Edgar O. Oviedo-Rondón

Edgar O. Oviedo-Rondón

For the September 2025 edition, Máire Burnett, Technical Director of the British Poultry Council, tells us that Biosecurity is more than just a disease safeguard; it is the foundation of a resilient and sustainable poultry meat sector.

We invite you to read the interesting article by Dr. Faran Hameed and Dr. Hamid Jawad, entitled Asian poultry industry shows rising sustainability consciousness, but challenges remain.

We will also see the interesting vision of Renata Steffen, Hatchery & Incubation Specialist: The hatch window will always be a challenge for all hatcheries, as it involves many variables from the farm to the hatchery.

Dr. Norma L. Calderón and Dr. Leopoldo H. Paasch, from Faculty of Veterinary Medicine and Zootechnics, UNAM, present us in their article The importance of Marek’s Disease and Lymphoid Leukosis in family and backyard poultry farming – Part I, the general aspects of these important poultry diseases. Dr. Ricardo Rauber, Animal Health Consultant, explains to us how biosecurity is a key component in Poultry production without antibiotic growth promoters in feed.

Once again, we are pleased to include the insightful work of Dr. Edgar O. Oviedo-Rondón in our magazine with his article Applications of Bioelectrical Impedance in poultry production. Here, he explains about bioelectrical impedance analysis (BIA), a promising technology that soon could be applied at commercial level to enhance our ability to understand development of birds, health status, and egg traits.

On the other hand, Dr. Sandeep Gupta, Ph. D. Animal Nutrition, Founder LSDA in India, in his article Livestock Scientific Development Association: a true environment-controlled research facility for poultry shows us that the continuous research, the use of innovative technologies as well as a fruitful breeding program are the pillars of modern-day poultry industry.

Elena Myhre, Director of Marketing and Communications IPWA and US-RSPE tell us a little bit about Advancing global poultry welfare: the role of IPWA in science, innovation, and education.

Dr. Oviedo delights us with another article, Implementing dynamic feed formulation and precision nutrition in poultry production, where he states that feed formulation should always consider the nutrient content of ingredients and the nutrient needs of animals based on the target growth or egg production rate to maximize profit, depending on market demands and economic conditions.

Closing this excellent edition, Maria Catalina Tan de Luna DVM, assistant professor (Institute of Animal Science, College of Agriculture and Food Science, University of the PhilippinesLos Baños), teaches us about Asia’s cage free journey: industry perspectives on evolving egg systems.

Enjoy reading it!

GRUPO DE COMUNICACIÓN AGRINEWS SL

ADVERTISING

Luis Carrasco +34 605 09 05 13 lc@agrinews.es

Miguel Martín Tamayo +34 664 660 603 sales@grupoagrinews.com

Nicole Carletti Ramírez +57 312 391 9330 avinewslatam@grupoagrinews.com

CUSTOMER SUPPORT

Mercé Soler

EDITORIAL STAFF

José Luis Valls

María de los Angeles Gutiérrez

Nicole Carletti Ramírez Héctor David Corredor Martínez

TECHNICAL DIRECTION

Edgar Oviedo

Eduardo Cervantes

Biosecurity as a Cornerstone of UK Food Security

Máire Burnett Technical Director of the British Poultry Council

Biosecurity is not just a safeguard against disease challenge. It is a cornerstone of our food security, and therefore sustainable poultry meat production.

Asian Poultry Industry Shows Rising Sustainability Consciousness, but Challenges Remain

Dr Faran Hameed

Dr Hamid Jawad2

1Senior Consultant (Animal Production & Feed Business)

2Technical Sales Manager (SAFA Agrifood Marketing)

Sustainability fundamentally involves the responsible use of resources to guarantee their availability for both current and future generations.

hatch

Renata Steffen Hatchery & Incubation Specialist

A Modern Approach to Infectious Bronchitis Control in Poultry

Ceva Technical Team

Infectious Bronchitis (IB) remains a major concern in the poultry industry due to its economic and health implications.

The Importance of Marek’s Disease and 36

Poultry Production Without Antibiotic Growth Promoters in Feed

Dr. Ricardo Rauber Animal Health Consultant

Biosecurity is a key component for the success of programs to replace antibiotic growth promoters (AGPs) in poultry farming.

Advancing Global Poultry Welfare: The Role of IPWA in Science, Innovation, and Education

Elena Myhre Director of Marketing and Communications IPWA and US-RSPE

The International Poultry Welfare Alliance (IPWA) serves as an independent resource committed to the continuous advancement of poultry welfare on a global scale.

Poultry production can gain more precision and consequently productivity by measuring body, meat, or egg composition affected by diverse factors. Applications of Bioelectrical Impedance in Poultry Production

Edgar O. Oviedo-Rondón Prestage Department of Poultry Science, North Carolina State University. Raleigh, NC

Dr. Sandeep Gupta

Ph. D. Animal Nutrition, Founder LSDA, India Livestock Scientific Development Association: A True Environment Controlled Research Facility for Poultry

The continuous research, use of innovative technologies as well as fruitful breeding program are the pillars of modern-day poultry industry.

Implementing Dynamic Feed Formulation and Precision Nutrition in Poultry Production

Edgar O. Oviedo-Rondón Prestage Department of Poultry Science, North Carolina State University. Raleigh, NC

Feed formulation should always consider the nutrient content of ingredients and the nutrient needs of animals based on the target growth or egg production rate to maximize profit, depending on market demands and economic conditions.

Asia’s Cage Free Journey: Industry Perspectives on Evolving Egg Production Systems

Maria Catalina Tan de Luna DVM

Assistant Professor (Institute of Animal Science, College of Agriculture and Food Science, University of the Philippines-Los Baños)

Increasing concerns about animal welfare and a rising consumer demand for cage-free eggs are driving interest in alternative farming systems in Asia.

Oviedo

Máire Burnett

Technical Director of the British Poultry Council

Biosecurity is not just a safeguard against disease challenge. It is a cornerstone of our food security, and therefore sustainable poultry meat production.

The effectiveness of our biosecurity determines our ability to maintain a stable and safe food supply chain. However, its effectiveness is only as strong as its weakest link.

Despite a clear understanding of the risks associated with highly pathogenic avian influenza, we find that weaknesses in biosecurity often stem from lapses in routine as opposed to a lack of awareness.

Addressing such behaviour requires a shift in mindset, investment in infrastructure, and a commitment to industry-wide collaboration – between Government, commercial businesses, and small backyard keepers.

Independent research in the UK shows that the most common biosecurity failings on our poultry farms are underpinned by human error and inconsistent adherence to protocols, combined with poor or old infrastructure.

The UK Poultry Health and Welfare Group, made up of representatives from UK poultry and game associations, in collaboration with the Animal and Plant Health Agency, has developed a photobook that visually contrasts good and poor biosecurity practices.

We wanted to create a resource that enables farmers and farm managers to identify areas for improvement, and the photobook is a useful tool to show how minor oversights—such as leaky roofs, improper foot dip usage, or exposed bedding—can create pathways for disease.

Additionally, the British Poultry Council’s biosecurity poster highlights key areas for improvement.

Designed to foster opportunities for learning and better compliance, the ‘checklist’ format provides a clear, actionable framework to assess on-site practices.

By breaking biosecurity down into simple, manageable steps, the poster reinforces key behaviours and controlled movements of people and equipment to turn best practice into routine habits.

While the Animal and Plant Health Agency has reported an improvement in biosecurity standards this avian influenza season in comparison to previous years, we believe that continual vigilance is necessary.

Embedding a culture of proactive biosecurity, where best practices are habitual rather than reactive, is essential for the industry’s long-term resilience.

Too often, biosecurity is viewed as an administrative burden rather than an operational necessity. We believe that in order for biosecurity to be truly effective, it must become second nature to those working within poultry production, be that farm managers, farm workers, delivery and collection services, or tradespeople.

Transforming perception begins with making biosecurity an integral part of daily routines.

The photobook created by the UK Poultry Health and Welfare Group and the Animal and Plant Health Agency serves as a critical educational tool for those working in commercial poultry.

It offers practical, real-world examples that show how small but consistent actions contribute to overall farm resilience.

There is only so much we can do as the British Poultry Council in driving behavioural change.

What we can do, in collaboration with other industry bodies, is create a forum for knowledge-sharing and open discussion.

Peer learning can reinforce good practices, shifting biosecurity to an instinctive responsibility and a shared duty rather than an individual obligation.

British Poultry Council member businesses understand that biosecurity is not about ticking boxes but about protecting their flocks and businesses. In this way it is easier to embed biosecurity into the culture of their operations, ensuring it becomes second nature and ingrained into every aspect of poultry meat production.

Disease prevention is not only a matter of welfare but one of economic success. A single outbreak of avian influenza can have a devastating impact on the farm owner, their staff, and families, as well as financial consequences. This makes proactive biosecurity measures a strategic necessity.

In British poultry meat production, we perceive biosecurity as less of an isolated cost and more a fundamental investment in the stability and long-term success of businesses.

The return on investment is clear.

Improved biosecurity reduces the risk of both endemic and exotic disease outbreaks.

It ensures healthier flocks, and enhanced productivity.

To ensure farmers recognise the value of investing in biosecurity, it must be framed as an integral component of broader farm operations. When biosecurity is embedded within an overall resilience strategy, rather than treated as a standalone expense, it strengthens the ability to withstand disease challenges.

Building resilience against future disease threats requires industry-wide collaboration. A study conducted as part of the Flumap project by the University of Cambridge found that farmers could benefit from additional guidance on disease transmission and biosecurity adaptation.

Therefore, a newly formed Government Poultry Biosecurity Group is taking proactive steps to address these gaps with a co-designed biosecurity programme. The British Poultry Council sits on this group.

We believe that a connected approach improves communication, and this is something we want to see improved across the entire supply chain.

Smallholders, as well as large-scale producers, play a crucial role in disease prevention.

Establishing a centralised network via the new Government Poultry Biosecurity Group could help facilitate structured, ongoing knowledge-sharing to reinforce biosecurity as a joint effort that protects the entire sector.

By fostering this level of collaboration, this programme has the potential to strengthen collective efforts, reduce disease risk, and enhance productivity.

We are optimistic and look forward to feeding into the group as it begins to take shape.

Advancements in biosecurity and disease management present new opportunities for improving resilience. Digital tools, real-time disease tracking, and early warning systems can help producers detect potential issues faster, enabling rapid response and reducing the spread of infection.

We are working with livestock protection solutions provider, Livetec Systems, to help our members embrace the latest biosecurity services for proactive disease management.

We want to evolve our approach to efficient and compliant disease prevention with data-informed decision-making.

Our work with Livetec Systems ensures that we can streamline operational efficiencies across farms and empower our members with the tools and expertise to stay ahead of the curve in

The UK is widely recognised for its strong approach to biosecurity and disease control. The absence of lateral spread of highly pathogenic avian influenza in the UK suggests that our current biosecurity efforts, and early reporting of disease, are effective in preventing large-scale outbreaks, as well as the rapid response from government to stamp out disease.

While there is always room for improvement, we are proud of the commitment and vigilance shown by our producers in upholding high biosecurity standards, even in the face of ongoing challenges.

Refining our systems to balance stringent protocols with practical implementation

Through forums such as the International Poultry Council, the British Poultry Council is actively engaging with global partners and equivalents on issues

Comparative studies on biosecurity enforcement and disease prevention offer valuable insights for all nations and organisations involved.

Meaningful cross-border collaboration ensures continuous improvement in biosecurity standards worldwide.

Biosecurity is more than just a disease safeguard. It is the foundation of a resilient and sustainable poultry meat sector. As we learn to live with highly pathogenic avian influenza, it is evident that the strength of our biosecurity efforts determines the stability of our production which, in turn, underpins our broader food security.

However, its strength depends on continuous vigilance and improvement, as even small lapses can lead to significant risk.

To build long-term resilience, we must shift our perspective from reactive to proactive. This requires addressing human error, investing in infrastructure, and fostering collaboration across the industry.

By embedding biosecurity into daily routines and making it a shared responsibility, we reduce the risk of disease outbreaks and enhance farm productivity.

Biosecurity is an investment, not a cost. It safeguards our birds and ensures our productivity as an industry that is feeding the nation. Through collaboration and innovation, we can strengthen our biosecurity and secure a sustainable poultry meat sector well into the future.

Biosecurity as a Cornerstone of UK Food Security DOWNLOAD PDF

Dr Faran Hameed, Senior Consultant (Animal Production & Feed Business)

Dr Hamid Jawad, Technical Sales Manager (SAFA Agrifood Marketing)

Sustainability fundamentally involves the responsible use of resources to guarantee their availability for both current and future generations.

It focuses on achieving harmony among environmental preservation, economic growth, and social welfare. This entails making decisions that do not exhaust resources or damage the environment, facilitating ongoing usage over time.

Asia is the largest in the world by both land area and population. It covers an area of more than 44 million square kilometers, about 30% of Earth’s total land area and home to 4.7 billion people constitute roughly 60% of the world’s population.

The Asian poultry industry is a significant and rapidly growing sector, with Asia accounting for nearly 40% of global poultry production, driven by population growth, rising incomes, and shifting dietary preferences towards protein-rich foods.

China is the largest producer of chicken meat in Asia, followed by countries like Indonesia and India, with the industry encompassing both large-scale commercial operations and extensive smallholder and village-level poultry farming.

The poultry industry in Asia, which is essential for regional food security and economic growth, finds itself at a pivotal moment.

The surge in population, urban development, and higher income levels have created an extraordinary demand for poultry products, positioning Asia as the leading continent in both poultry production and consumption worldwide. This significant growth, crucial for both nutrition and economic stability, has highlighted the urgent need for sustainability.

As we look ahead, the future success of this vibrant sector will depend on its ability to reconcile economic growth with environmental care and social accountability.

According to the UN Sustainable Development & Climate Targets report, Asia Pacific is falling behind on several goals among 17 sustainable development goals (SGDs) including:

Responsible consumption and production (Goal 12), quality education (Goal 4) and decent work and economic growth (Goal 8) are severely off track.

Of most concern, climate action (Goal 13) witnessed an ‘alarming regression’, driven by the region’s vulnerability to disasters and continued greenhouse gas (GHG) emissions, which account for half of global pollution.

Environmental sustainability remained a major roadblock, with land degradation and declining economic benefits from sustainable fisheries hampering progress on life below water (Goal 14) and life on land (Goal 15).

While data availability has improved slightly, with some 54% of indicators now having at least two data points – a slight increase from the previous year - there are still significant blind spots in measuring progress across different population groups, including by age, migratory status, disability, and gender.

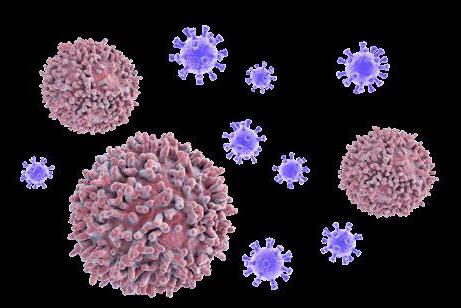

Antimicrobial-resistant organisms.

Flows to agriculture sector (LDCs).

Currently, official SDGs data is available to measure progress on 117 of the 169 targets across 17 goals, while data remain insufficient to measure the remaining 52 targets. Among the measurable targets, 14% (16 targets) are on track to be achieved by 2030.

Among the remaining measurable targets, 71% (83 targets) require accelerated progress to meet the 2030 targets, and the remaining 15% (18 targets) show a negative trend and need urgent reversal.

According to World Economic Forum report, 4 in 5 consumers in the Asean region value environmental sustainability and have made ecofriendly lifestyle changes. Sustainability is one of the biggest business opportunities today.

According to Kantar report, 58% of Asian consumers are willing to invest time and money supporting companies that do good, and in fact 63% are already factoring in sustainability concerns, at least once in a while, when making purchase decisions.

The present condition of sustainability in Asia’s poultry sector reveals a complex situation, marked by noteworthy progress along with ongoing hurdles.

Traditionally, the swift growth of poultry production often emphasized quantity at the expense of environmental considerations.

Nevertheless, a rising consciousness, changing consumer preferences, and stricter regulations are driving the sector toward more sustainable methods.

Numerous large-scale integrators and forward-thinking farms are incorporating modern farming technologies such as climate-controlled environments, automated feeding mechanisms, and enhanced waste management systems. These technologies lead to improved resource efficiency, lower emissions, and better animal welfare.

For example, the implementation of precision feeding methods reduces feed waste, a crucial economic and environmental issue. The installation of energy-efficient ventilation systems and LED lighting in poultry facilities cuts down on electricity use. Additionally, there is an increasing interest in renewable energy options like solar power for farming operations, especially in nations with plentiful sunlight.

Regarding waste management, many farms are progressing beyond basic disposal practices. There have been advancements in handling manure, with some transforming poultry litter into organic fertilizers, compost, or even biogas through anaerobic digestion. This not only helps lessen pollution but also generates valuable by-products, supporting a circular economy approach.

In terms of animal welfare, while obstacles persist, there is a growing acknowledgment of its significance. This awareness is often influenced by international standards and consumer expectations in more developed Asian markets.

Certain producers are making investments in larger cage-free environments for laying hens or enhancing stocking densities and enrichment for broilers.

However, these improvements are not evenly spread across the region. A considerable segment of the industry continues to function under traditional, less effective, and potentially more polluting practices, particularly in developing nations where smallholder farms are common.

Water usage continues to be excessive in many regions, and the dependence on imported feed, especially soybeans, contributes to deforestation elsewhere and raises the carbon footprint of the industry.

Although the widespread application of antibiotics for growth enhancement or routine disease prevention is declining in some areas due to global influences, it still presents a significant sustainability challenge due to the potential for antimicrobial resistance.

The path toward achieving full sustainability in the Asian poultry sector is laden with numerous interrelated challenges:

GHG emissions: The sector contributes to GHG emissions mainly through enteric fermentation (although it is less significant than in ruminants, it still plays a role), manure decomposition (producing nitrous oxide and methane), and energy usage in farming operations.

The carbon footprint linked to feed production, particularly soy farming in remote areas, is also considerable.

Water scarcity and pollution: Poultry farming necessitates a considerable amount of water for drinking, cooling, and sanitation. In regions facing water shortages, this creates competition with other industries.

If wastewater and runoff from farms are not adequately managed, they can pollute local water sources with nutrients (nitrogen, phosphorus), resulting in eutrophication, and potentially introducing pathogens.

Land use change: The growth of poultry farming, especially integrated systems, can result in land conversion that affects biodiversity and ecosystems. The need for feed crops such as corn and soy also drives global land use shifts.

Waste management: The substantial quantities of poultry litter, dead birds, and hatchery waste require proper management to avoid issues such as odor, pathogen spread, and environmental contamination. Insufficient disposal practices may result in soil and water pollution.

The extensive and often unregulated use of antibiotics in poultry operations, whether for growth enhancement or preventive measures, is a significant factor contributing to AMR.

This creates a serious global public health risk, making vital medicines for humans and animals ineffective. Although many nations are phasing out antibiotic growth promoters (AGPs),

Asia’s dependency on imported feed ingredients (such as soybean meal and corn) makes the industry vulnerable to fluctuations in global prices and disruptions in supply chains.

This not only affects profitability but also raises sustainability issues concerning the environmental impact of distant agricultural production and logistics. Additionally, the sustainability of sourcing methods for these ingredients (e.g., soy linked to deforestation) is increasingly concerning.

As consumer awareness and ethical considerations increase, traditional intensive farming practices are under greater scrutiny. Concerns about high animal stocking densities, insufficient environmental enrichment, and certain culling techniques raise ethical questions.

Adopting higher animal welfare standards often incurs extra expenses, which can be a challenge for producers, especially in cost-sensitive markets.

Environmental solutions:

Smallholder integration: A notable percentage of poultry production in Asia is attributed to small and mediumsized farms. Integrating these farms into sustainable supply chains, and providing them with access to modern technology, financing, and training, poses a complex social challenge.

Disease outbreaks: Avian influenza (AI) and other diseases consistently threaten the industry, leading to widespread culling, financial losses for farmers, and disruptions in supply chains. Biosecurity lapses, frequently associated with traditional practices, exacerbate these threats.

Labor practices: Ensuring fair labor conditions, safe work environments, and equitable wages throughout the poultry value chain, from farms to processing facilities, presents a challenge for social sustainability.

Addressing these issues necessitates a comprehensive and cooperative strategy that engages governments, industries, academic institutions, and consumers.

CIRCULAR ECONOMY APPROACHES:

Management and valorization of manure: Transforming poultry litter into useful products such as organic fertilizers, biogas (renewable energy), or biochar. This process minimizes waste, reduces emissions, and generates new income sources. Technologies such as anaerobic digestion or composting play a crucial role.

Wastewater treatment and reuse: Employing sophisticated wastewater treatment technologies in processing facilities to facilitate water recycling, which considerably cuts down on freshwater usage and prevents pollutant discharge.

Adoption of renewable energy: Committing resources to solar energy, biomass energy (from poultry litter), or wind energy to decrease dependence on fossil fuels for farming activities, ventilation, heating, and processing.

Precision agriculture and smart farming: Leveraging IoT sensors, AI, and data analytics for accurate feed management, environmental control (temperature, humidity, ventilation), and water usage, resulting in more efficient resource use and reduced waste.

Conservation of biodiversity: Encouraging the responsible sourcing of feed ingredients (e.g., certified sustainable soy) and supporting local biodiversity initiatives near farms.

ALTERNATIVE FEED INGREDIENTS:

Investigating and utilizing innovative, locally obtained, and sustainable feed components. This involves:

Insect protein (e.g., larvae from black soldier fly): A highly sustainable, nutrient-packed option that can thrive on organic waste.

Algae: A fast-growing alternative rich in protein and omega-3 fatty acids.

Valorization of food waste: Converting appropriate food waste into animal feed.

By-products: More effective use of by-products from other agricultural industries.

IMPROVED FEED EFFICIENCY:

Ongoing advancements in genetics and nutritional science to achieve even lower feed conversion ratios (FCRs). Utilizing enzymes (e.g., phytase, carbohydrase) to enhance nutrient digestibility, thereby reducing the dependence on expensive ingredients and limiting nutrient discharge.

OPTIMIZED HOUSING AND VENTILATION:

Crafting climate-controlled housing solutions that regulate temperature and humidity, leading to decreased energy use for heating and cooling while promoting bird welfare.

RESPONSIBLE USE OF ANTIMICROBIALS (AMU) AND ALTERNATIVES:

Elimination of AGPs: Enforcing strict regulations and industry initiatives aimed at banning AGPs.

Embracing alternatives to antibiotics: Increasing research, development, and implementation of non-antibiotic methods such as probiotics, prebiotics, organic acids, essential oils, phytogenic (plant extracts), and bacteriophages to uphold gut health and avoid diseases.

Enhanced biosecurity: Introducing rigorous biosecurity protocols at all farm levels, from staff entry to equipment sanitation, to deter disease introduction and spread.

Vaccination initiatives: Establishing strong and effective vaccination programs tailored to regional disease threats to combat common poultry ailments, thereby reducing the need for therapeutic antibiotics.

STANDARDS FOR ANIMAL WELFARE:

Enforcing and certifying enhanced animal welfare practices, including better stocking densities, lighting, enrichment, and humane handling methods, in response to rising consumer and international market expectations.

ENGAGEMENT WITH THE COMMUNITY:

Formulating strategies for responsible handling of waste and odor management to foster positive relationships with nearby communities.

FAIR LABOR STANDARDS:

Guaranteeing safe working conditions, equitable pay, and ethical treatment for all individuals involved in the poultry supply chain.

The future of sustainability within the Asian poultry sector is expected to be characterized by a swift acceleration of prevalent trends and the introduction of groundbreaking innovations.

The industry is set to adopt a precision agriculture model, utilizing data analytics, AI, and automation to enhance all facets of production, from formulating feed based on current bird performance to managing environmental conditions. This will result in unparalleled levels of resource efficiency.

There is significant potential for scaling up alternative protein sources for feed, especially insects and algae, which will diminish dependence on traditional ingredients that have a negative environmental impact. This also promotes greater self-sufficiency in feed among Asian countries.

Production devoid of antibiotics is anticipated to become the standard, driven by both consumer preferences and stricter global regulations. This transition will require significant advancements in managing gut health, disease prevention, and biosecurity measures.

Additionally, the industry will increasingly focus on principles of the circular economy, where waste materials are repurposed into valuable products like bio-fertilizers and renewable energy.

Digital traceability systems are set to become commonplace, providing consumers and regulators with complete transparency regarding the origins of products, animal welfare standards, and environmental consequences.

A life-cycle analysis (LCA) is a measurement of how a service or product impacts the environment. These analyses are an excellent tool for delivering transparent, verifiable data about a company’s environmental footprint.

LCAs consider all inputs, including ingredients, energy, transport, packaging and any pollutants generated in the production of a product. With this information, industries and businesses can explore how their choices impact the sustainability of their products and subsequently identify ways to eliminate waste and increase efficiency.

Finally, collaboration across sectors – including poultry producers, feed manufacturers, technology providers, governments, and research institutions – will be vital.

This integrative ecosystem will be key to creating and executing comprehensive sustainable solutions, ensuring that the poultry industry in Asia not only meets the rising protein demand but does so in a way that protects the environment, maintains social responsibility, and secures longterm sustainability.

The pursuit of complete sustainability is an ongoing process, but the dedication of the Asian poultry industry to this journey is clear.

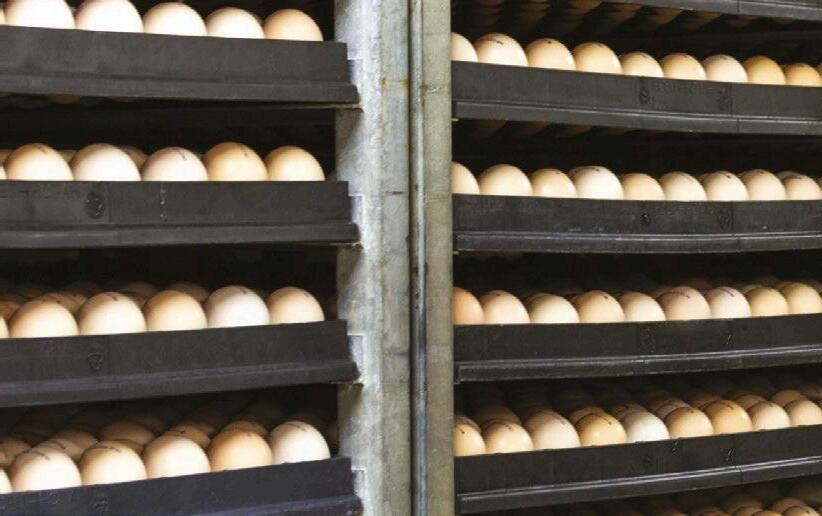

Through genetic evolution, broiler chickens reduce their field-rearing time, reaching slaughter weight sooner.

In mid-2010, chickens reached a weight of 2.5 kg at 42 days.

Meanwhile, in 2020, chickens reach the same weight at 36 days.

However, the embryonic development time has not changed, taking 21 days to develop and hatch, although the percentage of their life spent in the hatchery has increased due to improved efficiency in the field (Graph 1).

1. Participation of incubation in the life of a 2.5 kg chicken. Source: COBB.

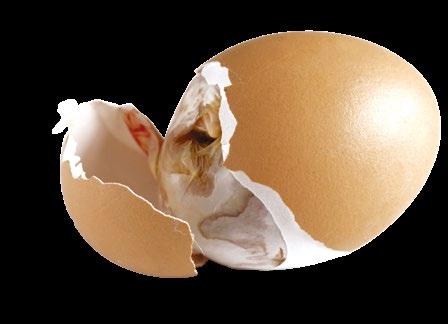

One of the key points for the quality of the chick is the hatch window which is the interval between the first and last chick born.

However, in practice, it is very difficult to know this precise interval of birth.

In a more didactic and practical way, the hatching window is calculated based on the percentage of chicks hatched x hours of incubation, thus establishing a curve of chicks hatched.

Hatcheries strive for excellence in chick quality, which can be greatly affected during the hatching window itself. Added to this is the time spent handling the chicks (sexing, vaccination, shipping, and transport), which can subject them to fasting for up to 72 hours until they arrive at the producer's housing facility.

This long time from hatching to placement can cause dehydration, impaired yolk sac absorption, and damage to intestinal development that weakens the chicks. This can increase mortality in the first week of life and lead to decreased weight at seven days.

Figure 1 represents:

A more uniform hatching window (blue line), shorter hatching time between the first and last chicks, with a large concentration of chicks hatching at the same time.

The wider the hatching window, the longer the fasting period for the first chicks to hatch, and together we will have chicks that are too bloated, as they were born very close to the withdrawal and did not have the necessary time to lose the moisture needed after birth.

A more open hatching window (yellow line) shows a large time difference between the first and last chicks hatched and there is no concentration of chicks hatching in the same interval. Time

Hatch window

Collecting chicks from the hatchery

To ensure a suitable hatching window, care begins even before incubation:

Egg quality and uniformity.

Egg storage management.

Incubation management, with correct loading into incubators.

Proper management of embryonic development.

These four management points are very important for chick quality and, in addition to being fundamental in controlling the hatching window, they correlate with the total incubation time of the chicks.

A very important point is differentiate the hatching window time from the total incubation time for removing the chicks from the hatchers.

The total hours of hatching or removal of chicks from the hatcher are counted from the time of incubation until the removal of the ready chicks and these hours will vary according to each hatchery, which can be 504 to 516 hours.

At the end of these hours the chick is removed from the hatcher and processed to be sent to the farm.

In Table 1 below we have some indicators that can influence the hatching window and/or chick collection time.

When we talk about incubation we must take into account the total number of hours incubated, which refers to the time from the start of incubation until the chicks are removed from the hatcher.

This indicator is closely related to incubation hours, as different strains have different incubation schedules and egg storage days also interfere with incubation hours.

Examples: When we have storage of 6 or more days, there tends to be an increase in the incubation time of 0.5 to 1 hour per day of additional storage, since we have slower embryos that need more incubation hours the longer they are stored.

The temperature of embryonic development is a very important factor for the quality of the chicks and will interfere with both the window and the time of removal of chicks from the hatchers.

High temperatures during development accelerate embryo development , causing them to be born earlier.

We can notice this problem when there is a high rate of pecked eggs in the transfer, between 18 and 19 days of incubation, and chicks can be found born inside the incubator.

Another factor that interferes with incubation hours is the seasons of the year.

In winter, due to low temperatures, eggs reach a temperature of 23ºC faster than in summer, and they tend to have less embryonic cell development.

In summer we have more embryonic cells and therefore fewer hours of incubation than in winter because the embryo is more developed at the time of incubation.

Ideally, there should be no pecked eggs during transfer, or less than 2%.

Graph A shows an example of an incubator with a uniform temperature that is high for embryos at 18 days, with an average temperature of 102ºF (38.9ºC).

40% Graph A. Temperature at 18 days of embryonic developmenttemperature higher than ideal 37.8 °C - average - 37.5 °C.

hours

Graph A1. Window design for developing embryos at a higher temperature throughout the incubation period.

In Graph A1: the birth window in this case will be a window in which 80% of the chicks were born between 468 hours and 492 hours (24-hour interval).

However, most of the chicks were born 32 hours before the brooder's departure time.

In this case, we can find chicks already in the early stages of dehydration, lower chick weight gain, and reduced liveliness upon arrival at the farm.

When there is a development problem at temperatures below 37.8ºC, embryo growth is slower and, when transferred at 19 days, their physiological age will be behind their chronological age.

In Graph B , we can see that the larger blue area shows an average embryo temperature of 37.5 °C, which is uniform throughout the machine.

Graph B. Temperature at 18 days of embryonic development - lower than the ideal temperature of 37.8ºC - with an average of 37.5ºC.

In Graph B1, the birth window has the majority of chicks born between 484 and 508 (24-hour interval),

However, the peak of birth occurred 12 hours before completing the 512 hours of incubation.

In this case, when the chicks are removed, they will still be quite wet and swollen (with high moisture yield).

In this case, we have a higher percentage of chicks eliminated in the classification, chicks with low liveliness.

% of chicks hatched

Incubation hours

Graph B1. Window model for embryos that were developing at a lower temperature throughout the incubation period.

Hatcheries have a wealth of valuable data available. Unlocking the potential of that data presents a major opportunity to improve the overall performance of hatcheries as well as of the entire value chain. With Eagle Trax™, Petersime offers the first intelligent hatchery software that turns data into maximum poultry performance. Eagle Trax™ allows you to digitise, analyse and optimally use data to advance ever more in hatchery efficiency, productivity and chick quality.

With Eagle Trax™, your hatchery will always maximise the genetic potential of each hatching egg and deliver predictable output of the most profitable day-old chicks for everybody involved in the poultry value chain.

Preheating is a very important factor in restarting embryonic development. The preheating allows all eggs to be heated evenly and resume uniform embryonic development.

When preheating is not performed or is only partially performed on the eggs to be incubated, there are consequences for the eggs to be incubated due to temperature inconsistencies between them.

In multi-stage incubators, eggs without preheating enter the incubator at an average temperature of 21ºC and are placed in the incubator where the other eggs are already at a temperature very close to 37.8ºC.

Managing egg inventory days is very important in the hatchery to prevent mixing between egg production dates and leaving larger stock egg loads in the hatchery , resulting in younger eggs being incubated.

These warmer embryos lose temperature to the environment, as an aid to warming the incoming egg load, slowing their development.

In the loading operation it is essential to always start from the highest date of laying to the lowest, so that it is taken as maximum 3 production dates within the same incubator.

An important point is to do an incubation load between the same lineage and the same age among the breeders or very close ages.

Example: if you incubate eggs from two farms, it is preferable that the age of the breeders of the incubated eggs is no more than 5 weeks, within the same incubator.

The quality of the shell is associated with the age of the breeder and as it ages there is an increase in egg weight, lower fertility rate, higher embryonic mortality and consequent drop in hatching.

This is because older birds produce eggs with thinner shells and larger pore diameters, and a higher yolk-to-white ratio.

These changes in eggshell quality directly interfere with the gaseous moisture exchange between the embryo and the incubator environment, which is an important factor in the incubation process because it directly affects the weight, incubation time, and quality of the chick at hatching.

A very important point is to monitor the temperature of the embryos inside the incubator to check that the temperature is uniform.

The more uniform the embryonic development temperature, the more uniform the hatching window will be among chicks.

Let's look at some examples of eggshell temperature graphs for 18-day-old embryos.

In Temperature Graph C , we observe that there is an unevenness in the development temperature of the embryos inside the incubator, which we call a heat island—embryos further back in the incubator are warmer (average red coloration 39.2 °C) and embryos located at the front of the machine are at an average of 38.5 °C.

This shows us a large heat island that will directly interfere with the hatching window and the quality of the chicks.

The chicks located at the back will hatch before the chicks located at the front of the incubator.

Lower Center 1 Center 2

A well-opened window curve trend, ending with a healthy chick beginning the dehydration process. Wet chicks are born later, closer to the time they are removed from the hatcher, as shown in Graph C1.

The hatch window will always be a challenge for all hatcheries, as it involves many variables from the farm to the hatchery. We need to understand each variable and how to minimize or synchronize them so that, together, they result in high-quality chicks for the customer, allowing them to demonstrate their full potential.

Challenges in Maintaining the Hatch Window DOWNLOAD PDF

The egg collection belts have greater capacity, and the entire system has been designed for easy installation and hassle-free maintenance. Efficiency and practicality in a single aviary.

Its intuitive structure allows the layers to adapt easily from the very beginning. The open design enables quick and direct visual inspection of the birds, eggs, and nests.

Infectious Bronchitis (IB) remains a major concern in the poultry industry due to its economic and health implications. The disease, caused by the Infectious Bronchitis Virus (IBV), primarily affects the respiratory system but can also impact the reproductive and renal systems.

Its high transmissibility and potential to cause secondary bacterial infections make effective control strategies essential for maintaining flock health and productivity.

IBV is highly contagious, with studies indicating that a single infected bird can transmit the virus to up to 20 others. This exponential spread underscores the importance of robust biosecurity, vigilant monitoring, and strategic vaccination.

Protecting poultry flocks from IB is critical not only for animal welfare but also for the economic sustainability of poultry operations.

Vaccination is a cornerstone of IB control. A successful strategy relies on three pillars:

Proper vaccine preparation,

Effective administration,

And continuous monitoring.

Key considerations include maintaining vaccine storage temperatures between 2°C and 8°C, using demineralized water for reconstitution, and employing flatnozzle spray equipment to ensure uniform coverage.

Droplet size should range from 100 to 200 microns to avoid deep respiratory penetration and adverse reactions.

Uniform application and equipment hygiene are vital. Tools like Ceva Desvac Droplate® can help visually verify the spray coverage quality, and dedicated equipment with cleaning-in place systems should be used to prevent contamination.

These practices ensure optimal vaccine efficacy and reduce the risk of disease outbreaks.

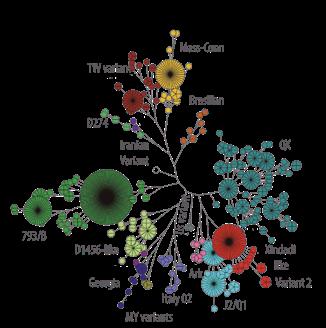

IBV’s ability to mutate and recombine leads to the emergence of multiple strains, often co-circulating within the same region. Broadspectrum cross-protection is essential to safeguard flocks against this diversity.

Combining vaccines such as IBird (strain 1/96 – GI-13) and Massachusetts (GI-1) enhances immunity across various serotypes. This approach helps maintain respiratory integrity, reduces secondary infections, and supports optimal growth performance.

Controlling Infectious Bronchitis requires a comprehensive strategy that integrates vaccination, biosecurity, and flock management.

Under Control

Beyond clinical protection, controlling virus shedding is crucial for long-term IB management. Reducing environmental viral load limits transmission, lowers the risk of secondary infections, and improves overall vaccine efficiency

Effective control strategies can significantly reduce the virus’s reproduction rate (R0), curbing its exponential spread and protecting future flocks.

Benefits of virus shedding control include decreased disease transmission, improved production performance, and economic gains. By limiting the spread of IBV, producers can ensure healthier flocks and more consistent production outcomes.

By focusing on both protection and prevention—through broad-spectrum vaccination and virus shedding control— poultry producers can safeguard flock health, enhance productivity, and secure long-term profitability.

A proactive, science-based approach is key to sustainable poultry production in the face of evolving IBV challenges.

PROTECT AGAINST ALL IBD VIRUS

Dr. Norma L. Calderón and Dr. Leopoldo H. Paasch

Faculty of Veterinary Medicine and Zootechnics, UNAM

In many rural regions, family poultry farming is key to food security and the economy, as it is accessible to the whole family and compatible with other agricultural activities. However, it is at risk due to the loss of local chicken breeds suitable for raising in rustic conditions.

In addition, ornamental and fighting bird breeding faces health problems due to the lack of adequate technologies, which creates challenges for field veterinarians who must diagnose serious diseases.

Two neoplastic viral diseases, Marek's disease and Lymphoid Leukosis, represent major threats.

Marek's disease causes tumor infiltrations in various organs and presents variable nervous symptoms, while lymphoid leukosis mainly affects the bursa of Fabricius, liver, spleen, kidney, and ovary, but does not infiltrate the peripheral nerves. It is essential to train rural veterinarians to protect non-technified poultry farming.

Previously, alphaherpesviruses were classified into three serotypes, but currently three species are recognized:

Gallid alphaherpesvirus 2 which is the etiological agent of Marek's disease (formerly serotype 1), with low and high virulence and attenuated strains.

Gallid alphaherpesvirus 3 (formerly serotype 2). It infects chickens but is avirulent and therefore non-oncogenic.

The virus that causes Marek's disease is an alpha herpesvirus belonging to the genus Mardivirus

The viral particles are enveloped and measure 150-160 nm in diameter.

The genome consists of a double strand of DNA, and the nucleocapsid is hexagonal with 162 capsomeres.

Meleagrid alphaherpesvirus 1, (Herpesvirus in turkeys, formerly serotype 3). Infects turkeys but is avirulent and non-oncogenic.

Gallid alphaherpesvirus 2 has four pathotypes:

Medium virulence (mEM).

Virulent (vEM).

Very virulent (vvEM).

Very virulent plus (vv+EM).

The Lymphoid Leukosis is caused by a Type C oncovirus belonging to the Retroviridae. This virus has:

Protein envelope encoded by the gag gene, which contains the group-specific antigen (gsa), useful for diagnosis.

Marek's disease: transmitted horizontally through dust containing flakes from the feather follicles, where the infectious virions are found.

Lymphoid Leukosis: can be transmitted horizontally or vertically:

Second outer envelope encoded by the env gene.

Genome composed of two RNA segments (35S) and a reverse transcriptase inside, encoded by the pol gene.

Avian leukosis viruses are grouped into subgroups A, B, C, D, and E:

A, B, C, and D: these are exogenous, transmitted horizontally or congenitally.

E: is endogenous, is transmitted genetically as integrated provirus into the host's DNA.

Congenital vertical: the embryo becomes infected in the hen's oviduct. This route is mainly caused by subgroups A and B.

Vertical genetic: the provirus is transmitted through gametes, both from the rooster and the hen. Involves endogenous subgroups E and J.

In 1991, Virus J (ALV J) was identified , which affects heavy-type birds and causes early neoplasms, specifically myelocytomatosis.

Subgroups A and B are the most common and the main causes of lymphoid leukosis.

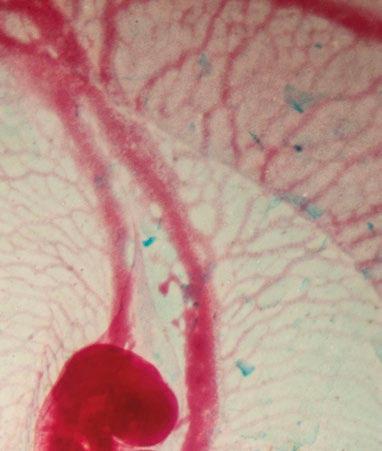

Marek's disease begins when birds inhale viral particles present in dust contaminated with flakes from feather follicles.

These particles reach the lungs, where they are captured by macrophages that transport them to the lymphoid organs (spleen, thymus, and bursa of Fabricius).

In these organs, the virus causes an initial cytolytic phase, causing atrophy of the lymphoid tissues and establishing a latent infection.

Infection of feather follicle epithelial cells, which produces complete viral particles without cell transformation but with the ability to transmit to other birds. (Table 1).

Cellular and humoral immunosuppression Phagocytosis by macrophages

Atrophy of the spleen, thymus, and bursa of Fabricius

Primary and secondary lymphoid organs

Restrictive productive infection

The avian leukosis virus does not have oncogenes, but its RNA is converted into Proviral DNA by reverse transcriptase, inserting itself into the genome of the infected cell.

In chickens, virions have been isolated in the ovary and oviduct, especially in the magnum, where they infect the zygote during egg passage, causing congenital vertical transmission.

At birth, some embryos already have virions in the liver and kidney.

Between the 6th and 8th week of life, giant lymphoid follicles can be detected in the Fabricius sac, indicating the onset of neoplastic transformation of B lymphocytes.

At 10 weeks, macroscopic tumors appear in the sac, and metastases to other organs occur from the 20th week.

The clinical signs of Marek's disease are mainly nervous, characterized by progressive paresis, paralysis of one or more limbs, and incoordination, as well as anorexia, depression, paleness of combs and wattles, dehydration, and diarrhea leading to cachexia.

In lymphoid leukosis, the main clinical signs are anorexia, cachexia, depression, ruffled feathers, paleness or cyanosis of combs and wattles, and a distended abdomen.

An increase in the tissue mass of the Fabricius sac and liver can sometimes be detected by palpation.

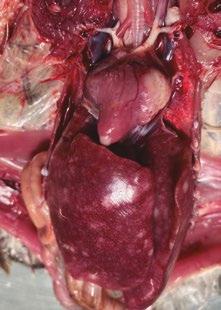

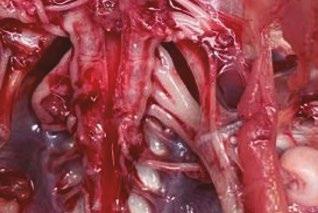

Figure 1. In situ exposure of the heart and liver of an adult fighting cock with Marek's disease. The heart has a large white nodule on the ventricular wall and a smaller nodule at the apex. The liver is enlarged with multiple white infiltrations in the parenchyma.

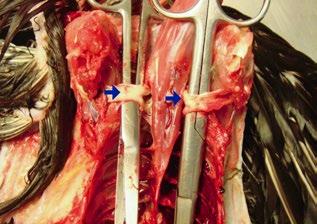

2. Thickened brachial nerves with discoloration; the nerve on the right side of the figure shows irregular deformities in an adult game bird affected by Marek's disease.

The lesions of Marek's disease consist of five types of tumor cell infiltrations, which are:

Visceral: Ivory-white or grayish nodules in organs such as the liver, kidney, spleen, heart, ovary, proventriculus, and lungs. They can be observed from the fourth week of age in acute cases, without involving the spinal cord or peripheral nerves

Cutaneous: Protruding masses in the feather follicles .

Muscular: White nodular masses in the pectoral muscles, although these are rare.

Neural: Affects between 20-40% of birds and is the most common form. The lesions are unilateral and are found in nerve plexuses ( brachial, lumbosacral, sciatic). The affected nerves thicken, turning yellow or pearly gray and losing their striations. The mesenteric and cranial nerves may also be affected.

Ocular: These are not described in detail, but usually include changes in the iris and other eye tissues, which are typical of the disease.

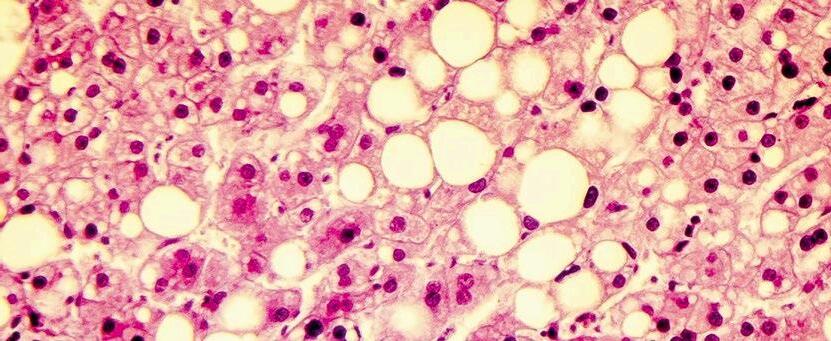

The characteristic lesions of lymphoid leukosis are mainly tumors that occur in various viscera. The most important points are:

Characteristics of tumors:

They are nodular in shape and are white, yellow, or gray.

Location of tumors:

The tumors occur most frequently in the following organs:

Liver

Spleen

Heart

Kidneys

Lungs

Ovary

Fabricius sac (almost always affected).

Tumors in the Fabricius sac:

The early tumors can be detected from 10 weeks of age.

They are characterized by a marked thickening of one or more folds of the inner wall of the sac.

Liver lesions:

In the liver, tumor lesions may be infiltrative rather than nodular.

They manifest as marked hepatomegaly (enlargement of the liver). (Figures 4 and 5)

5. Creole hen affected by lymphoid leukosis presenting diffuse nodular neoplastic infiltration of the apical lobe of the right kidney. Note that the nerve plexuses are normal.

4. Creole hen affected by lymphoid leukosis presenting severe hepatomegaly and small whitish nodules distributed multifocally.

In this first part, we presented the general aspects of Marek's disease and lymphoid leukosis. In the second part, we will address the histopathology, diagnosis, prevention, and control measures for these diseases in family poultry farming.

novusint.com/ poultryminerals ONLY MINTREX® BIS-CHELATED TRACE MINERALS DELIVER THE PROACTIVE ABSORPTION YOU NEED TO MAXIMIZE NUTRITION. Our authentic organic trace minerals are the only minerals proven to survive the digestive tract and reach the absorption site for greater tissue enrichment. With superior mineral bioavailability, MINTREX® bis-chelated trace minerals help reduce mortality and optimize growth for broilers with enhanced structural integrity to stay healthier and deliver stronger performance from start to finish. ® and MINTREX

Dr. Ricardo Rauber Animal Health Consultant

For over six decades, Antibiotic Growth Promoters (AGPs) have been widely used in animal production, especially in poultry and swine, due to their benefits in performance and feed conversion.

Studies indicate that the removal of AGPs may lead to an average 3.5% loss in feed conversion efficiency in broiler chickens, although in some cases no adverse effects are observed (CARDINAL et al., 2019).

Nevertheless, from the perspective of antimicrobial resistance development, the use of antibiotics at doses far below the minimum inhibitory concentration for the molecule, administered over long periods, significantly beyond those recommended for therapy, is not advisable, especially when the sole justification is performance improvement.

Despite AGPs having been used for more than 60 years, their mechanisms of action have only been elucidated in the last two decades, presenting a challenge for the production system, suppliers, and researchers searching for effective replacements.

Although there is no definitive scientific evidence that this practice causes antimicrobial resistance relevant to hospital settings, it has led some countries to ban AGPs, while others are considering similar measures.

Four primary mechanisms have been proposed through which AGPs enhance animal performance; all related to the intestinal tract:

Inhibition of subclinical infections;

Reduction of growth-inhibiting metabolites;

Decreased nutrient consumption by microorganisms;

Improved nutrient absorption and utilization due to a thinner intestinal wall.

In 2007, Niewold proposed an antiinflammatory mechanism, and in 2012, Cho and collaborators demonstrated both anti-inflammatory and antimicrobial effects of AGPs. Understanding these mechanisms is essential for the development of effective and safe alternatives.

To understand AGPs’ primary effect on the intestine, one must first define the concept of Gut Health. Over time, this concept has evolved with field experiences and technological advances that allow for a better understanding of the microbiota.

According to Kogut (2019), Gut Health involves a stable microbiota, a well-functioning mucus barrier, an appropriate immune response, and proper digestion and nutrient absorption.

Grasping these elements is key to identifying alternatives to AGPs, which can be grouped as follows:

Probiotics: Live microorganisms that, in adequate amounts, benefit host health. They act by modulating the microbiota, maintaining epithelial homeostasis, and modulating intestinal immune responses.

Prebiotics and Postbiotics: Nonviable dietary components that confer health benefits by acting directly on the gut microbiota (prebiotics) or the intestinal wall, regulating homeostasis and immune response (postbiotics).

Symbiotic: A synergistic combination of probiotics and prebiotics.

Phytogenics or Plant Extracts:

Bioactive compounds from plants with antimicrobial, antioxidant, antiinflammatory, and intestinal wallregulating properties.

Organic Acids: Mono- or carboxylic acids with direct antibacterial action and epithelial homeostasis support.

Enzymes: Proteins that aid in nutrient breakdown, improving digestibility and absorption. They may indirectly modulate the microbiota and reduce excessive immune responses.

These alternatives provide viable options to enhance animal performance and promote gut health, thus playing a key role in replacing AGPs.

Figure 1. Clarifies the relationship between various technologies available as AGP replacements and the desirable outcomes of their use.

Defining the desired effects for each phase of the animal’s life and production conditions requires identifying the key challenges and opportunities related to gut health.

Figure 1. group of alternative products to AGPs.

Unlike AGPs, where a single active principle can be used throughout the bird’s life without the need for combinations, the alternative approach requires attention to specific challenges and the development of tailored programs.

Neglecting this aspect can lead to ineffective or overly expensive programs without the expected economic return.

Therefore, it becomes clear that a feed-based alternative program to AGPs must be adapted to the specific challenges of each production phase and system.

Achieving the desired outcomes in each case requires combining two or more groups of alternative products. This tailored approach ensures effective and suitable results for each animal production context.

A personalized strategy and careful combination of alternative products will be essential for sustainably promoting gut health and animal performance.

Biosecurity plays a fundamental role in the effectiveness of AGP replacement programs in poultry production. It encompasses a set of preventive measures and strategies designed to minimize the introduction and spread of pathogens in poultry facilities.

These measures are vital for ensuring animal health and welfare, especially in production systems that do not rely on routine antibiotic use.

A key concept in poultry biosecurity is the control of access and movement of people, animals, and equipment on farms.

Hygiene measures, such as designated clothing and footwear and vehicle disinfection, reduce the risk of cross-contamination.

Another important element is maintaining a clean and appropriate environment within poultry facilities.

Regular cleaning and disinfection of barns, equipment, and drinkers help reduce the presence of pathogenic microorganisms. Vector and pest control, including rodents and insects, is also essential to prevent disease transmission.

Additionally, epidemiological surveillance and sanitary control measures are crucial aspects of biosecurity.

Regular health monitoring, laboratory testing, and taking quick actions in response to disease detection are vital practices to prevent outbreaks and minimize their impact on poultry production.

A strong commitment to biosecurity, combined with the judicious use of alternative products, can lead to a more responsible and efficient poultry industry, without compromising animal health or final product quality.

Biosecurity also involves the proper management of waste.

The treatment and disposal of manure and dead birds are essential to prevent environmental contamination and the spread of pathogens.

Ultimately, biosecurity is a key component of successful AGP replacement strategies.

It ensures a healthy environment for birds, minimizes disease spread, and contributes to the sustainability of poultry production.

Edgar

O. Oviedo-Rondon

Prestage Department

of

Poultry

Science, North Carolina State University. Raleigh, NC

Poultry production can gain more precision and consequently productivity by measuring body, meat, or egg composition affected by diverse factors. Knowing the body composition of animals is essential for several reasons.

It is important to assess nutritional needs and the impact of nutrients in metabolism, determining the meat value and fat content of carcasses, and monitoring health.

Understanding the proportions of fat, muscle, and bone in animals allows for better management of their diet, prediction of growth rates, and optimization of production efficiency.

Genetic characteristics dictate body composition, but it can be affected dynamically by multiple nutritional, environmental, and health status factors.

This information can be valuable to integrator companies, meat processors, geneticists, and nutritionists in decision-making.

Wet chemistry methods can help to quantify body composition. These are expensive, time-consuming, destructive, increase variability, and are not sustainable. Several alternatives have been proposed.

Near-infrared spectroscopy (NIRS) and bioelectrical impedance analysis (BIA) are the techniques with the most potential practical applications.

The benefits of NIRS have been presented in previous articles on AviNews International. This time, we will discuss BIA.

The BIA is non-invasive, safe, userfriendly, portable, real-time, and relatively inexpensive. This method evaluates the application of a low-level constant alternating current in biological structures that results in a frequency-dependent impedance to the current’s spread.

Bioimpedance (Z) is evaluated as a function of three elements: resistance (Rs), reactance (Xc), and phase angle (PA).

The Rs is a measure of the dissipation of energy in a conductive body or fluid.

The Xc is related to energy storage, and the PA is the time delay between a stimulating current and the voltage generated by an alternating current.

These electrical properties that are measured are contingent upon the integrity of the cell membrane and the presence of extracellular and intracellular fluids.

The impedance is usually labeled as Z, and it is calculated as Z = √ (Rs2 +Xc2). The phase angle is calculated as PA =Arc tangent (Xc/Rs)*180/π.

The Rs and Xc in Ohms are measured with body composition analyzers.

These devices measure the voltage drop in each proximal electrode after an excitation current is applied to each distal electrode, typically operating at around 50 kHz and 400 µA.

The device accuracy can be tested to verify impedance measurements with a known ohm resistor.

The BIA has been used in human medicine for several decades to estimate body composition, detect chronic diseases such as cervical cancer, and monitor malnutrition, changes in hydration status during pregnancy, and postpartum.

In animals, BIA has been used to estimate body and meat composition for fish, sheep, cows, pigs, and rabbits. In poultry production, BIA has been used previously to estimate body composition of broilers, breeder turkeys, and broiler meat composition.

The prediction equations used for BIA must be specific for each population of birds evaluated. These equations should vary between sexes, broiler strains, and age to gain more accuracy in the predictions.

There are distinct methods for applying BIA in poultry. The electrodes can be placed on both legs. This method displays higher values for Xc in comparison to Rs.

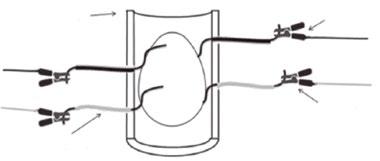

However, Rs is a more reliable predictor since it holds a greater proportion of the total impedance than Xc. Other options are to place two electrodes on the ventral surface of the wing and two on the inner thigh, or two on the right thigh and two near the sternum (Figure 1).

The Rs of a conductive material is proportional to its length and inversely proportional to its cross-sectional area.

Consequently, as animals grow, the Rs and Z decrease with age, despite the increase in fat content.

Then, Rs generally has a negative correlation with fat and energy, and a positive correlation with water, protein, and ash.

BIA has proven to be reliable in predicting body composition in male and female broilers with similar precision and accuracy comparable to other wellestablished techniques.

Figure 1. Electrodes location in broiler chickens. (Benítez Puñal et al., 2024, Poult. Sci 103, 3, 103447).

In one recent study conducted by Benítez Puñal and collaborators (2024), the coefficient of determination (R2) to estimate water (%), protein, fat, ash (% DM), and energy content (cal/g DM) was 0.909, 0.825, 0.795, 0.493, and 0.838, respectively. But, other researchers (Zuo et al., 2024) have been able to predict fat with higher accuracy (R2 = 0.884%).

Bioimpedance has also been used to detect myopathies in breast fillets (Figure 2). Severe woody breast filets exhibit significantly higher resistance and reactance compared to regular fillets, indicating that BIA can be used to detect them.

BIA can also differentiate between four woody breast severity levels using the whole filet. Significant differences were observed in resistance and reactance of normal and other woody breast categories.

Figure 2. Bioelectrical impedance analysis of whole breast filet (Morey et al., 2020, Front. Physiol 09).

Segmental BIA of those filets indicated that BIA can be used to separate cranial, medial, and caudal regions of the breast filet based on the presence of woody breast myopathy. This provides more granular data as well as a better understanding of the spread of the myopathy in the muscle.

The accidental finding on the interference of spaghetti breast meat in detecting woody breast indicates that BIA could be used to detect spaghetti breast myopathy.

The research also demonstrated that BIA can be altered with the freshness of the filets, and each processor must develop the resistance and reactance threshold values based on their process.

In its current state, the hand-held device can be used as a near-line technology by quality assurance departments to detect woody breast prevalence, differences between flocks, and determine the effects of nutrition and management practices on the prevalence of this myopathy.

Further processors can use BIA technology together with machine learning to separate woody breast meat from the normal meat, helping to reduce consumer complaints about woody breast.

At the 2025 European Symposium of Poultry Nutrition in Maastricht, NL, results from a project led by Kakhki and collaborators from Trouw Nutrition were presented. The project aimed to use BIA to predict liver traits in laying hens.

Bioelectrical impedance has been used to evaluate fertile egg freshness since the chemical reactions that occur inside the eggs during the storage period can alter impedance.

Liver health is a critical determinant of productivity and longevity in laying hens, yet traditional assessment methods remain invasive and destructive.

The preliminary results indicated some potential for BIA to detect heavier livers or with more fat content. The models likely require more samples from diverse age periods to improve accuracy.

Still, the concept has been proven that it may be possible to detect fatty liver in laying hens using BIA.

There are many laboratory methods to measure egg composition factors that may influence hatchability; however, all are invasive and do not allow eggs to be subsequently incubated.

Eggs stored for seven days exhibited higher resistance (Rs 457.20 Ohms) and a lower phase angle (PA, 55.04) compared to those stored for only one day (Rs 454.60 Ohms and 55.29).

Additionally, higher PA values and Xc indicate better chick quality and cellular integrity. The challenge in implementing these findings lies in how to place the electrodes and create a system for massive application in hatcheries (Figure 3).

Adapted copper electrodes

The BIA is a promising technology that soon could be applied at commercial level to enhance our ability to understand development of birds, health status, and egg traits. PVC support

Figure 3. Position of the bioimpedance apparatus electrodes on the eggs (Rev. Bras. Cienc. Avic. 18 (02) • Apr-Jun 2016).

Dr. Sandeep Gupta, Ph. D. Animal Nutrition, Founder LSDA, India info@lsda.co.in / www.lsda.co.in

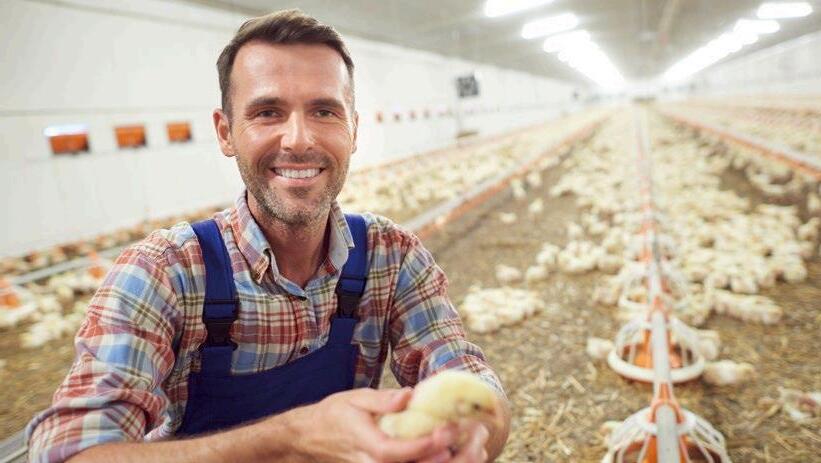

Poultry farming is the fastest growing sector within animal husbandry at global level. The continuous research, use of innovative technologies as well as fruitful breeding program are the pillars of modern-day poultry industry.

Poultry nutrition has now expanded into a broader field of research that extends beyond the primary ingredients and performance parameters studies.

Poultry nutritionists address various research aspects globally, including micro-nutrient trials, water treatment studies, and product validation in poultry.

However, there is a lack of facilities at institute level, which limits the research findings.

This results in the presence of pesticide residues, toxins, and heavy metals in poultry products, ultimately compromising human food safety.

Furthermore, a significant challenge faced by the poultry industry is the lack of precise research data from institutes, which hinders development and innovation of new products capable of meeting market demands.

Environmental factors play a crucial role in poultry production including temperature, humidity, gaseous exchanges light, altitude, wind velocity, air quality and population density.

Many research studies revealed the impact of environmental factors on growth of broilers.

A higher level of ammonia (NH3) in poultry houses has harmful impacts on caretaker’s and animal well-being (Ni, 2015).

Furthermore, the performance and productivity of broilers are influenced by factors viz., air temperature, relative humidity and air velocity (Giloh et al., 2012).

The housing environment, encompassing factors such as temperature (both cold and fluctuating conditions) and air quality including dust concentration, carbon dioxide (CO2) levels and oxygen (O2) levels are recognized as a key determinant of growth and contribute to the incidence of ascites in broiler chickens (McGovern et al., 2001).

These studies revealed that the environment plays a key role in poultry production. Thus, poultry research trials need standard environment and optimum nutritional conditions.

The lack of skilled human resources for various roles such as farm manager, farm supervisor, feed mill manager, feed mill supervisor, etc. hinders the management at poultry farms. This can lead to a decline in production of poultry products such as meat and eggs. These problems can be resolved by promoting proper training and an education program to these positions.

To response to these challenges, the Livestock Scientific Development Association (LSDA) has been established with the following objectives,

1The aim of this project is to establish a state-of-the-art research facility for institutes that can support their scientific endeavors and enhance the research & development in Indian livestock industry by conducting rigorous experiments.

Organize skill development program to enhance individual’s abilities and competencies to improve skill & knowledge by using research facilities for broilers, layers & breeders, laboratory facilities and feed mill facilities.

LSDA is registered under section VIII nonprofit organization to support various livestock research. It serves bridge between scientists, organizations, feed companies and institutes, facilitating collaboration, innovation & knowledge exchange.

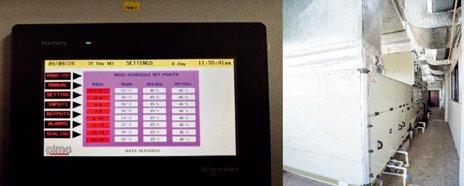

It is a state-of-the-art research and development (R&D) facility located at Indore (India) which boasts India’s first R&D house with HVAC system, feed pellet mill and advanced laboratory facility.

The HVAC system is designed to optimize environmental conditions and is employed to regulate the atmospheric conditions within poultry houses, utilizes the principle of fluid mechanics, thermodynamics, and heat transfer.

The Air Handling Unit (AHU) is a component of the HVAC system, engineered to manage and condition the air as it is processed within the system.

This system also provides a source of ventilation which facilitated the escape route for moisture.

Figure 1. An advanced HVAC with components such as Building Management System (BMS) and AHU installed at LSDA

The HVAC system installed at LSDA facility is as per latest standard compromising Heating unit, Air conditioning units, Ducts and Moisture vents. Sensors installed in HVAC unit are sensible to changes in levels of humidity, O2, CO2, NH3, etc.

Environmental conditions to be monitored inside the poultry house: An ideal environmental condition which was quoted by previous researchers is followed at LSDA experimental facility. The following norms at the facility are as per the following references:

Temperature 30–32°C at Diesel Oxidation Catalyst (DOC), To be Reduced 3°-4°C /week up to 4 weeks, 20° C > 5 weeks Ketelaars, 2005

50-80% Oloyo, 2018

Normal Oxygen concentration

Hulzebosch, 2004

Czarick and Fairchild, 2002

Lacy and Czarick, 1992

Table 1. Environmental conditions inside the poultry house

The LSDA experimental station is located in Indore, India. The LSDA aims to provide an optimum environmental condition for experimental birds as well as standardized experiment facility at common platform for devotee researchers.

The fastest growing poultry industry needs an optimum environmental condition with well- equipped experimental house. LSDA experimental station approved by Committee for the Control and Supervision of Experiments on Animals (CCSEA), Ministry of Animal husbandry, dairy and fisheries, Government of India with capacity of 840 birds, dedicated for broilers, layers and breeder.

Experimental house contains 84 adjustable pens/blocks can accommodate 10 experimental birds per block and the blocks can be further adjusted according to research protocol (20 birds/pen, 30 birds/ pen, etc.). Each pen is covered with automatic feeders and drinkers. It also provides an opportunity to conduct research studies through water soluble supplements.

The facility is also equipped to conduct trials on water and feed treatments, as well as digestibility studies of various nutrients, including micronutrients such as amino acids, minerals and vitamins.

An available feed pelleting mill at LSDA with capacity of producing pellets at 150 kg per hour and crumbler for crumbles production facilitates ease in feeding experiments. This feed pelleting mill enhances the opportunity for formulation of experimental diet for trial birds.

The State-of-the-Art pellet feed mill is equipped with modern technology and adheres to the safety and hygiene standards to guarantee the product integrity.

The pellet mill is used to manufacture standard and custom diets for animal models to meet the research objectives. The diet/ feed is exclusively formulated to meet the requirements of laboratory animals like, Rat, Rabbit, Mouse, Mice, Hamster, Guinea Pig and also for pet birds.

The R&D facility provides an advanced and well-equipped laboratory facility which includes different sections viz., microbiological, wet chemistry and instrumental section.

This helps in testing different samples of feed and feed supplements, excreta or digesta samples obtained during experimental studies.

The laboratory facility comprises of advanced instruments viz., High Performance Liquid Chromatography (HPLC), Gas chromatography/ Mass spectrometry (GC/MS), Liquid Chromatography-Mass Spectroscopy (LC-MS), Inductively Coupled Plasma Mass Spectrometry (ICP MS), etc., to aid in analysis of pesticides, dioxins, heavy metals, antibiotics, amino acids, vitamins, etc. from food and feed samples.

The available laboratory facility at LSDA stands as most advanced laboratory in the country.

LSDA facilitates numbers of experimental trial facilities with precise result outcomes. Apart from nutritional studies, LSDA provides a facility to conduct micro-nutrient digestibility trial by marker and fecal method.