3 minute read

Ways to finish a cedat sale

fr etXn SALES, whether for in' \J door or outdoor use, are natu' rals for add on sales of finishes and the tools to apply them.

While a customer maY think he wants to leave his cedar bare to weather naturally, he will probably be happier if he gives nature an assist. Some of the drawbacks to natural weathering are uneveness of color due to variations in boards and the light and moisture to which the wood is exposed.

Wood protected by overhangs will weather more slowlY than wood directly exposed to harsh weather. Cedar hit by the overspray of lawn sprinkers will color differently than that with less exposure to water.

The natural weathering Process can be improved with an application of water repellent preservative. These products apply easilY and allow the cedar to gradually change from its original reddish color to a lighter shade. Additional water repellent benefits include minimizing watermarks and surface checks as well as guarding against decaY and discoloration caused bY mold and fungal growth.

Another option is a bleaching oil applied to achieve a gray, weathered look sooner. The bleaching oil speeds up the natural color change and provides a more uniform appearance. It minimizes the initial darkening and accelerates the natural color change to the final driftwood graY.

Customers who don't want a natural finish should be guided to

Story at a Glance

How to write bigger cedar tickets.. suggestions for add on sales of finishes and tools. do's and don'tsfor recommending finishes.

the exterior stains. These come in two types: film forming and Penetrating.

The film forming, such as varnishes and urethanes do not Penetrate the wood, so they must be refinished in a few years. TheY also prevent the release of moisture within the wood, causing blisters and cracks.

Penetrating stains are often recommended since they Provide both a natural appearance and Protection from moisture. There is no peeling or blistering. Most of them contain water repellents and in many cases rot and mildew inhibitors.

Penetrating stains come in three types. The transparent have no pigment but offer water rePellent features to protect the wood and aid the natural color change. Semi-transparent stains have added pigment to modify the original color of the wood while allowing the natural beauty to show through. They are more durable than transparent stains. Opaque stains have a high pigment content and hide both the grain and color of the wood.

Latex stains even though theY do not penetrate the wood are acceptable if the customer wants a color. Their life span can be extended with the use of a stain resistant primer. Because they have some PorositY they have more stabilitY and allow limited moisture movement with the wood underneath.

Cedar used inside the house can be finished with either a transparent or semi-transparent finish that will protect its surface while enhancing its beauty. Clear lacquer can be used in areas where there is little moisture. It should not be recommended for bathrooms or kitchens.

Varnish can be used on smooth surface cedar, but it tends to darken the wood. A flat finish sanding sealer is best recommended under the varnish. If varnish is selected to be used in a bathroom or kitchen, at least

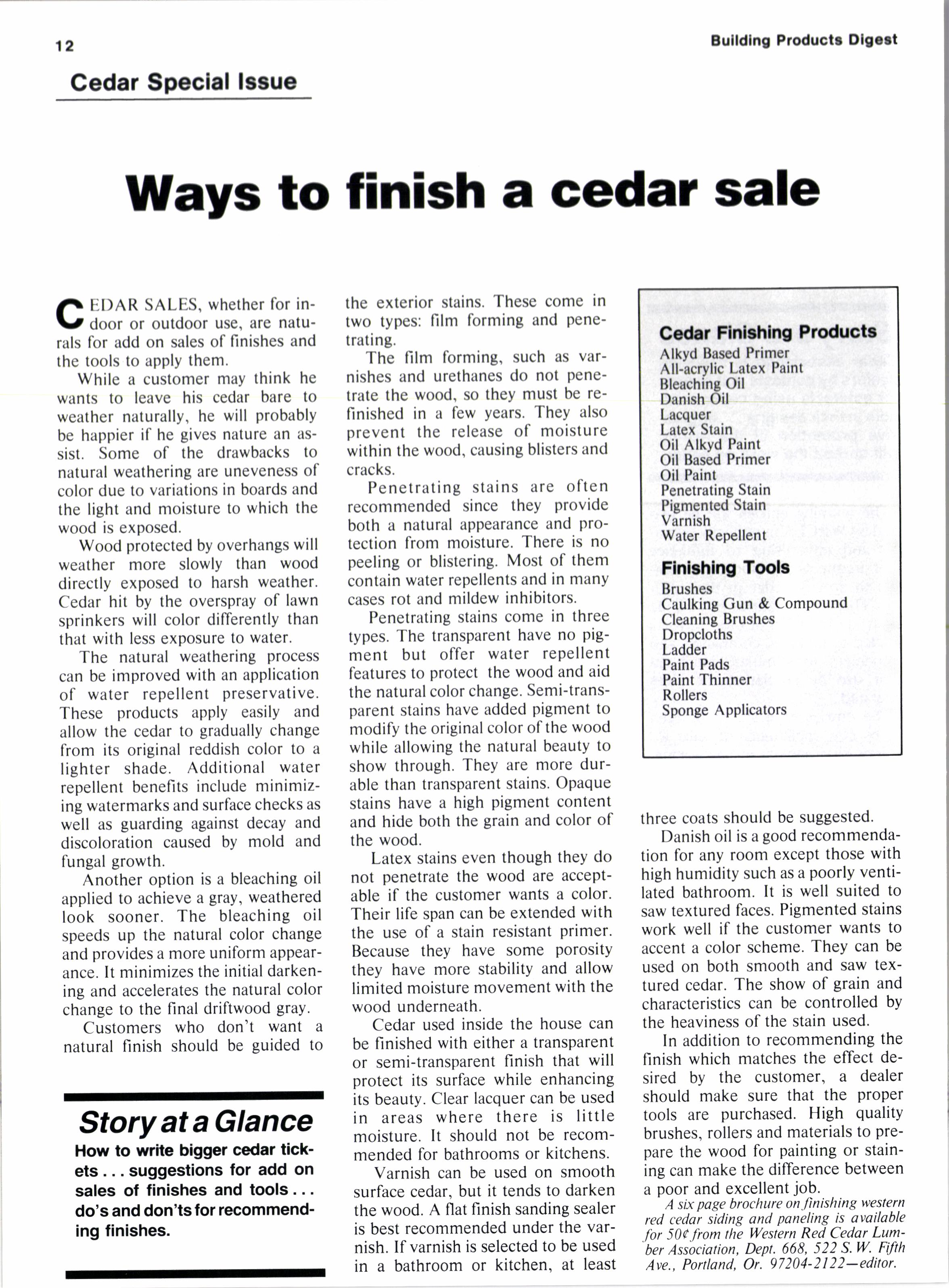

Ccdar FlnlCtlng Prcductl

Alkyd Based Primer

All-acrylic Latex Paint

Bleaching Oil

Dsnish Oil

Lacquer

Latex stain

Oil Alkyd Paint

OilBased Primer

OilPaint

Penetrating Stain

Pigmented Stain

Varnish

Water Repellent

Flnlehlng Tools

Brushes

Caulking Gun & Compound

Cleaning Brushes

Dropcloths

Ladder

Paint Pads

Paint Thinner

Rollers

Sponge Applicators three coats should be suggested.

Danish oil is a good recommendation for any room except those with high humidity such as a poorly ventilated bathroom. It is well suited to saw textured faces. Pigmented stains work well if the customer wants to accent a color scheme. TheY can be used on both smooth and saw textured cedar. The show of grain and characteristics can be controlled by the heaviness of the stain used.

In addition to recommending the finish which matches the effect desired by the customer, a dealer should make sure that the Proper tools are purchased. High qualitY brushes, rollers and materials to prepare the wood for painting or staining can make the difference between a poor and excellent job.

A six page brochure on.finishing western red cedar siding and paneling is available for 50( from rhe Western Red Cedar Lumber Association, Dept. 668, 522 S.ly. Fifth Ave.. Portland, Or. 97204-2 editor.

A S IF preparing to nimbly carry Fl eggs from the farm, lumber manufacturers are devising new, safer methods to protect their sensitive cedar during shipment to retailers and wholesalers.

"lt doesn't help us any to go to all the trouble of manufacturing it and milling it so it's looking good here, if by the time it gets to the customer it looks bad. We'd be wasting all that effort," says Mike Baldi, shipping superintendent for P&M Cedar Products, McCloud, Ca.

P&M tapes bundles together and affixes a special end cap constructed of four or six boards and featuring the company logo, a profile of the product, directions and applications information. Plastic film covers the shipment to protect the cedar's fine edges and tongues and grooves. Bolsters and spacers are strapped to each unit to keep the pallet together for a cleaner operation.

But the shipping additions provide retailers with more than good looking wood. After it is unloaded, the wrap can be left on the lumber while it sits in the yard to continue to protect it from the elements.

And P&M offers a specially designed ProPac, featuring prearranged 6, l0 and l6-ft. length boards. "When it gets to the yard, it's prepackaged in predetermined