ARCH 7082 Design 12 PORTFOLIO

ARCH 7082 Design 12

Roberto Requejo Belette SEMESTER 2, 2023-24

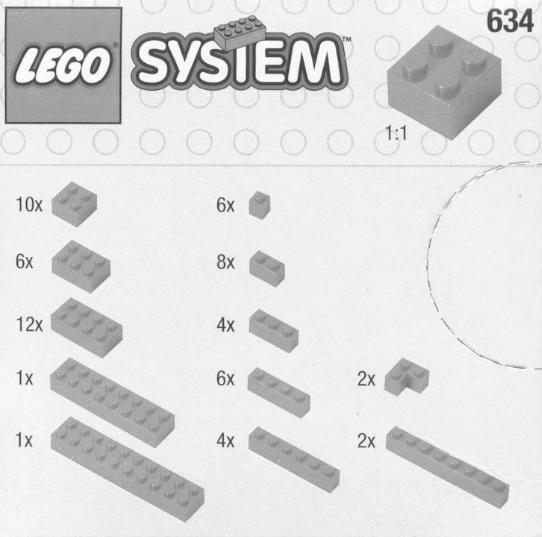

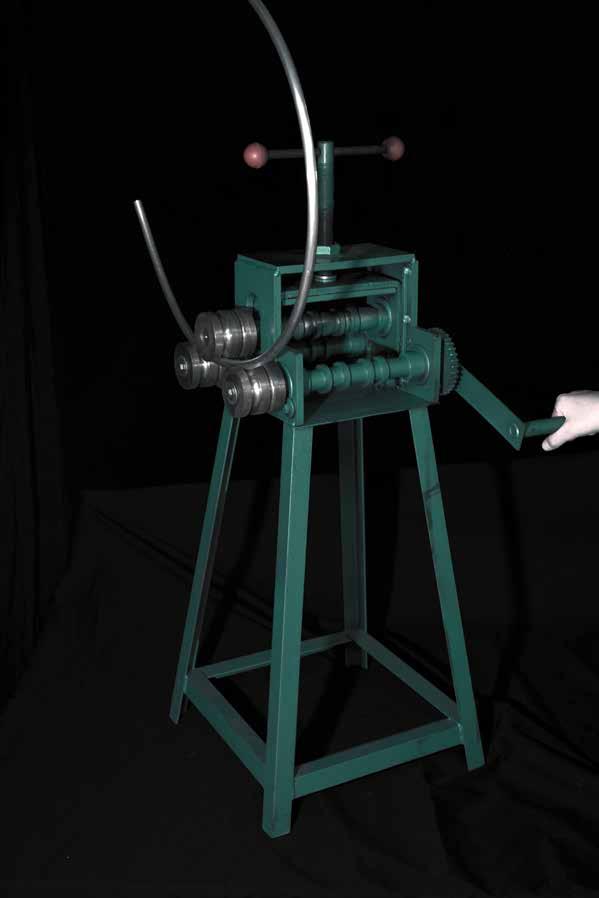

From left to right: 75mm diameter bender for 12mm OD pipe

32mm diameter bender for 6-8-10 mm OD pipe (RUBBER)

35mm diameter bender for 6-8-10 mm OD pipe

50mm diameter bender for 6-8-10 mm OD pipe

25mm diameter bender for 3-4-6 mm OD pipe

HOLLOW TUBES are strong in torsion and bending as well as being lighter weight than their solid equivalent.

The studio is concerned with QUICK AND EASY ASSEMBLY, and departs from an interest in exploring the potential of the tube and joint system with an interest in building quickly-assembled, dismountable, strong, light and reconfigurable event infrastructure.

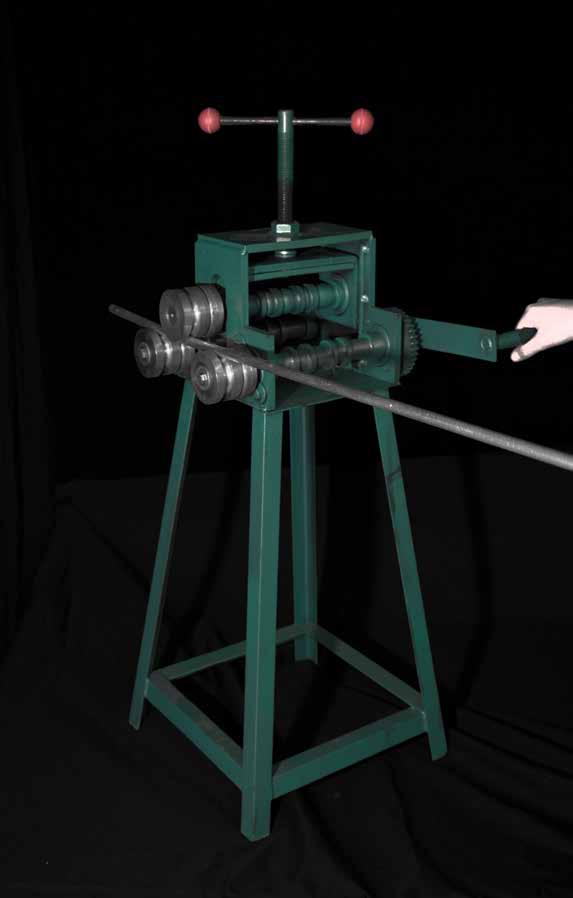

In the very beginning we are familiarizing ourselves of ways to manipulate the material, and within the process we were using manual pipe bender, pipe cutter and pipe curler, to archieve some configurations that we had in mind.

Quickly we realized the limitation of bending pipe, and we were trying to adapt as a method to learn about the craftability of the material. As a quick summary, we concluded the follows and carry the lesson through the next stage:

1. Steel tubing is a very densed material and has great flexibility, such that it has great resilient to bending. Bending is almost impossible even if we were handling 3mm or 6mm diameter tubing. There must be heat treatment to soften the material as to loosen the flexibility of it and curl it to an accurate position.

2. Copper tubing is soft and craftable yet very expensive. Amoung the three, ALUMINIUM TUBING is the most suitable material.

3. Repeated geometry is very difficult to produced with 100% resemblance, such that a "MOLD" or a "RIG" would be helpful.

With the knowledge in mind, we proceed to a bending exercise.

1. U-TURN SET: Provide 180-degree turning with various

ZIGZAG SET: Travel with z shape pattern within same distance but different count of turning

DETOUR SET: Provide a branching travel path with various profile but returning to the same direction

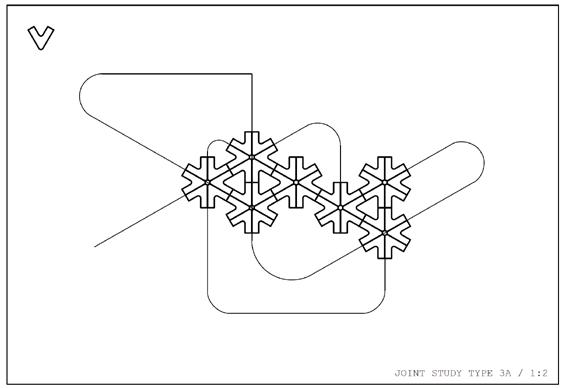

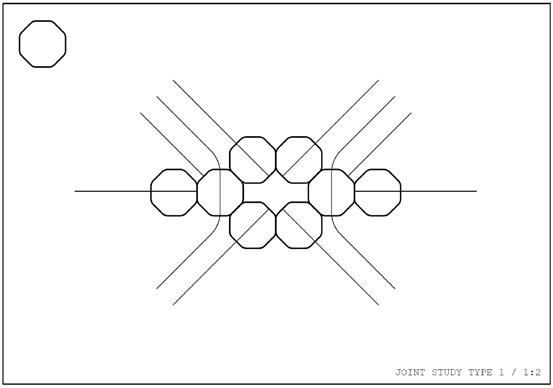

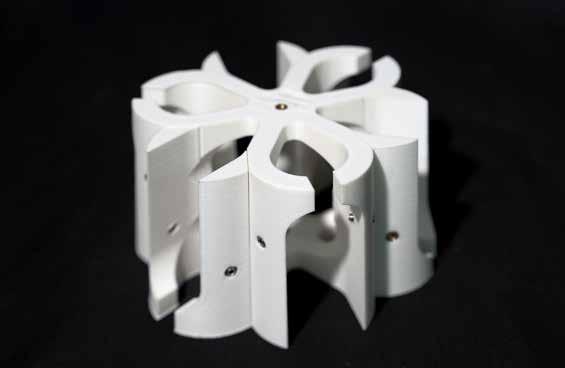

Hexagons and Octagons, 45° and 60°

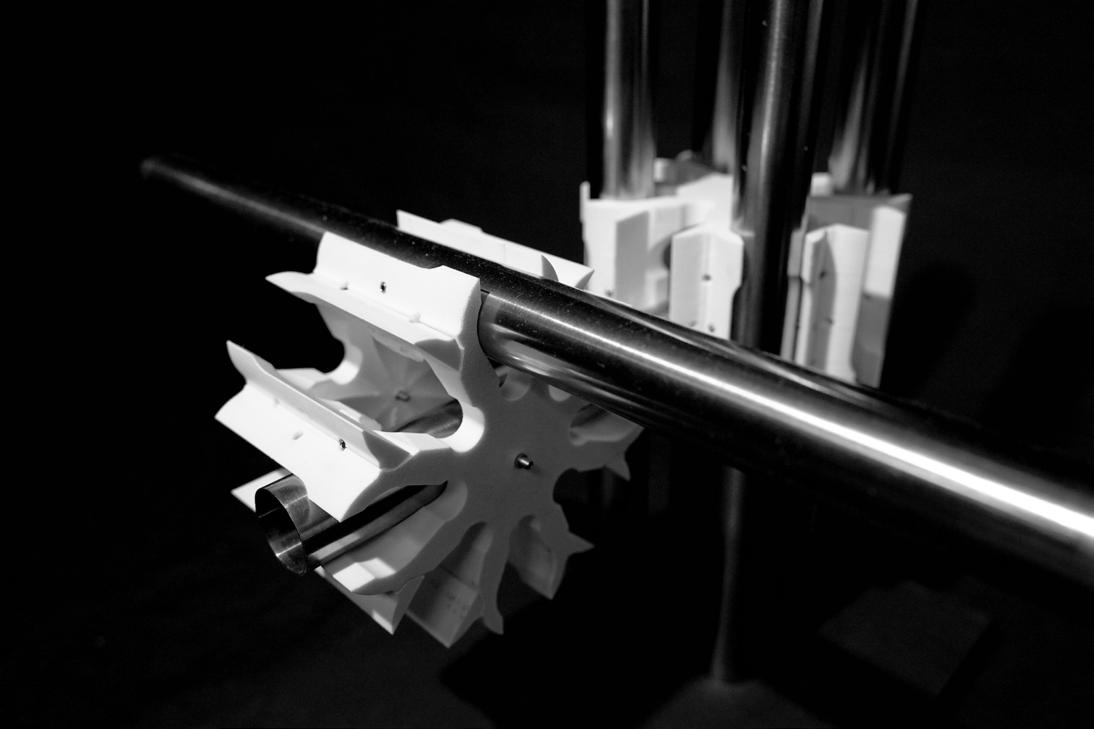

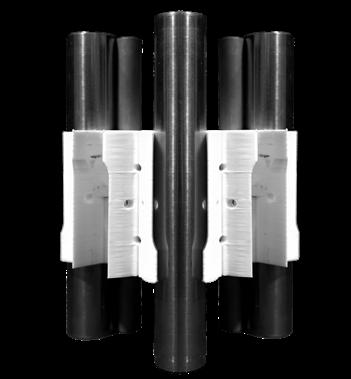

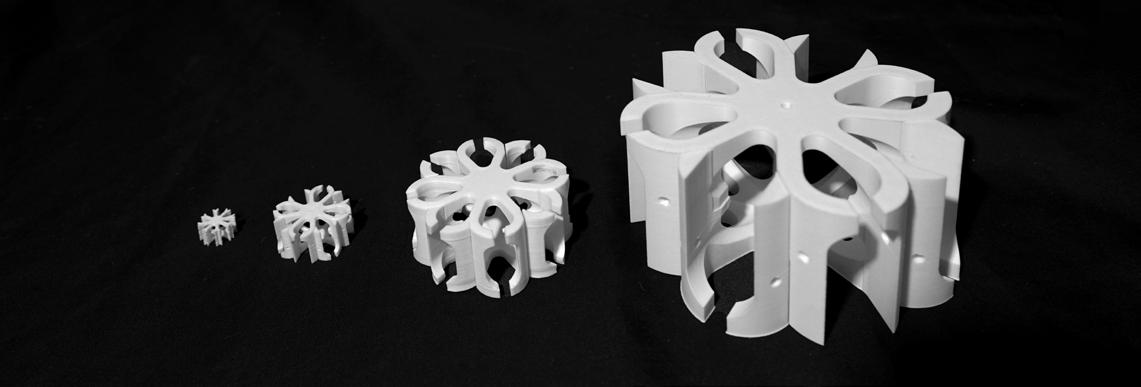

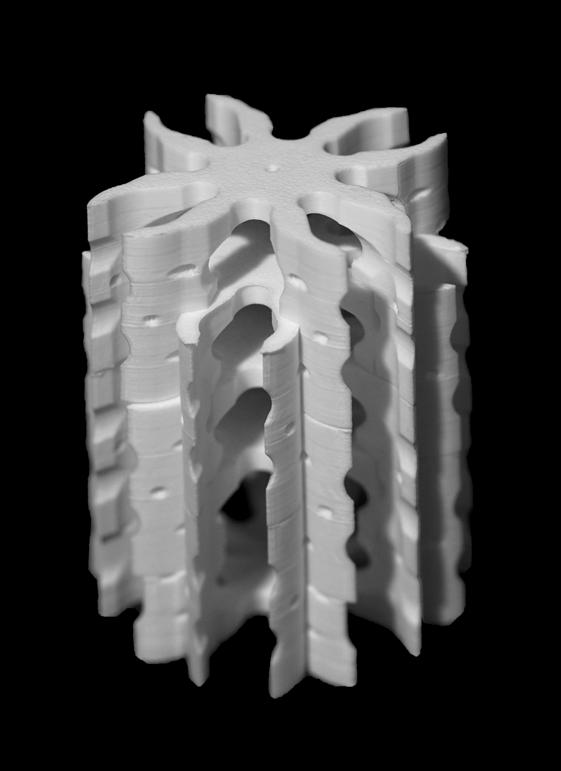

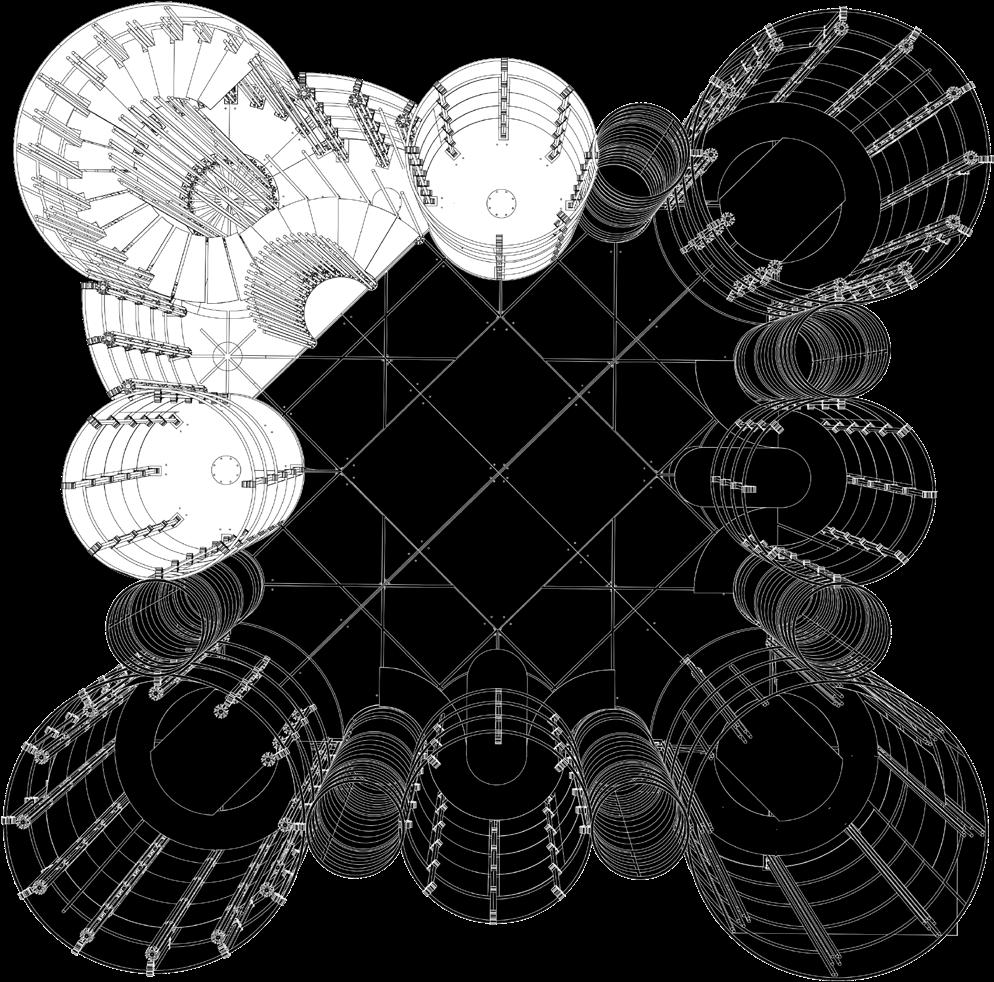

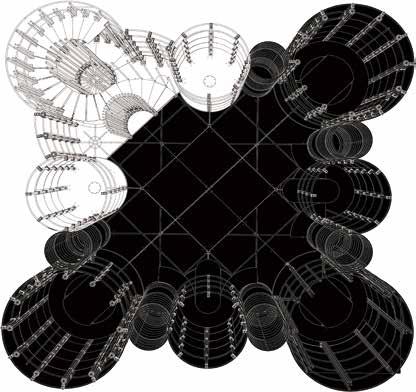

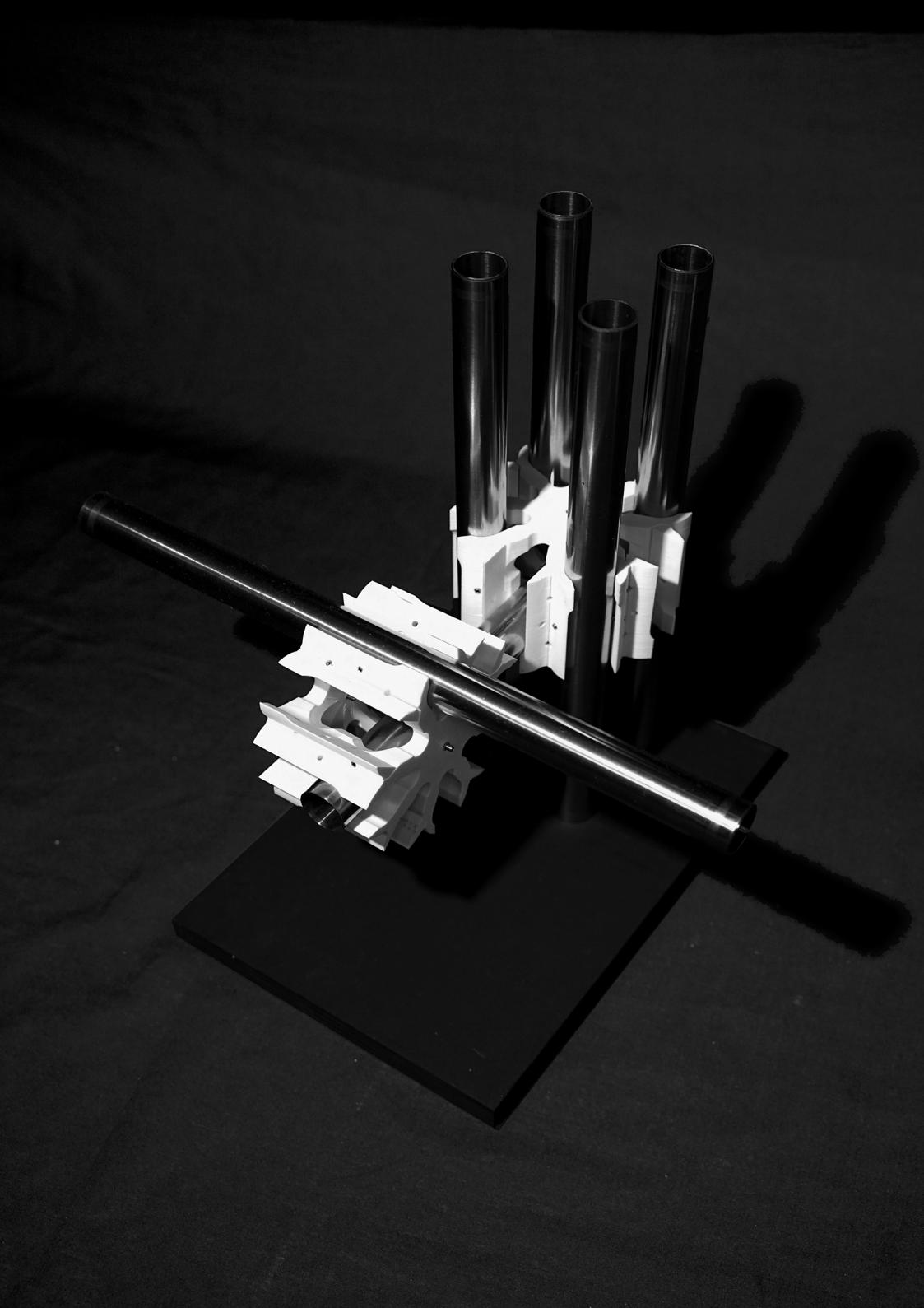

I dive into the joint designing with two simple direction: 1. Hexagon with 60-degree included angle ; 2. Octagon with 45-degree included angle

With such, most angles that appeared in my bending vocabulary would be included and also it would allow interconnection between module quite easily. Acknowlegded that there are plenty of mature stock product on joint that is not only economical but also sufficiently developed of strength or ease of using. I created my joint with the following ideas in mind to differ from the stock product and therefore possibily induced some new moments:

1. Multiple channels going to the vertical and the horizontal, allowing customization of ratio between verticals and horizontals.

2. Allowing tube to criss cross, at the joint with 2 layers of horizontal channels, instead of point weld at the node.It allows more tolerance during composing which increase the freedom for spontaneous creation.

Hexagons and Octagons, 45° and 60°

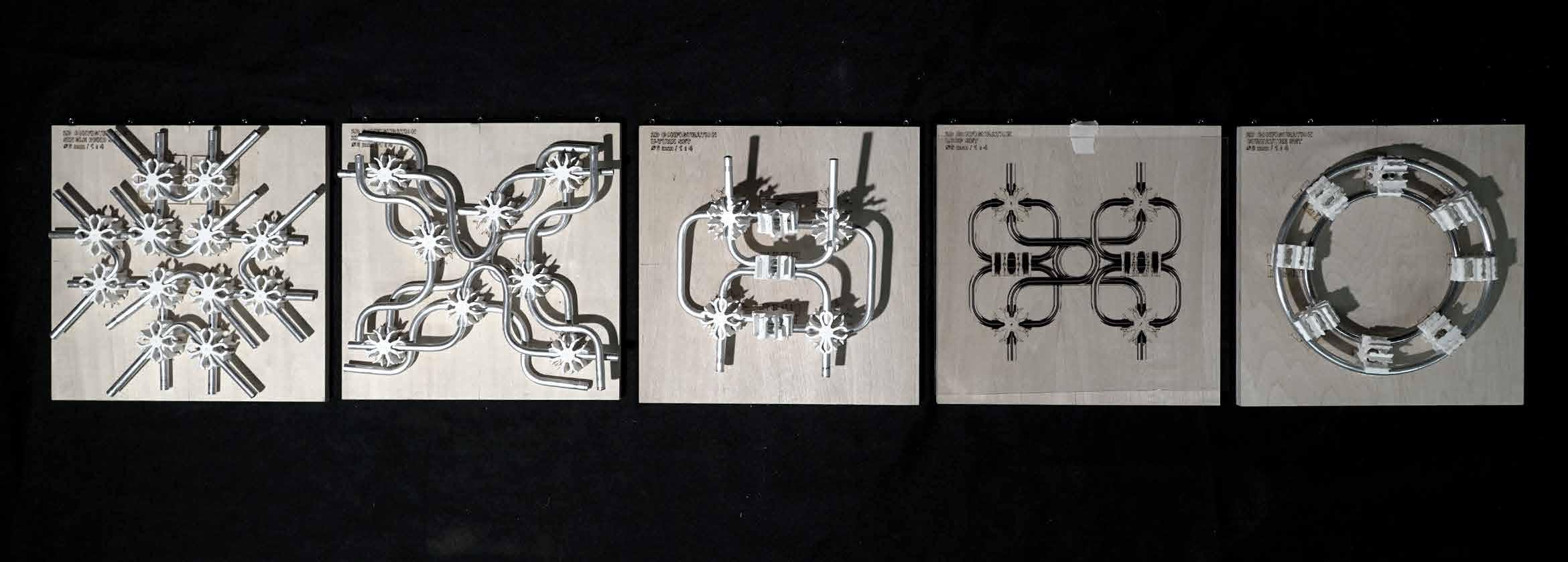

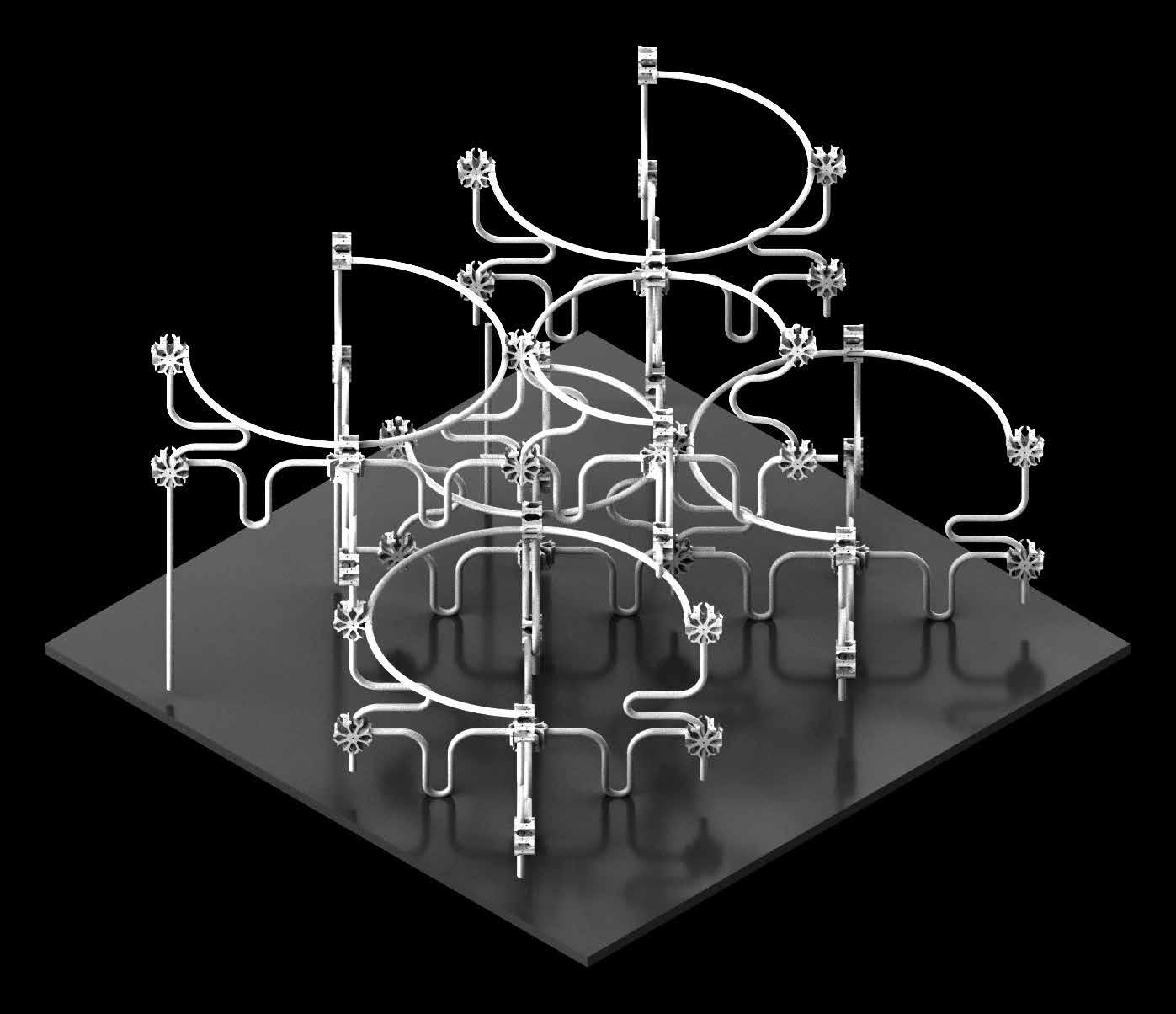

VOCABULARY OF DIFFERENT TUBING INTO 2D SURFACE

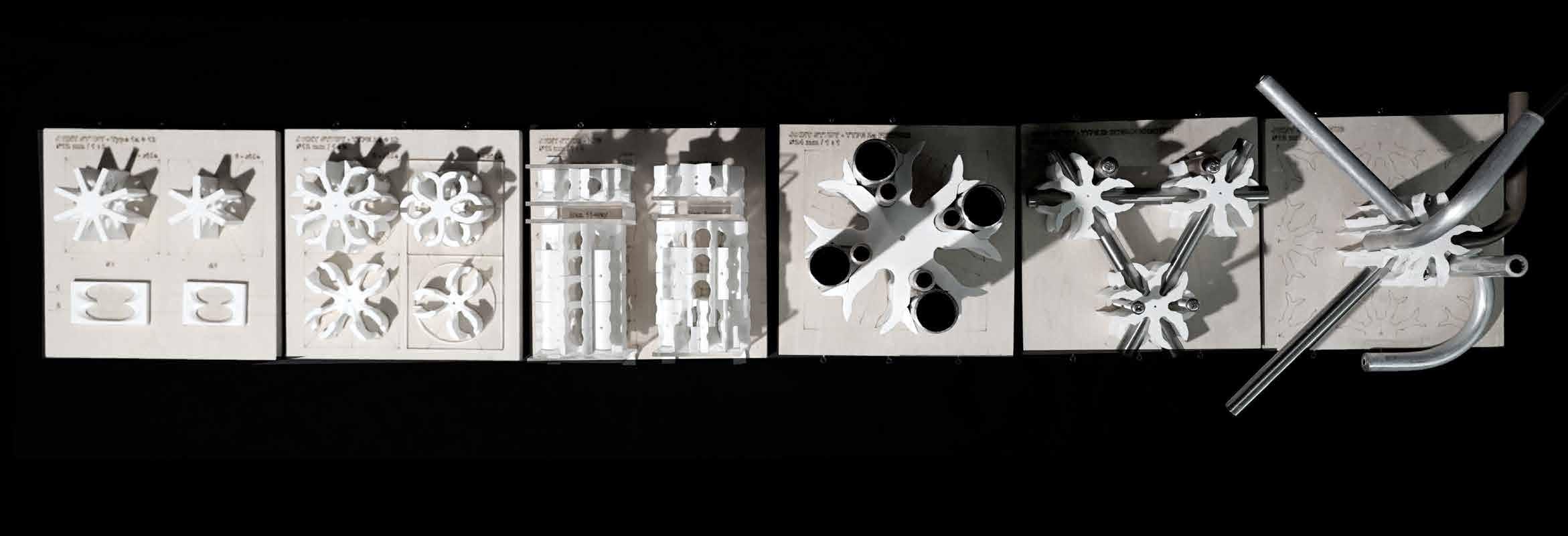

From left to right:

2D CONFIGURATION - SINGLE BEND SET

2. 2D CONFIGURATION - ZIGZAC SET

3. 2D CONFIGURATION - U-TURN SET

4. J2D CONFIGURATION - LOOP SET 5. 2D CONFIGURATION - CURVATURE SET

This set of 2d configuration ought to test the limit of the joint and with craftable bent aluminium tube segment,with complex criss crossing. In the process, not everyone of the configurations obtained close resemblance with the orthographic projection because the tighness of the joint denied the inaccurate bending segment.

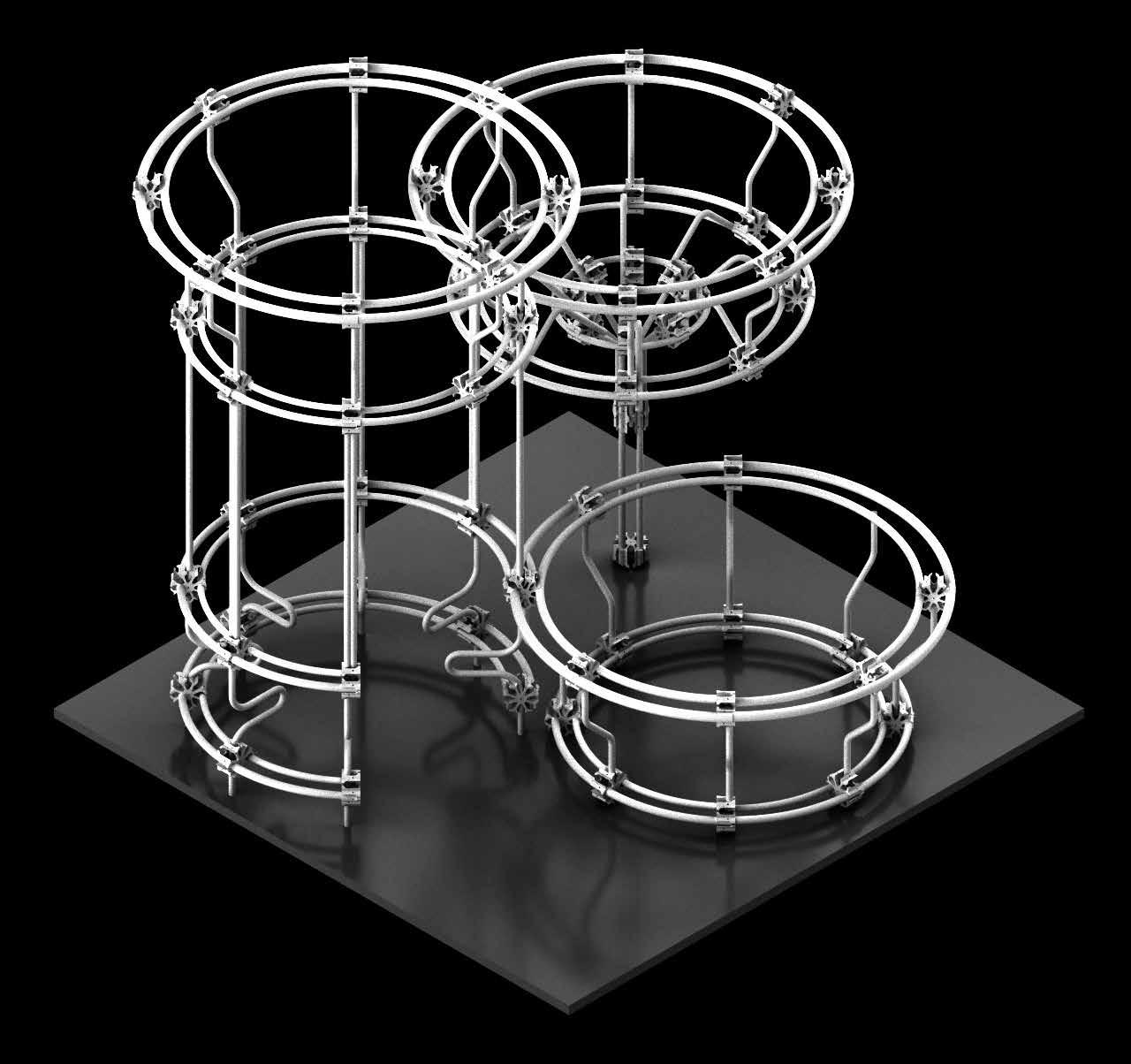

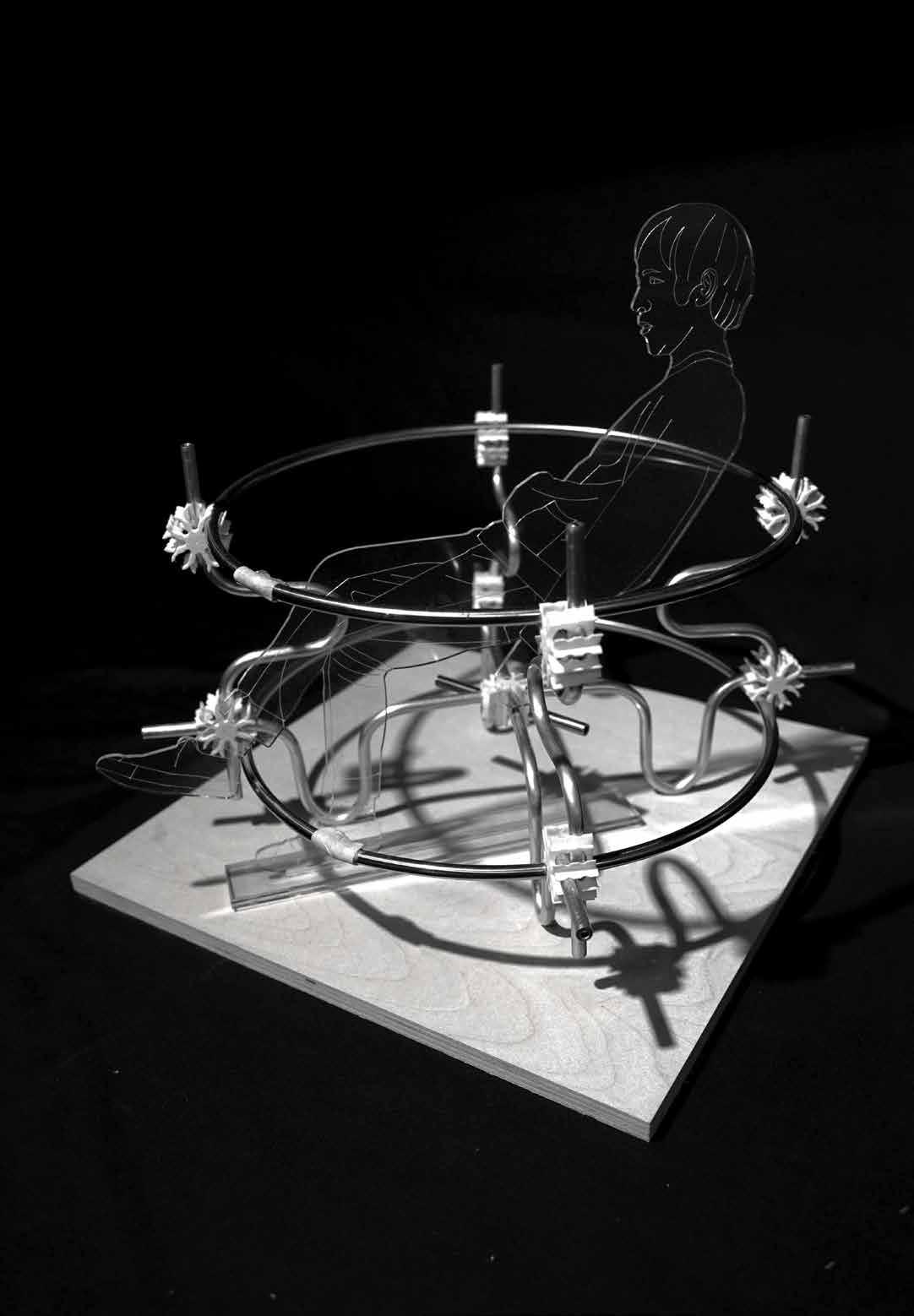

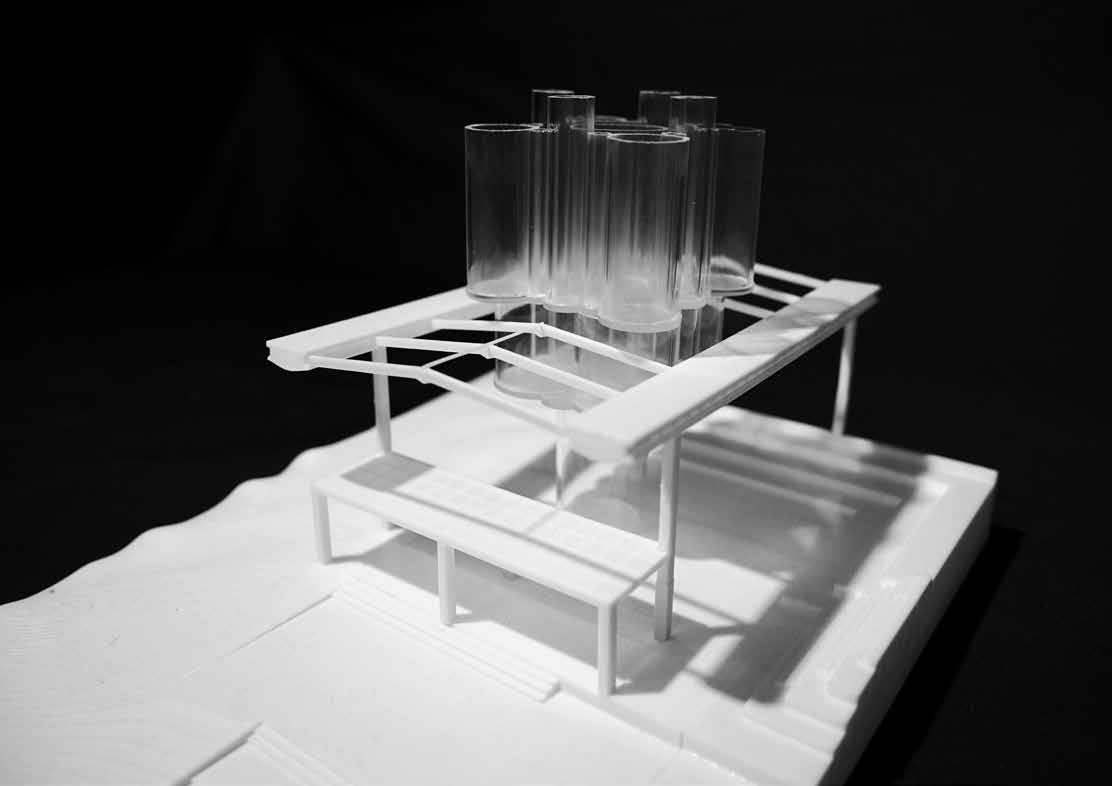

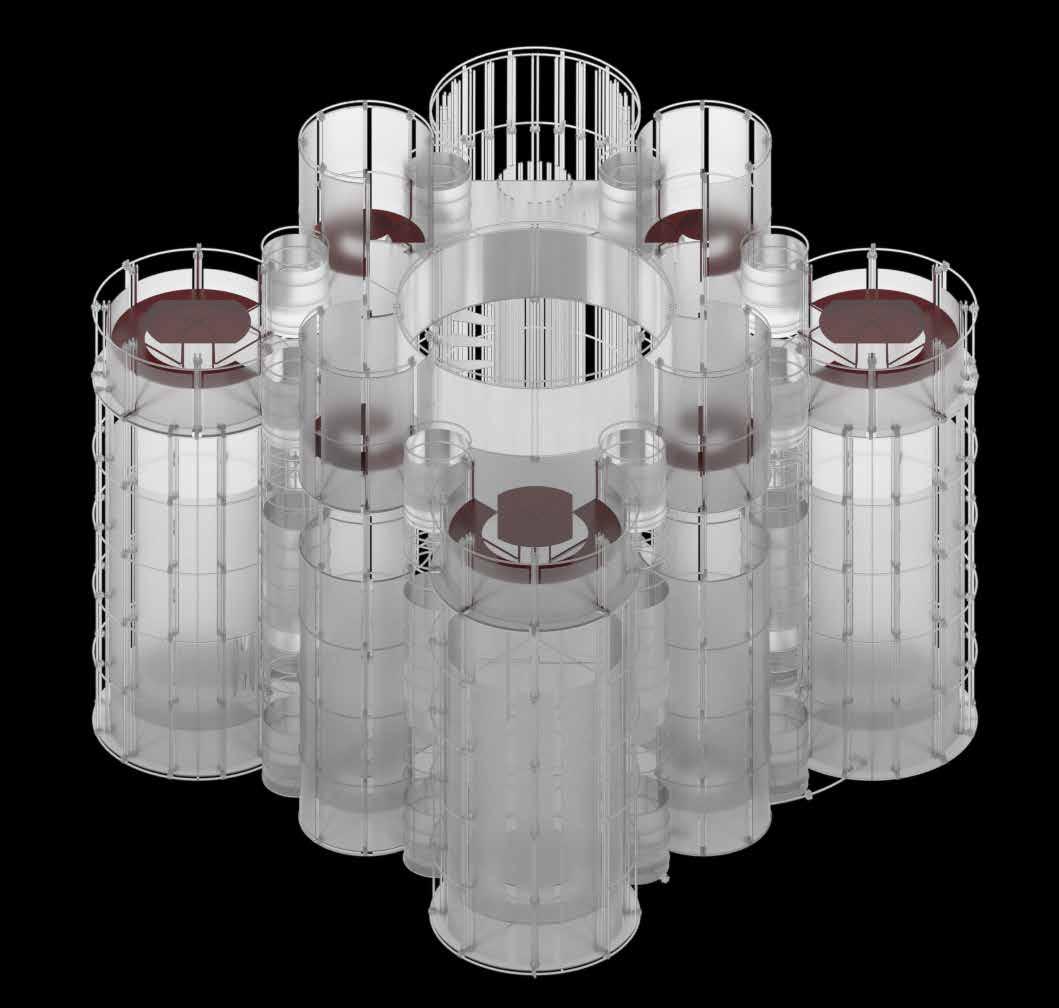

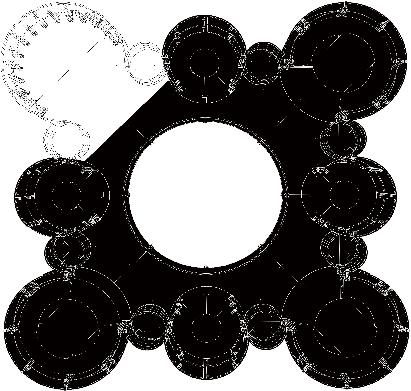

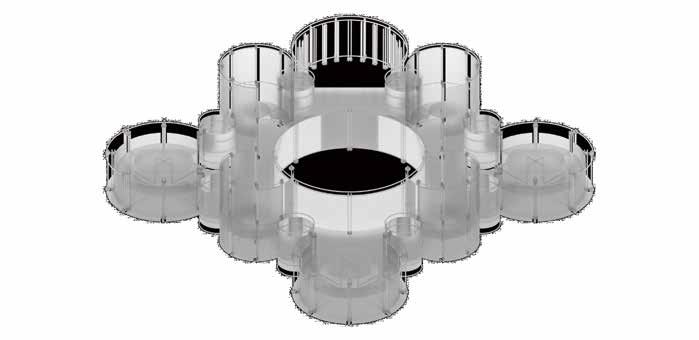

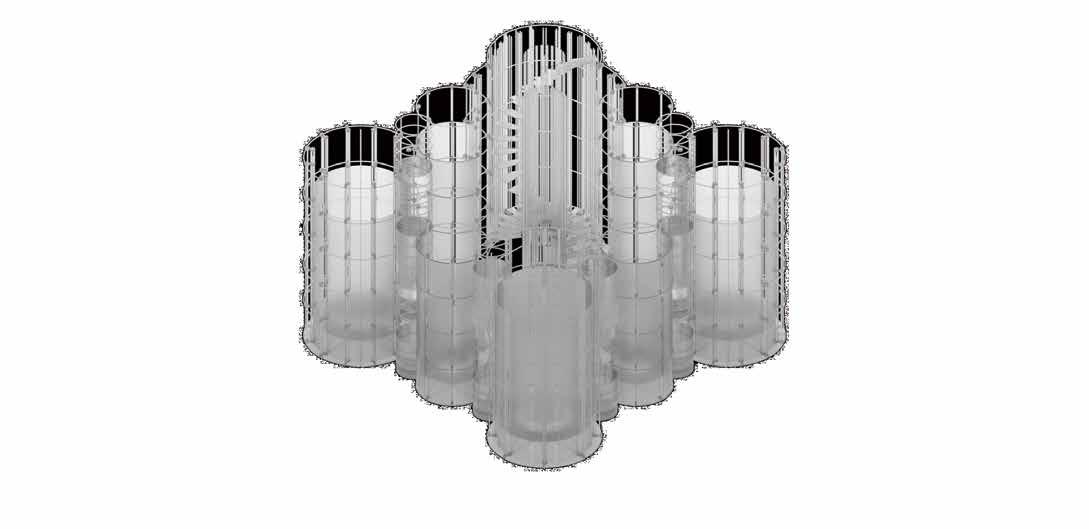

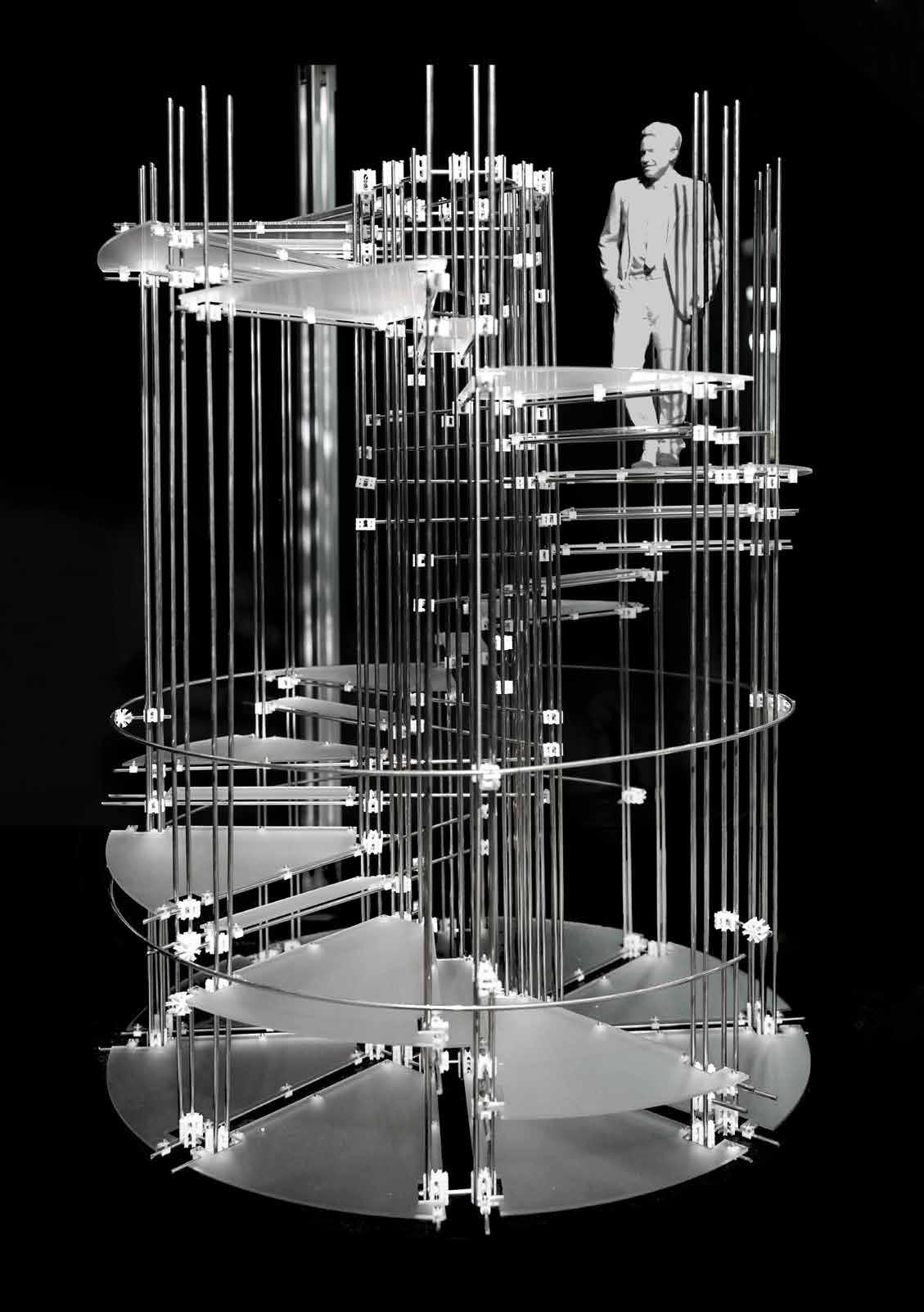

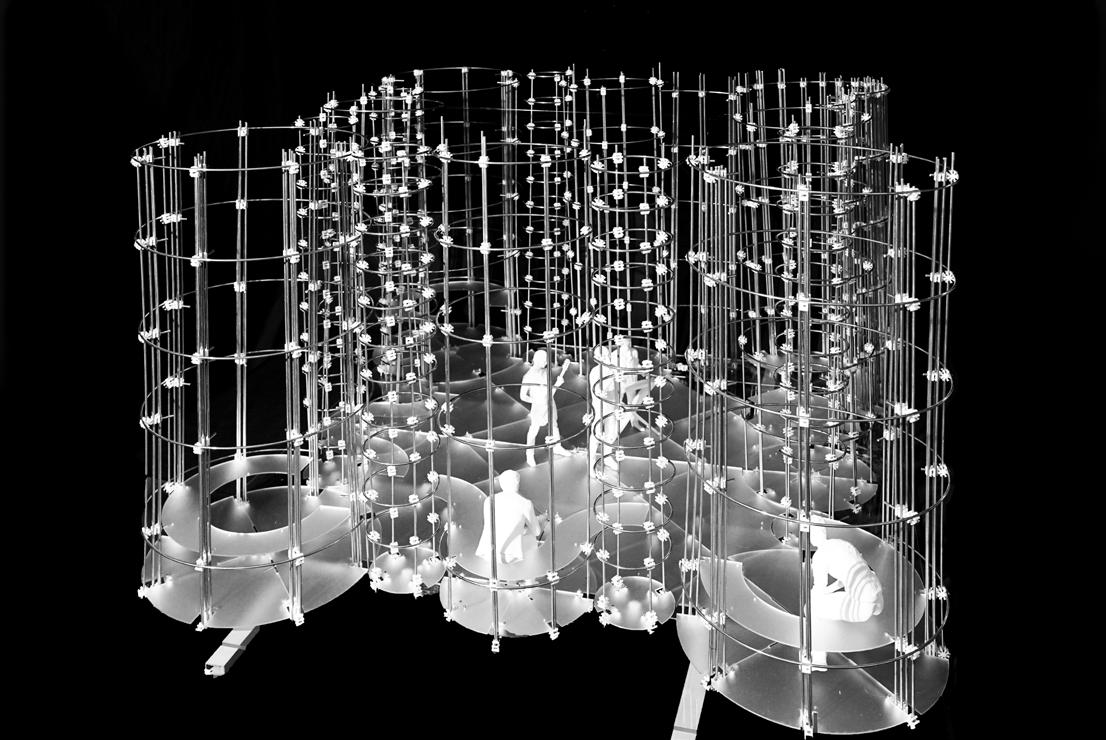

This set of 3d configuration were based on the idea of circular seating, with different positioning and group sizes. They are intended to be a development of the previous 2D exercise as we begin to articulate some elements or extensions perpendicular to the ground plane. The extension would then requires structural capacity, unlike a 2d plane. Noted that there was possibility of stretching surface over the framework as a skin, I have omitted the surface of the seating that might in the end come with various form.

From left to right:

1. CIRCULAR SEATINGS: a set of seating typology with various group seating sizes, various positioning relative to the stage 2. TOWERS: a set of seating typology but stacked into a connected tower format of multuple levels.

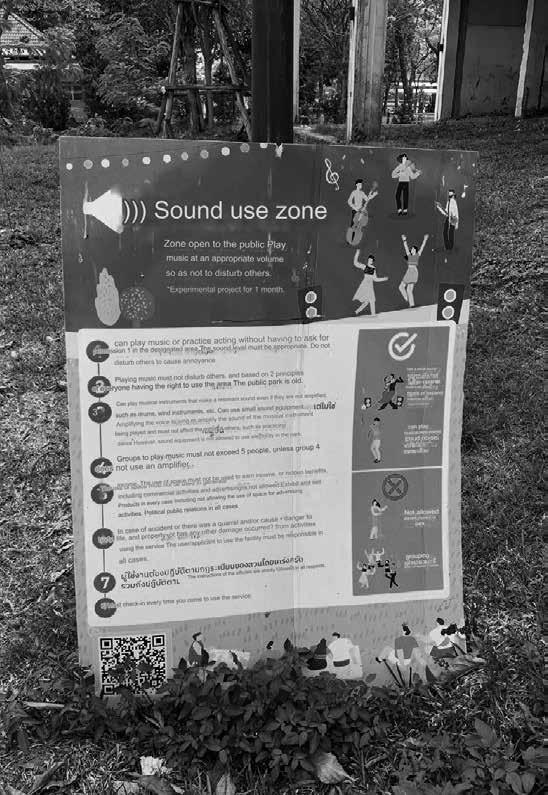

Moving onto the site, located at the city center of Bangkok, there is a vast, unused musuem space at the Benchakitti Park. As a testing ground for our occupyable space frames, I discovered there is a signage next to the auditorium which indicates the area as a "SOUND USE ZONE". However during the couple times of visiting, no one was using the area for anything even though the space is quite comfortable and clean.

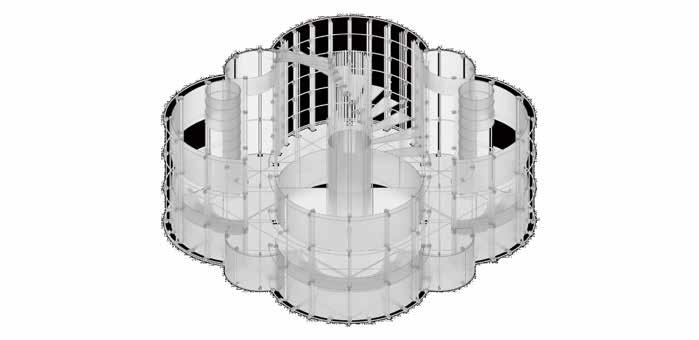

I aim to create stage and expand the capacity of the auditorium to a medium scale performance venue for 30-50 audiences.

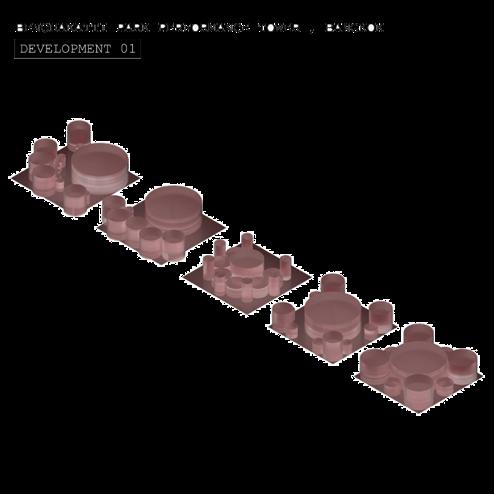

From left to right:

1. STRUCTURES: Structures of massing, possible to create with the previous 3d configuration and joint study

2. MASSING: Final massing with extra supported pillars (left) and unsupported (right).

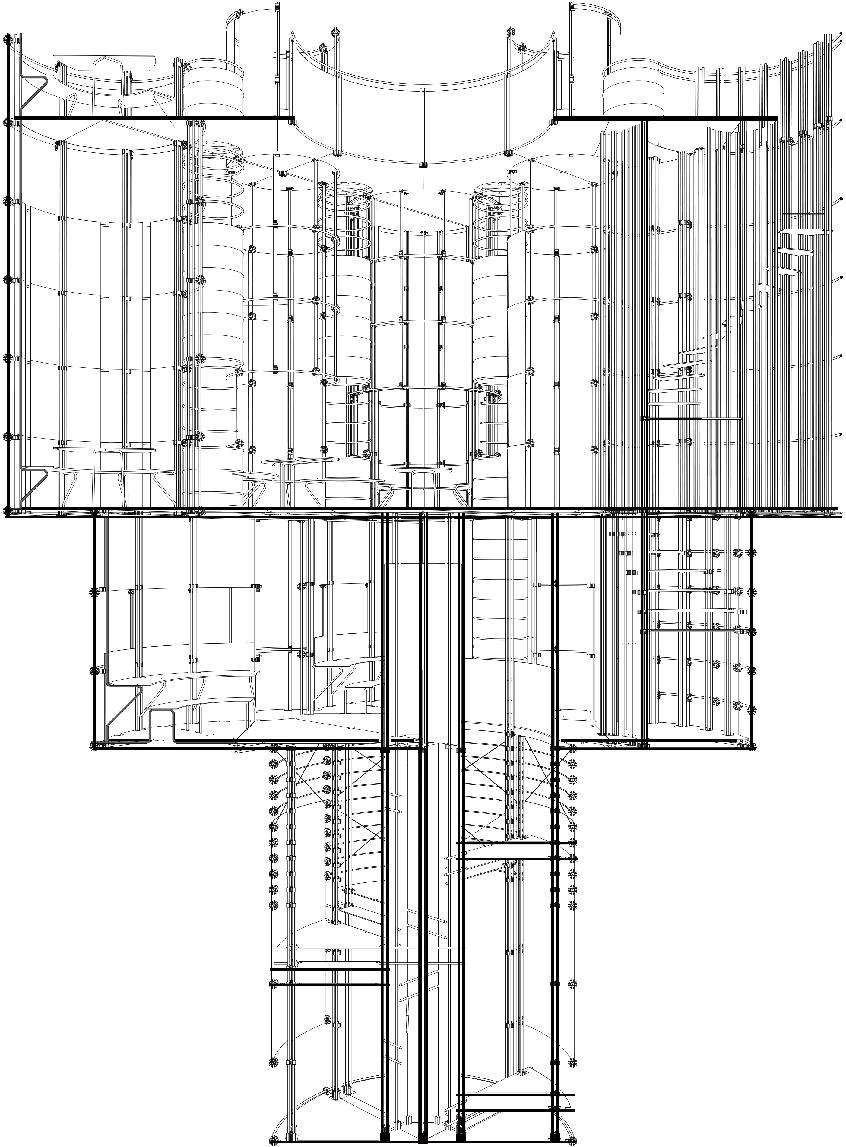

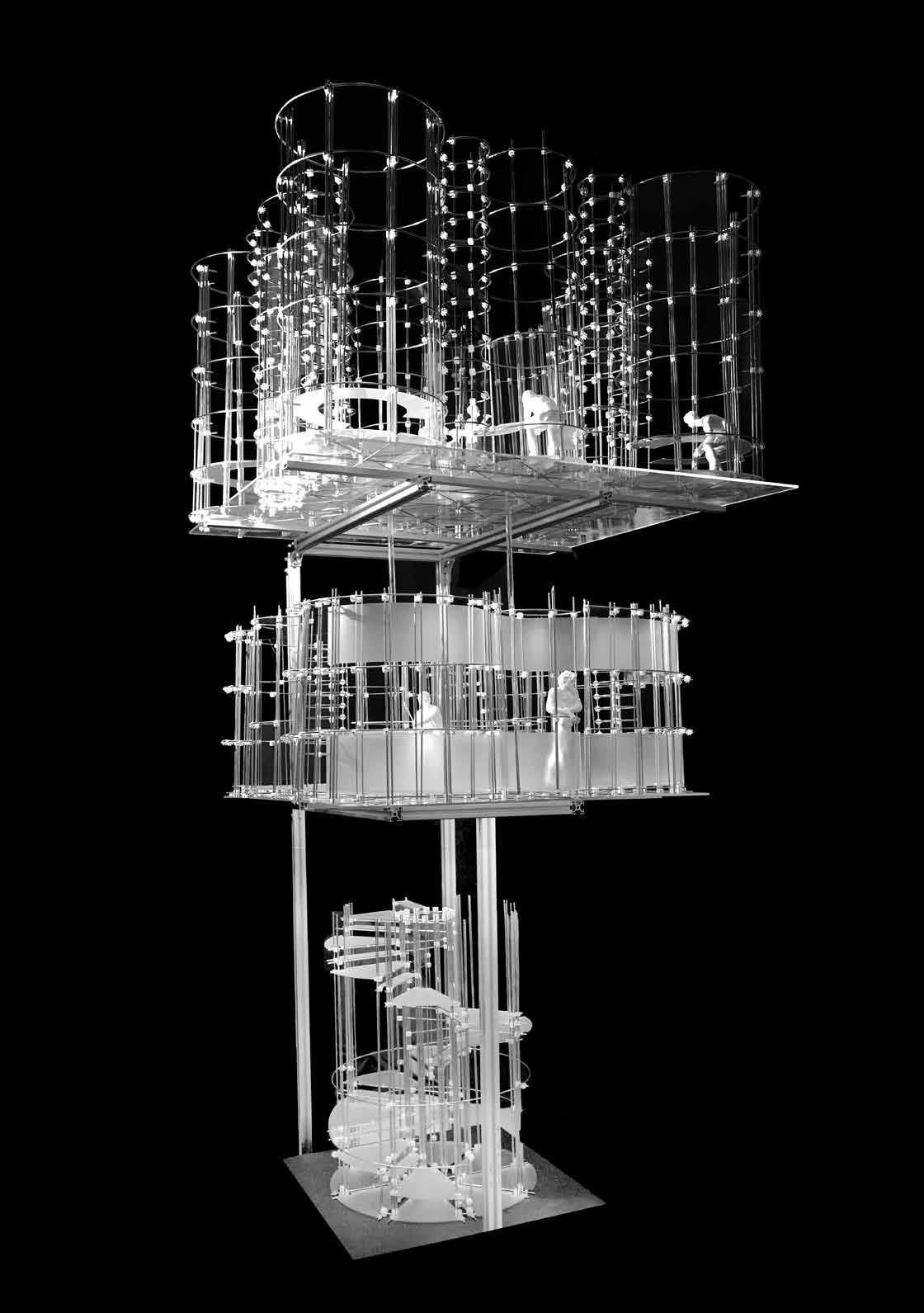

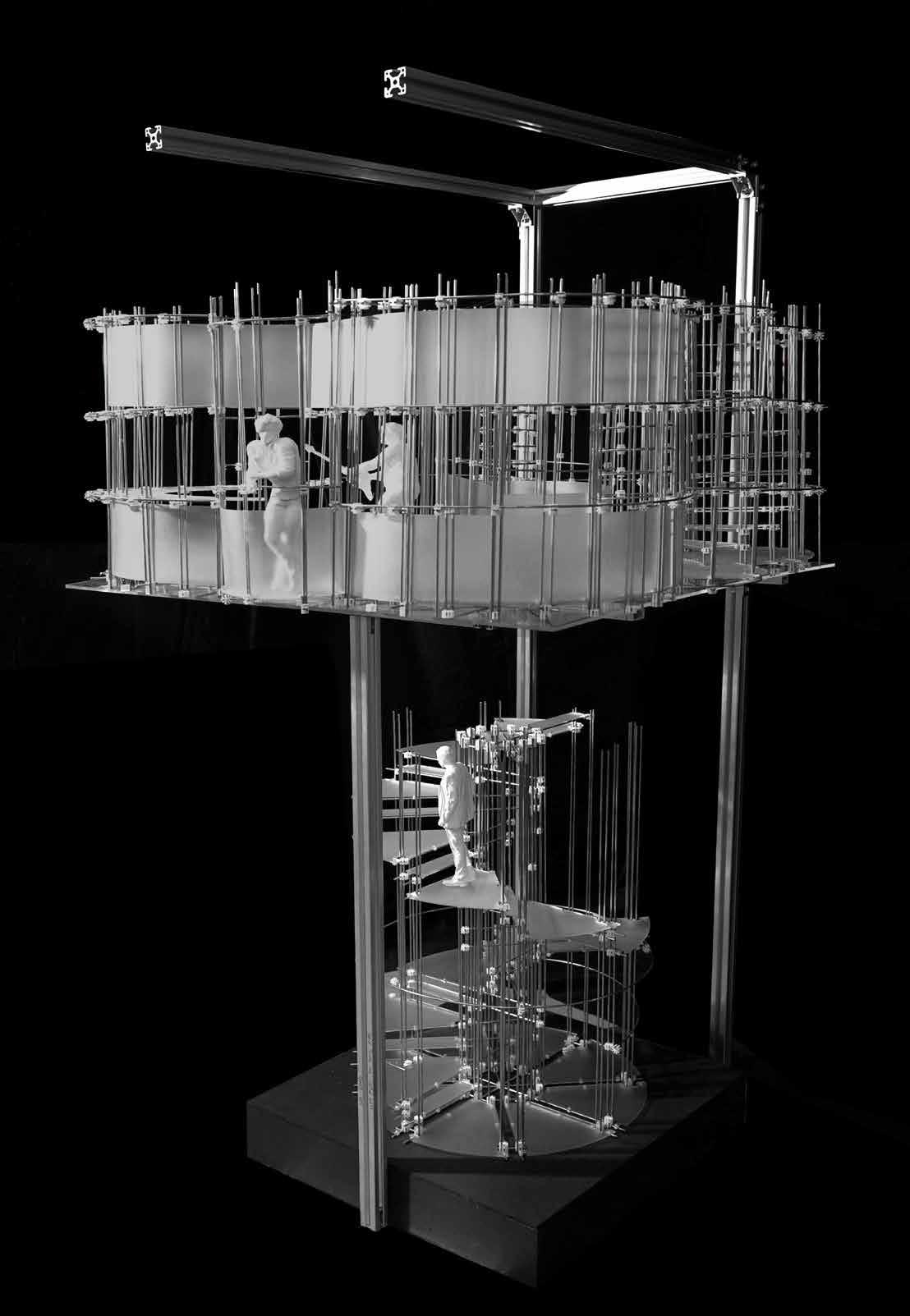

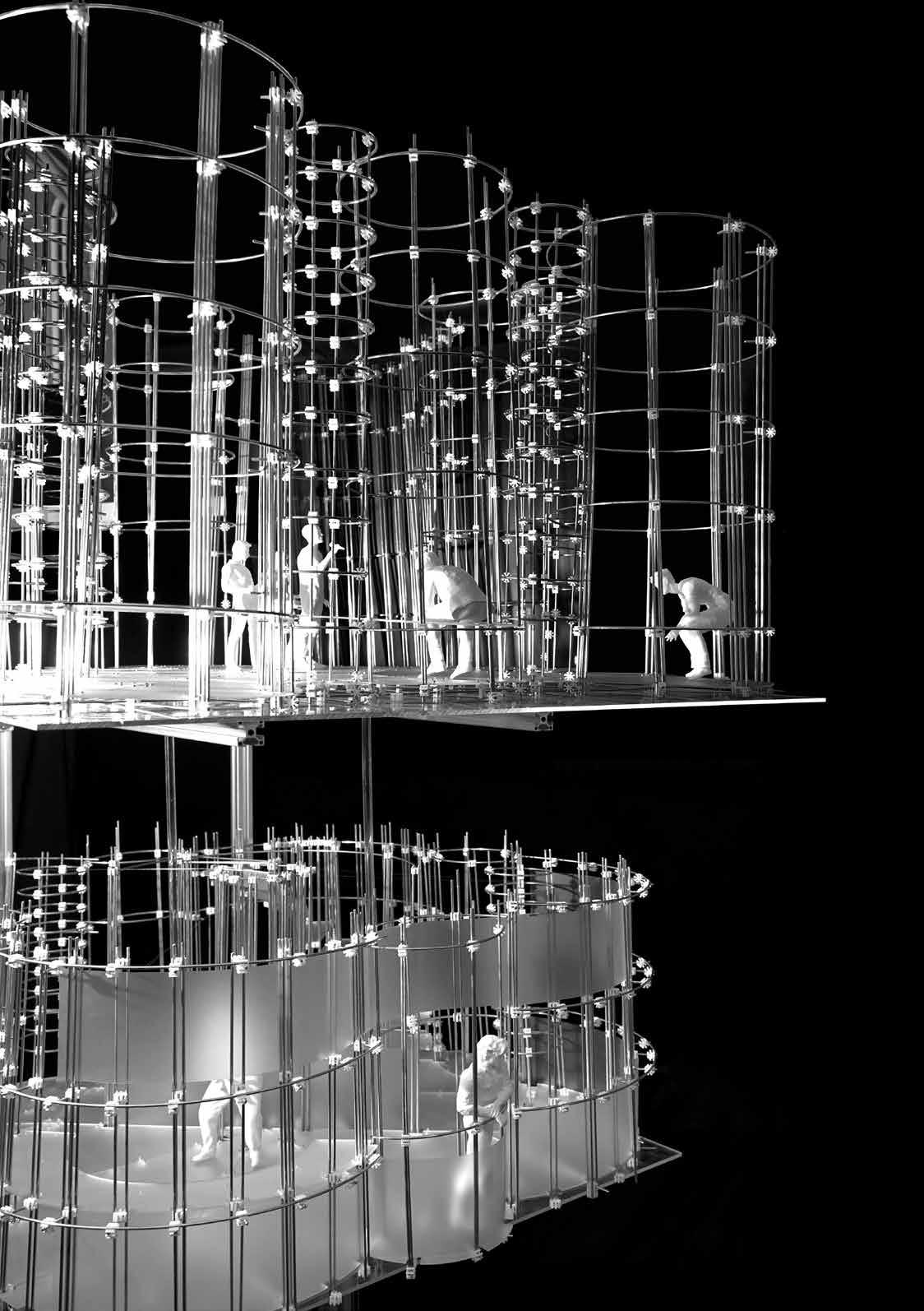

In the design, I "BUNDLED" cylinders (seatings, staircase, stage, ladder, planters) into a tower, much alike the way my joint is "BUNDLING" tubing of different diameter into a stronger and more meaningful verticle compound. These cylinders with various "heights" (Headroom), crossing multiple levels (staircases, ladders), join together at their perpendicular tangents and surround a stage area at the center naturally.

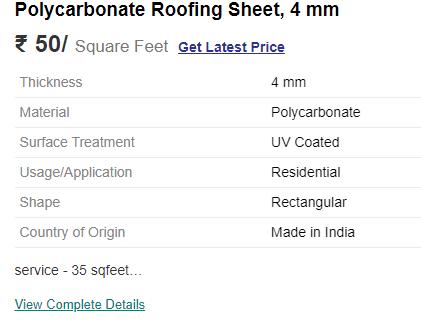

TRANSLUSCENT

I try to activate the site by the introduction of a perfomance tower, which consist of 3 storey. It stands at the original auditorium and protrude for one storey more through the original roof. The first deck is a circulation staircase and also a mega column to the tower. The second deck is a preparation area with desks and changing room. The third deck is the main perfomance space with around 25 seating and a 4 meter stage area. It opens to the sky with a skylight at the roof level.

The intended material for most of the skinning is transluscent polycarbonate sheet of 4-8 mm, which is a very strong and light material that partially reveal interior with the correct lighting. The purpose of such selection of facade material is based on:

1. It is easily customized and cut into panels without heavy machine involved, which synchronize the idea of the joint and the study process of easy-to-assemble tubular space frame.

2. It is light-weighted which does not impose great loading to the top-heavy tower.

3. It could not make the space completely sealed yet provide sufficient enclosure for acoustic and privacy

4. Most importantly, it partially reveals the interior and arouse curiousity of park users near by the performance lighting.

TRANSPORTATION, FLOORING AND INTERIOR FITTING

TRANSPORTATION:

Designs must fit into six wheel (6W) truck(s) in Thailand’s with cabin dimensions of 7.2x2.3x2.3 m.

After approximately fit the essential components, including joints and tubing, the entire tower only takes up around half of the capacity of the truck cabin.

FLOORING:

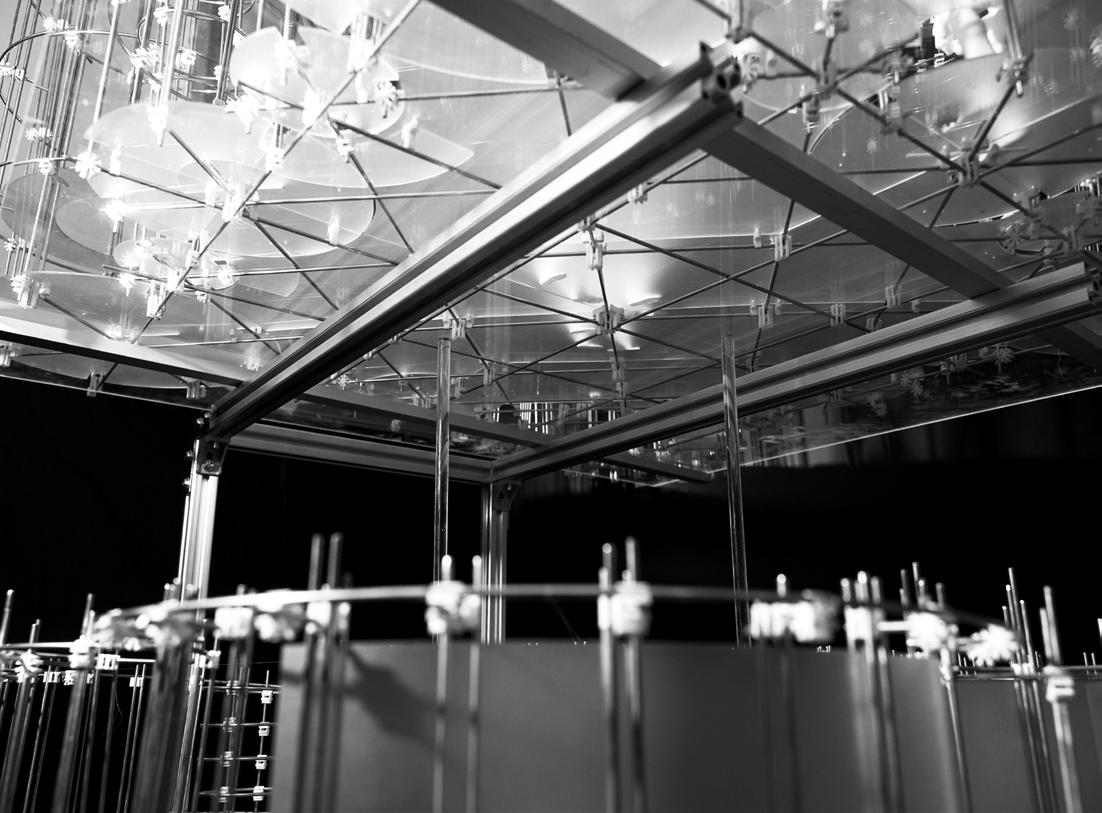

Flooring panels would continue to adopt polycarbonate as material for the same intention. However noted that it might be structurally insufficient for vigorious music activities. For such cases, thicker composite polycarbonate flooring, or even frosted tempered glass, would be the alternatives.

INTERIOR FITTING:

The interior fitting, including seating and desks, are made separated from the structures and interchangable after removing the floor panels. They are fixed onto the "slab" which is the horizontal framework underneath the floor panel.

A MANUAL FOR EVERYONE TO CONSTRUCT THEIR OWN VISION?

On the left it is a 1:1 detail which i frequently repeated in my design. It is a column connecting to a facade framework. And this format could be altered to fit in different situation of structural requirement. For example, reducing it to a 2-pipe column; expanding it to a 6pipe column; remove the facade framework and integrate it into the column as horizontal element; keeping solely the column as partition anchor...

It is an opportunity in the project that might be more intriguing, that a manual is developed to describe various cabability of such joint and tube system. For example, various vertical forms (refer to the image on the right), horizontal planes, branching formats....

Like a Lego Brick system that consist of basic modules, such system allows layman to be taken part in different stages of a building construction, and loosen the technical restriction of designing and construction simutaneously, making it closer to users and builder.

In such case, designer could take part in the construction of the their intended design, and more importantly, layman without profound knowledge of design could still take part in creating intuitive structure. Not to mention the possibility to easily alter, add, relocate the structure as desired. That depart from permanent architecture with one life and one form.