Welcome to the latest issue of Industrial Process News, where we delve into the innovations and trends shaping the future of industrial safety, efficiency, sustainability, and more.

As the pharmaceutical industry navigates an increasingly complex regulatory landscape, ensuring the compliance of purified water production on-site has become paramount. On page 5, we explore the next-generation Ionpro system from Veolia Water Technologies, a comprehensive and innovative solution tailored to address the different requirements of compendial water compliance.

Gina

Burton Editor gina@industrialprocessnews.co.uk

In this issue, we spotlight CHEMUK Expo, that recorded a 17% increase in visitors for the 2024 edition. The expo was described by Ian Stone, CHEMUK show founder as ‘electric’ with ‘so much volume and energy in the hall from its biggest concentrated audience ever!’ Page 19.

We’re pleased to spotlight Recontainers Ltd as one of our Top Exhibitors at CHEMUK 2024. Making its debut, this Lancashire-based company specialises in buying, selling, and reconditioning hazardous and non-hazardous chemical containers. Located in the Chemical Supply Chain Show Zone, Recontainers Ltd drew interest from sectors like logistics, transportation, packaging, and storage.

This article explores their expertise in offering reconditioned Intermediate Bulk Containers (IBCs) in various specifications, including UN-certified and non-UN-certified options, along with their IBC reconditioning wash and return service, highlighting their commitment to sustainability and efficiency. Page 21.

Other topics covered: Cleaning & Hygiene, Warehouse & Logistics, Print & Packaging, Industrial Process Technologies, Test, Measurement & Monitoring, Electrical & Electronics, Health & Safety, Manufacturing & Machining, Pumps & Valves.

Don’t forget to send us your latest Industrial news and updates and email us at: info@industrialprocessnews.co.uk

specialises in the buying, selling and cleaning of empty hazardous and non-hazardous chemical conditions

Publication Management

Fallon Waldron, Publication Manager

T 0121 550 2086

fallonwaldron@industrialprocessnews.co.uk

Production

Robert Sharp, Production Manager production@businessandindustrytoday.co.uk

Accounts

Paul Whitaker, Accounts Manager T 0121 824 4742 accounts@businessandindustrytoday.co.uk

Editorial

Gina Burton, Editor gina@industrialprocessnews.co.uk

As the public service sector heads towards a busy summer season, Kärcher UK, the leading provider of cleaning solutions, is thrilled to unveil an extraordinary offer designed to provide industry professionals with the means to level up their cleaning services.

From now all the way through to the end of August, customers of Kärcher Professional can take full advantage of the Summer Holiday Shutdown and receive a free vacuum, choosing between a 7/1 or a T 11/1 Classic when they buy or hire an item from the qualifying machines list such as the Puzzi 10/2 Adv, NT 30/1 and BVL 5/1 bp.

The offer was created by Kärcher with the knowledge that the summer holidays is an ideal time for those in the education sector to conduct a meticulous deep clean of their sites. The summer break also provides ample time to review cleaning suppliers and invest in the latest technology and machines, in order to maintain high quality standards of cleaning and care throughout the new academic year.

Conducting a deep clean in educational institutions during the summer holidays is vital for ensuring a healthy and conducive learning environment. With schools and universities typically empty during this period, it provides an ideal opportunity to thoroughly clean and disinfect

all areas without disrupting daily activities. This deep clean helps to remove accumulated dust gathered over time, the build-up of allergens, and germs that regular cleaning might miss, reducing the risk of illnesses spreading among students and staff when the new term begins.

This preparation time offers the ideal opportunity to invest in new cleaning machines. This is crucial for maintaining high standards of hygiene and efficiency in various environments. Modern cleaning equipment is designed with advanced technologies that significantly enhance cleaning effectiveness, reduce labour costs, and minimise environmental impact.

Alongside investing in innovative cleaning

products, Kärcher creates bespoke offers tailored to specific sectors. Offering the best and most suitable equipment for their customers, Kärcher UK is supporting public services in the education sector with a new summer holiday deep clean offer. This initiative provides new equipment for deep cleaning, helping to maintain high-quality standards and efficiency.

James Gordon, Marketing Director at Kärcher Professional UK, expressed his enthusiasm for this new promotion, “We are excited to announce the new Summer Holiday Deep Clean Public Services campaign, offering our customers exceptional value with a free vacuum when they buy or hire from our qualifying machines list. Keeping cleaning machinery updated ensures the best cleaning results and maintains impeccable hygiene standards, especially in the education sector. At Kärcher, we are committed to supporting our customers with innovative solutions that enhance their cleaning processes and help them achieve superior results.”

Don’t miss out on this limited-time opportunity to elevate your cleaning experience. Visit here to learn more about this offer and how you can claim your free vacuum cleaner after the purchase of a qualifying machine: www.kaercher.com/uk/professional/summerholidays-deep-clean.html

The next-generation Ionpro system is a compact and portable solution that ensures the production of high-purity, bacteria-free water that meets the stringent standards set forth by pharmacopoeias worldwide. By providing a streamlined and efficient approach to purified water generation, Ionpro empowers pharmaceutical companies to navigate the intricate landscape of regulatory compliance needed to provide safe and effective medicines while optimising their operational processes.

As the pharmaceutical industry navigates an increasingly complex regulatory landscape, ensuring the compliance of purified water production on-site, has become paramount. Stringent standards set forth by pharmacopoeias worldwide demand unwavering adherence to purity and quality benchmarks, presenting significant challenges for small-scale production facilities, laboratories engaged in scale-up processes, and research and development institutes. These challenges stem from their limited space, resources and fluctuating water demands.

Implementing and maintaining compendial water systems that meet regulatory requirements can be resource-intensive and costly, particularly for facilities with limited budgets and personnel. One of the main hurdles is ensuring consistent water quality and microbial control, which can be difficult due to stagnant water, frequent startstop cycles, and the complexities of designing and maintaining efficient piping and distribution systems within space constraints.

Additionally, validating and monitoring these systems to comply with evolving regulations can strain resources. Training and retaining personnel with the necessary expertise to operate & maintain compendial water systems is another challenge, especially in smaller organisations with high staff

turnover. Addressing these challenges requires careful planning, efficient water purification strategies tailored to specific needs, and effective resource allocation to ensure regulatory compliance & meet production demands.

The next-generation Ionpro™ solution Recognising these critical needs, Veolia Water Technologies has developed the next-generation Ionpro™ system, a comprehensive and innovative solution tailored to address the different requirements of compendial water compliance. Thanks to its new design, Ionpro offers enhanced management and control of consumption during production while retaining its compact and portable appearance.

n Ionpro is prefabricated and housed in a single cabinet. This compact system combines four technologies such as a softener, carbon filter, reverse osmosis (RO) technology and a pharmaceutically certified electrodeionisation module (EDI). Thanks to its plug-and-play

design, it can be connected directly to the main tap water supply on site, to produce highpurity, bacteria-free water.

n Ionpro is flexible due to its different models allowing the production of between 570 and 1,000 l/h of high-purity water but also due to its eight options allowing, for example, the addition of a carbon dioxide (CO2) membrane deaerator.

n Ionpro features enhanced control with the addition of an emergency stop button, a new RO40 controller and a 7” HMI screen compatible with Veolia's Hubgrade digital solution. These new features have been developed to ensure better management of water consumption and enable the system’s energy consumption to be anticipated and controlled.

Hubgrade digital services meeting customer challenges in the water industry

Hubgrade is a digital solution combined with Veolia’s human expertise that ensures compliance, operational excellence and sustainability of the water treatment process in a convenient, secure and resilient way. The three innovative services of this data management solution:

n Evaluate and continuously follow the quality of the service and communicate with transparency.

n Measure and improve performance and guarantee a quality level of service.

n Accompany clients in their progress plans and remotely advise in the piloting of their facilities.

One product for several applications. Ionpro produces pure water that meets pharmacopoeia standards, making it suitable for other pharmaceutical applications such as laboratory use, for example. This level of purity is also of interest to other markets such as cosmetics or, more widely, the microelectronics industries.

www.veoliawatertechnologies.co.uk

Hörmann UK has announced the launch of its new Roller Shutter TD door, an entry level door which has been designed and developed specifically for use in agricultural, light industrial and commercial properties such as shop fronts.

Manufactured from robust galvanised steel, the TD roller shutter is available with either a solid or perforated profile. Tested and certified to BS EN 13241, the roller shutter is supplied with ‘pull out’ protection as standard and conforms to wind class 3 making it suitable for both external and internal installation.

The roller door is particularly suited for installation in space limited areas & can be fitted either in front, behind or within the building opening. It has been designed and developed to be quick and easy to install, together with providing simple operation. Space saving 60mm side guides can be either welded to the building or mounted using pre-prepared fixing points, whilst the tubular drive is operated via a press and hold operation which can be either surface or flush mounted. In the event of a power failure, the shutter door can simply be opened or close with a sunblind pole from the barrel side

When fitted the door has a standard safety catch which prevents uncontrolled unwinding of the curtain and security is assured by inbuilt features which make it difficult to pull the curtain out of the side guides.

The TD roller shutter can be supplied to a maximum width and height of 4,000mm.

For more information on Hörmann sectional garage doors visit Rolling Shutters & Rolling Grilles | Hörmann (www.hormann.co.uk)

For the logistics sector, driver fatigue is a serious concern, leading to slower reaction times and increased risk of accidents.

Laws like the Drivers’ Hours Legislation and the Working Time Directive are in place to mandate safe working hours and protect drivers.

However, managing these regulations with paper logs can be a logistical nightmare, prone to errors and difficult to manage.

Luckily, CheckedSafe is offering a solution. The new addition to their award-winning platform aims to simplify compliance by digitising the tracking process, eliminating paper records and reducing errors.

The feature provides a real-time dashboard that monitors driving hours and rest periods, encouraging compliance with the law. Their app offers real-time alerts for potential breaches, allowing for immediate

action. It also generates detailed reports at the touch of a button, making audits and inspections stress-free.

Gary Hawthorne, Co-Founder and Director at CheckedSafe, commented, “Paper logs are not only inefficient but also susceptible to mistakes or manipulation. It's not uncommon to hear news stories about transport managers facing prison sentences and losing operational licences for failing to stay compliant. This puts significant pressure on fleet operators to get it right.”

For those interested in CheckedSafe’s new development, discover more at: www.checkedsafe. com or call them on 01282 937228.

More than four out of ten commerce and supply chain leaders across Europe say that they have needed to implement new technology including warehouse management systems (WMS) and order management systems (OMS) to help manage DTC fulfilment in response to growth over the past 12 months, while nearly 48% say they have needed to hire more technically skilled staff to fulfil orders.

These were among the key findings of recent DTC market research commissioned by Cloudbased omnichannel fulfilment software provider, Deposco, which polled the views and opinions of 200 senior decision-makers from leading commerce and supply chain organisations across Europe. The full report is available for download here.

Organisations are using the potent combination of talent and technology to engage more closely with their customers and understand them better. In line with this, 42% of respondents say, “focusing on building strong relationships directly with customers” is among the top reasons that DTC fulfilment is a priority for their organisation, while 38% want to gain a better understanding of customers’ spending behaviours.

38% of those businesses surveyed are able to offer Click & Collect services for DTC customers, and 37% report that they can easily combine several orders for delivery at the same time. This is a capability that Amazon and the third-party sellers on its platform have successfully demonstrated through the Prime offering, whereby

customers can order multiple different items and have them delivered together.

Will Lovatt, general manager and vice president of Deposco Europe, said, “Consumers are increasingly combining orders for the reduced environmental impact, appreciating the fewer vehicles on the road and the subsequent decrease in emissions. Additionally, they find it convenient to have a single combined order, eliminating the need to be at the delivery address multiple times for sporadic arrivals of separate packages.”

Leveraging multiple inventory points to achieve customer fulfilment, 38% can split orders to satisfy customer demand from more than one location.

According to Lovatt, “The most successful businesses will be those that invest in technologies that enable them to deliver products in the dynamic way consumers need. For example, many prefer to take items back to the store

if they buy them online.

“They want to try before they buy in-store and then buy online, having the item delivered to their house. Businesses will need cost-saving fulfilment technologies, like WMS and OMS software, that make these options a reality if they want to be successful.”

By building direct relationships and understanding consumer behaviour, businesses can enhance control over customer relationships including the capacity to deliver personalisation and the ability to foster trust and loyalty.

Other priorities are supporting product range expansion (34%) and making business operations more environmentally friendly (33%). It is clear that across Europe, in particular, the maturation of the ESG movement and growing emphasis on the quality and diversity of products are increasingly coming into play.

Lovatt added, “The emergence of ‘Zero Consumers’, who alternate between economising and luxury spending without brand loyalty, emphasises the need for businesses to build a deep understanding of their customers to reduce churn. Their preference for online research and sustainable delivery highlights the importance of direct-to-consumer fulfilment and sustainable practices in retail today.”

https://deposco.com

Manchester-based Psycho Peacock says working with ST-216 R Nightstar and ST-601 R Starlight has opened up more sustainable options for its customers

Large-format specialist

graphics supplier

Psycho Peacock has revealed how its use of ST-216 R Nightstar and ST-601 R Starlight fabrics from Soyang Europe is allowing the company to offer a more sustainable service to clients across a range of markets.

Based in Salford in Greater Manchester, Psycho Peacock has been providing specialist graphics to clients in the retail, events, museums, construction, and visitor attractions sectors for more than 40 years. This offering is expanded further by working with sister company Full Circle Exhibitions & Events, which focuses on event signage and branding knowledge.

For more than half of its life, Psycho Peacock has been working in partnership with Soyang Europe, drawing on the supplier’s extensive knowledge of markets and its far-reaching product range to create a wide variety of eye-catching applications.

Psycho Peacock recently expanded this relationship by starting to work with ST-216 R Nightstar and ST-601 R Starlight, both of which are designed to provide customers with a more sustainable offering that they can then pass on to their own clients.

ST-216 R Nightstar is a wrap-knitted blockout fabric with textured surface on its front side and black coating on the back. Mainly used for dyesublimation printing, the product offers excellent opacity, softness, bending resistance and wrinkleresistance, making it an effective solution for applications such as backdrops, pop-up displays

and frame systems.

As for ST-601 R Starlight, this is a coated backlit with woven based fabric featuring a tight textured structure with a coating. This means the material does not suffer from any light leakage, which, coupled with good wrinkle-resistance, makes it a popular solution for light box applications.

While their features differ, something that the two products have in common is that they are both made from recycled PET bottle yarn, offering a significant, environmentally friendly incentive for print companies and their customers.

It was this feature that particularly appealed to Andy McIntyre, General Manager of Psycho Peacock, as it aligns with the company’s own core values of sustainability and environmental responsibility.

“Choosing these sustainable materials fits seamlessly with our business goals and values,” Andrew said. “Our ESSA accreditation on the

exhibition side of the business underscores our commitment to sustainable practices, including the Reconomy sustainability closed loop.

“We didn’t adopt sustainability to gain a competitive edge, but it has naturally fortified our market position. Our goal is to lead by example, encouraging the industry to adopt sustainable practices.”

Psycho Peacock primarily uses its Durst P5 TEX i-Sub printer to produce work on the two materials. While the company has only been working with these latest introductions from Soyang Europe for a short period of time, Andrew said he is already looking at how the fabrics can help Psycho Peacock move into new markets.

“We’re poised for growth and innovation,” Andrew said. “Psycho Peacock is committed to strengthening its relationship with Soyang and is continuously developing its product offerings forits esteemed clients. Together, we aim to drive the graphics & printing industry towards a more sustainable future.”

+44 (0)161 765 3400 sales@soyang.co.uk https://soyang.co.uk

Rotech Machines, a pioneer in thermal inkjet technology, is excited to announce that they will be exhibiting at this year’s PPMA Show, taking place from 24-26 September 2024 at the NEC in Birmingham.

Well known for their customer-led solutions, Rotech will be at stand A31, ready to showcase their unparalleled range of printers and demonstrate their expertise and knowledge of the increasingly popular coding technology.

Over 20 years of innovation in thermal Inkjet technology

More than two decades ago, Rotech recognised the potential of thermal inkjet (TIJ) in the packaging industry. Since then, they have been advocating its benefits— clean operation, maintenance-free functionality and ability to produce excellent quality prints.

The evolution of TIJ technology took a significant leap forward around 2008 with the development of inks that adhere to standard packaging materials. Rotech was at the forefront, implementing some of the first installations for printing on blister pack foil and flow-wrapper films.

Expertise and industry-leading support

This leap forward in capability has led to many other companies adopting the technology as part of their product ranges, with varying levels of knowledge and aftercare.

“Although we all agree that the technology is an excellent choice for various applications, when not installed correctly, or not supported by a knowledgeable team, it could easily be labelled with the same negativity associated with more expensive, service hungry and unreliable technologies,” says Steve Ryan, Sales Manager at Rotech.

“This is where Rotech excel, we have industry leading knowledge, extensive experience with installing and supporting these systems across an array of different industry sectors and can provide a full range of system options.”

Trusted across the UK

With over 1,000 UK installations under their belts, Rotech are well trusted by manufacturers spanning a wide range of industry sectors. They maintain their position as a first-class supplier of the technology by constantly evolving their install techniques based on extensive industry experience.

Rotech invites manufacturers to engage with their coding experts to discuss unique challenges related to late-stage product customisation. “Our expertise lies in the correct application of TIJ technology to meet customer needs, from printer and ink selection to installation and interfacing,” explained Richard Pether, General Manager at Rotech. “Acquiring a printer is easy; getting it to work to its maximum advantage takes expertise.”

Solutions for offline coding

Also at the forefront of the Rotech stand will be a selection of their UK designed and built feeding systems, for applying variable information to packaging off-line.

These feeders are manufactured to handle a variety of flat-form substrates with ease. When paired with a printer and/or labeller, they reliably print and/or label at high speeds, offering a cost-effective solution for coding away from the main production line.

Among the showcased products will be the entry-level RF Lite, a lowcost solution for automating date coding processes, and the newly redesigned RF Auto, a heavy-duty feeder capable of handling products of varying thicknesses. Both systems can be seamlessly integrated with TIJ coders to provide a complete standalone solution.

01707 393700

sales@rotechmachines.com

www.rotechmachines.com

Jasic

EVO is the new UK standard in welding and is supported with an unparalleled 5 year out of the box warranty.

JASIC is a forerunner of IGBT inverter welding technology and its products have been used in some of the most ambitious products in modern history such as the historic Beijing Bird’s Nest Stadium.

JASIC is driven by its passion for the world's welding needs and strives to deliver reliable and ecological solutions.

One-stop shop for high-quality commutators and copper electrical components

What do we do?

Electric Materials, a premier copper mill headquartered in Pennsylvania, USA, has been a global leader since 1915, specialising in the extrusion, casting, and forging of high-quality copper electrical components and commutators.

Commutators:

the job, but if needed can be custom designed and built to your exact specifications in any shape and configuration needed.

JASIC’ EVO range offers a redefined industrial design and human machine interface. Solid welding performance and high standards in sustainability, safety and reliability.

For further information please visit: www.jasic.co.uk or contact your local JASIC Welding Distributor.

www.wilkinsonstar247.com

We are internationally recognised for its expertise in commutator manufacturing including V-ring, Glass band and shrink ring commutators. Our comprehensive capabilities encompass start-tofinish commutator production accompanied by compression seasoning, spin seasoning and profiling.

Busbars: Our busbars are not simply ‘off the shelf’ stock that may (or may not) fit

What does One-Stop Shop means? All our high-quality extruded shapes, rods, rings and bars are produced from billets we cast in-house. The necessary materials are carefully combined in our two large induction furnaces, and before pouring each heat, the chemical composition is evaluated in our laboratory. Do we work globally? Certainly! With a century-long legacy of excellence, Electric Materials ships its highquality electrical components globally. Just get in touch with us for your inquiries.

Contact: Selim Yetkin +44 (0)7387 140988 syetkin@elecmat.com www.elecmat.com

Milexia Group strengthens its offering by reinforcing its sourcing activities and delivery services. This will simplify customers’ procurement, globally.

Milexia is pleased to announce its expansion through the acquisition of Whistler Technology. Whistler Technology specialises in the procurement and management of electronic components, ensuring cost efficiency and reliability for its customers.

With this strategic acquisition, Milexia continues to expand its footprint and service offerings, reinforcing its commitment to delivering high-quality, reliable, and efficient supply chain solutions across various sectors. Whistler Technology has been serving the electronics industry since 2001 and has consistently grown to support customers globally across various industries, including military, medical, automotive, industrial, aerospace, telecommunications, and commercial. Their core business has always been strategic electronic component sourcing services, utilising their team’s experience and skillset, and leveraging their growing global supply chain built on

long-standing and trusted partnerships. As an AS9120B accredited supplier, they have a robust quality management system, ensuring that their team provides the highest levels of service and quality.

Jonathan Vincent, Managing Director, Whistler Technology, said, “Becoming part of the Milexia Group enables us to take a key next step in our growth plan of becoming a multinational organisation that offers customers, old and new, a broader, more complete service. This will enable us to become a much more strategic partner to our customers and also allows us to contribute to Milexia’s already impressive sales strategy and team. In addition, we are excited to bring our knowledge and expertise to Milexia

as an offering to their existing customers. We are very much looking forward to playing our part in making Milexia an even bigger global force in the electronics distribution industry making access to complex sourcing easier.”

Xavier Gaillard, CEO Milexia Group, said, “Whistler Technology’s teams, through their expertise in electronic components procurement services, complements those of Milexia. This acquisition will reinforce our group's position as the European leader in value-added technology distributors, adding among others key services to customers such as obsolescence management, strategic procurement outsourcing and following a rigorous quality, test and inspection process. This is in line with our growth ambitions in Europe and beyond to better serve our ecosystem of customers and partners."

Contact https://milexia.com www.whistler.technology

combines Gill’s market leading oil debris sensors with Gill’s new IoT data platform to provide seamless equipment oversight for confident asset management.

Gill’s WearDetect oil debris sensors reduce unplanned downtime by continuously monitoring ferrous wear debris in lubricating oil to give the earliest maintenance warnings.

This real-time condition monitoring, right in the heart of the equipment, is made all the more powerful when combined with the ability to collect, visualise and analyse that data using the Gill IoT Platform.

WearDetect IoT also allows alerts to be configured from multiple assets and multiple locations and sent straight to your PC, phone or other device, providing insight into gearbox and rotating equipment health, at your fingertips.

n Enhanced data collection and analysis – data assimilated from remote sensors in one simple-to-use platform.

n Remote monitoring and control –remote asset oversight enables timely maintenance.

n Scalability and flexibility –

additional sensors can be added to the platform enabling systems to meet changing requirements.

WearDetect IoT offers:

n Real-time condition monitoring –live updates, alerts and machine wear data insights direct to your device.

n Precision sensing – WearDetect employs advanced solid-state sensors (no moving parts) to detect both fine and coarse ferrous wear debris.

n Trending data for predictive analysis – the Gill IoT Platform allows data visualisation for clearer insights supporting informed decision making.

n Instant alerts – user specified alarms ensure users are aware of changes as soon as they occur.

n User-friendly intuitive interface – easy data access and setting configuration puts the user in control.

Contact www.gillsc.com/weardetect-iot

The German mixing and dispersion technology specialist ystral extends its machine portfolio with the YSTRAL Coflow, a continuously operating powder wetting and dispersing machine.

With the YSTRAL Coflow, powdered solids are inducted, mixed and dispersed into liquid streams in a controlled way and in proportion to quantity via volumetric or gravimetric solid dosing systems. The product is subjected to a pressure increase via an inducer installed between the premixing zone and the rotor-stator zone, which causes separation of the air inducted with the powder, thus resulting in a lower residual air content in the product. In addition, this inducer is used as axial pumping stage, to be able to also process more viscous products and then pump them from the dispersing stage.

The inline disperser is suitable for a broad range of applications in different industries. The focus here is on products which are produced in large series or are to be manufactured

in perspective in large volumes.

More about YSTRAL Coflow at: https://ystral.com/en/machines/ inline-dispersers/coflow

ystral is represented in the UK by S3 Process Limited. S3 Process is an exhibitor at the PPMA Show 2024 (Stand F95, www.ppmashow.co.uk).

For more information on ystral, contact the regional UK office (S3 Process Limited) in Derbyshire: 0845 505 3530 info@s3process.co.uk www.s3process.co.uk

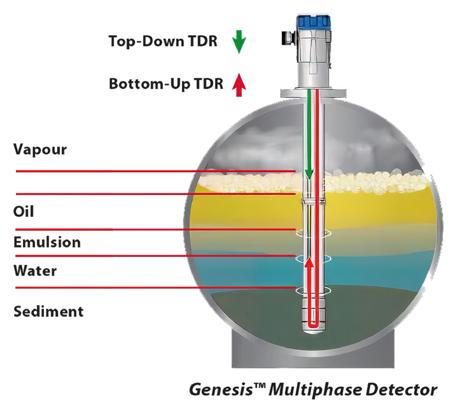

With the growth of TDR based level instrumentation, there is an emphasis on expanding the use of TDR into multiphase applications where mainly high-priced profilers or multi-probe arrays exist today.

Magnetrol’s Genesis Multiphase Detector is a Time Domain Reflectometry (TDR)based, 24 VDC level detector designed to accurately define and quantify the various layers in multiple interface level measurement applications. Encompassing a number of significant developments from Magnetrol’s progressive engineering team, this innovative level detector can deliver a full interface profile of a vessel with performance which surpasses many of the more traditional technologies.

Utilising patented ‘Top-Down’ and ‘BottomUp’ signals, along with advanced level detection algorithms, this single device

can be used in a wide variety of interface applications ranging from very light hydrocarbons to water-based media. For example, Genesis can be used to define the multiple interfaces in a separator vessel (sandwater-emulsion-oil-gas) with exceptional precision and can even determine the magnitude of any emulsion layer.

Multiphase level measurements exist throughout the process industries and are particularly relevant in the Oil & Gas and Petrochemical sectors due to the value derived from effective water and hydrocarbon separation. While level instrumentation has come a long way in measuring liquids of all varieties, multiphase level measurement is often

considered the greatest challenge in process control.

Despite the fact that there has been considerable effort by instrumentation manufacturers to measure multiphase levels, only now is there a cost-effective TDR-based multiphase level detector capable of widespread adoption. Radiometric and nucleonic technologies can profile multiphase media conditions, potentially without intrusion into the process vessel; however, they come with high upfront costs, regulatory burdens and increased safety requirements.

For more information on Genesis, please email: info@able.co.uk or visit: https://able.co.uk/product/ level-management/magnetrol-genesis

AtCable Services, the UK’s trusted supplier of electrical cable and specialist equipment, we have invested in an automatic winding and measuring cable cutting machine at our Wrexham facility. This £90,000 investment reflects our commitment to offering an economically valuable and highly efficient service for our valued customers.

We are known for providing tailored solutions that meet the exact needs of our customers. We recognise the growing demand for a flexible service that eradicates waste and delivers cost efficiencies. The efficiency and precision of this new machine support the industry’s commitment to operational sustainability and allow us to pass on cost savings to our customers.

Commenting on this latest investment, Jason Bostock, Managing Director of Cable Services Group, said, “We continue to make significant investments in our operations across the Group to better serve our customers. This new machine more than doubles our capacity,

and it also enhances our ability to meet the specific needs of our customers promptly and efficiently. Customers can order customcut cable lengths to suit the exact needs of their projects, providing flexibility beyond the traditional supply of full drums to sites.

“Installing the advanced Loimex TRG250 alongside our existing cutting machine has significantly boosted our cut-to-length capability. To achieve seamless integration and optimise performance, expert trainers from Loimex conducted an intensive three-day training programme for all warehouse operators at our Wrexham facility. This highly engaging, practical training course equipped our team with the skills needed to operate the machine efficiently, ensuring consistent quality and precision.”

Hailo, the pioneering chipmaker of edge artificial intelligence (AI) processors, announced that it has appointed NEXTY Electronics, one of the core members of the Toyota Tsusho Group’s electronics business, as Hailo’s second sales partner in Japan, where it will focus on further advancing Hailo’s AI solutions within the automotive market.

The appointment comes on the heels of Hailo’s recent announcement that leading autonomous driving solutions provider iMotion selected the Hailo-8 AI accelerator and Renesas R-Car V4H SoC (Systemon-Chip) to power the iMotion iDC High domain controller for advanced driver-assistance systems (ADAS) and automated driving (AD). A Chinese automaker is expected to begin mass production with the iMotion

iDC High domain controller in the second half of this year.

“ADAS is a key area of growth for Hailo and our partnership with NEXTY Electronics will be critical to help us expand our market presence,” said Nori Kojima, General Manager of Hailo Japan. “Hailo’s edge AI processors are cost effective and offer high-performance data processing and low power consumption to the automotive market, making advanced ADAS and autonomous driving features accessible for mass market vehicles. We’re thrilled to partner with NEXTY Electronics to be able to offer their automaker and Tier 1 customer base a wider range of AI options that can tackle even the most challenging automotive scenarios.”

NEXTY Electronics is one of the key companies in the electronics business sector of the Toyota Group Tsusho and specialises in automotive electronics, IT, communication, and industrial solutions to support smart factories, robotics and more. www.hailo.ai

Warren Hughes, Warehouse Manager, praised the training provided by Loimex. He said, “We were impressed with Loimex’s training, and the support received to date has been exceptional. Having direct access to the manufacturer’s training experts was invaluable, allowing us to ask questions that directly relate to our day-to-day operations. With this training, we are confident in our ability to use this technology to its full potential, ensuring we provide a highly responsive and agile service that meets the needs of industry.”

The new automatic TRG250 from Loimex handles electrical cables with the utmost accuracy. It accommodates cables ranging from 1 to 100mm in diameter, wire ropes from 1 to 33mm, and wooden drums up to 2,500mm, with a maximum weight capacity of 5,000kg. With its advanced safety features, the machine complies with CE directives, reflecting our consistent delivery of safe and reliable products that meet the highest industry standards.

For more information about our cable cutting capabilities or to place an order, please contact us at: www.cableservices.co.uk

New generation of compact 3 watt DC/DC converters with an ultra-wide 8:1 input range.

n Compact SIP-8 plastic case

n Ultra-wide input range: 9 VDC to 75 VDC

n Certification according to IEC/EN/ ES 62368-1

n Approved operating temperature from -40°C to +80°C

n I/O isolation 1,600 VDC

n Operating up to 5,000m altitude

n Short circuit protection and over current limitation

n Under voltage lockout

n Remote ON/OFF

The TEC 3UI is a series of isolated DC/DC converters with ultrawide input range. This new converter generation is designed

to seamlessly replace and offer an alternative to existing 2:1 and 4:1 input converter series, ensuring no compromise on performance or cost-effectiveness. With an input voltage ranging from 9 to 75 VDC, the TEC 3UI covers a variety of standard bus voltages, minimising the need for multiple model variants in an application.

All models are equipped with short circuit protection, over current limitation, under voltage lockout and feature remote control functions. The converters operate reliably up to a maximum temperature of +90°C, with an approved operating temperature range of -40°C to +80°C according to IEC/EN/UL 62368-1 and can operate at altitudes up to 5,000 metres. The compact SIP-8 plastic case makes the TEC 3UI series ideal for space-constrained applications. Available as both single and dual output models, these converters are suitable for various industrial applications.

Contact: Yves Elsasser

+41 43 311 45 11

+41 43 311 45 45 y.elsasser@tracopower.com www.tracopower.com

Wieland Electric presents the latest generation of highly efficient safety light grids and safety light curtains

The importance of occupational safety grows in modern industrial and logistical environments as machines and systems become more complicated. Against this backdrop, Wieland Electric introduces its next generation of safety light curtains and safety light grids, which complement the existing array of optoelectronic protection devices and are distinguished by a high level of safety, flexibility, and use.

The new SLG4 series safety light grids were designed for applications requiring dependable access protection over wide areas on machines or in production sites. While withstanding temperatures as high as 70°C, the light grids may be put into action swiftly thanks to their simple software configuration and plug-and-play installation. Clearly visible LEDs also enable immediate on-site diagnostics, reducing downtimes. Furthermore, the durable aluminium

housing and protection rating IP65/67 in accordance with EN 60529 ensure that the optoelectronic protective devices perform reliably even in adverse environmental situations.

The SLC4 series safety light curtains are perfect for protecting fingers and hands in the machine’s danger zone. When the machine is used frequently, they cut access times compared to physical guards, increasing production. Advanced functionalities like muting ensure safe material flow and contribute to cost-effective material supply and removal. Cascading two devices enables vertical access and horizontal presence monitoring in a single system. The SLC4 safety light curtains, like the SLG4 safety light grids, have a simple software-free configuration and the ability to do quick on-site diagnostics. This improves productivity and safety in industrial applications.

www.wieland.co.uk

For over 40 years, IEW Ltd. has been a cornerstone of the contract electronics manufacturing industry. With a dedicated team of over 60 professionals, we provide exemplary service to companies specialising in complex machinery.

Our Commitment

We take pride in providing a service aimed at delighting our clients. By understanding their specific needs, we tailor our services, so they can channel their efforts into developing their cutting-edge technology and pioneering designs.

Our Focus

We are driven by a dual commitment – delivering cost-effective solutions and ensuring every assembly is delivered to time and rigorously tested, guaranteeing peak quality and reliability.

Our Vision

To be the employer of choice: so we have the best people, trained to the highest standards, to service the Customer, innovate and grow the business, whilst keeping exceptional levels of quality, performance managed in an environmentally responsible way.

Our Mission

To meet the requirements of a constantly evolving electronics marketplace by delivering the exceptional; understanding the complex; innovating our service.

Designed to exceed ANSI & EN standards, Aqua’s gravityfed tank showers delivers 15 minutes of continuous drench time simultaneously from the shower and eye bath. The tank doses tepid water without the need for a mains water supply. Models are available for any environment: -55°C to +60°C temperatures, remote locations, hazardous or nonhazardous areas.

Built in the UK with corrosion-resistant materials, these robust units offer superior performance, reliability and longevity than any other option on the market. Many optional extras are available to suit your site requirements, such as alarms, sirens,

eye wash stations and inspection ladders.

Check out some of the major pros from investing in our TS1500:

n Low running costs

n Minimal operational spares and virtually maintenance free

n Built from corrosion resistant materials

n Ideal when working in extreme conditions

n Ideal for the Oil, Gas, Chemical and Water Industries

n Meets ANSI Z358.1-2014 specifications

For an unbeatable quote, contact: sales@aqua-safety.com or visit: www.aqua-safety.com

In the constantly changing world of workplace risk and the need to get risks identified when they present themselves – a larger format solution without unnecessary fuss is becoming ever more necessary.

Fuss is messy inks – tedious waiting for a multi-ribbon device to drag itself through four passes – software that requires qualified and trained users and for an outdoor durability some extra protective coatings or lamination.

To get an A4 Health and Safety message printed and in place can be both a very fast and an easy process if you use the SMS 830 from Rebo Systems. The SMS 830 is a new product for larger health and safety sign production.

Perfect for A4 output and for larger and longer messages.

It comes complete with pre-printed

safety signs in A4 format on a roll – so you only need to add the relevant texts and icons for Warning, Prohibition, First Aid and Fire Notices.

Easy to use software includes ready to use A4 safety templates – for minimum design time and faster output.

The SMS 830 is a compact, desktop device – unusual for printers with a 220mm output width.

+31 3560 16941 clinton@rebo.nl info@rebo.nl www.rebosystems.com

Supertouch, a leading provider of high-performance PPE (Personal Protective Equipment), is a key player in ensuring safety and efficiency within industrial environments. As one of the UK’s most extensive suppliers of hand protection, their comprehensive product range includes gloves, protective clothing, and footwear, all designed to meet the stringent demands of various industries. With over 25 years of expertise in developing and supplying protective gloves, Supertouch has established itself as a trusted partner, consistently delivering reliable PPE that adheres to the highest safety standards while enhancing productivity in challenging work conditions.

Take the NEW Pawa PG614 Type A Chemical-Resistant Thermal Gloves, for instance – engineered specifically for demanding tasks in cold environments. These gloves feature a brushed cotton liner treated with Silvadur , offering premium comfort, long-lasting freshness, and effective odour protection.

Key features of the SERIES SIX range include:

n Pawā®DRY Triple PVC Coating –Provides enhanced waterproofing and durability.

Building on this legacy, Supertouch has expanded its expertise with the launch of the PAWA SERIES SIX range. This new collection is engineered to provide advanced hand protection, offering industry professionals the latest innovations in comfort, performance, and chemical resistance. As industries continue to prioritise worker safety, the PAWA SERIES SIX stands out as a premier choice for those seeking superior protection in demanding environments.

n Pawā®THERM™ Cold Resistance – Ensures optimal performance in low temperatures.

n Pawā®GRIP Enhanced

Sandy Grip – Delivers superior handling in oily environments.

n Pawā®LIFE Heavy Duty Durability – Extends glove lifespan under tough conditions.

n Pawā®SHIELD Heat Resistance –Protects against contact heat up to 250°C.

n Food Contact Approved.

0345 130 9922 info@supertouch.com www.supertouch.com

Abbey Seals International Ltd is a second generation family-run business based in Dublin and Cork. Over the last four decades, we’ve been Ireland’s leading provider of seals and gaskets.

Since 2011, our Cork manufacturing facility has been a hub of innovation, with two state-of-the-art CAD knifecutting tables for creating custom gaskets with extreme precision and efficiency.

In 2015, we started manufacturing seals using next frontier CNC Lathes – the only Irish company using this process.

And we’re still the only company in Ireland that manufactures both seals and gaskets.

You’ve probably guessed by now that we like things running smoothly, but we’re big on things running quickly as well.

If you need a specific part, we can create it through our in-house manufacturing service, Abbey Seals Xpress.

We specialise in creating custom pieces with no minimum order quantity.

Contact:

Abbey Seals International Ltd, DUBLIN Unit B1 Nangor Road Business Park, Nangor Road, Dublin, D12 TNY6, Ireland

+353 (0)1 427 7900 dublin@abbeyseals.ie

Abbey Seals International Ltd, CORK 31A Euro Business Park, Little Island, Cork, T45 X310, Ireland +353 (0)21 500 3555 cork@abbeyseals.ie

Brixworth Engineering has produced its largest-ever side-mounting turnover stand. Supplied to the Croydon facility of leading power transmission specialist Voith Turbo, the Benco 1050 (an upgrade to Brixworth’s standard Benco 1000 engine stand) is helping this progressive plant to inspect and service a variety of engines and transmissions.

With a load capacity of 5,000kg (at 500mm from the mounting spindle) and a turning capacity of 10,000Nm, the Benco 1050 supplied to Voith Turbo facilitates the manipulation of complete engines for inspection, repair or modification. Moreover, it is a mobile version featuring a motor drive to deliver rotational speed up to 4rpm, although customers can opt for floor mounting and manual operation if preferable.

Control of the Benco 1050 at Voith Turbo is via a fixed pushbutton station, with pendant control available as an option. As a further point of note, Brixworth designed and manufactured additional mounting arms to minimise deflection throughout the loading & rotation process.

Rugged, cost-effective Benco engine stands are ideal for undertaking a whole host of new-build, repair and refurbishment operations quickly and easily. With these popular engine stands, users can rotate or horizontally and vertically manipulate engines with ease to minimise the dangers of personal injuries associated with the manual handling of heavy loads. An adjustable column facilitates working at a convenient height while maintaining access to all aspects of the operation.

www.benco.co.uk

CHEMUK 2024 opened its doors on Wed 15th & Thu 16th May at the NEC in Birmingham to a record attendance of 4,641 visitors (excluding exhibitor staff) over the two days, representing an increase of 17% from the 2023 edition. The total two-day attendance (visitors plus exhibitors) was 6,677.

CHEMUK show founder, Ian Stone, sums up the positive response to this year’s event, “Standing in the hall midmorning on the first day was electric! So much volume and energy in the hall with our biggest concentrated audience ever, from literally every corner of the sector.”

Minister Alan Mak represents the UK Government at CHEMUK 2024

Visitors to CHEMUK were invited to an exclusive prerecorded address by Minister Mak, Minister for Industry and Economic Security at the Department for Business and Trade, and Minister for the Investment Security Unit at the Cabinet Office. The address was supported by a comprehensive UK Government footprint at the show,

Verder Scientific stands at the forefront of high-tech laboratory and analysis equipment production, delivering solutions for sample preparation, analysis, and quality control across various industries. Within its extensive portfolio, Carbolite Gero and Microtrac, both part of the Verder Scientific family, stand out for their innovative contributions to material science and industrial processing. Verder Scientific excels in offering comprehensive turn-key solutions that encompass quality analysis, processing, and post-processing for a diverse area of application processes and industries.

with several government departments exhibiting this year, including the Department for Business and Trade, the Department for Environment, Food and Rural Affairs, the Health and Safety Executive, the Home Office, and the Department for Energy Security and NetZero.

CHEMUK Group of Events

CHEMUK redefined itself this year with the introduction of several sub-brands: the Chemical & Process Engineering Show, the Chemicals Supply Show, the Chemicals Management Show, and the Chemical Laboratory Show.

The CHEMUK 2024 Conference covers the big issues Reflecting on the enormous CHEMUK 2024 speaker programme, Ian Stone comments, “CHEMUK24 was our most comprehensive conference programme to date and certainly our best attended, with standing room only at so many of the keynotes and panel programmes.”

CHEMUK 2024 Partner support continues to underpin CHEMUK’s growth

The 2024 show welcomed several key new partners to the show this year who brought invaluable content and member groups to the show. The new partnering organisations included the British Plastics Federation, IMechE, ScotCHEM, CICA (Chemical & Industrial Consultants), and the CHCS (Chemical Hazards Communication Society).

The show’s success was underpinned by the continued support & input provided by their longstanding partner network, comprising the CBA, BCA, BASA, BVAA, BPMA, BioVale, BCMPA, BADGP, CPI, CCUK, IBioIC, GAMBICA, NEPIC, SIA, InnovateUK KTN, Chemicals Northwest, UKLA, and the UK & Ireland Spill Association, to name a few.

electrochemical properties significantly influence the efficiency, longevity, and safety of batteries. The furnace’s unique seesawing ability ensures uniform temperature and atmospheric exposure, guaranteeing reliable results.

The Carbolite Gero TSO furnace, is known for its precision in thermal treatment of high-value materials, essential for synthesising advanced materials that require specific thermal profiles to achieve optimal performance. This precision is particularly vital in the battery industry, where the material’s structural integrity and

The Microtrac instruments complement this by delivering advanced particle characterisation technologies (gas adsorption, particle size and shape, stability and dispersibility), ensuring that the final product achieves consistent quality and performance. This synergy between thermal treatment and particle characterisation reflects Verder Scientific’s approach to tackling the challenges faced by manufacturers in these sectors.

Carbolite Gero – laboratory & industrial furnace manufacturer (carbolite-gero.com)

Verder Scientific –Enabling Progress (verder-scientific.com)

MICROTRAC – Leader in Particle Characterisation (microtrac.com)

RSC as CHEMUK 2024

The Royal Society of Chemistry (RSC)

was again at the centre of CHEMUK, with a packed two-day programme including an RSC Team stand, an RSC Careers Clinic, an RSC Panel Discussion focusing on the importance of a positive science culture, an exclusive keynote from current RSC President, Professor Gill Reid, and a dedicated RSC member’s reception.

IChemE at CHEMUK 2024

The IChemE brought together a fantastic programme of content that included two keynote addresses by current President and CEO, Nigel Hirst, and Yvonne Baker OBE.

CHEMUK 2025: Looking ahead

In 2025, CHEMUK will introduce ‘The Formulated Product Manufacturer Show’. Ian Stone talked through his vision for 2025, “CHEMUK is all about providing a single destination where all strands of the chemical industries converge through its individual show stream brands, and 2025 sees the introduction of a brand new ‘5th stream’ with the ‘Formulated Product Manufacturer’ show.”

This is our second pick of the best exhibitors from last year’s event, listed here in alphabetical order: BASA, Llewellyn Europe, Meritics Ltd, MHT Technology Ltd, Recontainers Ltd, REMBE, Robinson Brothers & Verder Scientific. Further details can be found on this page and the next three.

Dates for Diary: CHEMUK 2025 (NEC, Birmingham) Wed 21st & Thu 22nd May 2025

www.chemicalukexpo.com

Meritics Ltd are proud to offer Mercury Scientific’s Revolution Powder Flow Analyser in the UK. Designed to significantly enhance your operations across chemical industries, including paint, coatings, petrochemicals, and detergents. This advanced tool provides invaluable insights into your powder’s behaviour by measuring its ability to flow, consolidate, granulate, cake, pack, and fluidise through detailed assessments of power, time, and energy variances within a rotating drum.

The Revolution Powder Flow Analyser, can precisely quantify particle behaviour during crucial processes such as blending, tableting, mixing, and transportation. This enables you to optimise your manufacturing processes, ensuring consistent product quality & improved efficiency.

With its non-destructive testing capabilities, it offers high sensitivity and accuracy, allowing you to detect subtle variations in powder properties. This leads to improved quality control, reducing waste, and ensuring that your products meet stringent industry standards. Additionally, real-time monitoring allows for immediate

adjustments during production, further boosting operational efficiency. Using the Revolution, you benefit from technological advancements that support safer and more environmentally friendly analysis techniques. You can adhere to strict environmental and health regulations, making it an indispensable asset for your industry.

Let us help you improve your chemical processes to new levels of precision and reliability.

Contact 01582 704807 info@meritics.com www.meritics.com

Recontainers Ltd specialises in the buying, selling and cleaning of empty hazardous and nonhazardous chemical conditions.

Established in 1991, the family-run business exhibited at CHEMUK 2024 for the first time to meet prospective new customers.

Located in the Chemical Supply Chain Show Zone, the Lancashire-based company showcased its products and services to visitors from the logistics & transportation, packaging & labelling and storage & containers sectors.

Recontainers Ltd buy and sell reconditioned IBCs (Intermediate Bulk Containers) in different specifications (grade, pallet, base and UN-certified and non-UN certified) and offers an IBC reconditioning (wash and return) service.

Health & Safety is a paramount concern for businesses needing to store and safely transport larger amounts of chemicals across the UK. IBC tanks have been a product of choice for many years due to the following benefits:

n Robust properties – IBCs are made of durable, galvanised outer steel frames built to

protect the inner polyethylene section.

n Space saving – IBCs are stackable due to its cubic shape

n Screw-cap lids –Allowing for easy filling, with a bottom outlet valve for emptying/decanting.

n Easy transportation –IBCs can be lifted onto pallets using a FLT or pallet jack for seamless transportation (also quicker to load/off load than chemical drums)

n Waste efficiency – 1,000Lt of chemicals can be stored in larger IBC tanks, which is advantageous with regards to removing waste when discharging and draining the containers.

n Sustainable best practice – IBCs are fullyrecyclable containers, demonstrating excellent circular economy practice.

n Cross-sector usage – IBCs can be used to store and transport a wide range of liquids, pastes or solids. In farming and agriculture, they can be used for water irrigation/collecting rain, fertiliser storage, with reconditioned ones ideal for storage solutions. On construction sites, they can store water for bulk cement mixing or dust suppression.

n Multi-purpose – IBCs can be used to store both UN chemicals (suitable for

hazardous/corrosive chemicals) or non-UN (non-hazardous chemicals)

Recontainers Ltd has an online shop facility for trade customers, with bulk orders possible by request. Three of the best-sellers include the following:

n Grade 1 Clear reconditioned 1,000L

IBC on metal/plastic pallet (non-UN)

n IBC cover weatherproof & UV protection 1,000L

n Grade 2 Clear reconditioned 1,000L

IBC on metal/plastic pallet (non-UN)

There is a large choice of IBC containers on offer, from grading (1 or 2), UN-approved or non-UN approved, to metal, plastic or wood pallet base. For customers unsure which container is best suited for their needs, Recontainers Ltd can offer full advice via email or telephone.

For more information, contact the team at Recontainers Ltd today: 01706 211112 Recontainersltd@aol.com https://recontainers.co.uk

Recontainers Ltd will return to CHEMUK 2025: 21-22 May 2025: NEC Birmingham.

Working pressure tolerances of 90% – now also for high-pressure applications > 400 bar g

The HPRRD reverse rupture disk offers a durable and sustainable solution for highpressure applications with pulsating process conditions. The new design dispenses with predetermined breaking notches or other mechanisms that impair fatigue strength. The compact design requires no additional support structures and guarantees direct installation in the on-site installation system. Independent and flexible machining of the outer contour allows unlimited freedom for the connections and sealing surfaces.

Burst pressures from 400 to 4000 bar g with a tolerance of up to ±2% of the nominal burst pressure can be realised thanks to consistently precise manufacturing and guarantee a reliable safety function from -5 to 350°C.

When triggered, the bursting diaphragm ruptures as a whole and releases the entire relief cross-section. This enables the process pressure to be relieved safely and quickly.

The unnotched design of the new ST-HPR high-pressure reverse rupture disc enables high pulsating working pressure tolerances of 90%. As the first reverse rupture disc in the REMBE®

universe, no mechanical weakening by blades, for example, is required for opening. The compact design and machining from solid material guarantee almost limitless freedom of shape of the outer contour – whether conical or flat sealing. Burst pressures of 400 to 4000 bar g with

a tolerance of up to ±2% of the nominal burst pressure can be achieved through consistently precise manufacturing and guarantee reliable opening behaviour from -5 to 350°C. When

triggered, the bursting diaphragm ruptures as a whole and releases the entire cross-section. This enables the process pressure to be relieved safely and quickly.

Most people associate REMBE with REMBE GmbH Safety+Control, the specialist for explosion safety and explosion venting worldwide. The company offers customers cross-industry safety concepts for plants and equipment. All products are manufactured in Germany and meet the requirements of national and international regulations. REMBE customers include market leaders in various industries, including the food, timber, chemical and pharmaceutical industries.

The company’s engineering expertise is based on 50 years of application and project experience. As an independent, ownermanaged family business, REMBE combines expertise with the highest quality standards and is involved in various specialist committees worldwide. Short co-ordination paths allow for quick reactions and customer-specific solutions for all applications, from standard products to high-tech special designs.

REMBE GmbH SAFETY + CONTROL 492617405-0 hello@rembe.de www.rembe.de

MHTTechnology Ltd is a leading global supplier of tank gauging, terminal automation and stock management solutions for bulk liquid storage and handling. Founded in 1994 as an independent, private company, MHT provides a range of services to the oil, gas and petrochemical industries. MHT has grown from its humble gauge servicing roots into a leading global supplier of bulk inventory management and stock reconciliation systems.

Now part of the Endress+Hauser group, we work with our parent company to develop groundbreaking software, hardware, and servicing solutions for our customers. MHT’s product range includes terminal automation systems, hardware devices to allow different manufacturer’s gauges

to coexist, and electronic process management. Our solutions offer minimal upgrade costs and revolutionise and improve safety with digitalisation.

From single-unit supply to full tank gauging systems, we offer bespoke, scalable solutions to match our customers’ needs and budgets. Leaning on our decades of combined industry expertise, we collaborate with our customers to provide the solutions that work for them, to help them increase their profits and ease the burden on busy site operators.

To learn more about MHT Technology and what we can do for you, we welcome you to visit our website.

www.mht-technology.co.uk

BASA has been representing the adhesives and sealants sector since 1983, and a new initiative open to all BASA member companies will recognise excellence and achievement within the adhesives and sealants industry.

Award categories include Manufacturer of the Year, Excellence in Supply & Services, Marketing Campaign of the Year, Best Product Packaging, Process Safety, Excellence in Training & Development, Community Engagement, Young Achiever, Environment & Sustainability Initiative, and Innovation.

“Sustainability and Innovation is really important to BASA and formally recognising our member companies’ achievements and excellence in these and a number of other areas is an exciting development,” says Lorna Williams, BASA CEO. “We are looking forward to maximum engagement and of course we look forward to receiving members’ entries and seeing everybody in November!”

We at Llewellyn (Safety Advisors) Europe Ltd cover all aspects of dangerous goods training (Road, Sea & Air), SDS Authoring, Data Sheets and DGSA representation and training and this allows us to offer a wide range of support on many levels.

We are happy to discuss any training requirements you may have, either in the UK or abroad. Our expertise is second to none. Our instructors have all been working in the industry for a number of years and are known and well respected in their fields.

Seeing and speaking to the public face to face is always an enjoyable part of the show and it was also nice for us to catch up with some of our clients that either exhibit or attend annually. It is definitely worth exhibiting at CHEMUK, not only for the possible business leads it may bring but also for the social aspect.

We spoke to a lot of people, some of which had no idea what our company offered, but found they actually needed!

Entries close on 29th July and details and criteria for each category, as well as the entry form, are available on the BASA website. If you are interested in sponsoring the event, please contact us.

The event, to be held at East Midlands Conference Centre, Nottingham on 22nd November, will be hosted by comedian, Jimmy McGhie and will include dinner and entertainment. Tickets are now available for purchase online.

Contact: Lorna Williams, Chief Executive Officer, British Adhesives & Sealants Association, +44 (0)330 223 3290 lorna@basa.uk.com www.basa.uk.com

We thoroughly enjoyed the whole Chem UK experience. We gained lots of positive contacts and feedback which was amazing. It was a very hectic 2 days but well worth it! There was a buzz this year that made the whole event much more enjoyable.

If you feel your company may need our support, please feel free to either email or give us a call.

We are more than happy to help!

enquiries@llewellyneurope.com www.llewellyneurope.com

ABB launches ABB AbilityTM OPTIMAX® 6.4, the latest version of its flagship digital energy management and optimisation system, to provide coordinated control of multiple industrial assets and processes, for improved energy efficiency, to reduce emissions and support decarbonisation.

The performance and usability upgrades to OPTIMAX include an AI module for improved forecasting of load demand, energy generation and energy pricing without manual interaction. This significantly reduces day-ahead and intra-day nomination errors when feeding energy to the grid, which helps avoid rising penalty payments for operators.

“At ABB, we believe that the greenest energy is the energy you don’t use, so driving efficiencies across the entire energy value chain is key,” said Dr Sleman Saliba, Global Product Manager Energy Management and Optimisation at ABB Energy Industries. “OPTIMAX has been upgraded to incorporate the newest technology and address the latest market opportunities, enabling the acceleration of industrial decarbonisation to help preserve resources, as well as sector coupling to replace the use of fossil fuels across energy systems and industrial sectors.”

Combining digital technologies with modular solutions, presented in a simplified user interface, it delivers an updated optimisation environment for solving the energy management challenges facing industrial enterprises and energy providers. In a complex steam and power plant in Germany, OPTIMAX led to an additional 1.5 percent reduction in energy costs in the first six months, enabling a ROI within one year for the customer.

Contact https://go.abb/processautomation

Carbon usage extends to so much more than petrol mileage and paper, and that’s what Ed Crowther, founder of My Square Metre is trying to help people to understand.

A passionate entrepreneur who’s love for biodiversity has turned into a planetsaving business – My Square Metre uses a carbon calculator and wildflower planting to help individuals and businesses offset carbon usage.

Using simple and flexible carbon calculation tools, so far 715kg of CO2 has been offset by 239 square metres of meadowland containing 179k of wildflowers.

With interest climbing, these numbers are only expected to flourish and working alongside experts at the University of

Lincoln, My Square Metre has developed an environmental and ecological strategy to improve the performance of its wildflower planting.

If you’d like to talk about the power of wildflowers and Ed’s to vision inspire others to start their wildflower-fuelled carbon-free journey, please come back to me.

For further information, take a look at Ed’s recent TED talk on a microoffset mindset – https://youtu.be/ f5NQM52J2jM?si=gTsOkxR7UkLFcM9G www.mysquaremetre.co.uk

Thermal Vision Research have over 10 years’ experience in the thermal imaging market. Founded by Matthew Clavey, we supply FLIR’s range of specialist IR thermography cameras for the research and development (R&D) sector.