From “abattoir by-product” to cosy fur

‘Skins’, ‘abattoir by-products’, even ‘abattoir waste’ – these are not exactly flattering terms. But when Neuenschwander collects its raw hides from butchers and abattoirs, what is technically called “disposal” becomes something meaningful. Through skilled craftsmanship, these by-products are turned into beautiful, long lasting furs – a thoughtful way to honour and reuse natural materials.

Respecting nature –even in the details

Anyone passing by the Neuenschwander plant might catch the familiar scent of a tannery – a reminder of a craft that has existed for centuries. In the past, tanners were even required to work outside city walls because of it.

Today, however, Neuenschwander ensures that everything else is as clean as possible. The tanning liquors – water enriched with tanning agents – are reused 10–15 times in a closed cycle. The tanning agents are then extracted from the liquor and the remaining water, thoroughly treated and officially certified as safe, is then released into the public wastewater treatment system.

Arrival at the hide cellar –where the journey begins

The transformation from raw hide to fine fur begins in the cool space of the hide cellar. Upon arrival, the hides are immediately chilled to prevent decay.

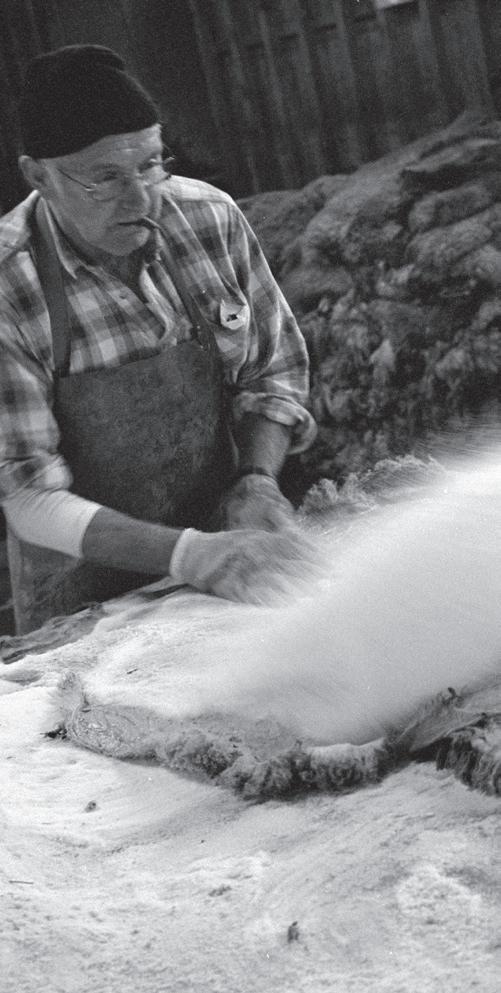

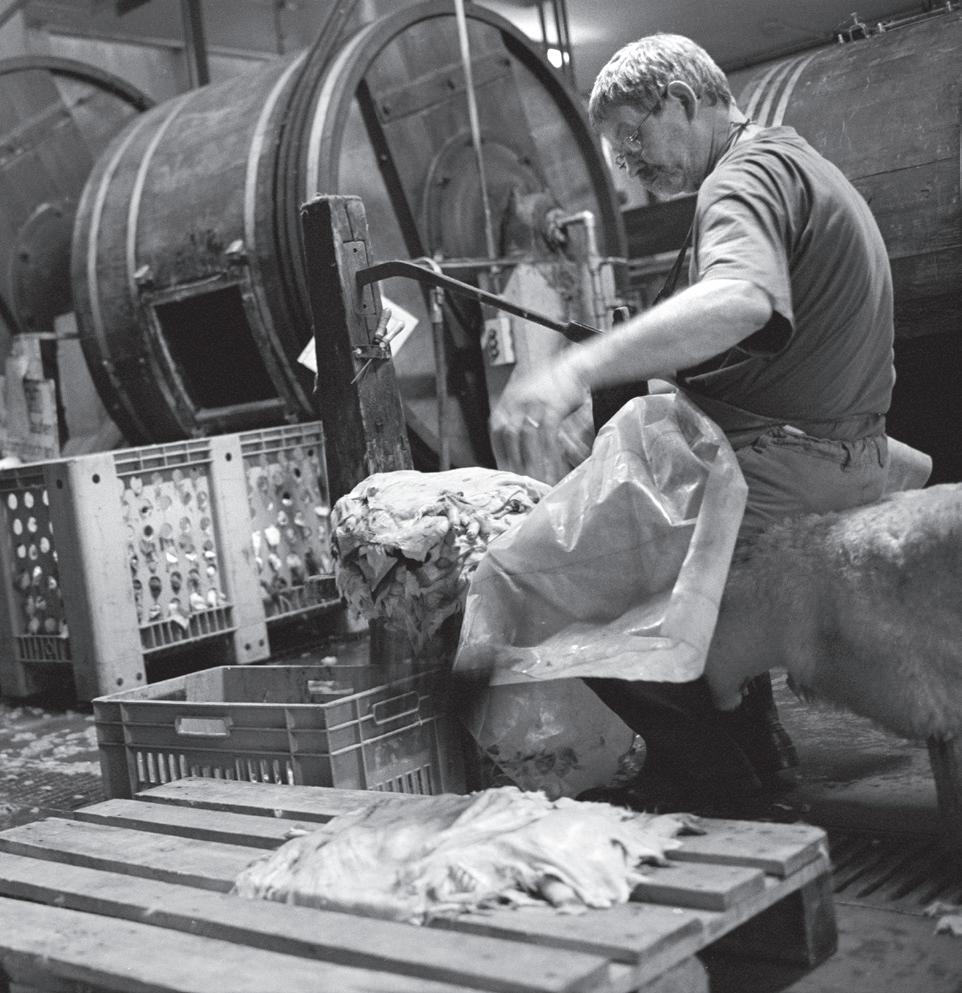

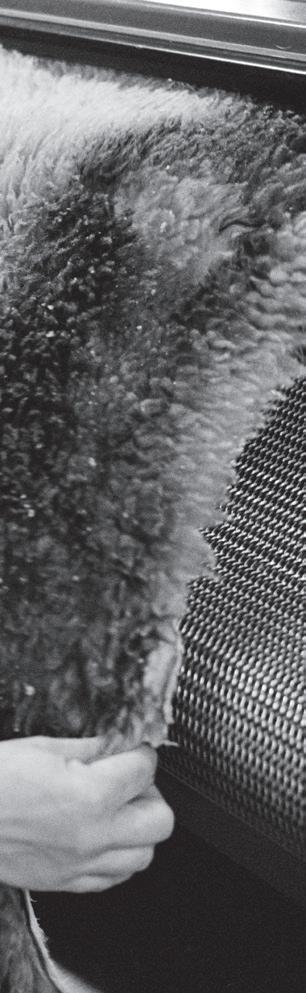

Preparing the hides –fleshing and shaping

Any remaining bits of fat or meat are carefully removed by hand, and the edges are neatly trimmed. Every hide is different, and the craftsperson’s eye is essential in recognising its potential.

Sorting – every hide has its story

No two hides are the same. In the main cellar, each one is examined and sorted by quality, colour, type and hair length. This step determines its next life – whether it will become a supple leather, a soft lambskin rug or a glossy fur.

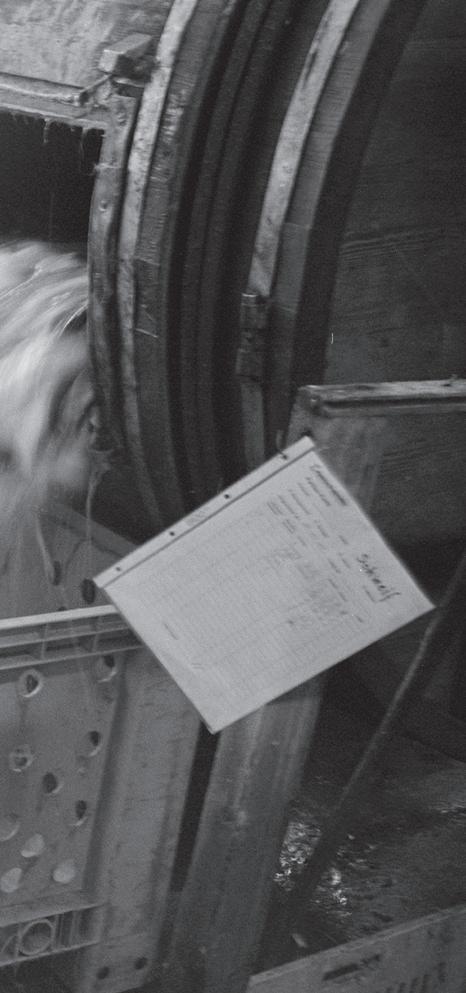

Assigning codes

Some hides come to Neuenschwander from hunters or customers, who wish to have them tanned and finished. To ensure every product can later be traced back to its origin, each hide receives a unique identification code, selected from an electronic database.

Code punching

This code is then physically impressed into the hide using a spiked punch. At the end of the finishing process, the fur can be identified by its stamp.

Salting – short-term protection

Salt is used to draw moisture out of the hide, preventing decay. This traditional preservation method keeps the hides stable until they are ready for the next stage.

Drying – for the long term

For longer storage, the hides are air-dried. Once dried, they can be stacked and stored compactly until they are needed again.

Storing

The dried raw skins are then stored in a space-saving manner until their further processing at Neuenschwander, or by their buyers.

Soaking – bringing the hides back to life

When it is time to begin tanning, the dried hides are moved to the tannery. There, they are soaked in warm water (around 30 °C) mixed with gentle detergent. Over the course of the day, the hides regain their natural softness as dirt, proteins, and salt residues are carefully washed away.

Fleshing – a clean slate

After soaking, any remaining fat, flesh, or impurities are removed with precision using a de-fleshing machine. The hides are now clean, pliable, and ready for tanning.

Pickling and greasing –setting the stage

Before the actual tanning begins, the hides must be conditioned so that they can fully and evenly absorb the tanning agents. During pickling, natural proteins are loosened within the hide, creating tiny channels that allow the tannins to penetrate deeply and evenly.

During greasing, fine layers of oils coat the hide’s fibres, restoring flexibility and resilience. This process enhances the leather’s characteristic strength, elasticity and breathability –the qualities that make every piece soft yet durable.

Shaving – precision at work

This delicate task demands skill and focus. The hides are shaved to an even, ideal thickness. If left too thick, they can become stiff; too thin, and they may tear or lose hair. Proper shaving ensures that each hide will absorb the tanning agents evenly and retain its supple texture.

Tanning – the heart of the process

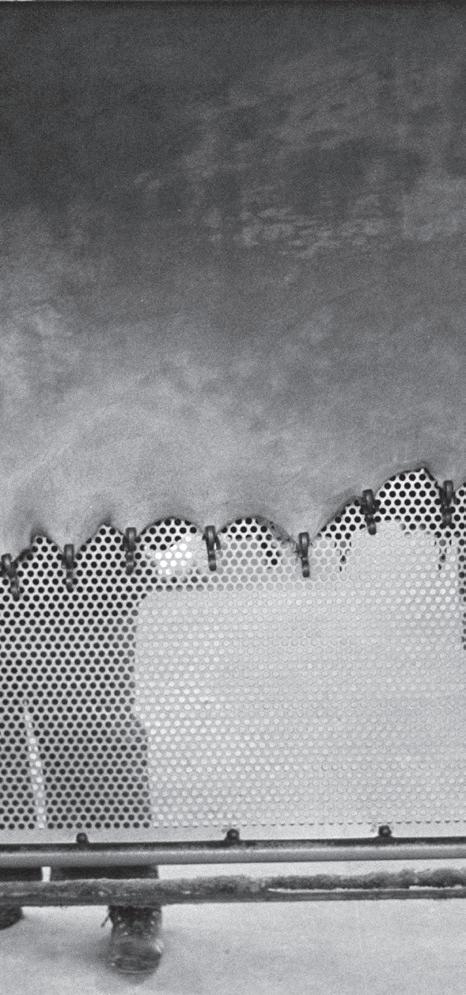

Now, the true transformation begins. The hides are placed in large rotating drums made of steel, or in a wooden barrel, where they are gently moved in the tanning liquor – a mixture of water and natural tanning agents.

Over the course of the day, the hides are slowly tanned, with drums turning periodically to ensure even absorption. During this process, the hide’s fibres become cross-linked, halting any decomposition and giving the leather its signature qualities: softness, strength, and breathability.

Four methods – one principle

Neuenschwander uses four tanning methods – all environmentally friendly and developed over decades of experience. The exact formulations are closely guarded secrets, safely stored in the company vault.

Alum tanning –preserving natural colours

The traditional method of using aluminium salts is ideal for furs / hides whose natural colours are to be preserved. The result is a beautiful hide that is neither heat-resistant nor washable.

Tara-aluminium tanning –for dyed furs

A natural tanning agent (tara) creates a robust, washable, and heat-resistant fur – perfect for decorative products or car seat covers.

Medical tanning –for health and comfort

Baby lambskins and medical furs such as mattress toppers or wheelchair cushions are tanned using glutaraldehyde, a synthetic agent that mimics the effects of plant-based tanning agents. The result: hypoallergenic, durable and fully washable furs.

Mimosa vegetable tanning –nature’s way

In pure plant-based tanning, Neuenschwander uses extracts from the bark and heartwood of the black wattle tree. This gentle, natural process is particularly suited for baby sheep- and lambskins as well as for therapeutic furs such as wool mattress toppers.

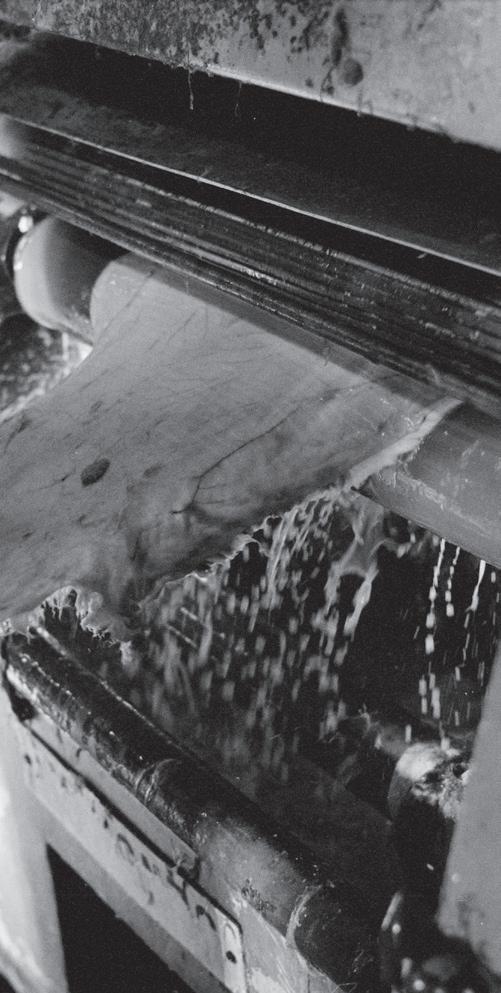

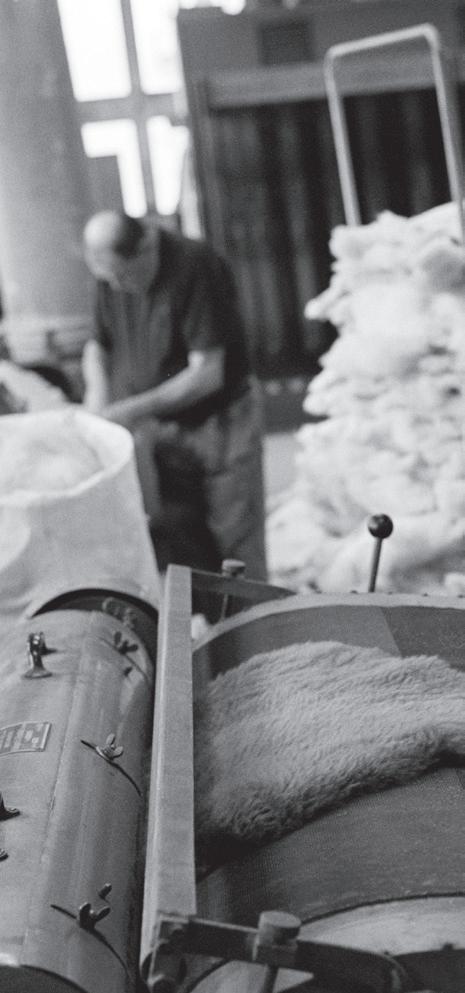

Spinning – removing the water

After tanning, the hides are spun in a centrifuge to remove excess water – preparing them for the next stages.

Calendering – restoring the shape and softness

After soaking and spinning, hides become slightly crumpled. While still damp, they are stretched and smoothed by hand. This restores their softness and original size.

Stretching and drying –back to the natural shape

Each hide is carefully stretched on a frame and dried in a warm room for around ten hours. The step requires expert judgment: the tension must be evenly distributed to prevent the fibres from sticking together or hardening.

Trimming and pre-sorting

Once dry, the hides are trimmed and shaped. Any unusable part is removed, and each hide is evaluated for its best use, based on size, wool density, and fibre length.

Cleaning in the ‘Rolls Royce’

A state-of-the-art cleaning machine gently removes oil and residues from both leather and wool. The result: supple leather and a neutral scent.

Degreasing – the old but gold method

For smaller furs, such as rabbit, fox or marten, a traditional method is used: the hides are tumbled with sawdust, which absorbs remaining oils and gives the coat a beautiful shine. Despite its simplicity, no modern process has yet matched its effectiveness.

Sanding and buffing –creating smooth perfection

Any remaining tissue on the leather side is carefully removed by sanding and buffing, leaving a flawless, soft surface.

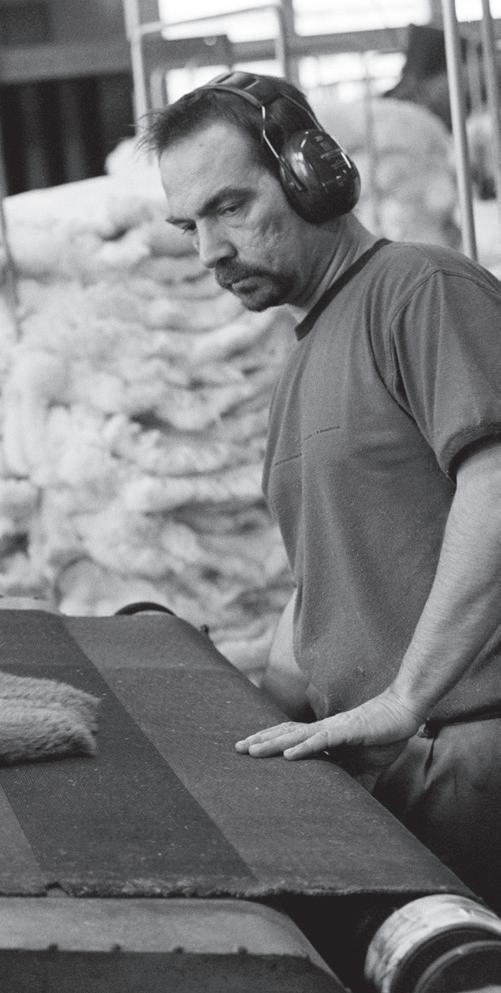

Combing – volume and beauty

The combing machine “opens up” the wool, adding natural volume and a more vibrant look. It is physically demanding work, but essential for the fur’s beauty. The excess wool removed in this process is collected and reused – for example as filling material. The machine also removes excess wool. This is vacuum extracted, collected and reused, for example as stuffing.

Shearing – millimeter precision

Medical furs, baby sheepskins, and car seat covers are shorn to an exact, even height – perfectly tailored to their purpose.

Ironing – silky shine

A final ironing gives the fur its characteristic sheen and silky feel. The wool is loosened, thus gaining elasticity and softness.

Scraping and final inspection –perfection by hand

Edges are carefully scraped to remove any sanding dust and then hand-combed to perfection. During the final inspection, every piece is examined with great care. Minor imperfections are corrected, seams adjusted, edges trimmed – until the fur is flawless and ready to leave the workshop.

G. Neuenschwander Söhne AG Industriestrasse 4 CH-3672 Oberdiessbach +41 31 771 14 11 info@neuenschwander.ch

neuenschwander.ch