Importance of the Global Harmonized System Having the Right Connections

Why Advocacy Matters at ARA Hill Days

Importance of the Global Harmonized System Having the Right Connections

Why Advocacy Matters at ARA Hill Days

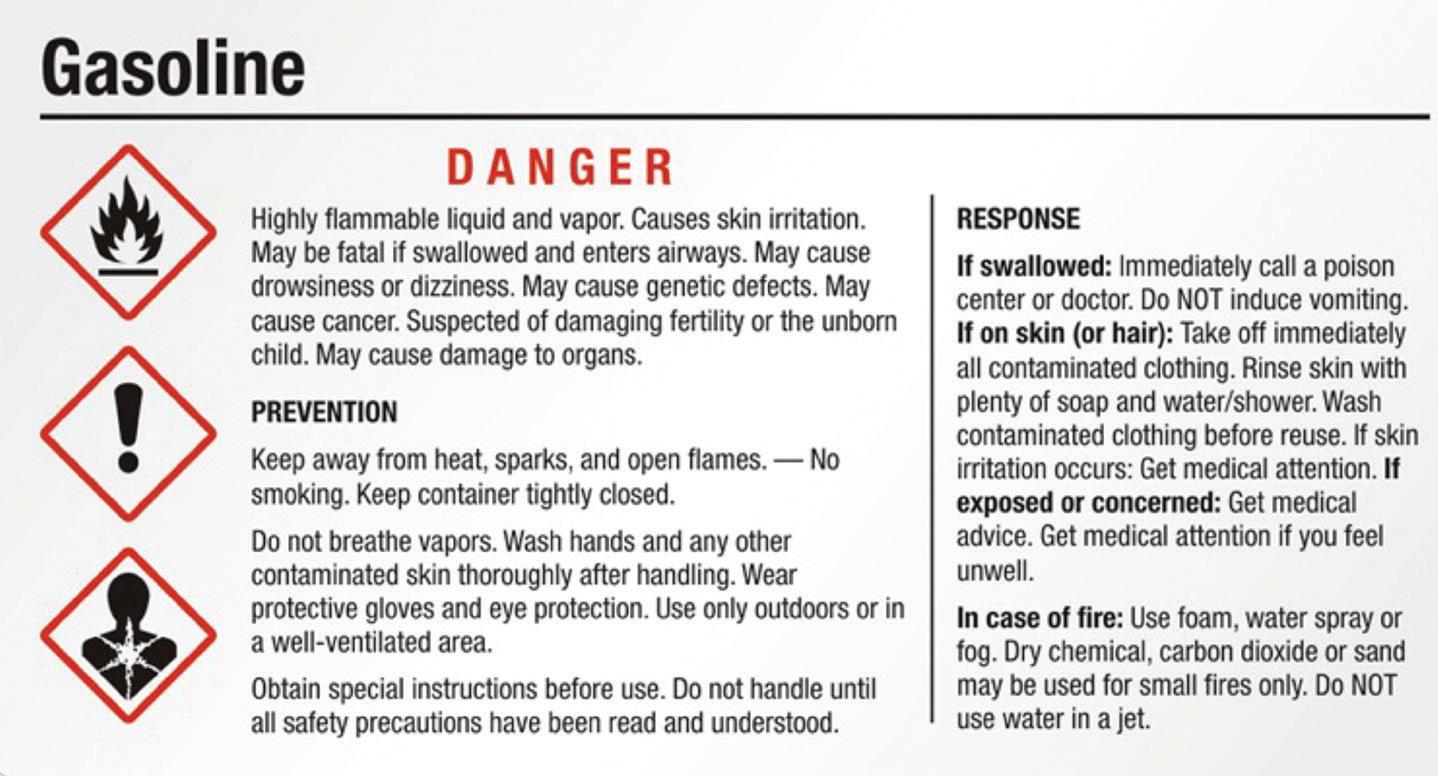

The Global Harmonized System (GHS) of Classification and Labelling of Chemicals is an internationally agreed-upon framework designed to ensure the safe production, handling, transport, use, and disposal of hazardous chemicals. Developed under the guidance of the United Nations, the GHS provides a standardized approach to classifying chemical hazards and communicating those hazards through labels and safety data sheets (SDS). Its adoption has improved global chemical safety and facilitated international trade by creating consistency in hazard communication across countries.

Key Components of the GHS

• HAZARD CLASSIFICATION: The GHS classifies chemicals based on their physical, health, and environmental hazards. For instance, flammable liquids,

toxic substances, and materials harmful to aquatic life each fall into specific hazard categories.

• LABELS: The GHS mandates the use of standardized labels featuring:

1. SIGNAL WORD: Either “Danger” for severe hazards or “Warning” for less severe ones.

2. PICTOGRAMS: Symbols within a red diamond border that visually convey the type of hazard (e.g., flames for flammable materials, skull and crossbones for acute toxicity).

3. PRODUCT NAME OR IDENTIFIERS: Identifies the chemical or substance. Should match the product name or identified used on the SDS.

4. HAZARD STATEMENTS: Descriptions of the nature and degree of hazard (e.g., “Causes severe skin burns and eye damage”).

5. PRECAUTIONARY STATEMENTS: Recommendations for safe handling,

Jonathan Kusowski is the owner of JAK Environmental LLC and currently services stormwater programs in Minnesota, Wisconsin, and Michigan. His work focuses on developing SWPPPs, SPCCs, meeting with regulators, and making sure all facilities maintain compliance. In addition, he also conducts ARA audits and works closely with Sue Schauls as part of the CAR program. He holds a bachelor’s and master’s degree in Environmental Engineering from Marquette University.

storage, and disposal of chemicals.

• SAFETY DATA SHEETS (SDS): The GHS standardizes the structure of SDS into 16 sections, including identification, composition, hazard information, first-aid measures, and exposure controls. This uniformity ensures that workers, first responders, and others handling chemicals can quickly access critical safety information.

1. ENHANCED SAFETY: The GHS ensures that workers and the public have clear, consistent, and accurate information about chemical hazards. This reduces the likelihood of accidents, injuries, and illnesses related to chemical exposure.

2. FACILITATES TRADE: A globally standardized system simplifies the import and export of chemicals. Businesses no longer face the challenge of reclassifying and relabeling products to meet the regulations of different countries, reducing costs and time.

3. LEGAL COMPLIANCE: Countries that adopt the GHS incorporate it into their regulations, ensuring companies comply with both national and international standards. This fosters legal predictability and uniform enforcement.

4. ENVIRONMENTAL PROTECTION: By clearly labeling chemicals with environmental hazards, the GHS encourages the safe handling and disposal of hazardous substances, reducing environmental contamination and ecological harm.

The National Fire Protection Association (NFPA) system is another critical tool for hazard communication, particularly in emergency scenarios. It employs

a diamond-shaped symbol with four colored quadrants indicating:

• HEALTH HAZARDS (BLUE): The potential for injury or illness.

• FLAMMABILITY (RED): The material’s susceptibility to ignition.

• REACTIVITY (YELLOW): The likelihood of a substance undergoing chemical change.

• SPECIAL HAZARDS (WHITE): Specific information such as water reactivity or oxidizing properties.

While the GHS is designed for broad global application, the NFPA system is tailored for emergency responders. By integrating these two systems, organizations ensure comprehensive hazard communication that addresses both routine and emergency needs.

1. HOLISTIC COMMUNICATION: GHS provides detailed hazard information for everyday use, while NFPA offers a quick-reference guide for emergencies. Together, they cater to diverse audiences, including workers, emergency personnel, and the public.

2. ENHANCED PREPAREDNESS: Emergency responders rely on NFPA labels to quickly assess risks and take appropriate actions, such as wearing protective equipment or evacuating areas. The GHS complements this by offering in-depth guidance on handling, storage, and first aid.

3. REGULATORY COMPLIANCE: Many jurisdictions mandate adherence to both systems, ensuring businesses meet all safety and legal requirements.

Below is an example of a label using both GHS and NFPA systems to provide as much detail as possible. Similar SDS Labels, meeting NFPA and GHS requirements for fluids commonly found at Auto Recycling Facilities can be found at http://www.sueschauls.com/sds.html. TB

In the iconic words of The Gambler, “You’ve got to know when to hold them, when to fold them, when to walk away, and when to run.” Today’s shifting platinum group metal (PGM) market underscores the significance of these words more than ever. After the historic highs of 2021 and 2022, PGM prices have cooled significantly, with the average catalytic converter value dropping by more than half. Prices have held steady throughout 2024 (see charts on p. 10). Many recyclers are stockpiling converters in response – an increasingly risky move in light of record-breaking catalytic converter theft.

So, where are PGM prices heading in 2025? We wish we had the ability to predict the future. Current market conditions draw parallels to the early 2000s, with a strong dollar, persistent inflation, global economic uncertainty, and supply disruptions from Russia and South Africa. Back then, palladium spiked to $1,100 per ounce before plunging 60% once production stabilized. Similarly, platinum hit a record high of $2,250 per ounce in March 2008 amid South African

supply issues, only to fall to $774 by November. And rhodium, which soared to $10,025 per ounce in 2008, crashed by 90% before the year’s end. These fluctuations remind us that while PGM prices can skyrocket, rebounds take time – often measured in years, not months.

THE PLATINUM MARKET IS ABOUT TO FACE ITS LARGEST SUPPLY SHORTFALL IN A DECADE, ACCORDING TO JOHNSON MATTHEY’S 2024 PGM MARKET REPORT.

shipments normalizing following significant sales of mined stocks in 2023. In South Africa, efforts to process untreated platinum stockpiles will help counterbalance restructuring by major PGM miners. Despite these supply challenges, demand for platinum is projected to remain robust, driven by investment in the glass industry and optimistic market sentiment. Automotive platinum use, though slightly contracting due to reduced diesel car production, will remain near fifteen-year highs.

The platinum market is about to face its largest supply shortfall in a decade, according to Johnson Matthey’s 2024 PGM Market Report. We predict a 2% decline in primary supply, with Russian

Meanwhile, we expect the deficits in the palladium and rhodium markets to narrow. Automotive demand for these metals is forecast to decline as global gasoline car production slows and manufacturers reduce PGM content in catalytic converters to cut costs. However, secondary supply is increasing, particularly through improved automotive recycling in China, where processors are handling previously hoarded scrap. These developments have stabilized palladium and rhodium prices following the sharp declines of 2023, aided by the consumption of surplus inventory accumulated during the pandemic years.

Becky Berube has served the recycling community for over thirty years. Based in Greenville, South Carolina as President of United Catalyst Corporation, she writes a monthly educational column for the industry, and serves on several ARA and ReMa committees. She is a newly appointed Advisor on the US Industry Trade Advisory Committee on Critical Minerals. She was a recipient of a 2023 South Carolina Women in Business Award and is a mentor in the Women in PGMs program. Additionally, Becky serves as an At-Large Director of the ReMa Southeast Board, Co-Chair of the IPMI Preventing Auto Catalyst Theft Committee, and is on the Board of Directors of the International Precious Metals Institute (IPMI), where she is a past President.

RATHER THAN HOLDING ONTO LARGE BACKLOGS, CONSIDER SELLING YOUR MOST RECENT ACQUISITIONS AT TODAY’S RATES.

For recyclers and investors, long-term strategy is key. Reflecting on my early career at Putnam Investments, I recall the importance of dollar-cost averaging – a method of managing price risk by consistently investing the same amount over time to achieve an average price. Applied to the recycling industry, this approach suggests that regularly selling converters, regardless of market prices, can help smooth out the highs and lows. Rather than holding onto large backlogs, consider selling your most recent acquisitions at today’s rates. If you partner with a reputable processor, you may also be able to process older inventory and hold the recovered metal on account, allowing you to sell later when prices improve.

Looking ahead, analysts predict platinum will play a vital role in the hydrogen economy, with the potential to surpass palladium in value over the next three to five years. Meanwhile, rhodium remains essential for reducing NOx emissions, with stricter global regulations driving increased demand.

The PGM market may be unpredictable, but with a measured, strategic approach, recyclers can navigate its ups and downs successfully. Whether you hold, fold, or sell, the key is to act with intention, not out of fear or speculation.

For daily updates on the PGM markets, subscribe to the United Catalyst Corporation daily e-newsletter, the 60-Second Report, visit unitedcatalystcorporation. com/daily-industry-news/. To learn more about recycling converters on assay or the United Ecosystem Bid Tool, you can also call an Account Executive at 864824-2003 or email a specialist at sales@ unitedcatalystcorporation.com. TB

Every autumn in northern Wisconsin, a small ladybug-like insect invades our area. They technically are not a ladybug, but they look a lot like them, so that is what we call them. These are a nuisance because they are so numerous, get into everything, and leave a terrible smell when they fly away. The other morning, as I was sitting in my favorite chair drinking coffee out of my favorite mug, I noticed one of the wretched beasties running around the rim of the cup. I didn’t watch him for very long before I noticed a pattern. He continued to circle at a steady pace, but at a specific location opposite the handle, he would dip down about half an inch off the rim, move forward an inch, climb back up to the rim, and then continue racing until he returned to the same spot. I was mesmerized and watched this for at least ten minutes without noting a change in pace or course.

chair. People may say coffee isn’t healthy, but spending time with God and planning for the day is. There are many things in our lives that we should probably look at and evaluate so that we know why we are doing what we are, if it is good to continue, or if we need to change it up a bit.

We often find ourselves circling around without a clear end in sight. We follow a pattern for so long we start to wonder why we are doing whatever it is in the first place.

The same goes for our business. Why do we have to process what we have? Do we keep on doing something without a process where one should be? Could we do better at buying or inventorying? Is our reason “because we have always done it that way” or “that’s how Dad did it?” Even though that’s common, I think it’s a good time to assess whether we’re in a rut or doing the right thing. As we start the new year, I encourage everyone to spend some time looking at how we are doing some of our core processes to see if we can’t make improvements.

It got me to thinking about how we have a way of doing this in our business and in our lives. We often find ourselves circling around without a clear end in sight. We follow a pattern for so long we start to wonder why we are doing whatever it is in the first place. I find myself doing that anyway. Some “ruts” are not bad and maybe even good. Take that morning ritual of coffee in my favorite mug in my favorite

Back to our little bug friend, it should be noted that after watching him for all that time, there was a deviation to the pattern. After a while, he reversed directions and ran around in the opposite direction. When he came to the same spot, he did the same little dip down the side and then resumed the race around. I never understood why the creature acted this way, but switching directions doesn’t guarantee you’ll get there. It’s possible to find yourself in a similar situation but heading in a different direction! TB

Jake Nawrocki, with sister Katy Joles, own and operate Rocki Top Auto Recyclers in Glen Flora, Wisconsin. The company was formed in 1988, and Jake and Katy took over operations in 2009. Since that time, they have been working both in and on the company, in a region that is economically challenged.

“Our goal is to make Rocki Top Auto a destination.” Contact Jake at 715-322-5774 or rockitopauto.com.

Bow Auto Parts in Bow, NH Received High Honors from ARA as the 2024 ARA Certified Auto Recycler of the Year.

ARA recently recognized Bow Auto Parts as the Certified Automotive Recycler (CAR) of the Year during the association’s annual convention in Reno, NV. Bow Auto Parts is a familyowned and operated used auto parts distributor and supplier in Bow, NH. Automotive Recycling Toolbox Edition connected with Chris Lindquist, owner and general manager of Bow Auto Parts to learn more about the company’s impact on the automotive recycling industry, its focus on being CAR certified, and its vision for the future.

ToolBox: Tell us about the history of your company.

Chris Lindquist: My father, Allen Lindquist, grew up loving cars. In 1986, he started Bow Auto Salvage with just a one bay garage and no inventory. He purchased a wrecker and started buying up used and junk vehicles throughout town, keeping inventory in a notebook. He soon got his first inventory system, and he started attending all the conventions – including ARA and URG and he joined Jim Counts Consulting groups.

It was his thirst for learning and willingness to try new ideas that helped the business progress throughout the years. My brother Kevin and I both grew up in the business and grew to love the business. Today my brother and I are running the business with Allen, who is still the president and my mother Sue, who is still the vice president.

Our largest and most significant growth period was when we joined PRP-Northeast about 11 years ago. At that time, we only had nine employees, two delivery trucks and processed about 70 vehicles a month. As a family, we decided that we needed to join, and it’s been the best decision we have ever made. We now have 70 employees, 13 delivery truck routes, one tractor trailer and process over 3,500 vehicles a year.

TB: What is the size of your facility size today?

Lindquist: Today we are running on 20 acres with over 23,000 sq. ft. of warehouse/dismantling space, a separate 4,000 sq. ft. office building and numerous outside racking areas.

Everything our customers order, besides the vehicles waiting to be dismantled, are already off and ready to go. So there’s no surprise damage that happens a lot when pulling parts off vehicles in the yard. Customers love that.

TB: What type of recycler is your company and how many cars are processed per year?

Lindquist: We are a full-service recycler. What makes us different from many yards is we don’t keep the vehicles after dismantling. We fully dismantle each vehicle, stock/shelf all the parts pulled and then crush the vehicle.

We process the 3,500 vehicles a year between seven bays. We also have dismantling teams where a backup dismantler is assigned to two dismantlers and break down the drivetrain once it’s out of the vehicle so that the dismantlers can finish removing the parts off the vehicle. This has helped increase our production without having to add more dismantling bays.

TB: What is the mission and vision for the company?

Lindquist: At Bow Auto Parts, quality is the cornerstone of our mission. We ensure every part meets top industry criteria for performance and reliability. We conduct meticulous inspections and maintain strict handling procedures to not only meet but set new benchmarks in the used auto parts industry.

TB: Why is ARA membership important to you?

Lindquist: We’ve been a member of ARA since the early 1990s. It was important back then for my father to learn from attending the shows and learning from all the great names in the industry back then and those that are still great today. ARA has been a great source for both knowledge and for helping the industry stay up-to-date on what’s going on. As owners we sometimes get too busy and caught up in our business and ARA is helpful, so we don’t miss the important things.

We are also members of ATRA-NH.

TB: With your ARA CAR Certification, why is it important for you to have this designation?

Lindquist: We were ARA CAR Certified just about every year when we joined, and the recertification got missed for a short period of time. We renewed our certification for about the

last four years. Being “clean and green” has always been something that my dad instilled from the beginning of Bow Auto Parts even before the word “green” became a thing in the industry.

It’s always been our goal to be unlike the “junk yards” out there. We wanted to have a place of business that everyone felt comfortable to walk into. We have customers and even new employees that we

interview and/or hire and the first word that comes out of their mouth is “Wow!”

TB: How has being CAR certified helped your business?

Lindquist: Being ARA CAR Certified and Recall Certified has helped us be able to sell airbags on eBay which has been very profitable. The rule about having to be certified has weeded out a lot of sellers and gives us more of an advantage in selling the air bags on eBay and selling them for a profitable price – unlike a lot of parts where it’s a fight to sell for the cheapest and it’s typically not profitable.

We also hold the ARA HVV Certification even though we are not processing fully electric vehicles in our facility.

TB: To thrive for years to come, in your opinion what is the key to success?

Lindquist: To be successful you must stay ahead of the game. This industry is constantly changing and is a very gray industry, meaning not everything is black and white on how to be successful. It takes trying new things, listening to your peers, finding out what

others are doing and how you might be able to apply that to your business. Be ready and willing to adapt and change. Always stay hungry and play well with others! TB

Based in Minneapolis, Minnesota, Maura Keller is a seasoned writer, editor, and published author, with more than 20 years of experience. She frequently writes for various regional and national publications.

In the old days, business was about connecting with people. People made deals with a handshake, eye contact, and a sense of trust. Today, things look different – but only if we let them be different. What significant changes have occurred over the last five years?

Think about it:

· Have you bought anything online lately?

· Entered your personal info on a website?

· Interacted with a business through chat, email, or text?

· Now, here’s the big question: How many of your customers or vendors do you truly know? And by that, I mean knowing them well enough to call and say, “Hey Bob, it’s Tony from InXpress. Can I ask you a favor?”

How many of us have those kinds of connections? And how many of us just see things as transactions? If we’re honest, most of us could use more personal connections with our customers and vendors. But that can change – if we make the effort. Instead of just buying and selling, think about ways to build genuine connections. It’s good for you and for your business.

Let me share why viewing your customers and vendors as part of your team makes sense.

In shipping, we often ask prospective customers to share invoices, Bills of Lading, or Airbills from other freight brokers or suppliers. Why? It lets us get a clear view of both the big picture and the small details of their shipping operations. By knowing the full scope, we can find ways to save you time and money – and, importantly, help your business grow.

Some people hesitate to share that information. But why? Maybe you’re worried that if I know what you pay now, I’ll try to overcharge you. Or maybe you think I’ll make money that you’d rather keep for yourself. But the truth is, sharing those details lets a shipping partner help in practical, valuable ways. With a full picture, we might find ways to save you a percentage on shipping costs, reduce fees like accessorials, or suggest tweaks to improve efficiency. And sometimes, we might look at everything and tell you, “Wow, you’ve really got this down. There’s nothing I can add here.”

And isn’t that better? A trusted partner analyzes the information, shares their expertise, and tells you exactly where they can – or can’t – help. No stress, no hassle. Just an honest look at where value can be added. And from that, you’re creating a connection that’s profitable for both sides, grounded in transparency.

Let’s be real – people in shipping want to make money, just like you do. But if you’re open with us about your shipping needs and your business goals, we have a much better chance

of getting things right. Together, we can create a long-term partnership that goes beyond a one-time deal.

That’s networking at its best. It’s about finding the right people, building trust, and helping each other succeed. Here’s how to start:

· Identify the people and businesses you genuinely want to work with.

· Take time to develop those connections.

· Reap the rewards of these strong, beneficial partnerships. To bring it all together: there will always be areas in business where being transactional works just fine. But when it comes to those essential areas – top customers, critical vendors – find the people who make a difference. Transform “transactions” into genuine connections, and watch your business thank you for it. TB

We, as an industry, have joined ranks together to give two vans to the Tunnel to Towers Foundation. On April 11, 2025, in Orlando, Florida, URG, Team PRP, and ARA are presenting two 6-8 passenger vans during the URG, Team PRP Annual Training Conference in Orlando, Florida.

The Tunnel to Towers Foundation, along with all of us in the recycling industry, wants to eradicate veteran homelessness. They can’t do it without all of us doing our part to help. Tunnel to Towers also has Veteran’s Villages in Houston, Texas, Riverside, California, and Phoenix, Arizona. They have broken ground in Bradenton, Florida, and Mableton, Georgia. The Mableton location is approximately an hour’s drive from my home in Georgia.

Before the end of this year, Tunnel to Towers will start additional Veterans Villages in Denver, Colorado. Nick Daurio, past president of ARA, is working on a van with a ramp, and a disabled person’s lift is already installed. Okay, helping others will sometimes require extra effort. So, here’s my next challenge. I discovered that installing wheelchair ramps isn’t cheap these days. Therefore, I need to raise $15-$20K to make two vans wheelchair accessible. If some of you have been looking for an opportunity to help but didn’t have a van to donate, here’s how you can help today.

Give me a call at 770-301-4122 or email me at dj@djsays.com, and I will be delighted to give you the name of the company for which you make your check payable. If all of us contribute to this goal, we can get it done very easily.

Nothing would give me more pleasure than to meet this monetary goal well before April. We plan on getting bids from three different companies that can install disabled ramps and lifts into these vans.

If by chance you already know a company that can do this, let us know soon. Also, it would certainly help if you talked to as many people as you could on our behalf. You might know someone outside the industry who’s looking for a way to help homeless veterans. Tunnel to Towers will be opening 5–7 centers each year. We need to tell as many people as possible about this need so they can help make it happen.

Now, get ready for the best conference that is just around the corner. URG and Team PRP are moving forward with their largest training conference ever. Remember, you don’t have to be a member of URG or Team PRP to come to Orlando, Florida, on April 10-12 for this premier event of the year.

As we present these two vans to Tunnel to Towers, it will be a joyful occasion and our gifts will help homeless veterans move about in their areas with the transportation they so greatly deserve. Speaking of what they deserve, you deserve to participate in this conference too. This top-notch conference boasts award-winning speakers, authors, and coaches who possess extensive knowledge of this industry. You don’t want to miss this time to educate your team. There will be a full schedule of training sessions by industry experts on a wide range of topics, from team building to sales, from compliance to marketing, and many other topics. The Annual Golf Tournament will help raise funds for the URG Scholarship Foundation, which is a certified 501(c)(3).

If you are a company owner seeking to engage with numerous decision-makers in the automotive recycling industry, it is crucial to be present. And your team needs to be there too. Don’t forget to bring something we can auction off, which will help raise money for the URG Scholarship Foundation. So, mark your calendar now and be there in April. April is only a few short months away! Call me or go to URG online at u-r-g.com and learn all about the best industry conference of the year.

See you on the next podcast. TB

D.J. Harrington is the President and Chief Executive Officer of Phone Logic, Inc., an international training company based in Atlanta, GA. He serves as a consultant and trainer to over 1,000 privately-owned businesses throughout the country, training personnel at all levels of the company, from the dispatcher to the customer service and sales staff. Please visit his website for more information at www.djsays.com.

BY MIKE FRENCH

We’re already a few months into the new year. So, how are your resolutions holding up? If you’ve already let them slip, don’t feel bad – you’re not alone.

Many people begin the year with high expectations, dedicating themselves to exercise programs, gym memberships, or new diets as part of their personal improvement plans. But the reality is that most resolutions don’t last.

In fact, a 2023 Forbes Health poll revealed that many people abandon their resolutions within the first few months. About 10% gave up after just one month, 21.9% lasted two months, 22.2% stuck it out for three months, and only 13.1% made it to four months. A mere 1% kept their resolutions for nearly a year.

I’ve been in that same boat. Over the years, I’ve set plenty of resolutions – especially to lose weight – but rarely succeeded. Why? Because, like many people, I hate diets.

I’ve tried a bunch of them, including fad diets, but they never worked for long. The problem wasn’t just the effort they required – it was the constant hunger and feeling of deprivation. As soon as I started cutting calories, my brain would panic, convincing me I was starving.

At the start of 2024, I weighed 197 pounds, way too much for me. Feeling stuck and frustrated, I decided to try the carnivore diet, which focuses entirely on meat. To my surprise, the weight started melting off. Within four months, I was down to 160 pounds – a weight I hadn’t seen since my 20s.

It wasn’t just the weight loss that amazed me – I’ve also maintained this weight for a year. That’s like shedding three and a half 10-pound bags of potatoes I no longer carry around.

I initially started the diet because I’d been struggling to lose weight after being diagnosed with long-term COVID. My symptoms included persistent fatigue, brain fog, and lung problems. On top of that, I was dealing with arthritis pain from two falls I had last winter. After two trips to the emergency room by ambulance, my future was looking dim – I seemed to be going downhill fast. I knew I had to make some changes or risk further decline.

– so bad that it left her wheelchair-bound – was completely reversed. Her bones and cartilage regenerated, and she’s now healthy and active. Inspired by her results, her parents adopted the diet themselves and experienced weight loss, improved muscle tone, and renewed energy.

Then I happened to see an interview on YouTube featuring Piers Morgan and clinical psychologist Jordan Peterson. Peterson shared how eating only meat transformed his family’s health. His daughter’s severe rheumatoid arthritis

I was intrigued and hopeful. I decided to try the diet for 30 days – figuring I could do anything for a month. When it worked well for the first month, I decided to keep going. Month after month, I continued, and now, a year later, I’m still on it.

Mike French is retired after 39 years of business in the automotive recycling industry. He is an author, publisher, consultant, and speaker. Mike is the founder and executive director of the Christian Auto Recyclers and Vendors Association (CARVA) and will be at upcoming recycler trade shows and events. Mike is available to speak at your group, conference, or event. He loves to share inspirational stories that demonstrate how the Word of God actively changes lives. He can be reached at mike@carva.group. Visit www.CARVA.group and/or www.PowerPackedPromises.com.

Before committing, I did extensive research online, including reading medical endorsements and watching countless testimonials on YouTube. Many people reported life-changing improvements, especially in inflammatory conditions like arthritis.

Since starting the diet, I’ve experienced similar benefits to those others have described:

• I no longer have any arthritis pain in my shoulders, fingers, or toes.

• My long-COVID symptoms, including lung issues and brain fog, have vanished.

• My weight reduced to what my body structure needed to be then has remained there.

• I feel healthier, lighter, and more energized than I have in years.

The carnivore diet involves consuming only high-fat, high-protein,

animal-based foods, such as meat and eggs. You don’t need to count calories; you can eat as much meat as you want, and you don’t feel hungry (I didn’t).

There are variations of the diet, such as the lion diet. I found helpful resources by searching “carnivore diet testimonials” on YouTube, which led me to many success stories, including from doctors, along with diet tips and recipes.

A Harvard study surveyed 2,029 carnivore dieters who had been following the diet for at least six months. Key findings included:

• 95% reported improved hunger/food cravings.

• 89% experienced better mental clarity.

• 98% were very satisfied or satisfied with the diet.

When I lost the weight, I shared my results with friends and family. My son, John, told me about a friend who achieved similar results by simply

My symptoms included persistent fatigue, brain fog, and lung problems. On top of that, I was dealing with arthritis pain.

cutting out sugar and wheat. Meanwhile, other family members swear by their vegetarian diets, which keep them in excellent shape.

Clearly, it’s important to find what works best for you. This diet may not work for everyone, but it has been a game-changer for me. If you’re curious, I recommend looking up “carnivore diet testimonials” on YouTube.

Now, my only problem is finding clothes that fit – I haven’t been this size since my 20s!

A word of caution: Always consult your doctor before making significant dietary changes, especially if you’re taking medications or have health issues. TB

Ernest “Bud” Roberts age 81 passed away on October 19, 2024 at his home in Hoschton, Georgia. Bud was the owner of Bud Roberts Company (www.budroberts.com) and involved in automotive recycling industry since the 1970’s.

Jonathan Morrow, past president of ARA, says, “I remember when he used to buy CV axle cores from ARA members and rebuild them. After his axle business, he began selling tires for loaders other heavy equipment. For years one of his eye-catching ads was for ‘Bomber Tires.’ These were aircraft tires that were beyond their safe life for planes but were still good for some heavy equipment applications. He sold attachments for loaders and other heavy equipment, like forks to handle cars, crusher forks, extra-long forks and various buckets and grapples.”

“Bud was always a very helpful advisor, honest and sold quality products,” he continued, “I’ll miss Bud.”

He is survived by his fiancé Myra Horn, his half-sister Kathy Roberts, his sons James Roberts and Jon Roberts, cousins Susan Tischler and Karen Oertel, nephew Richard Tischler and Myra’s family, Anita, Terry, Lindsay, Brandon, Andy, Jax and Ellie. Bud created two very successful companies Bud Roberts Company and CV Source which he continued to administer up until his death. TB

Lifetime Honorary Member and former ARA Board of Director, Paul Davis passed away on January 2, 2025. Born July 2, 1947, Paul was the owner of A-Plus Parts & Salvage, Wichita, Kansas for many years and a dedicated and influential figure in the automotive recycling community, especially at the local level. He was very active as an ARA volunteer and recognized with ARA “Regional Director of the Year” award in 2013 for his exemplary service.

Paul’s commitment to the industry was evident through his advocacy efforts and his work, and witty commentary and has left a lasting impact on the automotive recycling industry.

He is preceded in death by his wife, Darlene (Olinger) Davis; parents, Gorman Davis and Hydee (Babcock) Provence. Survived by son, David (Jennifer) Davis of Wichita; grandchildren, Stella, Cora, and Emma; brother, Dana (Paula) Honea of Wichita. TB

By Slater Shroyer, Chair, ARA Government Affairs Committee

ARA’s most important function is advancing the professional automotive recycling industry and promoting its beneficial effects on society. A huge part of that is helping automotive recyclers navigate a constantly evolving legal and regulatory landscape. In many cases, those responsible for creating laws and agency regulations know little about our businesses and the recycled parts market. ARA has a responsibility to monitor potential threats and opportunities, educate legislators and regulators, and inform the membership. ARA is often the only voice in the room fighting for the automotive recycling industry.

We continue to establish ARA as experts in every aspect of the dismantling and recycling process. This is only possible with your participation. ARA needs your contributions of time, expertise, and money.

In April, many of your peers will join ARA in Washington, D.C., for Hill Days and we want to see you there! At this event last year, we presented ARA’s position on the

PART Act to Members of Congress. This bipartisan legislation would require OEMs to start marking catalytic converters with VIN numbers or other unique identifiers. ARA has joined 120 related organizations by signing a letter of support for the bill.

ARA represents the industry on environmental issues. For example, in California when the Department of Toxic Substance Control attempted an emergency rulemaking change that would reclassify metal shredder aggregate as hazardous waste and exclude it from the definition of scrap metal. When the EPA requested comments for Sector Specific Stormwater Fact Sheets, ARA responded, pointing out practices and requirements that were obsolete or unrelated to efficient and safe vehicle dismantling and processing. These efforts had a direct impact on the final regulations.

ARA is working with several groups regarding the reuse, remanufacturing, repurposing and recycling of High Voltage Batteries from Hybrid and Electric Vehicles. We are working with legislators in California on Extended Producer Responsibility requirements for auto manufacturers who produce batteries with zero or negative recycling value.

ARA is active in the Right to Repair movement and continues to advocate for a seat on the Advisory Committee for the REPAIR Act. This bipartisan bill would require vehicle manufacturers to provide vehicle owners direct, real-time, in-vehicle data related to diagnostics, repair, service, wear and calibration of parts and systems.

Please consider meeting with elected officials by attending ARA Hill Days on April 2-3, 2025, volunteering for a committee, and/ or donating to the ARA Political Action Committee so we can continue to have a seat at the table when important policy decisions are made. TB

The Automotive Recycling Industry Development Committee (CARIDC), recently formed by the China Association for Economic Development in Asia (CAEDA), has agreed to be involved with the International Roundtable on Auto Recycling (IRT).

Chinese association joins in supporting the International Roundtable on Auto Recycling (IRT). CAEDA is a national social organization established under the guidance of the Ministry of Foreign Affairs of the People’s Republic of China, which is committed to promoting economic and cultural exchanges and cooperation between Asian countries and countries along the “Belt and Road.”

The goal of the association is to organize interaction between member enterprises and the Asian business community, enhance understanding and friendship, and contribute to the economic development of China and Asian countries.

The Automotive Recycling Industry Development Committee (CARIDC) aims to promote the sustainable development of China’s automotive recycling industry.

According to the characteristics and key points of the development of the automotive recycling industry chain, CARIDC will carry out the construction of recycling systems such as new and old automobile replacement, recovery, dismantling and reuse, new energy automobile power battery recycling and laddering, after-market services, recycling of second-hand automobiles and parts, etc., and will follow the development route of ‘double recycling’ in the refinement of the resource recycling and the practical aspects of the ESG practice. In addition, following the ‘doublecycle’ development route, CARIDC will work on the refinement of resource recycling and ESG practices.

“CARIDC is willing to cooperate with all parties, focusing on intelligence,

electrification, greening and recycling, to jointly promote technological innovation and international cooperation in the field of automobile recycling, and to achieve low-carbon development of automobiles,” stated President Zhang Ying with CARIDC. CARIDC is hosting the next Asian Automotive Environmental Forum in October 2025.

“We welcome the participation of CARIDC within the IRT. While we hear many things about the Chinese auto recycling sector, it is a great opportunity for all to learn more and to share information directly,” said Steve Fletcher, IRT Administrator.

The IRT is a voluntary forum to exchange ideas, trends, opportunities and challenges among progressive auto recyclers and their associations from around the world. The IRT is currently supported by key auto recycling associations in Canada, the USA, Japan, Australia, the UK, Poland, Malaysia, and Spain. TB

BY SANDY BLALOCK

In 1974, John Hochmiller’s father, John Hochmiller Sr., made a significant investment in a 40-acre tract of undeveloped I-3 land in Weld County, Colorado, purchasing it for just $54,000. What appeared to be a simple plot of land would go on to become the foundation for a thriving business – a legacy that would shape not only the family’s future but also the truck parts and salvage industry.

In 1976, John, inspired by his father’s foresight, founded Active Truck & Auto Parts. Starting small, he operated out of a modest ½-acre fenced lot situated in the center of the 40-acre property. The initial inventory was humble – 25 retired pickup trucks sourced from the Rio Grande Railroad – while marketing efforts relied heavily on classified ads in local newspapers, such as the Rocky Mountain News and the Denver Post. Despite these modest beginnings, John’s vision and drive quickly set the stage for success.

From the start, Active Truck & Auto Parts carved a niche by specializing in pickup trucks and 4x4s. Recognizing a need within the local farming community, John expanded the company’s inventory to include medium-duty trucks, and this shift became a hallmark of the business. Over the years, Active grew and evolved in tandem with the needs of the trucking industry.

Construction of the first building on the property in 1978 marked the beginning of several expansions over the decades. The company continued to innovate and expand, adding new services like major truck repairs, towing, truck sales, frame modifications, and equipment mounting. These expansions, in 1982, 2000, and 2012, were a direct response to the evolving needs of the trucking industry and reflected John’s commitment to innovation and excellence.

John’s passion for efficiency and innovation didn’t stop at expanding his business operations. In 1988, he revolutionized his inventory management by purchasing the Hollander System, a move that would later prove instrumental in streamlining operations. As the business continued to grow, the inventory increasingly featured an equal split between pickup and medium-duty truck parts. However, the limitations of the Hollander System – especially its inability to allow other yards to search for parts using standard interchange numbers – became apparent.

In 1998, John took a bold step to address this issue, partnering with a young computer programmer from Lincoln, Nebraska, who was developing a specialized inventory system for medium- and heavy-duty truck salvage. Recognizing the potential of the project, John, along with six other industry leaders, invested in and guided

the development of the system. This innovation would go on to become the go-to inventory solution for medium- and heavy-duty salvage yards across the country. For John, this development stands as one of his greatest contributions to the industry.

In 2002, John made another pivotal decision: to focus exclusively on medium- and heavy-duty trucks, scrapping all light-duty inventory and transitioning away from the Hollander System. To complement this shift, he sought out a manufacturing partner in Guadalajara, Mexico, to create a proprietary brand of aftermarket collision parts for mediumand heavy-duty trucks. This collaboration resulted in a brand that quickly gained popularity, further solidifying Active Truck & Auto Parts’ reputation as an industry leader.

John’s leadership and expertise extended beyond his own business, making substantial contributions to the industry as a whole. A dedicated member of the Colorado Automotive Recyclers Association (CAR) since 1986, John served on the Board of Directors for 13 years, including three years as Secretary and four years as President. He also played an active role as a regional director for the Automotive Recyclers Association (ARA). As the company’s focus shifted toward medium- and heavy-duty trucks, John became a Board Member of the International Truck Parts Association, further extending his influence within the industry.

Throughout his career, John earned the respect of his peers for his unwavering dedication to advancing the auto recycling industry. While the decision to retire was not an easy one, he looks back with pride at the relationships he built and the company he helped grow over 48 years.

As John steps away from the business that has been a cornerstone of his life, he takes a moment to reflect on the individuals and organizations that made it all possible. He extends his heartfelt thanks to the Colorado Automotive Recyclers Association for its guidance and support. He also credits his late father, John Hochmiller Sr., whose visionary decision to purchase the land laid the foundation for everything that followed. Above all, John acknowledges the role of his son, Ryan, who spent 15 years contributing to the company’s growth and success.

John’s legacy is not simply defined by the success of Active Truck & Auto Parts, but by the lasting impact he made on the professional auto recycling industry. His dedication to quality, innovation, and leadership will continue to influence the industry for years to come. As he steps into retirement, John’s story serves as a testament to the power of vision, hard work, and perseverance in building a family legacy that will endure for generations. TB

The Automotive Recyclers of Canada (ARC) Board of Directors are pleased to announce the hiring of Wally Dingman as their new Executive Director replacing Steve Fletcher, effective April 1, 2025.

Dingman has been a fixture in the auto recycling sector as the previous Chairman of the Ontario Automotive Recyclers Association (OARA) for 14 years, and as the Chairman of ARC for 10 years (2011-2021). He has helped guide those associations successfully through multiple years of incredible growth and diversification. Wally was also owner of Caughill Auto Wreckers in Niagara-on-theLake, a third-generation business – so he is intimately aware of the challenges and opportunities that confront auto recyclers every day.

Steve will be stepping away from day-to-day activities after the OARA Convention & Trade Show in Niagara Falls in March. He will retain the international activities of ARC, and work on important sector relationships and special projects with Wally.

“Having worked alongside Wally for over 25 years, the transition to his leadership will be virtually seamless,” said Steve. “I am very pleased that I will have a role to play going forward in this industry that has been so good to me.”

Wally had much to say about Steve and the ensuing responsibilities:

“It is impossible to talk about automotive recycling in Canada without recognizing the tremendous impact of Steve Fletcher. Over the past several decades, Steve has dedicated himself to elevating our industry, not just nationally but on the international stage. His leadership, vision, and tireless efforts have made him the face of automotive recycling, and his contributions have left a legacy that will endure for years to come.

“I’ve had the privilege of working alongside Steve for over 25 years, sharing experiences and responsibilities at both the provincial and national levels. As Chairman of both OARA and ARC, I witnessed firsthand his ability to lead with unwavering dedication, ensuring that our organizations remained at the forefront of innovation and advocacy. Steve’s passion for this industry has been nothing short of inspiring, and I cannot thank him enough for his incredible commitment and all he has achieved.

“As we look to the future, I am humbled and honored to be entrusted with continuing Steve’s work. While my role as Executive Director does not officially begin until April 1, 2025, I am eager to take on this responsibility and build on the strong foundation he has created.”

Wally can be reached at wally@autorecyclers.ca or (905) 651-7482. TB

BY RECYCLERS

IMPORTANT: RENEW YOUR SUBSCRIPTION AT https://autorecyclingnow.com/toolbox/subscribe THIS IS REQUIRED TO CONTINUE RECEIVING THE TOOLBOX!

The Automotive Recycling ToolBox™ Edition delivers peer-to-peer articles with information that you would get while networking at industry events and trade shows. Our mission is to be current, educational and inspirational. We bring you:

• Educational and instructional “how-to” articles written by fellow recyclers, top industry professionals, leaders & trade show speakers.

• Information from providers of industry-related products and service you typically find at industry events and trade shows.

PUBLISHED 6 TIMES A YEAR AutoRecyclingNow.com/Toolbox

AUTOMOTIVE RECYCLERS ASSOCIATION OFFICERS

YOUR TOOLBOX TEAM

Published by Driven By Design LLC

EDITOR

Caryn Smith, Toolbox@a-r-a.org

ART DIRECTOR

Caryn Smith

ADVERTISING SALES

Jay Mason, ToolboxAds@a-r-a.org

EXECUTIVE DIRECTOR

Vince Edivan

Automotive Recyclers Association

Vince@a-r-a.org

SENIOR DIRECTOR OF ASSOCIATE OPERATIONS

Jessica Andrews, Jessica@a-r-a.org

SENIOR DIRECTOR OF MEMBER SERVICES

Kelly Badillo, Kelly@a-r-a.org

VICE PRESIDENT OF STRATEGY AND GOVERNMENT AND REGULATORY AFFAIRS

Emil Nusbaum, Emil@a-r-a.org

CERTIFICATION CONSULTANT

Sue Schauls, Sue@a-r-a.org (319) 290-7843

PRESIDENT Eric Wilbert Wilbert’s U-Pull-It, LLC Williamson, NY eric.wilbert@wilberts.com

1ST VICE PRESIDENT Shannon Nordstrom Nordstrom’s Automotive, Inc. Garretson, SD shannon@nordstromsauto.com

2ND VICE PRESIDENT/TREASURER Sean Krause Speedway Auto Parts, Ltd. Joliet, IL sean.krause@speedwayap.com

SECRETARY Tom Andrade Everett’s Auto Parts Brockton, MA tandrade@everettsautoparts.com

IMMEDIATE PAST PRESIDENT Nick Daurio Daurio Auto Truck Pueblo, CO nick@daurioauto.com

ARA CONTACT INFORMATION

ARA Headquarters Manassas, VA (571) 208-0428 staff@a-r-a.org www.a-r-a.org

To reach readers with print & digital advertising, email ToolboxAds@a-r-a.org

For editorial contributions, e-mail Toolbox@a-r-a.org or call (239) 225-6137