Celebrating excellence in the glass, window and security screen industries

Celebrating excellence in the glass, window and security screen industries

Sleek in design, smooth in operation, the Forge long plate lever and Virtus hinged door mortice lock are a winning combination.

Two- or four-point locking, optional privacy snib, magnetic rod connectors, and 13 or 22mm deadbolt with single key turn retraction.

With Austral Lock it’s secure, with Forge it’s a family.

Ingrid began her role with AGWA in May 2021 looking after the training needs of members. Her role soon progressed to include working on BuiltView, safety, the AGWA Design Awards, the website and other marketing-related activities.

Prior to AGWA, Ingrid worked for a legal publishing company as an editor, a publishing manager and then an editorial trainer. Her time at Butterworths saw her work on their building and local government and environment suite of products and with the CSIRO and ABCB on other BCA projects. She also previously worked for many years as a part time teacher at TAFE teaching law, business, communications and work health and safety across multiple faculties.

Tom joined HIA as an Economist in 2018. As Senior Economist, he assists in the research and analysis of housing market trends and manages the assumptions and statistical modelling behind HIA’s residential building forecasts. He has also authored many of HIA’s wide range of economics publications. This provides him with the insight and expertise to advocate to all levels of government and media on behalf of the housing industry, for the purpose of informing policy debate. He has provided advice to both the private and public sectors across a range of areas.

Sahil Xavier holds qualifications in Mechanical and Manufacturing Engineering. With 2 years of experience as a graduate design engineer in the railway and rolling stock sector, Sahil transitioned into the glass and windows sector in 2022 when he joined AGWA.

Currently, Sahil is working as an Engineering Project Officer at AGWA, managing the WERS Platform and Thermal Performance space, while also being involved in industry committees and working groups.

James Whitehouse graduated in Structural Engineering in the UK before discovering building facades, working initially for systems’ companies before becoming a Facade Engineer at LendLease. Over the last decade working in Australia, he has worked for two of the largest WA commercial fabricators and then Capral Aluminium before joining AGWA in 2022.

He is a cricket fanatic and former state longbow champion.

Tim joined AGWA in July 2023. With a degree in Architecture from the University of New South Wales, as well as postgraduate qualifications in environmental management and economics, Tim has more than 25 years’ experience working in the built and natural environment, not for profit industry associations, private and government sectors.

Angela is a marketing and advertising Copywriter with Sydney’s Trade Advertising Agency, crafting words and ideas for all kinds of building-related brands. Growing up by her builder Father’s side and becoming a renovation aficionado — writing for AGWA is close to Angela’s heart and hands.

EDITOR

Melissa Baker

Ingrid Pagura

DESIGN

Webqem Pty Ltd

Sehar Maniar, AGWA

EDITORIAL & ADVERTISING ENQUIRIES

Helen Dawes

+61 2 9498 2768 marketing@agwa.com.au

PUBLISHED BY

AWA-AGGA LIMITED

ABN 57 629 335 208 Suite 101B, Level 1, Building 1, 20 Bridge Street, Pymble NSW 2073 +61 2 9498 2768 admin@agwa.com.au www.agwa.com.au

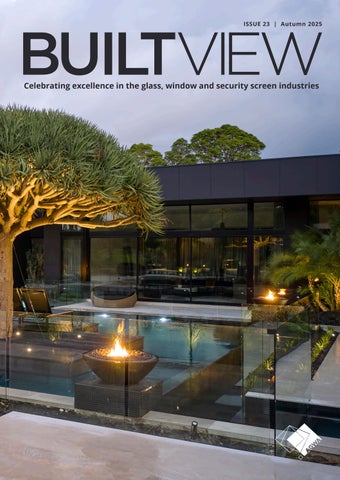

COVER IMAGE & CONTENTS PAGE IMAGES

Dural Residence, Dural NSW

Finalist in 2024 Design Awards, Bespoke Shower Screen and Barrier Category

Glazed Co, Daniel Chamoun Director

Photographer: Studio Pisani, David Pisani

CONTRIBUTORS

Clinton Skeoch, James Whitehouse, Sahil Xavier, Ingrid Pagura, Russell Harris, Vivienne Munter, Angela Farrell, Tom Devitt, Tim Johnston, Kellie Moore, Peter Condon, Carver Broomhall, Rafaella Kavouras, Allan Thiel, Ben Webster, Martin Blackey, Mari Lehtinen, Elizabeth Dimabuyu, Lido Russo, Jelena Ninkovic, Tarek Mostafa, Roger Bishop, Helen Dawes, Melissa Baker, Kerrie Henderson, Sehar Maniar, Tyler Gonzales and Dominique Macartney.

PRINTED BY

SOUTHERN IMPACT

southernimpact.com.au

Our printer conforms to the ISO-14001 environmental management standard and the ISO-9001 quality management standard.

DISTRIBUTED BY

D & D MAILING SERVICES

www.ddmail.com.au BuiltView Magazine is proudly packaged in Biowrap, 100% degradable plastic wrapping.

DISCLAIMER

Copyright © 2025. All rights reserved. Reproduction in whole or part without written permission from AWA-AGGA Limited is strictly prohibited. It is impossible for the publisher to ensure that the advertisements and other material herein comply with the Australian Consumer Law Competition and Consumer Act 2010. Readers should make their own inquiries in making decisions and where necessary, seek professional advice.

Clinton Skeoch

Executive Director and CEO

AGWA

As we navigate the evolving landscape of the glass and window industry, we face both challenges and opportunities.

The recent news of Oceania Glass entering administration underscores the importance of local manufacturing and the need for a level playing field in an increasingly globalised market. This situation reinforces the urgency of our ongoing efforts to secure stronger government engagement to ensure the long-term viability of Australian businesses. One area we have focussed on is advocating for increased scrutiny of compliance from certifiers across to state-based Regulators. Strengthening investigative measures will help uphold quality standards and protect the integrity of our industry.

At the same time, the complexities of these evolving modern supply chains demand a more structured approach to accountability. That’s why we are rolling out a new reseller and prime system compliance framework for all member companies in these sectors. This initiative will help ensure that businesses, at every level of the supply chain, meet the evolving regulatory and performance expectations that define our industry today.

Looking ahead, 2025 is shaping up to be a pivotal year, filled with a comprehensive advocacy agenda, policy initiatives, and memberfocused events. We encourage all members to engage, stay informed and be part of the conversations shaping our industry’s future. I personally look forward to seeing you at one of our statebased forums.

If you miss our state forums, there are lots of other ways to connect and stay engaged; if you haven’t submitted your Design Award entry, then hop to it! Remember also that AusFenEx25 is fast approaching, and we expect another outstanding turnout. If you haven’t secured your spot yet, now is the time to do so — don’t miss this essential opportunity to connect, learn, and help drive our industry forward.

I look forward to seeing you there.

Clinton Skeoch

Clinton Skeoch Executive Director & CEO

CEO WORDS ECONOMY

NEWS

MEMBER NEWS PRODUCTS

TRAINING 5 9 8, 29 11 12-13, 27, 42-43 14-15, 18-19, 20-21, 24-25, 40-41 30-31, 33 34-35, 53, 55 38-39, 45, 55 46, 48 49, 50, 51, 52 54

Ingrid Pagura Industry Development Coordinator, AGWA

The statistics from injuries resulting from falls from heights are quite sobering. In NSW alone, 16 people in the construction industry died because of a fall from a height between 2019 and 2023. Across Australia, falls from heights were the second highest cause of workplace fatalities in 2023, with 29 deaths across Australia, up from 17 the previous year.

South Australia, for example, reported that 2023 saw a 36% increase in the number of serious workplace injuries by falling from heights across all industries from the previous year. Of the 105 serious falls, more than half were in the construction industry, more than 5 times of any other industry. Carpentry had the highest injury rate and non-compliance associated with falls from heights, but construction, manufacturing and transport are in the top 10.

Another sobering statistic is that most of the people who were injured or died from a fall, fell only less than 4 m, however, as the fall is usually the head hitting the concrete it is no wonder that this is becoming a huge issue.

So why is this the case? Many workers are taking risks to get the job done faster or don’t think they need a hard hat and a harness as the window isn’t all that high. Ladders on staircases or not properly erecting a scaffolding, falling off a truck or falling in a void have all been examples of fall from height cases causing serious injuries. Only late last year, a 17-year-old fell backwards off a ladder into a void.

Common falls from heights hazards:

• Instability of the floor or ground surface such as slippery surfaces, broken concrete, or a sloping ground

• Stairs or steps

• Poor lighting

• Incorrect use of ladders

• Inadequate or improper footwear

• Distraction

• Unloading trucks

• Falling into a void or open hatch.

Let’s look at some tips to prevent these injuries. According to SafeWork, here is the best advice to eliminate the risk from falling from heights:

Work on the ground or on a solid construction. Working from the ground is the safest option as it eliminates the risk of falls. Failing this, work on a solid construction. This may

not always be reasonably practicable, so if you can’t eliminate the risk, then minimise it by providing adequate control measures such as:

• A fall prevention device (eg, a secure fence, edge protection, working platforms and covers, temporary work platforms, guardrails, and scaffolding);

• If this is not reasonably practicable, then provide a work positioning system . This will prevent a fall by a restraint system, or enable a person to work supported in tension in a way that prevents the person from falling eg, industrial rope access;

• If it is not reasonably practicable to comply with either of the above, provide a fall arrest system . A fall arrest system is only used when it is not possible to use either a fallprevention device or a work-positioning system. This may not prevent a fall, however, it stops a person who has fallen and reduces the impact of the fall and so reduce their injuries. Examples include industrial safety nets, catch platforms or harness-based fall-arrest. If you use a fall arrest system, you must have emergency and rescue procedures in place and test them to ensure they are effective.

Remember to use a combination of controls to minimise risks if a single control is not eliminating the risk completely. In all situations, always maintain a safe system of work and provide training on the safe use of ladders, appropriates signs and ensuring correct PPE is always worn.

If you work in the construction industry, you must prepare and implement a site-specific Safe Work Method Statement (SWMS) for work at heights above 3 m. If you are unsure of how to fill one in SafeWork Australia has made it much easier with their Interactive Tool, which can be found at: www.safeworkaustralia. gov.au/doc/interactive-swms-tool

SafeWork NSW has developed a Safety Checklist for working at heights in construction. If you would like a copy, please email training@agwa.com.au.

Be safe and make sure that every worker gets to go home at the end of the workday!

Tom Devitt Senior Economist, HIA

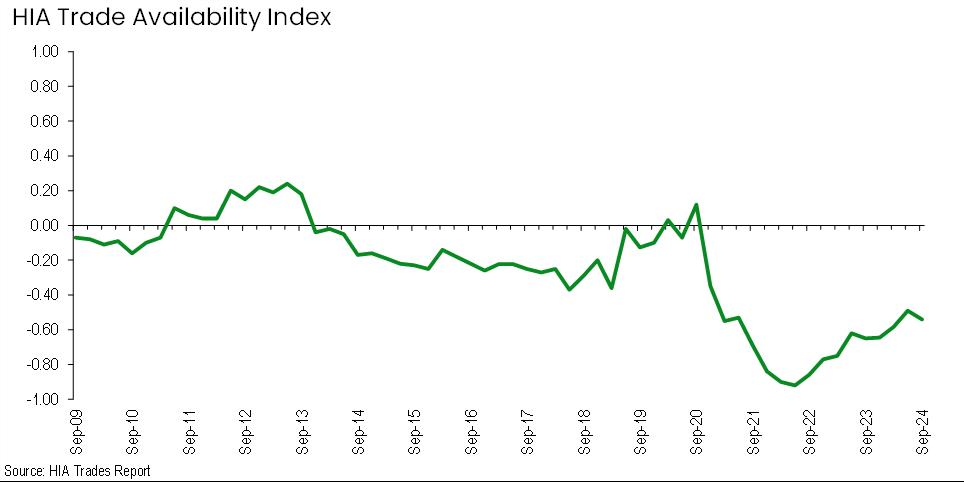

Australia continues to endure acute shortages of skilled trades. While these shortages have eased in recent quarters, they remain more acute than before the pandemic.

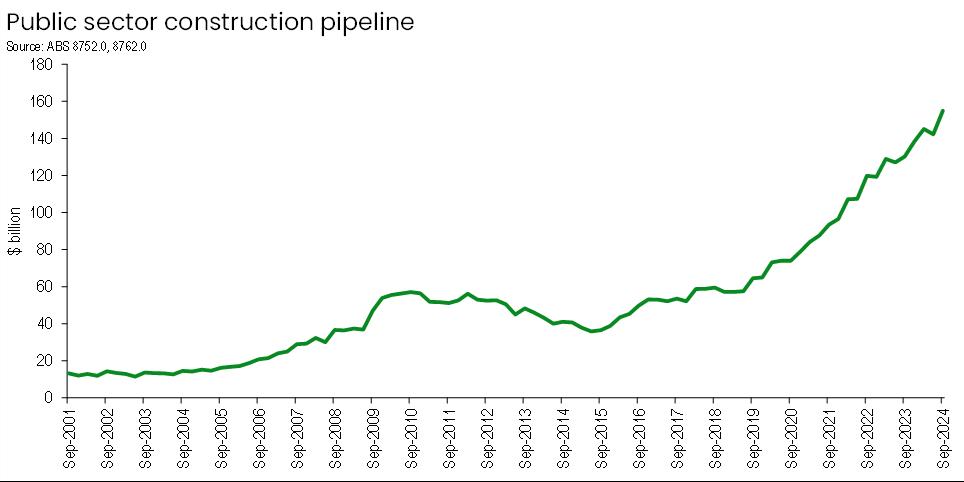

The challenge is that even as residential construction pipelines shrink, competition for skilled trades from other construction sectors, especially public infrastructure, is soaking up any excess labour. As at September 2024, the pipeline of public sector construction work reached a new high of $155 billion, compared to less than $50 billion back in 2016, when Australia was commencing construction on over 230,000 homes per year. The result is that trades shortages persist despite only 165,000 new homes commencing construction in the latest year, a 12-year low.

Successive governments have been aware of the persistent and structural skill shortages across key construction trades for decades, and the current policy approaches are doing little to shift the dial.

Australia needs to dramatically expand the size of its construction workforce.

HIA’s recent All Hands On Deck Report estimates that Australia requires approximately 83,000 additional workers in key construction trades to meet the Australian Government’s Housing Accord target of 1.2 million new homes over 5 years. This would represent approximately a 30% boost on current employment levels. A two-pronged approach is necessary.

Domestic workforce development

Over the medium-to-long term, we must give priority to Australia’s domestic workforce. This means greater support for apprentices, the public and private organisations that train them, and the businesses that provide them with supervision and on-site work experience.

We also need to attract more people into the construction industry, with a dedicated workforce development campaign to promote trades as a legitimate and rewarding career. There must be a concentrated effort to educate people on the benefits of a trade qualification, including to secondary school students, recent school leavers, and others looking to take their career in a new direction.

Skilled migration

This competition for skilled trades will make it harder for Australia to even build the volumes of homes seen in previous decades, to say nothing of the targets set by various governments to address the current housing crises around the country.

Given how urgent the matter is, we also require a short-term solution. This is why skilled migration is critical. Recent data from the Australian Department of Home Affairs shows that there were just 3644 workers on Temporary Skill Shortage Visas currently working in the key trade occupations needed to build homes in Australia. This equates to only 0.8% of the workforce in these trade occupations and not all these migrant workers are likely to be working in residential building.

A visa system that is complex and not fit for purpose does not help these numbers. The residential building industry needs a Construction Trade Contractor Visa tailored to suit the way work is arranged on building sites.

Failure to address the acute and persistent shortage of skilled trades means that Australia won’t be able to sustain healthy ongoing pipelines of residential, non-residential, and public infrastructure construction work required by our existing and growing population. This will act as a major constraint, not just on housing affordability, but on broader productivity and economic growth.

Discover the Future of Windows & Doors:

Transform your home with the precision and innovation of German uPVC windows and doors, expertly crafted to meet the unique needs of Australian homeowners. Whether you‘re retrofitting a charming weatherboard or heritagelisted home, or building a sleek, modern open space, our versatile, energyefficient solutions offer the perfect fit for every design.

With exceptional durability, security, and thermal performance, these windows and doors combine sophisticated German engineering with the ability to withstand Australia’s toughest conditions—from the harsh UV rays to coastal salt air. Elevate your home’s energy efficiency, style, and long-term value with solutions that truly endure. Experience the perfect blend of design, function, and luxury with German uPVC windows and doors – built for every Australian home.

Tim Johnston Head of Policy and Advocacy, AGWA

Slavery might sound like a concept from a distant century but sadly it still exists today, as modern slavery. Every business owner needs to be alert to their responsibilities and obligations, irrespective of where a business sits in the supply chain. For example, a business supplying to larger entities may be required to provide information to help those larger organisations meet their modern slavery reporting obligations.

Modern slavery is a pervasive global issue that involves practices such as forced labour, debt bondage, human trafficking, and other forms of exploitation. Despite being outlawed, modern slavery affects an estimated 50 million people globally, often hidden within supply chains. Modern slavery distorts global markets, undercuts responsible business and can pose significant legal and reputational risks to organisations. For Australian Glass & Window Association (AGWA) members, recognising and addressing modern slavery is not only a moral imperative but also a legal one under the Modern Slavery Act 2018 (Cth).

A common misconception is that modern slavery does not exist within Australian supply chains. However, many industries — including construction and manufacturing — source materials like glass, aluminum, and hardware from international suppliers where exploitation risks are high. These risks can arise at various stages, from raw material extraction to assembly and distribution. It is estimated that the construction industry accounts for 18% of labour exploitation cases globally. AGWA members need to be vigilant as ignorance is no longer an excuse. Businesses must take proactive steps to identify, address, and mitigate these risks.

Under Australian law, organisations with an annual revenue of $100 million or more are required to report on their efforts to combat modern slavery. These organisations must prepare an annual Modern Slavery Statement. The Statement explains how they are addressing modern slavery risks in their global operations

and supply chains. The statements are publicly available on the Modern Slavery Statements Register (https://modernslaveryregister. gov.au/ ). However, even small to medium-sized businesses (SMEs) must demonstrate a commitment to ethical practices, as clients, financiers and suppliers increasingly demand transparency.

Risk factors based on political, socio-economic and legal factors vary from one country to the next. To meet obligations, AGWA members should:

• Conduct thorough due diligence to map their supply chains.

• Engage suppliers with clear expectations regarding ethical labour practices.

• Implement robust policies, training, and risk assessment processes.

• Regularly review operations and seek third-party audits where necessary.

Being part of AGWA provides members with tools and resources to meet these requirements. By prioritising transparency and accountability, members can protect their businesses and contribute to the global effort to eradicate modern slavery. After all, safeguarding human rights is a responsibility we all share.

Warning signs can look different in different situations, depending on the type of modern slavery, the location and the person. Be alert to red flags such as control and manipulation, financial exploitation, living and working conditions, emotional and physical signs, isolation, lies and wrong information, and migration and migration documents.

The Australian Government has a number of online resources, including guides and case studies (https://www.modernslavery. gov.au/guidance-training-resources/business), to help strengthen business responses to modern slavery.

Backpacking around Europe and some serendipitous meetings led young electrician Peter Condon to a business and career in glass. We caught up with Peter to find out more.

‘You should go backpacking for a year, I recall my Mum telling me, after I completed my electrical trade apprenticeship in Queensland at age 21. I boarded the big bird Qantas plane with some excitement and a great deal of trepidation, arrived at Heathrow, and the next morning booked myself onto a 10 week bus tour around Europe’, begins Peter.

While the young electrician saw all the amazing places in Europe and widened this naive Aussie lad’s perspective on life, he met interesting people from all walks of life. While on his travels, he kept seeing a well-run, booked-out travel company called Contiki. Peter mustered up the courage to apply for a job with them so he could stay longer in Europe. In the meantime, he flatted in London with other Aussies and Kiwis and started working as an electrician at Watney’s Brewery in Mortlake. Peter recalls ‘I settled into 1980s London life very well; working and partying’.

Out of the blue, Peter received a call from Contiki telling him that he was one of 32 chosen applicants who would be going on the next 6 week intensive training trip around Europe. ‘To be out on the road every day somewhere in Europe, from Paris to Istanbul, in a 50-seater coach with no SatNav, no mobile phones, no internet, no laptops — only a manual, a driver and a wallet full of 10 different currencies — was a hell of a sensory overload at first.

But, like anything seemingly daunting at first, you soon get used to things, and I really loved it. I ran tours for Contiki in Continental Europe, Australia and Fiji’, reflects Peter.

In a sliding doors moment, Peter met an interesting Kiwi on one of his tours. His name was Robert Famularo, inventor of the frameless shower screen. He remained in contact with Robert. ‘My time in Europe came to an end when I met a Kiwi girl, Jane, at the Oktoberfest in Munich in Oct 1982’. Peter decided to stop touring and follow Jane home to New Zealand, and onto Australia and onto Fiji.

In 1985, Robert Famularo, the glass entrepreneur, proposed that Peter start a frameless shower screen business on the Gold Coast and Brisbane. Because of his interest in the product and hands-on skills in the electrical trade, Robert gave Peter a few days training on how to install a screen.

Sure enough, Peter came back to Australia in late January 1989 and made plans to start up a frameless shower screen business on the Gold Coast. ‘Because I had met both Jane AND Robert in Europe, we decided to name the new business Euroglass Australia’, he says, adding that ‘Robert even lent me $2000 to purchase a small Mitsubishi L300 van!’

The first few years were tough launching a never-before-seen frameless shower screen into the Australian market, and it took 3 years for Peter and Jane to turn a profit. ‘We had 2 young

daughters at this time, and I did everything in the business from quoting to measuring, ordering, and installing. I thought about giving up a few times in those early years and going back to electrical, but Jane provided amazing support through thick and thin’, says Peter.

Peter’s brother Chris joined Euroglass in 1991, and the team became well known as one of the first to install frameless

glass pool fencing in Queensland. In its 36 years, Euroglass has completed an astonishing 50,000+ jobs for clients all over Queensland and beyond.

Euroglass’ most notable projects include a 6-level internal frameless spider staircase at Energex in Brisbane in 2013 and 90 linear metres of spider fitted frameless glass restaurant awnings with 12 frameless stacking door systems in Brisbane Square in 2014. Euroglass has also been the frameless glass supplier to many top hotel bathroom refurbishments, famous superyachts, and luxury homesteads.

Peter and Euroglass Australia have received many accolades over the years, with the most recent being winning the 2024 AGWA National Design of the Year for his work on the Total Fusion Wellness Centre. He also won the Queensland Award for Commercial Project Over $750,000 for the same project. This project required all of Euroglass’s skill in installing various unique bespoke glass elements into the Centre including a 4-storey frameless glass lift shaft, a 140 sqm all glass curved high altitude training room, A New York warehouse style curved patterned glass reception/back of office centre, many bespoke sauna, shower and treatment rooms throughout and an external all glass travelator entry canopy to the carparks. This amazing project was unparalleled and a testament to Peter and his team at Euroglass.

‘They say imitation is the sincerest form of flattery, and I believe that many of our product innovations and initiatives have inspired a whole new industry of frameless glass businesses all around Australia, from importers and suppliers to installers’, explains Peter.

With Australians embracing energy efficiency and highperformance glass, Peter sees a bright future for long-lasting, high-end glass products throughout the industry. ‘It has certainly been a rewarding journey, from Queensland to Europe and everything since!’, ends Peter.

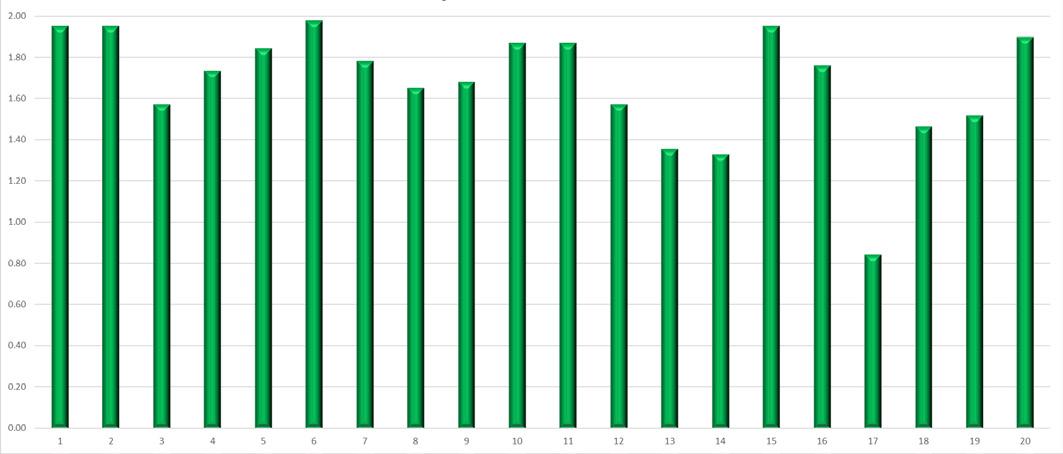

WESTERN PLAINS WINDOWS AND GLASS SAVES TIME AND MONEY

Western Plains Windows & Glass recently purchased a Quattrolifts Vector 500 Off Road Dual Vacuum Glazing Robot and a purposebuilt fully enclosed and lockable Drive on/off Tandem Trailer as a package to assist them with the handling of large panels, for both in the factory and out on site.

A perfect opportunity to try the new machinery arose not too long after. A contract to replace 5 small panels on a shop front for 2 large 350 kg (770 lbs) units was a perfect opportunity to evaluate the economy of using a machine rather than extra tradespersons.

The job site was 140 km away from their factory. Traditionally, 6 tradespeople in 2 work vehicles would have been sent to site (driving 2 hours each way) to replace these units manually. That is a total of 24 hours travel time for 6 tradespeople!

Traditionally, 6 tradespeople would have taken 6 hours to remove the smaller panels and install the 2 larger units. That adds up to a total of 36 hours of on-site installation time.

The Vector 500 OR PR Glazing Robot with its Variable Speed Control - Wired Remote was used to complete this job with only 2 people — 8 hours travel time instead of 24 hours.

Let’s have a look at the on-site installation breakdown. The 2 tradespeople:

• arrived at site 9.33 am;

• did prestart checks;

• did a site inspection;

• adjusted site fence and cleared area of debris;

• removed existing double-glazed panels, including framing x 6 (3 x lights per window);

• attached the Vector to the new windows and lifted directly off truck and installed into openings;

• did one reset in front of the openings per panel to optimise position;

• used the Vector to lift original panels from site and loaded directly on to the truck;

• tied down the load and tools packed (all tools needed were packed and secured in the front of the trailer);

• inspected the Vector and loaded and secured into the trailer;

• left the site 1.01 pm.

Time on-site 3.5 hours = total 7 hours

Travel time for 2 operators = total 8 hours

Time Study

Traditional manual glazing with 6 operators = 60 hours

Glazing with the Vector and 2 operators = 15 hours

Total cost saving using the Vector 500 OR Glazing Robot = 45 hours at $60 per hour

(Excluded from the calculation is the reduced Work Health and Safety risk for 4 operators from driving and musculoskeletal/ manual handling injuries dealing with 350 kg glass panels.)

Western Plains Windows & Glass said, ‘we are extremely happy with the results we are gaining with the Vector, and we will continue to incorporate it into our work practices, whenever possible’.

Quattrolifts is an Australian company that proudly designs, manufactures, and distributes their vacuum lifting machines worldwide. If you wish to enquire about how, you too can benefit from one of our machines, please contact Martin Blackey on 0415 895 327 or email martin@quattrolifts.com

Glass Only Data - including argon glass, coating on surface #2 (#3 with grey tint), NFRC standards

LowE, protected inside a double glazed unit with argon gas fill. For Total System Performance Data, see our WERS section on agg.com.au

Proven certified full frame performance data available in WERS

Australian Glass Group also understands the vital importance of certification and compliance of glass products. Our products are manufactured and certified to Australian Standards by an international certification body and compliance is certified and available on request in key areas including;

Neutral look, extreme Solar Control (low SHGC) without compromising a high Visible Light Transmittance (VLT), and supercharged Insulation (low U-Value).

Proudly manufactured, stocked and supported in Australia by Australian Glass Group

• Warm Edge spacer for further Thermal performance

• Tempershield ® toughened options for strength and Grade A safety

• Obscure Pattern and Acid Etch for privacy

• Laminated for security and Grade A safety – available in:

– Standard laminate – White translucent laminate for privacy

– Audioshield ® acoustic laminate for superior sound performance

Scan the QR code to view our Case Study: Your ideal 7+ Star high performance solution Australian Glass Group offers a full customised range with all Insulglass ® offerings

Alyssa Barr is an Architectural Designer who worked with Parkwood Doors to bring one of her recent residential projects to life.

Alyssa has a passion for designing spaces that are both practical and significant for those who use them. The ability to turn a concept from a sketch into a real, tangible, lasting part of the world is incredibly rewarding, with each project presenting fresh challenges and chances for growth. This is why she finds that working alongside clients and important partners is a wonderful aspect of the process.

Alyssa was tasked with creating a contemporary country family home that included ample space for entertaining extended family and friends. In a contemporary context, the layout of a country home will often feature spacious, function-based zones that have an indoor-outdoor flow. The home’s layout had been organised by function: the bedroom wing sitting on one side and the living quarters on the other.

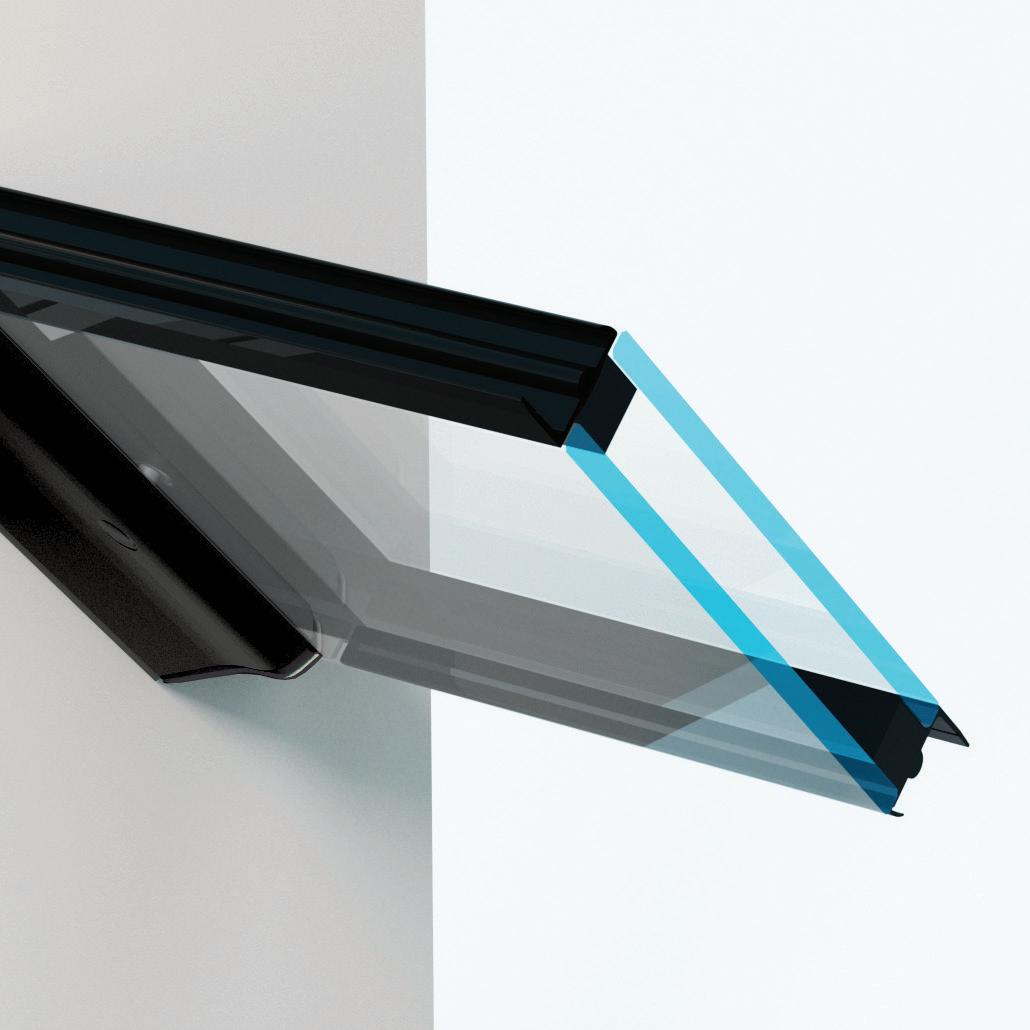

Alyssa chose Parkwood Doors for the ‘… quality product and service they provide. Their innovative products, like the Thermtek Aluminium doors, are aesthetically pleasing, while creating thermally comfortable homes that exceed compliance requirements’.

Thermtek is Parkwood’s unique thermally enhanced technology in aluminium front doors. Through the enhanced thermal properties of the Thermtek aluminium door, heat stays outside maintaining cool temperatures inside and vice versa. Additionally, this innovative technology minimises condensation on the door and serves as an excellent sound barrier. The door’s thermally enhanced properties work with the new and increasing thermal requirements for 7-star.

Alyssa and her client chose one of Parkwood’s aluminium styles, the HV03, as the home’s external door. ‘The contemporary look of the Parkwood Doors HV03, and its horizontal lines, complemented the home’s other surfaces’, said Alyssa.

A low maintenance home was important for the busy family, while not reneging on design and quality finishes. Front doors are often the only exterior house material that requires maintenance! Parkwood Doors’ aluminium styles are ‘strong and hard-wearing, so they can withstand the huge variety of extreme weather that Australia is known for, particularly the hot sun on large dark surfaces’.

Being able to have the door in a dark colour was high on the priorities. Monument is all the rage, and a light-coloured door in this façade just would not cut it. A beautifully crafted aluminium front door in their durable powder coat finish was the perfect solution.

Custom powder coating allowed Alyssa to match the home’s external door, the HV03, with the home’s aluminium windows and

its roof. Parkwood offers a large range of powder coat colours, including Dulux, Interpon and Colourbond colours. All standard aluminium window colours are available. Good quality powder coating is often more cost efficient, more hard wearing and more durable than conventional paint systems.

The family was thrilled with the results of their newly constructed home. The project’s refined, modern, and minimalistic colours and textures matched perfectly with Parkwood Doors. In particular, the contemporary look of the HV03, and its horizontal lines, complemented the home’s other surfaces.

For more information on Thermtek and Parkwood Doors, please see www.parkwooddoors.com.au

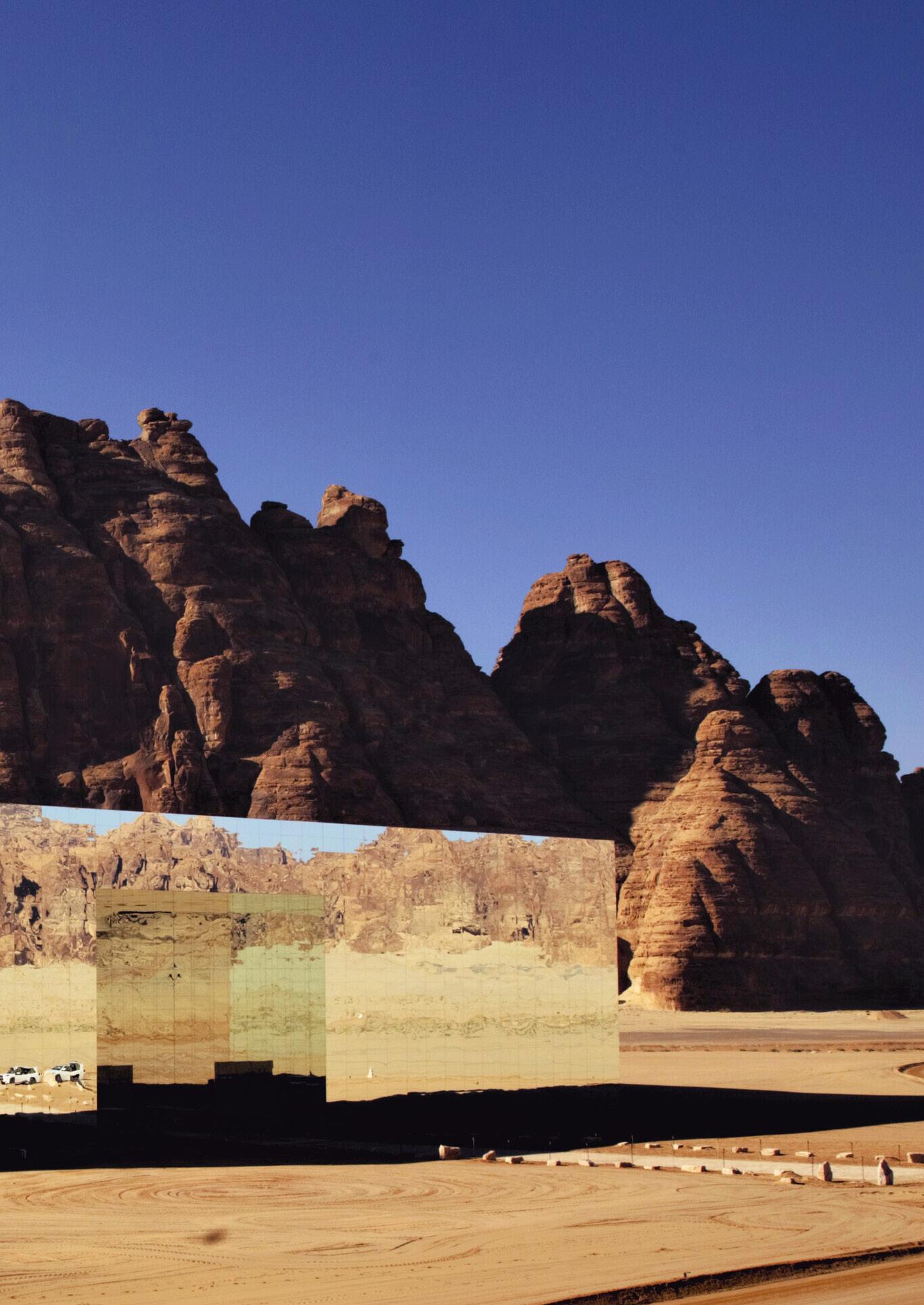

In the heart of the Arabian Desert stands the Maraya Concert Hall, the world’s largest mirrored building, a marvel of architectural innovation, and a drawcard for the region’s tourism. Guardian Glass, one of the world’s largest glass producers and innovators, accepted an impossible 3-month deadline and environmental challenges to turn this desert mirage into a reality.

Maraya, which means mirror in Arabic, was the vision of the Architects at Gioforma, who were determined that their 9740 m2 concert hall should not disturb or distort the ancient landscape around it, rather, it should reflect it. So, they specified a real mirrored glass exterior.

The harsh conditions of the desert environment (extreme wind, sand, heat, and sunlight) presented significant challenges to this mirrored design brief: corrosion, discolouration, and oxidisation occur in standard mirrored glass when outside.

Just 3 months before a fully-booked concert season was due to commence, there was still no viable solution for the Maraya’s facade. Instead, sections of buckled metal and other failed attempts from various engineering companies distorted the desert’s reflection. The pressure to find a solution was high. Certain that they could engineer an exterior mirrored glass that could withstand the extreme conditions of the Arabian Desert, Guardian Glass won the facade project.

Wasting no time, they developed a new copper mirror. It was based on their highly durable interior Guardian UltraMirror™, but with a unique protective coating that would ensure the longevity and visual integrity of the mirror. ‘It had to stand against some of the harshest elements on the planet, and the most outstanding features of copper are corrosion resistance and durability’, said Nabil El Ahmar, at the time the Mega Projects and Strategic Partnership Manager at Guardian Glass.

Once the copper mirror concept was approved, a new challenge emerged: the tempered glass panels would break if cut on site.

Guardian Glass devised a unique process where the raw annealed glass was sent to the processor, then cut to size and heat treated, before being returned to Guardian Glass for the application of the protective coating.

The result? Guardian’s durable and authentic mirror solution allowed the ancient, wind-carved, sandstone mountains to be perfectly reflected along the Maraya’s length, so that the structure almost disappears into the landscape.

The Maraya Concert Hall project was recognised by the Guinness Book of World Records as the largest mirrored building, standing as a testament to Guardian Glass’s commitment to research, a determination to deliver, and a firm belief in collaboration meaning it is constantly finding new ways to build, design, and inspire with glass. The Maraya was also a popular winner at the 2020 Architizer A+Awards in the Architecture and Glass category.

The project not only showcased Guardian Glass’s technical expertise but also highlighted their ability to create new value-added products, tailored to meet the most demanding environmental conditions and demonstrating their commitment to innovation and excellence in the glass industry. ‘Ingenuity and perseverance paid off as we had to develop solutions for Maraya Concert Hall’s unique needs. With this development, we have created a new value-added product that meets challenging conditions’ concluded Jasmin Hodzic, at the time AME Marketing Director at Guardian Glass.

For more information on the project or on Guardian Glass and their product range, please see www.guardianglass.com.

Featuring Series 726 ThermalHEART™ Fabricator: PAG Warnambool

Photographer: Tatjana Plitt

Architect: Design by AD

The harbour-side suburb of Double Bay in Sydney has long been synonymous with luxury and sophistication. Now, a new culinary gem is set to transform its dining scene. Song Bird, the latest venture by renowned chef Neil Perry, promises an elevated experience that blends Cantonese flavours with modern Australian influences. Housed in a heritage building reimagined by acclaimed architect Peter Hurley, the restaurant seamlessly marries historic charm with contemporary design, redefining fine dining in this prestigious waterfront locale.

The choice of Gaden House as the setting for Song Bird was no coincidence. This heritage-listed 1960s masterpiece, designed by architect Neville Gruzman, provides a stunning backdrop for Perry’s culinary creations. Capral Aluminium played a key role in the careful restoration, with their window and door systems essential to the vision that provided optimal thermal and acoustic performance.

One of the most striking features of the restaurant’s design is its extensive use of glazing, which not only floods the space with natural light but also offers diners breathtaking views of Double Bay and beyond. The project utilised the Capral AGS 629 and 429 Double Glazed Flushline systems to seamlessly connect the interior with the outside world, fostering a sense of openness and enhancing the dining experience with a strong connection to the surrounding environment.

Additionally, Capral’s AGS Commercial 900 High-Performance Sliding Door was also implemented in the project. Engineered to withstand the coastal environment, with features such as marinegrade stainless steel rollers and weatherproof seals ensuring smooth operation and longevity, the 900 Series provides an open, airy feel without compromise on practicality, offering robust security and weather protection.

To control sunlight and heat while achieving a sleek, modern look, the design of Song Bird incorporates Capral’s 45 mm Sunshade box louvre system. The adjustable louvres allow for precise control of natural light, creating a comfortable ambience that adapts to changing weather conditions throughout the day. By effectively managing heat and glare, the system ensures that diners can enjoy Neil Perry’s exquisite Cantonese-inspired cuisine in optimal comfort, whether seated indoors or in outdoor dining areas. The louvres also contribute to the restaurant’s energy efficiency, reducing the need for artificial cooling and lighting.

The seamless integration of these advanced systems was made possible through the skilled craftsmanship of Arch System Fabrication. Their close partnership with Capral Aluminium played

a crucial role in bringing Peter Hurley’s architectural vision to life with precision and excellence. This collaborative effort ensured that every detail of the design was executed flawlessly, resulting in a space that perfectly embodies the architect’s creative intent.

In conclusion, Song Bird seamlessly blends culinary mastery with architectural brilliance. The collaboration between Capral Aluminium and Arch System Fabrication has resulted in a dining space that showcases breathtaking views of Double Bay and provides an unparalleled sensory experience for guests. From the innovative use of glazing systems to the thoughtful integration of louvres, every element of Song Bird’s design contributes to its status as a new icon in Sydney’s fine dining scene. Song Bird perfectly balances form and function for a visually and gastronomically exceptional experience.

For vulnerable youth, forging a path into meaningful work can seem almost impossible, and work experience opportunities are typically limited.

This is the inspiration behind a remarkable program founded and run by O’Brien Glazing in Kewdale, WA called ‘A Day in the Life of a Glazier’. Now in its third consecutive year, the half-day session invites interested young people from the Parkerville Children and Youth Care in WA to step inside a real glazing business and see what a glazier does, have a go, and gain knowledge from glazing professionals.

For more than a century, Parkerville Children and Youth Care has supported vulnerable children, young people and their families with specialist advocacy, therapeutic services, education, and employment training, and out of home care.

Allan Thiel, Perth Metropolitan Operations Manager at O’Brien Glass explains that ‘each year, we approach Parkerville Children and Youth Care and ask the kids: Does anyone know what a glazier does? Does anyone want to find out? And that’s basically the interview! Anyone with an interest attends, and we share as much as we can about the profession, get them rigged up in PPE (which they love) then they have a go. We let them break glass, light the laminated glass once cut, cut shapes, the real deal!’

Last year everyone enjoyed their half day at O’Brien Kewdale, but it was 15-year-old Josie Murray who really stood out as showing potential. According to Senior Glazier Andrew Beard who ran the workshop, Josie was ‘a natural, showing promise straight away’.

Having never worked with glass before, Josie showed aptitude in the way she held the tools, worked with glass, and demonstrated a natural finesse. Andrew had already flagged her potential, but it was Josie who approached the team afterwards with great enthusiasm, requesting one week’s work experience with O’Brien, to which they said yes.

Josie fitted in well with the Kewdale team straight away. Glazing Team Manager Jarrod Boyle reports that ‘we started giving her jobs and she chewed them up, she was amazing! We gave her a speed cutter, and she handled that beautifully. We tasked her with building doggie doors, and she was able to construct them’.

The team were so impressed with her work and attitude that Allan spoke with Josie and her representative at Parkerville and offered her a Glazing Apprenticeship for 2025. She is thrilled, as are her father and grandparents who have supported her and are very proud of her.

‘We’re excited for Josie to start her TAFE course in June and then join us for the apprenticeship’, says Allan. ‘Outcomes like this make the whole team feel really good, and it’s inspired us to create a ‘Day in the Life of an Auto-Glazier Opportunity’ with our auto business, which is coming up.

Michael Bates, MD of Interform Supplies was also uplifted by Josie’s story. He had seen the LinkedIn story and got in touch with Allan wanting to help. He was going to Germany and shared the story with German glass consultant Peter Pokern, who kindly offered to donate brass-handled Bohle Silberschnitt glass cutters with names laser engraved on the handle. ‘To show these kids that someone cares enough to spend half a day with them, can shift their perceptions of the adults in their life and give them a start to a meaningful career’, said Michael.

Allan Thiel sees the potential to roll this out nationally and said ‘Parkerville Children and Youth Care is an outstanding organisation providing opportunities for youth who have not had it easy. O’Brien Glass Industries Glazing Kewdale is proud to be a part of helping the youth they support’.

At Viridian Glass, we know that consistent supply, exceptional quality, and unwavering reliability are key. You need a glass partner who not only delivers on time but also meets the highest industry standards.

From energy e cient double glazing to custom laminated, we deliver excellence in every pane.

Reliable Supply, On-Time Delivery

Your deadlines matter. We keep your production moving with dependable service.

Expert Support & Custom Solutions

Our team is here to help with tailored solutions for any project.

As part of our ongoing review of safety and safety-related topics, AGWA has released a new Safety Calendar for 2025. The Calendar is included in all member packs sent to you once you have renewed your membership. If you would like more hard copies, please contact training@agwa.com.au.

Each month of the Calendar is devoted to a specific topic. For example, January’s topic of the month was Return to Work. During that month AGWA sent out related information on that topic. This included tips to help you achieve the goals and sample topics for Toolbox Talks.

Throughout each month we’ll continue to provide you with useful information from around Australia with our Safety Round Up and of course, any important developments as they happen. Together with the Safety articles in BuiltView Magazine and all the Safety Documents on the AGWA website, keeping up to date with safety compliance will be easier than ever.

Together, we can make safety everyone’s business and make 2025 the AGWA Year of Safety

www.agwa.com.au/ausfenex25

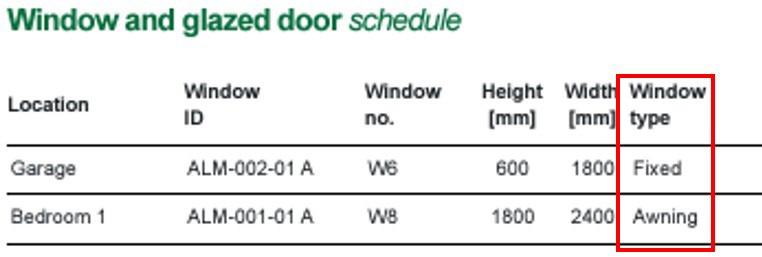

Step 1: Identify Window Types

First, check the ‘Window and Glazed Door schedule’. This will tell you the Operating Type of windows used in the assessment.

Step 2: Determine U-Value and SHGC requirements

In the realm of residential construction, energy efficiency is a key consideration affecting window and glass selection. One frequent query received by AGWA relates to quoting windows in accordance with NatHERS energy reports. These reports are crucial for ensuring that homes meet stringent energy performance standards.

Most NatHERS software includes all active residential window ratings from the Window Energy Rating Scheme (WERS) database under custom windows. These tools also offer default windows — placeholders used when actual windows are unknown — listed under WERS as WERSLink Default Windows.

Windows can be substituted with other products from manufacturers or suppliers, regardless of those specified in reports. When substituting listed windows, you must meet the following parameters:

• Operating Type

• U-value of the Window (within allowable tolerance, ie, less than or equal to the value in the report)

• Solar Heat Gain Coefficient (SHGC) of the Window (within allowable tolerance range, which usually is ±5%).

Frame materials and glazing types, among other parameters, act as indicators of the type of products that would meet the primary criteria but are not as critical.

To ensure compliance and accuracy when quoting on windows from the product suites offered by your organisation as per the requirements of the report, follow this procedure:

Step 1:

Identify Window Types

Step 2: Determine U-Value and SHGC requirements

Next, from the ‘Window and Glazed Door type and performance’ section of the NatHERS certificate, find the maximum U-value and Solar Heat Gain Coefficient (SHGC) requirements for each window type. For example, you might need:

• Awning Window: Max U-value of 6.7, SHGC of 0.57 (with limits 0.54 – 0.60 inclusive)

• Fixed Window: Max U-value of 6.7, SHGC of 0.7 (with limits 0.67 – 0.74 inclusive)

Step 3: Search the WERS Database

Use the WERS database to find suitable windows:

• Awning Window: Filter by Max U-value (6.7) and SHGC (0.57 ± 5% tolerance).

• Fixed Window: Filter by Max U-value (6.7) and SHGC (0.7 ± 5% tolerance).

Step 3: Search the WERS Database

Step 4: Select and Quote

The image below demonstrates the selection for the Awning Window.

Once all the necessary filters are applied, click on the ‘Search’ button to generate the list of records on WERS that are available within the search criteria.

Step 4: Select and Quote

Based on the search results, choose the frame and glazing combination that meets the NatHERS report requirements. Generate a WERS Certificate for compliance documentation. The WERS portal allows filtering by manufacturer, glazing type, and frame material to find suitable products.

Estimators often face challenges when quoting windows from reports, as Energy Efficiency Assessors (EEAs) may not consider supply constraints, aesthetics, acoustics, or bushfire requirements. For example, adjacent windows may need different tint levels for SHGC values, which may be undesirable, or meeting energy requirements may require a significant review to standardize glass make-ups. AGWA recommends contacting the EEA directly or through the builder for reassessment.

Including WERS codes in quotes helps EEAs recognise specifications, adjust as needed, and streamline future projects. Suggesting alternative windows with WERS codes can fast-track approvals. Further, substituting with products of lower U-value (Uw) can improve results, allowing more flexibility in SHGCw variations.

Matthew Graham, Sustainable Building Specialist from Graham Energy, notes, ‘Window performance is essential for a NatHERS assessment and varies by climate zone. Any changes to the U-value (Uw) can significantly impact the assessment, potentially allowing for adjustments to the solar heat gain coefficient (SHGCw). Developing a strong relationship with an Energy Efficiency Assessor (EEA) can help explore alternative options. After this evaluation, revising the NatHERS certificate can still lead to a compliant outcome that satisfies the star rating requirements and the desired window specifications.’

Remember, multiple window combinations can achieve the 7-star thermal performance rating, so the report’s specified windows are not the only compliant combination. As mentioned above, it may also help to liaise with stakeholders and send through product options with the ones that could potentially meet the requirements for reassessment.

For more information or support with quoting on windows and glazed doors for NatHERS requirements, or for assistance with the WERS database, feel free to contact our team at sustainability@agwa.com.au.

In these times of uncertainty and market turbulence, we want to take a moment to reassure you of our commitment and dedication to your success. At Guardian Glass, we understand the challenges that many of you are facing. Our priority has always been, and will continue to be, providing you with the support and resources you need to navigate these difficult times.

We are here to offer:

1. Open Communication: We believe in transparency and our customer service team is always available to address your concerns and answer any questions you may have.

3.

Reliable Service: Our team is dedicated to maintaining the high standards of service you have come to expect from us. We are working tirelessly to ensure that our operations remain smooth and efficient

2. Innovative Solutions: We are continuously building, designing, and inspiring with glass. By constantly exploring new ways to adapt and innovate, we aim to provide optimal solutions to meet your evolving needs. Our recent launches of LeanPaq™ and Wider Vinyl Back Mirrors are examples of our dedication to identifying and addressing market gaps.

We are grateful for your continued trust and partnership. Together, we will navigate these challenges and emerge str onger. Please do not hesitate to reach out to us if there is anything we can do to assist you.

For any inquiries or assistance, please contact our sales representatives:

Daniel McCluskey daniel.mccluskey@guardian.com

Cristina Graciano cgraciano@guardian.com

Russell Harris Head of Technical, AGWA

Australian Standards protect consumers by setting minimum product safety requirements. For example:

• Windows and doors must be tested to AS 2047 Windows and External Glazed Doors in Buildings to ensure their integrity during severe weather events.

• Grade A safety glass compliant with AS 2208 Safety Glazing Materials in Buildings is a minimum legal requirement for doors, sidelights, shower screens and windows in certain locations.

• Glazed balustrades must comply with the engineering requirements of AS/NZS 1170 and glazed in accordance with AS 1288 Glass in Buildings.

The use of non-compliant products, which do not meet these Standards, is illegal and a safety risk for consumers and the broader public.

Despite Australia having some of the most robust product safety standards in the world, we are increasingly seeing products that do not meet these minimum requirements installed into building sites. Not only can these products be potentially dangerous, but they are often not designed to withstand the harsh Australian environment or the high UV from the searing Australian sun.

In any given year, the AGWA undertakes between 100 and 150 investigations into non-compliance or disputes, associated with observed product failures or safety issues. Qualified industry experts, either on-staff or from our wide network of subjectmatter experts, undertake inspections. These investigations relate to windows, doors, facades, shower screens, or balustrades, and often range from issues such as improper installation, incorrect glass selection, water leaks, excess air infiltration or energy performance to large scale non-compliances and critical safety matters.

Overwhelmingly, our experience leads us to believe the key cause(s) for non-compliance (regardless of origin) is the general lack of awareness or understanding around the requirements of the NCC and relevant Australian Standards such as AS 2047 and AS 1288.

This is often compounded by additional challenges associated with a general lack of familiarity with federal and state building regulations. This situation is made worse by the fact that the construction industry, in general, is geared to place responsibility/ accountability on the supply chain to ensure products are fit for purpose. So, of course, when a builder is faced with 2 quotes, both purporting to be of equivalent compliance/performance, why would they not go with the cheaper option?

Consumers, when a non-conformity is detected, often find themselves with little to no support from the supplier. They are commonly left with little option but to pursue them through lengthy legal proceedings (often at significant cost and/or imposition) or pay a third-party to remediate the problem.

Unfortunately, a large proportion of non-conformities don’t become apparent until after construction is completed. This then

makes things much harder and often more costly to address, especially when the supplier or the transaction is based overseas or there are multiple parties involved in the transaction.

With ever-growing global supply chains and the growth of online business models, the number of ways to specify, supply and install window and glass projects can appear almost limitless. Visiting any of the emerging on-line trading websites, shows the sheer number of products available from around the globe. But how would you know if they meet all relevant regulatory requirements? And herein lies the issue: there is a certain amount of productspecific knowledge required to differentiate non-compliant products from those that are truly fit-for-purpose.

Without doubt, the rapidly evolving nature of business models in our sector appears to be making all this worse as fabricators begin to outsource elements of their projects. This, together with the evolution of offsite construction and the emergence of drop shipping, has culminated in a significant influx of an historically high level of new market entrants.

Unfortunately, with these new entrants and with rapidly evolving business models, many are ill-equipped and not educated sufficiently around what compliance looks like. AGWA continues to work with regulators to highlight non-compliance, to ensure transparency of members via our accreditation programs and to ensure the industry is educated to eliminate non compliance, ignorance and apathy. The development of out new Prime system and reseller accreditation programs is just one example of this.

AGWA is a non-regulatory body with a strong voice working with industry to achieve a level playing field and to effect meaningful change. To achieve this, we provide a range of services aimed at restoring/achieving a level playing field based on compliant and fitfor-purpose products. When purchasing windows, always look for an AGWA accredited supplier for assurance the products you are buying are compliant with relevant Australian Standards.

In late 2024, AGWA launched its NCC Compliance Guide targeting certifiers, specifiers, and regulators. The Guide’s mission is to demystify the essentials of compliance for our industry, and provide clear, unambiguous information around the requirements of the NCC across a range of products and applications.

To further make understanding regulatory compliance easier, AGWA has secured additional member benefits with 2025 membership renewal: Standards Australia mobile device subscriptions on the Window and Glazing pack of Standards. For more information, please see your Renewal Member Pack or contact members@agwa.com.au.

James Whitehouse

Technical and Accreditation Manager, AGWA

In recent years, innovations in products such as larger frame sizes, higher performing systems, and glass, increases in wind/ water performance and acoustics, to name a few, have seen our industry continue to evolve and modify business models to meet the demands of builders, projects, clients, and Regulations. AGWA has often heard members raise concerns about the use of noncompliant or non-conforming products and unfair competition from companies offering these. The evolution of the audit process has put our members at the forefront of compliance as traceability and certification requirements increase.

Traceability in construction is becoming increasingly important, with regulators and policy makers reviewing frameworks around traceability and transparency, like the ABCB’S Building

Product Registration Scheme. AGWA has been supportive of these developments as a way of reducing the potential for noncompliant products being used in construction in Australia.

AGWA has been enhancing its accreditation framework to support industry engagement in emerging programs, reflecting changes to Australian Standards and WHS requirements, including industrial manslaughter laws. All this, together with feedback from members and our own audits, has led us to update the Accreditation Company Program (ACP) to better align with the evolving industry landscape.

This diagram shows the full depth of our industry and the range that AGWA audits need to cover.

The Accreditation team thought it was worth providing an update for our members on the categories and the changes within each section. First, do you know where you fit in these categories?

Before the end of 2024, we sent out the Product Conformity Declaration to members of this category to gather up-to-date information on the scope of data/test reports. Throughout 2025, the team will be in touch with you to review this. If you haven’t seen the PCD or have any questions, please contact the Accreditation team.

Fabricators

As various states emphasise compliance, licensing, and more, we’ve updated our audit paperwork to reflect these changes. With projects becoming more complex, training is crucial to meet performance, window size, and customer expectations, distinguishing our members from industry cowboys. Access to both the NCC 2022 and current Standards is essential due to recent updates.

We have also revised the WHS Safety Pillar to support a safe and compliant workplace. Although PCBU responsibilities remain unchanged, new industrial manslaughter laws in each state require updates to some of your documents. In 2025, during face-to-face sessions, we’ll review product trends and assist with IGU compliance topics, addressing member feedback and the increasing disputes in this area.

In late 2024, we replaced the face-to-face audit with the Glazier Accreditation Program (GAP), an AGWA initiative conducted via online video calls. Auditors cover topics such as AS 1288, types of glass, NCC requirements and AGWA resources.

Training and access to the NCC and current Standards are becoming increasingly important. We have also revised the WHS Safety Pillar to support a safe and compliant workplace. Although PCBU responsibilities remain unchanged, new industrial manslaughter laws in each state require updates to some of your documents.

Some participants have already achieved a perfect score; will you be the next? Reach out to the accreditation team to schedule your session.

The evolving marketplace has led to an increase in members falling into this category. AGWA recognises this and has tailored the accreditation accordingly.

This is the first category where evidence of training in AS 1288, AS 4047 and the NCC is mandatory before the audit. The risk of sourcing products, without understanding compliance, can leave resellers exposed to potential legal issues. Strong knowledge and the ability to understand the nature of what a compliant and conforming product looks like will reduce the risk of disputes and potential prosecutions.

In conclusion, the AGWA Accreditation Program has been updated to align with evolving industry standards and regulations. By enhancing traceability, compliance, and training across all categories, the program ensures members are well-equipped to meet new challenges and maintain high standards of quality and safety.

If you want to chat with us about what type of audit you will be involved with or to schedule yours in to fit around work/holiday commitments or indeed any other question, please don’t hesitate to reach out to the Accreditation Team on accred@agwa.com.au

Ventus Louvre Galleries, proudly Australian owned and assembled in Sydney, provide a reliable and high-quality option for your window fabrication needs. Our louvre systems are manufactured from high-quality materials and rigorously tested to meet stringent Australian Standards, ensuring durability and performance in any environment.

Tested, passed and certified under the most stringent Australian tests.

Window restriction compliable with manual louvres. Made from environmentally friendly, UV stabilised, non-corrosive, non-toxic and resilient materials.

Designed for straightforward ease of installation.

Range of options and colours available.

Our Victorian golfers had a fantastic day at Northern Golf Club in Melbourne on Friday 22 November. As always, there were plenty of tall tales and cold beverages both on and off the course. With thanks to our sponsors who made the day possible:

Hole sponsors: AWS Drinks Sponsor: Viridian

A true conduit between land and sea

FABRICATOR: AVS Windows & Doors

ARCHITECT: Osmond McLeod Architects

BUILDER: Evolving Constructions

PRODUCT: Series 704 SlideMASTER™ Sliding Doors, Series 400 CentreGLAZE™ Windows, and FlowTHRU Pro™ Drain

Nestled among the serene landscape of Pearl Beach on the NSW Central Coast, Pearl Beach View House, designed by Osmond McLeod Architects, redefines the concept of coastal living. The home effortlessly treads the line between form and function; seamlessly integrated into the hillside while capitalising on the exquisite sea views that adorn the area.

The home’s material palette reinforces its connection to the landscape. Naturally weathered hardwood clads the exterior, with the rich tones echoing the hues of the surrounding bushland. Accents of charred Shou Sugi Ban, a traditional Japanese wood preservation technique, introduce a striking textural element, while providing a subtle nod to the cyclical nature of the coastal environment. A rooftop spa offers an exceptional vantage point from which to soak in the panoramic views. Here, residents can truly immerse themselves in the beauty of the coastline, enveloped by the sights and sounds of the ocean, even though the dwelling isn’t located directly on the water.

‘The original brief was to create a home that captured the waterfront views, but the property is not waterfront. It has another property between the ocean view and the home’, said Glen McLeod, Architect at Osmond McLeod. The architectural challenge of capturing extensive vistas, despite the proximity to the neighbouring dwelling, provided a creative foundation for a remarkable build that flawlessly balances the sense of seclusion and expanse.

‘We had to design a home that brought the ocean view into full focus but also obscured the neighbouring dwellings and less desirable features to give the property the feeling of being isolated

within its context’, Glen explains. ‘Pearl Beach is a sensitive coastal area, and we wanted to get as close as possible to the beach, but also the creek that wraps around the property. Addressing the structural requirements of touching the ground lightly was a significant factor, but also then designing the spaces, forms and glazing to bring these features into the home was a major challenge.’

The significant task of maximising the captivating sea vista, while simultaneously obfuscating neighbouring dwellings was a challenge the team at Osmond McLeod rose to with aplomb. It required a design that acted as a conduit, carefully framing the ocean view and screening out unwanted distractions. Crucially, expansive glazing would need to play a role in dissolving the boundaries between indoors and outdoors, creating the illusion of being directly on the beachfront.

To transform the Pearl Beach View House into a true conduit between the land and sea, the architects collaborated with the experts at AVS Windows and Doors to devise innovative glazing solutions. ‘The whole focus of the home was around the views and outlook and creating a coastal home that felt as if you were sitting on the beach or at the edge of the creek’, says Glen. ‘Having large expanses of glass in minimal frames, which disappeared into the backdrop, was critical in bringing the spaces to life.’

The home features oversized Series 704 SlideMASTER™ Sliding Doors that extend up to 9 m and disappear into wall cavities when fully opened, seamlessly integrating the natural environment and the living space. A particularly striking application of the Series 704 can be found in the upstairs living room, where wall-to-wall

doors offer breathtaking water views and, when opened, invite the refreshing sea breeze to flow through the entire house. This sense of indoor-outdoor connection is enhanced by the FlowTHRU Pro™ Drain, which provides a smooth transition between both environments, while its innovative design ensures a sleek, uninterrupted finish.

Additionally, Series 400 Single Glazed CentreGLAZE™ Framing is used throughout the home, accommodating diverse sizes of fixed windows. A stand-out element is the courtyard, where oversized fixed windows usher in abundant natural light that floods the interior spaces. Even when faced with a significant technical hurdle in creating a unique 90-degree angle corner stacking door — a challenge no other manufacturer was initially willing to undertake — AVS devised a bespoke solution that worked for the builder and stayed true to the architectural vision.

This remarkable dwelling embodies the unmatched potential of creativity, collaborative design, and innovation to craft dwellings that mindfully settle into their surroundings. Expansive Series 704 SlideMASTER™ doors and strategically placed Series 400 CentreGLAZE™ windows invite ocean views and sunlight to permeate the interiors, masterfully capturing the essence of coastal living. Tangibly anchored by the intricate beauty of its waterside locale, the Pearl Beach View House showcases AVS Windows and Doors’ ability to elevate architectural aspirations and transform ambitious blueprints into awe-inspiring structures that resonate with the tidal rhythms and the rugged beauty of the Australian coastline.

For more information, please contact marketing@awsaustralia.com.au

Well Hung Windows has been setting the benchmark for highquality window manufacturing in Townsville, North Queensland for over 2 decades. With a commitment to craftsmanship, customer satisfaction, and continuous improvement, this locally owned business, established by Colin Smith more than 20 years ago has built a reputation for excellence that keeps clients returning.

At the heart of Well Hung Windows is a simple philosophy: make quality products, deliver outstanding service, and never say no to a challenge. Rather than turning customers away, the team focuses on finding solutions, making adjustments, and ensuring every request is met with a practical approach.

‘It’s not about saying no’, explained Adam Hamilton, Director and one of the key figures behind the company’s success, ‘It’s about saying, “Yes, you can have it, but we need to do this”, or “We need to make that adjustment”. The right approach makes all the difference.’

One of the defining aspects of Well Hung Windows is its unwavering commitment to quality. A long-standing partnership with Capral Aluminium, manufacturing a full range of Capral window and door systems that are well-suited to the local market, means that unlike many of its competitors, Well Hung Windows rarely experiences product issues. Their products deliver the performance and integrity needed to meet the high expectations of builders and homeowners alike, a testament to the durability and precision of its offerings. Customers appreciate this reliability, often returning for repeat projects or recommending the company to others.

Customer feedback is the ultimate testament to this quality. Adam recalled a rare, but meaningful, message from a satisfied client: ‘I got an email the other day from a customer saying how impressed they were with the quality of our product and how the factory team should be commended. You don’t often hear feedback about quality because people expect it, but this one made a point of it. That tells you something.’

‘You don’t often hear feedback about quality because people expect it, but this one made a point of it. That tells you something.’

Ensuring top-tier manufacturing requires ongoing investment in precision tooling and production processes. When relocating to a larger facility, the company recognised the need for additional equipment to maintain its efficiency and high standards. This investment has not only enhanced production capabilities but also made it easier for new employees to learn the trade. Even those with no prior experience in glazing quickly adapt, thanks to the streamlined and user-friendly manufacturing processes.

Operating in North Queensland means designing windows that can withstand extreme weather conditions, particularly in cyclonic regions. Their relationship with Capral means an essential level of resilience for Well Hung Windows products, as they are engineered to endure severe wind loads, driving rain, and debris impact providing. Their customers know that their products will provide long-term security and reliability for homes and commercial buildings in cyclone-prone areas.

Beyond product quality, the Well Hung Windows’ proactive approach to customer service sets it apart: ‘Positivity, thinking outside the square, working as a team, communicating with clients, and following up — nobody does follow-ups! But we do!’, Adam emphasised. ‘That’s why we have so many repeat customers. They finish one project, sell the house, move to another, and use us again. If you’re not good, you don’t get used again.’

Beyond customer service, the company’s impact is visible throughout Townsville. ‘I drive around with the office team, and it’s like, “We did that one. We did that one. We did that one”. It’s good to see a local company competing with the bigger guys. It’s not all about the big players. If we can compete, we will. Let’s go. Let’s make it happen’.

For the Well Hung Windows’ team, work is more than just a job — it’s about being part of something bigger. The company fosters a strong culture of teamwork and accountability, where employees

take initiative and support one another to ensure smooth operations. This collective effort is evident in everyday tasks, from manufacturing to logistics, with team members stepping up without hesitation to get the job done.

As the business continues to grow, its core values remain unchanged: quality products, customer-focused service, and a commitment to excellence. Well Hung Windows is well-positioned to maintain its leadership in the industry for years to come.

We caught up with 2022 AGWA National Apprentice of the Year Matthew Bengtson to find out what he’s achieved and what’s changed since taking out the prestigious prize 3 years ago.

The 28-year-old Queenslander is still in glazing and still working with the same company, G.James Glass and Aluminium, although has changed his specialty within the organisation. ‘I have transferred to our commercial specialised glazing team, where we focus on larger architectural and unique scopes of glazing’, explains Matthew. ‘This has allowed me to be exposed to a great variety of glazing, learning and utilising different applications within really a very short period.’

Each year, AGWA recognises the very best Residential Glazing, Commercial Glazing and Glass Processing Apprentices in each state. The finalists then compete at a national level for Apprentice of the Year. The AGWA Apprentice Awards help recognise an apprentice’s excellence, encourage their endeavours, and help them to forge a long and rewarding career in the glass and window industry.

After winning the competition in 2022, Matthew received several enticing job offers. While some past winners used the prestige of the prize to seize other career opportunities straight away, Matthew chose to focus on succeeding where he was, at G.James. Matthew shares that he ‘felt a responsibility, in simple terms, to pay my dues at G.James, who put me through my apprenticeship. Having stuck it out, I have had the opportunity to take steps towards my future goals within the industry, from learning as much as I can from those older and more experienced within our team, the opportunity to be a leading hand on some projects and now working toward managing jobs on site’.

Matthew cites the connections he’s made with great people as the best part about winning the competition, including ‘other apprentices that I learned from alongside, my fellow competitors from all over the country, AGWA members that I connected with during the process, and all of the attendees I met and learned from at the Awards nights. I view some of these friendships and industry connections as invaluable as I move through my career’.

Matthew offers this humble advice to inspire future glazing apprentices and competition entrants:

• Be yourself.

• Aim for excellence in all you put your hands to, not just when people are looking.

• Integrity goes far beyond skill and talent.

• Take on everything people have to teach you and make your own way.

When we asked him what he would tell an apprentice who is thinking of entering the competition, he said ‘Just do it, because you have nothing to lose and everything to gain!’

Telling us what he enjoys most about being in the glass and glazing industry, he admitted he might be biased, but he genuinely believes that glazing is one of the best trades to be in.

In his own words, ‘beyond the days where the glass is heavy or difficult to install, the pride in seeing your work transform a building or space into something extraordinary — it is something I am grateful for every day.’ Matthew adds ‘each day is different with new challenges and new projects to work on, and personally, a great team of mates to work with every day!’

Now a fully qualified Glazier, Matthew Bengtson looks forward to what is to come in the future of the glass and glazing industry. AGWA wishes him all the best for a happy and successful career ahead and thanks him for being an inspirational ambassador for the industry.

The 2025 AGWA Apprentice Awards are now open. If are interested in entering, please go to www.agwa.awardsplatform.com

In an industry-leading initiative, aluplast and Think Manufacturing are revolutionising polyvinyl chloride (PVC) recycling in Australia. These leaders are setting new sustainability benchmarks by repurposing uPVC offcuts from window and door manufacturing.

PVC is a versatile and durable polymer used in various products, from flooring and cables to medical supplies. Despite being one of Australia’s most used polymers, PVC has historically had a poor environmental reputation due to limited recycling efforts. uPVC is the leading material for insulated windows and doors in Europe and North America.

With the introduction of the 7-star energy rating for new homes, uPVC insulated windows and doors are now poised for significant growth in Australia, offering superior thermal performance at an affordable cost.

aluplast, a global leader in thermally efficient uPVC window and door profiles, tackles the PVC recycling challenge head-on. The company collects uPVC offcuts from its fabricator network across Australia, shredding and granulating them at its state-of-the-art facility in Dandenong South, Melbourne, for reuse.

Its collaboration with Think Manufacturing epitomises a successful circular economy model. Led by founder Jack Fitzgerald, Think Manufacturing uses aluplast recycled uPVC to produce fencing and decking components.

Fitzgerald underscored the importance of this initiative: ‘PVC has traditionally been problematic due to increasing production and lack of recycling solutions. Our partnership with aluplast directly addresses this issue.’

In pursuit of further innovation, Think Manufacturing is partnering with CSIRO to develop an AI-powered PVC analyser. This pioneering technology will streamline the recycling process by accurately identifying the composition of individual PVC formulations. Fitzgerald believes this analyser could revolutionise the industry, enabling the production of high-quality recycled products. He states, ‘the potential is huge. We can take rigid PVC from any source and produce a repurposed finished product’.

The collaboration between aluplast and Think Manufacturing showcases the power of industry leaders working together to achieve a common goal. ‘Closing the loop on the ”plastic pipeline” has been our life’s work’, Fitzgerald said. ‘We aim to build a house predominantly from recycled PVC materials, making it an affordable, realistic product within the next 5 years.’