Feet Products

Developed for demanding and harsh environments

Hygienic certified components

No job too tough, sustainable development and growth

Minimized environmental impact, ecological sustainability

Lower operating cost, reduce water consumption

AUT company profile

At AUT, we are extremely proud to be considered one of the most respected castor suppliers and manufacturers in the UK.

With over 40 years of providing comprehensive solutions to customers in a wide range of sectors, our technical expertise and experience are unrivalled.

AUT has become a leading resource, technical authority and global supplier of wheels and castors. AUT has seen growth year on year and is considered one of the most respected castor suppliers and manufacturers in the UK.

Over the years AUT has worked on some of the most bespoke and demanding solutions within the industry. From offshore, fully submerged applications to aerospace end users requiring 22 tonnes capacity. With over 150 years’ of experience within the group, we are confident we can help.

Our feet products are used and a large variety of industries, food and pharmaceutical production, medical equipment, animal welfare and training industry, oils and gas industry, packaging machinery, meat & poultry processing equipment, dairy processing machines, etc.

We continuously innovate and design our products to satisfy the increasing requirements for a sustainable development and growth

Minimized environmental impact less water and cleaning agent usage

Ecological sustainability 100% recyclable materials

Lower operating cost reduced down time for cleaning and maintenance

Risk management for the processing industry

AUT is a leading global provider of hygienic machine parts for advanced machine systems for food processing, pharmaceutical production, medical equipment, animal welfare and training industry, oils and gas industry, packaging machinery, meat & poultry processing equipment, dairy processing machines, etc.

At AUT continuously adopt new technologies to ensure our leading position in development and design of cutting edge hygienic machine parts

It takes attention to many details to create a profitable processing business, including the freshness of ingredients, the right equipment and a dedicated, service-oriented workforce.

All processing businesses depend heavily on their equipment, much of which is highly automated. Imagine what would happen to a food business if the refrigeration were not working properly. When a mechanical failure takes place, the business often must close and face a loss of income.

Equipment Risk Management: Do not compromise the food safety on your machinery and avoid down time on your food processing machinery. Use cutting edge hygienic machinery parts, such as IP67 waterproof bearing unit and stainless levelling feet with FDA certificate and design according to 3A and EHEDG regulation

All our hygienic machine parts are designed with a smooth surface without any unnecessary ribs, flanges, recesses or mounting holes, minimising the risk of hidden sources of contamination. The smooth surface makes the cleaning easier and makes the use of a traditional shield unnecessary, which also minimises the risk of hidden contamination.

Certified 3A and EHEDG machine levelling feet

Our machine feet series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: Medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines

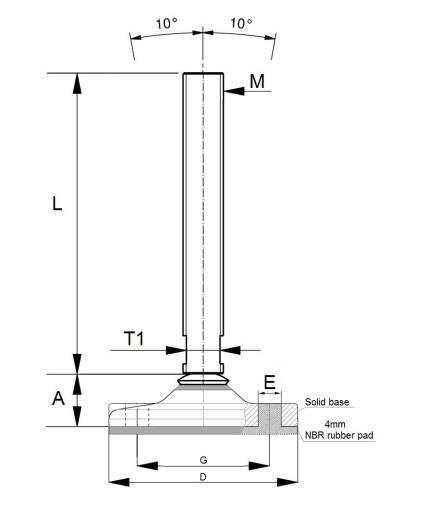

Features and advantages of our extra hygienic levelling system feet: The spindles are smooth at the end towards the base and a sleeve to ensure easy cleaning protects the threads. The sleeve also functions as a nut.

Features and advantages of our special sealed hygienic levelling system feet: The spindle and base are sealed with silicone gasket The sleeve is sealed with silicone gasket to the smooth end of the spindle and is sealed to the mounting plate with silicone gasket. The sleeve also functions as a nut. These features make our special sealed hygienic feet comply with 3A and EHEDG requirements

Machine feet material

Base plate Stainless steel 304 (Aisi 1.4301) or 316L (Aisi 1.4404)

Spindle Stainless steel A2-70 or A4-70

Rubber base NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

EHEDG Hygienic stainless solid base feet with sealed spindle

The special hygienic stainless solid base feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications. The spindle and base are sealed with silicone gasket. The sleeve is sealed with silicone gasket to the smooth end of the spindle and sealed to the mounting place at the equipment with silicone gasket. The sleeve also functions as a nut.

HSF EHEDG base with fixation

The solid stainless steel 1.4301 base plate can be fitted with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HSF79EHEDG-M16-L135-R, rubber pad height 4mm

Ordering ex.: HSF79-EHEDG-M16-L135-R, HSF79 base and 3A-M16-L135M10 spindle and RPB78 rubber pad

HSF EHEDG A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HSF EHEDG A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm

Adjustable height Min 80 mm – Max 120 mm

L=175 mm H=75 mm Adjustable height Min 100 mm – Max 160 mm

L=215 mm H=95 mm

L=255 mm H=115 mm

L=295 mm H=125 mm

Adjustable height Min 120 mm – Max 200 mm

Adjustable height Min 140 mm – Max 240 mm

Adjustable height Min 160 mm – Max 280 mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

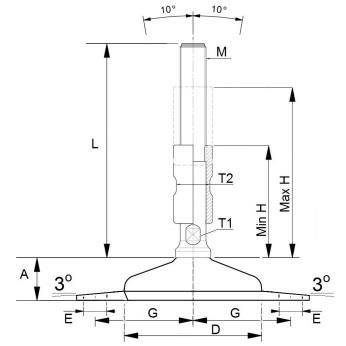

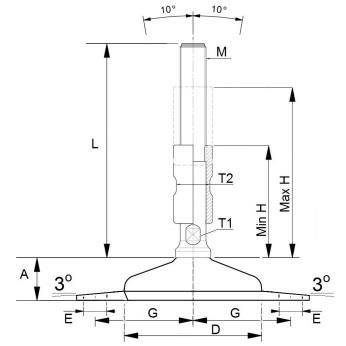

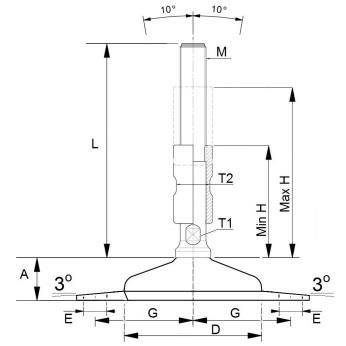

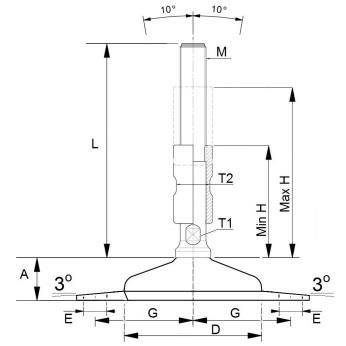

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

The HSF EHEDG levelling system are approved for machines and equipment for the dairy-, brewery and pharmaceutical industry, applications with the highest demands for hygiene and cleaning.

HSF79 EHEDG Hygienic stainless feet with sealed spindle mounting

HSF99 EHEDG Hygienic stainless feet with sealed spindle mounting

HSF119 EHEDG Hygienic stainless feet with sealed spindle mounting

HSF139 EHEDG Hygienic stainless feet with sealed spindle mounting

HSF159 EHEDG Hygienic stainless feet with sealed spindle mounting

HSF179 EHEDG Hygienic stainless feet with sealed spindle mounting

EHEDG Hygienic adjustable solid base feet with sealed spindle

Special hygienic adjustable solid base feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications. The spindle and base are sealed with silicone gasket. The sleeve is sealed with silicone gasket to the smooth end of the spindle and sealed to the mounting place at the equipment with silicone gasket. The sleeve also functions as a nut.

HAF EHEDG base with fixation

The solid blue anti-bacterial POM base plate can be fitted with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HAF79EHEDG-M16-L135-R, rubber pad height 4mm

Ordering ex.: HAF79-EHEDG-M16-L135-R, HAF79 base and 3A-M16-L135M10 spindle and RPB78 rubber pad

HAF EHEDG A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HAF EHEDG A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm Adjustable height Min 80 mm – Max 120 mm

L=175 mm H=75 mm Adjustable height Min 100 mm – Max 160 mm

L=215 mm H=95 mm Adjustable height Min 120 mm – Max 200 mm

L=255 mm H=115 mm Adjustable height Min 140 mm – Max 240 mm

L=295 mm H=125 mm Adjustable height Min 160 mm – Max 280 mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

HAF EHEDG sealed hygienic adjustable feet can cope with up to 10 degree slopes on floors and equipment.

The HAF EHEDG levelling system are approved for machines and equipment for the dairy-, brewery and pharmaceutical industry, applications with the highest demands for hygiene and cleaning.

HAF79 EHEDG Hygienic adjustable feet with sealed spindle mounting

HAF99 EHEDG Hygienic adjustable feet with sealed spindle mounting

HAF119 EHEDG Hygienic adjustable feet with sealed spindle mounting

HAF139 EHEDG Hygienic adjustable feet with sealed spindle mounting

3A Hygienic stainless solid base feet with sealed spindle

The special hygienic stainless solid base feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications. The spindle and base are sealed with silicone gasket. The sleeve is sealed with silicone gasket to the smooth end of the spindle and sealed to the mounting place at the equipment with silicone gasket. The sleeve also functions as a nut.

The solid stainless steel 1.4301 base plate can be fitted with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HSF78-3AM16-L135-R, rubber pad height 4mm

Ordering ex.: HSF79-3A-M16-L135-R, HSF79 base and 3A-M16-L135-M10 spindle and RPB78 rubber pad

HSF 3A A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HSF 3A A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm

H=55 mm

L=175 mm H=75 mm

L=215 mm H=95 mm

L=255 mm H=115 mm

L=295 mm H=125 mm

Adjustable height Min 80 mm – Max 120 mm

Adjustable height Min 100 mm – Max 160 mm

Adjustable height Min 120 mm – Max 200 mm

Adjustable height Min 140 mm – Max 240 mm

Adjustable height Min 160 mm – Max 280 mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

The HSF 3A levelling system are approved for machines and equipment for the dairy-, brewery and pharmaceutical industry, applications with the highest demands for hygiene and cleaning.

HSF38 3A Hygienic stainless feet with sealed spindle mounting

HSF58 3A Hygienic stainless feet with sealed spindle mounting

HSF78 3A Hygienic stainless feet with sealed spindle mounting

HSF98

3A Hygienic stainless feet with sealed spindle mounting

HSF118 3A Hygienic stainless feet with sealed spindle mounting

HSF138 3A Hygienic stainless feet with sealed spindle mounting

HSF158 3A Hygienic stainless feet with sealed spindle mounting

HSF178 3A Hygienic stainless feet with sealed spindle mounting

HSF79 3A

Hygienic stainless feet with sealed spindle mounting

HSF99 3A Hygienic stainless feet with sealed spindle mounting

HSF119 3A

Hygienic stainless feet with sealed spindle mounting

HSF139 3A

Hygienic stainless feet with sealed spindle mounting

HSF159

3A

Hygienic stainless feet with sealed spindle mounting

HSF179 3A Hygienic stainless feet with sealed spindle mounting

3A Hygienic adjustable solid base feet with sealed spindle

Special hygienic adjustable solid base feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications. The spindle and base are sealed with silicone gasket. The sleeve is sealed with silicone gasket to the smooth end of the spindle and sealed to the mounting place at the equipment with silicone gasket. The sleeve also functions as a nut.

The solid blue anti-bacterial POM base plate can be fitted with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HAF783A-M16-L135-R, rubber pad height 4mm

Ordering ex.: HAF79-3A-M16-L135-R, HAF79 base and 3A-M16-L135-M10 spindle and RPB78 rubber pad

HAF 3A

A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HAF 3A

A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm

L=175 mm H=75 mm

L=215 mm H=95 mm

L=255 mm H=115 mm

L=295 mm H=125 mm

Adjustable height Min 80 mm – Max 120 mm

Adjustable height Min 100 mm – Max 160 mm

Adjustable height Min 120 mm – Max 200 mm

Adjustable height Min 140 mm – Max 240 mm

Adjustable height Min 160 mm – Max 280 mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

The base can be fitted with a FDA approved rubber pad for vibration reduction HAF 3A sealed hygienic adjustable feet can cope with up to 10 degree slopes on floors and equipment.

The HAF 3A levelling system is approved for machines and equipment for the food and medical industry, applications with the highest demands for hygiene and cleaning.

HAF38 3A Hygienic adjustable feet with sealed spindle mounting

HAF58 3A Hygienic adjustable feet with sealed spindle mounting

HAF78 3A Hygienic adjustable feet with sealed spindle mounting

HAF98 3A

Hygienic adjustable feet with sealed spindle mounting

HAF118 3A Hygienic adjustable feet with sealed spindle mounting

HAF138 3A

Hygienic adjustable feet with sealed spindle mounting

HAF79 3A Hygienic adjustable

feet with sealed spindle mounting

HAF99 3A Hygienic adjustable feet with sealed spindle mounting

HAF119 3A Hygienic adjustable feet with sealed spindle mounting

HAF139 3A Hygienic adjustable feet with sealed spindle mounting

3A Hygienic levelling feet with vulcanized blue rubber base and sealed spindle

The special hygienic levelling feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications. The spindle and base are sealed with silicone gasket. The sleeve is sealed with silicone gasket to the smooth end of the spindle and sealed to the mounting place at the equipment with silicone gasket. The sleeve also functions as a nut.

HLF 3A blue base with 1 fixation

Base Diameter D

HLF 3A blue base with 2 fixation

G

E

The stainless steel 1.4301 base plate are embedded with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber with unique batch ID number for food safety traceability and comply with 3A and EHEDG regulation.

Ordering ex.: HLF81-3A-M16-L135, HLF81 base and 3A-M16-L135 spindle

HLF 3A A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HLF 3A A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm Adjustable height Min 80 mm – Max 120 mm

L=175 mm H=75 mm Adjustable height Min 100 mm – Max 160 mm

L=215 mm H=95 mm Adjustable height Min 120 mm – Max 200 mm

L=255 mm H=115 mm Adjustable height Min

L=295 mm H=125 mm Adjustable height Min

–

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

HLF50 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF60 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF80 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF100 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF120 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF140 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF61 3A

Hygienic levelling feet with sealed spindle (Blue base)

HLF81 3A Hygienic

levelling feet with sealed spindle (Blue base)

HLF101 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF121 3A

Hygienic levelling feet with sealed spindle (Blue base)

HLF62 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF82 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF102 3A Hygienic levelling feet with sealed spindle (Blue base)

HLF122 3A

Hygienic levelling feet with sealed spindle (Blue base)

3A Hygienic

machine feet with vulcanized black rubber base and sealed spindle

The special hygienic machine feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications. The spindle and base are sealed with silicone gasket. The sleeve is sealed with silicone gasket to the smooth end of the spindle and sealed to the mounting place at the equipment with silicone gasket. The sleeve also functions as a nut.

HMF 3A black base with 1 fixation

HMF 3A black base with 2 fixation

The stainless steel 1.4301 base plate are embedded with black NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber with unique batch ID number for food safety traceability and comply with 3A and EHEDG regulation.

Ordering ex.: HMF81-3A-M16-L135, HMF81 base and 3A-M16-L135 spindle

HMF 3A A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HMF 3A A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm Adjustable height Min 80 mm – Max 120 mm

L=175 mm H=75 mm Adjustable height Min 100 mm – Max 160 mm

L=215 mm H=95 mm Adjustable height Min 120 mm – Max 200 mm

L=255 mm H=115

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

HMF50 3A Hygienic machine feet with sealed spindle (Black base)

HMF60 3A Hygienic machine feet with sealed spindle (Black base)

HMF80 3A Hygienic machine feet with sealed spindle (Black base)

HMF100 3A Hygienic machine feet with sealed spindle (Black base)

HMF120 3A Hygienic machine feet with sealed spindle (Black base)

HMF140 3A Hygienic machine feet with sealed spindle (Black base)

HMF61 3A Hygienic machine feet with sealed spindle (Black base)

HMF81 3A Hygienic machine feet with sealed spindle (Black base)

HMF101 3A Hygienic machine feet with sealed spindle (Black base)

HMF121 3A Hygienic machine feet with sealed spindle (Black base)

HMF62 3A Hygienic machine feet with sealed spindle (Black base)

HMF82 3A Hygienic machine feet with sealed spindle (Black base)

HMF102 3A Hygienic machine feet with sealed spindle (Black base)

HMF122 3A Hygienic machine feet with sealed spindle (Black base)

Hygienic levelling feet with vulcanized blue rubber base

HLF Hygienic levelling feet with full threaded spindle mounting

The hygienic levelling feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

50

HLF blue base with 1 fixation

61

81

N

N HLF blue base with 2 fixation

62

The stainless steel 1.4301 base plate are embedded with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber with unique batch ID number for food safety traceability. Ordering ex.: HLF81-M16-L150, HLF81 base and M16-L150 spindle

HLF A2-70 spindle threads (M): M10, M12, M16, M20, M24, M30 and M36

HLF A2-70 Spindle length (L): 50mm, 70mm, 100mm, 120mm, 150mm, 180mm, 200mm, 230mm, 280mm and 330mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request The thread can also be customized according to specific request, ex trapezoid thread etc.

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

The hygienic levelling feet are easy to clean and are approved by the food processing industry

HLF50 Hygienic levelling feet with full threaded spindle mounting

HLF50 Hygienic levelling feet with full threaded spindle mounting

HLF60 Hygienic levelling feet with full threaded spindle mounting

HLF60 Hygienic levelling feet with full threaded spindle mounting

HLF80 Hygienic levelling feet with full threaded spindle mounting

HLF80 Hygienic levelling feet with full threaded spindle mounting

HLF100

Hygienic levelling feet with full threaded spindle mounting

HLF100 Hygienic levelling feet with full threaded spindle mounting

HLF120 Hygienic levelling feet with full threaded spindle mounting

HLF120 Hygienic levelling feet with full threaded spindle mounting

HLF140

Hygienic levelling feet with full threaded spindle mounting

HLF140 Hygienic levelling feet with full threaded spindle mounting

HLF61 Hygienic levelling feet with full threaded spindle mounting

HLF61 Hygienic levelling feet with full threaded spindle mounting

HLF81 Hygienic levelling feet with full threaded spindle mounting

HLF81 Hygienic levelling feet with full threaded spindle mounting

HLF101 Hygienic

levelling feet with full threaded spindle mounting

HLF101 Hygienic levelling feet with full threaded spindle mounting

HLF121

Hygienic levelling feet with full threaded spindle mounting

HLF121 Hygienic levelling feet with full threaded spindle mounting

HLF62

Hygienic levelling feet with full threaded spindle mounting

HLF62 Hygienic levelling feet with full threaded spindle mounting

HLF82 Hygienic levelling feet with full threaded spindle mounting

HLF82 Hygienic levelling feet with full threaded spindle mounting

HLF102 Hygienic levelling feet with full threaded spindle mounting

HLF102 Hygienic levelling feet with full threaded spindle mounting

HLF122 Hygienic

levelling feet with full threaded spindle mounting

HLF122

Hygienic levelling feet with full threaded spindle mounting

HLF LC Hygienic levelling feet with protected spindle (Blue base)

The spindles are smooth at the end towards the base and the sleeve covers the thread. These features ensure easy cleaning and protect the threads. The sleeve functions as a nut.

HLF LC blue base 1 with fixation

Base

LC blue base 2 with fixation

The stainless steel 1.4301 base plate are embedded with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber with unique batch ID number for food safety traceability and comply with 3A and EHEDG regulation.

Ordering ex.: HLF81-LC-M16-L135, HLF81 base and LC-M16-L135 spindle

HLF LC A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HLF LC A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm Adjustable height Min 80 mm – Max 120 mm

L=175 mm H=75 mm Adjustable height Min 100 mm – Max 160 mm

L=215 mm H=95 mm Adjustable height Min 120 mm – Max 200 mm

L=255 mm H=115 mm Adjustable height Min 140 mm – Max 240 mm

L=295 mm H=125 mm Adjustable height Min 160 mm – Max 280 mm For other threaded spindle length (L), please contact us Threads in inch is available upon request

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment. The extra hygienic levelling feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

HLF50 LC Hygienic levelling feet with protected spindle mounting

HLF60 LC Hygienic levelling feet with protected spindle mounting

HLF80 LC Hygienic levelling feet with protected spindle mounting

HLF100 LC Hygienic levelling feet with protected spindle mounting

HLF120 LC Hygienic levelling feet with protected spindle mounting

HLF140 LC Hygienic levelling feet with protected spindle mounting

HLF61

LC Hygienic levelling feet with protected spindle mounting

HLF81 LC Hygienic levelling feet with protected spindle mounting

HLF101

LC Hygienic levelling feet with protected spindle mounting

HLF121 LC Hygienic levelling feet with protected spindle mounting

HLF62

LC Hygienic levelling feet with protected spindle mounting

HLF82 LC Hygienic levelling feet with protected spindle mounting

HLF102 LC Hygienic levelling feet with protected spindle mounting

HLF122

LC Hygienic levelling feet with protected spindle mounting

Hygienic Machine feet with vulcanized black rubber base

HMF Hygienic Machine feet with full threaded spindle mounting

The hygienic machine feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

HMF black base

50

HMF black base with 2 fixation

62

HLF A2-70 spindle threads (M): M10, M12, M16, M20, M24, M30 and M36

HLF A2-70 Spindle length (L): 50mm, 70mm, 100mm, 120mm, 150mm, 180mm, 200mm, 230mm, 280mm and 330mm

The hygienic levelling feet are easy to clean and are approved by the food processing industry. HMF black base with 1 fixation

The stainless steel 1.4301 base plate are embedded with black NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber with unique batch ID number for food safety traceability. Ordering ex.: HMF81-M16-L150, HMF81 base and M16-L150 spindle

For other threaded spindle length (L), please contact us Threads in inch is available upon request The thread can also be customized according to specific request, ex trapezoid thread etc.

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

HMF50 Hygienic machine feet with full threaded spindle mounting

HMF50 Hygienic machine feet with full threaded spindle mounting

HMF60 Hygienic machine feet with full threaded spindle mounting

HMF60 Hygienic machine feet with full threaded spindle mounting

HMF80 Hygienic machine feet with full threaded spindle mounting

HMF80 Hygienic machine feet with full threaded spindle mounting

HMF100 Hygienic machine feet with full threaded spindle mounting

HMF100 Hygienic machine feet with full threaded spindle mounting

HMF120 Hygienic machine feet with full threaded spindle mounting

HMF120 Hygienic machine feet with full threaded spindle mounting

HMF140 Hygienic machine feet with full threaded spindle mounting

HMF140 Hygienic machine feet with full threaded spindle mounting

HMF61 Hygienic machine feet with full threaded spindle mounting

HMF61 Hygienic machine feet with full threaded spindle mounting

HMF81 Hygienic machine feet with full threaded spindle mounting

HMF81 Hygienic machine feet with full threaded spindle mounting

HMF101 Hygienic machine feet with full threaded spindle mounting

HMF101 Hygienic machine feet with full threaded spindle mounting

HMF121 Hygienic machine feet with full threaded spindle mounting

HMF121 Hygienic machine feet with full threaded spindle mounting

HMF62 Hygienic machine feet with full threaded spindle mounting

HMF62 Hygienic machine feet with full threaded spindle mounting

HMF82 Hygienic machine feet with full threaded spindle mounting

HMF82 Hygienic machine feet with full threaded spindle mounting

HMF102 Hygienic machine feet with full threaded spindle mounting

HMF102 Hygienic machine feet with full threaded spindle mounting

HMF122 Hygienic machine feet with full threaded spindle mounting

HMF122 Hygienic machine feet with full threaded spindle mounting

HMF LC Hygienic machine feet with protected spindle (Black base)

The spindles are smooth at the end towards the base and the sleeve covers the thread. These features ensure easy cleaning and protect the threads. The sleeve functions as a nut.

HMF LC black base with 1 fixation

Base

2 LC black base with fixation

The stainless steel 1.4301 base plate are embedded with black NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber with unique batch ID number for food safety traceability and comply with 3A and EHEDG regulation.

Ordering ex.: HMF81-LC-M16-L135, HMF81 base and LC-M16-L135 spindle

HMF LC A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HMF LC A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm

L=175 mm H=75 mm

L=215 mm H=95 mm

Adjustable height Min 80 mm – Max 120 mm

Adjustable height Min 100 mm – Max 160 mm

Adjustable height Min 120 mm – Max 200 mm

L=255 mm H=115 mm Adjustable height Min 140 mm – Max 240 mm

L=295 mm H=125 mm Adjustable height Min 160 mm – Max 280 mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment. The extra hygienic levelling feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

HMF50 LC Hygienic machine feet with protected spindle mounting

HMF60 LC Hygienic machine feet with protected spindle mounting

HMF80 LC Hygienic machine feet with protected spindle mounting

HMF100 LC Hygienic machine feet with protected spindle mounting

HMF120 LC Hygienic machine feet with protected spindle mounting

HMF140 LC Hygienic machine feet with protected spindle mounting

HMF61 LC Hygienic machine feet with protected spindle mounting

HMF81 LC Hygienic machine feet with protected spindle mounting

HMF101 LC Hygienic machine feet with protected spindle mounting

HMF121 LC Hygienic machine feet with protected spindle mounting

HMF62 LC Hygienic machine feet with protected spindle mounting

HMF82 LC Hygienic machine feet with protected spindle mounting

HMF102 LC Hygienic machine feet with protected spindle mounting

HMF122 LC Hygienic machine feet with protected spindle mounting

Hygienic stainless solid base feet

HSF Hygienic stainless feet with full threaded spindle mounting

The hygienic stainless solid base feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

The solid stainless steel 1.4301 base plate can be fitted with Blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HSF78-M16L150-R, rubber pad height 4mm

Ordering ex.: HSF79-M16-L150-R, HSF79 base and M16-L150-M10 spindle and RPB78 rubber pad

HSF A2-70 spindle threads (M): M10, M12, M16, M20, M24, M30, M36, M42 and M48

HSF A2-70 Spindle length (L): 50mm, 70mm, 100mm, 120mm, 150mm, 180mm, 200mm, 230mm, 280mm and 330mm

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

The hygienic stainless levelling feet are easy to clean and are approved by the food processing industry.

This high load capacity model has a smooth rounded design for ease cleaning

HSF38 Hygienic stainless feet with full threaded spindle mounting

HSF38 Hygienic stainless feet with full threaded spindle mounting

HSF58 Hygienic stainless feet with full threaded spindle mounting

HSF58 Hygienic stainless feet with full threaded spindle mounting

HSF78 Hygienic stainless feet with full threaded spindle mounting

HSF78 Hygienic stainless feet with full threaded spindle mounting

HSF98 Hygienic stainless feet with full threaded spindle mounting

HSF98 Hygienic stainless feet with full threaded spindle mounting

HSF118 Hygienic stainless feet with full threaded spindle mounting

HSF118 Hygienic stainless feet with full threaded spindle mounting

HSF138 Hygienic stainless feet with full threaded spindle mounting

HSF138 Hygienic stainless feet with full threaded spindle mounting

HSF158 Hygienic stainless feet with full threaded spindle mounting

HSF158 Hygienic stainless feet with full threaded spindle mounting

HSF178 Hygienic stainless feet with full threaded spindle mounting

HSF178 Hygienic stainless feet with full threaded spindle mounting

HSF79 Hygienic stainless feet with full threaded spindle mounting

HSF79 Hygienic stainless feet with full threaded spindle mounting

HSF99 Hygienic stainless feet with full threaded spindle mounting

HSF99 Hygienic stainless feet with full threaded spindle mounting

HSF119 Hygienic stainless feet with full threaded spindle mounting

HSF119 Hygienic stainless feet with full threaded spindle mounting

HSF139 Hygienic stainless feet with full threaded spindle mounting

HSF139 Hygienic stainless feet with full threaded spindle mounting

HSF159 Hygienic stainless feet with full threaded spindle mounting

HSF159 Hygienic stainless feet with full threaded spindle mounting

HSF179 Hygienic stainless feet with full threaded spindle mounting

HSF179 Hygienic stainless feet with full threaded spindle mounting

HSF LC Hygienic stainless solid base feet with protected spindle

The spindles are smooth at the end towards the base and the sleeve covers the thread. These features ensure easy cleaning and protect the threads. The sleeve functions as a nut.

The solid stainless steel 1.4301 base plate can be fitted with Blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HSF78-LCM16-L140-R, rubber pad height 4mm

Ordering ex.: HSF79-LC-M16-L135-R, HSF79 base and LC-M16-L135-M10 spindle and RPB78 rubber pad

HSF LC A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30 and M36

HSF LC A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm

L=175 mm H=75 mm

L=215 mm H=95 mm

L=255 mm H=115 mm

L=295 mm H=125 mm

Adjustable height Min 80 mm – Max 120 mm

Adjustable height Min 100 mm – Max 160 mm

Adjustable height Min 120 mm – Max 200 mm

Adjustable height Min 140 mm – Max 240 mm

Adjustable height Min 160 mm – Max 280 mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

The joint, where the hygienic stainless base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

The extra hygienic stainless solid base feet have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

The design of the HSF LC levelling system reduces the cleaning cost and effort to an absolute minimum.

HSF38 LC Hygienic stainless feet with protected spindle mounting

HSF58 LC Hygienic stainless feet with protected spindle mounting

HSF78 LC Hygienic stainless feet with protected spindle mounting

HSF98 LC Hygienic stainless feet with protected spindle mounting

HSF118 LC Hygienic stainless feet with protected spindle mounting

HSF138 LC Hygienic stainless feet with protected spindle mounting

HSF158 LC Hygienic stainless feet with protected spindle mounting

HSF178 LC Hygienic stainless feet with protected spindle mounting

HSF79 LC Hygienic stainless feet with protected spindle mounting

HSF99

LC Hygienic stainless feet with protected spindle mounting

HSF119 LC

Hygienic stainless feet with protected spindle mounting

HSF139 LC Hygienic stainless feet with protected spindle mounting

HSF159 LC

Hygienic stainless feet with protected spindle mounting

HSF179 LC Hygienic stainless feet with protected spindle mounting

Hygienic adjustable solid base feet

HAF Hygienic adjustable feet with full threaded spindle

The hygienic adjustable solid base feet in blue anti-bacterial POM have a solid rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

The solid blue anti-bacterial POM base plate can be fitted with Blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HAF78M16-L150-R, rubber pad height 4mm

Ordering ex.: HAF79-M16-L150-R, HSF79 base and M16-L150-M10 spindle and RPB78 rubber pad

HAF A2-70 spindle threads (M): M10, M12, M16, M20, M24, M30 and M36

HAF A2-70 Spindle length (L): 50mm, 70mm, 100mm, 120mm, 150mm, 180mm, 200mm, 230mm, 280mm and 330mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

The joint, where the solid blue anti-bacterial POM base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

The hygienic stainless levelling feet are easy to clean and are approved by the food processing industry.

HAF38 Hygienic adjustable feet with full threaded spindle mounting

HAF38 Hygienic adjustable feet with full threaded spindle mounting

HAF58 Hygienic adjustable feet with full threaded spindle mounting

HAF58 Hygienic adjustable feet with full threaded spindle mounting

HAF78 Hygienic adjustable feet with full threaded spindle mounting

HAF78 Hygienic adjustable feet with full threaded spindle mounting

HAF98 Hygienic adjustable feet with full threaded spindle mounting

HAF98 Hygienic adjustable feet with full threaded spindle mounting

HAF118 Hygienic adjustable feet with full threaded spindle mounting

HAF118 Hygienic adjustable feet with full threaded spindle mounting

HAF138 Hygienic adjustable feet with full threaded spindle mounting

HAF138 Hygienic adjustable feet with full threaded spindle mounting

HAF79 Hygienic adjustable feet with full threaded spindle mounting

HAF79 Hygienic adjustable feet with full threaded spindle mounting

HAF99 Hygienic adjustable feet with full threaded spindle mounting

HAF99 Hygienic adjustable feet with full threaded spindle mounting

HAF119 Hygienic adjustable feet with full threaded spindle mounting

HAF119 Hygienic adjustable feet with full threaded spindle mounting

HAF139 Hygienic adjustable feet with full threaded spindle mounting

HAF139 Hygienic adjustable feet with full threaded spindle mounting

HAF LC Hygienic adjustable solid base feet with protected spindle

The spindles are smooth at the end towards the base and the sleeve covers the thread. These features ensure easy cleaning and protect the threads. The sleeve functions as a nut.

The solid blue anti-bacterial POM base plate can be fitted with Blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad, for rubber pad, suffix "R" is added to numbers. ex.: HAF78LC-M16-L135-R, rubber pad height 4mm

Ordering ex.: HAF79-LC-M16-L135-R, HSF79 base and LC-M16-L135-M10 spindle and RPB78 rubber pad

HAF LC A2-70 spindle and sleeve threads (M): M12, M16, M20, M24, M30, M36, M42 and M48

HAF LC A2-70 Spindle (L) and Sleeve (H) Length

L=135 mm H=55 mm

L=175 mm H=75 mm

Adjustable height Min 80 mm – Max 120 mm

Adjustable height Min 100 mm – Max 160 mm

L=215 mm H=95 mm Adjustable height Min 120 mm – Max 200 mm

L=255 mm H=115 mm Adjustable height Min 140 mm – Max 240 mm

L=295 mm H=125 mm Adjustable height Min 160 mm – Max 280 mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

The joint, where the solid blue anti-bacterial POM base plate and A2-70 spindles are assembled, can cope with up to 10 degree slopes on floors and equipment.

The extra hygienic adjustable solid base feet in blue anti-bacterial POM have a solid rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

The design of the HAF LC system reduces the cleaning cost and effort to an absolute minimum.

HAF38 LC Hygienic adjustable feet with protected spindle mounting

HAF58 LC Hygienic adjustable feet with protected spindle mounting

HAF78 LC Hygienic adjustable feet with protected spindle mounting

HAF98 LC Hygienic adjustable feet with protected spindle mounting

HAF118 LC Hygienic adjustable feet with protected spindle mounting

HAF138 LC Hygienic adjustable feet with protected spindle mounting

HAF79 LC

Hygienic adjustable feet with protected spindle mounting

HAF99 LC Hygienic adjustable feet with protected spindle mounting

HAF119 LC Hygienic adjustable feet with protected spindle mounting

HAF139 LC Hygienic adjustable feet with protected spindle mounting

Plastic fully-threaded levelling feet

PFB Blue base levelling feet with full threaded stainless spindle

The blue base levelling feet in have a rounded and hygienic design which makes it easy to clean and suitable for demanding sanitary applications.

blue base

blue base with fixation

The REACH and RoHS certified blue PA6+30%GF base plate are fitted with anti-slip blue rubber pad

The blue anti-bacterial base plate are fitted with blue NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad

Ordering ex.: PFB79-M16-L150, PFB79 base and M16-L150-B15 spindle

PFB A2-70 spindle threads (M): M8, M10, M12, M16, M20 and M24

PFB A2-70 spindle length (L): 50mm, 70mm, 100mm, 120mm, 150mm, 180mm and 200mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request The thread can also be customized according to specific request, ex trapezoid thread etc.

The joint, where the blue base plate and A2-70 spindles are assembled, can cope with up to 15 degree slopes on floors and equipment.

The blue PA6+30%GF base plate feet are easy to clean and are approved by the food processing industry.

PFB38 Blue base levelling feet with full threaded stainless spindle

PFB48 Blue base levelling feet with full threaded stainless spindle

PFB58 Blue base levelling feet with full threaded stainless spindle

PFB78 Blue base levelling feet with full threaded stainless spindle

PFB98

Blue base levelling feet with full threaded stainless spindle

PFB79

Blue base levelling feet with full threaded stainless spindle

PFB99 Blue

base levelling feet with full threaded stainless spindle

PFB125 Blue

base levelling feet with full threaded stainless spindle

PF BZP Black base levelling feet with full threaded galvanized spindle

The black base levelling feet in have a rounded and hygienic design which makes it easy to clean and suitable for dry applications.

PF black base

PF black base with fixation

The REACH and RoHS certified black PA6+30%GF base plate are fitted with anti-slip black rubber pad

The black anti-bacterial base plate are fitted with black NBR FDA certified (FDA CFR 21 177 2600) anti-slip rubber pad

Ordering ex.: PF79-M16-L150-B15-BZP, PF79 base and M16-L150-B15-BZP spindle

PF BZP (bright zinc plated) spindle threads (M): M8, M10, M12, M16, M20 and M24

PF BZP (bright zinc plated) spindle length (L): 50mm, 70mm, 100mm, 120mm, 150mm, 180mm and 200mm

For other threaded spindle length (L), please contact us Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

The joint, where the black base plate and galvanized spindles are assembled, can cope with up to 15 degree slopes on floors and equipment.

The black PA6+30%GF base plate feet are easy to clean and are approved by the food packaging industry.

PF38 BZP Black base levelling feet with full threaded galvanized spindle

PF48 BZP Black base levelling feet with full threaded galvanized spindle

PF58 BZP Black base levelling feet with full threaded galvanized spindle

PF78 BZP Black base levelling feet with full threaded galvanized spindle

PF98 BZP Black base levelling feet with full threaded galvanized spindle

PF79 BZP Black base levelling feet with full threaded galvanized spindle

PF99 BZP Black base levelling feet with full threaded galvanized spindle

PF125 BZP Black base levelling feet with full threaded galvanized spindle

Stainless threaded bushings and welding plates

Welding plate for square tubes - Stainless steel 304 (Aisi 1.4301)

Square Welding Plate - Stainless steel 304 (Aisi 1.4301)

Threads M10 M12 M16 M20 M24

Plate size A x B

30 x 30 mm 3mm 3mm

Plate thickness

35 x 35 mm 3mm 3mm 3mm 40 x 40 mm

x 70 mm

80 x 80 mm 4mm 4mm

100 x 100 mm 4mm 4mm 4mm 4mm 4mm For other size, please contact us

Welding plate for rectangular tubes - Stainless steel 304 (Aisi 1.4301)

Rectangular Welding Plate - Stainless steel 304 (Aisi 1.4301)

Threads M10 M12 M16 M20 M24

Plate size A x B

50 x 30 mm 3mm 3mm

Plate thickness

60 x 30 mm 3mm 3mm

60 x 40 mm 3mm 3mm 3mm 3mm

80 x 40 mm 3mm 3mm 3mm 3mm

x

x

x 60 mm 4mm 4mm 4mm 4mm 4mm

100 x 80 mm 4mm 4mm 4mm 4mm 4mm

For other size, please contact us

Welding plate for round tubes - Stainless steel 304 (Aisi 1.4301)

Round Welding Plate - Stainless steel 304 (Aisi 1.4301)

Threads M10 M12 M16 M20 M24

Plate diameter OD

OD 30 mm 3mm 3mm

Plate thickness

OD 33 mm 3mm 3mm

OD 38 mm 3mm 3mm 3mm

OD 40 mm 3mm 3mm 3mm 3mm

OD 43 mm 3mm 3mm 3mm 3mm

OD 48 mm 4mm 4mm 4mm 4mm 4mm

OD 50 mm 4mm 4mm 4mm 4mm 4mm

OD 60 mm 4mm 4mm 4mm 4mm 4mm

OD 80 mm 4mm 4mm 4mm 4mm 4mm

For other size, please contact us

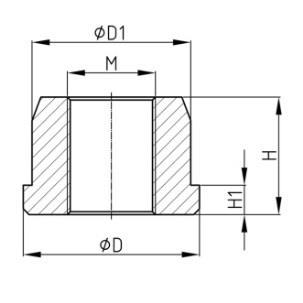

Stainless threaded tube bushings for welding

Stainless steel threaded tube bushings are integral in welding for pharmaceutical, food and beverage, chemical industries, as well as dairies and butcheries. These bushings ensure hygienic and secure connections, vital in these sectors where contamination control is crucial. Their corrosion-resistant nature and ability to withstand frequent cleaning and varying temperatures make them ideal for these environments. The precision threading offers a tight seal, maintaining the integrity of delicate processes. These bushings support the rigorous demands of these industries, ensuring durability and reliability in systems where hygiene, safety, and product quality are of utmost importance.

Stainless threaded tube bushings for welding (Aisi 1.4301)

TI 80x45 M30 80 75 45 10 M30x3.5

TI 80x45 M42 80 75 45 10 M42x4.5

TI 80x45 M48 80 75 45 10 M48x5.0

For other size, please contact us

Threaded plastic bushings with brass inserts

Threaded plastic bushings for square tubes

Threaded plastic bushings for square tubes

Thread diameter 10 mm 12 mm 16 mm 20 mm 24 mm

Insert size A x B Internal square size

25 x 25 mm X X

30 x 30 mm X X X

35 x 35 mm X X X X

40 x 40 mm X X X X X

50 x 50 mm X X X X

60 x 60 mm X X X

Please specify tube wall thickness when ordering 1.5mm, 2.0mm, 2.5mm or 3.0mm

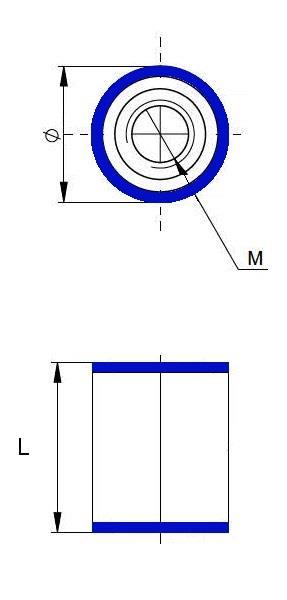

Threaded plastic bushings for round tubes

Threaded plastic bushings for round tubes

Thread diameter 10 mm 12 mm 16 mm 20 mm 24 mm

Insert diameter OD Internal diameter

OD 30 mm X X X

OD 38 mm X X X

OD 42.4 mm X X X X

OD 48.3 mm X X X X

OD 50.9 mm X X X X

OD 60.3 mm X X X

Please specify tube wall thickness when ordering1.5mm, 2.0mm, 2.5mm or 3.0mm

Material: polyamide reinforced with fiberglass.

Threaded insert in brass

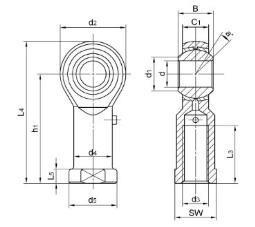

Tripod and Bipod

Bipod Specification:

2SB482 Tube ID 48.2mm

2SB509 Tube ID 50.9mm

2SB603 Tube ID 60.3mm

Tripod Specification:

3SB482 Tube ID 48.2mm

3SB509 Tube ID 50.9mm

3SB603 Tube ID 60.3mm

Outer diameter 500mm

Material: reinforced polyamide

Colour: Black

Bolt and nut in stainless steel A2-70

Brass insert in M12 or M16

For other sizes and types, please contact us

EHEDG Hygienic 3A conveyor parts in stainless steel

The food processing industry is a highly regulated sector that requires strict adherence to safety and sanitation standards. One of the key components in ensuring food safety is the use of conveyor parts in hygienic stainless steel design. These parts are designed to prevent contamination and ensure the safe transport of food products.

Enhancing Food Safety with EHEDG and 3A Hygienic Stainless Steel Conveyor Parts

EHEDG is a globally recognized organization dedicated to promoting hygienic design and engineering principles in the food, beverage, and pharmaceutical industries. It works collaboratively with industry experts to develop guidelines and standards that ensure equipment, including conveyor systems, is designed and manufactured to prevent contamination and facilitate thorough cleaning.

When it comes to hygienic conveyor parts, EHEDG certification is a hallmark of excellence. EHEDGcertified components are meticulously tested for resistance to corrosion, ease of cleaning, and compatibility with food processing environments.

Similar to EHEDG, the 3A Sanitary Standards organization is committed to advancing food safety through rigorous equipment standards. 3A certification specifically focuses on hygienic design criteria for dairy and food processing equipment, including stainless steel conveyor parts.

EHEDG Hygienic 3A spacer nut in stainless steel

3A Spacer nut

The spacer nut with blue sealing. These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

3A SN M5-L10 Ø12

3A SN M5-L20 Ø12

3A SN M5-L30 Ø12

3A SN M6-L10 Ø12

3A SN M6-L20 Ø12

3A SN M6-L30 Ø12

3A SN M8-L10 Ø15

3A SN M8-L20 Ø15

3A SN M8-L30 Ø15

3A SN M10-L10 Ø18

3A SN M10-L20 Ø18

3A SN M10-L30 Ø18

3A SN M12-L10 Ø22

3A SN M12-L20 Ø22

3A SN M12-L30 Ø22

3A SN M16-L10 Ø28

3A SN M16-L20 Ø28

3A SN M16-L30 Ø28

3A SN M20-L10 Ø32

3A SN M20-L20 Ø32

3A SN M20-L30 Ø32

3A SN M24-L20 Ø40

3A SN M24-L30 Ø40

3A SN M24-L40 Ø40

3A SN M30-L20 Ø46

3A SN M30-L30 Ø46

3A SN M30-L40 Ø46

EHEDG Hygienic 3A spacer nut welded in stainless steel

The spacer nut for welding with blue sealing. These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

3A spacer nut welded

3A SNW M5-L10 Ø12

3A SNW M5-L20 Ø12

3A SNW M5-L30 Ø12

3A SNW M6-L10 Ø12

3A SNW M6-L20 Ø12

3A SNW M6-L30 Ø12

3A SNW M8-L10 Ø15

3A SNW M8-L20 Ø15

3A SNW M8-L30 Ø15

3A SNW M10-L10 Ø18

3A SNW M10-L20 Ø18

3A SNW M10-L30 Ø18

3A SNW M12-L10 Ø22

3A SNW M12-L20 Ø22

3A SNW M12-L30 Ø22

3A SNW M16-L10 Ø28

3A SNW M16-L20 Ø28

3A SNW M16-L30 Ø28

3A SNW M20-L10 Ø32

3A SNW M20-L20 Ø32

3A SNW M20-L30 Ø32

3A SNW M24-L20 Ø40

3A SNW M24-L30 Ø40

3A SNW M24-L40 Ø40

3A SNW M30-L20 Ø46

3A SNW M30-L30 Ø46

3A SNW M30-L40 Ø46

EHEDG Hygienic 3A spacer in stainless steel

3A Spacer

The spacer with blue sealing. These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

3A S IØ5-L10 Ø12

3A S IØ5-L20 Ø12

3A S IØ5-L30 Ø12

3A S IØ6-L10 Ø12

3A S IØ6-L20 Ø12

3A S IØ6-L30 Ø12

3A S IØ8-L10 Ø15

3A S IØ8-L20 Ø15

3A S IØ8-L30 Ø15

3A S IØ10-L10 Ø18

3A S IØ10-L20 Ø18

3A S IØ10-L30 Ø18

3A S IØ12-L10 Ø22

3A S IØ12-L20 Ø22

3A S IØ12-L30 Ø22

3A S IØ16-L10 Ø28

3A S IØ16-L20 Ø28

3A S IØ16-L30 Ø28

3A S IØ20-L10 Ø32

3A S IØ20-L20 Ø32

3A S IØ20-L30 Ø32

3A S IØ24-L20 Ø40

3A S IØ24-L30 Ø40

3A S IØ24-L40 Ø40

3A S IØ30-L20 Ø46

3A S IØ30-L30 Ø46

3A S IØ30-L40 Ø46

EHEDG Hygienic 3A welded spacer in stainless steel

The welded spacer with blue sealing. These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

3A Spacer welded

3A SW IØ5-L10 Ø12

3A SW IØ5-L20 Ø12

3A SW IØ5-L30 Ø12

3A SW IØ6-L10 Ø12

3A SW IØ6-L20 Ø12

3A SW IØ6-L30 Ø12

3A SW IØ8-L10 Ø15

3A SW IØ8-L20 Ø15

3A SW IØ8-L30 Ø15

3A SW IØ10-L10 Ø18

3A SW IØ10-L20 Ø18

3A SW IØ10-L30 Ø18

3A SW IØ12-L10 Ø22

3A SW IØ12-L20 Ø22

3A SW IØ12-L30 Ø22

3A SW IØ16-L10 Ø28

3A SW IØ16-L20 Ø28

3A SW IØ16-L30 Ø28

3A SW IØ20-L10 Ø32

3A SW IØ20-L20 Ø32

3A SW IØ20-L30 Ø32

3A SW IØ24-L20 Ø40

3A SW IØ24-L30 Ø40

3A SW IØ24-L40 Ø40

3A SW IØ30-L20 Ø46

3A SW IØ30-L30 Ø46

3A SW IØ30-L40 Ø46

EHEDG Hygienic 3A corner nut in stainless steel

3A Corner nut

The corner nut with blue sealing. These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

3A CN M5-L15 Ø12

3A CN M5-L25 Ø12

3A CN M6-L15 Ø12

3A CN M6-L25 Ø12

3A CN M8-L15 Ø15

3A CN M8-L25 Ø15

3A CN M10-L20 Ø18

3A CN M10-L30 Ø18

3A CN M12-L20 Ø22

3A CN M12-L30 Ø22

3A CN M16-L30 Ø28

3A CN M16-L40 Ø28

3A CN M20-L30 Ø32

3A CN M20-L40 Ø32

3A CN M24-L40 Ø40

3A CN M24-L50 Ø40

3A CN M30-L40 Ø46

3A CN M30-L50 Ø46

EHEDG 3A Hygienic nut in stainless steel

The hygienic nuts with blue sealing. The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly. The nuts have self-draining surfaces with a maximal roughness of 0.8 pm Ra. The design of the nuts does not deviate from the sizes of current standard nuts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard nuts. This is the right choice of nuts to be used on all machinery in all certified hygienic wash-down environments.

3A Hygienic nut

3A HN M5-L12 Ø12

3A HN M5-L18 Ø12

3A HN M6-L12 Ø12

3A HN M6-L18 Ø12

3A HN M8-L14 Ø15

3A HN M8-L21 Ø15

3A HN M10-L16 Ø18

3A HN M10-L24 Ø18

3A HN M12-L18 Ø22

3A HN M12-L27 Ø22

3A HN M16-L20 Ø28

3A HN M16-L30 Ø28

3A HN M20-L22 Ø32

3A HN M20-L33 Ø32

3A HN M24-L24 Ø40

3A HN M24-L36 Ø40

3A HN M30-L26 Ø46

3A HN M30-L39 Ø46

EHEDG 3A Hygienic bolt M5 to M8 in stainless steel

The hygienic bolts with blue sealing. The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly. The bolts have self-draining surfaces with a maximal roughness of 0.8 pm Ra. The design of the bolts does not deviate from the sizes of current standard bolts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard bolts. This is the right choice of bolts to be used on all machinery in all certified hygienic wash-down environments.

3A Hygienic bolt

3A HB M5-L10 Ø12 H=12

3A HB M5-L12 Ø12 H=12

3A HB M5-L16 Ø12 H=12

3A HB M5-L20 Ø12 H=12

3A HB M5-L25 Ø12 H=12

3A HB M5-L30 Ø12 H=12

3A HB M5-L35 Ø12 H=12

3A HB M6-L10 Ø12 H=12

3A HB M6-L12 Ø12 H=12

3A HB M6-L16 Ø12 H=12

3A HB M6-L20 Ø12 H=12

3A HB M6-L25 Ø12 H=12

3A HB M6-L30 Ø12 H=12

3A HB M6-L35 Ø12 H=12

3A HB M6-L40 Ø12 H=12

3A HB M6-L50 Ø12 H=12

3A HB M6-L60 Ø12 H=12

3A HB M6-L80 Ø12 H=12

3A HB M6-L100 Ø12 H=12

3A HB M8-L10 Ø15 H=14

3A HB M8-L12 Ø15 H=14

3A HB M8-L16 Ø15 H=14

3A HB M8-L20 Ø15 H=14

3A HB M8-L25 Ø15 H=14

3A HB M8-L30 Ø15 H=14

3A HB M8-L35 Ø15 H=14

3A HB M8-L40 Ø15 H=14

3A HB M8-L50 Ø15 H=14

3A HB M8-L60 Ø15 H=14

3A HB M8-L80 Ø15 H=14

3A HB M8-L100 Ø15 H=14

EHEDG 3A Hygienic bolt M10 and M16 in stainless steel

The hygienic bolts with blue sealing. The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly. The bolts have self-draining surfaces with a maximal roughness of 0.8 pm Ra. The design of the bolts does not deviate from the sizes of current standard bolts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard bolts. This is the right choice of bolts to be used on all machinery in all certified hygienic wash-down environments.

3A Hygienic bolt

3A HB M10-L10 Ø18 H=16

3A HB M10-L12 Ø18 H=16

3A HB M10-L16 Ø18 H=16

3A HB M10-L20 Ø18 H=16

3A HB M10-L25 Ø18 H=16

3A HB M10-L30 Ø18 H=16

3A HB M10-L35 Ø18 H=16

3A HB M10-L40 Ø18 H=16

3A HB M10-L50 Ø18 H=16

3A HB M10-L60 Ø18 H=16

3A HB M10-L80 Ø18 H=16

3A HB M10-L100 Ø18 H=16

3A HB M12-L12 Ø22 H=18

3A HB M12-L16 Ø22 H=18

3A HB M12-L20 Ø22 H=18

3A HB M12-L25 Ø22 H=18

3A HB M12-L30 Ø22 H=18

3A HB M12-L35 Ø22 H=18

3A HB M12-L40 Ø22 H=18

3A HB M12-L50 Ø22 H=18

3A HB M12-L60 Ø22 H=18

3A HB M12-L80 Ø22 H=18

3A HB M12-L100 Ø22 H=18

3A HB M12-L120 Ø22 H=18

3A HB M16-L16 Ø28 H=20

3A HB M16-L20 Ø28 H=20

3A HB M16-L25 Ø28 H=20

3A HB M16-L30 Ø28 H=20

3A HB M16-L35 Ø28 H=20

3A HB M16-L40 Ø28 H=20

3A HB M16-L50 Ø28 H=20

3A HB M16-L60 Ø28 H=20

3A HB M16-L80 Ø28 H=20

3A HB M16-L100 Ø28 H=20

3A HB M16-L120 Ø28 H=20

3A HB M16-L150 Ø28 H=20

EHEDG 3A Hygienic bolt M20 and M30 in stainless steel

The hygienic bolts with blue sealing. The seal blocks out water and bacteria and also prevents a non-hygienic metal-to-metal assembly. The bolts have self-draining surfaces with a maximal roughness of 0.8 pm Ra. The design of the bolts does not deviate from the sizes of current standard bolts. Therefore, wrench sizes, thread heights etc. all remains the same making it very easy to upgrade and replace standard bolts. This is the right choice of bolts to be used on all machinery in all certified hygienic wash-down environments.

3A Hygienic bolt

3A HB M20-L20 Ø32 H=22

3A HB M20-L25 Ø32 H=22

3A HB M20-L30 Ø32 H=22

3A HB M20-L35 Ø32 H=22

3A HB M20-L40 Ø32 H=22

3A HB M20-L50 Ø32 H=22

3A HB M20-L60 Ø32 H=22

3A HB M20-L80 Ø32 H=22

3A HB M20-L100 Ø32 H=22

3A HB M20-L120 Ø32 H=22

3A HB M20-L150 Ø32 H=22

3A HB M24-L25 Ø40 H=24

3A HB M24-L30 Ø40 H=24

3A HB M24-L35 Ø40 H=24

3A HB M24-L40 Ø40 H=24

3A HB M24-L50 Ø40 H=24

3A HB M24-L60 Ø40 H=24

3A HB M24-L80 Ø40 H=24

3A HB M24-L100 Ø40 H=24

3A HB M24-L120 Ø40 H=24

3A HB M24-L150 Ø40 H=24

3A HB M30-L30 Ø46 H=26

3A HB M30-L35 Ø46 H=26

3A HB M30-L40 Ø46 H=26

3A HB M30-L50 Ø46 H=26

3A HB M30-L60 Ø46 H=26

3A HB M30-L80 Ø46 H=26

3A HB M30-L100 Ø46 H=26

3A HB M30-L120 Ø46 H=26

3A HB M30-L150 Ø46 H=26

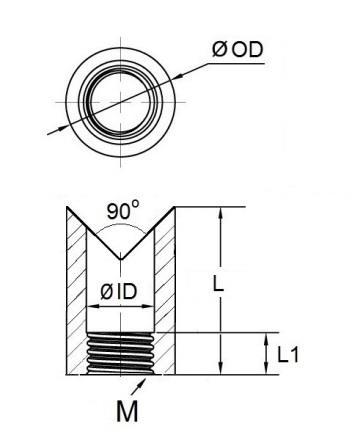

Hygienic corner nut and spacer in stainless steel

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 - ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-25 - ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 - ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 - ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 - ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 - ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 - ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 - ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Corner spacer 6.8-16-15 - ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 - ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 - ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 - ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 - ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 - ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 - ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 - ID=14.0 – OD=26.0 – L=25

Spacer nut in stainless steel (Aisi 1.4301)

Spacer nut M8-16-9 - ID=8.2 – OD=16.0 – L=9 – L1=6

Spacer nut M8-16-18 - ID=8.2 – OD=16.0 – L=18 – L1=12

Spacer nut M10-18-9 - ID=10.2 – OD=18.0 – L=9 – L1=6

Spacer nut M10-18-18 - ID=10.2 – OD=18.0 – L=18 – L1=12

Spacer nut M12-22-9 - ID=12.2 – OD=22.0 – L=9 – L1=6

Spacer nut M12-22-18 - ID=12.2 – OD=22.0 – L=18 – L1=12

Spacer nut M16-26-9 - ID=16.2 – OD=26.0 – L=9 – L1=6

Spacer nut M16-26-18 - ID=16.2 – OD=26.0 – L=18 – L1=12

Spacer in stainless steel (Aisi 1.4301)

Spacer blank 8-16-9 - ID=8.2 – OD=16.0 – L=9

Spacer blank 8-16-18 - ID=8.2 – OD=16.0 – L=18

Spacer blank 10-18-9 - ID=10.2 – OD=18.0 – L=9

Spacer blank 10-18-18 - ID=10.2 – OD=18.0 – L=18

Spacer blank 12-22-9 - ID=12.2 – OD=22.0 – L=9

Spacer blank 12-22-18 - ID=12.2 – OD=22.0 – L=18

Spacer blank 16-26-9 - ID=16.2 – OD=26.0 – L=9

Spacer blank 16-26-18 - ID=16.2 – OD=26.0 – L=18

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: Medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A designmeat & poultry processing equipment, dairy processing machines

EHEDG enclosures parts

Enclosures parts with blue sealing. These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

The seal blocks out water and bacteria and prevents a non-hygienic metal-to-metal assembly.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Hygienic lock SUS304 IP67 3A H=24

Hygienic lock SUS304 IP67 3A H=28

Hygienic lock SUS304 IP67 3A H=32

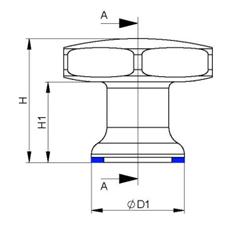

Hygienic Star Knob 3A M6-24

Hygienic Star Knob 3A M6-30

Hygienic Star Knob 3A M8-36

Hygienic Star Knob 3A M10-46

Hygienic Star Knob 3A M12-60

Hygienic Handle 3A M6-CC88

Hygienic Handle 3A M6-CC100

Hygienic Handle 3A M6-CC120

Hygienic Handle 3A M6-CC160

Key for hygienic lock

Enclosures parts

These accessories are the optimal choice for equipment that must comply with strict hygiene requirements.

Self-draining surfaces with a maximal roughness of 0.8 µm Ra.

Hygienic lock SUS304 IP67 H=24

Hygienic lock SUS304 IP67 H=28

Hygienic lock SUS304 IP67 H=32

Hinge 40x40mm 1.4404 / Aisi316

Hinge 50x50mm 1.4404 / Aisi316

Hinge 60x60mm 1.4404 / Aisi316

Hygienic Star Knob M6-24

Hygienic Star Knob M6-30

Hygienic Star Knob M8-36

Hygienic Star Knob M10-46

Hygienic Star Knob M12-60

Hygienic Handle M6-CC88

Hygienic Handle M6-CC100

Hygienic Handle M6-CC120

Hygienic Handle M6-CC180

Key for hygienic lock

Side guide with stainless steel brackets in hygienic design

For hygienic side guide and conveyor parts, please contact us, all is made according to costumer design

Our side guide series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: Medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines

Side guide in stainless steel

Side guide SG bracket in Stainless steel 304 (Aisi 1.4301), eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301), knob in polyamide with brass insert.

Side guide SG SW swivel bracket in Stainless steel 304 (Aisi 1.4301), eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301), knob in polyamide with brass insert.

Hygienic spacer for side guide

Hygienic spacer 10mm

Hygienic spacer 20mm

Hygienic spacer 30mm

Hygienic side guide in stainless steel

Side guide HSG bracket in Stainless steel 304 (Aisi 1.4301), eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301), stainless steel hygienic nut.

Side guide HSG SW swivel bracket in Stainless steel 304 (Aisi 1.4301), eyebolt and washer in stainless steel AISI 304 (Aisi 1.4301), stainless steel hygienic nut.

Hygienic spacer for side guide

Hygienic spacer 10mm

Hygienic spacer 20mm

Hygienic spacer 30mm

Side guide in reinforced polyamide

Side guide PSG150 bracket in reinforced polyamide, eyebolt and washer in stainless steel AISI 304, knob in polyamide with insert.

Side guide PSG177 bracket in reinforced polyamide, eyebolt and washer in stainless steel AISI 304, knob in polyamide with insert.

Single clamps for conical side guide rails with stainless steel rod

Clamp in polyamide with stainless steel A2-70 screw Rod in stainless steel AISI 304 (Aisi 1.4301)

Single clamps for conical side guide rails types

SCC 12-L100

SCC 12-L150

SCC 12-L200

SCC 12-L250

Single

clamp long for conical side guide rails

Clamp in polyamide with stainless steel A2-70 screw Rod in stainless steel AISI 304 (Aisi 1.4301)

Single clamp long for conical side guide rails types

SLCC 12-L100

SLCC 12-L150

SLCC 12-L200

SLCC 12-L250

Double clamps for conical side guide rails with stainless steel rod

Clamp in polyamide with stainless steel A2-70 screw Rod in stainless steel AISI 304 (Aisi 1.4301)

Double clamps for conical side guide rails types

Guide rail distance 40

DCC 12-40-L100

DCC 12-40-L150

DCC 12-40-L200

DCC 12-40-L250

Guide rail distance 66

DCC 12-66-L100

DCC 12-66-L150

DCC 12-66-L200

DCC 12-66-L250

Single clamps for round side guide rails with stainless steel rod

Clamp in polyamide with stainless steel A2-70 screw Rod in stainless steel AISI 304 (Aisi 1.4301)

Single clamps for round side guide rails types

SCR 12-L100

SCR 12-L150

SCR 12-L200

SCR 12-L250

Single clamp long for round side guide rails

Clamp in polyamide with stainless steel A2-70 screw Rod in stainless steel AISI 304 (Aisi 1.4301)

Single clamp long for round side guide rails types

SLCR 12-L100

SLCR 12-L150

SLCR 12-L200

SLCR 12-L250

Double clamps for round side guide rails with stainless steel rod

Clamp in polyamide with stainless steel A2-70 screw Rod in stainless steel AISI 304 (Aisi 1.4301)

Double clamps for round side guide rails types

Guide rail distance 40

DCR 12-40-L100

DCR 12-40-L150

DCR 12-40-L200

DCR 12-40-L250

Guide rail distance 66

DCR 12-66-L100

DCR 12-66-L150

DCR 12-66-L200

DCR 12-66-L250

USDA Waterproof bearing units IP67

Our USDA certified IP67 bearing units are designed for industries with continuously heavier demands on the material resistance and a design for easy-to-clean. In order to reduce the risk of bacteria growth, this design is characterized by smooth surfaces and rounded corners.

IP67 bearing units comply with 3A and EHEDG regulation

The protection class is IP67 which ensure that the bearing units can be cleaned high pressure water from all directions. An oil seal ring with a stainless steel spring ensures that water cannot penetrate the housing. The bearings are maintenance free and resistant to all cleaning agents and to most chemicals

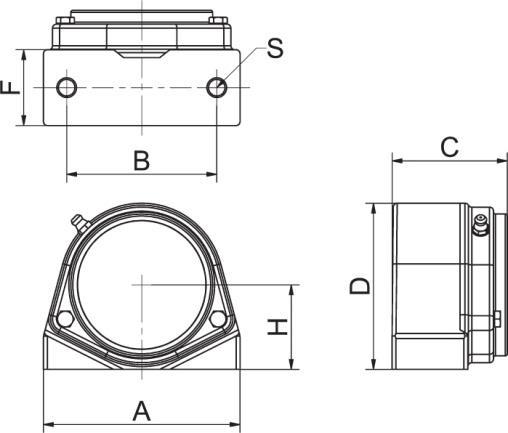

IP67 F-type

IP67 P-type

IP67 FL-type

IP67 PA-type

We are proud to support pro-active food safety by providing food-safe bearing units that are completely sealed, lubricated for life and designed for increased bearing performance, even in the harshest processing and cleaning environments

Features and advantages of our IP67 bearing units:

/// Compact and strong bearing housing base, with the cover bolted to the base

/// Bearing housing is made by Dupolit, which is of extreme stability and strength.

/// Stainless grease nipple for optimal food grade grease filling, preventing condensation in the housing

/// The bearing housing is fitted with a spherical lifetime lubricated ball bearing with eccentric locking collar.

/// The spherical bearing is self-aligning

/// The bearing housing measurements are similar to market standards for easy replacement.

/// The bearing housing can be mounted in all angles

/// The stainless spherical insert bearings for an easy and precise assembly

/// The bearing housing is heat resistant from -30°C to +100°C

/// The bearing inserts are lubricated with NSF H1 registered grease that meets requirements DIN 51825

/// The bearing units are USDA accepted and meets the NSF/ANSI/3-A 14159-1-2010 standard

/// Food grade according to the framework of regulation (EC) No. 1935/2004

Waterproof 4 hole square flange bearing units with spherical inserts IP67 F-type

The construction permits a misalignment of the bearing, of up to +/-3°

Technical specifications for spherical stainless insert

m (mass); Cr (basic dynamic load, radial); Cor (basic static load, radial)

• FDA food grade according to the framework of regulation 21 CFR 175.300.

• EU approved according to the European Parliament and of the Council Regulation (EC) No. 1935/2004

• The flange bearings are USDA accepted and meets the NSF/ANSI/3-A 14159-1-2010 standard.

Waterproof 2 hole oval flange bearing units with spherical inserts IP67 FL-type

The construction permits a misalignment of the bearing, of up to +/-3°

Technical specifications for spherical stainless insert

(basic

• FDA food grade according to the framework of regulation 21 CFR 175.300.

• EU approved according to the European Parliament and of the Council Regulation (EC) No. 1935/2004

• The flange bearings are USDA accepted and meets the NSF/ANSI/3-A 14159-1-2010 standard.

Waterproof 2 hole pillow block bearing units with spherical inserts IP67 P-type

The construction permits a misalignment of the bearing, of up to +/-3°

All measurements are in millimetres. When ordering please use the catalogue no.

Technical specifications for spherical stainless insert

m (mass); Cr (basic dynamic load, radial); Cor (basic static load, radial)

• FDA food grade according to the framework of regulation 21 CFR 175.300.

• EU approved according to the European Parliament and of the Council Regulation (EC) No. 1935/2004

• The flange bearings are USDA accepted and meets the NSF/ANSI/3-A 14159-1-2010 standard.

Waterproof 2 hole tapped base bearing units with spherical inserts IP67 PA-type

The construction permits a misalignment of the bearing, of up to +/-3°

All measurements are in millimetres. When ordering please use the catalogue no.

Technical specifications for spherical stainless insert

(mass); Cr (basic dynamic load, radial); Cor (basic static load, radial)

• FDA food grade according to the framework of regulation 21 CFR 175.300.

• EU approved according to the European Parliament and of the Council Regulation (EC) No. 1935/2004

• The flange bearings are USDA accepted and meets the NSF/ANSI/3-A 14159-1-2010 standard.

Waterproof 3 hole one side flange bearing units with spherical inserts IP67 FB-type

The construction permits a misalignment of the bearing, of up to +/-3°

All measurements are in millimetres. When ordering please use the catalogue no.

Technical specifications for spherical stainless insert

m (mass); Cr (basic dynamic load, radial); Cor (basic static load, radial)

• FDA food grade according to the framework of regulation 21 CFR 175.300.

• EU approved according to the European Parliament and of the Council Regulation (EC) No. 1935/2004

• The flange bearings are USDA accepted and meets the NSF/ANSI/3-A 14159-1-2010 standard.

Thermo plastic bearing units

For tasks a little less demanding, and for a more economical solution, our product range also covers thermoplastic bearings.

The bearings are characterized by high quality and finish for both the bearing and the bearing housing.

Our thermo plastic bearing units are designed for the food industry and other industries with continuously heavier demands on the material resistance and a design for easy-to-clean.

In order to reduce the risk of bacteria growth, this design is characterized by smooth surfaces and rounded corners.

Features and advantages of our thermo plastic bearing units:

/// Thermoplastic housings in Black, White or Green

/// Stainless bearing inserts AISI 440C

/// Chrome steel bearings 100Cr6

/// Stainless grease nipple AISI 304 M6x1 mm

/// Operating temperature from -30°C to +100°C.

/// Cover material: Polypropylene

/// Oil seal material: NBR Rubber with stainless spring

/// The spherical bearing is self-aligning.

/// The bearing housing measurements are similar to market standards for easy replacement.

/// The bearing housing can be mounted in all angles

/// The stainless spherical insert bearings for an easy and precise assembly

/// The bearing inserts are lubricated with FM222 grease which meet requirements like DIN 51825, Halal, Kosher, etc.

/// Possibility for private label

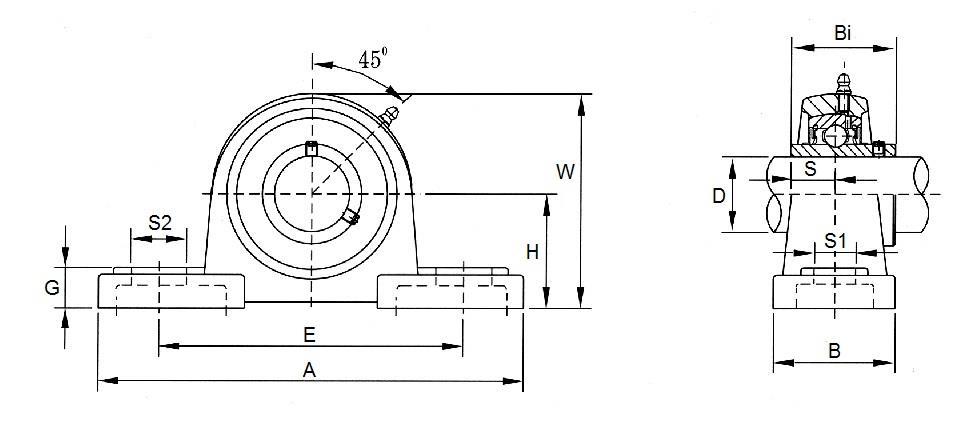

Thermoplastic PPL 2 hole spherical pillow block bearing units

Technical data:

PPL with closed cover

PPL with open cover

/// Stainless steel bearings AISI 440C

/// Chrome steel bearings 100Cr6

/// Stainless steel grease nipple AISI 304 M6x1 mm

/// Operating temperature from -30°C to +100°C.

/// Cover material: Polypropylene

/// Oil seal material: NBR Rubber with stainless spring

Ø60 mm PPL 212 60

Please contact us for more information

Please contact us for more information

All measurements are in millimetres. When ordering please use the catalogue no.

For bearing inserts please see page 70 to 73 For covers and back seal please see page 69

Thermoplastic FPL 4 hole spherical square flange bearing units

Technical data:

FPL with closed cover

FPL with open cover

/// Stainless steel bearings AISI 440C

/// Chrome steel bearings 100Cr6

/// Stainless steel grease nipple AISI 304 M6x1 mm

/// Operating temperature from -30°C to +100°C.

/// Cover material: Polypropylene

/// Oil seal material: NBR Rubber with stainless spring

All measurements are in millimetres. When ordering please use the catalogue no.

For bearing inserts please see page 70 to 73 For covers and back seal please see page 69

Thermoplastic FLPL 2 hole spherical oval flange bearing units

Technical data:

FLPL with closed cover

FLPL with open cover

/// Stainless steel bearings AISI 440C /// Chrome steel bearings 100Cr6

/// Stainless steel grease nipple AISI 304 M6x1 mm

/// Operating temperature from -30°C to +100°C.

/// Cover material: Polypropylene

/// Oil seal material: NBR Rubber with stainless spring

Please

Please contact us for more information

All measurements are in millimetres. When ordering please use the catalogue no. For bearing inserts please see page 70 to 73 For covers and back seal please see page 69

Thermoplastic PAPL 2 hole spherical tapped base pillow block bearing units

Technical data:

PAPL with closed cover

PAPL with open cover

/// Stainless steel bearings AISI 440C

/// Chrome steel bearings 100Cr6

/// Stainless steel grease nipple AISI 304 M6x1 mm

/// Operating temperature from -30°C to +100°C.

/// Cover material: Polypropylene

/// Oil seal material: NBR Rubber with stainless spring

All measurements are in millimetres. When ordering please use the catalogue no.

Tapped Base with Inch thread also available on request For bearing inserts please see page 70 to 73 For covers and back seal please see page 69

Thermoplastic FBPL 3 hole spherical one side flange bearing units

Technical data:

FBPL with closed cover

FBPL with open cover

/// Stainless steel bearings AISI 440C

/// Chrome steel bearings 100Cr6

/// Stainless steel grease nipple AISI 304 M6x1 mm

/// Operating temperature from -30°C to +100°C.

/// Cover material: Polypropylene

/// Oil seal material: NBR Rubber with stainless spring

Ø45

Ø50 mm

Ø55 mm

211 55

Ø60 mm FBPL 212 60

Please contact us for more information

Please contact us for more information

Please contact us for more information

Please contact us for more information

All measurements are in millimetres. When ordering please use the catalogue no.

For bearing inserts please see page 70 to 73 For covers and back seal please see page 69