• Safest, most economical way to pull trucks through fields in tough harvesttime conditions.

• Safe-T-Pull hitches and towing systems are safe and efficient.

• Hitches attach and detach from trucks, tractors and implement frames with no chains or cables to break.

With Torac ® Insecticide, you get control of Colorado Potato Beetle and a broad spectrum of other troublesome pests including aphids, psyllids, leafhoppers, and thrips. Torac works quickly, causing rapid feeding cessation, and it is effective on all life stages of target pests. Additionally, the unique mode of action of Torac makes it an excellent rotational option to manage pest resistance in potato, onion, and vegetable crops. With all this, you’ll want to fit Torac in your CPB spray program this season. To learn more, contact your distributor or local Nichino America sales representative.

On the Cover: How about that red onion harvest picture on the cover of this Vegetables & Farm Safety/Insurance issue? The ground is the color of honey, the sky blue and white, and the farm implements yellow (AGCO Challenger MT765C tractor), teal green (Lee Schuknecht & Sons harvester) and red (trailer). The harvest photo is courtesy of Dean Kincaid Inc. of Palmyra, Wisconsin.

The ridgeline is beginning to lodge (when the onion tops tip over) in this photo taken of onions planted in mineral soil on Dean Kincaid Inc. farmland in Walworth County, Wisconsin. This issue’s interviewee, Corey Kincaid, who’s a third-generation potato and onion grower for the operation based out of Palmyra, is proud of how the farm has diversified and progressed, including using AI, a Laserweeder, Ecorobotix sprayer and spider robots.

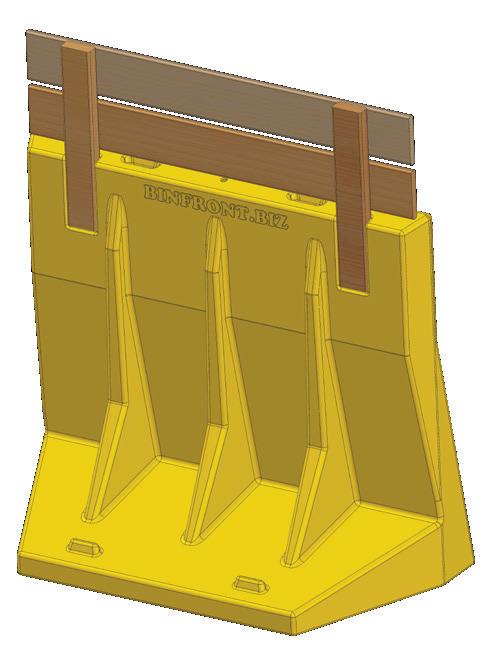

Badger Plastics & Supply is adapting to grower needs

WPVGA Board of Directors:

PresideNt: JohN Bustama Nte

Vice PresideNt: WeNdy Dykstra

Secretary: Josh KNights

Treasurer: JohN HopfeNsperger

Directors: Mike BagiNski, Ra Ndy Fleishauer, Bria N Lee, J.D. Schroeder & Jeff SuchoN

Wisconsin Potato Industry Board:

PresideNt: Heidi Alsum-Ra Ndall

Vice PresideNt: ANdy Diercks

Secretary: Nicola Carey

Treasurer: Keith Wolter

Directors: JohN FeNske, Rod Gumz, Jim Okray, Eric Schroeder & Tom Wild

WPVGA Associate Division Board of Directors:

PresideNt: Matt SeleNske

Vice PresideNt: Etha N OlsoN

Secretary: Melissa Heise

Treasurer: Paul Salm

Directors: Brady Patoka, Scott Scheer, Morga N Smolarek, Sally Suprise & Bra NdoN Taylor

Wisconsin Seed Potato Improvement

Association Board of Directors:

PresideNt: Charlie HusNick

Vice PresideNt: ANdy Schroeder

Secretary/Treasurer: Markus Shafel

Directors: Mitch Mattek & CloVer Spacek

Wisconsin Potato Growers

Auxiliary Board of Directors:

PresideNt: Heidi Schleicher

Vice PresideNt: Dakotah Smiley

Secretary/Treasurer: Sama Ntha Cypher

Directors: Jody BagiNski, Misti KiNNisoN, JeNN a SuchoN & EriN Meister

WPVGA Staff

ExecutiVe Director: Tamas Houliha N Ma N agiNg Editor: Joe Kertzma N Director of PromotioNs & CoNsumer

EducatioN: Da N a Rady

FiN a Ncial Officer: KareN RasmusseN

ExecutiVe Assista Nt: Julie BrauN

Program Assista Nt: Ja Ne GuilleN

WPVGA Office

(715) 623-7683 • FAX: (715) 623-3176

E-mail: wpvga@wisconsinpotatoes.com

Website: www.wisconsinpotatoes.com

LIKE US ON FACEBOOK: www.facebook.com/WPVGA

The WPVGA staff was out and about in the community over the past couple months representing the potato and vegetable growing industry at shows, farm tours and cooking demonstrations. To raise funds for the industry, WPVGA Financial Officer Karen Rasmussen and Program Assistant Julie Braun (shown pulling cashier duty in the above image) join the Wisconsin Potato Growers Auxiliary, along with grower and Associate Division members, in setting up and running a baked potato and French fry booth at the WPS Farm Show each year. I also attended the 63rd Annual WPS Farm Show, April 1-3, on the Experimental Aircraft Association grounds in Oshkosh. There, industry representatives and community members see the latest in farm equipment, services and technology, with 400 exhibitors from the United States and Canada setting up booths and equipment at the show.

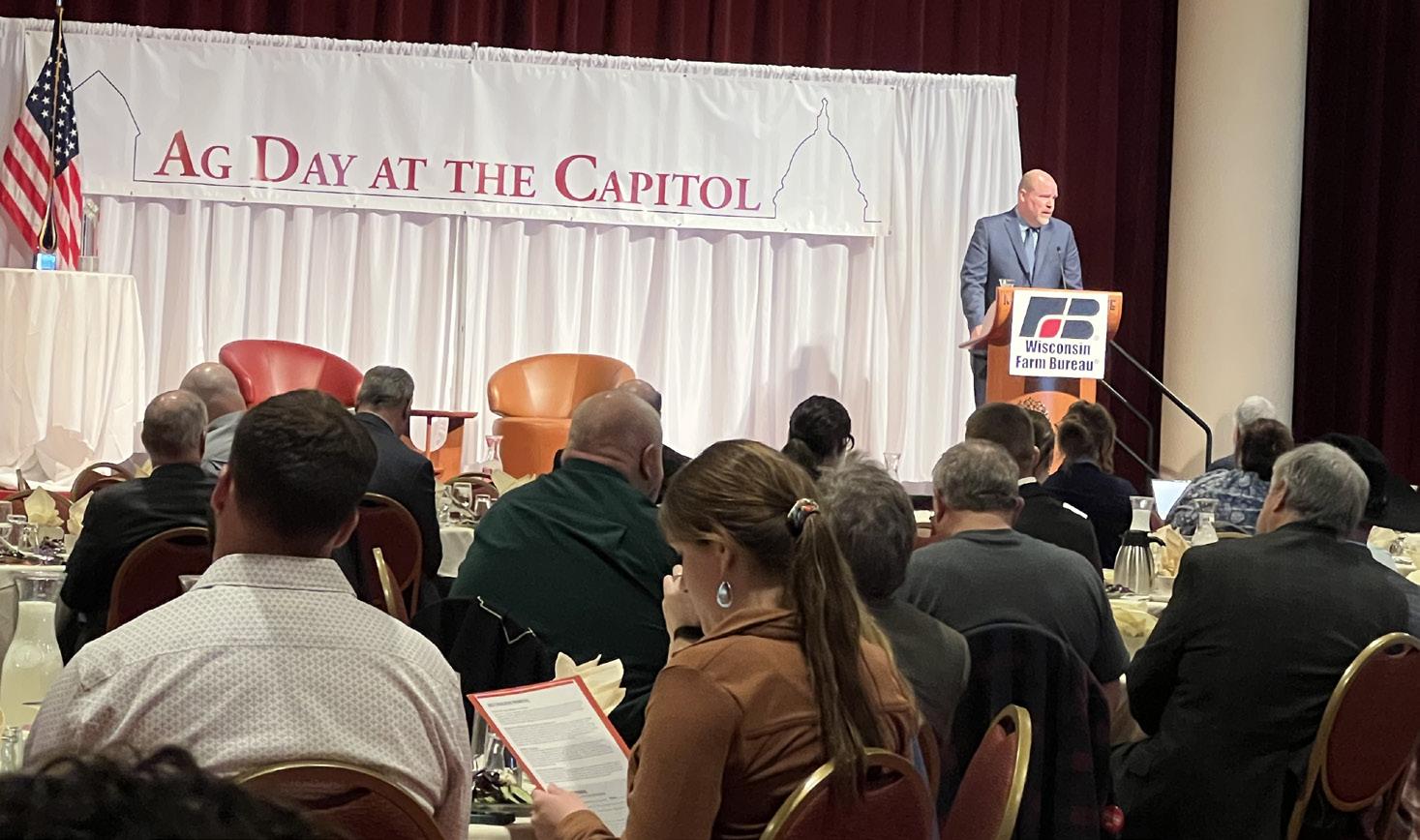

On March 26, WPVGA Executive Director Tamas Houlihan joined Morgan Smolarek of McCain Foods and Mark Finnessy from Okray Family Farms, along with many industry professionals, during Ag Day at the Capitol, in Madison. Ag Day at the Capitol is an annual event open to Wisconsin farmers and agriculturalists so they can learn more about issues affecting the industry and meet with their state legislators. WPVGA is a co-sponsor of the annual gathering that offers a unique opportunity to connect with lawmakers, delve into critical issues affecting agriculture, and advocate for policies that matter most to the farming community.

Houlihan also joined members of the Producer-Led Watershed Protection Group known as the Central Wisconsin Farmers Collaborative, who met at Gagas Farms in Rosholt, March 28, for a tour of wetlands on the farm. The wetlands provide habitat for ducks, geese, sandhill cranes, beavers and other wildlife. See “Now News” for the full scoop on the three events.

WPVGA Director of Promotions & Consumer Education Dana Rady received a request to do an interactive culinary demonstration at the Food + Farm Exploration Center (FFEC), in Plover, as part of the Wisconsin Association of Family and Consumer Sciences (WAFCS) Annual Conference. Rady was honored to use the Kitchen Lab at the FFEC to promote the use of Wisconsin potatoes and vegetables for 36 middle and high school FCS teachers. See “Marketplace” herein for the story and photos.

Please email me with your thoughts and questions. If you wish to be notified when our free online magazine is available monthly, here is the subscriber link: http://wisconsinpotatoes.com/blog-news/subscribe.

Joe Kertzman Managing Editor jkertzman@wisconsinpotatoes.com

N1435 Cty Rd D

Antigo, WI (715) 623-2689 farm@sbfi.biz johnt@sbfi.biz

NAME: Corey Kincaid

TITLE: President

COMPANY: Dean Kincaid Inc.

LOCATION: Palmyra, WI

HOMETOWN: Palmyra

YEARS IN PRESENT POSITION: Three

SCHOOLING: 1994 graduate of Palmyra Eagle High School, and Bachelor of Science degree in agricultural sciences, University of Wisconsin-Madison, 1999

ACTIVITIES/ORGANIZATIONS: Wisconsin Potato & Vegetable Growers Association (WPVGA) Research Committee, and treasurer of the Wisconsin Muck Farmers Association

FAMILY: Wife, Stacey, and three sons, Colton (17), Cason (14) and Camden (11)

HOBBIES: Waterskiing, biking, woodworking, hunting and travel

Above: Representing the third and fourth generations

the

By Joe Kertzman, managing editor, Badger Common’Tater

Growing vegetables in the rich muck soil of Southeastern Wisconsin seems like an ideal way to spend one’s career, but it is not without its challenges.

Dean and his father, R.E. Kincaid, grew onions in Grant, Michigan, for a few years before selling the land. Dean went to Florida and raised onions there for a year, but he had difficulty controlling diseases due to the humidity and limited fungicidal materials.

That’s when, in 1950, he returned to the Midwest looking for land to drain. He found what he was looking for in Palmyra, Wisconsin. Over the years, he slowly expanded the farm with the help of his sons, Gary (Corey’s father), and John, to make the farm what it is today.

Dean Kincaid, Inc. specializes in growing onions and red potatoes in Jefferson, Waukesha and Walworth Counties.

Are you still farming 6,000 acres, and how much of it is in fresh market potatoes and onions? We are now down to just under 2,500 tilled acres.

Nine-hundred-and-forty-five acres went to solar and 1,760 of the muck

went back to the Department of Natural Resources and is currently being converted into a wetland.

We have been trying to diversify our farm over the years to make it last well into the future. I tried growing other crops, like organics, beets, shallots, pearl onions, and canning carrots, and none of them really panned out or made much of an impact. So, we as a family decided to diversify in other ways.

We have a portion of the farm that is in solar that came online last month and have also gotten into apartment and office development projects, mostly in the Milwaukee metropolitan area.

It is nice having some assets with a roof on them and not having to worry quite so much about impacts from the weather.

I’m sure there have been quite a few technology updates on the farm over the years. Can you hit on two or three? We are using four

8 BC�T May

AI (artificial intelligence) robots on the farm now—a Carbon Robotics Laserweeder, an Ecorobotix sprayer and two Smart Vision Works spider robots to help with grading in the packing shed.

This summer will be the first with the Ecorobotix sprayer, but this past year, we used the Laserweeder extensively.

Onion growth is delayed/stunted by the microdosing of herbicide throughout the growing season, and the Ecorobotix sprayer drastically reduces the use of plant protection products, decreasing labor costs while increasing efficiency.

The Laserweeder and the Ecorobotix will hopefully reduce the hand weeding labor. I currently spend over $300 per acre on hand-weeding labor. These tools will also reduce herbicide usage.

We have seen 20 percent yield gains and a shift in the size profile to a larger crop, which, in the case of onions, the larger sized onions are worth more.

Other things we have seen with this technology include better control of resistant weeds, a crop that matures 7-10 days earlier, and healthier plants that withstand disease, insects and other stress.

After the first year’s use of the Laserweeder, I have seen that I can cut my onion acreage due to the increase in yield. This is a significant cost savings and helps with crop rotation.

There are some negatives to the Laserweeder. It is expensive, slow and creates a 24-hour job if you want to get some ground covered. We’re able to cover about 1 acre per hour on average.

We were able to run a few stretches

Above: To have marketable onions in early August, Dean Kincaid Inc. plants them in five greenhouses in early February and transplants the onion plants onto about 40 acres in mid- to late-April using a Minoru OPT 40 Transplanter from Japan.

of 13 to 14 days, 24 hours a day, stopping only for fuel and quick maintenance. Carbon Robotics is coming with technology this year where they can have someone operate the machine remotely, much like drones in the military.

continued on pg. 10

What varieties of potatoes are you growing and on what rotation? We grow red and yellow onions and Dark Red Norland potatoes, the latter entailing only 60 acres for RPE, Inc.

We no longer pack potatoes ourselves and focus mostly on onions. We also grow about 1,000 acres of field corn and 1,000 acres of soybeans on rotation.

What varieties of onions do you raise, and why those? My main onion varieties are Braddock, Bradley, and Safrane, with Oneida and Killington being for early maturity.

We annually plant about a 15-20acre test plot. Onion varieties don't change very fast over time. Finding one that adapts to our area and is bacteria resistant takes many years.

We also plant 40 acres of transplants to have marketable onions in early August. We used to get plants from Arizona to plant but this was a time-consuming and labor-intensive practice.

We imported a Minoru OPT 40 Transplanter from Japan and grow our own plants in trays placed right on top of the soil within five greenhouses. They are planted in the greenhouses in early February and then transplanted into the field in mid- to late-April.

We’ve been getting better at it over time and have learned much from Japanese YouTube videos trying to figure out their process. The transplants allow us to get our shed running early and use an onion storage warehouse twice in

Corey

says

farm has been tiling fields for water drainage a second time. The old tiles that were installed 4 feet deep are getting hit with tillage equipment at 10 inches, with the muck soil having subsided that much since the first tiling in the 1950s.

a growing season.

Are red potatoes as popular with your customers as they used to be, and if not, how have you weathered that storm? The baby potato market seems to have taken much of the market share from the red potato.

When I started working here, we grew 900 acres of red potatoes and could sell all of them off the field in the fall. Now, it seems difficult

to sell 60 acres at times. The market also demands much higher quality potatoes with minimal blemishes, which can be a challenge.

Is most of your acreage muck soil, and why is it ideal for onions and the potatoes you raise? We are now about half muck and half mineral soil. The muck is 4560 percent organic matter and decomposes over time.

We have been tiling fields for water drainage a second time. The old tiles that were installed 4 feet deep are getting hit with tillage equipment at 10 inches. The muck has subsided that much since the 1950s.

As the farm gets lower over time, we build up the dike around it to prevent the river from coming in. The river is now above field level. The muck won’t last forever.

I have been experimenting with onions on Plano silt loam and have had decent results and plan another

“We are using four AI robots on the farm now—a Carbon Robotics Laserweeder, an Ecorobotix sprayer and two Smart Vision Works spider robots to help with grading in the packing shed.”

– Corey Kincaid

20-acre experiment this summer.

I imagine, then, that you don’t have to irrigate as much as on the Central Sands, correct? We have about 60 percent of the farm covered with pivots but usually only use them a maximum of three times per season. We typically spend more time and effort on drainage than irrigation.

But doesn’t the muck invite more fungus and diseases, and whether it does or not, how are you treating

potatoes and onions for pests and diseases? The muck releases a lot of nitrogen [N] for the crops grown. I only use 50 units of N/acre for my onion crop, 40 N/acre for potatoes and 90 units for field corn.

Excessive N use promotes too much above-ground growth, which can lead to disease issues.

I like to plant soybeans ahead of onions, and white mold can be an

Contact: Jim or John

issue. We have been trying to combat that with low populations of 90,000 plants per acre in 30-inch rows. We also use Valent Cobra herbicide to burn them back, followed by fungicides, and yet, we can still get white mold and lodging (the onion

tops tipping over when mature) on the muck.

You are secretary/treasurer of the WPVGA Muck Board, on our Research Committee, and I believe involved with state muck organizations. Why is it

important for you to stay involved in those boards, committees and associations? There are fewer and fewer farmers, especially muck farmers. Attending meetings and meeting other farmers and researchers have helped our farm continue to increase yields and be the best farmers we can be.

I have been attending National Onion Association meetings across the country and have learned as much from farmers as I have from the meetings themselves.

Have GPS (Global Positioning System), remote sensing and larger planters and harvesters changed the way you farm? GPS has definitely helped with driver fatigue and in eliminating any overlap or underlap of seeds and pesticides.

Above: Braddock yellow onions are ready to be undercut at Dean Kincaid Inc. in the first image, and a yellow onion ridgeline is beginning to lodge (when the onion tops tip over) in the second photo. The onion tops tip over when mature. Undercutting gets the roots and the onions, which are then left in the field a bit to dry before the harvester picks them up.

Remote sensing, such as Climate, along with yield maps have helped make targeted decisions on where to best place new drain tiles and which varieties outperformed others.

The Laserweeder and some of the newer AI machines can count the

number of onions in our field and give us stand counts, as well as map the weeds in the field so we can make decisions going forward as to which field to treat next or address a problem area.

Benefits, Rates and Timings:

Enhances Water Penetration: Ensures optimal moisture levels for healthier potato crops. Boosts Nutrient Uptake: Promotes robust plant growth and higher yields.

Improves Soil Structure: Prevents soil compaction, allowing roots to thrive and produce better-quality potatoes

Application at Planting:

Rate: 1 quart per acre

Timing: Apply at planting to provide available calcium for new roots and stems.

Application with First Watering:

Rate: 1-2 quarts per acre

Timing: Apply with the first watering to enhance water penetration, release tied-up nutrients, and neutralize salts in the root zone.

Regular Application During Season:

Rate: 1-4 quarts per acre

Timing: Reapply every 20-30 days throughout the growing season to ensure continuous availability of calcium, improve water penetration, and support plant health during stress periods

Who are your main buyers of onions and potatoes? Currently all our potatoes go to RPE, Inc. About 60 percent of our onions go to retail grocery chains in 3-pound bags, and the remainder in 50-pound bags to re-packers across the country. Hopefully, this percentage changes as we grow larger onions and more medium-sized onions with the implementation of the AI driven weeding machines.

Do you have family members involved in the business, and if so, who and in what capacities? My dad, Gary, has retired, which pretty much leaves my brother, Chase, and brother-in-law, Jay Wendt, alone on the farm.

Thankfully, we still have Dad around to consult and help with some of the broader changes we are making on the farm.

Above: A Smart Vision Works spider robot grades onions at Dean Kincaid Inc. using artificial intelligence. About 60 percent of the farming operation’s onions are sold to retail grocery chains in 3-pound bags.

How many full- and part-time employees do you have? Dean Kincaid Inc. has 26 full-time employees and up to 38 additional hands seasonally.

Is there community involvement and pride concerning Dean Kincaid Inc. in the Palmyra area? Yes, we take pride in donating to the local FFA and scouting programs and schools. I also donate 40,000-80,000 pounds of onions to Feeding America in Milwaukee annually.

How are you farming more sustainably now than in the past? We’re using grid soil sampling to make informed variable fertilizer applications, and thus, we have cut way back on nitrogen usage.

Using and implementing cover crops to help with soil erosion allows us to be more sustainable, as do the new AI weeding machines to reduce herbicide usage.

The packing shed that was built on the farm in 2014 has also allowed us to be more sustainable because it cut out a middleman/re-packer, and we ship many more onions directly to

the end users.

It also gives our employees a better working environment and helped the farm recapture some of the money lost to middlemen as we’ve shipped onions to the store.

What farm safety measures do you take for your employees? In our packing shed, we put perforated metal panels in the ceiling and walls to greatly reduce noise and protect everyone’s hearing.

We also installed two dust extraction systems to help keep dust levels down. Onions are quite dusty when packing them, and no water is used as it is in potatoes.

RIght: The underside of Dean Kincaid Inc.’s Ecorobotix AI sprayer shows the nozzles and camera system.

How does your county compare to others when it comes to soybean cyst nematodes?

By Rhonda Brooks Reprinted

with permission from Farm Journal

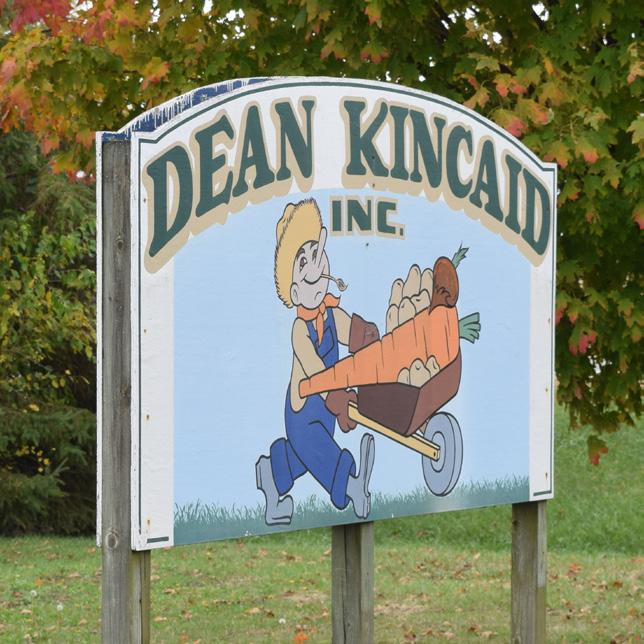

Red, white and blue are colors of patriotism in the United States, but a new map showing the presence of soybean cyst nematode (SCN) uses those colors in an altogether different way.

Soybean growers can take a quick look at the map provided by the SCN Coalition to tell whether the pest is in their counties, and thus, if they are in areas potentially at risk.

Specifically, red areas on the map indicate counties in each state where SCN has been found. Blue signals the newest counties or areas that the pest has moved into. White indicates counties or areas where SCN has not been confirmed, but they aren’t necessarily SCN-free.

Some states have SCN in every county. Consider the top two soybean producing states:

• Illinois has SCN in all (102) of its counties and 88% of all soybean fields.

“I tell my farmers there’s a three-out-of-four chance that any field they grow soybeans in has SCN.”

– Greg Tylka

director of the Iowa Soybean Research Center at Iowa State University

• Iowa also has SCN in all 99 of its counties and at least 70% of all soybean fields.

“I tell my farmers there’s a three-outof-four chance that any field they grow soybeans in has SCN,” says Greg Tylka, director of the Iowa Soybean Research Center at Iowa State University.

He says fields with low levels of infestation might show very few symptoms of damage, but it becomes more pronounced as populations climb.

“There’s stunting and there’s yellowing, but it won’t be uniform in the field. It’ll be patchy,” he says.

“Some indirect symptoms include areas of a field with poor weed control,” Tylka continues. “The soybeans might not look sick, but

Above: Soybean cyst nematode (SCN) often goes unnoticed in soybean fields until it impacts 30% of yield potential. Photo by Iowa State University and illustration courtesy of Farm Journal

because of poor weed control, they are stunted, and the plants don’t close over as quickly.”

In 2021, Pioneer tested 439 soybean fields in Illinois, Indiana, Iowa, Kansas, Michigan, Minnesota, Missouri, Ohio and Wisconsin to determine SCN pressure. The company reports SCN infestations were found throughout the study area, with over 80% of fields sampled having some level of SCN infestation.

Furthermore, 27% of fields sampled had SCN population levels capable of causing heavy to severe crop damage.

Tylka says many farmers don’t even realize they have SCN, which can make it a silent yield robber. “We can have up to 30% yield loss without any loss of color to the plants, height of the plants, or weight of the leaves,” he explains.

“When you get into severe situations where you can see even mild stunting, or mild yellowing, it goes up from there,” Tylka remarks. “Simple math shows that a 30% loss on 70 bushels of beans equates to 21 bushels. With $10 soybeans, that equates to $210 per acre.”

Farmers need to soil sample and have a diagnostic laboratory test done specifically for SCN to determine the population level present in the soil, a practice that can still be done this spring and even during the growing season.

According to the SCN Coalition, some state soybean boards offer free SCN testing. This changes from year to year, but in the past, states offering free SCN testing included Michigan, Nebraska, North Dakota, South Dakota and Wisconsin.

Once SCN is detected, farmers can use an integrated pest management plan, which includes varietal selection, crop rotation and seed treatment, to combat the pest.

“Farmers should rotate to corn because corn is a non-host crop,”

Above: The map illustrates known distribution of SCN in the United States and Canada. Those counties and rural municipalities first reported as infested between 2020 and 2023 are shown in blue, and those known as infested before 2020 are indicated in red. White indicates counties or areas where SCN has not been confirmed, but they are not necessarily SCN-free. Map courtesy of C.C. Marett and G.L. Tylka, Iowa State University

Tylka states. “Any year a farmer grows corn in a field, SCN egg numbers will drop.”

“Some of the eggs are going to hatch out, and the little worms are going to starve,” he says. “That drop can be as little as 5-10% and on up to 50%, so corn is our best tool to lower numbers.”

Tylka explains that an excellent

resource for farmers is the Soybean Cyst Nematode Management Guide originally published by the SCN Coalition and recently updated and reissued by the North Central Soybean Research Program.

The fifth edition is available to read or print in .pdf format by visiting https:// scn.plantpath.iastate.edu/files/inlinefiles/SCN_Management.pdf.

By Attorney Sam Moheban, Ruder Ware

All employers, regardless of whether they sponsor employees for work visas, should closely monitor the Donald J. Trump Administration’s evolving immigration policies.

This is critical due to the surge in enforcement of immigration laws and potential labor supply disruptions stemming from significant changes to immigration policy.

Employers who are unsure about their I-9 compliance, operate in immigrant-reliant industries (including agriculture, hospitality, construction, and manufacturing), or lack a plan for managing unannounced site visits from federal officers seeking to enforce immigration laws, should act now to prepare for the new landscape.

Employers should brace for a large increase in the frequency of I-9

audits. Over the past four years, enforcement has been minimal, but during the next four, audits are projected to rise by 20-50 times compared to levels under the Biden Administration.

This trend is consistent with enforcement patterns observed during President Trump’s first term.

For example, in 2019, approximately 6,000 audits were conducted nationwide, with plans to increase that figure to 15,000 for 2020 before the pandemic intervened. By contrast, in 2023 under former President Joe Biden, only a few hundred audits occurred nationwide.

Employers who have not conducted recent self-audits or are unsure of their compliance status would be well served by establishing policies and

getting their records in order now.

The why is simple. There are real financial consequences for even the most minor paperwork violations, as employers can be penalized up to $2,789 for each individual whose I-9 form is not in compliance.

There are far more serious penalties, including imprisonment, for those who knowingly employ persons not authorized to work in the United States.

Do you have a plan for handling an immigration site visit? A notice

Above: Sam Moheban is an attorney with Ruder Ware focusing his practice on litigation while also expanding the firm’s business immigration offerings.

Above: Certain industries, including agriculture, hospitality, construction, and manufacturing, are particularly reliant on migrant workers.

informing an employer that their I-9 records need to be produced for inspection is not the only enforcement tool employers should be prepared for, as site visits also occur.

Employers should have a plan for handling immigration site visits so that when federal officers arrive at your workplace unannounced, they do not have access to your facility and employees without first obtaining an enforceable warrant or your permission.

Some issues that employers should have in mind when planning for site visits include:

• Is access controlled to keep visitors out of the non-public sections of the facility?

• Is anyone trained to greet, identify, and investigate the presence of law enforcement at the facility? Is that same person trained to promptly contact management and/or legal counsel?

• Do you know the difference between an administrative warrant and a judicial warrant and how your obligation to comply with one versus the other may differ?

• Does your business have contractual or other legal obligations to cooperate with an investigation?

If you’re unsure about any of these issues, consult with an experienced immigration attorney to develop a robust site visit response plan.

Employers in immigrant-reliant industries should prepare for labor supply shocks. Immigrants, whether documented or not, make up a significant portion of the U.S. workforce.

Certain industries, including agriculture, hospitality, construction, and manufacturing, are particularly reliant on immigrant workers.

Already, just months into the second Trump Administration, there have

been numerous major immigration policy changes that will reduce the number of immigrants participating in the U.S. workforce.

These policies include:

Executive Order Protecting the American People Against Invasion

• Calls for the maximum enforcement of immigration laws

• Requires the registration of undocumented aliens and

prioritization of enforcement against those who do not comply

• Directs fines and penalties to be levied against undocumented aliens and those who facilitate their presence in the United States

• Seeks to limit grants of humanitarian parole, temporary protected status, employment authorization, and public benefits

• Creates Homeland Security Task Forces in every state to coordinate enforcement efforts between federal and local law enforcement

Executive Order Securing Our Borders

• Calls for the establishment of a physical wall and other barriers and methods to secure the southern border

• Reinstates the “Remain in Mexico” protocol

• Ends “catch-and-release” practices

• Terminates humanitarian parole for Cubans, Haitians, Nicaraguans, and Venezuelans

Executive Order Declaring a National Emergency at the Southern Border

• Declares a national emergency at the southern border to permit use of Department of Defense resources to enforce the border and immigration laws

Executive Order Protecting the United States from Foreign Terrorists and Other National Security and Public Safety Threats

• Calls for the maximal scrutiny of visa applicants and those already

Immigrants, whether documented or not, make up a significant portion of the U.S. workforce.

in the United States in lawful status

Executive Order Realigning the United States Refugee Admissions Program

• Suspends the U.S. refugee program indefinitely

N7158 6TH DRIVE P.O. BOX 215 PLAINFIELD, WI 54966 OFFICE: (715) 335-6660 FAX: (715) 335-6661

INHIBITING • FRUIT GUARD APPLICATIONS • SMART BLOCK APPLICATIONS • CIPC, CLOVE OIL APPLICATIONS

Executive Order Initial Rescissions of Harmful Executive Orders and Actions

• Rescinds many of the Biden Administration’s executive orders regarding immigration, including many that facilitated humanitarian immigration programs or reversed immigration enforcement priorities of the first Trump Administration

Unless offset by further changes to immigration law, many of which would require congressional approval, employers in industries that are particularly reliant on immigrant workers would be well served by planning for a decrease in their availability going forward.

Disclaimer

This article was originally published on January 23, 2025. Readers should be aware that U.S. immigration policy is constantly evolving, and regulations have since been published in furtherance of the executive orders mentioned in the article.

Increased size of farm equipment leaves little room for drivers to see around it

Article provided by SECURA Insurance Companies

What are the rules for driving tractors on the road?

Yes, there are laws and regulations you need to follow to be able to drive a tractor on the road. Most states require you to have a slow vehicle sign, which is an orange triangle that turns red at night on the back of tractors. You should check your state’s laws and regulations before driving a tractor on the road.

Laws and regulations may differ from state to state on what’s required to be able to drive a tractor on the road.

How fast can a tractor go on the road?

Tractors are allowed to travel up to 25 miles per hour (mph) on roads, even if the tractor can go faster. If you are towing equipment behind the tractor, you may have to go slower than 25 mph.

Some people follow the tractor until it gets to its destination, while others step on the gas and take the risk of passing.

What is the best way to prevent tractor accidents on the road?

A study done by the University of Iowa College’s Great Plains Center for Agricultural Health found that a large factor in tractor accidents on the road is the lack of lighting on the farm vehicle.

Although there are specific lighting standards, not all states require them by law. But those states that do enforce them found fewer crashes.

So, what can farmers do to decrease the number of farm vehicle crashes?

• Light up the tractor with headlights, taillights, turn signals, and reflectors.

• Mark the tractor with “slow-moving vehicle” emblems.

• Use magnetic LED lights for older and newer equipment that may not have sufficient lighting.

• Don’t forget visibility from the side-use lights and reflective tape to show traffic the size of the load being pulled.

Overall, the study done by students

at Iowa estimates crashes would decrease by 60% if the above bullet point practices were implemented.

For more information, contact SECURA Insurance Companies at https://www.secura.net, or find an independent agent near you at https://www.secura.net/find-anagent.

Staff enjoys Ag Day at the Capitol, producer-led tour, and WPS Farm Show

Members and staff of the Wisconsin Potato & Vegetable Growers Association (WPVGA) have been busy representing the association, growers and industry at area tours, shows and events during the offseason prior to planting.

On March 26, WPVGA Executive Director Tamas Houlihan joined Morgan Smolarek of McCain Foods and Mark Finnessy from Okray Family Farms, along with many industry professionals, during Ag Day at the Capitol, in Madison, Wisconsin.

Ag Day at the Capitol is an annual event open to Wisconsin farmers and agriculturalists so they can learn more about issues affecting the industry and meet with their state legislators.

WPVGA is a co-sponsor of the annual gathering that offers a unique opportunity to connect with lawmakers, delve into critical issues affecting agriculture, and advocate for policies that matter most to the farming community.

Above: Members of the Central Wisconsin Farmers Collaborative met at Gagas Farms, on March 28, for a tour of wetlands on the farm. Pictured, from left to right, are Randy Fleishauer of Plover River Farms, Casey Kristof of Specialty Potatoes, Mark Gagas of Gagas Farms, Mike Firkus of Firkus Farms, Curtis Gagas of Gagas Farms, Tracy Hames of the Wisconsin Wetlands Association and Dan Walsch of Plover River Farms. Farm fields surround the wetlands shown here, in Rosholt, providing a habitat for ducks, geese, sandhill cranes, beavers and other wildlife. WPVGA Executive Director Tamas Houlihan joined the tour and took the photo.

Houlihan also joined members of the Producer-Led Watershed Protection Group known as the Central Wisconsin Farmers Collaborative, who met at Gagas Farms in Rosholt, March 28, for a tour of wetlands on the farm. The wetlands provide habitat for ducks, geese, sandhill cranes, beavers and other wildlife.

Through the Producer-Led Watershed Protection Grant Program, the Wisconsin Department of Agriculture, Trade and Consumer Protection (DATCP) provides funding to producer-led groups that focus on nonpoint source pollution abatement activities.

continued on pg. 24

Above Left: Wisconsin DATCP Secretary Randy Romanski addresses a large crowd during the Ag Day at the Capitol event. Romanski pointed out that one in nine Wisconsin jobs depend on agriculture and that one farmer feeds 166 people.

Above: Agricultural displays line the Capitol rotunda as part of Ag Day activities. Pictured is a sprayer simulator.

As agriculture has evolved, the nature of the industry has become more complex and regulated. At Ruder Ware our attorneys act as legal counsel for producers and businesses providing products and services for the agriculture industry, and partner with a client’s current trusted advisors, such as accountants and lenders. Contact us today to see how our team approach yields the best results for your farm or business.

ruderware.com | visit our blogs at blueinklaw.com

The program goal is to improve Wisconsin’s soil and water quality by supporting and advancing producer-led solutions, such as cover cropping, minimal tillage and wetland restoration, that increase on-the-ground practices and farmer participation in local watershed efforts.

Badger Common’Tater Managing

Editor Joe Kertzman joined many WPVGA growers and Associate Division members at the 63rd Annual WPS Farm Show, April 1-3, on the Experimental Aircraft Association grounds in Oshkosh.

Ag businesses and community members jump at the chance to see the latest in farm equipment, services and technology at the WPS Farm Show, with 400 exhibitors attending from the United States and Canada.

To raise funds for the industry, WPVGA Financial Officer Karen Rasmussen and Program Assistant Julie Braun join the Wisconsin Potato Growers Auxiliary, along with grower and Associate Division members, in setting up and running a baked potato and French fry booth at the WPS Farm Show each year.

For more on their efforts, see

Collaboration expands GreenSolutions portfolio & increases availability of products

American Vanguard® Corporation announces that its crop business unit, AMVAC®, entered into a regional distribution agreement with DPH Biologicals®, a leading developer and supplier of agricultural biologicals. The agreement significantly expands

American Vanguard’s GreenSolutions portfolio and increases availability of biological products throughout the United States while also expanding DPH Bio’s footprint into specialty crop markets.

Under the long-term agreement,

Left: Brady Patoka and Julie Cartwright represent Jay-Mar, Inc. at the 63rd WPS Farm Show, April 1-3, in Oshkosh, Wisconsin, happy to pose for this photo taken by Badger Common’Tater Managing Editor Joe Kertzman.

Right: Sand County Equipment sets up a booth at the WPS Farm Show every year, here represented by, from left to right, Paul Cieslewicz, Brion Hackbarth and Jarod Cieslewicz.

“Auxiliary News” in the upcoming June 2025 Badger Common’Tater.

The WPVGA is proud to represent and advocate for its growers and associated business members at agricultural events across the state.

AMVAC resells DPH Bio’s key products, which include TerraTrove® SP-1 Classic® and TerraTrove AmplAphex® biofertilizers as well as BellaTrove® Companion Maxx®, a novel Environmental Protection Agency-approved biocontrol product with both fungicidal and nematocidal activity that is unique in its category. In addition, AMVAC distributes future product offerings, utilizing DPH Bio’s TerraTrove technology platform for biofertilizers and the BellaTrove platform for biocontrol products.

DPH Bio significantly strengthens its market access in the United States by partnering with AMVAC’s U.S. commercial and operational teams, having an initial focus on specialty crop markets. With the agreement, AMVAC is servicing DPH Bio’s existing customers in the western and southern regions by providing enhanced commercial and technical support.

The combination of DPH Bio’s leading products with AMVAC’s GreenSolutions portfolio provides an industry-leading offering for AMVAC’s grower, distributor, and retail partners.

The addition of DPH Bio’s TerraTrove products complements AMVAC’s current bio-stimulant portfolio, while Bella Trove Companion Maxx provides a novel biocontrol solution for AMVAC to complement its extensive crop protection portfolio.

“Our biological technology platform

has been refined across millions of acres to rapidly improve soil and plant health while offering alternatives and complements to traditional fertility and crop protection programs,” says Mick Messman, chief executive officer (CEO) of DPH Biologicals.

“We’re pleased to take the next step in our company’s evolution by partnering with AMVAC and gaining the advantages of its market access and sales team,” Messman adds.

“This relationship is pivotal for more growers to access DPH Bio’s technology and enables further expansion into the rapidly growing biocontrol segment.”

Douglas (Dak) A. Kaye III, CEO of American Vanguard, highlights DPH Bio’s technical know-how and

experienced management team as key advantages of the distribution agreement.

“DPH Bio, in addition to its current products, also has a great pipeline of future products,” Kaye remarks. “Along with our growing GreenSolutions portfolio, this collaboration has the potential to significantly increase the value, access, and use of biological products in western and southern U.S. crop markets for years to come.”

For more information, visit https:// www.douglasplanthealth.com, or to learn more about Vanguard Corporation, please reference https:// www.american-vanguard.com.

Sand County Foundation recognizes landowners employing conservation practices

Nominations are now being accepted for the 2025 Wisconsin Leopold Conservation Award®.

The award honors farmers and forestland owners who go above and beyond in their management of soil health, water quality, and wildlife habitat on working land.

Sand County Foundation and national sponsor American Farmland Trust present Leopold Conservation Awards to private landowners in 28 states. In Wisconsin, the $10,000 award is presented in conjunction with the Wisconsin Farm Bureau Federation and Dairy Farmers of Wisconsin.

Given in honor of renowned conservationist Aldo Leopold, the award recognizes landowners who inspire others to consider

conservation opportunities on their land.

In his influential 1949 book, “A Sand County Almanac,” Leopold advocated for “a land ethic,” an ethical relationship between people and the land they own and manage.

Award nominations can be submitted on behalf of a landowner, or landowners may nominate themselves. The nomination form can be found at www. sandcountyfoundation.org/ApplyLCA. The nomination deadline date is August 1, 2025. Nominations must be emailed to WisconsinLCA@ sandcountyfoundation.org.

Nominations are reviewed by an

independent panel of Wisconsin agricultural and conservation leaders. Last year’s recipient was the Adamski family of Seymour. To view profiles of all past recipients, visit https:// sandcountyfoundation.org/our-work/ leopold-conservation-award/state/ wisconsin.

“We are proud to sponsor the Leopold Conservation Award and celebrate our dairy farmers’ dedication to animal care and sustainable land and water,” says Dairy Farmers of Wisconsin CEO Chad Vincent.

“In Wisconsin, 99 percent of the farms are family owned,” Vincent explains. “Caring for the land and water is crucial to helping keep Wisconsin communities and dairy farms strong for future generations.”

“Farmers across Wisconsin are leading the charge in advancing conservation. At Wisconsin Farm Bureau, we celebrate Wisconsin’s agricultural heritage by advancing sustainable practices that protect the land and support future generations,”

remarks Wisconsin Farm Bureau President Brad Olson.

“We are proud to recognize those efforts as a supporter of the Wisconsin Leopold Conservation Award,” Olson continues. “I encourage farmers to apply or nominate someone who deserves this special recognition for their continued conservation efforts.”

“Leopold Conservation Award recipients are examples of how Aldo Leopold’s land ethic is alive and well today,” says Sand County Foundation President and CEO Kevin McAleese. “Their dedication to conservation is an inspiration to their peers and a reminder to all how important thoughtful agriculture is to clean water, healthy soil, and wildlife habitat.”

“As the national sponsor for Sand County Foundation’s Leopold Conservation Award, American

“I encourage farmers to apply or nominate someone who deserves this special recognition for their continued conservation efforts.”

– Brad Olson

Wisconsin Farm Bureau President

Farmland Trust [AFT] celebrates the hard work and dedication of the award recipients,” says AFT President and CEO John Piotti.

“At AFT, we believe that exemplary conservation involves the land itself,” Piotti adds, “the practices employed on the land, and the people who steward it. This award recognizes the integral role of all three.”

The Wisconsin Leopold Conservation Award is made possible thanks to

the generous support of American Farmland Trust, Dairy Farmers of Wisconsin, Wisconsin Farm Bureau Federation, Sand County Foundation, Culver’s, Compeer Financial, The Nature Conservancy, USDA Natural Resources Conservation Service, Wisconsin Corn Growers Association, Wisconsin Corn Promotion Board, Wisconsin Land and Water Conservation Association, and the Wisconsin Potato & Vegetable Growers Association.

Factors other than temperature, like soil moisture and crop residue, can influence the viability of pathogens

By Amanda Gevens, chair, professor and extension specialist, University of Wisconsin (UW)-Madison Department of Plant Pathology, and Ben Bradford, researcher, UW-Madison Department of Entomology

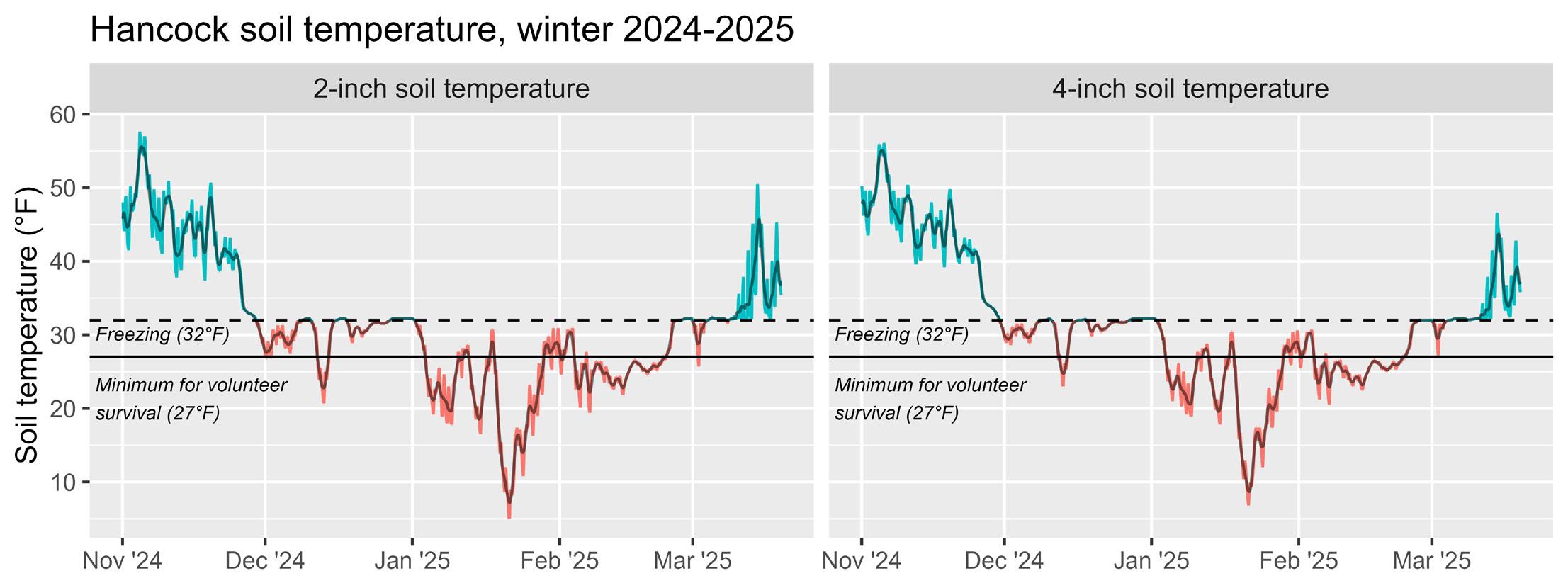

This winter of 2024-’25 was markedly different than the last in terms of air and soil temperature and risk of potato volunteer survival.

As per the University of Wisconsin Climatology Office, the winter saw minimal snowpack and sustained subfreezing conditions through early to mid-February, and frost extended deep into the ground until the

mid-February snowstorms added insulation.

These conditions further slowed frost progression despite subzero temperatures in some areas. By February 20, the statewide frost

Above: Amanda Gevens, chair, professor and extension specialist, UW-Madison Department of Plant Pathology, updates attendees of the 2023 Langlade County Agricultural Research Station Field Day on potato and vegetable diseases.

depths ranged from 10 to 35 inches, which is considered normal to below normal (read more: https:// climatology.nelson.wisc.edu/ february-and-winter-2025-climatesummary/).

Based on 2008 work conducted by Dr. Willie Kirk (Michigan State University) and Dr. Phil Wharton (now at University of Idaho), 4-inch soil depth temperatures below 27° Fahrenheit (F) for 120 hours are sufficient to kill off any volunteer potatoes remaining in the field (https://www.canr.msu. edu/news/potential_survival_of_ potato_volunteers_in_mich).

Volunteer survival can result in sprouts that might be challenging to manage and may serve as a potential source of pathogen inoculum in the spring.

The table, left, illustrates the model used to determine the likelihood of volunteer survival over winter based on soil temperatures between November 1 and March 31.

Based on soil temperature data retrieved from the University of Wisconsin Hancock Agriculture Research Station (HARS) weather station (https://wisconet.wisc. edu/stations/hancock/), these low temperatures were reached this

winter for durations greater than 120 hours. So, the risk of potato volunteers is low for the upcoming 2025 growing season.

Volunteer potatoes can introduce an increased risk of serious diseases, such as late blight, since they

typically appear in fields and margins that are not being managed as potato in the current growing season. Therefore, they do not receive preventive fungicide applications (https://vegpath.plantpath.wisc.edu/ diseases/potato-late-blight/).

Above, we share the soil temperature records from the HARS weather station, winter 2024-2025 and 20232024, for comparison.

Note the differences in sub-freezing soil temperatures and durations of sub-freezing soil temperatures between the years. In 2024-25, the soil froze to below 27° F for December-March, indicating a low risk for potato volunteer survival.

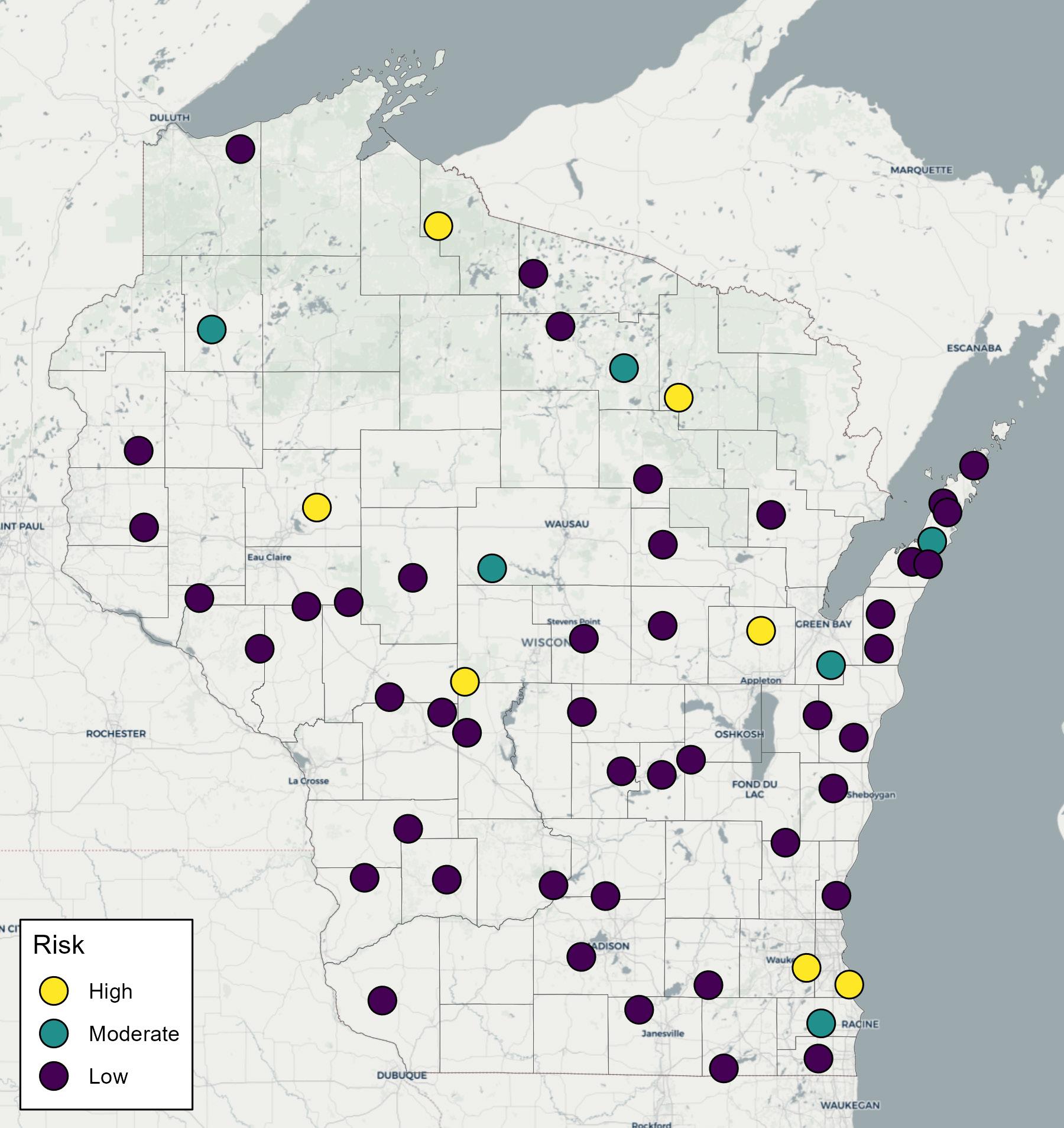

A look around the state of Wisconsin reveals that there are seven weather station locations with high risk of volunteer survival and five locations with moderate risk.

The figure on page 30 shows the Wisconet weather station locations (circles), with the color of circle indicating potato volunteer survival risk. The deep purple circles indicate low risk, teal is moderate risk, and yellow is high risk.

These stations are located among grassy and generally open areas outside of agricultural fields and away from tree lines. Explore the data in the online dashboard by visiting https://connect.doit.wisc.edu/potatovolunteer-risk/.

Cooler winters can create conditions less than favorable for the survival and activity of soilborne and debrisborne potato pathogens that

continued from pg. 29

challenge growers in Wisconsin and other regions.

It’s important to note, however, that factors other than temperature alone, like soil moisture and crop residue, can also influence the viability of pathogens. The pathogens that persist in our growing region are hearty and have adapted well to overcome inhospitable environmental conditions.

Fundamentally, most soil microbes require temperatures between 5096° F to sustain life. Soil microbial activities decrease with low soil temperatures and at freezing (32° F), and most activities stop, likely killing the microbe if not protected or insulated in some way.

The magnitude and duration of the cold, as well as soil moisture content and the presence of protective structures, are critical pieces of information in considering the disease risk.

Pathogens of concern in potato, which reside in agricultural fields (in and outside of plant debris) over the winter months, include fungi

Alternaria solani causing early blight, Alternaria alternata causing brown spot, Colletotrichum coccodes causing black dot, and Fusarium spp. causing wilt and dry rot.

Other pathogens of concern in potato are Helminthosporium solani causing silver scurf on tubers; Rhizoctonia solani causing black scurf and Rhizoctonia stem canker; Sclerotinia sclerotiorum causing white mold; and the Verticillium dahliae causal agent

along with nematode Pratylenchus penetrans in potato early dying.

More pathogens of concern are oomycete or water mold

Phytophthora infestans causing late blight; Phytophthora erythroseptica causing pink rot; Pythium ultimo

causing Pythium leak; bacteria Streptomyces scabies causing common scab; Pectobacterium and Dickeya spp. causing blackleg and tuber rot; and plasmodiophorid Spongospora subterranean causing powdery scab.

PATHOGEN CHALLENGES

While this list is not comprehensive and omits pathogens vectored by insects, it’s still imposing to consider the potential pathogen challenges in the production field.

Integrated management is essential in addressing the pathogens that you anticipate based on knowledge of field history and seed quality.

Key elements of a best disease management program include host resistance, clean seed, cultivation (especially leading to enhanced biodegradation of plant residues harboring pathogens), planting timing, crop rotation, irrigation management, fertility, weed management inputs, insect management inputs, and pathogen management.

Pathogen management encompasses chemical, biological, and biopesticidal inputs. Note the holistic listing of just about every crop production input! A stressed plant is a plant with greater susceptibility to infection.

We have been successful in keeping late blight out of potato production in Wisconsin and the northern United States in recent years. This outcome reflects the tight control of seed potato crop health and disease management in production fields.

Late blight is initiated from mycelium of the pathogen that survives between growing seasons by overwintering in infected potato tubers intended for seed, as volunteer tubers that are left in fields

at harvest, or within discarded cull and rock piles.

Recall that the late blight pathogen we have in North America is by-andlarge asexual and does not produce soil-persistent long-term oospores.

As a reminder to Wisconsin growers, as per the Wisconsin Administrative Code ATCP 21.15 Potato Late Blight, cull potato piles must be destroyed by May 20 of each year to prevent late blight spore production and disease initiation in the state.

Destruction can be achieved by land spreading the culls with incorporation, feeding culls to livestock, landfill, or other approaches that require Wisconsin Department of Agriculture, Trade and Consumer Protection written approval. For more

details, visit https://docs.legis. wisconsin.gov/code/admin_code/ atcp/020/21/16/1/b/6?up=1.

Wisconet, Wisconsin’s Environmental Mesonet (https://wisconet.wisc. edu/), is a growing network of weather and soil monitoring stations across Wisconsin that provides high-quality data at high spatial and temporal resolutions.

There are currently 58 weather stations with plans to expand to 80 by 2026. Each station provides more than 12 measurements every 5 minutes.

For more information about our potato and vegetable disease modeling support, please visit our UW Vegetable Pathology website at https://vegpath.plantpath.wisc. edu/.

Chameleon: Scientifically formulated to maximize the effectiveness of agricultural chemicals.

Impact: Promotes better tuber development by breaking soil clods, breaking hardpan and loosening the soil. Impact also prevents dry pockets in the hill by enhancing water infiltration.

Foam Cutter: A concentrated defoamer that saves tank fill up time and prevents pesticide spillage.

by Dana Rady, WPVGA Director of Promotions & Consumer Education

WPVGA director of promotions and consumer education leads a culinary demo

Cooking is something I have always enjoyed doing. No one in my family was a chef by trade, but I can’t say

that I ever complained about a dish my mom or grandmothers made. In fact, I love sharing their recipes

with Eric and the kids, reminiscing about stories from the past as we eat the dishes.

Occasionally, I still venture into trying to create a dish of my own or even modifying an existing recipe, depending on how adventurous I feel at the time or based on the ingredients at hand.

Since joining the Wisconsin Potato & Vegetable Growers Association (WPVGA) 13 years ago, I have thoroughly enjoyed expanding my creativity and learning about the versatility of America’s favorite vegetable.

In February, I had the opportunity to share some of that creativity and

Above: Prior to the potato culinary demonstration, on February 27, Chef Davey Lynch of the Food + Farm Exploration Center, in Plover, briefs attendees on the immersive education and activity center, its offerings and connection to the Wisconsin potato and vegetable growing industry.

Left: The “Potato Pocket Apple Crisp” recipe is courtesy of America’s favorite grill’n buddies Mad Dog and Merrill. Image courtesy of Susan Turgeson, Family & Consumer Sciences professor, UW-Stevens Point

versatility with 36 middle and high school Family and Consumer Science (FCS) teachers.

The request came toward the end of 2024 for WPVGA to do an interactive culinary demonstration at the Food + Farm Exploration Center (FFEC), in Plover, as part of the Wisconsin Association of Family and Consumer Sciences (WAFCS) Annual Conference.

“Please use the Kitchen Lab at the FFEC to promote the use of Wisconsin

potatoes and vegetables in the FCS classroom,” were the instructions.

Quite excited, I began thinking about a recipe that would not only be delicious, but also impactful, prompting others to think about new and creative ways to use potatoes.

By the time February 27 rolled around, I was sure that my chosen recipe would check all the boxes. And I wasn’t wrong.

I recalled a previous episode of Mad Dog and Merrill’s “Midwest

Above: Members of the Wisconsin Association of Family and Consumer Sciences (WAFCS) have fun preparing “Potato Pocket Apple Crisp” during the organization’s annual conference at the Food + Farm Exploration Center (FFEC) Kitchen Lab. Making the apple crisp filling was easy and just half the fun! Images courtesy of Susan Turgeson and Dana Rady

Grill’n” television show in which they showcased a special dessert using Wisconsin potatoes.

It’s called “Potato Pocket Apple Crisp”

continued from pg. 33

and is essentially an apple crisp filling in grilled (or baked) potato halves, all served in cardboard boats. Topped off with ice cream or whipped cream, and there’s a culinary experience you aren’t likely to forget!

It was an easy enough recipe to demonstrate and for a group to handle preparing, and unique enough to make a memorable impact.

I prepared the boats the day before by partially baking the russets and cutting out the centers. With the help of Chef Davey Lynch, FFEC’s Kitchen Lab facilitator, I set up a station at each table and prepared for the interactive demonstration.

Each table of five or six participants prepared the apple-crisp filling together and chose a halved potato to fill with the sweet treat. When the filled spuds were back in the oven heating through, I shared a presentation about additional unique

Participants were excited to taste the “Potato Pocket Apple Crisp,” most even adding a dollop each of whipped cream to their sweet and savory spuds.

ways to use Wisconsin potatoes that are delicious and quick.

For example, a recent on-the-go dinner for my family consisted of mashed potato sundaes in pint-sized mason jars. Another simple and

healthy breakfast was placing fried eggs on top of hash brown waffles that I had made the day prior and stuck in the freezer.

The point? America’s favorite vegetable can be prepared in simple, quick, easy and fun ways, and it’s one of the best whole foods you can give your body.

The notion that potatoes need a long time to cook is a myth. And the idea that potatoes are unhealthy is the biggest misconception. They are incredibly satiating, provide vitamins and nutrients in which we are commonly deficient, and are perfect for any meal, snack, or occasion.

After the presentation, the conference participants indulged in smothering their apple-crisp potato boats with whipped cream and tasted the sweet and savory creations. Many indicated the recipe would be easy enough to make in their own classrooms.

It was a great way to get more people eating more potatoes in more ways, more often.

Executive committee includes Wendy Dykstra of Alsum

Potatoes USA, the national marketing, research and promotion board for the potato industry, elected Steve Elfering of Boise, Idaho, as Chair of the Board at its annual meeting. Potatoes USA also announced its Executive Committee members to lead the organization through 2025-2026.

Elfering is chief executive officer of 1,4GROUP, Inc., a family-owned chemical distribution business that supports potato growers. He has a wide range of experience spanning his more than three decades in the industry, from growing and marketing fresh potatoes to research and serving as a supplier.

Elfering has also been engaged with Potatoes USA for 14 years, including most recently chairing the Communications Committee.

“It’s an honor to be elected to lead this group where we all have such a clear sense of why we do this work,” Elfering says. “We have passion for the product itself, passion for strengthening demand for this fantastic, versatile food, and passion for bringing together the deep expertise of people who make this an amazing industry.”

Elfering wants to continue building on the work that has been done at Potatoes USA while also keeping an eye toward changes in the international market. He has a unique perspective when it comes to the global picture, with approximately 80% of 1,4GROUP’s business being international.

“We’re on such a good path. Continuing to educate people about potato nutrition is key, and grower outreach and communication back

to the industry is key,” he says. “I also want to look at the impact that competition is having in international markets and make sure we have the best possible strategy in place for U.S. potatoes.”

Elfering also believes the way the industry comes together through Potatoes USA is one of the most important strengths of the organization.

“Those involved in Potatoes USA are competitors to some degree, but when we’re here, we’re walking hand-in-hand to support the industry as a whole and implement programs that make things better for all of us,” he says.

In addition to Elfering, Potatoes USA’s 2025-2026 Executive Committee members include:

• Hunter Gibbs of Washington, N.C., Chair, Market Development Consumer Committee

• Kathy Sponheim of Urbana, Ohio, Chair, Nutrition and Health Committee

• Nathan Bender of Bakersfield, Calif., Co-Chair, Production Research Committee

• Trever Belnap of Hamer, Idaho, Chair, Communications Committee

• Dave Masser of Sacramento, Pa., Chair, Market Development Retail Committee

• Jess Blatchford of Baker City, Ore., Co-Chair, Production Research Committee

• Wendy Dykstra of Rio, Wis., Chair, Finance and Policy Committee

• Cliff Shaw of Monte Vista, Colo., Chair, Culinary Committee

• Travis Meacham of Moses Lake, Wash., Chair, Market Development Foodservice Committee

• Shelley Olsen of Othello, Wash., Immediate Past Chair

“I have full confidence that this Executive Committee is going to make a notable impact in the year ahead, along with all the Potatoes USA board members,” Elfering concludes.

Company works with growers of cash crops such as potatoes and vegetables, dairy producers and more

By Joe Kertzman, managing editor, Badger Common’Tater

Located in Plover, Wisconsin, Badger Plastics & Supply is a distributor of mechanical and industrial plastics, including a full line of machined plastic parts, sheets, rods, tubes, and truck and industrial liners of all types.

The company specializes in custom plastic machining and fabrication services, manufacturing, sales, parts, field service, and installation.

The shop includes seven vertical CNC (computer numerically controlled)

machining centers, a 5’x10’ gantry mill, three CNC turning centers, CNC beam saws, and plastic welding.

In its 40-plus-year history, the company has adjusted to a rapidly evolving agriculture industry, particularly when it comes to what materials or supplies it can provide to meet the modern needs of customers in Central Wisconsin and beyond.

“Over the years, we found opportunities,” Roger Nelson, Jr., outside sales representative for Badger Plastics & Supply, says. “We developed a line of heavy-duty augers to serve the dairy industry and got deeper into truck lining and other bin and hopper liners.”

When it comes to steel and plastic augers, Nelson explains, while the steel ones are typically for dairy customers to transfer manure from barn entryways to pits, plastic models can be used to move fertilizer, seed and even wastewater.

The company assembles parts from several different manufacturers to create a heavy-duty auger system that is sold and installed through a dealer network.

“One of the major food processors in

the area uses an auger system that we built,” Garret Dawley, outside sales rep specializing in agriculture and liners, says.

“In the case of shelling peas,” he adds, “or the same with husking corn, the scraps, waste and other parts of the vegetables are all mixed in with water and taken away in plastic troughs.”

“We’ve made plastic auger troughs that are resistant to abrasion and chemical attack,” Nelson adds. “We’re pretty flexible, having assembled steel troughs with plastic augers and

“We’re pretty flexible, having assembled steel troughs with plastic augers and plastic troughs with steel augers.”

– Roger Nelson, Jr., Badger Plastics & Supply

plastic troughs with steel augers.”

“For our steel augers, we can do anything from 2 1/2-inch diameter up to 60 inches in diameter, in custom lengths up to 20 feet long, and with customizable flighting in variable thicknesses,” Dawley explains.

“Flighting” as it relates to augers refers to the helical screw blades attached to rotating shafts.

Left: Plastic augers from Badger Plastics & Supply come in tubing sizes from 4-16 inches in diameter with flighting, each riding on a stainless-steel head shaft. The company can go down to a 1.5-inch regular stainless round tube, but not a hex tube. Once 4 inches or larger, then the flighting rides on a hexagon-shape tube.

“The variations are endless, including types of steel or stainless steel used, left- or right-hand or variable pitches, and type of flighting, whether sectional or helicoid,” Dawley says.

Badger Plastics & Supply Can Customize Augers for You . . .

continued from pg. 37

If a customer has an old piece of equipment and can’t find an auger for it, Badger Plastics & Supply can custom make something for them.

“With plastic augers, flighting diameter ranges from 2-19 inches depending on whether a cup or straight flight is used, and rides on a stainless-steel hex shaft,” Dawley states.

Nelson explains that plastic augers are more efficient, lighter, don’t corrode like steel augers, take less energy, are easier on parts, and output less friction and noise.

“Usually, an auger will have one end where the flighting wears out over time,” he remarks. “With steel, you need to replace the whole section of auger. Plastic auger flights can be replaced individually.”

“This time of year, farmers need the augers right now, and steel on order is eight weeks out,” Dawley says.

“I just visited one of the larger potato growers in the area and set up a plastic auger system on a fertilizer

A Badger Plastics & Supply customer called wanting to replace the rusted augers on his seed tender truck, consisting of one 7-inch straight auger running under the hoppers and one 9-inch folding auger running on the side and back of the truck. He was concerned about not being able to find a replacement for the folding auger. Four weeks later, he has a complete folding auger with male and female sockets and a heavy cable guide. Note, both augers have cupped flights for gentle seed running, and the sockets on the center tube are stainless steel to resist corrosion.

truck, double checking the diameter and measurements, and got it set up with sockets and a floating auger so it can go on down the road,” he relates.

This is a 6-inch-diameter auger Badger Plastics & Supply built to be mounted on a gravity box, complete with swivel-style pan hopper. Overall lengths on these vary depending on customer but generally fall into the 10-14-foot range and are used for seed and fertilizer in this type of application. The customer dropped this one off for repair as he clipped the side of a building and needed a new swivel flange installed.

“This one was fully customized and had a two-week wait on it. You can slide the bottom two sections of the flighting off, so if they wear out, the grower can purchase two new ones instead of replacing the whole auger,” Dawley explains.

Badger Plastics & Supplies’ dealer network includes P&D Sales of Pulaski, and Spiegelberg Implement, Inc. in Weyauwega, as well as others.

“Those dealers will design, install, and maintain the augers,” Nelson details. “We provide the whole assembly to the dealer, and Garret does help with design, too.”

“If you’re buying something off the shelf, the augers are usually cheaper. They’re thinner, the gauge of steel is not as thick, and they come in 10-foot sections that you’d need to modify,” he adds.

HEAVY-DUTY AUGER

“We provide a heavy-duty auger.

A 6-inch auger is being built for a cross planter with a custom-size intake hopper and downspouts.

Usually, for the auger, a strip of steel is stretched around the outside of a shaft, and the flights end up being thinner on the outside than the inside. All wear happens on the outside of the auger,” Nelson explains.

“Our disc is cut out of steel with a hole and slot in it,” he continues,

For steel augers, Badger Plastics & Supply can work with sizes ranging from 2 1/2-inch-diameter up to 60 inches in diameter in custom lengths up to 20-foot long, and with customizable flighting of variable thicknesses (within limitations, of course).

“and welded around the shaft so the thickness of the steel is maintained all the way to the edge of the auger flight.”

“I have a lot of customers I’ve known since I was 19, and I’m 47 years old,” Dawley relates.

“We’re a good neighbor,” Nelson

imparts. “We contribute to the community when we can, employ 27 people from the area, and help with schools such as tech colleges.”

“We try to keep it simple here,” he concludes. “If you take good care of customers and employees, you have a successful business.”

By Dakotah Smiley, Vice President, WPGA

Key achievements in the fifth decade include initiatives to engage communities

(WPGA) marks its fifth decade (2015–2025), the industry has continued to evolve. All the while, the Auxiliary has continued embracing new opportunities and staying true to its core mission of promoting Wisconsin potatoes, supporting growers, and educating the public.

This is the last of the five-part series. Thank you for reading along as we walked through the last five decades.

The Fifth Decade: 2015–2025

Over the past 10 years, the WPGA has expanded its outreach, strengthened industry partnerships, and introduced innovative initiatives to engage communities.

From educational programs to new events and offerings, the Auxiliary has worked tirelessly to enhance awareness and appreciation for Wisconsin potatoes.

Key Achievements of the Fifth Decade: Year-Round Membership Events

– WPGA has continued to foster industry collaboration through annual networking events and educational workshops, providing members with valuable insights and a chance to reconnect.

A New Partnership with the Food + Farm Exploration Center – A major milestone, this collaboration has created a hub for agricultural education, offering visitors an immersive experience into modern farming, sustainability, and food production.

The Spudmobile’s Continued Impact – The mobile educational unit has remained a critical outreach tool, traveling to schools, fairs, and community events to share the story of Wisconsin potatoes and their impact on global food systems.

Harvest Fair – A recent addition to Wisconsin’s agricultural celebrations, Harvest Fair has provided an opportunity for the Auxiliary to sell Wisconsin baked potatoes in a festive atmosphere at the State Fairgrounds.

As WPGA celebrates 50 years of dedication, its members remain committed to advancing the industry, fostering innovation, and ensuring a bright future for Wisconsin’s potato growers.

Join Us for the 50th Anniversary Celebration!

We invite everyone to join us for a special milestone event, the Auxiliary’s 50th Anniversary Celebration! The anniversary party will take place at the Food + Farm Exploration Center on Thursday, June 26th, 2025, from 5-8 pm.

The Food + Farm Exploration Center is a hub for agricultural education, offering visitors immersive experiences involving modern farming, sustainability, and food production. Collaborating with the Food + Farm Exploration has presented opportunities for the Auxiliary to expand its mission of promoting Wisconsin potatoes.

From left to right, the Auxiliary’s Misti Kinnison, Dakotah Smiley, and Andrea Topper mix ingredients for Potato Curry Soup in the Food + Farm Exploration Center Kitchen Lab.

The Spudmobile has remained a critical outreach tool, traveling to schools, fairs, and community events to share the story of Wisconsin potatoes and their impact on global food systems. The mobile education unit was open to visitors, June 10, 2023, during the Portage County Dairy-Palooza at Feltz Dairy Store, in Stevens Point.

The evening of reflection, networking, and celebration will honor the industry’s accomplishments and look forward to its promising future.

Mark your calendars, and we hope to see you there!

Until next time,

Right: A recent addition to Wisconsin’s agricultural celebrations, Harvest Fair has provided an opportunity for the Auxiliary to sell Wisconsin baked potatoes in a festive atmosphere at the State Fairgrounds. Ready and willing volunteers at the Harvest Fair in Milwaukee include, from left to right, Janina Petrick, Datonn Ammel, Dana Burns, and Marie Reid.

By Frank King,

suicide prevention speaker, including 13 TEDx Talks and the sharing of insights with corporations and associations

Good news: Eight out of 10 people who are suicidal are ambivalent; they cannot make up their minds, and nine out of 10 give hints in the last week leading up to a suicide attempt.

This means that you can make a difference. You can save a life, and you can do it through something as simple as having a conversation, if you know how, and I will tell you how.

You may ask why certain workplaces have such a high rate of suicide. There are a number of factors that put workers at higher risk:

• Construction and agriculture, for example, are male-heavy occupations, and currently, eight out of 10 suicides in the United States every year are men.

• Suicide is the second-leading cause

of death for men under 45 in the United States.

• Women attempt suicide three times more often than men, but men tend to complete a suicide because they frequently use a firearm.

• One of the causes is toxic masculinity. There is an ideology among males where they believe they should suppress their emotions.

• Men are often pressured to suppress these emotions, especially vulnerability, which can lead to a deterioration of mental health and difficulty forming healthy relationships.

Some additional risk factors are:

• Many are of an age where we see the highest rates of suicide nationwide.

• Many are veterans who struggle with PTSD (Post-Traumatic Stress Disorder).

• Many injuries are treated with opioids.

• Recent research studies show that there is a relationship between physical pain and mental health disorders.

The problem is a vicious cycle: workers experience pain, which impacts their mental health, which can affect their job performance. This leads to increased difficulties at work, which exacerbates their mental health problems, and so forth.

Above: Agriculture is a male-heavy occupation, and currently, eight out of 10 suicides in the United States every year are men.

Again, the good news is, you can make a difference, you can save a life, and you can do it by doing something as simple as starting a conversation, if you know how, and I’m going to tell you how.

Signs of Depression:

• They eat too much or cannot eat.

• They sleep too much or cannot sleep.

• They have trouble getting out of bed in the morning, so they are often late for work or school.

• However, they often rally in the afternoon as if they are a different person.

• They let their personal hygiene go, clothes may be dirty, and hair not so clean.

What should you say to someone who you believe is depressed, or who has told you they are depressed? Let’s start with what you don’t say.

What You Don’t Say:

• Pull yourself up by your bootstraps.

• Turn that frown upside down.

• Have you tried fish oil (at which point I go from being suicidal to homicidal).

What You Do Say:

• I’m here for you and I mean it.

• I know that you’re not lazy, crazy or self-absorbed.

• I know that depression is a mental illness.

• I know that, with time and treatment, things will get better.

• I will take the time, and I will help you get the treatment.

And you must ask them, “Are you having thoughts of suicide,” just like that. If you cannot ask that question, find someone who can. And if you cannot find anyone who can, call me, and I will ask them. I can be reached at (858) 405-5653.

There is an urban legend that you should never mention the word suicide in front of someone who is depressed, because “It might give

them the idea.” When in fact, the opposite is true. Mentioning it out loud reduces the chance that they will die by suicide.

Signs There Are Thoughts of Suicide:

• They talk a great deal about death and dying.

• You notice them Googling death, dying, or how to die by suicide.

• Death and dying appear as themes in their artwork, music or writing.

• They are getting their affairs in order.

• They are giving away prize possessions, as they want them to go to a special person when they are gone.

• They have been depressed for a long time, and now they are happy for no apparent reason (they may be happy because they have chosen a time, place, and method, and they know the pain is coming to an end).

Suicide Prevention as a Workplace Health & Safety Priority . . . continued from pg. 43

What do you say if you believe someone is suicidal or they have told you they are? Let’s again start with what you don’t say:

• You are just looking for attention.

• No one who talks about it ever does it.

• You’re just being melodramatic.

danger to others, they will take that person into custody and bring them before a judge, who will determine if they should receive a three-day, involuntary hold.

You’d be healthier, too, if you spent your winters in Hawaii.

What you ask:

You’d be healthier, too, if you spent your winters in Hawaii.

• Do you have a plan?

• If they have a plan, “What is your plan?”

• If the plan is detailed as to time, place, and method, “Will you let me take you to a mental health facility for evaluation?”