December • January • February Issue 26 W inter 2022/3 The Products & Services Magazine for the UK’s Drinks Production Industry ISSN 2398-2489 Plus all the latest pr oducts & ser vices news fr om the UK drinks industr y’s suppl y chain SHOWC ASES In this issue • Production Equipment • Business Services

Brewing & Beverage Industries Business is a quarterly ‘Supply Chain’ magazine targeting the UK drinks production industry. If your company supplies products and services to brewers, distillers, cider makers, etc, then this is the platform for you.

Subscription is free and printed copies are mailed out throughout Great Britain and Northern Ireland. If you are one of the very few UK brewers, distillers, or cider manufacturers, not receiving a regular copy, then please contact us today. The

RUTH EVANS MBE

Ruth is CEO of BFBi, whose membership represents the supply chain for the brewing and beverage industries

JULIAN GROCOCK

Julian Grocock is a former chief executive of SIBA with extensive experience in beer, brewery and pub politics

ALAN POWELL

Alan Powell is a specialist excise duties consultant, who heads up the British Distillers Alliance.

ADRIAN TIERNEY-JONES

‘Beer Writer of the Year 2017’, Adrian Tierney Jones is a leading UK beer journalist and international brewing judge

STEPHEN BEAUMONT

Award winning North American-based beer and travel writer with an insight into trends ‘across the pond’

Published by freerbutler limited PO Box 9666 • Nottingham • NG10 9BY United Kingdom

Tel: 0115 8 549 349 brewingbusiness.co.uk

Our print circulation is audited and certified

Brewing & Beverage Industries Business magazine is an independent publication delighted to be a MEDIA PARTNER to

Representing the entire value chain supplying the Brewing, Food & Beverage Industry

Members of

freerbutler limited is a Supplier Associate member of

All rights reserved No part of this publication may be stored in a retrieval system or transmitted in any form or by any other means, electronic or mechanical, photocopying, recording or otherwise, without the prior permission of freerbutler limited

Whilst every effort is made to ensure that the information in this publication is accurate and up to date, freerbutler limited does not take any responsibility for errors or omissions Opinions expressed in editorial contributions to this publication are those of their respective authors and not necessarily shared by freerbutler limited © freerbutler limited 2022

5

WELCOME TO

Production Industry ISSN 2398-2489 ALWAYS IN PRINT & ONLINE - Now into our 7th year! Magazine Editor Chris Freer Digital Editor Simon Butler WHO WE ARE For editorial or advertising enquiries, call the Editor on 0115 8 549 349 or e mail: chris@brewingbusiness.co.uk

Products & Services Magazine for the UK Drinks

WHO WRITES FOR U S

Shop

Cover illustration Courtesy of Beer Box

Ruth Evans MBE

Time to put our heads together

As we approach 2023 against a backdrop of chaos, in terms of the aftermath of Covid, Brexit, the Ukraine war and our own Government, all companies are looking to their short-term strategies to address the challenges we are all experiencing

Here at BFBi, as with other Associations, we are supporting Members with the information they need to increase their business resilience

In the long history of our Association, we have partnered with other industry Associations, when needed, to share information in order to benefit all companies whether it be technical information, lobbying strategy or, as we need now, information to build business resilience against unknown economic, political and environmental challenges, not of our making

I would like to suggest that this is a time when we should consider collaborating, developing an Industry Business Resilience Working Group

Issues that are common across all sectors and business sizes appear to be:

• Staffing

• Rapidly increasing costs of production

• Energy security

• CO2

• Meeting Government environmental sustainability targets

• HR issues (burn out within senior management post Covid)

You may well feel there are others of importance or that those I have listed are not but, by partnering and working together, we can develop a list of issues and, from there, establish working groups of industry experts to address and support our industry as well as providing an industry strategy to present to Government

Collaboration throughout the supply chain has always been a point of difference within the brewing and beverage industry and, if ever there was a time to put our heads together to strengthen our businesses, it is now

Please do contact me if you feel this would be a worthwhile initiative (or not), indicating what you feel would be the most constructive format/process ruth evans@bfbi org uk

Ruth Evans MBE, BFBi C.E.O.

BFBi annual Trade Directory

New issue now out!

The most authoritative directory of the UK food & drinks market available

The directory is free of charge to all drinks manufacturers and BFBi members

For details of how to obtain a copy, please contact admin@bfbi.org.uk

Established in 1907, BFBi’s membership represents the entire value chain supplying the brewing and beverage industry from seed geneticists through raw materials, brewhouse and process equipment to dispense, point-of-sale and brewers/ distillers. The Association’s objective is to be the foremost trade association providing opportunities for its Members to develop within the brewing, food & beverage industry

As well as offering many benefits and services to suppliers of raw materials, process and packaging machinery, dispense and point of sale products, BFBi is a Trade Challenge Partner for various overseas exhibitions and owner and organiser of the oldest international brewing and cider Awards in the world.

6

Photo by Gerardo Jaconelli

SEE

FOR MORE

Word from the BFBi For some important news about our next issue, and an even stronger Media Partnership between Brewing & Beverage Industries Business (B&BIB) magazine, and BFBi (Brewing, Food and Beverage Industry Suppliers Association), please see the announcement on Page 51 of this issue.

PAGE 50

INFO

Adrian Tierney-Jones

Widen out the language surrounding beer

What do you think of when you order an IPA, an India Pale Ale? Presumably you might have a ponder on the hop varieties, or maybe ask what kind of sub-style it is. Is it a Milkshake IPA, an IPL, a session IPA or maybe just an IPA whose home might be the West Coast, East Coast or Belgium? Every few months we seem to have a new iteration of IPA, with the Cold variation seemingly the latest (unless I have missed one, do let me know if I have)

However, I’m guess what the average modern beer lover might not think of is the historical context of this most popular of styles, even if its name has a suggestion of the Victorian heyday of the beer, when it was sent to the Indian Raj courtesy of the East India Company, the British Empire’s occupying forces in the sub continent of India

When I first started writing about beer in the late 1990s, the only IPAs I can recall are Worthington White Shield, Freeminer ’s Trafalgar IPA (that was such a gorgeous beer) and Burton Bridge’s 7 5% Empire Pale Ale (oh and the odd American import) The label of Burton Bridge’s example featured (and still does according to its image on the website) two Victorian men, one a soldier and the other in cricketing whites, relaxing with a crate of Empire Pale Ale, somewhere in the Empire It’s all rather innocuous and portrays the British Empire as a paternalistic and benign force, rather than the brutal and racist reality

At this stage you might be wondering what has this distant history has got to do with the IPAs we drink, especially one that looks like a smoothie and has enough fruit on the palate to open its own grocery store? My answer would that it has a lot to do with beer, in the same way as in the last couple of decades campaigners have called out breweries who give their beers sexist names To paraphrase Trotsky, you might not be interested in bad beer but bad beer is interested in you

Fortunately there are attempts to change things October saw the release of Empire State Of Mind, but this time here was a beer that attempted to face up to the way the beer style has often been marketed

with benign images of the East India Company and the Empire The beer was the brainchild of award winning beer writer David Jesudason, who got together with the south east London brewery Villages to produce a post colonial IPA (Jesudason was also the driving force behind the British Guild of Beer Writers’ Diversity in British Beer Writing Grant) This was a beer that followed in the path of the ground breaking article he wrote last year for Good Beer Hunting, which focused on the way IPA is often branded

“When I wrote a piece for Good Beer Hunting about how modern IPAs are marketed in a way that often glorifies colonialism in India, the next logical step was to attempt to brew a 'decolonised IPA',” he told me “It had been tried before but brewers felt it was too much explaining for one beer and too much wording on a can went against the clean aesthetics often found in craft packaging

“I hope Empire State of Mind proves that it can be done It took my favourite craft beer Village’s Big Salad IPA and gave it an Indian twist It was brewed with coriander, amchoor, turmeric and jaggery The spicy is really subtle and mixes well with the lime and mango additions

“Despite IPAs being a product associated with the war machine that was the East Indian Company, which asset stripped India and pillaged its wealth, I don’t want to 'cancel' IPAs They’re a great way to introduce people to craft I just wish we could also explain their dark legacy at the same time.”

Refreshing and benevolent on the palate, the beer (naturally it’s hazy)

has a benign juiciness and tropical fruitiness in its mouth feel and on the palate, joined by delicate spice notes and a very light sweetness It’s easy drinking and hopefully this will be the start of a realignment in the way in which IPA is viewed

The release of Empire State of Mind is just the latest instalment in which brewers, commentators and beer fans are attempting to widen out the language and the understanding that surrounds beer It’s not about ‘canceling’ or being woke, it’s more about realising that beer needs to embrace everyone in society and besides there are no free passes for lazy history any more

After all, it can’t be said enough times: beer is for everyone

Adrian Tierney-Jones

Voted

He’s

8 Called To The Bar

Beer Writer Of The Year 2017 • Best Beer Writer, National Media 2019

‘Beer Writer of the Year 2017’ by the British Guild of Beer Writers, Adrian Tierney-Jones is a freelance journalist whose work also appears in the Daily Telegraph, Pellicle, Good Beer Hunting, Daily Star and Beer Magazine amongst many others

been writing books since 2002 and they include West Country Ales, Great British Pubs, Britain’s Beer Revolution (co written with Roger Protz), The Seven Moods of Craft Beer and his latest, United Kingdom of Beer He is also general editor of 1001 Beers To Try Before You Die and contributor to The Oxford Companion to Beer, World Beer and 1001 Restaurants You Must Experience Before You Die.

Chair of Judges at the World Beer Awards and also on the jury for several other competitions

9

Stephen Beaumont

Patting Ourselves on the Back

As I type these words, I am drinking a glass of beer. I understand if you find this unsurprising, since I imagine that a lot of readers expect we beer writers to be more-or-less perpetually soused. But the truth is that we are not, or at least I’m not, at least most times, since what one writes while drinking seldom stands up to sober reading.

In this case, however, I am drinking in celebration Just a few days ago, I and the Canadian Craft Brewers Association released the results of the inaugural edition of the Canada Beer Cup, and as the overseer of the judging, although not a judge myself, I could not be happier with the results

In total, we awarded 175 gold, silver, and bronze trophies across 70 style categories, including one category I personally created, Canadian Style Beer, challenging brewers from coast to coast to coast yes, we have three of them, including one rather jagged one in the north to create a beer they deemed to be classically Canadian, and explain their reasoning in a mini essay (The winner, incidentally, was a beer brewed using maple sap in place of water, with Canadian malt and landrace Canadian hops, and yes, predictably maple wood spirals and maple syrup added to conditioning The brewer was Toronto’s Shacklands Brewing, certainly a stand out in the city, although the beer is one I have not as yet tasted )

You may now be asking yourself why you should care about an all Canadian beer competition, and I’m going to tell you. Because the reason I took on this rather massive project, which involved receiving almost double the number of entries we anticipated, over 1,300, and co ordinating several ever shifting judging scenarios, was because Canadian beer has over the last several years risen to extraordinary heights of quality and creativity And yet hardly anyone knows about it

What’s more, and I say this as a long standing city sceptic, my hometown of Toronto has become a beer city the equal of any in the world

This is why, when the originators of the Canada Beer Cup, the above noted CCBA, approached me to oversee the judging, I agreed on the understanding that I would be able to invite international judges to experience Canadian beer and the Toronto beer scene They agreed, so for the first time in Canadian beer competition history we had judges from England, including Pete Brown, Italy, and the United States, as well as several esteemed judges from across Canada

While I cannot speak directly to the experiences of any of the judges, the feedback I received was uniformly positive although there is always the possibility they were just being polite guests More to the point was my personal tasting experience behind the scenes, both towards the end of the judging days when we backstage actors would allow ourselves a sample of a beer here and there, and in the aftermath as I now continue to sample my way through the leftovers Based upon that, I can safely say that the general quality of the beer submitted was as high as I have experienced in any competition anywhere

Now before this column becomes a promotional vehicle for Canadian beer and Destination Toronto, let me quickly add that this national brewing prowess has been some time in development Through to about 2010, Canadian brewers were very good at producing reliable interpretations of classic beer styles, from Pale Ale to Porter to Bock, but lacked the creative excitement I would regularly experience elsewhere Beer here was perfectly fine, occasionally excellent, but hardly the stuff to make a visitor sit up and take notice

In 2022, on the other hand, I can drink beer made from maple sap, spontaneously fermented beers that speak to lambic traditions, but with a Canadian accent, Scottish style ales conditioned in barrels that previously held Canadian single malt whisky Callister Brewing’s Wee Laird Wee Heavy, the ultimate Canada Beer Cup winner and any number of beers that invoke brewing traditions while at the same time speaking emphatically to their Canadian ness

This is a remarkable shift in my home country’s brewing landscape, as extreme as Toronto’s evolution into a legitimate beer tourism destination, and so please forgive me if I might seem a tad too emphatic in my exuberance But as the guy who spent years being criticized for not ‘supporting the locals’ because I judged beer on a global rather than provincial or national basis, it is refreshing to finally be able to say, “Hey, come to Canada, we have a truly world class beer scene here!”

Now, excuse me, I have a pretty terrific brown ale to finish Stephen Beaumont

A professional beer writer for 30 years, Stephen Beaumont is an award-winning author or co author of fourteen books on beer, including his latest solo work, Will Travel for Beer: 101 Remarkable Journeys Every Beer Lover Should Experience, and the fully revised, rewritten and updated third edition of The World Atlas of Beer, co authored with Tim Webb and available now.

Stephen can be found online at beaumontdrinks com and on both Instagram and Twitter @BeaumontDrinks

10 Letter From Nor th America

BEST BEER & TRAVEL WRITER 2017

Award-winning, family-owned Wold Top Brewery has recently installed an automatic wraparound case packing machine supplied by packing and wrapping specialists, Atlanta UK.

The investment, which replaces a manual case packing and shrink wrap operation at its site, has generated production efficiencies with scope to enable future growth. There are environmental benefits and a positive re direction of labour resources resulting in reduced exposure to repetitive strain injury

Using traditional methods to produce high quality beers from tits 600 acre farm high on the Yorkshire Wolds, the brewery asked Atlanta UK to provide an automated solution to replace the manual tray and plastic shrink wrap process being used to pack its beer products Atlanta UK introduced Wold Top to two similar microbreweries

packing automation

producing cardboard case packed product using the Atlanta Raffaello. Following several project meetings at Wold Top to fully understand the requirements, Atlanta UK was able to design a bespoke solution to meet the objectives

The Atlanta Raffaello machine is ideal for medium levels of production, automatically collating the loose product into pack format, then forming and gluing the carton around the product from a flat blank The Wold Top solution included an infeed accumulation conveyor to receive and buffer product from the production line. Further new conveyors to the outfeed completed the full solution As a result, Wold Top also accrues some key environmental benefits, including no plastic usage, improved recyclability of material and greatly reduced energy in its packing operation

“Installation of the Raffaello system was a very smooth process and the complete solution was commissioned on time,” said Alex Balchin, a director at Wold Top Brewery. “I can’t fault Atlanta UK for their service and support they provide a knowledgeable single point of contact and look for solutions, rather than focus on installing just a machine

“The equipment not only helps improve efficiencies, it has also made us move away from our previous process to complete carton board units, which is definitely a plus from a sustainability point of view ”

Atlanta UK’s Roger Cope added: “Wold Top Brewery was using an old method of fulfilment that was inefficient and restrictive to growth The right thing to do was to automate the process and at the same time, move to a full cardboard carton We took time to review a number of layout solutions which involved re working conveyors and retaining the option of their existing shrink wrap facility before we settled on a complete solution based around our Atlanta Raffaello case packing machine ”

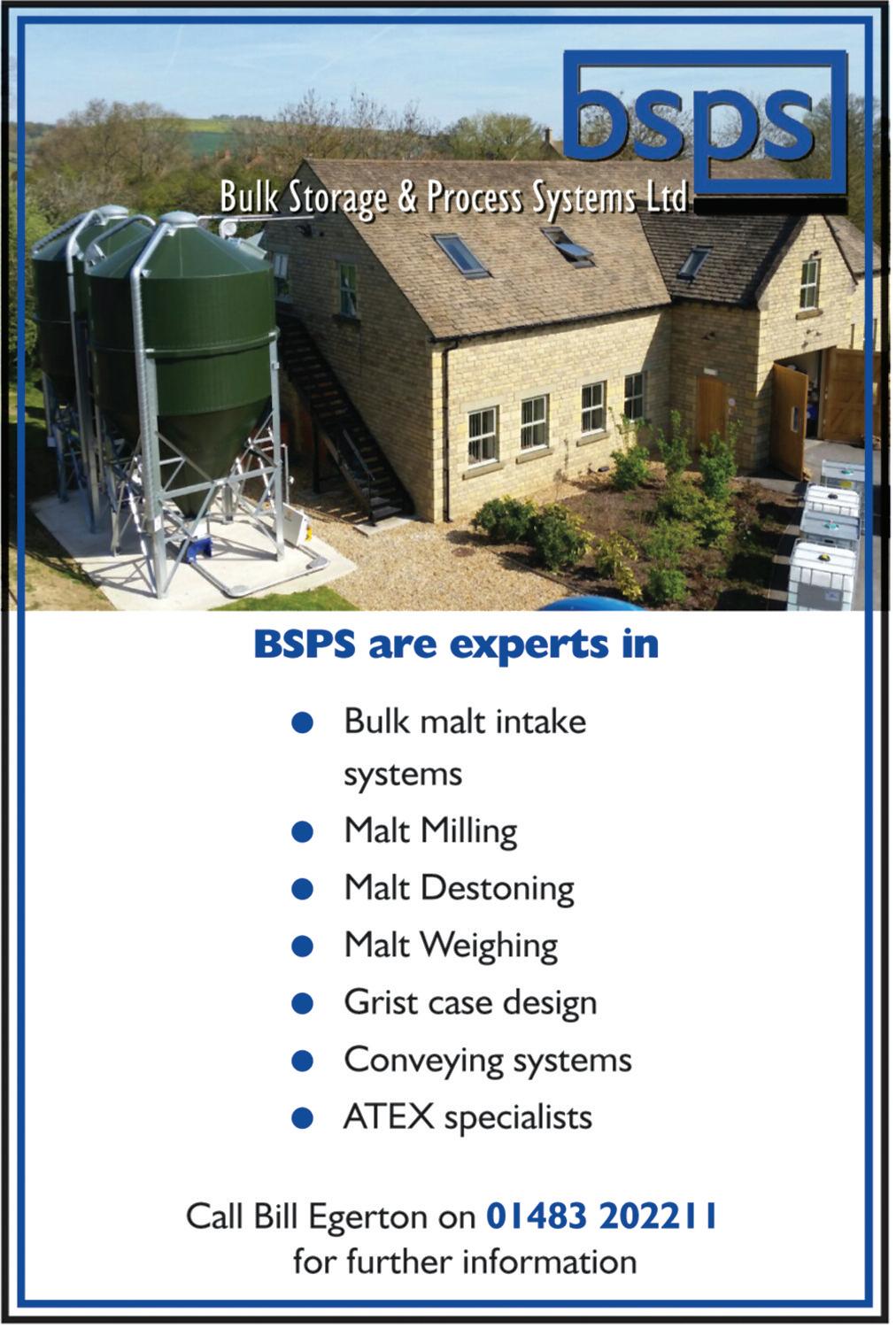

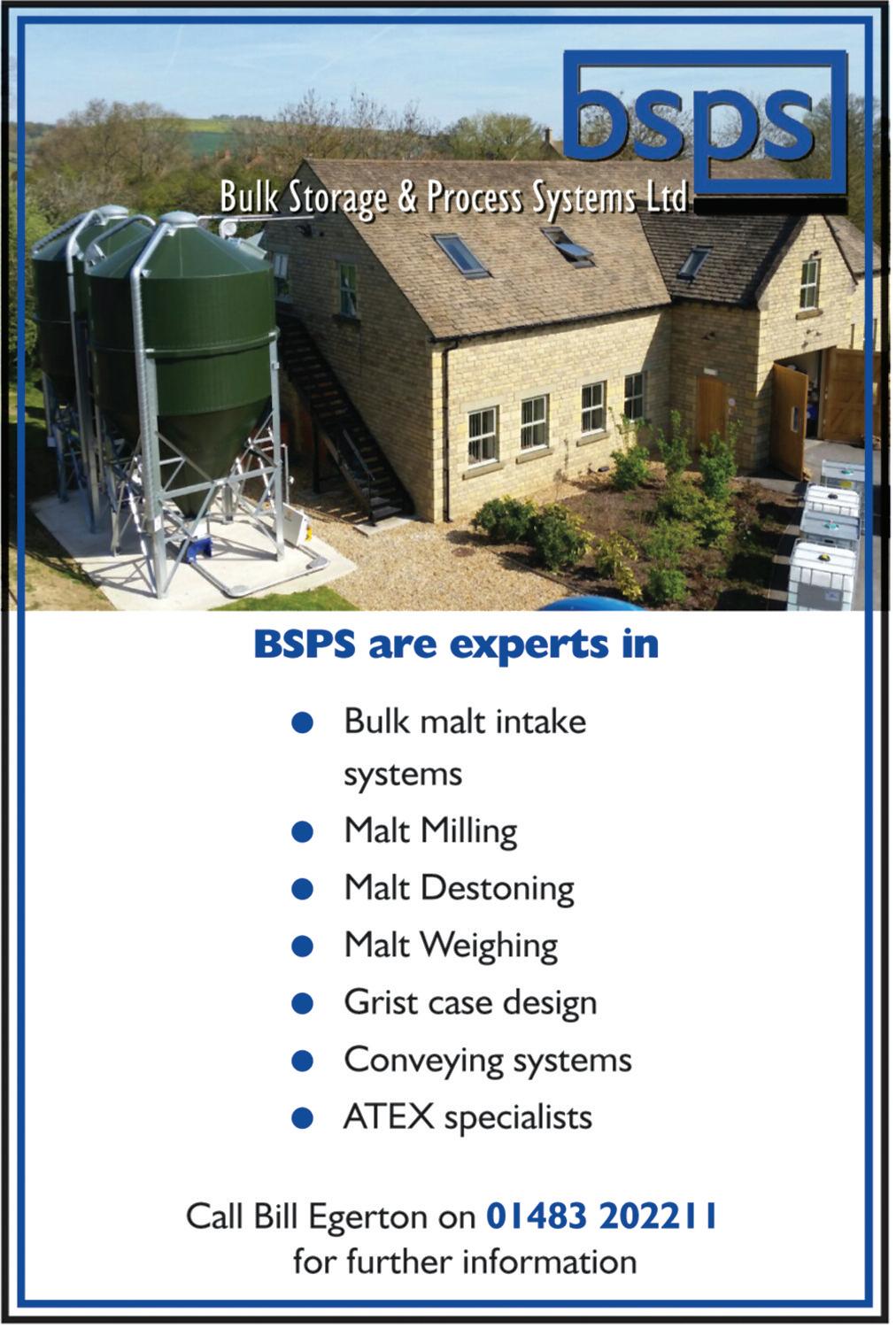

Bulk Storage and Process Systems Ltd was selected by Diageo to replace two 23tph 316 grade stainless screw conveyors in the wet draff handling plant at a large distillery in Scotland

The two 350mm screw conveyors were designed to a very high specification to run 24/7 for 50 weeks of the year at a high temperature over 85°C The strip out and installation was carried out by BSPS fitters during the Summer shutdown in 2022 The install was completed on time and within budget, and the machines have

been running since installation without any issues

Bulk Storage and Process Systems undertake all types of work from changing a single machine to full plant design and installation

For more information about screw conveyors and other materials handling equipment or storage requirements please contact Bill Egerton

12 01483 202211 bill@bulksystems.co.uk For further information:

Top invests

case

SHOWC ASE Production Equipment We asked companies supplying the following products and services to let us know something about themselves l New or pre-owned production equipment available to UK brewers, distillers & cider-makers. l Companies that will install your equipment and work with you in commissioning and initial production, in addition to providing tuition. Screw conveyor to run 24/7 www atlantapackaging co uk For further information:

Wold

in

13 Cask and Keg Repair & Refurbishment Specialists l A Genuine Alternative to Cask and Keg Replacement l Repairs to casks and kegs of all sizes l We can supply refurbished casks too l Fast On-Site Turnaround l Competitive R ates l Over 60 years of Industr y Experience Please contact us for details of our other onsite ser vices. Head Office: 01283 740807 • Mob: 07952 152 099 Email: repairs@dhmbreweryservices co uk • Contact: Jason Miller Web: www.dhmbreweryservices.co.uk • Twitter: @DHMBreweryServ

Where’s Warmley and why? The answer is a can

St Austell Brewery, based in Cornwall, purchased Bath Ales in 2016 and set about building them a £7 million state-of-the-art production site that opened in Warmley in 2018.

And why Warmley? The latest investment in the Warmley site has seen the installation of a flexible world class canning facility The project was some time in the planning and Enterprise Tondelli as a specialist supplier of canning and bottling equipment was selected as one of the line suppliers Established in 1977 Enterprise Tondelli has made a name for itself for attention to detail, ability to provide alternative scenarios quickly and flexible working approach

The space allocated for the project was compact and so line design was a challenge Enterprise Tondelli provided a number of line designs which were optimised until revision 12 was selected allowing good materials access, third party equipment, common working areas and an efficient use of space whilst still giving an efficient operation A single common accessway reaches to the secondary packaging area with two packing machines opposite each other with one operator for both machines. A second operator has a work area off the central accessway for the self adhesive labeller and filler and lid feeder magazine A link conveyor allows the use of an existing robotic palletiser to maximise utilisation of assets On the project there were four other suppliers contributing to the overall success

Enterprise Tondelli supplied a high level empty can depalletiser manufactured all in stainless steel from its subsidiary Eurosistemi The unit can handle both layer sheets as well as recyclable plastic interlayers with a high level magazine A full length high level platform supplied by Enterprise allows full access to both the depalletiser and all empty can conveyors. Open electronic architecture allows Bath Ales to adjust the machine as required A VPN provides remote access for support, reducing total cost of ownership

Pressure type combiner for empty can conveyors feed into a triple channel gravity can cleaner Automatic divert

gates at the rinser inlet allow feeding of the various can sizes down dedicated lanes reducing change over time to a simple switch Can inversion is by easy openable “suitcase” type machined plastic can twists rather than conventional bars Conscious of its environmental footprint, ionised air is used for can cleaning saving around 8,000 litres of water per shift.

A fully enclosed can drier from Eurosistemi with adjustable drying nozzles removes any water prior to coding and packaging Empty and full can conveyors from depalletiser to packer were manufactured by Eurosistemi and supplied and managed by Enterprise Tondelli

A sixteen platform self adhesive labeller supplied by Enterprise Tondelli from manufacturer BRB Globus applies a wraparound self adhesive label to plain cans To prevent can crushing during this operation and to give an effective adhesion the cans are pressurised with air on the labelling carousel. Guillotine guards allow easy access to the machine which is also fitted with a VPN connection for remote assistance in real time

As a sustainable business the company wanted to ensure that smaller runs of non printed cans can be labelled with 'Wood Film' labels which were developed in conjunction with the large papermills of Scandinavia Tree oils are extracted as a by product of the paper making process and converted into a chemical structure which forms the basis of a white and clear Polyolefin Wood Film self adhesive material The label material performs the same as a standard PP self adhesive material and is highly durable, and can be supplied in clear or white faced material The BRB labeller is able to handle both these and other types of labels without any difficulties

The main Eurosistemi conveyor control cabinet is located out of the way on the high level platform so a local operator panel was located at low level adjacent to the labeller/filler well for easy access. Again to reduce cost of ownership and provide support in real time, a VPN is also fitted to this panel

Bath and St Austell have historically tended towards the turnkey approach which can sometimes lead to equipment compromises However they have been very pleased with the results this time by selecting some of the best suppliers in the industry who are specialists in their fields

Brewing Director, Georgina Young (pictured top) said, “Over the years I have worked with many suppliers in this industry although had not worked with Enterprise Tondelli before but found it a positive experience Their continuing attention to the project throughout the process and unfailing willingness to adjust to our requirements has been refreshing As the conveyor supplier for the project, Enterprise became key in the management of the project They dovetailed with hard working and dedicated St Austell and Bath Ales teams and other contractors on site Thank you ”

Craig Wilson Managing Director of Enterprise Tondelli stated, “It was a great pleasure to work with Bath Ales and the team who were very collaborative Despite some challenges given by Covid, customs, shortage etc the final result is a tribute to Bath Ales and St Austell and we look forward to working together on any future projects that may arise I now know where Warmley is and what it is really famous for ”

For further information:

www.enterprisetondelli.co.uk info@enterprisetondelli.co.uk

14

SHOWC ASE

Production Equipment

15

Carbonating and kegging – the whole story

As a manufacturer of stainless-steel vessels for more than 45 years, Moeschle is also experienced in the process demands required from a system (as pictured right).

So the company was delighted when the Chantry Brewery team asked Moeschle to work with them from, initial design, layouts and selection of equipment through to project management, installation and commissioning and handover of the system.

On the left of the image are three Dual Purpose Vessels (DPVs), which are just over 7000L each in capacity With a design pressure of 0 5 bar, they bring the flexibility to be used as both a fermenter and a conditioning tank Each vessel is connected to a central control panel, which allows their live temperatures to be checked and adjusted, as well as the pump speed to be altered, to increase or decrease the outlet flow of beer Upon exiting the DPVs, beer undergoes a 3 stage filtration process, ensuring consistent clarity and the desired bright colour

Whether a higher or lower level of carbonation is desired, all the beer passes through the carbonator, which can add up to 6g of CO2 per litre Moeschle worked with Pentair, who

designed a carbonator capable of carbonating at the remarkable level of 100 litres per minute The system is fully customisable, meaning that the correct CO2 level can be adapted for each brew and stored for repetition This prevents, for example, an over carbonated ale from coming to a head, as a set CO2 level is achieved every time

Carbonation is followed by storage in a 600L pressure rated buffer vessel, which gives the adaptability for brewers to keg at their desired pace The pressurisation of this vessel ensures that the CO2 remains in suspension before beer reaches the kegging process The kegging

Smart Lab Analysis from Vitikit

Vitikit has teamed up with DNA Phone, an Italian tech company that offers an innovative solutions to the food and beverage industries. In particular, the company develops and markets analysis tools for the quality control of wine, cider and beer.

At Vitikit, we are excited to present Smart Analysis, an equipment that revolutionises the world of rapid analysis and diagnostic tests It simplifies quality control and allows our customer to improve their product day after day

Smart Analysis is a portable, accurate and reliable enzyme analyser The system uses patented fibre optic and LED source technologies, which makes Smart Analysis a compact and rugged spectrophotometer that does

not require any particular maintenance DNA Phone has developed a remote diagnostic system to check whether your device is working properly

The Smart Analysis comes with an app that can be downloaded directly on to your mobile or tablet The APP is a simple and intuitive to use application for any type of user. It allows our customers to manage all the analysis operations in a guided way The equipment automatically identifies the type of analysis via the QR code of the reagent kit

The results from the analysis are saved on the app, which can be downloaded for further analysis in a convenient format It’s possible to process the data anytime and anywhere, using this information to obtain, over time, the historical record

machine was made by M+F and achieves a speedy fill rate of 50L in 40s, which, along with cleaning time, allows around 30 kegs per hour The resourceful and hygienic built in keg cleaning method is steam sterilisation and it has proven to be very effective

Commented Mick Warburton, Co owner / Director of Chantry Brewery Limited, “We have worked together with Moeschle from setting up the brewery and we find them great to deal with and always helpful and knowledgeable ”

For further information:

www.moeschle.com/en

of your product; thus increasing its usefulness to help with decision making.

DNA Phone reagent kits are designed to simplify the analysis process, making it accessible for users of all knowledge levels The key to this is minimising the number of manual operations required. The use of disposable cuvettes, with standard optical paths that are pre filled with the reagents, helps to create clear, reliable and effective testing

For further information:

16 info@vitikit.com

SHOWC ASE

Production Equipment

Peaceful co-existence on the bar, a new age of choice for the drinker and a dose of commercial reality for brewers

Says David Smith of Brewing Services Ltd

For anyone reading the wider press and brewing periodicals of late it may not be immediately apparent that we have witnessed a complete sea change in respect to the selection of styles of beer available on the bar.

Recent press articles might suggest cask is doomed whilst others seem to suggest a revival of ‘traditional’ beers and cask is back However, this isn’t a revival as such because cask beers have never really been away, they simply weren’t as easy to source during Covid and fell out of favour with the industry pundits writing the column inches week on week Whilst they have been busy telling us about the latest canned beers from this new brewery or that new brewery, they continually overlook the many great beers that sell many thousands of litres week on week What has become apparent in recent years is that beer in all its formats is acceptable, and more than ever it’s the drinker ’s choice as to what style or format of beer he or she wishes to drink on a night out The recent GBBF, with its many bars and beers styles on show, typifies this new approach to both selling and producing beers

More importantly however, the penny has finally dropped for many craft brewers that it is actually a commercial world out there and the beers you produce need to appeal to a sufficiently large audience for a brewery to survive This means not limiting the types of products you sell. The downfall for many brewers is in thinking that whatever beer they produce is good beer, often given

this impression and buoyed up by the odd favourable mention in a beer review Then, when they fail to find a sufficiently large market for their beers, that is somehow the fault of the uneducated consumer One well known brewer in the north would continually boast to anyone who would listen about how good his beers were right up until the point he went out of business A little more humility on his part and looking around at all the beers that were selling well around him and keeping his beers off the bar, might have made him realise the customer is always king

For the brewers with longer pedigree and a better understanding of the beer market, breweries such as Fyne Ales, Saltaire and Brew York are bringing in their new, more exotic flavoured beers, alongside a core of high quality keg and cask beers thus providing a more diverse offering with wide appeal However, it is still these core beers which week on week actually pay the wages, whilst the other more esoteric products simply grab the headlines and provide a temporary talking point.

In a major reversal of attitude to traditional beers, brewers such as Brewdog and Cloudwater, who once said ‘never ’ to cask beers, are finding producing cask beer is now quite appealing, as well as profitable A sudden awakening to the fact that all beer styles have a following and to overlook any sector of the market is a complete own goal Simply sticking to one form of beer packaging is neither a sensible nor commercial stance on which to build a successful business

The divergence of packaging formats that once separated pubs into either craft keg and can verses traditional cask or bottle venues is quickly coming to an end What we are witnessing now is greater convergence with canny landlords happy to have cask alongside keg on the bar with bottles or cans sitting comfortably side by side in the fridge

Craft brewers who might once have seen cask beers, along with CAMRA and The Great British Beer Festival, as outdated dinosaurs with keg and can and Craft Beer Rising being the only true place to market their beers, should now be rethinking their beer portfolios and their approach to marketing their beers

We will perhaps see more of the new craft brewers that are starting up, or at least the commercially minded ones, viewing all drinkers as a potential market and this may well save breweries blessed previously with such narrow product tunnel vision from failure before they have started This exciting realisation that we can have peaceful co existence of all products on the bar is ushering in a new age of greater choice for the drinker whilst throwing a lifeline to craft brewers in these tough trading times, ensuring a greater survival rate thanks to a welcome dose of commercial reality

New potentiometric sensor ‘raises the bar

Sensor specialist BAUMER continues to develop its awardwinning IO-Link sensors, with the latest example being the CombiLevel PLP70 level sensor, designed to excel in applications with high grade diversity and frequent media changes such as those occurring in the beverage, brewing and other similar liquid handling processes.

The key benefits of this innovative potentiometric sensor make continuous level measurement easier and more flexible including the ability to automati cally adapt to a wide range of media Typical applications include precise monitoring of process levels in feeding containers, storage and buffer tanks and fast changing levels in filling lines

Operators will also appreciate the easy monitoring and control of the sensor via the proven Baumer display which

includes a background changing colour and effectively provides all the required information at a single glance, even from longer distances Functions of the touch display include temperature, pressure and conductivity enabling quick and convenient operator intervention directly at the sensor display www.baumer.com

18

SHOWC ASE Production Equipment

www brewingservices co uk For further information:

For further information:

’

19

Brew-School courses are truly international

Says Chris Horne, Director

We have just finished running a two-week Trainee Brewer Program that has included hosting four trainee brewers from Croatia. It never ceases to amaze me at the sheer international nature of our brewing, wine making and distilling courses.

We regularly welcome students from all corners of the globe including Australia, America, Hong Kong, India as well as right across Europe However, on a trip just down the road from our premises in Bakewell to Brampton Brewery to take part in a brewday and following a lunch time sampling of one of their excellent cask beers, Jerusalem, it struck me that, despite the international nature of beer, what an amazingly unique British product cask beer is No other country brews beer like it!

Intensive Trainee Brewer Program 14 Days of Brewing Insights and Knowledge

Our trainee brewer program running over 14 days is intended to provide the foundations for people looking at

of Brewing

working or entering the craft beer industry with at its core the syllabus of the IBD’s GCB. In addition we look at beer recipe development, the all important cask beer management, along with drilling down into the science of brewing and the importance hop based compounds play in the emergence of big hoppy flavoured IPA’s with our Hop Masterclass run with Charles Faram

Brewing Roots

Having run our craft drinks and brewing courses for 10 years I can report that we have many success stories where we have assisted a whole new generation of brewers to keep the art of traditional cask beer brewing alive. This was crystalized very recently for me when I returned to my home town of Rugeley to visit the Vine Pub, a 200 year old wet led pub in the heart of this market town The owners Ollie and Chris attended one of our first GCB based courses back in 2016 and they are still only in their 20’s so young!

They have now reinstated a microbrewery in the pub and are

producing a range of cask beers As I sat in front of a roaring open fire with a pint of their amazing best bitter, in the company of my oldest school friend, I enjoyed a cracking evening

If there is such a thing of legacy then, renewing and reinvigorating another generation of brewers and breweries has been a privilege

For further information:

info@brew

Campden BRI launches ‘Campden Learning’

Campden BRI, a leading global training provider to the food and drink industry, has launched its innovative ‘on demand’ e-learning platform, Campden Learning

The new platform brings together deep industry knowledge and expertise using dynamic digital tools to deliver an interactive and engaging training experience With Campden Learning, participants can enjoy first rate training in any location they choose and are able to play and pause their learning to suit their professional and personal commitments

Campden Learning training manager, Jo Rathkey comments, “Campden Learning is a fantastic example of the many initiatives that Campden BRI is developing for the food and drink industry

“The nature of our sector means that businesses cannot afford to be left behind on information, knowledge and

the latest thinking around a number of topics We know the pressures the food and drink industry must manage and that time is often scarce as a consequence, so we designed Campden Learning to offer a practical solution to time pressured employees who need to fit the demands of their profession around their learning Our new platform allows participants to dip in and out of their courses whilst easily keeping track of their progress.

“In addition, we know businesses require assurance that their employees are receiving the very best high quality training available, with minimal downtime and optimal results to maximise their training budgets. By choosing training from the market leader, via the Campden Learning platform, they know they can trust the quality of the information and its delivery Adopting on demand e learning means that no matter where your workforce is, whether in

one location or scattered across continents, all of them can benefit from the learning provided by the market leading experts in food and drink industry training.”

Campden Learning content is developed by Campden BRI’s experienced subject matter experts to produce audio led bitesize sessions using a combination of video, animation, graphics and interactive tools, ensuring an engaging experience for participants

For

20

www.campdenbri.co.uk

SHOWC ASE Production Equipment

further information:

school com

CO₂ - Protect your pocket and the planet

In recent years the price of CO₂ has gone up exponentially, with some breweries seeing over a 600% increase in recent months. Lest we forget the shortages from 2018 due to two factories going through routine maintenance at the same time, and CO₂ being in such short supply. It became headline news around Europe

CO₂ has therefore been, for some time now, one of the most volatile components for many craft brewers’ businesses Without it many brewers are unable to meet the demands of their customers and yet, as we all know, CO₂ is a byproduct of brewing, something that all the major brewery’s harness to remove the turmoil created through a precarious supply and demand structure within CO₂ generation

Brewery support

A Yorkshire based equipment specialist is helping brewers manage cost-efficient production and maintenance amid the challenges of a global energy crisis.

Collective Motion Brewing has a 1,000 sq ft base in Bradford which will operate as a warehouse, workshop and R&D centre for the supply of a range of equipment, automation and services which are designed to improve quality control, reduce running costs and minimise waste Its portfolio includes newly developed and upgraded systems alongside refurbished machinery and a fast diagnostics and repair service for the brewing, distilling, and cider making industry

Director Dominic Smith said: “With our passion for the brewing industry, we identified a need for a service to help smaller brewers survive by servicing essential machinery to keep them in operation and helping to source high quality second hand equipment We hate waste and love breathing new life into old non working units ” cmbrewery.co.uk For further information:

Earthly Labs from the USA and Dalum from Denmark are two companies leading the way in this new and exciting technology. With small footprints and a tested purity above 99%, these new CO₂ capture companies are set to pave the way for many craft brewers to finally take control of their CO₂ costs and remove their reliance on third party supply

Kim Dalum, Managing Director of Dalum Equipment, highlights; “Dalum Beverage Equipment has invented and tested technology for craft scale recovery of CO₂, which will help prepare your brewery for the future, by allowing you to secure your CO₂ supply from your own natural source and improve economy while reducing your CO₂ emissions by 200% for every Ton recovered All component parts are stainless steel with no oil or chemicals in contact with the CO₂, meaning that the recovered CO₂ is not only food safe, but also 99 98% pure The Dalum machine is exceptionally simple to use and in fact once running, is fully automatic, taking away the stress from brewers and allowing them to save money and the planet through pre programmed automation ”

Eddie Gadd, Owner of Ramsgate Brewery, which has a Dalum CO₂ Recapture unit, used the phrase “This unit is pretty awesome” when talking about his equipment, and “the whole system is extremely reliable, very efficient and produces first class quality CO₂ ” when asked about the cost of running the capture technology In fact, Eddie has already ordered another unit for one of his other businesses

However, and there is always a ‘but’ when it comes to new technology, to buy these machines, even at the craft beer level, the outlay is significant. For a single 15kg machine with a 2T storage tank and associated collection stations, vaporisers and safety valves, the capital cost is above £100,000, which is where Ninkasi Rentals and Finance have stepped in to support craft brewers

James Lewis, Managing Director of Ninkasi Rentals and Finance, explained, “We have been watching CO₂ capture technology for the last 3 years, and for us it seemed irrational

that breweries were being forced to expel CO₂ produced during fermentation to then buy it in to complete packaging We believed that this was not only wasteful but costly, and something that as an industry we should try and alleviate

“We were introduced to this craft brewery technology in early 2022 and have since been working to understand the principles, the benefits and of course the realities of regulations around this technology. After working closely with the manufacturers and learning from brewers who have already brought this technology to the UK, we strongly believe that we are not only able to offer financial support to our industry, but also add value to our customers, acting as a consulting bridge between craft brewers and the manufacturers ”

Ninkasi is currently offering a free installation survey to enable brewers to get a more in depth understanding of what the technology can do to assist their brewery’s growth

With Ninkasi able to offer rental or finance options on the CO₂ capture technology, cash flow is protected while savings are generated

22

Evans 07741 846650

SHOWC ASE Production Equipment

Paul

Paul@ninkasirentals.co.uk For further information:

£6.1m funding boost to accelerate digitalisation among SME food and drink manufacturers

A trailblazing programme that has backed 2,500 manufacturers to adopt new digital technology and skills to create growth and jobs has secured £6.1m funding to continue for three more years

Made Smarter ’s adoption programme in the North West has helped small and medium sized companies start their digital journey by providing them with specialist advice and a digital roadmap to help them select the right approach, level of investment and tools for their business

More than 250 of them, including dozens in the food and drink sector, have invested in new technology, ranging from software and sensors to robotics and extended reality, to become more efficient, build resilience, increase their productivity and grow sustainably

As a result, Made Smarter supported

manufacturers are set to create 1,250 new jobs, upskill almost 2,300 existing roles, deliver an additional £176 million in gross value added to the region, and help the UK meet its net zero target by 2050

Now with a further £6 1m funding from the government, Made Smarter can accelerate its drive to support hundreds more SME manufacturers to embrace the industry 4 0 movement

Meanwhile, as a result of the trailblazing work in the North West, the national roll out of the Made Smarter adoption programme has continued, and now includes the West of England and East Midlands They join the North East, Yorkshire and the Humber, and the West Midlands regions

Alain Dilworth (pictured), Programme Manager for the Made Smarter Adoption Programme in the North West, said: “I am delighted that the

Government has recognised the extraor dinary impact that Made Smarter ’s adoption programme is having on digitalisation of SME businesses and the adoption of Industry 4 0 technologies in the North West whilst continuing to fund our work for the next three years

“This new funding means we can renew our ambition to reach out to the region’s SME manufacturers to connect them to the tools that will make an everyday difference to their businesses, build resilience and enable them to keep up with a fast moving industry ”

For further information:

www.madesmarter.uk

Jobs saved as Quantuma secures the future of Boss Brewing Company Ltd

Business advisory firm, Quantuma, has rescued Swansea based Boss Brewing Company Ltd through a pre-pack sale The administration was led by Gary Thompson and Michael Kiely, both managing directors at Quantuma.

An award winning brewery, Boss saw early rapid growth and success following its incorporation in 2014. It built an impressive brand and a firm customer base, with a turnover of nearly £700,000 in 2020

Following the effects of Brexit on trade with the European Union, coupled with the Covid 19 pandemic and the national lockdown, the company saw its sales and profits cease almost overnight With the cost of living crisis

affecting businesses and individuals nationwide, customer demand for products reduced while trading costs increased, causing the company significant financial distress

The successful sale has now ensured the survival of Boss Brewery, and its single factory site will continue to operate as a result Its eight members of staff will continue to keep their roles as no redundancies have been made.

Gary Thompson, managing director at Quantuma, said: “Our priority is to achieve the best outcome for Boss Brewery and the pre pack sale was the way to ensure its longevity The company faced a barrage of obstacles, but, not only has the sale saved the brewery, but ensured the continuation of jobs for all eight employees It is rewarding work to

help keep a previously successful enterprise running, and we’re proud to have played a part in the journey of this fantastic Welsh brewery ”

Quantuma is a leading business advisory firm which works with businesses at the key milestones, helping them to take advantage of opportunities and overcome a range of operational and financial challenges, enabling them to achieve their business objectives and ambitions. The company has specialist expertise in restructuring and insolvency, financial advisory, corporate finance, forensic accounting and investigations, cross border asset recovery and creditor

24 SHOWC ASE Business Services

services

www.quantuma.com For further information: We asked companies supplying the following products and services to let us know something about themselves l Insurance, financial and legal services, recruitment, business training and other business services l Hardware & software designed to smooth administration and production flow l Drinks wholesaling and distribution, plus associated sales consultancies and websites

What to look out for when taking out a new insurance policy for your brewery

There are just over 2,400 breweries in the UK alone, according to the latest figures from Statista, a number which has risen by more than 60% in the past four years But like any other fully functioning business, breweries need to be properly insured to protect themselves from potential liabilities

Russell Scanlan, leading independent insurance broker for more than 140 years, offers expert insight on the ins and outs of specialist policy packages

Specialist brokers and dedicated teams hold the key to effective insurance cover

Choosing a dedicated team that has access to a panel of insurers ensures that you are offered the right support and guidance for your specialist cover Brokers and teams that take the time to work closely with you to understand your business will help you to tailor a

package with all the right ingredients, developing a policy that gives you peace of mind

The one-size-fits-all approach rarely works

It’s important to remember that a one size fits all approach will never provide you with the comprehensive cover that you and your business need Breweries are often involved in so many different activities, whether it be attending trade fairs, brewery tours or shipping goods overseas, that tailoring a package and speaking to an expert helps to ensure your business is fully protected against any future issues

Never a glass half empty when you work with specialists

Taking out multiple insurance policies under one trading business has the potential to complicate the insurance recovery proceedings immensely, and possibly even undermine certain terms.The relation of "other insurance"

clauses, allocation schemes, and the practical impacts of interacting with multiple insurers can often leave breweries with some difficult questions. This is why it is always advisable to work with a specialist team who understands the insurance industry

For further information:

www.russellscanlan.com Tel: 0115 947 0032

Cotswolds Distillery is set to increase production following £3m funding from Santander UK

Cotswolds Distillery has unveiled plans to ramp up its production of English whisky and gin with the support of funding from Santander UK

The Shipston on Stour headquartered drinks company is on track to increase its annual alcohol production from 125,000 litres currently, to reach a capacity of 500,000 litres, having built a new distillery at its Cotswolds site which was due to be commissioned in the autumn

Santander UK has provided Cotswolds Distillery with a £3m funding package to support business liquidity, enabling it to lay down additional stock to meet future demand, improve production efficiencies, and bolster its status as an English whisky producer.

Cotswolds Distillery was established in 2014 by founder Daniel Szor and its inaugural Signature Single Malt was released in 2017 Cotswolds Distillery

has also developed a range of award winning super premium gins and liqueurs to supplement its product range In the UK, its Cotswolds range is sold in leading supermarkets, bars, luxury hotels, restaurants and direct to consumers through its visitor centre, three stores and online business

With UK sales well established, Santander UK is supporting the business with its export growth strategy, building on existing sales in the US, France, Germany, China and Australia, as it works toward doubling its overseas sales over the next few years Cotswolds Distillery is targeting annual sales growth of 15%, with plans to achieve £25m turnover by 2030 as it grows its business, particularly in export markets It currently employs 65 people and plans to hire new staff over the next few years in line with growth

Daniel Szor, Founder and Executive Chairman at Cotswolds Distillery said:

“I am delighted that we have had the support of Santander UK in enabling us to maximise our sales potential, allowing us to meet growing demand from the single malt consumer in this luxury category that is forecasting strong growth globally ”

Chris Evans, Relationship Director at Santander UK, said: “Santander UK has a dedicated specialised whisky sector team as well as expertise and resources to help UK businesses in the sector expand internationally ”

For further information:

If you’d like to arrange a chat with one of our specialist team, see info below www.santander.co.uk/business

26

SHOWC ASE Business Services

27

New analysis shows a distinct shift

A new piece of analysis from corporate finance house, Oghma Partners, has looked at early stage investment in the UK Food & Drink Industry between 2012 22 and how it has shifted to more later stage funding. This progression is viewed by the company as a healthy reflection of businesses maturing and investors backing perceived growth winners

2012 2017 saw £312 4mn invested in 304 companies over 583 investment rounds, and 2018 2022 (ytd) funding increased to £1 8bn, a six fold increase in value compared to the prior period The total number of companies which received investment in the latter period was 449, with 1017 capital raises, highlighting that each company is having more and larger investment rounds

Global mega trends such as the explosion of interest in craft spirits is reflected in data for venture investments recorded since 2012 Over the last decade, the alcoholic beverage sector has seen almost 3x as much volume of investment compared to any other sector, as well as the highest total value of deals

Whilst crowd funding activity can garner a lot of press interest as a source of funding, its funding role is less than that of seed/angel investors and early stage venture investors Government backed enterprises i e , Innovate UK and Scottish Enterprise have been amongst the most active backers of early stage food and beverage businesses

Mark Lynch, Partner at Oghma Partners, said: “Whilst 2022 appears to have seen investment momentum continue, we believe that with a changing risk dynamic the appetite for all venture investing will wane Layered on top of this potentially decreasing interest from investors is a cost of living crisis that appears to be challenging some D2C business models.”

Shakespeare Martineau launches expert food and drink sector group

Law firm Shakespeare Martineau has launched a new food and drink sector group to provide a full-service legal offering to support the industry, which is valued at more than £100 billion

Offering tailored advice and a one stop shop to the food and drink market, the group covers commercial, employment, corporate and real estate law, alongside intellectual property, business immigration, landlord and tenant disputes, commercial disputes, food regulatory and uninsured loss recovery advice

The firm which already works with major retailers and multiple supermarkets including Iceland and Farmfoods has launched the group to support the food and drink industry at a time when it is facing multiple challenges following Brexit and the coronavirus pandemic

Matt McDonald (pictured), partner and food and drink sector lead at Shakespeare Martineau, said: “The food and drink industry has been particularly impacted by political events such as the cost of living crisis and Brexit, as well as staff shortages, material price increases and Covid 19

“Working in food and drink is different from many other commercial enterprises it is highly competitive and brings with it a plethora of ever evolving industry specific regulatory regimes, taxation considerations, and technological and logistical challenges

“Our legal teams already represent many major retailers and supermarkets, and we are delighted to be bringing that expertise together to create a food and drink specific group, which will focus on providing a full and bespoke service to one of the largest manufacturing sectors in the UK economy ”

Experts working within Shakespeare Martineau’s food and drink sector group include partner and head of commercial, IP and employment Phil Pepper; uninsured loss recovery partner Ian Evans; litigation partners

James Fownes and Ben Humphreys; commercial partner Carys Thompson; corporate partner Jody Webb; legal director and immigration specialist Tijen Ahmet; corporate associate Jade Price; and real estate associate Samantha Vaughan.

Recent analysis by Shakespeare Martineau found that the food and drink industry accounted for 6% of administrations in the first six months of 2022 the sixth highest sector in the UK More than 620 businesses 39 of which came from the food and drink industry, which included several breweries and restaurant chains filed for administration between 1 January and 30 June 2022, marking a 60% increase compared to 2021

Matt added: “Most businesses have suffered to some extent over the past two years, but some businesses within the food and drink sector have been particularly hard hit not least those in the hospitality sector like restaurants and pubs

“Lockdown and the associated drop in footfall in towns and cities during the pandemic has been devastating and clearly for some companies this has, very unfortunately, been fatal to their business

“Looking ahead, there is cause for cautious optimism as we return back to something approaching ‘normality’, but there are still huge challenges facing the sector including the continued reduced footfall, during weekdays in particular, increased food prices due to the war in Ukraine and the ongoing cost of living crisis forcing consumers to tighten their belts.”

28

www.shma.co.uk

further information: www.oghmapartners.com For further information:

For

SHOWC ASE Business Services

Carbonating equipment for cider

Carbonation Techniques Ltd is a family-run business with more than 45 years of experience in the bottling and brewing industry, supplying new, used and reconditioned equipment and engineering services with full technical support and advice

The company manufactures carbonating and premix machines, which will carbonate a vast range of products, including water, cider, beer, wine, alcopops and soft drinks

Carbonation machines include: CARBO 200, 500 and 1000, denoting litres per hour capacity Machines are

suitable for beer, cider, wines, soft drinks etc, and capable of carbonating products for filling directly in kegs In addition they can be customised to suit customers CO2 or Nitrogen requirements.

These machines are manufactured to CE standards and customer required specifications Numerous bespoke machines have now been installed across the UK, Ireland, Europe and internationally

Carbonation Techniques Ltd offers various services, from complete bottling lines and complete keg filling lines to spare parts with a full aftercare service

The company is also a UK agent for NT Technics kegging lines, and Ferrero bottling lines

www.carbotech.co.uk info@carbotech.co.uk

ŠRAML cider making equipment from Vitikit

The first stage of cider making is apple pressing, which is why Vitikit Limited has gone ‘above and beyond’ to provide its customers with cutting edge apple pressing equipment. Vitikit is partnered with Šraml, one of the world most experienced manufacturers of fruit processing machinery.

Apple juice is extracted on an industrial scale using different devices Several different press construction solutions are used in the fruit processing industry One of the most popular of these is the belt press Šraml offers 4 types of single and 4 types of double belt presses with different capacities and specifications Vitikit can help turn harvested apples into clean apple juice ready for fermentation

Flash Pasteuriser

Šraml plate flash pasteurisers are designed for heating liquid products to the pasteurisation temperature, holding the product at this temperature for a desired time, and rapidly cooling it after The heat source, for heating water, can be oil, gas fired burner, electric heater or steam The pasteuriser features a user friendly touchscreen interface which allows simple control of the pasteurisation process and quick and easy cleaning after use with the help of the cleaning program All the

components are assembled on a stable stainless steel frame with adjustable feet For non carbonated juice and cider, Vitikit supply “hot fill” solutions

Final Stage Processing

Sraml CP fillers are a series of counter pressure fillers, suitable for filling carbonated or still (cold or hot) liquids into bottles/cans The fillers are mechanical, the individual filling steps are mechanically operated with reliable cams The filler consists of a rotary carousel and a pressure bowl,

with a set of filling valves, allowing the filling of multiple bottles/cans at the same time in continuous motion, without stopping The pressure in the tank is plc controlled via a digital pressure sensor It is precisely maintained inside the tolerance of ±0,05 bar of set pressure Filling valves are built from machined stainless steel parts, with no welds or threads in contact with the product The liquid is gently poured on the side of the bottle, minimising the product agitation. The filling height is set by changing the filling tubes on the valve

For further information: info@vitikit.co.uk

For further information:

30

FO CU S UK Cider

Showcasing the British spirit

Alan Powell

Ding-Dong the WOWGR’s Dead –and so is the Delivery Order!

Further to my previous column (Whither WOWGR for spirits and beer?) setting out my withering critique of the law, HMRC announced the findings of their review of the Warehousekeepers and Owners of Warehoused Goods Regulations 1999 (WOWGR). Their preferred option, revealed to industry at a meeting in September, is to repeal that law next year (following an administrative and legal process) Frankly, given the lack of legitimacy or logic to these obstructive and potentially dangerous provisions, there is precious little alternative than to repeal the law.

This will mean that any revenue trader will be able to deposit, hold or trade all excise goods, including beer and spirit, in a third party excise warehouse without prior registration from HMRC or, if not a UK business, appointment of a duty representative This will re set the position to September 1999 before WOWGR was foisted upon owners of beer and spirits; the underlying and sane requirements of the Excise Warehousing (Etc) Regulations 1988 (EWER) remain in effect for records of ownership and transfers of ownership of goods in an excise warehouse

The myth of the Delivery Order Concerning sales of spirits in excise warehouse, an additional review of the original version of the Alcoholic Liquor Duties Act 1979 (ALDA) seems to explain the “convention” of the Delivery Order for transfer of spirits in an excise warehouse Section 32 of ALDA, headed “Restriction on transfer of British spirits in warehouse” stated: “(2) Spirits manufactured in the United Kingdom chargeable with duty which has not been paid which are in any warehouse other than a distiller's warehouse shall not be transferred into the name of a purchaser until the purchaser produces to the officer in charge of the warehouse a written order for the delivery of the spirits signed by the person in whose name they are warehoused and countersigned by the occupier of the warehouse or a servant of his acting for him at the warehouse.”

This rather archaic provision written when HMCE had officers permanently physically present in distilleries and warehouses requires the preparation of a “delivery order” to be handed over (“produced”) to the officer (sometimes a

team of officers) assigned to the warehouse to notify the transfer of ownership The law prescribing delivery notes in section 32 of ALDA was repealed by the Finance Act 2006 under the headline of section 5 of the FA 2006: “Repeal of provisions of ALDA 1979 of no practical utility etc”. This means there is no longer a legal requirement for the delivery note to be raised for transfer of ownership of spirits.

Under the Excise and Inland Customs (EICS) control philosophy, HMRC commits to focus on systems based control whereby HMCE/HMRC uses traders’ own records to control the revenue akin to VAT principles Accordingly, in order that third party warehousekeepers can keep track of owners and changes of ownership of goods in their warehouses, HMRC now simply states in Notice 197 at paragraphs 8 2 and 8 3 that the seller and buyer each: “inform the warehousekeeper that the goods are to be sold/purchased and give details of the purchaser ’s registration” That is all that is required by HMRC in law; the above passage is effectively a Direction HMRC has made in a public notice under the delegated powers of regulation 7(1) of EWER When WOWGR is repealed, there will no longer be any registration, so no “details” of same will be required either

A format equivalent to the Delivery Order may be used to inform the warehouse keeper of the transfer of ownership per paragraphs 8.2 and 8.3 of Notice 197, but it is no longer prescribed by law, nor is any other method to inform the warehousekeeper of the transfer a lesser standard

Drinks

factory on the way!

More goods news concerns the developments from the government’s Alcohol Duty Review and publication of an Alcohol Duty Bill to repeal the archaic ALDA I will write more in my next column but what is really significant is that producers of all alcohols in duty suspension may be authorized by HMRC to produce and store any alcoholic type “under the same roof” what we called a “drinks factory” thirty years ago The “drinks” factory” will encompass traditional distillers and maturation processes, as well as the production of gin or flavoured alcohol (“rectifying and compounding”) Currently this has to take place in a highly regulated excise warehouse approved by HMRC This consequentially means that there will no longer be the archaic requirement for licensing of distillers, rectifiers/compounders of spirits, wine producers and made wine producers respectively Similarly, the rectifying and compounding of duty paid spirits (eg to make gin outside duty suspension) will no longer require a licence or the “making of an entry”.

Hooray!

Alan Powell

Alan Powell is a specialist excise duties consultant, formerly a Policy official within HMCE’s HQ teams. He is excise duties advisor to the Chartered Institute of Taxation, honorary advisor to the UK Warehousing Association and founded the British Distillers Alliance as a conduit for consultation with, and representation to, Government bodies and to assist and advise on technical matters

www.britishdistillersalliance.com

32

For further information:

The British Distillers Alliance (BDA) is a non profit making body which provides a professional service for independent and craft businesses in the spirits production industry and supply chain The BDA represents distillers, rectifiers and compounders and those in related sectors New members always welcome

Micro Matic acquires Porter Lancastrian

With the acquisition of Porter Lancastrian, Micro Matic has fortified its leading market position in draught beer fonts and dispense equipment in the UK

Porter Lancastrian, a leading UK manufacturer of draught beer fonts, which employs 40 people, is located in Chorley, North of Manchester, and has its own manufacturing facility with in house design, engineering and sales functions

With a dedicated focus on standard draught beer fonts, Porter Lancastrian offers a wide variety of beer fonts, tap handles and lenses, and customers can also create their own artwork and have a complete branded draught beer font

Micro Matic already has a strong market position in custom designed draught beer fonts (with the whole solution designed specifically to the customer ’s

wishes), and the acquisition of Porter Lancastrian thus compliments Micro Matic’s current business extremely well In addition to a strengthened position in the important UK market, the acquisition makes it possible to sell Porter Lancastrian’s products outside the UK through Micro Matic’s global sales network.

Andrew Brown, Managing Director of Porter Lancastrian, who will continue in his role of managing the day to day business of the company after the acquisition, has said that, ”By becoming part of Micro Matic we can achieve positive synergies in our home market, and at the same time we get access to valuable knowledge and know how, not least through Micro Matic’s global sales organization ”

John O’Neill, Managing Director of Valpar Micro Matic, reiterated the advantages that this acquisition would bring to the UK market, saying that,

“Porter Lancastrian is a proficient enterprise with a long history, competent employe and visionary management We do not often find a company that complements our own business so well ”

At the same time, Søren Vilby, CEO of Micro Matic, confirmed that “the acquisition of Porter Lancastrian clearly indicates our high expectation of the UK market, Europe’s largest market for draught beer Acquiring Porter Lancastrian will allow us to form close relationships with our UK customers and together we will strengthen our UK market position ”

com For further information:

micro-matic

New online tool launches to help publicans save money

A new online tool has been launched to help publicans, landlords and bar managers see how much money they could potentially save weekly, monthly and annually by utilising high tech beer line systems

Created by Beer Piper, a leading manufacturer of high tech cleaning systems for beer lines in any type of venue that sells draught beers, lagers and ciders, the simple to use tool calculates how much beer can possibly be saved every week, which is offset against the cost of installing and running the system It then provides the theoretical maximum cost saving totals per week and per annum

Jeff Singer from Beer Piper said: “The cost of living crisis, especially the cost of energy bills, is adversely affecting Britain’s hospitality industry and as an integral part of that industry we wanted to demonstrate clearly that installing systems such as our popular BP4 machine can actually contribute to the bottom line and produce a yield on your draught sales in excess of 100%

“An average boozer in Britain with a total of 10 taps in the pub each holding two pints in their lines, with pints priced at the national average of £4 09, would

potentially be able to save over £3,800 per year by installing Beer Piper ’s most recent BP4 system, which enables you to sell the beer in the lines as you are cleaning them, saving a lot of beer waste ”

Jeff ’s Six Tips to ‘Save Money Behind the Bar ’ are:

1 Install a high tech beer line cleaning system

Advanced beer line cleaning systems such as the BP4 will clean your lines to a high standard, guarantee perfect pints, increase staff productivity, save beer and save money

2. Keep line coolers well maintained If not properly maintained, the heat produced by coolers can increase your running costs substantially Where possible, move all remote coolers outside the beer cellar as they emit heat from their condenser systems Additionally, ensure they are situated away from other equipment with space for air to circulate around it, and their fans kept clean

3 Check your cellar cooling fans

Keep fans well maintained To avoid costly replacements or increased running costs, it is advisable that you periodically check that the fan blades and grills on both your indoor and outdoor units are clean and not blocked,

as blocked grills can increase running costs by up to 40%

4 Insulate your cellar

To ensure your cellar works well, and all equipment works efficiently, consider your insulation needs You may need to install thermal insulation PVC strip curtains and draught stripping. If heating pipes have to pass through cellars, the pipes and fittings should all be insulated and draught stripping should be applied in places where pipes pass through walls Additionally, beer cellar doors and hatches should also be draught proofed and insulated

5 Keep doors shut

Keep your cellar doors closed as much as possible If cellar doors are left open, cold air escapes and warm air enters This can cause excess frost on the evaporators that the defrost mechanisms cannot cope with, and if this happens, manual defrosts may be required which involves switching machinery off for 24 hours

6. Train staff in the art of Pint Pulling Avoid unnecessary wastage by taking the time to train staff in the art of pulling the perfect pint, with minimum wastage

34

beerpiper co uk For

further information:

NEWS Bar & Cellar

Putting the fizz into fizzy drinks requires carbonisation with Carbon Dioxide (CO2).

The CO₂ that is injected into the liquid beverage and then stored under pressure must be free of particles, micro organisms, and unwanted chemical compounds

Any trace of these contaminants can result in quality issues that will impact negatively on a brand To prevent this the quality of the CO₂ used is paramount and filtration key

Download the White Paper “Carbon Dioxide Quality Incident Protection Safeguarding against the threat of contaminated gas in soft drink bottling by Danny Silk” to discover more

LalBrew NovaLager™ is a true bottom fermenting Saccharomyces pastorianus hybrid from a novel lineage that has been selected to produce clean lager beers with distinct flavour characteristics and superior fermentation performance.

It is a robust lager yeast strain with ideal brewing properties, including fast fermentations, high attenuation, and high flocculation The distinct flavour profile is very clean, slight esters over a wide temperature range

LalBrew NovaLager™ is the result of the research and development work of Renaissance Yeast (Vancouver BC, Canada) in partnership with Lallemand Brewing It was selected using classical and non GMO breeding methods to obtain a novel Saccharomyces cerevisiae x Saccharomyces eubayanus hybrid strain that defines a novel Group III (Renaissance) lager lineage, different from any other traditional

Championing malt – at a new level

Colin Johnston has long cared about the relationship between the land, food and drink A career in brewing, and more latterly malting, has reinforced his respect for that relationship.

Now, after six years at Crisp Malt, Colin (pictured) has been promoted to sales and marketing director

“This new role recognises Colin’s achievements over the years in terms of sales and customer service,” says CEO Stuart Sands “More than that: it gives him the opportunity to expand the craft brewer and distiller education programme that he helped to create This will help in the quest to take malt knowledge in these sectors to a new level.”

Colin’s new position sees him directing the marketing team, as well as the team of UK sales managers

He says, “This is the dream job I get to champion barley growers at one end of the supply chain, brewers and distillers at the other end and of course