Celebrating excellence in the glass, window and security screen industries

DESIGN AWARDS

Showcasing our State Design Award Winners

TECHNICAL

Windows After NCC 2022

TECHNICAL

A Level Playing Field

Celebrating excellence in the glass, window and security screen industries

DESIGN AWARDS

Showcasing our State Design Award Winners

TECHNICAL

Windows After NCC 2022

TECHNICAL

A Level Playing Field

The Forge series by Austral Lock provides a modern, whole of house solution for hinged and sliding security screens, surface mount patio doors, mortice sliding and hinged doors as well as bifolds.

Designed to share a consistent aesthetic, the range of door furniture is backed by expert locking technology and can be locally powder coated to colour match systems.

With Austral Lock it’s secure, with Forge it’s a family.

BuiltView Magazine is a quarterly publication of the Australian Glass & Window Association.

EDITORS

Melissa Baker

Ingrid Pagura

SUB EDITOR

Helen Dawes

DESIGN

Webqem Pty Ltd

Sehar Maniar, AGWA

EDITORIAL & ADVERTISING ENQUIRIES

Helen Dawes

+61 2 9498 2768 marketing@agwa.com.au

PUBLISHED BY

AWA-AGGA LIMITED

ABN 57 629 335 208

Suite 101B, Level 1, Building 1, 20 Bridge Street, Pymble NSW 2073 +61 2 9498 2768 admin@agwa.com.au www.agwa.com.au

COVER IMAGE & CONTENTS PAGE IMAGE

Decjuba’s Head Office by ODS Windows, entry in 2025 AGWA Design Awards Commercial Window or Glass Project Over $750,000.

Builder: Figurehead Construction

Architect: Jackson Clements Burrows

Photography: Peter Clarke

CONTRIBUTORS

Clinton Skeoch, Glen Qi, Ingrid Pagura, Adam Davies, Tim Johnston, Jesse Ross, Vivienne Munter, Rafaella Kavouras, Matteo Patalocchi, Francesco Querci, Rick Carlei, Shane Sweet, Mari Lehtinen, Elizabeth Dimabuyu, Lido Russo, Jelena Ninkovic, Daniel Johns, Roger Bishop, Davide Giaccotto, Samara Davis, Lucy Kendall, Helen Dawes, Melissa Baker, Kerrie Henderson, Sehar Maniar and Tyler Gonzales.

PRINTED BY

SOUTHERN IMPACT

southernimpact.com.au

Our printer conforms to the ISO-14001 environmental management standard and the ISO-9001 quality management standard.

DISTRIBUTED BY

D & D MAILING SERVICES

www.ddmail.com.au BuiltView Magazine is proudly packaged in Biowrap, 100% degradable plastic wrapping.

DISCLAIMER

Copyright © 2025. All rights reserved. Reproduction in whole or part without written permission from AWA-AGGA Limited is strictly prohibited. It is impossible for the publisher to ensure that the advertisements and other material herein comply with the Australian Consumer Law Competition and Consumer Act 2010. Readers should make their own inquiries in making decisions and where necessary, seek professional advice.

Clinton Skeoch

Executive Director and CEO, AGWA

As we welcome you to the Spring edition of BuiltView, the industry continues to navigate a period of considerable uncertainty. At the time of writing, the final scope, timing, and stringency of NCC 2025 remains unknown, creating ambiguity for window and glass manufacturers, builders, and designers alike. While I expect that the change will come through and it will likely align to the consultation process to date, exactly what it will look like, and when it will go live is at this time still unclear.

This regulatory ambiguity is all playing out in a policy environment heavily focused on reducing regulatory burden. Across both state and federal levels around the country, governments remain fixated on the challenge of building more homes, faster. That focus will no doubt bring opportunity, but it will also bring complexity, as longstanding compliance frameworks — particularly those tied to energy and performance — compete with new planning and supply-side pressures.

Tim Johnston’s article on page 42 of this edition captures the energy landscape emerging from NCC 2022, and the continuing rollout of 7-star requirements. The article outlines, in clear detail, the change towards higher performing glass and windows, noting that many of the specifications coming in planning approvals are unlikely to be fully realised for at least 6 months.

We also recognise that many AGWA members continue to face a challenging operating environment. Tight margins, delayed approvals, and fluctuating demands remain part of the day-to-day reality. It’s why our commitment to a fair and level playing field remains as strong as ever.

The continued rollout of the Prime Auditing System, alongside our recent overseas factory inspections explained later in the magazine on page 32, demonstrate the Association’s commitment in action. These efforts are not about bureaucracy — they are about making sure that all players, no matter where they’re based, are held to the same compliance expectations.

Thank you again for your continued support. This edition continues the ongoing traditions of celebrating industry excellence in products, projects and people, and I want to take a moment to congratulate all our state 2025 AGWA Design and Industry Award winners and their teams. I wish you all the best in the upcoming National Awards.

Clinton

Executive Director and CEO

Ingrid began her role with AGWA in May 2021 looking after the training needs of members. Her role soon progressed to include working on BuiltView, safety, the AGWA Design Awards, the website and other marketing-related activities.

Prior to AGWA, Ingrid worked for a legal publishing company. Her time at Butterworths saw her work on their building and local government and environment suite of products and with the CSIRO and ABCB on other BCA projects. She also previously worked for many years as a part time teacher at TAFE.

and

Adam holds a degree in Materials Engineering and started his glass career as a part-time employee at the Viridian Ingleburn float line in his final year of study, moving into a full-time role as a Process Engineer and later to Technical Manager at Viridian.

Adam has seen most aspects of the industry. Adam’s role supports and participates in extensive technical enquires, technical documentation development, dispute resolution, non-conformance investigation and independent technical inspections and reporting.

Clinton has more than 20 years’ experience across building products, research and development and member services’ industries and with roles covering areas as diverse as supply chain management, sales, marketing, export market development, strategic management and planning, research and development, and industry advocacy. He is known for his passionate collaborative style when it comes to working with industry stakeholder groups and aligned partners. He is also the Chair of the Australian Fenestration Rating Council.

Jesse Ross holds a Bachelor of Civil Engineer (Honours) Degree with research and practical experience in testing the structural resistance of timber composite members as a part of his thesis project. Having graduated from university, Jesse joined AGWA full-time in the beginning of 2025 to take on the AFWI Modernising Timber Windows project.

Copywriter, Trade Advertising Agency

Angela is a marketing and advertising Copywriter with Sydney’s Trade Advertising Agency, crafting words and ideas for all kinds of buildingrelated brands. Growing up by her builder Father’s side and becoming a renovation aficionado — writing for AGWA is close to Angela’s heart and hands.

Glen graduated with a Bachelor of Economics from the Australian National University in 2024.

He joined HIA in 2025, and his responsibilities involve contributing to HIA’s suite of publications and articles.

Tim joined AGWA in July 2023. With a degree in Architecture from the University of New South Wales, as well as postgraduate qualifications in environmental management and economics, Tim has more than 25 years’ experience working in the built and natural environment, not for profit industry associations, private and government sectors.

COMMERCIAL PROJECT OVER $750,000 Winner

Dowling Street Bespoke Facade Venture Projects

ARCHITECT: Smart Design Studio

PHOTOGRAPHER: Michael Kennedy Photography

COMMERCIAL PROJECT OVER $750,000 Highly Commended

COMMERCIAL PROJECT $250,000 TO $750,000 Winner

Addler Building

Arch System Fabrication Pty Ltd

ARCHITECT: TKD Architects

BUILDER: Grindley Construction

PHOTOGRAPHER: Brent Chidgey

Bay Street Double Bay

Arch System Fabrication Pty Ltd

ARCHITECT: Lawton Hurley Pty Ltd

BUILDER: Alliance Living Pty Ltd

PHOTOGRAPHER: Tyrone Branigan Productions

COMMERCIAL PROJECT $250,000 TO $750,000 Highly Commended

DLG Aluminium & Glazing

DLG Aluminium & Glazing

ARCHITECT: Leanne Luhrs

BUILDER: Dean Luhrs

PHOTOGRAPHER: Threefold Studio

COMMERCIAL PROJECT $250,000 TO $750,000 Highly Commended

Iglu Apartments

Paarhammer Windows

ARCHITECT: Icon Construction

COMMERCIAL PROJECT UNDER $250,000 Winner

Surfrider Dee Why Railsafe

ARCHITECT: RHM Consultants

BUILDER: Rod Finlayson Remedial Building

PHOTOGRAPHER: Online Projects

COMMERCIAL PROJECT RETROFIT Winner

RESIDENTIAL PROJECT OVER $80,000 Winner

Montana Apartments

Paarhammer Windows

BUILDER: Renfay

Janet St Merewether Shamrock Joinery & Associates Pty Ltd

ARCHITECT: ASJP Architecture

BUILDER: Ledbury Constructions

PHOTOGRAPHER: Ben Hosking

RESIDENTIAL PROJECT OVER $80,000 Highly Commended

Ahearn Street - Coogee Magic Glass

ARCHITECT: Pinnacle Design Studio

BUILDER: Alpha Build PHOTOGRAPHER: Tom Wholohan Photography

RESIDENTIAL PROJECT OVER $80,000 Highly Commended

Terra Firma Evolution Window Systems

ARCHITECT: Luigi Rosselli Architects BUILDER: Buildability Constructions

RESIDENTIAL PROJECT UNDER $80,000 Winner

Hume House Tweed Coast Glass

ARCHITECT: CMR Constructions

BUILDER: CMR Constructions

PHOTOGRAPHER: Simon Langford

RESIDENTIAL PROJECT UNDER $80,000 Highly Commended

Cake House Mollymook Australian Glass Group

ARCHITECT: Alexander Symes Architecture BUILDER: Skylar Construction PHOTOGRAPHER: Barton Taylor

RESIDENTIAL PROJECT RETROFIT Winner

Natural Haven - Project 465 Paarhammer Windows

ARCHITECT: Robertson Collectif Studio BUILDER: Arthouse Projects PHOTOGRAPHER: Annamul

RESIDENTIAL PROJECT RETROFIT Highly Commended

BESPOKE PROJECT DESIGN Winner

BESPOKE PROJECT DESIGN Winner

Castlecrag Retrofit Windoor Joinery

BUILDER: Grantham Provincial PHOTOGRAPHER: Ladyphoto

The Potting Shed Grose Vale Evolution Window Systems

ARCHITECT: Michael Brookes

BUILDER: Michael Brookes PHOTOGRAPHER: Donna Brookes

King Street Wharf Magic Glass

ARCHITECT: PMDL Architecture + Design Pty Ltd

BUILDER: Mainbrace Constructions

PHOTOGRAPHER: Reeled Media

BESPOKE PROJECT DESIGN Highly Commended

Ozone Cronulla Magic Glass

ARCHITECT: PBD Architects

BUILDER: Versatile

LARGE SHOWROOM OF THE YEAR Winner

SHOWER SCREEN OR BARRIER PROJECT Winner

Aluluxe Gallery

Tweed Coast Glass

BUILDER: Tweed Coast Glass

PHOTOGRAPHER: Simon Langford

Collaroy Plateau Residence

Glazed Co Pty Ltd

PHOTOGRAPHER: Studio Pisani

SMALL SHOWROOM OF THE YEAR Winner

Aura Windows & Doors

Aura Windows & Doors

BUILDER: The Goods Carpentry

COMMERCIAL PROJECT OVER $750,000 Winner

Kangaroo Point Green Bridge

G.James Specialised Glazing

ARCHITECT: Blight Rayner Architecture and Dissing+Weitling

BUILDER: BESIX Watpac PHOTOGRAPHER: Fortitude Valley 4006

COMMERCIAL PROJECT $250,000 TO $750,000 Winner

ARUP Brisbane City MHC Carpentry Glazing Tiling

ARCHITECT: HASSELL BUILDER: Buildcorp PHOTOGRAPHER: Mizzi Media

COMMERCIAL PROJECT UNDER $250,000 Winner

COMMERCIAL PROJECT RETROFIT Winner

Brunswick Street Fortitude Valley Next Gen Glass & Aluminium

ARCHITECT: Red Door Architecture

BUILDER: Apollo

PHOTOGRAPHER: Apollo

Chermside Regional Office Park G.James Facade Solutions

ARCHITECT: Plus Architecture

RESIDENTIAL PROJECT OVER $80,000 Winner

BESPOKE PROJECT DESIGN Winner

Blackwood Doonan

G.James Windows & Doors

RESIDENTIAL PROJECT UNDER $80,000 Winner

Warraba House

Bretts Architectural Window Solutions

ARCHITECT: OH Architecture

BUILDER: JH Dixon Builders

PHOTOGRAPHER: Jack Gibson Photographer

SHOWER SCREEN OR BARRIER PROJECT Winner

Inside Glass Art Installation

G.James Specialised Glazing

ARTIST: Jana Sterbak

Paddington

Euroglass Australia

ARCHITECT: Winacres and Euroglass

BUILDER: WinAcres Property Group

PHOTOGRAPHER: Rob Gerlach

MOST INNOVATIVE PRODUCT OR SERVICE Winner

Grace House Kintrol Pty Ltd

ARCHITECT: Tzannes Architects BUILDER: Sherington Project Management

COMMERCIAL PROJECT OVER $750,000 Winner

Coopers Brewery Packers

BUILDER: Built

COMMERCIAL PROJECT OVER $750,000 Highly Commended

COMMERCIAL PROJECT $250,000 TO $750,000 Winner

Burnside Village Shopping Centre Aluco

ARCHITECT: Buchan Group

BUILDER: Hansen Yuncken

Flinders Chase Visitor Centre Pagel Glass

ARCHITECT: Troppo Architects

BUILDER: Harrold & Kite

PHOTOGRAPHER: Harrold & Kite

COMMERCIAL PROJECT $250,000 TO $750,000 Highly Commended

Lyndoch Recreation Park Aluco

COMMERCIAL PROJECT UNDER $250,000 Winner

COMMERCIAL PROJECT RETROFIT Winner

ARCHITECT: Walter Brooke

BUILDER: Built West Beach Surf Life Saving Club Packers

BUILDER: Partek Construction & Interiors

PHOTOGRAPHER: Packers

RESIDENTIAL PROJECT OVER $80,000 Winner

ARCHITECT: Studionine Architects

BUILDER: F&E Rocca Builders & Contractors PHOTOGRAPHER: Tyler Marsland

ARCHITECT: D M Lawrence Design BUILDER: Gaston Developments 45 Pirie Street Redevelopment Construction Glazing

Wirrina Cove Residence Project Mount Barker Glass

RESIDENTIAL PROJECT UNDER $80,000 Winner

RESIDENTIAL PROJECT RETROFIT Winner

RESIDENTIAL PROJECT UNDER $80,000 Highly Commended

BESPOKE PROJECT DESIGN Winner

ARCHITECT: JPE Design Studio

BUILDER: BADGE

PHOTOGRAPHER: Brendan Mann

SHOWER SCREEN OR BARRIER PROJECT Winner

Burnside Village Balustrades Construction Glazing

ARCHITECT: Buchan Architects

BUILDER: Hansen Yuncken

PHOTOGRAPHER: Tyler Marsland

COMMERCIAL PROJECT OVER $750,000 Winner

LARGE SHOWROOM OF THE YEAR Winner

South Pacific Aluminium Windows & Doors

South Pacific Aluminium Windows & Doors

COMMERCIAL PROJECT $250,000 TO $750,000 Winner

COMMERCIAL PROJECT UNDER $250,000 Winner

Laurderdale Primary School City Glass Tasmania

ARCHITECT: X - Squared Architecture

BUILDER: Fairbrother Construction

PHOTOGRAPHER: Marcus Turner

RESIDENTIAL PROJECT UNDER $80,000 Winner

Lyne Street Eaglehawk Neck City Glass Tasmania

ARCHITECT: Martin Stephens

BUILDER: Lawless Builders

RESIDENTIAL PROJECT OVER $80,000 Winner

Brambletye Homestead Cityline Windows & Doors

ARCHITECT: Design Intent

BUILDER: Hadyn Brewer Constructions

PHOTOGRAPHER: Prime Perspectives

BESPOKE PROJECT DESIGN Winner

Mary’s Cathedral

COMMERCIAL PROJECT OVER $750,000 Winner

COMMERCIAL PROJECT OVER $750,000 Highly Commended

Name of Place Name of Company

The Esplanade Brighton Reynaers Australia

ARCHITECT: BUILDER: PHOTOGRAPHER:

ARCHITECT: Wood Marsh DEVELOPER: SC Land PHOTOGRAPHER: Chris Matterson Photography

COMMERCIAL PROJECT $250,000 TO $750,000 Winner

Truganina Community Centre SMB Glass Windows & Doors

ARCHITECT: Canvas Projects BUILDER: CICG PHOTOGRAPHER: CICG

Bert Newton Retirement Village - Building 1 SMB Glass Windows & Doors

Name of Place

Name of Company

ARCHITECT: City Glass & UTAS BUILDER: Ryman Healthcare PHOTOGRAPHER: ANCR

ARCHITECT: BUILDER: PHOTOGRAPHER:

COMMERCIAL PROJECT $250,000 TO $750,000 Highly Commended

Knox Regional Netball Centre SMB Glass Windows & Doors

ARCHITECT: k20 Architecture BUILDER: Devco Project & Construction Management PHOTOGRAPHER: Courtesy of Devco

COMMERCIAL PROJECT UNDER $250,000 Winner

Aspendale Life Saving Club SMB Glass Windows & Doors

ARCHITECT: NBRS

BUILDER: 2 Construct

PHOTOGRAPHER: Tom Roe

RESIDENTIAL PROJECT OVER $80,000 Highly Commended

River House Ocean Grove

Portland Aluminium & Glass

ARCHITECT: AD Architecture

BUILDER: Surfview Builders

PHOTOGRAPHER: Seebeck Photography

RESIDENTIAL PROJECT OVER $80,000 Winner

Melbourne Project European Window Co.

ARCHITECT: Christopher Doyle Architects BUILDER: Davies Henderson

PHOTOGRAPHER: Mark Roper Photography

RESIDENTIAL PROJECT OVER $80,000 Highly Commended

The Panel House Warrandyte BINQ Windows

ARCHITECT: Sustainable Building Design

BUILDER: G-LUX Builders

PHOTOGRAPHER: Marnie Hawson

RESIDENTIAL PROJECT OVER $80,000 Highly Commended

ARCHITECT: SJB Interiors BUILDER: Easton Co.

RESIDENTIAL PROJECT UNDER $80,000 Winner

ARCHITECT:

RESIDENTIAL PROJECT UNDER $80,000 Highly Commended

RESIDENTIAL PROJECT UNDER $80,000 Highly Commended

RESIDENTIAL PROJECT UNDER $80,000 Highly Commended

Murray Street, Gol Gol Vivid Glass, Windows & Doors

BUILDER: 808 Constructions

PHOTOGRAPHER: AdMedia

BESPOKE PROJECT DESIGN Winner

RESIDENTIAL PROJECT RETROFIT Winner

Glint House BINQ Windows

ARCHITECT: Imogen Pullar Architecture BUILDER: J&RC Builders PHOTOGRAPHER: Marnie Hawson

Moonga Road Toorak K&B Windows Pty Ltd

ARCHITECT: STA Architecture and Interior Design BUILDER: H Daniel Constructions

SHOWER SCREEN OR BARRIER PROJECT Winner

Hubert Opperman Showerscreens SMB Glass Windows & Doors

ARCHITECT: Ryman Health Care BUILDER: Ryman Health Care PHOTOGRAPHER: Ryman Health Care

COMMERCIAL PROJECT $250,000 TO 750,000 Winner

Hands Oval Stadium

LGA (WA) Pty Ltd

ARCHITECT: Cameron Chisolm & Nicol (WA) Pty Ltd

BUILDER: Perkins Builders

PHOTOGRAPHER: Ange Wall

COMMERCIAL PROJECT UNDER $250,000 Winner

Dane Design Australia Office

Busselton Aluminium Windows

ARCHITECT: Dane Design Australia

BUILDER: Dane Design Australia

PHOTOGRAPHER: Ange Wall Photography

RESIDENTIAL PROJECT OVER $80,000 Winner

RESIDENTIAL PROJECT OVER $80,000 Highly Commended

Fern Road

Busselton Aluminium Windows

ARCHITECT: Dane Desing Australia

BUILDER:Dane Desing Australia

PHOTOGRAPHER: Ange Wall Photography

Mosman Park

Westec Doors & Windows Pty Ltd

ARCHITECT: Mowbray Architecture

BUILDER: Luxus Homes

PHOTOGRAPHER: Stephen Nicholls Photography

RESIDENTIAL PROJECT UNDER $80,000 Winner

The Luxe Jason Windows

BUILDER: Novus Homes

PHOTOGRAPHER: Novus Homes

SHOWER SCREEN OR BARRIER PROJECT Winner

BESPOKE PROJECT DESIGN Winner

ARCHITECT: State 28 Interiors

BUILDER: Project West Pty Ltd

PHOTOGRAPHER: Tracey Hilton

ARCHITECT: Smith Sculptors

MOST INNOVATIVE WINDOW SYSTEM Winner

ARCHITECT: Silver Thomas Hanley BUILDER: Multiplex Constructions Pty Ltd

Glen Qi Economist, HIA

Victoria stands out as the only mainland state in which home prices have remained stagnant in the last few years. While home prices nationally have risen by 15.4% since late 2022, and Western Australia has observed more than a 40% increase in prices, Victoria’s home prices have only increased by 1.4%.

The reasons for this are simple; the price is a result of demand and supply.

Demand side

The loss of population explains much of Victoria’s home price trends, with a population of 210,000 fewer than its pre-pandemic trajectory would have implied by now.

Population growth in Victoria was 2.0% per year in the decade prior to the pandemic. From June 2020 an exodus of population from Victoria occurred, with 67,200 people leaving Victoria in the 2020-21 financial year. This is 5 times the population loss observed in New South Wales in the same period. The return of overseas migration has backfilled only some of this population loss, most recently slowing back to 1.9% in 2024, below its prepandemic pace.

This significantly slower growth in population equates to slower than anticipated growth in demand for homes. This is central to why Victoria has been more successful in matching supply and demand for homes, and stabilising house price growth.

Supply side

The volume of new home building in Victoria continued, largely unabated, through the pandemic and beyond. In the 5 years to 2019, Victoria commenced 332,000 homes. Despite the disruption of the pandemic, Victoria still commenced a further 301,000 homes in the 5 years to end 2024. That is just a 10% fall in home supply at a time that population fell.

The ongoing demand for homes through this cycle reflects the depth of the housing shortage in Australian capital cities. Even a population decline for 2 years, combined with home building at capacity, wasn’t sufficient to lower home prices.

Confidence problem

There is a third factor that has adversely affected home prices in Victoria, and this is confidence.

The Victorian Government introduced significant land tax reforms on the 1 January 2024 through a reduction in the tax-free threshold and increased rates. These changes prompted domestic investors to exit the market, increasing the volume of established homes available for purchase.

These additional taxes have damaged market confidence and affordability, further contributing to lower levels of demand and slower home price growth than what might otherwise occurred.

Conclusion

Victoria is a prime example where increasing supply, relative to demand, is still the key determinant of home prices.

Looking ahead, with migration returning to high levels and the volume of new home starts in Victoria falling under the weight of higher interest rates, it is unlikely that Victoria will maintain these stable home prices for long. There is a risk that we will observe a ‘bull whip’ effect if home building in Victoria is suppressed by ongoing increases in taxes and red tape.

After all, even a parrot can be an economist. All it must learn are the words ‘supply’ and ‘demand’.

Ingrid Pagura Industry Development Coordinator, AGWA

As a PCBU, we spend a lot of time identifying hazards and controlling them to fulfill our primary duty under the WHS Act and Regulations. We put up posters to make sure that our workers have the correct PPE and know where the fire exits are located. We might even make them sit through a Toolbox Talk.

But is that enough to ensure our workplaces are safe? A safe workplace really relies on more than that. It relies on us having good worker capability. So, what does that mean? Simply, that our workers are only as safe as the information, instruction, training and supervision we provide them, so that they can understand the potential risks, the systems and control measures in place, how to work in a healthy and safe way and how to respond to emergencies.

To ensure that good worker capability here are some simple steps for PCBUs.

1. Induct workers

When a new worker starts in your workplace, you must give them training to help them become familiar with their work, coworkers and environment. This means more than just getting them to read something and sign it.

Use this time to discuss with them their obligations to WHS, how to use equipment safety, the hazards in the workplace and how they are controlled, how to report hazards, injuries and incidents, emergency procedures and anything else specific to your workplace. This is a great opportunity to set the tone for safety in your workplace and make sure that they understand how important it is.

2. Provide information to suit individual needs

There are different roles within your team so you can’t provide a one-size-fits-all solution to information available. For example, workers on the factory floor cutting glass will need to know about different types of PPE to those who are delivering glass. Some roles may also require specific training or licences, eg, overhead cranes.

Finally, consider the diversity of workers. Those workers who are from a culturally diverse background, young workers and labourhire workers may, for example, also need additional assistance. Keeping information simple and easy encourages better uptake.

3. Make sure workers are trained and competent

Make sure that all your workers are competent to perform the tasks they are required to do. This means making sure that they gain the knowledge and skills required to perform tasks. You can’t just assume that they know how to perform a procedure correctly. Demonstrate it step by step, watch them do the task and then assess their ability to complete it safely. This should be done for all new workers but also for new tasks or new work practices and procedures. I know you are busy but rushing this now will mean you spend twice as long correcting things later!

Do they need a licence to complete a task? Check this and make sure it is current and appropriate for the task they are completing. Keep records of all the training you’ve done with your workers and review it regularly to make sure it is still working well. For any formal training the worker may have completed, keep a record of that as well and track any expiry dates so they can retrain before that date.

4. Provide the right supervision for workers

Finally, supervising your workers will make sure your procedures are followed correctly, that no one is taking dangerous shortcuts and that everyone is looking out for their own and coworker’s safety. Check that everyone has the correct PPE for the task they are performing and that they don’t bypass any safety controls.

Spending a bit of time to make sure your workers are well equipped in their safety knowledge will save you a lot of time and money later. Invest time in your workers and you’ll reap the benefits with a safe workplace and minimal downtime for injuries.

For help with all your Safety needs and resources to assist you, please see agwa.com.au/members/businesssupport/safety or contact training@agwa.com.au.

Not sure of what to talk about in your next Toolbox Talk?

Let AGWA make that task easy for you. As part of AGWA’s ongoing commitment to safety, we launched the 2025 AGWA Safety Calendar with a different topic focus every month. Throughout that month you’ll receive news posts and emails on a specific topic filled with information, tips, and resources. You’ll also receive a toolbox talk on an element of that topic. Why not let AGWA do the hard work for you and use these free resources. For more information, please contact training@agwa.com.au.

Clinton Skeoch Executive Director and CEO, AGWA

In late May this year, AGWA sent our Head of Technical Russell Harris and our staff Auditor Leanne Xerri to China to support our on-the-ground audit team in our annual accreditation audits. The review encompassed a 2-week mission across the window manufacturing hubs of Shanghai and Guangzhou. Our goal? To support compliance and a level playing field for products destined for the Australian market, ensuring that companies trading in Australia understand and meet the rigorous performance standards expected of members — and, ultimately, Australian consumers should receive.

The primary purpose of this trip was to conduct a comprehensive assessment of the compliance and quality assurance practices within the window manufacturing and testing sector.

The core components of this process include:

1. Assessment of Product Conformity Declarations (PCDs)

A primary objective of our investigations was to perform a comprehensive review of Product Conformity Declarations submitted by manufacturers. These assessments are undertaken to ensure that PCDs accurately represent the full range of products supplied to the Australian market and confirm that each product has undergone complete and comprehensive testing.

On-site audits of manufacturing facilities to verify compliance with AS 2047 and the NCC, focused on production processes, quality control systems, material traceability, labelling practices, and the overall conformity of manufactured products with the performance and safety requirements mandated by the Standards and the NCC.

Inspections of window testing laboratories to assess their adherence to the requirements outlined in AS 4420.1 Methods of test for windows and AS 2047 Windows and external glazed doors in buildings, evaluating the laboratories’ testing methodologies, equipment calibration, accreditation status, and their ability to produce reliable and repeatable test results in accordance with the prescribed Standards.

Over the 2-week period, AGWA conducted a series of targeted assessments across multiple sites, including audits of both physical test specimens and production outputs to evaluate critical attributes such as framing, hardware, glass selection, and construction methods. These were then compared against supporting documentation to verify compliance with Australian Standards for structural capacity (wind loads), water penetration resistance, energy efficiency and, where appropriate, bushfire or acoustic requirements. Certifications for safety glass (AS 2208) and IGU (AS 4666) production were independently verified.

All production records were reviewed in detail, with specifications cross-referenced against test reports to confirm consistency between declared performance and actual output.

Why all this effort? It’s no secret that AGWA is about supporting a fair and level playing field and enhancing the confidence and integrity of our industry, the cornerstone of which is our unwavering support for fair and equitable competition based on compliance and a level playing field.

Importantly, this level playing field must extend beyond our borders. By including overseas manufacturers in the same accreditation and audit framework as local producers, AGWA can

ensure that the products entering the Australian market are held to the same rigorous standards as locally-made product. This not only protects consumers but also upholds the integrity of the Australian industry by preventing non-compliant or substandard products from gaining an unfair advantage. This approach fosters transparency, accountability, and a stronger, more competitive market for everyone.

AGWA audits are third-party, objective peer assessments conducted at a technical level, based on product conformity to the NCC and relevant Australian Standards. These surveillance audits are complex and time-intensive, but they are the foundation of AGWA’s commitment to integrity, consistency, and market confidence.

In the weeks ahead, our team will address dozens of followup actions to ensure all accreditation conditions are met. We will continue the implementation of the Product Conformity Declaration (PCD) process, both domestically and internationally. These ongoing efforts reinforce AGWA’s commitment to a fair and consistent regulatory framework — ensuring the industry operates on a level playing field. While demanding, this process is fundamental to maintaining the strength, credibility, and reputation of the entire sector.

AGWA is a NATA-Accredited Inspection Agency operating under ISO/IEC 17020 Conformity assessment – Requirements for the operation of various types of bodies performing inspection. The scope of ISO/IEC 17020 covers the independence, impartiality and integrity of the inspection body and the competence of its people, its inspection processes, and its equipment.

Windows that stand up to Australia and stand the test of time.

From coastal winds to scorching summers and cool desert nights, Australia’s climate calls for more than standard windows. Kömmerling delivers high performance, German engineered uPVC window and door systems designed to handle it all — helping homes across the country stay cooler, quieter, and energy smart.

Whether you‘re building in the tropics, temperate zones, or bushfire prone regions, our advanced window and door systems support 7 star energy ratings and long term savings. Trusted by architects, builders, and homeowners alike, Kömmerling combines modern style with outstanding durability — built for Australia, without compromise.

Because Australian homes deserve comfort that lasts.

Choose windows that do more than open — choose Kömmerling. kommerling.com/au

Ross Graduate Engineer, AGWA

In early 2025, AGWA, in collaboration with the Timber Development Association (TDA), launched a national initiative to modernise the design and manufacturing of timber window systems in Australia. The project, valued at over $600,000, would not have been possible without the matched funding from Australian Forest and Wood Innovations (AFWI) and the support of key timber window companies within AGWA. The project’s goal is to deliver a suite of traditional and European-style timber window systems that are not only aesthetically pleasing, but also structurally sound, thermally efficient, and accessible for widespread use by joiners across the country.

This initiative was established to address longstanding gaps in the Australian timber window sector. Unlike aluminium or uPVC window systems, which typically benefit from a prime systems operator, timber lacks a centralised design and performance framework. As a result, many timber window systems in circulation today often claim to rely on outdated configurations within AS 2047 Appendix F, which no longer meet the performance standards or thermal requirements of modern buildings. The designs outlined in Appendix F do not support insulated glass units (IGUs), account for laminated timber, or provide guidance on species substitution, factors now critical to meeting current performance and energy standards in an environment with rapidly changing forest resources.

A key objective of this initiative is to establish future compliance pathways by embedding these technologies into the new base designs, while still accommodating existing production methods. This includes provisions for IGU integration without excluding the option for single glazing, and the incorporation of drained glazing channels, an established practice in many modern window systems to mitigate water ingress and improve durability. These updates also reflect the realities of modern timber supply, where plantation species are increasingly processed in smaller sizes, necessitating laminated construction to achieve large profiles. Collectively, these design improvements aim to support sustainable practices across the entire timber window supply chain, from milling through to fabrication and installation.

One of the early steps in the project involved material evaluation and testing. Timber, being a natural and variable material, presents unique engineering challenges that differ from those posed by synthetic products. To develop a flexible and inclusive design approach, the team initiated a small-scale testing program to assess a range of Australian timber species and engineered wood products (EWPs) for their structural viability under N3 wind load conditions including 4 point bending tests.

Another section of work included supporting the development of a species substitution methodology, examining key properties such as Modulus of Elasticity/Rupture, density, and material consistency. While several hardwoods like Spotted Gum and Blackbutt demonstrated strong performance, the project purposefully focused on lower-benchmark species to ensure designs could accommodate a broad spectrum of timber resources available across the Australia’s changing forests. This approach helps future-proof the timber window industry and system design to proactively work with sustainable supply chains and plantation timber resource.

In parallel with the testing program, the design development of the window and door systems commenced. These designs were engineered to support 55/58 mm sash profiles and 24 mm glazing pockets, optimised for modern IGUs and laminated timber. The 58 mm sash profiles were informed by the European staple IV-68 (still allowing enough room for the ‘euro groove’ and hardware to seamlessly integrate), modified for local fabrication and supply capabilities. These dimensions were ultimately chosen to allow

the scaling up of the system for multiple feedstock parameters, further enhancing the flexibility of the fibre and designs. The aim is to deliver systems that not only perform well but can also be manufactured by small-scale workshops with minimal barriers to entry.

Industry engagement has been a critical part of the project’s success. Throughout 2025, AGWA and TDA hosted state forums, met with joiners, hardware suppliers, timber processors, and testing labs. These conversations revealed a widespread interest in transitioning to modern, high-performance timber systems particularly among those open to adopt engineered timber products in the future, address IGU compatibility, or move away from non-compliant systems. Many businesses expressed the need for clear documentation and guidance on topics like lamination practices, species substitution, and thermal compliance.

As the project transitions from design to testing, AGWA is developing a robust documentation suite to support adoption. This includes technical manuals, substitution procedures, CAD shop drawings, and simplified guidance to ensure that even the smallest joineries can integrate the new designs with confidence and consistency.

This initiative reflects AGWA’s ongoing commitment to driving industry collaboration, performance uplift, and material innovation in Australia’s building sector. By laying the foundations for a nationally accessible timber window suite, AGWA is helping ensure that sustainable timber remains a viable, competitive, and compliant solution for future generations of Australian buildings.

ARCHITECT: Six Degrees

BUILDER: Buildcorp

FABRICATOR: SMB Windows and Doors

PRODUCTS: Series 626 Double Glazed FrontGLAZE TM

Series 50 Sliding Doors

Series 52 Hinged Doors

Forming part of the City of Melbourne’s invigorating Munro Development, the angular contours of the Narrm Ngarrgu Library and Family Services spill across the perimeter of Queen Victoria Market with its inclusive, environmentally forward design. Envisioned by Six Degrees, the modern vernacular of this 11-story corner structure has been profoundly influenced by the collaboration with the Wurundjeri people.

The name of the library translates into ‘Melbourne Knowledge’ in the Wurundjeri Woi-wurrung language, symbolising the building’s commitment to weaving Indigenous narratives into its very fabric, from specified materials and captivating artworks to the dynamic patterns of floor coverings.

With a collection of over 30,000 books, cutting-edge technologies and a range of amenities, including a roof-top terrace featuring a striking skylight, this culturally responsive design — grounded by the environmental efficiencies of its industrial expression— establishes inclusivity, sustainability and connection as the cornerstones of the $250 million Queen Victoria Market Renewal.

This sympathetic project successfully addresses the multifaceted needs of the community, integrating its distinct facade into Melbourne’s multicultural inner-city locale, as an embodiment of architectural inclusivity. Realising this intricate design intent didn’t come without its challenges.

It was paramount for the project team to prioritise architectural, high-quality, and high performing products that excelled in terms

of sustainability and aesthetics. These considerations became even more apparent in the specification of frames and glazing for the skylight and the internal glass doors. It was essential for the interiors to be filled with natural light, maintaining comfortable temperatures and prioritising the structure’s thermal efficiency.

Similarly, it was crucial to maximise the glazing area to promote an uninterrupted flow between the internal spaces and to maintain a sense of connection with the neighbourhood’s thriving cityscape. Lastly, the design had to reflect the layered character of the local community, fusing the industrial language of darker finishes and pronounced shapes with the organic dynamism of Indigenous storytelling.

To bring to life this highly resolved vision, Six Degrees and Buildcorp collaborated closely with SMB Windows and Doors to curate a selection of high-quality architectural openings that would effectively accommodate the project’s complex requirements.

The specified range of Architectural Window Systems (AWS) solutions far surpassed simple functionality, emerging as a powerful design tool inherent to the project’s success. The captivating skylight, equipped with automated louvres and glazed in AWS Series 626 Double Glazed FrontGLAZETM, became a stand-out design feature of the project. The contrasting geometry of glass and dark aluminium framing emerges from the library’s landscaped terrace with patient confidence.

Reinforced tall glazing beads bolstered the durability of the 45 sqm glass structure by increasing its tolerance for high wind loads. At the same time, the expansive glazing leveraged the robust size of the opening to immerse the interiors with natural light, promoting that same sense of bright openness. The lively yellow staircase, connecting the indoor and outdoor realms inside the skylight, boosted that optimistic quality, encouraging interaction and creativity.

In addition to its immense aesthetic potential, the solution offered outstanding sustainability benefits as the framing had been designed to accommodate Insulated Glass Units (IGU) of up to 24 mm, improving the building’s thermal performance and contributing to energy efficiency and occupant comfort. This environmental performance was augmented by the seamless integration of the automated louvres, which aided in regulating internal temperatures by releasing trapped heat and creating a welcoming and comfortable atmosphere. Indoors, the exceptional role of the skylight was further amplified through the incorporation of the AWS Series 50 Sliding Doors and AWS Series 52 Hinged Doors.

Constructed from durable aluminium, the robust frames mirrored the skylight’s industrial angularity, setting a contemporary stage for the vivid visual stories of the Wurundjeri people. Extensive double glazing helped facilitate uninterrupted flow between the light-filled spaces, while keeping the busy neighbourhood’s soundtrack at bay. This dialogue between transparency and robustness — and openness and seclusion — yielded a tranquil environment ideal for studying, reading or just a moment of respite amongst the city’s emphatic hustle and bustle.

With a robust, high-performing structure reflecting the resilience of its community, culturally responsive architecture that echoed the stories of the Wurundjeri people, and open, yet rigorous, design language prioritising comfort, uninterrupted flow and a sense of connection, the Narrm Ngarrgu Library and Family Services adds a precious page to Melbourne’s vibrant story. Living up to its inspired name, it offers an invaluable lesson in inclusive sustainability in the public sphere, putting the diverse needs and the future of its multifaceted community on full display.

For more information, please contact marketing@aws.com.au.

Fenzi Spacer Bars offer strong mechanical support and precise edge spacing for insulating glass units in structural glazing applications. Crafted from high quality aluminium, they provide excellent dimensional stability.

These spacer bars integrate seamlessly into established IGU production lines, supporting efficient fabrication without compromising structural integrity.

Alu-Pro Aluminium Spacer Bars are manufactured using specialised aluminium alloys, making them one of the pioneering solutions for spacer bars in glazed units. Their durable, precision-engineered design ensures reliable window sealing and long-term stability.

Thermix Spacer Bars sets the standard in modern spacer systems, delivering optimal thermal performance, outstanding rigidity, and a distinctive design.

Engineered with a stiffened technopolymer and stainless steel foil, Thermix bars offer exceptional insulation and serve as an effective gas barrier, further enhancing thermal performance.

Chromatech Ultra S warm edge spacer combines the stability and strength of steel and the insulating properties of polycarbonate in a single rigid structure. It will actively contribute to less condensation, extend the lifetime of windows and provide a more comfortable indoor temperature, reducing both energy bills and carbon emissions.

Tim Johnston Head of Policy and Advocacy, AGWA

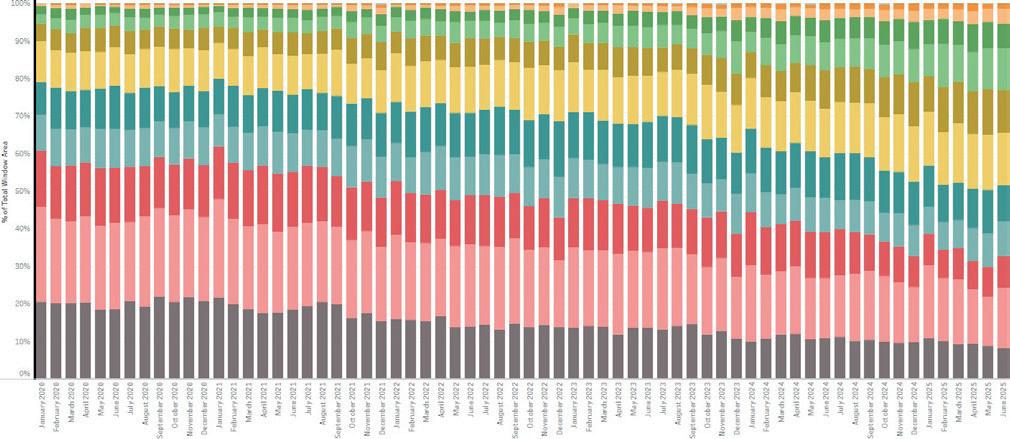

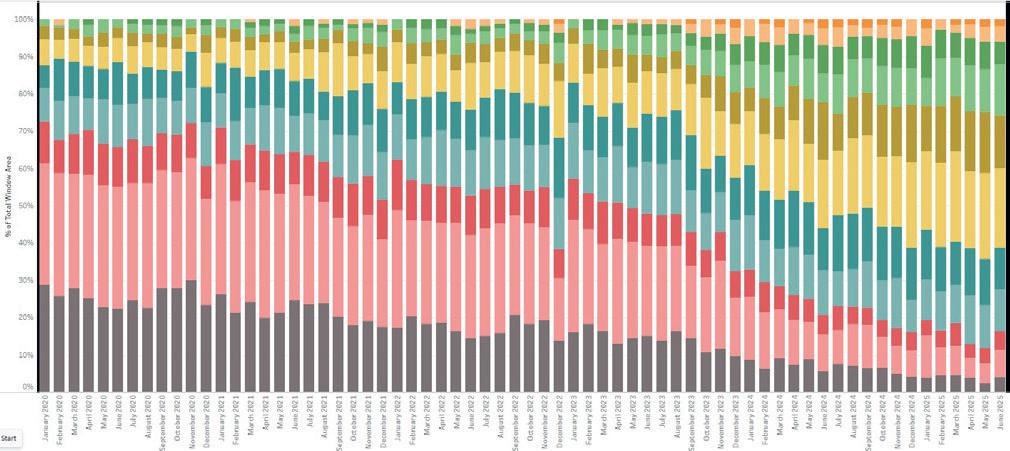

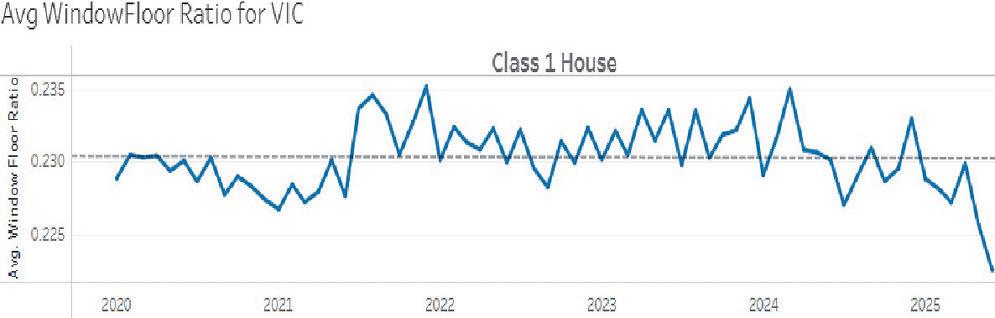

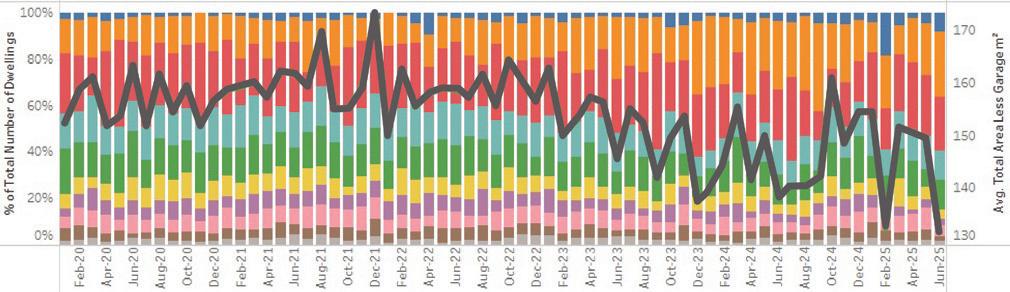

The latest compliance data from the Nationwide House Energy Rating Scheme (NatHERS) reveals a significant development: the implementation of the National Construction Code (NCC) 2022, with its 7-star regulatory stringency, is beginning to transform window performance in new homes across Australia. One notable trend is the shift to lower U-values across most window markets, as builders and designers strive to meet the enhanced energy-efficiency requirements now embedded in NatHERS 7-star assessments.

Interestingly, some anticipated changes have not materialised. Despite predictions that tighter performance standards would lead designers to reduce glazed areas by up to 10% across all markets, the data suggests little to no change outside of recent movements in Victoria. In fact, markets such as Queensland and South Australia have shown slight growth.

This trend is likely due to a greater share of second and third home buyers, who typically opt for larger homes with more amenities and glazing. In these markets, window areas have increased alongside larger house floor areas, while average thermal performance has improved, thanks to higher-performing glass and frames.

Ratio by State (Class 1) National

Average Window Area by State (Class 1)

National Window To Floor Area

It’s important to note that some jurisdictions, like Western Australia, have only recently moved to full 7-star compliance and are not yet showing the full impact of the NCC 2022 energy changes in their data. Additionally, the double brick construction in certain regions offsets some of the performance gains seen elsewhere. Nevertheless, the overall trajectory across the country points towards better-performing windows in both volume and quality.

These approvals reflect early-stage planning data and are likely indicators of future demand in the next 6-9 months. While some current installations still reflect pre-NCC 2022 designs, the sub-7-star pipeline is narrowing. As energy assessors gain more experience with the new standards, we expect to see more consistent and reliable ratings emerge.

During this transitional period, AGWA will continue to monitor specification trends and support members through initiatives such as presenting at certifier and energy assessor conferences and forums. This ensures good practice and product understanding are maintained in the market and on-site certified products.

When it comes to optimising natural ventilation, Ventus louvres stand out as the most practical window system with the versatility of being used almost anywhere.

Paraflow is a double bladed louvre system featuring two off-set parallel blades of glass per clip which increases performance in acoustic suppression, weather protection, and improved thermal efficiency when closed while maximising natural airflow when open. Information and sales, contact our Techincal Sales Representative Team for details.

Adam Davies Technical and IGMA Manager, AGWA

The accompanying article (on page 42) on the impact of 7-star ratings underscores the growing adoption of higher-performing windows and the increased use of Insulated Glass Units (IGUs).

As with any job, post-installation issues may arise and these can result in costly replacements, damage customer perception, and result in legal conflicts, affecting both consumers and suppliers. Addressing these issues early is more cost-effective than fixing them later however, with IGUs these potential issues can be particularly complex.

I have been directly involved in numerous inspections of installed IGUs that have failed prematurely. My experience suggests that post-installation failures of IGUs are almost evenly split into 2 main categories — fabrication-related or installation-related. In both cases, a better understanding of the fabrication or specific installation requirements for an IGU could have potentially prevented many of these failures.

A notable example involves several IGUs installed in a difficult-toaccess atrium roof. Significant visual quality issues related to dirty internal glass surfaces were only discovered post-installation. The only solution was to replace all the units as they did not meet relevant Standards. Although the units were worth approximately $5000, the restricted access and location resulted in a total replacement cost exceeding $50,000! With a better understanding of IGUs, this issue may have been caught prior to the installation. Compounding what was already a stressful situation for those involved was significant conflict between the manufacturer and installer on who should be contributing to the replacement cost. Unfortunately, this was resolved in court where further costs, and stress, were incurred by both parties.

This highlights that we must continually evolve our skills and keep pace with the ever-increasing complexity of our industry. So, to address these challenges, AGWA is developing a series of short, self-directed learning courses to arm our members with the necessary understating of IGU fabrication and installation to minimise the chances of a poor outcome. The training will focus on 2 main areas:

1. Common Manufacturing-Related Issues: This course highlights common manufacturing issues and how to identify them. Aimed at manufacturers and glaziers/installers, the course equips them to assess and inspect IGUs to identify issues before dispatch or installation, avoiding costly and reputational consequences from failed IGUs.

2. Common Installation-Related Issues: Specifically aimed at installers and glaziers, this course explains the unique installation requirements of IGUs and identifies common installation mistakes that can lead to premature unit failure.

The manufacturing course will launch later this year, with the installation course following shortly after. In the meantime, if you do have any questions be they IGU-related or on any other areas of our industry, as always, I encourage you to reach out to our technical team at technical@agwa.com.au.

Want to know more? Join us at AUSFENEX25 and attend the presentation on Low-Hanging Failures; Easy to Spot, Costly to Ignore, 8 IGU Red Flags, which will highlight these issues and what we can learn from these.

When A Touch of Glass decided to continue its journey toward greater automation, the next step came with the introduction of Bovone’s ELB 12 FA Edging Machine. More than just a machine, the ELB 12 FA represented the beginning of a new phase: one in which efficiency, precision and sustainability converge in a smarter, more scalable production process.

‘In an industry like ours, which is rapidly changing, technological innovation is an indispensable ally’, says Shaun Moran, General Manager of Operations at A Touch of Glass Group. ‘With the ELB 12 FA, we’ve taken a major leap forward: not just in edge finishing, but in our entire operations management.’ A Touch of Glass, which specialises in custom glass for residential construction, faces complex challenges every day: custom design requests, short lead times, and increasingly stringent regulations. ‘The answer to these needs’, Moran continued, ‘is a production system that is both fast, flexible and accurate’.

A machine that simplifies, standardises and innovates

The value of the ELB 12 FA Edging Machine is not only measured in terms of technical performance. Its automation features have enabled A Touch of Glass to reduce manual intervention, speed up work cycles and improve final quality consistently. ‘The machine reduces operator input requirements, which allows for faster running speeds resulting in greater output and consistency, difficult to achieve before, especially on custom projects where every detail counts’, Moran said.

The intuitive interface, preset programs and integration with other production departments have helped make the workflow smoother and more predictable. The result is more efficient production, optimised resource management and a work organisation that enhances the internal team. ‘Today we can plan more accurately and spend more time on quality control, design and customer relations.’

Beyond supply: a relationship of shared growth

The decision to choose Bovone as a technology partner resulted from a thorough analysis of the market. ‘We visited numerous plants and observed machines from different manufacturers reliability, polishing quality, reliability and ease of integration of Bovone machines were superior’, said Moran. The relationship built with the Bovone team did the rest. ‘Matteo was transparent, knowledgeable, and attentive to every detail. We never felt like customers: we felt like partners.’

A concept also confirmed by Matteo Patalocchi, Bovone’s Far East Sales and Marketing Manager: ‘With companies like A Touch of Glass, it’s not just about selling a machine. It’s about building a path. The ELB 12 FA is just the first step of a larger project, made of listening, customisation and joint development of solutions that evolve over time.’

It is this synergy that has allowed the ELB 12 FA to be adapted to the specific needs of A Touch of Glass, optimising every aspect of integration. A machine built for the present, but already ready to face future challenges: Bovone, with its technological vision and its ability to provide continuous support, is an important technological partner capable of accompanying A Touch of Glass on its journey.

A look ahead: smart manufacturing and continuity of investment The company’s vision does not stop with today. A Touch of Glass aims to continue to develop increasingly automated and smart manufacturing, capable of combining craftsmanship and innovation. ‘Artificial intelligence in quality control, robotics for handling, and integration of CAD/CAM systems are areas where we see great potential’, Moran noted.

Considering this, the adoption of the ELB 12 FA Edging Machine is only a first step. ‘We don’t exclude the option, in the future, of enhancing it further with other complementary solutions to further expand our production capacity.’ The direction is set: build a smart, scalable, sustainable production facility.

Back in 2004 Rick Carlei started Quattrolifts after an idea formed when working with Pilkington Glass as an OHS consultant delivering hazardous manual handling training to all the Pilkington sites across Australia and New Zealand.

A chance meeting with an operator at the Pilkington site in Morwell, Victoria started the process of developing mechanical equipment to help glaziers and glass workers. During this meeting, the young operator in his early 30s became quite emotional as he was suffering with chronic tendonitis in both wrists because of lifting glass for many years. The real agony emerged when he said he could no longer lift his young children.

Feeling the emotional turmoil suffered by this young glass worker, Rick started to investigate what equipment was available on the market. For in-factory use, overhead cranes were widely used but the problem was out on-site. There were robotic machines

available in Europe, but still in their design infancy and they weren’t practical for the small ‘Mum and Dad’ glazing businesses in the Australian and New Zealand markets.

The aim was to develop a small, lightweight machine that could be easily assembled and disassembled to use on-site. Rick started the development of the Nomad 200 and was fortunate to find Bob Reid, a mechanical engineer working in the golf industry. Bob was the genius who took the initial idea and made the Nomad into a machine that is still sold today, 21 years later.

Around about the same time Rick also met with Alan Reidy, who was the head of Glass and Glazing Department at Victoria’s Holmesglen TAFE. Alan gave Rick a wealth of advice and support to develop the Nomad, which included using the department to run countless tests and demonstrations.

The result, after 32 prototypes of the Nomad, was a portable glazing machine that could lift and transport glass off a truck but also had the capacity to glaze side-pocket window frames with the side shift (2 opposing acme threads) on the diagonal brace. Then came the addition of a rotating head allowing glass plates up to 4.5 m tall to be rotated from landscape to portrait — critical for glazing in shopping centres.

In 2005, Quattrolifts entered the Workcover Awards and becoming a finalist for the Best Solution for Sprain and Strain Injuries Award.

Quattrolifts started selling the Nomad in Australia and New Zealand, knowing that the market was too small to sustain the business. After contacting the USA National Glass Association, Rick met its past president, Ron Clawson who was excited by the Nomad, and the benefits it presented, and felt that there was a good opportunity to sell the machine in North America.

Quattrolifts attended the 2006 Glassbuild Trade Show and presented the Nomad. Initially there was a lot of scepticism, but the first machine was sold to a customer in Las Vegas at the show. Slowly the Nomad started to get support and sales increased both here in Australia and North America.

Around 2007, Quattrolifts was contacted by 2 European distributors who were also interested in the Nomad. Quattrolifts was now selling the Nomad across 3 continents, with sales becoming quite heathy, allowing for funds to be reinvested into R &D. The Nomad has since ‘grown up’ now handling up to 400 kg plates of glass and stone.

In 2008, Quattrolifts released the Mule 300 designed to help with the handling of glass on polishing machines and loading/unloading of trucks. Again, Bob Reid developed an innovative idea of the ‘swinging counterweights’ allowing the removal of the castors ‘in front’ of the glass, which overcame the problem of obstacles (water tanks) under the polishing machine and rear truck wheels

impeding the handling of glass, on and off truck racks. This design also allowed the Mule to have a small footprint to move in between glass racks in a factory.

In 2010 the Express 150 was then released to huge success in Europe. Bob designed the machine to have some useful features allowing one person to handle up to 150 kg of glass. First, it could be easily disassembled into 2 pieces, each weighing less than 20 kg allowing for easy loading. Second, the front castors were retractable, allowing the operator to use their foot to counterbalance the glass while glazing. Finally, Bob developed a vacuum head that allowed for side pivot to walk the glass through narrow doorways, as well as rotation so that the glass could be spun from landscape to portrait in preparation for glazing.

Quattrolifts has continued to heavily invest in R &D and now has over 20 different machines and variations. These include the OMNI 550 and 800 which attach to a forklift or telehandler for the elevated glazing jobs, the Horizon for use in factory to handle glass vertically and horizontally and then the Vector range of glazing robots which are now our largest selling machines.

Today Quattrolifts employs 14 people with its head office and R&D facility located in Melbourne. Quattrolifts also has distribution warehouses in Los Angeles and Pittsburgh in the USA, Odense in Denmark and in Singapore.

Quattrolifts would like to thank the Glass and Glazing industry in Australia and New Zealand for their support over the past 21 years, allowing the business to succeed overseas in North America, Europe, and Asia. Naturally, we wish to take this opportunity to also thank our many and varied Customers over the 21-year journey and look forward to supporting those wishing to benefit from our Aussie-designed machines in the future.

Since 1996, Elegant IG has connected the highest-performing brands in the IGU industry to the people shaping the future of glass.

Every sealant, spacer, and system we deliver is part of a bigger picture. Like the pieces of a puzzle, each product and partner we represent plays a role in delivering uncompromising quality, performance, and trust.

We don’t just supply. We unify. We support.

Automated IG Production, Made Easy

Produce up to 850 gas-filled IG units per shift with Glaston COMFORT. Compact, energy-efficient, and fully automated—from glass washing to sealing. Perfect for rectangular, shaped, and stepped units.

Smart. Fast. Reliable.

Effortless Glass Handling

Boost productivity and reduce strain with Cimec EasyLift— ergonomic, versatile lifting equipment designed for smooth, safe glass handling in any workspace.

Lift smarter. Work easier.

glass technology

Developing the Value Chain with HEGLA Group

With machines and integrated systems from HEGLA, you can achieve maximum precision, quality and automation.

Efficient software solutions optimize your production control and planning. Innovations such as laser-assisted finishings for birdfriendly glass or better cell reception further increase your added value. QR code marking makes your glass trackable in the process and in the field –for the whole product life cycle.

In an ever-evolving construction landscape, Kömmerling stands as a pioneer of progress, precision, and purpose. From its humble beginnings in 1897 to its global leadership in high-performance building solutions, Kömmerling’s journey spans over 125 years of progress, purpose, and reinvention. Every era tells a story — not just of products, but of visionaries, turning points, and a relentless commitment to building better.

1897: The Foundation of a Vision

Karl Kömmerling established the company in Pirmasens, Germany, laying the groundwork for what would become a brand synonymous with technical precision. Initially focused on adhesives and sealants, the company quickly earned a reputation for quality and innovation in industrial chemistry.

1952: The uPVC Era Begins

The post-war construction boom demanded new materials — strong, light, and durable. Kömmerling responded by entering the uPVC sector, setting its sights on modernising building components with advanced polymers.

1954: A New Chapter in Extrusion

1954, the first commercial uPVC window profile was introduced under our Trocal brand — setting a new industry benchmark. Then in 1957, Kömmerling began its own extrusion journey, producing profiles for roller shutters and laying the foundation for decades of innovation in uPVC systems.

1960s: Manufacturing the Future

With the demand for energy-efficient solutions rising, Kömmerling began manufacturing uPVC window profiles, revolutionising the way windows were made and used. These systems offered a transformative alternative to timber and aluminium — longlasting, thermally efficient, and low maintenance.

2003: Formation of profine GmbH

A defining moment: Kömmerling, KBE and Trocal were unified under the umbrella of profine GmbH, bringing together decades of expertise and innovation. This consolidation sparked rapid international expansion, cementing the group’s position as a global powerhouse in window and door systems.

2012: A New Era of Leadership

Doctor Peter Mrosik acquired the company and assumed the role of CEO and owner. His leadership marked the beginning of a dynamic era focused on sustainability, digitalisation, and long-term strategic growth. Doctor Mrosik’s vision expanded the brand’s reach while deepening its roots in research, responsibility, and resilience.

2020 and Beyond: Pioneering Sustainable Innovation

In response to the global climate challenge, Kömmerling accelerated its sustainability mission:

• The first bio-attributed uPVC window profile, reducing reliance on fossil-based raw materials.

• ReFrame, the world’s first uPVC window system made from 100% recycled materials.

• A growing portfolio of energy-efficient systems designed to exceed 7-star home requirements — reducing CO2 emissions, lowering energy bills, and supporting circular construction for a more sustainable future.

These inventions demonstrate, not only technical capability, but also the company’s enduring belief: that progress must serve both people and the planet.

In Australia, Kömmerling has introduced the ReKönvert Program — a local circular recycling initiative where offcuts and fabrication waste are collected and reprocessed into new products. This closed-loop model keeps valuable materials out of landfills and supports fabricators in meeting sustainable construction targets.

By combining energy efficiency, low maintenance durability, and an Australian waste recovery system, Kömmerling continues to lead the way in sustainable window and door solutions, built for Australia, without compromise.

Today, Kömmerling operates in over 100 countries, supported by local partners and trusted fabricators worldwide. In Australia, that legacy is carried forward through sustainable practices, certified solutions, and a commitment to support every stage of the construction journey — from architectural design to on-site delivery and beyond.

By combining global expertise with local collaboration, Kömmerling continues to build strong, future-ready partnerships across Australia’s window and door industry.

From Karl Kömmerling’s early beginnings to today’s international leadership under Dr Mrosik, the company’s vision remains clear: to create window and door systems that stand the test of time, not just in performance, but in purpose. In a world that demands more from our buildings, Kömmerling delivers more from every window.

As the company moves into its second century, one thing remains unchanged: the pursuit of excellence that began in 1897. Because the best way to build the future is to learn from the legacy that shaped it.

At Alumach, supplying high-performance aluminium machinery is just one part of the equation. What truly sets us apart is our aftersales service — a national operation built on the skills, dedication, and experience of a tight-knit team that lives and breathes machinery.

Based in Thomastown Victoria, Alumach supply and service machinery for all types of aluminium and uPVC profile fabrications. As the national supplier for the premium Italian brand Emmegi, we deliver high-performance machinery to fabricators all over the country. But what really sets us apart is what happens after the machine is delivered. Our customers know that when they choose Alumach, they’re not just buying a machine — they’re gaining a long-term partner.

Our service department is at the core of everything we do. From the moment a machine arrives at a customer’s site, our team is already thinking about how to make it perform at its best — not just today, but for years to come. Installation, operator training, technical support, preventative maintenance — these aren’t side services, they’re central to the way we do business.

Leading the service operation is Alex, our senior technician and a long-time expert in the Emmegi range. With a deep knowledge of CNC machining centres and automated cutting lines, Alex is known for his ability to calmly resolve even the most complex technical issues. Working alongside him is Nathan, whose reliability and practical approach make him a trusted figure among fabricators around the country. Whether he’s commissioning a new machine or responding to a time-critical repair call, Nathan gets the job done with minimal fuss and maximum efficiency.

The team was recently strengthened with the addition of Ludvig, who joined Alumach from Emmegi Scandinavia. With international experience and a strong technical foundation, Ludvig brings a valuable global perspective and a sharp eye for diagnostics. In NSW, Antoine serves as the frontline technician, providing handson support and rapid response to customers across the state. His focus on maintaining high service standards ensures our reputation stays strong, no matter the location.

Overseeing the broader operation is General Manager Adrian, who began his career as a technician. His time in the field gives him a

unique understanding of both the technical and operational sides of the business. Adrian continues to support the service team dayto-day, ensuring they have the resources and backing needed to deliver exceptional outcomes.

One of the more distinctive roles in the team belongs to Director Len. While not as visible to customers, Len plays a key role behind the scenes. In our workshop, he personally sets up and tests each manual machine before it’s dispatched. His sign-off is a final quality check that reflects the pride and precision we aim for in every delivery.

Supporting this in-house team is a trusted national network of contractors who extend our service reach across Australia. These technicians work closely with our team to provide consistent, expert-level support — wherever our customers are based.

Our dedicated service team travels across Australia to install equipment, train operators, and support businesses of all sizes. Our technicians work with this equipment every day. They understand how it performs on the factory floor and know exactly how to keep it running at its best. From CNC machining centres to double mitre saws, automated cutting lines, and manual machines, we have hands-on experience across the entire Emmegi range. We also offer preventative maintenance programs that catch problems early, helping you avoid breakdowns, extend the life of your equipment, and keep production running smoothly.

Regular training at Emmegi’s headquarters in Italy ensures our team stays ahead of the curve, equipped to handle the latest advancements in machinery and automation. But more than that, it reflects our commitment to constant improvement. Our technicians aren’t just problem-solvers, they’re partners in our customers’ success.

At Alumach, service is not an add-on — it’s a promise. We are with our customers from the first bolt to the final calibration, and every step after. That dedication is what drives us, and what drives the trust our clients place in us every day. When you team up with Alumach, you are getting more than machinery — you’re getting a service team that’s with you every step of the way.

If you’d asked 17-year-old aspiring cricketer Shane Sweet what he wanted in life, he probably would have said to be able to play cricket while doing a job he loves. Now 36 years on, Shane has achieved all this and more, and we spoke to him about his impressive 25-year business innings, his collection of glazing awards, and building a family business while playing representative cricket.

Shane Sweet finished high school and was playing cricket for SA Country and Australia Country XI when he was first introduced to glazing through a family friend who owned Mount Barker Glass. After a couple of years, he moved over to Q Glass, working there for 8 years. ‘I was fortunate that Q Glass supported me through my glazing apprenticeship where I was first introduced to Richard Sarre, who is now my senior glazier.’

His cricket coach at the time was a local builder who convinced Shane to start working with him, learn the basics of carpentry, and be his in-house glazier. A couple of years later Shane faced an important decision — continue glazing for the builder, or ‘go for a six’ and start his own glazing business. Shane’s wife Natasha was expecting their first child when they decided to start Federation Glass in 1999, and they have continued to put runs on the board ever since.

The business name was ‘inspired by the Federation home style that was popular in the 1990s’, explained Shane. ‘We were doing lots of this style of glazing, and I thought Federation Glass had a nice ring to it.’ Like many Aussie glazing business stories, Shane started his business on his own with a second-hand ute, his wife doing the bookwork, and based out of their family’s home. The business grew steadily, and soon Shane was able to rent a small shed through a local car dealership in Bridgewater, a suburb in the Adelaide Hills known for its English-inspired architecture.

‘We began glazing larger projects throughout Adelaide, as subcontractors for Aluco. One of the largest projects was the Repomed Fertility Clinic in 2002, where another glazier and I glazed the entire building between us. It was a challenging time trying to complete such a large project at the same time, experiencing extreme joy with the birth of my second daughter and an all-time low as my wife’s mother passed away 6 months later. It was a very stressful time for all of us’ Shane recalls.

In 2004 Shane took on his first apprentice who then contributed to the Federation Glass journey for 16 years. Shane’s strategy all along was to own and operate a family-run business, taking on friends and family whenever possible.

Even today, as a highly awarded glazing company, they employ just 6 people. Shane’s wife manages the office, his sister-in-law is the receptionist, his nephew is a fourth-year apprentice, another local Hills lad and Richard Sarre, Federation Glass’ longest serving employee of almost 20 years and Shane’s mentor from Q Glass. ‘Richard taught me to be a glazier and has been in the industry for almost 40 years! He really has been a great support and an advocate for achieving results for our company, we share our knowledge and bounce off each other’, Shane reflected.

In 2019 Federation Glass took its biggest risk yet and purchased its own premises in Totness, allowing them to implement better machinery and to invest in new vehicles for an expanding team, and they’ve never looked back.

Federation Glass claims an impressive 9 apprentices over its journey with 3 ‘South Australian Apprentices of the Year’. Shane was a guest speaker at the 2019 AusFenEx Conference, where he spoke about his experience in the industry and becoming a part of the new AGWA Accreditation Scheme and Master Glazier concept. He was delighted to become an accredited Master Glazier along with Richard at the SA State Awards Night. The jewel in the crown for Shane, Natasha, and the team, was being honoured with Australia’s first Accredited Glazing Company in 2016.

Federation Glass has won many state Awards for glazing projects, claiming 4 straight in 2016-2019. This included a Safety Award, which was a credit to the value they placed on a well-maintained workshop, lifting equipment and exceeding industry safety standards. ‘AGWA has really improved the standard of how glass performs in our homes and changed perceptions from what used to be a cowboy’s industry into a recognised trade. Since AGWA introduced the program and Standards in 2000-2001, it’s allowed

us to meet higher standards, gain trade support, weed out those not up to standard, and elevates glazing as a profession’, said Shane.

In 2024, Federation Glass won the SA and National Awards for ‘Commercial Window or Glass Retrofit Project’ with the Cobbs Hill Estate Project, installing mirrors, splashbacks, and high level bi-fold windows. ‘Expectations are always high for architecturally designed work, but when it all came together the results were amazing’, says Shane. ‘We’ve been fortunate enough to work with many builders who like to push the boundaries, and this allowed us to express our flare with glass throughout the building process. Architect Pauline Hurren was a professional who really showcased glazing in her designs. Unfortunately, Pauline passed away recently, and she will be sorely missed.’

On top of his many professional achievements, Shane values the friendships and relationships he’s built within the glazing industry over 36 years, telling us ‘I believe it’s an industry where glazing companies tend to stick together and help each other. If you’re busy and need extra labour, you just call on someone and they’ll be there to help’.

Looking to the future of Federation Glass, Shane predicts that many homeowners will continue to want environmental upgrades to their homes to save on heating and cooling, with double glazing and Low-E glass requests on the rise. Shane also predicts he will still find time for cricket, water sports, skiing, and Queensland holidays with his wife and 2 daughters.

Higher transmittance of visible light and natural daylight, and clear appearance

Suitable for cold or extremely cold areas where heating is required

Good heat preservation performance, effectively reducing indoor heatloss and providing a warm and comfortable indoor environment

Higher shading coefficient and lower heat-transfer coeffi-cient,effectively reducing the heating costs in winter

THERMOTECHNICAL & OPTICS PERFORMANCE DATA

PROJECT NAME:

4Venus#2+12Ar+4C

5Venus#2+12Ar+5C

6Venus#2+12Ar+6C

4Mercury_A#2+12Ar+4C

5Mercury_A#2+12Ar+5C

6Mercury_A#2+12Ar+6C

4Venus#2+12Ar+4Vesta#4

4Venus#2+14Ar+4Vesta#4

5Venus#2+12Ar+5Vesta#4

6Venus#2+12Ar+6Vesta#4

6Vesta

Solar spectrum: 300-2500nm,visible light is 380-780nm.

Winter nighttime: Outdoor temperature: -18℃, indoor temperature: 21℃, windspeed: 5.5m/s, no sunlight.

Summer daytime : Outdoor temperature: 32℃, indoor temperature: 24℃, windspeed: 2.8m/s, solar density: 783w/㎡.

The calculations are base on 1000*1000 specimen,only for reference.

Above glass datas allow for ±3% difference as a tolerance and U-Value is ±0.2w/㎡·K