June • July •August Issue 28 Summer 2023 ISSN 2398-2489 Plus all the latest pr oducts & ser vices news fr om the UK drinks industr y’s suppl y chain FO CU S UK Distilling The Products & Services Magazine for the UK’s Drinks Production Industry Incorporating SHOWC ASE In this issue Containers

Brewing & Beverage Industries Business is a quarterly ‘Supply Chain’ magazine targeting the UK drinks production industry. If your company supplies products and services to brewers, distillers, cider makers, etc, then this is the platform for you.

Subscription is free and printed copies are mailed out throughout Great Britain and Northern Ireland. If you are one of the very few UK brewers, distillers, or cider manufacturers, not receiving a regular copy, then please contact us today

The Products & Services Magazine for the UK Drinks Production Industry

ALWAYS IN PRINT & ONLINE - Now into

WHO WE ARE

Magazine Editor

Chris Freer

Digital Editor

Simon Butler

For editorial or advertising enquiries, call the Editor on 0115 8 549 349 or e-mail: chris@brewingbusiness.co.uk

WHO WRITES FOR U S

RUTH EVANS MBE

Ruth is CEO of BFBi, whose membership represents the supply chain for the brewing and beverage industries

JULIAN GROCOCK

Julian Grocock is a former chief executive of SIBA with extensive experience in beer, brewery and pub politics

ALAN POWELL

Alan Powell is a specialist excise duties consultant, who heads up the British Distillers Alliance.

8th year!

ISSN 2398-2489

Members of

Cover illustration - Gerard Christie of Advanced Packaging Materials

Whilst every effort is made to ensure that the information in this publication is accurate and up-to-date, freerbutler limited does not take any responsibility for errors or omissions Opinions expressed in editorial contributions to this publication are those of their respective authors and not necessarily shared by freerbutler limited © freerbutler limited 2023

We are delighted to be the new home of News from the Brewing, Food & Beverage Industr y Suppliers

5 freerbutler limited is a Supplier Associate member of WELCOME TO Published by freerbutler limited PO Box 9666 • Nottingham • NG10 9BY United Kingdom Tel: 0115 8 549 349 brewingbusiness.co.uk Our print circulation is audited and certified Representing the entire value chain supplying the Brewing, Food & Beverage Industry Brewing & Beverage Industries Business magazine is an independent publication delighted to be a MEDIA PARTNER to

rights reserved No part of this publication may be stored in a retrieval system or transmitted in any form or by any other means, electronic

mechanical, photocopying,

or otherwise,

Association

All

or

recording

without the prior permission of freerbutler limited

our

Word from the BFBi

Getting Brexit sorted ... when?

Why is it that January of every year takes so long to get through and then the year speeds up like a bullet train. 2023 is no exception to this and I think we are all now running at full steam to keep up.

BFBi is certainly finding that peoples’ diaries are filling up fast, if not already full and, with the staffing issues we are all encountering, it is difficult to take time out of the working schedule to fit in some time to gain knowledge, make new contacts, just – basically – catch our breath But, please do remember that time taken to learn and connect really pays dividends

I have just come back from CBC and been speaking with colleagues from around the world The UK is not alone with the current challenges of staffing, energy costs, post covid catch up BUT, the one issue the UK is enduring, which no other country is subject to, is B****Y BREXIT No matter your views on the issue, the one thing that should be in place by now is Government support in terms of legislation, customs procedures and export

routes for UK companies

By now there should be a level playing field where UK companies may trade with their European counterparts, without restriction and significant extra cost HOWEVER, we are far, far, far away from this scenario A good example being thus - having been lobbying HMRC and DBT recently about the issue of exporting beer samples and then receiving the answer below from Lord Johnson of Lainston CBE, Minister for Investment Department for Business and Trade:

“As you will be aware, at the moment there is no specific agreement regulating export of samples between the UK and EU, therefore beer samples are subject to the same regulations as commercial products entering the EU market ”

There appears to be no hurry in

sorting this issue out I have been offered a meeting to discuss further but am not holding my breath In the vain hope that such a meeting will take place and Lord Johnson will have his listening head on, please send me your issues/questions on exporting your products into Europe to ruth evans@bfbi org uk so that I can raise with him

Ruth Evans MBE, BFBi C.E.O.

Why not take a fresh look at the BFBi website?

It has been recently updated and the Members’ area is about to be totally changed, with a lot more features for members to be able to use free-of-charge.

www.bfbi.org.uk

Established in 1907, BFBi’s membership represents the entire value chain supplying the brewing and beverage industry – from seed geneticists through raw materials, brewhouse and process equipment to dispense, point-of-sale and brewers/distillers. The Association’s objective is to be the foremost trade association providing opportunities for its Members to develop within the brewing, food & beverage industry

As well as offering many benefits and services to suppliers of raw materials, process and packaging machinery, dispense and point of sale products, BFBi is a Trade Challenge Partner for various overseas exhibitions and owner and organiser of the oldest international brewing and cider Awards in the world.

SEE PAGE 66 FOR MORE INFO ON HOW TO JOIN BFBi

6

Ruth Evans MBE

Photo by Gerardo Jaconelli

The View Through My Glass Bottom

Julian Grocock ...and still counting the cost

‘By the way, we have lost more than 200 breweries from our mailing list in the last 12 months.’

The closing words of Chris the Editor ’s email – sent primarily to advise me of my latest article deadline – make a solemn and compelling case for me to continue to focus on the depressing industry themes of the moment

And I’m sorry if that exacerbates the gloom, but we really cannot turn a blind eye to what’s happening, in the rose-tinted hope that the survivors will emerge revitalised and ready to restore a familiar semblance of normality.

As I write, the crisis feels significantly worse with the news that a business as well-established and successful as Black Sheep Brewery is appointing administrators – possibly the final step in an increasingly desperate strategy to attract investment, via takeover or merger, after being ‘hit very hard’ by the pandemic and punishing operational costs

Furthermore, the effect across the industry is reflected by the statistic that 153 pubs called time for good in the first three months of this year, compared with a 2022 total loss of 386 – an increase of almost 60% ~

So where does this leave us? It might not help that I’m highlighting the problems without proposing practical solutions, but I’m hoping there are sharper-brained tacticians out there, still active in our threatened sector, who can formulate a pragmatic way forward What I believe must be taken on board is that this is not just the latest phase in a timeless cycle of economic ups and downs, which we just have to ride like a roller-coaster The changes are far-reaching and potentially irreversible, and ultimately about more than their money-based roots Their cultural – and community – implications cannot be overlooked Nor can we ignore the effect on health We know that alcohol-related deaths rose during Covid lockdowns, due I am sure to a rise in drinking away from social (and controlled) environments – by which I do of course mean pubs Subsequent figures, however, have shown this higher trend has persisted beyond the

worst of the pandemic The pubs are open again, but death rates remain above previous averages – reported by news media with an element of surprise, as though it was newsworthy because it was unexpected

Surely I’m not the only person who isn’t surprised ~

I did once experience a socially ingrained drinking culture that wasn’t pub-based Forty years ago, I went on holiday to Denmark with my girlfriend (now my wife) to stay with one of her closest college friends, who was living in a rural community with the chap she’d fallen for when he was working on her parents’ Yorkshire farm There was a bar in the village, but I was told it was a place for loners and misfits (Needless to say, I insisted on going there; it was dimly lit and bleak, with no more than half-a-dozen punters, and must have struggled to maintain commercial viability ) What my new friends did, with their longstanding local circle, was take turns to host social evenings – not full-on parties, you understand, but just high-spirited and good-natured get-togethers, fuelled mostly by a case or two of big-brand bottled beer Do we want something like that here? It was enjoyable, the company was excellent, and I did learn how to flick the crown cork off the top of one bottle with the unopened top of another. But the far more valuable thing it taught me was just why British pubs deserve such an iconic worldwide reputation My Danish friend has always been fanatically enthusiastic about them, and on his visits he’s consequently

enjoyed the company of strangers well beyond any concept of an exclusive ‘local circle’ And I have of course already told you about the friends I only have because I’m a pub person ~

I know I began this article with reference to brewers, and apologise again for drifting off into the on trade But I will repeat myself: businesses across our sector are united in their difficulties, and must remain so in their quest for solutions I hope the passion that brought me into this industry still thrives, from mash tun to cellar, and in every other intrinsically connected and essentially integral specialist support corner

A long time ago now, as SIBA’s chief executive, I hosted an Annual Conference with Canned Heat’s classic LET’S WORK TOGETHER! as our theme Well, the heat is pretty much out of the can now, so the song’s exhortation has never been more important

So, astute industry strategists, where are you and are there any answers?

Julian Grocock

Julian Grocock is a former pub landlord, managing director of Tynemill/Castle Rock, and chief executive of SIBA.

Extensive experience in beer and pub politics, brewery and pubco operations, and on the front line in the pub trade...‘from cellar to ceiling’.

8

Showcasing the British spirit

Alan Powell Grogginess without fear –hose out those casks!

Excise law is often arcane and opaque and sometimes apparently, well, odd. The Alcoholic Liquor Duties Act 1979 (ALDA) is the primary law concerning alcohol duty that will be overhauled by a new Alcohol Act, currently at Finance Bill stage.

A curiosity of ALDA is at section 34 which states:

Prohibition of grogging

(1) No person shall

(a) subject any cask to any process for the purpose of extracting any spirits absorbed in the wood thereof; or

(b) have on his premises any cask which is being subjected to any such process or any spirits extracted from the wood of any cask

(2) A contravention of this section shall attract a penalty under section 9 of the Finance Act 1994 (civil penalties)

(3) All spirits extracted contrary to this section and every cask which is being subjected to any such process or which, being upon premises upon which spirits so extracted are found, has been subjected to any such process shall be liable to forfeiture.

Given that the section of law is headed “prohibition of grogging”, it is curious there is no interpretation of the term “grogging” in law, which is almost a colloquialism to express the purposeful extraction of spirits absorbed in the wood of a cask. Anyway, you can’t do it legally! No ifs or buts (or butts, even!)

Yet there will inevitably be grogging which is not done “on purpose” and where the extraction of spirits is fortuitous (ie happenchance, not

“fortunate”) such as cask rinsing or where beer or cider may be matured in an empty spirits cask. There was a famous case of a Fullers’ strong beer made very strong indeed by fortuitous grogging during maturation in an ex whisky cask and HMRC (in my view) getting the law wrong to say it was spirits production which it was not (in my view it was fortification of a fermented liquor, being a fortified made-wine since the law does not permit fortification of beer and still be classified as beer, but that’s another story) Curiously, "cask rinsing" may be applied for in the application forms from HMRC for excise warehouse approval but - with cross referencethis is modified by the standard approved processes in warehouse of paragraph 7 1 of HMRC's Notice 196 which states, inter alia: "cask rinsing, subject to the warehousing of the contaminated cleaning agent." This is unclear but implies that the cleaning agent (let’s call it “water”) will be “contaminated” ie it will contain extracted spirits and must be warehoused ie held in duty suspension in the excise warehouse OK, what then? And is that not in breach of absolute prohibition of grogging expressly in ALDA s34?

In America, Bourbon casks are being subject to cask rinsing to extract the absorbed spirits which is “re-used” by blending with full strength whiskey (such as Jim Beam’s Devil’s Cut) but would be totally unlawful in Blighty

Grogging will be legalised

Maybe to regularise the practical

The British Distillers Alliance (BDA) is a non-profit making body which provides a professional service for independent and craft businesses in the spirits production industry and supply chain The BDA represents distillers, rectifiers and compounders and those in related sectors New members always welcome.

situation, after repeal of ALDA, grogging will be treated as production of spirits as currently set out Schedule 6 paragraph 2 in the Finance Bill 2023

Production of spirits will not be subject to the current distillers' licence and warehousing approvals, but will be incorporated in the simplified alcohol production ("drinks factory") regulations to be made under what is currently clause 88 of the Finance Bill 2023 This will or ought to mean though that excise warehousekeepers occupying maturation warehouses that grog will need to be approved as producers of alcohol Presumably, after being approved this would simply be a record of the spirits extracted and then “re-warehoused” in the accounts? There may be some consideration about the W1 monthly stock return since the spirits will have been generated “from nowhere”, so to speak In April, I requested clarification from HMRC’s team working on the new law but have not had a response to date Anyway, what is lost as the angels’ share during maturation might be hosed out to take some back from the freeloaders!

Alan Powell is a specialist excise duties consultant, formerly a Policy official within HMCE’s HQ teams. He is excise duties advisor to the Chartered Institute of Taxation, honorary advisor to the UK Warehousing Association and founded the British Distillers Alliance as a conduit for consultation with, and representation to, Government bodies and to assist and advise on technical matters

For further information:

www.britishdistillersalliance.com

10

Alan Powell

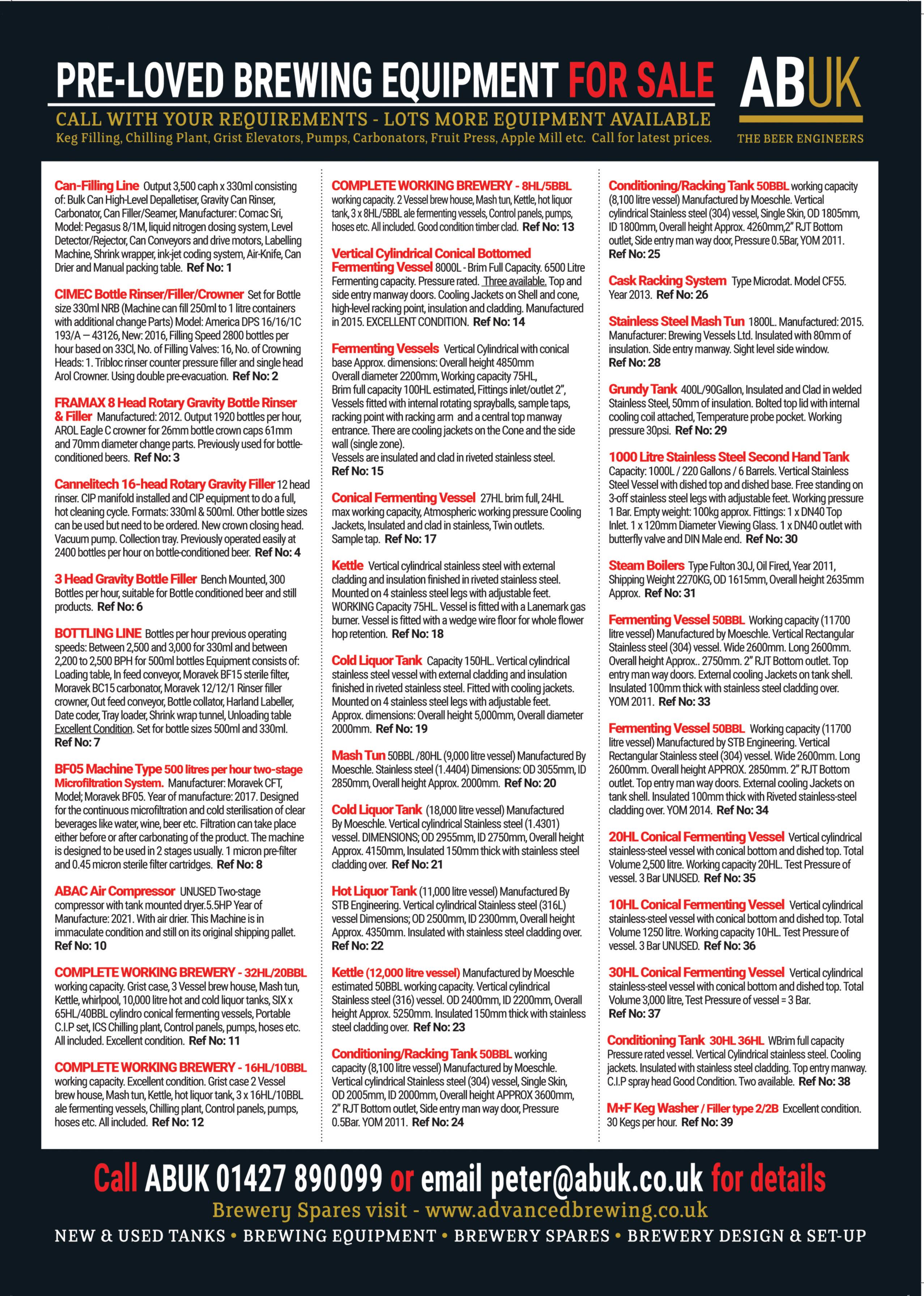

We asked companies supplying the following products and services to let us know something about themselves.... l New, or pre-owned and re-furbished casks and kegs – for purchase or lease – plus cask repair and branding services, and container closures l Container systems for drinks dispense l Bottles & cans plus labelling and decoration, and on-shelf packaging l Bulk packaging & associated labelling for transportation of beer and other beverages l IT systems for container tracking

Croxsons relocates to historic post office building

After 40 years of being based in nearby Morden, leading glass packaging supplier, Croxsons, has moved back to its former home of Sutton, taking residence in the town’s stunning old post office building Its future-ready, purpose-built workspace has been designed by the UK's leading interior design consultancy, Blue Jelly.

Given its heritage, Croxsons wanted to ensure the space was well-used and reflected the site’s past history - an old postman’s bike hangs on the wall above the sales suite, and it even has its very own post box

The office, which provides a fresh take on a typical glass packaging supplier ’s premises, is a creative space that will allow customers to imagine how their

brand will look With an in-built bespoke bar, the environment has been created to allow customers to see their vision in context Simply put, it is the perfect place to have creative discussions, be inspirational and be inspired The Croxsons team members now have an office that matches their culture, providing them with the impetus to be aspirational, not only for themselves, but also for the business Croxsons is confident that future collaborations in its new setting will undoubtedly benefit both the high performing team and customers alike.

“Our new home is a conclusion of a fiveyear plan,” says CEO, Tim Croxson “The space is unique - how we will use it will demonstrate the way that we choose to operate as a business We have

Labelnet works with UK brewery to create eye-catching beer labels

Labelnet has been printing selfadhesive labels for breweries for more than 23 years and recently worked with Brewing Brothers to print its range of beer labels, offering advice on the best materials and finishes to create stand out labels for their design

Brewing Brothers is a brewery based in Hastings, East Sussex, established by Ned and Charlie in 2016 The business was created after the duo took a visit to the U S A and soon realised that the UK seemed to be falling behind in the world of craft beer After some blood, sweat and tears the doors to the first brewhouses opened where a wide range of ales and stouts is on offer

The company was looking for a new label supplier who could offer fast turnaround times “Ultimately, we wanted to find a UK-based label supplier with several years trading behind them who had worked with substantial brands as clients,” said Ned “Our reason for

this was if larger brands can place their trust into a business, then our growing brand can do the same ”

There were a few challenges along the way, with instances where the design on the label affected the label application which Brewing Brothers was not aware of This caused some issues with the production So offering finished samples of the designs before placing an order helped Brewing Brothers to trial its labels beforehand

Continued Ned, “Labelnet was on hand to offer advice on materials and textured varnishes to enhance the finish of our range of creative label designs for our ales and stouts Free sample packs were offered to show examples of previous work printed on the same or similar materials which was really helpful Rep Neil was and has always been a phone call away for support too “The range and quality of labels which are offered from Labelnet are more impressive than previous suppliers

developed an environment that encourages collaboration across our teams to achieve the best possible results for our customers We can’t wait to welcome you through our doors ”

For further information:

www.croxsons.com

Tel: 020 8337 2945

Their prices are competitive which is a great bonus and they offer quick turnaround times for our orders

“We are very likely to recommend Labelnet to other breweries Try them out and you will not be disappointed!”

Labelnet can offer free label samples and quotations offering a range of unique varnishes, luxurious embellishments and sustainable material options

For further information:

12

www labelnet co uk

SHOWC

ASE Containers

Pioneering keg rental firm

Konvoy has vowed to solve the brewing industry’s key problems with technology since expanding to the UK & Europe at the beginning of this year

The UK’s newest addition to the keg solutions market has already become the leading supplier in Australia and New Zealand despite launching only as recently as 2019

Konvoy has been quick to set out its stall in the UK, Europe and beyond by showcasing its ‘game-changing’ solution to common industry problems like inefficient re-use of kegs, inconsistent beer quality, keg thefts and low sustainability

The company, founded by Adam TrippeSmith and headed in the UK & Europe by Christian Barden, has been making waves already this year by taking large stands at some of the major trade brewing events, such as SIBA’s BeerX in Liverpool and the Craft Brewers Conference in Nashville, USA

Konvoy and its proprietary IoT (Internet of Things) keg tracking and datacollection device, will also be highly visible at UK industry events this summer, including Brew//LDN,

Konvoy hits the road with its IoT keg tracking technology Bingo on a Bottle for Hobson’s

Hobsons Brewery wanted to produce something special for its 30th Birthday, which would not only taste great, but also catch people’s attention and get everyone involved in the celebrations.

The company was inspired to create a Bingo themed label, having selected the name of ‘Dirty Gertie’, the traditional bingo callers name for number 30, and so worked with the print and data specialists at Mercian Labels to create a unique ‘interactive’ label, incorporating numerous design elements which celebrate the 30th, whilst staying true to the brand

Starting with a sustainable Forest Film label in line with the company’s environmental aims, the design included Silver Foil to showcase the Dirty Gertie

Manchester and London Craft Beer Festivals

Christian Barden, Konvoy’s CEO for UK & Europe, said: “The brewing industry has keg problems – and we are unashamedly here to help solve them And we want to achieve that quickly, to give brewing and hospitality a chance to not only survive today’s challenges but to actually thrive

“We’re offering a way for brewers to become more efficient, more effective, more circular, more sustainable and more economical with their keg fleets and requirements But first, we all need to ‘hug the monster ’ and accept that whatever we’ve been doing for centuries with traditional keg tracking hasn’t worked

“Konvoy is confident its technology is game-changing – and can assure the industry that we’re here for your beer!”

Konvoy offers one of the world’s most sustainable keg fleets, spearheaded by a small tracking and data capture device fitted to each keg It is capable of sharing a multitude of real-time data with a central cloud network using a combination of Bluetooth, satellite, cellular and wireless technology

The device measures the temperature,

location and motion of each keg as well as its precise orientation – all without the need for manual scanning or logging

The end result is real-time information to speed up the re-use of kegs through the supply chain, improved condition management, reduced labour and resource requirement and a significant removal of keg thefts and losses, which costs the global industry an estimated $300m-$500m per year

Konvoy has also launched a partnership with climate action platform Net Zero Now, in order to help brewery clients get a head start towards meeting the UK Government’s 2050 Net Zero target The company is already underway with its own global sustainability audit through Australian carbon and energy management specialists Pangolin Associates, in an effort to set the benchmark in sustainability for a logistics business

name and number 30, a cream overprint, creating a pearlescent effect on the Hobsons logo, and pastel colours to highlight the bingo balls, traditional Hobsons’ hats and hop leaf icons, adding further interest and brand relevance.

To add sensory interest and extra grip on the bottle, Hobsons chose a rough sandpaper varnish and the ‘icing on the cake’ was the inclusion of variable data printing on the bingo balls, making the bottle an interactive game and allowing customers to win one of 30 prizes if the numbers on their bottle matched the winning combination The bingo numbers were printed in 8 positions and ranged from 1 to 90, as standard in bingo The data was generated with a random number being printed for each ball (position) using Mercian’s software and paginated for printing at 100 metres

per minute at 600 dpi To ensure the majority of bottles were not winners, the number 30 was suppressed, leaving 89 to the power of 8 possible combinations The winning numbers were then added randomly to the output file to evenly distribute the winners

Hobsons Brewery Commercial Director, Kate Pearce, said, “Mercian Labels delivered a unique, eye-catching result as always, but the interactive bingo game on a bottle really took this to another level ”

14

www mercianlabels com

further information: SHOWC ASE Containers www.konvoykegs.com

further information:

birthday

For

For

Containers

How clean are your kegs? asks Lambrechts

Just how clean are my kegs? this is a vitally important question for the craft brewer, as the quality of the ingredients and the care taken during production in producing a great pint can be wasted if your kegs and spear are not surgically sterile internally

To wash a keg requires the dirty keg to be de-ullaged, before moving onto the wash cycle: The first wash at 60°C usually re-uses the last wash water saving on average 9 litres per keg Followed by a caustic wash usually conducted at 75-85°c with a 2 to 2 5% concentration A final wash always using clean water ideally above 80°C. All purge gasses and steam used for this purpose must be filtered to 0.2 micron.

All these processes are constantly monitored by a Lambrechts machine Lambrechts firmly recommend the use of Saturated Steam for the sterilisation process, stating that if heated to 135°C

for a period of 60 seconds you can guarantee destroying all beer spoilage organisms An investment in a boiler or electric steam generator gives peace of mind of a sterile keg and useful capacity for CIP systems within the brewery

However, what can brewers with no access to saturated steam for sterilising do to minimise the risk of infection A high degree of disinfection using a sanitiser eliminates nearly all recognised pathogenic microorganisms but not all microbial forms - eg bacterial spores In short it does not ensure ‘’overkill’’ so lacks that margin of safety achieved by sterilisation

According to Lambrechts spokesman Mike Hickman, “We are selling an increasing number of ‘entry level’ washers with the Lambrechts NANO, offering excellent value to the craft brewer with a budget of under £20,000 “We have received a particularly enthusiastic reaction to a YouTube video

Binary Beer expanding to Europe

A global leader in Smart Keg technology, Binary Beer is expanding to Europe, making existing keg fleets ‘smart’

In today's competitive market, it’s more important than ever to have a fleet of kegs that are efficient, cost-effective, and keep beer tasting great Binary Beer has announced a solution that can “save thousands of dollars” and completely change how breweries manage kegs

Binary Beer's KegLink is a globally proven smart keg solution that is empowering brewers to manage their keg fleets simply and more efficiently Binary Beer already manages thousands of kegs across four continents and is trusted by leading macro brewers With KegLink technology, existing keg fleets become ‘smart’, tracking location 24/7, increasing keg rotations, improving sustainability, protecting beer quality, and unlocking sales insights

Understanding where kegs are located is the foundation of efficient keg fleet management With KegLink, location is monitored in real-time, seeing through distributors all the way to on-premises stock levels. This unprecedented level of visibility facilitates a ‘digital distribution

chain’ enabling data-driven decisions to optimise brewery operations Of course, location data is only one output of the KegLink system The real value comes from the Binary Beer smart analytics platform, which combines multiple data points, with deep analytics and AI to deliver valuable business insights Customisable reports and alerts allow brewers to compare real data with unique business KPIs increasing keg rotations and boosting revenue for breweries

But Smart kegs aren’t just about increasing revenue Data also helps breweries become more sustainable Studies show over 40% of energy consumption occurs from brewery to glass, and KegLink provides the data needed to reduce fuel consumption and eliminate spoilage waste, benefiting a brewery's bottom line and the environment.

Quality assurance is another area where the data and analytics delivered by Smart Kegs are improving business outcomes Understanding the live environmental conditions of a keg enables brewers to monitor the ‘freshness’ of their beer in trade, better managing inventory and ensuring beer is transported and stored correctly

of a NANO install at En Stoemelings craft brewery ”

Utilising a PLC-controlled washing regime, the NANO can incorporate, following on from a sequenced detergent wash, a dosing system for a peracetic acid sanitisation to substitute for steam A manual filling head is included in the specification if needed

The more automated stand-alone MICRO washer offers a rate of 25 kegs per hour

Traceability from brewery to glass empowers brewers to maintain beer quality and protect brand reputation For the first time, brewers are able to stay connected with their keg assets all the way through the distribution chain, collecting data and insights every step of the way Live stocktake of kegs on-premise, including full/empty status, as well as consumption rates and customer behaviour data, unlock valuable sales insights, and giving sales teams a competitive edge so increasing the conversion rate of sales and marketing efforts

Smart kegs represent a major technology advancement in the draught beer industry Binary Beer ’s recent pilot with the macro-European brewer demonstrates that, globally, the industry is serious about adopting smart keg technology, and the data-driven business future this technology unlocks.

16 contact@binarybeer.io For further information:

hickman56@outlook com

For further information: SHOWC ASE

mike

S.Clymans@lambrechts-group.be

17 Cask and Keg Repair & Refurbishment Specialists l A Genuine Alternative to Cask and Keg Replacement l Repairs to casks and kegs of all sizes l We can supply refurbished casks too l Fast On-Site Turnaround l Competitive R ates l Over 60 years of Industr y Experience Please contact us for details of our other onsite ser vices. Head Office: 01283 740807 • Mob: 07952 152 099 Email: repairs@dhmbreweryservices co uk • Contact: Jason Miller Web: www dhmbreweryservices co uk • Twitter: @DHMBreweryServ

Bag-in-box - the pros and cons

By Arlington

Packaging with the help of the ChatGPT AI chatbot!

We interviewed the ChatGPT AI chatbot on the pros and cons of returnable, collapsible bag-in-box ale transport containers (this is for real! Please excuse any American spellings):

Ar lington:

So why is bag-in-box a good option for transporting beer?

ChatGPT

Bag-in-box packaging is a good option for transporting ale (and other beverages) for several reasons:

1. Protection: The bag inside the box protects the ale from oxygen and light, which can cause the beer to spoil or become "skunky" This helps to ensure that the ale stays fresh and tastes its best

2 Convenience: Bag-in-box packaging is easy to handle and transport, as the boxes are lightweight and stackable This makes it an ideal option for transporting ale in large quantities

3 Sustainability: Bag-in-box packaging is generally considered to be more environmentally friendly than other types of packaging, as it uses less material and generates less waste

4 Longer shelf life: Compared to traditional glass bottles or cans, bag-in-box packaging can extend the shelf life of ale by several weeks or even months, which can be beneficial for breweries and retailers

Overall, bag-in-box packaging is a good option for transporting ale because it helps to protect the quality of the beer, is convenient to use, environmentally friendly, and can extend the shelf life of the product

Ar lington: Is returnable flatpack packaging more environmentally friendly?

ChatGPT

Returnable flatpack packaging can be more environmentally friendly than traditional packaging in many cases Here are a few reasons why:

1 Reusability: Returnable flatpack packaging is designed to be used multiple times, which can significantly reduce waste and promote sustainability By returning the packaging to the manufacturer or supplier for reuse, the environmental impact of the packaging can be minimised

2 Reduced Carbon Footprint: Returnable flatpack packaging can be transported in bulk, which can help to reduce transportation costs and carbon emissions compared to traditional packaging

3 Durability: Returnable flatpack packaging is often made from durable materials, such as plastic or metal, which can help to extend the lifespan of the packaging and reduce waste

4. Cost savings: While returnable flatpack packaging may have a higher initial cost than traditional packaging, the long-term cost

savings can be significant, as the packaging can be reused multiple times

However, it's important to note that returnable flatpack packaging may not always be the most environmentally friendly option, particularly if the packaging is not reused enough times to offset the initial production and transportation costs It's also important to consider the end-of-life disposal options for the packaging, and whether the materials used can be recycled or repurposed

Overall, returnable flatpack packaging can be a more environmentally friendly option than traditional packaging in many cases, but it's important to carefully evaluate the environmental impact of different packaging options and consider the entire lifecycle of the product before making a decision

Ar lington:

How does a bag-in-box system help to reduce dissolved oxygen in ale

ChatGPT

A bag-in-box system can help to reduce the amount of dissolved oxygen in ale by minimising the exposure of the beer to air during storage and dispensing Here's how it works:

1 The beer is filled into a flexible plastic bag, which is then sealed inside a cardboard box

2 As the beer is dispensed, the bag inside the box collapses, which helps to prevent air from entering the bag and coming into contact with the beer

3 The bag-in-box system can also be equipped with a dispensing tap that has a special valve that minimises the amount of air that comes into contact with the beer during dispensing

By reducing the amount of air that comes into contact with the beer, the bag-in-box system helps to prevent the beer from oxidising, which can lead to the formation of off-flavours and spoilage This is particularly important for ales, which are often more sensitive to oxidation than other types of beer

In addition to reducing dissolved oxygen, the bag-in-box system also offers other benefits for storing and dispensing ale, such as ease of use, minimal maintenance requirements, and the ability to store large volumes of beer in a relatively small amount of space

Ar lington:

What are your thoughts on Arlington Packaging as a company?

ChatGPT

As an AI language model, I don't have personal opinions or experiences, but I can provide some information on Arlington Packaging as a company

Arlington Packaging is a UK-based company that specialises in the design and manufacture of bespoke packaging solutions for a range of industries, including food and beverage The company offers a range of packaging options, including flexible packaging, rigid packaging, and speciality

packaging, and works closely with its customers to develop custom solutions that meet their unique needs

Arlington Packaging has a strong focus on sustainability and has implemented several initiatives to reduce its environmental impact, including the use of recyclable materials, waste reduction programs, and energy efficiency measures The company has received several awards for its innovative packaging solutions, including the UK Packaging Awards and the World Beverage Innovation Awards It also has a reputation for providing high-quality products and exceptional customer service Overall, Arlington Packaging appears to be a reputable and innovative company with a strong focus on sustainability and customer service

For further information:

Cask repair

Morrow Brothers Ltd is a leader in the repair and refurbishment of casks and kegs with an “unparalleled” reputation in the UK but also exports to all major continents around the world From internal and external cleaning to the removal of beer stone we are able to offer a comprehensive range of cleaning services Our cleaning processes are so advanced we are able to get rid of mineral deposits and wild yeast infections We offer a sliding scale of repair services, ranging from a simple chime straighten to a complete overhaul All of our services can be tailored to create a bespoke service to meet your requirements As well as containers we can also refurbish all types of extractor tubes including resizing them to fit your container population Also on offer is a rebranding service where the containers are fully cleaned, refurbished and rebranded to your specification This can also include containers which were not originally purchased from us

18 www morrow-brothers co uk For further information:

arlingtonpackaging com Tel: 01672 563723

www

SHOWC ASE Containers

19

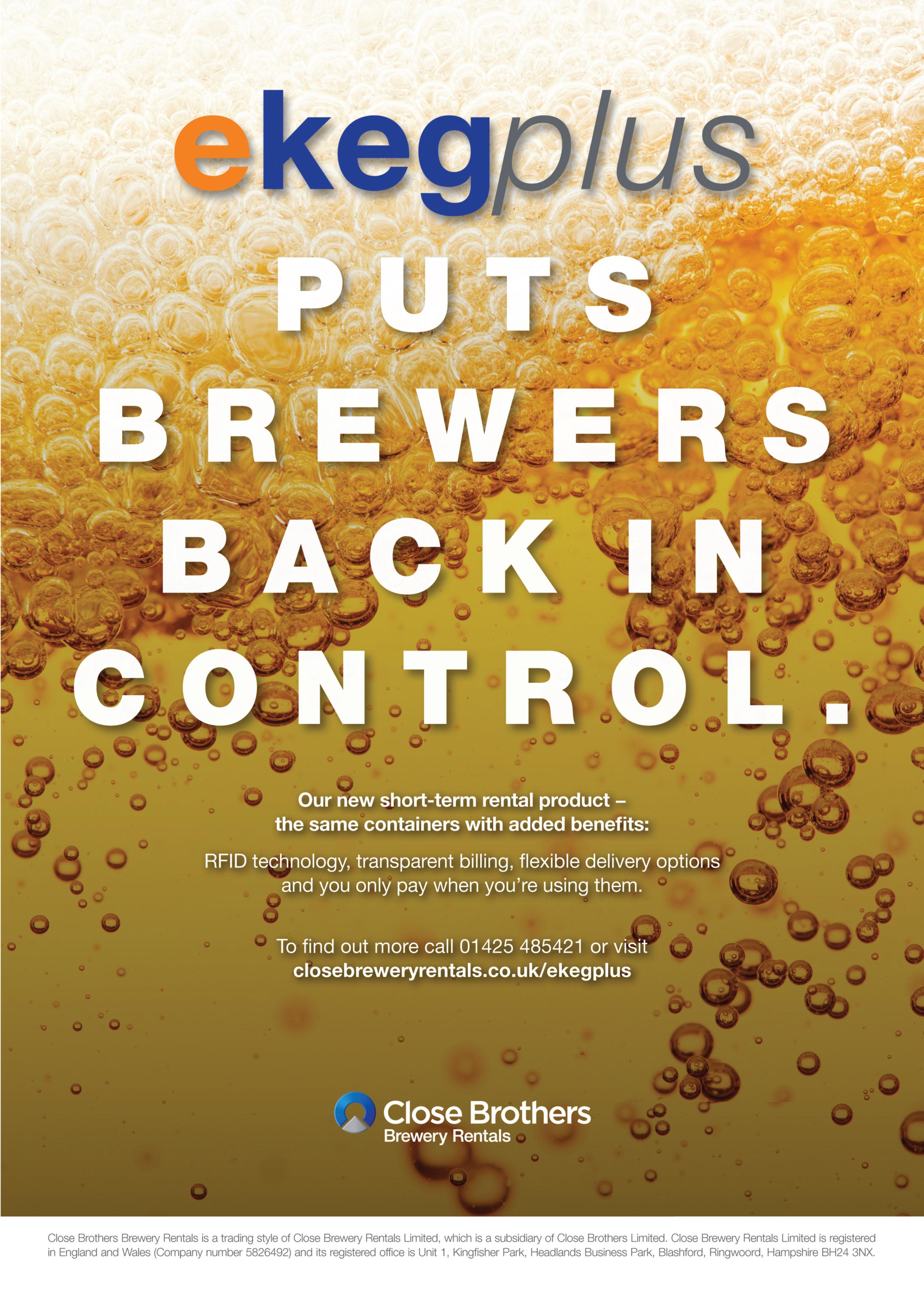

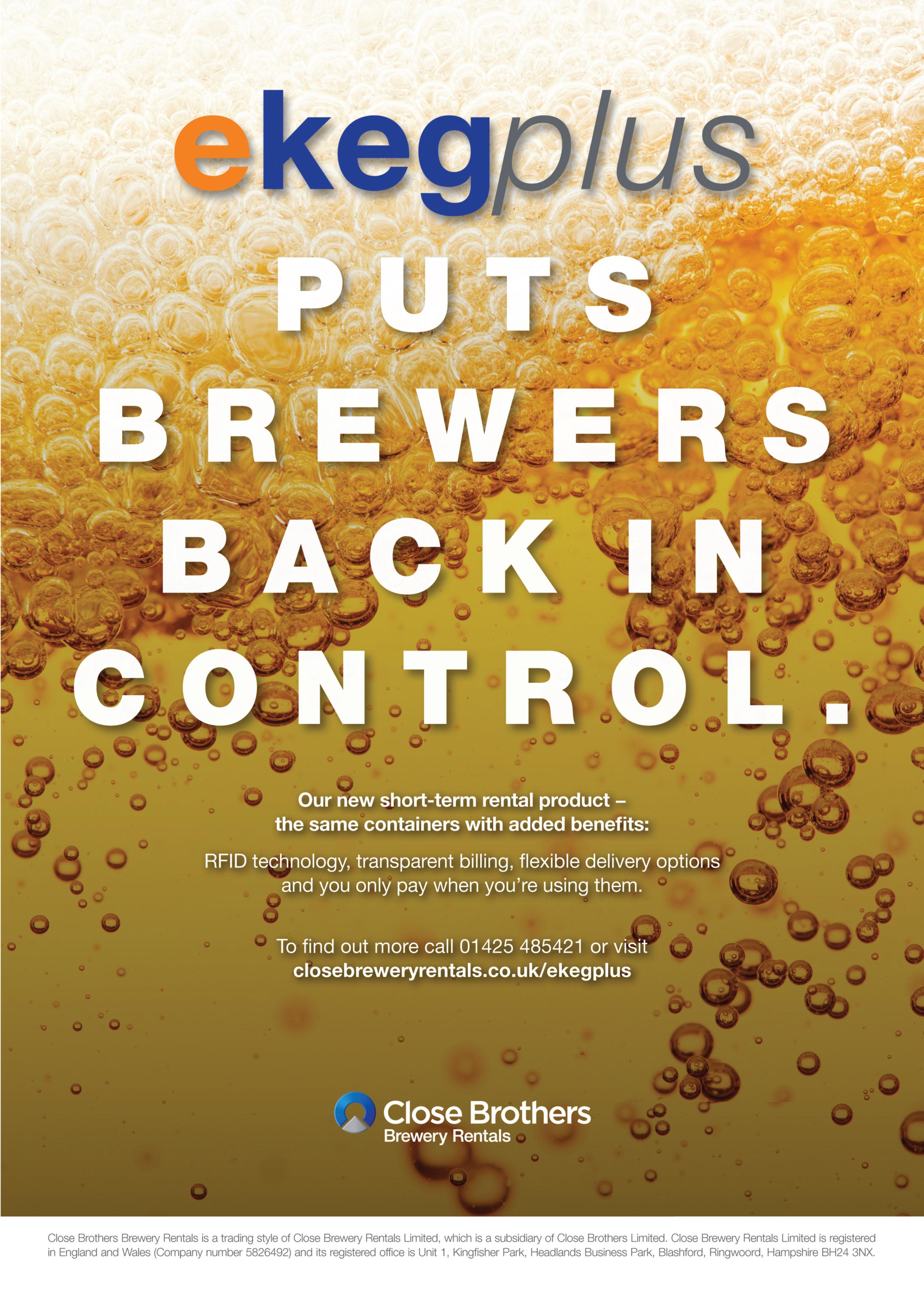

Flexible container solutions from Close Brothers

Brewers from small to large are reducing costs and gaining additional flexibility in their container fleet by using EkegPlus from Close Brothers Brewery Rentals

EkegPlus is a rental solution that enables you to only pay for containers when they are being used This means the shorter the hire cycle, the less you are charged

How does flexible container leasing work?

The pay-as-you-fill model gives users more control and access to a container pool of over 400,000 ekegs and ecasks

As one of the largest keg pooling networks, it gives the freedom to adjust the size of your rental fleet as often as needed With fixed RFID tags, you can also track and manage hundreds of containers in seconds, giving access to data that enables better understanding of products, logistics and supply chains, as well as increased asset visibility, via an online system

The hire cycle works in four steps: GET containers you need –collect them from a local depot or arrange for a stockpile to be kept on site

FILL AND SCAN containers to start the hire cycle

DELIVER the product direct to a venue or to an approved wholesaler

COLLECT AND RESCAN the empty containers – you can reduce charges by collecting them or wait for EkegPlus to collect, automatically ending the hire cycle

Flexible leasing in practice

Brew York was established in 2016 by two friends with a passion for craft beer Since then, the brewery has grown quickly and now boasts a range of beers, as well four tap rooms in and around York The brand is well-known for its rich flavours and quality Brew York has worked with Close Brothers Brewery Rentals since it opened As a partnership they have invested in the business and provided access to a container fleet

Having previously used a mixture of longterm and short-term rental solutions, during the coronavirus pandemic, the brewery required a more flexible container solution that would mean they could reduce and increase their fleet usage when needed

With consultation from container rental experts at Close Brothers Brewery Rentals, Brew York started to use a more adaptable rental solution, EkegPlus Benefits of flexible leasing for Brew York, EkegPlus means that the company can

access ekegs and ecasks as needed and has more control over distribution costs Using the platform it has oversight of costto-serve and daily hire charges This system removed any issues around keg availability due to market fluctuations that can’t be predicted, allowing for dynamic responses to increases in demand, without logistical headaches

Having previously used some plastic casks, Brew York was also pleased with the quality of the fleet All EkegPlus containers are made of stainless steel, the preferred solution across the brewing industry, making them more environmentally friendly due to their high quality, hard-wearing, and reusable nature

Wayne Smith, Co-Founder and Managing Director of Brew York, said: “Ekegplus works really well for our brewery We use both kegs and casks, and it’s a better solution for us Everyone is happy with the product While prices have increased elsewhere in our operations, moving to the new rental option has helped us to save on packaging and distribution costs The payper-use model gives us more flexibility, so we can top up our container fleet when we need to ”

For further information:

www.closebreweryrentals.co.uk/ekegplus

Glass is best for beer, says Beatson Clark

Trends come and go but glass is still the number one choice when it comes to premium packaging for breweries

Leading UK-based glass packaging manufacturer Beatson Clark currently has capacity in amber glass, which is visually appealing and has the added benefit of protecting the contents of the bottle from harmful ultraviolet light Glass is 100% infinitely recyclable, so glass bottles really are the environmentally responsible packaging option, as Dawn Pugh, Sales and Marketing Director explains

“Not only are our amber bottles made with over 60% recycled content, but glass is the only primary packaging material that doesn’t require a plastic layer between the product and the packaging,” said Dawn “Many people are surprised to discover that all other mainstream beverage containers – including aluminium cans –are lined with plastic which is in constant contact with your drink

“Glass meanwhile can be used without a liner as it’s completely inert This means

it’s safe to be in contact with the beer inside the bottle as the glass will not contaminate the product inside ”

Not only is glass environmentally friendly and rated as the safest packaging material around, it’s also a perfect medium for breweries looking to get creative with their bottle designs Glass bottles can be manufactured in any number of shapes, sizes and designs, and Beatson Clark can achieve stunning decorative effects too, from embossing and debossing to textured surfaces, spray coatings, sleeving and screen printing

The option of embossing words, logos and patterns onto glass containers can elevate a brand and achieve better shelf presence

Recent advances in technology have revolutionised what Beatson Clark’s inhouse design team can now achieve with embossing, and using the latest sculpting software means that the results are better defined and easier to manufacture

“Nine out of every ten bespoke designs we produce for our customers includes unique embossing – names, straplines, logos or patterns embossed on the glass to

enhance its appeal and make the container truly unique,” said Dawn “For those

producers who can’t afford a completely bespoke design, we offer the flexibility of a standard bottle with custom embossing added, which saves on the cost of having totally new finish moulds made ”

Beatson Clark recently launched a 330ml amber drinks bottle (pictured) for general sale Its design is based on an Alpha Sirop medicine bottle, so it chimes with the current trend for pharmaceutical designs being used for beverages to convey a retro, vintage feel The versatile amber bottle can be manufactured with a standard crown neck finish, and unlike the original pharmaceutical design it’s tested to 3 0 bar which makes it suitable for carbonated drinks

For further information:

www.beatsonclark.co.uk

20

SHOWC ASE Containers

Oasthouse Engineering - a step change to a greener, digital world

Having 20+ years in the industry, Oasthouse Engineering, a familyrun and independently-owned business, is taking a leap into a greener, digital world.

For years small producers (food, drink and so much more) have had to work around large MOQ’s for printed cans, instead utilising sleeves and labels to decorate their product Oasthouse Engineering has been a voice in can supply and decoration for 5 years, building a link between can producers and customers, supplying almost 60 million cans a year to industry. In 2022 the company made a £3,000,000 investment, purchasing a digital printing machine for direct-to-object can printing

The printer is a breakthrough for sustainability, removing the need for

plastics from labels and sleeves; improving the recyclability of the can, while making digitally-printed cans available to all producers The machine allows for MOQ=1can, which is significantly less than can producers

customers will have an opportunity to attend proof and print sessions to engage with the key part of the branding experience – taking a can home

using digital traditional print methods and opening printed cans to producers of any size

The machine has 360 degree print up to 1200dpi and full can print including the neck / shoulder, including the ability to print most can sizes – 500ml, 440ml, 330ml standard, 330ml Sleek, 250ml and 150ml standard

The technology will not only reduce MOQ’s but improve marketing appeal, branding opportunity and yield while decreasing lead-times, line speed, waste and, in some cases, reducing costs for small producers who are the backbone of the industry Oasthouse will also be able to provide some ‘Just in Time’, on the fly print runs for special occasions and events

Every design will have a ‘can in the hand proof ’ Oasthouse’s central location is beneficial for transport and

Says Sam Morris of Oasthouse, “Post COVID, Brexit and entering a period of economic uncertainty, we made the decision to make an investment / finance The search for investment was, in itself, a tumultuous journey, with an inevitable amount of barriers and limited support With help from Praetura we secured the investment needed and our printer #27 is up and running and already printing cans ”

Oasthouse recently held a launch event providing current and potential customers with the opportunity to view the equipment and meet the Oasthouse ‘family’

Continues Sam Morris, “In addition to sharing this with our customers and suppliers we made this a media event, spreading a truly good news story to the nation We would love to discuss our story further, the ups, the downs, the risks, the rewards, the challenges and the victories ”

For further information:

digican@oasthouseengineering.co.uk www.oasthouseengineering.co.uk

Leibinger launches new coding and marking system

Leibinger, the global innovation leader in coding and marking systems, presented an all-new at the interpack exhibition in Düsseldorf from 4-10 May 2023. With what it describes as a “groundbreaking innovation”, the company is raising the benchmark and promising a new era in the marking of, for example, best-before dates and other codes on a wide range of materials

“Especially in the case of cost-sensitive applications, such as in the F&B sector

or in the Fast Moving Consumer Goods (FMCG) segment, it is decisive that the marking runs smoothly and without any interruptions We have developed an entirely new Coding & Marking System that delivers exactly what it promises: absolutely worry-free printing,” reveals Christina Leibinger, CEO of Paul Leibinger GmbH & Co KG, who goes on to say, “Also worthy of mention is the fact that the new system boasts the lowest operating costs in the industry Just one of the reasons we are talking about a new era ”

22

www leibinger-group com

further

SHOWC ASE Containers

For

information:

We asked companies supplying the UK Distilling market to let us know something about their products and services

BSPS Ltd Opens Scottish Office

Bill

Egerton, Managing Director of Bulk Storage & Process Systems

Ltd, has announced that Adam Proud has joined the company, and will be based in Scotland. He brings over 25 years of experience to the business

Adam (pictured) started as a draftsman learning his trade in the agricultural and distilling industries, having moved to Aberdeenshire to work for Clark & Sutherland He soon moved on to designing and costing jobs and finally running projects

After 15 years, a move into sales with JW Installations and then back into

agriculture with GrainTek saw him working on projects and helping them design and establish the GrainTek Drier

More recently Adam has been working for Perry of Oakley as a Senior Internal Sales Engineer before joining BSPS this April as a Projects Manager

Adam will be assisting Bill Egerton with projects both locally in Scotland and throughout the UK His recruitment further establishes BSPS as one of the specialists in materials handling in the malting, brewing, agricultural, food and chemical industries

Together they will continue to offer unbiased advice on plant and equipment

selection, alongside a full project management service from conception and design through to commissioning

For further information:

Tel: 01483 202211

www bulksystems co uk

Move over gin - white rum is on the rise

Caleb Simpson, Managing Director of Simpson’s Beverages, on the rise of white rum

White rum is tipped to replace gin as the spirit of choice for many.

Sales of all varieties of rum are growing around the world, and are forecast to reach $21.5bn by 2028, as reported by The Food People. In the UK, sales of rum topped £1bn in 2022, according to Nielsen IQ, making it the fastest growing spirits category

The age-old spirit holds appeal for all drinkers thanks to its broad flavour profiles, ranging from spicy and botanical to floral and fruity

Of the dark, light, spiced and golden varieties, though, white rums are arguably the most versatile Which is one of the range of reasons why we’re now seeing white rum leading the charge

White rum is already well-loved when mixed with lime, coconut or cola mixers It can work just as well with tonic water too Its neutral palette gives it some edge over its juniper-based predecessor, able to be easily elevated with extra flavours So we think ‘R&T’ could soon be the new G&T

Increasing interest in global spirits has also been helping rum Flavoured varieties of dark and spiced rums have

paved the way for RTD rums Bacardi is already selling RTDs and flavoured rums and ‘spiked’ coconut waters are also on offer We think this sets out the stall for more fruity, floral or herby additions to white rums

Bold tropical flavours are the obvious additions for flavoured rums – like passionfruit or pineapple Big flavours can be created with botanicals like basil, chamomile, or hibiscus too And subtler fruit tastes work just as well - pear or watermelon can create softer, more sophisticated white rum cocktails.

Drinkers have become familiar with flavoured rums, perhaps most notably from Dead Man’s Fingers’ eye-catching varieties This familiarity is another factor working in white rum’s favour

And classic white rum-based cocktails like Mojitos, Daiquiris and Pina Coladas mean everyone from experienced

professionals to adventurous amateur mixologists are used to reaching for the spirit White rum can be the base for both sweet, creamy cocktails or classy, clarified rum-based cocktails We’re now expecting to see more white rum cocktails creep onto menus this year

Simpson’s Beverages develop and manufacture liquid flavour compounds for spirits, liqueurs and ready to drink cocktails

Visit: www simpsonsbeverages com/ flavour-compounds-for-alcoholic-drinks/

For further information:

www simpsonsbeverages com

26

FO CU S

UK Distilling

27

Labelnet works with UK distillers to create luxurious labels

Labelnet has recently introduced a range of embellishments to its range to create luxurious labels ideal for UK distilleries.

Hot and cold foiling are a great way to add eye-catching detail to a label design like Kingdom Gin who launched a range of flavoured gins and worked with Labelnet to create its ideal labels

Founder of Kingdom Recommends, Karen Thenga, and the team were looking for a label manufacturer to assist them with their new gin labels They came across Labelnet whilst researching on the internet, speaking to lots of different companies to find ones who could help with what they needed and then evaluating them against each other

What they liked about Labelnet was a desire to help the company achieve its goals Right from the beginning Labelnet was brought in to help the team deliver its labels and seals in double quick time Labelnet rep, Richard, helped Kingdom Recommends with its project, with a very positive attitude whilst listening to the ideas and vision

Both cost and turnaround times were very important when choosing a supplier but Kingdom also considered how the business worked, how quickly questions were answered and how much help and

advice was available A big question was whether it felt it could trust the company to fulfil its promises and commitments without causing any concerns or worry Ultimately, Kingdom Recommends was looking for long-term partners it could work together with and create a good business relationship with

Whilst Karen and the team found their way through various decisions of volumes, sizes, colour and finishes, Labelnet’s patience was available in bucketloads – you name it, they changed it and always the Labelnet team came back quickly with lots of suggestions and good ideas Richard even video-called Karen and the Kingdom Recommends team to explain how the labels were wound onto labelling machines to ensure they understood the concept

Because of the depth of knowledge Richard had, together with the team at Labelnet, they were able to turn a creative idea into a workable design This really helped Kingdom Recommends achieve what it was looking for at an affordable price with a great finish

The ability to have open constructive conversations about changes really helped the team understand any required changes and create a great label

Get your kit from Vitikit

Vitikit Limited is your comprehensive supplier for all your distilling, brewing and cider-making needs. We are a leading supplier of high-quality goods and services, providing the latest distilling, wine, cider and brewing equipment

Our products are carefully selected from top manufacturers worldwide to ensure that our clients receive only the best quality We provide a variety of distilling and brewing equipment suitable for producing any type of spirits or beer, including craft beer, wheat beer, ale, stout, and lager We also have a range of cider-making equipment that can be used for the production of unique blends

of delicious apples Our wine-making equipment is ideal for creating sparkling wine, white, rose, or red

At Vitikit, we are committed to providing excellent customer service Our team of experts is always available to help you find the right specialist equipment for a unique drinks product We are constantly adding new products to our range, and we hold many items in stock, such as filtration equipment and stainless steel tanks.

Our aim is to provide our clients with the best possible products and services at competitive prices

For further information:

“The Labelnet team worked really hard to deliver the gin labels in a very tight window and despite there being issues whilst on press they still got the order out on time, never causing us to worry,” said Karen Thenga “They saved Kingdom Recommends both time and money and gave ideas for improvement

We are delighted with our labels, they look fantastic We wouldn’t hesitate to recommend Labelnet and our advice to any customer would be talk through your ideas and work together to find the best solution ”

For further information:

The Institute of Brewing & Distilling (IBD) is launching a new entry-level course for the spirits industry.

The Essentials in Distilling course has been specially designed for professionals working in a distillery in supporting roles or in the hospitality sector to educate them on the whole distilling process It is also perfect as a starting point for anyone with an interest in spirits and no experience in the industry The course provides a multimedia and interactive introduction to the different spirits produced worldwide and the processes used to make them. The course also offers downloadable PDF summaries of the learning material for future reference

At the end of the course, learners will receive a Certificate of Completion from the IBD, the world's most recognised learning provider in the drinks industry

For further information: www.vitikit.com

Ibd.org.uk

28

FO CU S UK Distilling

labelnet co uk

www

Distilling course

29

CIMEC rotary canning lines added to Vigo portfolio

Vigo, part of the Rawlings Group, has announced the addition of CIMEC counter pressure rotary canning lines to its canning line range to offer high-speed canning under counter pressure fill conditions

Commercial Director, Andy Pegman, comments: 'Having supplied and supported CIMEC bottling lines for 19 years, the inclusion of CIMEC's counter pressure filling rotary canning lines is a natural transition Our Engineering Team (9 engineers in all) has extensive experience of working with CIMEC machines We're really pleased now to be able to offer customers wanting to increase their canning output the benefits of CIMEC's high build quality coupled with UK support from our renowned engineers CIMEC machines are robust and reliable - the oldest CIMEC filler we service is 22 years,

which really speaks for itself '

CIMEC counter pressure rotary canning lines have throughputs up to 6,000 cans per hour and can be supplied with an optional can rinse unit and ink jet printing As with all filling lines supplied by Vigo, ABE lines and CIMEC lines,

they are installed commissioned and backed up by Vigo Engineers Service contracts are also available

PakTech and Braukon partnership brings first automated handle applicator of its kind to Europe

Leading brewery systems supplier and manufacturer, BrauKon, has started operating PakTech’s automated handle applicator equipment for the first time in Europe

The collaboration between BrauKon and PakTech, a leading producer of 100% recycled secondary packaging handles and automated handle applicator equipment, will allow BrauKon to propose a more holistic offer when it comes to contract brewing – from planning, manufacturing, filling and applying secondary packaging Thanks to the installation, BrauKon will be able to apply PakTech handles in significant quantities for its customers

BrauKon will also use the handle applicator to apply PakTech handles on its new line of Camba cans for its own brewery, the Camba Bavaria The new Camba cans will be available in black, high-quality and opaque cans with eyecatching and individually designed labels that will be available in select beverage markets and beverage wholesalers

“With the introduction of our new can

line and the refreshed appearance of our portfolio, we were looking for a applicator equipment partner whose products and services matched the excellence we strive for in our beers, as well as strong priceperformance ratio PakTech ticked both boxes,” states

Folkert Kupferer “Now with the operation of the CCA 120/180 can carrier applicator we will offer even more possibilities for our clients and become a truly holistic contract brewing service ”

The Head of Technology Brewery further adds, “The recent switch from bottles to cans aligns with our constantly evolving sustainability expectations when it comes to resource efficiency and circularity This makes PakTech handles the perfectly complementary secondary packaging for our new Camba can products as they are manufactured from 100% recycled plastic that are also

recyclable in turn

“We are excited to see our automated handle applicator machine come to action in Europe for the first time,” says Jim Borg, the Founder and President of PakTech “Our partnership with BrauKon is a first step to bringing our sustainable and smart solutions to the European market We also look forward to learning more about the specific needs and expectations of this very important client base ” https://paktech-opi.com For further information:

”

30

NEWS Equipment Tel: 01404 892 100 www.vigoltd.com

further information:

For

NEWS Equipment

New look for Atlanta UK

Leading packing and wrapping specialists, Atlanta UK, has recently undergone a brand refresh, in addition to launching a new website, providing an impressive showcase of its highquality automation machinery and end-of-line packaging technology

Atlanta UK, formerly Atlanta Packaging, provides UK technical sales and aftersales service for the Italian-based Atlanta Group, which manufactures a range of automatic and semi-automatic pallet stretch-wrapping equipment, highspeed wrap-around case and shrinkwrapping solutions The group supplies the OEM and integrator sector, as well as direct-to-end user across all industries including food, beverages, pet food, detergent, lubricants and personal hygiene industries

Incorporating a fresh and contemporary new logo design, created to be eyecatching and visually impactful, Atlanta

UK’s new fully responsive website provides users with an inviting and structured layout giving easy access to its product portfolio

Offering a clear format, incorporating high-quality imagery throughout and supported by product videos, the site is modern in its approach and functionality

In addition to details on each of its highquality packing and wrapping solutions, visitors to the site will find useful information and guidance on Atlanta UK’s service and spares support An insights page highlights the company’s recent news, while alongside, a ‘success stories’ section demonstrates Atlanta UK’s achievements in providing customers with market-leading automation and end-of-line solutions

Hach nitrogen LCKs now ISO standardised

Hach lays claim to still being the only supplier able to implement the original formulation of the international COD standard ISO 15705 in cuvette tests

The company has announced the ISO standardisation of several nitrogen LCK cuvette tests Its nitrogen cuvette tests also meet the strict criteria of international norming and are standardised according to ISO 23695 (ammonium), ISO 23696 (nitrate), and ISO 23697 (total nitrogen)

Accurate results are not just dependent on ISO standardisation, or the quality of the reagents and instruments used It is also the competence and training status of the Hach user which leads to such excellent accuracy in water testing

More on Hach ISO Standard Methods

Tips for getting most accurate measurement results with Hach can be found on the Hach website at https://info hach com

On the website you will find analytical

tips from our chemists and laboratory technicians as well as information on training and services which are helpful in your daily measurements

Topics include:

• Select the correct measuring range

• Pay attention to the temperature of the sample and reagents

• Check the shelf life of the reagents

• Use the Hach Truecal function

• Determine a standard solution with a known concentration

• Check the result by diluting or spiking the sample

• Check the pH of your sample

• Check the pipettes

• Maintain your instruments and continue your training

Atlanta UK’s Robert Johnston said:

“With its modern design and easy-tonavigate appeal, the website will provide visitors with a comprehensive account of our offering and, importantly, how they can utilise our automation solutions to their advantage Investments in state-of-the-art stretch wrapping, shrink wrapping and case packing machinery, are all designed to increase efficiencies and enable greater productivity, all backed by a flexible, knowledgeable and dependable service ”

SSV Limited has announced a move to a new location. This move is a significant milestone for the company as it enables it to build and grow a dedicated servicing and aftersales team along with allowing it to hold stock of tanks from 5hl to 100hl along with increasing parts storage capacity by more than 600%

Customers are asked to update their records with the new contact information and direct all future correspondence to the new address which is: Unit 8, Swinnow View, Leeds, LS13 4TZ The telephone number remains unchanged

32

www uk hach com For further information: Tel: 0113 873 0021 For further information: atlantauk.com For further information: SSV Limited

on

move

is

the

33

Complete portable party kits available from Booth Dispensers

In those scorching summer months, it's more important than ever to cater for outdoor festivities, to enjoy the sun while remaining refreshed and cool. Booth Dispensers has long understand the difficulty and importance of keeping your drinks at optimal temperatures during this period and has developed bespoke solutions to ensure drinks stay ice cold from the first drop to the last Whether you're planning a wedding, a festival, or a beer garden party, Booth’s mobile event carts can fit your every need Steady, durable and reliable, the event cart allows you to move the dispense point of your venue to different locations or cater for

an event that does not have access to a cellar

There are three distinct contemporary styles to choose from: stainless-steel, vintage wood, or black powder coated. Booth Dispensers can also build a complete cart that is fully equipped with coolers, taps, regulators, and keg couplers to your specifications All you need to do is provide the gas and the product, and you're good to go!

Booth event carts can also be personalised with artwork that advertises your brand, company, or product and gives your set-up a unique flair Its magnetic material makes it easy to remove and replace quickly

Booth is also Introducing its new KegBox Cooling Systems When space is limited, the Cold-room KegBox systems provide a cold storage environment

KegBoxes are available for both remote and undercounter applications There are several sizes available, ranging from 2 to 10 kegs,

complete with fridge unit In addition to being eco-friendly and energy efficient, the units are also easy to install and maintain Booth can also supply keg coolers for the event industry, catering for up to 20 kegs

If you are interested in learning more or need help with your own custom setup, please telephone 01253 501800 or send an email to customerservice@ booth-dispensers co uk

For further information:

New AP-CODE lot and date coding module

The AP-CODE Lot and Date Coder is a new accessory for the label application process, adding the feature of printing dates, lot codes and text directly onto glass, metals, plastics and even laminated labels

As announced by DTM Print, international OEM and solution provider for speciality printing systems, this date coder, manufactured by Primera Technology, Inc , is ... “compact, affordable and easy to use.” It is designed to work seamlessly with the AP-Series Label Applicators, including new and existing installed units.

With no tools required, AP-CODE installs quickly to the AP360e and AP362e Label Applicators. It doesn’t need a separate power supply and includes a full-colour touchscreen to enter data and configure date and lot codes The print fields are free-format

and can include letters, numbers and many symbols Formats can be stored for later use to speed up production

As AP-CODE is attached to an APSeries label applicator, you get one integrated machine that prints lot codes, dates and more directly onto round containers while at the same time labels are applied. Of course, AP-CODE can add this information without the need to simultaneously apply a label and can also print on pre-applied labels

It uses a single black solvent-based ink cartridge that is long lasting, immediately dry, waterproof, scratchand UV light resistant Decap time,

during which the cartridge can remain uncovered, is more than 24 hours, eliminating clogs and needing to cap print heads overnight

“AP-CODE, in combination with the AP360e and AP362e Label Applicators, eliminates the need of applying extra labels or using hand-stamping devices to add lot codes, dates or texts to your container,” says Lea König, Product Manager for Labelling Solutions at DTM Print. “That’s a huge benefit for our customers as it significantly increases their production efficiency.”

The AP-CODE sells for € 1,149 (MSRP) and is available from DTM Print or through authorised DTM Print partners in Europe, Middle East and Africa

For further information:

34

01253 501800

Tel:

www.booth-dispensers.co.uk

NEWS Equipment

dtm-print.eu

Anton Paar launches inline oxygen sensor

Anton Paar has announced the launch of the Oxy 4100 Transmitter inline oxygen sensor, for the measurement of dissolved oxygen in real-time, directly at the production line

The Oxy 4100 Transmitter is a standalone entry-level unit that is easy to use and install It comes equipped with analogue outputs, a sensor cap, and a user-friendly touchscreen interface, making it a powerful solution for any production environment.

The sensor provides accurate, driftfree measurements throughout the entire production process and is

available in both trace and wide range versions, offering even more flexibility for manufacturers With a simple exchange of the sensor cap, users can conveniently switch between ranges and tailor the sensor to their specific needs

The Oxy 4100 Transmitter also

features Toolmaster® technology, which automatically detects the sensor cap and transfers all set-up parameters to the sensor This ensures that the Oxy 4100 Transmitter is ready to use right out of the box, and that inline measurement can start immediately once the cap is mounted.

Designed according to hygienic criteria, the Oxy 4100 Transmitter is capable of withstanding CIP and SIP cleaning procedures up to 130°C for 30 minutes Once the CIP/SIP routines are completed, the sensor reactivates in just minutes to minimise downtime

For further information:

info.uk@anton-paar.com

Baumer ’s ultra-compact sensor for optimum conductivity measurement

Measuring conductivity in smaller sized production facilities, especially in the food and beverage industries, demands the most compact, yet robust sensors and the new BAUMER PAC50 process sensors meet these critical requirements.

According to the company, these ultracompact sensors “set new standards” and are based on the proven performance and durability of their ‘bigger brother ’ the Baumer AF14/5 conductivity sensor

Due to continued requests from customers for increasingly smaller components to fit into tight production lines these sensors feature a housing measuring just 60mm, with the potential for reducing the display size even further down to 32mm x 25mm IO-Link is also a standard feature

Despite their compact design the sensors deliver high temperature stability up to 140ºC allowing them to be specified for permanent use, even in CIP (Cleaning-in-Place) and SIP (Sterilisation-in-Place) systems Their robustness and durability is largely

due to an innovative one-piece sensor tip design which means optimum resistance to strong and or frequent temperature fluctuations, compared to other sensors which typically feature a two-piece tip

Experience shows that many sensors have lower temperature limits (typically 100ºC) and lower resistance to chemicals This is why PAC50 sensors have a sensor tip made entirely of high-performance plastic polymer or ketone (PEEK) which offers much better resistance to chemicals and higher temperatures

Another important feature is the all stainless steel sensor housing with all parts laser welded ensuring optimum resistance to all ambient conditions outside the pipe.

PAC50 in its H version complies with EHEDG (European Hygienic Equipment Design Group) hygiene standards as required for many food, and beverage applications They are

also 3-A certified and all media contacting parts are FDA certified Like other Baumer sensors, IO-Link is a standard feature allowing the collection of secondary data, such as temperature for process monitoring and communication to control devices

This means users can quickly and easily parameterise the sensor prior to and during operation – even when the sensor is integrated via an analogue interface

Furthermore, to optimise flexibility the dual channel feature allows users to operate the PAC50 via analogue or digital channel, or even both in parallel

For further information:

www.baumer.com/gb/en

36

NEWS Equipment

B&B Attachments announced as the official distributor for SW Paratus in the UK and

Ireland

B&B Attachments, leading manufacturer and supplier of forklift truck attachments and material handling solutions, has announced its official role as authorised distributor for SWParatus, in the UK and Ireland.

Founded in 2016 by now Managing Directors Lars Wellerdiek and Ralf Schauties, SW-Paratus has developed and manufactured the innovative pallet sliding device, PSVULTRA, from its manufacturing facility in Halle, Germany

The PSV-ULTRA is an innovative system which aims to optimise pallet handling and accelerate the flow of goods during the logistics process The system works by allowing the forklift operator to place a loaded pallet into the device, the truck then pushes the new pallet under the load and into the PSV-ULTRA system, which quickly and efficiently exchanges the pallet

The heavy-duty, roller-mounted slider easily compensates for any height differences between the old and new pallet. Pallets are exchanged and re-palletised in a matter of seconds, regardless of the pallet type The pallet changer does not require any

additional drive energy or complex hydraulics, and operating personnel can be trained in just a few simple steps to carry out the pallet change

This patented pallet sliding device is used in various industries around the world, for effortlessly swapping pallets whilst under a load The system enables a smooth transition from wood to plastic pallets (including H1 hygienic pallets) or aluminium pallets

The PSV-ULTRA can be made in stainless steel for hygienic areas or cleanroom production

Mike Barton, Managing Director at

B&B Attachments, comments: “We are excited to add the innovation of the SW Paratus system to our already extensive portfolio of material handling solutions The simple and ingenious creativity of the PSV-Ultra system makes it the perfect addition to our product range We are looking forward to working together with SW Paratus and distributing this new technology, that will be game changing for many industries ”

For further information:

www.bandbattachments.com

Hypro's Liquid CO2 Evaporator the ‘ultimate solution for decarbonisation’

In today's world, where sustainability is a top priority, every industry must take conscious efforts to reduce its carbon footprint. The brewing industry, responsible for producing one of the world's most beloved alcoholic beverages, must lead by example.

Unfortunately, traditional methods of CO2 evaporation including air heated, steam heated processes are very energy intensive

Hypro's Liquid CO2 Evaporator with a proven technology for the brewing industry's carbon footprint has been in

use for more than 2 decades With Hypro's innovative decarbonisation technique, breweries can now significantly reduce their carbon footprint while also tapping into the high refrigeration energy of CO2. Unlike thousands of installations worldwide that contribute to positive CO2 emissions, Hypro's liquid CO2 evaporator delivers a negative release of CO2 emissions, making it a most sustainable and efficient choice for breweries looking to make a positive impact on the environment

Said a spokesperson for the company, “Having undertaken more than 65 installations so far, the system

ensures that the decarbonisation process takes place while leading to negative CO2 emissions, making it one of the most sustainable systems available in the market.”

For further information:

www.hypro.co.in

38

NEWS Equipment

39

Nectaron® - To NZ and beyond

Prior to its official launch in 2020, Nectaron®, developed by NZ Hops in partnership with the team of horticulture specialists at Plant & Food Research and generational NZ hop growers, was affectionately known as “wow” and that should say it all really

Nectaron®, now in its second year of commercial harvest, is a shining example of where science meets art and it is certainly a hop that punches above its weight So much so that this ‘new kid on the block’ hop was voted as the fifth most desired hop variety that brewers would like to see more of in the future, in a survey conducted last year by America’s Brewers Association.