Celebrating excellence in the glass, window and security screen industries

Celebrating excellence in the glass, window and security screen industries

Imagine a V6 quoting experience built for today’s estimators: faster, smarter, and more accurate than ever to win more projects.

Complete Precision Optimised Speed Intelligent Tools Soft Tech and Darley Aluminium have partnered with estimators to create the most advanced V6 software to date: Darley Designer.

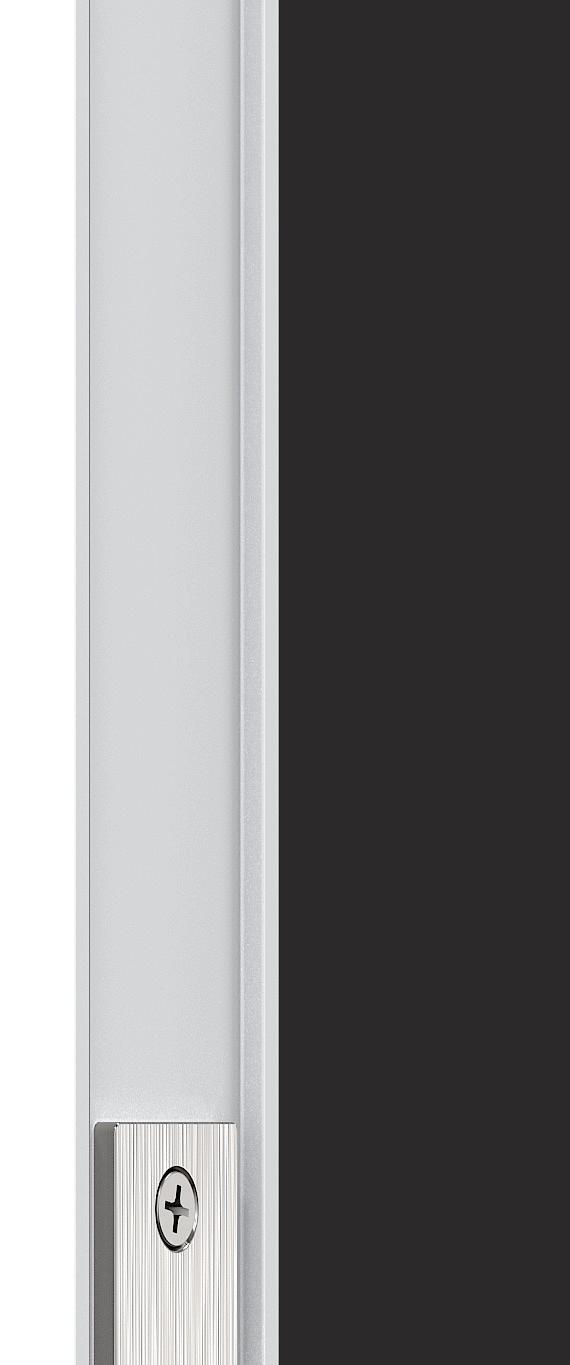

Sleek in design, smooth in operation, the Forge long plate lever and Virtus hinged door mortice lock are a winning combination.

Two- or four-point locking, optional privacy snib, magnetic rod connectors, and 13 or 22mm deadbolt with single key turn retraction.

With Austral Lock it’s secure, with Forge it’s a family.

HMAS Perth Memorial

2025 National Design Award

National Winner Bespoke Design Project

Western Australia Winner Bespoke Design Project

ARCHITECT: Smith Sculptors

Joint National Winner Commercial Project Over $750K

New South Wales Winner Commercial Project Over $750K

ARCHITECT: Smart Design Studio PHOTOGRAPHER: Michael Kennedy Photography

Joint National Winner Commercial Project Over $750K

Queensland Winner Commercial Project Over $750K

ARCHITECT: Blight Rayner Architecture and Dissing+Weitling

BUILDER: BESIX Watpac

PHOTOGRAPHER: Fortitude Valley 4006

National Winner Commercial Project $250K to $750K

New South Wales Winner Commercial Project $250K to $750K

ARCHITECT: TKD Architects

BUILDER: Grindley Construction

PHOTOGRAPHER: Brent Chidgey

National Winner Commercial Project Under $250K

South Australia Winner Commercial Project Under $250K

ARCHITECT: Walter Brooke

BUILDER: Partek Construction & Interiors

PHOTOGRAPHER: Packers

2025 National Design Award Highly Commended National Winner Commercial Window or Glass Retrofit Project Queensland Winner Commercial Window or Glass Retrofit Project

ARCHITECT: Plus Architecture

National Winner Residential Window or Glass Project Under $80K

New South Wales Winner Residential Window or Glass Project Under $80K

ARCHITECT: CMR Constructions

BUILDER: CMR Constructions

PHOTOGRAPHER: Simon Langford

National Winner Residential Window or Glass Retrofit Project

Victoria Winner Residential Window or Glass Retrofit Project

ARCHITECT: Imogen Pullar Architecture

BUILDER: J & R C Builders

PHOTOGRAPGER: Marnie Hawson

2025 People’s Choice South Australia Winner Commercial Project $250K to $750K

ARCHITECT: Troppo Architects

BUILDER: Harrold & Kite

PHOTOGRAPHER: Harrold & Kite

National Winner Bespoke Shower Screen or Barrier Project Western Australia Winner Bespoke Shower Screen or Barrier Project

ARCHITECT: State 28 Interiors

BUILDER: Project West Pty Ltd

PHOTOGRAPHER: Tracey Hilton

National Winner Large Showroom of the Year

New South Wales Winner Large Showroom of the Year

PHOTOGRAPHER: Simon Lanford

National Winner Small Showroom of the Year

New South Wales Winner Small Showroom of the Year

BUILDER: The Goods Carpentry

2025 NATIONAL HIGHLY COMMENDED Commercial Project Over $750K

2025 NATIONAL HIGHLY COMMENDED Commercial Project $250K to $750K

Packers Coopers Brewery

BUILDER: Built

2025 NATIONAL HIGHLY COMMENDED Commercial Project $250K to $750K

Paarhammer Windows Iglu Apartments

ARCHITECT: Icon Construction

2025 NATIONAL HIGHLY COMMENDED Commercial Project Under $250K

Glass Windows & Doors

Community Centre

ARCHITECT: Canvas Projects BUILDER: CICG PHOTOGRAPHER: CICG

Busselton Aluminium Windows Dane Design Australia Office

ARCHITECT: Dane Design Australia

BUILDER: Dane Design Australia PHOTOGRAPHER: Ange Wall Photography

2025 NATIONAL HIGHLY COMMENDED Commercial Project Under $250K

SMB Glass Windows & Doors Aspendale Life Saving Club

ARCHITECT: NBRS

BUILDER: 2 Construct PHOTOGRAPHER: Tom Roe

2025 NATIONAL HIGHLY COMMENDED Residential Project Over $80K

2025 NATIONAL HIGHLY COMMENDED Residential Project Over $80K

European Window Co. Melbourne Project

ARCHITECT: Christopher Doyle Architects BUILDER: Davies Henderson

PHOTOGRAPHER: Mark Roper Photography

G.James Windows & Doors Blackwood Doonan

2025 NATIONAL HIGHLY COMMENDED Residential Project Under $80K

Glass Tasmania

ARCHITECT: Martin Stephens BUILDER: Lawless Builders

2025 NATIONAL HIGHLY COMMENDED Residential Project Under $80K

2025 NATIONAL HIGHLY COMMENDED Residential Retrofit Project

BINQ Windows Northcote House

ARCHITECT: LLDS

PHOTOGRAPHER: Tom Ross

2025 NATIONAL HIGHLY COMMENDED Bespoke Design Project

Paarhammer Windows Natural Haven - Project 465

ARCHITECT: Robertson Collectif Studio

BUILDER: Arthouse Projects PHOTOGRAPHER: Annamul

2025 NATIONAL HIGHLY COMMENDED Bespoke Design Project

Evolution Window Systems

ARCHITECT: Michael Brookes

BUILDER: Michael Brookes

PHOTOGRAPHER: Donna Brookes

ARCHITECT: PMDL Architecture + Design Pty Ltd

BUILDER: Mainbrace Constructions

PHOTOGRAPHER: Reeled Media

2025 NATIONAL HIGHLY COMMENDED Bespoke Shower Screen or Barrier Project

Glazed Co Collaroy Plateau Residence

PHOTOGRAPHER: Studio Pisani

2025 NATIONAL HIGHLY COMMENDED Bespoke Shower Screen or Barrier Project

Construction Glazing Burnside Village Balustrades

ARCHITECT: Buchan Arcitects

BUILDER: Hansen Yuncken

PHOTOGRAPHER: Tyler Marsland

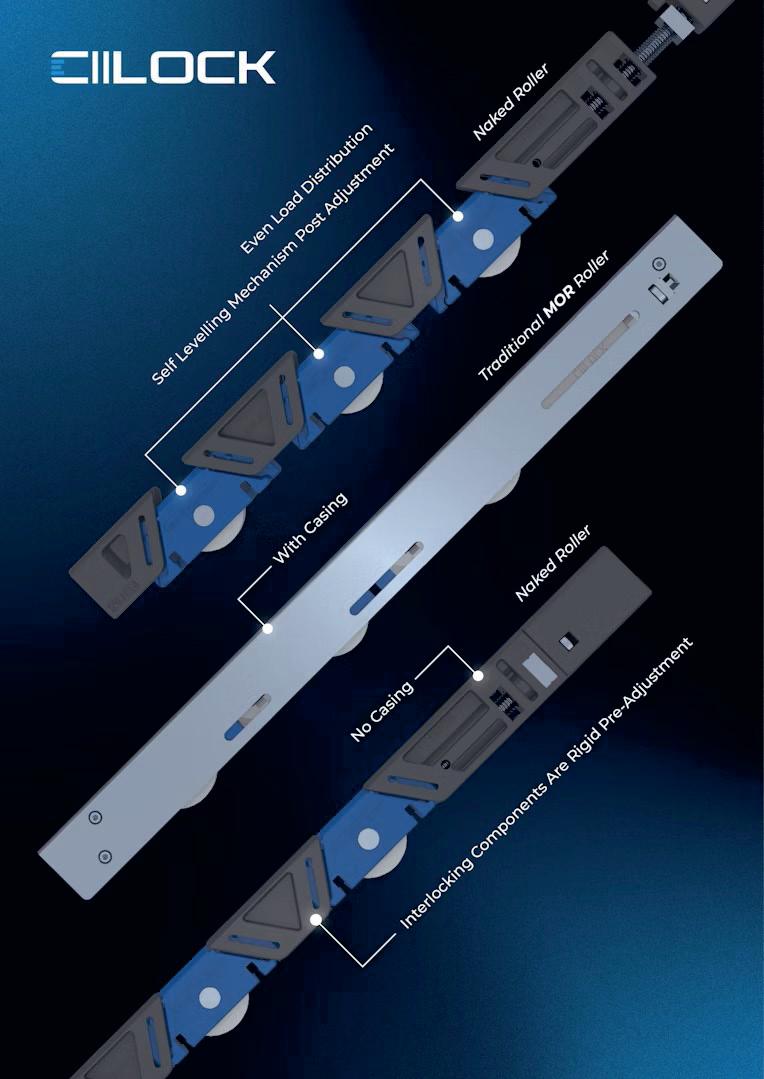

2025 NATIONAL HIGHLY COMMENDED Most Innovative Component

2025 NATIONAL HIGHLY COMMENDED Most Innovative Component

I always put my heart into everything I do and it’s the same with my apprenticeship. I want to be the best I can be … and I’m grateful for the opportunity to learn new things and get better all the time.

Matthew Fontaine, from SA, is employed by Festival Glass and Glazing and attended TAFE SA. He became a glazing apprentice as he liked working with his hands on different types of projects and the combination of inside and

He thought it would be a great career to build his life on, and he has been lucky because he has been able to work on a lot of different projects, allowing him to learn a lot of different skills.

Congratulations Matthew on your win and on being a great representative for our industry.

Matthew is employed by Stoddart’s Windows and Doors and studied at TAFE NSW. In his own words ‘the fact that I can attribute that transformation to the work I have done is very rewarding to me. And as well as it just looking better, also knowing it will function better and serve its purpose better for the people using it, is also quite satisfying’.

Cooper is employed by Clearview Aluminium Windows and studied at TasTAFE. In Cooper’s own words ‘the most challenging part of the job for me is when something isn’t quite right. I thrive on the challenge of being able to problem solve and fix the problem on the spot to create something that works’.

Jordan is employed by G.James Glass and Aluminium and studied at TAFE QLD. In Jordan’s own words, he says ‘seeing the end product is always the most satisfying part — knowing that the job you and your colleagues manufactured or installed is now complete and looks great. It gives you a real sense of accomplishment by the end of the day’.

Bailey is employed by Crystal Glass Windows and studied at North Metro TAFE. In Bailey’s own words, taking on responsibility ‘was extremely difficult to learn, with plenty of challenges along the way. I’ve learned so much more, and I’m now extremely confident in my work. I’m very proud of what I do and how I overcame that challenging part of my apprenticeship’.

2025 saw a record number of apprentices entering the various categories of the Apprentice Awards, making the judging task very difficult.

AGWA is proud to congratulate all the entrants who have shown a passion for our industry.

AGWA is particularly proud of our winners who have shown themselves to be excellent ambassadors for the future of our industry.

Thank you to our judges for all their dedication and hard work: Paul Land, Peter den Boer, Mark Nicholls and Mike Hidderley.

Thank you also to all the RTOs and employers who supported their entries.

Morgan Sherman (NSW)

TAFE NSW, Apsley Glass & Showers

Maverick Brown (WA)

Progressive Training, Jason Windows

Asher Valentine (WA)

North Metropolitan TAFE, Byford Glass

Thomas Young (QLD)

TAFE QLD, G.James Glass and Aluminium

Gilbert Cash (Tas)

TasTAFE, O’Brien Glass

Jordan Richards (SA)

TAFE SA, Mount Barker Glass

Luca D’Amato (Vic)

Holmesglen TAFE, All Points Glass

Samuel Blackman (QLD)

TAFE QLD, G.James Glass and Aluminium

Isaac Peers (SA)

TAFE SA, Willos Carpentry

Kaleb Lacey (TAS)

TasTAFE, Alfab Glass and Aluminium

Craig Moran (NSW)

TAFE NSW, JBL Glass

Harrison Michael (WA)

North Metro TAFE, Deluxe Glass

Elisha Palupe (NT)

TasTAFE, GGS-Tarna Enterprises Aboriginal Corporation

Lachlan Nassar (QLD)

TAFE QLD, G.James Glass and Aluminium

Luke Troha (NSW)

TAFE NSW, Liverpool Glass

Kobyn Dewis (TAS) TasTAFE, GP Glass

Ping Rachata Likhitcharoenchai (QLD)

TAFE QLD, APH Glass and Aluminium

Jackson Patten (WA)

North Metro TAFE, Glass Co

Thanks to our program Sponsors.

When it comes to optimising natural ventilation, Ventus louvres stand out as the most practical window system with the versatility of being used almost anywhere.

Paraflow is a double bladed louvre system featuring two off-set parallel blades of glass per clip which increases performance in acoustic suppression, weather protection, and improved thermal efficiency when closed while maximising natural airflow when open.

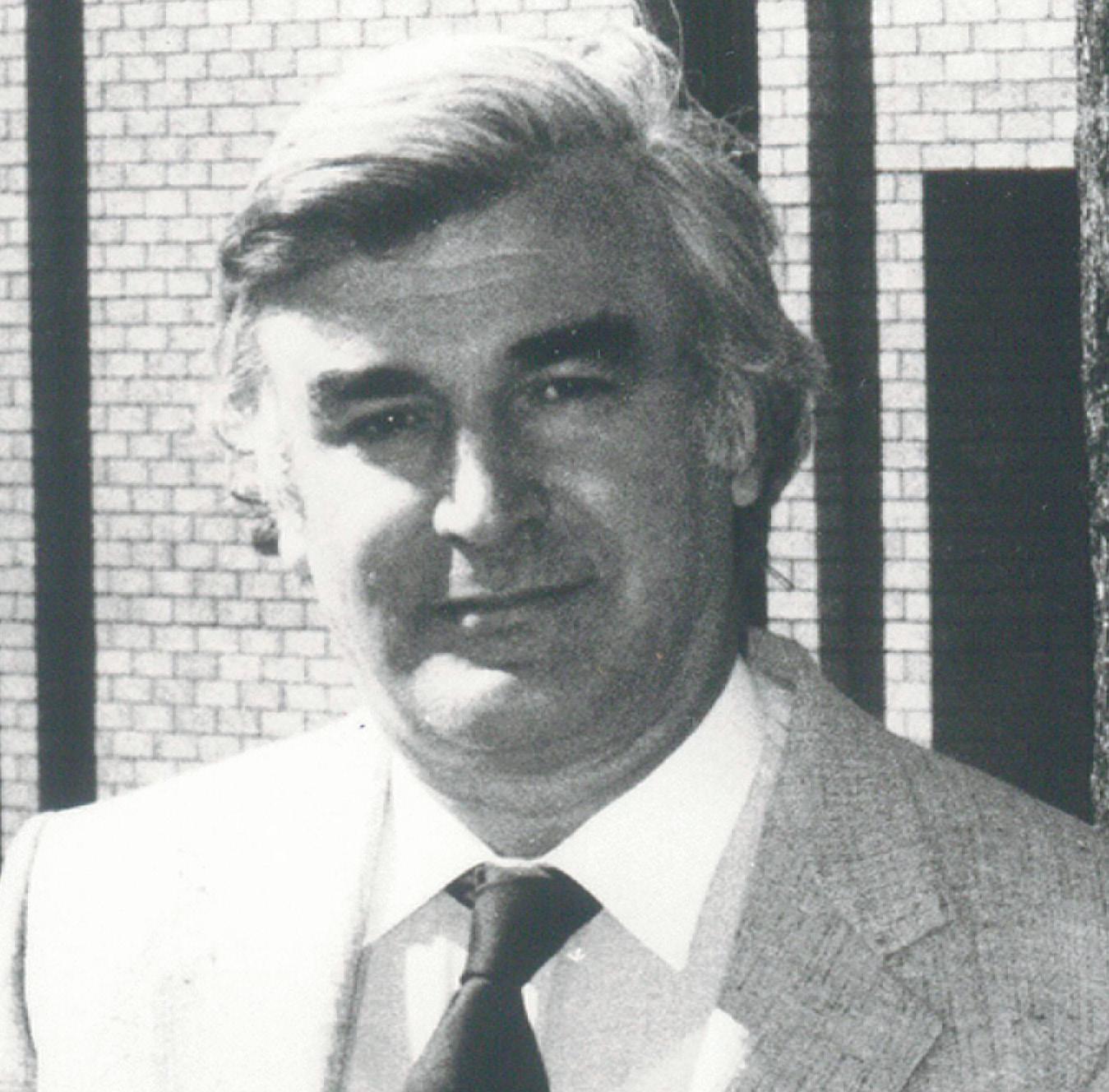

Tony Paarhammer’s journey spans continents, decades, and countless innovations. His journey began not in a boardroom or a factory, but in a small shed in country Australia … and even earlier, in places far from here.

This well-deserving winner first became familiar with the wonders of the Southern Hemisphere at the age of 21, when he moved to Papua New Guinea to teach, having armed himself with 6 weeks of English language lessons in London before taking the leap — an early sign of the boldness that would define his career.

After 3 years in PNG, he returned to complete his formal studies at university, followed by a role in middle management at a furniture company. This then led to a position in a window manufacturing firm, his first exposure to our great industry, and just like many, those seeds and a lifelong passion for our industry were planted.

In the summer of 1990, he and his amazing wife, Edith, made a life-changing decision to move to Australia. They settled in a small shed in Greendale, Victoria, and began crafting furniture under the name Design and Handicraft Furniture.

Always the visionary, he showcased his work in the National Bank Office in Bacchus Marsh. While much of the furniture was ahead of its time, a keen observation of the growing demand for windows set the business on its first evolution.

And so, Tirol Windows was born, introducing the then-novel ‘tilt and turn’ windows to excited crowds at home shows across the country. Feedback was welcomed, innovation embraced, and with their feet firmly planted in Australian soil, the business transformed a short time later — this time into a name we all know as for quality, excellence and customer focus: Paarhammer Windows.

Tony has never stopped pushing boundaries. In May 2004, his company became one of the first traditional timber joineries to undertake AS 2047 testing. In February 2011, they were the first member to complete a flame zone-rated window system in Australia following the terrible 2009 Victorian bushfires.

While Paarhammer Windows has been a proud AWA and AGWA member for many years, they have also been strong supporters of the Australian Passive Haus Association, joining in 2017. In 2009-10, he also founded Siegware, the new-to-market supplier of European hardware and building supplies, further augmenting his business as a valued supplier to the growing Australian uPVC window sector.

This year’s winner has served on the Board of the AWA, spent 8 years on the Board of the Australian Fenestration Rating Council, where he continues to serve as its treasurer. He’s currently in his second term representing the Southern Region Window Seat on the AGWA Board and is also AGWA’s treasurer. Tony helped co-found the AGWA Timber Window Subcommittee with Adam Duce and has been instrumental in securing support and contributions for the AFWIsupported timber window system project.

Tony’s journey is a testament to innovation, perseverance, partnership and teamwork. The businesses he has built with Edith are a testament to customer orientation, resilience, and vision. Paarhammer Windows is not just a business, it’s the result of 2 people who believed in each other, worked side by side, and built something extraordinary — a guide to all of us who wake each day seeking to leave the world a little different.

He has shaped an industry, ultimately won far too many design awards over the years, and he is creating a legacy that will endure for years to come.

Tony, congratulations on your National Industry Person of the Year award and thank you.

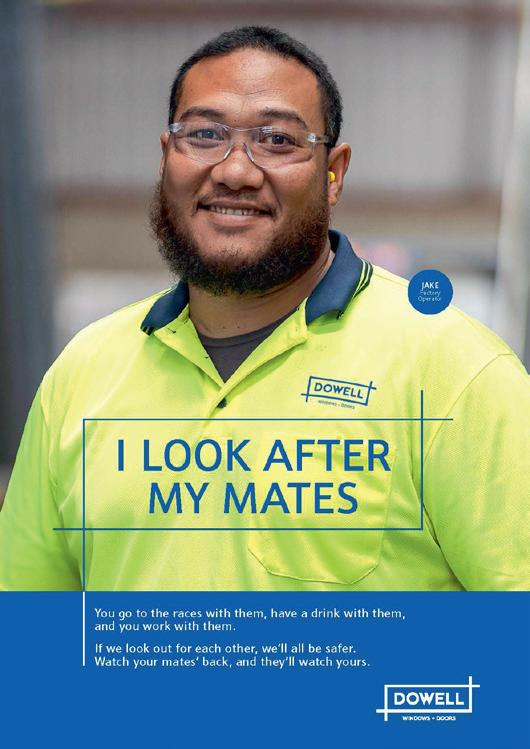

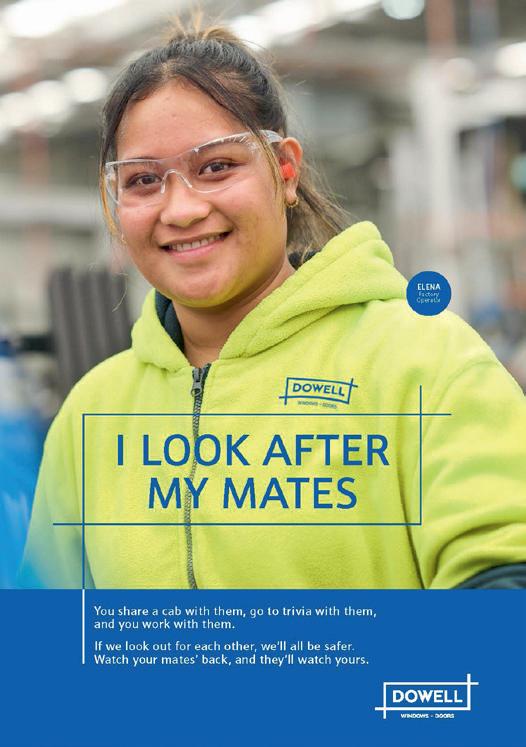

It is with great pleasure that AGWA announces that the winner of the 2025 AGWA National Safety Award is Dowell Windows with their ‘I Look After My Mates’ safety culture campaign. We congratulate them on their win.

AGWA asked Dowell Windows, to tell us a little more about their winning entry.

What was your entry for the 2025 AGWA Safety Awards?

Our entry was the ‘I Look After My Mates’ campaign, a grassroots safety culture program launched nationally across Dowell in January 2024. The campaign was designed to take the next step in developing our safety culture to move beyond focusing on our individual safety, to instilling a culture of accountability for the people around us. Through toolbox talks, team rotations, storytelling, and visible recognition, the initiative empowered employees to look out for one another every day, making safety a shared value across all sites.

How did you come up with your safety idea? Did something happen that prompted you to change your safety procedures?

The idea has existed in the mind of our Communication’s team for some time and aligns with the Dupont Bradley Safety Curve that illustrates the relationship between safety culture and operational performance. It’s an expansion of previous work and learnings from peer organisations that achieved great results. After some adjustment and input from our leaders, it was reborn and adapted to suit Dowell’s people and culture.

Can you please talk us through the steps you undertook to implement the change and the timing? How do you now ensure that this new procedure/change is being followed?

The campaign launched in early 2024 with a structured but simple rollout. Each month, a different team was nominated to lead the safety focus. They observed and shared positive safety behaviours, from helping with safe lifting to correcting PPE use, during toolbox talks supported by posters, templates, and visual materials. Managers facilitated, but employees drove the examples. Recognition was built in, with customised high-vis vests and national shout-outs celebrating everyday safety leaders.

Was your staff engaged from the outset? Please share some examples of how you got them on board. All new campaigns take time to gather momentum, but this one resonated quickly because it felt authentic. Teams created their own commitments, observations, and toolbox sessions often ended with shout-outs to mates who had stepped in or supported others. In one example, operators corrected each other’s PPE use without conflict. In another, forklift drivers paused to assist colleagues. These everyday acts showed that staff weren’t just engaged, they were leading the change themselves.

Have you seen a change since implementing your safety idea?

The change has been clear. In its first quarter alone, we received substantial nominations nationally, reflecting diverse acts of safety leadership. Toolbox talks shifted from compliance check-ins to genuine conversations about care and responsibility. We’ve seen stronger collaboration across shifts, increased hazard reporting, and greater PPE compliance.

Most importantly, employees now feel confident speaking up and use the language of the campaign — ‘I’ve got your back’ and ‘look after your mates’ — in their daily interactions. Most importantly, key safety metrics relating to reportable injuries, lost time and restrictions have reached record lows throughout the campaign.

What advice would you give your colleagues in the industry about making changes to the safety culture in their own workplaces?

Keep it simple and make it about people, not systems. The most powerful change happens when safety messages feel personal and relatable. Start small, empower employees to lead, and recognise everyday champions. Safety culture isn’t built by policy alone, it grows when teams look after each other and celebrate those individuals who demonstrate these qualities. We invite any organisation that is serious about safety to adopt the premise of the ‘I Look After My Mates’ campaign and make it their own, just as we did.

AGWA hopes that this award-winning entry has given you some ideas on how you can make safety in your workplace an everyday thing rather than a tick box on a form. We are committed in helping our industry improve its safety culture.

Discover the Future of Windows & Doors:

Transform your home with the precision and innovation of German uPVC windows and doors, expertly crafted to meet the unique needs of Australian homeowners. Whether you‘re retrofitting a charming weatherboard or heritagelisted home, or building a sleek, modern open space, our versatile, energyefficient solutions offer the perfect fit for every design.

With exceptional durability, security, and thermal performance, these windows and doors combine sophisticated German engineering with the ability to withstand Australia’s toughest conditions—from the harsh UV rays to coastal salt air. Elevate your home’s energy efficiency, style, and long-term value with solutions that truly endure. Experience the perfect blend of design, function, and luxury with German uPVC windows and doors – built for every Australian home.

Vivienne began her employment with AGWA in mid-2017 assisting in the administrative duties in the Sydney office on a casual basis. Later she was offered a full-time position split between managing the administrative side of AGWA’s Accredited Companies Program (ACP) and Dispute Resolution Services.

Prior to AGWA, Vivienne worked as a high school teacher for 12 years teaching Business Studies, Commerce and Geography and marking HSC exams. She was also employed as a reading tutor for MultiLit, a program designed to assist struggling students improve their reading ability.

Ingrid Pagura is the AGWA Industry Development Coordinator initially looking after the training needs of members. Ingrid’s role progressed to include coeditor of BuiltView, managing safety resources, the Design and Apprentice Awards and other marketing-related activities. Prior to AGWA, Ingrid worked for a legal publishing company seeing her work on their building and environment suite of products and with the CSIRO and ABCB on other BCA projects and also as a part time teacher at TAFE.

With over 20 years’ industry experience, Russell Harris, AGWA Head of Technical, has a thorough understanding of fenestration, including compliance, product design, development, and testing. Since joining AGWA in 2016 and with his background in R&D, Russell has been a noteworthy leader in the technical space, and an active contributor to the ongoing development of the Regulatory framework affecting the window industry.

Angela is a marketing and advertising Copywriter with Sydney’s Trade Advertising Agency, crafting words and ideas for all kinds of building-related brands. Growing up by her builder Father’s side and becoming a renovation aficionado — writing for AGWA is close to Angela’s heart and hands.

Glen graduated from the Bachelor of Economics from the Australian National University in 2024.

He joined HIA in 2025, and his responsibilities involve contributing to HIA’s suite of publications and articles.

BuiltView Magazine is a quarterly publication of the Australian Glass & Window Association.

EDITORS

Melissa Baker

Ingrid Pagura

SUB EDITOR

Helen Dawes

DESIGN

Webqem Pty Ltd

Sehar Maniar, AGWA

EDITORIAL & ADVERTISING ENQUIRIES

Helen Dawes

+61 2 9498 2768 marketing@agwa.com.au

PUBLISHED BY

AWA-AGGA LIMITED

ABN 57 629 335 208 Suite 101B, Level 1, Building 1, 20 Bridge Street, Pymble NSW 2073 +61 2 9498 2768 admin@agwa.com.au www.agwa.com.au

COVER IMAGE & CONTENTS PAGE IMAGES

HMAS Perth Memorial by Cooling Brothers Glass Company, Winner of the 2025 AGWA Design Award and WA 2025 Bespoke Design Project Award.

Architect: Smith Sculptors

CONTRIBUTORS

Clinton Skeoch, Glen Qi, Ingrid Pagura, Russell Harris, Rebekah Brown, Janith Pathirage, Mike Ward, Vivienne Munter, Mari Lehtinen, Elizabeth Dimabuyu, Lido Russo, Lucy Kendall, Dimity Schofield, Roger Bishop, Daniel Johns, Helen Dawes, Melissa Baker, Kerrie Henderson, Sehar Maniar and Tyler Gonzales.

PRINTED BY

SOUTHERN IMPACT

southernimpact.com.au

Our printer conforms to the ISO-14001 environmental management standard and the ISO-9001 quality management standard.

DISTRIBUTED BY

D & D MAILING SERVICES

www.ddmail.com.au BuiltView Magazine is proudly packaged in Biowrap, 100% degradable plastic wrapping.

DISCLAIMER

Copyright © 2025. All rights reserved. Reproduction in whole or part without written permission from AWA-AGGA Limited is strictly prohibited. It is impossible for the publisher to ensure that the advertisements and other material herein comply with the Australian Consumer Law Competition and Consumer Act 2010. Readers should make their own inquiries in making decisions and where necessary, seek professional advice.

Dear Members,

Clinton Skeoch

Executive Director and CEO AGWA

As we reflect on another remarkable year, I want to extend my sincere thanks to everyone who joined us at this year’s AusFenEx25. The strong attendance and enthusiastic support from across the industry was both energising and inspiring, reaffirming the strength, unity and opportunity in front of our industry.

From my perspective, a defining moment of the conference was the announcement of the development of the Australian Window and Glass Bureau. This is a significant initiative that will serve as a central public-facing platform to elevate the visibility, credibility, and performance of window and glass suppliers in the Australian market.

Aligned with this vision, AGWA has commenced the process of undertaking a comprehensive and rigorous assessment of all window and door system suppliers currently marketed in Australia, regardless of their membership of AGWA, to verify their compliance with Australian Standards. This is a mammoth undertaking, but one that is essential to our mission of fostering a sustainable and level playing field. Importantly, this process will also serve to highlight — through the Bureau — those companies whose systems are unable to demonstrate full compliant testing and where further questions should be asked by consumers, builders, certifiers and regulators. By doing so, we aim to support informed decision-making across the industry and highlight and uphold the integrity and sustainability of compliant companies in our built environment.

While this work will take time, we are committed to keeping the industry informed as we progress. Your engagement and feedback will be vital as we move forward together, and more information will be available on this and other initiatives in the forums in the new year, so stay tuned.

Finally, I would like to congratulate the winners of this year’s National Design and Industry Awards. Your innovation and dedication continue to set the benchmark for excellence in our field. I welcome you to review the showcase of national winners in the pages that follow.

As this is the last edition of BuiltView for the year, I wish you and your staff a safe, restful, and joyful end to the year.

ClintonExecutive Director and CEO

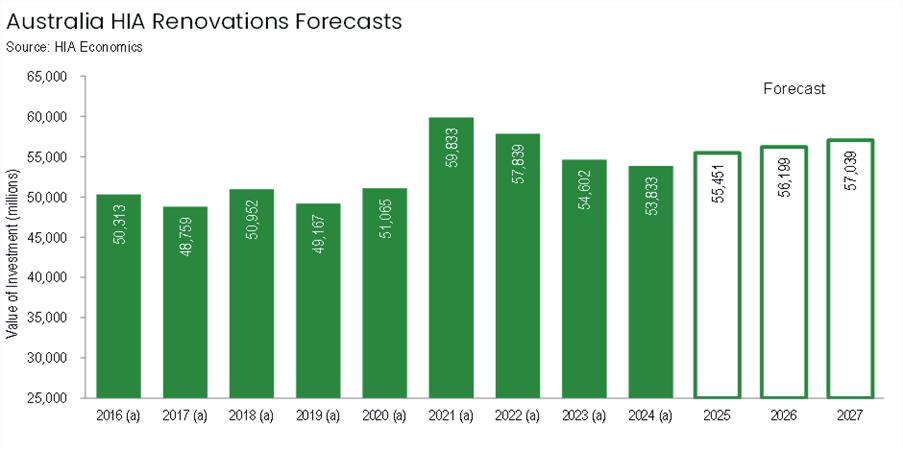

Glen Qi Economist, HIA

The pandemic sparked a surge in renovation, which has been sustained because of flexible work arrangements and changes to consumer preferences. HIA forecasts renovation investment to pick up from 2025 onwards, off the back of improving economic conditions, to be well-above anything seen prior to 2020.

In 2024-25, the number of loans issued for major home renovation work across Australia increased by 8.4% compared to the previous year, with some markets seeing significantly faster growth.

Lending for major renovation work increased in 2024-25 in Queensland by 13.1% and in Western Australia by as much as 21.8%. This reflects the height of demand for a limited pool of established homes, ready to move into, has shaped buyer behaviour and demand for renovations.

In the last 5 years, the prices of building materials have increased by 36.6%. The fastest increase in prices has been seen in those materials that are most energy-intensive to manufacture. This includes timber windows, aluminium windows and doors, sand and mirrors and other glass products. Despite the rising cost of materials, homeowners continue to stay active in the renovation market.

The supply of new homes has not been able to keep up with elevated levels of population demand, which has placed upward pressure on dwelling prices. The question has always been whether

to build, buy or renovate. Homeowners are now more comfortable to borrow against their home equity to carry out these renovations. By renovating, homeowners also avoid having to uproot their lives, and avoid additional costs associated with moving.

Many existing dwellings, if they have not already, will reach a point where they no longer meet modern standards or household expectations. In this case, renovation becomes more of a necessity than a choice. Upgrading older homes can improve liveability and safety, all while extending the lifespan of the dwelling, without the hassle of relocating. It also is a necessity for homes requiring repair from weather-related wear-and-tear or damage.

For some, renovations are also seen to build equity. In areas where property values have risen rapidly, upgrading an existing home can be a strategic move to make it more attractive and move-in ready for the next buyer. This is especially true in well-located suburbs where there are strong demand, unique location-based amenities and limited supply.

It is all these factors combined that are set to push renovation activity and keep volumes elevated in the coming years. This is great news for product suppliers and manufacturers looking to market their products to consumers looking to upgrade and modernise their existing homes.

Trusted testing that builds confidence and compliance.

Balustrades

AS1170-1 standards. AS 1288 for glass Expert testing for high performance and safety.

Pool Fencing

AS1926: Swimming Pool Safety. Fences with a >1 m fall are considered balustrades. AS1288 or AS/NZS1170.1 standards.

Key AS1926 Updates

Cycle rate increased to 25,000. Checks every 2,500 cycles for 25 mm closures.

Testing now includes glass panels.

Why Type Test Balustrade Barriers?

This home in Denman Prospect is situated in the challenging climate of Canberra, ACT, where seasons are more extreme and you can sometimes experience multiple seasons in one day. This makes it a challenging area for building materials, and it is critical to select products that are capable of enduring these conditions.

This impressive Classic Constructions’ display home boasted a distinctive presence that blended seamlessly with its environment and has been judged the Best Display Home in the ACT by the Housing Industry Association (HIA).

Classic Constructions build high end homes and Parkwood’s aluminium doors are a great solution for them, providing peace of mind and confidence to be able to put in a product that they can rely on from a quality perspective, which provides a great solution for their clients.

‘We partner with Parkwood because they provide a quality product, and align with our values, as a builder and as an offering for our clients. It gives us peace of mind and confidence to be able to put a product in that we can rely on from a quality perspective and provide a great solution for our clients’, said Jason Tanchevski Classic Constructions’ Director

The classic beauty of the elegantly curved exterior is mirrored inside with a striking curved kitchen island, rangehood, custom cabinetry, lighting fixtures, and mirrors. A split-level layout

enhances solar access to the primary living spaces while highlighting the stunning views that change throughout the day.

Make an Entrance Suits your style. Fits your frames.

Traditionally, Classic Constructions had been using timber doors for front entries. Unfortunately, these are more susceptible to weather-related problems, which can result in maintenance and warranty issues. Parkwood provides aluminium doors that offer greater durability, utilising darker colours without having to worry about the impact of the weather. Longer term, they understand that aluminium doors present an excellent solution for both clients and projects alike, effectively providing answers to common problems.

The front door chosen for this display home was the aluminium Strata TGV in Basalt Matt, measuring 2691 mm in height and 1200 mm in width. An aluminium front door was selected to showcase their preferred door choice for clients going forward, demonstrating its modern design, durability, and low maintenance. The doors are perfect for all types of entrances, including those in exposed locations, and can be powder coated to a variety of colours, including dark colours!

The door fitted snugly into the aluminium window fabricator’s entry frame. This gave the builder a complete, and matching, ‘door+window’ exterior joinery package.

Parkwood specialises in supplying custom-fit aluminium front doors to window fabricators. Add Parkwood’s premium doors to your product offering, powder coated in any colour.

For more information, please visit www.parkwooddoors.com.au Connect with your local aluminium front door specialist at sales@parkwooddoors.com.au.

Russell Harris Head of Technical, AGWA

Water penetration resistance is a critical performance requirement for windows and external glazed doors in Australian buildings. As construction practices evolve and expectations for quality assurance rise, building designers and manufacturers are increasingly turning to on-site testing methods to validate product performance. Among these, AAMA 501.2 (water-spray testing) has gained attention — but how suitable is it for Australian projects, and how does it align with the National Construction Code (NCC) and Australian Standard AS 2047?

What is AAMA 501.2?

AAMA 501.2 is a North American Standard developed by the American Architectural Manufacturers Association. It outlines procedures for field testing installed fenestration products using a controlled water-spray system to simulate rain. The test involves spraying water at a specific pressure and angle while observing for uncontrolled water ingress.

Importantly, the scope of AAMA 501.2 is limited to curtain wall systems and fixed windows. It is not designed for operable windows, doors, or other movable components. This distinction is crucial, as many Australian residential and commercial buildings rely heavily on operable windows and doors for ventilation and access. Using AAMA 501.2 outside its intended scope can lead to misleading results and non-compliant practices.

Regulatory requirements: the NCC and AS 2047

While AAMA 501.2 is valuable for identifying workmanship issues and installation defects, it is not a substitute for compliance testing under AS 2047. The NCC references AS 2047 as the deemed-to-satisfy (DTS) pathway for window and door compliance which in turn requires performance to be proven through laboratory testing to verify performance across multiple criteria, including:

• Water penetration resistance

• Air infiltration

• Operating force

• Serviceability deflection

• Ultimate strength.

Products that cannot meet the required water rating under AS 2047 must be part of a performance solution. This may involve additional protective measures such as verandas, drainage systems, or other integrated design options. In such cases, the building designer must certify the solution and provide evidence in accordance with NCC requirements (refer clause A2G2).

practice recommendations

For building designers, specifiers and certifiers, we recommend the following approach:

• Use AS 2047 testing for compliance: Ensure that products are tested in accredited labs to meet NCC requirements. This is especially important for operable windows and doors.

• Supplement with AAMA 501.2 for quality assurance: Use on-site testing to validate installation quality and detect workmanship issues, but only for fixed windows and curtain walls.

• Document performance solutions thoroughly: If relying on alternative methods, ensure all aspects of compliance are addressed and certified.

• Educate stakeholders: Clarify the limitations of AAMA 501.2 to clients, builders and certifiers to avoid misapplication and ensure regulatory alignment.

AAMA 501.2 and other on-site water testing methods offer valuable insights into installation quality and real-world performance. However, they must be understood as complementary tools — not replacements — for the rigorous testing protocols outlined in AS 2047. By combining laboratory testing with field verification, the industry can uphold both compliance and quality, ensuring safe and durable outcomes for Australian buildings.

Understanding the scope and limitations of each testing method is essential for informed decision-making and regulatory compliance.

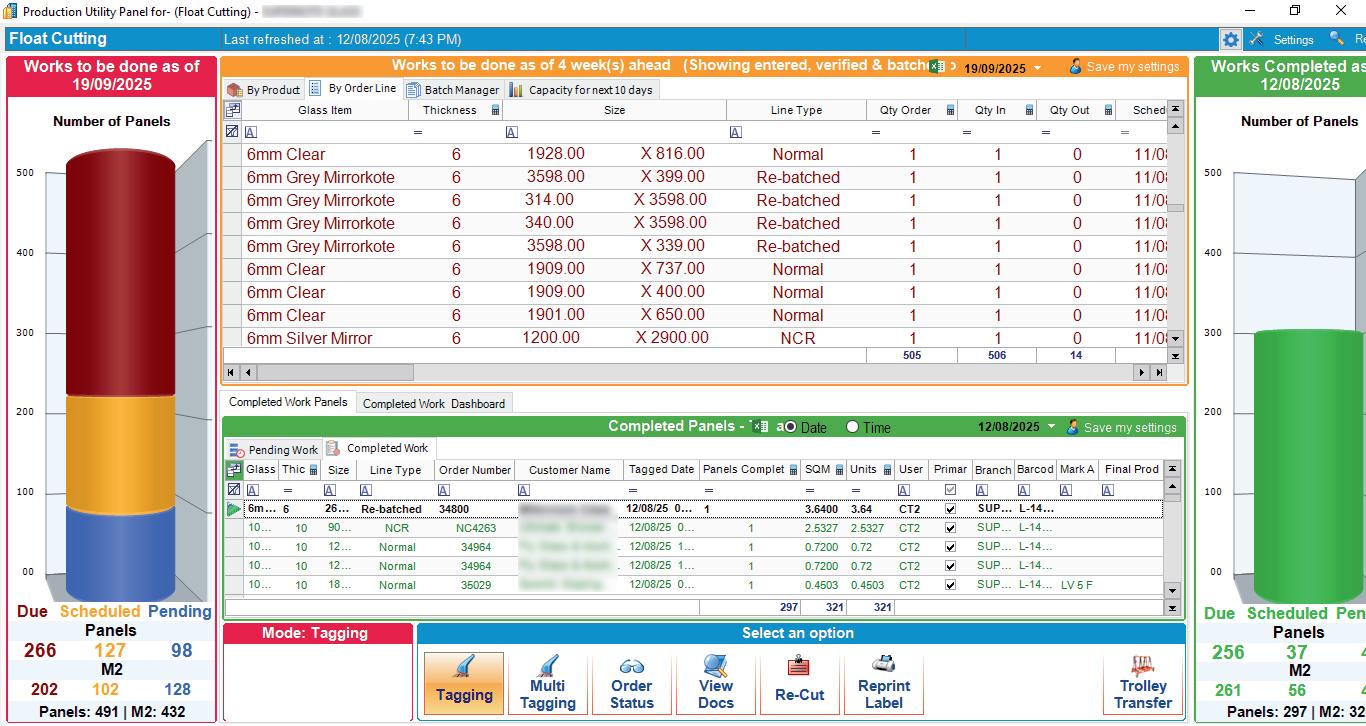

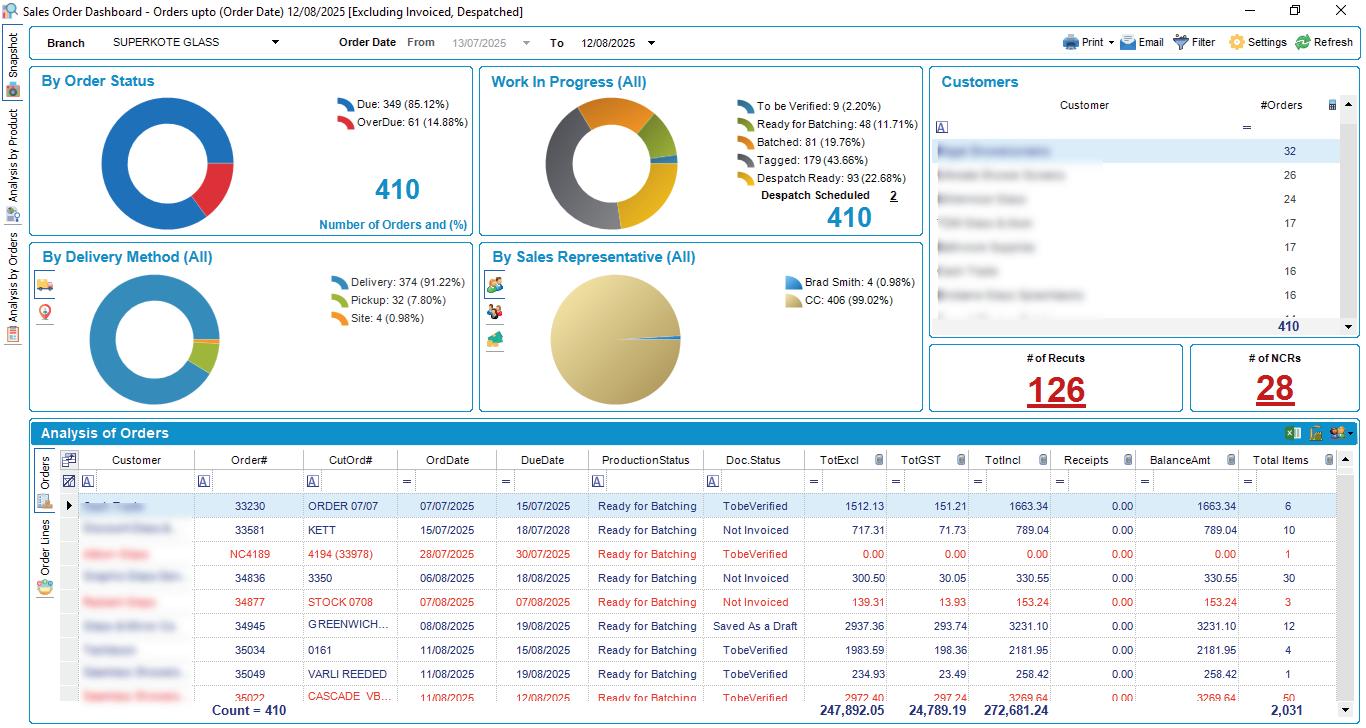

In New Zealand’s competitive glass industry, one flat glass fabricator stood out by combining craftsmanship with smart technology choices. In 2016, they partnered with SPIL Glass Software, a platform developed for the flat glass industry, to bring structure and visibility to their operations.

The Challenge

Driven to consolidate systems and prepare for the future, the company implemented a major international ERP. While it offered scalability and integration, the platform quickly showed gaps in meeting the unique needs of glass fabrication.

Several challenges emerged:

• Rising Costs: Licensing, implementation, and consultancy fees pushed up total ownership costs.

• Operational Disruptions: Downtime during transition affected orders and deliveries.

• Complexity: Previously simple tasks became rigid and required retraining.

• Loss of Visibility: Real-time insight into fabrication status was reduced, making resource management harder.

The mismatch between a general ERP and specialised manufacturing needs ultimately led to performance declines.

After evaluating months of disruptions, the company’s leadership concluded the new system lacked practical value, despite its reputation. The careful review of bottlenecks, staff input, and business goals led to a consensus: success required the right system, not a more complex one. Reimplementing SPIL was a

strategic move to restore a proven, intuitive platform aligned with their needs.

The Decision

The return to SPIL was smooth and efficient. Since SPIL Glass Software was already part of the organisation’s workflow, reconfiguration and onboarding were quick, supported closely by SPIL’s team to restore setups and add improvements.

Key benefits of the return included:

• Rapid Deployment: Existing configurations enabled a fast rollout.

• Process Alignment: SPIL fitted naturally with established workflows, minimising disruption.

• Staff Reengagement: Familiar interfaces helped employees regain productivity quickly.

• Reliable Support: Direct access to experts ensured timely, relevant assistance.

Within weeks, the fabricator not only recovered but positioned itself for stronger future performance.

Results

Metric Impact After Reimplementation

Production Downtime Reduced by over 40%

Staff Efficiency Restored to pre-ERP levels within 4 weeks

System Adaptability

Executive Reporting

Cost of Ownership

Custom process changes implemented in days

Real-time dashboards restored for faster decision-making

Reduced through simplified licensing and lower support needs

This flat glass fabricator’s journey underscores a key truth: fit matters more than size. Industry-specific solutions consistently outperform one-size-fits-all platforms because they reflect frontline realities, optimise proven processes, and focus on driving results rather than appearances.

The lesson is clear; progress doesn’t come from reinventing the wheel but from ensuring it’s built for the right road. For companies aiming to scale, while maintaining clarity, visibility, and efficiency, SPIL Glass Software remains a trusted partner in getting it right.

‘You don’t need to reinvent the wheel — just make sure it’s built for your road.’

For more information, please see www.info@spil.com.au

Russell Harris Head of Technical, AGWA

The term ‘like-for-like replacement’ is often used to describe the process of replacing a building element with one that is similar in form, function, and specification. While this approach may seem straightforward, it raises complex questions about compliance with current building codes, particularly when the original installation predates modern Standards.

Australia’s building compliance framework is governed by the National Construction Code (NCC), which sets minimum standards for safety, health, amenity, and sustainability. The NCC is supported by Australian Standards, including 2 specifically for windows and glazed elements that are referenced:

• AS 1288 – Glass in Buildings: Selection and Installation

• AS 2047 – Windows and External Glazed Doors

Each state and territory also have their own building legislation, which may interpret or enforce these requirements differently.

What happens when replacing elements in older buildings?

In limited cases, like-for-like replacement may be acceptable if:

• The replaced element does not compromise safety.

• The building is not undergoing significant renovation or change of use.

• The replacement meets the minimum performance requirements of the NCC.

However, for elements like glass in balustrades, doors, and windows, safety standards have evolved significantly, and like-forlike replacement is often not sufficient.

One of the most common scenarios involves reglazing a broken pane in a sliding patio door, where the broken pane was not Grade A Safety Glass. Current industry guidance requires the broken pane to be replaced using Grade A Safety Glass in accordance with current Standards: but does this also extend to the unbroken pane as well?

Another common scenario is replacing a pane in a glass balustrade. For example, a balustrade built in the 1990s may have used 6 mm toughened glass, which was compliant at the time. However, under AS 1288: 2021, laminated safety glass is now required for barriers located 5 m or more above ground level. This raises the question: Can the broken pane be replaced with another 6 mm toughened glass panel (like-for-like), or must it comply with the current Standard? The answer depends on whether the work is classified as repairs and maintenance or new building work.

Repairs v new building work: a legal distinction

Australian building legislation generally does not apply retrospectively. This means that buildings constructed under older versions of Standards are not automatically required to be upgraded to meet new Codes, unless the building is undergoing significant renovation or change of use or a council order or fire safety directive mandates compliance.

New work must comply with the current NCC, but existing buildings are not required to be upgraded, unless the new work affects the performance of the building.

• If the replacement is classified as repairs, and the building is not undergoing renovation, a like-for-like replacement may be permissible, provided it does not compromise safety.

• However, if the replacement introduces a new material or design, or if the building is subject to a council order, it may need to be upgraded to meet current standards.

The Upgrading Existing Buildings Handbook by the Australian Building Codes Board (ABCB) provides guidance on how to approach compliance when working with buildings that predate current Standards.

Key principles include:

• Compliance with current Standards: All new building work must adhere to the current NCC and applicable Standards.

• Use of performance solutions: If full compliance is not feasible, a performance solution may be implemented to demonstrate that the replacement meets the NCC’s mandatory Performance Requirements.

• Impact-based prioritisation: Any identified non-compliance should be evaluated based on its potential impact to determine whether existing building elements remain suitable for their intended purpose.

• Exemptions for unjustifiable hardship: In certain cases, particularly those involving accessibility, exemptions may be considered where compliance would cause unjustifiable hardship. However, this generally does not apply to elements critical to safety.

If, during replacement or remedial work, a practitioner becomes aware that the original installation is non-compliant with the NCC or relevant Australian Standards, they may be obligated to inform the owner.

Courts have found that ‘reasonable care’ includes compliance with the NCC and relevant Standards, and installers must not proceed with work that they know will not comply and must take steps to manage risks. Failing to notify the owner of known non-compliance may constitute a breach of this duty.

To exercise reasonable care where circumstances require, AGWA recommends that installers should:

• Document the issue clearly.

• Notify the building owner in writing, outlining the risks and potential consequences.

• Recommend appropriate remedial actions or further expert assessment.

• Not proceed with work that would perpetuate or conceal the non-compliance.

While like-for-like replacement may seem like a practical solution, it must be approached with caution. The non-retrospective nature of legislation provides some flexibility for repairs and maintenance, but safety and compliance remain paramount.

In many cases, replacing a building element, even as part of repairs, requires adherence to current Standards, especially for safetycritical components like glass in balustrades and doors, to ensure that replacements are not only legal but safe and fit for purpose.

DESIGNED IN GERMANY. PERFECTED FOR AUSTRALIAN HOMES.

The new aluplast IDEAL 2000 Slimline Reveal Frame System is the first uPVC window system developed exclusively for the Australian market.

It combines refined slimline aesthetics with smart installation and fabrication features — delivering outstanding performance, faster build times, and long-term reliability.

Fully compliant with Australian Standards, the system achieves superior thermal efficiency, increased SHGC, and exceptional durability across all climate zones.

BUILT FOR FABRICATORS

• Fabrication is faster, requires less labour, and can be streamlined with advanced automation to boost productivity and reduce operating costs.

• Easy solution to expanding your product range to capture new market opportunities and meet more rigorous energy targets.

• The system delivers outstanding thermal performance and is fully tested to meet Australian Standards.

• IDEAL 2000 Slimline Reveal Frames are more affordable than existing market options, enabling more competitive pricing and stronger profit margins.

• The slim, contemporary design enhances aesthetics for modern architectural styles.

• A wide range of colours offers flexibility to suit every design vision.

• aluplast is a trusted global brand, backed by German engineering and proven durability.

SMART INSTALLATION FEATURES

• Built-in inline and stepped reveal options

• Plasterboard and EzyJamb adapters

• Floor-fixing adapter

• Wide selection of installation accessories

These engineered details simplify fabrication, installation and ensure a premium, high-end finish every time.

Same trusted German performance –now with a sleek new look, designed and engineered for Australia.

• Modern, 60mm 3 chamber profile system.

• Current Double Glazed, WERS Uw values 1.4 to 2.5(Depending on Glass Selection)

• Current Triple Glazed, WERS Uw values 0.6 to 1.9(Depending on Glass Selection).

• Current Double Glazed, WERS SHGC values 0.13 to 0.64 - (Depending on Glass Selection)

• Current Triple Glazed, WERS SHGC values 0.14 to 0.58 - (Depending on Glass Selection).

• Up to 39dB acoustic reduction.

• Up to 34mm glazing pocket.

• Up to BAL29 rating.

Enquire today to discover how the new IDEAL 2000 Slimline Reveal Frame System can expand your product range and profitability.

For all system and fabrication enquiries, email ben.webster@aluplast.net

Visit aluplast.com.au to connect with an aluplast fabricator near you.

The sun shone and 144 golfers from AGWA’s Queensland Chapter enjoyed another very successful golf day at Nudgee Golf Club on Thursday 26 June (postponed from its original date in May due to the unseasonably wet weather).

A huge thank you to Major Sponsors Viridian, Signet, Lisec and to Hole Sponsors G.James, Next Gen Glass & Aluminium, Ara Hardware, Doric Products, Pivotech and Suburban Glass.

The Advanced Thermoplastic spacer solutions for Structural and Residential IG Units

FENZI offers both standard and reactive TPS materials. Both products are trusted by the industry, approved by the major TPS applicators producers, proven over time, and certified under globally recognised laboratories.

Both Butylver TPS Standard and Reactive is guaranteed by a perfect PIB matrix integrated with molecular sieves which prevents the diffusion of the water molecules and block the penetration inside the IG cavity Even under harsh conditions (Lab data 24/7 constant RH 85% and temp. 23°C) it takes 25 years to saturate the moisture absorption capacity of the TPS. In real service life conditions the durability of the units can be even longer

The reactive version keeps most of the main advantages of the Butylver TPS Standard adding a strong chemical adhesion to the glass, a key factor that allows to combine the TPS with silicone secondary sealants.

Silicone sealants contain a high amount of plasticizers/ oil which, over time, can migrate within the cavity and degrade the adhesion between the TPS and the glass, resulting in units failure. The Reactive TPS has been designed mainly to prevent these failures, thanks to the chemical bond of TPS to the glass, which is essential when using silicone as the secondary sealant. This avoids the delamination of TPS from the glass, ensuring to keep the IGU's gas and moisture barrier secure over time.

Excellent results to guarantee the best barrier to moisture penetration and gas leakage

5 TIMES LOWER than EN 1279-2 normative requirements ensuring to keep the IGU's gas and moisture barrier secure over time.

The IG units system is affected by dynamic mechanical, thermal and environmental factors. Butylver TPS Standard ensures exceptional and proven adhesion to the glass, forming a robust and at same time flexible barrier that prevents gas leakage and blocks moisture penetration under harsh conditions for a long-lasting service life of IG units.

Butylver TPS Standard consumption per linear meter is approximately 4% lower compared with reactive thermoplastic spacer available in the market, thanks to a lower density. This reduction directly translates into cost savings in the IGU production process.

360 Access, Tullamarine, VIC

Atlas Windows and Doors, Dandenong South, VIC

BenM Glass Glazing, Warragul, VIC

Bluesea Wang Australia, Sherwood, QLD

Deep Homes, Broadmeadows, VIC

Embassy Glass Solutions (VIC), North Geelong, VIC

Fenestrate Pty Ltd, Pakenham, VIC

Flawless Glass Aluminium, Ormeau, QLD

GN Windows and Doors, Carlton, NSW

Halliday and Baillie, Chippendale, NSW

insulbar − North America, New Jersey, USA

Jensen Hughes Fire Testing, Dandenong South, VIC

Penot Double Glazing, Subiaco, WA

SS Glass and Glazing, Moonah, TAS

Surefit Glass, Coopers Plains, QLD

Triple E Windows and Doors, Cranbourne West, VIC

Finally a 1 step solution that actually works.

Glasweld Gforce max scratch removal kit has proven time and time again that it can easily remove most small to medium scratches in only a few minutes with absolutely no distortion.

For heavy damage, weld splatter, graffiti and logo removal ask us about he the optional microforce micro abrasive accessory kit.

Has definitely performed beyond my expectations. It literally paid for itself within a few days! We have tried several other products over the years, and this has been the best by far.

Peter. K - Oneglass Victoria

If you would like further information on all GlasWeld products please visit our website www.elegantig.com.au or contact one of the Elegant team on 02 94736500

SCAN HERE TO SEE HOW IT WORKS

When it comes to optimising natural ventilation, louvres remain one of the most practical window systems. They offer minimal resistance to airflow when opened, provide protection from rain when tilted, and can be fully closed to seal a building against the elements. Their versatility allows them to be used almost anywhere, from opening a single room to ventilating an entire building enhancing comfort, improving energy efficiency, and promoting healthier indoor environments through natural air circulation.

The Ventus Paraflow Louvre takes this proven concept further. Recognised with the AGWA 2025 National Design Award for Most Innovative Component, Paraflow is a high-performance double-bladed system developed by Doric to meet the needs of both residential and commercial applications. Whether specified for floor-to-ceiling installations or high-set windows, it delivers measurable performance in acoustic suppression, weather protection, and thermal efficiency when closed, while maximising airflow when open. Paraflow, the louvre that is not just for the hot climates but developed for Australia-wide.

Paraflow stands apart for 3 key reasons:

1. Dual-blade, dual-seal design: Significantly improves thermal efficiency, acoustic dampening, and defence against wind and water ingress, ensuring comfort and protection in all conditions.

2. Axis-symmetric mechanism: Achieves balanced weight distribution, making handle operation smooth and responsive.

The Ruth Everuss Aquatic Centre in Lidcombe NSW is making waves with the installation of 7 Smartech motorised folding doors. These innovative doors create a seamless indoor-outdoor experience — transforming the centre into a sheltered haven in winter and an open-air pool in summer. With this smart design, swimmers now enjoy a space that adapts effortlessly to Sydney’s changing weather.

Each door measures 2700 mm by 4000 mm and features 6.38 mm laminated glass, ensuring clear visibility across the facility. Safety is a top priority, with dead man’s mode operation providing controlled, reliable movement for staff and peace of mind for visitors.

Sealed for Comfort

Smartech’s advanced sealing system guarantees year-round performance. Dual acoustic foam or wool pile seals, paired with a nylon brush seal, deliver superior gap control. A PVC bulb seal compresses against the threshold for added protection, with an optional neoprene sweep for enhanced sealing.

Strategic placement of the doors optimises crowd management during peak times. Whether hosting competitions or managing summer traffic, the doors provide multiple entry points, reduce congestion, and support efficient evacuations.

3. Glass and blade clip replacement: Built into the system, enabling quick, straightforward maintenance and reduced downtime when servicing is required.

Tested to rigorous performance standards, Paraflow achieves Rw 32 acoustic performance, U-value 2.8 thermal insulation, and weather resistance up to 450 Pa. These proven credentials provide architects, builders, and developers with confidence across diverse projects.

Ease of operation has also been carefully considered. A low-profile manual lever ensures smooth control without compromising sightlines, while a motorised option integrates utilising the 2019 AGWA Design Award winning Ventus Plug & Play Automation System giving specifiers flexibility to meet project requirements.

By combining ventilation, sealing, energy efficiency, usability, and maintainability, the Ventus Paraflow Louvre proves that innovation is not just about new ideas, but about delivering smarter, sustainable solutions to real-world challenges.

For details on how Paraflow can enhance your next project, contact our technical sales team on 1300 132 389 or email customer.service@ doric.com.au. Or visit ventuslouvres.com

From aquatic centres to luxury pools, Smartech’s expertise can transform your space. For further information about any Smartech products or services, please visit www.smartechdoorsystems.com.au, contact our Sales Department at (03) 9747 9233, or send an email to sales@smartechdoorsystems.com.au.

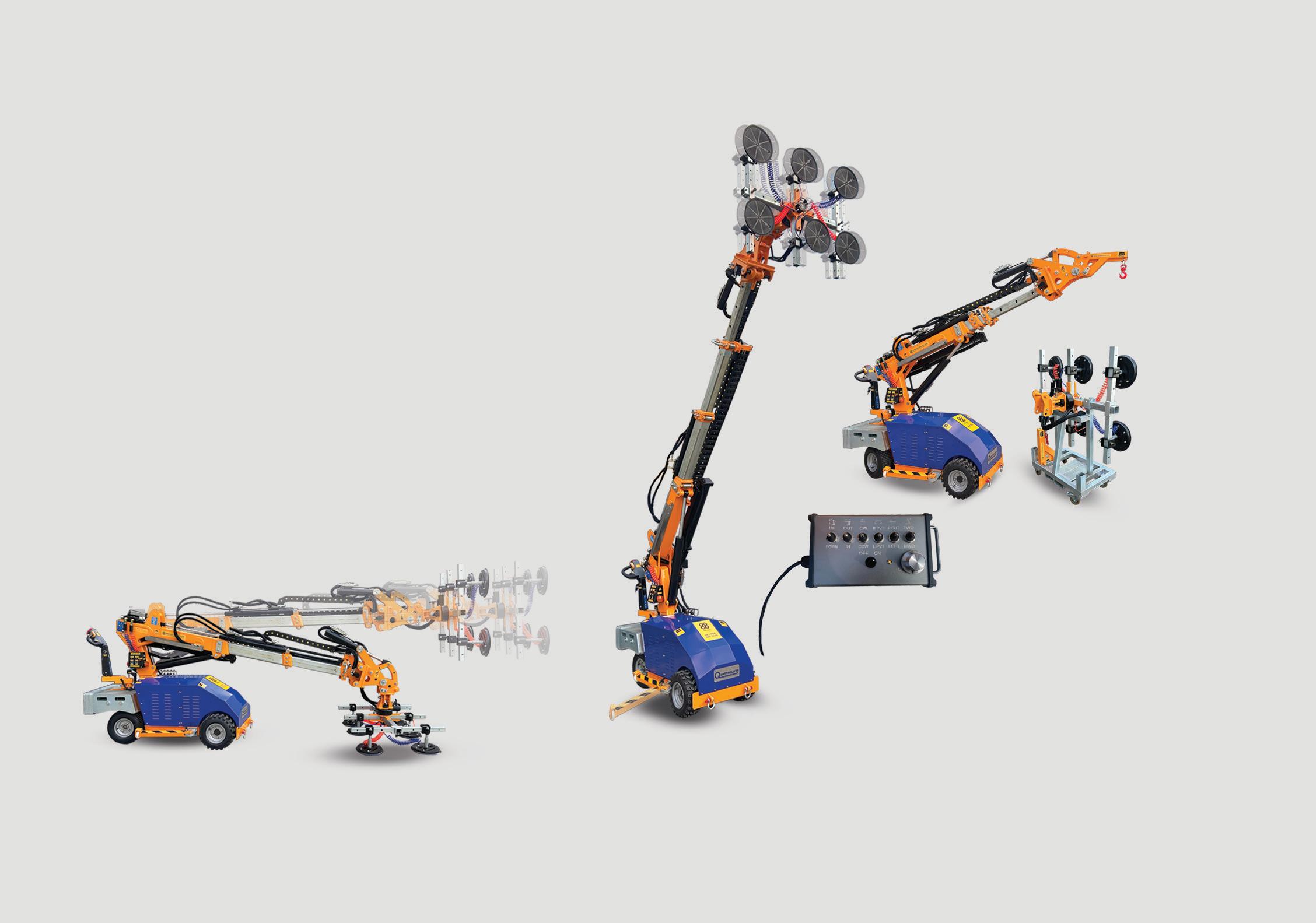

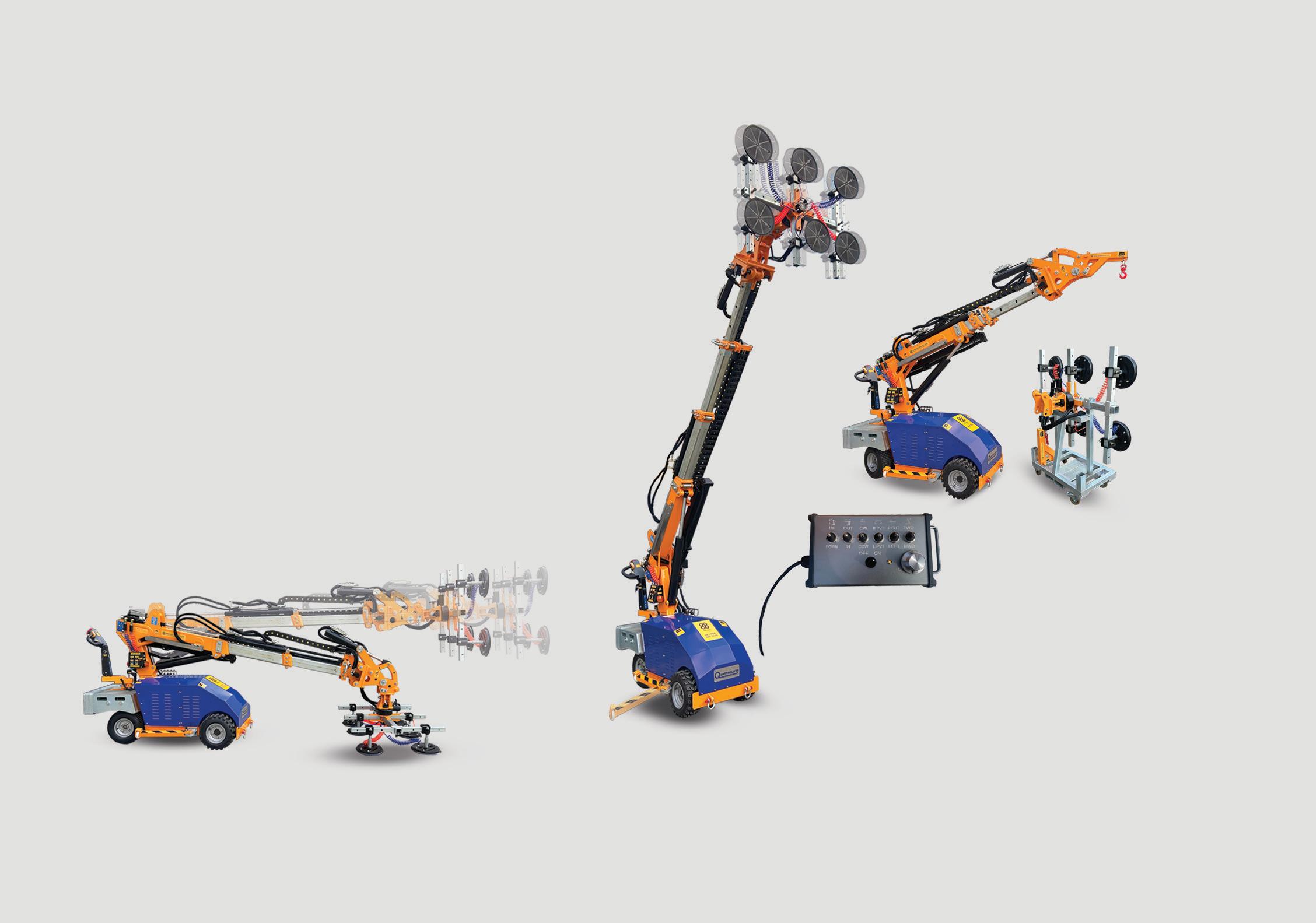

XTRA REACH WITH POWERED ROTATION

LIFTING CAPACITY UP TO 600KG

• Rechargeable Batteries via 240V Outlet

• 3 x Stage Boom: 2 x Powered & 1 x Manual

• Interchangeable: Vacuum Head to Jib Hook

• Custom Storage Stand on Castor Wheels

• Dual Vacuum System with Sensors & Alarms

• 6 x Adjustable Vacuum Cups

• Front Wheel Drive with Off Road Tread

• 800mm Width – using only single Front Wheels

• EXTRA – Set of Front Wheels for Traction & Stability

• EXTRA – Set of Out Riggers for Stability at 5m heights

• Will combat Firm, Uneven ground – Not 4WD terrain

*Optional Drive-on/off; Lockable; Tandem Trailer

5 x Degrees of Precision Movements…

• Elevation • True Side-shift at the Vacuum Head

• Forward Extension • Tilt Vertical to Horizontal

• Powered 360° Rotation

FLACHGLAS Wernberg’s latest upgrade to its second laminating line marks a significant leap forward in glass manufacturing technology and sustainability. By integrating Glaston’s ProL system with patented Convection Control, the German glass specialist has not only streamlined its production processes but also unlocked new potential for high-value, complex laminates.

The modernisation follows a successful upgrade in early 2024 and continues FLACHGLAS’s strategic investment in advanced equipment. The new line handles intricate sandwich structures up to 100 mm thick and demanding interlayers like SentryGlas® and acoustic films — traditionally a challenge requiring manual packaging and trial-and-error recipes. With Convection Control, these laminates are now produced seamlessly, eliminating manual steps, reducing waste, and freeing up autoclave capacity.

Technical Manager Martin Geiss and Project Manager Julian Lobinger both emphasise the transformative impact of the technology. Uniform heating, achieved through precise airflow and temperature control, ensures consistent quality across all glass types — coated, painted, or Low-E — without the need for customised heating profiles. This not only simplifies operations but also minimises human error.

The results speak volumes. During the Glaston factory tour at GPD 2025 in Tampere, visitors witnessed an 83 mm thick laminate produced flawlessly in a single pass — no recipes, no delays, just precision and efficiency.

895 327

Beyond operational excellence, the upgrade delivers substantial energy savings, aligning with FLACHGLAS’s sustainability goals and reinforcing its competitive edge in the market. With a new tempering furnace already on order for 2026, FLACHGLAS continues to demonstrate its commitment to innovation and environmental responsibility.

This modernisation isn’t just a technical upgrade — it’s a strategic move that positions FLACHGLAS Wernberg as a leader in the future of laminated glass production.

For more information, please see www.glaston.net.

Here are three reasons why Glaston ProL technology is your best choice:

1. Unmatched yield and output

2. Lowest operating cost – highest

3. Lifetime business growth

Discover Glaston laminating technology.

SPIL Glass Software streamlines every step of your glass business from order entry to delivery while linking seamlessly with your accounting systems and any factory machinery It boosts productivity, cuts wastage, and maximises ROI Customisable and scalable, SPIL adapts to the needs of small to large-scale glass fabricators, helping you scale faster, serve better, and run a smar ter, more profitable operation.

In glass processing facilities, handling heavy drums filled with raw materials or chemicals can be challenging, especially in tight spaces where forklifts can’t reach. Drum lifters are the ideal solution, allowing precise and safe lifting without the need for large equipment.

Designed for delicate and secure grip, vacuum or mechanical drum lifters enable workers to load, unload, and position drums around machinery efficiently. They minimise the risk of damage to glass and prevent accidents in confined work areas.

Using the right drum lifter can improve safety, enhance productivity, and help maintain a safe working environment in space-constrained glass manufacturing settings.

For more information, please contact the team at Elegant IG on 02 9437 6500 or email office@elegantig.com.au

At Australian Glass Group (AGG), innovation goes hand in hand with our commitment to supported practical, sustainable solutions. We are proud to introduce product advancements, alongside an expanded service platform designed to support fabricators, architects, specifiers, and builders in meeting evolving glazing performance needs.

Insulglass Select® range of hardcoat LowE coatings, designed to provide maximum flexibility and choice at a time when local alternatives are no longer manufactured in Australia (the closure

of Oceania Glass). AGG ensures continuity for the industry by delivering these robust, durable coatings that can also be used single glazed:

• Select Clear (4 mm, 5 mm, 6 mm and 8 mm)

• Select Neutral (6 mm)

• Select Grey (6 mm)

• Select Reflective (6 mm)

Underpinning these product innovations is AGG Tech & Spec™, our dedicated technical guidance and specification support services. With decades of experience and deep industry integration, our team provides clear, practical advice to ensure glazing solutions meet compliance, performance, and design expectations. From energy efficiency compliance to complex façade requirements, AGG Tech & Spec™ gives our partners confidence in every stage of the process.

With new product options and expanded support, AGG continues to lead the way by combining innovation, choice, and expertise - ensuring every project achieves the perfect balance of performance, compliance, and value.

For more information, please see www.agg.com.au.

Cooling Brothers Glass Company has completed its acquisition of Bent & Curved Glass. This strategic move positions Cooling Brothers as Australia’s first fully integrated glass processor, capable of manufacturing and delivering a comprehensive range of architectural glass solutions nation-wide.

Through facilities located in Perth, Melbourne, and now Sydney, Cooling Brothers offers fabricators, glaziers and builders a singlesource glass design and manufacturing solution for any and every project requirement.

‘This acquisition streamlines and simplifies the way our clients order, receive and even install glass’, said Paul King, Managing Director of Cooling Brothers. ‘As an integrated processor, we are able to reduce transport costs, streamline administration and mitigate the supply chain risks that would typically be encountered when dealing with multiple glass suppliers.’

Sales and Marketing Director Vince Bianchini commented, ‘With everything from toughened laminated IGUs to curved and digitally printed glass now available under Cooling Brothers, we’re giving customers faster turnaround, fewer headaches, and more flexibility in design. In addition, the integration of curved glass creates new

From a single customer 16 years ago, to an international customer base spanning New Zealand, USA, Canada and Europe, SPIL Glass Software has become a trusted leader in glass industry technology.

Their journey began with Melbourne Safety Glass, their very first customer. Soon after, companies such as Chevron Glass, Geelong Glass & Aluminium, Stevens Glass, WA GlassKote, Direct Glass and Glasstech Cairns joined the SPIL family. Each one placed their confidence in SPIL to streamline operations, improve efficiency, and lead the digital transformation of an industry that had long relied on manual processes. Chevron Glass’ Steve Reynolds says ‘The dedicated SPIL Glass team worked closely with Chevron Glass staff and continue to do so, offering efficient program development and communication with key Chevron staff. A good working relationship has been established and continues to develop’.

What makes SPIL unique is its foundation: the software is architected in Australia, purpose-built for the specific demands of glass fabricators, yet scalable for global markets. Over time, SPIL evolved from a robust ERP into a complete ecosystem, covering order processing, capacity planning, MES integration, optimisation, cost tracking, and real-time business intelligence dashboards.

Today, SPIL empowers hundreds of users worldwide, delivering measurable improvements in productivity, traceability, and

opportunities for product innovation, especially in decorative glass, something we are very excited about.’

Founded in 1985 by Neil Finn, Bent & Curved Glass has long been recognised as Australia’s leading specialist in curved toughened, laminated, and annealed glass. The Sydney-based, family-owned company has contributed to some of the country’s most iconic projects. The business is now led by Mick Finn, who will continue to shape its future as part of the Cooling Brothers team.

‘This merger allows us to offer greater value to customers’, said Mick Finn. ‘Cooling Brothers is the ideal partner to carry forward Bent & Curved Glass’s legacy and unlock new design potential through integrated supply.’

This acquisition marks a bold new chapter for both companies and for the future of architectural glass in Australia.

profitability. As they celebrate their 16th year, SPIL continues to invest in AI, mobile apps, and predictive analytics, ensuring they don’t just keep pace with industry change — they help define it.

Sixteen years in, the story of SPIL is still being written, and it all began with a simple belief: that Australian innovation could set the benchmark for glass software worldwide.

For more information, please see www.spil.com.au or email info@spilglass.com.au.

As the Australian Glass Group (AGG) enters an exciting new chapter, it acknowledges the retirement of its long-serving CEO, whose leadership has been instrumental in establishing AGG as a leader in high-performance glass across Australia’s East Coast. With deep gratitude for his legacy, AGG now welcomes a new Country Manager, alongside refreshed leadership from 3 General Managers, each ready to guide AGG into the future.

Jason McGrath steps into the Country Manager role with a strong foundation in AGG’s business, having for the past 8 years served as Chief Financial Officer. His promotion reflects not only his proven leadership and financial expertise, but also his deep understanding of AGG’s culture, operations, and long-term vision. This continuity ensures stability during the transition, while his forward-looking approach positions AGG to grow strategically and continue delivering excellence to our valued partners, clients, and stakeholders.

AGG’s state-based General Managers bring a combined 94 years of glass industry expertise and local market knowledge. Together they strengthen AGG’s customer relationships, uphold technical and

compliance excellence, and ensure innovative, reliable solutions are delivered across every region we serve. Their leadership ensures that AGG remains agile, customer-focused, and well-positioned to meet the evolving demands of Australia’s construction and glazing industry.

Together, our Country Manager and State GMs bring a wealth of experience and energy, ensuring AGG remains the trusted partner for compliant, high-performance glazing solutions, made and supported right here in Australia.

Promoting daylighting, views, occupant well-being, energy efficiency and decreased carbon in buildings, glass is a wonderful building material. At the same time, typical glass facades are not friendly to bird wildlife. In North America alone, as many as one billion birds are killed every year flying into windows.

Compared to humans who have strong binocular vision, which enhances depth perception, a bird’s anatomy provides more spatial vision, enabling them to constantly scan their surroundings in search of food and places to land. Whereas human eyesight clearly detects the presence of glass, birds cannot perceive glass as a barrier.

Fortunately, this is a solvable environmental issue with the development of bird safe glass technologies, bird safe legislation and building codes. As bird preservation and bird-friendly architecture continues to gain traction, architects and building owners will be seeking high quality products and solutions to prevent bird collisions while maintaining the strength and glazing performance characteristics of glass.

At least 25 cities and states in the USA including Washington and NYC, have enacted legislation requiring bird safe glass in buildings.

While in Europe, Germany and Finland are among the first European countries to begin implementing similar polices. Locally, there are several bird conservation groups who have been actively lobbying government, local councils and architects to follow suit.

There are several options available. Bird protection patterns can either be added directly in production or applied retroactively with laser printing process.

For more information, please contact one of the Elegant IG team on office@elegantig.com.au or call us 02 94736500.

are killed ever y windows

The National Association of Testing Authorities (NATA) is Australia’s leading accreditation and testing body, with over 350 accredited organisations listed on its website. AGWA is proud to be among them.

The NATA audit is a key component of AGWA’s Accredited Companies Program (ACP), reflecting our commitment to compliance and quality as the leading authority in the Australian window industry.

In mid-2025, AGWA representatives met with Laura Ciocan, NATA Accreditation Specialist, for our annual audit. While more rigorous than member audits, the process adhered to the same principles: certainty, competence, compliance, and integrity.

The audit was conducted over a full day at AGWA’s Pymble Head Office, where ACP processes and documentation were thoroughly reviewed. Procedures were examined and verified against ISO/IEC10720 Standards.

Following the audit, an interim report was issued noting any nonconformities and minor findings. The report identified remedial actions with follow-up required within a specified timeframe. Observations and minor issues were also recorded for future improvements.

We are pleased to report that AGWA successfully passed the audit. This outcome reinforces the reliability and integrity of our ACP and assures members that our internal standards meet the same high level of compliance we expect from them.

Gold and Platinum tier members were not required to undertake an on-site audit in 2025.

Instead, Self-Declaration forms were sent out mid-year to those who qualify with regular reminders to return.

If you haven’t got it in yet it’s not too late. If you need the form resent, please advise.

For specific queries about the form or accreditation in general, please contact either me (Viv Munter at accred@agwa.com.au) or our Accreditation Manager James Whitehouse on 0448 610 203.

Thank you for your assistance and wishing you all a very safe and happy festive break.

In the small state of Tasmania, GP Glass, founded by Brian Imlach in 2004, has grown to become one of the largest glazing and fabrication companies,.

In June 2025, after a short battle with cancer, Brian sadly passed away. His loss was deeply felt across the company — not only as a founder and leader, but also as a mentor and friend to many.

Brian was dedicated to creating a workplace that was welcoming, safe and well-equipped. He invested heavily in modern machinery, vehicles and cranes to ensure his team had the right tools to make their jobs easier and safer. One of his most notable innovations was the ‘Glass Lifter’, designed specifically for the NRAS project, where the commercial team was tasked with installing 100 kg windows across 9 storeys. Brian’s design was lightweight, strong and transportable. In 2016 it won the Tasmanian Glass and Aluminium Association Safety Award, followed by the National Award from the Australian Glass and Glazing Association.

In GP Glass’ early years, Brian was hands-on in every sense, not only within the company but also within the Tasmanian Glass and Aluminium Association. He generously shared his knowledge with both his team and the broader industry. In recognition of his contributions, he was awarded Service Person of the Year in 2017, honouring his commitment to advancing the Tasmanian glazing and fabrication industry.

It is with deep respect and admiration that we remember the life and legacy of Michael Harry Millard, the visionary founder and pioneer behind Alspec.

Michael’s journey is one of remarkable grit, determination, and entrepreneurial spirit. A true pioneer in the aluminium industry, he began by selling swimming pool handles and towel rails from the back of his VW Beetle, door-knocking his way through Western Sydney. That humble image captures the essence of who Michael was; driven, hands-on, and never afraid of hard work.

From those modest beginnings, Michael laid the foundation for what would become a national leader in the aluminium industry. His one-man operation grew into a business that has shaped the built environment across Australia, setting standards in innovation, quality, and service.

But Michael’s legacy extends far beyond business success. He was a proud company man who believed deeply in the power of people. He knew that Alspec’s greatest strength wasn’t just in its products or its growth — it was in its team. Michael made it a point to know people’s names, their stories, and their contributions. He built a culture of respect, loyalty, and shared purpose that continues to define Alspec today.

There are many business owners in the world, but Brian was truly one of a kind. His passion for his work, his customers and above all, his employees, was something that couldn’t be taught. From the very beginning, he led his team with integrity, care and vision.

Brian’s legacy will live on through GP Glass, with his management team — Martin, Tristan, Wilfred and Marcus — continuing to carry the company forward in the way Brian always intended.

Michael was a true visionary and pioneer. As Alspec looks to the future, it does so on the solid ground built by his values, his leadership, and his unwavering belief in what could be achieved through hard work and unity.

We honour Michael’s memory and the extraordinary legacy he leaves behind.

SUITS YOUR STYLE. FITS YOUR FRAMES.

Bold, beautiful aluminium front doors, custom made to fit your own frames. Add Parkwood’s premium doors to your product offering, powder coated in any colour, for the complete exterior joinery package.

Connect with a door specialist on 1800 681 586, at sales@parkwooddoors.com.au or visit parkwooddoors.com.au