INTO THE DIGITAL REALM:

TOM KELLY EXECUTIVE DIRECTOR & CEO AUTOMATION ALLEY

TOM KELLY EXECUTIVE DIRECTOR & CEO AUTOMATION ALLEY

Forget the crystal ball and shapes in tea leaves. Digital Twins can predict the previously unpredicted and help technologies optimize production in ways unheard of or unthought of. This is the essence of Industry 4.0, a transformative force enhancing efficiency and productivity across industries.

With digital twin simulations, new layouts for production optimization can be calculated in a tenth of a second, implemented in the metaverse, and ranked in terms of the cost-per-part savings and maintenance needs of machines. This actionable data can be used as the blueprint for physical implementation with little to no surprises along the way.

These seconds matter in manufacturing, where minuscule line downtimes equate to big losses. For example, in the 10 seconds you took to read this far into the foreword, the average manufacturing operation would’ve lost $722 in productivity if there was no movement on the line.

Imagine an hour or a day to rearrange machines to fit into a new assembly. If a company is going to go that route, digital twins provide calculations to back it up if the time is worth it and provide projections into the future on how well a new layout will work.

However, no matter how close a digital twin can mirror reality, it will be just that — a mirror.

DEAN OF ENGINEERING, MANUFACTURING & INDUSTRIAL TECHNOLOGIES

OAKLAND COMMUNITY COLLEGE

This playbook aims to address the challenges and benefits of implementation of digital twin in its current state in the industry. Furthermore, it will focus on how organizations from all levels of industry are implementing digital twins. Are some focusing more on predictive maintenance? Are others pairing digital twins with AI?

Lastly, there are major concerns with cybersecurity in uploading a detailed copy of hardware and facilities to a network. How can organizations keep their digital twins secure in a world of evolving cyber threats?

These complicated questions require nuanced answers. That is why Automation Alley, in partnership with our members in manufacturing, academia, and government, proudly hosted an Integr8 Roundtable on digital twins, exploring how this innovative technology is used in industry.

With our esteemed partners, we can define the best use cases and address the challenges of digital twins in the spirit of collaboration. As leaders in industry, we have a responsibility to chart the best course for all stakeholders to follow. Let us take on that challenge together.

TOM KELLY EXECUTIVE DIRECTOR & CEO AUTOMATION ALLEY

KATHY GALUARDI RELATIONSHIP MANAGER AUTOMATION ALLEY

BEAU EVERITT DEAN OF ENGINEERING, MANUFACTURING & INDUSTRIAL TECHNOLOGIES, OAKLAND COMMUNITY COLLEGE

GEORGE CARAVIAS CEO GEOFABRICA

LUV AGGARWAL PORTFOLIO DEVELOPMENT EXECUTIVEDIGITAL MANUFACTURING SIEMENS

STEVEN LOPEZ BUSINESS DEVELOPMENT SPECIALIST THE RIGHT PLACE/MICHIGAN MANUFACTURING TECHNOLOGY CENTER

SAM HOFF PRESIDENT/CEO PATTI ENGINEERING

CHRISTOPHER BAKER CEO NEW EAGLE

REINHOLD NIESING VICE PRESIDENT AUTOMOTIVE & BATTERY VEHICLE MARKETS SIEMENS

SADIE MCKINSTRY BUSINESS DEVELOPMENT SPECIALIST THE RIGHT PLACE/MICHIGAN MANUFACTURING TECHNOLOGY CENTER

BRAD FLEMING ENTERPRISE ACCOUNT EXECUTIVE NAVVIS

CARL HOBSON CEO OASIS ADVANCED ENGINEERING

SCOTT CIESLAK CHEIF COMMERCIAL OFFICER DETROIT MANUFACTURING SYSTEMS

BRIAN BREUHAN GLOBAL MANUFACTURING OPTIMIZATION STRATEGIST GENERAL MOTORS

SIMONE BONINO VP OF BUSINESS DEVELOPMENT, MANUFACTURING SOLUTIONS ALTAIR

CHRISTINA KELLER CEO CASCADE ENGINEERING

DAVE MORTON GROUP DIRECTOR, EVENTS SME

As sandboxes of innovation, digital twins provide the perfect conditions for engineers to analyze the performance of real-world designs. It is no wonder why we have seen such an explosion in their use; a report from the Capgemini Research Institute shows that 61% of aerospace and defense organizations now consider digital twins a strategic part of their overall digital transformation.

With a new era in store for the manufacturing industry through the rise of Industry 4.0, it is imperative to take a deep dive into the potential benefits and implications of implementing digital twins for all levels of manufacturers and other sectors of the economy.

Digital twins create virtual models of real-world objects and subject them to continuous use to evaluate how they handle regular use, added stress, and redesigns to test for stability, determine flaws, and make a system more efficient.

In manufacturing, components are the smallest aspect of digital reproduction and include valves, sensors, injectors, and edge devices. Components comprise thousands of products that are created in a virtual environment. For example, a car manufacturer can re-create the interior of a vehicle to determine the passengers' comfort level, potential blind spots that could impede the driver's field of vision, and the instrument panel's aesthetic and ease of use.

A virtual hybrid engine can also be monitored and tested to comply with government performance regulations.

Manufacturers looking to improve the performance of their production lines will find digital twins an invaluable tool.

"As we transition towards smart factories, the focus shifts towards closed-loop quality control,” said Luv Aggarwal, Portfolio Development Executive - Battery, Industrial Machinery, Energy & Utilities, SIEMENS. “Embracing technological advancements in manufacturing, we aim to minimize quality inspection costs to the level of hardware expenses."

A virtual twin will replicate an entire production line, from carts and conveyors to robots and floor space, with the data collected from the simulation analyzed to improve efficiency, quality, and worker safety. A manufacturer can also create twins of a factory's power system, shipping area, inventory warehouse, disposal process, and office space.

A virtual representation of every system under one roof will provide data on integrating or adding new systems with few disruptions or future complications. Digital twins can also map supply chains to determine optimal routing for speed, energy use, and potential inventory shortfalls. Adding weather conditions, construction, international shipping concerns, and availability of transport vehicles to the simulations will signal possible delays of raw materials. The data gathered from within and outside a factory can help decisionmakers produce and deliver their products more efficiently while saving money and resources.

Continued on next page >>

The United States Department of Defense and NASA are investing in digital twins to enhance military satellite programs and space exploration. Also, municipalities are increasingly turning to digital twins to manage complex infrastructure systems and urban development. Cities like Boston and Las Vegas are utilizing digital twins to model physical landscapes, assess environmental impacts, and optimize energy usage and emergency management.

Aerospace, energy, machine tooling, healthcare, and electronics are among other industries benefiting from using the technology to improve product quality and design.

• Test new product designs

• Test systems collaborations

• Find production slowdowns

• Risk analysis

• Predictive maintenance

• Factory layout and design

• Assessing potential supply chain disruptions

• Government and safety compliance

This stream of data to analyze provides manufacturers with new levels of decision-making power across their operations.

Given their benefits, it is no secret that the manufacturing industry is adopting digital twins. According to a 2022 survey by McKinsey comprised of senior executives in industry, 86% say digital twins are applicable to their operations, and 44% already have fully functional digital twins implemented. Furthermore, the global market for digitaltwin technologies is forecasted to reach $73.5 billion by 2027 .

"Addressing the challenges of evolving business models, it is crucial to understand the transformative journey of companies,” said Aggarwal.

“Many are investing in IIoT and Industry 4.0, seeking to seamlessly integrate shop floor data into digital twins for predictive maintenance and optimization of production lines."

At its core, digital twins offer a new level of visibility into how advanced systems perform in the field, as well as insight into how they can be optimized.

“First, we need to define what a digital twin is,” said Brad Fleming, Enterprise Account Executive, NavVis. “There is a digital twin of a product, of production, and of performance, which is your feedback of the asset in reality. Then you can bring that performance data back to your product twin.”

What this looks like on the factory floor is using digital twins to keep track of equipment and improve manufacturing processes. Meanwhile on the tech side, this looks like engineers monitoring performance and making improvements through digital iterations until a desired outcome is achieved.

The result of these two approaches coming together? Higher efficiency, lower costs, and increased productivity. Altair reported 92% of 2,000 digital twin implementers worldwide said it made products and processes more sustainable. With the right data in hand, operators can better understand how assets perform amidst changes in operating conditions and are positioned to make more informed decisions about things like maintenance schedules and energy consumption. The ability to simulate different scenarios in a controlled environment provides answers to "what-if" questions without impacting actual production, allowing for more efficient problem-solving and troubleshooting.

In an environment driven by strict time requirements, digital twins can be a savior in preventing downtimes, and shortening them in the future by finding the perfect digital process through many iterations. This is crucial because the average large company loses $260,000 worth of productivity in only one hour of downtime.

One of the most exciting aspects of digital twin technology is that it can be applied to every physical aspect of manufacturing. Any process involving the use of machines, equipment, or products can reap the benefits.

Maintenance is a practical use case for everyone, as digital twins can be created after the fact for existing assets of all kinds. It is simply a matter of outfitting the real-world version with sensors, cameras, and other data-gathering devices to create a digital representation. This allows for remote monitoring, predictive maintenance, and real-time feedback on equipment performance.

For example, if a machine started experiencing abnormal vibrations or heat levels, the digital twin could alert maintenance personnel to investigate and potentially prevent a breakdown before it occurs. The benefit here is twofold because prevention has both time and life-saving power. Imagine a world where equipment failures in critical industries, such as healthcare or transportation, are predicted and prevented before they happen. Businesses would be able to innovate like never before and truly prioritize the safety and efficiency of their operations.

According to a Fraunhofer initiative on digital twins, enabling predictive maintenance with a digital twin requires “an industrial internet-of-things architecture, and a systematic approach derived from this architecture.”

Digital twins can also assist with design by simulating different scenarios and providing valuable insights before a product even enters production. Designers can test out different materials, configurations, and operating conditions without the need for physical prototypes — or the investments of time and resources that come along with them. With digital twins, designers can parse hundreds of iterations of an idea before producing it.

While digital twins are promising, implementing them is far from easy. A large up-front investment is required to bring a factory floor online to the Industrial Internet of Things. However, this number is falling in terms of hardware costs: the average sensor today costs less than .50 cents in comparison to $1.50 in 2004 and can do much more.

“Some companies have to work backwards with digital twins; start out with what they are trying to do then figure out the implementation,” said Beau Everitt, Dean of Engineering, Manufacturing and Industrial Technologies, Oakland Community College.

“This new digital process brings the departments together. It used to be you design something, throw it over to the next cubicle and pass it along. This makes everyone come together.”

There is also added complexity when implementing digital twins since they deal with copious amounts of data that are often sourced from more than one place. Organizational silos can easily stand in the way of insight by fracturing what elements of an asset are reported on and when — inhibiting the real-time visibility many implement this technology for in the first place.

Then with an abundance of data comes the responsibility of managing it all. Organizations need to have the proper infrastructure and systems in place to handle the vast amounts of data being collected, processed, and analyzed by digital twins. This can require significant investments in hardware, software, personnel training, and developing new business models. Those with existing legacy systems are further challenged by the ability to integrate. It is both complicated and expensive to try and integrate data from various sources and systems, not to mention risky to finally switch over and begin relying on a fully integrated digital twin architecture.

“Reduction of cost is a big factor for digital twins. There is a lot of process optimization and collection of data for use in the future,” Fleming said.

“There is also time, money, and data management. How many different data sets do you have in your systems and how are you going to organize them? You may have to have buyers and suppliers understand this digital process before you can implement it.”

Viable solutions to these challenges are often found in artificial intelligence (AI) and machine learning (ML). These advanced technologies can assist in managing large datasets, identifying patterns and trends, and making predictions based on historical data. They can also help automate processes and reduce the need for manual monitoring of digital twins. The same AI vision system that monitors the real-life physical health of a machine and its products can be used to measure the same standards in the metaverse.

“ This new digital process brings the departments together. It used to be you design something, throw it over to the next cubicle and pass it along. This makes everyone come together. ”

- Beau Everitt Oakland Community College

“Internal know-how is also a struggle for digital twin adoption,” Everitt added. “Having someone inside able to do it, release it, and maintain it is a challenge.”

Despite the challenges, adoption secures a more competitive future, Aggarwal said.

"Unlocking actionable insights from IoT sensors and digital twins is paramount in driving operational improvements within the manufacturing sector."

Adoption growing pains are normal, Fleming added.

“In the digital twin journey, everyone is already behind. There is not one company ahead in their digital twin journey. It can be an amorphous thing of the future you are constantly trying to nail down.”

Cybersecurity is quickly becoming a critical issue for manufacturers across the board, affecting those in verticals from consumerpackaged goods to aerospace. Everyone may specialize in making a different product, but there is one thing that unites them all — an increasing reliance on technology.

"In the realm of manufacturing, data integrity is paramount. Prioritizing data protection through robust mitigation plans, policies, and adherence to standards is imperative," Aggarwal said.

Digital twins are just one example of the many ways this vulnerability can manifest. As more facilities hop on board with digital twins and connected technology, bad actors will have new tools to compromise operations. The concerning part is that unlike traditional security threats, cyber-attacks on digital twins can cause physical harm. If hackers access a digital twin and can manipulate its data, they could cause real-world damage or disruption on the factory floor and beyond.

“For cybersecurity, start with zero trust as the baseline. On premises data security is still a major reality for many companies,” Fleming said. “Dollars for cybersecurity training is important.”

Addressing this potential threat means manufacturers will need to approach security from a different angle. Digital twins require constant data flow and communication between the physical asset and its virtual counterpart, so simply locking down access points is not enough. The entire system needs to be securely designed, monitored, and updated regularly.

There are currently little to no standards for the use or management of digital twin technology in manufacturing. The closest thing America currently has to regulatory guidance is the North American Electric Reliability Corporation Critical Infrastructure Protection (NERC CIP) plan, which primarily applies to nuclear facilities. This means that manufacturers are responsible for creating their own cybersecurity protocols and strategies.

Experts at the AFCEA recommend recruiting the help of a Chief Information Security Officer (CISO) to keep this an ongoing priority. Although the creation of an added role is an added expense, it is also an invaluable insurance policy against what can happen when complacency runs free. CISOs deliver value beyond just keeping data safe - they also operate within the entire organization to raise security awareness and promote best practices.

Other, more tactical changes with the potential to minimize digital twin vulnerability include encrypting data transmissions, implementing firewalls and access controls, and adopting a "zero trust" approach to security. This means that each user, whether internal or external, must be fully authenticated and authorized before being allowed to access any resources. Combining this with regular security audits and employee training can help prevent insider threats and keep digital twin systems secure.

"In preparing for potential cyber threats, it is vital for companies to establish contingency plans to maintain manufacturing operations. Implementing compartmentalization strategies within the production process can mitigate the spread of cyber threats across different sections," Aggarwal said.

The new technologies at our disposal today can transform business for the better. Yet at the same time, innovation always comes with risk. Navigating the uncharted territory of digital twins will require diligence from both organizations and individuals. Embracing a culture of security awareness, implementing best practices, and regularly evaluating systems for vulnerabilities will be critical in ensuring the success of digital twin technology.

Conversations among stakeholders are also a key piece of the puzzle. By staying informed and discussing the potential benefits, implications, and challenges that come with digital twins in the manufacturing industry, we can create a stronger and more adaptable manufacturing base.

The automation industry is at the forefront of developing and implementing new and creative technology to improve efficiency and limit financial expenditures while delivering high-quality products and services. Digital twins are an integral part of the present and future of research and development.

Previously, manufacturers were stuck in the physical world when they wanted to create something new or redesign an existing product. They had to build models using raw materials and were required to build new models as they changed the concept. Digital twins takes planning and execution into a virtual environment that allows for quicker adjustments, changing of variables, and immediate cost analysis without using, and potentially wasting, physical resources.

There are many opportunities with digital twin technology, but there are also roadblocks to implementation, including integration with legacy systems, data quality, security, cost, regulatory compliance and workforce training. Addressing these roadblocks requires a comprehensive approach involving technology investments, organizational changes, skill development, and collaboration among stakeholders, including manufacturers, technology providers, regulators, and industry associations.

Below are recommendations for the manufacturing industry on how to best address the roadblocks to digital twin adoption:

The goal of any technology is to provide cost savings while improving product quality and safety. According to a recent article by Andrew Burak , CEO and founder at Relevant Software, digital twins can increase efficiency by as much as 15% and reduce maintenance costs by 13%. Before recognizing these savings, a company must invest financial resources into creating a platform. According to a January 2024 article by RisingMax , the average cost of setting up a platform is between $45,000 and $60,000. Also stated in the article, factors such as the size of the business, outsourcing areas of the project, coding languages, and the complexity of the platform can increase the cost.

A company should conduct an in-depth analysis of what it expects from a digital twin platform. Determining the application's use in product quality, system, efficiency, training, safety regulations, government compliance, supply chain structures, and overall facility management is essential. The greater the scope of use, the more a platform will cost.

Companies can enhance data quality and availability through robust collection processes, sensor deployment, and data cleansing technologies. They can foster industry collaboration for data interoperability standards, facilitating seamless integration across manufacturing systems.

Businesses can leverage edge devices like sensors and smartphones for real-time data collection, ensuring regular inspections for accuracy. Employ cloud storage with strong cybersecurity measures for IoT data management, backed by internal network backups. Choose software tailored to CAD drawings, edge device applications, middleware, and real-time analytics based on system size, network capabilities, customization needs, user proficiency, support, and budget considerations.

Prior to digital twins platform development, conduct a comprehensive audit of software, hardware, and employee capabilities. Consider outsourcing audits to industry experts for thorough evaluations, especially for smaller businesses lacking in-house expertise.

Implement robust cybersecurity measures to protect digital twin ecosystems from potential threats and vulnerabilities. This includes adopting encryption technologies, implementing access controls and authentication mechanisms, and regularly updating security protocols to address emerging threats.

Stay abreast of relevant regulations and standards governing digital twin implementations in the manufacturing industry. Work closely with legal and regulatory experts to ensure that digital twin initiatives comply with applicable laws and regulations, incorporating privacy-bydesign principles and data protection measures into the design and implementation of digital twin solutions.

Provide training and development opportunities for employees to acquire the skills needed to implement and manage digital twins effectively. This may involve partnering with educational institutions, offering certification programs, and fostering a culture of continuous learning within the organization. Proactively communicate the benefits of digital twin adoption to employees and stakeholders, emphasizing how it can improve operational efficiency, product quality, and decision-making processes. Involve employees in the design and implementation of digital twin initiatives to increase buy-in and mitigate resistance to change.

By addressing these recommendations, manufacturing organizations can overcome the roadblocks to digital twin adoption and realize the full potential of this transformative technology to drive innovation, improve competitiveness, and enhance operational excellence.

A company should conduct an in-depth analysis of what it expects from a digital twin platform.

The greater the scope of use, the more a platform will cost.

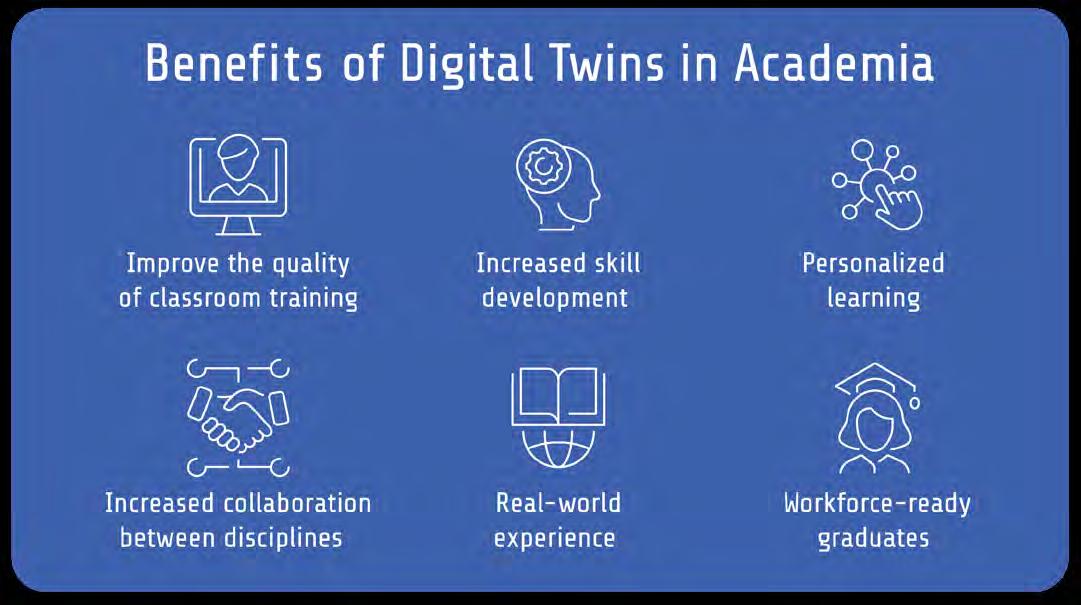

Academia must position itself to train the talent pipeline for jobs of the future by using digital twins in the classroom and collaborating with industry leaders and government officials to understand how to overcome the lack of well-trained workers.

As Digital Twins become more commonly used in industry, the demand for experts in the field continues to grow, and the overall shortage of skilled workers could slow down the implementation of the technology across all industries. 29% of global manufacturing companies have either fully or partially implemented their digital twin strategies . It is critical to begin preparing the future workforce to fill the ever-increasing demand. According to a recent article , the demand for skilled technology workers will continue to grow, but the talent pool will be shallow. By 2030, as many as 85 million jobs could go unfilled because there isn't the talent to fill them. These shortages could result in as much as $8.5 trillion in revenue loss.

Academia must position itself to train the talent pipeline for jobs of the future by using digital twins in the classroom and collaborating with industry leaders and government officials to understand how to overcome the lack of well-trained workers.

Several colleges and universities offer digital twin classes and certifications. These courses provide an understanding of the technology, implementation, and uses and a look at future trends in technology and employment.

Digital twins require several proficiencies, including CAD, programming, cloud computing, IoT, edge device maintenance, data analytics, cybersecurity, and logistics. Some areas will be used directly with a company's digital twin project, while others will be used adjacent to the platform. For example, a hardware specialist who maintains a production line's sensors and 3D cameras might not be assigned directly to work on a digital twin project. Still, the data those edge devices collect is crucial to creating a successful simulation.

Academia must break down the silos between areas of study to develop a workforce capable of handling the demands of the automation industry. Creating the platform, designing the virtual models, gathering and protecting the data, analyzing the results, and implementing new strategies based on simulations are all critical pieces to the digital twins puzzle.

Colleges and universities must assess students' interests and capabilities in many technology areas, which should be fostered during K-12 learning. Beginning at the elementary level, schools should introduce students to computer design, programming, complex math, statistics, and basic cybersecurity knowledge. Interpersonal skills are also crucial as developing any complex computer simulation requires collaboration from several people with various areas of expertise.

The best way to prepare students for the workforce is hands-on experience, especially with something as complex and multifaceted as digital twins. Colleges or universities should create digital twin projects involving students from several areas of study. The project should include creating simulations of working systems, adding variables that will affect outcomes, large amounts of data to study, and plans to change existing systems based on analysis.

An exciting and effective project will not only include students studying hardware, software, analytics, and logistics but also include cybersecurity and marketing components. Cybersecurity is an obvious addition. Data, personal information, trade secrets, patents, and future growth plans are part of a simulation that needs protection from outside hackers. Setting up teams, one trying to hack the information and one trying to protect against cyber-assaults, would be a great learning tool that students can take into many technology-based fields.

Marketing could be one academic silo easily overlooked in such a project, but it shouldn't be ignored. Digital twins are becoming more commonplace in various industries, but many companies are not large enough or equipped to create the platform, so the demand for outsourcing is expanding. Companies that provide the services will need marketing and sales experts to advertise and represent the technology to potential clients properly.

The best way for academia to help fill the talent gaps in the workforce is to ask industry leaders and government officials to identify the current shortfalls and the future outlook of staffing needs to create the proper curriculum for a digital twins certification or degree.

The collaboration between academia and industry should include more than a list of class requirements and testing. There are tremendous benefits to allowing industry leaders in the classroom to share their expertise and guide digital twins projects. Academia can also leave the confines of the campus by partnering with companies to provide onsite training to reskill workers in the technology needed to create and benefit from digital twins. These courses can be offered online or onsite with credentialed teachers proctoring the exams.

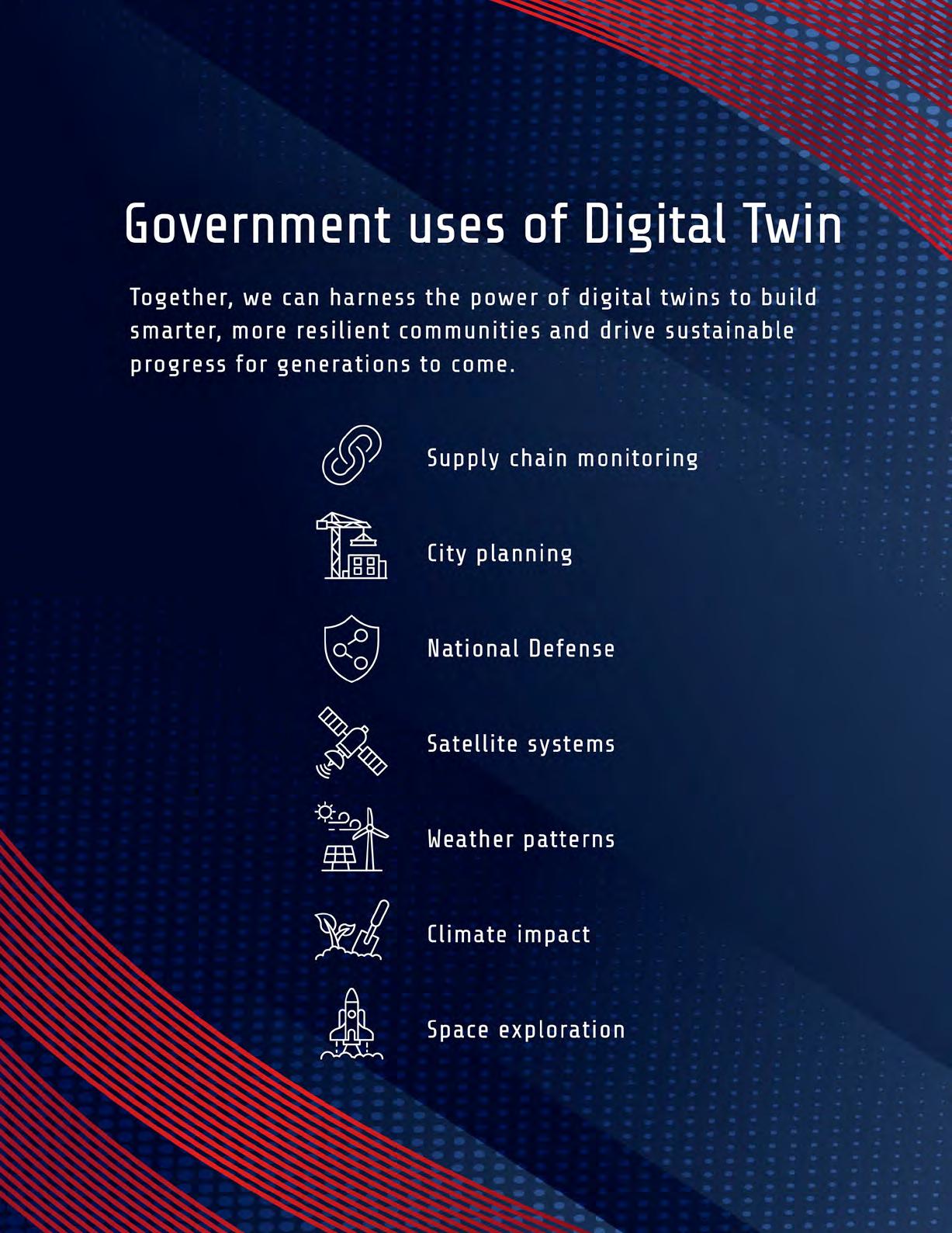

Local, state, and federal governments use digital twins for various projects, including modeling buildings, neighborhoods, and cities to improve their management. Governments are interested in a deep talent pool and can aid with graduating more experts by offering education grants for students and institutions for technology associated with digital twins.

The projected global growth of the digital twin market size will go from over $10 billion in 2023 to $110 billion by 2028.

As governments strive to advance technology adoption in the manufacturing industry, the implementation of digital twins emerges as a transformative solution. According to Markets and Markets , the projected global growth of the digital twin market size will go from over $10 billion in 2023 to $110 billion by 2028. While digital twins’ virtual modeling capabilities is well documented in the manufacturing sector, the technology has great potential to empower government agencies and drive progress across other critical sectors of the economy, including adoption in city planning, national defenses, climate impacts and space exploration. In collaboration with industry and academia, policymakers have a unique opportunity to harness the potential of digital twins to address complex challenges and unlock new opportunities for growth and innovation. Below are recommendations on how to do so.

The projected growth of the global digital twin market presents immense opportunities for industry collaboration. Policymakers should incentivize partnerships between government agencies, academia, and private sector firms to drive innovation in digital twin platforms, sensors, cloud services, and cybersecurity solutions. By fostering an ecosystem of collaboration and investment, governments can catalyze industry growth and ensure the widespread adoption of digital twins across sectors.

Governments should prioritize funding for research and development in digital twin technologies. This includes allocating grants, subsidies, and tax incentives to encourage innovation in digital twin platforms, data analytics, simulation tools, and real-time monitoring systems. For grants, governments should consider programs to support academic institutions and startups focusing on cutting-edge digital twin research and applications.

As digital twins become more integrated into supply chains, critical infrastructure and national systems, robust cybersecurity measures are essential to protect against data breaches, cyberattacks, and system failures. Governments should develop and implement comprehensive best practice cybersecurity frameworks tailored to the unique challenges of digital twin environments, including secure data transmission, storage, and access protocols. In addition, policymakers can be leaders in the development of regulatory frameworks and ethical guidelines to govern the use of digital twin technologies, ensuring they are used responsibly and ethically.

The success of digital twin implementation heavily relies on a skilled workforce that can design, deploy, and manage these sophisticated systems. Government can collaborate with educational institutions to develop curriculum and training programs focused on digital twin technologies, including data science, IoT, AI, and cybersecurity. This should include the establishment of internship and apprenticeship programs that provide hands-on experience with digital twin projects, fostering practical skills development, certification programs to validate the skills and knowledge of professionals working with digital twin technologies, and workforce transition and upskilling programs to support workers looking to move from traditional manufacturing and engineering roles to digital twin-related positions.

To fully leverage digital twin technologies, it's crucial to ensure that data from different sources can be integrated and utilized seamlessly. Government should encourage open data initiatives that promote the sharing and accessibility of data across different sectors and agencies and support the development and adoption of data standards and protocols to ensure interoperability between digital twin systems and other technologies.

Automation Alley posted weekly polls in March 2024 for our LinkedIn followers of over 5,000 professionals in the technology and manufacturing ecosystem on the topic of digital twin in the industry. This is how the industry responded at a glance. What are your digital twin goals?

Digital Twin Adoption: 86% of senior executives in the manufacturing industry find digital twins applicable to their operations, with 44% already having fully functional digital twins in place. The global market for digital-twin technologies is forecasted to reach $73.5 billion by 2027.

Efficiency and Productivity Boost: Digital twins enhance efficiency, lower costs, and increase productivity. 92% of digital twin implementers reported that it made products and processes more sustainable.

Wide Applications Across Manufacturing: Digital twins can be applied to practically every aspect of manufacturing, including maintenance and design. They enable remote monitoring, predictive maintenance, and real-time feedback on equipment performance.

Cybersecurity Challenges and Solutions: Manufacturers must address cybersecurity concerns as digital twins become more prevalent. Tactics such as encryption, firewalls, access controls, and adopting a "zero trust" approach are essential for securing digital twin systems.

Government Agencies: The United States Department of Defense and NASA are investing in digital twins to enhance military satellite programs and space exploration. Also, municipalities are increasingly turning to digital twins to manage complex infrastructure systems and urban development. Cities like Boston and Las Vegas are utilizing digital twins to model physical landscapes, assess environmental impacts, and optimize energy usage and emergency management.

Training the Digital Twin Workforce: Academia plays a crucial role in preparing the future workforce for the growing demand for digital twin expertise. Offering classes and certifications in digital twins provides students with essential knowledge in areas such as CAD, programming, IoT, cloud computing, cybersecurity, and logistics. Breaking down silos between disciplines ensures that graduates are equipped to handle the multifaceted demands of the automation industry.

Cost Savings & Prevention of Downtimes: While initial investment is required to set up a digital twin platform, the potential cost savings can be significant. Studies suggest that digital twins can increase efficiency by up to 15% and reduce maintenance costs by 13%. However, companies must conduct a thorough analysis of their needs and scope of application to determine the platform's cost-effectiveness. Factors such as business size, outsourcing, complexity, and compliance requirements impact the overall cost. Digital twins can also prevent and shorten downtimes.

Proper Tools: Implementing a digital twin requires proper hardware and software tools. Edge devices such as sensors, cameras, and servers collect and transmit data, while cloud storage and computing capabilities are essential for data storage and analysis. Choosing the right software and hardware depends on various factors like system size, network capabilities, customization needs, and budget constraints. Regular inspections and audits ensure the reliability and efficiency of the digital twin infrastructure. 1 2 3 4 5 6 7 8

By Luv Aggarwal

By Luv Aggarwal

Portfolio Development

Executive - Digital Manufacturing

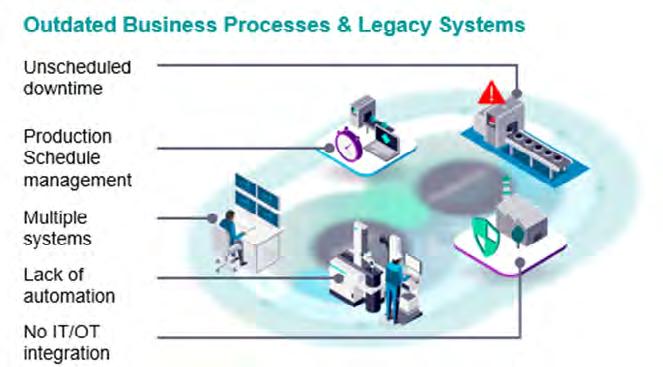

Machine builders are heavily reliant on providers of specialist components and equipment. These organizations are typically producing large volumes of products, supplying their customers with standardized parts defined in product catalogs or with a small degree of configuration or customization. Technology is driving rapid change in customer requirements, as a result, manufacturing processes and the workforce need to be agile, keeping pace with lower product runs, increasing variability and updates in product lines. Many of these companies struggle to keep pace with technological change and need support in areas such as automation and cybersecurity.

To maintain a competitive edge, manufacturers of industrial equipment and components must transform their businesses – refining processes and delivering products with maximum efficiency. These improvements must be made alongside a positive impact on quality, sustainability, and industrial security. The IIoT opens up new opportunities to optimize production lines with advanced analytics and AI.

To stay relevant, equipment and component manufacturers will need to: Innovate

• Integrate technologies including robotics, IIoT, machine vision, artificial intelligence, cloud and edge computing to deliver highly efficient, smart factories

• Adopt an Executable Digital Twin to support continuous improvement

• Automation is critical to achieve improvements in efficiency and quality

• Simulation is the fastest, lowest cost method to successfully implement manufacturing process improvements

• Integrate IT and OT to deliver new levels of agility and resilience

• Become data driven enterprises, powered by Industry 4.0 technologies

• Build ESG metrics into working practices

Large, medium and small companies are increasing the pace of embracing “Digital Transformation” in order to boost competitiveness by improving speed, flexibility, efficiency, quality, compliance, productivity and sustainability. Digital transformation is a journey involving a constant process of renewal and change. However, on account of the complexity involved (people, systems and process) many companies lack the expertise in digitalization solutions and technologies to keep up with the pace of change, leaving them constrained by outdated business processes and legacy systems. The traditional approach to navigating complexity significantly impacts the ability to optimize production performance and meet new operational and sustainability targets because of:

• A lack of visibility into machine performance and reliability

• Lack of agility in production processes

• Incongruent views of critical data

• Lack of skills to automate processes

• Cybersecurity risks

How can you accelerate your adoption of digitalization across operations, whilst maximizing production and reducing carbon emissions? Siemens, for example, provides a complete package of simulation software, automation hardware and digitalization experts to accompany organizations throughout their transformation.

Organizations need to adopt an efficiency optimization mindset that champions cost efficient operational transformation through simulation using the digital twin. By leveraging a smart manufacturing digital thread, companies can unlock limitless possibilities, using the plan, optimize, and execute imperatives. We have identified six generic process steps to demonstrate our capabilities that can support your business digitalization (Figure 1).

Our solution brings together three core areas of capability, enabling you to rapidly adopt digital and automation tools that will enhance your manufacturing efficiency. It's a smart, connected factory that provides end-to-end visibility of your production assets, moving you towards a fully integrated manufacturing system, or Closed Loop Manufacturing (CLM).

Siemens supports the planning, design and implementation of smart, agile production lines and automation solutions. We help to deliver digital transformation, boosting competitiveness and increasing speed with our innovative software and digitalization service experts.

Proper planning can help you accelerate the integration of automation to drive efficiency into your manufacturing operations. Here's how:

· Accelerate technology adoption through digitalization service experts, accompanying you throughout the entire lifecycle

· Integrate your new product introduction process into manufacturing with minimal disruption, gain early visibility of energy usage

· Integrate enterprise systems with manufacturing planning to optimize production processes using real-time data

· Quickly create and deploy highly customizable apps on edge devices that allow you to act on data fast and make better decisions

· Gain new insights into operational performance and sustainability to power business outcomes and innovation

Digital twin execution supports greater process flexibility and efficiency, complete integration of regulatory and quality requirements along with synchronized production processes for optimal supply chain management. Use cloud and edge analytics to support predictive maintenance.

Here's how you can operate agile production lines at maximum efficiency:

· Connect your machines, lines, factories and supply chain with an open, comprehensive IIoT solution

· Eliminate silos of data to achieve end-to-end visibility of your entire production process and increase process efficiency

· Eliminate disruption from changes in product runs – delivering a “batch of one” with the same efficiency and quality as a batch of 1,000

· Rapidly identify and predict production and quality issues, even before they occur

· Take advantage of advanced analytics that turn high volumes of data into actionable insights

Utilize operational data to drive continuous improvement in your manufacturing processes. Collect all relevant data across plants and lines, enabling modeling and executing smart KPI analysis, driving towards Closed Loop Quality.

Connect operating assets with engineering simulation for continuous improvement. Here's how:

· Maintain and leverage engineering simulation models from PLAN to evaluate changes driven by technology or product updates

· Run a self-contained digital twin model on the industrial IoT platform for modeling continuous improvement

· Model and analyze the operational efficiency of high-value assets using virtual sensors

· Create new opportunities for optimizing manufacturing processes using predictive insights from AI and analytics

· Adopt the latest advances in process automation to improve overall equipment efficiency (OEE) and lower your total cost-of-ownership

Automation Alley is a nonprofit technology business association and Digital Transformation Insight Center focused on driving the growth and success of businesses in Michigan and beyond through innovation and automation. With a global outlook and a regional focus, we foster a vibrant community of innovators, entrepreneurs, and business leaders through opportunities for collaboration and learning. Our programs and services help businesses develop the skills and expertise needed to effectively jumpstart or accelerate digital transformation. By bringing together industry, academia, and government, we aim to create a dynamic ecosystem that drives innovation and growth across Michigan.

At Automation Alley, our mission is to help businesses thrive in the rapidly changing digital economy. We equip them with the knowledge, insights, and tools to develop a software-first mindset that leverages the power of automation, AI, and other cognitive technologies. We believe that by working together, we can build a stronger, more innovative, and more competitive economy for the future.

Wealth, prosperity and equality through technology.

Publication Credits

Editorial: Nicole Kampe, Dennis Burck, Joseph Gray

Graphic Design: Laura Gearhart

Photography: Sean Healey

Team Sense - The High Cost of Downtime in Manufacturing & How to Reduce It https://www.teamsense.com/blog/cost-of-downtime-manufacturing

Capgemini Research Institute - Digital Twins in Aerospace and Defense https://www.capgemini.com/insights/research-library/digital-twins-in-aerospace

McKinsey - Digital twins: The next frontier of factory optimization https://www.mckinsey.com/capabilities/operations/our-insights/digital-twins-the-next-frontier-of-factory-optimization

McKinsey - Digital twins: The key to smart product development https://www.mckinsey.com/industries/industrials-and-electronics/our-insights/digital-twins-the-key-to-smart-product-development

Altair - 2023 Digital Twin Survey Report Vertical Breakdown: Manufacturing https://altair.com/resource/2023-digital-twin-survey-report-vertical-breakdown-manufacturing?lang=en

Fraunhofer - Using Digital Twins for Predictive Maintenance https://www.iao.fraunhofer.de/en/press-and-media/latest-news/using-digital-twins-for-predictive-maintenance.html

McKinsey - A Manufacturer’s Guide to Scaling Industrial IoT https://www.mckinsey.com/capabilities/mckinsey-digital/our-insights/a-manufacturers-guide-to-generating-value-at-scale-with-industrial-iot

Forbes - What To Know About AI-Enabled Digital Twins In Manufacturing https://www.forbes.com/sites/forbestechcouncil/2023/11/27/what-to-know-about-ai-enabled-digital-twins-in-manufacturing/?sh=77e4afae2f86

NERC - Standards https://www.nerc.com/pa/Stand/Pages/Default.aspx

AFCEA - Investments in Digital Twins Can Drive Transformation https://www.afcea.org/signal-media/investments-digital-twins-can-drive-transformation

LinkedIn - Exploring the Power of Digital Twins: Revolutionizing Product Development and Beyond https://www.linkedin.com/pulse/exploring-power-digital-twins-revolutionizing-product-andrew-burak/

RisingMax - Digital Twin Development Cost https://risingmax.com/blog/digital-twin-development-cost

IoT Analytics - Digital Twin Market: Analyzing Growth and Emerging Trends https://iot-analytics.com/digital-twin-market-analyzing-growth-emerging-trends/

LinkedIn - The US Tech Talent Shortage and 6 Strategies for Companies to Combat It https://www.linkedin.com/pulse/us-tech-talent-shortage-6-strategies-companies-combat-jon-jennings/

Space News - Digital Twins Gaining Traction in Military Satellite Programs https://spacenews.com/digital-twins-gaining-traction-in-military-satellite-programs/

New Space Economy - What is Digital Twinning and its Relevance to the Space Economy? https://newspaceeconomy.ca/2023/05/07/what-is-digital-twinning-and-its-relevance-to-the-space-economy/

Science and Technology Corp - Rapid Prototype of Earth Observing Digital Twin of the NESDIS Ground System https://nesdis-prod.s3.amazonaws.com/2024-02/STC_EODT_202311302023_FINAL_REPORT_v3.pdf

GovEvents - IoT in Government: How Government is Using Digital Twins https://www.govevents.com/blog/2022/07/07/iot-in-government-how-government-is-using-digital-twins/

Markets and Markets - Digital Twin Industry worth $110.1 billion by 2028 http://marketsandmarkets.com/PressReleases/digital-twin.asp

Made possible in part through ongoing support from the