Includes: HR advice, Case Study, Aircon, Alignment & ADAS & more…

Includes: HR advice, Case Study, Aircon, Alignment & ADAS & more…

OPPORTUNITIES TO ADD REVENUE & STREAMLINE BUSINESS PRACTICE

Welcome to the April issue! Event season has well & truly begun, with Alldata’s first Repair Excellence event held at Shaikly Motor Company in Colchester, which provided guests with practical sessions on EV repair, diagnostic process and wiring diagram troubleshooting, plus sessions from James Dillon and our own HR expert Amy Blick, see page 12. An EV Repair Experience open day has just taken place at Pro-Moto in Surrey, which gave detailed overviews of high voltage shutdown procedures and battery repair, see page 10, and the trade eagerly awaits the mighty Automechanika Birmingham, which we will preview in the May issue. See page 4 for news of the official event programme.

In this issue, we focus on the opportunities available to proactive workshops in the fields of aircon, diagnostics and ADAS. We hope this inspires – do let us know of your plans!

Nicola St Clair Editor

Nicola@autotechnician.co.uk

* View and download previous digital issues at: www.autotechnician.co.uk

instagram.com/autotechnician_magazine youtube.com/@AutotechnicianMagazine facebook.com/Autotechmagazine bsky.app/profile/autotechnician.bsky.social

The official event programme for the upcoming June event is now LIVE, packed with seminars, hands-on workshops, demos, and much more

There is a full schedule of seminars, handson demos and Q&As planned throughout the three days of the event within several areas – the Workshop Hub, Aftermarket Hub, Innovation4Mobility, Paint & Spray Live, Body Repair Live, Vehicle Detailing Live and our autotechnician Workshop.

Topics covered within the Workshop Hub, in association with autotechnician, include ‘Future-proofing your workshop: Navigating modern vehicle diagnostics’, the evolution of alignment technology with ISN, vehicle diagnostic processes fit for the 21st century with James Dillon, ‘Powering your workshop’ with JLM Lubricants & a panel discussion hosted by Alldata on how OEM repair data helps independent workshops thrive. The full programme can be found here | Register for your free tickets here

The Motor Ombudsman has entered into a partnership with Alliance Automotive Group, to reinforce AAG’s commitment to industry best practice and customer service excellence through their 1,200-strong, nationwide Approved Garages Network across the UK, including AutoCare, Top Truck, United Garage Services, and NexDrive.

Should any member of AAG’s Garage Networks programme have an unresolved dispute with a customer, they will be invited to apply for accreditation to The Motor Ombudsman’s comprehensive Chartered Trading Standards Institute (CTSI)-approved Motor Industry Code of Practice for Service and Repair. Subject to meeting the stringent qualifying criteria, garages will be able to signpost consumers to the Ombudsman for fair and swift assistance to help conclude disputes using the body’s in-house and expert automotive service. www.TheMotorOmbudsman.org

HEVRA, the Uks largest network of workshops specialising in electric and hybrid vehicle repairs, now supports over 400 models of EV and hybrid vehicles, underlining its commitment to providing comprehensive technical expertise and support for the growing car parc.

The association provides its members with access to the latest training, diagnostic tools and technical support, enabling them to work on the vast range of models across the manufacturers. https://hevra.org.uk/

The IMI Jobs Portal has launched work experience placements for school-aged pupils in 2025 in a bid to address the workforce skills gap.

Launched by the School of Thought Automotive, in partnership with The Institute of the Motor Industry (IMI) and Autotech Academy, the AWE Programme is tackling the skills crisis that has left the industry with an estimated shortfall of nearly 18,000 skilled professionals.

Dave Reece, Founder of School of Thought Automotive, comments: "Addressing the skills gap is not just about filling current vacancies. It's about investing in the future. Work experience is vital in showcasing the diverse career paths within the automotive industry, helping young individuals realise their potential and passion early on."

For participating businesses, the initiative provides an opportunity to engage with the next generation of skilled professionals. Placements can be tailored to suit each company’s needs, ranging from a single day to a week or even a few hours per week, ensuring flexibility for both pupils and employers. With nearly 100 placements already pledged, the portal remains open for more businesses to register their support.

"This programme isn't just about inspiring the next generation," Dave continues. "It's about opening up a direct dialogue between businesses and young people. By pledging work experience, businesses not only help solve the skill shortage but also discover talent that could ultimately drive their success."

The School of Thought Automotive also ensures that businesses receive comprehensive support, including work experience packs with clear guidance on structuring placements, adhering to safety protocols, and supporting pupils’ growth during their time in the workplace.

Businesses interested in pledging work experience placements can do so at AWE Business Registration

For peace of mind always use a Garage Equipment Association member. GEA accredited engineers work to an industry code of conduct. Your assurance their skills and knowledge have been independently assessed.

Oldfields Garage in Herefordshire has been named ‘Garage of the Year’ at the recent Castrol Service Conference. Tim Benson, managing director at Oldfields Garage, said: “We take immense pride in delivering outstanding service to our customers, and to be recognised among so many of the UK’s leading independent garages is something special.

“Our commitment to investing in technology, training, and customer experience ensures we remain at the forefront, and this award is a reflection of that dedication.”

The conference featured a range of expert-led sessions covering topics such as digital marketing, business management, and customer engagement. Attendees also had the opportunity to network with suppliers, such as Garage Hive, and explore the latest tools and services to support independent workshops.

The evening concluded with a gala dinner, where the ‘Forever Forward Awards’ celebrated the achievements of outstanding businesses within the Castrol Service network. Tim was joined by Oldfields vehicle technician, Sam Peters, as they collected the award together in recognition of their team’s hard work.

1TEC Auto Hub’s second annual members event, 1TEC Auto Hub Connect, will take place on 3 April at Silverstone where its 350-strong network of independent garages will convene to gain insights into key trends.

Attendees will hear from industry-leading speakers including LKQ Europe Executive Managing Director Andy Hamilton and Quentin Le Hetet, UK Director of market intelligence experts GiPA. Members will also be able to interact with the network’s technical partners and invited exhibitors during the event, providing valuable networking opportunities with fellow community members.

The event will be capped off with the first annual 1TEC Auto Hub Awards, which will commend the impressive work of members from across the network.

The network was launched in July 2023 by LKQ Euro Car Parts in conjunction with MPM Oil, Pagid, Schaeffler, Shell, Valeo, VARTA and ZF Aftermarket. Members can enjoy a wide range of benefits including the latest technical and diagnostic data, marketing materials and business support to help unlock further revenue streams. www.1tec.co.uk

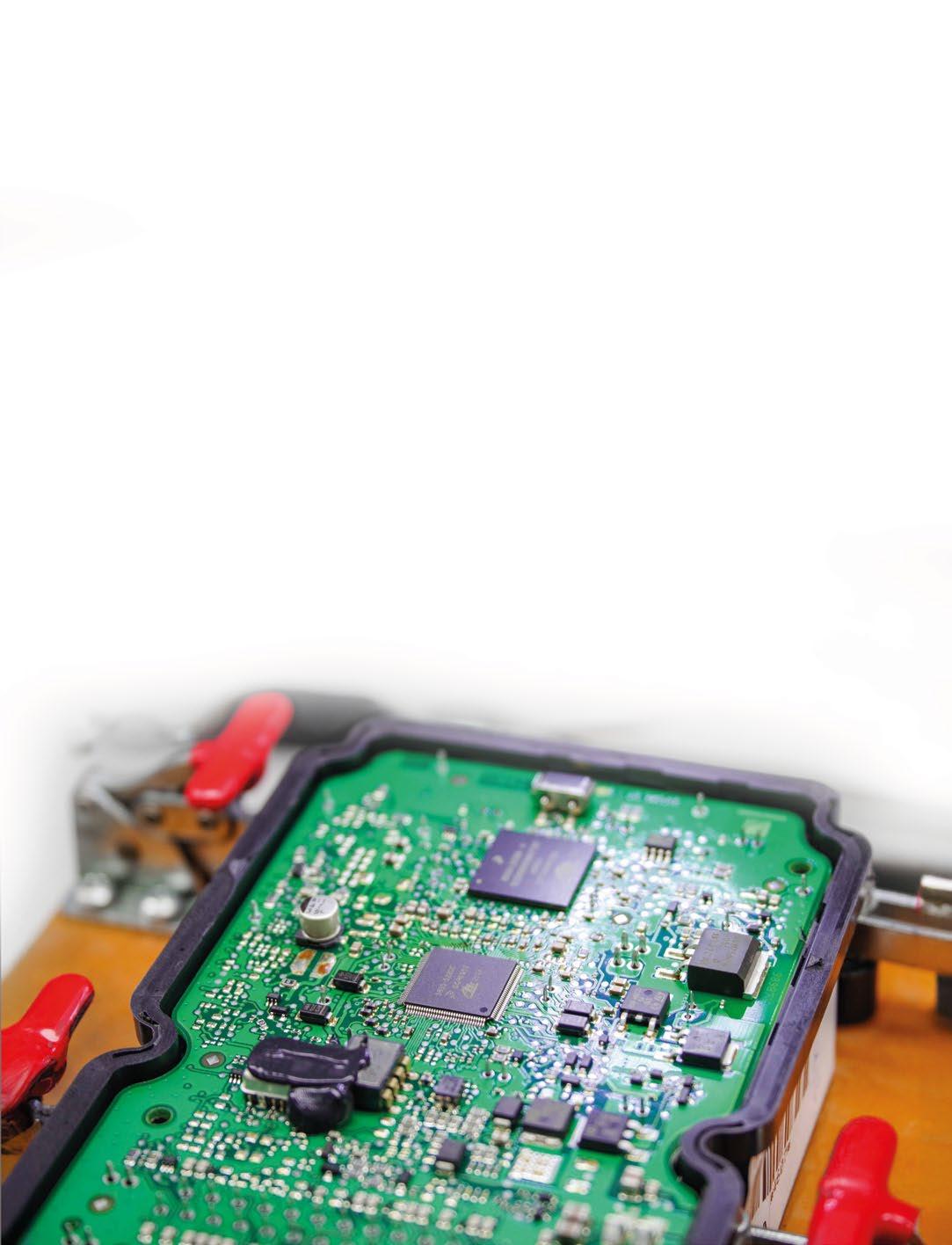

For over 20 years ACTRONICS has been at the forefront of our industry developing sustainable remanufacturing solutions for you.

Our solutions are a cost effective, environmentally friendly alternative to replacement parts. Our Plug & Play solutions ensure a top-quality service backed by a 2-year warranty

The whole ethos behind autotech is to help technicians identify gaps in knowledge and improve fault-finding skills through free, online assessments, technical information from our industry partners and through live fault scenarios at our Workshop Takeover – are you ready to put your skills to the test?

Can you diagnose this Adaptive Headlamp fault?

autotech is an evolving bank of free, confidential online assessments created by independent automotive trainers. All you need to do is log in or register by entering a few details at https://autotechnician.co.uk/registration/, click an automated email reply and you get instant, free access to the multiple-choice tests focussing on various topics and scenarios.

The online test is completely confidential, and you’ll receive your scores, correct answers and technical explanations of the topics covered. Test 18 is now live and involves an adaptive headlamp assessment:

A customer has presented his 2006 BMW E61 to the service department, insisting on a new Xenon headlamp bulb for the right side. According to the customer, the headlamp suddenly stopped working following a heavy downpour.

You accompany the customer to the car park to verify the issue firsthand. Upon inspection, you confirm that the left headlamp is functioning normally, and on the right side, the side marker, angel eyes, and high beam are operational. However, the low beam on the right headlamp is completely inoperative.

Given these symptoms and from your own past experience, you explain to the customer that a simple Xenon bulb replacement is unlikely to resolve the fault. After discussion, the customer agrees to authorise one hour of labour for a thorough diagnosis to identify the underlying issue.

This initial diagnostic approach allows for an accurate assessment of potential causes, rather than simply replacing parts without confirmed evidence of their failure.

You are provided with the circuit schematic and guided through the process to diagnose the problem without replacing parts unnecessarily.

Log in or register by entering a few details at https://autotechnician.co.uk/registration/ and access the entire library of confidential assessments now!

Workshop Takeover returns to Cheltenham Saturday 6th September

Hands-on, guided fault-finding scenarios will once again be on offer to guests at this year’s Workshop Takeover at Cleevely Motors, Cheltenham on Saturday 6th September.

Both experienced diagnosticians as well as those with less years of experience under their belt, will gain valuable takeaways on how to find faults more effectively on both combustion and electrified vehicles. Guests can also enjoy dinner and drinks with the team the night before.

Click above right to view a video summary of last year’s Workshop Takeover.

Click here to register your interest and be the first to know when subsidised tickets go on sale.

In association with:

By Autotechnician resident HR columnist, Amy Blick

As we move into April, businesses face a complex period balancing year-end responsibilities, HR policy changes, salary reviews and statutory pay adjustments.

In last month’s article, I spoke about reverse mentoring, however one key initiative that many businesses I speak to already have (but don’t realise it) is mentoring. 9 out of 10 readers I speak to think they have mentoring in place, yet they forget to communicate this very important fact to their teams effectively. If your team is unaware of mentoring, they miss out on valuable learning opportunities, and you put yourself at risk of losing incredible knowledge in your business.

Mentoring is a brilliant, cost-effective way to upskill your team while enhancing and promoting your company’s culture. While it may require some downtime for mentors, it is significantly more affordable than sending employees on external training courses for days on end. It also ensures that knowledge remains within the company, aligning skills and approaches with business values and client experience.

My top tips for getting the best out of your mentoring:

Clearly define your mentoring structures within individual development plans when you hold 121s

Identify subject matter experts and ask them to volunteer themselves as knowledge experts in your business

Encourage knowledge sharing within teams to build on everyone’s skill and development levels

Communicate mentoring structures and plans to everyone to make sure they are engaged and they sign up!

Embedding consistent mentoring into your business will do brilliant things for your culture – enhancing employee development, improving retention and creating knowledgeable, trained ambassadors. Now is the perfect time to formalise and communicate your mentoring initiatives!

Do you want to implement mentoring but don’t know how? Are you struggling to train everyone in the team? Are you constantly facing knowledge gaps within your team? Do you need support to begin mentoring the right way?

Implementing an incredible mentoring programme in your business doesn’t need to be complicated or expensive. If you need guidance on getting mentoring in place, a Power Hour will be ideal for you – message me if you would like to have an online one-to-one, packed with top tips and strategies for your business.

* Amy@exhilhrate.co.uk

Pro-Moto opened its doors on Saturday 29th March to technicians from across the UK who had undertaken EV Level 3 and 4 qualifications but were keen to get more hands-on experience with common faults and battery repair. Several technicians had undertaken their training at Pro-Moto but for some, it was their first visit after hearing many positive reviews of their practical electric vehicle training.

Ray presented the first session, detailing best practice when isolating the high voltage system on a Renault Zoe before any work can take place. Ray says that as part of their accredited EV training, they run through a more comprehensive 7-point process before each of the delegates puts the theory into practice within the workshop: “Each person removes the service plug and each one does the absence of voltage test, we then put the vehicle back together and check it goes into Ready mode.”

Obvious, but sometimes overlooked, points were reinforced, such as the importance of the ‘Live, dead, live test’ to confirm the vehicle is safe to work on and also the functionality of your multimeter when performing a shutdown; ensuring the EV vehicle is dry before any work takes place, and not blowing into safety gloves when checking they are not faulty. Inaccurate voltage readings and moisture have no place in EV work!

Ray also gave an overview of the various safety features present on the vehicle, should someone without the critical knowledge attempt to access high voltage components – something which one guest said was a literal life-saver when he was an eager apprentice – saying, “I am living proof that these safety systems work!”

Pro-Moto trainer Gary then took over, providing insights into a common electric system problem and charging fault on the Zoe, demonstrating the checks that should be made as part of the diagnostic process.

Automotive lecturer and author Graham Stoakes was also on-hand throughout the day to add useful tips and practical advice, as well as Steve Rouse of Vehicle Technology Solutions, VTS, which supplies a range of diagnostic tools to the trade.

Pro-moto founder Eliot Smith concluded the day with his afternoon session, running through the HV battery repair process.

“The topics covered seem to hit the spot as far as concerns and challenges working on EVs. Some of the subjects covered dealt with areas of technology not usually considered, like charging, 12 volt associated issues and unfamiliar HV start up procedures. Everyone agreed when it came to the Battery Repair session in the afternoon, that this would be one of the biggest challenges and concerns for the trade, so was well received by the audience.”

Eliot Smith, Pro-Moto

ALLDATA's first Repair Excellence event, held at Shaikly Motor Company in Colchester, in partnership with Opus IVS, attracted over 80 technicians and workshop owners, who benefit from a mix of business and technical content during talks, live demos and hands-on training.

Michael Shaikly shared his passion of customer profiling, which he told us has reduced stress, enhanced customer relationships and ensured they are busy with the right type of customers. Our own HR expert Amy Blick presented overcoming HR challenges in the workshop and James Dillon homed in on an effective diagnostic process.

The afternoon practical sessions saw SimplyDiag’s Steve Scott deliver a masterclass on fault finding, Mechanic Mindset’s Darren Quinn dive into wiring diagrams and technical data and Gary Clayton of HEVRA described EV faults and diagnostics in detail, explaining how lucrative EV repair work can be, offering a highly competitive service to customers when compared to the main dealers.

Organisers donated £300 to automotive charity Ben and colleagues from LKQ Euro Car Parts, ACtronics and Shell networked and highlighted their latest products and services to delegates.

Guests travelled to the event from across the UK – Dean Clark of West End Garage Nairn, based near Inverness, commented: “I’ve been using ALLDATA Europe for several years, mainly for wiring diagrams but also for technical service bulletins. The genuine diagrams make a difference, as they give me confidence and reassurance that they are correct – not altered in any way – so when I learned that it was launching its own event, I had to come down!

“The event went well and was worth the travel. The opportunity to hear from some of the industry leaders in training, diagnostics and business was invaluable. The networking was a real bonus, and the willingness of everyone to collaborate and help others was amazing.”

ALLDATA UK Sales Director, Simon Frost, was delighted with its first event: “We are thrilled with how the first Repair Excellence Event has been received. The reaction has been fantastic, and it’s clear that our attendees found value in the combination of content.

“Seeing so many industry professionals collaborating – on a Saturday – to learn and share experiences shows that we’re on the right path. We’re excited to build on this momentum and bring more insights to the industry in future events, starting with our next one in Cheshire.”

The next Repair Excellence Event will take place at DC Lomas, Cheshire, on Saturday 26th April.

To register a place at the second Repair Excellence Event, click here.

Staff shortages, pre-planned holiday & sickness cover

Skilled & experienced techs and MOT testers

Contracts from one day to six months

450+ vetted contractors across the UK

Weekday & weekend cover available

EV-qualified vehicle technicians

febi has launched a comprehensive range of OE turbochargers, including both new and remanufactured models. We work with leading OE manufacturers Garrett & BorgWarner together to always give you the highest quality.

Your Advantages at a Glance:

OE Turbochargers

Available both New and Remanufactured from leading suppliers BorgWarner and Garrett

Our comprehensive range is always expanding to cover the newest models added to the market.

DRIVEN BY YOU

A huge range of periphery products including Mounting Kits, Oil Feed Pipes and Charger Intake Hoses.

Soon we will be introducing Turbocharger Repair Kits including everything you need for a complete repair.

By Neil Currie AMIMI

Have you ever had that horrible feeling after finishing a job where you find a problem exists and you don’t know whether it was there before or is a result of something you have done? This happened recently to one of my work colleagues and I thought it would make an interesting case study...

The vehicle in question was a 2015 Mitsubishi L200 and the owner booked the vehicle in to have the cylinder head gasket replaced – one thing to note before we start, is that the customer declined us checking and confirming the head gasket actually needed doing, as it had been diagnosed elsewhere. This is a subject that could make its very own article as, rightly or wrongly, each garage has their own opinion on whether a job should be taken on without confirming the diagnosis is correct.

The job was given to one of my work colleagues who completed the job and found while replacing the gasket, it had indeed failed. The vehicle was then road tested upon completion and now exhibited an intermittent lack of power and poor running concern. The vehicle had not been road tested prior to the work being carried out as it was overheating.

My colleague rechecked all his work and plugged in a diagnostic scan tool to check for fault codes and none were stored. He then road tested the vehicle again and now to his surprise it ran well but after parking up and trying it again a few hours later, it still had an issue and exhibited the same symptoms previously experienced. It was at this point he wondered whether this was a fault he had introduced, or the fault had been present before the vehicle even entered the workshop.

This is where a somewhat tricky conversation may have to take place, do we phone the customer to ask the question was this fault present before the work was carried out? The problem with that though is that it can be all too easy for the customer to then say no, it was not when in fact it actually was and they then look for their complaint to be fixed by the affected garage for free. Now, I am not saying this is always the case but I am sure we have all experienced this at some stage or another to then diagnose the issue and find it was not related to the work carried out and had to have been present when the vehicle was booked in for work to be carried out.

The other option is you diagnose the fault and then consider if it is because of the work that has been done or has no link and had to be present beforehand. The problem with this is who then pays for that diagnostic time and without the gaining customers authorisation, they can argue permission was not granted to go ahead and find the fault, so it can be a tricky situation to be in. My boss decided we were to diagnose the issue then decide based on what was found whether it was directly linked to the head gasket replacement work that had just been done or was present before the vehicle was brought in.

Rightly or wrongly, you have to respect this decision and do what you are told to do. It was at this point I was given the job and asked to see if I could find what was going on. Road testing the vehicle showed it drove well and performed as expected so it was clearly an intermittent fault and I would need to have patience to catch it in the act. I decided just to scan the vehicle again and check for faults and found no pending codes. I also looked through live data and took a snapshot of the known good data just in case I needed it down the line.

A few hours later I drove the vehicle again and this time within a few miles it started to lack power considerably and I had to turn around and limp back to the workshop. It now had a severe lack of power and giving it a rev made the engine misfire, cough and splutter just like my colleague had experienced, however no warning lights were illuminated on the dashboard. Upon reconnecting the scan tool, I had no stored or pending fault codes, so I had no clues to help pinpoint the issue. At this point, it was back to looking at live data and scanning through it to see if anything stood out as being wrong.

As we can see in Figure 1, with the engine at idle the air mass value no 114 was sitting at 380mg. This seemed awfully low to me for this vehicle, I expected a value much higher and comparing the known good snapshot when the engine was running as it should, it read around 670mg. Now the question is what could be causing a low air flow reading, do we have a dirty or blocked air filter, is the air flow sensor faulty/ dirty causing it to under read? What is the other component on the engine that directly effects air flow in its operation? If you are thinking EGR (exhaust gas recirculation) then you are correct. When the EGR valve opens, some of the gases which leave the cylinder into the exhaust manifold after combustion enter the intake system via the EGR system, since these gases have already burned, they will not take place in the next combustion process. As they are drawn into the cylinder on the intake stroke, they take up some of the space, reducing the amount of incoming air needed to fill the cylinder. This causes a drop in intake air flow as less air is required to fill up the cylinder. The air flow sensor detects this drop and reports back it to the ECU.

So now I had found something amiss, I now had to decide whether it was an issue on the air intake side or the EGR side of things. The next thing I checked was the desired and actual EGR position to see if the EGR valve was being commanded open – if it was, this would explain the low air flow reading. An important thing to remember is that with EGR at idle, with the vehicle stationary, the valve will normally be open partially, but after a period of time if the vehicle is left long enough, the engine control unit will command the valve closed; this is done to stop the engine choking on its own exhaust fumes. However, touching the throttle will cause the ECU to command the valve back open again. This function can be useful if your scan tool does not list an actuator test, or you do not want to start powering the valve without the correct wiring diagram to allow you to see the varying state of air flow in different EGR valve positions.

Both actual and desired EGR position on this vehicle showed 0% shortly after starting the engine, which seems to be normal operation comparing it others I have since seen. So, this shows the ECU is not looking for EGR to be activated and the valve should be fully closed preventing any exhaust gases coming through into the intake system. There should be a high air flow reading as all the incoming air is filling the cylinder, however I have a low air flow reading so this would indicate that even though the EGR valve is closed in live data, it may in fact be stuck partially open. To rule out an issue on the air intake side I unclipped the air box lid and checked the air filter and air flow sensor, both were clean and in good condition. I also checked the air flow sensors plausibility with the ignition on, which showed it to be reading 0, as there is no engine running and no air flowing over the sensor this showed me the sensor was plausible.

My next thought was if the EGR valve was sticking open why was the position sensor not detecting this and showing it in data or even logging a fault code? I decided to actuate the EGR valve using the actuator test of my scan tool and measure the position signal voltage from the valve to see if it was changing. The actuator test allowed positions of 0, 50 and 100% positions. Carrying out the test showed desired and actual EGR positions to match at all 3 points, so from the ECU’s perspective, all was OK, hence no fault codes being stored. What normally would happen if the valve was sticking open is the low air flow input would cause the control unit to log a plausibility code for the air flow of the engine, as comparing it to other key inputs for comparison would show it to be wrong, however the software on the control unit for whatever reason does not do so.

Things

So at this point, I suspect the EGR valve is sticking open, however the position sensor is saying it is closed and the ECU is not logging any error codes. The air filter is clean and the air flow sensor is plausible with the engine off and giving the engine a rev showed the air flow to increase with engine rpm, I just have this low air flow reading with the EGR valve commanded closed. So, how do I prove it? Do I unbolt the EGR valve and check it physically? Do I fit a blanking plate into the pipework to prevent the exhaust gases entering the intake? As a failsafe, most EGR valves have a large spring fitted which pushes against the valve head and holds it in the closed position with no electrical

power applied to it, so if my valve was indeed stuck open, it had to be due to excessive carbon on the internals of the valve holding it open.

At this point, there isn’t really a right or wrong answer, it just depends what works for you. I decided for ease and that I had the ability with my scan tool to actuate the valve to 100% and 0 repeatedly for a few minutes just to see if the EGR valve would unstick and close again. If this happened, I would be happy it’s a valve issue without getting my hands dirty. While doing so, the valve was heard to give a more defined click as it snapped closed. I then started the engine back up and rechecked my air flow reading in live data. As Figure 2 shows, we can now see a higher reading as expected, with a closed EGR valve 680mg. This was definitive proof I had to have a sticking open EGR valve. Giving the engine a rev while monitoring data showed the ECU to command the valve open on overrun and once the engine returned to idle speed and idled for a few minutes, the command changed to 0. However, the airflow stayed low, giving the valve an actuation test a few times and then commanding it back to 0 showed the airflow to rise to 670mg confirming, without doubt, the cause of the complaint was a stuck open EGR valve.

This explained the lack of power and poor running complaint experienced by my colleague and myself – under acceleration, the EGR valve should be fully closed as we want a cylinder full of fresh, clean air to create good compression and power but with the valve stuck open, this was not happening due to the burnt gases being present in the cylinder. This also proved the fault was clearly unrelated to the work carried out on the head gasket replacement. When the customer was contacted and quoted a price to replace the valve and the associated gaskets, they verified the fault was indeed present before the vehicle was brought in and felt it was due to the faulty head gasket and would be rectified after replacement.

The customer was offered the option of cleaning the existing valve or a replacement part. A new valve was fitted and multiple road tests showed the vehicle to perform as expected. Checking the old valve showed it to be stuck partially open with carbon as expected. As an afterthought, I decided to check why, even though the valve was partially stuck open, it read as closed 0% in data. After doing some checks, I discovered this valve shaft has to move quite a distance before the signal voltage change reaches a point where the ECU confirms it as movement, so just something to be aware of. What you will find now on newer EU6 spec vehicles is that everything is closely monitored by position sensors and different methods of feedback to ensure what has been told to happen, has actually happened. In theory, it should be detected more easily by the ECU. Older systems like my vehicle aren’t as strictly monitored so can slip through undetected.

In this instance, contacting the customer before diagnosing the issue would have proved worthwhile as they would have confirmed it, but as I mentioned before, unfortunately, this is not always the case. How do you approach this situation in your own workshop? It is relatively rare, or at least I hope it is. Just some food for thought, in case it happens to you.

Topdon makes vehicle repair easy for everyone, from professionals to beginners. We offer advanced diagnostic tools, battery solutions, thermal imaging devices, ADAS calibration tools, and key programming products. Focused on accuracy and efficiency, we provide cutting-edge solutions to help you find and fix problems with confidence

New MG diagnostic tool training

Complex vehicle systems require specialist knowledge and tooling, and its crucial independent workshops stay ahead of advancements in order to provide a dealership-level service. To support this, Maverick Diagnostics’ sister company, Automotive Training Academy, has introduced a new MG Diagnostic Tool Training Course, to equip independent technicians with the skills and confidence to manage MG vehicles effectively.

The training course has been designed for technicians who want to take full control of MG diagnostics, software updates and module programming. It provides hands-on experience with MG’s Vehicle Diagnostic System (VDS) and Service Information Portal (SIPS). These are vital for fault-finding, programming new modules and updating software.

The one-day intensive training is conducted at the Automotive Training Academy in Wrexham and covers: Understanding and navigating VDS and SIPS; Software updates and programming; Fault finding and troubleshooting; and Best practices for module replacements.

Mick Hitchcock of Available Car comments: “The MG dealer tool has enabled us to manage all MG issues inhouse, taking away the need to use the dealer network. It’s been invaluable for software updates and module replacements. Working with Maverick and the Automotive Training Academy has enabled us to hit the ground running.”

https://automotivetraining.info/

Essential workshop tools in one system

Delphi’s DS Hub brings together essential tools and services, including training, diagnostics, technical data and parts information, into one intuitive system.

“The DS Hub is a comprehensive, centralised digital ecosystem,” said Phil Mitchell, Workshop Solutions Lead at Delphi. “It’s an all-in-one approach that simplifies the workflow and allows technicians to focus on completing the job efficiently.”

The hub consolidates diagnostics, technical data, training, how-to videos and parts catalogues, updates throughout 2025 will add advanced remote diagnostic features.

“The DS Hub helps technicians fix vehicles more quickly,” said Phil. “By bringing together data, support, training, parts, and services into one place, the DS Hub enables workshops to complete more jobs effectively and keep their customers satisfied.”

For more info, click here.

View this 7-minute video to learn about Bosch Secure Diagnostic Access

3-5 June 2025

Start your engines… the most important event for the UK automotive sector returns and you’re invited to join us!

500+ leading brands

150+ hours of technical & business advice, hands on demos in the Workshop and Aftermarket Hubs

50+ product launches, the best rates, discounts and giveaways

3 action-packed days of hands-on learning and business opportunities

Back by popular demand and better than ever! The Modern Garage, the Garage Awards with IAAF

This isn’t just any old trade show – it’s your front-row seat to the future of the automotive industry. You’ll gain more in a single day than you would in months from behind your workshop doors.

Darren Quinn, creator of YouTube channel Mechanic Mindset, has detailed the top 10 features technicians should look for when choosing a scan tool, using the AI-enabled Thinktool Euro 399 tool to explain what makes each feature essential.

His must-have features are:

1) Diagnostics

2) Component activation

3) Service functions

4) Programming

5) Remote diagnostics

6) ADAS

7) Secure gateway

8) EV pack diagnostics

9) Fault guidance

10) Artificial intelligence

Darren says: “One of the great things about the 399 is the really extensive coverage it offers.” Then there is component activation. “When you are doing diagnostics, it is very important that you can go in and drive components. The 399 is particularly useful for this, as you can even access systems like EGR valves.”

On the importance of programming, Darren noted: “Dealer technicians now spend most of their time doing programming, and this capability is critical for any modern workshop.“

Moving onto remote diagnostics, which is available on various Thinkcar and Thinktool devices including the 399, Darren said: “This feature is really going to help you get out of trouble should you come across something where additional support or dealer level diagnostics is required.”

Click here to view the video

A1 Remote Diagnostics introduces remote programming for the latest BMW group vehicles.

Adam Molloy, operations director, said: “Until now, there was no choice but to send models such as the IX and 7 Series to the main dealer for software updates, coding, or programming following module replacements. The new diagnostic infrastructure on these vehicles means that if, for instance, you replace the steering rack, you have to update almost 50 control units overall. We’ve developed a solution that means you can just code the part being replaced. This is big news for BMW workshops.”

In the first week of launch, A1 reported immediate demand for the service and saw it remotely program, code, and calibrate a steering rack on a BMW IX1 in just an hour. Without the interface, the garage would have potentially been waiting up to 30 days for the vehicle to be programmed and returned by the main dealer.

Find out more

Can you diagnose this Adaptive Headlamp fault?

autotech is an evolving bank of free, confidential online assessments created by independent automotive trainers. All you need to do is log in or register by entering a few details at https://autotechnician.co.uk/registration/, click an automated email reply and you get instant, free access to the multiple-choice tests focussing on various topics and scenarios.

The online test is completely confidential, and you’ll receive your scores, correct answers and technical explanations of the topics covered.

Test 18 is now live and involves an adaptive headlamp assessment:

A customer has presented his 2006 BMW E61 to the service department, insisting on a new Xenon headlamp bulb for the right side. According to the customer, the headlamp suddenly stopped working following a heavy downpour.

You accompany the customer to the car park to verify the issue firsthand. Upon inspection, you confirm that the left headlamp is functioning normally, and on the right side, the side marker, angel eyes, and high beam are operational. However, the low beam on the right headlamp is completely inoperative.

Given these symptoms and from your own past experience, you explain to the customer that a simple Xenon bulb replacement is unlikely to resolve the fault. After discussion, the customer agrees to authorise one hour of labour for a thorough diagnosis to identify the underlying issue.

This initial diagnostic approach allows for an accurate assessment of potential causes, rather than simply replacing parts without confirmed evidence of their failure.

You are provided with the circuit schematic and guided through the process to diagnose the problem without replacing parts unnecessarily.

Log in or register by entering a few details at https://autotechnician.co.uk/registration/ and access the entire library of confidential assessments now!

Save £300 on Hella Gutmann S20 diagnostics kit

The Hella Gutmann S20 provides coverage for more than 48,000 vehicle models, including DoIP and CAN/FD vehicles, and Core Diagnostics is offering a £300 discount on the equipment until 1 June.

The S20 can be used to read and delete fault codes, perform service resets, basic settings, adaptions and coding, as well as for ADAS calibrations. It allows vehicle identification via both VIN or registration plate, can display live parameter readings, and offers explanations of fault codes as well as suggesting possible causes.

As with all the latest Hella Gutmann diagnostic equipment, the S20 is PassThru compatible and allows secure gateway connection with no additional fees.

In addition, during the promotional period a two-year HGS Technical Data subscription can be purchased for just £800 when bought together with an S20, rather than £900 when purchased separately.

Vehicle health checks open up additional revenue streams

Auto3iii provides AI-powered electronic vehicle check technology that standardises workshop processes, generates more custom and enhances levels of service.

‘Intelligent Technician’ offers mileage-based advisory maintenance schedules. Tyres Northampton saw an increase of 51% booked back into the workshop while using the system and 98% of its customers had received a digital report, so understood what work was needed and when, so were happy to receive the follow-up phone call.

The mobile app allows technicians to follow the health checks or services on customer vehicles, add notes and measurements, take photos or video.

The software can be fully customised – if you want to remind customers of a recommended tyre replacement at 3mm, or a 1.6mm legal tread warning instead, either can be incorporated. Or, if you’re focusing on winter health checks or summer air conditioning re-gas work, these elements can be added too. Find out more: https://auto3iii.com

Email sales@corediagnostics.co.uk Fuel trim analysis by Des Davies

Des explains in detail how to test and diagnose faults within the engine and fuel systems of the vehicle using the fuel trim PIDs on your scanner. Read the article here

For 2025, we are powering up our Schaeffler REPXPERT Millionaire promotion by giving participating members the chance to win a fantastic garage makeover!

It all kicks off on April 1st, and we are not joking! Don’t be a fool - simply register for your chance to win this amazing opportunity to grab a professional makeover for your workshop and reception areas.

To enter, scan the QR code or head to: www.repxpert.co.uk/garage_makeover

Registration is simple, we just need ‘before’ pictures of your workshop along with a minimum of 50 words explaining why you think your site deserves to win a makeover.

You can then boost your chances of winning each time you install a LuK, INA or FAG product and scan the box to claim your points. The more you scan, the more chances you get to win!

www.repxpert.co.uk | vls.schaeffler.co.uk |

With spring around the corner, Rob Marshall reminds garages not to forget the opportunities that air conditioning brings throughout the year

Heating, Ventilation and Air Conditioning systems are not so different to other motorcar systems, in that regular maintenance is vital not just for efficient operation but also to ward off expensive repairs. This approach need not harm your business, though. Denso reasons that routine checks and early identification of issues can save customers money, while creating a steady revenue stream. Yet, LKQ ECP recognises that garages are missing revenue opportunities, because workshops wait for customers to report problems, instead of identifying them proactively, especially before the summer rush hits.

Nissens reasons that the modern aftermarket repairer needs to consider air conditioning systems differently. While AC tends to be thought about solely as a comfort aid by the public, its role has evolved far beyond just cooling the cabin on a hot day. We are moving into the age of 'Thermal Management', where the energy within the refrigerant system, be it cooling, or heating, is utilised elsewhere in the vehicle to increase performance, range, efficiency and lifespan of the running gear. Therefore, should the AC system cease to function, or not work efficiently, the car will not function as its maker intends. Owners of such vehicles, Nissens advises, must become used to an annual refrigerant system service – if anything, to preserve their car's reliability.

Electrification opportunities

Meyle agrees and admits that the motor repair industry must promote annual AC servicing, irrespective of mileage for high-voltage electrified vehicles especially. The work must include replacing the cabin filter. Yet, LKQ Euro Car Parts reasons that this is not easy to communicate to the car owner, due to the widespread misconception that electric vehicles equal less complex maintenance. When it comes to the air conditioning system, the opposite situation is true. Reaffirming Nissen's stance that the refrigerant circuit is vital for the efficiency and longevity of electric motors, axles and battery systems, it highlights the specialist knowledge necessary. LKQ Euro Car Parts uses the example of the wrong oil in the compressor creating the risk of voltage leaks (or shut-down of the highvoltage system) and reveals that it is seeing strong demand from EV-qualified garages, which offer specialised air conditioning maintenance.

When the car’s fitted with a DENSO A /C Compressor. The very best materials make them durable and efficient so your vehicle cabin will always be as cool as you need it to be. Much more pleasant for everyone. It‘s a wise choice.

CHOOSE DENSO. Free your thinking.

Nissens reinforces the importance of fitting high-quality parts, especially the condenser that is exposed to the harsh outdoors. For more information, check out: nissens.com/condenser.

Nissens' stance is that knowledge is power but to get it, training is needed not only to understand the various designs, layouts and functions but also to keep up to date with the new refrigerants and chemicals. You can find out all of these answers, and more, through the Nissens Experts program, which offers both online and on-site training. There are over 100 learning sessions, from which to choose, offered in ten different languages via nissens. com/training

Denso highlights its Technic website (www.denso-technic.com) as a valuable resource for professional training on HVAC repairs and maintenance, including 'How To' videos. Note also the technical bulletins and materials from www.denso-am.eu, which are updated frequently.

LKQ Euro Car Parts has developed a comprehensive training pathway through its LKQ Academy, to support garages that desire to expand their air conditioning capabilities. It recommends its 'Understanding Vehicle Air Conditioning' course, as one that provides essential diagnostics and tooling knowledge, costing £299+ VAT. In addition, the Level 3 Refrigerant Handling assessment course is available for R134a systems, costing £250+VAT.

Making AC equipment work for you

Meyle reminds technicians not to forget to charge the humble cabin filter with a quality replacement every 1015,000 miles, when servicing the HVAC system.

It is always worthwhile keeping up with the latest equipment to create opportunities for your workshop. Before we look at the current crop of machines, Denso highlights that existing machinery needs looking after, too. Interestingly, it states that 15% of all air conditioning system failures are caused by ill-maintained workshop equipment being used. Nissens reports that the expanding variety of refrigerants, such as R456A and R444A, creates a need for new AC machines to keep them separated, because not all of them can be mixed. LKQ ECP has focussed on the most popular R134a and R1234yf and reports strong trade interest in dual-gas equipment that can handle both of these refrigerants, with a range of machines that starts from £1,499 to £6,999 (+VAT) for a main dealer-level machine. Should you feel that it is a little premature to invest in new machinery, you may be interested in Nissen's 2025 troubleshooting and testing ranges. These include leak detectors, a pressure test kit, and a sight-glass tool for checking loop cleanliness. More information can be found at www.nissens.com/climate. LKQ Euro Car Parts is offering air-con bundles starting from £3,699+VAT. These include nitrogen test kits to leak detectors, all of which are supported by a three-year service warranty and technical support package.

Many high-voltage vehicles use the refrigerant circuit to manage running gear temperatures. The layouts vary but Nissens provides some useful background information about the layouts you might encounter:

One method uses the conventional AC system alone to cool the battery pack. Alternatively, a more complex heat pump system might be employed. While this uses the same working principles of an AC system, you can find up to ten times more refrigerant tubing installed, because refrigerant is diverted to the most efficient route of cooling, or heating, the vehicle. Any weaknesses in the heat pump circuit will mean that the car will, at best, not function properly, or will break down.

Few things are certain in life but the number of ADAS-equipped cars on UK roads is certain to increase but are you grasping the opportunity?

Modern technology that requires considerable investment in equipment and training can seem more of a threat to your workshop than an opportunity. So, to whom should you look? Rob Marshall does some digging...

While high-voltage electrification is struggling to gain widespread acceptance, the situation is not the same with ADAS. Additionally, with virtually every motorcar having wheel/suspension alignment adjustment points, the average age of vehicles on our roads increasing and our road surfaces getting worse, if you are not taking advantage of these opportunities, why not? It will benefit not only your workshop but also your customers.

One would have thought that calling wheel alignment, 'tracking', in front of specialist alignment equipment suppliers would be met with a similar reaction as shouting 'Garlic Bread' at a Bolton comedian. Yet, while they are tolerant, they are keen to evolve old notions. Should you think that tracking and alignment are the same, it is worth updating your terminology, so you can help change your customers' preconceptions. A1 ADAS advises that we should think of tracking as an analogue historical term; one that could be conducted years ago with a length of string. Even if performed only on the front axle, 'Wheel Alignment' is a digital process and works to tighter tolerances, calculated to a fraction of a degree.

Hella concurs but finds that most modern garages know that wheel alignment is a far more comprehensive process than the older tracking procedures. Even so, Straightset reports that many garages exist that conduct 'tracking' adjustments alone, because that is all that they have ever done.

Should this be you, you may wish to make 2025 the year you make the change. Straightset reasons that adopting change starts with empowering technicians. This task commences with updating basic knowledge, including realising the differences between tracking and full four-wheel alignment, which will then give technicians the confidence to relay the relevance and differences to the customer. Straightset reasons also that workshop alignment equipment has had to evolve over the decades to keep up with modern vehicle design. A1 ADAS agrees, adding that suspension technology continues to advance, resulting in more sophisticated equipment being introduced, such as drive-on systems that not only take the weight of the vehicle into account but can also measure tyre tread depths in seconds. Such systems save workshops time and create obvious opportunities for adjustment work.

For ADAS to work correctly, the car must be able to judge the distances of potential hazards. Poorly calibrated sensors, following repair, create an obvious safety risk. Remember, there is a difference between 'calibration completed successfully' to the calibration having been completed properly.

Hella agrees with Straightset that garages must communicate with the customer about why wheel alignment is necessary and what the consequences could be if it is not carried out. Yet, this can only be performed effectively, if the technician (or the front-of-house staff) possesses the knowledge and means of getting the message across to a non-technical mind. The simplest means of doing this is to explain that incorrect wheel alignment has a notable impact on fuel consumption, handling and tyre wear – all of which have cost and safety implications. For older customers, who may be stuck in the way of thinking that all they need is a £20 tracking adjustment, or for technically-interested owners, you may also have to justify your charges, by sharing your knowledge about why four-wheel alignment is needed on certain models, not just the toe of the front wheels. Consider also that front wheel alignment alone (including the old-fashioned 'tracking' term) addresses the front axle's toe adjustment and not the camber, let alone anything to do with the rear wheels. Four-wheel alignment, obviously, takes longer to measure and adjust, especially when some procedures are highly convoluted. This dictates more accurate and costly equipment, hence why prices have had to rise.

We have detailed the wisdom of checking the alignment of every car that enters your workshop before, and we emphasise it again. Striaghtset provides the financial rationale, in that the typical charges for wheel alignment, comprising measuring, adjusting and final checks, range from £30 to £150. These rates depend on whether garages offer front-toe adjustment alone, or a more involved four-wheel alignment. Presuming an average £70 charge, Straightset highlights that an entry-level laser wheel aligner from Supertracker could pay for itself in fewer than 30 alignments. Yet, this figure does not include extra revenue from corrective work.

These days, one cannot talk about wheel alignment in isolation. Hella reports that, since 2022, all vehicles have been required to include a minimum level of ADAS coverage. Note that this includes even budget models; higherend brands have featured some ADAS functionality for many years. Even so, the growing core of cars and vans in the UK that will need their sensors aligning as part of routine repair work cannot be denied. As the proportion of ADAS-equipped cars grows, Hella argues that the profit opportunity will increase.

ADAS calibration can be conducted successfully, only if the thrust angle is correct. The measurement is taken from the rear of the car and explains why you cannot separate ADAS from wheel alignment.

The A1 ADAS Group reports that garages, which do not conduct ADAS calibrations but offer wheel alignment services, are missing a significant opportunity, because these two tasks cannot be separated. Mahle says that ADAS is not just about wheel alignment but setting the vehicle systems to ensure they function together. Yet, some garages could find themselves locked out of the most lucrative work due to their inability to offer ADAS calibration. Hella reasons, therefore, that garages need to consider their market and invest accordingly as a result.

Meyle says that some garages are coping, by bearing the variable cost of sending vehicles to contractors, who perform the ADAS calibration for them. By doing so, they might offer the service, but their profit is being wipedout. A1 ADAS says that, should a specialist third-party not be engaged and the work not done, the vehicle will be returned to the customer with its sensors misaligned. Any reasonable technician cannot view this as an acceptable repair.

The stumbling block for many garages is committing to the capital investment in calibration equipment. A1 ADAS reassures garages that this can be done in stages: a business can start with entry-level equipment, which will increase revenue. For instance, this might involve utilising the ADAS function on diagnostic equipment and many tablets on the market possess this function. The garage can then use the extra revenue generated, to progress to further investment in physical rigs. A1 ADAS reports that the return on investment at each stage tends to be swift, owing to the volume that this type of work offers.

Thankfully, plenty of training opportunities exist, so you are not on your own. A1 ADAS recommends IMI training and the AOM012 for wheel alignment in particular. Interestingly, A1 ADAS highlights a difference between aftermarket garages and the car body repair sector, because bodyshops work to BSI 10125 to satisfy insurance industry requirements, part of which stipulates that technicians hold the relevant IMI qualifications. As this is not the case in the garage sector, training tends to be conducted in-house. A1 ADAS admits that there is nothing wrong with this, provided that the knowledge is correct. Historically, wheel alignment training has been classed as a low-level requirement and, sadly, this remains the case, even though it is crucial for ADAS.

Hella reports that, when replacing ADAS hardware, be wary of the lower-quality sensors that represent a false economy. Such non-OE parts cannot always be coded into the vehicle, and they tend to fail within a year. The problem is that a poor-quality part can look identical to a quality OE component, such as that pictured.

In terms of suspension alignment, accurate ADAS calibration relies on a correct thrust angle. This is a centre line down the vehicle, taken from the rear axle, which confirms that the rear wheels are pointing forward. Should the rear wheels not be straight, the incorrect alignment will cause the vehicle to adopt a ‘crabbing’ stance. This thrust angle must be correct, before any attempt is made to calibrate the ADAS.

Hella explains that ADAS systems rely on data from sensors that are positioned around the car. For these systems to operate effectively, this information must be correct. Should a sensor be misaligned, ADAS-reliant systems will receive incorrect information. When these systems include safety-critical features, such as adaptive cruise control and lane-keeping assist, the resultant consequences of them not functioning correctly could be very serious.

Straightset agrees, adding that incorrect data can cause malfunctions, or in some cases, deactivation of not just driving aids but also safety net systems such as Lane Keep Assist, Front Brake Assist and Active Emergency Brake. This, potentially, creates danger for not just the driver but also other road users and pedestrians.

A1 ADAS clarifies that accurate calibration is essential, because the error multiplies considerably with distance and so a small deviation of several millimetres might cause the ADAS system to think that an object 200 metres away is three metres further away than it is. ISN reminds us that the Insurance Industry Requirements place the onus on workshops to ensure that these systems are functioning correctly following the repair, service or maintenance of any parts that affect ADAS functionality, or vehicle geometry. However, A1 ADAS has witnessed situations, in which technicians treat ADAS calibration as a tick-box exercise, where static calibrations have been conducted in unsuitable environments, including in car parks. Yet, why does this matter, when the diagnostic readout confirms ‘calibration completed successfully’? A1 ADAS highlights that this is why training is important. Technicians, who do not hold the relevant IMI ADAS qualifications, may assume there’s nothing wrong but the reality is that a successful calibration does not mean a correct calibration.

The aftermarket's attitude with ADAS and wheel alignment repairs should be, 'Do it right, or not at all'.

As we reported last year, Hella's IMI-approved Academy has been offering ADAS training as a priority. The ADAS IMI AOM 230 course grants technicians the required insurance approval to work on ADAS-equipped vehicles, while the ADAS L2 Award encompasses calibration, vehicle alignment and workshop requirements. Both two-day courses cost £500+VAT and we understand that places are available.

While Straightset offers offsite training at its head office in Worksop, Nottinghamshire, onsite flexible product demonstration and training are provided with its systems at any time, dependent on your requirements.

Straightset offers wheel alignment equipment and its range has been tailored carefully for the range of needs and budgets within the aftermarket. These are available not just from Straightset's own brand, Supertracker, but also Beissbarth, HPA-FAIP and CEMB. These alignment products vary from robust laser aligners to popular CCD systems, plus innovative 3D technology to state-of-the-art touchless systems. For support, Straightset highlights its national fleet of wheel alignment engineers, who offer wheel alignment calibrations, database upgrades, equipment repair, spare parts and training. Customers can also visit Straightset's dedicated wheel alignment studio at its head office in Nottinghamshire.

While Hella Gutmann does not provide wheel alignment equipment, its prowess in the ADAS arena needs no introduction. For the aftermarket, the firm's ADAS calibration tool range starts with the entry-level CSC-Tool, followed by the significantly more powerful CSC-Tool SE. Mobile calibration is catered by the CSC-Tool Mobile. Using these tools, says Hella, technicians can offer common camera and radar system calibrations for the front, rear and surrounding areas, including laser scanners, fitted to the latest Audis.

The A1 ADAS Group supplies both wheel alignment and ADAS calibration products and advises that garages can consider a combined piece of equipment that does both tasks, such as Autel's IA900. The alternative option is to purchase two separate pieces of hardware, one for alignment, the other for ADAS. The advantage of having both tasks performed separately is flexibility, making it ideal for larger workshops, where space is less of a premium. For these garages, A1 ADAS recommends the Absolute Alignment Bluetooth Pro alongside either the Autel IA600, or Hella's CSC Tool, as mentioned earlier.

It’s news unlikely to startle any time-served technician – motorists are keeping their cars for longer. Worryingly, when the Motor Ombudsman recently surveyed technicians on the challenges facing them, over half said that customers were putting off essential repairs and neglecting servicing and, that customers were also neglecting routine maintenance.

As the global cost of living continues to rise, such counterproductive customer behaviours are likely to become more entrenched. But, with older cars come components increasingly likely to fail. Cooling systems are no exception to this.

Granted, whilst today, components such as the radiator, water pump and heater core are better quality, they still have a finite lifespan. They will eventually fail. With cars staying on the road for longer, only visiting the workshop when all other options have been exhausted, some motorists are likely to face unaffordable repair bills. This puts the technician in an invidious position; having to deliver this unwelcome news, knowing a customer is unlikely to have the funds, or the desire, to pay for a new radiator, water pump or heater.

There is an affordable solution; one that has been tried, tested and crucially is trusted by technicians globally. K-Seal Coolant Leak Repair, known as ‘the miracle in the little blue bottle’ is a top product for technicians worldwide. It is the best-selling product in its category in the USA, with 12 million global sales. Underpinning these sales are crucial independent test results which no technician should ignore.

Mike Schlup, MD of K-Seal International, believes these tests are why technicians can turn to K-Seal with confidence, commenting: “Recent surveys, not to mention our regular conversations with technicians, reveal they are increasingly using additives as part of the growing trend of repair over replace and products over parts. Trust in the provenance of a product is key. With K-Seal we established an internationally recognised test standard as a benchmark against which to measure K-Seal’s performance and that of competitive products that were on the face of it, making bold, unsubstantiated claims. The ‘ASTM D-3147 Standard Test Method for Testing Stop-Leak Additives for Engine Coolants’, outlines the necessary test equipment and procedures to verify the efficacy and safety of coolant stop leak products. Significantly, the test data shows that K-Seal is capable of sealing 0.025in (0.635mm) diameter holes and 0.010in (0.254mm) wide by 0.5in (12.7mm) long slots, satisfactorily in accordance with this test method. Further testing demonstrated that K-Seal sealed the leaks in test conditions 100% of the time. Another important part of the test standard is to prove that the stop leak product will not block the cooling system. It must pass through a 0.85mm sieve without clogging. K-Seal passed with flying colours making it compatible with all water-cooled engines. These independently tested results carry more credibility with technicians than any marketing hype.”

It is important that technicians make an informed decision when selecting a coolant leak repair additive for customers' vehicles. For newer vehicles, especially those still under warranty, opting for a full mechanical repair is the right choice. When a vehicle ages however, and cooling system repairs become costly compared to its value, using a reliable additive is the smart choice.

So, independent test results aside, what should a technician look for when choosing a coolant leak repair product?

Make sure the product is safe to use with all types of antifreeze. Certain products use sodium silicate which does not mix well with ethylene glycol (antifreeze). Other products are antifreeze friendly and can therefore be safely added to any coolant.

Look in the back of an AA or RAC van to see which coolant leak repair product they use (and have used for many years) for roadside repairs, without any draining or flushing.

Make sure the product is a multi-purpose repair. Many coolant leak repair products are quick fix radiator solutions with the sole purpose of getting your customer home. A top tier multi-purpose repair product will fix leaks in all hard parts of the cooling system. And, not just the radiator, but also the head, head gasket, cylinder head, heater matrix, water pump casing and freeze plug. Better still, if it is a ceramic formula, you can be confident it will make a lasting repair. This means customers are happy on the road and happy to bring their car back to you for future servicing and maintenance.

“Whilst many readers of autotechnician are vocal advocates for K-Seal, we know that some are yet to put it to the test,” says Mike. “So, we welcome conversations with all technicians. We encourage you to look more closely at K-Seal. This includes asking us for the independent laboratory assessed results, so you can compare additives in this category on a like-for-like basis.”

www.kseal.com

New products, fitting tips & technical advice to ease fault-finding and installation

Do not forget about the cabin filter!

UFI Filters says that the cabin air filter often ends up being overlooked because it is not the mechanical efficiency of the vehicle that depends on it, but more importantly, the health of passengers – removing dust, pollutants, allergens, bacteria and mould.

UFI has been developing filter products for over fifty years and its experience of supplying original equipment and the research carried out within its innovation centre, have resulted in six different types of filter media. UFI Filters ARGENTIUM®, a filter with a powerful antibacterial function has three layers (antimicrobial, adsorbent and structural), and a non-woven filter media containing silver particles with a powerful antimicrobial action that is capable of inhibiting bacterial growth by up to 99%.

The combination of layers enables this filter to not only block pollen, dust (including from tyre wear and brake action) and road dirt, but also to prevent the growth of fungi and mould, and block substances such as sulphur dioxide (SO2) and nitrogen oxides (NOX).

High Efficiency Particulate Air (HEPA) filters – currently destined for the original equipment of battery-powered vehicles, will soon be available to the aftermarket too.

A new range of OE turbochargers is available from febi, encompassing both new and remanufactured turbos from BorgWarner and Garrett. The range covers popular car and LCV models from the VW Group, Stellantis, Mercedes-Benz, BMW and many more.

The programme also has mounting kits, oil feed pipes, charger intake hoses and complete turbocharger repair kits.

A promotion running until the 30 April offers a febi branded jacket or gilet, t-shirt and confectionary with every OE turbocharger purchased. Customers wanting to claim the offer simply email fen-marketing@bilsteingroup.com with their account name, article number purchased, size & style required and their contact name and delivery address.

febi’s new turbocharger range can be found on partsfinder, the online parts catalogue of the bilstein group: www.partsfinder.bilsteingroup.com

LKQ Euro Car Parts has launched TechClub, an exclusive new members club, enabling individuals to buy tools and training directly from the supplier, while benefiting from special offers and benefits.

Members of the free new service can set up their own dedicated profile on LKQ’s Omnipart platform. Users can track their unique order history and warranties online, so technicians can maintain the same profile and data when working in different garages.

Members can benefit from access to exclusive offers and added value promotions including extended warranty options, free tools and bundle deals.

https://omnipart.eurocarparts.com/lkq-techclub

ISN Garage Assist introduces a new lift into its expanding Luxus range of vehicle lifts. The Luxus SX50-AL+, a 5,000kg capacity scissor lift, has been designed specifically for wheel alignment, wheel and brake service applications. This incorporates an integrated ‘double elevation’ scissor with a 4,000kg capacity, enabling technicians to quickly access the underside of the vehicle and remove the wheels quickly.

Safety features comprise automatic mechanical locks, pneumatic locking rear slip plates, an emergency lowering system in the event of power loss, and a pressure overload valve on the hydraulic system.

Other features include built-in LED lighting with protective guards to enhance visibility during inspections and a low-profile design with a minimum height of 220mm.

For more information, click here: https://bit.ly/4hAM374

Adblue injectors join Motaquip portfolio

Motaquip introduces AdBlue injectors and pressure sensor glow plugs to its range of parts.

Manufactured in the UK, the injectors comprise an aluminium heatsink design, which dissipates heat efficiently, reducing the temperature and promoting long-lasting performance. The simple design means there is ample space for the connector and pipe attachment, making for an easier and quicker fit.

Currently, 16 million vehicles in the UK rely on AdBlue to comply with Euro 6 emission regulations. However, Motaquip is aware of a growing number of AdBlue injectors failing prematurely, leading to vehicle shutdowns, highlighting the importance of this technology.

Motaquip Business Line Manager, Lee Downey, expanded: “One of the most common AdBlue injector failures is when there is a block caused by crystallised urea. Over time, AdBlue can crystallise, clogging the injector and housing, which prevents the AdBlue fluid from entering the exhaust. This causes vehicles to fail emissions standards, triggering sensors to stop the vehicle from starting until the injector and housing are replaced.

“Additionally, high exhaust temperatures can lead to AdBlue injector failure, making heat management crucial in this area.

“At Motaquip, we are always looking to develop our range, not just to include the latest technologies, but where there is a need and demand. There are only a limited number of suppliers offering this product, and we’re pleased to be one of those.”

Motaquip’s new AdBlue injectors cover a broad range of vehicle applications, including Audi, Mercedes, Jaguar, Land Rover, Hyundai, Opel, Renault, Vauxhall and Ford. Part numbers and compatible are available on https://motaquip.com/new-product-adblue-injectors/.

Headlight glare continues to hit the headlines as 25% of drivers report that they now drive less at night due to the problems caused by bright headlights, according to research by the RAC.

OEM headlight manufacturer HELLA, warns that the highlight output of modern headlights has made proper alignment more critical than ever. “While brighter headlights improve road safety by enhancing visibility, improper alignment, the rise of higher-riding vehicles, and the intensity of advanced lighting technologies are contributing to driver discomfort and reduced confidence,” said Dave Clark, Lighting Product and Brand Manager. “It’s vital to strike the right balance between illumination and safety.”

Misalignment caused by suspension issues, vehicle load changes, or improper installation can significantly increase glare for other road users. Hella emphasises the importance of using OE-quality bulbs, replaced in pairs, to maintain balanced performance and reduce glare-related issues.

The company also highlights the growing adoption of technologies such as adaptive front lighting systems (AFS) and asymmetrical light distribution, which focus light on the road while minimising glare for oncoming traffic. “For these systems to perform properly, correct ADAS calibration is essential,” Dave added. www.hella.com/techworld/uk/

Remanufacturer Shaftec Automotive’s latest additions comprise 19 driveshafts – key applications include the FO415R for the Ford Kuga II (DM2) (2014 onwards), the HY227R for the Hyundai Tucson (2015 onwards), and the VA303R for the Vauxhall Astra (2015 onwards).

Shaftec Marketing Manager Adrian Kitchen said: “Driveshafts are essential components in vehicles, and our remanufactured options provide a cost-effective and sustainable choice for the market. Each of our driveshafts undergo rigorous testing and refurbishment to meet or exceed original specifications, offering the same reliability and durability as new ones, but at a lower cost.”

Signs that driveshafts might need changing: Signs of damage, such as cracks or dents; play or looseness in the inner/outer joints; vibrations or clunking/grinding noises while driving.

By Autotech Training

Advanced Driver Assistance Systems (ADAS) are now a standard feature in modern vehicles, with over 90% of cars manufactured in 2018 equipped with at least one ADAS function. As these systems become more prevalent, the aftermarket faces a growing challenge—an urgent shortage of trained technicians capable of maintaining and calibrating these complex safety features.

A report from the Institute of the Motor Industry (IMI) projected that by 2030, 106,000 ADAS-trained technicians will be required, yet current trends indicate a shortfall of 51,000. Despite increasing demand, only 14% of businesses are prioritising ADAS training. This skills gap not only impacts operational efficiency but also raises significant safety concerns. ADAS is not a simple plug-and-play system. Functions such as lane-keeping assist, adaptive cruise control, and collision avoidance rely on intricate networks of sensors and cameras that require precise calibration. Even routine repairs, such as windscreen replacements or wheel alignments, can affect sensor positioning. If calibration is not performed correctly, ADAS features may fail, increasing the risk of accidents.

ADAS training and accreditation explained: There are different levels of ADAS training to ensure technicians develop the expertise needed to service these systems correctly:

ADAS Accreditation: This course provides technicians with a fundamental understanding of the technology – its advantages, limitations, and the critical importance of calibration. It also covers the practical aspects of calibration procedures.

IMI Level 2 & 3 ADAS Qualifications: These advanced qualifications equip technicians with the knowledge and skills required to safely diagnose, test, and repair ADAS sensors and systems. This level of expertise enables technicians to handle complex calibration processes and ensure ADAS features function correctly.

Ongoing Compliance: For those with accreditation, this must be renewed every three years, and for those who have the qualification, continuous professional development (CPD) is mandatory to remain on the IMI TechSafe™ register. As ADAS technology evolves, technicians who do not stay updated risk falling behind industry standards.

For workshops that have invested in ADAS equipment, failing to train technicians can result in underutilisation, making the investment redundant. There is also a broader ADAS knowledge gap—not just among technicians, but among vehicle owners. IMI research shows that only 47% of motorists recognise ADAS calibration as an essential service, and just one in five can identify ADAS features in their vehicle. This lack of awareness highlights the need for trained professionals to educate customers on the importance of proper calibration.

While ADAS calibration may require additional time and cost, it is a crucial safety measure. Failure to maintain and recalibrate these systems correctly can lead to inaccurate readings, false alerts, or complete system malfunctions— compromising vehicle safety. Additionally, uninformed vehicle owners may opt for garages that lack ADAS-trained technicians, resulting in incomplete recalibration and potential road safety risks.

Upskilling to meet the needs of the modern automotive industry Everyone within a workshop, from technicians to service advisors, should have a foundational understanding of ADAS. As manufacturer warranties expire, and more ADAS-equipped vehicles enter independent workshops, the ability to correctly service and recalibrate these systems will be a key differentiator in the aftermarket.

Autotech Training provides IMI-accredited ADAS courses – including accreditation and Levels 2&3 qualifications. Training is available at their Milton Keynes head office or can be delivered onsite at workshops across the UK. Additionally, Autotech Training’s online Autolearn platform offers CPD modules to ensure technicians remain compliant with industry regulations and up to date with the latest advancements in ADAS technology.

www.autotechtraining.co.uk

Green laser wheel alignment