SYSTEMS THAT SUCCEED

TUNING UP Expense Management

Seasons of uncertainty challenge us to make difficult decisions based on limited or short-term data. The secret to weathering this turning lies in knowing when and how to tighten our belts. For without caution, restraint, or the foresight to see the need to conserve and mitigate our finances, we soon can become susceptible to losing our shirts. Having the vision to see what the cost is and what is worth the price you will pay is better budgeting at its finest. Currently, many recyclers are evaluating routinely where to trim the fat and what endeavors are still worth pursuing. Discovering where we can cut back while still applying the adequate resources needed to move us forward is where we should be focusing. We should do our research and remain aware of the industry’s scope, market trends, and our business plans. In that case, we can better assess how to cut our costs while prioritizing our imperative investments.

Expense management can be a fickle fiend among auto recyclers, especially those reluctant to change.

How many times have we heard the phrase “If it ain’t broke, don’t fix it?” Just because we are experiencing a good thing does not guarantee sustainability or future success. Markets shift, regulations change, and consumer opinions, well, we know how unpredictable those can be. Sooner or later, push will come to shove, and what we have relied on to keep us pushing forward and getting by must be questioned. This scenario is no easy task for any business, big or small,

If we are not making time to review our costs in conjecture with our business plan and the current state of things, then we are not preparing to succeed.

because we are always busy. The Achilles heel is change, like it or not, embrace it or not, it has swept us all off our feet at one point or another. From our sales staff to our dismantling team, inventorying and shipping, we are all busy.

Throughout our operations, we are tasked with wearing many hats and are often shorthanded or limited by our resources, or even within the parameters in which we are to work. How in times like these, where we are compensating

in any way we can in response to either current trends, market downswings, or the state of our bottom lines, are we supposed to make time for expense management?

Failure to Plan is Planning to Fail

If we are not making time to review our costs in conjecture with our business plan and the current state of things, then we are not preparing to succeed. Expense management should not be saved for times when waters become murky or the future becomes a foreign land. Evaluating our costs must remain a routine process that we must all undertake regardless of our position within the business. Efficiency, innovation, and direction are often instantly discoverable when we review where we spend too much time, effort, and money, and where we do not invest enough. Time is money; each of us should plan ways to make our time worth the effort we put in. If we

Brian Bachand is a second generation auto recycler, who helps own and operate Westover Auto Salvage in Belchertown, MA. He is on the Board of Directors for the Auto Recyclers Association of MA and a proud ARA Member. Brian has a Bachelor’s Degree in Accounting and paired with almost 25 years of auto recycling experience, will continue to implement ARA Advocacy for being a leader in the auto industry.

address the issue of “This isn’t making the business money,” then we can move forward with a plan of action on how to cut costs while implementing operations that do generate revenue.

There is no comfort zone when it comes to finances. The worst thing we can do is to expect things to work themselves out. Bills are not going to pay themselves magically. Our outstanding accounts receivable are not going to come pouring in upon the miraculous changing of financial priorities of our customers, nor are the supplies or equipment going to stop needing to be replenished and serviced. We need to be involved, stay involved, and be proactive about being problem solvers.

Knowing the fixed expenses of the business, the department, or our position is the first step to understanding our costs. Fixed costs can include your rent, monthly communications contracts, subscriptions, dues, and fees. These costs are a regular set price regardless of usage or utilization. Seek out the information that will give you the weekly, monthly, and/ or quarterly totals. Evaluate what drives the price to be what it is, and how we can optimize or utilize it to our advantage – can it be renegotiated or cut entirely? Understanding their value to our position, department, and operations can help us determine if they are necessary or not, and if they are worth continuing to afford.

We are not going to get rid of our monthly internet cost, but we can surely call up our provider and renegotiate a new contract. We are not going to cancel our software subscriptions. Still, we can ensure that we are maximizing the service by leveraging its full benefits and opportunities. If you can go without, then trim the fat – just be aware of cancellation fees and any domino effect a cancellation may cause.

Managing the Sliding Costs

Variable costs are usage-based and adjustable-rate costs, and are the hardest to control. The company’s electric bill variables are kWh usage and variable supply, demand, and other tax-oriented charges. Both the rate and usage change

An upfront expenditure could cut costs moving forward and yield a return in the future.

monthly. We can’t just say no more electric bills and have the production team use hand tools. But we could maintain a team culture of conserving electricity. The other way to look at this may be an investment, such as exploring if the facility is viable for solar power. An upfront expenditure could cut costs moving forward and yield a return in the future.

Other variable costs we experience can be payroll, repair and maintenance costs, cost of goods sold, and other non-fixed or unexpected overhead expenses. Understanding situational and variable costs and what drives these expenses can help us determine how to trim the fat. We should look at these expenses through a situational lens.

Ask questions like, if we took the time to maintain our equipment more routinely, could we have eliminated the cost of repairs? Would proactive supervision have ensured we were not wasting or underutilizing the supplies we have on hand? Do we find a new vendor for those Red Car Plugs, or do we think smarter by tightening up our inventory control with procedures to minimize waste and implementing better supply buying?

How you choose to manage your expenses, whether fixed or variable, the solutions to your budgetary needs and limits come down to your ability to be creative and innovative when cutting costs.

Saving is Profit

Cost savings is one of the most significant benefits we provide to our customers. Incorporating this value into our expenditures and routinely evaluating our costs for waste and underutilization is pivotal to managing our expenses. We understand we still have certain things to buy and acquire, and there is only so much cost-cutting we can do on these acquisitions before we cause problems or miss out on them. However, we can assimilate the cost savings mentality into our expenses. In that case, we can put in place a program that is consistently trimming the fat instead of waiting for times of uncertainty and toil to force us to tighten the belt. This practice is universal from the guy running quality control, the girl managing production, or even the big boss orchestrating the oversized picture items. In both our business and personal lives, evaluating our expenses and determining what we can and cannot afford is crucial. Comparing this to what we want and need is essential for moving forward. As we become more fiscally responsible and cost value-minded, be reminded again that failure to plan is planning to fail. If we are not making expense management a part of our routine operations and an integral part of everyone’s mindset, it becomes all too easy to lose our shirts. For the moment, a time will come when the market bottoms out, new regulations set in, or the latest trend becomes a derailment. So, to be bold, spend your resources on what generates revenue. What can’t you operate without? Get creative with your cost-cutting ideas. We are stewards of sustainability that embody a circular economy model. Why not bring the Reduce, Reuse, Repurpose, and Recycle to our expense management endeavors? Too many of us in this industry are out there working harder rather than working smarter. It is time to take the uncertainty out of these challenging times by controlling our costs and taking the necessary steps to keep moving forward towards a financially favorable future. Work smarter; “Don’t be afraid to give up the good to go for the great,” said John D. Rockefeller, even if it means adjusting the belt until you find the comfort zone that fits your business type. TB

Driving SMARTER Yards

Why Integration and Innovation Matter More Than Ever in Automotive Recycling

The automotive recycling industry is at a turning point. With more complex vehicles, evolving customer expectations, and razorthin margins, recyclers who rely solely on traditional processes are finding themselves buried in inefficiencies. Those who invest in education and smart systems, however, are not only keeping up – they’re leading.

As someone who’s spent years working alongside recyclers and ERP providers, helping yards integrate payments, messaging, and customer workflows directly into their YMS, I’ve had a front-row seat to the transformation happening across the industry. The truth is simple: better systems lead to better margins, better compliance, and ultimately, better businesses.

Let’s explore what “smarter” really means – and how it’s reshaping how modern recyclers operate.

The Yard Management System as the Nerve Center

For most auto recyclers, the Yard Management System (YMS) is the heart of the business. Whether you’re using Powerlink, Pinnacle, Checkmate, or another ERP, everything flows through this system: inventory, pricing, sales orders, shipping, and customer communication.

But too often, important workflows live outside the YMS. Think about it:

• You’re taking payments manually or using disconnected terminals.

• You’re emailing tracking numbers separately from your order screen.

• You’re using four or five tools to send messages, request reviews, handle returns, and respond to disputes. These disconnects aren’t just a minor inconvenience – they create friction that leads to lost revenue, miscommunication,

and increased chargebacks. I’ve seen yards lose thousands on fraudulent orders simply because they didn’t have a process for verifying cardholders or documenting proof of delivery – all things that can be automated when systems talk to each other.

That’s why integration matters. When your messaging, payments, and dispute workflows are connected directly to your YMS, you eliminate manual entry, reduce risk, and save time.

The Real Cost of Staying Manual

Let’s break it down with a common scenario:

You sell an engine for $2,200.

The customer pays by card. You email them a payment request outside your YMS, then ship it via a separate system, and maybe someone forgets to log the tracking number. The customer calls two weeks later and says the part never arrived. There’s no signed delivery confirmation, no IP address logged for the cardholder, and the payment was processed without 3D Secure.

What happens?

You lose the chargeback – and the engine. That’s a $2,200 loss you could have avoided with a connected,

secure payment system and simple automation.

Now multiply that by just three incidents a year. Add in the time your staff spends tracking orders, updating buyers, answering the same questions repeatedly, or trying to resolve disputes manually. The cost of inefficiency isn’t just operational – it’s financial.

Educating the Industry: What Smart Yards Are Doing Differently

Across the country, I’ve worked with yards that are modernizing how they do business – without overcomplicating it. Here’s what they have in common:

• Integrated Payment Requests

• Real-Time Messaging

• Automated Tracking & Returns

• Proactive Reviews & Dispute Protection

This isn’t just about tech – it’s about creating a smarter operation that supports your team and protects your profit.

You Don’t Need to Be a Tech Company

to Modernize

One concern I hear often: “We’re a yard, not a software company.”

Exactly – and that’s the point.

Your YMS should be the hub, but you shouldn’t need to patch together five disconnected platforms just to get the basics done. The industry is evolving, and modern solutions are built to plug directly into your existing workflows.

I’ve made it my mission to bring simple, scalable tools directly into the systems recyclers already use every day – because no one should have to leave their ERP just to take a secure payment or track a customer dispute.

Why This Matters Now

The recycled parts industry is no longer just local – it’s digital. eBay buyers, body shops, insurers, and individual consumers expect fast responses, real-time shipping info, and secure

online payments. If your yard can’t provide that, someone else will.

And here’s the hard truth: platforms like Podium, Stripe, and Square are actively marketing to your customers –but they don’t understand the recycled parts business. They won’t integrate with your YMS. They won’t help you handle returns, identify chargeback risk, or offer shared revenue models.

If we want to keep ownership of our industry, we need to educate, evolve, and empower our yards with systems that actually work for how we operate.

Education as a Competitive Edge

This isn’t just about automation – it’s about ownership.

When you educate your team and

adopt tools that connect directly to your core systems, you build a business that runs smoother, responds faster, and earns more.

You free up your staff to focus on what they do best: sourcing quality parts, helping customers, and growing the yard.

Smarter doesn’t mean more complex. It means connected, secure, and streamlined.

The good news? You don’t have to do it alone. Whether you’re evaluating what tools to integrate or just exploring how other yards are evolving, resources like ARA’s Tool Box are here to help.

Because when we learn together, we lead together. TB

Lisa Samuel is the founder of PayBuddy™ – the architecture and support behind leading industry integrations – and Sabhi™, two platforms built to serve the real-world needs of the recycled parts industry. With deep integrations into leading Yard Management Systems, she works with recyclers across North America to streamline operations, reduce fraud, and scale smarter through technology. Lisa is passionate about empowering yards to take back control from disconnected tools – and helping them thrive in a digital-first world.

Save Money with Air Compressor Efficiency

Compressed air systems are a valuable tool in automotive salvage facilities. While it is an unavoidable business expense, air leaks could be costing more in excessive energy losses than expected. Even a small leak is an unnecessary financial drain.

Because it is easy to use and readily available, compressed air is often considered a “fourth utility” in its wide industrial use, and it is likely the most expensive utility found in the facility. Approximately 19 percent of the total power used in a compressed air system, even on a well-maintained one, is converted into clean, compressed air flow. The other 81 percent is lost as heat.

According to the average estimate, between 7 and 8 HP of electrical power is required to produce just 1 HP of compressed air power. Compressed air is often more expensive than electricity, natural gas and water when it comes to the costs of maintaining an operation.1

Leaks place an unnecessary demand on compressed air systems. On average, a small quarter-inch leak in a compressed air line can cost upwards of $8,000 per year.1

Leaks also cause the overall performance of your system to decline, resulting in a 25% to 50% waste in the system’s total output, negatively impacting pressure settings.

Fixing leaks and preventing future ones is extremely important when it comes to energy expenditure, not to mention the lower productivity and stresses placed on pneumatic tools that

result from an inefficient compressed air system.

For a compressed air system with a 30 percent loss of output due to leakage, consider the annual cost of a 200 HP system. If the compressor power has a total of 60 HP in leakage, it could result in an energy expense of $31,000 per year at 0.07 per KWh.1

In the United States, energy waste is becoming an increasing concern as estimates place a $3.2 billion expense in wasted utility payments each year due to poorly designed and maintained compressed air systems.1

Reasons why you should fix compressed air leaks include:

• Inefficient tools and lower productivity: Drop in air pressure resulting from leaks can greatly impact productivity by causing tools to operate

inefficiently and creating an overall less-productive environment.

• Reduction in the longevity of your equipment: Because leaks cause a higher demand for air power, compressors need to cycle more frequently, which can result in a decreased lifespan of the compressed air system. Replacing equipment can be avoided through routine maintenance and inspection so leaks are identified and repaired.

• Increased maintenance expenses: Air leaks not only reduce your compressor’s longevity by putting a higher demand on the system but also mean more frequent repairs and maintenance expenses than if the compressor were operating at peak performance and output.

• Losses due to downtime: If the system is experiencing higher

Sue Schauls is an environmental and safety expert whose career started 28 years ago at the Iowa Waste Reduction Center at University of Northern Iowa. She is the Certification Consultant to the ARA and can be reached at sue@a-r-a.org. She is also the Executive Director of the Iowa Automotive Recyclers association and compliance consultant to the industry through the ARA’s Certified Auto Recyclers (CAR) program and the I-CARE program – Iowa Certified Automotive Recyclers Environmental Program.

maintenance issues, then increased downtime can hamper productivity –and profits.

Detect Compressed Air Leaks

Some leaks can be heard, and the easiest way to detect them is to simply walk around the compressed air system during low activity periods. By scanning the area of the system, you may be able to identify if you have a leak and what assessments can be conducted following your inspection.

Not all compressed air leaks can be detected with human ears. To detect these hidden leaks, use an ultrasonic leak detection device. While not as inexpensive as using your ears, ultrasonic leak detection is the best way to find leaks in an air system. It utilizes an acoustic detection device that can recognize the unique, high-frequency sounds created by compressed air leaks. The devices range from as little as $100 to thousands. Your air compressor service

technician may also provide the detection service.

When searching for leaks in your compressed air systems, some specific areas might be more susceptible to leakage than others. During inspections, be extra vigilant when looking at:

• Air hoses and air hose connections or couplings

• Worn disconnects, or disconnects missing O-rings

• Filters, lubricators and regulators, if improperly installed

• Open blow-offs

• Open condensate traps

• Leaking or botched drains

• Failed or inferior quality thread sealants, or incorrectly applied thread sealants

• Control and shut-off valves

• Worn out seals or gaskets

• Old or poorly maintained pneumatic tools

• Idle or unused machine or production equipment with air input

• Inappropriate use of air, i.e. as a blower for cleaning instead of using other cleaning tools

Are You Wasting Money by Not Fixing Leaks?

In an automotive shop, air compressors typically maintain a pressure of 90 PSI (pounds per square inch) for most pneumatic tools. However, some tools, like those used for tire inflation or body work, may require higher pressures, sometimes reaching 130 PSI or even 175 PSI. A tire machine typically requires an air compressor that can provide a pressure of 125-150 psi. This pressure is necessary for the machine to mount properly and dismount tires, as well as to seat the beads of the tire against the wheel rim.

General Use: Most air tools, such as impact wrenches, ratchets, and grinders, operate effectively at 90 PSI.

Tire Inflation: Tire changers and inflation tools often need higher pressures, potentially around 130 PSI.

Body Shop Applications: Body shop tools and equipment can require a range of pressures, but 115 PSI, 145 PSI, or even 175 PSI are common.

Compressor Settings: Many automotive shops set their air compressors to a maximum pressure of 125 or 175 PSI, with the regulator typically set to 90 PSI for general tool use.

Importance of CFM: While PSI is important, the CFM (Cubic Feet per Minute) rating of the compressor is crucial for ensuring it can handle the air demands of all tools used simultaneously.

Cost-Effective Ways to Save on Energy Expenses

While nothing can supplement leak repair and prevention for energy savings, some of the best solutions at a low/no cost.

Simple steps to reduce compressed air system energy consumption include:

• Turning the system off: When the air compression system is not being utilized,

turn off the equipment. This could help you reduce your electric bill by up to 20 percent.

• Fixing the leaks: Repair leaks as soon as possible. Neglecting a small leak can cost thousands of dollars every year.

• Reducing the pressure: Maintaining only the needed pressure to perform the job can help reduce the workload on machinery – and the amount of energy consumed to complete the task.

• Changing the filters: Changing the filters frequently can help improve system performance and can prevent pressure drops.

• Identifying and eliminating any inappropriate use of compressed air: Compressed air is an expensive utility, but by identifying which uses for the system are appropriate and which are not, you can start saving money by cutting unnecessary tasks.

• Checking for abandoned equipment: Another source of leakages can result

from equipment that is not in use while is still being supplied with air flow. Consider the benefits of automatic shut-off valves that will close when the machine is turned off.

• Performing routine maintenance and leak prevention: Mitigating the risk for future leaks, assessing existing problems and working on a schedule to detect new problems can help identify issues before they become too costly. Maintaining the system’s optimal performance will ensure higher productivity and more efficiency of equipment and tools.

Remember doing nothing costs money too! TB

Reference:

1

• https://www.quincycompressor.com/ why-you-need-to-fix-compressed-airleaks/

• https://www.energy.gov/sites/prod/ files/2014/05/f16/compressed_air3.pdf

• https://www.rasmech.com/blog/fixcompressed-air-leaks/

The Big Picture

“There are no small roles, only small actors.”

This quote is credited to a gentleman by the name of Konstantin Stanislavski. Don’t worry; I’ve never heard of him either. But I have heard that quote, as you probably have. I was thinking about this a while back after attending our state association’s annual convention. It was an event where salvage yards from across Wisconsin and other places gathered at the recycling facility known as Badger Motors in Wisconsin Rapids. I can tell you firsthand that the crew there is top-notch and is doing all the right things. Not only that, but they also did a great job hosting the convention.

While there, we got to hear some great speakers, and for me, the best part was meeting friends in the industry, old and new alike. The size and type of yards we see around here and in the entire industry, range across the spectrum from large high-volume recyclers to very small yards that do only a small handful of vehicles per week, or even per month. Some have high invoice counts weekly, some have only a few. The average invoice amount is all over the place, too.

So, what is the right answer to what is the best strategy to be successful in the auto recycling industry? The answer is simply that there is no single answer to that question.

A company footprint boils down to a couple of factors that are largely influenced by the owner’s style and desire. Probably, the most important factor is why you are in this industry, and what is your ultimate goal? Why did you get to where you are in the first place? Was it a lifelong dream to operate a salvage yard? Did you inherit the company? Did you get into this business by accident?

(While that sounds silly, I am aware of at least one scenario where that is exactly what happened.)

Very often, the reason why we do this determines how we do it. Suppose the philosophy of the ownership is to make as much money as possible as quickly as possible. In that case, we are going to find ways to maximize the number of invoices, get the average total as high as possible through extended warranties, upcharges, and whatever else we think we can get away with, and then scale that to the capacity of our property and maximize our manpower. We also consider expanding to other locations or acquiring another business and adding to our holdings.

Conversely, suppose our philosophy is more concerned about the highest quality parts and exceptional service. In that case, we might have discovered that this is very difficult to do in large volumes as a smaller business, if that is a preference, as it requires a larger team of highly skilled individuals, as well as people who share your values.

Is it possible to do both quality and quantity? Of course it is. Most of us in

the industry view quality as an ultimate goal. The quantity aspect is the variable.

Whatever your size and scale, consistency is the word that comes to mind in either case. If we can put in place a system that helps us get it right consistently, a system that delivers the best quality at a competitive price, and the right team to make our regular customers actually look forward to calling us, over time, this will add up. Strike that, it will do better than add up, it will compound.

I don’t think I have to educate anyone about the power of compounding anything. It can be hard in the beginning, as we feel we are just banging our head against the wall every day with no headway, but keep going. It’s coming. Your spectacular future success depends on the bland everyday consistency today. And tomorrow and next week. But keep going. And of course, while you are consistently grinding away, don’t forget to take time for growth. There are also many ways to expand your knowledge.

The industry’s regional and national associations are a great place to start. Attending meetings and conventions

Jake Nawrocki, with sister Katy Joles, own and operate Rocki Top Auto Recyclers in Glen Flora, Wisconsin. The company was formed in 1988, and Jake and Katy took over operations in 2009. Since that time, they have been working both in and on the company, in a region that is economically challenged.

“Our goal is to make Rocki Top Auto a destination.” Contact Jake at 715-322-5774 or rockitopauto.com.

typically provides great sessions that will benefit anyone, regardless of their industry experience or level of success.

Reading books on topics that will help expand your skills and knowledge is another. There are tons of great books. If you don’t like to read, get the Audible app and listen to audiobooks or subscribe to industry-related podcasts (The Automotive Recycler’s Experience, U-R-G On the Go, and Depollution from Salvage Wire are several).

If none of that is your thing, make sure to take the time to visit other yards that you admire. If you are a smaller yard like us, it is good to see how the big yards do it, but also how some of the medium-sized players get it done. From personal experience, the help and input from other yard owners is a huge part of the success we have had so far.

If you are a smaller yard like us, it is good to see how the big yards do it, but also how some of the medium-sized players get it done. From personal experience, the help and input from other yard owners is a huge part of the success we have had so far.

Don’t forget those who have a little bit of a niche thing going on. Typically, that yard has tapped into something that obviously everyone cannot do, but they are making the absolute most out of what they have.

So, no matter if you are a mega retailer, scrap metal focused, or a quirky one who only wants to sell parts

off of 1980s crap cans that were featured in old movies, do your very best at being the best at what you do. You don’t have to be large to play a big role; make sure you are a big actor in the role your business plays. Our industry needs every kind of auto recycler, and would be incomplete if yours did not thrive. Stay hungry. TB

Gritty Reminders

My grandson is a special person in my life. Born with autism, Ayden loves technology with passion but dislikes his schoolwork. While putting Ayden to bed recently, I noticed a sign on the room wall where he sleeps most of the time. It was titled “Daily Reminders” and listed traits a person must exercise daily to succeed. Most of us need a refresher with our daily reminders. Let me explain.

Hustling toward a goal means we’re determined to make it no matter what happens, and we must be consistent with our efforts.

The other verb on that sign was grind. It said, “to perform repetitive tasks over and over to attain a goal.”

NO ONE WANTS TO BE AN AVERAGE PERSON WHO BARELY GETS ALONG IN THIS WORLD.

Ayden rushes to his technology right after school, and sometimes, we make him stop for a breather. I get it. He wants his YouTube channel to be a great hit. Have you ever thought you need to hustle a little more or work harder on your business daily? I know I have. Sometimes, it means to stop talking and put into action the work that needs to be done. Well, that’s Execution.

patience, and requires learning to be successful. Grit is strength of character, perseverance, and passion for longterm goals, all in a tiny word. However, without the next word, success wouldn’t happen. That word is discipline. It means doing what needs to be done, even when you don’t want to do it. Most of us want to be successful at what we do. No one wants to be an average person who barely gets along in this world.

Ayden’s sign listed 10 words in sequential order: Hustle, Grind, Execution, Persistence, Perseverance, Sacrifice, Success, Grit, Discipline, and Ambition. The meaning of each trait is also listed. I was intrigued by why it was on the wall and asked Ayden about it.

The truth is we should all adhere to those traits in our lives and careers. With 10 traits, two were verbs (action words), Hustle and Grind, while the rest were nouns. In our lives, Hustle is the only controllable pillar of success we must possess to make sure we’re successful. It means we must continue to keep going. The operative word there is CONTROLLABLE.

Many times, Ayden has trashed his YouTube channel and started over. Even as an adult, I’ve risen from failures, achieving success through trial and error. Success comes after we get up after failing and keep going no matter what because we’ve persisted through failure. Coupled with persistence is perseverance. Perseverance is “steadfastness in doing something despite difficulty or delay in achieving success.” Give me an employee with character traits of Persistence and Perseverance, and they’ll become a valuable team member for my business after all.

Sacrifice is another essential trait that we must remember each day.

Even in the dictionary, sacrifice comes before success. Being successful is not an accident. It’s hard work, takes

As I was driving in my car today, I heard a radio host at a local station in Atlanta say that he knew he had to change his surroundings when he was younger. His family didn’t have much ambition, and he knew if he wasn’t best with his schoolwork and persistent with his desire to have a better life, he would grow up and remain in the lifestyle his family had endured for generations. I felt bad for him, but he realized discipline was all he needed to succeed. Here’s the best part. He also needed another trait to make it to the career that he wanted.

Without the last trait, none of us will be successful either. That word is ambition. Here’s what Ayden’s daily reminder sign said about ambition. “Ambition is the strong desire and determination to achieve success.” I bet that radio personality relied heavily on ambition to achieve his current success.

How about you? Which of these daily reminder traits have you relied on to make it in this industry? Most of us know someone who’s worked very hard to be successful. There’s no reason why you can’t be successful, too. Make sure these reminders are part of your daily activity, and I promise you WILL BE SUCCESSFUL!

I’ll see you on the next URG “On-the-Go” podcast. TB

D.J. Harrington is the President and Chief Executive Officer of Phone Logic, Inc., an international training company based in Atlanta, GA. He serves as a consultant and trainer to over 1,000 privately-owned businesses throughout the country, training personnel at all levels of the company, from the dispatcher to the customer service and sales staff. Please visit his website for more information at www.djsays.com.

Marketing 101 How One Word in a Headline Can Change Everything

A Simple Word, A Powerful Shift

If someone had told me when I first started my advertising agency that a single word in a headline could determine the success – or failure – of my company, I would have laughed out loud. But I’m here to tell you: it’s absolutely true.

The Early Days: Competing on Price

Back in 1982, I began working with businesses in the automotive recycling industry. I was proud to offer prices far lower than anyone else in the field. In fact, no one even came close. That simple truth became the foundation of my entire marketing strategy.

A Big Mistake?

To promote my agency, I created a flyer with a bold headline:

“We offer the best prices for advertising products and services in the auto recycling industry – guaranteed!”

The flyer was beautiful – loaded with colorful photos, service lists, and attractive illustrations. I was thrilled. I imagined a wave of new business once recyclers across the country received it.

An Unexpected Wake-Up Call

Before sending it to print, I shared the flyer with a friend – an experienced and successful marketing consultant in another industry. I expected praise. Instead, his face changed as he read it. Then he looked at me and said something that shocked me:

“Mike, don’t mail this. It’s wrong –and it could destroy your business.”

“What?! Why?”

I stared at him. “Why would you say that?” I asked.

He replied, “Mike, you must never lead with price. If your business lives by its prices, it will die by its prices.”

I pushed back. “But my prices really are the best. That’s what people love. They save money and get great results!”

He nodded, “That might be true. But if price is your main selling point, it becomes a race to the bottom. Someone else will undercut you by a few dollars, and then what? You’ll feel pressure to drop your price again – and again. That’s a losing battle. Trust me: if your business lives by its prices, it will die by its prices.”

I was stunned. And I was running out of time – I had scheduled the print job for that very afternoon.

The One-Word Fix That Changed Everything

Then, he smiled. “Mike, I’m going to fix your ad by changing just one word in the headline.”

He crossed out ‘prices’ and replaced it with ‘value’:

“We offer the best value for advertising products and services in the auto recycling industry – guaranteed!”

He explained, “People will always argue over price. But value includes everything they get: strategy effectiveness, material quality, delivery speed,

service, guarantees, availability – things that truly matter. And here’s something that might surprise you: it’s rarely just about the money.”

When people value something, they find a way to get it. Even those with a limited income still manage to buy TVs, cars, and other things they truly want. That’s why your advertising – and your business – should always emphasize value, not just price.

How to Emphasize Value Over Price in Your Marketing

Let’s say you sell recycled auto parts. You want your ad to highlight their value – not just their affordability.

Start by asking yourself:

• “What’s in it for the customer?”

• “Why should they buy from me instead of someone else?”

Then turn those answers into strong, benefit-driven headlines and sub-headlines that communicate real reasons to choose you.

Seven Value-Based Messages for Recycled Parts

Here are seven compelling reasons to buy recycled auto parts, each with a headline or sub-headline you can adapt. Price is mentioned in a couple of them, but it’s not the emphasis.

1. Trust & Quality-Focused

“Recycled doesn’t mean second-rate –our parts are tested, trusted, and ready to go.”

2. Value & Reliability

“The part you need, the quality you want, and the price you’ll love.”

3.

Service & Peace of Mind

“Need a part you can count on? We’re here to help – with real people

and real guarantees featuring our 101-day warranty on every part!”

4. Mission-Driven

“Great parts. Great prices. Greater purpose. Recycled for the road – and for a reason.”

5. Speed & Convenience

“Right part. Right price. Right now. We make it easy.”

6. Confidence & Experience

“Not just parts – peace of mind. We’ve been doing this right for years.”

7. Values-Based

“We care how we do business –because people matter more than parts.”

The Bottom Line

Therefore, if you want your advertising to attract loyal customers, inspire trust, and stand the test of time – don’t sell on price. Sell on value. One word can change a headline. One message can change a business. Choose your words wisely – because the right one might be worth everything. TB

CODES OF EXCELLENCE

CHECK OUT THESE POPULAR INDUSTRY RESOURCES AVAILABLE TO PROFESSIONAL AUTOMOTIVE RECYCLERS!

DATA You Can U$E Reusing Auto Parts Reduces the Carbon Footprint of Vehicle Repairs

ARA and Worcester Polytechnic Institute (WPI) Research Report Summary

Acomprehensive study of the materials and processes used to manufacture 30 specific automotive parts, from headlights to tailgates, documents the significant greenhouse gas emissions saved when reclaimed parts are used to repair vehicles instead of newly manufactured parts.

Given the magnitude of auto repairs across the United States, indeed across the world, the use of reclaimed auto parts can help consumers, companies and communities reduce their carbon footprint and make progress toward carbon neutrality goals.

The details of the research are reported in the study “Quantifying the greenhouse gas emissions (carbon) impact of reusing automotive parts for vehicle repairs”, conducted at Worcester Polytechnic Institute (WPI) by Hyunsoo Jin, PhD, a Post-Doctoral Fellow in the Mechanical & Materials Engineering Department and Professor Brajendra Mishra, PhD, the Kenneth G. Merriam Distinguished Professor of Mechanical & Materials Engineering and Director of the Metal Processing Institute at WPI.

Public Purpose

When a vehicle needs repair, the owner often faces an important decision; whether to use brand new parts or used original equipment parts reclaimed from end-of-life vehicles that are suitable for the repair.

Historically, choosing between a new part and the same part reclaimed from a used vehicle has been viewed as an economic decision. It is also, however, a major environmental decision with significant potential impact on greenhouse gas emissions.

The financial metrics of the choice are clear to the consumer. Both the new and used automotive parts are priced at the point of transaction. The environmental metrics of that decision, however, are vague at best, and typically unknown to the consumer.

The principal aim of this study is to document the savings in greenhouse gas (carbon) emissions when a specific automotive part is reclaimed and reused for vehicle repair, compared to using a newly manufactured part for the same purpose. Having the environmental data available at the point of transaction, in addition to the prices, will help consumers make more informed decisions.

Scope of Study

This project focused on 10 of the most common automotive parts that are now reclaimed by auto recyclers and made available to automotive repair shops and consumers.

The study covered 10 parts from three classes of vehicles: a sedan, an SUV, and a pick-up truck. More specifically the subject vehicles were 2015 models of:

• Toyota Camry with a 4-cylinder gasoline engine

• Jeep Grand Cherokee with a 6-cylinder gasoline engine

• Ford F-150 with an 8-cylinder gasoline engine

The following parts, from each subject vehicle, were analyzed:

• Engine

• Front bumper

• Front door

• Fender

• Hood

• Transmission

• Headlight

• Wheel

• Tailgate

• Door mirror

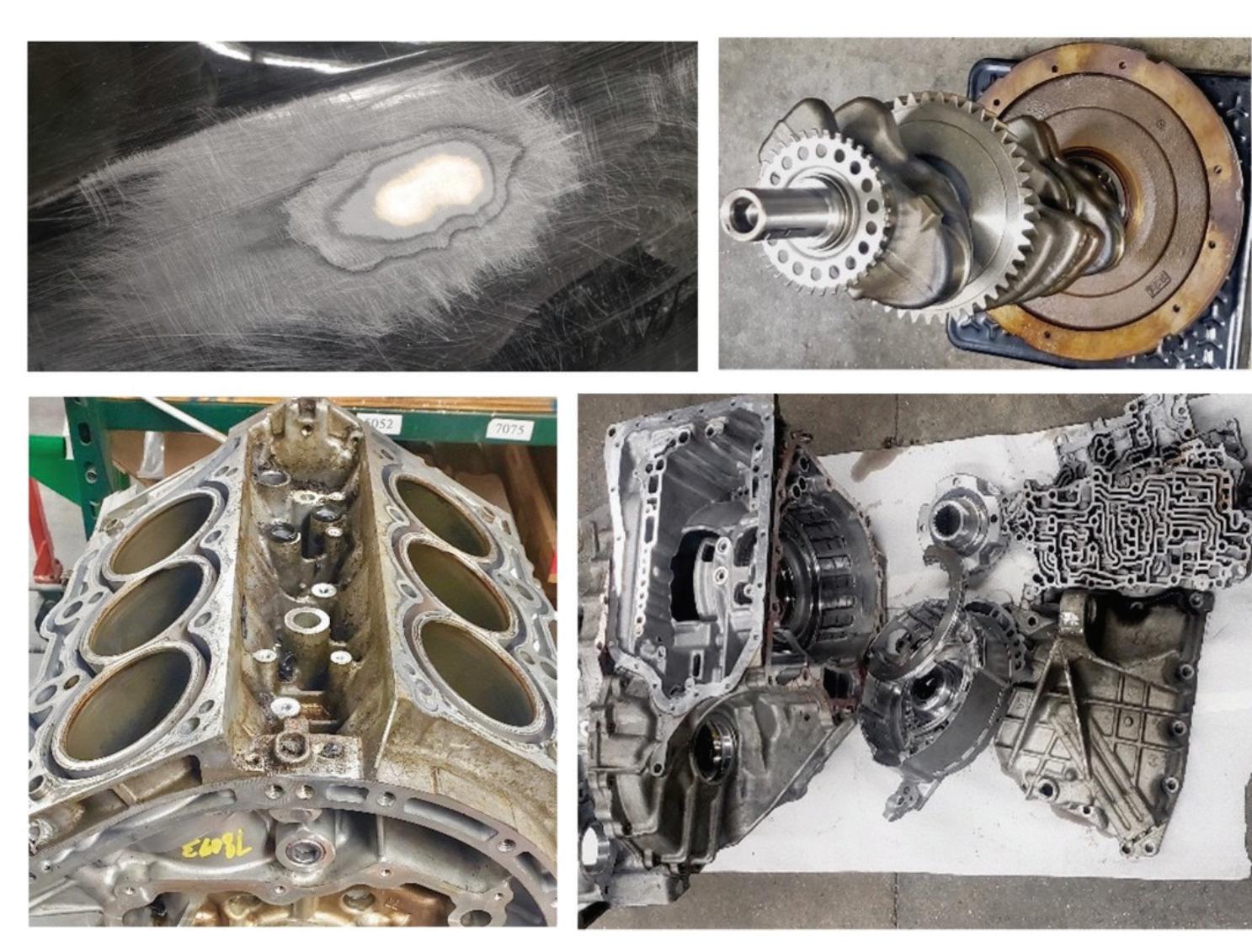

These parts were shipped to WPI’s metal processing laboratory in Worcester, Massachusetts for analysis. Each part was dismantled and processed to determine the amount and type of materials (i.e. metals, plastics, rubber, etc.) used to manufacture that part.

Most auto parts are made from composite materials and different grades of alloys which are not typically public knowledge

Sample of parts in varying states of dismantling and analysis at WPI.

due to industrial competition. So, it was important for WPI to break down each part into its constituent components for precise analysis whenever possible. The research team used several technologies to perform the materials analysis. These methods included:

• Inductively coupled plasma optical emission spectrometry (ICP-OES). Acid digestible samples were analyzed by ICP-OES. To check for homogeneity of materials, results from multiple spots on a specific sample were compared.

• Optical emission spectroscopy (Spark-OES). Bulk and flat samples were analyzed by Spark-OES. This method uses arc spark discharge to vaporize the sample and collect the radiation emitted from atoms and ions to identify the constituent materials.

• X-ray fluorescence (XRF). Handheld XRF was used for items with variable shapes and did not need any pretreatment. In addition, XRF is a non-destructive method, so the samples can be kept or reused.

Energy Analysis

Using the detailed composition of the specific parts, researchers then quantified the energy required to manufacturing those parts. This analysis included calculating the energy used to:

• Mine raw materials

• Manufacture steel, aluminum, copper, and other inputs from raw materials

• Manufacture specific auto parts (engine, transmission, etc.) from those materials

All of these manufacturing activities use a variety of fuels and

The financial metrics of the choice are clear to the consumer. Both the new and used automotive parts are priced at the point of transaction. The environmental metrics of that decision, however, are vague at best, and typically unknown to the consumer.

energy sources, including electricity, natural gas, residual oil, diesel, coal, LPG, and gasoline. For the purpose of consistency in carbon footprint analysis across sectors, the best practice is to convert all the energy inputs into kilowatt hours of electricity.

Results: Table 1 lists the energy needed to make the specific parts studied in terms of kilowatt hours (kWh) of electricity.

Table 1

Carbon Footprint Assessment

With the amount of energy needed to make each specific part known, the next step in the study was to calculate the greenhouse gas emissions (carbon footprint) associated with generating the energy used to manufacture specific new parts.

This assessment is based on the Argonne National Laboratory’s GREET2 (Greenhouse gases, Regulated Emissions, and Energy use in Transportation) model and EPA (U.S. Environmental Protection Agency) guidelines.

The study also used data from the U.S. Energy Information Administration (EIA) which quantifies electrical generation in the United States and the resulting CO2 emissions based on the fuel used to power the plant.

Sample of parts in varying states of dismantling and analysis at WPI.

The carbon footprint for each auto part studied is presented in the Table 2 and Table 3. The first table shows emissions is based on natural gas generation, the second on electricity generated by oil/petroleum burning power plants.

Table 2: Carbon dioxide emissions for each part in kilograms. (Fuel source natural gas.)

Table 3: Carbon dioxide emissions for each part in kilograms. (Fuel source natural gas.)

Conclusion

It is common sense that a reclaimed auto part, by definition, doesn’t have to be manufactured, so its use avoids the greenhouse gas emissions generated by using a newly manufactured part. The data presented here, however, add facts to the discussion and show the significant and specific greenhouse gas emissions saved when using a reclaimed part instead of a new part, manufactured from virgin materials.

Furthermore, there a several factors that make these results conservative.

Given the scope of the project, the final metals data presented here is based on the quantification of steel, aluminum

Consumers can see many other carbon saving equivalences by entering the specific parts data into the EPA calculator here: https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator.

and copper, which account for the majority of materials (by mass) of the parts. Numerous other metals were detected in smaller quantiles. If those materials were included in the energy/carbon analysis, the greenhouse gas emissions savings would be even higher.

In addition, because original equipment auto parts are manufactured across North America and then transported to end users in varying locations the emissions from these transportation steps were difficult to estimate so they have not been included.

It is clear, however, from site-visit evaluations of auto recycling companies, that the energy attributed to transportation of newly manufactured parts and the labor inputs of making those new parts are significantly higher than the energy used to dismantle automobiles and reclaim parts.

So, we estimate the carbon savings from using reclaimed parts are likely to be greater, perhaps 15 to 20 percent more than the conservative results presented here.

Although this report is conservative, the data presented still shows significant environmental benefits. For example,

according to the EPA Greenhouse Gas Equivalencies Calculator, reusing one Camry engine saves 710.82kg of carbon dioxide (natural gas) which is equivalent to the carbon sequestered by 11 tree seedings grown for 10 years; or the equivalent of the electricity used to charge 44,449 smartphones.

Study Sponsor and Disclosures

The research question was proposed to WPI by the Automotive Recyclers Association (ARA), a non-profit organization that represents the interests of over 4,500 professional automotive recyclers across the United States and in 17 countries internationally. ARA is dedicated to the efficient removal and reutilization of genuine original equipment manufacturer (OEM) automotive parts.

ARA provided financial support to WPI for the study and ARA members provided the 30 auto parts analyzed by the WPI team at no cost.

ARA played no role in the conduct of the research, ensuring the independence of the analysis and conclusions of the research team. TB

© 2025 Automotive Recyclers Association. All rights reserved. This work is protected by copyright law and may not be reproduced, distributed, transmitted, displayed, published, or broadcast without the prior written permission of the Automotive Recyclers Association. Unauthorized use and/or duplication of this material without express and written permission from this site’s author and/or owner is strictly prohibited.

Auto Recycler’s South East News

FADRA’s Don’t Stop Believin’ 50th Anniversary Delivers on All Levels

ARTICLE

AND

PHOTOS BY CARYN SMITH, ADDITIONAL PHOTOS BY MIKE FRENCH

FADRA 2025 brought together the historic and the new, veteran owners with new faces establishing themselves in our dynamic industry to celebrate the past and look to the future at the newly renovated Sheraton Sand Key Resort.

The event started with dinner on the StarLite Yacht with evening views of St. Petersburg-Clearwater, Florida. The dinner and fundraising auction closing party concluded with a concert by Majesty of Rock – a tribute band to Journey and Styx – who had all the attendees dancing the night away, in their “era” costumes from the 1960s to today. JC Cahill, VIN Match Pro, and Katrina Hall, Field Rep at Rebuilders Automotive Supply, took home the prizes for best “era” outfits. The fast and fun auction raised over $30K for FADRA’s legislative efforts.

In between the fun and networking by the pool were stellar training sessions and keynotes that make FADRA’s convention a staple event for south-eastern automotive recyclers. Tom Andrade, Everett’s Auto Parts, an Executive Committee member of the Automotive Recyclers Association (ARA) and Vice President of the Automotive Recyclers of Massachusetts (ARM), was the Keynote Speaker, and then later presented an excellent talk on finding profit through efficiency and due diligence on Material Harvesting & Scrap Sales - Taking a Deep Dive, shared over two sessions.

Andrade reviewed best practices and lessons from his time, first serving as the company’s Controller in 1996 to now as co-owner of the family business. As a business, they emphasize customer service, quality control, and employee retention. Everett’s Auto Parts processed 25,000 vehicles last year and is on track to break 30K this year. Among other profit centers, they opened a tire center in 2017, earning $81K the first year, which will reach $1M in sales this year.

“Being a u-pull-it yard, tires are the number one part type that we sell, but we weren’t capturing any of the labor costs. This facility allowed us to perform that service and capture that labor. It has taken on a life of its own with customers being only Everett’s Tire Center customers,” he shared.

“One of the things that helped us grow as much as we did is all of that information that we learned from other yards, all the relationships that we built with other yard owners and managers,” he said. Being a hybrid yard ‘back then’ in peer groups made the facility an oddity, and not a total fit with the full-service yards. Yet, he noted, “We still learn things from every single group and every single person,” encouraging yard

owners and managers to network with industry groups. “Our sales guys handle everything, being a true hybrid. They handle retail, they handle commercial, they handle self-service, they handle full-service.”

“I believe that one of the secrets to our success,” says Andrade, “is that our hybrid structure enables those customers to have some interaction with a salesman. Traditionally, in a pull-it-and-pay fee structure, you find your part and see a cashier. Here, they get some face time with a salesperson. They inform the customer of the location of the car, the quantity of the part, and, oh, by the way, we have a used one on the shelf, or we have an aftermarket one in stock, which helps on that side. When we’re busy, unfortunately, you can tend to over serve the self-service customer and under serve the full-service customer, but for the most part, with enough staffing at the counter, it works out.”

Peer-driven input and utilizing the industry’s resources were valuable to Everett’s growth. “If you’re not in a peer group, I highly recommend doing so. Some of my closest friends in the industry have come from peer groups, as well as information that we track. I would urge you to become an ARA member if you are not one. Several programs are free member benefits, like ARA University, which has a full line of training by job category, such as the dismantling and sales curriculum. ARA offers peer mentoring programs. I participated in this a couple of times as a mentor.” He also spoke highly of the certification program, “It will help you go through your facility, perform audits, clean things up, offer warranties,

CARYN SMITH

and do customer service surveys. It is a valuable checklist of all the things that you know you should do. The program also offers Gold Seal, High Voltage Vehicle, and Recall certifications.”

Everett’s processes about 100 cars a day just for scrap value, down to pulling cables, and boasts a 10,000-aftermarket part inventory that also yields $1M a year. Andrade made a point to share how deep of a dismantling they perform at Everett’s, “If you’re leaving the vehicles complete, you’re absolutely leaving money on the table. There’s just no other way to say it. Drive trains, radiators and condensers, wires, tires, frame suspension, electrical cores, all of it.”

Mike Kunkle presented multiple sessions on The Do’s and Don’ts of Running a Successful Salvage Yard, Building a Strong Operational Foundations, Making Sales Great Again, and The Interplay of Buying, Inventory, and Pricing.

Kunkle delivered a wealth of information over his sessions that would help any business identify and address potential hindrances or move to the next level. In fact, he focused on so many aspects of running a company that a note-taker might have a sore hand by the end of the sessions.

His key points covered improving communication, understanding costs, enhancing business processes, and the importance of honesty in financial reporting. He emphasized the need for clear communication, efficient processes, and the impact of cultural aspects like safety and employee satisfaction. Metrics, such as return rates and cancellation rates, were examined, and the conversation also touched on the challenges of generational business succession, the role of AI in sales, and the importance of planning and professional performance.

Communicating with your team was a key point early in his talk. The way an employee interprets the communication is important: “How many people have a younger staff than what they’ve had before, a staff that has experience of five years? How do they know some of this stuff?” he noted, talking to the seasoned owners in the room, who are full of knowledge. “If I leave the average employee to figure things out, how much is that in cost of goods? That means that every dollar that comes in, how much do we keep? We don’t want to be honest and say, ‘This is how much you make, this is the way it works, this is the process. And when you run over that $600 door, this is the impact of that.’” While honesty is the best policy, he quickly made another point, “You also need to smile and communicate that what we do is fun. We play with cars. As DJ Harrington says, ‘God gave us two ears and one mouth for a reason.’” Listening is also important.

He also spent time talking about the use of AI in recycling businesses. “Some people are using it for overflow calls. Some people are using it to capture nighttime calls,” he noted, but advised that it should not replace your trusted relationships. “Relationships can’t be outsourced.”

Craig Gleerup, from the LKQ Corporation, spoke on Keeping You Out of the Slammer - HR Relations. First, he recommends before making any HR-related policies that auto recyclers seek legal professional legal counsel, as we live in a highly litigious time. You want to do things properly when it comes to hiring, firing, and employee management.

His main points emphasized the importance of having a written hiring procedure, an up-to-date employee handbook, and proper training on workplace discrimination and harassment to mitigate legal risks, referencing free resources from the U.S. Chamber of Commerce and the Equal Employment Opportunity Commission (EEOC).

Hiring can be tricky, as the phrasing of interview questions can come back to haunt you. “Check your questions to make sure that you’re not asking for personal information and avoid gender-based questions. They can cause you problems,” Gleerup notes. “Avoid questions that go against Title VII, a federal law that prohibits discriminatory employment discrimination based on race, color, religion, sex, and national origin, which includes pregnancy.” So, for example, asking ‘Do you plan to have kids?’ can appear discriminatory. “If you don’t choose that person, they can claim the reason was because they are female. … Focus on the work history, like ‘explain how you dismantle whatever type of car, or tell me how you take the engine out of a car.’ Ask basic questions. If they have industry experience, they’ll be able to answer a specific one, like, “Describe the toughest vehicle you ever dismantled.”

Once a candidate is an employee, “You need to prep the employee and set clear expectations, such as attendance. You must set the expectation up front of what you expect for attendance, what time you’re going to start, what time you can finish in the day, and how many times you’re allowing them to be late before there is action taken. Then, what are your expectations for quality of work, conduct, etc.”

CARYN SMITH

If the workplace has gotten out of hand, he suggested, “The best way to stop the bad habits is to get everybody together and say, ‘we’ve let things slip. The past is the past. But from now on, we’re going to start going back to our policy.’ And if it were me, I would have the policy written down and have everybody sign it.”

Lastly, in discharging an employee, he suggests keeping it simple. Document if an employee is not performing as expected. Review it with them as needed. If they don’t comply, then just let them go.

In a review, he said, “Number one, know basic workplace law. Number two, prepare your workforce. Make sure that they know what your expectations are and follow up on those expectations. Number three, correctly document those who go astray from the policies.”

Other sessions included Heather Sauls and Dakota Todd from Green Star Auto Recyclers spoke on Using Social Media to Attract and Maintain Customers and Miranda Wroten, AESOP Auto Parts, gave an info-

packed session on An Assembly for Disassembly: Production Strategies

Both sessions provided practical insight into creating a marketing strategy for your business and streamlining production for efficiency.

The Sales Trivia Competition with Host Tony Quarno was a fast and fun contest of obscure industry and automotive facts. About 10 recyclers tested their knowledge, and only one came away with the welterweight belt!

Over the two and a half days, over 30 vendors, many of whom were sponsors, hosted attendees for several meet-and-greet receptions. The expo hall was buzzing with activity, offering opportunities for new and old friends to meet and vendors to share the latest and greatest from their company.

Outgoing president Phil Riffel, ACS Auto Parts of Georgia, summed it up properly: “It was the best convention to date, and I will remember it forever.” TB

Caryn Smith is the editor of Automotive Recycling magazine and Automotive Recycling ToolBox Edition. She has been covering the industry for 25+ years. As a freelance writer, she is a contributor for other industry publications, such as Recycling Today, International Filtration News and International Fiber Journal, among others.

Auto Recycler’s South News

Team PRP Sales School –San Antonio 2025

Team PRP is working with state associations to promote trading relationships be-tween regional Team PRP partners. In 2025, we’ve partnered up with the Texas Automotive Recyclers Association and Profit Teams to offer a Team PRP Sales School. It will be a one-day session that will run concurrently with regularly scheduled TARA agenda sessions and be led by all-star sales consultant, Jer Banta. After great success at the Automotive Recyclers of Michigan conference, we’re hoping to see as many salespeople in attendance as possible. Regional trade is the biggest driver of brokered business, getting together matters!

Most of your brokered sales come from trades within your regional hub. Make the most out of this opportunity by bringing your salespeople to benefit from both training and networking! It’s a worthwhile investment in your business and your sales-people!

The separate salesperson session will help drive regional brokered sales, strengthen relations, and promote best practices. The partnership with state associations will help to bolster attendance at these critical state shows and build upon the long history of collaborative success. TB

DON’T MISS OUT!!! REGISTER NOW

MIKE FRENCH

CARYN SMITH

CARYN SMITH

BY RECYCLERS FOR RECYCLERS

TOOLBOX® MISSION

The Automotive Recycling ToolBox™ Edition delivers peer-to-peer articles with information that you would get while networking at industry events and trade shows. Our mission is to be current, educational and inspirational. We bring you:

• Educational and instructional “how-to” articles written by fellow recyclers, top industry professionals, leaders & trade show speakers.

• Information from providers of industry-related products and service you typically find at industry events and trade shows.

PUBLISHED 6 TIMES A YEAR AutoRecyclingNow.com/Toolbox

AUTOMOTIVE RECYCLERS ASSOCIATION OFFICERS

YOUR TOOLBOX TEAM

Published by Driven By Design LLC

EDITOR

Caryn Smith, Toolbox@a-r-a.org

ART DIRECTOR

Caryn Smith

ADVERTISING SALES

Jay Mason, ToolboxAds@a-r-a.org

ARA OPERATIONS

EXECUTIVE DIRECTOR

Vince Edivan

Automotive Recyclers Association Vince@a-r-a.org

SENIOR DIRECTOR OF ASSOCIATE OPERATIONS

Jessica Andrews, Jessica@a-r-a.org

SENIOR DIRECTOR OF MEMBER SERVICES

Kelly Badillo, Kelly@a-r-a.org

VICE PRESIDENT OF STRATEGY AND GOVERNMENT AND REGULATORY AFFAIRS

Emil Nusbaum, Emil@a-r-a.org

CERTIFICATION CONSULTANT

Sue Schauls, Sue@a-r-a.org (319) 290-7843

ADMINISTRATIVE ASSISTANT

Tiffany Jackson, Tiffany@a-r-a.org

PRESIDENT Eric Wilbert Wilbert’s U-Pull-It, LLC Williamson, NY eric.wilbert@wilberts.com

1ST VICE PRESIDENT Shannon Nordstrom Nordstrom’s Automotive, Inc. Garretson, SD shannon@nordstromsauto.com

2ND VICE PRESIDENT/TREASURER Sean Krause

Speedway Auto Parts, Ltd. Joliet, IL sean.krause@speedwayap.com

SECRETARY

Tom Andrade Everett’s Auto Parts Brockton, MA tandrade@everettsautoparts.com

IMMEDIATE PAST PRESIDENT

Nick Daurio Daurio Auto Truck Pueblo, CO nick@daurioauto.com

ARA CONTACT INFORMATION

ARA Headquarters Manassas, VA (571) 208-0428 staff@a-r-a.org www.a-r-a.org

To reach readers with print & digital advertising, email ToolboxAds@a-r-a.org

For editorial contributions, e-mail Toolbox@a-r-a.org or call (239) 225-6137

Recycled Original Equipment