Julian Grocock is a former

executive of SIBA with extensive experience in beer, brewery and pub politics ALAN

Alan

Julian Grocock is a former

executive of SIBA with extensive experience in beer, brewery and pub politics ALAN

Alan

What a busy three months are ahead of BFBi. We have a full programme of events coming up, not least the International Brewing & Cider Awards, which has relocated to Mayfield Depot, Manchester.

For the first time in the Awards’ long history, a Festival showcasing the entered beers and ciders, together with local manufacturers follows the competitions

Medal announcements will be made on Friday, 22nd March at Mayfield Depot. A celebration of the winning brewers and cider makers, everybody is invited to attend You can register for a trade ticket on https://ibcfest.com/tickets.

Or, visit the Festival, organised on a not-for-profit basis with the intention of showcasing participating brewers, cider makers and other manufacturers

– going beyond the product to the ethos of the producer

The pinnacle of celebration is our National Lunch, being held 1st May at Guildhall, City of London where all medal winners from around the world are invited to attend and receive their medals and, if they are a gold medal winner, hear if they have won a trophy With winning beers and ciders from around the world available to sample in the Crypts, it is a very special day and we look forward to seeing you there

Other events can be found in our diary of events and, in an industry where collaboration, community and sharing of

The most authoritative directory o UK food & drinks market availab

The directory is free-of-charge to drinks manufacturers and BFBi members

For details of how to obtain a copy please contact admin@bfbi.org.uk

knowledge enhances our strength, doing just that with a beer and in good company can’t be beaten

We hope to see you soon!

Ruth Evans MBE, BFBi C.E.O.

Established in 1907, BFBi’s membership represents the entire value chain supplying the brewing and beverage industry – from seed geneticists through raw materials, brewhouse and process equipment to dispense, point-of-sale and brewers/distillers. The Association’s objective is to be the foremost trade association providing opportunities for its Members to develop within the brewing, food & beverage industry

As well as offering many benefits and services to suppliers of raw materials, process and packaging machinery, dispense and point of sale products, BFBi is a Trade Challenge Partner for various overseas exhibitions and owner and organiser of the oldest international brewing and cider Awards in the world.

Cryptic or what? If you’re intrigued, please read on The answer is in the future...although its historical foundations are of course built in the past.

It relates to the optional letters in a couple of words facing each other across the beer-drinkers' spectrum; words I used towards the end of my last article – and have quite probably banged on about countless times before that!

Yes, it's a subject that's pretty much a constant in the thought-processes of my beer-and-pub-obsessed brain There is however a recent reason why the SUPPER vs SIPPER confrontation has once again taken pole position ~

Just to prove I'm not entirely and inescapably immersed in the sepia-tinted (boring brown?) etchings of my youth, it's a highlighted Facebook memory that's brought this back into sharp focus I might well be approaching the three-score-and-ten birthday milestone, but I really do embrace much of the modern world's so-called 'smart' technology

And the memory? Apparently, it's five years since I drew attention to an opinion piece, by a blogger called The Burnt Out Beer Guy, entitled Is Craft Beer Burning Out? (The author described himself on his WordPress pages as an award-winning beer writer and craft brewery founder, so I did assume he spoke with considerable depth of personal experience )

He wrote: 'IPAs so cloudy they look like radioactive pond water, double mocha-wocha choco-vanilla fudgy wudgy pastry stouts, double dry hopped fruit smoothies, and salty goses that taste like gym instructor sweat Is craft beer trying so hard these days it's in danger of burning itself out?' Pointing out the craft aficionado's perpetual compulsion to be trying something new, he continued with an assessment of the extent to which this forced the new generation of brewers to keep ringing the changes and pushing the boundaries, leaving them with precious little opportunity to actually take the time required to 'craft' a recipe to perfection and reliable consistency

It's fair to acknowledge this market has perhaps calmed down somewhat since then, but I do believe my comment at the time remains relevant, and effectively highlights the U or I reference: 'Thought-provoking wisdom, worth sharing before I go out for several pints of beautifully balanced, well kept, perfectly presented, cask-conditioned "boring brown" bitter ' (My post also earned positive responses from, among others, the head of a renowned family brewery, an established microbrewer, an independent beer wholesaler, and a highly respected beer journalist and author )

~

Needless to say, this whole issue –which entrenches the distinction between suppers and sippers –depends on an accepted definition of craft beer About fifteen years ago SIBA was intensely embroiled in this debate, trying to decide whether it could designate all its full brewing members and their products as 'craft'. Ultimately it couldn't, due in no small part to the strength of derisive 'micro' opinion telling one meeting I attended that Timothy Taylor's Golden Best was 'a bland supping ale and in no way a craft beer' Which told me whose side I was on

Furthermore, there's an ongoing consequence of an elitist standpoint belittling such classic British ales You would probably automatically blame the huge national and international conglomerates, who care little about the authenticity of what they see as 'commodity' brands, so think nothing of closing historic breweries, and transferring or farming out production regardless of any ensuing effect on familiar flavour and character. But just consider how much they might feel

encouraged to do this, without any sense of guilt about destroying our brewing heritage, when they see that heritage sneered at by those who have set themselves up as the only sector of the industry worth defending I don't need to name all the famous brands mistreated – and destroyed –in this despicable manner Except the latest, at the hands of Carlsberg Marston's The discontinued use of the last four Burton Union sets for the brewing of Pedigree is the final loathsome step in the emasculation of a once legendary cask ale

And do craft sippers care?

I've said it before Suppers make up the broad backbone of support for the beer and pub trade, enjoying quaffable pints and affable company in a social environment Sippers pursue a hobby, geared far less to any of those traditional community-oriented values There's some appropriate irony in those two letters, isn't there? The U in SUPPER is outward-looking and inclusive, in contrast to the I in SIPPER, which hints somewhat egotistically at exclusivity and self-importance

And it's U, rather than I, who must take control and decide our future direction.

Julian Grocock

Julian Grocock is a former pub landlord, managing director of Tynemill/Castle Rock, and chief executive of SIBA

Extensive experience in beer and pub politics, brewery and pubco operations, and on the front line in the pub trade...‘from cellar to ceiling’.

The requirement to be licensed by HMRC to make gin or any other rectified or compounded spirits (eg spiced rum) has been repealed since 1 August 2023 and confirmed to the British Distillers Alliance 2 February 2024. Ta-dah! Although there has been no fanfare from HMRC and their public notice on such matters has not been amended as of 3 February to explain the changes.

I have reported on the developments in UK law for simplification of alcohol production by the introduction of a unified “drinks factory” to replace individual alcohol production regimes (registered brewers and cider makers, licensed distillers and wine makers etc) In fact, all alcohol licences will go

The Finance (No 2) Act 2023 repealed the Alcoholic Liquor Duties Act 1979 (ALDA) but some parts of ALDA for licence and approvals to produce alcohol have been kept alive in a “zombified” state by bridging legislation until section 82 of the FA (No 2) Act 2023 and regulations made under section 83 of that Act to approve such production are enacted by HMRC Technically, section 18 of ALDA was not "zombified" (and is now fully repealed), so there is no longer a requirement to hold a licence to rectify and compound spirits or to make entry of rooms and equipment per regulation 7(1) of the Spirits Regulations 1991

Following request for help from applicants for licences to make gin

who had been told by the processing unit there had been a policy decision to put such matters “on hold”, which stymied the licences being issued, I got in touch with HMRC Policy who told me:

“ the requirement to hold a licence to carry out the rectifying and compounding of spirits was removed as part of the 1 August 2023 alcohol reforms For anyone rectifying or compounding duty paid spirits (with no change to the duty liability of the spirits as a result of that rectifying or compounding), then there is no longer a requirement to hold a licence from HMRC

“If, as a result of, the compounding and rectifying there is an increase in duty that would be payable if it had been carried out before the duty point, it can only be done in an excise warehouse (or in future on approved alcohol premises)

Once the new alcohol approvals go live (ie implementation of Section 82 and 83 of the Finance (No 2) Act 2023), rectifying and compounding with duty suspended spirits will be possible on approved alcohol (production) premises” (ie not under the severe excise warehousing

The British Distillers Alliance (BDA) is a non-profit making body which provides a professional service for independent and craft businesses in the spirits production industry and supply chain The BDA represents distillers, rectifiers and compounders and those in related sectors. New members always welcome.

approval per section 92 of the Customs and Excise Management Act 1979 as is currently the mandated law)

This is HMRC’s iteration of the drinks factory implementation, which is not a big bang but to be implemented in phased stages The completion is expected to be before this year end

Finally, to clear up confusion, have asked that section 15 of HMRC’s Notice 39 (Spirits Production) be amended because the reader is still told erroneously that a licence and entry are required for rectification and compounding of spirits Be careful out there!

Alan Powell is a specialist excise duties consultant, formerly a Policy official within HMCE’s HQ teams. He is excise duties advisor to the Chartered Institute of Taxation, honorary advisor to the UK Warehousing Association and founded the British Distillers Alliance as a conduit for consultation with, and representation to, Government bodies and to assist and advise on technical matters. The BDA represents distillers, rectifiers and compounders and those in related sectors New members welcome!

For further information:

www.britishdistillersalliance.com

We asked companies supplying the following products and services to let us know something about themselves....

l Malts, hops, fruit, yeast and any other raw materials which contribute to the finished product

l Chemicals and other adjuncts used in the drinks production process

l Companies providing power and other resources, plus products and services to help meet hygiene regulations

Lallemand Brewing proudly has released its latest innovation, developed for craft, regional and industrial brewers alike, hoping to make great tasting, consistent Low and No alcohol beers.

Low-and-No-alcohol beers have seen a recent boom in popularity as consumers cut back on alcohol and opt for healthier alternatives

LalBrew LoNa™ is a hybrid Saccharomyces cerevisiae yeast strain that has been selected for the easy and consistent production of low and nonalcoholic beers Advanced classical and non-GMO breeding methods were used to select a strain that does not consume maltose or maltotriose, resulting in very low attenuation. LalBrew LoNa™ is the first maltose-negative Saccharomyces cerevisiae strain specifically selected for beer fermentations As a S cerevisiae strain, LalBrew LoNa™ performs like an ale producing a clean and neutral aroma profile, no phenolic flavours, and significantly reducing aldehydes that cause worty flavours

Additionally, the patented technology from the University of California Davis

(USA) ensures that the strain will not produce sulfurous offflavours, allowing the malt and hop flavours to shine through

LalBrew LoNa™ is available globally in 500g sachets and 10kg bulk packs Pasteurisation is required when brewing with LalBrew LoNa™ to avoid refermentation after packaging and ensure beer stability.

Lallemand Brewing is a business unit of Lallemand Inc , a privately held Canadian company specialising in the research, development, production, marketing and distribution of yeast and bacteria Lallemand Inc has over 4,500 employees located in more than 45 countries on 6 continents

For further information:

www lallemandbrewing com/en/united-kingdom

A “carbon footprint calculator” has been created to help small craft brewers identify the scale of their carbon emissions

Developed by a research team led by the University of Leeds, the freely available calculator - which can be downloaded as an Excel document from the figshare website - will enable breweries to see how sustainable their operations are

Baseline data “hard-wired” into the calculator will enable brewery managers to estimate carbon emissions across the entire production process, from growing

and sourcing raw ingredients to producing and transporting the beer, with account taken of the way the beer is packaged, which can have a big effect on carbon emissions

Marcos Ramirez runs the Piglove Brewing Company in Leeds with two colleagues which produces 12,000 litres - just over 21,000 pints - of beer a month He says the calculator will improve the accuracy of the estimates of his brewery’s carbon emissions

Malt traditionally contributes between 35-39% of the CO₂ emissions of every pint of craft beer

At Muntons we have taken our commitment to producing the world’s most sustainable malt into every strategic decision and progress step we make It’s a truly holistic approach With our extensive experience and knowledge we can help breweries to map and reduce their carbon impact for raw materials as part of their own sustainability story

Sustainability is a core part of our ethos and has been for over 20 years

We were the first maltster to set a Science Based target (45% reduction of our scope 1 and 2 co2 emissions by 2025) and the first maltster to celebrate meeting and beating that target 3 years early As the world’s greenest maltster, we believe passionately in creating a positive impact on society and the planet We are proud to produce malt the lowest carbon malt in the world

If you would like more information on our world-leading sustainability programme Our ESG Report is available to download on www muntons com/ practical-sustainability

Wimbledon Brewery and Charles Faram hop merchants are working in collaboration to showcase recently developed English hops in a new series of Pale Ales and IPA’s for release in 2024.

These classic styles of beer are quintessentially English, with the term ‘Pale Ale’ first appearing in England in 1703 These beers were made from malts dried with high-carbon coke which resulted in lighter beers It is from these early new pale beers that so many beer styles around the world have been developed

Simon Lewis, Managing Director of Wimbledon Brewery, said, “Over the last 20 years the UK brewers have turned to using American and New World hops to make distinctive and full flavoured IPA’s and Pale Ales These beer styles have very much driven the ‘craft beer ’

revolution We are working with Charles Faram on a range of beers that will show the amazing range of hops available in this country.”

Will Rogers, Group Technical Director in charge of the Charles Faram Hop Development Programme said, "We are very proud to be working with Wimbledon Brewery on their new series of sustainably brewed beers featuring British hops Using locally grown hops from our hop breeding programme will bring vibrant fruity flavours to the beers and help support the British hop industry at a time when it support is genuinely needed "

Charles Faram’s hop development programme is focussed on exciting new modern style hop varieties including a focus on English hops The brew team at Wimbledon Brewery has been working in collaboration with the hop supplier doing trials to highlight the

development of English hops including several experimental hop varieties that could one day be produced commercially.

The 2024 range of beers will focus on the popularity of IPA’s and Pale Ales for which Wimbledon Brewery has a great reputation Wimbledon Brewery will be working with all its customers to make these beers available across the on and off trade The range of beers will be announced over the coming months

This programme of beers is one step in Wimbledon Brewery’s initiatives toward reducing its own carbon footprint and promoting an attitude of sustainability Steps are being taken across the business to reduce waste, control energy usage, recycle and reuse wherever it is possible

For

www.charlesfaram.co.uk

In the ever-evolving world of brewing, we believe consistency and quality still reign supreme.

As the UK's oldest continuously operating Maltings business, our legacy isn't simply our rich history; it's centuries of experience and tradition which provide the bedrock upon which we have evolved and craft our specialty malts, trusted by generations of brewers.

We believe that it's through our enduring partnerships with some of Britain's most established brewers, including Shepherd Neame and McMullen's, that for over a century, we've honed this commitment by actively listening to their needs and consistently delivering fine roasted malts Our passion for malting, on parity with their dedication to brewing has cemented this bond, ensuring mutual success and unlocking product growth and diversification

With great pride we supply our diverse portfolio of speciality malts to stand as the foundation upon which breweries choose to build their dedication to quality and innovation This is why we

meticulously craft our malt to cater to precise brewing needs, ensuring optimal performance and unwavering flavour profiles

From the unmatched versatility of our Crystal malts to the distinct specifications offered by our Patent Malts, every option is tailored for brewers to create truly unique beers to captivate consumers

We work hard to maintain and leverage a strategic network of farms within a 50mile radius to our Maltings, securing the finest Winter Barley, whilst reducing transportation emissions and minimising our carbon footprint We have also expanded our selection of malts to offer a select assortment of organic malts, catering to partners who seek to differentiate their products and cater to the growing demand for sustainable ingredients Our maltings is powered by zero-carbon electricity, ensuring our brewers can lead with both quality and responsibility This localised sourcing

model has helped us foster resilience and operational efficiency, ensuring the consistent supply of high-quality ingredients for our diverse brewery partners

As we continue to embrace the future of brewing, we invite brewers of all sizes to join us in our evolution, honouring the legacy and traditions that paved the way to the present We would be delighted for you to explore our malts, and to embark on a shared journey where success becomes part of our shared story

For

As early as 200BC Romans noticed beverages stored in swim bladders of sturgeon fish had magical clarity. Fast forward a few centuries and via a bit of processing and a nifty German / Dutch naming, isinglass became the linchpin of the British cask beer. Authentic isinglass still enjoys unrivalled status as “premier league” in cask fining but despite the production process removing any “fish material” from the collagen, there are sections of consumers preferring a vegan route

As brewers search for alternatives, Murphy’s Super F is proving a popular option for the fining of cask beer

There are two principal components of beer that require clarification following end of fermentation The first of these is protein which comes from the malt and other cereal adjuncts in the grist The amount of protein varies according to barley variety, growing conditions, malting skill and the brewers own processing techniques Protein is required in beer for yeast growth, flavour, colour, aroma and foam all desirable characteristics.

However, there is usually an excess in the final beer which unless removed, accelerates the deterioration of beer quality in the form of loss of flavour and development of haze Other troublesome processing conditions present themselves in the brewery with slow fining and difficult filtration

The second component that needs clarification is the removal of the yeast In cask beer, a small

amount is required to maintain or “cask” condition the beer to give the beer a pleasant mouthfeel when consumed. This amount is so small that the beer will appear bright even though some yeast cells may still be in suspension However, the removal of yeast, once the fermentation is over, needs to be done quickly in order to preserve the freshness of the beer and to stop the dying yeast from autolysing and contaminating the fresh beer with off-flavours

Understanding these two components and balancing a finings regime to suit is critical if the brewer is going to get high quality fresh cask beer to trade quickly or to filter the beer for kegging or small pack. When fining beer, the objective is to coagulate the protein particles and yeast cells to increase their density hence increase settling speed. The larger particles are called flocs The principle of attraction is based upon molecular electrical charge where opposites attract.

At the pH and temperature of green beer, proteins have an excess of positive charges so a finings that carries a negative charge is used These can be polysaccharide or silicaceous in origin They are acidified so complement beer pH and create the right conditions to make flocs

In the same way, live yeast cells fresh after fermentation carry a negative cell charge so a finings agent like isinglass is used These are also acidified; the lower the pH, the more negative charges they carry.

Super F is manufactured in a similar way to some auxiliary finings but during the production, the solution is alkalised instead of

acidified The high pH causes a reversal of polarity in the silica sol so that it carries a positive charge like isinglass and attracts the yeast Handling and addition points in the process are the same as for isinglass – normal auxiliary finings can be added to remove the protein then the Super F added to clear the yeast

Isinglass is a huge collagen molecule with space to attract many yeast cells forming large flocs whereas Super F is a much smaller molecule forming smaller flocs so it takes a little longer to settle after each movement but when used properly supported with regular optimisation Super F is a ‘go to’ product for vegan friendly cask beer

If you have any questions or want to discuss the process further, please get in touch with Dr Celina Dugulin; Celina dugulin@murphyandson co uk

With a PhD in Brewing Science and Engineering Technology from the University of Nottingham and KU Leuven, Celina has a wealth of experience from Lallemand’s R&D in Montreal focused on the development of a new recipe for production of dried brewing yeast, different fermentation and propagation techniques through to fruit and malt ferments through her work as a quality technician at Bevisol

She currently works at Murphy & Son as a technical projects manager driving forward new innovations in clarification, stabilisation, flavour modifications and product consistency.

Hawkins Farming, situated in Bosbury, Herefordshire, has announced that its outstanding hop variety, Harlequin®, once again secured the prestigious title of the overall Champion Hop at the 2023 Institute of Brewing and Distilling (IBD) British Hop Awards. This achievement marks a consecutive victory for Sarah Hawkins and her dedicated team

The IBD British Hop Awards, renowned as the pinnacle of recognition in the UK hop industry, brought together samples from hop growers across the nation The expert judging panel, consisting of leading brewers, selected Harlequin® as the standout hop, reaffirming its status as a pioneering variety Harlequin® has been developed by Malvern-based hop merchant Charles Faram and Co Ltd

Its Hop Development Program crafts new and exciting hop varieties, with a huge focus on sustainability These hops are then used to flavour your favourite beers Harlequin® was specifically crafted to enable UK growers to compete with the popular "new world" hop varieties from the USA and New Zealand The aim is to give more intense hop flavours and choices for British craft brewers, particularly for beer styles like New England IPAs and India Pale Ales

As part of the celebration, Renegade Brewing hosted the awards ceremony and created a special cask beer with the winning homegrown hop, aptly named 'Harlequin ' Harlequin® is described as moderately bitter and sweet in equal quantities, presenting notes of peach and pineapple with a tropical fruit flavour and a long, clean finish

Adjuncts play an important part in the brewing process and using high-quality adjuncts can help control costs while delivering a great tasting finished product.

Silvery Tweed Cereals supplies premium-quality ingredients to the baking and cereal industries and works with breweries of all sizes to supply adjuncts for the brewing process Managing Director, Robert Gladstone, looks at the different types of adjunct and their benefits to beer production

Part of the brew

Brewing beer, especially craft beer which has become so popular of late, is a perfect balance of science and creativity Brewers are looking to create something unique to stand out in the market, whilst maintaining the highest possible quality and customer satisfaction

Brewing adjuncts are key to beer production as they not only improve head retention, reduce the gluten content of the final beer, and they can manipulate the flavour and aroma of the

brew while adding colour They are also a great way of increasing the alcohol content of a beer

The rise of rye and coating

While we have seen rye becoming increasingly popular as an adjunct, wheat, barley and rice can also be used

To achieve something different in terms of flavour, aroma or colour, the ingredients need to be treated or coated with flavours or colours Cereals coated with malt extract could be a way to help save costs without compromising the malt flavour that remains eternally popular

Adjuncts can be supplied as whole grains, flakes or kibbled grits or cut to the required particle size depending on the brewer's requirements, and the provider ’s capabilities

Adjuncts in action

Much like Silvery Tweed, Vocation is known for its passion for innovation. Vocation came to us as it wanted to use wheat flakes instead of malt in its brewing process These flakes give a better yield as well as giving more body,

"

For further information:

Our grains are steam-cooked and/or toasted before being rolled The end product is a light, consistent cereal flake that is great for a range of different uses We can also adjust the qualities of the flakes, such as thickness, colour, size, and moisture, to fit individual requirements

Working with Vocation, we produced wheat flakes that exactly matched their requirements to match the brewing process that they employ Working with us, they have the benefit of buying directly from a supplier who can tailor a product to their exact requirements , rather than through a third party which may offer limited options

a crisper taste and added opacity to the final beer

Being staged at Liverpool Exhibition Centre from 13th - 14th March 2024, BeerX is back once more

Over the following pages we give exhibitors an opportunity to let brewers, delegates and other visitors to the show, know a little of what they can expect to see and hear on their stands at the show.

Enterprise Tondelli has been working in the beverage industry for more than 45 years We supply complete bottle or can filling lines from 2,000 – 80,000 containers per hour or standalone items

This year at BeerX 2024 we will be showcasing some new developments and also labour saving equipment that form part of the lines

4 packs - Baumer Srl supplies machines that can handle wraparound cartons for 24 and 12 cans in a wraparound carton with corrugated board In addition we can now handle kraft board material to produce an FEC or fully enclosed fridge pack carton This can be 4’s, 6’s, 8’s or 12’s too and means the marketing department or budding entrepreneur has almost no limits! Even in a limited space Machines speeds start at 20 packs per minute and can be up to 65-70 packs per minute

STOP PRESS - new cartonner at 100 cartons per minute Further details to follow

Can filling - Our rotary high precision can fillers can fill from 6,000 to 80,000 cans per hour using flow meters – come and see the technology including widget filling

Labelling - We are also active for can labellers Enterprise label the can empty or post pasteuriser Recent installations include a cost-effective inline labeller for 3,000 empty cans per hour and also a rotary machine at 20,000 cans per hour

The rotary machine has a special empty can pressurisation system so that effective wiping of the can will give perfect application

Pasteurisation - We will also share our tunnel pasteurisation equipment wit very low water consumption and energy saving devices even for very small lines such as 2,000 cans per hour

Enterprise Tondelli’s in-house design department can visit your site, survey the area and then produce a layout showing the equipment included in the line so that the project is future-proofed and sense checked

Join us for an interactive session led by hop experts from Charles Faram and a panel of specially selected brewers. Together, we will walk you through the Charles Faram hop development process, unveiling new and exciting flavours.

After the popularity of our panel interview last year, this sequel session builds on the insights into our Hop Development Programme, showcasing a selection of beers crafted with the desirable hops chosen by you last year Take part in the tasting, ask questions,

and share your thoughts on our up-andcoming varieties. So, join us on this flavourful journey, where your opinion plays a vital role in the next wave of the hop revolution

We’ve been hop suppliers for over 150 years, so we’ve got a lot of hop history Charles Faram Hop Merchants and Factors has one of the largest range of hop varieties available from stock in our temperature-controlled hop storage warehouses in both nitrogen-flushed leaf hops, Type 90 (T90) pellets and Type 45 (T45) pellets

Varieties come from the UK, Belgium,

Czech Republic, France, Germany, Poland, Slovenia, New Zealand and the USA Faram’s provides an artist’s palette of flavours to create every type and style of beer from the traditional varieties to exciting new developmental varieties from Faram’s own breeding and development program Our own varieties include Archer®, Emperor®, Godiva™, Harlequin®, Jester®, Most™, Mystic™, Olicana® and Opus®

We will be using BeerX 2024 to promote how its class-leading fuel-fired and electric steam boilers and portfolio of aftercare solutions can help with a brewery’s or distillery’s decarbonisation strategy and put your company on the road to ‘Net Zero’.

While Fulton will continue to promote the many features and benefits of its Classic and award-winning VSRT vertical steam boilers, the company will also be promoting its range of electric steam boilers at a time when fuel costs continue to soar and efficiency is vital to an organisation’s on-going strategy

Some believe that electric steam boilers are superior to fuel-fired steam boilers in many ways, believing that using electric boilers may be less expensive than using a fuel-fired boiler in the long term, whilst also possibly being more environmentally friendly

Using Fulton’s portfolio of electric steam

boilers as an example, including Compack, Electropack and Europack models, less ancillary equipment is required than a traditional steam boiler, therefore helping to reduce the installation costs that come with a fuel-fired boiler Electric boilers also generally have a smaller footprint and can therefore fit into smaller areas thanks to the way they are constructed and the lack of ancillaries that a fuelfired boiler needs to operate

Additionally, because no flue system nor fuel supply is required, electric steam boilers can sometimes be located closer to the process, which reduces pipe work losses and improves steam system efficiencies

However, this doesn’t mean the end for fuel-fired boilers which, given the correct infrastructure and process requirements, will play a huge role in a company’s decarbonisation strategy

Beyond its product portfolio, the company will also be showcasing the many solutions on offer from its

aftercare division, which can support Fulton’s own installations and those from other boiler manufacturers

As well as offering boiler spares and repair service for all makes and types of heat transfer equipment, Fulton’s aftercare portfolio also includes training, technical boiler house risk assessments, boiler and water treatment service contracts, water treatment training to BG04 and EN12953, steam trap surveys, site mass balance assessments and system design, etc

For further information on Fulton’s heat transfer and aftercare solutions, visit stand 83 at BeerX

The renowned manufacturer of keg washing and filling equipment, Lambrechts, is seeing a strong demand for its equipment from the European craft beer sector, a market estimated to increase by 8% CAGR over the next five years.

To meet that demand Lambrechts is building its smaller ranges of standalone keg washers Nano and Micro, and single-head 60 x kph fillers for stock, as well as the ubiquitous Compact 235 combined washer -filler

Capable of washing /sterilising twentyseven kegs per hour and supplied with the option of an electric steam boiler, the Nano utilising caustic washing offers great value combined with Lambrechts quality The more automated Micro is capable of sterilising thirty kegs per hour Both options offer cost-effective solutions to keg sterilisation, and both

normally supplied with a manual beer filling system at a small extra price

According to Lambrechts spokesperson, Mike Hickman, these dynamic young brewing companies are experiencing exciting growth, and want to move quickly once they press the button, expecting negligible lead times from order to meet a Spring schedule or a local festival

With Lambrechts, whatever the size of the machine, the brewer will have the opportunity to ensure 100% surgical sterility inside the keg, so important with the vast range of beers now produced To meet this demand, Lambrechts must be pro-active, and as all our machines have been ‘’tried and tested’’ from years of refinement in trade it makes sense to have them ready off the shelf, particularly having a global customer sales base in reserve Experience has showed us that as the craft brewer

expands, they will return to Lambrechts trading in their 25 to 35 keg per hour machines, for something with a higher throughput and a higher degree of automation So, an investment in the future by both parties

Konvoy, the newest entrant to the UK’s keg and cask fleet management solutions space, is excited to be at BeerX marking the first anniversary since launching its leading edge IoT (Internet of Things) keg tracking solution (Katch) which enables greater efficiency, effectiveness, quality, circularity and sustainability from producer to venue and back again

Konvoy is this year ’s National Bar Sponsors again, in addition to sponsoring the Keg Session Lager, Brewery Business of the Year and Empowering People awards as part of its continued support of SIBA’s National Independent Beer or Business Awards

The team has been busy in the last year working with brewers across Europe and the USA, picking up their own Startup Packaging Award and Good Design Australia commendations, whilst activating customers fleet assets in Australia, England, Ireland, Scotland and France

Konvoy’s tracking device and Cloudbased technology has been deployed on more than just kegs and casks across brewery operations with tracking devices used within mobile event equipment, along with other up and downstream products in consideration from transportation of yeast, hops, retail roll cages and CO2 shipments Within the

brewing sector, the team is delighted to have begun tracking journey’s with Brewpoint, Titanic Brewery, Salopian Brewing Co , Lost & Grounded, Barney’s Beer, Brasserie du Mont Blanc (to name a few) and a steadily growing number of high-profile brewers, suppliers, wholesalers, cold chain operators and retailers

Christian, the UK & Europe’s founding CEO at Konvoy, and previously Kegstar where he also served as global CEO, is also scheduled to lead a talk on measuring the real impact of lost and idle kegs and casks for a better world He said, “Cask and keg management is a packaging headache for breweries of all sizes, but the impact is bigger than just multiple financial pain points, there is significant carbon impact that is little-measured or understood ”

With Corporate Sustainability Reporting Directive (CSRD) fast upon us and Scope 3 emissions (emissions that are not produced by the company itself and are not the result of activities from assets owned or controlled by them, but by those that it's indirectly responsible for up and down its value chain) making up ~85% of Brewers and ~70% of Hospitality carbon footprints, it is an important topic to tackle and track

The Konvoy team will be offering SIBA members a “BeerX” Katch tracking device exclusive saving of 25% (T&C’s apply) and a limited number of tracking devices on a two year, pay-per-month ownership plan enabling brewers to track their kegs from their desk for less than £1 60 per keg per month

Drop by the Konvoy stand over the

It’s fast approaching that time of year again. Beer X has always been a favourite exhibition of ours, as it gives the whole team a chance to meet and catch up with so many of our customers, existing and new.

Liverpool has turned out to be a great venue, and we look forward to showcasing NDL’s products and capabilities

Whether its kegs, casks and growlers, or brewhouses and tanks, we are here to

help you find the best fit for your business So come and join us for a beer and a chat and lets see if we can offer some solutions to your needs

NDL Keg Europe

LTD offers the most competitive and comprehensive range of stainless steel kegs and casks We offer top chime embossing, paint banding and laser etching, and Micromatic and DSI safety spears with our kegs

NDL’s flexibility means we can offer low minimum order quantities and good discounts on larger orders And a speedy delivery when you need it

NDL Craft offers a great range of brewhouse solutions, from a traditional two-vessel infusion system, to a fully automated four-vessel system with mash conversion vessel, lauter and whirlpool Fermentation tanks are double-skinned with seamless welding and are insulated and rated to 2 bar pressure They can be conical or domed to suit your taste

French & Jupps is thrilled to be exhibiting at SIBA BeerX 2024, and amidst this year's packed agenda, we warmly invite all attendees, delegates, and fellow exhibitors to visit our stand, #72

There, we will be showcasing our latest selection of premium Crystal and Patent Malts, sourced from the finest local barley and meticulously crafted to unlock the full potential of your brewing and beverage product range

We proudly supply numerous awardwinning breweries across the UK and beyond With our expert team on hand to answer your questions, share invaluable knowledge, and guide you through our selection of hand-crafted malts, we would be delighted to help breweries of all sizes find the perfect malts for your unique operation

Here’s a taste of what we will be

showcasing at the French & Jupps stand:

• Discover our diverse range of crystal and patent malts: Crafted with precision for centuries, our diverse range of fine quality malts deliver outstanding sensory results

• Meet our Maltsters: Our knowledgeable team will be on hand to discuss our malt profiles, brewing trends, and everything in between

• Explore our speciality malts in award winning beers: Discover a selection of some of the award-winning beers crafted using our small batch malts, showcasing their incredible versatility and depth of flavour

• Evaluate our Malt Teas: Let our Maltsters guide you through a sensory evaluation of our Spirit Malt Teas, exploring the flavour characteristics of

We warmly invite all attendees to explore our malts and share insights into your brewing projects with our passionate maltsters who will be available to discuss flavour profiles, answer your questions, and help you find the perfect malts for your unique creations

Connect with us online or book an appointment for personalised guidance before BeerX We look forward to meeting you at stand #72 and sharing our malt expertise!

In today's business landscape, prioritising sustainability and curbing carbon emissions is critical across all sectors. With heightened consumer awareness and more stringent regulations, businesses face challenges in implementing changes that reduce their environmental impact.

For the brewing industry, a substantial contributor to carbon dioxide (CO2) emissions is the fermentation process, significantly impacting the carbon footprint of beer production

Recognising the urgency to address these emissions, breweries are increasingly adopting CO2 recovery systems as part of their sustainability initiatives These systems capture CO2 emitted during fermentation, purifying it for reuse in the brewing process This not only reduces atmospheric CO2 emissions but also yields significant cost savings, given the essential role of CO2 in beer production and the wide-ranging fluctuations seen over recent years in CO2 prices and the difficulty at times for breweries to secure supply

SSV Limited is actively engaged in reducing its carbon footprint and has introduced the innovative Hypro CO2

Recovery Unit This system offers notable advantages over others, operating at moderate pressures of 15-18 bar, enabling breweries to leverage existing infrastructure without the need for high-pressure storage vessels The design minimises flashing losses, typically found in higherpressure systems, resulting in enhanced efficiency, cost savings and overall value

The Hypro unit boasts user-friendly operation with an intelligent monitoring system overseeing CO2 quality and managing the recovery process automatically Its versatility can be further amplified by the option of a CO2 distillation column to achieve even higher purities

Notably, the Hypro CO2 Recovery unit eliminates the need to handle CO2 cylinders, enhancing safety and operational convenience in brewery settings Fully automated with PLC and remote access capabilities, it represents a cutting-edge solution for breweries committed to sustainability, operational efficiency, and safe practices

Embracing CO2 recovery technology not only aligns with environmental goals but also delivers tangible benefits for breweries promoting sustainability,

realising cost savings, providing a shortterm ROI, and fostering operational excellence in the long term By investing in innovative solutions like the SSV Limited Hypro CO2 Recovery Unit, breweries can actively contribute to a more sustainable future while reducing their environmental impact

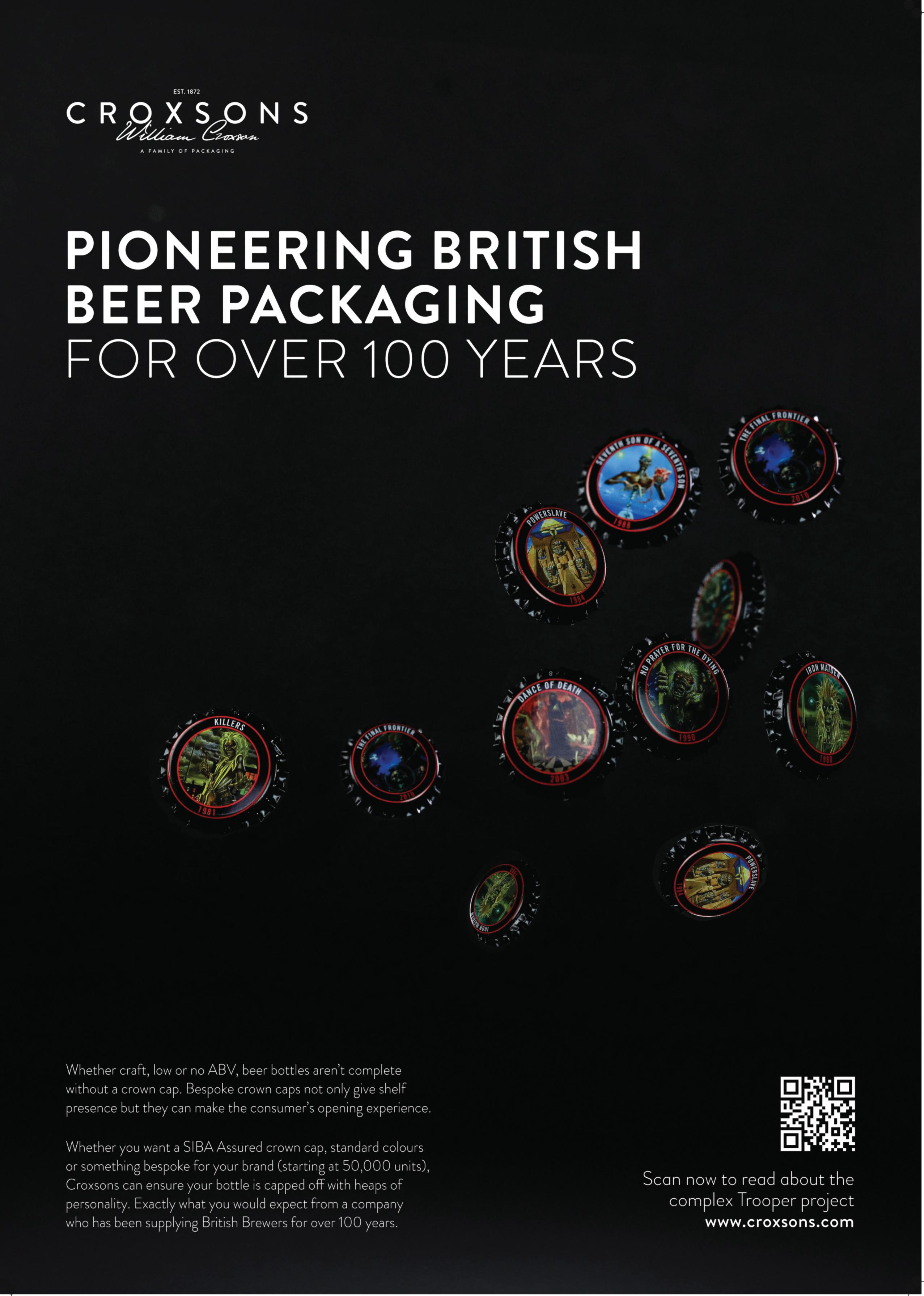

In exhibiting at BeerX once again this year, we're not just bringing a century of expertise in supplying beer bottles and crowns to the industry, we're bringing a legacy.

With over 100 years under our belt, our presence at BeerX has become a tradition, one that we're thrilled to continue

Whether you've been partnering with us for decades or we're yet to embark on a journey together, we're excited to become an integral part of your story this year

The landscape of beer consumption in 2024 is transforming, with a clear tilt towards premiumisation Today's consumers are not just buying a beerthey're seeking an experience, a story in every sip This shift opens up a golden opportunity for breweries to captivate

their audience through smallbatch brews and special runs, turning each drink into an adventure

Our 'Speciality Beer Bottles' range is designed to be the perfect container that carries these unique stories to your customers, ensuring that the first impression is as compelling as the brew itself

Our role as a full-package supplier goes beyond just the bottle We crown your creation with the perfect cap, offering everything from the classic hues to custom designs that speak your brand's language, creating a cohesive and memorable drinking experience for your customers

Join us at BeerX on 13th and 14th March for an inspirational packaging

It’s great to be returning to Liverpool again this year and we are looking forward to seeing customers old and new on Stand 135

We’re celebrating our 14th year of showcasing our Cask Force cleaning systems With almost two decades of experience in providing originally caskwashers and then keg washers to the market you can be assured of the right level of service whatever your requirements

As a family-run business our ethos has always been to provide our customers with the best solutions to meet their cleaning needs as cost effectively as possible

Our range of cask and keg washers is designed and built to order from our manufacturing facility at Acle in Norfolk Our systems are rugged yet simple to operate The Cask Force machines accelerate the cleaning process, thus saving money, labour and time Using state-of-the-art manufacturing processes, we pride ourselves on providing our clients with the

best quality components and through innovation we are continuing to update and invest in the range helping us to maintain our position as one of the leading manufacturers in this sector

Cask Force has a great heritage It is a wholly-owned subsidiary of Hugh Crane (Cleaning Equipment) Ltd who have been manufacturing specialist cleaning equipment systems across a range of industries for over 40 years and our machines are recommended by breweries everywhere.

thoroughly clean returned casks and kegs

What makes Cask Force the cleaning system of choice?

• Simple to Operate and Maintain Casks/kegs are placed once, without the need of additional lifting

• Saves Time

Fully automated washing process

• Saves Water

Recycled water from the process is cleverly reused minimising usage costs and the environmental impact

• Reduced Problems

Eradicates the expensive issue of contaminated casks/kegs

• Reduces Bottlenecks

Quickly restores the supply of clean units to circulation

The cleaning process is simple and clients have seen massive savings in manual labour and time taken to

Lallemand Brewing, a global leader in yeast and fermentation products, has recently launched three new innovative products for brewers: AB Vickers’ ISY Enhance, LalBrew NovaLager™ and LalBrew Lona™.

LalBrew NovaLager™ is a novel hybrid lager yeast strain that combines the genetic background of an ale yeast with that of a lager yeast It can ferment at higher temperatures, with lower pitch rates and faster fermentation times than traditional lagers, while producing low levels of diacetyl and no H2S.

AB Vickers ISY Enhance is an inactivated specific yeast autolysate that can improve the body, mouthfeel and drinkability of any beer style It

can also reduce harsh flavours and astringency, and increase the flavour perception of lighter beersincluding low-alcohol and non-alcoholic beers

Remaining on the theme of low alcohol beers, LalBrew Lona™ is a another novel hybrid The strain has been bred to remove its ability to ferment maltose and maltotriose leading to naturally lower attenuation In addition, this strain produces no H2S and exhibits good aldehyde reduction during fermentation

The machines also provide other financial benefits They save water, as the recycled water from the cleaning process is cleverly reused for pre-rinsing minimising usage costs and the environmental impact It also significantly reduces the likelihood of not cleaning effectively, potentially spoiling batches. This improves the customer experience knowing that products are going to arrive with the client in first class condition

If you are looking to make an investment in our range please visit Tim and Chris at BeerX on Stand 135 on March 13-14th We look forward to seeing you there

while saving time, energy

With these three new products, Lallemand Brewing aims to provide brewers with more tools and solutions to create unique and high-quality

At OPM we love being part of the brewing community and supporting the brewers that make it happen.

Labels are an essential marketing and selling component giving your brand a story, communicating the essence of the product and helping to create brand loyalty We offer keg labels, can labels, bottle labels – OPM’s diverse capabilities give you the flexibility to produce the shape, size, look, personalised and decorative finish to create a ‘show stopping’ label Printed Digitally or Flexo, Long or Short runfrom glow in the dark skulls and holographic horses to peel-able glasses

View the

& moustache labels; we are always eager to work with our clients on exciting (and often the unusual) projects

If you would like our assistance designing or producing your next runs, please feel free to give us a call We have an in-house beer-label specialist who would be happy to help you!

Contact the OPM Team today – Who will be at BEER X Liverpool 2024 come and meet the team at STAND 100

For further information:

www.opmgroup.co.uk

Tel: 0113 2311000

polymer

After years of designing and testing, i-Keg will unveil its patent-pending line of polymer Kegs, Casks and IOT spear at this years’ trade show.

Each Keg and Cask in our range is not only individually numbered for absolute traceability, but also comes equipped with optional state-of-the-art global tracking with i-spear

The i-Keg patented design combined with our unique manufacturing approach, ensures that our kegs and casks outlast the industry’s standard life expectancy, provide unparalleled data analytics whilst delivering consistent performance, even in challenging operating conditions

i-Keg is focussed on delivering widespread benefits for the environment As a sustainable product, the plastics used in the kegs and casks can be recovered by mechanical recycling and is 100% recyclable The outer shells of our kegs are manufactured to be fully recyclable, meaning old shells can be recycled to form new shells or as recycled material within another manufacturing process Our patent pending i-Spear, software and cloud platform has been built from the ground up by i-Keg to deliver the

industry’s first data analytics in near real-time Secure, unobtrusive, no-welding or screw fixings, the i-Spear has been designed to replace your current steel fleet existing spears

Daily or hourly, the i-Spear captures and reports critical data of ACTUAL beer consumption down to the millilitre, location, temperature and journey without any human intervention such as barcodes, RFID systems etc. with their inherent problems.

AWS hosted secure cloud infrastructure ensures global accessibility and security with full suite of data analytics at your fingertips!

This will improve distribution, vastly reduce grey trading, open up marketing opportunities and can help streamline purchasing throughout your entire organisation

In today’s modern world, beverage manufacturers are dedicated to ensuring their beverage arrives in the consumers glass in premium condition Our i-Keg and i-Spear will allow beverage manufacturers to monitor the full journey and improve services to meet the consumers high expectations

For further information:

Brewing Services Ltd has worked with over 250 breweries in the UK and abroad, offering training, advice and technical support

Our mission is to help establish breweries with a complete commitment to quality, promote excellence throughout the brewing process, assist brewers in producing beers of the highest possible standard and train brewers to achieve their full potential.

At Brewing Services, we believe that good technique, consistency and efficiency are the foundations of great beer Through a combination of on-site surveys and remote technical support, we provide a service tailored to your needs, looking at your brewing process and procedures, from raw materials to the quality of the beer on the bar, along with microbiological checks, analytical testing of products and hygiene monitoring

Providing on-site training, exam mentoring and brewing courses, Brewing Services has helped increase the knowledge of hundreds of brewers ‘Brewing: The Fundamentals’, a four-day residential training course held in March and November each year, covers the basics of brewing theory and good brewing practice through a combination of lectures, workshops and visits, with participants gaining greater insight into the art, science and craft of brewing

We aim to help you make a better beer before you’ve even brewed your first pint Our Start-Up Consultancy service covers initial feasibility studies, through site and equipment planning, to training, recipe development and commissioning We provide full support over those first critical brews

The team at Drinks Packaging Ltd / Beer Box Shop is celebrating the company’s 10th anniversary and looking forward to a 10th BeerX this year

It’s amazing to think that we’ve now been supplying specialist packaging to all sectors of the U K ’s beer industry for over 10 years and it feels like we’re just getting started

It’s the most collaborative and creative industry and we love working with our brewery partners, whether we’re helping them with bespoke packaging projects, or we’re supplying next day orders from our in-stock range

We’ve been continually investing in the Beer Box Shop range, launching more new products than ever, and holding more stock to guarantee availability We’ve expanded our can gift box range, launched a full range of 250ml slim can gift and shipping boxes, and increased the number of can and bottle shipping box options We’ll be displaying some of our favourite printed boxes at this year ’s show, together with some of the exciting new design concepts we’ve been working on

Our DPL services have proven extremely popular; this part of our business continues to focus on high volume, high-quality, low-cost packaging solutions which range from auto-pack retail packaging, bottle trays and trade boxes to bespoke shelf ready packaging and gift boxes, all supported by free of charge bulk storage with a next delivery service

We’re really excited about the new products and services we’ve launched in 2024:

By consolidating orders, we were able to launch a full colour bespoke advent style box last year with a very low MOQ for each brewery We’ll be running this project again and extending this service for gifting throughout 2024 Come along to our stand at BeerX to see the can advent boxes we produced in 2023 and discuss your plans for 2024

Fulfilment services

We’ve recently launched an end-toend home fulfilment service for our brewery partners We can store, pick, pack and deliver our partner ’s online beer orders to their customers’

We can now produce full colour labels in-house, with multiple specification options including polypropylene labels for canning and bottling, or paperbased labels which are perfect for gift and shipping boxes

If you’re attending this year ’s event then please come over to see us on stand 144, it would be great to talk about your packaging requirements

Leading glass packaging manufacturer Beatson Clark will be attending this year ’s BeerX event at the Liverpool Exhibition Centre in March

Beatson Clark has 270 years of experience in the glass packaging industry and will be showcasing its range of beer bottles at the 2024 BeerX trade show in Liverpool

Beatson Clark offers standard beer bottles, customised bottles and completely bespoke designs This flexible approach allows the company to cater to a wide range of breweries, from smaller craft brands wanting standard bottles available from stock, to larger companies looking for fully bespoke bottles from 500,000 units

Thanks to its years of experience and flexible approach, the company is a popular choice for many beer brands such as BrewDog, Robinsons and Greene King

Charlotte Pike, Marketing Manager at Beatson Clark, said: “As silver sponsors of SIBA we have been attending BeerX for a number of years and we are really looking forward to this year ’s event It’s a great way for us to make new connections in the industry and stay versed in upcoming industry trends ” Beatson Clark’s amber bottles are widely used by its customers in the brewing industry as they offer over 90% protection from UV rays The company will be exhibiting both its standard range of amber bottles at BeerX and its latest bespoke and customised containers

“Our standard amber bottles are very popular, and for a small extra cost we can customise these the reflect the brewery’s branding,” continues Charlotte

Pike “We offer embossing options on our standard bottles, perfect for ordering in smaller volumes, as well as more tailored services including bespoke bottle design, decoration and crowns If you’re interested in finding out more, please come and see us at BeerX!”

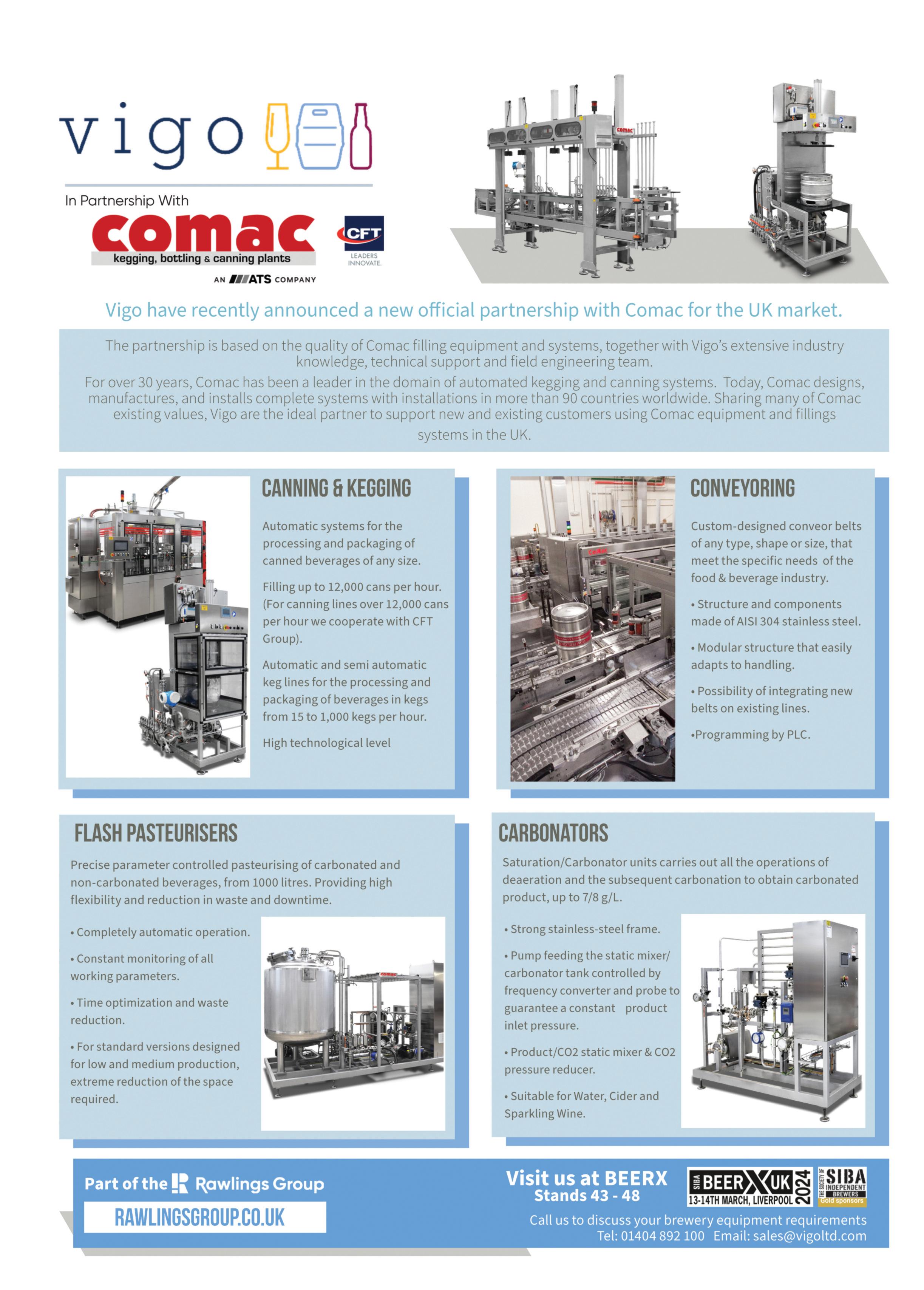

Vigo has recently announced a new official partnership with Comac for the UK market

The partnership is based on the quality of Comac filling equipment and systems, together with Vigo’s extensive industry knowledge, technical support and field engineering team.

For over 30 years, Comac has been a leader in the domain of automated kegging and canning systems. Today, Comac designs, manufactures, and installs complete systems with installations in more than 90 countries worldwide Sharing many of Comac existing values, Vigo is the ideal partner to support new and existing customers using Comac equipment and fillings systems in the UK Canning & Kegging

• Automatic systems for the processing and packaging of canned beverages of any size

• Filling up to 12,000 cans per hour (For canning lines over 12,000 cans per hour we cooperate with CFT Group)

• Automatic and semi automatic keg lines for the processing and packaging of beverages in kegs from 15 to 1,000 kegs per hour

• High technological level

• Custom-designed conveyor belts of any type, shape or size, that meet the specific needs of the food & beverage industry

• Structure and components made of AISI 304 stainless steel

• Modular structure that easily adapts to handling.

• Possibility of integrating new belts on existing lines.

• Programming by PLC.

Precise parameter controlled pasteurising of carbonated and noncarbonated beverages, from 1000 litres Providing high flexibility and reduction in waste and downtime

• Completely automatic operation

• Constant monitoring of all working parameters

• Time optimisation and waste reduction

• For standard versions designed for low and medium production, extreme reduction of the space required.

Saturation/Carbonator units carries out all the operations of deaeration and the subsequent carbonation to obtain carbonated product, up to 7/8 g/L

• Strong stainless-steel frame

• Pump feeding the static mixer/carbonator tank controlled by frequency converter and probe to guarantee a constant product inlet pressure

• Product/CO2 static mixer & CO2 pressure reducer

• Suitable for Water, Cider and Sparkling Wine.

Visit us at BEERX

Stands 43 - 48

When I picture non-alcoholic beer, my mind goes back to a simpler time of Shandy Bass sold at the local newsagents.

It is a product that slowly disappeared from the shelves, replaced by highly caffeinated and oversized canned drinks But as the next generation of health-conscious drinkers arises, the concept is making a comeback

Now, I see increasingly low or no-alcohol brands popping up the shelves. With things like Lucky Saint now included in top supermarket lunchtime deals, it is time for traditional brewers to join the revolution

The challenge of creating a beer like this calls for new skills With little hops or malt to cover the flaws, the brewer must push the formula of a session beer even further Finding a way to combine the aroma, body, and colour,

all while keeping carbs low for the diet conscious Add to that the expense of mashing at an elevated temperature, the strength of your brand is more important than ever to ensure you make an impact in the market

We see continued demand for canning machines to service the direct-to-consumer market as well as the pub market for landlords unsure of sales volume We have also seen people investing in display fridges and alternative size kegs to generate more traction and awareness With different methods of brewing, including the dilution method to increase the usage of one batch, it can be a real income generator But the need for product awareness coupled with increased availability has seen many reach out for cashflow support.

More tap rooms continue to open, with in-house or container catering to

boost visitor rates in a stark contrast to the reducing pub market Cashflow for these projects also remains crucial, whether the hero product is a low/no-alcohol alternative or not Alongside these products, we work closely with the brewing industry to also support green cost saving initiatives like carbon capture and solar Partnered with the health conscious, the ever-important green energy projects help both the environment and your bank balance

We are keen to support brewers in growing, developing, and widening the reach to health, sustainability and beyond

Happy to answer all your questions on the stand will be Adrian Corke, Managing Director, ably assisted this year by Lorna Prime, our Office Administrator.

We are at the show to promote our fantastic facilities and expertise in the field of contact packaging

We have been bottling beer for ourselves since 2002, bottling beer for others since 2011

Staffordshire Brewing and Packaging Supplies has been offering contract packaging services for over 10 years We are SALSA accredited and pride ourselves on the standard and yield of the customers finished product

on these smaller amounts

We specialise in packaging both short and big runs from 800ltrs upwards and the system we have developed over the years has enabled us to maintain a high yield percentage even

Come along and see us on stand 161 to what we can do for your business

For further information:

www staffordshirebrewery co uk

Manufacturing the largest range of returnable containers of any global keg producer, Schäfer will be exhibiting at BeerX.

As well as the standard stainless steel 50, 30 and 20 litre kegs produced with Europeanproduced material, Schäfer has also pioneered designs of lighter weight kegs and improved branding recognition

The returnable ECOKEG will reduce the average weight of the empty keg by 2 5 kg on a 30-litre size and 3 4 kg on a 50 -litre size keg Utilising comfortable to handle, customer-designated coloured polypropylene hoops, when combined with silk screening they offer an attractive contemporary solution to bulk beer packaging.

The well-known PLUS keg, like the ECOKEG, is fully stackable and reduces noise in the kegging hall and during offloading by 70 % Also available in slimline designs, both the ECOKEG and PLUS help to promote your quality brands We will also be displaying Schafer ’s new two-chamber 10-litre draft2go beer system, not requiring power to dispense or to keep cool while pouring, whilst at the same time offering

Water plays a pivotal role in the art and science of brewing beer, acting as a fundamental ingredient that significantly influences the taste, aroma, and overall quality of the final product

Water is not merely a neutral solvent but a complex matrix with a unique composition of minerals, ions, and other elements Each source of water brings its own distinctive characteristics, imparting subtle nuances that can elevate or detract from the desired flavour profile of a brew

Regular analysis of water is crucial for brewers to maintain consistency in their beer production The mineral content, pH levels, and other water attributes can vary, even from the same source over time

By closely monitoring these factors, brewers can adjust and fine-tune the water composition to match the specific requirements of different beer styles

Consistency in water quality ensures that the brewing process remains predictable, allowing brewers to reproduce the desired flavour and characteristics batch after batch This

pub quality beer without the need for pythons, coolers and Co2 cylinders

The system is ideal for small volume outlets, while creating for the discerning home craft beer drinker the real pub experience. Distributed from tap rooms, draft2go offers your customer ’s sample room quality beer at home The 10-litre keg using a deposit scheme is ideal for this summer ’s Euros Unlike other systems the draft2go is 100% reusable and will have a life of twenty plus years So go green go draft2go

Both Mike Hickman and Divisional Director Edward Ros will be attending the show

meticulous attention to water analysis is integral to delivering a consistent and exceptional taste experience for beer enthusiasts, fostering brand loyalty and reputation in the competitive world of craft brewing

Visit our technical support team on the Murphy & Son stand 65-67 at BeerX for more details and for any brewing queries, plus take advantage of our event exclusive free water sample analysis

Britain’s oldest brewer has improved its sustainability credentials by switching to a pallet wrap film with 30% recycled content

The brewery runs 300 pubs across London and the South East and has a 400-year heritage Having already made its product packaging more sustainable, the company wanted to find a pallet stretch film with recycled content and turned to Lindum Packaging for help

Previous attempts to resolve the issue resulted in using films that would snap when used on high-speed wrapping machines This in turn stopped the pallet wrapper from working and was causing issues with line downtime and production inefficiencies

Lindum’s solution was recycled packaging in the form of its highperformance Carestretch 30% Recycled Nano film In addition to the use of 30% recycled content, less total film weight per pallet was used. This

Smurfit Kappa has released its 2024 market research report

The Report offers a comprehensive exploration into the latest needto-know industry insights, emerging trends, evolving consumer behaviours and future trajectories that are shaping the packaging landscape

A copy of the Report can be downloaded at www.smurfitkappa.com/uk/ newsroom/blog/insights-report-2024

meant it was a cost-neutral project which made it a win–win for the brewery

Rick Sellars, Sales Manager at Lindum, said: “All manufacturers and producers want stable pallets and secure goods during transport, so it’s important that the correct type and amount of pallet wrap is used

“There’s also an increasing demand for sustainable plastic packaging –including pallet wrap with recycled content – and this is where our Carestretch range can provide real sustainable packaging solutions. The properties of our pre-stretched Carestretch film meant that not only is performance excellent, but less is needed for each pallet wrapped We are very happy to raise a glass to the company’s success!”

Lindum is a leading UK expert on pallet stability and stretch film wrap

The company is based in Stallingborough near Grimsby and provides a wide range of pallet stability testing, sustainable packaging products and consultancy

lindumpackaging.com For

Manchester-based manufacturer, Lemur Labels Ltd, has supplied labels to a new joint project between Cumbria-based Fell Brewery and Michelin-starred chef Simon Rogan

Rogan’s Our Farm has teamed up with Fell to create a range of locally made craft beers, using produce grown on the farm and ingredients foraged from areas surrounding the Lake District village of Cartmel

Four brews will be released, one each season Woodruff Stout - with earthy sweet notes from the farm’s woodruff leaves - debuted first, with Spring, Summer and Autumn brews making use of seasonal ingredients, bringing a taste of the Cartmel countryside to every can

Fell is a brewery based in South Cumbria, producing craft beer that is deeply rooted in its surroundings Its founder Tim Bloomer grew up locally and recalls tales of hearing about a “mysterious chef from Southampton” who was moving to Cartmel

Simon Rogan has since gone on to shape Cartmel into the gastronomical hotspot we know now Simon’s collaboration with Fell Brewery reflects their mutual appreciation for the bounty and bonds of the local area, exploring its seasonal quirks and celebrating the people that work on its land

The beers will be available through Home by Simon Rogan and Simon Rogan’s Lake District restaurants, as well as for purchase through Fell bars in Cumbria and their e-retail site

Bradford-based brewery equipment specialist, Collective Motion Brewing, is raising a glass to a record year of business with turnover up by 60% in 2023.

The company, which supplies and services a wide range of production systems, has also seen revenue rise by 60%, largely through growing demand from independent brewers looking to improve energy efficiency, minimise waste and reduce running costs

Sales have increased across Collective Motion Brewing’s range of products, which includes newly developed and upgraded systems alongside refurbished machinery.

Dominic Smith, director at Collective Motion Brewing, said: “2023 was the year when our business really took off We have become a very wellestablished name in the industry, and we have developed relationships with new clients throughout the UK

“Many brewing, distilling, and cider making companies have purchased products from Collective Motion Brewing and then signed up for our planned maintenance package to ensure that their facilities are free of downtime and remain optimised for efficiency and quality control ”

Tomasz Lenartowicz (pictured above), director at Collective Motion Brewing, said: “The brewing industry, like many

other manufacturing sectors, has been challenged in recent years by rising energy prices, but many brewers have been proactive in finding ways to mitigate those costs

“They have recognised that investing in enhanced efficiencies will deliver substantial long-term savings A number of our clients have estimated that the equipment upgrades we implemented will achieve between £50,000 and £100,0000 in savings per year in running costs ”

Collective Motion Brewing plans to build on its success with increased investment in R&D in 2024 Its 1,300 sq ft premises in Bradford includes a workshop and R&D centre to trial new solutions in keg washing and filling Dominic Smith said: “Innovation is a

big part of what Collective Motion Brewing offers as a company I have a mechanical engineering background and Tomasz has a background in electrical engineering as a lead designer of control systems We apply that experience to design and test new concepts in brewing equipment

“We will be launching some new costeffective systems in 2024 which are designed to help smaller breweries to manage their operating costs and help to take a first step towards automation in their production facility This is important to minimise the cost of production and stay above the red line or simply to increase the profit margin ”

https://cmbrewery.co.uk/

Krones has completed an agreement regarding the acquisition of 100% of Netstal Maschinen AG (Netstal) from KraussMaffei

Based in Naefels, Switzerland, Netstal is a leading supplier of injection moulding machines to the beverage market (PET preforms and caps). The company is a technological leader in its markets and has already been a strategic partner of Krones in the past

In the 2023 fiscal year, Netstal generated with a workforce of more than 500 employees revenue of more

than EUR 200 million The profitability of the company is currently below the Krones Group level but is expected to close this gap over the coming years

Netstal will be reported as part of the segment Filling and Packaging Technology Krones finances the purchase with existing liquid funds, but also may take advantage of partial debt financing

The acquisition of Netstal is benefitting Krones on various dimensions Netstal’s PET and Cap businesses complement Krones’ product portfolio for the beverage

market With respect to PET closedloop solutions Krones then covers all technologies required from injection molding to PET container production through to filling/packaging and recycling Netstal will retain its business responsibility within Krones, while benefitting from the international set-up and scale of Krones

With the acquisition of Netstal, Krones continues to successfully implement its M&A strategy

When Wye Valley Brewery in Bromyard, Herefordshire started planning its new packaging hall with Enterprise Tondelli, it was important to maximise the flexibility of the hall to allow both bottling and canning. Both lines were combined and supplied and installed by Enterprise Tondelli

The all stainless steel empty can depalletiser from Enterprise Tondelli has automatic layer card removal and a very compact footprint, not much

inverted, pass through an air drying tunnel with directionable nozzles and punt drying prior to coding After drop twist the cans feed to the Baumer packer This incredibly flexible machine packs cans into fully enclosed kraft board fridge packs in fours/sixes, or it can pack 12 cans into a kraft board wrapround carton This machine also packs the bottles into corrugated wrapround cartons Small packs need to be consolidated for palletising so a second Baumer packer was installed alongside the

bigger than an empty can pallet

Cans are fed at high level to a twin lane gravity can cleaner that uses de-ionised filtered compressed air to remove any foreign bodies The use of de-ionised air means no water consumption which can be as much as a thousand litres per hour on conventional rinser thus reducing impact on the environment

Cans can be either pre-printed or for some smaller runs they are labelled on an empty labeller supplied by Enterprise Tondelli As cans are filled at 2-4 degrees C the cans are prelabelled before filling to ensure good adhesion by the self-adhesive labels to a clean and dry surface, with no bubbles or wrinkling or slippage

A rotary counter pressure can filler/seamer was installed Cans are flushed with CO2 from a separate gas ring before sealing and multiple times after sealing against the filling valve. The filler is fully enclosed with hepa filtration and laminar flow of air for hygiene.

After level inspection, cans are

first, allowing one operator to watch both Baumer machines The second machine has a continuous motion 90 degree infeed turner for laning and then automatically loading into a filmfree high-sided tray for palletising

Some products running on the line include 330 ml Fandango This humdinger of a hoppy brew is full of tropical flavours and light, citrusy crowd-pleasing undertones that will have craft-beer fans dancing with delight! Also 1985, a deliciously refreshing premium lager that boasts a moreish malty base, flecked with delicate floral notes

Enterprise Tondelli has been working in the industry since 1977 and supplying equipment in over 40 countries The Wye Valley Brewery canning project is just one of the latest projects by Enterprise, which supplies canning lines from 1,500 to 72,000 cans per hour, bottling from 600 to 60,000 bph and kegging lines too

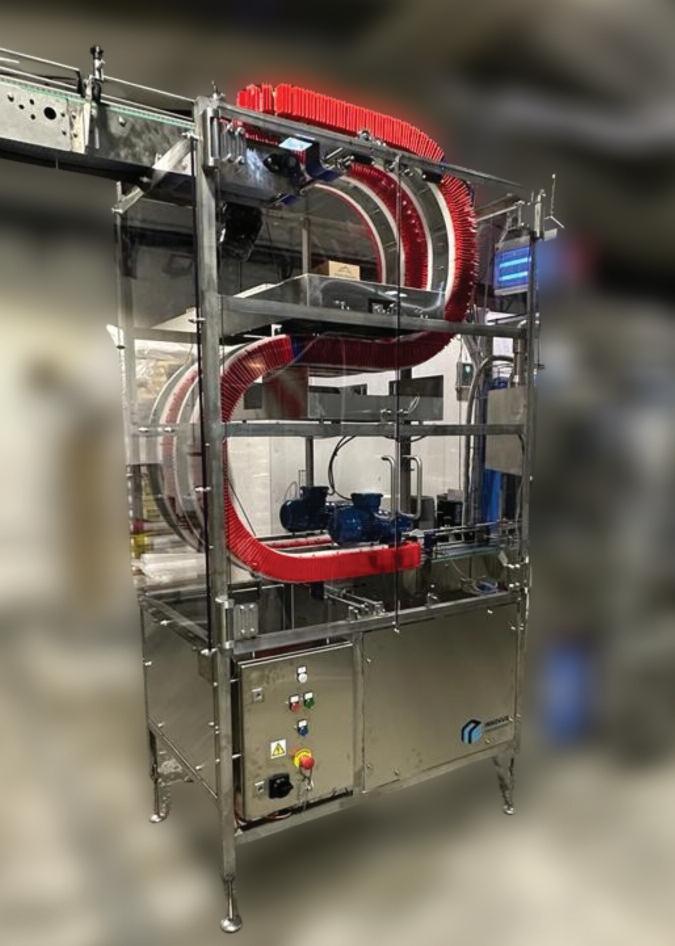

In January, Innovus Engineering delivered the first of its newly developed LWR-F lowerator machines.

A lowerator is an adaptable and cost-effective alternative to using a can twist to move cans from a depalletiser to the canning machine

The key advantage is that swapping between standard, slim and sleek cans takes just seconds, with no tools required, a task that would otherwise involve swapping out expensive and fragile can twists – a complex and time-consuming task, especially when production pressure is on!

The LWR-F features inverter driven motors for adjustable speed control, and incorporates a can rinse, drip tray and drain hose to further increase automation of the line