bimonthly-daily companion

bimonthly-daily companion

SUSTAINABILITY

How to create a net-zero port decarbonisation framework

MARITIME

Baltic and European shipyards’ performance in 2022-23

TECHNOLOGY

Ocean-based carbon removal

Unlocking GenAI’s full potential in terminal operations with real-time data

The Port of HaminaKotka is a versatile Finnish seaport serving trade and industry. The biggest universal port in Finland is an important hub in Europe and in the Baltic Sea region.

Welcome to the Port of HaminaKotka!

Another year found its way under our belt – a round 20th in our publication’s journey! Are there any other reasons for it to make history? Some may say that shipping becoming part of the European Union Emissions Trading System was such a happening. In this context, we reported this year on the many future-oriented developments from across the Baltic Sea region, on- and offshore, especially green ones as encapsulated in our Baltic Green Map and its Catalogue (updated seven times this year, which gives a pretty good understanding that our corner of the world makes hay while the sun shines in a time when one increasingly needs to embrace change).

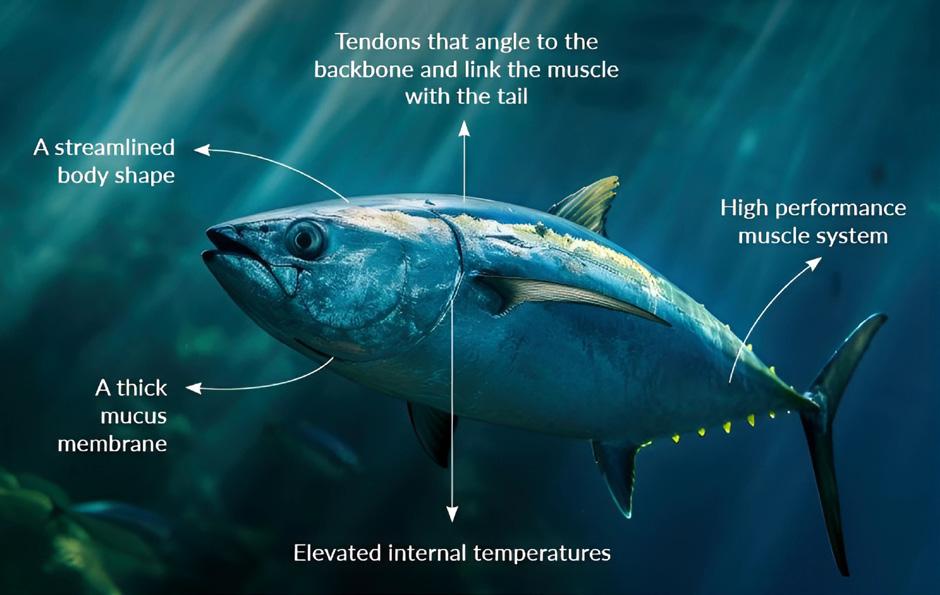

Talking of change, the Legal column houses two articles on marine insurance and how it’s impacted by climate change and geopolitics. Sustainability focuses on decarbonisation of the port and shipping industries – first, by crafting a strategy, then by implementing concrete measures, such as green methanol for bunkering or using simulators for training (here with the bonus of heightened safety). This theme follows in Technology, including a piece on removing carbon dioxide from seawater (on a gigatonne scale!). This section also digs into the use of artificial intelligence (AI) in mobility & logistics – and specifically how Europe intends to make the use of this revolutionary tech efficient, safe, and ethical. Another AI-focused read starts by citing a claim that this technology will result in changes beyond our imagination (no worries, the article itself goes through more tangible applications of the different AI types). Technology also features what I believe is BTJ’s second article from Japan, this time on learning from nature how to create a hull paint that helps shipowners & operators cut fuel consumption, hence their carbon footprint (and if I remember correctly, that first made-in-Japan read was about using modern sails as auxiliary propulsion; lo-and-behold, a few years later and several companies, also from the Baltic, are producing such equipment; what’s more, wind-assisted propulsion comes with a bonus in EU regulations aimed at making shipping greener).

The Maritime column hosts the comeback of our Roving Editor and his summary of Baltic and European shipyards’ performance in 2022-23. Here, heavyweight keywords are “cruise,” “cruise,” and “cruise” (with a healthy pinch of fishing, at least in the Baltic). In this section, we also celebrate our partner’s anniversary, with 2024 marking the 50th birthday of Liebherr’s mobile harbour cranes. Congrats!

We wish you a peaceful end of the year and a favourable wind in 2025! Oh, and nothing but a good read, too!

Przemysław Myszka

Baltic Transport Journal

Publisher BALTIC PRESS SP. Z O.O. Address: Aleja Zwycięstwa 96/98 81-451 Gdynia, Poland office@baltictransportjournal.com

www.baltictransportjournal.com www.europeantransportmaps.com

Board Member BEATA MIŁOWSKA

Managing Director PRZEMYSŁAW OPŁOCKI

Editor-in-Chief

PRZEMYSŁAW MYSZKA przemek@baltictransportjournal.com

Roving Editor MAREK BŁUŚ marek@baltictransportjournal.com

Proofreading Editor EWA KOCHAŃSKA

Contributing Writers EMIL BERLIN, ARNAUD DIANOUX, JEROEN DIERICKX, ALEXA IVY, LARS LANGE, ROBERT MACKAY, KAZUAKI MASUDA, EIRIK OVRUM, MONIKA ROGO, MONIKA ROZMARYNOWSKA-MROZEK, FITZWILLIAM SCOTT, JOHANNA STAPELBERG, DEVON VAN DE KLETERSTEEG, CHAD VAN DERRICK, JIN WANG, MARTIN WHITE

Art Director/DTP DANUTA SAWICKA

Head of Marketing & Sales PRZEMYSŁAW OPŁOCKI po@baltictransportjournal.com

If you wish to share your feedback or have information for us, do not hesitate to contact us at: editorial@baltictransportjournal.com

OPŁOCKI tel.: +48 603 520 020

3 Editorial 8 BTJ calendar of events

10 Safety news by TT Club

12 Market SMS

14 What’s new?

16 Map news

18 Venture forth

22 What’s in the Cabinet

24 Chart of the issue: Map of Green Shipping Corridor initiatives

70 Who is who

26 Adapting to great change(s)

Present & future challenges facing marine underwriting by Lars Lange

28 Enabling confidence – Climate and geopolitical shifts require a rethinking of marine insurance by Robert Mackay

30 Detect > decide > deploy

– How to create a net-zero port decarbonisation framework by Ewa Kochańska

34 Unlocking the code

– Strategies for meeting upcoming decarbonization targets by Eirik Ovrum

38 Sustainability in numbers

– How EU regulations will boost the economic value of renewable methanol in shipping by Jeroen Dierickx

42 Smarter ports = cleaner & safer future

– Leveraging simulation for efficiency, sustainability, and safety by Devon Van de Kletersteeg

44 No option but to change – New approach to seafarer training for new fuels by Martin White

46 Less is more (and vice versa) – Baltic and European shipyards’ performance in 2022-23 by Marek Błuś

50 Half a century of excellence – Celebrating the Liebherr mobile harbour crane by Fitzwilliam Scott

52 Baltic Ports for Climate Conference 2024 – compete less, cooperate more! by Monika Rogo

53 Impact of the war in Ukraine on the Baltic port market by Monika Rogo

54 Seeking (a revolutionary) change – AI-powered solutions for present & future challenges in logistics by Satish Gutta

58 Maritime’s next great revolution – How data standardisation will change shipping by Arnaud Dianoux

60 Beyond imagination –

Unlocking GenAI’s full potential in terminal operations with real-time data by Chad Van Derrick

62 Smooth sailing

Exploring lessons from nature to develop sustainable products by Kazuaki Masuda

64 Potential disruptor – Assessing the viability of nuclear power systems in ship, port and fuel production applications by Jin Wang

66 Yesterday’s fossil fuel infrastructure – tomorrow’s climate solutions – Ocean-based carbon removal by Alexa Ivy

68 Into perspective – The role of AI in transforming European mobility by Emil Berlin and Johanna Stapelberg

Advertisement

Transport Week , 18-19/03/25, PL/Gdynia, transportweek.eu

Day 1 will focus on addressing the Europe – a leader or a follower? question, while Day 2 will house the Baltic Ports for Climate Conference organized with the Baltic Ports Organization. The 2025 edition of the event will tackle the topic of the impact of European policies on the transport sector as well as highlight port investment strategies, including investing in electrification, onshore power supply, and the digital twin technology.

Net Zero Maritime Conference , 23-24/04/25, SE/Gothenburg, leaftinevents.com/events

The two-day event will focus on various aspects and areas of decarbonization to meet the IMO’s regulations, including alternative marine fuels, collaboration and best practices, innovation in shipping, financial considerations, sustainable port operations, digital solutions.

ESPO Conference , 8-9/05/25, GR/Thessaloniki, espo.be/events

The next annual meeting of the European seaport industry will take place in Thessaloniki on 8-9 May 2025. We are looking forward to seeing you – as well as some 200 other port professionals – there!

Baltic Ports Conference 2025, 6-8/10/25, PL/Gdańsk, balticportsconference.com

After a very successful and well-attended Baltic Ports Conference (BPC) in Klaipėda, the Baltic Ports Organization (BPO) already welcomes you to the 2025 edition to be held in Gdańsk on 6-8 October 2025 under the auspices of the Port of Gdańsk. As always, BPO’s BPC will touch on the most topical issues facing the port and shipping businesses in the Baltic and beyond. Stay tuned for more info before long!

With a 10-part scheme of work, the Standard , published free of charge by The Nautical Institute , provides guidance to training providers to offer programmes of learning that ensure seafarers will have the knowledge to handle bunkering of alternative fuels safely and confidently. “As the first milestone in the IMO’s [International Maritime Organization] 2023 GHG [greenhouse gas] strategy approaches with the requirement for between 5% and 10% of the world fleet expected to be powered by zero or near-zero GHG emission technologies, many shipowners have had to take a decision on how they will fuel their fleets before all the variables have been fully tested. The result is that we can expect vessels powered by a number of different fuels such as ammonia, methanol and hydrogen to be launching within the next few years before the IMO will be able to establish STCW [the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers] competency requirements,” underscored The Nautical Institute in a press brief. “This standard doesn’t replace the STCW requirements that will be established in the coming years. Rather, it seeks to offer interim support that bridges the gap until that time and, having been designed as a living document, it will be able to evolve with industry best practice,” added Capt John Lloyd FNI, CEO of The Nautical Institute.

The global insurance provider released this autumn a series of its TT Talks, covering a broad range of safety and legal topics concerning the transport & logistics sector. Legal Eagle reflects on relying on a ‘force majeure’ clause; Slips, trips and falls focuses on the most common safety-related incidents faced by businesses operating in the supply chain; four other ‘managerial’ TT Talks look at asset management in the face of climate change, leadership in supply chain risk management, spare part inventory management, and at port environmental sustainability from a ballast water management point of view; another TT Talk delves into incident response strategies for logistics. The two latest highlight the UNCITRAL project (on negotiable cargo documents and electronic cargo records) and the importance of personal protective equipment (as the last line of defence).

Marine Medical Solutions is calling on the International Maritime Organization (IMO) to update the May 2007-published Guide, which it sees as essential for providing medical care on board ships and that serves as the primary reference for pharmacies that supply the list of essential medicines for seafarers. The company has raised concerns about the outdated nature of the Guide, emphasising that advancements in medicine over the past 15 years have not been reflected in the current recommendations. “[…] without regular updates from the IMO, seafarers are at risk of not receiving the most effective care. A doctor’s insight is crucial in ensuring that the medical supplies on board are not only adequate but also improved for current medical standards,” underlined Doctor Jens Tülsner, CEO of Marine Medical Solutions. His company outlines that flag states and other organisations have become active in improving the situation, e.g., the Maritime Medical Service of the German Flag published a completely revised version of the Maritime Medical Handbook for ships flying the country’s flag in 2019/2020 (German/English version), including adaptations of the medical equipment on board. In 2023, the International Chamber of Shipping provided a new handbook aimed at improving onboard medical care. However, Marine Medical Solutions notes that none of them have been adopted by the IMO. “By updating the Guide and ensuring that it reflects modern medical practices, we can provide better support and care for seafarers, who often face challenging and isolated conditions at sea,” Doctor Tülsner urges the global body.

Following a multi-year development project, Baltic Exchange has partnered with Moody’s to launch the Know-Your-Customer (KYC) data platform for the maritime sector. The initiative utilises the latter’s Orbis for Compliance database, which covers over 445 million entries both in shipping and nonshipping, along with its Global Regulatory Information Database (GRID) that provides 12m+ records on known or suspected corrupt private and public sector figures, fraudsters, illicit financiers, money launderers, and more. “KYC is a regulatory requirement in the banking and financial services sectors to ensure businesses do their due diligence on customers to prevent fraud, money laundering, and terrorism financing. With shipping a vital part of global commerce, the need to manage the risk of fraud and compliance with regulatory sanctions have become paramount, particularly surrounding reputational management and liability issues,” Baltic Exchange said in a press release. KYC is available to both members and non-members who can purchase credits in order to undertake the required checks and scans (with the former receiving a discount when using the platform).

4.27 million passengers served in I-IX 2024 (-2.2% yoy)

The Estonian ferry company’s fleet also transported 613k private vehicles (-8.2% year-on-year) as well as carried 239k trucks & trailers (-3.7% yoy).

Tallink & Silja Line’s passenger & cargo traffic in January-September 2024

The Port of Odense:

1.09 million tonnes handled in H1 2024 (-11.9% yoy)

Dry bulk turnover totted up to 864kt (-9.6% year-on-year), with liquid goods adding 116kt (+27.5% yoy), and general cargo (iron & steel products) the remaining 112kt (-41.1% yoy). While liquids noted increases across the board, +34.7% yoy for other liquid bulk goods to 101kt and +7.1% yoy for liquid gas to 15kt, the dry bulk part witnessed a mix of results. Ores and scrap metal contracted by 4.7% yoy to 485kt, followed by boulders, sand and gravel that altogether advanced by 6.1% yoy to 294kt.

This year saw the launch of intra-Baltic cruises on board Birka Gotland, which attracted 296,085 travellers since spring. Viking Line’s fleet also transported 98,779 ro-ro cargo units, up 5.6% on the January-September 2023 result.

The Port of Oxelösund:

3.23 million tonnes handled in I-IX 2024 (+2.9% yoy)

According to Ports of Sweden’s statistics, the Swedish seaport took care of 2.27mt of goods classified as other dry bulk (+2.3% year-on-year), followed by 658kt of iron ore & steel products (+9.3% yoy), and 157kt of wheeled (ro-ro) cargo (-1.9% yoy). The Port of Oxelösund also handled 71kt of forest products (+54.3% yoy), 64kt of containerised freight (-22.9% yoy), and 14kt of other liquid bulk (-41.7% yoy; there was no turnover of oil & oil products versus 10kt in I-IX 2023). A total of 5,487 TEUs went through the seaport’s quays (+1.8% yoy), as well as 5,016 ro-ro cargo units (-20.4% yoy).

of

85,294 TEUs handled in I-IX 2024 (+19.8% yoy)

Tonnage-wise, containerised freight totalled 670 thousand tonnes, up 21.1% on the January-September 2023 result. The Swedish port took care of 2.83 million tonnes over 2024’s first three quarters (-1% year-on-year), also including 642kt of other dry bulk goods (-11.3% yoy), 615kt of oil & oil products (-7.7% yoy), 594kt of forestry products (-4% yoy), 284kt of other liquid bulk (+0.7% yoy), 16kt of other break-bulk (+23.1% yoy), and 15kt of steel products (+114% yoy).

78,042 ro-ro cargo units handled in I-IX 2024 (+32.5% yoy)

Measured in tonnes, wheeled cargo totted up to 1.63 million tonnes, an increase of 31.2% year-onyear. The Swedish seaport overall handled 3.6mt in January-September 2024 (+0.8% yoy). Apart from the above, also 687kt of other liquid bulk goods (-12.6% yoy), 651kt of forestry products (-25.4% yoy), 370kt of dry bulk (+10.4% yoy), and 260kt of oil & oil products (-21.9% yoy). Karlshamn’s ferry traffic saw 175,328 passengers (+15.7% yoy) and 45,690 private vehicles (-2.6% yoy). The port also handled 151 commercial cars vs 61 in I-IX 2023. There was no container traffic in I-IX 2024 vs 522 TEUs in the corresponding period last year.

The Swedish seaport’s January-September 2024 rail container traffic totted up to 376 thousand TEUs, a year-on-year increase of 7.4%.

The Port of Aarhus:

4.61 million tonnes handled in H1 2024 (-5.6% yoy)

Containerised freight, the Danish seaport’s leading trade, totalled 2.31mt, down 4.9% year-on-year. Altogether, general cargo handling amounted to 2.51mt (-5.1% yoy), followed by 1.69mt of dry (-6.5% yoy) and 402kt of liquid bulk (-5.4% yoy).

“Although the number of containers handled at the Port of Gothenburg has slightly decreased during the third quarter of this year, the port is still on track for a record year,” a press release from the port authority read. The Port of Gothenburg also handled 389k ro-ro cargo units (-4% yoy) and 188k new vehicles (-1.6% yoy). The turnover of liquid bulk advanced by 14.3% yoy to 16 million tonnes and so did the handling of dry and break-bulk, up 16% to 378kt. On the other hand, Gothenburg’s passenger traffic contracted by 7.7% to 1,157k ferry & cruise travellers. Finnlines: 595 thousand ro-ro cargo units carried in I-IX 2024 (+12.1% yoy)

According to Statistics Denmark, ferry cargo, Hirtshals’ prime trade, totalled 779kt over this year’s first half, up 3.3% year-on-year. Freight classified as ‘other goods in ro-ro units’ came in second with 58kt (+/-0% yoy), followed by 37kt of other liquid bulk (+8.8% yoy), 30kt of break-bulk (+36.4% yoy), 16kt of other dry bulk (no handling in H1 2023), 9.0kt of boulders, sand and gravel (also no turnover last year), and 3.0kt of oil products (-70% yoy). There was no handling of wood and commercial vehicles in H1 2024 vs 2.0kt and 1.0kt last year, respectively. Statistics Denmark says that the Port of Hirtshals served 933k passengers in international ferry traffic, an increase of 4.4% on the January-June 2023 result. Whereas fewer ro-ro cargo units crossed the seaport’s quays, down 3% yoy to 61,689, more private vehicles (cars, busses, caravans, motorcycles, and mopeds) were brought on board the ferries serving the Danish port, up by 6% yoy to 308,013.

On the other hand, Aarhus’ domestic passenger traffic was up 0.5% on the January-June 2023 result, totalling 1.49 million travellers. The link with Odden accounted for 1.46m (+0.4% yoy) while with Sælvig for the remaining 30k (+3.4% yoy).

The company’s fleet also served more passengers in January-September this year, up 36.4% year-on-year to 764 thousand travellers.

“As anticipated, passenger travel increased considerably on Finnlines’ vessels during the summer season. All four ro-pax lines performed well, and the number of private passengers more than doubled on the route between mainland Finland, Åland and Sweden. The growth on our Naantali-Långnäs-Kapellskär route during January-September [2024] was 122% compared to the previous year,” Finnlines highlighted in its financial review for Q3 2024. Finnlines also transported 962 thousand tonnes of non-unitised freight (-5.7% yoy) and 63 thousand vehicles (excl. private cars; -46.6% yoy).

The Danish seaport took delivery of a Liebherr LHM 550 that will primarily be used for handling project cargo, such as offshore wind energy components, as well as dry bulk goods and containers. The mobile machinery offers capacities of 144 tonnes (hook), 19/25 m3 (stone/grain Nemag grab), and 54 metres of outreach (Bromma EH170U container spreader). Aalborg’s LHM 550’s minimum/maximum radius lifting heights are 51/31 metres. “With players like Siemens Gamesa and CS WIND Offshore in the East Harbour, we experience a great need for handling project cargo. The wind energy market is moving incredibly fast. As an infrastructure, we need to be able to handle some of the world’s largest wind turbine blades, which are currently over 115 metres long and cannot be transported by road. We must support this development with efficient logistics and transport solutions regardless of cargo size,” highlighted Michael Hasselager, Office Manager, Planning & Operations, the Port of Aalborg.

The terminal operator has put the rail-mounted portal slewing crane in the Port of Brake (the first of its kind in Germany), where it will be used for handling dry bulk and general cargo. The LPS 600 from Liebherr Rostock features a 61-metre boom, a motorised grab control, an e-drive, and video monitoring at the portal. The crane has an extra-large cable drum, making it possible to move 650 metres in one direction. A curve-going chassis with various pivot points has also been installed so that the machinery can travel on winding roads. Special seals on the wheels serve as heightened flood protection. Under ideal conditions, up to 1,000 tonnes of dry bulk can be handled per hour. The use of a largely closed grab reduces dusting when handling goods such as grain and animal feed. The crane can also be used to take care of general cargo and allows for direct shipto-ship handling. “In addition, the new cab of the LPS 600 improves operator comfort and safety and reflects the company’s commitment to social responsibility,” the manufacturer underlined in a press release.

MT Højgaard Danmark completed adding 100 thousand square metres of areas that the Danish island seaport will use to execute offshore wind energy projects. “With the completion of stage 3, we have taken an important step in strengthening the supply to Bornholm, also ensuring that we can continue the growth of shipping of offshore wind from Bornholm by now being able to handle two simultaneous projects,” underscored the Port of Rønne’s Managing Director, Lars Nordahl. Dan Harborg Locht, Project Director at MT Højgaard Danmark, added, “When entering the contract for stage 3, we knew we would be under a lot of time pressure. It has been so throughout the entire execution, but with a sound collaboration between the Port of Rønne, their adviser NIRAS, our adviser Rambøll, and a skilled and dedicated project team at MT Højgaard Danmark, we delivered a fine result – and on time. We can all be proud of that.” The Port of Rønne underlined in a press release that MT Højgaard Danmark spent some DKK60 million (€8.05m) on local subcontractors. Rønne’s future-fitting plans include extending the port’s outer harbour, setting up a larger turning basin, erecting a new multi-purpose quay, and deepening the inner parts of the port.

Port Gdański Eksploatacja (PGE) will spend some PLN400 million (about €93m) on new infra- & superstructure in the Port of Gdańsk’s Inner Harbour for handling and storing agricultural products. The investment will see the construction of nine grain silos, five on the Wiślane and four on the Szczecin Quay, the modernisation of road, rail & port infrastructure, and the purchase of conveyor belts and Liebherr cranes – all to handle ships carrying up to 36 thousand tonnes. The project will increase PGE’s yearly storage capacity by fivefold to 152kt, while its agricultural goods handling capacity will increase from 700kt to 2.9mt/year. The investment will also pave the way for setting up another agro terminal dedicated to grains and feedstock. The Port of Gdańsk added that its overall grain handling capacity rose from 2.0mt/year in 2019 to 4.3mt today.

The Swedish shipping line has entrusted the China Merchants Jinling Shipyard (Dingheng) with the construction of four oil products/ chemical tankers. The 119.9 by 19.4 metres, 1A Ice Class, 7,999 of deadweight tonnage (dwt) tankers will offer 9,700 cubic metres of capacity in MarineLINE coated tanks, making it possible to handle 11 grades of cargo. The vessels will be equipped with 420kWh batteries for peak shaving, as well as 1,000kW connectors for drawing electricity from the shore. The Evolution 8K class was jointly designed by Sirius Shipping and FKAB. These join the shipowner’s order book of two 15,000 dwt oil products/chemicals, methanol-ready tankers, the first of which will be delivered by the China Merchants Jinling Shipyard (Yangzho) in 2026.

Kalundborg Tank Terminal has received two tanks, shipped on a barge from Masnedø, that will extend the company’s storing capacity in the Port of Kalundborg’s East Harbour by 3,000 cubic metres. The 50/50 JV between the Port of Kalundborg and Schultz Shipping currently has 17 tanks (38k m 3 in total) in the Danish seaport, all of which are leased out.

The German company handling biofuels will start its operations in the Swedish seaport at the beginning of 2025, following a long-term terminal area & quay access lease deal with the Ports of Halland. The Brüning Group will handle biofuels coming from a wide range of residual & waste products from the forestry industry, including woodchips, fuelwood, pellets, and bark. These will be offered to Swedish energy and heat plants to replace mineral oil and gas.

The Helsinki-headquartered manufacturer will supply APM Terminals MedPort Tangier with 20 hybrid straddle carriers, which will join the 65 Kalmar machines already on the ground. The company will also integrate the new carriers, due for delivery in Q2-Q3 2025, with the customer’s terminal operating system via Kalmar One software, complemented by services, maintenance and support.

The project – launched by the Ports of Stockholm, the Baltic Ports Organization, and Interlegal – will receive €17.3 thousand in grants within the Ukraine Cooperation Programme to help Ukrainian ports move closer to EU standards and the block’s transport network. IntegraPorts will also see training the Ukrainian side in applying for EU funds as well as host study visits to the Baltic Sea region. The project will run from November 2024 to October 2025.

The Norwegian-Swedish company has placed an order for two additional 11,700-CEU pure car and truck carriers (PCTC) at the China Merchants Jingling Shipyard, plus decided to up-scale two earlier orders from 9,300 to 11,700 CEUs. As such, Wallenius Wilhelmsen will have 14 Shaper class vessels on order, eight 11,700 and six of the 9,300-CEU range. The company also holds options for two more vessels (declarable by H2 2025). In late October 2024, Wallenius Wilhelmsen shared its first order of the enlarged – 14 instead of 12 decks, dual-fuel (methanol-capable) PCTCs.

United European Car Carriers (UECC) has entrusted the China Merchants Jinling Shipyard (Nanjing) with the delivery of two multi-fuel pure car and truck carriers (PCTC) in a deal that includes an option for two more newbuilds. The first pair of the 4,500-CEU-capacity vessels is scheduled for delivery in 2028. The PCTCs will offer 10 decks, including two hoistable, together with a quarter stern ramp capacity of 160 tonnes. The newbuildings will feature multi-fuel, liquefied natural gas (LNG)-driven engines, plus battery packs, shore power connectors, and a photovoltaic system installed on their top decks. “UECC’s existing multi-fuel LNG battery hybrid vessels, Auto Advance, Auto Achieve and Auto Aspire, currently exceed the IMO’s target for a minimum 40% reduction in carbon intensity by 2030. Furthermore, its fleet is already running a compliance surplus in relation to FuelEU Maritime, set for implementation next year,” UECC underscored in a press brief. The shipping line also shared that it has started bunkering biomethane and is on track to increase the use of biofuels to 50% across its fleet this year. The company aims to eliminate the use of fossil fuels by 2040.

The Benelux Scandinavia Baltic X-PRESS (BSB) links the ports of Antwerp, Rotterdam, Fredericia, Gdynia, Gävle, and Rauma on a weekly basis. Two vessels serve the rotation: the 1,036-TEU X-Press Agility and the 1,436-TEU Essence. X-Press Feeders says the service includes an option for inducement calls into other Bay of Bothnia ports.

The Japanese container shipping line has introduced the SCX (Scandinavia Express) service that links the ports of Rotterdam, Gothenburg, Helsingborg, Aarhus, and Copenhagen. Cape Ferrol (1,440 TEUs of capacity) and Langeness (1,781 TEUs) serve the loop.

The sister ship of Wallenius Marine’s Future Way, which took her first shipment of Volkswagens from Europe to the US in September 2024, also began her charter for the German car manufacturer. The 200 by 37 metres Way Forward offers 6,500 CEUs of capacity. Both car carriers of the Sleipner class were designed by Wallenius Marine and KNUD E. HANSEN and built by CIMC Raffles in China. Way Forward and Future Way feature several eco-solutions, including optimised hull design, a shaft generator of active front end type (said to cut up to 10% of emissions), multi-fuel engines (liquefied natural gas and its bio version, plus regular and synthetic diesel), and connectors for drawing shore electricity while berthed. Also, when fully loaded, the two car carriers don’t need ballast water.

The company has connected Baltic Hub in the Port of Gdańsk with iHub Centrostal in Łódź in Central Poland, offering two weekly runs, each with a capacity of 54 containers/108 TEUs and 24 hours of transit time. At the same time, Loconi Intermodal, which recently became part of PSA, has upgraded its Intermodal Terminal Radomsko in Central-south Poland. The around PLN52 million (approx. €12m) investment doubled the facility’s yearly handling to 300 thousand TEUs. The 8.5-hectare terminal now has second rail siding, a 3,000-TEU-yard, 10 reefer plugs (with the option to add 10 more), and is also capable of handling trailers. The facility was operational during the construction works carried out by Atlas Ward.

• PARS Termināl is scrutinising the construction of a production plant in the Latvian capital seaport, set to supply 93 thousand tonnes of hydrotreated vegetable oil and 87kt of sustainable aviation fuel per year. The €120-million investment, the completion of which is

estimated to take 20 months and to be carried out with the help of Ukrainian partners, will be located in Kundziņsala in the Port of Riga. It will have the capacity to process 236kt/year of feedstock (mainly vegetable oils). •

• WT Terminal, operating in the Port of Riga, has commissioned a photovoltaic (PV) installation that comprises 480 panels with a total capacity of 220.8kW. “One of the WT Terminal business areas is the processing of sawn timber – drying, sorting, packaging. These are quite energy-intensive processes, so self-generated energy definitely makes our company more cost-efficient and less dependent on fluctuations in the electricity market,” underlined Andis Bunkšis, the company’s Board Member. He also announced, “Next year, an innovative, electricity-powered hydraulic crane will be installed on the terminal’s berths. A new transformer

substation has been built to ensure the operation of the electric crane, and three berths have been equipped with a power supply. Thus, the company will be provided with a single green infrastructure facility that will increase the terminal’s performance and energy efficiency while reducing harmful emissions and environmental impact.” The two other PVs in the Port of Riga are the 4.61MW system of Kronospan Riga and the 0.875MW of Baltic Container Terminal. Riga Universal Terminal is also working on its 250kW installation. In addition, the TFS Trans logistics centre houses a geothermal plant, which generates energy to heat buildings. •

• The government of Latvia has approved a €64.5 million investment to develop 30 hectares within the Port of Riga’s Kundziņsala into a production hub for the (off- and onshore) wind energy industry. The port authority added that €40m of private, clean tech investments are expected by 2029. •

• Operated by Hydri, the 1,500 kg of capacity/35 trucks per day station sits next to the Port of Gothenburg’s Gate 6, the entrance to the Gothenburg RoRo Terminal (and with 400 thousand vehicles/year, one of Sweden’s most heavily trafficked roads). The facility, partly founded by the Swedish Energy Agency, is Hydri’s first in what will become a network of 20 hydrogen stations across the country in 2024-25. “The large flow of trucks to the port and the possibility to refuel work machinery make the location for this hydrogen refueling station ideal. Combined with several existing charging stations around the port, heavy land transport at the Port of Gothenburg is now fully ready for a transition to both electricity and hydrogen,” highlighted Viktor Allgurén, Head of Innovation at the Port of Gothenburg. •

• European Energy has inaugurated its first hydrogen-producing facility in Måde, near Esbjerg, with the output delivered to the Port of Esbjerg and an industrial gas company. The Danish Stiesdal supplied the first electrolyser to the plant (which was completed in June this year). “Plans are already in place to expand the facility with two additional electrolysers, of which the next is expected to be installed in 2025. When all three electrolysers are operating, the plant will have a total capacity of 12MW and an expected annual production of 1,500 metric tonnes of hydrogen,” European Energy added in a press brief. Excess heat generated from the hydrogen

production process is utilised by DIN Forsyning, a local heating utility. Centrica serves as the facility’s balancing and optimisation partner, ensuring that energy usage and hydrogen production are managed to maximise output and minimise costs. European Energy is also in the commissioning phase of its Kassø methanol facility (52MW-capacity-electrolyser provided by Siemens), which is expected to produce the first green methanol by end-2024. Sourcing energy from the Kassø 300MW solar park, the plant will have the possibility to produce up to 32kt/y, with offtakes already secured by Maersk, Novo Nordisk, and the LEGO Group. •

• Following a trial on one of Langh Ship’s vessels, the Damen Shipyards Group will install the company’s system for onboard carbon capture (OCC) on four dry bulk carriers in 2025 (in tandem with hybrid scrubbers). “The pilot plant has shown that it is possible to [achieve] capture rates [of] over 80% from the exhaust gas flow coming into the system. The overall CO2 emissions can be reduced at least by 20 to 30%, depending on the available space and other ship and product specifications,” Langh Tech highlighted in a press release. The Finnish company also underscored, “A unique feature of the system is the possibility to sell and utilise the sodium carbonate, which results at the end of the chemical process, for diverse applications in other industries [such as glass and detergent manufacturing].” Langh Tech’s OCC system applies a postcombustion technique in which CO2-containing exhaust gases are directed into a capture unit. CO2 then dissolves into the liquid phase through a counter-currently flowing aqueous NaOH solution. The manufacturer says that a maximised surface area ensures the highest

possible carbon capture rates. As a result of several consecutive reactions, CO2 is chemically bound into a thermodynamically stable product of sodium carbonate. With “[…] post-combustion capture, there is no need for solvent regeneration or CO2 compression, which significantly reduces the additional energy consumption on board, as well as the resources needed to operate the OCC system. No additional specialised equipment is needed. In turn, the capture reagent, sodium hydroxide, can be produced by electrolysis of sodium chloride using renewable energy,” Langh Tech explained. The company also underlined that its OCC system is adaptable and scalable and can be used with different ship types. The bulker installation is part of a project between Langh Tech, Atal Solutions, BAM Shipping, and the Damen Shipyards Group, the aim of which is to retrofit ships with different technologies for maximum CO2 as well as SOX and NOX emission reduction while using traditional fuels. The project’s goal is to axe ships’ CO2 footprint by up to 60% with OCC (coupled with other measures, including voyage planning). •

• The service organisation that tests, inspects, and certifies technical systems has positively evaluated FERNRIDE’s safety & security concept for autonomous terminal tractors. TÜV SÜD has reviewed the hazard and risk analyses, safety design, specifications of the safety functions, and validation plan. “The evaluation concluded that FERNRIDE’s safety concept is robust and well-founded while also identifying clear next steps to further enhance the overall safety framework,” FERNRIDE shared in a press release. The company that is testing remote-toautonomous terminal tractors in HHLA’s container terminal in the Port of Tallinn’s Muuga Harbour says that TÜV SÜD’s stamp of approval is the first stage on the path to compliance certification according to the Machinery Directive for its fully CE-certified autonomous terminal tractors. “The evaluation by TÜV SÜD marks an essential step in preparation for the autonomous driving tests without a safety driver present in the vehicle. The first driverless tests are scheduled to start as early as December 2024,” FERNRIDE underlined. “The European Union is renowned for its stringent and comprehensive regulations and standards, making the process of achieving compliance and obtaining necessary certifications highly complex. As a result, many autonomous driving companies are hesitant to enter the market.

FERNRIDE is pioneering the development of a benchmark when it comes to safety in autonomous trucking in the European Union. Being a deep-tech start-up, we put a strong focus on industrializing safe and secure products, so we are very pleased with the positive outcome of the evaluation by TÜV SÜD,” said Hendrik Kramer, the company’s CEO and Co-Founder. The company’s Director for Systems, Safety and Security, Tilmann Ochs, added, “At FERNRIDE we are committed to building ‘safety by design.’ This is a first-of-its-kind process in the European Union, and our priority is to set the highest benchmark in safety & security standards for our product. The comprehensive examination by TÜV SÜD combined with our seasoned engineering teams, who have experience launching safety-critical products – we are well-positioned to achieve this goal.” Benedikt Pulver, Head of the Machine Safety Department at TÜV SÜD, also shared, “Working with FERNRIDE is very solution-oriented, and the topic of safety is taken very seriously. We are regularly provided with new and adapted safety concepts for review. Not only are existing protection concepts skilfully implemented, but new technological approaches are also developed. This combination could make FERNRIDE one of the first manufacturers with a CE-compliant solution for autonomous port applications.” •

• The French company has reserved a plot in the Oritkari Harbour of the Finnish Port of Oulu for the potential set-up of a plant for producing hydrogen and synthetic fuel. AFRY Finland, involved in evaluating the investment, has estimated the probability of the project coming to fruition to be high. “We are interested in building a high value-added production plant in Oulu because the area offers plenty of affordable renewable energy and biogenic carbon dioxide. The University of Oulu, which carries extensive research

related to hydrogen, and the region’s large R&D investments ensure a sufficient pool of experts. The existing business environment also provides us with potential customers and subcontractors. As part of the EU TEN-T Core Network, the Port of Oulu, with its excellent rail and road networks, offers good connections to the rest of the world,” Antoine Huard, Verso Energy’s CEO, highlighted. His company already produces synthetic fuels in France with the use of its own green hydrogen and CO2 captured from paper and pulp mills. •

• A number of organisations – including the Liepāja Special Economic Zone Authority, Van Oord, Euroports, and GI Termināls – have set up the Hub to push forward a few green projects, totalling €4.0+ billion

over 2025-35. The investments include an offshore wind energy (OWE) support base and three terminals in the Port of Liepāja: for handling heavy OWE cargo, storing & exporting CO2, and producing green hydrogen. •

• JetGas has signed a 30-year agreement with the Estonian seaport to set up a liquefied methane facility in the Muuga Harbour. Upon final completion by 2030, the terminal – covering some 7,000 square metres in the eastern part of Muuga – will feature up to five storage tanks and a quay-connecting pipe. The first tank is expected to be erected by end-2027. “The construction of the new liquefied methane terminal in the Muuga Harbour will allow us to obtain primarily bioLNG [bio liquefied natural gas], but also other methane fuels in larger consignments from the world market, resulting in cheaper prices and better security of supply,” underlined Janek Parkman, JetGas’ Management Board’s

Chair. Earlier, in late September 2024, the Port of Tallinn signed a memorandum of understanding with the US-based Protio for the production of e-fuels (e-methanol, sustainable aviation fuel, and potentially e-NG) at the Muuga Harbour. Valdo Kalm, Chairman of the Port of Tallinn’s Management Board, commented on the occasion, “Switching to alternative fuels for ships reduces greenhouse gases, improves air quality, and helps protect the marine environment. The goal of the Port of Tallinn is to achieve climate neutrality and zero emissions from ships docked at the port by 2050. Increasing the availability of alternative fuels allows shipping to become more environmentally friendly and reduces the carbon footprint of ports.” •

• The joint project of the ports of Aarhus, Bremerhaven, Gothenburg, and Stockholm will receive €18.8 million from the Connecting Europe Facility for the set-up of cold ironing infrastructure for container ships. “Through this project, The Port of Gothenburg will be able to build a highvoltage substation at the container terminal, which is a crucial part of the infrastructure needed to offer onshore power supply to container ships. It is an investment of about €20 million, with nearly half of the funding coming from the project,” Julia Christensson, Grants Manager at the Port of Gothenburg, shared. Her port estimates that by cold ironing in Gothenburg, container carriers can spare the environment some 5,600 tonnes of CO2 emissions annually. The EU.OPS.Network project, to last from 2024 to 2027, has a total budget of €37.61m. •

• The Swedish port authority, with the help of Bravida and Halmstads Energi och Miljö, has set up a high-voltage transformer station to create sufficient charging capacity to electrify the machinery fleet of the Port of Halmstad’s container terminal. “With the new charging infrastructure, we are taking an enormous leap towards our vision of electrifying the terminal’s whole machine park. This investment is

instrumental in reducing our carbon footprint and creating a more sustainable port environment in Halmstad,” underlined Jimmy Eklöf, Technical Manager, the Ports of Halland. The Port of Halmstad also saw the deployment of an electric reachstacker, manufactured by Kalmar. The 587kWh cargo handling equipment is Sweden’s second (with the first running in Helsingborg). •

• The global container carrier from Copenhagen has signed a longterm offtake agreement with the Chinese LONGi Green Energy Technology for the supply of bio-methanol for the former’s growing fleet of dual-fuel vessels. The first batch of the green bunker, produced at LONGi’s facility in Xu Chang in Central China from residues such as straw and fruit tree cuttings, will be supplied in 2026, with full production expected by the end-decade. “It will meet Maersk’s methanol sustainability requirements, including at least 65% reductions in GHG emissions on a lifecycle basis compared to fossil fuels of 94g CO2e /MJ,” the Danish shipping company said in a press release. Maersk’s combined offtake agreements now meet

over 50% of the dual-fuel methanol fleet’s bunker demand in 2027 (seven vessels are already operational, also sailing in the Baltic). “Bio- and e-methanol continue to be the most promising alternative shipping fuels to scale up in this decade, and the agreement with LONGi serves as a testament to this. Global shipping’s main net-zero challenge is the price gap between fossil fuels and their alternatives with lower greenhouse gas emissions. We continue to strongly urge the International Maritime Organization’s Member States to level the playing field by adopting a global green fuel standard and an ambitious pricing mechanism, which the industry urgently needs,” Rabab Raafat Boulos, Maersk’s COO, stressed. •

• The Copenhagen-headquartered ferry company has partnered with the manufacturer to scrutinise the conversion of the MaK diesel engines of the Gedser-Rostock hybrid ferries to run on green methanol. Caterpillar Motoren will provide a test engine in its workshop by 2025. If Scandlines concludes that it meets the expectations and fulfils the

conditions, then the first ferry diesel engine could be converted in 2027. Scandlines has committed itself to zero direct emission ferry operations by 2040. The Berlin and Copenhagen diesel vessels that serve the GedserRostock service are also equipped with batteries (1.5MWh systems from Corvus Energy) and rotor sails (from the Finnish Norsepower). •

• Headquartered in Lübeck, the company saw the installation and operational deployment of three Rotor Sails from the Finnish Norsepower on board the dry bulker Chinook Oldendorff. These are expected to

reduce the vessel’s fuel consumption by about 10-15% on transpacific routes (Chinook Oldendorff carries Elk Valley Resources’ steelmaking coal from the Port of Vancouver to customers across the Pacific Ocean). •

• The Swedish port’s heavy-duty machinery fleet has grown with two electric forklift trucks from Linde Material Handling Sweden, the first of their kind deployed in the country. The trucks offer 12 tonnes of

lifting capacity, up to six metres. They feature batteries that make it possible to run them for about four hours. The Port of Uddevalla will use its Linde E120s for handling pulp and paper (particularly rolls). •

• The Copenhagen-based shipping company has selected the windassisted propulsion system developed by the tech company from Barcelona to be installed on five of its tankers. Maersk Tacoma, Maersk Tampa, Maersk Tangier, Maersk Teesport, and Maersk Tokyo will see the installation of altogether 20 eSAIL® 26-metre-tall suction sails during their dry docking in 2025-26. The eSAIL® system is automated, adjusting the sails to the wind conditions for optimal performance. Njord, appointed by Maersk Tankers

as their green transition partner for the project, has managed the design and technology selection process end-to-end and will lead the integration and installation of the systems while also validating the savings. “Maersk Tankers expect double-digit percentage reductions in fuel consumption and CO2 emissions per vessel,” said the owner-operator of a fleet of 240+ tankers and gas carriers in a press release. The order is bound4blue’s biggest to date, with its eSAIL® system set up on four vessels thus far. •

• The Port of Kalundborg, together with 14 industrial partners, has founded the association in question, tasked with creating a carbon capture and storage value chain on the largest island in Denmark proper. “We see significant value in contributing to a unified and efficient value chain for CO2 management. By working together across sectors, we can strengthen the necessary infrastructure and

share experiences that create innovative solutions for the benefit of both companies and society,” the parties underlined in a press brief. Apart from the Port of Kalundborg, CCS Zealand includes AffaldPlus, ARC – Amager Ressourcecenter, ARGO, CarbonCuts, CTR I/S, Evida, Gas Storage Denmark, HOFOR, CO2 Storage Kalundborg, the Novo Nordisk Foundation, Novonesis, VEKS, Vestforbrænding, and Ørsted. •

In late October 2024, the European Commission (COM) shared that it selected 85 initiatives that will receive €4.8 billion in grants from the EU Emissions Trading System Innovation Fund (one of the tools of the European Green Deal Industrial Plan). “For the first time, projects of different scales (large, medium and small, alongside pilots) and with a cleantech manufacturing focus are awarded under the 2023 call for proposals. This is the largest since the start of the Innovation Fund in 2020, boosting the total amount of support to €12 billion and increasing the number of projects by 70%,” COM said in a press release. The selected projects are set to enter into operation before 2030 and, over their first 10 years, are expected to reduce emissions by about 476 million tonnes of CO2 equivalent. Among others, they’ll contribute to 3.0GW of photovoltaic and 9.3GW of electrolyser manufacturing capacity in the EU; contribute 13%

The European Commission’s Directorate-General for Mobility and Transport has summarised the functioning of the initiative – which saw the establishment of alternative transport routes to keep Ukraine’s imports & exports going in spite of the Russian war of aggression – in May 2022April 2024. Since their start, the Solidarity Lanes have allowed Ukraine to export around 136 million tonnes of goods, according to data from the Ukrainian customs registers. This figure includes around 76mt of Ukrainian agricultural products (out of which grains, oilseeds, and related goods accounted for about 70mt), while the remaining 60mt comprised ores, steel, and related products. On the import side, the Solidarity Lanes saw 52mt of goods going eastwards, mainly fuel, vehicles, fertilisers, as well as military and humanitarian assistance. The total value of trade via the Solidarity Lanes since May 2022 is estimated at around €157 billion, with imports totting up to around €107b and exports €50b (of which agricultural goods totalled some €25b). “The Solidarity Lanes are also laying the ground for the longer-term connectivity between Ukraine and the EU and will play a key role for Ukraine’s reconstruction and integration in the EU single market,” the Directorate-General underlined in a press brief.

of the Net-Zero Industry Act target of storing at least 50mt of CO2/year; and deliver 61kt/y of renewable fuel of non-biological origin (RFNBO) from green hydrogen, plus 525kt/y of RFNBO from other sources. Successful applicants are due to sign their grant agreements with the European Climate, Infrastructure and Environment Executive Agency in Q1 2025. Besides the 85 projects selected for funding, other promising but insufficiently mature proposals will receive development support from the European Investment Bank. For the first time, all the 149 projects that scored above all Innovation Fund evaluation thresholds (including 64 nonfunded ones) were given the STEP Seal, the EU’s new quality label awarded to high-quality initiatives contributing to the objectives of the Strategic Technologies for Europe Platform (STEP; the STEP Seal is to facilitate access to further opportunities of public and private support for these projects).

“The Draghi Report estimates that €40 billion in annual investments will be needed between 2031 and 2050 for the energy transition of shipping. Building a supply chain for clean fuels in Europe is a priority for the industry to meet its decarbonisation targets and for Europe to achieve its climate targets,” said the European Community Shipowners’ Associations (ECSA) and Transport & Environment (T&E) in a joint statement. The two organisations call on EU policymakers to ensure the international competitiveness of the European industry stays strong by positioning shipping, clean energy, and technology producers at the forefront of the green transition to speed up the transition of European shipping by investing revenues from the EU Emissions Trading System (EU ETS) into maritime decarbonisation through national and EU investment plans, and by facilitating access to public and private finance; include shipping in an ambitious Clean Industrial Deal, ensuring that at least 40% of clean fuels and clean and innovative technologies needed to achieve EU’s climate targets for shipping are manufactured in Europe; and to enable shipping’s access to green energy through dedicated supply requirements on fuel producers in European ports. ECSA’s Secretary General, Sotiris Raptis, underlined, “The energy transition has become the new international battlefield of economic competition and security. The Draghi Report has recognised the global leadership of European shipping and the need to remain internationally competitive. Being a frontrunner in green investments puts European shipping in a leadership position internationally. We urge policymakers to ensure and further leverage this competitive advantage by investing in clean fuels and innovative technologies for the energy transition. We need all hands on deck to maintain the industry’s competitiveness and to achieve net-zero emissions by 2050.” T&E’s Shipping Director, Faig Abbasov, added, “As Draghi acknowledges, shipping is one of Europe’s key industries. To maintain its competitive edge, Europe must take the lead in producing green shipping fuels of the future, especially those derived from green hydrogen. Policymakers must fill the regulatory gap by requiring fuel producers to make available green marine fuels in European ports, while carbon market revenues should support this endeavour.”

The Clean Maritime Fuels Platform released a similar call, recommending, among others, that the EU should de-risk investments in renewable and low carbon fuels, e.g., via schemes based on contracts for difference and auctions as a service, as well as to launch dedicated sectoral calls under the Innovation Fund for the first deployment of decarbonisation solutions. “The 20 million EU ETS allowances allocated to the decarbonisation of the maritime sector until 2030 should be used as soon as possible,” the Platform Members said in this regard.

Australia-New Zealand 4. Hamburg-Shanghai 5. Philippines Corridors

Rotterdam-Singapore GDSC

Singapore-Australia GDSC

25. Stockholm-Åbo

26. Sweden–Belgium

45. Los Angeles/Long BeachSingapore GDSC

Singapore-Tianjin GDSC

UK-Singapore-ASEAN

The Silk Alliance

Åland Mega Green Port 14. Dover-Calais/Dunkirk Ferry

UK-Singapore-ASEAN

Dublin-Holyhead 16. Esbjerg-Immingham

FIN-EST

18. Gothenburg-Frederikshavn Pilot Study

Åland Mega Green Port 14. Dover-Calais/Dunkirk Ferry 15. Dublin-Holyhead 16. Esbjerg-Immingham 17. FIN-EST

19. Gothenburg-Rotterdam 20. Larne-Liverpool

21. Liverpool – Belfast

22. Northwestern England-Ireland

18. Gothenburg-Frederikshavn Pilot Study 19. Gothenburg-Rotterdam 20. Larne-Liverpool

21. Liverpool – Belfast

23. Oslo-Rotterdam Pilot Study 24. St Helier-St Malo

Northwestern England-Ireland 23. Oslo-Rotterdam Pilot Study

St Helier-St Malo

27. Trelleborg-Lübeck

25. Stockholm-Åbo

28. Tyne-Ijmuiden

26. Sweden–Belgium

27. Trelleborg-Lübeck

29. UK-Belgium

30. UK-Denmark

28. Tyne-Ijmuiden

31. UK-Norway

29. UK-Belgium

32. Vaasa-Umea

30. UK-Denmark

33. West Mediterranean Cruise

31. UK-Norway

34. Great Lakes Iron Ore

32. Vaasa-Umea

33. West Mediterranean Cruise

34. Great Lakes Iron Ore

35. Gulf of Mexico Green Shipping Corridor

36. Halifax-Hamburg

37. Ireland-to-Indiana container

35. Gulf of Mexico Green Shipping Corridor

36. Halifax-Hamburg

37. Ireland-to-Indiana container

38. Port of Houston-Port of AntwerpBruges

39. US Green Bulk

38. Port of Houston-Port of AntwerpBruges

39. US Green Bulk

40. US-UK Green Shipping Corridors Taskforce

41. Hueneme-Pyeongtaek Green Automotive

40. US-UK Green Shipping Corridors Taskforce

41. Hueneme-Pyeongtaek Green Automotive

42. Hueneme-Yokohama Green Automotive

43. LA-Nagoya

44. LA-Yokohama

42. Hueneme-Yokohama Green Automotive

43. LA-Nagoya

44. LA-Yokohama

45. Los Angeles/Long BeachSingapore GDSC

46. North Pacific Green Corridor Consortium

46. North Pacific Green Corridor Consortium

47. Pacific Northwest to Alaska Green Corridor

48. LA-Guangzhou

47. Pacific Northwest to Alaska Green Corridor

48. LA-Guangzhou

49. Port of Los Angeles-Port of Long Beach-Port of Shanghai

50. Port of Oakland-Yokohama

51. Seattle and Tacoma-Busan

49. Port of Los Angeles-Port of Long Beach-Port of Shanghai

50. Port of Oakland-Yokohama

52. Seattle and Tacoma-Korea PCTC

51. Seattle and Tacoma-Busan

52. Seattle and Tacoma-Korea PCTC

53. US and Pacific Blue Shipping Partnership Green Corridors

54. US and Panama Green Corridors

55. Namibia Corridors

53. US and Pacific Blue Shipping Partnership Green Corridors

54. US and Panama Green Corridors

55. Namibia Corridors

56. South Africa-Europe Iron Ore Corridor

57. The Caribbean Green Shipping Corridor Initiative

56. South Africa-Europe Iron Ore Corridor

58. Chile Piscicultura

59. Chile Sulfuric Acid

57. The Caribbean Green Shipping Corridor Initiative

58. Chile Piscicultura

59. Chile Sulfuric Acid

60. Chile-Japan/Korea copper concentrate

61. Taurange-Zeebrugge

62. West Green Shipping Corridor

60. Chile-Japan/Korea copper concentrate

Taurange-Zeebrugge

by Lars Lange, Secretary General, IUMI

Each year, the International Union of Marine Insurance (IUMI) collects and analyses statistics from most of the national insurance associations to report on the current state of the marine insurance market. This ‘Stats Report’ has become widely accepted as the definitive bellwether for the industry. In September of this year, we presented our findings for 2023 at our 150 th annual conference in Berlin. Overall, we were pleased to report an encouraging year for marine underwriters. The global insurance premium base grew by 5.9% to reach 38.9 billion US dollars. This was driven by a continued rise in global trade volumes and values, an increase in the value of most vessel classes, and an oil price rally. From a purely insurance perspective, a reduced market capacity also had a positive impact.

By line of business, cargo insurance increased by 6.2%, hull insurance by 7.6%, and offshore energy by 4.6%. By geography, Europe continued to dominate with a 48.5% share of the global premium base, followed by Asia/Pacific (28.1%), Latin America (10.9%), North America (7%), and the rest of the world (5.5%). We found that the European markets continued to trend upward after a period of decline – as did Asia/Pacific (since 2016). The Americas were also enjoying growth.

A key element of our reporting is to calculate loss ratios for each line of business. In essence, this is a measure of profitability: the amount of premium collected less the amount paid out in claims. To break even, the sector must not pay out in claims more than it collects; likewise, it also has to take into account costs related to acquisition, capital, management, and such. In 2023, we reported loss ratios in the offshore energy sector to be higher (i.e., less profitable) than in 2021 and 2022 – but still relatively healthy. This was a similar position for hull loss ratios, whereas those for cargo loss were low and stable.

By their nature, our statistics refer to the previous year, and whilst 2023 was a relatively sound one, it is important to review the challenges our industry faces this year and beyond.

Top of the list is, without question, the ongoing geopolitical situation. The war in Ukraine and in the Middle East has most definitely disrupted international shipping and trade. War risk is a very real consideration, where the safety of life, vessels and their cargoes takes priority. To date, it is pleasing to see that the marine insurance sector continues to offer appropriate cover to vessel owners wishing to transit these areas. A related issue is where operators choose to take the longer sea routes to avoid the high-risk zones. This can introduce greater navigational and other challenges by taking ships outside of their normal operating areas.

Financial implications also come into play – as do environmental concerns. With a new administration soon to take over at the White House, it remains to be seen how the geopolitical picture will play out. Suffice to say, the associated risks will evolve, and marine insurers will continue to facilitate seaborne trade.

Geopolitical tensions are also affecting how global markets are adapting. Protectionism appears to be rearing its head in many parts of the globe – and this will impact trade and maritime routes. Logistics chains are likely to be organised differently in the future, particularly if nearshoring becomes more prevalent.

This will affect both insurance coverage as well as the overall premium base.

Equally impactful on marine underwriters is the general move to a greener society. The International Maritime Organization (IMO) has agreed that shipping will achieve ‘net zero’ by/close to 2050, and this requires a step-change in the way ships are fuelled and operated. Hydrogen, ammonia, fuel cells, and other technologies are all being pursued, with none yet coming out ahead. In the interim, liquefied natural gas, wind, and other initiatives are increasingly being utilised as transitional means of propulsion (not to mention numerous hard- and software energy efficiency measures). These alternative technologies all come with a range of ‘new’ risks (including cyber, as these are often data-driven advancements) that have the potential to adversely affect those serving at sea as well as the vessels themselves. Marine underwriters are investing resources to fully understand the new risk profile so they may develop products that allow vessel owners and others to trade in a low- or zero-carbon environment.

Our pursuit of a low-carbon future is also beginning to impact the types of goods carried by sea. One example is the fast-growing trade in lithium-ion batteries, either as energy storage units or as the propulsion source for electric vehicles. Whilst

not inherently dangerous, these batteries do pose a significant risk if they ignite – as extinguishing them is particularly challenging. Fighting fires at sea is no easy task and vessel operators, as well as their insurers, must be cognizant of the new risks involved with this type of ‘green’ cargo.

Besides these two overarching issues, marine underwriters continue to grapple with a number of ongoing risks. The general claims environment has been relatively benign of late – vessel losses are, thankfully, minimal. However, fires on large container ships and car carriers remain stubbornly high; this has resulted in large claims as well as tragic loss of life. The root cause is suspected to be undeclared or mis-declared dangerous cargoes in containers – these are not properly packed and stowed on board.

Added to this are the sometimes inadequate on-board fire-fighting capabilities – an issue that IUMI is actively working on with others at the IMO level. The accumulation of onboard risks, or at shore-side freight facilities, is also a growing concern. Larger vessels carrying more cargo and big ports accommodating more ships mean a concentration of risk that is potentially exposed to a catastrophe such as a fire or natural hazard.

Offshore energy insurers are facing a step-change in the way they operate as fossil fuels give way to renewables. Investment in more efficient and less carbon-intensive extraction will be required for many years to come. They may incorporate many new technologies, among others, carbon capture and storage. Underwriters will need to work in

partnership with energy companies to fully understand some of these not-seenbefore projects to allow them to provide suitable insurance solutions.

All in all, marine insurers are facing a changing landscape, one where technology (and the associated cyber risk) will be front and centre. But underwriters can take comfort in knowing that their line of insurance has been around for hundreds of years, during which their predecessors have successfully adapted to great change. Marine underwriters of today – and the future – will demonstrate similar resilience, so they remain in a position to offer a range of covers that will keep global maritime trade flowing.

The International Union of Marine Insurance e.V. (IUMI) is a non-profit association established for the purpose of protecting, safeguarding and advancing insurers’ interests in marine and all types of transport insurance. It also provides an essential forum to discuss and exchange ideas, information and statistics of common interest for marine underwriters and in exchange with other marine professionals. IUMI currently represents 42 national and marine market insurance and reinsurance associations. More information can be found at www.iumi.com

by Robert Mackay, Business Development Lead, FDR

The effects of climate change are increasingly evident across the globe, with a strengthening trend of frequent and severe weather events causing widespread disruption. In 2024, the average global temperatures will exceed 1.5°C, with the United Nations projecting averages of 3.1°C this century on the current trajectory. These temperature trends increase erratic weather conditions – including hurricanes, heatwaves, floods, and fires – which will rise in frequency and ferocity.

For the shipping industry, there are several recent examples that suggest climate change-triggered weather events are increasingly the norm, posing a number of questions for marine insurers. Hurricane Milton serves as a recent instance of this new normal, intensifying damage across the Caribbean and halting operations for cruise lines and commercial vessels alike. Milton’s quick succession after Hurricane Helene created a scenario where ships faced ongoing re-routing and delays, which intensified logistical challenges.

In Europe, the floods of Valencia in October this year offered another stark reminder of how quickly a weather-related crisis can strike. Here, heavy rainfall caused flooding that led to significant damages and delays to the city’s port, as well as further inland, all of which had a knock-on effect on all its services.

(Un)usual

Geopolitical risks add another layer of complexity when assessing shipping insurance risk profiles. Conflicts in Ukraine and the Middle East have impacted key shipping routes, most notably the Red Sea and the Suez Canal. In recent months, Yemen’s Houthi rebels have executed over 130 attacks in the Red Sea. With shipping companies increasingly redirecting vessels around the southern tip of Africa to avoid this volatile area, the economic burden of these disruptions underscores the need for insurance

solutions that reflect both current and anticipated threats. Traditional policies are proving insufficient, with a clear shift towards bespoke coverage solutions that offer protection for diverse and evolving risks.

What was once considered unusual is increasingly usual. Earlier viewed as a static cost, insurance must now be re-evaluated in order for shipowners and operators to manage these new and dynamic risks. It is no longer enough to protect against isolated, predictable events; today’s insurance landscape demands an understanding of the compounded effects of climate & political instabilities.

This dual reality of environmental and geopolitical disruption demands a proactive, adaptable approach to marine insurance. Insurers and brokers are collaborating to craft solutions that not only respond to today’s challenges but also prepare for future risks, enabling owners-operators to sustain operations and mitigate costly setbacks in this rapidly changing environment.

As extreme weather events increase in frequency and intensity, some insurers are exploring innovative solutions to meet the needs of today’s maritime industry. Parametric insurance – which provides predefined payouts when specific events occur – is emerging as one valuable tool to protect against unpredictable but high-impact incidents. Unlike traditional insurance models

that require lengthy claims processes, parametric insurance offers near-instant compensation when a specified event, such as a hurricane or typhoon, occurs. This enables operators to recover more quickly from disruptions, minimising financial and operational impacts.

For example, in the offshore renewable energy sector, parametric insurance helps offset delays caused by adverse weather. Offshore wind installations, vulnerable to high seas and strong winds, face significant risks during construction phases, with studies showing that 20-30% of operational downtime can be attributed to unfavourable weather. In such cases, parametric coverage is triggered when independent weather data verifies that conditions exceeded agreed-upon thresholds, allowing for a fast payout that helps cover costs associated with project delays.

Suitable for the offshore renewables sector, parametric insurance is also becoming increasingly relevant to the commercial maritime industry. Standard P&I reports indicate that climate-driven storms and typhoons are now among the leading concerns for insurers, generating a 46% rise in weather-related disasters since 2000. These result in complex, high-value claims, often related to cargo delays or damage. By offering a streamlined, responsive model, parametric insurance allows operators to avoid the protracted claims processes typical of traditional insurance, addressing the immediate impacts of weather-driven disruptions.

While parametric insurance doesn’t extend into areas and vessels affected by volatile geopolitical landscapes, other options are available. Shipping companies operating near conflict-prone regions, like the Red Sea, can utilise war risk insurance to address the financial implications of rerouted voyages or unexpected disruptions, including operational downtime.

For owners and operators, keeping pace with emerging insurance trends has become essential to staying competitive in an increasingly complex market. This is particularly relevant for smaller businesses, where elevated risks can amplify volatility. Parametric insurance offers a practical solution by safeguarding revenue and ensuring cash flow stability during disruptions, allowing operators to bypass the lengthy claims procedures associated with traditional coverage.

Among others, fuel quality issues can lead to machinery breakdowns and expensive operational delays, while cargo liabilities – especially for bulk commodities like grain or minerals – pose significant financial risks due to damage or contamination.

By working with a hands-on broker to develop tailored insurance policies, operators can mitigate these specific risks, ensuring that their coverage aligns with evolving market demands.

Parametric insurance is only one example of the innovative solutions emerging in response to new pressures. In tandem with more adaptive policy structures, some brokers and insurers are exploring models that account for non-traditional risks, such as cyber threats and political instability. In high-risk areas, having the right insurance coverage provides not only financial stability but also operational continuity, allowing owners-operators to make informed decisions in the face of geopolitical and environmental threats.

As insurance models continue to evolve, data-driven insights and close collaboration between brokers and shipping actors will become increasingly essential

to identifying and managing potential risks. Marine insurers are more and more leveraging analytics to assess risk exposure with greater precision, ensuring that policies are well-aligned with current realities. In a time of rapid change, the ability to anticipate and adapt to emerging risks agilely sets resilient operators apart from those left exposed.

At FDR, we recognise that adapting to these changes requires innovative solutions. We see that while premium increases are likely, data analytics and digitalisation are playing an increasingly important role in marine insurance, helping insurers model potential risks more accurately – allowing costs to be better managed. Investing in adaptable, forward-thinking insurance models not only provides critical financial protection, but enables owners and operators the confidence to navigate future challenges.

We offer you more than just insurance services. Our commitment extends beyond that – we act as an extension of your team, managing all aspects of risk management. With our direct connections to major global maritime insurance markets, we enhance the speed and efficiency of insurance operations, ensuring fast quotes, seamless policy issuance, and prompt claims resolution for our customers. Our philosophy centres around building strong and collaborative relationships with our clients, and we are fully devoted to your success. Head to fdr-risk.com to learn more.

by Ewa Kochańska

Decarbonising ports is a critical step in achieving worldwide sustainability goals and addressing climate change. Therefore, as pivotal hubs in the global supply chain, ports face mounting pressures and challenges in balancing efficiency with sustainability. The report Getting Ports to Net Zero, summarising a research project by Thetius and Ericsson, clears a concrete pathway leading to carbon-free operations. It describes a systemic approach, beginning with the detection of emission sources, followed by informed decision-making on technologies and funding needs, and effective, thoughtful deployment of solutions. Highlighting advanced monitoring systems and smart technologies, electrification and renewable energy integration, the publication examines implementation factors as well as real-life case studies, allowing ports to identify a proper strategy that best suits their operational framework.

Subpar port performance disrupts logistics and inflates end costs, while significant greenhouse gas emissions damage ecosystems and degrade the quality of life for surrounding communities. With that in mind, the complexity of port ecosystems makes reducing emissions a daunting and, at times, ambiguous task.

Getting Ports to Net Zero explores decarbonisation strategies that include smart technologies, electrification, and renewable energy, also highlighting the critical role that advanced networks play in achieving net-zero goals. Additionally, robust infrastructure, stakeholder collaboration, phased implementation, and continuous evaluation are also pointed out as critical to successful emissions reduction. To encompass all this intricacy in a user-friendly guide, the report narrows down the port decarbonisation framework to three main pillars: detect, decide, and deploy.

Detect

Detection is an obvious first step on the road to reducing and, later, eliminating emissions. Ports must pinpoint their most significant sources thereof to address the problem effectively, and there could be many: quay cranes and other cargo handling equipment, harbour vehicles, port facilities (like warehouses and workshops), as well as visiting vessels, trucks, and trains. Being able to deduce who the main offenders are allows ports to identify what is done well and what areas need improvements. This also

involves determining whether the existing infrastructure is sufficient for implementing reduction measures or if upgrades are necessary. Sharing these findings with other ports and stakeholders promotes transparency and offers valuable insights into effective strategies, fostering collective progress in reducing environmental impacts. While ports differ, requiring individual approaches, they also share many touch points to make decarbonisation a group effort.

Getting Ports to Net Zero advises that creating a baseline for emissions and port performance is critical to setting realistic reduction targets. Importantly, having current data on emissions (and related achievements as well as failures) and sharing that information not only builds public trust but also ensures compliance with regulations. Currently, despite increasing awareness of the need for decarbonisation, few ports publicly disclose their emission data sets. A richer statistics base could better inform environmental policies and help in regulatory compliance across the entire maritime & logistics supply chains.

Measuring emissions is also tied to financial incentives and penalties, such as carbon taxes imposed based on CO2 outputs. Port players can mitigate these fees by adopting greener practices like using low-emission fuels, installing shore power systems, and promoting efficient vessel call scheduling and truck arrival times. These measures not only reduce emissions but also support compliance with goals like the European Green Deal (which aims for a 90% reduction

in emissions by 2050). Compliance with these regulations is essential for securing funding and avoiding reputational damage. Advanced technologies enable precise emissions monitoring and improved operational efficiency. Digital tools like sensors, drones, and air quality monitors provide real-time data on pollutant levels, while remote sensing and satellite technologies offer broader monitoring capabilities. Digital twins integrate real-time data to optimise port operations, such as berth planning and reducing inefficiencies and emissions.

These innovations require reliable connectivity to function adequately, ensuring seamless data collection and analysis. Consequently, robust connectivity and digitalisation are essential for decarbonising ports and, thus, sustainable maritime operations. Modern technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and high-speed wireless networks, enable real-time decision-making and predictive analysis. High-quality connectivity is also vital for operating autonomous equipment and mobile assets within ports, driving greater efficiency while reducing emissions.

It is now time to pick out what solutions must be deployed to reach the net-zero emissions objective. Getting Ports to Net Zero underscores three ‘key routes to choose from:’ implementation of smart technologies, equipment electrification and shore

Diagram 1

Diagram 1

power provision, and introduction/escalation of renewable energy.