Grégoire

Rossier l Anthony Marquié l Kox l Ash Lambe

Grégoire

Rossier l Anthony Marquié l Kox l Ash Lambe

© 2025, Watchprint.com Sàrl., Martigny, Switzerland

All rights reserved. No part of this publication may be reproduced in any manner whatsoever.

The texts in this book are independent of Omega SA. The watch models are illustrated for identification purposes only.

ISBN 978-2-940506-65-1

Publishing Managers: Fabrice Mugnier and Suzanne Wettstein

English Translation and Proofreading: Susan Jacquet, Transcribe

Photographs: Luca Garbati and Michael Repetto

Printing: Daneels Graphic Group, Belgium

See our watch and jewelry-related publications on our website, www.watchprint.com

SEAMASTER...the master of the sea. An evocative name referring to Poseidon (or Neptune in Roman), god of the seas and horses in Greek mythology. This was the name chosen by OMEGA in 1948 for its water-resistant models and from 1957 onwards for its full-fledged dive watches. It is thus hardly surprising that the Seamaster’s emblem is a seahorse (whose scientific name is hippocampus), a legendary figure pulling Poseidon’s chariot.

Another direct link between mythology and the Seamaster is Cronos, the titan of time and none other than Poseidon’s father.

Seamaster is one of four names chosen by OMEGA for its professional models:

• Seamaster for dive watches,

• Speedmaster for chronograph watches,

• Railmaster for anti-magnetic watches,

• Flightmaster, a name first used in the late 1950s on Railmasters for the Peruvian Air Force, then for a specific model for pilots and keen travelers in the late 1960s.

While some animals stay in one place for most of their lives, humankind has always been driven by a natural instinct to explore: first to find food, then in a spirit of conquest – and more recently for professional and leisure purposes. Technological developments have also made it possible to explore unknown territories, whether on land, in the air or in space – and even in the depths of the ocean. It is precisely these three domains –land, air and sea – that have inspired most of the major watch brands to design watches adapted to each of these environments. Space aside, the liquid element remains by far the most unexplored territory, covering 71% of the globe’s surface and extending into a third dimension, down to 10,935 meters at its deepest point. With the exception of specialized vehicles for extreme diving (submarines, bathyscaphes), humans can only reach depths of a few hundred meters on their own. In practice, most divers oper-

ate between 30 and 40 meters, while professionals can go slightly lower.

It was precisely to withstand these depths that the watch industry set out to design suitable models: first simple water-resistant watches and then genuine dive watches, capable of withstanding the increasing pressure of around one bar for every ten meters of depth, in addition to the surface bar. By the 1950s, dive watches were typically capable of withstanding a depth of 100 meters and sometimes 200, like the Seamaster 300 model. Such technical characteristics were therefore sufficient to meet any diver’s needs. What really made the difference at the time was the model’s robustness (shock resistance) and maintenance (replacement of gaskets, wearing parts, etc.). Over time, major innovations were introduced, such as the screw-down crown, chronograph pushers that could be handled underwater, the use of pressure itself to reinforce water resistance, as well as the introduction of new materials.

Today, the watchmaking world has reached a new milestone with the OMEGA Seamaster Ultra Deep: capable of withstanding a depth of at least 6,000 meters, this commercial model is reasonably sized for its capabilities. It is inspired by a prototype developed for Victor Vescovo’s Five Deeps expedition and attached to an articulated arm designed to reach the deepest point on the planet, the Mariana Trench.

Gianni Agnelli was instrumental in popularizing the Seamaster Ploprof among the general public, as it appeared on his wrist on numerous occasions He usually wore his Ploprof on a strap in robust Isofrane rubber that he placed directly over his shirt sleeve In the right-hand photo taken in 1983, we see him talking with Marco Piccinini, then sporting director of the Formula 1 Scuderia Ferrari racing team

This legendary collection has naturally won over the most seasoned and renowned divers and adventurers, such as Captain JacquesYves Cousteau and Calypso crew members, who used Seamaster 600 “Ploprof” and Seamaster 1000, as well as the ultra-specialized divers of COMEX (Compagnie Maritime d’Expertises), a pioneering company in underwater engineering.

The Seamaster has also established itself as an essential tool for certain armed forces and continues to be so for some special units. It has delighted both professional and amateur divers, as well as non-divers who are simply fans of the model and can use their Seamaster in complete confidence for swimming.

Other celebrities to have adopted the Seamaster include Marlon Brando, who wore

a first-generation Seamaster 300 during the filming of Bedtime Story in 1964. In the 1970s, Giovanni “Gianni” Agnelli, the emblematic boss of the FIAT group, helped popularize the Ploprof among a non-diver public.

More recently, the Seamaster Diver 300M has been worn by Jon Hamm and Joe Biden. While Tom Hanks naturally wore a Speedmaster Moonwatch when he played astronaut Jim Lovell in the film Apollo 13, the actor is also a well-known Seamaster enthusiast, whether the Planet Ocean or the 300 Heritage model. In addition to all these celebrities, there are many others who are linked to OMEGA through commercial collaborations.

Written in collaboration with OMEGA’s Heritage Department

Ever since the invention of wearable timepieces, starting with 16th century pocket watches and the much later invention of wristwatch models, watchmakers have had to contend with the problem of permeability to natural elements.

While we now naturally associate this concept with water and humidity, this was not the main concern in bygone years.

Watchmakers back in the day had few concerns about the liquid element, as early timepieces were highly unlikely to be exposed to moisture. In the event of inclement weather, watches remained mostly sheltered in the pocket of waistcoats generally worn by men at the time. The question of bathing, for its part, only arose much later.

What then were the most problematic natural elements for watchmakers before the 20th century? The real enemy was an omnipresent, invisible yet formidable element: dust.

Capable of covering any surface and seeping into the smallest interstice, dust inevitably affected even the most hermetically sealed watches. This phenomenon is still a reality today for many technical objects.

Tiny dust particles easily infiltrated the watches and clocks of the time, accumulating in nooks and crannies and on oil-lubricated movement components. As this dust

accumulated, it slowed down the movement, leading to a gradual loss of precision, or even complete stoppage of the watch.

It is thus hardly surprising that watchmakers lavished great attention on designing systems to improve cases’ dust-tightness. As well as working on the structure of the case itself, the main challenge was to avoid any unnecessary opening, particularly for time-setting operations, notably any involving manually moving the hands or opening the back of the case to make adjustments using a screw. With this in mind, the development of systems for winding and setting the time by means of an external crown was a decisive step forward in protecting internal components.

Another point where watches were vulnerable to dust related to fastening a watch glass in place, traditionally secured by simply pressing it onto the case.

To remedy this, several systems were explored with a view to ensuring a tighter fit.

By way of example, some pocket watches were fitted with perfectly adjusted, locked caps and inner covers on the movement’s most exposed areas.

These innovations underscored the importance of optimal mechanical water resistance and paved the way for the first attempts to use screw-in rather than press-fitted glasses and casebacks, marking a decisive step towards better-protected watches.

In the early 20th century, a growing number of watch companies began to attach particular importance to dustproofing their watches by means of new advances in the field. This coincided with the real debut of the wristwatch, which had become – at least for some people – an everyday object exposed to the hazards implied by all kinds of situations that by then included contact with water during accidental dips or deliberate swimming. An

essential question then arose: could a watch designed to resist dust also offer protection against water?

Although the answer is not that simple in that water resistance implies additional mechanical challenges, more and more timepieces seemed to be capable of achieving a certain degree of water resistance, albeit with varying degrees of effectiveness.

Among the most famous examples are the Waltham Depollier wristwatches. As early as 1915, Charles Depollier began ambitious

research to create a truly water-resistant case. The result unveiled in 1918 was the Waltham-Depollier Field & Marine: a military model considered the first truly dustand water-resistant watch. The following year, a more luxurious version in solid silver or gold was produced: the Thermo. These watches incorporated notable technical innovations, including a screw-down crown and a three-element caseback, thereby guaranteeing total air-and-water- tightness.

Advert from circa 1919/1920 for the Depollier Thermo, a watch resistant to heat, cold, water and dust, promoted as an aviator’s watch

1919 advert celebrating the altitude record of 34,610 feet (10,549 meters) set by pilot Roland Rohlfs, equipped with a Depollier Fields and Marine watch The ad highlights the watch’s remarkable resistance to extreme temperature variations as far down as -44°C, thanks to a caseback-integrated thermoregulating asbestos disk

The U.S. Army was in contact with Depollier and ordered 10,000 of these timepieces for its soldiers involved in trench warfare towards the end of World War I. These hermetically sealed watches were perfect for the temperature and humidity conditions in Northern Europe.

It is interesting to note that the Field & Marine distinguished itself in the air by participating in two world altitude records set by pilots Roland Rohlfs (34,610 feet/10,549 meters) and Rudolph William Schroeder (36,130 feet/11,012 meters) in 1919 and 1920 respectively.

Most of the first dive watches were designed for military use. Although diving was long perceived by the general public as a dangerous activity useful solely for military purposes, it is in fact an ancient practice that began long before the advent of modern equipment. Freedivers taking considerable risks – such as sponge fishermen in the Mediterranean or pearl harvesters in Japan, the Persian Gulf or

the Gulf of Mexico – were involved in diving long before it became a mainstream activity. OMEGA developed its first diver’s watch in the early 1930s. The aptly named “Marine” was distinguished by its innovative design featuring a double case in which the outer part slid to protect the inner case housing the movement, dial and hands, guaranteeing optimum water resistance. Introduced in 1932, the Marine was considered the first genuine

civilian dive watch, accessible to a wide audience.

The latter point is worth emphasizing, as it embodies one of OMEGA’s most important promises: to offer watches of exceptional quality, not only to professionals or the military, but also to the public at large.

After 1968, development of the PloProf One continued until at least 1972, with a view to its eventual commercialization. The project was put on hold however before being unexpectedly relaunched around 1975. Thanks to technical advances, notably including the adoption of a 5 mm-thick glass, the production model offered guaranteed water resistance to 1,000 meters, a record for a watch at the time. Christened the Sea-

master 1000 by OMEGA, it was nicknamed “The Grand” by enthusiasts and collectors alike.

The Seamaster 1000 quickly established itself as the tool of choice for many professional divers, including Captain Cousteau and several members of the Calypso crew. It was also tested in extreme conditions at a real-life depth of 1,000 meters, attached to the robotic arm of the Beaver Mark IV submarine.

During the 1970s and 1980s, OMEGA produced a wide range of “standard” diving watches under the Seamaster name, alongside its “ultra-professional” line. These models met the varied needs of a consumer base ranging from amateur divers to military personnel and explorers, while remaining accessible to the general public. Robust, reliable and sufficiently water-resistant for swimming or recreational diving, these watches

belong to the “skin divers” category: instrument-watches with designs that are often lighter and more versatile than professional models.

The first of these was the Seamaster 120, Reference ST 166.073, nicknamed “Deep Blue”. Marketed from 1970 onwards, it is often considered the natural heir to the Seamaster 300 and was used by the Israeli armed forces. In 1973, OMEGA introduced the Seamaster 200, Reference ST 166.0177, featuring an angular case typical of bold 1970s

Seamaster 120 “Deep Blue”, Reference ST 166 073, produced from 1970 onwards Considered the natural heir to the Seamaster 300 Date, it shares several of the latter’s features such as self-winding Caliber 565 as well as the same rotating bezel, date display, hands and screw-down crown

design trends. This model is now known by its nickname “SHOM”, a reference to the Service Hydrographique et Océanographique de la Marine française , which ordered a batch in 1979. The caseback of these watches was engraved with these initials. French Navy divers also acquired this model, recognizable in this instance by the initials “MN” (Marine Nationale) on the caseback. Other models were produced and are detailed in Part 6. The Legacy of the Seamaster 300

Seamaster 200, Reference ST 166 0177, nicknamed “SHOM” This model with its angular case emblematic of the 1970s was adopted by the French Navy’s Service Hydrographique et Océanographique de la Marine française (Hydrographic and Oceanographic Service), whose initials are engraved on the caseback

In 1993, OMEGA launched one of its most iconic collections: the Seamaster Professional 300M. Aesthetically speaking, this watch clearly evokes the silhouette of the legendary Seamaster 300 of the 1960s, while incorporating modern innovations such as the screw-in helium valve on the left-hand side of the case.

True to the spirit of OMEGA, the Seamaster Diver 300M offered a uniform water-resistance level of 300 meters for both men’s and women’s models – a rare feature in the world of diver’s watches. The collection was

immediately available in several sizes, in a variety of materials (steel, gold, titanium) and powered by either quartz movements or mechanical self-winding calibers – of which the first was chronometer-certified Caliber 1109.

One of the highlights of this collection was the launch of the Seamaster Professional 300M Chrono Diver: a revolutionary chronograph enabling pushers to be used underwater down to a depth of 300 meters – a performance extending the innovation introduced 20 years earlier by the Seamaster 120 “Big Blue” then limited to 120 meters.

Left: Seamaster 300M Chrono Diver, Reference 2296 80, launched in 1993 This was the first chronograph with pushers fully functional to a depth of 300 meters and was available in several versions, including this model in titanium, rose gold and tantalum

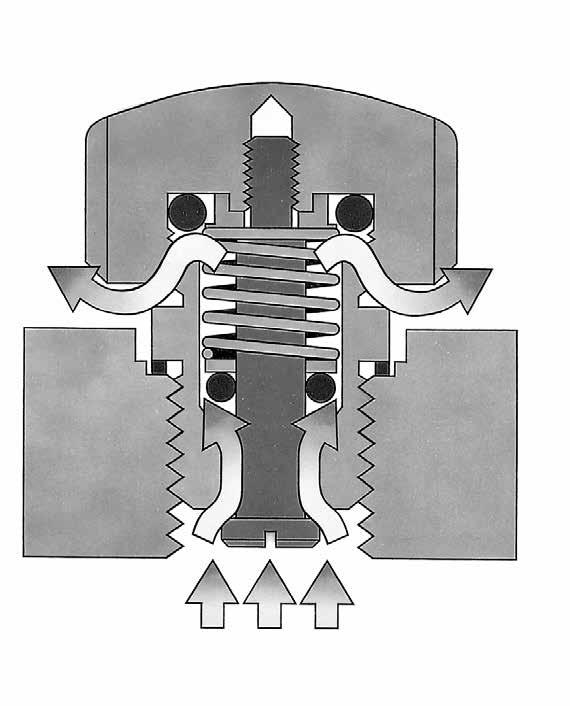

Opposite: Cross-section of the helium valve fitted on the Seamaster Diver 300M During decompression stops, the diver can manually unscrew the valve to allow helium to escape, without compromising the watch’s water resistance

Like its prestigious predecessors, the Seamaster Diver 300M quickly became the preferred instrument for many professional divers, including exceptional freediver Roland Specker, who set new depth records with it, as well as underwater specialists and members of the armed forces. Nor was its adoption confined to the field of diving, as the world of sailing also embraced it, notably during such famous competitions as the America’s Cup, thanks to legendary sailor Sir Peter Blake and his yacht christened Seamaster True to the Seamaster line’s heritage of robustness and reliability, the Diver 300M was

also chosen by certain British special forces, along with several other military units. It was however undoubtedly cinema that made it iconic. In 1995, James Bond, the world’s most famous spy, adopted the Seamaster Diver 300M in GoldenEye. Equipped with gadgets worthy of Q, this watch became one of 007’s emblematic attributes, accompanying Pierce Brosnan in the next three films, followed by Daniel Craig in 2006 for Casino Royale. Perpetuating the legend, the 300M made a remarkable return to Bond’s wrist in 2021 in No Time to Die.

Throughout its production, the Seamaster 300 was powered by OMEGA’s in-house automatic mechanical movements from the 5xx series. This highly regarded range of calibers featured a full-rotor automatic winding mechanism with central seconds, a frequency of 19,800 vph/2.75 Hz and a Glucydur balance. Glucydur is an alloy known for its exceptional elasticity, hardness, antimagnetic properties and resistance to corrosion. The movement parts were crafted using brass or beryllium bronze: this copper alloy contains up to 3% beryllium, a metal highly suited to this application due to its ease of machining, resistance to oxidation, non-magnetic properties and remarkable durability. These qualities have also made it valuable in industries like precision tooling, aerospace and even armor-piercing bullets. To enhance durability further, the base material was electroplated with copper, providing additional protection and imparting the distinctive copper hue familiar to collectors of vintage OMEGA watches. The pinion wheel shaft sizes for the hands remained constant throughout the entire manufacturing period, at 1.5 mm for the hours hand, 0.8 mm for the minutes hand and 0.18 mm for the seconds hands.

This uniformity ensures that hands from all Seamaster 300 models are compatible with the movements originally fitted to the various references.

During the Seamaster 300’s production, the United States imposed higher taxes on imported watches with movements containing more than 17 jewels and/or adjusted to more than two positions. In response, OMEGA adapted by equipping U.S.-bound models with movements limited to 17 jewels and adjusted to no more than two positions. These modified movements were assigned unique caliber numbers and marked accordingly to comply with import regulations. The omitted jewels, all from the winding mechanism, were replaced by metal bearings.

Movements used in the first three Seamaster 300 references – CK 2913, CK 14755 and ST 165.014 (the symmetrical-case models) – were housed within the case using a stainless steel movement holder ring. In contrast, all subsequent references secured the movement directly to the case, eliminating the need for a holder ring. Notably, the screw-hole positions for attaching the ring to the movement differ between the Caliber 50x and 55x series.

Adjustment spring for regulator

Movement serial number

Caliber reference

Number of jewels

Adjusted or Unadjusted

Rotor end

Calibers 50x

501 (20 jewels)

(17 jewels, USA)

Every Seamaster 300 Reference CK 2913, from the earliest 2913-1 to the final 2913-8, was factory-equipped with either a Caliber 500 or Caliber 501 movement. While Caliber 500 was introduced earlier in OMEGA’s production (with other models), the very first Seamaster 300 models produced in late 1957 were fitted with Caliber 501. This movement featured 20 jewels, automat-

ic winding and a maximum power reserve of 46 hours. Shortly thereafter, the 17-jewel Caliber 500 was used in CK 2913 models intended for the American market. To comply with U.S. regulations, these movements were marked with “SEVENTEEN 17 JEWELS” and “ADJUSTED TWO (2) POSITIONS” on the rotor, as well as “OXG” (OMEGA’s U.S. import code) on the body of the bal-

• Mechanical, full rotor self winding with center/sweep seconds

• Copper electroplated beryllium bronze or brass

• Two-arm balance made of Glucydur

• Frequency: 19,800 vph / 2.75 Hz

• Power reserve: around 46 hours (max)

• Dimensions: 12.5 lignes (diameter: 28 mm – thickness: 5.55 mm)

• Pinon/wheel shaft sizes – hand-hole sizes in mm: (H) 1.5 x (M) 0.8 x (S) 0.18

• Dial feet located at 11:15 and 4:45

• Movement/casing ring:

• External diameter: 33.4 mm; internal diameter: 27.7 mm

• Screw holes at ~2:00 and 8:00

ance-cock. American-market CK 2913 models with Caliber 500 are only observed in subReferences 2913-3 through 2913-6. Both Calibers 500 and 501 (classified as category A movements) shared identical dimensions, with a diameter of 28 mm (12.5 lignes) and a thickness of 5.55 mm.

• Additional cutouts in the retaining ring allowing access to the dial feet screws (previous page, left), positioned just past 11:00 and just before 5:00 (previous page, right). This feature is found only on Reference 2913-1 and until early examples of the 2913-3

Applied markers

No T flanking SWISS MADE

Irregular T flanking SWISS MADE

Regular T flanking SWISS MADE

C1. No T (1964)

*There are some rare C2/C3 hybrid versions with both characteristics Hight T and Lumed 12

High T (1964-1965)

12 without applied tritium

12 with applied tritium

In early 1964, OMEGA introduced a new dial design. The recessed triangular hour markers were replaced by large trapezeshaped luminescent hour-markers applied directly to the surface of the dial. The luminescent material used during the production era is now exclusively tritium (later service dials use Super-LumiNova®). The white text on the dial also had a subtle change of font. The alignment notch seen on the edge of previous dials is no longer present on C dials. On the rear of the dial, the two feet and the Incabloc setting recess remained in the same position as the B dials since the movements used were still of the 55x series.

The early C-series dials are believed to all have a deep black glossy black finish when new, although aging can turn this into a more matt result, while the white numbers and text can evolve into a golden or “gilt” color. During the production run of the C4 dial, the finish changed to matt with a very dark gray shade.

The earliest C dials (C1), despite using tritium lume, were not marked with “T’”s on either side of “SWISS MADE”. This omission occurred because these dials were manufactured and installed before October 1964, when OMEGA mandated that all dials carry such markings to comply with a Swiss law enacted in October 1963. These C1 dials can be seen fitted on 165.014-63 and 165.024-63 references.

After October 1964, the T marking appeared on all Seamaster 300 dials. However, during

this transitional period before October 1964, C1 dials in stock (whether already fitted to watches or not) were brought into compliance with the addition of the T markings. The additional printing process is quite obvious on close inspection as the “T”s tend to be larger than the original printed text, sometimes misaligned or in a slightly different shade. These particular dials, classified as C2, are seen on Reference 165.014-63, 165.024-63 and 165.024-64 until about the latter part of 1965.

The next dial version (C3) is rare. It is distinguished by a unique feature: luminescent material was applied to the 12 o’clock numeral. While there is no official explanation for this, identification at a glance of the “12” might have been intended to create a unique reference point, enhancing readability in low-visibility underwater conditions. This may have been an initial experiment that ultimately culminated with the Big Triangle dial seen in later production and enabling instant orientation of the dial. All the examples observed so far fall within a narrow production window from late 1965 to early 1966 and were delivered to the United Kingdom. They have been found on both 165.014-64 and 165.024-64 references, featuring either added “T”s like the C2 dial, or standard “T”s like the C4.

The C4 dial, in production from late 1965 to early 1967, saw the transition from the black glossy dial finish to the dark gray matt version. While the difference can be subtle, especially on well-aged examples, it

becomes evident under strong light when compared side by side. The transition from glossy to matt occurred around the latter half of 1966. Notably, the golden, or “gilt” printing is absent on matt dials. Additionally, a slightly different font with serifs has occasionally been observed on the word “Automatic” on both these C4 and the subsequent C5 dials.

The C5 dial, which first appeared in late 1966, introduced an intriguing new feature: tiny holes in the lume marker at 12 and 6 o’clock, commonly referred to by collectors as “pinholes”. While these pinholes can be difficult to spot on some examples, they are easily confirmed by inspecting the rear of the dial to which the holes run through. The function of these holes remains unclear, but it is likely the result of a change in the method of production used by the Stern Frères dial manufacturer, perhaps to assist with handling and orientating the dial during printing and luming. In all other respects, the C5 dial is identical to the matt C4 dials. Interestingly, these C5 dials were also used on some of the earliest British Army-issue watches (further details are provided in the military chapter, pp.365-366).

Most later dials, such as the Big Triangle and Date versions also featured these pinholes.

The caseback is a component of the watch case, much like the caseband. It follows that these two elements would logically originate from the same manufacturer. All evolutions of the vintage Seamaster 300 feature a screw-down caseback, designed with six slots around its circumference to accommodate a tool for easy fitting and removal (such as illustrated p.201). The caseback securely screws into the caseband, where a rubber gasket is held in place by pressure to effectively prevent the ingress of moisture and dust.

Each example is marked on the inner side with an engraved case reference number and additional engravings (such as the case maker), as well as a decorative circular-grained finish (with a few rare exceptions).

The outer side is adorned with varying styles of engravings, depending on the specific model. Except the very first version (A1),

all casebacks bear the seahorse emblem, introduced by OMEGA engraver Jean-Pierre Borle in 1958, inspired by the seahorse sculptures adorning gondolas in Venice (see image below).

The majority of these casebacks are crafted from Acier Staybrite, a corrosion- and heat-resistant formerly trademarked stainless steel alloy. This material contains 18% chromium, 8% nickel and 0.2% carbon, offering exceptional durability and resistance to the elements. Staybrite steel is a specific form of stainless steel, prized for its superior quality. In later production runs, Staybrite steel was replaced by more generic steel, probably for cost reasons. These later casebacks were inscribed with Acier inoxydable (stainless steel). The dimensions on the following pages, measured by us, may vary slightly – especially if the caseback has been polished.

We have classified the casebacks in three categories:

• Category A: small flat area and fitted to Seamaster 300 models equipped with Calibers 500 and 501

• Category B: larger flat area and longer slots

• Category C: smaller flat area and shorter slots than Category B.

Note that this chapter only covers civilian versions. The serial ranges and production years do not include military-issue watches, which extend beyond those of the civilian models. For more details, (see Part 5. MilitaryIssue Seamaster 300). Furthermore, all inside engraving variations have been compiled in Part 7. Appendix.

Maker’s mark

Circular graining External diameter Internal diameter

Reference /

In 1961, OMEGA introduced the second version of the first-generation Seamaster 300, known as the “straight-lug” model, Reference CK 14755.

The major change that led to the adoption of a new reference was the introduction of a new automatic movement: Caliber 552. Featuring 24 jewels, it also existed in a specific version for the U.S. market, where the number of jewels was reduced to 17 for tax reasons and it was designated as Caliber 550.

This new caliber brought with it some modifications to certain components:

• The dial retained the same design as the first Seamaster but differed in the positioning of the feet on its underside to accommodate the new caliber.

• Its height reduced by 1 millimeter enabled the production of a slimmer caseback with a larger central surface area.

The CK 14755 maintained the case with its straight lugs and symmetrical sides, meaning it did not have crown guards. The bezel also remained unchanged, featuring a 0-60 scale. The “Small Arrow” hand configuration –introduced during the production of the CK 2913 – was retained, where the minutes

hand ends in a triangle. Three types of seconds hands were possible:

• a straight seconds hand, known as “Straight”, which tapers slightly at the tip,

• a “Lollipop” seconds hand, characterized by a circular tip filled with luminescent material,

• a “Drop” seconds hand, distinguished by a teardrop-shaped counterweight and a diamond-shaped tip filled with luminescent material. The diamond shape extends into a long, pointed tip (“Long Tip”).

In 1963, the CK 14755 was replaced by Reference ST 164.014, complying with OMEGA’s new Mapics coding system (see next section). During the implementation of this system, there was a transitional period during which the inside of the casebacks could be stamped with the inscription “14755-62”, “165.01462”, or sometimes both, with the new Reference “165.014-62” often engraved later. As a result, the case reference and the reference recorded in OMEGA’s archives may not always match (see the next section for more details). Except for some later examples of the 165.01462, the models are identical, which is why we have grouped both references together in this chapter.

In 1958, OMEGA became the official supplier to the Peruvian Air Force, known as the Fuerza Aérea del Perú (or FAP for short). Although these watches were not always issued in the strict military sense, the partnership granted them official status and led to certain customizations, such as a name change for the Railmaster model, which was renamed “Flightmaster” at FAP’s request. As such, the FAP was the first military organization to order the Seamaster 300 to their personnel and they did so shortly after the models release. Indeed, OMEGA started production on the first batch of watches

for the FAP in January 1959 with case Reference 2913-3. It wasn’t long before another batch was delivered, this time consisting of References 2913-7 and 2913-8. A final batch of Seamaster 300s, now under Reference CK 14755, was manufactured for the FAP in March 1962.

These watches had no major modifications made at the factory although, interestingly, the Lollipop seconds hand (named after circular well of lume on the tip of the hand) made its debut on the first Reference CK 2913s manufactured for the FAP, quite possibly as a special request. Additionally, the outside

of each caseback was engraved with the FAP acronym, most likely done after the watches left the OMEGA factory. The size, style and positioning of this engraving differs between models and these differences are discussed in the chapter on components..

We estimate that about 300 Seamaster 300s were manufactured for FAP by OMEGA. The Peruvian Air Force also placed orders with OMEGA for the other models such as the Ranchero and the two models composing the famous “Trilogy”: the Speedmaster and Railmaster/Flightmaster.

On the left: cover page of an FAP brochure, stating in Spanish that the watches listed on the following pages are exclusively reserved for FAP members It also mentions that OMEGA has been the official supplier to the FAP since 1958

Opposite: description of the Seamaster 300 Ref CK 2913 and the special FAP price of USD 58 90 The public price is indicated in the local currency (sol de oro) corresponding to a price of USD 237

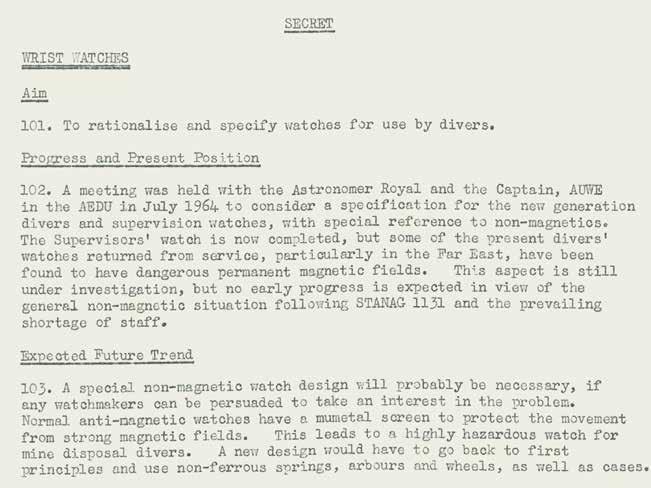

Great Britain’s Ministry of Defence had been using OMEGA as an approved supplier of watches since World War I and had long been OMEGA largest military customer, so it is perhaps logical that they turned to this Manufacture again in the 1960s when the need for a reliable military diving watch arose. Initial testing of the OMEGA Seamaster by the Admiralty Experimental Diving Unit (AEDU) was undertaken in the early 1960s, the stated aim of the work being “to rationalize and specify watches for use by divers.”

This work eventually led to the document titled “SD 37 Navy Department Experimental Diving Unit Specification” dated 12 May 1966, replaced two years later by the MoD’s “Defence Standards – Watches, Wrist, Divers’ Part 1, Issue 1” manual created in 1968 (shortened to Def Stan 66 – 4.) This document “Specifies the materials, methods of test and other requirements for watches, wrist, divers to be used by the Navy, Army and Air Force Departments of the Ministry of Defence.”

Table detailing the specifications “DEF STAN 66 – 4” required for the diver’s wristwatch intended for the Army (W10) and the Navy (0552) This includes a black dial with a 12-hour dial and a graduated scale with one-minute increments There must be three hands, including a sweep-second pointer) The movement must be self-winding with minimum

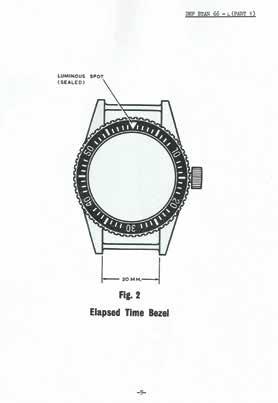

The illustration of the watch dial shown in the DEF STAN 66 – 4 issue 1 document is clearly based on the OMEGA Seamaster 300 dial (named C5 ‘Pinholes’ in our classification) with which the first watches supplied were indeed fitted. The document

17 jewels and a power reserve of at least 30 hours

The glass must be acrylic It must resist a pressure of 12 52 kgf/cm2, which corresponds approximately to 12 3 bars The case must be made of a corrosion-resistant steel and bear a rotatable bezel with an elapsed-time graduation Source: UK Ministry of Defence

on the right shows a bezel with a luminous marker at 12 o’clock and a 60-minute scale Here again, the drawing is inspired by the Seamaster 300 Source: UK Ministry of Defence

This Defence Standard Document was updated in 1971 to issue 2 with some slight changes, such as the dial and the screwdown crown. OMEGA actually started to implement these changes in 1968 already and the watch illustrated in the specifications was now based on a Seamaster 300 with a Big Triangle dial (named M.D1 in our classification,) which began to be fitted to supplied watches during the production run. An initial order of approximately 300 to 400 watches was placed (quite likely through the

UK’s long-term OMEGA distributor Goldsmiths) and production began in March of 1967 with deliveries made throughout the year. This initial batch was destined for the Army, probably for use by special forces and the Royal Engineers. A new order was made in 1968 for a batch of watches destined for the Royal Navy for use by Clearance and Search & Rescue (SAR) divers. Further watches for the Navy were supplied over the next couple of years, with approximately 700 to 800 manufactured in all. The final mil-

itary Seamaster 300s for the UK’s MoD were produced and delivered to the Royal Navy in late 1970, after civilian production of the ST 165.024 had ceased.

The procured watches were subject to very extensive testing, including extremes of temperature, heavy shocks, vibrations, magnetic fields and water-resistance testing to 400 feet (120 meters.)

This excerpt from the Def Stan issue 2 from 1971 shows a case and dial clearly based on the Seamaster 300 The dial shows the Big Triangle and the large screw-down crown typical of the Seamaster

300 Source: UK Ministry of Defence

The Def Stan documents from 1968 & 1971 also required that a clearly visible circled “T” (to denote the use of tritium lume on the hour-markers and hands as opposed to the more dangerous radium lume used previously) was printed on the dial. We believe it likely this was not done at the factory, but once again by the MoD watchmakers. However, the first watches issued – those marked W10 and destined for the Army –did not initially feature the circled “T” and the dial fitted was a standard civilian version known as C5 in our classification. This is probably because they were ordered and supplied before the Def Stan requirements laid out in 1968 had been determined. It wasn’t until the subsequent batches of watches issued to the Royal Navy (marked 0552) that the M.C5 (Pinholes) and M.D1

(Big Triangle) dials printed with the circled T were fitted. However, given the extremely harsh working conditions, these watches were subject to regular repairs and servicing were necessary, so it is fairly common to see later dials fitted to earlier watches and vice

versa

Other updates were also made during the production run, including changing the Naiad crown system to the more reliable screw-down crown in 1968. This update was regularly retrofitted during maintenance service, so it is common to see earlier watches fitted with screw-down crowns, whereas issue watches that retain their original Naiad crown are quite rare. Replaced and updated components are in fact quite common on all the issue watches and are perfectly acceptable to collectors as long

as they conform to original military issue standards.

Despite the factory modifications, all the MoD-issue watches carry the same 165.024 case reference number as the civilian versions. The cases were manufactured for OMEGA by Huguenin Frères (HF) and La Centrale Boites (CB.)

Beside the military-issue watches, Seamaster 300s were also sold in military base stores around the world for private purchase by military personnel and the archival records held by OMEGA occasionally show delivery to base stores such as the US Army & Navy exchange (PX), the Royal Canadian Airforce (RCAF) and the UK’s Navy, Army and Air Force Institute (NAAFI) among others. These watches were regular civilian models and not modified for military use.

The printed circled “T” appears in a high position above the dial center and just beneath the word “AUTOMATIC” However, on some dials this marking is placed lower, below the center These markings were applied locally to indicate the presence of tritium, a radioactive substance used on the dial hands and hour-markers

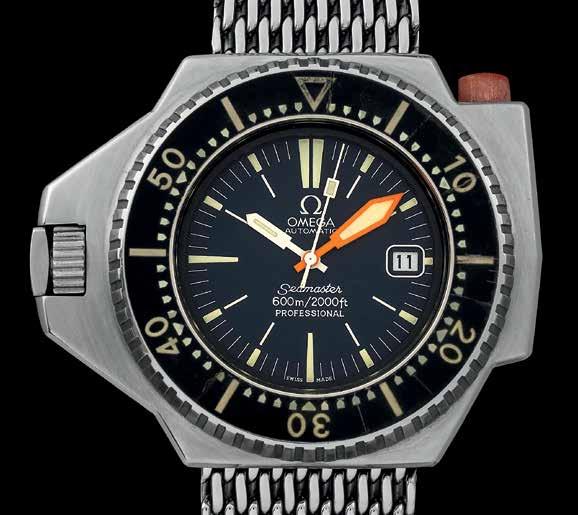

REFERENCE ST 166.077

Material Steel

Diameter 55x45 mm

Movement Automatic

Caliber 1002

Functions Date, dive bezel

Water resistance 600 meters

The model illustrated represents the ultimate evolution of the Ploprof, recognizable mainly by its dial indicating depth in meters (600) and feet (2000) – and is the most common version of all Ploprof models.

This model is presented with a fourth bracelet option, called “mesh” because of its structure composed of interwoven metal links.

Next page, bottom right, a version with a vintage service dial, distinguished by rounder “0” numerals.

Functions

Water

As soon as the collection was launched, the Seamaster Diver 300M was also offered with a quartz movement, in three different sizes. The 28 mm ladies’ version was only available in quartz. Quartz versions are distinguished by the absence of “CHRONOMETER” on the dial. Certain details help identify the different formats, such as the size of the index to the right of the date window. The table below compares the five variants. With the exception of a few details, such as the transition from tritium to luminova/Super-LumiNova in terms of material, this model remained unchanged until around 2005. The 41 mm version is particularly popular, as it was the first OMEGA model worn by James Bond in the 1995 film GoldenEye (see p.553).

REFERENCE 2842.21.53

Numbered, with no indication of the total (quartz version)

Material Steel

Diameter 41 mm

Movement Quartz

Caliber 1438

Functions Date, dive bezel

Water resistance 300 meters

For the 1994 Lillehammer Winter Olympics, OMEGA supported the Swiss team by creating a special edition of the Seamaster Diver 300M named Olympia, with the Swiss Olympic Team logo on the dial.

Each Swiss athlete taking part in the Games received one of these watches. At the same time, a limited series was marketed exclusively in Switzerland, comprising:

• 49 gold timepieces and 194 steel timepieces for each size (36 mm and 41 mm) of the automatic version, all numbered

• a numbered yet unlimited series for quartz versions

In a nod to the five Olympic rings, every watch was delivered in a case containing five leather straps, each in one of the ring colors.

REFERENCES

522.30.46.21.01.001 / 522.33.38.20.04.001

Limited edition of 2,014

Material Steel

Diameter 45 5/ 37 .5 mm

Movement Automatic

Caliber 8500 / 8520

Functions Date, dive bezel

Water resistance 600 meters

For the 2014 winter edition, OMEGA chose to offer for the first time not just one but two Planet Ocean 600M models, produced in numbered series of 2,014 each. The first corresponds to the large-sized 45.5 mm model, equipped with a black dial and a black ceramic bezel. The other is a white 37.5 mm-diameter version. References to the Games remain discreet. In addition to the customized caseback, the dive scale engraved on the bezel features the first five minutes in red, followed by the next five in blue – evoking the host country’s national colors, The white iteration also picks up these hues on the 6 and 9 o’clock numerals.

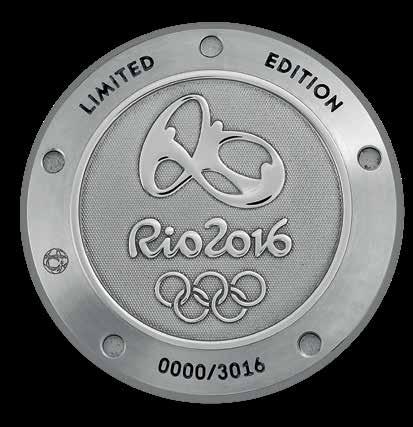

REFERENCE 522.30.41.20.01.001

Limited edition of 3,016

Material Steel

Diameter 41 mm

Movement Automatic

Caliber 2500

Functions Date, dive bezel

Water resistance 300 meters

For the 2016 Summer Olympic Games in Rio de Janeiro, OMEGA introduced a Diver 300M in a 41 mm diameter. While the caseback is customized with an event-dedicated engraving, the most eye-catching feature is the dive bezel on which the 20 to 50-minute numerals follow the five colors of the Olympic rings. Not to be outdone, the black dial is adorned with a wave motif magnificently inspired by the famous white calcite and black basalt promenade along Copacabana beach.

A total of 3,016 of these watches were produced, 1,000 more than in 2016, probably in response to high public demand for these Olympic series.

REFERENCE 232.30.42.21.01.001

Material Steel

Diameter 42 mm

Movement Automatic

Caliber 8500

Functions Date, dive bezel

Water resistance 600 meters

Four years later, Bond was back in Skyfall. The Planet Ocean he wore was part of the new generation launched in 2011, equipped with the Manufacture Caliber 8500 and featuring an innovative, scratch-resistant ceramic bezel. The 42 mm-diameter Reference 232.30.42.21.01.001 combines performance and refinement, while still comprising no modifications from the Q laboratory.

REFERENCE 233.32.41.21.01.001

Limited edition of 7,007

Material Steel

Diameter 41 mm

Movement Automatic

Caliber 8400

Functions Date, bidirectional bezel

Water resistance 300 meters

This watch marked the noteworthy return of Q’s laboratory, which equipped James Bond with a brandnew model: the Seamaster 300 Heritage, Reference 233.32.41.21.01.001. In the film, it conceals a detonator with a built-in explosive charge.

Inspired by the 1957 Seamaster 300, this updated version features Master Co-Axial Caliber 8400. To enhance onscreen legibility, OMEGA enlarged both the logo and brand name on the dial. There is also a “Lollipop” seconds hand and a NATO strap in a nod to the military. This was the first time Bond used a commemorative Seamaster, in this case issued in a 7,007-piece limited edition.

REFERENCE 212.30.41.20.01.005

Limited edition of 11,007

Material Steel

Diameter 41 mm

Movement Automatic

Caliber 2507

Functions Date, dive bezel

Water resistance 300 meters

Launched in 2012, this 41 mm Diver 300M was created to mark the 50th anniversary of James Bond’s on-screen presence. It was produced in a limited edition of 11,007. Its black dial is adorned with the 007 logo in a diagonal pattern. The matt black ceramic bezel bears a white diving scale, with the exception of the number 50 in red to commemorate the 50th anniversary. The caseback is stamped with a gun-barrel motif, with a gilded central pattern reminiscent of the back of a bullet, inscribed “JAMES BOND 50 YEARS”.

This edition also exists in 36.25 mm, Reference 212.30.36.20.51.001 and produced in a limited series of 3,007. It is distinguished by a small brilliant as an index at 7 o’clock.

World-renowned for being prominently featured in all James Bond films since 1995, the OMEGA Seamaster nonetheless made its debut back in 1948, thanks to the wartime expertise the brand had acquired in developing water-resistant watches. Almost a decade later in 1957, OMEGA introduced its famous Speedmaster – Railmaster –Seamaster 300 trilogy marking a major milestone in the field of ‘professional’ watches. Worn by both civilian and military divers, the Seamaster 300 laid the foundations for a range that has been constantly evolving ever since. In the early 1970s, the Seamaster 600 (the famous Ploprof) and Seamaster 1000 models pushed the limits of diving watches, while the 1990s marked the start of the collection’s veritable ascent to fame with the Diver 300M (1993), Aqua Terra 150M (2002), Planet Ocean 600M (2005) and finally the incredible 6000-meter water-resistant Ultra Deep. The Seamaster has also captivated a wider audience thanks to watches produced for the Olympic Games.

This historical and technical new volume in the “ONLY” collection focuses on diving models and particularly on the Seamaster 300. With regards to the latter, the authors have adopted their characteristic in-depth analytical methodology now deployed for over a decade. This approach will allow enable novice enthusiasts and seasoned collectors alike to delve into the intricacies of these iconic models, from their creation through to the present day.