ANTIMICROBIAL RESISTANCE IN

THE POULTRY

FOOD CHAIN AND NOVEL STRATEGIES OF BACTERIAL CONTROL

Edgar O. Oviedo-Rondón

RODENT CONTROL, THE IMPORTANCE OF STAFF TRAINING, MAIZE AND SOYBEAN MEAL DEMAND IN INDIA AND ANTIMICROBIAL RESISTANCE IN THE

POULTRY

FOOD CHAIN

In our June 2025 publication, we take a closer look at how Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability. Dr. M. Verónica Jiménez from Chile shares with us the excellent article The Importance of Staff Training on Animal Welfare Issues in Poultry Industry, while Dr. Ricky Thaper shows us Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry.

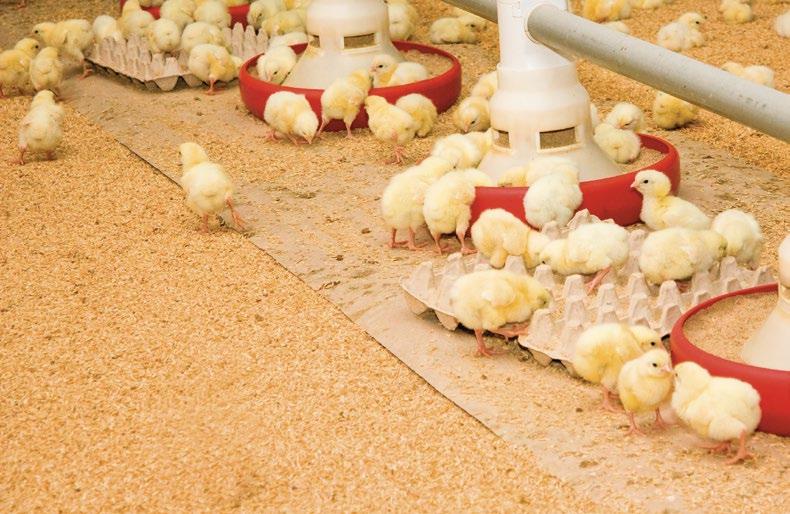

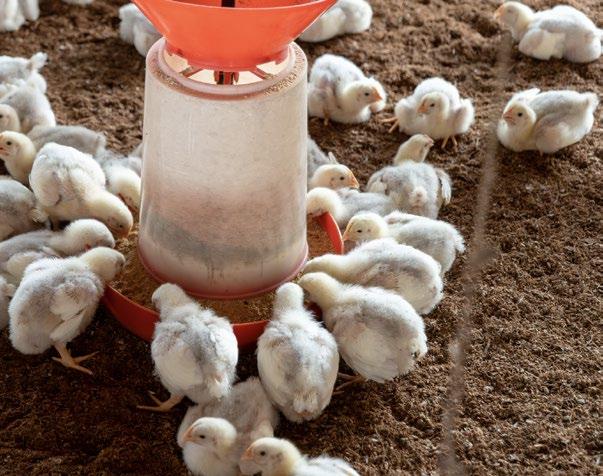

Animal welfare is all the daily practices that are carried out on layers, eggs, chicks and broilers; daily practices as, handling, restrain, broiler breeders and fattening procedures, etc. that we do routinely in every phase of the production chain.

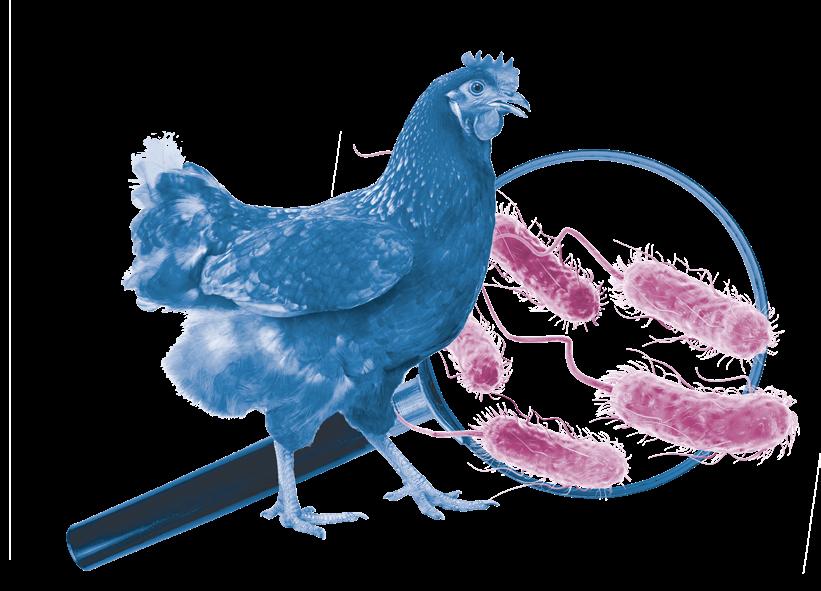

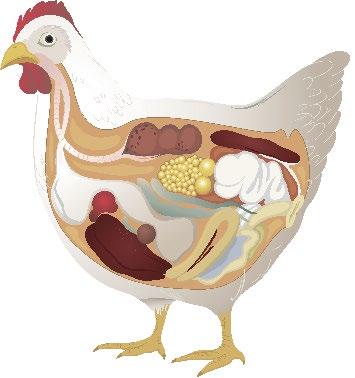

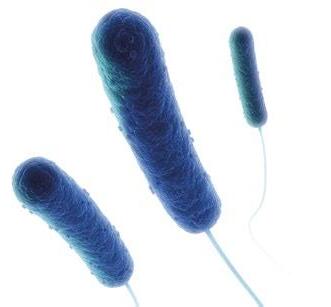

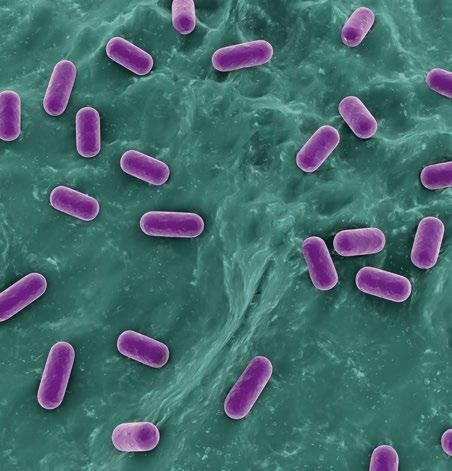

Dr. Cecilia Rosario Cortés, in her article Avian Pathogenic E.coli (APEC): Serotypes and Virulence, establishes that Escherichia coli has long been underestimated, traditionally considered as an environmental and opportunistic agent in immunocompromised animals, or as a complicating agent in viral infections in poultry.

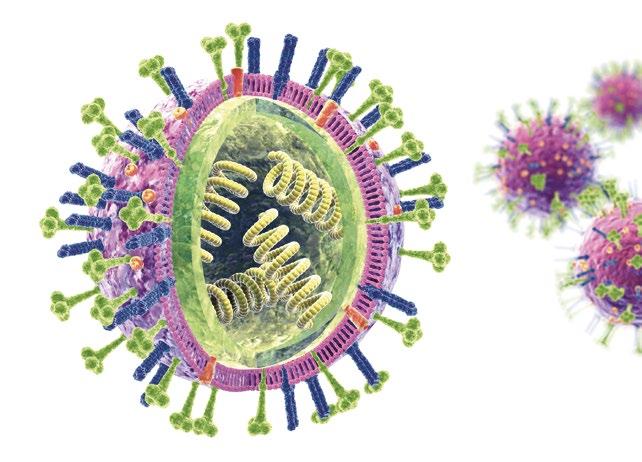

Once again, we are pleased to include the insightful work of Dr. Eliana Icochea D’Arrigo in our magazine with her article Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions, Part II. Here, she continues to explain more about Newcastle disease virus (NDV) and review what prevention, biosecurity and vaccination measures area available.

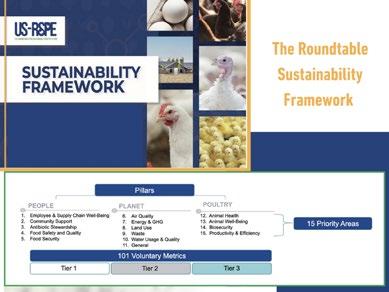

Elena Myhre, Director of Marketing and Communications IPWA and US-RSPE teaches us that the U.S. Roundtable for Sustainable Poultry & Eggs (US-RSPE) has recently released the Inaugural Sustainability Framework Report, marking a significant milestone in the pursuit of transparency and continuous improvement within the U.S. poultry and egg industries.

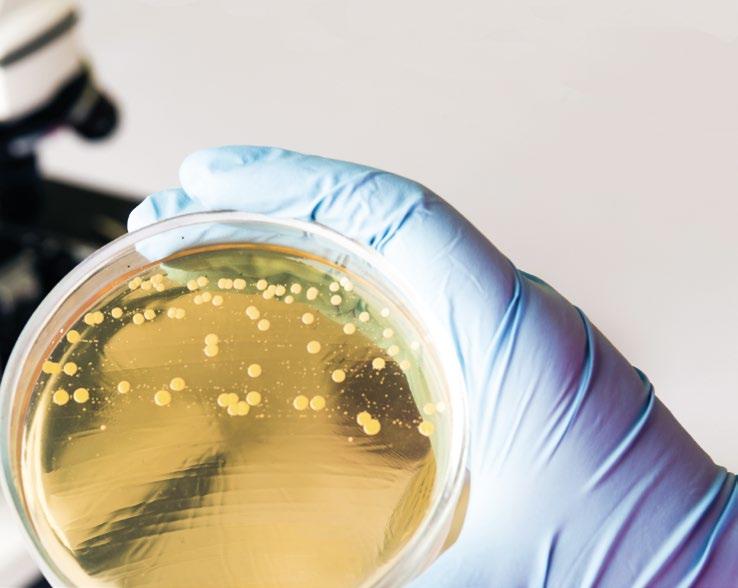

On the other hand, Dr. Edgar Oviedo, in his article Antimicrobial Resistance in the Poultry Food Chain and Novel Strategies of Bacterial Control shows us that most poultry flocks are raised under intensive conditions, increasing the need for microbial control. In the past decades, the continuous use of diverse antimicrobial products to prevent and treat pathogens has increased the risk of antimicrobial resistance (AMR) in the poultry production chain.

Leonardo Ortiz Escoto also contributes with a delightful article, entitled Production of Formed Injected Smoked Chicken Ham, where we will learn the most important points to produce this kind of ham, considering all stages of the process with technical advice.

In this edition, we are privileged to present an exclusive Interview with Mr. Greg Tyler, President and CEO of the USA Poultry & Egg Export Council.

Enjoy reading it!

GRUPO DE COMUNICACIÓN AGRINEWS SL

ADVERTISING

Luis Carrasco +34 605 09 05 13 lc@agrinews.es

Miguel Martín Tamayo +34 664 660 603 sales@grupoagrinews.com

Nicole Carletti Ramírez +57 312 391 9330 avinewslatam@grupoagrinews.com

CUSTOMER SUPPORT

Mercé Soler

EDITORIAL STAFF

José Luis Valls

María de los Angeles Gutiérrez

Nicole Carletti Ramírez Héctor David Corredor Martínez

TECHNICAL DIRECTION

Edgar Oviedo

Eduardo Cervantes

Rodent Control is a Key Factor in Poultry Biosecurity and Sustainability

Edgar O. Oviedo-Rondón Prestage Department of Poultry Science, North Carolina State University. Raleigh, NC

Biosecurity is gaining more importance with the outbreaks of multiple poultry diseases worldwide. Rodents have been a threat to public health and linked to epidemics for centuries.

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

M. Verónica Jiménez Grez MV, MSc Ethology and Animal Welfare, Animal Welfare Consultant

Animal welfare has acquired a fundamental role in the management and production of poultry systems, not only due to regulatory, ethical or customer requirements, but also for production purposes.

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service

Petersime Technical Team

Petersime’s data-driven incubation support service is designed to ensure no detail is overlooked while helping hatcheries achieve optimal hatchery performance.

Cecilia Rosario Cortés Faculty of Veterinary Medicine and Zootechnics, UNAM

Escherichia coli has long been underestimated, traditionally considered as an environmental and opportunistic agent in immunocompromised animals, or as a complicating agent in viral infections in poultry.

Avian Pathogenic E.coli (APEC): Serotypes and Virulence The Strategy for a Proper Infectious Bronchitis Control

Ceva Technical Team

Protecting poultry flocks against IB is crucial for maintaining productivity, ensuring animal welfare, and securing the profitability of the poultry industry.

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II

Eliana Icochea D’Arrigo Avian Pathology Laboratory, Faculty of Veterinary Medicine, UNMSM-Lima-Peru

In this second part of the article, we will continue to learn more about Newcastle disease virus (NDV) and review what prevention, biosecurity and vaccination measures.

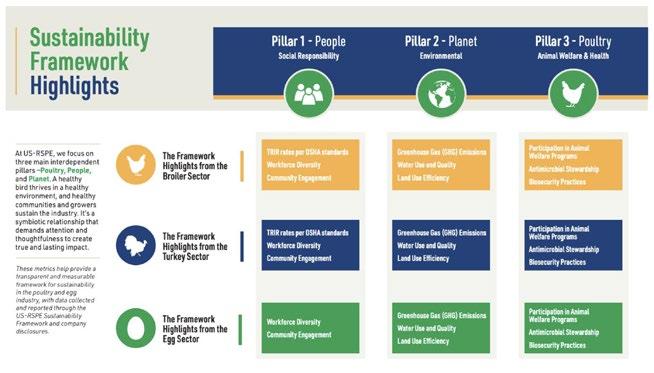

Elena Myhre Director of Marketing and Communications IPWA and US-RSPE

The U.S. Roundtable for Sustainable Poultry & Eggs (US-RSPE) has recently released the inaugural Sustainability Framework Report, marking a significant milestone in the pursuit of transparency and continuous improvement within the U.S. poultry and egg industries.

Greg Tyler

President and CEO of the USA Poultry & Egg Export Council

AviNews International had the privilege of speaking with Greg Tyler, President and CEO of the USA Poultry & Egg Export Council.

H&N International Technical Team

The longer longevity of the laying hens requires an improvement of management, nutrition and health practices.

Production of Formed Injected Smoked Chicken Ham

Leonardo Ortiz Escoto General Manager Improasa

Smoked injected chicken ham is now in high demand all over the world, as it is a product with good texture, flavor and juiciness.

Maize and Soybean Meal Demand and Supply Situation in Indian Poultry Industry

Ricky Thaper Joint Secretary, Poultry Federation of India

Poultry sector is the most organized of all agricultural sectors in India and increasing demand for eggs and chicken is evolving into a very vibrant and modern industry.

Edgar O. Oviedo-Rondón

Prestage Department of Poultry Science, North Carolina State University. Raleigh, NC

Antimicrobial resistance is an issue to follow closely, and control strategies should be implemented since they affect the sustainability and profitability of the poultry production system.

RODENT CONTROL IS A KEY FACTOR IN POULTRY BIOSECURITY AND SUSTAINABILITY

Biosecurity is gaining more importance with the outbreaks of multiple poultry diseases worldwide. Rodents have been a threat to public health and linked to epidemics for centuries.

Rodent control is critical for biosecurity programs due to the close connection or synanthropic relations between rodents, humans, and domestic animal facilities.

In recent years, rodents have been connected with 40% of known communicable zoonoses.

Rodents are involved in the cycle of these diseases in multiple ways.

They can be microorganism reservoirs, intermediate hosts, replicators, or infection vectors.

RODENTS IN AVIAN INFLUENZA CONTROL

Recent research published in the Journals of Pathogens (2024, 13(9), 764) and Viruses (2025, 17(4), 495) by researchers from Tottori University in Japan and University of Hong Kong, respectively, indicated that mice (Mus musculus), brown rats (Rattus novergicus), and black rats (Rattus ratus) are permissive hosts for multiple influenza A virus subtypes prevalent in birds or humans, including H5Nx, H7N9, H9N2, H10N8 and the 2009 pandemic H1N1.

The Japanese study indicated that synanthropic wild rodents are susceptible to infection with avian-origin H5N1 subtype of highly pathogenic avian influenza viruses (HPAIVs) and contribute to the virus ecosystem as replication-competent hosts.

These results indicated that rats should be considered in influenza A virus ecology.

The asymptomatic yet pathogenic nature of infection, combined with rodents’ global synanthropy, underscores their potential role as cryptic reservoirs in viral maintenance and transmission.

While their role as “mixing vessels” remains speculative, the risk of environmental virus amplification and spillover to domestic animals or humans cannot be dismissed.

Detection of infectious viruses in oral swabs indicated that wild rodents exposed to HPAIVs could contaminate food, water, and the environment in poultry houses and play a role in introducing and spreading HPAIVs in farms.

These studies highlight the need for expanded surveillance and control of rodents in influenza ecology to mitigate zoonotic risks.

Mice (Mus musculus)

Brown rat (Rattus novergicus)

Black rat (Rattus ratus)

RODENTS IN ANTIMICROBIAL RESISTANCE AND EMERGING PATHOGENS

Some infectious microbial agents have developed antimicrobial resistance (AMR), threatening poultry and human health.

Rodents act as reservoirs and vectors of organisms with AMR for first-line and last-resort antimicrobial agents.

Organisms with AMR proliferate in insects, rodents, and pets, as well as in their skin and gut systems.

Numerous reports have indicated that rodents are a potential source of multidrug-resistant bacteria.

Escherichia coli, Salmonella spp., Staphylococcus aureus, and Enterobacteriaceae with multiple AMR genes have been isolated from rodent feces and intestines.

It is also well known that rodents carry not well-known pathogens, making them potential sources for emerging diseases.

Rodents can be used as potential sentinels of AMR occurrence, transmission, and human health risks.

RODENTS DAMAGING POULTRY FACILITIES AND POULTRY PERFORMANCE

Rodents also damage infrastructure. In poultry houses, they can damage the electrical network, electronic sensors, water lines, and insulation. Mice eat four to five grams of feed daily, and rats consume 25 to 30 grams daily. Large populations of rodents can cause significant feed losses in a poultry house, influencing apparent flock performance.

RODENT CONTROL

Rodents are prolific omnivorous mammals, extremely adaptable to changing environments, and fast learners. An integrated rodent control plan includes cleanliness, physical barriers to minimize access, traps, baits with rodenticides, and biological control techniques.

Maintaining a high level of cleanliness deprives rodents of feed and shelter.

Making water sources inaccessible to rodents reduces their multiplication.

Feed should be stored in rodent-proof containers, rotated frequently, and any spills promptly addressed.

Regular disposal of poultry waste is essential since it can be a feed source or nesting material.

Composting should be done far away from the main poultry housing, and these facilities should receive exceptional control since they are prone to receiving rodents.

Habitat control is also essential. The farm area should be free of unnecessary equipment, debris, or stored materials that can provide shelter for rodents. Areas around the houses should be free from overgrown vegetation that can provide cover or nesting sites.

Rodent baiting strategies have changed little since the introduction of anticoagulants in the 1950s.

Non-anticoagulant rodenticides, which include bromethalin, cholecalciferol, and zinc phosphide, are used only in cases of massive infestations and only under expert management to reduce populations very quickly.

There are two generations of anticoagulant rodenticides.

1

Rodent-proofing facilities through physical barriers are a proactive method to prevent infestation. This includes identifying and sealing any potential entry points, such as gaps, holes, cracks, doors, vents, and windows, using metal, wire mesh, and concrete that rodents can not break.

Structures should be repaired and maintained frequently. Feed storage containers should be elevated to make them less accessible.

Traps can be placed in high-activity zones where droppings and gnaw marks are observed. Snap traps, glue boards, and live traps can be used. For this strategy to continue being effective, traps require regular maintenance, resetting, and timely removal of captured rodents.

2

The first-generation anticoagulants, which include chlorophacinone, coumatetralyl, diphacinone, and warfarin, require multiple bait ingestions over a period to be effective.

These products have more acceptable DT50 and Log Pow values, which indicate their low persistence in soil and ability to bioaccumulate in living organisms.

Second-generation anticoagulants are more potent and can kill with a single feeding. Examples include brodifacoum, bromadiolone, flocoumafen, difenacoum, and difethialone.

These products are currently the most widely used rodenticides by professional managers.

However, they are classified as persistent, bioaccumulative, and toxic and don’t meet environmental and public health safety criteria.

RODENT CONTROL AND SUSTAINABILITY

Anticoagulants are highly toxic compounds and are very persistent in the environment, move up the food chain, and accumulate in the bodies of predators and scavengers in a process called bioaccumulation. Rodenticides can also affect birds, mammals, and reptiles and intoxicate rodent predators.

The spread of these products in the environment can cause cascades of zoonotic diseases by disrupting ecosystems.

This cumulative process reduces ecosystem function and increases rodent resilience and proliferation.

Consequently, indiscriminate, largescale, and continuous use of rodenticides is known to harm biodiversity and contribute to environmental pollution.

It is necessary to take appropriate measures to reduce their harmful impact on poultry production systems.

The European Union may ban the currently available rodenticides at rates exceeding 30 ppm. Then, products with lower doses will need to be used.

Anticoagulant combinations can successfully control rats in doses lower than the standard and reduce the release of these products into the environment.

In contrast, integrating natural predators into the rodent control strategy has been considered an eco-friendly and efficient way to manage rodent populations.

Predatory birds, such as owls and hawks, can be attracted to the farm, and farm cats can be efficient predators.

However, all these predators raise biosecurity concerns.

Another biological control technique gaining importance is the rodent birth control. Some products contain active botanical ingredients and pheromones to attract females to ingest them.

These products may include cottonseed oil and extracts of plants such as stone seed root (Collinsonia canadensis), silphium herbal, blue cohosh (Caulophyllum thalictroides), rue herb (Ruta graveolens), and others with contraceptive properties.

These are non-toxic, non-lethal, and environmentally safe products, meeting EPA minimum-risk standards under FIFRA 25(b) exemption. They integrate with pest control plans, have a long shelf life, and can be used in conjunction with traps. The effects can be observed over a period of six weeks to a few months.

MONITORING RODENT POPULATIONS

Consistent and regularly monitoring feed storage zones, poultry housing, and the farm’s perimeter is essential in the rodent control strategy.

Early signs of rodent activity should be detected and immediately addressed.

Modern monitoring tools like motionactivated cameras and ultraviolet urine trackers can provide valuable information about rodent activity.

The most crucial factor in rodent control is the engagement of farm staff to identify and report signs of rodent activity.

THE IMPORTANCE OF STAFF TRAINING ON ANIMAL WELFARE ISSUES IN POULTRY INDUSTRY

M. Verónica Jiménez Grez

MV, MSc Ethology and Animal Welfare

Animal Welfare Consultant

mvjgrez@gmail.com

Animal welfare has acquired a fundamental role in the management and production of animals in production systems, not only due to regulatory, ethical or customer requirements, but also for production purposes.

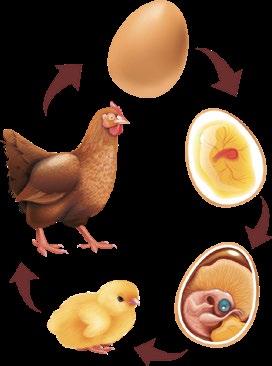

Animal welfare has a direct relationship with productivity.

Animal welfare is all the daily practices that are carried out on layers, eggs, chicks and broilers; daily practices as, handling, restrain, broiler breeders and fattening procedures, etc. that we do routinely in every phase of the production chain.

This article addresses the importance, concepts, relevance of audits and commitments of the companies regarding the training of the personnel involved, examining how personnel training contributes to a better quality of life for the animals, and consequently the quality of the final product.

Those countries that do not have specific animal welfare regulations can base their programs on the international recommendations of the OMSA, Chapter 7 of the Terrestrial Code, among other bodies, which serve as essential guidelines in this field.

The Concept of Animal Welfare 1

According to OMSA, animal welfare is defined as “the physical and mental state of an animal in relation to the conditions under which an animal lives and dies.”

Welfare depends not only on immediate physical conditions, such as good fitness, beak conformation, limbs in hatchery chicks, or proper body condition in breeders, among other direct indicators, but also in environmental or external resources.

Key Welfare Indicators are important.

For animal welfare assessment, according to the approach proposed by Mellor, Beausoleil, Dr. Temple Grandin’s wrote a paper entitled in 2022; Practical Application of the Five Domains Animal Welfare Framework for Supply Food Animal Chain Managers, focuses on the “Five Domains”.

The Five Domains model is being increasingly used as a framework for assessing animal welfare on farms, Table 1.

Animal Welfare

Domain

First Nutrition Water

Breast blisters

Hock burn

Foot pad lessions

Secod Enviroment

Third Health

Fourth Behavior

Cleanliness of plumage

Space-Day of catch- Boirds can move away 1m

Housing requeriments and specifications

3 point gait scoring

Bruise scoring

Effectiveness of stunning

Environmental enrichments

Acts of abuse

Broken wings due to poor handling

Table 1. Key Welfare Indicators for Broiler Chickens. Source: Practical Application of the Five Domains Animal Welfare Framework for Supply Food Animal Chain Managers, Grandin, 2022.

2

Corporate commitment

Corporate commitment to poultry welfare is a fundamental priority in poultry production, as it directly influences product quality, animal health, in other

These domains are: (include positive/negative aspects)

Nutrition: refers to the quality and availability of food.

Physical environment: includes the conditions of space, climate and facilities.

Health: encompasses disease management and access to medical care.

Behavior: assesses the animal’s ability to express its natural behaviors and avoid stress or unnecessary suffering.

Mental: measures the animal’s emotional states, such as stress, fear or comfort.

Companies that assume this voluntary responsibility seek and choose to certify their production chain in animal welfare, they are not only looking for a stamp on their final package, but also to improve their breeding and production skills, better manage their resources and make informed and timely decisions and, finally, also to ensure compliance with high international animal welfare standards and the most demanding customer regulations.

The company’s commitment also involves continuous training of employees in several themes, like management practices, proper restraint, humane euthanasia, SOP´s, daily checks, emergency plans, among others, ensuring that personnel are prepared to intervene appropriately in situations of stress or disease of the birds and to make timely and informed decisions.

A company committed to bird welfare always seeks continuous improvement, ensuring that all its operations are aligned with management principles aligned with bird welfare.

Training provides staff with the tools and knowledge to recognize and address animal needs and implement corrective measures when necessary.

3

The Fundamental Role of Animal Welfare Training

Dr. Temple Grandin, a leading expert on animal behavior and welfare in production systems, has emphasized that staff training is one of the key pillars in ensuring animal welfare.

According to Dr. Grandin, when workers understand the natural behavior of animals, they can significantly reduce stress and suffering during handling, which translates into better production results and improved welfare.

Staff training is essential to ensure that best practices in animal welfare are applied, especially in sectors where animals are handled intensively, such as factory farming and poultry production.

The High Cost of Not Training, or Lack of training in animal welfare not only affects the animals, but also the profitability of companies. Studies in the production sector have shown that handling errors can generate up to 10% of production losses due to injuries,

World Organization for Animal Health (WOAH) has identified that poor animal handling can result in economic sanctions and trade restrictions for companies that do not comply with regulations.

Have you ever measured the cost of train or not train? (Costs and Benefits of Improving Farm Animal Welfare, Fernandes, 2021).

A study by Dr. Grandin (2014) indicates that rough handling of animals in poultry production facilities can significantly increase stress levels, resulting in lower weight gain and higher mortality.

“Training in animal welfare is not expensive, but not training is” Temple Grandin.

Improving farm animal welfare costs money.

People who have animals in their care must consider many factors when modifying their practices to improve welfare, and it is not always obvious what the optimal course of action is.

Animal welfare decision support systems, such as economic cost-benefit analyses, are useful at the time of quantification.

Other studies have shown that workers who receive constant training are able to reduce the percentage of chickens injured during the catching and transport process, which has a direct impact on the quality of the final product and the reduction of economic losses.

Minimun legal requirements

1. Welfare of the animal.

Trainingbenefits

In addition to the benefits for the animals, animal welfare training also brings significant advantages for organizations, as it empowers employees and makes them stakeholders in the system.

Enhanced Product Quality.

Educated employees can recognize and prevent welfare issues like broken eggs in hatcheries, overcrowding, rough handling, and poor stunning practices.

Consistent stunning efficiency ensures proper electrical or controlled-atmosphere stunning, reducing blood spots and hemorrhages in the meat.

Reduces carcass defects (bruising, broken bones, wings).

Reduces stress and suffering during handling, transport, and slaughter.

Enhances workers’ ability to recognize and address welfare concerns

Reduces losses due to mortality, injuries, and downgraded meat

Enhances brand reputation, increasing consumer trust and market access.

Ensure proper treatment throughout the production chain.

Figure

Animal Welfare Certification/ Animal Welfare Audit 4

The role of an animal welfare auditor is crucial to make a diagnosis of the company, detect the strengths and weaknesses of the system, as well as to detect the training needs of employees in the farm, transport and slaughter plant and their issues.

The main purpose of an internal animal welfare audit is to evaluate various aspects of animal handling, such as housing conditions, feeding, transport, treatment at slaughter plants and compliance with established operating procedures.

During the process, records are reviewed, personnel practices are observed, employee interviews are conducted, and facilities are inspected to identify possible deficiencies that may affect animal welfare.

Internal

audits serve as a proactive tool for continuous improvement by:

Detecting problems early and implementing corrective actions before they escalate into major compliance violations.

Ensuring that best practices and welfare protocols remain up to date with industry standards and regulatory requirements.

Strengthening accountability and transparency in animal handling operations.

Chain Audits

Farm Animal Welfare Auditors

These auditors specialize in the evaluation of animal conditions within the farm, broiler breeders, hatcheries, broiler farms.

Their work includes inspection of housing, environment systems, feeding, access to water, health and disease management, animal behavior and general facilities conditions.

They evaluate compliance with regulations and best practices to ensure that animals are treated properly from birth to slaughter. Review protocols and SOP´s in the field and check if the employees are following the program.

Animal Welfare Transport Auditors

Their focus is on animal transport conditions, evaluating in the catching (manual, automatic), density, loading, handling during transport, vehicle conditions, coops conditions, environmental conditions, travel time.

Auditors verify that animals are transported in a safe and humane manner, complying with established transport regulations.

Slaughter Plant Animal Welfare Auditors

Review the practices from the entrance of the trailer until the bird dies. Their task includes

inspection of stunning and slaughter methods, handling of animals prior to slaughter, compliance with emergency procedures and minimization of suffering during the slaughter process, and also quality of meat to prevent injuries and train personnel.

Beyond facility inspections, audits also assess the competency of employees in handling animals humanely. This includes:

Observing employee-animal interactions and adherence to welfare protocols.

Identifying knowledge gaps through staff interviews and training record reviews.

Evaluating the correct execution of emergency procedures and preventive measures.

When deficiencies in animal welfare are identified, targeted training programs can be recommended to address critical issues and enhance compliance and create a urgency training program, and of course, annexes to contracts that impose liability on employees if they abuse animals.

The Role of The Trainers 5

Trainers are fundamental in ensuring that all personnel involved in animal handling acquire the necessary skills and knowledge to perform their roles ethically and competently.

Training programs provide employees with a clear understanding of the best practices in animal welfare, fostering a culture of responsibility and continuous improvement.

The role of the trainer includes:

Delivering specialized education on animal welfare legislation, industry standards, and SOPs to ensure compliance and proper implementation.

Providing theoretical and practical training on identifying and managing stress, pain, and discomfort in animals at different production stages.

Teaching the correct use of equipment and handling techniques that minimize suffering and enhance animal well-being.

Training content 6

These are the minimum contents that a poultry farm employee should receive and should address key aspects to ensure proper animal handling. Some essential areas include:

Introduction to Animal Welfare.

Definition and concepts of animal welfare.

Importance of animal welfare in animal production.

Animal welfare assessment (indicators).

Animal Behavior and Management.

Welfare in each area; hatcheries, breeders, fatteners, broilers, transport and slaughterhouse.

Bird restraint.

Human-animal relationship.

Verification of Environmental and Infrastructure

Conditions.

Adequate space per animal and environmental enrichment.

Food and Nutrition Management.

Daily verification and routine.

Verification records.

Maintenance of facilities.

Health animal vs sick animal identification of signs of disease.

Emergency protocols and emergency euthanasia.

Biosecutiry / Foodsafety.

Good practice in catching, loading and transport.

Impact of improper handling on the quality of the final product.

Personnel Responsibility.

Importance of animal welfare in product quality.

Acts of Abuse and/or Neglect.

Training personnel in animal welfare is not just a regulatory or ethical obligation, it is a strategic investment that enhances productivity, product quality, and operational efficiency.

The evidence presented throughout this article underscores that well-trained employees are fundamental to ensuring humane animal handling, minimizing stress and suffering, and optimizing production outcomes.

Companies that commit to continuous training and implement robust welfare programs not only improve their brand reputation and market access but also strengthen the sustainability of their operations.

Internal audits and certification processes play a crucial role in identifying training needs and reinforcing welfare standards across the production chain.

Ultimately, animal welfare training is a dynamic and essential component of responsible animal production.

By equipping employees with the necessary knowledge and skills, organizations can foster a culture of compassion and accountability, ensuring that welfare principles translate into tangible benefits for animals, workers, and businesses alike.

The Importance of Staff Training on Animal Welfare Issues in Poultry Industry

Animal Welfare

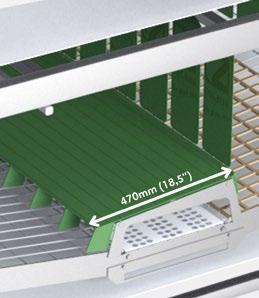

ELEVATE HATCHERY

PERFORMANCE WITH PETERSIME’S NEW DATA-DRIVEN INCUBATION

SUPPORT SERVICE

Petersime Technical Team

Managing a hatchery means handling daily operations while striving for continuous improvement. What if you had a trusted partner to help optimize your incubation process effectively?

Petersime’s data-driven incubation support service is designed to ensure no detail is overlooked while helping hatcheries achieve optimal hatchery performance.

Recurring and data-driven support of your incubation performance

At Petersime, we see a dynamic and evolving service offering as an important cornerstone of our business. Our goal is to ensure continuous improvement in our service delivery to customers, adapting to their ever-changing needs.

With the introduction of our new datadriven incubation support service, we are taking our commitment to exceptional support to the next level.

Our experienced incubation specialists analyze your critical data, such as incubation graphs, OvoScan™ readings and alarm logs, to identify inefficiencies and uncover trends.

In the hundreds of incubation graphs, they provide an extra pair of eyes to scan for anomalies, deviating incubator behaviour or potential issues.

This approach allows you to concentrate on daily operations while we provide valuable insights based on our analysis of the data from the Eagle Trax™ Basic module.

How will this look in practice?

Every four months, you will participate in an in-depth online session with an experienced Petersime incubation specialist who will present a detailed report filled with expert advice and practical insights.

During this session, the incubation specialist will share important findings, answer your questions and help you implement actionable steps to enhance efficiency and overall hatchery performance.

Hatchery

Key benefits of our incubation support service

Expert insights three times a year

Ongoing analysis of incubator data

Guarantee consistency in your incubation performance with an external pair of eyes making sure no sign of potential issues in the incubation process gets overlooked.

Detailed reports based on periodic analysis of the hatchery’s incubation results, along with online sessions with a Petersime expert.

A commitment to Operational Excellence

This innovative service is part of Petersime’s commitment to empowering hatcheries through expertise, technology and customer care.

It complements a broader range of offerings, including 24/7 support, audits and training programs, all designed to ensure your hatchery performs at its best throughout its entire life cycle.

With Petersime’s incubation support service, you gain a competitive edge, uncovering the insights needed to achieve optimal performance and drive consistent results.

Customized solutions

Maximized e ciency

While incubation specialists handle the analysis, you can dedicate your time to operational priorities.

Tailored recommendations based on the speci c

Elevate Hatchery Performance with Petersime’s New Data-Driven Incubation Support Service DOWNLOAD PDF

Hatchery

Eagle Trax™

Intelligent hatchery software that turns data into maximum poultry performance

Hatcheries have a wealth of valuable data available. Unlocking the potential of that data presents a major opportunity to improve the overall performance of hatcheries as well as of the entire value chain. With Eagle Trax™, Petersime offers the first intelligent hatchery software that turns data into maximum poultry performance. Eagle Trax™ allows you to digitise, analyse and optimally use data to advance ever more in hatchery efficiency, productivity and chick quality.

With Eagle Trax™, your hatchery will always maximise the genetic potential of each hatching egg and deliver predictable output of the most profitable day-old chicks for everybody involved in the poultry value chain.

© Petersime 2025 - All rights reserved.

AVIAN PATHOGENIC E.COLI (APEC): SEROTYPES AND VIRULENCE

Cecilia Rosario Cortés Faculty of Veterinary Medicine and Zootechnics, UNAM

Escherichia coli has long been underestimated, traditionally considered as an environmental and opportunistic agent in immunocompromised animals, or as a complicating agent in viral infections in poultry.

However, for some years now, it has been considered a primary pathogen causing multi-million dollar losses worldwide, although it is difficult to estimate its real impact.

The economic impact has been related to a decrease in growth and seizures in the broiler processing plant, low production in laying hens, as well as an increase in mortality. Even when rearing conditions are inadequate, E. coli infections compromise bird welfare.

Escherichia coli was discovered in 1886 by Theodor Escherich, who found this microorganism in the feces of children. Since then, it has been considered a normal inhabitant of the intestinal biota of various animals and humans and plays a very important role in the digestion and regulation of the intestinal microbiota.

This bacterium belongs to the family Enterobacteriaceae, is gram negative, facultative anaerobic; it grows at temperatures between 15°C and 45°C, does not produce spores, can be motile or immotile and is normally a lactose fermenter, although there are strains that are not able to use this substrate.

This microorganism has been classified into three main groups:

Commensal strains

Intestinal pathogenic strains (InPEC) or diarrheogenic strains

Extraintestinal pathogenic strains (ExPEC), depending on their pathogenic potential.

The latter group includes uropathogenic strains (UPEC), those causing bacterial meningitis (BMEC) and those causing infections in birds known as avian pathogens (APEC).

BIOCHEMICAL IDENTIFICATION

Traditionally, its identification in the laboratory is based on its biochemical properties (Figure 1) since sophisticated equipment is not required, however, given the diversity of this bacterium it is not sufficient to know the virulence of the strain in question, nor is it possible to differentiate between pathotypes.

Therefore, other methods are required to elucidate whether a particular strain has the pathogenic capacity to cause an infectious problem in a flock.

Figure 1. Short biochemistry (from left to right) classic of an E. coli strain, TSI, citrate, LIA, urea and SIM.

Pathology

SEROTYPING

Serotyping has been used as a very useful tool for epidemiological purposes. In the case of this bacterium, the Kauffman-White scheme is used, similar to that of Salmonella, which is based on the identification of somatic “O”, capsular ‘K’ and flagellar “H” antigens.

In the case of E. coli, 197 somatic, 80 capsular and 60 flagellar antigens have been identified.

When only the somatic antigen is referred to, it is called a serogroup, and

When both the somatic and flagellar antigen are mentioned, then it is called a serotype.

In the case of the “O” antigen, it is part of the lipopolysaccharide (LPS) that is part of the outer membrane of gram-negative bacteria, which is composed of lipid A, the inner core, outer core and side chains that are repeated polysaccharide units containing 2 to 5 sugar residues.

As is evident, the great diversity of the “O” antigen offers advantages to the bacterium to survive in specific niches, in fact, it is considered a very important virulence factor, not only for APEC strains, but also for ExPEC strains.

Since it prevents the binding of host antibodies to antigens that are located in more internal structures in the bacteria, it is also known to prevent the binding of phages to membrane proteins; it has even been shown that this antigen is capable of inhibiting the enzymatic action of lysozyme.

On the other hand, the “O” antigen is highly immunogenic and is the main antigen against which the immune response is mounted, which represents a great challenge for the production of vaccines, because as mentioned, at least 197 antigens are recognized and between most of them there is no cross-protection.

Until a few years ago, it was recognized that the most common serotypes among APEC strains were O1, O2 and O78.

However, as more strains involved in poultry infections have been analyzed, it has been determined that serotypes vary depending on the geographic area, time of isolation, type of bird and location of infection.

Although serotyping can be very useful to relate certain serotypes to some disease outbreaks, as well as biochemical identification, it does not provide information on the virulence of the isolated strains.

For this reason, various methods such as molecular methods have been used to define the virulence of a given strain.

ISOLATED STRAINS SEROTYPED

In Mexico, several studies have been carried out in which strains isolated between 1997 and 2019 have been serotyped, which were obtained from broiler breeders, layer breeders, hatcheries, broiler chickens, chicken carcasses in processing plants and points of sale, laying hens, backyard poultry and quails; a total of 1235 strains were serotyped, which are shown in Figure 2.

Quails

Backyard birds

Laying hens

Chicken carcasses at point of sale and...

Broiler chickens

Hatcheries

Layer breeders

Broiler breeders

Figure 2. Origin of the 1235 E. coli strains isolated in Mexico that were serotyped from 1997 to 2019.

In total, 131 different serogroups were identified, of which 30 only one strain was identified, while the most frequent were the non-typeable strains, followed by strains O25, O8, rough strains, O2 and O82, as shown in Table 1.

It can be seen that most of the serogroups found are not those traditionally reported as characteristic of APEC strains.

Table 1. Most common serogroups of E. coli isolated from different poultry samples from 1997 to 2019.

Table 2. Common serogroups of E. coli isolated among the groups with the highest numbers of strains analyzed.

In addition, we compared the serogroups that were most frequently found in the samples for which we had the greatest number, as shown in Table 2.

In this one you can see that O19 and O84 were common in broilers and broiler carcasses both at the point of sale and in processing plants;

While in the case of strains O82 and O153, they were found in both carcasses and laying hens;

Finally, serogroups common in chickens, carcasses and hens were found, such as O2, O8, O25 and O103, which could be considered as candidates for the development of an immunogen for the prevention of avian colibacillosis.

APEC INVOLVEMENT IN EXTRAINTESTINAL DISEASES

APEC strains have been implicated in a wide variety of extraintestinal diseases in different avian species, from localized infections, such as:

Omphalitis, yolk sac infection, cellulitis, swollen head syndrome, diarrhea, venereal infections, salpingitis, salpingoperitonitis and peritonitis, orchitis and epididymitis;

Head: Swollen Head Syndrome

Heart: Myocarditis and pericarditis, often with brinous deposits

Liver: Perihepatitis, often caseous. Stained liver lesions

Systemic infections such as colisepticemia of respiratory origin, enteric, neonatal or sequelae of these infections such as meningitis, panophthalmitis, osteomyelitis, spondylitis, arthritis, synovitis and salpingitis, among others.

This same versatility has called into question whether the APEC group can actually be considered as a single pathotype or whether there are subpathotypes that are responsible for the different syndromes and therefore possess specific virulence genes that cause the clinical manifestations caused by E. coli in birds.

Lungs and air sacs:

In ammation (aerosaculitis)

Exudate in lungs and air sacsRespiratory distress

Legs: Ulcerative pododermatitis (Bumblefoot)

Kidney: Nephritis and lesions

Reproductive system: Salpingoperitonitis syndrome (SPS)

Inhalation leads to respiratory tract infection

Spread from the alveoli to the underlying tissue of the reproductive tract

Ascending cloacal infection of the reproductive tract

Extraintestinal spread from the gastrointestinal tract to other organs

APEC’S ENTRY ROUTES

One of the main routes of entry of APEC is through the respiratory tract by inhalation of contaminated dust, for which adhesion to the trachea is a critical initial step in causing subsequent septicemia; an important structure in this process is fimbria type 1 which binds to the D-mannose residues of tracheal and pharyngeal epithelial cells via the adhesin FimH.

It is known that bacterial isolates that colonize the trachea, lungs and air sacs commonly express fimbria type 1, while those that are capable of colonizing internal tissues or causing septicemia do not.

In contrast, strains that cause infections in air sacs, lungs or internal organs express P-type fimbria, whose adhesin PapG binds to the glycolipid galabiose;

This adhesin has three allelic variants, of which most APEC strains are reported to possess PapGII.

However, in a study in which different genes were detected in 30 strains of E. coli isolated from laying hens with peritonitis in the region of Los Altos de Jalisco, only one of them was positive for this gene, while 100% were positive for FimH.

OTHER CRITICAL FACTORS FOR E. COLI VIRULENCE

Other critical factors for E. coli virulence are iron acquisition systems through siderophores; it has been reported that 40% of APEC strains possess the aerobactin system, while it was only found in 30% of strains isolated from healthy birds.

These virulence factors are regulated by bacterial communication systems (quorum sensing) through autoinducers, of which autoinducer 2 (AI-2) is widely distributed among several bacteria and plays a crucial role in the survival and formation of biofilms.

There are two types of AI-2 receptors, LuxP and LsrB, both of which are able to bind AI-2 despite having a different structure; recently Zu et al. (2009) demonstrated that deletion of the lrs operon, composed of 8 genes, including lrsB, decreased virulence 294-fold in APEC strains as the amount of bacteria present in blood, liver, spleen, kidney, was significantly lower than in the wild-type strain.

Despite all the factors that have been described in APEC strains, Johnson et al. in 2008, after analyzing a significant number of virulence genes, concluded that most virulent strains possessed at least three of five genes that could be identified by a multiplex PCR test called pentaplex, as shown in Table 3.

GEN FUNCTION

iroN Salmochelin receptor gene

ompT Gene of an episomal outer membrane protease

hlyF Putative avian hemolysin gene

iss Episosomal serum survival enhancement gene

iutA Aerobactin siderophore receptor gene

Table 3. Virulence genes considered in the pentaplex to determine the virulence of APEC strains of E coli.

However, it is worth mentioning that in our laboratory we have found strains that have shown virulence in birds and in embryonic lethality tests that do not have them, which reinforces the idea of the existence of subpathotypes.

An example of this is found in the study by Maturana et al. who observed that strains isolated from different syndromes had some characteristics in common with each other, but differed from those found in other syndromes, suggesting that APEC is not a homogeneous pathotype.

These findings have led several groups around the world to study APEC strains, which will undoubtedly result in a better understanding of the virulence mechanisms and pathogenesis of APEC strains, and, consequently, in the design of better strategies to control the impact on the health of poultry flocks and the economic impact on poultry producers.

Avian Pathogenic E.Coli (APEC): Serotypes and Virulence DOWNLOAD PDF

Tailored with farmers in mind.

Cylindrical air circulation fan made of plastic

• Fan body made of plastic

• Special impeller shape design

• Three-phase to single-phase conversion

• Designed for harsh enviroment

• BessLab certified

• Reduced weight

• Compliant with ErP 2026 (only 26”)

• Designed and produced in Italy

THE STRATEGY FOR A PROPER INFECTIOUS BRONCHITIS CONTROL

Marco Aurélio Elmer Lopes1, Mathilde Lecoupeur2, Guillermo Gonzalez & Jean Leorat3

1Global Poultry Director, CEVA Santé Animale

2Vaccination Services Manager, CEVA Santé Animale

3Veterinary Services Manager, CEVA Santé Animale

It is well-known that Infectious Bronchitis (IB) is a significant disease in the poultry industry for several technical economic reasons.

This can lead to long-term health issues in the flock, such as secondary bacterial Infections, which can impact severely at farm and further processing levels by increasing mortality and meat yield loss (e.g. increased condemnation rate due to airsacculitis, lack of carcass uniformity, etc.).

The Virus

Caused by the Infectious Bronchitis Virus (IBV), this disease primarily affects the respiratory system but can also impact the reproductive and renal systems, leading to severe economic losses in commercial poultry farming.

Considering the high spread capability of this virus (IBV), which according to some studies 1 bird can infect up to other 20 birds, an effective IB management must consider good biosecurity practices, vaccination, and monitoring for early signs of the disease.

Protecting poultry flocks against IB is crucial for maintaining productivity, ensuring animal welfare, and securing the profitability of the poultry industry.

Strategy Control

Since vaccination is a key point on the IB control, see the 3 pillars should be considered for a solid strategy:

Provide an homogeneous protection, since day 1 for all the ocks chicks (aiming 100% of chiks)

Provides a broad-spectrum protecction against sereval IBV strains

Virus control by the reduction of sheeding (lower Ro, lower transmission)

When conducting spray vaccination at a hatchery, consider the following main points to ensure effective and efficient spray vaccination at the hatchery, to achieve the best vaccine efficacy against infectious diseases:

Vaccine Preparation: Ensure vaccines are stored properly, at the correct temperature 2 to 8°C, typically in a refrigerator dedicated to vaccines, and follow the recommended & standardized procedures.

Water Quality: quality, non-chlorinated water with low mineral content to reconstitute the vaccine. Demineralized water is the ideal.

Hygiene: Maintain strict hygiene standards to prevent contamination. Use dedicated equipment for vaccine preparation and application

Monitoring: Regular checks to ensure that the spray equipment is functioning correctly and that the vaccine is uniformly applied. Use the Ceva Desvac Droplate® tool in a empty chick boxes to verify coverage

Coverage and Timing: Aim for even and complete coverage of the chicks.

Spray Equipment: Use appropriate spray equipment, with flat nozzles, to ensure even and consistent coverage.

Spray Droplet Size: Ensure the spray produces coarse droplets (100 to 200 microns) to avoid deep inhalation into the respiratory tract, which can cause adverse reactions. The droplet size is the key aspect to define of vaccine virus multiplication area in respiratory system.

The percentages are for informational purposes only. The outcomes can vary from one hatchery to another according to the equipment used, and the training received to use the machine. They should not be considered as definitive

Flat nozzle system. Correctly vaccinated

Disease control

Broad spectrum cross-protection is crucial for controlling Infectious Bronchitis (IB) in poultry, as in the field multiple IBV clusters can impact simultaneously.

The IB is caused by various strains of the coronavirus, which can mutate and recombine, leading to new variants.

Broad spectrum cross-protection helps cover a wider range of these strains, reducing the risk of outbreaks

Even in the same region, more than one strain can be found and challenge the birds. This way, a broad-spectrum cross-protection helps cover a wider range of these strains, reducing the risk of outbreaks, protecting the birds and flocks.

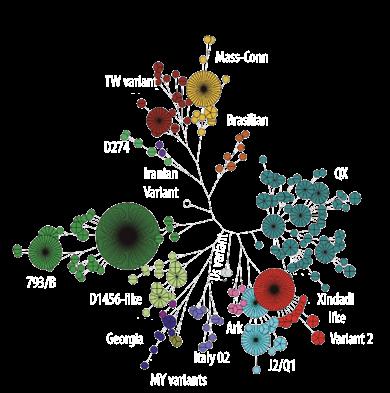

See 2 examples of IBV epidemiology:

South Asia (2021-2025)

(793B-like)

(793B-like)

Some vaccines can provide crossprotection against different IB strains. The combination of 2 different vaccines, such as IBird (1/96 strain – GI-13) and Massachusetts (GI-1) can provide protection against multiple serotypes and enhance the overall immunity of the flock.

Europe (2021-2025)

GI-13 (793B-like)

GI-13 (793B-like)

GI-13 (793B-like)

GI-13 (793B-like)

GI-13 (793B-like)

GI-13 (793B-like)

GI-13 (793B-like)

GI-13 (793B-like)

Broad spectrum protection helps maintain the integrity of the respiratory tract, reducing the occurrence of secondary bacterial infections, and allowing the expression of the full genetic potential of the chicks.

GI-13

GI-13

GI-19 (QX)

GI-19 (QX)

GI-19 (QX)

GI-16

GI-16

GI-19 (Xindadi)

GI-19 (Xindadi)

Disease prevention

IBV spreads rapidly to neighboring flocks and farms due to its rapid capacity. In this context besides the disease clinical protection, blocking the field virus replication and shedding to the environment will be essential for Infectious Bronchitis control.

If the protection is achieved, it is possible to achieve too the disease prevention by the reduction of field virus shedding. It will provide several key benefits for poultry health and overall production efficiency, such as:

Under Control

Not controled

Decreased Disease Transmission

Because of the virus shedding control, the dissemination of the virus will be reduced, and over time the control of the Infectious Bronchitis. 1 2 3 4 5 6

Lower Secondary Infections

Better Vaccine Efficiency

Improved Production Performance

Economic Benefits

Protection of Future Flocks

Conclusion

The protection of poultry against Infectious Bronchitis is essential for sustainable poultry production. A comprehensive approach that includes effective vaccination, stringent biosecurity, and proper flock management is necessary to mitigate the risks associated with IBV.

In a scenario in which the IB can reach Reproduction Rate R0 close to 20, what means that each infected bird can infect another 20 birds.

As a result, IB transmission is exponential. With a proper control by the vaccination program, as the combination of IBird + Mass, the R0 will be strongly reduced.

By adopting these measures, poultry producers can safeguard flock health, improve production efficiency, and minimize economic losses, ensuring a stable and profitable poultry industry.

The Strategy for a Proper Infectious Bronchitis Control DOWNLOAD PDF

Ceva Santé Animale S.A.

NEWCASTLE DISEASE: KNOWING THE VIRUS BETTER TO MAKE THE BESTCONTROL DECISIONS

PART II

Eliana Icochea D'Arrigo

Avian Pathology Laboratory

Faculty of Veterinary Medicine, UNMSM-Lima-Peru

Newcastle disease (ND) is a highly contagious viral disease that affects commercial poultry, domestic and backyard poultry.

Caused by the Newcastle disease virus that can cause significant losses in poultry, which in many cases include chickens and hens, but is also known to affect turkeys, ducks, geese and other birds.

In this second part of the article we will continue to learn more about Newcastle disease virus (NDV) and review what prevention, biosecurity and vaccination measures are in place to control this disease that continues to be a problem in many countries around the world.

HOSTS AND VIRAL RESERVOIRS

The virus is known to have a wide host range, with at least 236 species classified in 27 of 50 orders of birds being susceptible (Kaleta EF and C Baldauf. 1988).

However, the greatest impact of the disease is on domestic poultry, chickens and hens, both technified and backyard, where the disease can cause large economic losses (Miller and Koch, 2020).

1980s. Genotype V, Associated to Genotype VII. Dissemination Africa, Western Europe and South America.

Late 1970s. Genotype V, Associated with pigeon variants PPMV 1

The four panzootics described by Dr. Alexander since 1926, when NDV was first recognized, have involved wild pigeons and imported psittacines in the spread of the virus throughout the world (Figure 2).

However, outbreaks of ND in cormorants in the USA in 2010 and in Chile in 2007, caused by genotype V mesogenic type virus (Diel et al., 2012; Moreno et al., 2009), have been of concern to poultry producers in those countries.

End of 1969. Begins in the Middle East. Genotype V, Associated with imported Psittacides

1926 in South Asia

Cormorants: Canada, USA, Chile. Genotype V

Figure 2. Wild birds associated with virus spread and outbreaks of Newcastle disease virus.

Disseminated to England Genotypes II, III and IV

These findings highlight the importance that not only psittacine and columbiform birds represent in the spread of pathogenic strains of the virus, but also wild birds in general, especially in those countries free of vvVEN (Figure 2).

1a

On the other hand, even though it is known that wild birds generally harbor lentogenic strains, while outbreaks in domestic birds are caused by mesoor velogenic strains (Sahoo et al., 2022), historical records and phylogenetic sequence analyses available in the gene bank also suggest that:

Virulent viruses currently circulating may have emerged from low virulence viruses of the 1920s-1940s, by mutational changes at the fusion protein cleavage site (Afonso CL, 2021).

Although, multiple studies have attributed to wild birds the responsibility for outbreaks, considering them natural reservoirs of the virus, the analysis of the casuistry of the Laboratory of Avian Pathology (LPA) of the Faculty of Veterinary Medicine of the UNMSM, and recent studies carried out with isolates obtained during almost 20 years, have shown that:

Fighting birds largely outnumber the occurrence of ND outbreaks over time, showing that they carry the greatest diversity of genotypes, with only virulent viruses of genotypes XII and VII being detected in them.

So in Peru, they constitute the main source of contamination and reservoir of the virus.

The route of transmission of the virus is horizontal, birds are infected by inhalation or ingestion of aerosols or contaminated material;

The infected birds eliminate the virus in nasal and ocular secretions; on the other hand, besides the fact that the ND virus replicates in the respiratory tract, it also replicates in the intestine, being transmitted through the feces (Alexander, 1998).

TECHNIFIED BREEDING

Chickens, Layers, Turkeys, Quail.

Figure 3. Horizontal transmission of the virus.

Secretions and excretions

Infected bird droppings, Aerosol or debris on clothing, shoes etc.

Formites: Man, vehicles, movement of equipment, contaminated water, rodents

CLINICAL SIGNS

The incubation period varies from 2 to 15 days, with an average of 5 to 6 days.

Lentogenic strains cause mild respiratory infection (postvaccination reaction);

Velogenic viscerotropic strains, which are the main strains circulating in the world, cause severe depression, edema around the eyes, swelling of the head and greenish diarrhea (Figure 4 and 5).

Neurological signs include torticollis, opisthotonos, leg and wing paralysis; In birds in production, decrease or cessation of laying and alterations in the external and internal quality of the eggs, whether discolored to white, (Miller and Koch, 2020; Koffi X et al, 2021) the latter even in birds with multiple vaccinations (Figure 6 and 7)

RESERVOIRS

Fighting birds

Backyard birds

Wild birds

Cormorants

Pigeons

Psittacines

Turtledoves

Figure 4 and 5: Neurological signs, facial edema and green diarrhea, in unvaccinated birds.

Figures 6 and 7. Presence of discolored, white or farfara eggs in vaccinated layers.

The birds without immune protection infected with virulent strains;

They show severe depression from the second day post infection, being able to reach 100% mortality at the third or fourth day post infection (Figure 8 and 9).

Macroscopic lesions

The vvVEN cause hemorrhagic lesions in the lymphoid aggregates of the gastrointestinal tract: eyelid mucosa, cecal tonsils, Peyer's plaques proventriculus and fabricius bursa (Figures 10, 11 and 12).

In adult birds in production, egg peritonitis, atrophy of ovarian follicles and degeneration of the oviduct can be observed;

In well protected birds with many vaccines there is no mortality and lesions may go unnoticed (Miller and Koch, 2020; Koffi X et al, 2021 ).

8 and 9. Neurological signs, facial

and green diarrhea, in unvaccinated birds.

Figure

edema

Figures 10, 11 and 12. Hemorrhagic lesions in lymphoid aggregates of gastrointestinal tract.

DIAGNOSTIC

Comparing diagnostic methods for ND:

The main diagnostic tools include:

Viral isolation, serological tests (hemagglutination and hemagglutination inhibition, ELISA).

Molecular tests : Conventional PCR, real-time PCR and F-gene or whole genome sequencing.

Viral isolation is the standard strategy considered as the “Gold standard” test for virus diagnosis, being universally used since the early 1960's (Alexander DJ. 2003)

It is performed by inoculation of Specific Pathogens Free (SPF) embryonated eggs,

however, the allantoic sac inoculation route allows the virus to be isolated from non-SPF commercial embryonated eggs as well.

Rapid diagnosis is necessary to implement immediate control measures, an RT-PCR test using highly conserved primers such as the M and L protein genes can detect all viral genotypes allowing immediate results (Hoffmann B et al. 2009).

To identify virulence, sequences including the cleavage site of the gene encoding the Fusion protein are required.

To identify the genotype, sequencing of the complete F gene is required, which in turn provides us with the virulence identification; This means that the genomic analysis that should not be missed when you have positive isolates is the analysis of the complete fusion gene.

BIOSECURITY

The main objective is to prevent the introduction of the virus to the farm, to avoid the exposure of the birds to the pathogenic virus.

Most of the time isolation is not possible, therefore, strict biosecurity protocols must be implemented, including: Control of people, vehicles, rodent/ fly pests and waste, at all levels of the production process. These measures should also be applied to backyard poultry farms.

People and vehicles are the main carriers of the virus inside the farm, therefore it is essential to follow the protocols of cleaning and disinfection, raising awareness of personnel, and providing the necessary exclusive clothing and materials to comply with basic biosecurity measures such as: bathing, change of clothes, shoes, etc.

Sequencing and phylogenetic analysis have become the method of choice for characterizing circulating strains in the field, showing genetic diversity and a constant emergence of new genotypes in the world (Dimitrov et al., 2019)

On the other hand, the farm infrastructure should contemplate the protection of the shed, equipment, water and feed to avoid access of wild birds, mainly columbiformes that could be carriers of the pigeon-type virus.

VACCINATION

Vaccination is the second most important prevention tool, it does not prevent infection, but has three main objectives:

Decrease or avoid the pathological impact of the disease.

Decrease viral shedding,

Increase the dose necessary to cause infection (Dimitrov KM et al, 2017).

By decreasing viral shedding, the spread of the virus in infected flocks is controlled (Miller and Koch, 2020).

Live and/or inactivated virus vaccines

Live and/or inactivated virus vaccines have been used for many decades for the control of Newcastle disease. The most commonly used vaccines are live vaccines prepared with low virulence strains such as strain B1, La sota, C2 or enteric tropism vaccines such as VG/GA and PhLMV-42 among others.

The La sota strain and its cloned version as live vaccines have been shown to induce the best protection against challenge with vvENC, but one of the problems it faces when used in broilers is its reactivity and that of reducing productive performance.

In Peru and in many Latin American countries where the disease is endemic, there are regulations for the control and prevention of the disease, which require vaccination of all industrial and backyard domestic poultry, mainly chickens and turkeys (SENASA, 2003; OIRSA, 2015; ICA, 2012).

Rocha et al., 2022, compared the postvaccination reaction caused by the La sota strain and an intestinal tropism strain, demonstrating that at 14 and 21 days post-vaccination the La sota strain caused severe histopathological lesions which included a multifocal inflammatory infiltrate and moderate tracheal deciliation compared to the intestinal strain that did not cause such lesions.

This demonstrates that the post-vaccination reaction induced by ND vaccines is of variable severity, with some strains, such as enteric tropism and Hitchner B1, usually causing a mild post-vaccination reaction, while the La Sota strain can cause severe post-vaccination reactions.

Therefore, although the latter induces a rapid and efficient local and humoral immunity, it is not recommended to apply it as a primary vaccination, but as a booster vaccine (Alexander et al., 2003).

Vectorized vaccines

A good current option is the use of vectored vaccines against Newcastle disease that are applied on the first day of age, these have the fusion gene inserted in a viral vector such as the Turkey Herpes virus (HVT).

They have the advantage of not causing post-vaccination reaction while inducing better and longer lasting vaccination protection.

Therefore, it has been pointed out that vaccines based on La sota strain are more commonly used in countries where the virulent virus is endemic, and on the contrary low reactivity strains are used in areas of low challenge or in birds at a very young age (Dimitrov KM et al, 2017)

A disadvantage of the HVT vector is its incompatibility of use with other HVT vaccines, which creates a problem mainly for commercial layer hens that require vaccination at the first day of age against other agents, such as Laryngotracheitis (HVT-LT) or Avian Influenza (HVT-IA).

In a study in broilers challenged with a vvVEN strain of genotype XII, lower mortality (2%) was obtained with a vectored HVT/ND vaccine than with two live vaccines containing enteric strains (12.5% and 18%), as well as a lower frequency of clinical signs (p<0.05).

These results also suggest that the use of enteric vaccines in high-risk areas is not enough to induce good protection against challenge with virulent strains (Sialer M et al (Sialer M et al. 2020).

Therefore, there are currently commercially available vaccines with double insert that are designed to simultaneously protect birds against three diseases at the same time: Marek's disease, ND and Laryngotracheitis or ND and Gumboro disease.

Another aspect related to immunoprotection is that even though the ND strains have been classified into genotypes, they belong to a single serotype. For this reason, lentogenic strains of genotype II are widely used as vaccines.

Many studies have demonstrated the protection of the La Sota strain vaccine, controlling mortality and clinical signs caused by virulent strains; However, it has been reported that vaccines prepared on the basis of genotypes homologous to the virus circulating in the field significantly reduce viral shedding compared to traditional genotype II (heterologous) vaccines.

This contributes to better control of ND outbreaks by reducing the horizontal spread of virus shed by infected birds (Miller PJ et al, 2007).

In one study, protection in broilers was compared between a vaccine with a live, inactivated genotype XII homologous strain developed by reverse genetics and a vaccine with a live, inactivated La sota strain.

Vaccination programs using the genotype XII (homologous) vaccines reduced cloacal viral shedding at 5 and 9 dpi.

Whereas groups vaccinated with La sota strain (heterologous) reduced cloacal shedding at 5 dpi, but not at 9 dpi with a vvENC genotype XII.

Newcastle Disease: Knowing the Virus Better to Make the Best Control Decisions. Part II DOWNLOAD PDF

These results confirm once again that vaccines with homologous strains better control viral shedding to the environment (Cribillero CH Nelly G. 2019).

Pathology

INSIGHTS FROM THE INAUGURAL US-RSPE FRAMEWORK REPORT

Elena Myhre

Director of Marketing and Communications

IPWA and US-RSPE

The U.S. Roundtable for Sustainable Poultry & Eggs (US-RSPE) has recently released the inaugural Sustainability Framework Report, marking a significant milestone in the pursuit of transparency and continuous improvement within the U.S. poultry and egg industries.

This comprehensive report, introduced during the International Production & Processing Expo (IPPE) in January 2025, offers aggregated results of sustainability metrics across the entire supply chain, encompassing broilers, turkeys, and eggs.

Genesis and Mission of US-RSPE

Established as an independent, multistakeholder organization, US-RSPE is dedicated to advancing, supporting, and communicating continuous improvement in sustainability throughout the poultry and egg value chain.

The organization brings together diverse stakeholders, including growers, producers, integrators, processors, retailers, food service companies, civil society organizations, and allied industries.

This collaborative approach ensures that sustainability initiatives are comprehensive and inclusive, addressing the needs and concerns of all parties involved.

The Three Pillars of Sustainability

US-RSPE’s sustainability efforts are structured around three fundamental pillars: Our Poultry, Our Planet, and Its People.

Our Poultry

This pillar focuses on animal health, well-being, biosecurity, and productivity.

Our Planet Its People

This pillar emphasizes environmental stewardship and addresses energy conservation, greenhouse gas emissions, air quality, land use, and water quality.

This pillar recognizes the human dimension of sustainability and covers community support, food safety and quality, and workforce welfare.

Poultry

Development of the Sustainability Framework

The journey towards the Sustainability Framework began in early 2019, driven by the need for a standardized tool to assess sustainability practices across the poultry sector.

US-RSPE embarked on a collaborative process, engaging a wide range of industry participants in a precompetitive, collective effort to create a framework that is both practical and reflective of the industry’s diverse perspectives.

In 2021, the framework underwent rigorous testing through pilots encompassing broilers, eggs, and turkeys.

Leading companies such as Butterball, Cal-Maine Foods, Cargill, Darling Ingredients, Herbruck’s Poultry Ranch, Kreher’s Family Farms, McDonald’s Corporation, Peco Foods, Sanderson Farms, Tyson Foods, and West Liberty Foods participated in these pilots.

Their involvement was crucial in reviewing the framework’s metrics and ensuring its applicability across various operational contexts.

Key Components of the Sustainability Framework

The US-RSPE Sustainability Framework is a voluntary assessment whose indicators encompass a broad spectrum of sustainability aspects, including environmental impact, animal welfare, and social responsibility.

The framework is designed to be scalable and adaptable, allowing organizations at different stages of their sustainability journey to participate and benefit.

The US-RSPE Sustainability Framework and its data are the launchpad for additional work.

Participants are encouraged to report on as many metrics as possible, with the understanding that comprehensive data collection serves multiple purposes:

Individual Benchmarking

Organizations can assess their current sustainability performance, identify areas for improvement, and track progress over time.

Supply Chain Insight

Aggregated data provides a holistic view of sustainability practices across the supply chain, facilitating better collaboration and informed decisionmaking among stakeholders.

Industry Transparency

By contributing to a collective dataset, participants help enhance the overall transparency of the U.S. poultry and egg industries, building trust with consumers and other external audiences.

Highlights from the First Sustainability Framework Report

The inaugural Sustainability Framework Report offers valuable insights into the current state of sustainability within the U.S. poultry and egg sectors. While specific data points are anonymous to protect individual participants, the aggregated findings shed light on several key areas:

Environmental Stewardship

Animal Welfare Community and Workforce Engagement

The report highlights ongoing efforts to reduce greenhouse gas emissions, conserve water, and implement energy-efficient technologies.

Many organizations have adopted renewable energy sources and are actively working to minimize their environmental impact.

Continuous improvement in animal health and well-being is evident with the widespread adoption of enhanced biosecurity measures and welfare standards.

The industry demonstrates a strong commitment to ensuring the humane treatment of poultry throughout their lifecycle.

The report underscores initiatives to support local communities, ensure food safety and quality, and promote workforce well-being.

Programs focused on employee training, community outreach, and food security are prevalent, reflecting the industry’s dedication to social responsibility.

Looking Ahead: The Future of Sustainable Poultry and Egg Production

The release of the Sustainability Framework Report signifies a pivotal step forward and serves as a foundation for future endeavors. US-RSPE is committed to continuously refining the framework, incorporating participant feedback, and adapting to emerging sustainability challenges.

Insights from the Inaugural US-RSPE Framework Report DOWNLOAD PDF

GREEN WAY

Increased density and comfort for higher production

Available in two different widths and combinable in the same vessel

100% of the in the system in one same conveyor

with higher capacity NEW EGG BELT

Two nest levels for better distribution of the birds during laying hours, allowing better uniformity in production

GREG TYLER

QUESTIONS FOR GREG TYLER

AviNews International had the privilege of speaking with Greg Tyler, President and CEO of the USA Poultry & Egg Export Council. Mr. Tyler has a Bachelors and master’s degree in Agricultural Economics, with concentrations in Marketing from the University of Georgia. Prior to working for the USA Poultry & Egg Export Council (for the last 28 years), he worked for 4 years with USDA’s Foreign Agricultural Service in Washington D.C.

What is the USA Poultry & Egg Export Council about?

The USA Poultry & Egg Export Council (USAPEEC) stands as a non-profit, membership-based trade organization established by the industry with the sole mission of enhancing the global export sales of U.S. poultry and egg food products.

Encompassing a broad spectrum, the Council advocates for virtually all poultry and egg food products, spanning chicken, turkey, duck, eggs, game birds, and their associated processed derivatives.

Established in 1984 through a grant from the Southeastern Poultry and Egg Association, USAPEEC gained independent status in 1985.

Guided by its member companies, the Council provides an array of services and advantages to industry members.

These include acting as an information hub, conducting market research and facilitating foreign market access, engaging in advertising and promotional activities, offering trade servicing and leads, organizing educational programs, coordinating trade contacts and meetings, providing sales data, and fostering the positive image of U.S. poultry and egg products.

It is important to note that all activities undertaken by the Council are export-focused, with no involvement in domestic promotional initiatives.

Tell us about the role played by the poultry sector in the USA

The U.S. poultry meat industry, a cornerstone of American agriculture, has established itself as a global leader, consistently exceeding expectations in both production and meeting evolving consumer demands.

Over the past 30 years, the industry has made significant investments in advanced production and processing technologies, aligning with market expectations for product variety, quality, and affordability.

This investment has cemented poultry meat as the primary protein source in American diets, with chicken and turkey becoming household staples.

Similarly, the egg industry has adapted to consumer preferences, positioning eggs as a versatile and nutritious option in a variety of culinary applications.

Growth in the U.S. poultry and egg sectors is fueled by a rising global population, changing dietary habits, and increasing awareness of the health benefits of protein-rich foods like poultry and eggs. These factors have not only driven domestic consumption but also bolstered the industry’s role in global food security.

What are the USA Poultry & Egg

Export Council’s main objectives and priorities for the coming years?

USAPEEC’s strategy blends a standardized global approach with localized strategies to diversify target markets, establish a strong marketplace, and promote sustainable growth. Ongoing assessments and adaptations will ensure the strategy aligns with changing market dynamics and evolving consumer preferences.

This approach aims to maintain the U.S. poultry industry’s position as a trusted and preferred choice in global markets, even as competition intensifies.

As a result, the U.S. poultry sector is a key player in global markets, consistently achieving commercial success while contributing significantly to the global protein supply.

USAPEEC’s strategic planning includes objectives to improve market access, increase awareness of the health, safety, and economic advantages of U.S. poultry products, and expand trade relationships.

Through continued market research, product development, technical seminars, and promotional efforts, USAPEEC is well-equipped to guide the U.S. poultry industry’s future success.

What

challenges does the American poultry industry currently face?

The U.S. poultry industry has faced significant challenges due to HPAI outbreaks in recent years. These outbreaks prompted several major trading partners to impose bans on U.S. poultry imports, severely disrupting trade.