bimonthly-daily companion

bimonthly-daily companion

Baltic transport 2024 highlights

How to develop a high-efficiency onboard carbon capture system

EU’s roadmap for ports navigating towards environmentally responsible future AI-powered farming for a healthier, more resilient maritime workforce

The Port of HaminaKotka is a multipurpose seaport serving trade and industry. This major Finnish port is an important hub in Europe and in the Baltic Sea region.

Welcome to the Port of HaminaKotka!

Ihope you all have had a strong start to the new year (certainly, our shipping readers had one with the FuelEU Maritime Regulation entering into force…). While we don’t have a crystal ball to predict what 2025 will bring about, the year’s opening issue traditionally rounds up the transport & logistics highlights from across the past 12 months. This time around, wind came to the fore (though at some point, it was hit by a powerful headwind in Sweden…), with the port industry gearing more & more actively to cater to the needs of the wind-energy-harvesting sector. There was also a not insignificant number of developments on the future fuels front, likewise in the area of electrifying operations (most notably trucking, but the Baltic welcomed a few additional onshore power supply facilities in the region’s seaports, too). Several parties also tied the various knots by striking partnerships to establish green shipping corridors, an advancement that earned them a separate section in the Report this time; well done! The Baltic is also progressing with carbon capture – on- & offshore (and here, the Technology column hosts a read on how to develop an onboard carbon capture system, which, besides its high efficiency, also delivers a sellable end product for the circular economy). The past year also resulted in several ‘conventional’ developments in ports, like new quays, and in shipping (newbuilds, especially for Swedish owners-operators).

Other than that, the 1/25 issue is laden with reads that focus, from different angles, on seafarers’ health, physical and mental alike. The advancements here are made possible thanks to modern technology, from artificial intelligence that can spot whether somebody’s well-being may be at risk, through Virtual Agronomists helping grow those wholesome veggies right on board ships, to a new digital platform designed to support people at sea on multiple fronts, professional and social among others. In a world awash with tech that wants nothing but to capitalise on us, it’s genuinely refreshing to see solutions that got the backs of people doing really, really hard work.

The remaining articles touch upon more than up-to-date topics, including lithiumion battery fires aboard vessels, how to green your seaport (particularly if you’re a smaller one) as well as getting hold of actual emissions data, cyber security, taking care of equipment’s safety (you know, ‘before’ it breaks!), and, of course, developing a robotic application for handling container railway wagon pins. Finally, yet equally important, we’re welcoming a new organisation tasked with bringing ports to the next level, the International Association for Port Development.

Wishing you a strong read!

Przemysław Myszka

Baltic Transport Journal

Publisher BALTIC PRESS SP. Z O.O.

Address: Aleja Zwycięstwa 96/98 81-451 Gdynia, Poland office@baltictransportjournal.com

www.baltictransportjournal.com www.europeantransportmaps.com

President of the Board BOGDAN OŁDAKOWSKI

Managing Director PRZEMYSŁAW OPŁOCKI

Editor-in-Chief

PRZEMYSŁAW MYSZKA przemek@baltictransportjournal.com

Roving Editor MAREK BŁUŚ marek@baltictransportjournal.com

Proofreading Editor EWA KOCHAŃSKA

Contributing Writers

JOHANN BERGMANN, HINRICH BRUMM, SVANTE EINARSSON, ALEXA IVY, MARINOS KOKKINIS, LAURA LANGH-LAGERLÖF, INGELA MANDL, PETAR MODEV, DR. HOLGER MÜLLER, HANNAH PACHE, MONIKA ROGO, OREN SAAR, FITZWILLIAM SCOTT, GURINDER SINGH, BRITTA SOMMER, YOLANDA BATISTA VENTURA

Art Director/DTP DANUTA SAWICKA

Head of Marketing & Sales PRZEMYSŁAW OPŁOCKI po@baltictransportjournal.com

If you wish to share your feedback or have information for us, do not hesitate to contact us at: editorial@baltictransportjournal.com Contact us:

Never mind our stunning sea view. Every port has one. We’re talking about the railroad and motorway right outside our office windows. For a port, that’s a view, and a location worth its weight in gold. At the Port of Oxelösund, we have a direct connection to the Swedish railway system, and to Sweden’s biggest motorway, European route E4. This gives us unique possibilities when it comes to processing and transporting goods. If you value logistics with speed and flow, give us a call.

The Port of Oxelösund is more than a port. We can handle your entire logistics chain and optimize every part of your goods’ journey, from start to finish. Our goal is to be the Baltic’s leading port terminal, with Europe’s best stevedoring services.

26 Small is green

– EU’s roadmap for ports navigating towards environmentally responsible future by Ewa Kochańska

30 A fresh revolution at sea

– AI-powered farming for a healthier, more resilient maritime workforce by Oren Saar

32 From start to finish

How transitioning to electro-fuels could increase emissions (before we see a reduction) by Ingela Mandl

34 Resilient, efficient – and caring

How digitalisation helps seafarers open up about their mental health by Fitzwilliam Scott

36 Forward-thinking healthcare

– From reactive to predictive handling of seafarer health issues by Marinos Kokkinis

38 Training as an enabler

– Interview with Raal Harris, Chief Creative Officer, Ocean Technologies Group & OneOcean by Alexa Ivy

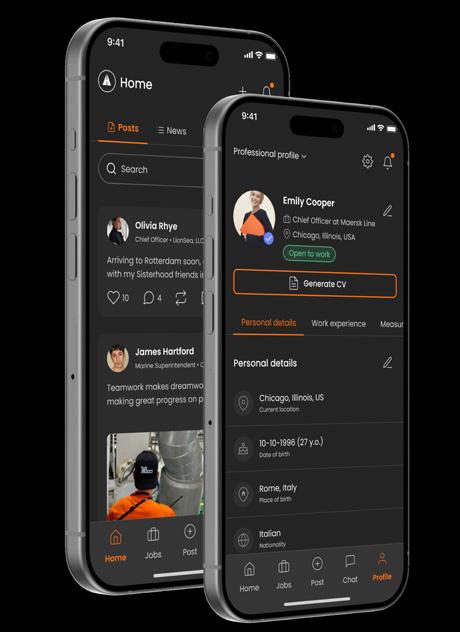

40 All good in The Hood

– A new maritime platform redefines connectivity by Alexa Ivy

42 Unlikely to ease off any time soon

– Tackling a growing cyber security threat in an increasingly connected industry by Svante Einarsson

44 Integration and strengthening

Introducing the International Association for Port Development by Yolanda Batista Ventura

74 Fintraffic VTS joins BPO by Monika Rogo

75 BPO, in an industry-wide open letter, addresses the EU Member States by Monika Rogo

76 Pin up & down

– Developing and testing a robotic application for handling container railway wagon pins by Johann Bergmann, Dr. Holger Müller, and Britta Sommer

78 The future of – proven – maritime GHG reporting

– The DIVMALDA research project by Hannah Pache, and Hinrich Brumm

80 Capturing a greener future

– How to develop a high-efficiency onboard carbon capture system (with a saleable, eco-friendly, circular economy end product) by Laura Langh-Lagerlöf

82 Getting in good condition

– How a digital strategy can support condition-based safety by Gurinder Singh

Baltic Sea Offshore Wind Summit , 10/03/25, PL/Gdańsk, www.balticwindsummit.eu

This year’s Summit will convene under the theme ‘How to win the Baltic Sea wind,’ with the programme centred on several distinct but closely interconnected thematic priorities that drive the Baltic Sea wind industry forward: safety, infrastructure, value chain, workforce, and innovation.

Transport Week , 18-19/03/25, PL/Gdynia, transportweek.eu

Day 1 will focus on addressing the Europe – a leader or a follower? question, while Day 2 will house the Baltic Ports for Climate Conference organized with the Baltic Ports Organization. The 2025 edition of the event will tackle the topic of the impact of European policies on the transport sector as well as highlight port investment strategies, including investing in electrification, onshore power supply, and the digital twin technology.

Net Zero Maritime Conference , 23-24/04/25, SE/Gothenburg, leaftinevents.com/events

The two-day event will focus on various aspects and areas of decarbonization to meet the IMO’s regulations, including alternative marine fuels, collaboration and best practices, innovation in shipping, financial considerations, sustainable port operations, digital solutions.

ESPO Conference , 8-9/05/25, GR/Thessaloniki, espo.be/events

The next annual meeting of the European seaport industry will take place in Thessaloniki on 8-9 May 2025. We are looking forward to seeing you – as well as some 200 other port professionals – there!

transport logistic 2025, 2-5/06/25, DE/Munich, transportlogistic.de/en

As the world’s leading trade fair for logistics, mobility, IT, and supply chain management, transport logistic in Munich brings together the entire industry. Decision-makers, experts, and innovators gather here to discuss the latest trends and developments and explore business opportunities. Join us and take advantage of this unique platform to propel your company forward and become part of the future of logistics.

Nor-Shipping , 2-6/06-25, NO/Oslo, nor-shipping.com

The only constant is change. In a rapidly evolving maritime and ocean industry, how can we work to find the strategies, solutions and partners to mitigate risk, maximise opportunity and meet ambitious climate goals? Understanding is key, collaboration is critical. Nor-Shipping 2025 will gather industry leaders from across the world to debate pathways, share knowledge, showcase innovation, and help build the relationships necessary to navigate towards a future of sustainable success.

TOC Europe 2025, 17-19/06/25, NL/Rotterdam, tocevents-europe.com

With an unrivalled 40+ year heritage, TOC Europe is the place to learn from and network with the world’s leading port decision-makers, policy experts, solution-providers and more, enabling you to both supercharge your strategies and make your port operation visions a reality. Whether your focus is on adapting to the unpredictable economic climate or simply embracing the exciting new technologies revolutionising the sector, join us on the road towards growth at the essential container supply chain event. The meeting place where business comes to life!

Baltic Ports Conference 2025, 6-8/10/25, PL/Gdańsk, balticportsconference.com

After a very successful and well-attended Baltic Ports Conference (BPC) in Klaipėda, the Baltic Ports Organization (BPO) already welcomes you to the 2025 edition to be held in Gdańsk on 6-8 October 2025 under the auspices of the Port of Gdańsk. As always, BPO’s BPC will touch on the most topical issues facing the port and shipping businesses in the Baltic and beyond. Stay tuned for more info before long!

The International Symposium on Optimising Container Design to Mitigate Risks of Pest Contamination – organised by the International Plant Protection Convention (IPPC) Secretariat in partnership with the Bureau International des Containers (BIC), the Container Owners Association , and the World Shipping Council (WSC) – gathered carriers, leasing companies, container manufacturers, biosecurity experts, and plant health stakeholders to discuss how to address the $423 billion global challenge posed by invasive pests every year. A study by the Australian government took centre stage, revealing that while 8% of standard containers showed signs of pest contamination, the rate dropped to just 1.45% in modified units. “Data from interceptions collected by several countries indicate that approximately 90% of pest contamination found on the external surfaces of sea containers is linked to the understructures, while contamination on internal surfaces is primarily associated with the floorboards,” shared Rama Karri , Director at the Australian Department of Agriculture, Fisheries and Forestry. Practical anti-pest modifications, aimed at making containers less hospitable to invasive pests without compromising functionality or cost-efficiency,

include floor designs that eliminate gaps and cracks and prevent nail holes, understructures with fewer horizontal ledge configurations, and the elimination of bitumastic under-coatings. Mike Downes , Senior Technical Expert at BIC and Chair of the Container Cleanliness Industry Advisory Group supporting the IPPC’s Sea Container Focus Group (SCFG), commented, “Container design has historically focused on production efficiency and durability, but in a global supply chain we must also prioritize pest resistance. By rethinking container design, we can mitigate the risks of invasive species and safeguard biodiversity, forests, and global food supplies.”

Lars Kjaer, Senior Vice President of WSC, added, “This is a critical societal issue, and collaborative efforts like this Symposium are helping broaden our industry’s recognition of the problem and strengthen its commitment to accelerate efforts to create a pest-resistant supply chain.” At the end of the meeting, a working group was established to move forward with the many promising ideas introduced. The group will present proposals for container design modifications to the IPPC’s SCFG and ultimately to the Commission on Phytosanitary Measures that oversees the IPPC’s activities in regard to container cleanliness.

TT Club released its latest publication that looks back over the full 12 months of 2024, covering key themes, events, and initiatives for the global provider of mutual insurance and related risk management services to the international transport & logistics industry. The release focusing on the past year includes topics such as climate

change adaptation and energy transition, contractual management and theft trends, personal protective equipment, and safe mooring, plus expert insight from TT’s Claims Executives on complex issues like nuclear verdicts in the US and freight forwarder liability in relation to recent events in the Red Sea.

TT Club also released a new edition of the publication in question , this time putting the spotlight on the latest advances in carrying equipment technology that can be considered to give supply chain stakeholders an advantage in the ongoing battle against the criminal fraternity. “A common theme when considering supply chain security is that the criminals behind the theft activity are getting smarter. They are leveraging technology to their advantage, and it appears continually gaining ground on legitimate stakeholders,” warns the insurer. “There have been more extreme cases where those

behind cargo theft have used technology to block or jam GPS tracking devices and even cases whereby a recruited insider has placed a covert GPS device for the criminals so that they have full visibility of their target as it transits through the supply chain, affording them the opportunity to choose an opportune moment to strike.” The Bulletin focuses on smart containers and their promise of greater visibility, safety and compliance benefits, and real-time tracking – altogether a potential solution against illicit activity. The publication explores several solutions and the impact that they could deliver.

Speaking of insider threat , one of TT Club’s latest TT briefs tries to answer the question at hand. “Criminals acting in the supply chain target all stakeholders and modes of transport to conduct illicit activity, including theft and trafficking of contraband goods. All employees, full-time, part-time, and contract, are useful to criminal organisations as they seek to penetrate the defences against illicit activity,” the insurer warns. “Although they may be directly involved in outright theft of goods, insiders are quite often most useful to criminal organisations as sources of information […] such as stockholding records, load and route plans, and even CCTV records,” TT Club furthers. There are, fortunately, ways to tackle the insider threat, among others, discerning between legitimate and illegitimate recruiters (the former look for skills and strengths, the latter – for weaknesses that can be later leveraged),

thoroughly vetting prospective employees, or considering whether systemic access should be limited (such as maintaining segregation between warehousing and transportation parts of the business). Having strong & trusted leadership, effective communication, and trustworthy whistle-blower policy are also key to mitigating the risk of insider collusion, TT Club says. “Criminals exploit workers through blackmail and intimidation to make them feel isolated and vulnerable. Businesses can counter this tactic by talking openly about the issue and offering workers understanding, protection, and even amnesty for past misdeeds. Workers who feel trapped in a cycle of blackmail and criminal action may struggle to see a way out of the trap in which they find themselves. Businesses may break this cycle by effectively showing a worker a way out,” the insurer notes.

GREEN MAP 2025 BALTIC GREEN MAP 2025

overview of products, infrastructure, overview of products, infrastructure, services, and many, many, many services, and many, many, many more greenstuff in one place more greenstuff in one place – on your wall, computer, or phone! – on your wall, computer, or phone! plus the digital plus the digital

BALTIC GREEN MAP CATALOGUE BALTIC GREEN MAP CATALOGUE with plenty of wholesome details! with plenty of wholesome details!

At the same time, the Swedish seaport’s rail container traffic advanced by 6.8% year-on-year to 505 thousand TEUs. Fewer ro-ro cargo units went through Gothenburg’s quays in 2024 (-3% yoy to 524k), the same as new vehicles (-3.7% yoy to 257k). Passenger traffic also noted a drop (-8.3% yoy to 1,389 thousand travellers). On the other hand, the handing of liquid bulk rose (+18.5% yoy to 21.8 million tonnes), likewise of dry & break-bulk (+5.5% yoy to 463kt).

Rostock Port:

30.1 million tonnes handled in 2024 (-2.4% yoy)

The German Baltic seaport’s main trade, ferry & ro-ro cargo, totalled 16.5 million tonnes (including trucks’ tare), a result on par with 2023. Rostock also handled 7.9mt of liquid goods (+/-0% year-on-year), 5.05mt of dry bulk (-11.4% yoy), and 655kt of break-bulk (-13.6% yoy). Despite the decreases, it was the seaport’s second-best cargo handling year on record. Rostock’s ferry traffic totalled 2.57m travellers (30k more than in 2023). Some 666k private vehicles were brought on board ferries, too (+2% yoy). The 2024 cruise season also saw more visitors, up to 532k from 419k. The finished vehicle logistics sector rose from 32k to 122k units. On the other hand, Rostock’s combined traffic by rail contracted by 3% yoy to 112k cargo transport units.

1,069,678 TEUs handled in 2024 (+1.8% yoy)

According to Statistics Lithuania, the Lithuanian seaport also took care of 240,943 ro-ro cargo units last year, an advance of 16.5% year-over-year. Overall, the Port of Klaipėda handled 35.22 million tonnes in 2024 (+7.8% yoy). The passenger side of the business also saw increases: +0.8% yoy to 370.7 thousand ferry travellers, plus 64.3k cruise passengers (+52.4% yoy).

Port of Gdynia:

974,586 TEUs handled in 2024 (+11.5% yoy)

Overall, the Polish seaport took care of 26.89 million tonnes last year, down 8.5% on the 2023 result. While general cargo (excluding timber), Gdynia’s leading trade, advanced 6.3% year-on-year to 16.01mt, other freight groups contracted: liquid bulk by 11.9% yoy to 3.04mt, grains by 17.2% yoy to 5.59mt, coal & coke by 59.6% yoy to 1.14mt, other dry bulk goods by 3.2% yoy to 991kt, and timber by 33.1% yoy to 119kt.

The overall drop was chiefly caused by the 41.8% year-on-year decrease in coal handling, down from 13.4 to 7.8 million tonnes. Liquid bulk, Gdańsk’s prime trade, was up 5.1% on the 2023 result, totalling 39.5mt. With 23.4mt (+1.3% yoy), general cargo came in second, including 20.7mt of containerised freight (+1.0% yoy). The Port of Gdańsk also handled 2.9mt of grains (-6.5% yoy) as well as 3.7mt of other dry bulk goods (-2.6% yoy). Container traffic advanced by 9.7% yoy to 2,249 thousand TEUs. The Polish seaport also saw more ro-ro cargo units, up 3.7% yoy to 139k, likewise passengers –an increase of 4.5% yoy to 166.2k ferry & cruise travellers.

The Port of Rauma:

4.63 million tonnes handled in 2024 (-2.1% yoy)

International cargo traffic amounted to 4.48mt (-0.6% year-on-year), of which exports totalled 3.02mt (-1% yoy) and imports – 1.46mt (+/-0% yoy). Domestic traffic added the remaining 145.5kt (-32.1% yoy). The Finnish seaport handled a total of 203,514 TEUs (-4.7% yoy): 202,222 in international (-3.6% yoy) and 1,292 in domestic traffic (-65.7% yoy).

The Port of Tallinn: 13.13 million

The Port of Turku:

1.69 million tonnes handled in 2024 (+0.5% yoy)

Totalling 1.66mt, international freight traffic was up 1.9% on the 2023 result, including 855.2kt of imports (+11.2% year-over-year) and 806.7kt of exports (-6.4% yoy). Domestic cargo traffic added the remaining 28kt (-44.1% yoy). A total of 79,188 trucks & trailers went through Turku’s quays (-6.5% yoy), plus 1,619 TEUs (-45.8% yoy). The Finnish seaport also welcomed fewer passengers, down 9.8% yoy to 2,196,223.

The handling of dry bulk noted the highest advance of 19.4% year-on-year to altogether 2.58mt. Wheeled (ferry & ro-ro) cargo, Tallinn’s prime trade, totalled 6.57mt (+2.6% yoy). The Estonian seaport also took care of 2.11mt of containerised freight (+12.3% yoy), 1.36mt of liquid bulk (-19.8% yoy), 487kt of break-bulk (+16.4% yoy), and 23kt of goods classified as ‘non-marine’ (-6.3% yoy).

The Port of Tallinn’s container traffic amounted to 261,822 TEUs (+18.3% yoy). The seaport’s passenger traffic was up 3.6% on the 2023 result, totalling 8.2m travellers (including 153k cruise guests, -7.1% yoy). The ferry service with Helsinki totted up to 7.23m passengers (+3.3% yoy), with Stockholm – 563k (+4.8% yoy), while the Muuga-Vuosaari crossing saw 153k (-7.1% yoy). Passengers classified as ‘other’ amounted to 53k (+17.5% yoy). TS Laevad, the Port of Tallinn’s domestic ferry subsidiary, transported 2.46m passengers (+2.1% yoy) and carried 1.17m vehicles (+3.6% yoy).

134,219 ro-ro cargo units carried in 2024 (+7.1% yoy)

On the other hand, the ferry line served fewer passengers, with 4,646,676, down 5.1% on the 2023 result. The first year of operating Birka Gotland (together with Gotland Company’s Destination Gotland) saw 438,743 travellers boarding the interBaltic cruiser.

The Port of HaminaKotka: 13.14 million tonnes handled in international traffic in 2024 (-6.9% yoy)

Exports totalled 8.61mt (-8.5% year-over-year), while imports – 4.54mt (-3.6% yoy); additionally, the Finnish seaports took care of 131.2kt in coastal traffic (-33.2% yoy). The Port of HaminaKotka’s container traffic amounted to 571,097 TEUs, 7.5% fewer than in 2023.

The Swedish seaport will invest around SEK700 million (€62.1m) in infrastructure development and equipment, including quay lengthening, a crane, dredging, and yard space, as well as in railways and a marshalling yard. The project is set to be completed in H1 2027. “The investment will strengthen our own as well as the region’s competitiveness as we open up for new businesses and client cooperation. The Port of Oxelösund has the potential to be one of the Baltic Sea’s most important transport nodes for numerous industries,” commented Staffan Thelander, the Port of Oxelösund’s CEO. He furthered, “With these investments, we’re enabling faster and more environmentally friendly transports, remaining a part of a value chain that will noticeably lower carbon emissions in the steel industry. We see this as a model of how we can help more companies offer climate-smart and effective logistics solutions.”

Meriaura’s heavy-load open deck carrier Meri transported the mobile harbour crane from Liebherr Rostock to Forth Ports Group’s Port of Tilbury (London). The fully assembled machinery was unloaded with the help of another piece of Liebherr’s heavy-duty gear, the LH 150 Port Litronic material handler. Tilbury’s new LHM 550, offering an outreach of 54 metres and a 144-tonne configured lifting capacity, will be used for, among others, handling granulated blast furnace slag (GBFS) from the expected to start operating in 2026 Aggregate Industries’ new cement grinding manufacturing facility and import terminal in the English seaport. Due to the aggressive nature of GBFS, an over-pressure system has been fitted to force-ventilate the crane’s slewing platform to prevent product ingress into the machine rooms. Additionally, the LHM 550 has been covered in the same paint finish as Liebherr’s offshore and ship cranes for corrosion control that goes beyond most port standards. The mobile harbour crane also features the LieGEN energy recovery system, can run on hydrotreated vegetable oil, and is ready to draw power from an electrical power supply.

The Port of Fredericia, as well as the ports of Lübeck and Trelleborg, will receive funds from the Connecting Europe Facility’s Alternative Fuels Infrastructure Facility (AFIF) for setting up onshore power supply (OPS) facilities. The Danish seaport’s project will receive just over €2.05 million, while the joint initiative of the two other ports – €2.23m. “This will be an extension of our wind turbines that can now supply our customers’ vessels with fossil-free electricity. There are several environmental benefits of onshore power, including avoiding carbon dioxide emissions when the vessels are in the port. Through the project, we contribute to a green shipping corridor in the Baltic Sea between Sweden and Germany,” commented the Port of Trelleborg’s Ulf Sonesson.

The Helsinki-headquartered manufacturer of auxiliary wind propulsion has fitted the dry bulker, on commission by IINO LINES and J-Power, with one 24-metre-tall and 4.0-in-diameter Rotor Sail. The device, installed on the forecastle deck, utilises artificial intelligence to automatically control the rotation, direction, and speed of the rotor, using real-time meteorological information from sensors, such as wind direction and speed. In combination with a voyage optimisation system, Yodohime ’s Rotor Sail is expected to reduce fuel consumption and CO2 emissions by approximately 6-10%. It is IINO LINES’ second Norsepower retrofit (the very large gas carrier Oceanus Aurora received her two 20-by-4 sails in November 2024) and J-Power’s first.

Port Gdański Eksploatacja (PGE) will spend some PLN400 million (about €93m) on new infrastructure in the Port of Gdańsk’s Inner Harbour for handling and storing agricultural products. The investment will see the construction of nine grain silos, five on the Wiślane and four on the Szczecin Quay, the modernisation of road, rail & port infrastructure, and the purchase of conveyor belts and Liebherr cranes – all to handle ships carrying up to 36 thousand tonnes. The project will increase PGE’s yearly storage capacity by fivefold, to 152kt, while its agricultural goods handling capacity will increase from 700kt to 2.9mt/year. The investment will also pave the way for setting up another agro terminal dedicated to grains and feedstock.

Each of the Norwegian shipping line’s two general cargo vessels, to be constructed by Jiangsu SOHO Marine Heavy Industry, will house a pair of 24-metre-tall and 4.0-metre-in-diameter Rotor Sails from Norsepower. The first 130-metre-long ship, designed by Marine Design and Consulting, is set for launching by end-2025. The sister vessels will also feature battery packs and shaft generators.

The Ports of Halland, an authority that governs the Swedish seaports in Halmstad and Varberg, and the Danish Port of Grenaa have struck a strategic partnership to work on developing sustainable logistics solutions. The Kattegat Port Alliance will focus on optimising cargo traffic as well as on energy projects, especially in the area of offshore wind (but also the production of biogas and hydrogen, plus carbon capture and storage). “We see this partnership as an essential strategic element in our continued growth and development. For both our customers and us, we see great potential and strong synergies in strengthening and expanding our collaboration across the Kattegat. The Ports of Halland and the Port of Grenaa have enjoyed a positive and close working relationship for many years, and this partnership agreement is a natural yet innovative step forward in our cooperation,” underscored Henrik Carstensen, CEO of the Port of Grenaa. The Ports of Halland’s CEO, Carl-Henrik Hägg, added, “This collaboration enables us to offer our customers even more efficient and sustainable solutions by combining our resources and expertise. Together with the Port of Grenaa, we are creating new opportunities to optimize cargo flows, improve storage, and streamline the handling of complex projects.”

After the initial purchase of a 40% stake back in 2022, the company added 58.5%, becoming the biggest shareholder in the port cargo handling operator that takes care of around 4.0 million tonnes/year. Bulk Cargo – Port Szczecin offers 3.5 kilometres of quay wall in the Polish port spread across 11 berths, chiefly for handling dry bulk and break-bulk.

The container terminal operator from the Port of Klaipėda saw Realtime Business Solutions (RBS) migrating the terminal operating system (TOS) from TOPS Advance to TOPS Expert. The migration marked the last step of a project that took under eight months from the initial kick-off to the go-live stage. The transition itself was completed within four hours and without disruption to the daily activities of Klaipedos Smelte. “The new TOS version offers advanced capabilities for vessel operations, yard management, equipment control, and data analytics. Notably, it enhances automation and accelerates planning processes, enabling terminal planners to respond more effectively to dynamic situations while offering greater flexibility to customers such as MSC,” RBS said in a press brief. The tech company also underscored, “This migration does not mark the end of the process but rather the beginning of new opportunities and possibilities to integrate additional modules and features in the future. The latest version of TOPS Expert can seamlessly integrate with RBS’ new TOPX Intelligent Engine, which will further enhance the terminal’s efficiency in scheduling, dispatch, and execution.”

For the next four years, with two one-year prolongation options, the Yara Siilinjärvi plant will ship out its iron oxide output through the Port of Kokkola. In the past couple of years, Yara’s iron oxide traffic through the Finnish seaport amounted to 250-300 thousand tonnes per year, a volume that might very well double in the future. Plans speak of dispatching two train sets per day between Siilinjärvi and the port. “Iron oxide is a by-product […] generated when pyrite brought from the Pyhäsalmi mine is burned in sulfuric acid production. Iron oxide is mainly transported from the Port of Kokkola as a raw material for the steel industry. The circular economy, such as the utilization of side streams, is one of Yara’s strategic focus areas,” Yara Finland shared. Jyrki Furu, Logistics Manager for the Siilinjärvi plant, said, “We get really efficient supply chains by utilizing the railway network. For example, the wagon rotation time can be completed in a day, while in many other cases, wagon rotation time takes two days. The Iisalmi-Kokkola section is now completely electrified, which significantly reduces the carbon footprint of our products. The port operator Rauanheimo and Valtavirta in Siilinjärvi and VR Transpoint are also an integral part of this fine-tuned supply chain.”

Van Oord’s recently upgraded heavy lift installation vessel Svanen has put in place the first foundation, consisting of a monopile fitted with a transition piece, of ORLEN and Northland Power’s 1.2-gigawatt offshore wind energy (OWE) farm 23 km off Poland’s coast. The developers have contracted Van Oord for the transport and installation of 78 foundations, atop which 15-megawatt turbines will sit. To make the installation possible, Van Oord had to extend Svanen’s crane by 25 metres. According to the company, she is now one of the largest vessels of such type in the world. Baltic Power is expected to be completed in 2026. Svanen already took part in the set-up of OWE farms in the Baltic, including Kriegers Flak (605MW), Baltic 2 (288MW), Arkona (360MW), and Baltic Eagle (476MW).

Wallenius Wilhelmsen has won the procurement and, as of February 2026, will operate the Port of Gothenburg’s vehicle & ro-ro terminal for 12 years. The Norwegian-Swedish shipping line will also invest almost €6.0 million in modernising the terminal’s areas, buildings, and other infrastructure. The terminal in question offers two berthing places, 240 thousand square metres of space, is rail-connected, and features facilities for pre-delivery inspection. Apart from vehicles (including heavy-duty machinery for, among others, the mining industry) and ro-ro cargo units, the terminal also handles project cargo (such as wind turbine components, transformers, and house modules). The terminal in question has been since 2011 operated by Logent Ports and Terminals.

The onshore power supply (OPS) facility, delivered by PowerCon, has been commissioned in the Port of Kalundborg’s East Harbour. The station has enough capacity to provide electricity to three ships simultaneously. The Danish seaport said that up to 40% of vessels visiting it annually can connect to the new OPS facility, meaning that 28 ships can turn off their auxiliary engines when visiting Kalundborg. The seaport also underlined the role of the low electricity tax of 0.4 øre/kWh to incentivise shipping lines to draw power from the shore, a scheme that will run till 17 June 2027.

The Ystad-based company will take hold of the 5,900-deadweight (dwt) freighters ordered by BAAS Shipping in China. The first one, Baymar, was delivered on 26 October 2024, while the second vessel, Soundmar, in January of this year. The remaining four are scheduled for delivery within 2026. Each of the 1A Ice Class vessels, designed by the Dutch Groot Ship Design, has one 71-metre-long box-shaped cargo hold of 321 thousand cubic feet as well as a partial tween deck, which can also be used as bulkheads. AtoB@C Shipping underlined that the newbuildings will enable an almost 50% reduction in CO2 emissions vs the 5,000 dwt vessels currently in its fleet.

The Swedish shipping company kicked off a new container feeder loop in the first week of 2025, connecting the Baltic ports of Kokkola, Oulu, Tornio and Piteå with Antwerp and Rotterdam. The 860-TEU-capacity Peyton Lynn C serves this bi-weekly service.

The Gothenburg-based shipping line will incorporate their fellow professionals from Harwich, extending the company’s scope westwards as well as within the Baltic. “This acquisition will, among other things, result in a larger fleet and an expanded port network stretching from the Baltic countries to North West Europe,” commented Elvir Dzanic, CEO, WALLENIUS SOL. The Swedish company will see the addition of new offices in Estonia, Latvia, and the UK, as well as some 200 clients. In the Baltic, Mann Lines’ ro-ro Service 1 (operated with the use of the 2,850-lane-metre ML Freyja) connects the ports of Paldiski (Southern) and Turku with Bremerhaven, Cuxhaven, Rotterdam, and Harwich.

Dania Connect has launched new services, each with 80-TEU-capacity, that link the Port of Helsingborg with Jönköping and Älmhult on a weekly basis. Trains to Jönköping depart from the Swedish seaport on Mondays, Wednesdays, and Fridays; to Älmhult – on Thursdays (here, Dania Connect is working to secure additional volumes to kick off departures also on Tuesdays; the Port of Helsingborg shared that Eimskip and IKEA are among the Monday-through-Friday customers of the new shuttles). SHN Cargo (former CFL cargo Sweden) is responsible for rail traction.

The Polish Laude Smart Intermodal has set in motion the weekly container service that connects Zamość and Sosnowiec in Poland with the Dutch Oss. The company underlined in a press brief that Zamość functions as an import/export centre for trade with Ukraine, while Sosnowiec acts as a transhipment point for made-in-Germany metal sheets, bars and rods on their way to Belgium and the Netherlands and handles fertilisers coming in containers. Trains leave Zamość on Sundays and Sosnowiec on Tuesdays, arriving in Oss on Thursdays.

After a charter gig for Irish Ferries (as James Joyce between Dublin and Holyhead), the ferry has returned to the fleet of Tallink and is, as of 9 February 2025, sailing between Kapellskär and Paldiski. Before entering service, the ro-pax, offering room for 2,080 passengers and 2,000 lane metres for vehicles, underwent renewal and preparatory work at Turku Repair Yard in the Port of Naantali. Star will replace Regal Star and Sailor (the two will remain on standby).

The 1,436-TEU feeder Essence has started her service on the revamped Baltic Bridge Express (BBX) of the Japanese ONE. While the former instalment connected the ports of Rotterdam, Klaipėda, and Riga, the new version also includes calls to Kotka and Tallinn. In Klaipėda, Essence berths at Klaipėda Container Terminal, Riga – Baltic Container Terminal and Riga Universal Terminal, Kotka – Steveco, and in Tallinn at HHLA TK Estonia. In Rotterdam, the feeder visits Hutchison Ports’ ECT Euromax & ECT Delta, as well as Rotterdam World Gateway.

• Visy, with the help of partners from the recently acquired Autepra, installed optical character recognition (OCR) equipment, alongside the TopView system, on 14 ship-to-shore cranes at the Baltic Sea region’s largest container terminal. “The system goes beyond a traditional OCR solution, delivering a complete automation ecosystem with multiple applications that cover the entire load/ discharge process – from ship to terminal tractor and yard – while providing razor-sharp recognition accuracy for container IDs, ISO codes, and other attributes,” the company from the Finnish

Tampere highlighted in a press release. The deployment also features Visy’s newly developed Wharf App. This interface for crane operators includes a view of the ongoing operations (such as active work queues), a tool to browse and review ship’s current situation (containers on board, planned loads and discharges), loading instructions to the ship (both in text and audio), as well as a view on terminal tractors with containers approaching the crane (the system informs the driver whether the box can be transferred onto the ship or if something else needs to be loaded first). •

• Liquid Wind and Turun Seudun Energiantuotanto (TSE) have signed a memorandum of understanding as a step towards establishing a 100 thousand tonnes per year e-methanol production plant to be located in the former Neste harbour area. The facility – for which the final investment decision is expected in 2026, ahead of operations commencing in 2029 – will sit next to TSE’s Naantali 4 power plant, which will feed the e-fuel production with 160

thousand of biogenic CO2 and which will, in return, receive process and waste heat for district heating. “Locally, in the City of Naantali, we will focus on carbon capture and utilization and the reuse of CO2 and waste heat. Globally, we aim to support the transition by allowing our off-takers to shift from fossil fuels to low-carbon eFuel produced at this facility,” Claes Fredriksson, CEO and Founder of Liquid Wind, highlighted. •

• The German Baltic seaport has chosen Fintraffic’s POLO Port Activity app to expand the situational picture available to the port authority and to enhance various harbour operations through digitalisation. The open-ecosystem POLO Port Activity allows ports to use and develop the service according to their own needs with

the partners of their choice. Among others, POLO provides real-time arrival and departure times for ships, emission calculations, quay and resource planning, ship notifications for the EU area, invoicing functionality, tug and pilot requests, as well as requests for water and waste management. •

• VTT Technical Research Centre of Finland, the Port of Oulu, and 20 other parties, including tech companies and academia, will carry out a three-year €12.8 million project tasked with enhancing secure situational awareness in critical cyber-physical systems. “Unexpected events – such as accidents or physical and virtual attacks – can threaten the resilience of critical systems. These may result in blocked access to essential functions and resources, misuse of critical data, compromised physical safety, and lack of vital resources, which may cause fatalities, bankruptcies and even societal instability. Therefore, the project aims to develop secure situational awareness solutions, which are very important for critical logistics, mobility, energy, and security systems operating, e.g., in ports,” Juhani Latvakoski, Principal Scientist and Project Lead, VTT, explained. The project partners

added in a press brief, “The project focuses on developing a secure situational awareness concept that enhances trust and security by building autonomous resilience into the system. This contributes towards ensuring that the port can recover from incidents and lower the risks for various digital and physical attacks.” Soila Riutta, Development Manager at the Port of Oulu, further detailed, “We are developing a digital twin of the port area using various sensors, detectors, and radars. Additionally, innovative tracking and identification systems for port area traffic are of particular interest. New technologies provide opportunities, but a current challenge is that they primarily operate as separate applications. In this project, our goal is to create a comprehensive situational overview, particularly for managing safety and critical incidents.” •

• In a deal worth €1.4 million, the MT Group has contracted Nord Steel to design, manufacture, and deliver three advanced hydrogen tanks to the Port of Klaipėda. The contract includes a 40-bar buffer tank and two storage tanks capable of withstanding pressures of 550 and 1,000 bars. “We believe this project will not only act as a catalyst for the development of green hydrogen technologies in Lithuania but

will also make a significant contribution to the region’s sustainable energy breakthrough,” commented Mindaugas Zakaras, CEO of the MT Group. “We see the Klaipėda Port green hydrogen station project as an opportunity to set a benchmark for such facilities across the Baltic region. Our primary focus is ensuring the highest safety and quality standards,” added Remigijus Kurgonas, Nord Steel’s CEO. •

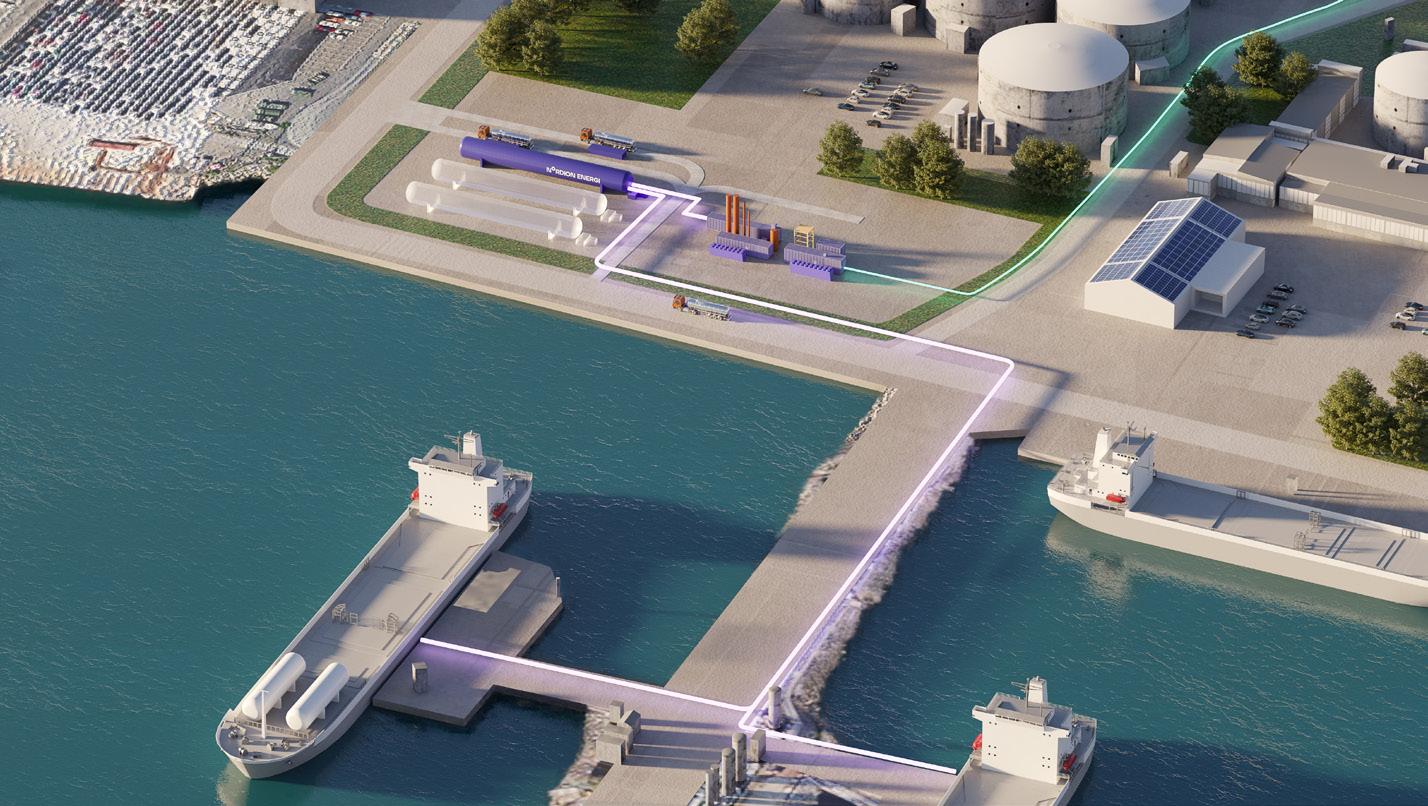

• The Swedish energy infrastructure company and the Finnish energy company are eyeing the set-up of a liquefaction terminal for bio liquefied natural gas (bioLNG) in the Port of Gothenburg. The facility of 250GWh of biogas liquefaction capacity will be directly connected to the West Swedish gas network. For clients outside the grid, liquefied biogas will be temporarily stored in a tank before onward delivery, either by truck or by pipeline, for direct ship bunkering. St1 has already reserved a portion of the capacity. The company also shared that it plans to sell 6.0TWh of biogas till 2030. “This is a great opportunity to reach

out with biogas to ships, road transport, and also industries that are not directly connected to the gas grid,” Carolina Wistén, Marketing Manager at Nordion Energi, commented. Matti Oksanen, Director of Gas Business at St1, added, “Biogas is an important part of our energy transition, and we are investing heavily in the expansion of both the production and distribution of liquid biogas. Collaborations with players such as Nordion Energi give us the opportunity to expand our production and sales of biogas, and are an important enabler for supplying, among other things, the transport sector with locally produced bioLNG.” •

• Together with Andion CH4 Renewables and Equitix New Generation Fund, Gotland Company will erect a biogas production plant near Eskilstuna, scheduled for commissioning in 2026. The bulk of the 5,400 tonnes/year output has been earmarked for Destination Gotland’s two gas-run ferries, which currently sail on a blend of liquefied natural gas (LNG) and its bio version. Gotland Company said that it already secured the feedstock supply so that biogas production could start in Q2 2026. Within a decade, replacing LNG with bioLNG will reduce the ferry line’s CO2 footprint by some 100 thousand tonnes. Eskilstuna Biogas is responsible for constructing the production plant. “We are pleased that we could take another step towards our goal of offering climate-neutral transport between Gotland and the Swedish mainland by 2045 at the latest. Today, access to fossil-free bunker is far too limited for the transition of both sea shipping and other transport modes. Through this business, we’re

contributing to an increased production of high-quality biogas, securing up to 10% of Gotland traffic’s demand,” Håkan Johansson, CEO, Gotland Company, said. Destination Gotland’s CEO, Marcus Risberg, added, “Bunker is the single biggest operational cost for our company, likewise stands as our largest impact on the environment, and we’re securing a considerable volume of high-quality biogas for a 10-year period. The business forms part of our preparatory work for those regulations that are entering into force, such as FuelEU Maritime.” Johansson also commented on the company’s work on hydrogen-powered vessels (a ferry and a high-speed catamaran), “When working on the next-generation ships, we see immense challenges with access to bunker. Our long-term goal is to run the traffic on hydrogen and other fossil-free bunkers, but the required volumes will only come in the distant future. That is why it’s important to invest in and secure the supply of other fossil-free fuels today.” •

• The Turkish Sanmar Shipyards will deliver the ASD electric 1,818kWh tug in H2 2025 for serving traffic in the Øresund Strait between Denmark and Sweden. The 356-gross tonnage, 25.4-metre-long vessel, of the ElectRA 2500-SX design by Robert Allan, will have a 70-tonne bollard pull. She will also feature two backup generators for extended endurance and firefighting operations. “In recent years, we have experienced an increasing demand for green towage services in Scandinavia, including the Øresund Strait. At the same time, we have committed to doing our part to significantly reduce CO2 emissions in the industry by 2030. Getting a new battery-powered tug solves both challenges as we can continue to provide reliable and safe services to our customers while reducing the carbon footprint,” Mathias Jonasson, Managing

Director Scandinavia, Svitzer, commented. Earlier, in mid-September 2024, Svitzer contracted the shipbuilders from the Turkish Uzmar to construct a 6.0-megawatt, dual-fuel (methanol) tug that will be, as of H2 next year, stationed at the Port of Gothenburg. The TRAnsverse tug design, this one also created together with naval architects from Robert Allan, will be 34.9-metre-long, deliver a bollard pull ahead of 85 tonnes as well as utilise steering and breaking forces rated at 150t and 200t, respectively, measured at 10 knots (the vessel’s max speed will be 14kn). The escort duty tug is expected to conduct over 90% of operations using its battery-electric powertrain, taking care of up to a quarter of Svitzer’s work in the Swedish seaport. The dualfuel methanol engines will serve as a backup and range extension. •

• The installation spans over 900 square metres across a vaulted roof and is expected to generate 181 thousand kWh/year. Should the Port of

Otterbäcken use all the energy produced by the new photovoltaic (PV) system, it would cover 40% of its yearly electricity needs. •

• The Swedish Environmental Protection Agency’s Climate Leap programme will support the French company with up to €11 million (SEK130m) for the development of a 10-megawatt electrolyser site in Vaggeryd in South-central Sweden. The first batch of renewable hydrogen is expected to be produced in 2027, with the capacity to deliver 4.4 tonnes/day. The output will supply refuelling stations currently under construction in the area. Besides the transportation sector, the hydrogen would also be supplied to industries for heating and production processes. “Green hydrogen is a key enabler in the transition, strengthening the competitiveness of the Swedish industry while increasing domestic energy security with locally produced energy,” said Sara Wihlborg, Country Manager Sweden at Lhyfe. She furthered, “Additionally, the waste heat generated during the production process

will be utilized in the existing district heating network in Vaggeryd. Lhyfe already delivers green hydrogen to industrial customers in Sweden, and with the two facilities now granted Climate Leap support [also 10MW in Trelleborg], Lhyfe ensures a robust and competitive supply solution for green hydrogen for our customers in Sweden moving forward.” The support – which will fund the development & design phases, equipment procurement, and construction work – represents approximately 35% of the total estimated investment cost for the project. Implementing the project is subject to the granting of foreign investment authorisation, operational, environmental & building permits, and a financial investment decision. Lhyfe has already installed four hydrogen production facilities (in France and Germany) and has a project pipeline totalling some 10GW across 12 countries in Europe. •

• The Finnish Outokumpu will invest around €40 million in a plant for producing biocarbon, some 15 thousand tonnes per year, in the Mukran Port. The factory, slated for commissioning in H1 2026, will use secondary wood raw materials as feedstock. The end product, a fine granulate that looks like black sand, will be shipped to the Port of Tornio for further processing into biocoke pellets (with the pelletising plant ready in mid-2025). These, in turn, will be used by Outokumpu to replace coal and other fossil energy sources in various stages of stainless steel production (with biocoke specifically used as a reductant in ferrochrome smelting). The waste heat generated by the Mukran plant will be fed into the district heating network on the island of Rügen. The Finnish company says that approximately 50% of its direct emissions could be reduced by replacing fossil coke with biocoke. “Outokumpu’s decision in favour of Mukran is the result of an intensive process. It shows how attractive our port is for companies that rely on multimodal transport chains. The planned delivery of raw materials by rail and shipment of the end product by ship will strengthen the site’s logistics diversity. With Outokumpu, we are not only gaining a world-leading company in its sector but also increasing the attractiveness for other potential industrial

customers and supporting the transformation of the location with regard to new energy sources,” highlighted Fridjof Ostenberg, back then Mukran Port’s Interim Managing Director. Outokumpu’s Chief Technology Officer, Stefan Erdmann, also shared, "We are proud that our stainless steel has the lowest carbon footprint in the industry [1.52kg CO2e per kg of stainless steel in 2023], and we are progressing steadily towards our target to reduce our emission intensity across our direct, indirect and supply chain emissions by 42% by 2030 from a 2016 base year. Currently, biocoke represents the best available technology to decrease our direct emissions, and we are also investigating other innovations as well as the use of carbon capture technology to achieve further reductions.” To this, Timo Huhtala, General Manager at Outokumpu EvoCarbon, added, “Biomass-based raw materials offer exciting possibilities for Outokumpu to cut direct emissions. I am proud of our team’s innovative thinking in developing an industrial concept that ensures technical readiness and financial viability for the new investment, driving progress in the green transition today. We want to take an active role in developing the biocoke market, which will give us scale-up and new business opportunities also going forward.” •

• The City of Pori, the Port of Pori, and Tahkoluoto Offshore have signed a memorandum of understanding aimed at developing the Pori Offshore Wind Hub. The collaboration will define the role of the Hub as the primary logistics and pre-installation base for the Tahkoluoto Offshore Wind Farm Extension project. The 42-megawatt Tahkoluoto, the world’s first offshore wind energy farm erected in freezing waters and operational since 2017, will see the addition of 40 turbines of 15-20MW capacity in 2027-29.

To that end, the memorandum provides a two-year time frame for implementing the necessary infrastructural investments in the port area. “This agreement emphasizes joint development: we are sharing knowledge to support the planning and implementation of both port infrastructure and logistics. Resource optimization is also key – our collaboration ensures that all necessary resources and functions required for the project are available,” said Lauri Kilkku, Executive Director of the City of Pori. •

• The Land and Environmental Court in Umeå has given its green light for the development of the e-methanol production facility that will be connected to the Dåvaverket cogeneration plant of Umeå Energi. The site, expected to be up & running in 2027, will be able to capture 230 thousand tonnes of carbon dioxide per year, using it to produce up to 130 thousand tonnes of e-fuel. “The received permit marks a significant milestone in our journey and ambition to reduce dependency on fossil fuels in the hard-to-abate sectors such as shipping and aviation. This project exemplifies our dedication to pioneering innovative technologies for eFuel production, which are crucial in shaping a greener future,” Claes Fredriksson, Liquid Wind’s CEO and Founder, commented. •

Transport agencies of Denmark, Finland, Norway, and Sweden have signed a memorandum of understanding to work towards securing the resilience of the transport system that binds the Nordic region together. “Nordic cooperation in transport preparedness is improving the readiness for major accidents, natural disasters, and other social crises. At the same time, the countries are expanding their cooperation to deal with exceptional situations, the seriousness of which exceeds that of normal peacetime situations,” the parties said in a press brief. Jarkko Saarimäki, Director-General of the Finnish Transport and Communications Agency Traficom, added, “The importance of preparedness and security is particularly

relevant in the world we are currently living in. Our job is to ensure that the transport system works under all conditions. Infrastructure must be crisis-resilient, and transport services must be accessible to people. All this serves both civilian and military needs.” Traficom’s Preparedness Manager, Hannu Hakkarainen, also underlined, “The Nordic countries share common threats, risks and vulnerabilities that affect transport preparedness planning. We have one common and sustainable transport system, which we are constantly developing through cross-border cooperation.” The new partnership follows the previous one struck between Finland and Sweden. The parties expressed their openness to welcome Iceland to the pact as well.

During the 14-January-2025 Summit of Baltic Sea Allies, the North Atlantic Treaty Organization (NATO) initiated the activity in question to deter any future attempts by a state or non-state actor to damage critical undersea infrastructure in the Baltic Sea region. “The multi-domain activity, which will continue for an undisclosed amount of time, is in response to damage to undersea cables connecting Estonia and Finland on Dec. 25 [2024],” NATO said in a press brief. Baltic Sentry will involve a range of assets, including frigates, maritime patrol aircraft, and new technologies (such as a fleet of naval drones), as well as integrating national surveillance assets – all to improve the ability to protect critical undersea infrastructure and respond if required. NATO will also work within the Critical Undersea Infrastructure Network, which includes industry, to explore further ways to protect infrastructure and improve the resilience of underwater assets. Following the quoted incident, Finland seized the oil tanker Eagle S on suspicion of sabotage of electrical and data cables at the bottom of the Gulf of Finland. NATO has also launched a probe into the so-called shadow fleet that carries Russian oil from the country’s Baltic seaports. According to an investigation carried out by the Swedish branch of Yle, the Finnish broadcasting company, half of all oil tankers from Russia lack Western insurance (having instead a Russian one or lacking

insurance altogether), are old, some are in such a poor condition that they’re blacklisted, and only 10 out of 68 had ice class. Mark Rutte, NATO’s Secretary General, commented, “Ship captains must understand that potential threats to our infrastructure will have consequences, including possible boarding, impounding, and arrest.” Swedish authorities detained another ship suspected of damaging a data transmission cable on 26 January 2025 (the cable belongs to the Latvian LVRTC and connects Latvia and Sweden). The possible act of sabotage took place in Swedish waters (near Gotland) at a depth of around 50 metres. The Bulgarian “shipowner” denies any purposeful wrongdoing, instead blaming bad weather conditions that might have caused the vessel’s anchor to drop (the Swedish Expressen published a photo showing that the “anchor” is indeed missing one of its “flukes”). According to an investigation by another Swedish media outlet, Kinamedia , the detained Vezhen is in fact a Chinese asset (owned by Hai Kuo Shipping 2015B, in turn belonging to the state-owned ICBC Leasing tied with the Industrial and Commercial Bank of China). Kinamedia also brought up a report by Newsweek that China’s patent office received an application for a device that looks like a ship anchor but is in reality an underwater cutter. In November 2024, the Chinese Yi Peng 3 cut two communication cables in the Baltic.

To achieve net-zero greenhouse gas (GHG) emissions from international shipping by 2050, the International Chamber of Shipping (ICS) has joined 47 governments in a joint submission to the final round of negotiations at the International Maritime Organization (IMO) to adopt a GHG emission pricing mechanism. “The key purpose of this mandatory GHG charge will be to reduce the cost gap between zero/near-zero GHG emission (ZNZ) fuels (such as green methanol, ammonia and hydrogen) and conventional marine fuels, to incentivise the accelerated uptake of green energy sources. Revenue generated will be used to reward the production and uptake of ZNZ fuels whilst also providing billions of US dollars annually to support the maritime GHG reduction efforts of developing countries,” ICS said in a press release. The Chamber’s Secretary General, Guy Platten, furthered, “The industry fully supports the adoption by IMO of a GHG pricing mechanism for global application to shipping. The joint text put forward by this broad coalition is a pragmatic

solution and the most effective way to incentivise a rapid energy transition in shipping to achieve the agreed IMO goal of net-zero emissions by or close to 2050. We are very pleased that such a large and diverse group of nations now firmly supports a common approach to maritime carbon charging. This proposed joint text has been hard-fought and is broadly based on ideas which ICS has been advocating for the past 10 years. While a large number of governments now support a universal flat rate GHG contribution by ships – or something similar – a minority of governments continue to have concerns. Working in co-operation with all IMO Member States, we will do our best to allay such concerns during the final stages of these critical negotiations about the regulatory text.” The proposal will be considered by a critical IMO meeting in midFebruary 2025. If IMO approves the MARPOL amendments in April 2025, they should enter force globally in early 2027, with the collection of annual GHG contributions from ships beginning in 2028.

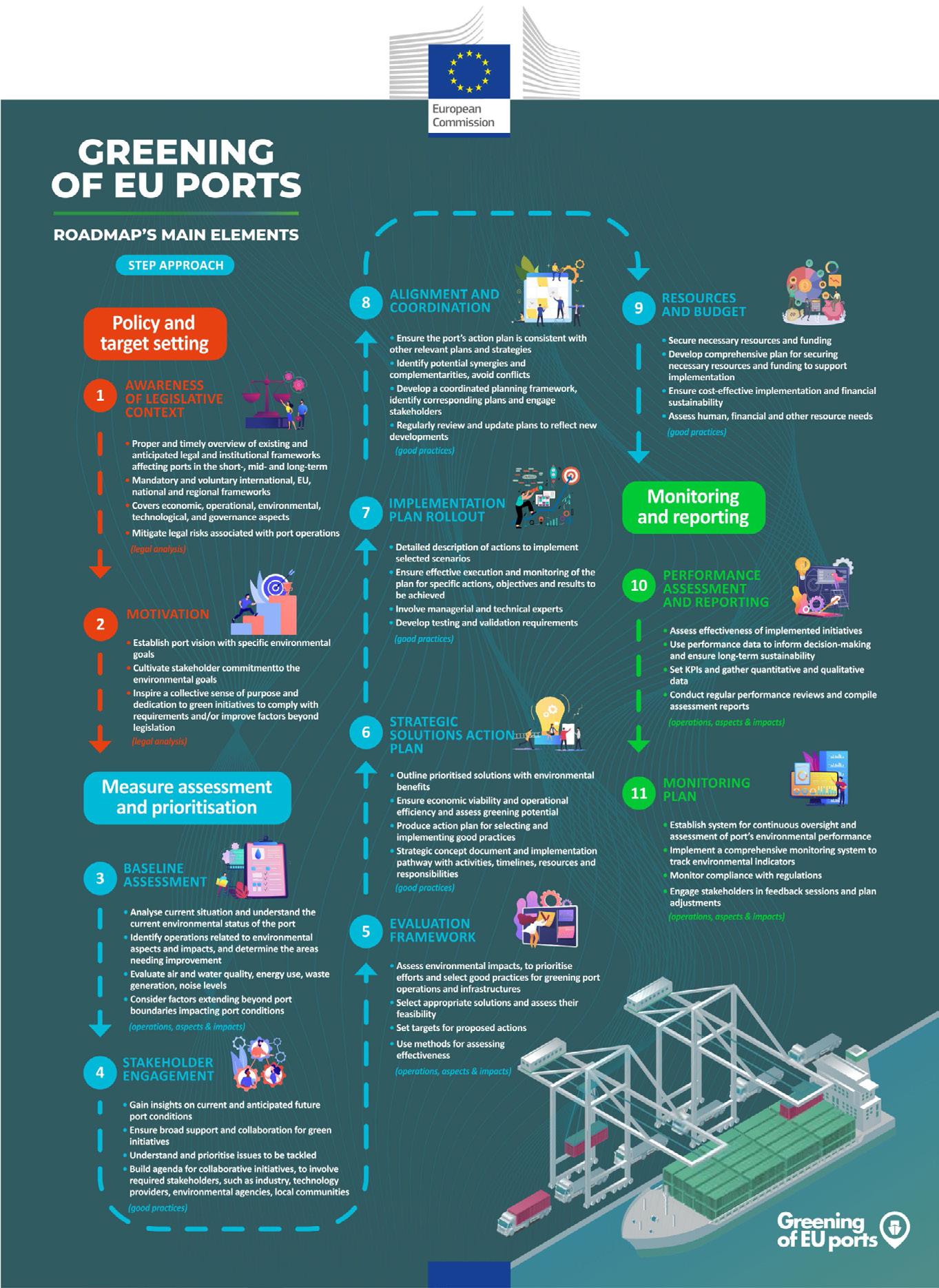

Source: European Commission

by Petar Modev, Head of Ship Inspection, The UK P&I Club

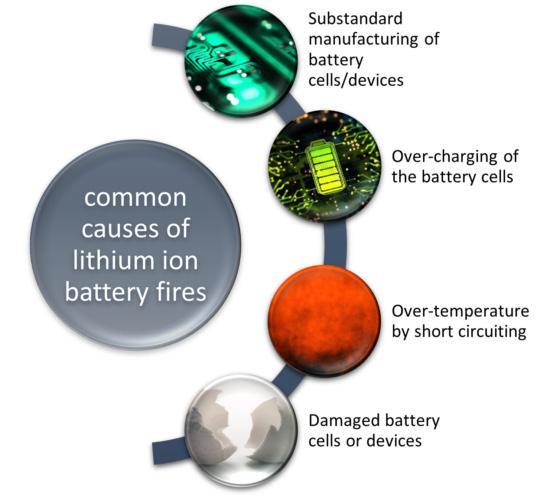

The environment in which seafarers operate has always been fraught with risk, but for the modern crew member, they are now having to contend with an increasingly more complex operational environment. The continued integration of more sophisticated systems on board, the pressures to adhere to strict regulatory provisions to reduce carbon emissions, not to mention the very real threat of physical attack stemming from macro-geopolitical issues, all combine to create an increasingly more complex operational landscape. However, as a result of the energy transition, there are also emerging risks from new cargoes, particularly the health and safety implications of the rising carriage of electric vehicles (EV) on ships.

The EV and hybrid automotive market is developing at an exponential rate, with current projections suggesting that it is set to grow by nearly 10% each year, accounting for over 17 million vehicles in 2028. Although these are encouraging signals in the development of sustainable transportation, the implications for supply chain participants, especially carriers, are significant. This particularly relates to the inherent fire risks posed by lithiumion (li-ion) batteries within EVs.

The defining characteristic that makes li-ion fires such a significant risk is the creation of an extremely hot thermal runaway; this is a primary risk where the battery’s internal temperature rapidly increases, leading to a fire or explosion. Physical damage, manufacturing defects, or exposure to

extreme temperatures can trigger this. Even worse, a li-ion battery fire will sustain itself, meaning that rather than lasting minutes or hours, a fire can continue for days. As a result, early identification of such incidents is vital, which means that vessels need systems that use intuitive technologies to identify the fire quickly, as well as suppression systems with additional foam and CO2 capabilities to control the outbreaks.

Several regulatory instruments are being discussed at the International Maritime Organization (IMO) level. In March 2024, the IMO’s Sub-Committee on Ship Systems and Equipment considered specific proposals related to container ship fires and discussed detailed evaluations of the adequacy

of fire protection detection and extinction arrangements with regard to vehicle carriers.

However, due to the pace of the green automotive market’s growth, proactive stakeholders across the shipping industry have recognised that they can’t afford to wait until international regulation catches up. This has led to the launch of collaborative initiatives across shipping, such as the CARGOSAFE study by the Danish Institute of Fire and Security Technology to identify cost-effective risk control options for cargo fires, as well as the kick-off of the Cargo Fire & Loss Innovation Initiative by Lloyd’s Register’s Safetytech Accelerator.

Although these collaborative efforts establish a blueprint for further partnerships, it is not the role of the maritime industry alone to manage this risk.

This is a complex, interconnected issue that requires the collaboration of multiple stakeholders throughout the supply chain.

To address the risk implications of li-ion batteries on board, the Vehicle Carrier Safety Forum has recently published its first good practices guidelines regarding the Common guidance on the loading and presentation of vehicles. Based on shared practices and supported by the International Group of P&I Clubs, the International Chamber of Shipping, and TT Club, this guidance advises vessel operators and supply chain partners on the safety aspects of booking, planning, and presenting electric and largebattery hybrid vehicles at port terminals, as well as loading, stowage and monitoring vessels during a voyage, with a specific focus on car carriers, ro-ro vessels and ferries.

As one of the world’s leading providers of P&I insurance for the maritime sector, The UK P&I Club is actively supporting its Members as they navigate new and emerging risks. Equipping vessel operators and crew with suitable guidance to better understand the challenges they face is part of building the foundation for change. As a result, The UK P&I Club has developed, in collaboration with TT Club and BrookesBell, material such as our white paper on the Continuous Threat of Transporting Li-ion Batteries.

In order to ensure that our service offering continues to align with the modern challenges our Members face, we recently launched the new Safety & Risk Management division, which re-positions our in-house loss prevention capability in order to encourage Members to deepen their

understanding of the evolving risk environment in which they operate and adopt tighter monitoring and reporting of safety performance.

Our Safety & Risk Management team is helping Members to mitigate the risk of li-ion fires on board. One of our priority focuses is to promote the value of advanced and effective crew training. This is an essential tool for building crews’ confidence and effectiveness in managing this growing and opaque challenge. For example, in June 2024, The UK P&I Club – in association with React and Simwave – conducted the Modern Fire Risk training workshop. Delivered at Simwave’s Maritime Training Centre of Excellence in Rotterdam, the programme combined classroom and simulation-based learning for superintendents, HSEQ professionals, and technical managers in shipping companies that operate car carriers or container ships. Although physical training is the gold standard, leveraging advanced technologies, such as simulations and online training platforms, can act as a valuable tool for providing the most effective scenario-based training packages.

Unfortunately, despite the documented risk that li-ion batteries pose to the safety of crews, reports have suggested that onboard vessel fire safety standards are in decline. A recent study from the Paris

Memorandum of Understanding on Port State Control – which was further corroborated by RightShip – revealed a 14% noncompliance rate for basic fire safety standards aboard inspected ships, with at least 30% of issues identified relating to a basic lack of implementation of the International Safety Management Code. When considered within the context of the enhanced threat of li-ion fires, this lack of preparedness to effectively manage the outbreak of fires on a ship is troubling, to say the least.

Rising EV volumes are reshaping the risk profile of how we manage hazardous cargoes, and this is only going to increase as the market continues to grow. However, if the industry is to ensure it’s well-positioned to manage this risk, attitudes and approaches to preparing against such events must also evolve. From a safety and risk management perspective, P&I clubs play an important role in working with carriers and the wider supply chain partners to understand and manage these risks. Although this issue is complex and multifaceted, the development and implementation of strengthened and standardised training will make a marked difference in giving crew members a greater level of competence in managing the immediate risk that the presence of li-ion batteries pose on board vessels that either carry EVs, make use of powerful battery packs themselves, or both.

The UK P&I Club is one of the oldest such organisations in the world and one of the world’s leading mutual insurers of third-party liabilities for ocean-going merchant ships. The Club insures over 250 million tonnes of owned and chartered ships from 50 countries against potential claims for damage or compensation. Visit ukpandi.com to learn more.

by Ewa Kochańska

The European Commission’s Greening of European Sea Ports report addresses the environmental, logistical, and administrative challenges faced by ports across Europe. The study places particular emphasis on supporting smaller ports to improve their ecological footprint and thus progress towards long-term environmental sustainability for the maritime sector as a whole. By analysing real-world examples of successful green initiatives, the study provides practical guidance for implementing sustainable practices. It also highlights the importance of tailored strategies that consider the unique conditions and operational limitations of each port, ensuring more effective and adaptable solutions.

Large ports worldwide certainly enjoy considerably greater financial resources and risk-resilience compared to their smaller counterparts, which, along with better-established organisational structures, enables them to invest in more cutting-edge solutions and research & development projects. Their access to highly skilled professionals, considerable stakeholder influence, and ability to form strategic alliances position them as leaders in advancing sustainability initiatives. In contrast, smaller ports often struggle with constrained budgets and a resulting cautious approach to risk, favouring instead proven, low-risk environmental solutions, which are usually less effective. Also, a lack of in-house expertise can make identifying and adopting sustainable practices challenging, necessitating costly external support and training.

Additionally, smaller ports often require assistance in securing funding and leveraging technical resources, as they may underutilise financial aid and have minimal involvement in research programmes. Collaborations with larger ports and industry partners can help bridge these gaps, allowing for knowledge sharing, creating alliances, and strengthening the ability to implement green initiatives effectively.

It is undeniable that ports are pivotal to achieving the EU’s climate objectives, as they are central hubs for global trade and transport. The block’s 2019 European Green Deal addresses this issue by aiming to achieve climate neutrality by the mid-century, with interim goals such as a 55% reduction in greenhouse gas emissions by 2030.

To support the Green Deal, the EU also came out with the Fit for 55 package, which targets key polluting sectors, including maritime. Specific regulations within this framework promote alternative fuel uptake, energy efficiency, and emission reduction in shipping. For example, the FuelEU Maritime and the Alternative Fuels Infrastructure Regulations incentivise sustainable practices, including the adoption of green energy technologies and zero-emission solutions.

However, the report also notes that the complexity of the EU environmental laws requires special attention to the legality of operations to ensure compliance and effective implementation. That is why legal advisors will play an increasingly critical role in helping port authorities through the regulatory maze, enabling them to align with sustainability targets.

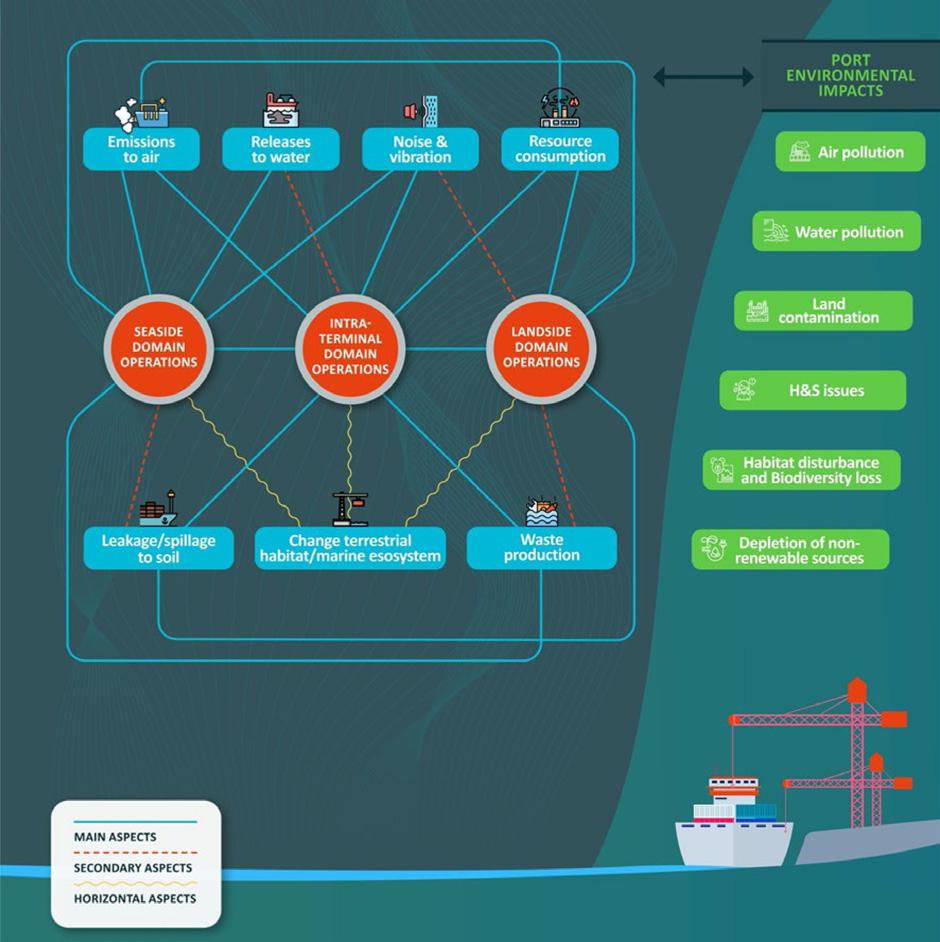

Port operations encompass a wide range of activities, both on the water- and the landside, which have significant environmental implications. These include vessel handling, cargo and passenger services, and developing and maintaining port infrastructure. The current ecological situation and subsequent governmental directives have additionally expanded the role of ports with activities like renewable energy generation and logistics innovation. These operations are influenced by factors such as terminal scale, the types of cargo processed, and the availability of transport infrastructure connecting ports to hinterlands, which are related to geographical location, size, and traffic patterns. The environmental effects of these operations can, in turn, be classified into direct impacts, such as air emissions from bunkering, and indirect ones, like soil leakage and water pollution.

The report underscores four factors that affect the ability of the port to adopt environmentally sustainable measures: cargo and passenger handling capacities, financial capacity and administrative & management scale, geographical location, and multiplicity of activity.

Cargo and passenger handling capabilities are critical indicators, as the type and volume of traffic processed, including diverse freight and transit patterns, define the port’s operational demands and potential environmental impacts.

The financial and administrative scale involves evaluating the port authority’s decision-making framework, organisational structure, workforce expertise, and training programmes; investment capabilities in infrastructure modernisation, technological advancements, and sustainability projects are also vital. The management model adds another layer of complexity to how ports balance environmental goals with operational efficiency and governance structures.

Geographic positioning significantly affects a port’s market reach and ability to integrate into transport networks; proximity to land and water routes enables efficient intermodal transport, reducing delays and improving logistics efficiency. Ports situated near industrial zones or with access to renewable energy resources can amplify their role in fostering economic and sustainable development through resource optimisation, energy production, and manufacturing synergies.

The multiplicity of activities can also be leveraged in ports to enhance operational and environmental performance. By ensuring seamless logistics, ports minimise downtime and handle diverse cargo types more efficiently. The integration of renewable energy infrastructure, such as wind and solar facilities, alongside industrial activities within or near the port reinforces their capacity for sustainable growth while promoting energy transition and environmental responsibility.

Analysing these factors provides actionable insights into how each port can address sustainability challenges, at the same time adapting to the dynamic maritime and logistics landscape. Strategic considerations, like land utilisation, throughput capabilities, and stakeholder collaboration determine a port’s ability to implement green initiatives effectively. These assessments guide investment priorities and foster partnerships with stakeholders, including shipping lines, investors, and policymakers, to strengthen the port’s competitive edge and environmental resilience.

Identifying and sharing best practices globally enhances the maritime sector’s transition towards sustainability. The results of case studies analysed for the Greening of European Sea Ports report allowed for the development of a taxonomy of best green practices, which can serve as a valuable resource in enabling the successful adoption of sustainable practices across ports of varying sizes and capacities.

However, best practices can be adopted as long as their transferability (i.e., ability to modify initiatives developed in larger, well-resourced ports to smaller ones) potential is first carefully examined. Key aspects of transferability include addressing the complexity and scale of green initiatives, which may require simplified implementation strategies, custom-made formulas, and capacity-building efforts for smaller seaports to align with their resources and capabilities.

Technology transfer is another significant component, emphasising the need to adapt environmentally friendly technologies to suit the operational and technical frameworks of smaller harbours. Ensuring compatibility and relevance of these technologies enhances their applicability and success in less complex settings.

Capacity-building programmes further support the transferability process

by equipping personnel with the knowledge and skills necessary to implement and sustain green practices effectively. These efforts can involve training, knowledge-sharing collaborations, and partnerships with industry experts to bridge the expertise gap that smaller ports often face.

Finally, financial resources are fundamental to enabling ports to adopt and maintain sustainable practices, and for smaller organisations, financial constraints can present insurmountable roadblocks. Addressing these challenges involves exploring diverse funding options, such as government grants, green bonds, public-private partnerships, and technical assistance programmes.

Assessing these components of transferability ensures that smaller ports can effectively incorporate green initiatives, considering the challenges they face due to limited resources, capacities, and lower risk-resilience. Drawing lessons from the experiences of larger entities allows fellow professionals managing smaller seaports to navigate challenges more effectively and focus on practical, actionable strategies. This holistic approach facilitates the equal distribution of sustainable practices across the port sector, promoting environmental responsibility on a broader scale.

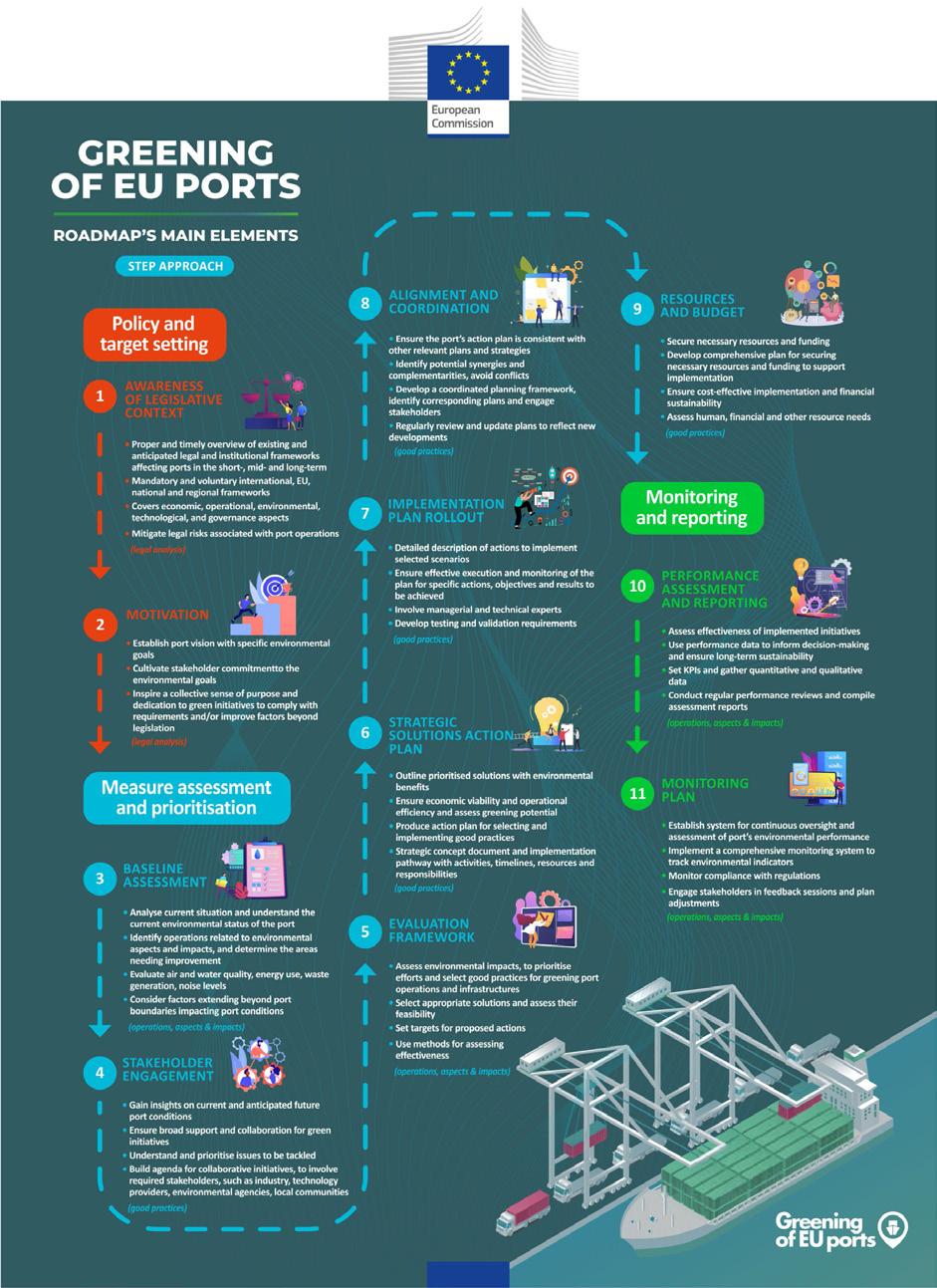

the green brick road

The roadmap put forward by the report is a strategic guide designed to help ports adopt eco-friendly practices, ensuring their operations remain sustainable while meeting regulations and supporting broader environmental goals. The roadmap’s main areas of intervention include policy and target setting, measure assessment and prioritisation, and monitoring and reporting.

Policy and target setting for ports involve two key steps: understanding the legislative context and fostering motivation among stakeholders. Compliance with legal frameworks, including EU directives, national laws, and local regulations, is essential for ensuring adherence to existing rules and preparing for future ones. Ports must analyse relevant legislation, sometimes with legal experts, to mitigate risks. The complexity of regulatory compliance is exemplified in dredging projects, where ports must assess environmental impacts, secure permits, and manage waste disposal according to legal requirements; addressing legal considerations early is crucial to the success of sustainability-focused initiatives.

Motivating stakeholders is equally important in making green steps, requiring a clear vision, defined goals, and active engagement. Communicating the

benefits of sustainable practices through preliminary assessments and structured discussions helps align stakeholders, from employees to regulatory bodies. Engagement strategies range from formal committees for large projects to informal meetings for smaller ones. For instance, in a solar panel installation, assessing energy use, setting reduction targets, and maintaining stakeholder involvement through updates and feedback ensure commitment and long-term success.