owned publication for U.S.-based builders and contractors that specialize in decking and other outdoor living projects. Copyright®2025 by 526 Media Group, Inc. Cover and entire contents are fully protected and must not be reproduced in any manner without written permission. All Rights Reserved. We reserve the right to accept or reject any editorial or advertising matter, and assumes no liability for materials furnished to it. Opinions expressed are those of the authors or persons quoted and not necessarily those of 526 Media Group, Inc. Articles are intended for informational purposes only and should not be construed as legal, financial or business management advice.

July/August 2025 • Volume 9 • Number 4

Vanilla Ice brings passion, creativity, and “ninja skills” to outdoor living.

The industry’s top builders are honored in our fifth annual Deck Specialist of the Year Awards.

Built for the Islands

Hawaiian contractors share strategies for lasting island decks.

Kitchen Lights, Backyard Nights

Layered outdoor kitchen lighting enhances function, safety, and ambiance.

Parks & Deck Creation with Bobby Parks

Set the Standard with Brendan Casey

Tool Reviews with Andy Henley and Mike Mitchell

Market Yourself with April Edwards

New Products

Date Planner

Ad Index

Plugs are fabricated using actual deck boards for a virtually invisible finished look.

Plugs come on collated strips with pre-aligned grain, making that perfect fit 50% faster.

Cortex is guaranteed to last for the life of the project and matches major board brands including Trex, TimberTech and more.

While visiting Santa Barbara last month, my daughter, our best friends and I found ourselves driving out onto the city’s old wooden pier. We hadn’t planned on it—it was one of those spontaneous detours.

The sky was muted in that soft, overcast gray that marks the start of a Southern California summer—what locals call “June Gloom.” The wooden boards beneath us creaked and clattered with each slow rotation of the tires. Raised steel bolts popped up slightly as we rolled over them, and the weathered planks flexed under the car’s weight. We all looked at each other with the same reaction: This thing is made of wood?

Not just wood—but weathered, timeworn wood. And yet it was still holding the weight of cars, crowds, and decades of salt air. Wooden piers near where I live, just a few hours south, were replaced with concrete long ago after collapsing into the ocean during strong El Niño storms. But this one? Still standing. Still doing its job.

It made me think about what it was built with—and by whom. It must’ve been a deck specialist.

And if there’s any season that separates the deck

This time of year belongs to the pros pushing through long days and tight deadlines—building spaces meant to hold up under pressure.

specialists from the rest, it’s summer. This time of year belongs to the pros pushing through long days and tight deadlines—building spaces meant to hold up under pressure. The ones who show up, even when it’s hard.

The kind of builder that this issue is dedicated to. Our annual Deck Specialist of the Year awards recognize builders who set the standard—those who bring a deep understanding of the products they work with and elevate them through thoughtful design and expert execution. These are the pros who know that a great deck isn’t just about how it looks today, but how it performs years from now. They bring a level of craftsmanship and care that doesn’t just meet expectations—it raises them.

It’s a theme that extends beyond our award winners. We open this issue with someone who also understands the value of building something that lasts: Vanilla Ice.

While most know him for his music, he’s spent the past three decades remodeling homes, hosting renovation shows, and partnering with brands like Regal ideas. His passion for design makes him an unexpected but fitting addition to this issue, especially as he reflects on the value of quality materials and doing things right to last the test of time.

So here’s to the specialists. Whether you’re featured in these pages or out there quietly raising the bar on job after job, your work is making a lasting impact.

Sara Graves is the managing editor of Deck Specialist. Reach her at sgraves@526mediagroup.com

Digger Specialties is partnering with American Lumber to bring Westbury Aluminum Railing to more pro deck contractors across the Northeast.

Headquartered in Walden, N.Y., American Lumber has been a trusted distributor of building products to lumberyards and home centers in Northeast markets since 1918.

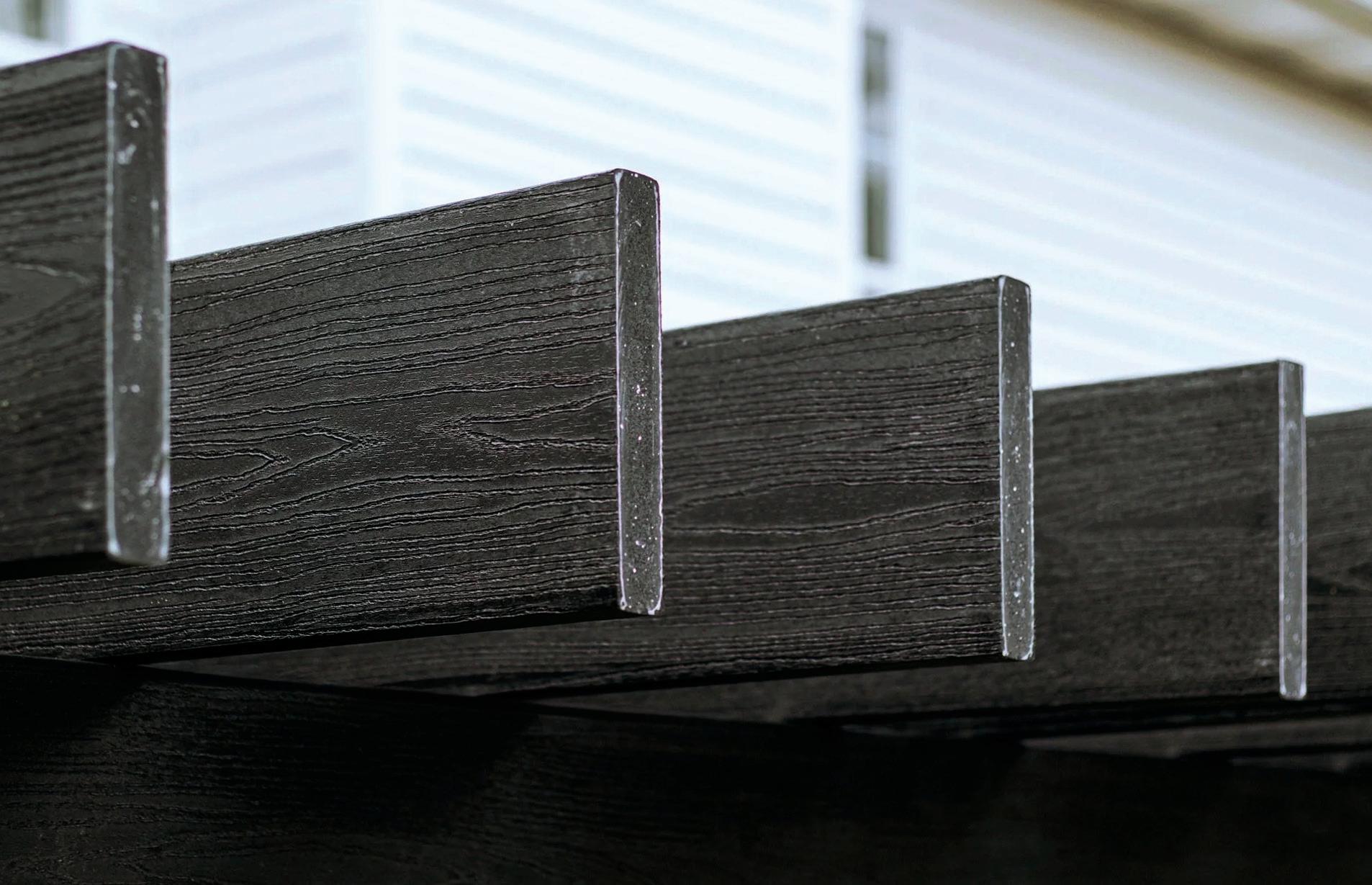

Millboard, the U.K.-based manufacturer of premium wood-look composite decking and siding, has entered a strategic distribution partnership with Russin, a Montgomery, N.Y.-based building materials distributor serving the Northeast and Mid-Atlantic states. Millboard products will now be available through Russin’s established dealer network, covering 13 states.

“Russin is a respected leader in the building products industry, known for its dedication to quality, customer service, and experience introducing premium brands to the Northeast markets,” said Justin Kurysh, GM of Millboard North America.

MoistureShield has entered a distributor partnership with Timberstone Distribution to distribute its composite decking portfolio throughout Western Canada, including British Columbia, Alberta, Saskatchewan, Manitoba and parts of Northern Ontario.

MoistureShield’s Vision, Meridian, Elevate and Vantage lines are now available through Timberstone Distribution.

Parksite Inc. will expand its offering of IG Railing to North Carolina, and will stock IG Armor, which provides protection against the elements, at all Parksite stocking locations.

“This past year, we’ve had the majority of installations be first-time user experiences in Parksite’s territory and we are happy to say that through our networks support, many of these deck builders are converting future jobs to IG Railing from user experience,” said Mike Kunard, co-owner of IG Railing.

BY SARA GRAVES

NOWADAYS, THE VOICE behind “Ice Ice Baby” is more likely to be found wielding a power tool than a microphone. But for Rob Van Winkle—better known to the world as Vanilla Ice—the rhythm of hard work and craftsmanship has become a way of life. A contractor, designer, professional motocross racer, and TV personality, Rob has spent the last three decades transforming homes and inspiring a new generation of builders through his hit show The Vanilla Ice Project. And his message to contractors is clear: build with passion, live with purpose—and don’t forget to dance through it all.

“I wake up very early every morning because I do construction, but I love it,” Rob says. “It’s developed a very fun, competitive drive that I showed my daughters. They have it now.”

While fans remember him for topping charts in the ’90s, Rob’s second act has been anything but performative. After commissioning a team of highend designers to build a customer’s house on Star Island, he realized he felt “very cold” coming home to his own nine-room home. “It felt like a shopping mall after closing hours and you’re in there all by yourself,” he recalls. That experience drove him to enroll in design school, learn the fundamentals of construction and color psychology, and dive deep into real estate and flipping homes.

Fast forward nearly 30 years, and Rob has built a successful career in South Florida. He focuses on high-end, artful renovations that cater to the people who will live in the home. “I learned how to think like a lady,” he says regarding designing a home. “The woman always buys the house—never the man. Do not cater to a man.”

“Outdoor spaces are everything,” says Rob, recalling a project he worked on for Rob’s good friend, and celebrity chef, Guy Fieri. When Fieri considered putting up a standard picket fence between his home and neighbor Brooke Shields, Rob said, “You can’t do that.” Instead, Rob partnered with Regal ideas—his “favorite railing”—to donate and install $35,000 worth of crystalclear railing along the seawall.

For his own home, Rob added a cascading lap pool with an infinity edge, a helicopter hangar, an expansive garage to house his one-of-a-kind car collection, artificial turf to protect the pool from grass clippings, and a nine-hole putting green.

Building a Team of ‘Ninjas’

Rob’s crew—the “ninjas”—are with him from start to finish on every project. “On our TV show, they make it look very glamorous.” He says his show takes longer to film than similar shows because “we don’t have B team to come in and finish what we just started here on TV.”

Each member of Rob’s crew is selected as much for who they are as what they can do. “That helps me put in perspective how to judge people’s character—so I can place them in the right role,” he explains. He illustrates, saying that Wes Kain, Rob’s “right-hand man” on the show—a Marine who is reliable, disciplined, and allin on the jobsite—can’t be put in a cubicle, behind a computer, or in front of a filing cabinet. “He just wouldn’t fit,” Rob explains.

Rob encourages builders to develop what he calls “ninja skills”—the ability to solve problems creatively in the field. “There might not be a part made to fix the problem that you’re looking at. You might have to think of a way to fix it. Maybe weld something, zip tie it, figure out a way. That’s ninja skills.”

Rob’s projects span every corner of luxury—from mammoth closets with price tags hitting $500K to a custom acrylic staircase that doubled as a live fish tank. But his real mission is simpler: to build and showcase homes that people fall in love with—and inspire builders to find joy in their craft.

That mission will be front and center in two new, back-to-back seasons of The Vanilla Ice Project, recently filmed in historic St. Augustine, FL. Once distribution details are finalized, each season will feature 13 episodes showcasing next-level design, sustainable products, and, yes, more ninja skills.

When he’s not building homes, Rob is on tour—bringing back the energy of the ’90s one stage at a time. “The ’90s get everybody dancing. That’s why I’m on the I Love the ’90s Tour right now—I’m the oldest teenager in town,” he says with a laugh. “Dancing was a common thing we did—around school, anywhere—even if you weren’t very good at it.”

The tour keeps him connected to the joy and freedom of that era. “Obviously, on Monday, I’ve got to be my real age because it’s construction time. But on the weekends? The I Love the ’90s Tour keeps me dancing, keeps me young, and pushes out how great the ’90s really was. It is the last of the great decades,” he says.

That joy-through-motion mindset isn’t just his own. Rob’s mother—affectionately known as “Mama Ice”— offers this advice: “Keep your dancing shoes on. When you wake up, dance through your problems in life, and you won’t take everything so serious. You’ll be more happy, and all the people who are dancing around you— they’re going to be happy too.”

Catch the full interview with Rob on the Deck Specialist Podcast, available on all podcast channels. DS

In today’s industry, it takes more than just quality craftsmanship to stand out as a professional contractor. Sustained success requires visibility and credibility. As the oldest and largest contractor loyalty program in the decking industry, the TrexPro® Program helps builders take their businesses to the next level by elevating their profile, providing them with expert support and, most importantly, connecting them with more customers.

The TrexPro Program is a tiered network of professional contractors who have been trained by Trex®, the world’s #1 brand of composite decking and residential railing. The program includes three levels – TrexPro, TrexPro Gold, and TrexPro Platinum – allowing contractors to gain recognition and rewards based on their company size, experience and performance. Each level brings increasing benefits, from marketing support and customer leads to enhanced warranty privileges.

Becoming a “TrexPro” makes you a member of an elite group of contractors, qualifying you to receive benefits designed to help grow your business:

Among the biggest advantages of being a TrexPro builder are increased visibility and a steady flow of qualified leads. Each year, Trex spends millions of dollars on marketing that drives awareness and demand for Trex products and generates referrals for Trexapproved builders through its Find a Builder directory populated exclusively with TrexPro contractors.

Trex actively directs homeowners to its TrexPro partners through two of the industry’s most visited websites – Trex.com and Decks.com. These sites attract millions of visitors annually, many of whom are actively seeking professional help with their decking projects. This elevated level of exposure can make a significant impact on business, especially when compared to relying solely on traditional marketing or word of mouth.

“One of the biggest perks of being a TrexPro [builder] is getting leads directly from the Trex website.”

- Cameron Crawford, CFC Fences & Decks

Today’s homeowners do their homework and are selective about who they invite into their homes. TrexPro builders benefit from instant credibility with a designation that tells potential clients they’re not only experienced but also endorsed by America’s Most Trusted Decking Brand*.

“Trex’s dependability and support for their contractors is why I continue to use Trex.”

- Michael Jaskowski, Texas Deck Pros

To earn a TrexPro designation, companies must prove expert proficiency in working with Trex decking, railing and fastening products. Trex provides onsite training, literature, videos and ongoing technical support to ensure proper installation and a consistent brand experience. The company also provides its TrexPro partners with access to premium tools for closing more sales. From professional web services and advertising support to branded vehicle wraps and apparel, these resources help reinforce your image as a high-quality, reliable contractor, boosting client confidence and supporting long-term growth.

Another major advantage TrexPro members enjoy is backing by Trex on products and installation. TrexPro Gold and Platinum builders can o er extended labor warranties to clients – up to as long as 12 years – an added value that builds customer trust and enhances your competitive edge.

The TrexPro Program is more than just a certification; it’s a partnership designed to help your business succeed. With increased visibility, brand credibility, exclusive training and marketing support, TrexPro builders are uniquely positioned to stand out and thrive in a crowded marketplace.

Whether you’re a seasoned builder or just starting to build your business, the TrexPro Program o ers a proven path to more leads, a stronger business presence and greater client satisfaction. Learn more at Trex.com.

Deck Specialist for the fifth year has partnered with leading manufacturers in outdoor living to honor top builders that specialize in their brands, based on sales growth or artistic excellence.

In this special issue, the winners discuss their businesses, passions, and what they look forward to seeing in the future.

OWNER: Sean Lutgen

LOCATION: St. Cloud, MN.

YEAR FOUNDED: 1983

WEBSITE: lutgensco.com

INSTAGRAM: lutgencompanies

FACEBOOK: lutgen.companies

How did Lutgen get its start?

In the early ’80s, company founder John Lutgen was working for a siding company. One day, John said to himself, “I can do this on my own.” He borrowed $1,000 from his parents, bought a truck and a few supplies and started siding homes in the St. Cloud, MN., area. It was a struggle for the first few years, but as the customers began to see John providing exceptional service with quality craftsmanship, Lutgen Companies began to build a reputation that had customers asking for more and more services. As the demand grew, so did Lutgen Companies.

Why do you prefer using Armadillo products?

Armadillo provides a few unique benefits for us. They’re a local company that we and our customers feel proud to support. Second, we see a strong value proposition in the strength and durability of Armadillo Decking. Finally, the product options and appeal offer the quality and aesthetic that our customers have come to expect from us.

Describe a recent project in which you used Armadillo decking. This past fall, we had a massive deck that overlooked a secluded lake. The customer was looking to replace an existing wood deck that was nearing the end of its lifespan. We stabilized a foundation for the new deck with 24 helical piers, then used Armadillo decking to create a highly functional and great looking platform for the customer. Now they have a gorgeous deck that helps them enjoy the beauty of the lakeside just beyond.

What inspires your projects?

We want to provide more than “just a deck.” We want to create a space where people can live their lives. In Minnesota, the months without snow are not always easy to come by. So, you better believe when the weather is nice, we want to make sure that our clients have the best space for living, grilling, relaxing, entertaining, and enjoying. Armadillo’s array of products help us to create these spaces that not only look amazing but also hold up under the extreme weather conditions they’ll be put through in our state.

What’s ahead for Lutgen?

We’re growing. In 2025, we’ll be breaking ground on a new facility and have already expanded our territory to meet the demand. We’re finding people need guaranteed quality work. We’re the oldest, family-owned contractor in central Minnesota. We attribute a lot of our success to being committed to providing tremendous value to everyone we serve. We’ve been building a better community for more than 40 years. We are going to keep doing that for many more to come

From the makers of YellaWood® brand pressure treated pine comes a contractor loyalty program that can help build your business. Pocket 1.5% of qualifying purchases by earning YellaBucks SM credits. Sign up today at YellaSource.com and earn towards items like tools, apparel or truck wraps.

OWNERS: John Coffelt, Jonathan Bailey, Zack Willmore, Jamie Breneman

LOCATION: Chattanooga, TN. (serving the greater Chattanooga area, North Georgia, and expanding into south Knoxville)

YEAR FOUNDED: 2012

WEBSITE: chattanoogaexteriors.com

FACEBOOK: chattanoogaexteriors

Tell us how Chattanooga Exteriors got its start. Chattanooga Exteriors was founded with a clear vision: to bridge a gap we noticed in the market—where homeowners were too often offered what the contractor wanted to build, rather than what they truly envisioned. We set out to change that by creating a company rooted in listening first, then delivering with precision and care.

From the beginning, our mission has been to provide an exceptional customer experience—one where each homeowner feels heard, valued, and confident in the final result. By combining top-tier products with craftsmanship and personalized service, we ensure that every project not only meets but exceeds

expectations. At Chattanooga Exteriors, we’re committed to transforming homes with integrity, quality, and a level of care that makes the process as rewarding as the finished product.

How did CAMO become one of your primary vendors?

CAMO became one of our primary vendors because their innovative fastening systems align perfectly with our commitment to delivering high-quality, efficient, and aesthetically pleasing deck installations. Their comprehensive product line—including hidden deck clips, collated screws, and stand-up fastening tools— streamlines our workflow, allowing us to build smarter, faster, and better decks. Partnering with CAMO has empowered us to elevate our craftsmanship and deliver exceptional outdoor living spaces that meet and exceed our clients’ expectations.

Where do your design ideas come from?

Our design inspiration comes from a blend of modern trends and client collaboration. We stay current by following leading exterior design companies and engaging with platforms like social media, where fresh ideas and innovative concepts are constantly emerging. But what truly sets us apart is our dedication to working closely with each homeowner. We take the time to understand their vision, then bring it to life with creativity and craftsmanship. Whether it’s incorporating new materials, exploring unique layouts, or trying bold design concepts, we’re always open to fresh ideas that push the boundaries of traditional outdoor living spaces.

What are some of your favorite products, and why?

We enjoy using the entire CAMO suite; however, some of our favorite products include CAMO Hidden Wedge Clips and CAMO ledger screws, both for their ease of installation and hidden fastening design that creates a seamless, professional look without compromising strength. We use Trex and TimberTech decking for their durability and low maintenance. We also rely on James Hardie siding for its proven performance and curb appeal, and Key-Link railing for its sleek, modern design. The ground screws supplied by Ground Breakers are a game-changer for efficient foundation work, and Nichigo G-Tape is a must-have for its strong, weather-resistant seal for the tops of joists and beams. These products help us deliver long-lasting, high-quality results our clients can count on.

What’s ahead for Chattanooga Exteriors?

Chattanooga Exteriors is focused on continued growth and innovation in the outdoor living space. We’re expanding our services, adopting new technologies, and partnering with top industry brands to deliver even greater value. As always, our priority is helping homeowners bring their outdoor visions to life with quality, creativity, and care.

OWNER: Jonathan Moeller

LOCATION: Morrison, CO.

YEAR FOUNDED: 2015

WEBSITE: coloradocustomcoversanddecks.com

INSTAGRAM: colorado_covers_decks

FACEBOOK: coversanddecks

Take us to the beginning of your company.

We started back in 2015, originally working in new construction. At the time, I had a business partner, but we quickly realized that new construction didn’t offer the future we envisioned. We wanted the freedom to design our own projects and build truly unique decks. So, we shifted our focus and started taking on smaller deck projects. By 2020, that dedication paid off—we built our first deck valued at over $100,000. From there, we never looked back.

How did you begin using Deckorators?

Early on, we had a customer raise concerns about the slipperiness of their decking. As contractors, our options were limited—either we installed a different product or accepted the issue as-is. Determined to find a better solution, we did some research and came across Deckorators Vault. This was before the Voyage line existed, and once we installed our first deck with it, we never looked back. The performance, durability, and improved traction made it an easy choice for us and our clients.

Where do you get your project ideas from?

Our project ideas come from all over the U.S. I’m constantly inspired by the incredible deck builders we have in this country. Being part of NADRA has given me the opportunity to see some of the best in the industry create truly breathtaking projects, and that inspiration never stops. Since we’re based in the mountains of Colorado, we really lean into the rugged outdoor aesthetic. Big beams, rich stains, and that classic mountain lodge feel guide our designs. We want our decks to complement the natural beauty around them while still offering modern functionality and craftsmanship.

Tell us about your team.

We have an incredible team! Our carpenters are true craftsmen— they take the most challenging designs and bring them to life with precision and skill. It’s one thing to design a project on paper, but building it in the real world can be a whole different challenge. Time and time again, they rise to the occasion and execute flawlessly.

We also have a talented in-house designer who really listens to homeowners, translating their ideas into something both beautiful and functional. It’s truly a team effort, and I’m grateful for every single person who helps make these projects a reality.

For Colorado Custom Covers & Decks, the future is all about pushing boundaries—both in design and innovation. We want to continue creating one-of-a-kind outdoor spaces that blend craftsmanship with cutting-edge materials. Expect to see even more unique, high-end projects that challenge conventional deck-building, whether that’s through intricate curves, massive structural elements, or seamless indoor-outdoor integration.

We’re also looking to grow our team and further refine our design process, ensuring that every project we take on is not only visually stunning but also functional and built to withstand Colorado’s rugged climate. Staying involved with NADRA and learning from the best in the industry keeps us inspired, and we’re excited to keep raising the bar.

In short—bigger, bolder, and even more custom. The best is yet to come!

OWNER: Bill and Carro Thomas

LOCATION: St. George Island, FL. and Lake Oconee, GA.

YEAR FOUNDED: 2008

How did ARK Home Solutions get started?

ARK Homes got started after the real estate crash of 2006-2008. Carro and I went on our own to build homes at St. George Island, FL., by ourselves. We originally started building homes with my sister and her husband under Northstar Builders in 1998. My son’s name is Noah, and we liked the Noah’s Ark biblical name association, and so ARK Homes was born.

What gives your company a competitive edge over competitors?

If I had to talk about our competitive edge, I would say that it is a combination of three things. First, we typically build custom specs so we can do whatever we want creatively. Second, we self-fund our custom specs which gives us pricing leverage with vendors/trades, which in turn allows us to deliver custom materials at competitive pricing. Thirdly, our team members work with us exclusively, which allows us to deliver consistent quality work on time.

Describe a recent project where you used DeckWise.

A recent project we completed is a beachfront custom home and pool at St. George Island, called Mysterious Waves. The project called for extensive porches, stair and pool decking where we utilized 1x6 plus cumaru decking and the DeckWise hidden fasteners.

Tell us about your team.

Our team consists of our main supplier Advantage Lumber, family construction managers (Noah and Gracie Thomas, Tyler and Ashlyn Kreps) and a dedicated group of skilled trim carpenters led by Eddie and his crew (Joey, Heath, Flaco, Henri).

What’s ahead for ARK Home Solutions?

ARK Homes in 2025 is currently working on four new builds at St. George Island, while Carro and I expand our footprint in the Lake Oconee, GA., area. We will begin building custom specs in Reynolds Plantation and the surrounding lake area in 2025 and going forward.

All our homes have custom decks and woodwork that utilize the DeckWise product and we have been very happy with it.

DeckWrap PowerBond® is the quick and easy way to extend the life of deck support systems and posts. Our patented PowerBond® adhesive aggressively adheres to all wood types, even in temperatures as low as 25°F. Self-adhering and self-sealing for protection you can trust, roll after roll.

OWNER: Chris Longwell

LOCATION: Poway, CA.

YEAR FOUNDED: 2005

WEBSITE: techtonconstruction.com

INSTAGRAM: techtonconstruction

How did you get your start in construction?

Building forts in the backyard as a child with friends sparked my passion for building. Taking art classes from grade school to college helped mold my curiosity for design.

After taking drafting and architecture classes in college, I realized that I needed to understand how to build the things I was drawing. I started doing small, odd jobs to figure out how to build things—retaining walls, tile, flooring, paint jobs.

I went to work for a custom home builder, gaining knowledge in how to build homes from the ground up. I got my general contracting license and started doing everything under the sun. I landed in decking. Decking has all of the elements I love about building. Each project

is its own unique experience with its own challenges. The finished product gives me pride and keeps me building.

Tell us about your team.

It’s been mainly a one-man show for a long time. I have used laborers from time to time and have brought in a couple of my children to help out in the summers. I enjoy keeping control of the projects and how things progress. Quality before quantity.

How did you first begin to use FastenMaster?

I first viewed the Cortex plug system back in 2012. The local lumber distributors brought us out to a job site to show us the products they stock and how they were being installed. I was amazed by the matching plugs at

first sight. This was how I would finish all of my decks. I reached out to my lumberyard and started using the system immediately. I was introduced to the local rep at that time and found him to be very helpful and supportive. My relationship grew into using more of the products and meeting more of the team at FastenMaster throughout the years. I’ve been part of some focus groups looking at new ideas and products over the years. I always enjoy meeting up with the team at lumber events and am honored to showcase their logo on my sponsored work truck.

What are some of your favorite FastenMaster products, and why?

Cortex is my number one product that FastenMaster makes. I prefer not to see face screws in the decking and fascia. I use ThruLoks and LedgerLoks on almost all of my decks for the ease of installation and quality of the product.

What’s next for Techton Construction?

As for the future of Techton, I look forward to building better, safer decks for the next generation of homeowners. I know with a product partner like FastenMaster, I can achieve these goals. The future is “Loked” with FastenMaster. “Lok On!”

OWNER: Andy Henley

LOCATION: Uniontown/Hartville, OH.

YEAR FOUNDED: 2017

WEBSITE: ohiodecking.com

INSTAGRAM: henhouse_decks

FACEBOOK: ohiodecking

How did your company get its start?

Living in Northeast Ohio, where making the most of good weather is essential, I quickly realized the importance of outdoor spaces. My journey started in PVC decking sales, where I saw firsthand how a well-designed deck could transform a home. With an entrepreneurial mindset and a passion for thinking outside the box, I took a leap and pursued my dream of becoming a custom deck builder. My goal was to offer homeowners not just a deck, but a truly unique and high-quality outdoor experience.

The name Hen-House Decks comes from a combination of my family names, Henley and Greathouse. Since our founding, we’ve built a reputation as true custom deck builders, winning multiple national awards and pioneering innovative designs in the industry.

How has using MoistureShield products enabled your company to grow?

MoistureShield has been a game-changer for Hen-House Decks. In an industry filled with competition, I needed a product that would set us apart. MoistureShield’s CoolDeck Technology allows us to provide customers with more than just a visually stunning deck—it gives them a space that remains cool and comfortable, even on the hottest days.

This has made a huge difference for homeowners who previously struggled with overheated deck surfaces. By incorporating MoistureShield into our designs, we’ve been able to offer long-lasting, highperformance decks that stand out from the rest.

Tell us about your team.

Hen-House Decks wouldn’t be where it is today without the incredible team behind it. I truly value every member of my crew—they are the heart of our success. From our expert carpenters to our project managers and shop crew, we operate like a welloiled machine, constantly pushing for innovation and excellence.

We’re also a family-driven company. My brother serves as a salesman. My dad is a project manager, my brothers-in-law are carpenters, and my uncle is one of our key suppliers. Our close-knit team allows us to bring a personal touch and deep commitment to every project, ensuring our customers receive the best craftsmanship and service possible.

Tell us about a project featuring MoistureShield decking.

One of our standout projects using MoistureShield came from a homeowner who wanted to rebuild their existing composite deck. Their biggest complaint? The old deck trapped too much heat, making it nearly unusable. Not only did it burn their feet, but it also made the entire space feel uncomfortably warm.

When I introduced them to MoistureShield CoolDeck, they were immediately drawn to its beautiful aesthetics and heat-reducing technology. Once we completed the project, they were thrilled with the results—their new deck was comfortable, functional, and exactly what they had envisioned. To this day, they still send us messages about how much they love their deck and how it has completely transformed their outdoor experience.

What’s next for Hen-House Decks?

For Hen-House Decks, the sky is the limit. We are always learning, evolving, and staying ahead of the latest products and technologies in the industry. My passion for decking goes beyond just building—I am a proud member of NADRA (North American Deck and Railing Association), and I plan to continue contributing to the industry while upholding the highest standards of craftsmanship and innovation.

Our mission remains the same: to create one-ofa-kind, high-quality outdoor spaces that homeowners love for years to come. We’re excited for the future and look forward to pushing the boundaries of custom deck building even further!

OWNER: Phil Duran

LOCATION: Santa Cruz, CA.

YEAR FOUNDED: 2020

WEBSITE: duranconstruction831.com

INSTAGRAM: duranconstruction_831

Tell us about how you started in construction?

Right out of high school, I jumped into the trades and began my career as a framer. Over the years, I worked my way up to foreman, gaining valuable experience and leadership skills along the way. At 33, with a vision to build something of my own—and with the unwavering support of my wife and family—I took the leap and started my own company. Their encouragement and belief in me made it all possible.

How did you first come familiar with MOSO?

I was first introduced to MOSO approximately a year ago and quickly recognized its potential for our market here in Santa Cruz. Many of our clients prioritize sustainable, durable decking solutions, and MOSO has proven to meet those demands exceptionally well. The product’s high quality, combined with its range of color options, has made it an ideal choice for our clientele.

What inspires your projects?

Every project starts with a vision—sometimes it’s sparked by the unique character of a site, other times by the client’s passion or a challenge that needs solving. What inspires me most is the opportunity to transform ideas into spaces that are not only functional but also reflect the people who will use them. That creative process—blending craftsmanship, design, and purpose—is what drives me every day.

Tell us about your team.

I have been fortunate to assemble a highly capable and dedicated team. Several members have worked alongside me for years across previous companies, while others joined through unexpected yet welcome encounters—even as spontaneous as meeting in a Home Depot parking lot. Regardless of how they came on board, they share a strong work ethic, unwavering loyalty, and a commitment to excellence in everything they do.

What’s on the horizon for Duran Construction?

Our goal is to strategically grow the company by expanding our workforce and taking on larger-scale projects. As we scale, we remain firmly committed to delivering exceptional quality and upholding the highest standards in every aspect of our work.

OWNER: Tony McKlem

LOCATION: Fernandina Beach, FL.

YEAR FOUNDED: 2019

WEBSITE: hollywooddecks.com

INSTAGRAM: hollywooddecks

FACEBOOK: hollywooddecks

YOUTUBE: hollywooddecks

Tell us about your construction beginnings. I’ve been in construction for about 19 years, but I actually started out volunteering. My former career was in finance and investments, but when I left the office in the evening and on weekends, I would go volunteer in construction.

Eventually, I grew tired of the office world and its environment. I ditched the suit and tie, but I didn’t know what to do. Because I was already 10 years deep in the construction world, had a truck, some tools, and some experience, I started building custom homes in El Segundo, CA., for a couple of years. Then I got into doing concrete work, rebar, footings, and some foundation work. Finally, I met a colleague in the Los Angeles area who was building decks.

Having a finance background, I started to run the numbers in my head, and I realized that he was turning a nice profit off a deck. So, we started doing that when we were still in Los Angeles—residential construction for outdoor spaces.

Eventually, my wife and I discussed moving out here to Florida. My thought was that Florida is a great market for outdoor spaces. We established Hollywood Decks in California, and by the time we moved, I already had a project lined up. We started the company six years ago, and we have not stopped working since.

How did you first start using ProWood in your projects? That started when we moved to Florida. We had to learn the different products and availability in this market. Compared to operating in Los Angeles, Florida has a significant difference in requirements and codes. It wasn’t until I came to the East

Coast that I saw this green, flat, solid, pressure-treated lumber. We started researching and doing a lot of homework to figure out what the most durable, suitable and readily available product on the market here was. ProWood was one of the first lumber products we learned about, and what stood out to me was that, here in Florida, you not only have Above Ground Contact and Ground Contact, but also Marine Grade. Florida is a harsh environment—you’ll get 100° temperature, then the next minute it’s five inches of thunderstorms and rain, and then back to sun and 80% humidity, all in the same day. So, the question was, what are we going to use that can withstand that beating?

ProWood became the standard for us, because we could say, “We’re going to build it with this because we want our builds to be durable, long-lasting, and give us and our customers peace of mind.”

What inspires your projects?

I always credit the homeowners. They’re the ones who are being generous enough to welcome us into their homes and share their dreams. And, in turn, we have to design with that in mind and deliver.

I am always grateful to the homeowners for giving us that opportunity. But it’s finding that balance between their vision and what we can do. Sometimes that means pushing the envelope. They might say, “This is what I want, because it’s what I’ve seen on Pinterest or in the magazines, searching the internet.” Well, we

tell them what we can take from their ideas, but we also tell them what we can add to them. A lot of that comes down to challenging not only ourselves, but also the products we use in terms of quality and longevity. How do we ensure that it’s not only a long-lasting project, but also make it beautiful for the customer while doing something different? We pride ourselves on our high-end decks, and we don’t want to just do a typical rectangle/square. We’re one of the few companies in the nation that still does curve decking. It can be a little ambitious, but it always looks great at the end.

Any projects for which the use of ProWood was useful?

We recently finished one about a year ago, and it’s got all the bells and whistles. Outdoor kitchen, a beautiful pergola, built-in trees and benches and planners. It’s a beautiful project that we’re really proud of. It’s also waterside, so the framing was all ProWood.

We’re conscious of the environment here— we want to mindful of bodies of water, trees, and greenery. So, to minimize us needing to tear anything down or move around the water, we used the Marine grade pressure-treated wood, because it allows us to build right up to where the water line is and around the trees. This deck is two or three blocks away from the beach and installing with ProWood allows us to tell the client, “By using this product, you can expect your deck to still be here in 30 years.”

What’s ahead for Hollywood Decks?

We try to keep it simple. We really enjoy what we do day-to-day. I have three wonderful crews (demo, framing, and finishing), and they make these projects happen.

Coming from the West Coast to the East Coast, one of the first things I learned was budget and scale for the company. In Los Angeles, it was all ‘go big’, but here in Florida, you want to keep it simple and manageable. But we’re blessed and fortunate. We haven’t stopped working a single week in the last six years.

At the same time, we absolutely want to expand our reach—and we intend to do so by getting into distribution. So, it will operate under a different name, but Hollywood Decks will soon be opening up a lumber yard for distribution. Getting materials can be a big challenge here in Northeast Florida. So, we figured we’d try to be part of the solution. We’re excited to get into the supplier world, and we’ll have some big announcements on that in the coming months.

OWNER: Mahlon Esh

LOCATION: Keuka Park, N.Y. (Rochester/Finger Lakes region)

YEAR FOUNDED: 2013

WEBSITE: keystonecustomdecksny.com

INSTAGRAM: keystonecustomdecks_ny

FACEBOOK: keystonecustomdeckny

Tell us how Keystone Custom Decks got its start. Keystone Custom Decks started as a family-operated business in 1983 in Lancaster, PA., by Amos Esh. In 2013, Mahlon Esh, who is a nephew to Amos Esh, moved to the Finger Lakes region of New York and expanded the business into that area.

How did you first start using RDI products? RDI was supplied by one of the local suppliers in the area so naturally it made sense to start using the products.

Where does your project inspiration come from?

We listen to the customer needs and add our ideas to what the customer needs. Our design team takes it from there and provides a nice 3D rendering of the proposed project.

What are some of your favorite RDI products? Finyl Line vinyl rail.

What’s ahead for Keystone Custom Decks? Continued growth to meet the demands of the region.

Deck railings are featured in the 3D renderings included in Keystone’s proposals.

OWNER: Brett Smith

LOCATION: Kingston, Ontario, Canada

FOUNDED: 2018

WEBSITE: infinityoutdoorliving.ca

INSTAGRAM: infinityoutdoorlivin

FACEBOOK: infinityoutdoorliving

YOUTUBE: infinityoutdoorliving

Tell us the history of how Infinity Outdoor Living began. Infinity Outdoor Living began with a passion that was sparked early in life. Growing up, I spent time helping my dad on his side jobs—learning the ropes of building and developing a strong work ethic along the way. That handson experience, especially with decks and fences, quickly turned into something I loved doing.

Eventually, that passion led to the launch of my first business, originally known as Dura Contracting. As the business grew, so did my vision. I wanted to do more than just build—I wanted to create meaningful outdoor spaces where people could relax, entertain, and make memories.

That’s what inspired the transition to Infinity Outdoor Living. Today, we focus on crafting personalized outdoor living spaces that bring each client’s vision to life with quality, creativity, and care.

Why do you prefer using Regal ideas as a primary vendor? I prefer using Regal ideas as a primary vendor because they consistently deliver on the key things that matter most—quality, price, ease of installation, and variety. Their products are top-notch in terms of durability and finish,

which gives me confidence in what I’m building for clients. The pricing is competitive, making it a great value without sacrificing quality. Plus, their systems are designed to be straightforward and efficient to install, which helps keep projects moving smoothly. On top of that, Regal offers a wide variety of styles and options, so it’s easy to find the right fit for any design or vision.

Please share where your creative spins come from. Creativity has always been a part of who I am—even as a kid, I was constantly coming up with ideas and finding new ways to make things stand out. That mindset naturally carried into my work. I’m always thinking about how I can improve a design or add a unique touch that sets it apart while still being functional.

One example of that was last year when I customized a Regal railing system by incorporating a drink rail. It added

a practical feature for the client without compromising the clean, seamless look of the railing. For me, it’s all about blending creativity with purpose to create something that’s both beautiful and useful.

What are some of your favorite Regal ideas products, and why?

One of my favorite Regal ideas products is the Urban Rail system. I really like the textured finish—it gives a clean, highend look that stands out. The prebuilt panels are a huge plus too; they make installation incredibly efficient, saving both time and labor. The overall design of Urban Rail is simple, modern, and unique, which makes it versatile for a variety of spaces. Another thing I really appreciate is that it’s costfriendly without sacrificing durability. You get a sleek, longlasting product that looks great and holds up well, all without breaking the budget.

Looking ahead, the goal for Infinity Outdoor Living is to continue building high-quality outdoor spaces while delivering the best customer service possible. We’re committed to growing the business without ever losing sight of what matters most—attention to detail, craftsmanship, and making sure every client feels valued and heard. As we move forward, we’ll keep pushing the creative boundaries and refining our process to ensure every project is a space our clients can truly enjoy and be proud of.

OWNER: Jamie Ruddy

LOCATION: Bloomfield Hills, MI.

YEAR FOUNDED: 1995

WEBSITE: cedarworks.net

Cedar Works Deck Builders has been a Trex Platinum Pro since the program’s inception—delivering expert craftsmanship, standing behind every build, and always ready to service issues and support their customers with reliable, responsive care.

How did Cedar Works get started?

I started it by myself, building decks in high school and during the summers. I went to Michigan State for a building construction management degree. I started doing repairs on decks, that turned into major projects. I was building decks and getting my builder’s license while I was in college. I paid for college and room and board by building decks on weekends and during the summers. I learned on my own. I slowly learned the business aspect through college.

What Trex products are among your regulars?

I would say we mostly build with Trex Transcends Tropicals and Lineage and Trex Enhance Naturals decking. As for the rail products, we use mostly the Signature Railing, which is more of a modern look. I think Trex is our main product because they offer everything needed. They have a very wide range of products. There’s no reason to go to the competitors because you have everything you need at Trex. It’s also an Americanmade product and they’re going to be around for the long run. I have their backing and support with any issues or problems so that’s a big, important part for me.

Any upcoming projects that you’re excited about?

I love starting and finishing a project. I get a lot of special satisfaction out of that. I think it’s great to start and finish a project in a short amount of time. We build an average of 200250 decks a year and they average around 500 sq. ft. We get them done in approximately one to two weeks. In Michigan,

we do a lot of walkout-basement upper-level decks with Trex RainEscape deck drainage systems for a dry space under the deck. That’s really our specialty. A walkout-basement is what people in Michigan are looking for. There’s a lot of low hills and great variations. Your house is worth more if you have a walkout basement.

Tell us about your team.

I have a team that consists of an office manager that runs the office, permitting, tech permits, customer service and calls. Design and sales is handled by me and Robert Sala. We both have over 30 years of design and sales experience. We have six in-house, construction crews. I have a guard and materials manager and a designated pickup and delivery driver. That helps a lot because you can’t always rely on the lumberyards to deliver on time if we need something quick. We do a lot of glass rail, cable rail, horizontal modern-looking rails, and roof enclosures to make the total outdoor living space.

Why is reputation important to you?

When you’re hiring a company to build a deck, it’s one of the largest purchases. You’re not only hiring the company because you want a warranty working with that company, but you don’t want to gamble on it. There’s someone that you believe is going to do a good job.

With us, we’ve got a long history of doing the perfect job and people feel safe with us. I think that’s why we’re so busy because you’re not gambling. You’re getting dealt two kings.

People hire us to build their deck while they’re in Florida during the winter, or while they are at work. They don’t have to police us or stay home and worry about it because they know they’ve hired the right person.

What means the most to us in this business is keeping a good reputation and doing quality work. That’s what we specialize in. That’s always been the most important thing for us and when it comes down to it, if anyone’s not happy or it’s an issue, we just fix it on our dime. It’s all about the reputation at the end of the day. I run into my customers on a daily basis outside of the office. They come up and talk to me. “Hey, we’re loving the deck.” Reputation is the most important thing—more important than money.

What’s next for Cedar Works?

We have a lot of decks to build. I’ve got my son who is going to be in college soon and possibly continuing the business if he likes. What are the options out there for going to work for someone? He could work for me for five years and he’ll get paid five times what he can working for someone else, and 10 times more once I turn the business over to him.

After college, I actually worked for a builder building homes for one year while I ran my deck building company on the side. Fresh out of college, I made more money that year with my deck building company than I made working for the builder.

If I put 100% more effort in working for someone I might get a 5% pay raise. If I put 100% more effort working for myself, I’m going to make 100% more.

It’s my duty to offer that to my son, and to stay in business, and keep it going.

OWNER: Graham Perry

LOCATION: Manassas, VA.

YEAR FOUNDED: 2018

WEBSITE: buildhd.com

INSTAGRAM: hdexteriorsllc

FACEBOOK: buildhd1

How did HD Exteriors get its start?

HD Exteriors began as a three-person team: Graham Sr., his wife Beth, and son Graham Jr. Right from the beginning, we focused on developing systems that solved common bottlenecks and shortcomings in the industry. This approach allowed us to market our business efficiently, manage projects effectively, and deliver a unique experience to our customers. The quality of the systems we developed, combined with our primary focus on people before profit, allowed us to quickly scale our business and deliver repeatable results to our customers.

Why is YellaWood an important vendor of yours?

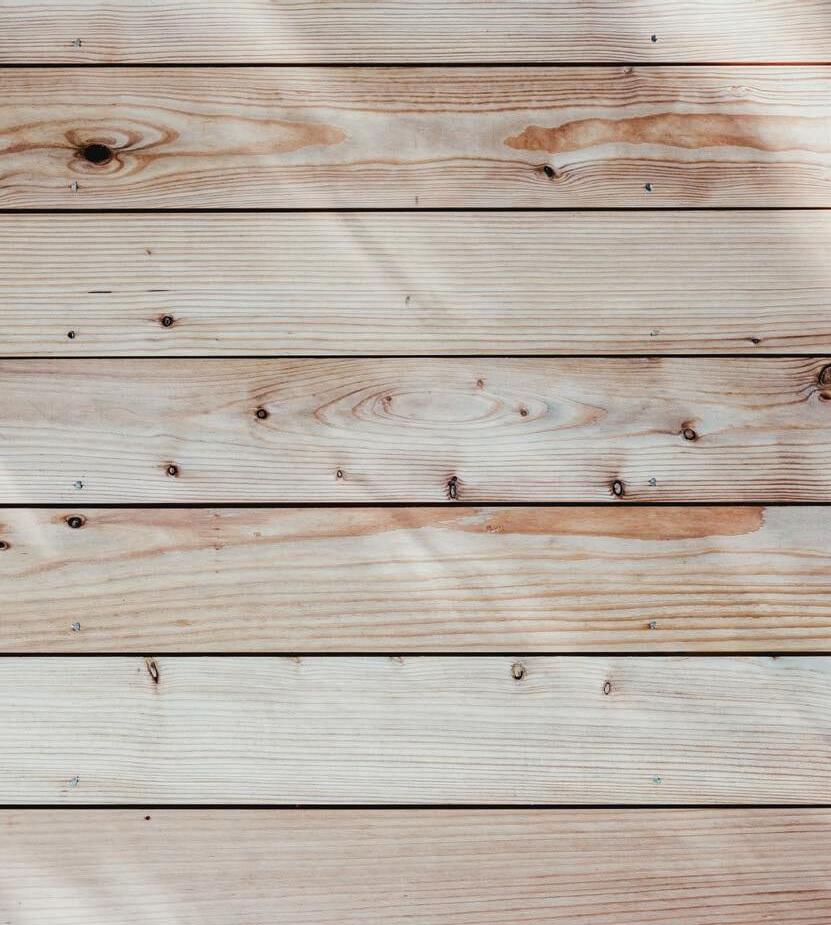

HD Exteriors is committed to offering its customers high quality materials. It’s important that our decks and porches are constructed with lumber that is consistent with minimal defects, that’s why we prefer YellaWood. To avoid production delays, we need product that is stocked locally and available for same-day pickup and/or next-day delivery. YellaWood stands behind their products and does a good job maintaining relationships with dealers like The Deck and Fence Depot which makes vendors like them the right partner for our fastpaced business.

Where does your project creativity come from?

Creating happy customers that want to tell their friends and family about HD Exteriors is based

on three core principles. Quality materials, installation standards, and communication throughout the process. Our designers keep these non-negotiable elements in mind while creating outdoor spaces that fit the budget and creativity of our clients. We design and build simple spaces with great resell value along with large outdoor staycations that leave our clients in awe. So, whether the project is large or small, our designers are there to ensure the right expectations are set and each client’s unique needs are met.

Any projects for which the use of YellaWood was helpful?

Every deck and porch is custom and made to fit the client’s needs. YellaWood has a natural appearance without the green treatments like other products which makes the finished product aesthetically pleasing. Having the wide range of available sizes helps to eliminate waste, and the 24-ft. joist comes in clutch for larger projects. Another benefit to YellaWood is the eased edge 4x4’s which make deck lighting easy to wire. These small but simple details show that YellaWood is in touch with market needs and is committed to offering solution-based products.

In summary, YellaWood’s proven long-term protection against rot, fungal decay, and termite attack, combined with its natural appearance, availability, and lifetime warranty make it the right choice for our business.

What’s ahead for HD Exteriors?

HD Exteriors is committed to helping as many customers as possible, and more importantly, providing a work environment with a ceiling high enough to fit those who want to grow professionally. The proprietary systems that we developed to manage our unique business needs were also designed with growth in mind. We are opening two new markets in 2025 and have plans to expand to five additional locations by 2030, which we expect will help us to achieve our revenue goal of $100 million annually. Our primary focus is to recruit and retain dynamic individuals that share in our commitment of excellence and to build strong partnerships with vendors like YellaWood that will make our ambitious vision a reality. DS

We are proud to Deliver the Difference with high-quality exterior products that stay on trend and meet the highest standards for durability and versatility. Committed to sustainable products, we aim to meet the highest environmental standards and responsible forestry practices. From pools to patios and observation decks, we have decking solutions for all your needs.

DESIGNING OUTDOOR SPACES IN HAWAII isn’t just about showcasing views—it’s about building to survive the elements. Local builders know that creating lasting structures here requires equal parts craft, foresight, and respect.

“Living and building in Hawaii means balancing the beauty of the natural environment with the harsh realities of sun, salt, moisture, and insects,” says Chad Hilweh, owner of Hawaii Deck Builders, a division of Hilweh Builders, Honolulu, HI.

Durability is the top design priority in Hawaii. Nearly every project begins with a conversation about moisture or termite damage. Builders in the islands are constantly planning for ventilation, specifying composite or PVC decking, using stainless steel fasteners, and leaning on coastal-grade materials—even if those choices might be

considered overkill elsewhere.

“In our climate, it’s essential,” Hilweh emphasizes.

But it’s not just the elements that shape these decks—it’s the way people live on them.

“We also think a lot about how people use their decks here,” he explains. “A lot of our clients are walking barefoot outside year-round, using their outdoor spaces for parties and extensions of their homes.”

With many families living in multigenerational homes, functional outdoor space plays a critical role in creating comfort and flow. The more room families have to spread out, the better.

“Ultimately, we prioritize solutions that are built to last because here decks aren’t seasonal,” Hilweh says.

Permitting and logistics present their own unique challenges in the islands. “Another local insight is just

how much goes into getting materials and permits here,” Hilweh says. Homeowners often wait a year or more for a new deck permit. In addition to structural plans, stormwater runoff requirements must also be met— especially near protected watersheds.

“These rules are in place to protect the island’s natural resources, so working with architects and engineers is essential to ensure compliance.”

Delays of six to eight weeks are common for material deliveries, which often need to be special ordered. Storage is limited, crew availability is tight, and costs are higher. That means every measurement and every order must be accurate the first time.

“Mistakes are expensive, so accuracy and logistics matter,” Hilweh adds.

To keep projects running smoothly, Hilweh says success comes down to collaboration and creativity. His team trains and invests in its crew, partners with engineers as needed, and stays flexible with every build.

Lex Allen, owner of Solid Built Construction, Inc., Honolulu, agrees that the demands of Hawaii’s environment raise the stakes for durability.

“Our number one priority is building a durable deck—a deck that lasts; a deck that can withstand the salt in the air, any potential hurricanes or earthquakes, and the powerful rays from the sun,” Allen says. “Our decks are built beyond standards.”

For his team, beauty and design are natural outcomes of building with care, intention, and high performance in mind.

Asked what truly sets Hawaii builders apart, Allen keeps it simple: “Respect is everything. Respect your workers. Respect your suppliers. And of course, respect your client. Talk less, listen more, and build with passion.” DS

JAKE JOHNSON, OWNER of Stone Ridge Decking, Meadow Vista, CA., shares how his company became the first on the West Coast to integrate AZEK’s Full Circle Recycling Program, and how innovation and sustainability influences how he builds decks.

Can you share a bit about your company’s history and how you got started in the deck-building industry? I’ve always been drawn to building things and figuring out how they work. As a kid, growing up, my mornings were spent in the shop with my dad, fixing and fabricating, and my afternoons were spent out in the woods with my buddies, scavenging materials to build forts.

I was raised with an old-school work ethic in a small cabin on a big piece of land—there was always something that needed doing. Naturally, I gravitated toward construction. All through my teens and into college, I worked part-time in the trades, learning hands-on.

Over the next 10 years, I worked for various home

builders, soaking up as much experience as I could. At 28, I took the leap and started my own business, with the goal of building custom homes.

But I quickly realized how complex and difficult it was to scale a broad construction company. Finding subcontractors who matched my attention to detail was a constant struggle, and streamlining the process proved even harder. I began to crave a simpler, more focused business model—something I could refine, repeat, and grow.

The solution was to bring everything in-house and focus on specialization. Outdoor living checked all the boxes for me, particularly deck design and construction.

My background in high-end residential work pushed me to set a higher standard than my competitors, who often came from landscaping and fence construction backgrounds.

About 18 months into this transition, we officially became a deck-only company. With a refined process, the next challenge was scaling. With a relentless focus on systematizing our procedures and methods were able to move from five decks in our first year to over 100 decks by our fourth year.

Today, my team and I continue to refine our systems and push for further growth and innovation.

How did your company become the first on the West Coast to integrate the AZEK Full Circle Recycling Program?

I first learned about AZEK’s Full Circle Program online and immediately reached out to our local representative to get involved. That led to a meeting at the International Builders’ Show with Amanda Cimaglia, AZEK’s head of Environmental, Social and Governance (ESG), who shared the company’s goal of expanding the program to the West Coast, but noted logistical challenges.

I jumped on the opportunity to spearhead this effort, and partnered with the AZEK team to bring the program to our region.

We were able to utilize existing distribution partners to make it a reality. AZEK has also opened a brand new recycling center in the Pacific Northwest to reduce travel costs and further bolster their position on the West Coast as a major player in the recycling industry.

How has working with AZEK and promoting sustainable decking influenced how you build decks and run your business?

The construction industry has a reputation for its large carbon footprint, and California is known for leading the charge in finding more sustainable building practices. The decking industry has made significant strides by shifting from wood to recycled composite materials.

However, one of the biggest challenges with composites is finding efficient ways to recycle scrap material; it is extremely expensive to utilize any of the waste.

Composites were a great step in the direction towards sustainability; however, TimberTech’s PVC decking is a game-changer. It’s not only made with high-recycled content, but is also 100% recyclable itself.

With a few simple procedural changes on-site, we’ve been able to send thousands of pounds of PVC back to AZEK for reuse, keeping it out of our landfills.

CONTINUED >>

Where do your innovative design ideas come from?

I’d love to say our innovations come from sudden flashes of inspiration, but in reality, they are built on the foundations laid by those before us. My extensive background in construction has given me a good base understanding of how materials are joined together to blend form and function.

As previously mentioned, since a young age I always enjoyed how things were put together. Still as an adult I find myself examining everything from the overall layout and configuration to the minor details of joinery and function. It sits somewhere between a habit and an addiction. I find that inspiration is everywhere if you take the time to look.

As an outdoor enthusiast, I’m constantly drawn to nature’s structural designs and solutions to problems. I have been fortunate to see a lot of the world as well so my travel experiences also plays a role—I’ve been fascinated by the diverse architectural solutions different cultures have developed to meet their design needs.

When it comes to business procedures and growth, I look to strategies used in the commercial and tract home industries to refine and scale our approach. No reason to invent the wheel here; just taking the time observe and ask questions of those much smarter than I has brought a lot of value to my businesses.

Tell us about your team.

Stone Ridge currently employs about 15 people, and subcontracts an equal number. We continue to grow each year. I’m fortunate to work with an incredible team, from our newest laborers to my right-hands in the office and field.

Everyone shares our mission: Helping clients spend more time enjoying the outdoors. Our motto is to “Do everything in excellence.” Whether it’s complex

carpentry, organizing a spreadsheet, or simply digging a hole, we believe that satisfaction and life fulfillment comes not just from what you do, but how you do it.

What’s next for your company in terms of innovation, sustainability, or expansion?

Stone Ridge has strong momentum, and while we continue refining our craft, my primary focus is fostering an environment that promotes long-term retention of our incredible team while attracting new talent eager to join an elite group.

I want everyone at Stone Ridge to see it as a career, not just a job, so we will keep investing in the wellbeing and growth of the hardworking people who make us who we are.

Beyond Stone Ridge, I have launched several other businesses in the decking industry.

LUME Deck Lights is a premium lighting company dedicated to creating innovative, user-friendly, and affordable deck lighting solutions, you should see products on the market this spring.

SelectADeck is an online deck configurator that has been a driving force behind Stone Ridge’s growth. With this subscription-based tool, I aim to provide deck builders with a scalable solution to streamline their businesses and utilize the amazing tool we created to simplify the entire deck design and build process.

As we’ve grown, we’ve also begun sourcing our own materials, essentially creating a micro lumberyard. While not yet finalized, expanding further into the supply business is an opportunity we’re seriously considering.

Most importantly, as a father of three young children, I’m learning to balance ambition with presence—ensuring I cherish this fleeting time with the ones who matter most. At the end of the day, they are the reason I do what I do. DS

LIGHTING OUTDOOR KITCHENS has evolved far beyond the finishing touch. Today, it’s integral to how the space looks, functions, and feels.

Jason Faist, North American product trainer for in-lite outdoor lighting, says effective lighting relies on three layers: task, ambient, and accent lighting.

Task lighting is the workhorse, playing a critical role over grills, sinks, and prep areas, where focused light ensures safe, accurate cooking. “Nothing is worse than trying to cook the perfect steak in the dark,” he says.

Wall-mounted ambient lighting defines the space with a welcoming vertical glow, while recessed accent lighting adds depth and drama to the space.

Ensuring the three layers of lighting work cohesively starts with a solid lighting design. “Coordinating with other trades early on is key to planning fixture placement and running lowvoltage cable during construction,” says Faist. Pre-

planning pays off, he adds. By integrating lighting into walls or structures early, builders can create a clean, finished look that saves time later. “A strong lighting design helps ensure that aesthetics and functionality work hand-in-hand from the start.”

Builders, Faist adds, want lighting systems that are durable, flexible, and low-maintenance. They want fixtures that withstand the elements and avoid callbacks. “Systems that are expandable offer added value—especially when backed by strong warranties.”

For instance, when lighting cabinetry, Faist says he prefers a hybrid approach. Standalone fixtures offer flexibility and ease of maintenance, while integrated options—such as in-lite’s Hyve, Dot or Fusion—recessed into cabinetry or counters, deliver a polished, high-end look.

As for trends, Faist sees a growing demand for smart control and customizable color options. These features allow homeowners to adapt lighting scenes to suit any outdoor gathering. “Homeowners love being able to control zones and dim lighting from their phones,” he says.

Overall, he says, customer want smarter lighting control and clean, timeless design that “blends in during the day, transforms the space at night, and works effortlessly through apps or automation.” DS

DEPENDING ON YOUR MARKET DEMOGRAPHICS,

many of you encounter customers whose backyard project involves more than decks or covered structures. These homeowners may want a more extensive outdoor living project that includes patios with pavers, stamped concrete, concrete coatings, tile, or flagstone. It may involve fire pits or outdoor kitchens.

Often these potential customers are looking for a turnkey contractor. With these leads, the more you can provide, the better your chances of getting the job.

Some contractors prefer not to take on projects that require other outdoor living elements. Many are willing to contract the deck while other specialty contractors deliver other aspects. But there are opportunities and benefits for those who want to expand and improve their competitive position by offering more of a turnkey program in markets where the demand is common.

Use commission-based referrals

Offering hardscapes and patios is not complicated. It can be as simple as establishing a relationship with a hardscape contractor that you refer and who pays you a 10%-20% commission for bringing them in. A more

complex approach is to take a more hands-on approach where you become more involved in the delivery process and make full margins.

The commission option offers an opportunity to become more profitable without adding to your deck building payroll or taking on full delivery responsibility. For example, if you outsourced $100,000 of patio work or hardscapes each year, you could add $10,000-$20,000 into your bank account. The fact that you could provide the service also helps you get jobs you otherwise may not have contracted.

Turnkey projects offer a competitive edge

There are plenty of high-end outdoor living companies that offer a wide range of outdoor living options for their projects. You see photos of their work in this magazine and in social media. The volume, complexity, and how they go about it varies, but most have staff and structure in place and a reliable pool of subs to facilitate the deliveries.

My column in this issue is to share a suggested approach for one-crew operators or smaller companies that have minimal structure or staff. It is for those

The benefit for the customer was that they received a quality job without having to worry about getting proposals or coordinating the contractors involved.

that are open to adding bottom-line profitability by coordinating an added aspect to the job.

I am not even suggesting that you market for hardscapes work, but rather suggesting that you offer at least limited options when the lead requires. It keeps you in contention with jobs that you may not have gotten in the past when another competitor provided a turnkey package.

Keep in mind that customers wanting outdoor projects can become overwhelmed if they need to get more than one trade quote. In addition to getting three proposals from deck builders, they must also search for and get multiple quotes from hardscape contractors as well. Sometimes, the process or thought of coordinating their own job causes them to freeze up and do nothing.

A good homebuilder organizes and coordinates multiple trades to build every house they deliver. They know the process, sequence, and order of appearance of all involved. It is the same with outdoor living on a smaller scale in that having one contractor in charge simplifies the process for a homeowner and creates added comfort levels.

It increases the chances of smooth job coordination compared to multiple independent contractors advancing on the same job without proper planning or organized schedules. Without communication or an overall plan in place, the process can quickly become job chaos.

It is not to say communication between different contractors cannot happen and a job cannot run smoothly–it can. But speaking from experience, sometimes it does not.

Most projects in the North Atlanta averaged nine to 12 elevations or higher, so patios below decks were common. I approached jobs using a combination of “all inclusive” along with a referral for hardscapes.

My outdoor living projects included decks, porches, watertight decks, and patios. Porches often included tile floors and fireplaces which were included in the contract. Multiple trades were involved, and my process was to include everything for a turnkey package. I learned enough to know how to price each subs cost or got a quote from them based on the items and work involved. If necessary, I would send them pictures and details, so

they rarely had to visit a job site.

I added margin to each one, which was included into my sales price, so when I quoted or contracted it was all inclusive with profit built in for each trade involved. The customer knew everything was included, what the total investment cost would be, and that I was supervising the project.

The only trade that I often did not include in my contract was the hardscapes or patio work. This was a simple in-house referral arrangement of bringing in a contractor or sub that could deliver specialty work to complete the turnkey aspect.

When I consulted with customers, I could give them a range of cost based on product choice line items and square footage for any type of patio they wanted. They knew I had a delivery history with all aspects and that I would be coordinating the overall job. They were able to view proof through photos of our past jobs which included patio projects.

I explained that the cost range for all aspects was reliable and that they would meet with my hardscapes contractor to make product selections and final design. Price would only change with increase in size or upgrades in choices.

The benefit for the hardscape contractor was they knew I would be a repeat customer and that they already had the project. I did not have them running around giving estimates. If I called them, it was a job. Their price to me was more of a “builder cost,” which left room for a retail markup and sales commission for my company for setting up the sale.

The benefit for the customer was that they received a quality job without having to worry about getting proposals or coordinating the contractors involved. From a cost standpoint, they paid the same or within a few points of what other contractors may have charged them.

This approach requires establishing a relationship with a hardscapes contractor that can handle all aspects of the delivery. They supervise the work, do material takeoffs, order, and purchase material, and do the cleanup. I had one contractor for stamped concrete and coatings, one for pavers, and one for flagstone, fire pits, and outdoor fireplaces.

This approach allows the contractor to meet with the customer, do their presentation of options, and contract directly with the customer. They deliver the job and provide the homeowner a warranty. Your company coordinates and schedules the overall project bringing in the hardscapes as needed.

Estimating for hardscapes without overcommitting

It requires that you learn to estimate the pricing on the standard items and site conditions to offer a range of cost for the customer during your meetings so they understand what the overall cost of a project will be.

Otherwise, you are sending your subcontractor out to give “estimates” to someone you have not closed the deal with, which could result in the customer using your sub with another deck contractor.

Another option is to include the hardscapes on your contract, sub the work out to a skilled tradesperson, do the takeoffs, pay the labor, order and pay for material, provide the warranty, and charge a better margin. For companies that have the staff structure this is doable, but for major hardscapes projects, I preferred the commission approach.

I used subcontractors for specialty trades and kept carpenters focused on carpentry. My crew leaders were onsite and helped with getting subs in and calling in for inspections. This allowed me to have eyes on the job during most of the build.

Utilizing subs that I profited from allowed my annual contract dollar amount and overall profitability to be well beyond what my deck crews alone could build out each year.