Union Industries, the UK’s leading manufacturer of bespoke industrial doors, has assisted Crown Lift Trucks in addressing multiple operational challenges with the installation of its cutting-edge high-speed Ramdoor.

Crown Lift Trucks, based in Warrington, faced several issues at its facility, including the need to segregate two adjoining units with different temperature requirements while allowing the movement of high-mast forklift trucks through a large opening.

To tackle these challenges, Union Industries produced a bespoke solution to accommodate the building configuration, ensuring the required opening height could be achieved without compromising functionality. Additionally, the limited space at high-level, between structural steel frames, posed a significant obstacle.

Since launching their UK operations in 1960, Crown Lift Trucks have become one of the world's leading manufacturers of forklift and material handling equipment. Designing and manufacturing up to 85% of its forklift components, Crown provide their wide customer base with forklift rentals, servicing and maintenance, used equipment and a variety of support services.

The installation of the Ramdoor not only addressed the temperature control and safety concerns but also enhanced operational efficiency. Union Industries designed the door to accommodate Crown Lift Trucks’ requirements while incorporating a pedestrian access door to segregate

flow, ensuring a safer working environment.

The Ramdoor features a dual height opening facility, allowing for optimal heat retention while accommodating different forklift sizes. Furthermore, the engineered seals and infills achieve a seamless finish, enhancing both functionality and aesthetics.

It has also been designed to achieve a Class 5 wind resistance rating, making it able to withstand strong winds and to remain operational even during severe weather conditions.

Achieving this rating is supported by a number of the Ramdoor’s features, including its thick Ramhide door curtain material, which is high frequency welded to give the strongest fabric joins available.

With colder weather in our midst, it is essential to keep roads safe by having the storage facility for salt or grit in an easy-access container ready to use in the event of ice or snow.

To help weather-proof your streets, Grit Bins of either 200 or 400 litre capacities are included in Leafield Environmental’s range of street furniture. They are ideal for grit, salt or general storage and are made with an extremely hard-wearing premium plastic material.

As standard, the Grit Bin’s extra strong lid has double wall edges, a moulded-in

‘GRIT SALT’ sign, and a fork-lift space for easy manoeuvrability. Custom signage, labels, or crests are available as an optional extra.

Find out more: https://leafieldrecycle. com/product/grit-bin/

Leafield Environmental is an awardwinning UK manufacturer of premium litter and recycling bins, and street furniture. For more information about Leafield’s products, visit: www.leafieldrecycle.com or call 01225 816500 or email: recycle@leafieldenv.com

In addition, it features heavy-duty wind-brace and wind-bar systems for added strength, plus extra-deep side-guides, which all contribute to the Ramdoor’s ability to cope with high wind loads and pressures. Like other doors in the Union range, it also benefits from a ‘Crash Out’ facility, in case of vehicle or personnel impact to the bottom beam, thus ensuring minimal downtime and repair costs.

Alan Hirst, Sales Director at Union Industries, said, “We are delighted to have assisted Crown Lift Trucks in overcoming their operational challenges with our high-speed Ramdoor. This project highlights our ability to provide innovative solutions tailored to our customers’ specific needs.”

Mark Eccleston, Branch Manager, at Crown Lift Trucks, said, “Union Industries’ Ramdoor has revolutionised our operational efficiency and safety standards. Their dedication to understanding our unique requirements and delivering a bespoke solution underscores their commitment to customer satisfaction. The Ramdoor not only enhances temperature control and traffic segregation but also contributes to our sustainability goals. We are grateful for their expertise and partnership in achieving our objectives.”

T 0113 244 8393 enquiries@unionindustries.co.uk www.unionindustries.co.uk

We are delighted to showcase Peter Hirt GmbH as the recipient of our Manufacturing Company of the Month

Peter Hirt GmbH is an industry-leading manufacturer of highprecision Linear Ball Bearing, Displacement Transducers and OEM high precision mechanical assemblies and parts.

Established in 1943, the primary focus was on trading activities. Over the years, the family-owned company has evolved steadily into a secondgeneration provider of innovative products and solutions to a diverse range of applications including: semiconductor manufacturers, optical system producers, and metrology providers and integrators. The linear ball bearings and probes are versatile, therefore suitable for a variety of applications beyond any single industry.

The primary headquarters are close to the flourishing economic city of Zurich in Switzerland, which operates multiple production and assembly facilities across the country. With an ever-increasing international outlook, distributors worldwide supply the international probe and sensor division products.

With a view to ongoing excellence, Peter Hirt GmbH specialises in three key areas:

t High-precision linear bearings –the oldest product line, known for its precisely defined preload and exceptional quality.

t Pencil probes – designed for diverse applications across various industries.

t OEM parts and subassemblies –Custom-manufactured solutions tailored to meet specific client requirements.

provide unmatched precision and play-free positioning, meeting the highest quality standards. Moreover, we manufacture these products according to each customer’s specific requirements, ensuring tailormade, high-precision solutions.

“With the growing digitisation of sensors, we are proud to be, as far as we know, the first manufacturer to offer IO-Link pencil probes. Nearly all our probes are now available with this technology, providing exceptional measurement stability and linearity,

as well as seamless integration into SPS/PLC systems.

“Our linear bearing solutions have seen great success this year, enabling customers to achieve precise positioning in their machinery and apparatus, alongside the growing market acceptance of our digital IO-Link probes.”

IO-Link Probes are precision-designed for a diverse range of applications, with seamless digital integration and the enhanced separability sensor to cable at the measuring point lowers the installation effort.

In the circular economy era, it’s important that every company contributes to sustainability best practice. Peter Hirt GmbH provides stability and longevity for customers, with many product lines remaining

available for 20 years or more. Simultaneously, the team are committed to continuously improving the production processes, particularly through advancements in automation and robotics.

“Looking to the future, we plan to continue refining our production processes to deliver even higher precision products, faster response times, and enhanced flexibility for small series. Additionally, we are expanding our pencil probe product range, along with dedicated accessories to further enhance model versatility.”

For further information or to speak to the sales team, see the contact details and website below: T +41 44 251 24 39 info@peterhirt.ch www.peterhirt.ch/en

Videojet Technologies, a global leader in coding, marking and printing solutions, is bringing innovation to laser marking technology with the new Videojet 7920 UV laser marking system, designed to boost ease-of-use, flexibility, and reliability in coding operations. This UV laser offers integration features, high-quality code production, and is supported by a five year source warranty, equipping the consumer packaged goods, parts marking and pharmaceutical industries with confidence on their production lines.

Usability – The 7920 UV laser marking system

incorporates Videojet SmartFocus™ technology to reduce the need for manual adjustments while preserving the integrity of packaging materials. To help ensure consistent code clarity and simplify the process of product changeovers, the 7920 offers multi-level surface marking, an auto-adjustable focal distance, uniform flat field correction, and a pilot beam focus finder. These features work together to minimise the need for packaging system modifications, resulting in a more cost-effective solution compared to many UV laser systems and other custom marking solutions.

Videojet Remote Service (VRS) proactively minimises

downtime for 7920 users by sending timely maintenance alerts and facilitating software updates, helping to reduce unexpected downtime and boost productivity. With VRS, Videojet proactively monitors any laser source life degradation and provides proactive maintenance by expert Videojet service technicians.

Adaptability – The Videojet 7920’s compact design and beam turning units allow for a 360degree rotation, facilitating integration even into tight manufacturing lines. It comes with IP54 environmental protection, as well as an optional IP65 rating, to help enable reliable operation in a range of conditions.

Consistency – The Videojet SourceSecure warranty delivers five years of protection on the 7920’s laser source, giving users long-term confidence in the laser’s performance. Additional benefits include proactive monitoring of the laser source’s life to help mitigate the risk of unexpected downtime.

Expertise – The Videojet 7920 UV laser delivers superior codes on common UV laser applications like white HDPE containers, as well as on products with enhanced potential for recyclability, such as monomaterials, helping manufacturers meet demands of eco-conscious consumers and regulators. The new laser can mark at speeds up to 2,000 characters per second with excellent code quality and is backed by rigorous testing and expert Videojet service.

Connectivity and integration – The 7920 features advanced cellular and Wi-Fi connectivity options for secure remote interface control and analytical

capabilities. The system is engineered to assist manufacturers in minimising IT time and investment, and to boost overall equipment efficiency. The 7920 is also designed for seamless integration into production and control networks using EtherNet/IP™ and ProfiNet® protocols.

Testing for quality assurance

Comprehensive Videojet sample testing provides users with the confidence that marking with the 7920 meets specifications. Detailed reports are offered with optimised setup parameters for specific code and substrate requirements.

For more information about the Videojet 7920 laser marking system, visit: www.videojet.co.uk/7920

In this issue of Industry Update, we are delighted to select Benchmark Consulting as our Carbon Transparency & Cost Accuracy Company of the Month for the packaging industry

In the battle against global warming, one software solution provider is stepping up to provide unprecedented insight into the commercial cost and carbon emissions. Benchmark Consulting is revolutionising how we understand and measure the environmental impact of packaging, offering a breakthrough solution that could change the way businesses approach sustainability.

The Packaging Paradox

Packaging often gets a bad rap. Criticised for waste and environmental damage, it’s an easy target for environmentalists. But the reality is far more nuanced. Packaging isn’t the villain – it’s a critical component of modern commerce that serves multiple essential functions.

From protecting delicate products during transportation to extending the shelf life of food, packaging does much more than often realised. It communicates vital information, ensures product safety, and increasingly, is being designed with environmental considerations in mind.

The Carbon Challenge

The numbers are stark. Global food waste alone generates greenhouse gas emissions that would rank third in the world if considered as a country. In the UK, packaging contributes approximately 10-12 million tonnes of CO2 equivalent annually – roughly 2-3% of total greenhouse gas emissions. But without packaging particularly in food, this waste often generates methane. Methane and carbon dioxide are

both greenhouse gases, but methane is more potent and has a shorter lifespan than carbon dioxide. Methane is 80 times more potent than carbon dioxide over 20 years, and 30 times more potent over 100 years.

In short: packaging is necessary so the question is how it should be managed from source to end of life:

The UK Government needs to legislate and regulate business to a standard to avoid voluntary self-regulation by paper, plastic, glass and metal industries. These vested interests -in particular solutions have led to a myriad of confusing messaging often resulting in either ‘Greenwashing or Greenhushing’.

t Packaging Producers need to report Scope 3 emissions: these are all the indirect emissions that occur outside of an organisation’s scope 1 and 2 internal boundaries. They are a result of activities that the organisation indirectly affects in its value chain, such as buying, using, and disposing of products from suppliers.

t Brands and retailers need to provide objective data to enable consumers to make informed decisions.

t Consumers need to play their part by disposing or returning their packaging responsibly. For this to happen meaningfully consumers need clear communication on packs relayed as to what they do with the packaging.

t Waste collectors and sorters at the end of life also need to easily identify the materials and sort such that material can be commercially recycled.

t The solution also needs to be simple and transparent!

t The solution is to report all packaging stock keeping units (SKU) with a commercial cost and a CO2e value to enable informed decisions. This is not a pipe dream: it is possible today.

Founded in 2011 by Tim Barbary, Liam Barbary, and Paul Waters, Benchmark Consulting has developed a groundbreaking software solution that does something previously thought impossible: calculating carbon emissions and cost at an incredibly granular level for packaging producers and is used for consulting with packaging buyers.

“To illustrate a point,” says Tim Barbary, “if you have a red and blue packet of crisps, though the packaging

processes are the same, possibly attracting the same cost to produce and selling price the pigments (colours) are not, which result in minuscule, yet differing carbon footprints.”

The company’s digital package is a game-changer:

t A sophisticated CO2e calculator

t Carbon certification for packaging

t Precise cost modelling and price setting for packaging materials

t Commercial performance calculation and analysis

t Granular data accurately and consistently calculated & transparently reported.

What sets Benchmark apart is its ability to convert complex data, often many thousands of rows of data with different units of measure (area and weights, metric and imperial and volumes, multilayer specifications and currencies) – all in minutes.

The Bigger Picture

The UK Government has published the Industrial Decarbonisation Strategy and set targets on a journey to carbon net zero emissions (back to the 1990s).

Businesses and society as a whole need to recognise this is not a simple steady as we go: evolution is more akin to a revolution.

This isn’t just about numbers. It’s about driving meaningful change in the packaging industries (plastic, paper, glass and metal) critical to global commerce. As governments introduce more stringent regulations – like the UK’s current Packaging Recovery Notes (PRN) and upcoming mandatory food waste separation laws, Plastics tax, Extended Producer Responsibility (EPR), Deposit Return Scheme (DRS) tools like Benchmark’s become increasingly vital. And if the Global Warming current trajectory is not reversed in the near future, one can also envisage a carbon emissions tax.

“Once you start to meaningfully measure granular data,” Barbary explains, “you can begin to identify savings in both commercial costs and planetary impact (CO2e).”

The team behind Benchmark Consulting brings decades of experience from packaging production, purchasing, life cycle assessment, data analysis and IT industries. Their software is used for daily estimating by over 100 major packaging producers across Europe and North America, they’re not just observers – they’re active participants in identifying the cost of the sustainability revolution.

The future is promising. With increasing investment in renewable energy and innovative materials, packaging is transforming. Biodegradable solutions, compostable materials, and smarter design are becoming the norm rather than the exception.

accurate and consistent cost & carbon calculating and transparent reporting verified by authentic thirdparty to ISO: 14067.

In a world desperately seeking solutions to climate change, sometimes the most profound impact comes from the most unexpected places. Who would have thought that the key to reducing carbon emissions might be found in data granularity – the subtle nuances of a crisp packet’s pigmentation? Only then do we move beyond greenwashing to create truly sustainable solutions.

Benchmark Consulting stands at this exciting intersection of technology, sustainability, and commercial intelligence.

The path to sustainability isn’t just about policies and numbers – it’s about transformation. The UK’s journey from tentative environmental acknowledgments in the 1980s to today’s comprehensive net-zero commitments demonstrates both the challenges and possibilities of systematic change. While initiatives like the Green Claims Code and Extended Producer Responsibility schemes show promise, their success ultimately depends on the collective will of businesses, governments, and consumers to embrace genuine transformation.

The packaging industry stands at the forefront of this revolution, where sustainability isn’t just an option – it’s an imperative. The road ahead demands more than superficial changes; it requires a fundamental rethink of how we design, produce, value and dispose of packaging materials.

Benchmark software enable holistic objective decisions that come from granular data collection,

As we look toward 2050’s net-zero target, one thing becomes clear: the future of packaging isn’t just about maintaining the status quo – it’s about reimagining what’s possible. For businesses ready to embrace this challenge, the opportunity isn’t just to survive in a changing market, but to lead the way in creating a more sustainable future for generations to come. Benchmark’s team are ready to support business.

As Tim Barbary puts it, “We know wherever there is a commercial cost, there is a carbon footprint, and we have the know-how and the tools to measure it at a low cost.” The question isn’t whether packaging can be sustainable – it’s whether we have the courage and commitment to make it so.

Benchmark Consulting is exhibiting at: Packing Innovations & Empack 2025: 12-13 February: NEC, Birmingham (Stand B60).

For more information, speak to the team below or click on the website: T 0115 697 5500 www.benchmark-consulting.co.uk

In the realm of metal fabrication, Charles Day Steels understand that precision and efficiency are paramount.

Over the years, various cutting methods have emerged, each with its own advantages and limitations, and as leading providers of metal profiling solutions, we endeavour to develop a series of metal profiling services to meet a range of requirements. One such method that has gained significant popularity is waterjet bevel cutting through the multiple benefits it is able to offer, chief among which is the ability to cut at angles up to 60 degrees, providing a cost-effective and cold cutting alternative to the machining of parts.

Perfect for a diverse range of applications, profiling via a waterjet machine hosts a range of versatile benefits, some of which include:

Versatility in material compatibility

One of the standout features of waterjet

cutting is its compatibility with a wide range of metal materials. Whether it’s aluminium, stainless steel, titanium, copper, brass, or alloys, waterjet cutting can precisely profile these metals without causing any heatinduced distortion or altering their inherent properties. This characteristic is particularly crucial for industries that require intricate cuts and shapes while maintaining the material’s integrity.

Intricate and complex designs

Waterjet cutting technology allows for precise and intricate metal profiling, making it ideal for industries that demand complex designs and tight tolerances. The high-velocity water stream can effortlessly manoeuvre through metal, creating intricate patterns, holes, and sharp corners that may be challenging to achieve using

alternative cutting methods. This versatility enables manufacturers to produce intricate components and parts for industries such as aerospace, automotive, architecture, and more.

No Heat-Affected Zone (HAZ)

Unlike traditional heat-based cutting methods like plasma cutting or laser cutting, waterjet cutting operates without generating heat during the cutting process. The absence of heat eliminates the risk of thermal distortion, melting, or hardening of the metal. Consequently, waterjet cutting minimises the formation of a heat-affected zone (HAZ), ensuring that the cut edges retain their original properties, such as strength, hardness, and structural integrity. This characteristic is particularly vital for applications where material properties cannot be compromised.

Environmentally friendly and safe

Waterjet cutting stands out not only for its versatility but also for its eco-friendly nature. The cutting process is typically water-

based, and the water used can be recycled and reused, reducing water consumption significantly. Additionally, waterjet cutting does not involve the use of hazardous chemicals or produce harmful fumes, making it a safe and clean cutting method for operators and the environment alike.

Minimal secondary processing

Another advantage of waterjet cutting in metal profiling is the reduced need for secondary processing. The precise and clean cuts achieved by waterjet technology often eliminate the necessity for additional finishing, such as grinding and deburring This saves time, labour costs, and ensures a

more efficient production process; providing an economically viable alternative.

Charles Day and the Waterjet Sweden BevelJet 60

Charles Day is proud to possess three of the UK’s largest cutting beds for waterjet cutting services, and can profile materials up to 9m x 4m in size. Drawing on relevant technologies as part of our continuous ethos for self-improvement, we have also invested in our latest revolutionary waterjet machine, the Waterjet Sweden BevelJet 60

Renowned as one of the most advanced pieces of metal profiling technology

available on the market, this newest addition to our unrivalled suite of profiling machines allows our professionals at Charles Day to meet the most stringent of material specifications. Featuring dual cutting heads (3D and 2D), 125hp pump, and adjustable pressures for rapid cutting, the Waterjet Sweden BevelJet 60 is yet another invaluable improvement in Charles Day’s legacy.

Read more about our latest Machine Investment

T 0114 244 5544

sales@daysteel.co.uk

www.daysteel.co.uk/bevel-cutting/ water-bevel-cutting

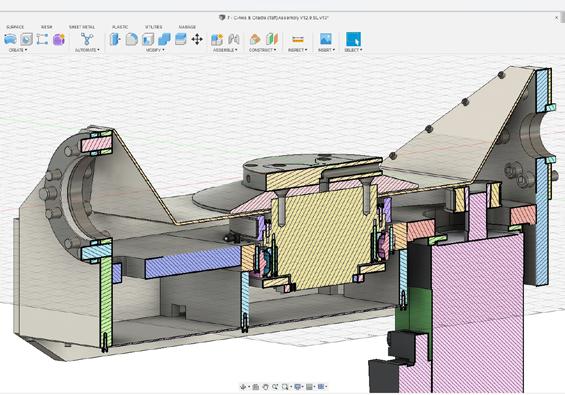

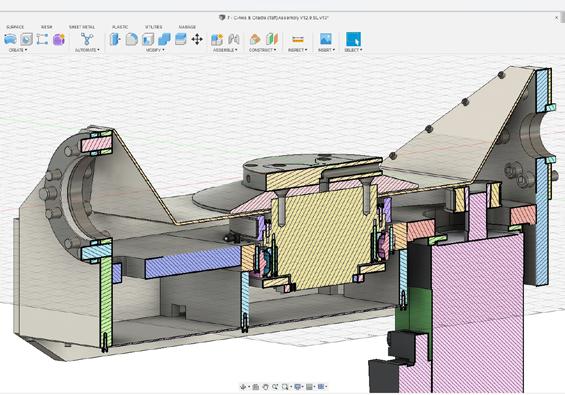

We are delighted in this issue of Industry Update to select Effective CNC Solutions Ltd as our CNC System Design Company of

Effective CNC Solutions was founded in 2017 by Managing Director and experienced CNC Controls Engineer Gary Pearson. Based in Crewe, Cheshire, the company is firmly positioned in the manufacturing sector for metal and composite machine tools, with a growing global customer reach across aerospace, defence, nuclear, oil & gas and R&D manufacturing.

The industry-leading company provides the following services:

t Control system retrofits, upgrades, mechanical refurbishment, and through life servicing for high-value machine tool assets.

t Bespoke machinery design and build.

t Machine tending solutions – robotics and automation integration.

With a customer-centric approach, Effective CNC Solutions provides high-value solutions at lower costs, as Gary outlines, “We bring a wealth of experience from across the machine tool industry and due to our lower overheads, we pass all savings on to our growing customer base. With a focus on innovation, we have recently developed Evolution 600: an advanced 5 axis metal additive, milling/turning/ grinding hybrid machine capable of producing complex finish machined

components from a clear build plate, in a single machine package.

“This patented new concept uses a 3-axis bed mill format with a 2-axis trunnion table to manipulate the workpiece in 5-axis around fixed position spindle, turning turret and WAAM additive head stations.

Controlled by the powerful SiemensSinumerik One - CNC, and a bespoke tool probing system from Renishaw, this cutting-edge machine has unparalleled capability.

“Designed to manufacture components in excess of 800mm diameter or 600mm cube, using inverted workpiece horizontal milling spindle configuration for efficient swarf clearing, the hybrid process allows near net shape metal deposition for minimal material removal and wastage, saving raw material and tooling costs.

“We had the original idea for the design concept back in 2019 and it’s been a real labour of love, supported through Innovate UK grant funding and our partner: GB Engineering (Nantwich) Ltd. Throughout the COVID Lockdown, we focused on building a successful working machine, spearheaded throughout by state-of-the-art CAD machine technology.”

This first-to-market machine brings a

bold vision: offering a comprehensive solution for manufacturing complex components in metal from a blank build plate to a finished product on a unique single platform. Concept machine tools have been traditionally demarcated into milling, turning and grinding separately, alongside the latest category of additive manufacturing. Some market designs have seen cross-overs between mill/ turn, mill/grind, turn/mill and mill/ additive but with limited capability. The Evolution 600 bypasses these limitations with its game-changing design, providing high-speed 5 axis milling, with accurate medium and low speed turning, versatile cylindrical grinding and 3D printing/additive manufacturing capabilities in a onestop unit.

“To reiterate, our new machine tool concept synchronises milling, turning and grinding formats into one single platform, seamlessly incorporating additive manufacturing capability- all without having to needlessly switch between different machine types. By extension, the Evolution 600 is perfectly placed for low volume, highvalue workpieces across aerospace, defence, nuclear, oil/gas/petrolchemical, medical and other related application.

“In the future, we are looking to create a training facility for machine tool engineering, to provide the highly specialised skills in the field of machine tool service and repair.”

To find out more about Effective CNC Solutions, see the details below: M +44 (0)7787 553251 info@effectivecncsolutions.co.uk https://effectivecncsolutions.co.uk

Magog Industries are long established UK designers, manufacturers and suppliers of processing, mixing and conveying screws and barrels. Based in Hertfordshire, the company operate across the UK, Ireland and Europe.

Coatings and materials available are designed to enhance longer life and greater wear resistance in for increasingly demanding processing using recycled material.

“We constantly strive to offer solutions from optimal design to reduce wear to offering a wide range of surface technologies,” explained Michael Bate, General Manager.

“We design everything in-house but also

work closely with specialist partners to meet our customers’ specific processing and production requirements. Our three core competencies run through everything we do: process experience, manufacturing expertise and engineering excellence.”

Enhanced coatings include: Thin Dense Chrome (TDC) to enhance wear with low friction and is FDA Approved for food process environments. Ceramic Seal coatings reduce porosity and increase plating/coating life 4 to 10 times longer in corrosive environments, HVOF (High Velocity Oxygen Fuel) provides a crack-free 98% density with hardness of 62 to 72 HRC. This scratch-resistant tungsten carbide coating has gained much interest among plastics moulders.

Magog also specialise in refurbishment of pre-used parts which extends the life of screws and barrels by re-honing, partial re-line of barrel bores and hard welded re-build of screw flights in bi-metallic alloy as standard. This provides a cost-effective option and ensure lower operating cost.

For more, contact Magog Industries: T 01920 465201 enquiries@magog.co.uk www.magog.co.uk

By provisioning preventative maintenance programmes in good time, plant operators avoid costly downtimes. This is all the more important for non-standard configurations. An Argentinian steel mill operator commissioned Menzel Elektromotoren to build a special motor based on an existing motor having the type of construction IM 7311.

In order to future-proof and since this is a considerable investment, the old, still operational motor is to be stored as backup. Therefore, the new machine must replicate it in every detail, although, due to modern design techniques, Menzel implemented a performance increase at the customer’s request.

The new slip ring motor provides a nominal torque of 43,245Nm at 6,600V rated voltage and 1,345kW rated power. The format is unusual: at a total weight of 21.9 tons, the rotor alone weighs full 10.4 tons. Various accessories were installed, including HALL effect current transformers to measure the rotor current, customer-specified accelerometers on the bearings, and a level sensor for the electrolyte in the starter.

The motor features IP23 protection and IC 01 cooling (open-circuit ventilation). It has

LogiDataTech supplies innovative gas measurement systems for directly determining gas concentration in a gas mixture. The explosion-proof MF420Ex-2.1 range measures the concentration of toxic or combustible gases and vapours in an explosive air mixture at an ambient temperature range of 0-50°C. They operate by utilising either a pellistor or a specific electrochemical sensor.

Calibration is a simple procedure and is carried out on-site using an alphanumeric display with the use of buttons, so the device does not need to be opened. The aluminium housing is suitable for wall mounting. The measured values are outputted via a linear current output (4-20mA) and the evaluation and further processing of the measured values are transmitted to

a device connected downstream by the user. The instruments comply with the current European ATEX standard and are approved for operation in zones 1 and 2.

LogiDataTech GmbH T +49 7221 97062-0 sales@LogiData.Tech www.LogiDataTech.com

to withstand ambient temperatures up to 45°C in the rolling mill. The German, familyrun company counts special motors among its core business and also designed the starter in such a way that it caters for the new motor and the original one equally.

Before shipping, the motor underwent a complete type test with additional tests according to customer specifications, including partial discharge and dissipation factor measurement (tan δ). Menzel will also handle the mill drive commissioning, which the operator will schedule to suit production planning.

More information about customised motors: www.menzel-motors.com/modification

There is a common misconception that all breather valves are rigorously tested to a certain standard before they are sold, but unfortunately, this is definitely not the case. Many breather valves on the market are not subject to stringent testing protocols, leading to significant safety and operational risks. When these untested and, more importantly, unsafe breather valves are procured, the end user unknowingly takes on many risks.

It is crucial to know the facts by conducting thorough due diligence from the initial purchase and throughout the entire lifecycle of the unit. First, ask yourself: Are your breather valves set correctly?

Incorrect settings can lead to valve malfunction, causing potential overpressure or vacuum conditions that could compromise tank integrity. Are your breather valves performing safely? Regular testing ensures they function within safety parameters, preventing hazardous situations.

Do you know your breather valve leak rates, and is your media hazardous, flammable, costly or toxic? Understanding leak rates is vital for environmental, occupational health and safety compliance. Do they function as per intended design and specification, and do they meet the set point? This ensures that valves operate as required under specific conditions.

Has your breather valve been tested in accordance with API2000 Section 5.4? Compliance with this standard guarantees that valves meet industry requirements. Do you monitor your breather valves as part of your aging plant management plan? Regular monitoring can identify wear and tear before it leads to failures. Lastly, are you confident that all your breather valves maintain optimum efficiency and performance? Ensuring this can prevent costly downtime and environmental hazards.

The only irrefutable test method is using the Vent-Less test bench. This groundbreaking technology is revolutionising testing, ensuring that breather valves are tested prior to installation and during

Hansford Sensors is a leading global manufacturer of industrial vibration monitoring equipment. We design, develop and manufacture a range of high-performance industrial accelerometers, vibration sensors, 4-20mA transmitters, cable assemblies, industrial enclosures and ancillary equipment. These products can be used in a wide range of industries including petrochemical, metal, paper & recycling.

Visit hansfordsensors.com, contact 0845 680 1957 or email sales@hansfordsensors.com

the life term of the unit. The award-winning Vent-Less test bench aligns with the API2000 Section 5.4 test protocol, and the instantly generated certification stands up to regulatory scrutiny. The documented leak rate is also invaluable for LDAR, IED, and Regulation 61 reporting. These questions are critical for assessing your vulnerabilities and ensuring the safety and efficiency of your operations. Don’t leave it to chance – make sure your breather valves are thoroughly tested and maintained using the Vent-Less test bench.

Contact T +44 (0)1726 844707

info@assentech.co.uk www.assentech.co.uk

Maintec is the longest standing exhibition for the predictive maintenance, reliability and asset management industry, and Chris Hansford, Managing Director of Hansford Sensors Ltd, has been attending the show for almost 40 years.

As a globally recognised leader in industrial vibration monitoring, Hansford Sensors designs & manufactures a broad range of high-performance equipment. Its offerings include accelerometers, vibration sensors, 4-20mA transmitters, cable assemblies, and industrial enclosures. At Maintec 2024, Hansford Sensors highlighted key products like its Accelerometer Power Supply Modules and Vibration Sensors, showcasing its commitment to delivering reliable solutions for industrial applications.

As well as Vibration Systems and Switches, Hansford Sensors also offer a range of accessories for vibration monitoring that include DIN rail mounted monitoring and protection modules, vibration switches and charge amplifiers.

Vibration monitoring products are crucial in industry because they help detect early signs of machinery malfunction, such as misalignment, imbalance, or bearing failures. Hansford Sensors systems are ideal to support various outputs like AC acceleration and velocity, ensuring versatility in usage. Its products are designed for robustness with IP ratings suitable for harsh environments, making them ideal for industries such as manufacturing, power, and mining.

What’s more, Hansford Sensors also provide an online calculator designed to simplify your vibration analysis. From an input of acceleration, velocity or displacement the Vibration Calculator converts the amplitude and frequency into a range of engineering units to optimise analytical performance.

For more information on all products, or to use the calculator, please see below: T 0845 680 1957

sales@hansfordsensors.com https://hansfordsensors.com

Multi-award-winning CheckedSafe offers a complete digital cloud solutions package to fleet management across commercial fleet transport, public and private transport, emergency services and plant-hire vehicles. This effectively allows companies to monitor vehicle compliance across every vehicle in the UK and even while abroad. It costs as little as £1 per vehicle per week for a cost-effective paperless reporting system.

These multiple award-winning solutions have entirely digitised vehicle compliance, significantly streamlining the daily operations of both fleet drivers and management. Bus, HGV, Van, Car, Grey Fleet, Plant & Machinery (any commercial vehicle) drivers can download a handy app onto their mobile devices to use tailor-made vehicle checklists. The app even functions while in remote areas with no phone signals to enable checks to be completed on the move. This flexible, handy app is so easy to use: just check and go! The main office then receives each report allowing for a complete audit trail across the company. This seamless system makes sure that vehicles are Driver and Vehicle Standards (DVSA) compliant and automatically generates scheduling slots for vehicle ad-hoc repair as well as routine MOTs and servicing.

We caught up with Director & Co-Founder, Gary Hawthorne, to find out how CheckedSafe has fared over 2024, “We expanded our portfolio of compliance tools to include Driver Licencing Checks and GB Domestic Hours modules – these have all been successfully completed and launched. We are delighted to say that the GB Domestic Hours App is a market-first in the UK and was the result of intensive R&D. We created the algorithm around a complex set of rules that are currently managed by paper systems only.

“CheckedSafe is a compliance tech company cocreated by Darran Harris and myself ten years ago. Darran has over 20 years’ industry expertise as a Litigation Solicitor, specialising in road traffic issues and has worked as a solicitor with major logistics companies, successfully representing them at Public Enquiries. I have over 30 years as a Transport Professional, from, initially Driver, Manager, TFGM (was GMPTE), Central Government Owner/ Operator and as a DVSA Accredited Earned Recognition Auditor.

“Our unique joint partnership has thrived in the commercial fleet community, as we know our product inside out and why it’s required. We are happy to collaborate with other ‘professional companies’ and prefer to do so, rather than try to compete with established solutions. In fact, new tech collaboration with APIs is much easier now, so bringing together expert areas is a far better model than trying to split the atom alone.”

Commercial fleet compliance has historically remained heavily paper-based but the trend is now moving towards technology, especially with increased Grey Fleet ownership. CheckedSafe are the go-to experts in this domain and

support private employees and whole fleets manage compliance, as Gary continues, “Moving people from paper to technology ensures huge savings in time, paper and storage – all of which impact the environment. You can now effectively manage a 100strong vehicle fleet from your mobile phone, if you so wish (though a laptop is advisable, with secure back-office options). Therefore, there really is no need to store copious boxes of reports plus everything is received in ‘Realtime’ so any defects/issues can be resolved quickly. This reduces overall long-term costs and downtime as better repair planning can be achieved.”

“We are professionals in our respective industry not salespeople or tech people. We both have a passion for compliance facilitating change for the better. As an ex-Operator, I fully understand the issues at hand and as an Accredited Auditor, I know the challenges companies face daily. This has allowed us through CheckedSafe to develop our product base from an expert knowledge base. After designing our ideas on paper, we hand it over to our Tech Wizards to digitise those concepts. This ‘old school’ format allows us to really thrash out the ideas on paper first before committing to the tech stage.”

Looking ahead to next year and beyond, CheckedSafe is focused on building further on this year’s product line by tweaking existing products, providing add-ons to new products and back links to other areas of the platform. With growing client demand, CheckedSafe is looking forward to future collaborations.

“We have a very exciting project for early 2025 but are keeping tight-lipped for now. It will be a very exciting addition to our existing product portfolio. We take great pride in our customer-centric focus: developing off the basis of customer feedback. All requests are evaluated and then we develop and launch that feature for the whole CheckedSafe client base. We do not charge for this as we believe in sharing good practice and one idea may actually benefit many others.”

To find out more about CheckedSafe or to access the 30 day free trial, please visit the website below: T 01282 908429 info@checkedsafe.com www.checkedsafe.com

We are delighted to showcase Platelet Dispatch as our Emergency Courier Technology Company of the Month

Blood Bikers are a cornerstone for NHS Trusts across the country, transporting essential clinical products like blood, platelets, samples, donor milk and surgical instruments between healthcare units, hospitals and patients’ homes.

Keeping blood bikers moving

The Platelet Dispatch open-source dispatch system was the brainchild of Director Theo Cranmore and formally established in 2023 for the purpose of supporting blood bikes.

Platelet Dispatch is a dispatch system for real time, on demand pick-up and delivery of medical items and blood. It has in-built fleet management features, consignment history, and a locations directory. The system uses offline first design, with users able to seamlessly update consignment statuses, even in poor signal areas.

The serverless system is markedly more costeffective and provides high reliability, as Theo explains further, “We maintain the Platelet Dispatch open-source dispatch system and provide services centred around it. These include hosting, support,

training, and feature development. The app is published to Google Play and Apple App Store and connects to our hosted environment.

“Many users of Platelet Dispatch are only on the rota a few days a month, and they can be up and running quickly with an easy to use and intuitive interface.

“We regularly communicate with blood bike volunteers and involve them in testing and feature development. Each month around 1,200 consignments are recorded and completed by blood bikers using our app. Daily deliveries of blood to air ambulance bases across the country are also coordinated with the software.

“Moreover, there are no license fees to use Platelet Dispatch. Our offerings centre around services, and an open-source model keeps things simpler for everyone.”

Spotlight on the Platelet Dispatch system

Platelet Dispatch offers a streamlined digital alternative to traditional paper-based systems. Controllers work with the web interface to record requests and coordinate riders. Riders use the mobile app to update consignment status. The charities also benefit from better data security, and faster reporting and statistics gathering.

Some of the notable key features include:

t Real-time dashboard updates.

t Record inventory for each delivery. You can specify the items, count, and unit.

t Assign consignments to riders, and other controllers.

t Statistics and reporting features, with the ability

to export your data.

t Easy to use, modern, and responsive user interface that works on any screen size.

t Offline location directory and online address search.

t Mapping tools to see directions and distances.

t User comments and private notes.

Looking to the future

“Looking ahead to 2025, there is a long list of features we wish to add to Platelet Dispatch.

“Live tracking of vehicles, task scheduling, unit management that lets controllers assign consignments to teams, and better fleet management are just a few things being worked on or planned.

“Further beyond, we’d like to expand and create software for other use cases, putting together a suite of tools focussed on real time operations. In particular we are looking into making software for search and rescue, and drone delivery services.”

To access a demo today, click here: https://demo.platelet.app

For further enquiries and to find out more, contact the team directly on:

T +44 (0)141 674 7548 info@platelet.app www.platelet.app

Southern Manufacturing & Electronics, held at Farnborough International Exhibition Centre from 4-6 February 2025, is the most comprehensive annual industrial exhibition in the UK and a major pan-European showcase for new technology in machinery, production equipment, electronic production and assembly, tooling and components as well as subcontract services across an impressively wide range of industry.

Seize the opportunity to build meaningful connections with industry leaders, innovators, and peers. Engage in exclusive networking sessions designed to foster collaboration, share ideas, and create long-term partnerships.

Over the course of three days, you’ll meet engineers and manufacturers from OEMs, SMEs and startups, giving you the opportunity to develop new connections and share best practice.

Stay ahead of industry trends by attending insightful seminars from top experts. Gain practical knowledge that you can apply to improve efficiency, adopt new technologies, and enhance your competitive edge. Discover the free-to-attend, new and enhanced seminar programme, focusing on Engineering and Electronics technology, encompassing all industry sectors.

Experience the future of manufacturing and electronics first-hand with live demonstrations of cutting-edge tools, systems, and solutions that can revolutionise your operations. Seize this opportunity to see at first hand, the products, components and solutions you’re looking for, at the first event in the 2025 industrial calendar.

Connect face-to-face with over 500 world-class suppliers offering the latest industrial technology, products and services. Whether you’re sourcing new materials or seeking innovative solutions, you’ll find the partners you need to enrich your supply chain

NOTE is a leading Contract Electronics Manufacturer (CEM), highly proficient at building endto-end manufacturing solutions – turning visions into reality. With a history spanning over 40 years, NOTE has been synonymous with industry-leading printed circuit boards, PCBAs, box builds and final assemblies. The CEM has four sites across the UK: Windsor, Stonehouse, Haddenham, and Basildon, serving a loyal national customer base.

All customers are at the heart of all operations, with a focus on delivering ‘gold-standard’ manufacturing and the team are delighted to be exhibiting at Southern Manufacturing & Electronics at Farnborough International Exhibition Centre from the 4th-6th February 2025 (Stand D70).

across all sectors and industries.

The Southern Manufacturing & Electronics Show has a rich history steeped in tradition and innovation. Originating as a family-run exhibition, it has served as a cornerstone event in the manufacturing and electronics industry for decades.

Over the years, it has evolved and grown, attracting exhibitors and attendees from across the globe. In a testament to its success and relevance, the show has been acquired by Easyfairs, a leading organiser of events and exhibitions.

Despite this transition, the show remains deeply connected to its roots, continuing to work closely with the previous owners to preserve its legacy of excellence and dedication to the industry.

Since its inception as a regional event, Southern has grown into a significant national show, gaining popularity and influence both nationally and internationally.

www.southern-manufacturing-electronics.com

specifications for resounding success results.

NOTE offer the following solutions: a journey guaranteed to provide expertise every time: t Concept – idea: here ideas blossom into a feasible working design concept. Design: the in-house design service brings all the hallmarks of success with leading PCB knowledge and PCB manufacturing partners. The superlative prototyping service and Design for Manufacturer (DFM) assessments offer quality assurance time after time, while the New Product Introduction (NPI) processes promote clear drawings, data and

t Supply – Procurement: outsourcing material procurement to NOTE enables streamlined operations at every corner, with limitless benefits including reduced stock holding, enhanced cash flow, maximised warehouse space, access to expertise and much more – allowing companies to focus on strategic business goals.

t Prototyping – Looking to turn a prototype into volume manufacturing? NOTE has the industrial expertise to get your product into production, all with timely lead times, highquality and cost efficiency. Manufactuing: end-to-end manufacturing includes PCBA, cables,

electromechanical, full box build and more to get all products finished, tested, boxed and ready for dispatching.

t Support – Fulfilment: working in a truly bespoke manner, NOTE can deliver on everything from build to order, end customer shipping, customer consignment, managed warehousing and more.

t Logistics – Effective supply chain management guides market dominance accordingly, with an onus on high customer expectations. NOTE takes care of all inbound freighting, global shipping, to localised delivery, navigating the complexities of custom & excise. Customer service: NOTE provides professionalism and expertise at every juncture, with well-honed customer service for every project and scenario.

If your business is looking for end-to-end manufacturing solutions under one roof, trust NOTE to move your operations to the next level in 2025 and beyond.

Visit NOTE at Southern Manufacturing & Electronics: Farnborough International Exhibition Centre; 4th-6th February 2025 (Stand D70).

Find out more here: https://note-ems.co.uk

CHEMUK launched in 2019 and is now established as the UK’s largest trade show supporting the R&D, engineering, manufacture, and management of chemicals and formulated products.

The event will run in one giant hall at Birmingham’s NEC from 21-22 May 2025 and showcase over 550 specialist exhibitors across five show zones: the Chemicals Supply Show zone; the Chemical Management Show zone; the Process & Chemical Engineering Show zone; the Chemical Laboratory Show zone; and, new for 2025, the Formulated Product Manufacturer Show zone.

At the Chemicals Supply Show, attending R&D, product development, and supply chain teams will be able to meet with specialist chemical manufacturers and distributors supporting industry covering: Chemical Manufacturing; Food Ingredients; Lubricants & Metalworking; Homecare & Industrial Cleaning; Water Treatment; Pharmaceuticals; Agriculture; Coatings, Adhesives, Sealants & Elastomers; Beauty & Personal Care, plus many others.

The Chemicals Management Show zone will present specialist chemical supply chain organisations providing products, services & equipment in the areas of: Chemical Logistics & Transportation, Storage, Containment, Labelling and Packaging, HSE Management, REACH, and Regulatory Compliance, Waste Management & Recycling Services, Skills, Training & Recruitment and Business & Operational Support.

The Process & Chemical Engineering Show Zone will showcase the latest technology and specialist services to attending process, plant, and control engineering and safety professionals across the following sectors: Chemical, Food & Beverage, Pharma, Oil & Gas, Water & Waste, and Energy.

The Chemical Laboratory Show zone will showcase specialist laboratory chemicals and laboratory equipment suppliers supporting Research & Development, Analysis, Process Design & Development, Scale-Up, and Quality Testing within the chemical & chemical Product Industries covering: Adhesives & Sealants; Bio Chemicals, Materials & Fuels; Industrial

Chemicals; Specialty Chemicals; Pharmaceutical; Polymers & Performance Materials; Lubricants; Automotive; Composites; Solvents; Cosmetics & Personal Care; Agrochemicals; Surface Treatments/Paints etc, plus lots more.

The Formulated Product Manufacturer Show zone will present specialist contract service and industry partners providing: Specialist Ingredient Sourcing, Toll & Contract Manufacturing Services, Mixing & Blending, Bottling & Filling, Packing & Labelling, Logistics, Sample Management, White Label & Private Label Services, Aerosol & Dispensing Systems, Small Batch & Big Batch, Pilot Scale & Full Production run capabilities, Order Processing, Distribution Services, Coding & Barcoding and Custom Formulation services.

The CHEMUK 2-day speaker programme will host some 100+ expert speakers discussing the big challenges and opportunities affecting the UK’s chemical and chemical product industries.

www.chemicalukexpo.com

Recontainers Ltd specialises in the buying, selling and cleaning of empty hazardous and nonhazardous chemical conditions.

Established in 1991, the family-run business exhibited at CHEMUK 2024 for the first time to meet prospective new customers.

Located in the Chemical Supply Chain Show Zone, the Lancashire-based company showcased its products and services to visitors from the logistics & transportation, packaging & labelling and storage & containers sectors.

Recontainers Ltd buy and sell reconditioned IBCs (Intermediate Bulk Containers) in different specifications (grade, pallet, base and UN-certified and non-UN certified) and offers an IBC reconditioning (wash and return) service.

Health & Safety is a paramount concern for businesses needing to store and safely transport larger amounts of chemicals across the UK. IBC tanks have been a product of choice for many years due to the following benefits:

t Robust properties – IBCs are made of durable, galvanised

outer steel frames built to protect the inner polyethylene section.

t Space saving – IBCs are stackable due to its cubic shape

t Screw-cap lids –Allowing for easy filling, with a bottom outlet valve for emptying/ decanting.

t Easy transportation –IBCs can be lifted onto pallets using a FLT or pallet jack for seamless transportation (also quicker to load/off load than chemical drums)

t Waste efficiency – 1,000L of chemicals can be stored in larger IBC tanks, which is advantageous with regards to removing waste when discharging and draining the containers.

t Sustainable best practice – IBCs are fullyrecyclable containers, demonstrating excellent circular economy practice.

t Cross-sector usage – IBCs can be used to store and transport a wide range of liquids, pastes or solids. In farming and agriculture, they can be used for water irrigation/ collecting rain, fertiliser storage, with reconditioned ones ideal for storage solutions. On construction sites, they can store water for bulk cement mixing or dust suppression.

t Multi-purpose – IBCs can be used to store both UN chemicals (suitable for hazardous/

corrosive chemicals) or non-UN (nonhazardous chemicals)

Recontainers Ltd has an online shop facility for trade customers, with bulk orders possible by request. Three of the best-sellers include the following:

t Grade 1 Clear reconditioned 1,000L IBC on metal/plastic pallet (non-UN)

t IBC cover weatherproof & UV protection 1,000L

t Grade 2 Clear reconditioned 1,000L IBC on metal/plastic pallet (non-UN)

There is a large choice of IBC containers on offer, from grading (1 or 2), UN-approved or non-UN approved, to metal, plastic or wood pallet base. For customers unsure which container is best suited for their needs, Recontainers Ltd can offer full advice via email or telephone.

For more information, contact the team at Recontainers Ltd today: T 01706 211112

Recontainersltd@aol.com

https://recontainers.co.uk

Recontainers Ltd will return to CHEMUK 2025: 21-22 May 2025: NEC Birmingham.

Wieland Electric presents the latest generation of highly efficient safety light grids and safety light curtains.

The importance of occupational safety grows in modern industrial and logistical environments as machines and systems become more complicated. Against this backdrop, Wieland Electric introduces its next generation of safety light curtains and safety light grids, which complement the existing array of optoelectronic protection devices and are distinguished by a high level of safety, flexibility, and use.

The new SLG4 series safety light grids were designed for applications requiring dependable access protection over wide areas on machines or in production sites. While withstanding temperatures as high as 70°C, the light grids may be put into action swiftly thanks to their simple software configuration and plug-and-play installation. Clearly visible LEDs also enable immediate on-site diagnostics, reducing downtimes.

Furthermore, the durable aluminium housing and protection rating IP65/67 in accordance with EN 60529 ensure that the optoelectronic protective devices perform reliably even in adverse environmental situations.

The SLC4 series safety light curtains are perfect for protecting fingers and hands in the machine's danger zone. When the machine is used frequently, they cut access times compared to physical guards, increasing production. Advanced functionalities like muting ensure safe material flow and contribute to cost-effective material supply and removal.

Cascading two devices enables vertical access and horizontal presence monitoring in a single system.

The SLC4 safety light curtains, like the SLG4 safety light grids, have a simple software-free configuration and the ability to do quick on-site diagnostics. This improves productivity and safety in industrial applications.

www.wieland.co.uk

The oxygen sensor MFOxy-Comp has been specially developed for use in composting plants. The materials used meet the high requirements of this field of application. The measurement method is based on a dynamic process at two zirconium dioxide slices, which form a hermetically sealed chamber. The entire measuring range is linear.

During operation the sensor system monitors its own function and reports in case of hardware and sensor malfunction.

The calibration is done without reference gas in atmospheric air. The output of the measurement values takes place via an analog (420mA) and a digital channel, the latter transmits the error messages.

The oxygen sensor MF-OxyComp is designed for the measuring range 0.1 to 25 vol% oxygen and equipped with an analog interface with 4-20mA and has a digital output as well.

sales@logidatatech.com www.logidatatech.com

We all agree the ‘cradle to grave’ material traceability is the goal that we should all be aspiring to, but bale identification has not been reliable and has depended on inefficient manual processes.

Let us introduce you to the new, patented BALEiD by PAAL system, which is set to revolutionise traceability within the industry.

Let us allow you to shake off the limitations of manual process and bring you an efficient closed loop patented system. It is now possible to generate, print and attach a label to each bale automatically and securely.

Our initial challenge was to devise the process that would automatically and securely attach the label

to the bale. The patented PAAL applicator has achieved this and is linked to a label printer. With this set up it is possible to automatically generate, print and attach each label to a bale that shows whatever relevant information that is contained within the baler control system.

We appreciate a huge amount of work and effort goes into producing a bale and now for the first time BALEiD by PAAL enables the complete picture to be captured in a convenient label. Not only will this system capture the fundamentals such as date/time/location and material type, it can also track each bale individually for shipments.

Let us open up a world of opportunities for your waste management system, by attaching a label (containing a unique RFID chip) to each bale you would be able to automatically record, monitor and control your bale output with valuable information, for example:

t Date and location where the bale is produced

t Precise weight of bale

t Purity of material

t Storage location and shipment onto truck

By implementing the BALEiD by PAAL you can eliminate the rejection of material (by the end processor) which is hugely costly and disruptive, any

such risks are addressed prior to despatch.

The scanning of the RFID tags on the bales, the end processor receives, updates the RFID database. This results in the provision of evidence for the recycler that the material has been processed in a certain way, giving the necessary ‘cradle to grave’ traceability.

Our priorities are changing, driving today’s standards and business practices. Closed loop recycling is at the heart of today’s circular economy demonstrating a strong commitment to sustainability. Adhering to environmental regulations is crucial, closed loop recycling helps businesses stay compliant with waste management and sustainability regulations.

Let us take you to the next stage of waste management efficiency, let us maximise your potential with BALEiD by PAAL.

Contact www.kadantpaal.com

Industrial and commercial cleaning has faced a multitude of challenges post-Brexit with a record high of cleaning operator shortages since 2022. With increased demand across the sector, many companies are increasingly turning to the innovative world of robotic cleaning.

The future is here today. Autonomous Mobile Robots (AMR) are powered to clean narrow, hard to reach spaces, allowing staff to prioritise other tasks at hand. In large-scale warehouses and factories, these machines are designed with safety in mind, offering cordless cleaning and eliminating slip hazards in seconds.

Nimble robots

Introducing the next generation of robotic floor scrubbers from Tennant. In partnership with Brain Corp: advanced AI enabled intelligence, the geniuses at Tennant have invented world-class robotic cleaners. With optional ec-H20 NanoClean®, sustainable cleaning has arrived with nanobubble technology, reducing the amount of detergent and water needed.

The X4 ROVR Autonomous Floor Scrubber is the latest addition to the robotic cleaning machine family.

“Nimble is the best way to describe the X4 - with advanced manoeuvrability, this scrubber can easily clean those hard-to-reach spots, with a cleaning path of 500mm. The estimated coverage is up to 1,860m² (per solution tank), powered by lithium-Ion battery, heralding the renewable energy era. That’s a run time of approximately 2.5 hours and with a sound level as low as 62dBA, the hearing of workers is protected. Designed with the end-user in mind, the X4 can be programmed quickly with as little as three steps on the intuitive touch screen. Tennant understands the pain points of the industry and the X4 has programmable colour-coded maintenance: yellow for daily and blue for monthly maintenance tasks,” explains Jamie Harris, Head of Industrial Sales UK & Ireland, Tennant UK.

History of expertise

Multi-award-winning Tennant Company was established over 150 years in 1870 by George H Tennant, who after selling wooden flooring realised there were no cleaning products available. Not to be defeated, he simply invented floor polish and the company grew from there. In 1932, the first motorised floor cleaning equipment came to market and by 1947, the first vacuum-equipped power sweeper arrived in the industrial sector. What

followed over successive decades was a series of world and industry-firsts, marking Tennant as a global leader in innovation and R&D.

The full-range includes: scrubber-dryers, sweepers, sweeper scrubbers, extractors and vacuums across a diverse range of sectors from healthcare, retail, industrial to commercial. Alongside the nimble X4 ROVR, Tennant also offers the T16AMR, the worlds-first robotic cleaning machine designed for industrial and manufacturing facilities.

Solid UK presence

scrubbing at every wet or dry turn with FloorSmart® integrated cleaning system technology. The ec-H20™ technology offers smooth delivery, with up to 70% less water used.

Tennant UK has been operational for over thirty years with a Northampton office and service centre in Bolton. With a lion’s share of the market, Tennant’s products can be found across 98% of the UK market from large supermarkets to purpose-built facilities. Jamie Harris oversees the industrial division, with the aggregate sector for example favouring Tennant machinery to reduce silica dust exposure across factories. Silica dust is a huge health & safety challenge and relies heavily on optimised cleaning practices to reach OSHA compliance. With cutting edge HEPA-filtration approved systems, Tennant is proud to be supporting cleaner, healthier workplaces across the UK.

“We have many go-products such as the 800 Industrial Ride-on Sweeper and multi-functional M30 Ride-on Sweeper Scrubber. The 800 is top of the class, with wide cleaning path, quad filtering system and robust steel construction, this sweeper can handle heavy-duty cleaning indoors and outdoors. Precision-designed for the harshest environments, it can capture cement dust, pellets, rocks and grass, leaving a clean path in its wake. The M30 Ride-on Sweeper Scrubber offers optimised sweeping and

“If you’re looking to have a return-on-investment, we can offer world-class services and products as an asset not expense. We offer sustainable best practices for a greener era: our products provide cleaner working conditions for staff, with less chemicals and airborne gases and dust.

“We have an expert team of over 60 field service engineers to support repair and maintenance round the clock and with our world-leading Autonomous Mobile Robots, Tennant is trailblazing the age of robotics.”

See the X4 ROVR Autonomous Floor Scrubber in action at IWLEX 2025 and Hillhead 2026.

To find out more today, contact Tennant UK below: Customer Service 01604 583191 www.tennantco.com/en_gb.html

Specialist hygiene solution provider Christeyns Food Hygiene has recently announced the purchase of hygiene equipment application specialists H&M Disinfection Systems Ltd

operate with all staff in place, the threeyear site lease having been transferred to CFH.

Christeyns Food Hygiene is highly regarded in the industry for its effective formulations of detergents and disinfectants for all applications in the food, dairy and beverage industries with customers from across a range of household consumer brands and suppliers to the UK’s food retailers. It is part of Belgium parent company, Christeyns NV.

Warrington based Christeyns Food Hygiene (CFH) has acquired H&M Disinfection Systems Ltd, who design, manufacture and install cleaning and disinfection systems for the Food, Dairy and Beverage industries.

In operation since 1989, H&M’s modern manufacturing site near Northwich manufactures high quality pump sets, control panels and hygiene systems as well as bespoke units built to individual requirements. With over 30 years of experience in their respective fields the two firms have been partners for many years, providing a turn-key solution for effective cleaning and disinfection operations. The acquisition will see the H&M facility continue to

“As we continue our growth strategy, we are delighted to confirm that H&M has become part of the Christeyns family. This acquisition will increase CFH’s engineering team and significantly bolster our service offering to clients across the UK and Eire,” commented CFH Operations Director & Managing Director, Andy Bethel.

of water, energy consumption, dosing, time and labour will be further strengthened, combining both chemical and engineering expertise including an expanded equipment portfolio, CIP sets, Washdown Systems, Bulk tanks and bespoke engineering.

“We regard H&M as an expert in its field, with a reputation for providing high quality, bespoke hygiene application equipment, the cornerstone of many customer’s food safety management systems. Already working with us as a partner, this was a natural move forward and will ensure a broader, highly enhanced service and health and safety offering for all our customers.”

The current CFH engineering offering for the optimisation

Maintaining a safety shower is crucial for ensuring its optimal performance and effectiveness during emergency situations. Here are several reasons why maintaining a safety shower is essential:

1) Reliable Emergency Response

Regular maintenance ensures that the safety shower is in proper working condition and ready to be used when needed. By conducting routine inspections and maintenance activities such as testing water flow, checking water temperature, adjusting controls, and inspecting valves, any potential issues or malfunctions can be identified and addressed promptly, ensuring that the safety shower will function reliably during an emergency.

2) Employee Safety

The primary purpose of a safety shower is to provide immediate decontamination in case of exposure to hazardous substances. Regular maintenance helps ensure that the safety shower delivers the appropriate water flow rate, temperature, and coverage necessary for effective decontamination.

3) Compliance with Regulations

Safety showers are often subject to regulatory requirements and standards that specify their maintenance and inspection. By adhering to these regulations, organizations demonstrate their commitment to compliance and workplace safety.

4) Extended Lifespan

Proper maintenance and care can significantly extend the lifespan of a safety shower. By promptly addressing any

issues, replacing worn-out components, and conducting regular cleaning, you can prevent major breakdowns and costly repairs.

5) Reputation and Employee confidence

Demonstrating a commitment to maintaining safety showers indicates a strong safety culture within an organization. Regular maintenance instils employee confidence in the workplace safety measures and shows that their wellbeing is a top priority.

Conclusion

Maintaining a safety shower is essential for its reliable performance, employee safety, regulatory compliance, and overall operational readiness. Regular maintenance and inspections help identify and address any issues promptly, ensuring that the safety shower is always ready for use during emergencies.

For more information on service and maintenance, please contact Aqua Safety Showers on: +44 (0)1942 318096 or sales@aqua-safety.com

“We hope this will be a pivotal move for CFH with new opportunities for the original H&M team and a further blending of skills and experience creating a stronger engineering division overall,” concludes Bethel.

T +44 (0)1274 393286 enquiry.uk@christeyns.com www.christeyns.com/uk-en www.hmdis.co.uk

INDUSTRIES has launched a series of new ‘pull-down’ soap and paper towel dispensers, which represent the latest additions to its ‘Classic Behindthe-Mirror’ range.

The new units include a touch-free 2-litre soap dispenser and large capacity paper towel dispenser. They are designed to operate from behind a mirror or panel and are intended principally for incorporation into bespoke cabinets.

The distinctive ‘pull down’ feature of the new products supports easy replenishment; the new units feature lockable sliding cartridges. They drop down below the bottom of the cabinet, providing easy access to the soap and paper towel containers. Once refilled, they can be raised back and locked in place to protect the consumables from tampering.

In this respect, they differ from many other cabinet systems, which typically require the front-facing mirror to be opened outward like a door.

All the dispensers in the range are designed to be easy to install. They require an aperture to be cut into the cabinet’s base; the dispenser is then inserted and screwed into position. Detailed technical data and installation guides are available.

Supported by a 10 year warranty, all the products in the range have been designed by our team and are manufactured at our production facility in Lytham, Lancashire.

Specification details for the new Behindthe-Mirror dispensers are available at NBS Source and bimobject.com

For more information, please visit: www.dudleyindustries.com

In this issue of Industry Update, we are pleased to feature Beyondly Global Ltd as our Environmental Consultancy of the Month

Beyondly is a B Corp environmental compliance scheme and consultancy that helps businesses to become more confident about their environmental choices. Whether you’re looking for help with meeting compliance obligations, managing environmental data, or achieving sustainability expectations of your stakeholders, Beyondly endeavour to be the root of action, acting as your environmental partner to navigate environmental change. At the heart of Beyondly is you.

Based in Skipton, North Yorkshire, Beyondly works with product-based brand owners across the UK and internationally in the retail, food & drink, toy, beauty, and manufacturing sectors.

positively impact society and the environment, states Cherry Whittaker, Marketing Manager.

Beyondly’s service offering includes:

“From compliance obligations, to contributing to a circular economy, and going beyond net zero, our company purpose is to lead, inspire and educate to

t Packaging EPR Compliance, t WEEE and Batteries Compliance,

t International Compliance, t Streamlined Energy and Carbon Reporting (SECR),

t Energy Savings Opportunity Scheme (ESOS),

t Plastic Packaging Tax Data Management,

t Packaging Data Management, t Environmental, Social, Governance (ESG), t Carbon Management,

t Zero Waste to Landfill Certification and Training, t Life-Cycle Assessment, t B Corp Consultancy and Training, t Net Zero Training.

One key factor that differentiates Beyondly, is its unique offering of a full circle environmental solution from compliance to sustainability, all under one roof.

“None of our competitors offer the full breadth of services we do, so we can support businesses with all of their environmental goals. Beyondly is a customer-focused business and was founded to provide a customer-centric service. Underpinning this, we are the only company in our sector who has held the Cabinet Office’s Customer Service Excellence Standard since 2014,” adds Cherry.

Beyondly will have the option to utilise this new service to improve and automate EPR data collection, storage and categorisation,” adds Cherry.

Already trusted by 1,845 members, Beyondly’s complete data management package includes services like Data Gathering, Obligation Calculations, Data Insights, and Nation Data.

Back in 2023, beyondly rebranded from its previous name Comply Direct. This past year has been gamechanging for the company, seeing its sustainability offerings expand beyond belief. The new name was chosen to better reflect these offers, and it has so far proven effective in helping ensure customers needs are developed further and met quicker.

Beyondly’s comprehensive, bespoke data management service is more than 10 years established. Over this time, Beyondly has assisted hundreds of organisations with their own tailored approach. This service essentially enables companies obligated under Extended Producer Responsibility (EPR), to save resource and ensure an accurate data submission to the regulator. For 2025, Beyondly has revamped this service to now include more features.

“It is a significantly enhanced data management service. In 2025, packaging producers joining

As the new year begins, we asked Cherry what the company’s plans are going forward.

“We have a roadmap to 2030 with a set of company objectives across the 3 principles of B Corp – People, Planet and Performance. This represents company growth across customer base and employees, as well as environmental and social impact commitments.”

Beyondly is exhibiting at the upcoming Packaging Innovations and Empack event in February 12-13th 2025. Visitors can find Beyondly at Stand: C74 where their team of experts will be available to discuss the latest challenges and opportunities in Extended Producer Responsibility (EPR) for Packaging. Click here to register today for your free place.

www.beyond.ly

The safe laser scanner UAM-05LP offers maximum vewrsatility for safe area monitoring