Editor’s note

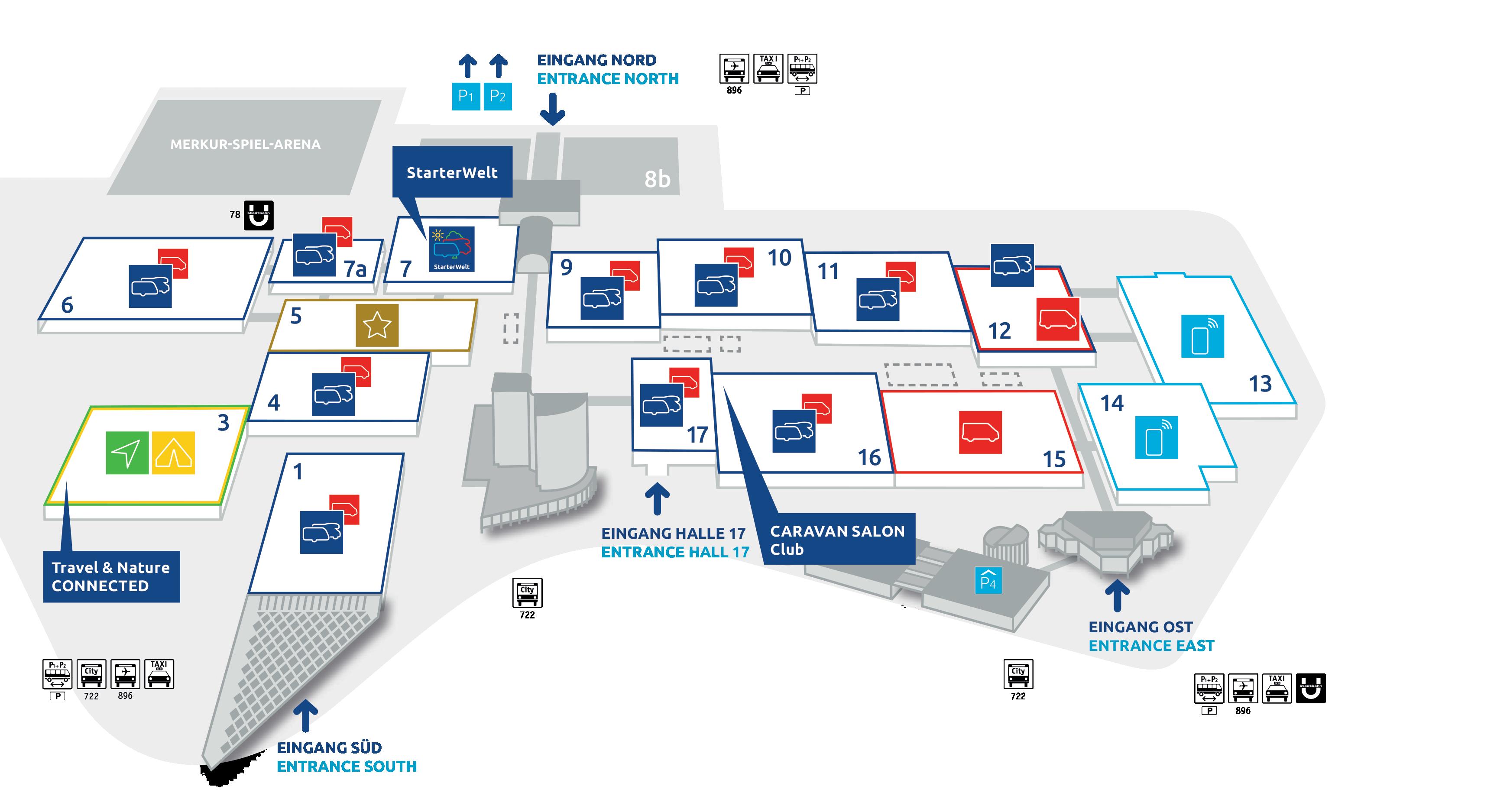

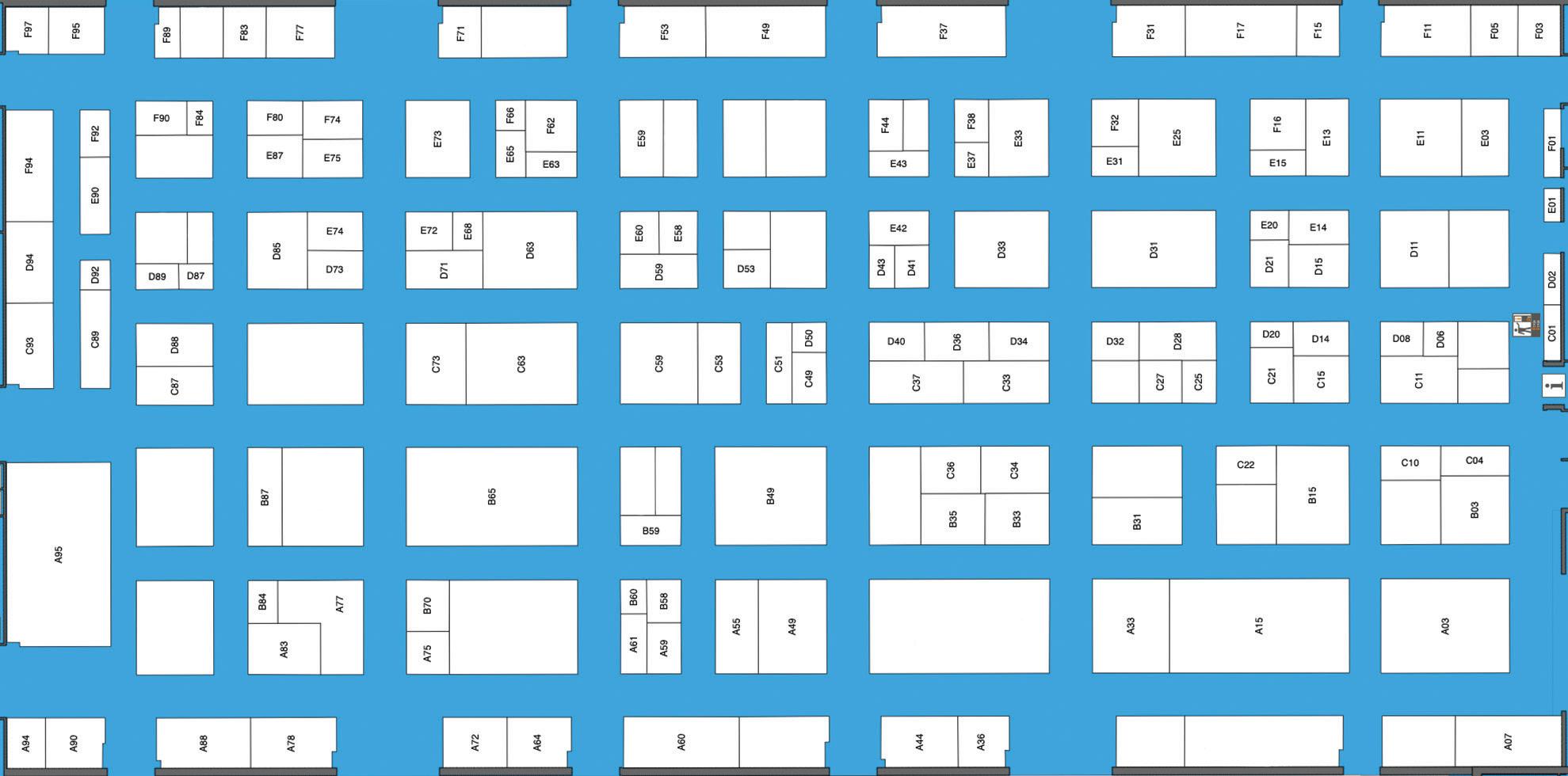

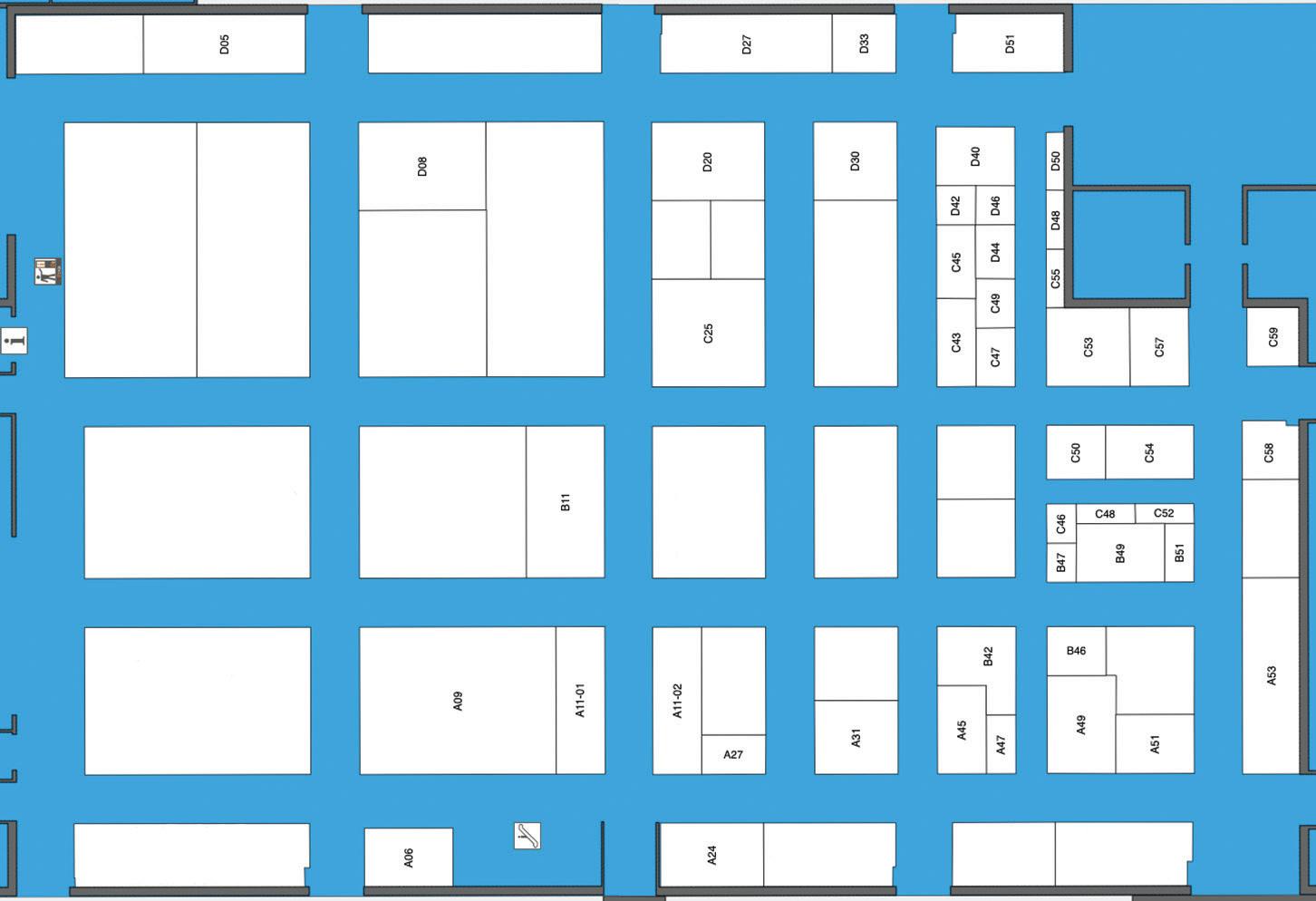

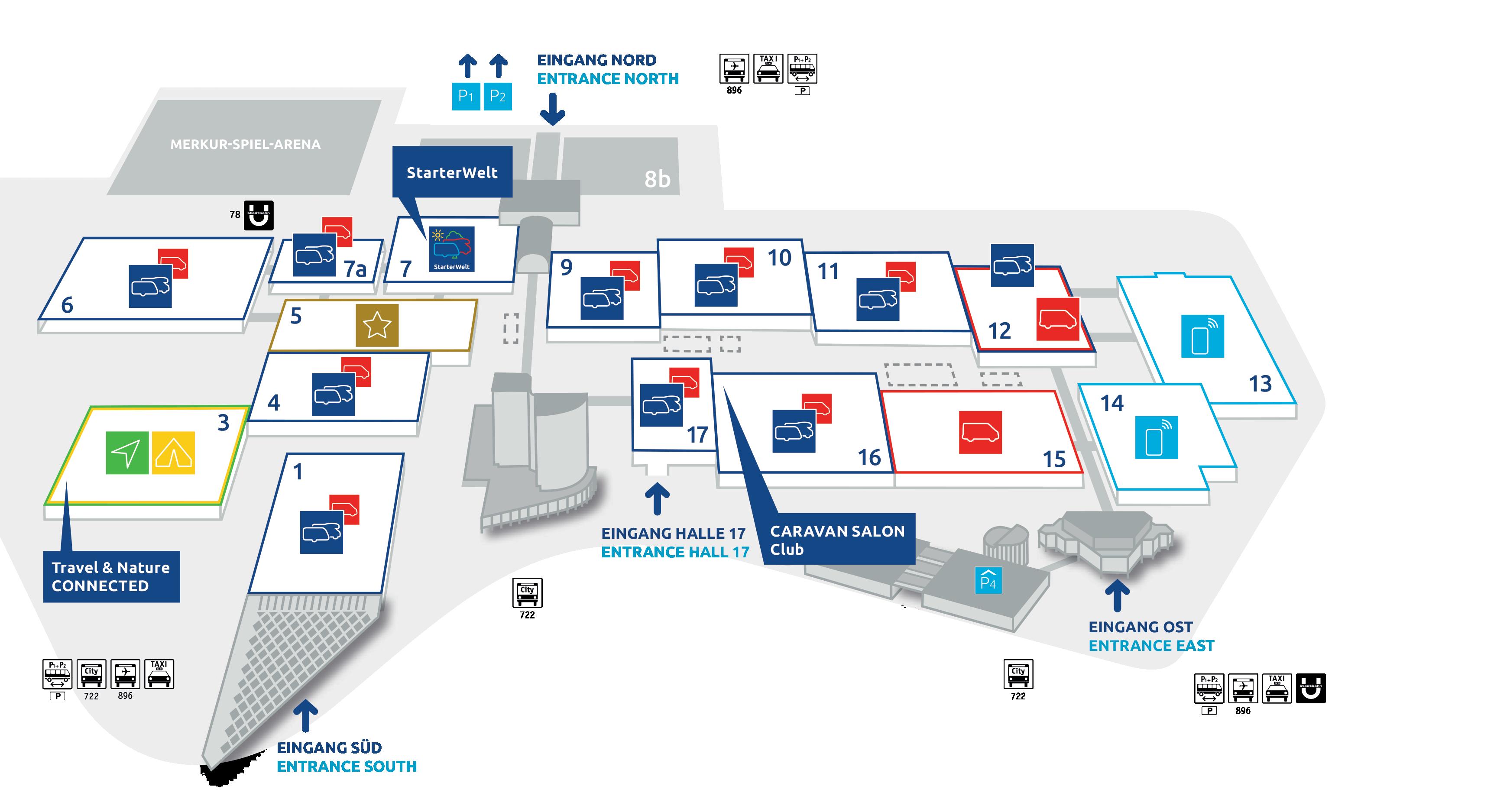

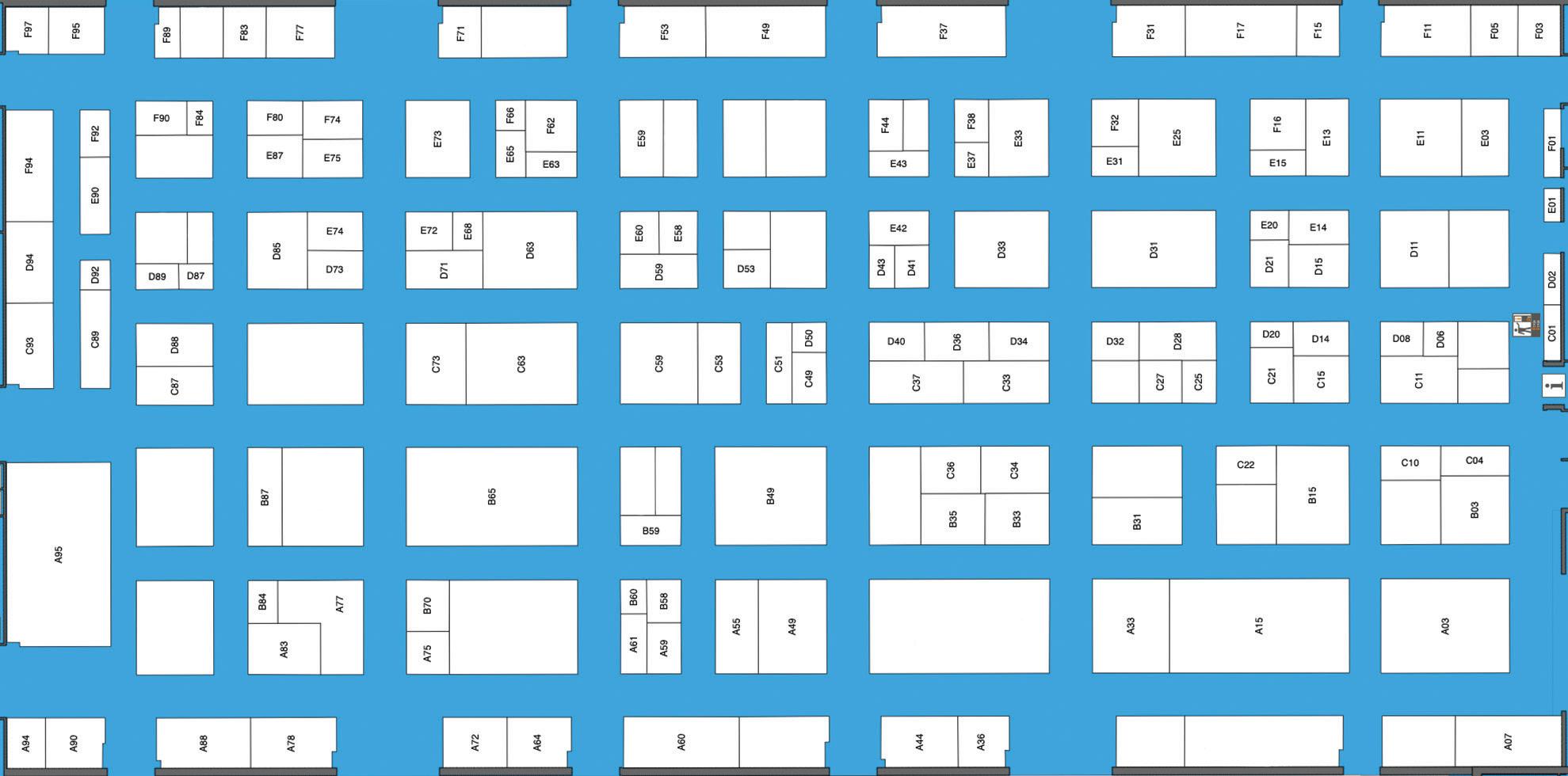

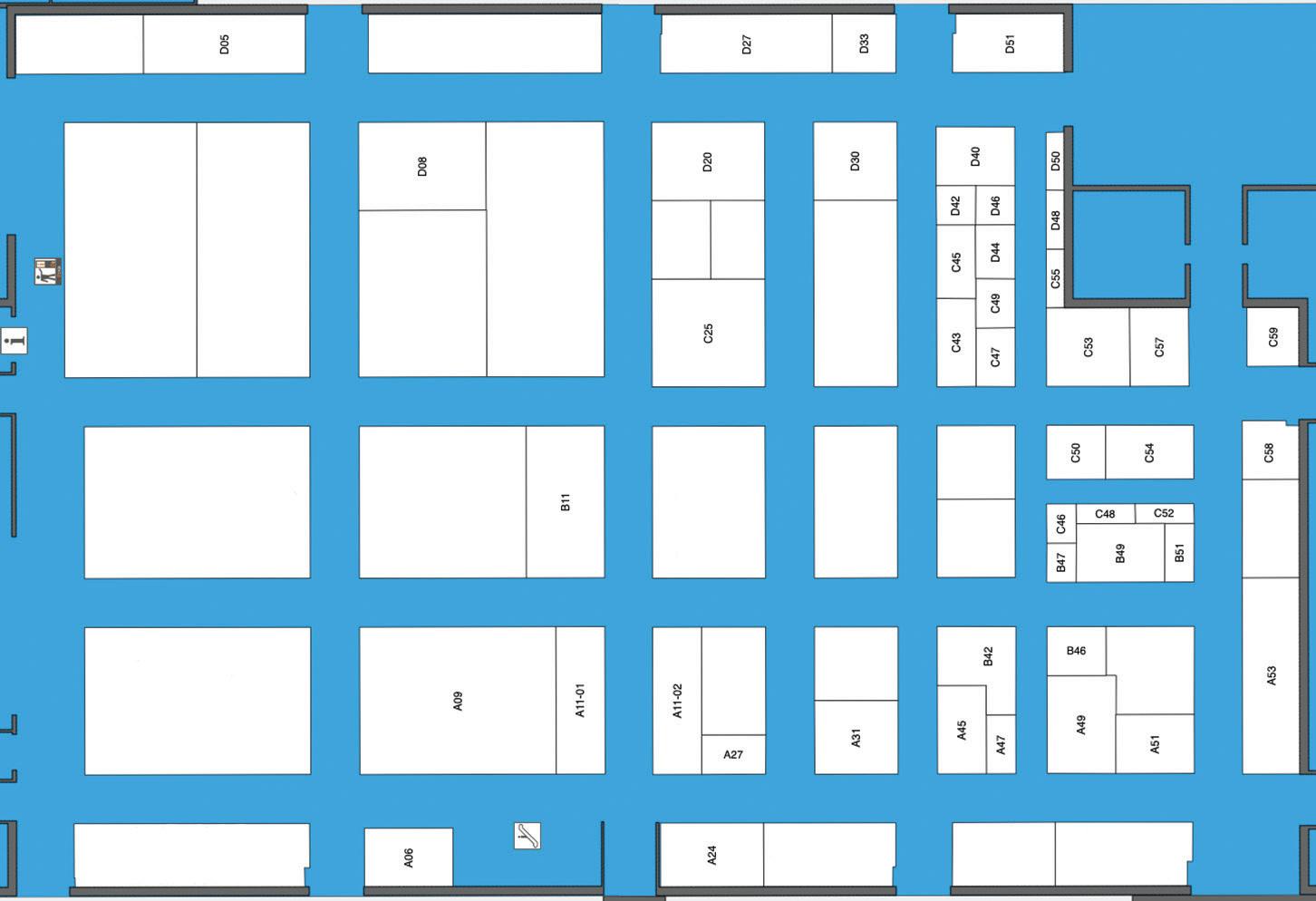

We are on the eve of a new and extraordinary edition of the Caravan Salon in Düsseldorf. Extraordinary because the numbers are impressive: 16 halls, 250,000 m² of exhibition space, and 700 exhibitors. These are roughly the same numbers as last year, which set a record for the world’s largest fair in the caravanning industry, and this year is celebrating its 62nd edition. As usual, we are providing you with a map of Halls 13 and 14, the “Technology & Components” area, which this year hosts a total of 246 exhibitors. Our journalists from all over Europe will be there to gather information, take photos and shoot video reports with a focus on products, technologies, materials and innovations of interest to caravan and camper manufacturers worldwide. This has been our mission for the last 11 years.

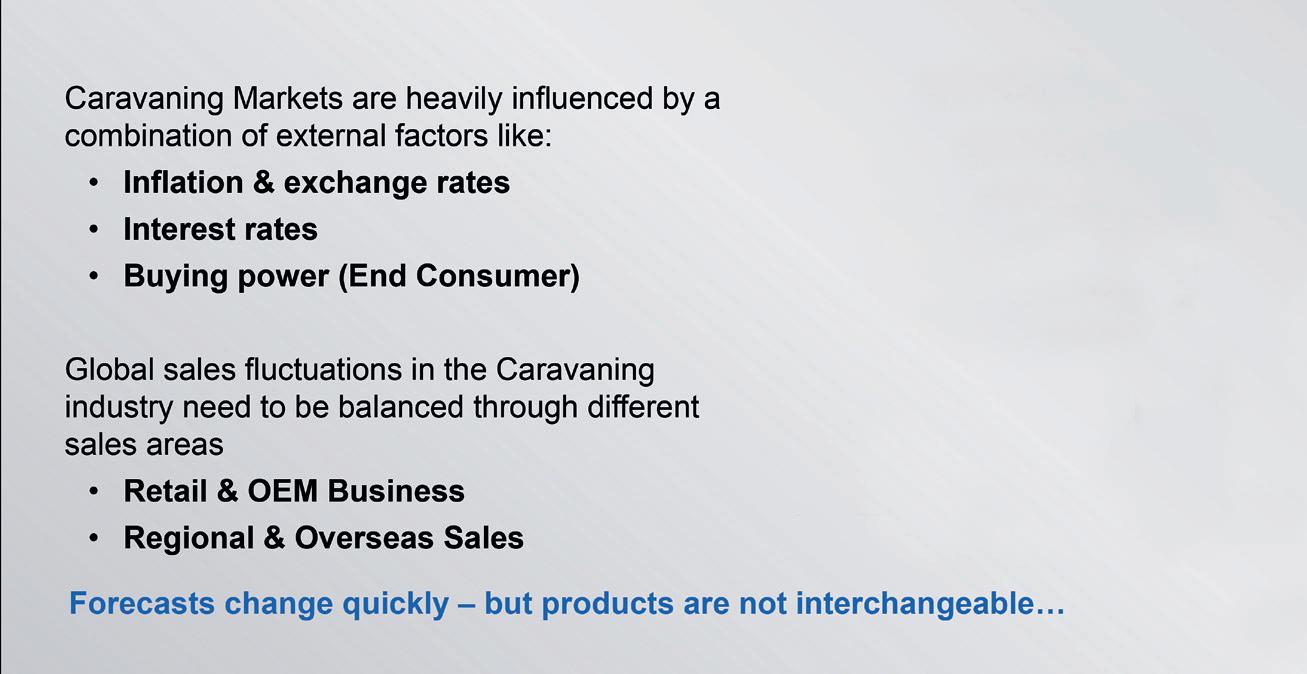

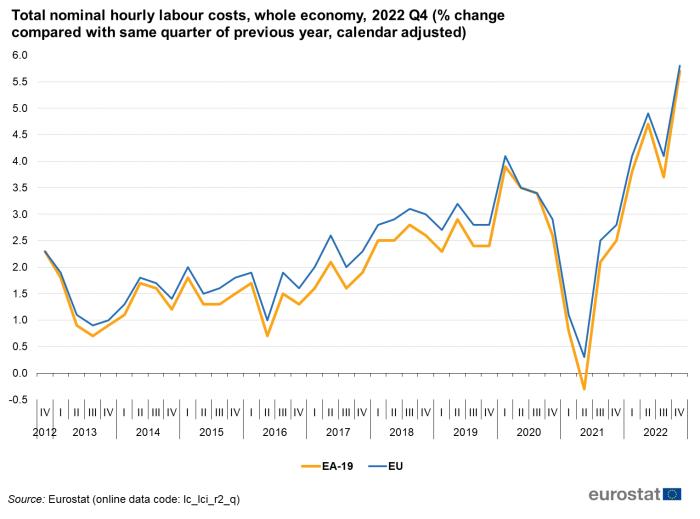

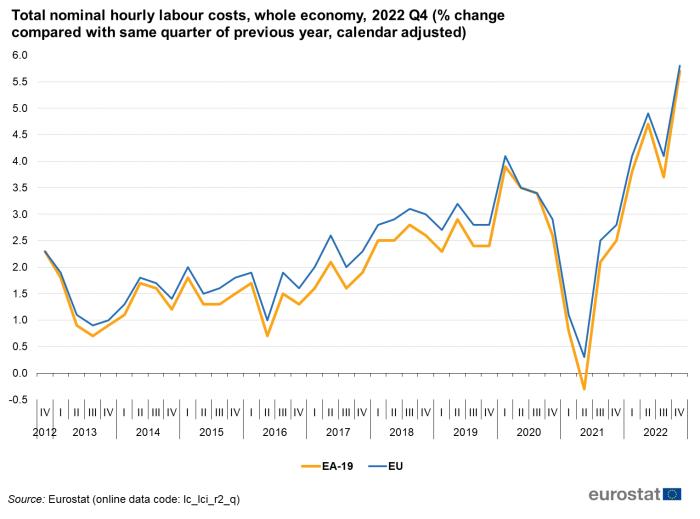

This 40th issue of our magazine showcases almost 60 pages dedicated to the products offered by component manufacturers for OEMs. However, there is much more to read. Unfortunately, we could not attend the ECF (European Caravan Federation) meeting in person this year, so our reportage is less comprehensive than usual, but nonetheless, we present two very interesting articles: one from Thor Industries and the other from the Truma Group. External factors such as high inflation rates, exchange rates and interest rate hikes are impacting consumer buying power. The industry is also facing further challenges with high production costs, increasing labor costs and supply chain complexities, especially with chassis deliv-

Columns

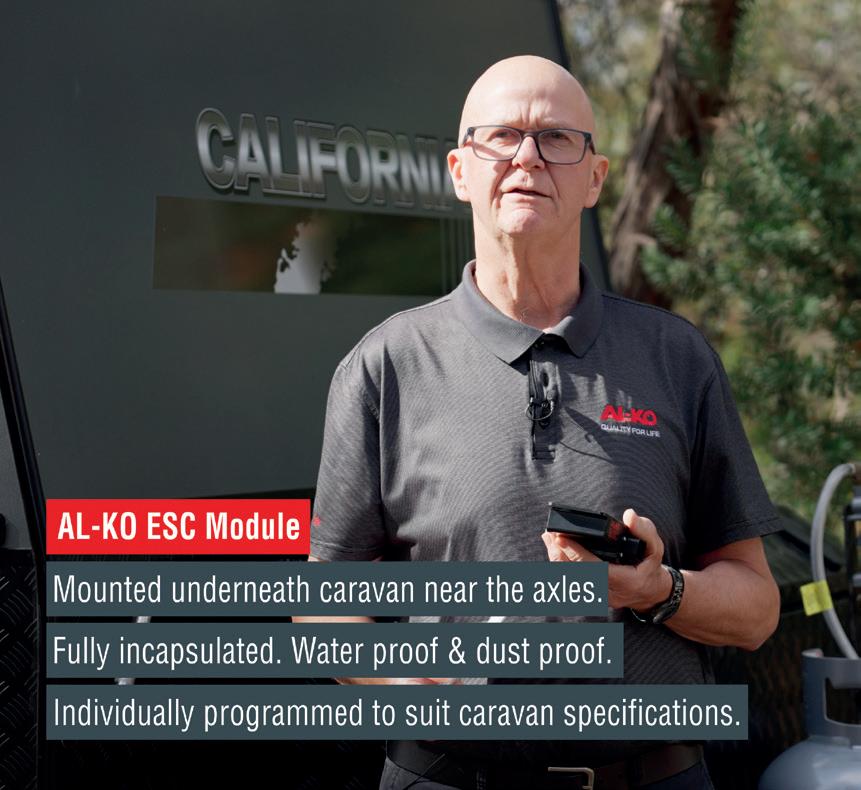

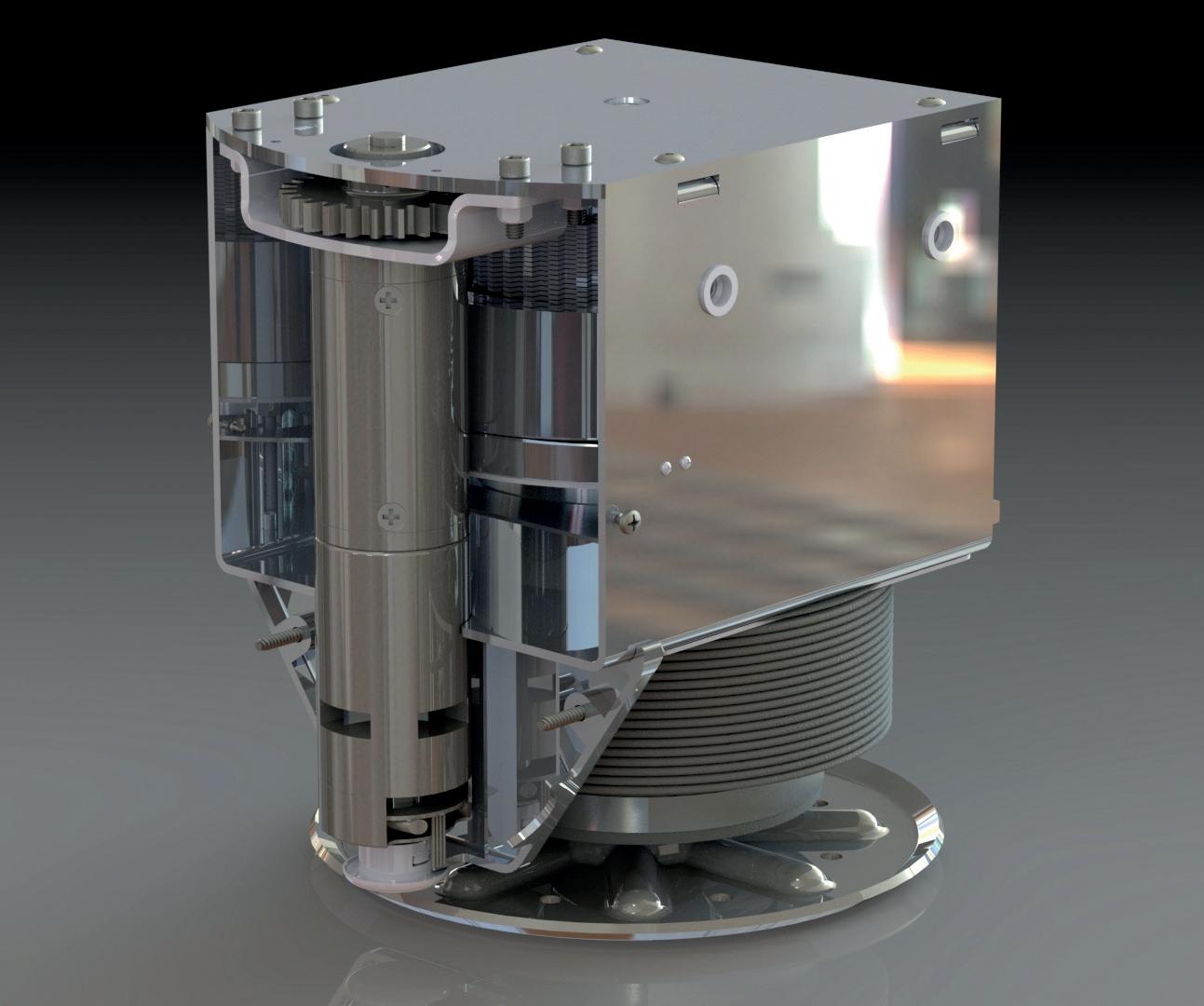

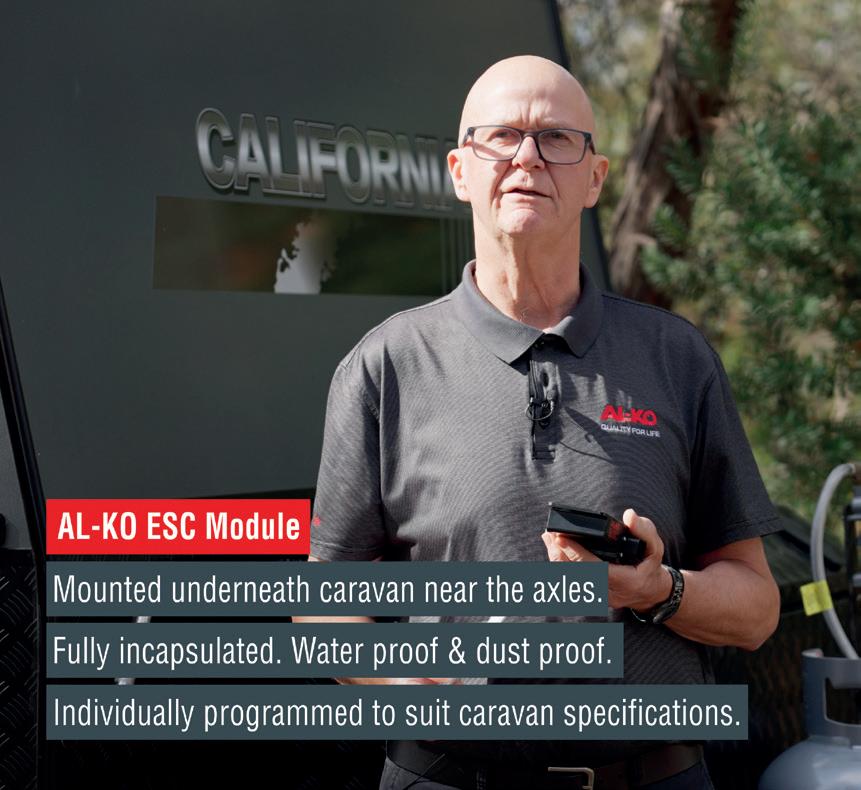

• 58 AL-KO VT

The journey of safety

• 60 AL-KO VTE

Power and automation on board

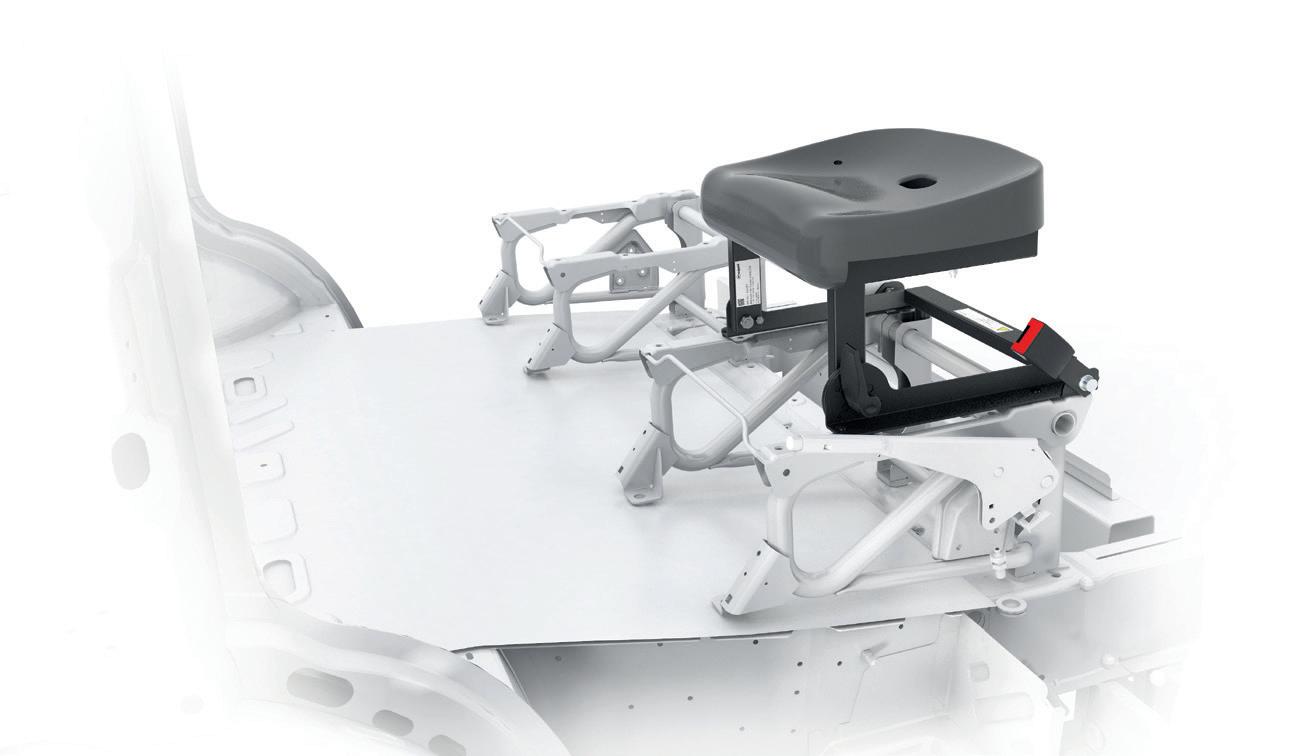

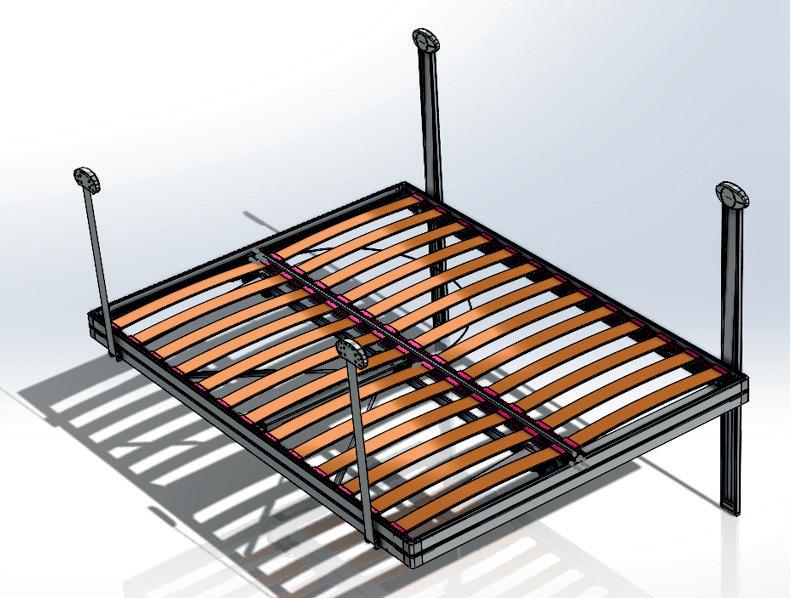

• 62 Aguti

At the heart of the product

• 64 Lippert

Lippert’s vision

• 68 Airxcel

Induction and gas

• 70 Brianza Plastica

Set for more success

• 72 CTA

Slimming treatment, and more

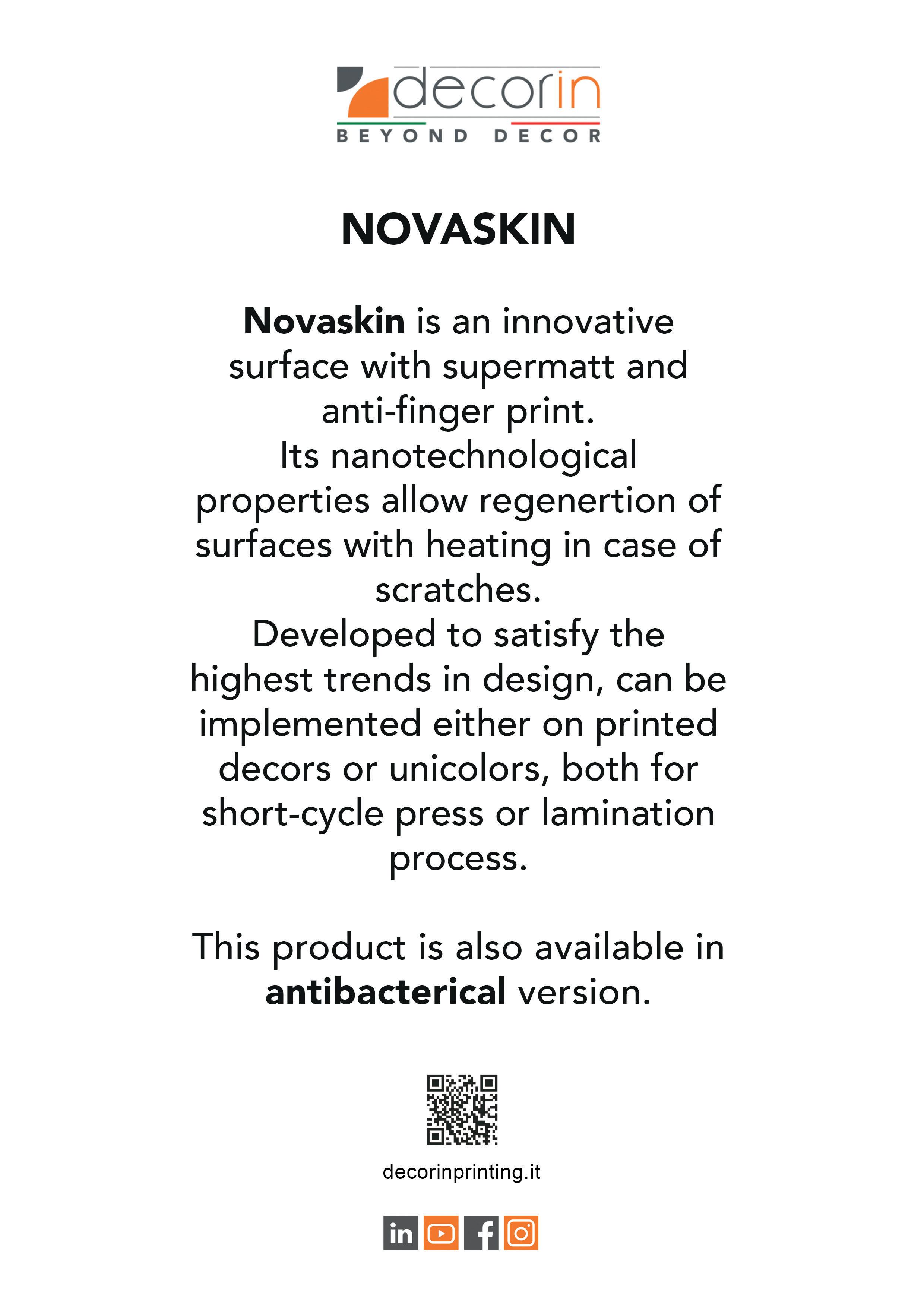

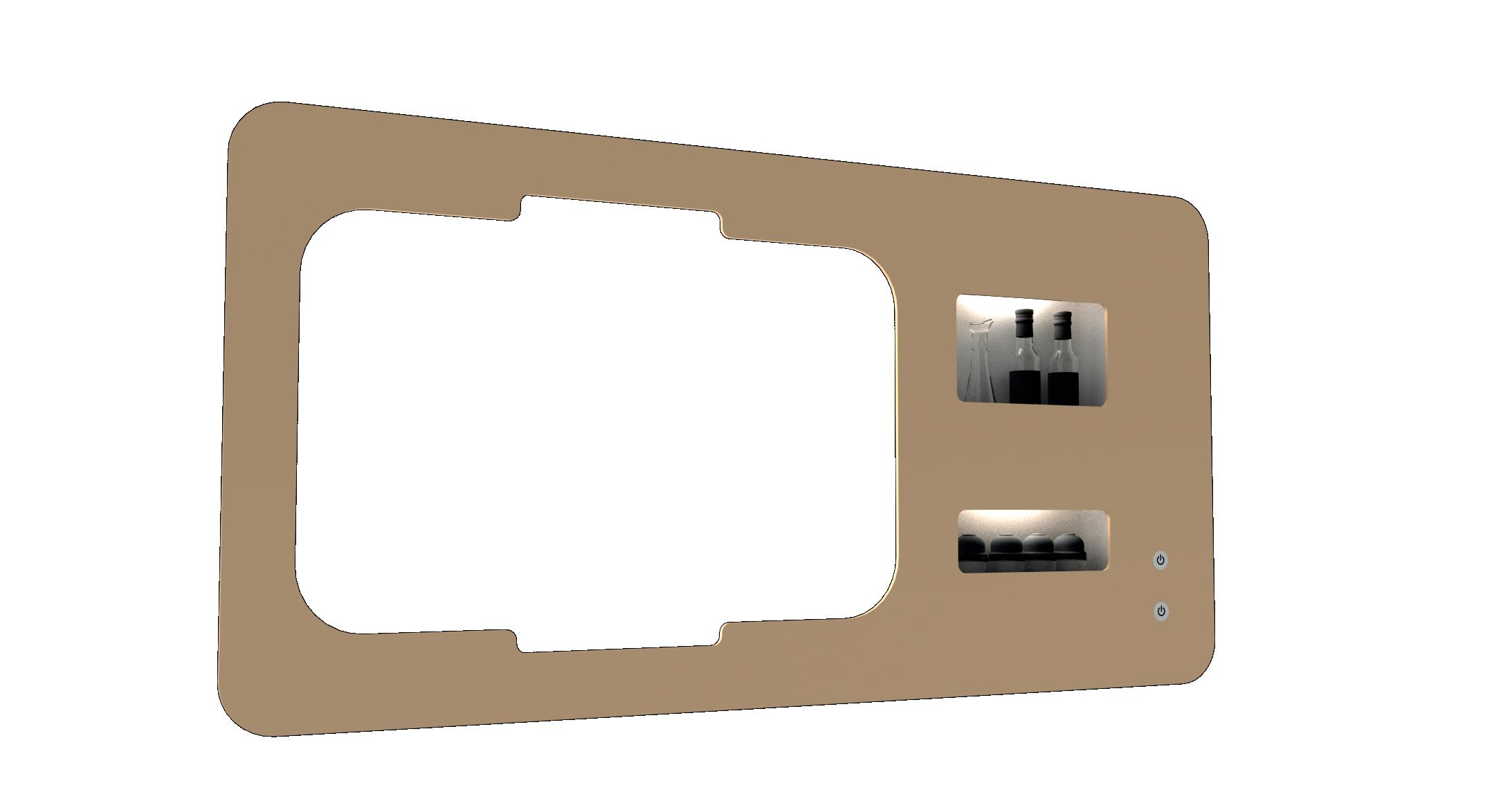

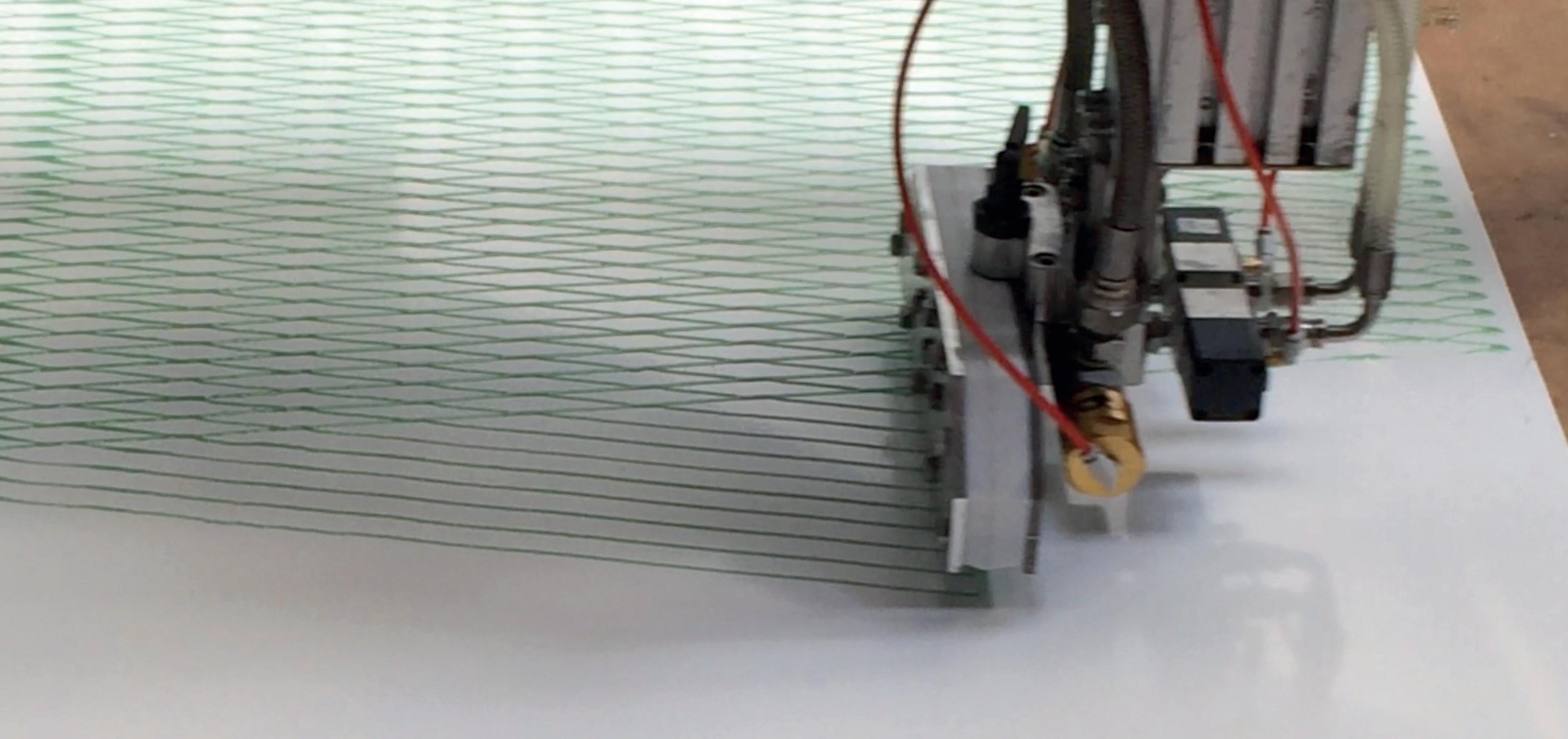

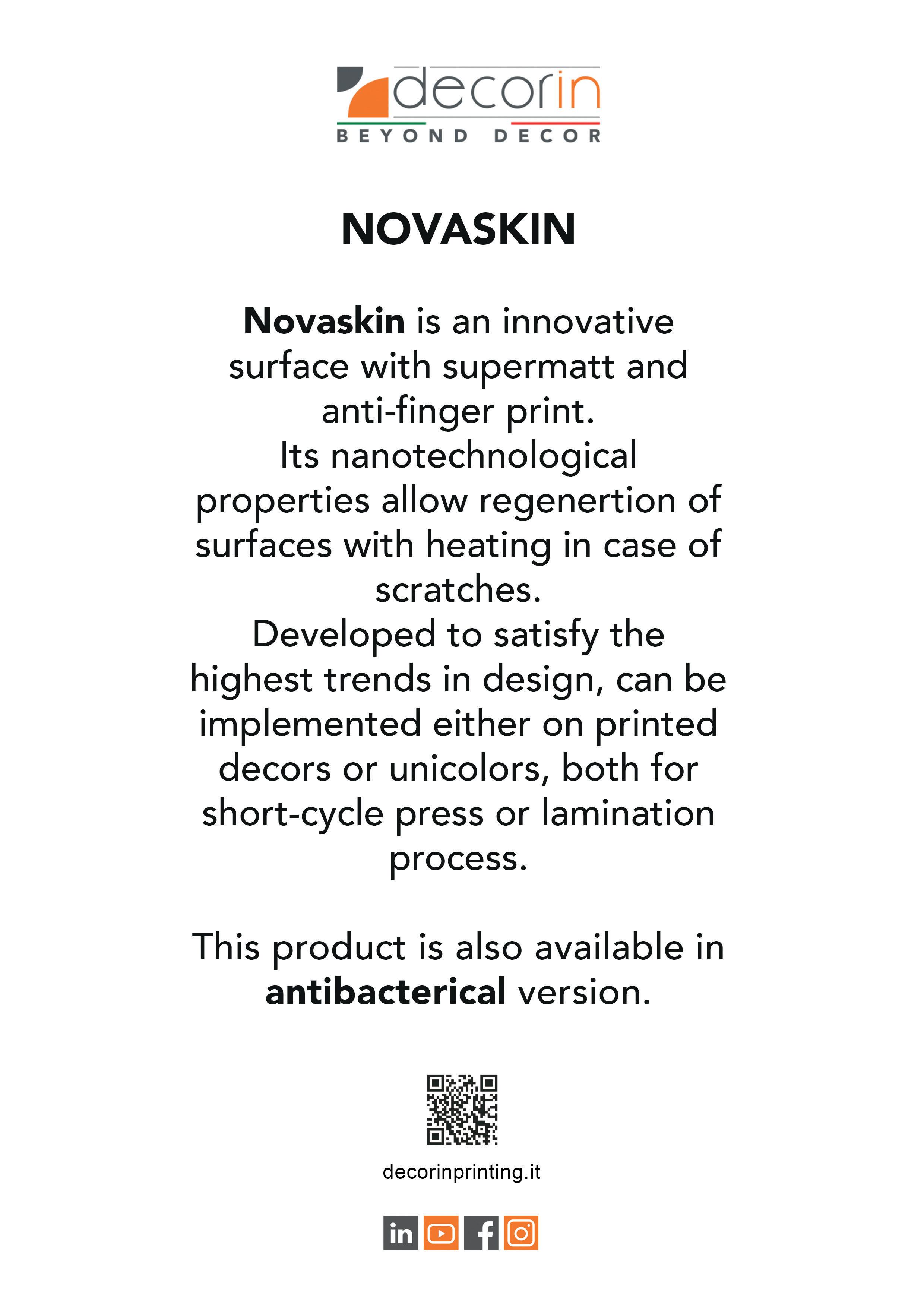

• 74 Decor In Printing

Technologically advanced surface

• 76 Dimatec

A 40-year history

Plants

• 24 Winnebago Forest City, Iowa

Speech

• 36 Carthago Ormož, Slovenia

• 46 Alexander Wottrich

Let’s create a sustainable future together

eries. But, for the speakers of both companies, the solution is to face the future together: the success in the RV industry relies on continuous innovation and adaptation to meet customer demands, and the collaboration of industry members with a customer-centric approach is seen as essential to create a sustainable and inspiring future for the caravan sector.

Moreover, we have visited two production facilities: the new factory in Slovenia for Malibu campervans, a brand of Germany’s Carthago Group, and the Winnebago plant in Iowa, USA. Our Swedish journalist, Stefan Janeld, who has been collaborating with us for years, also had the opportunity to test Winnebago’s fully electric camper.

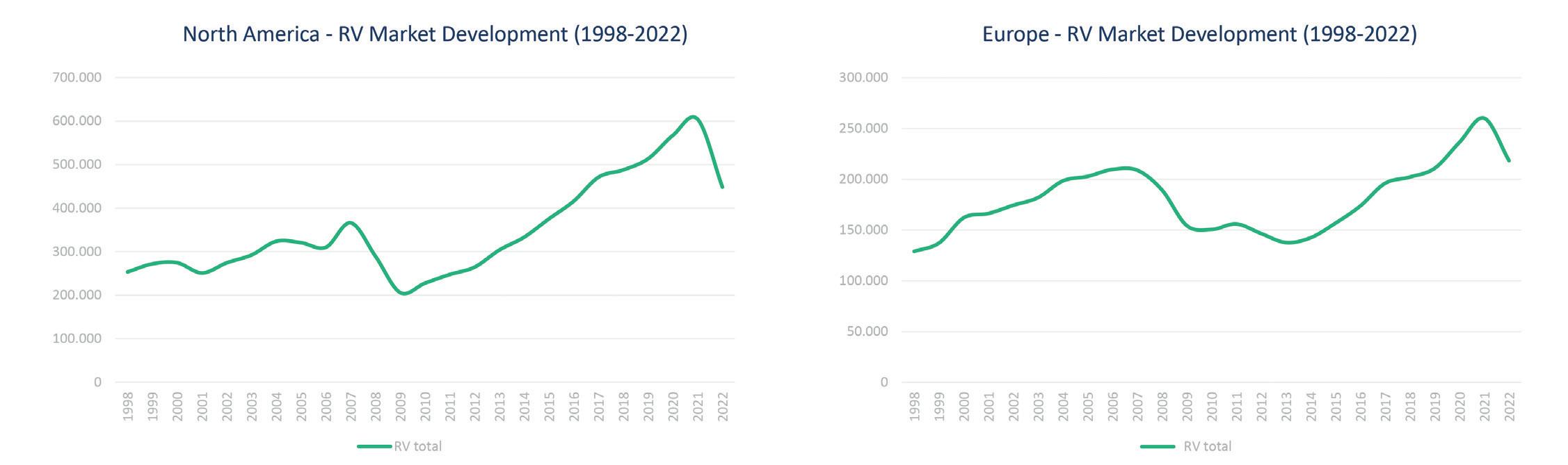

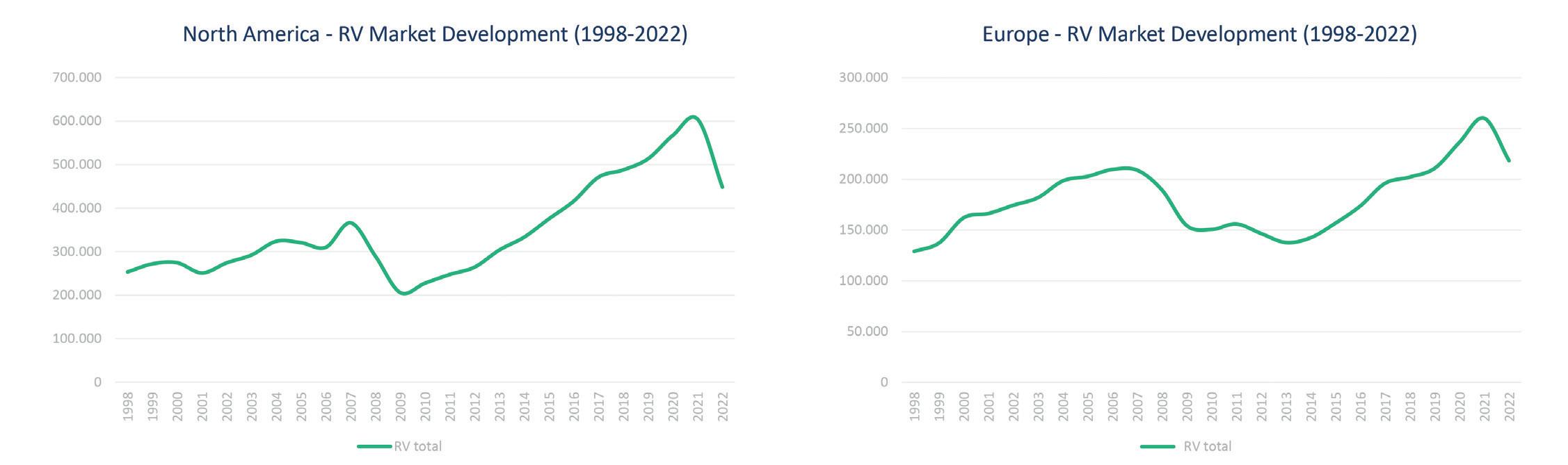

You won’t find many statistics in this issue. Both the American and European markets are experiencing difficulties and slowdowns. We are eagerly awaiting the results of the Caravan Salon to understand how the German market, the driving force of the European caravan industry, is reacting to the current economic scenarios.

See you at the Caravan Salon, and if you want to meet us, just write or call to schedule an appointment.

Antonio Mazzucchelli

• 78 AMA Composites

The future of insulation is now

• 80 Filippi 1971

“Experience innovation”

• 82 Palomar

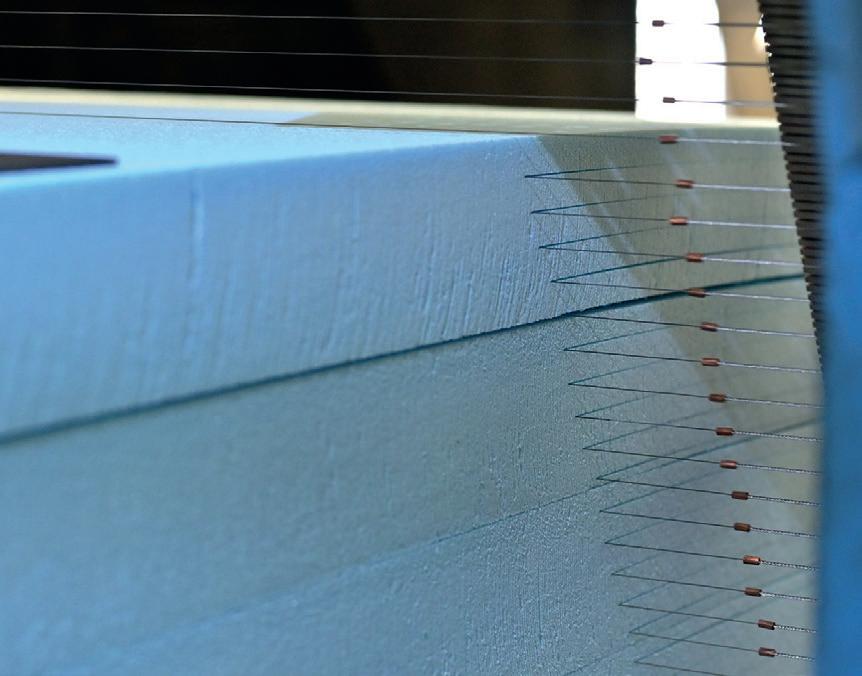

Sandwich 4.0

• 84 Tecnoform

How to deal with change

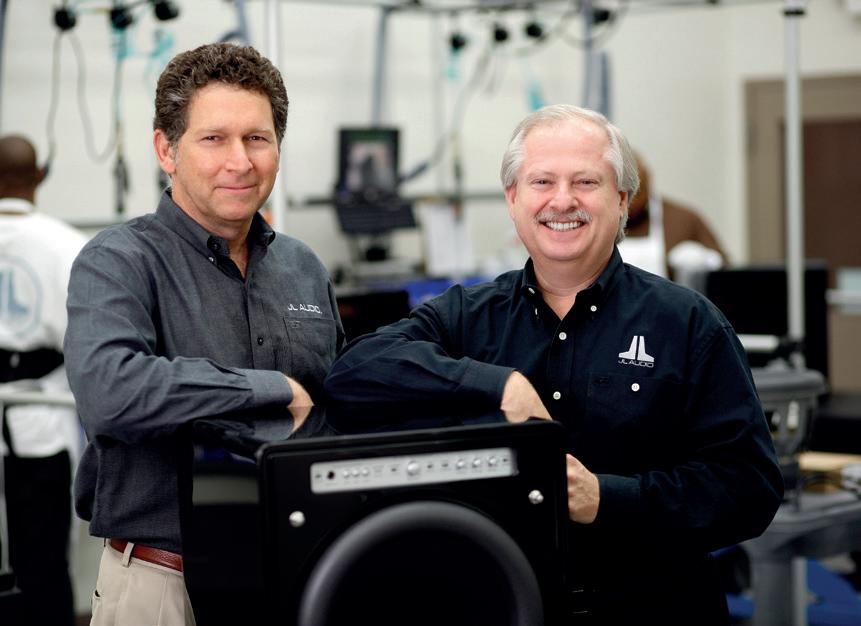

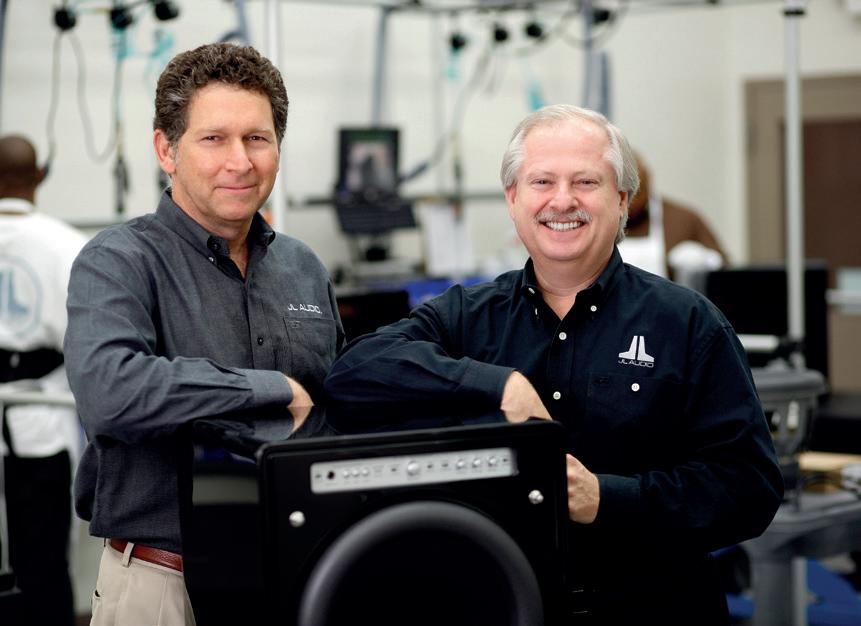

• 86 JL Audio

This is how they play

• 88 MB Trading

Bespoke tailoring for RVs

• 90 Dometic Off-grid power

• 92 Hella SlimLine Bi-LED headlamps

• 94 Schattdecor Decorative foils and overlays

Focus

• 30 Winnebago eRV2

A glimpse into the future

Guide

Market

• 96 Optiplan

From r-PET, new GRP for panels

• 98 Super B

Powerful battery solution

• 100 Fiamma

Ready for new challenges

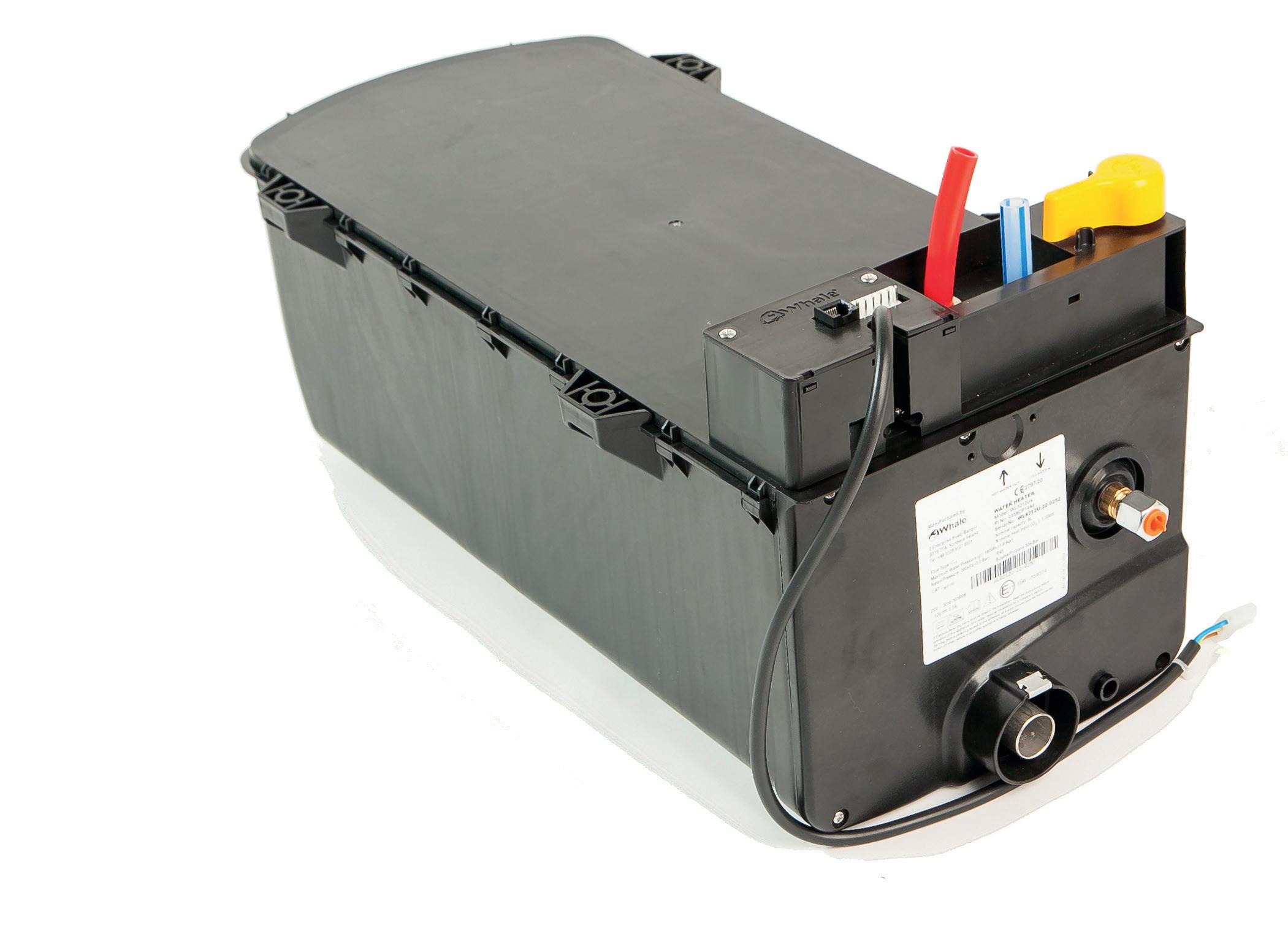

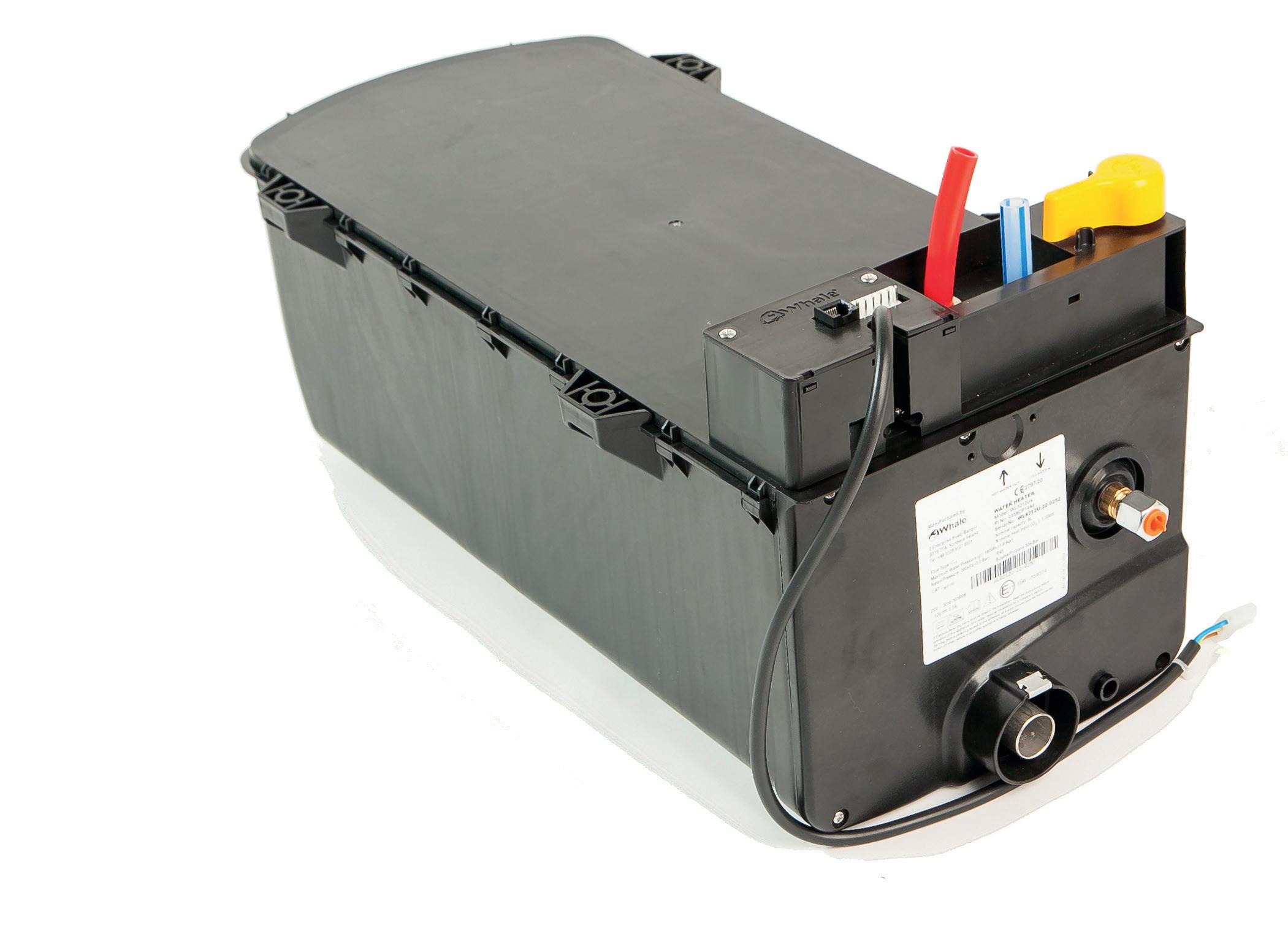

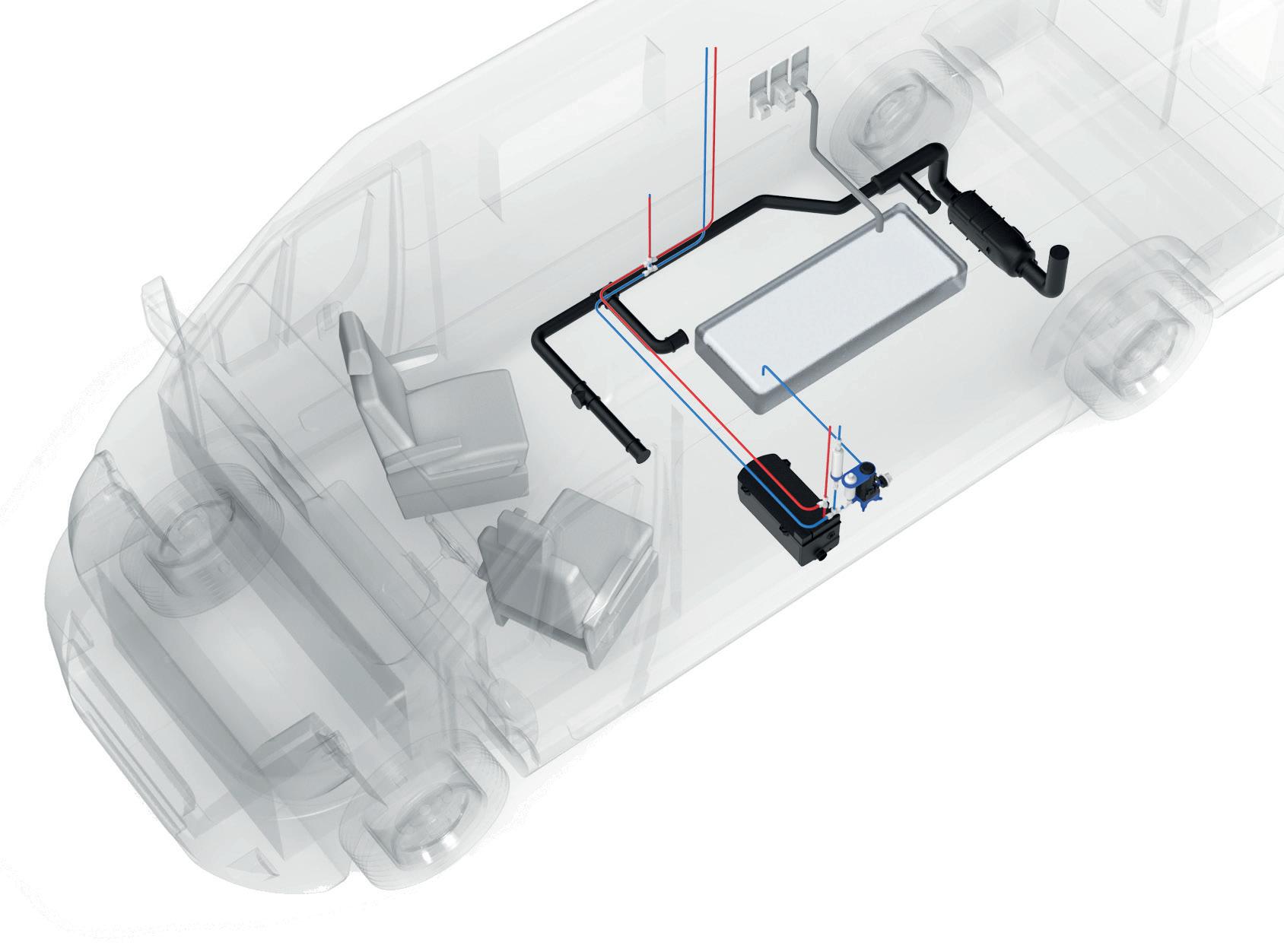

• 102 Whale

Expanse fills the gap

• 104 Thule

Investment for the future

• 106 FAP

Entrance and driver doors

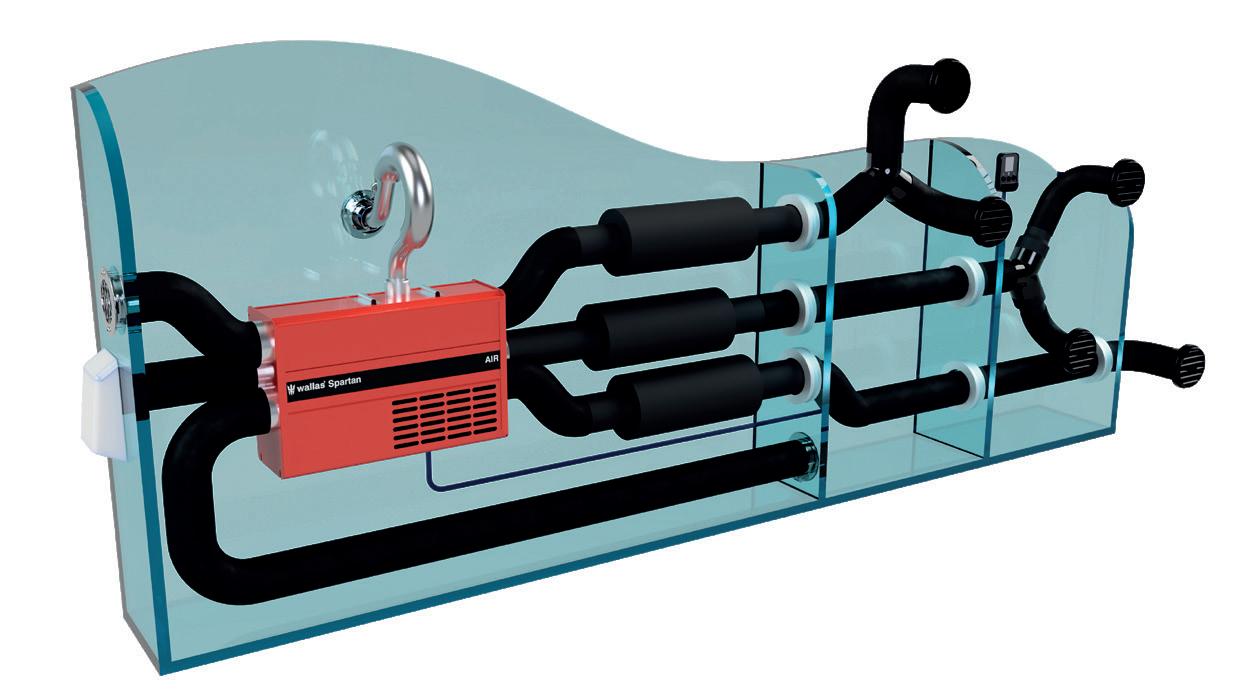

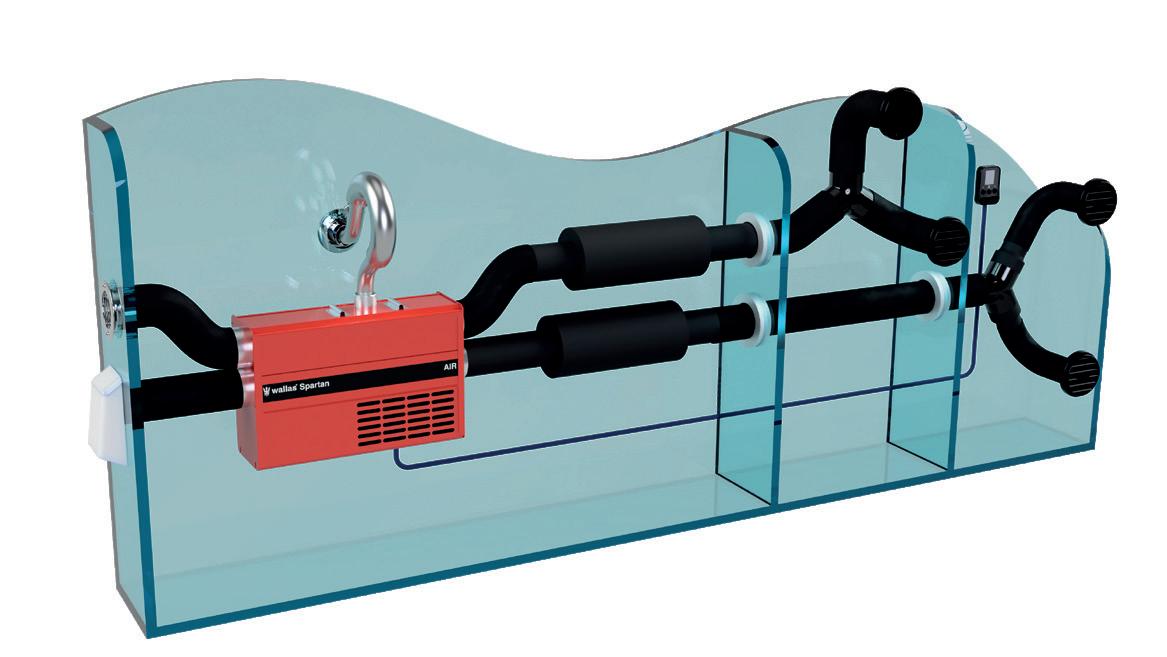

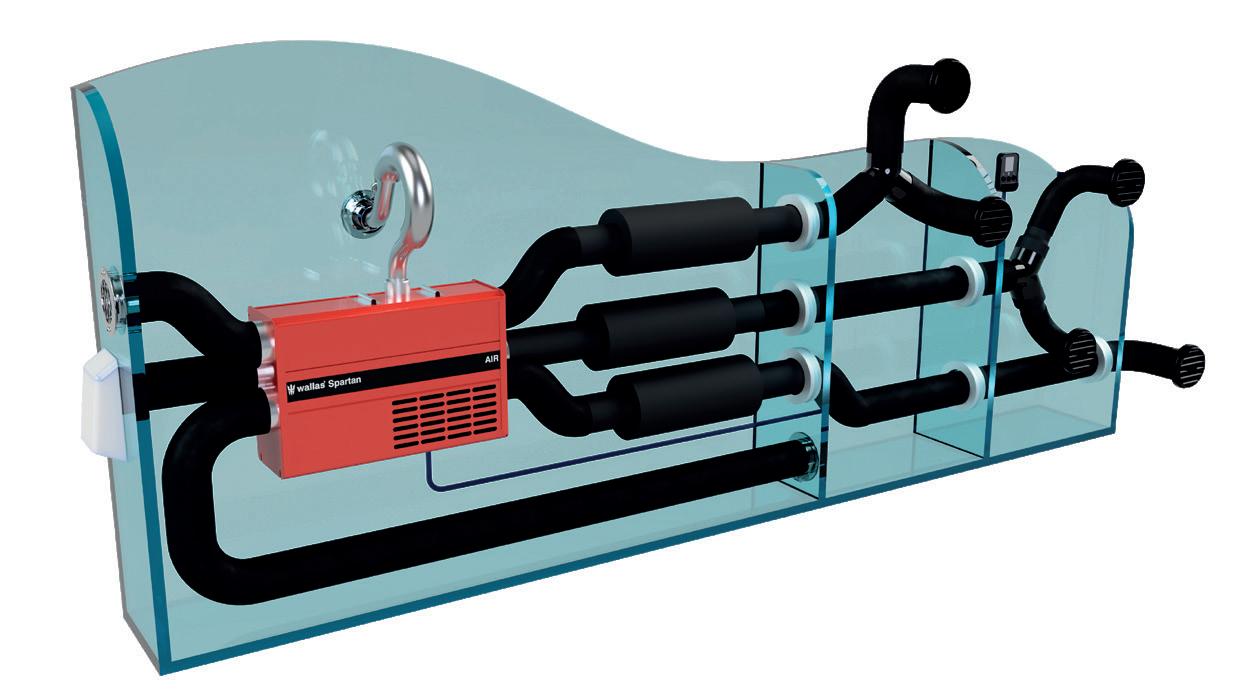

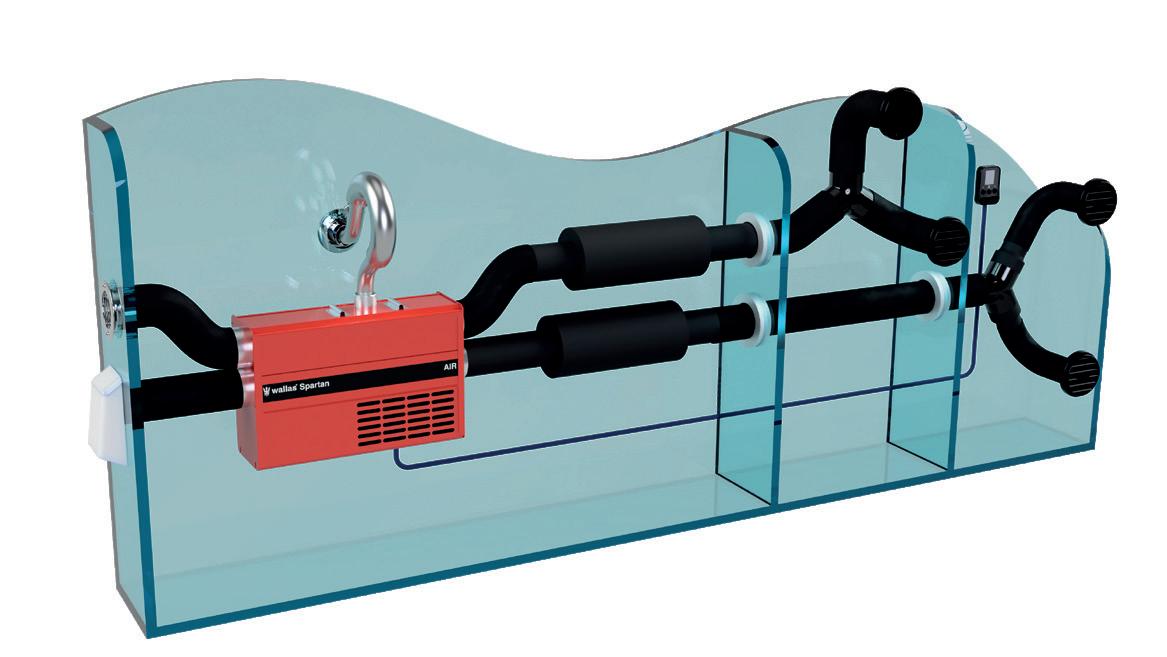

• 108 Wallas

Viking and Spartan

• 110 Ravago

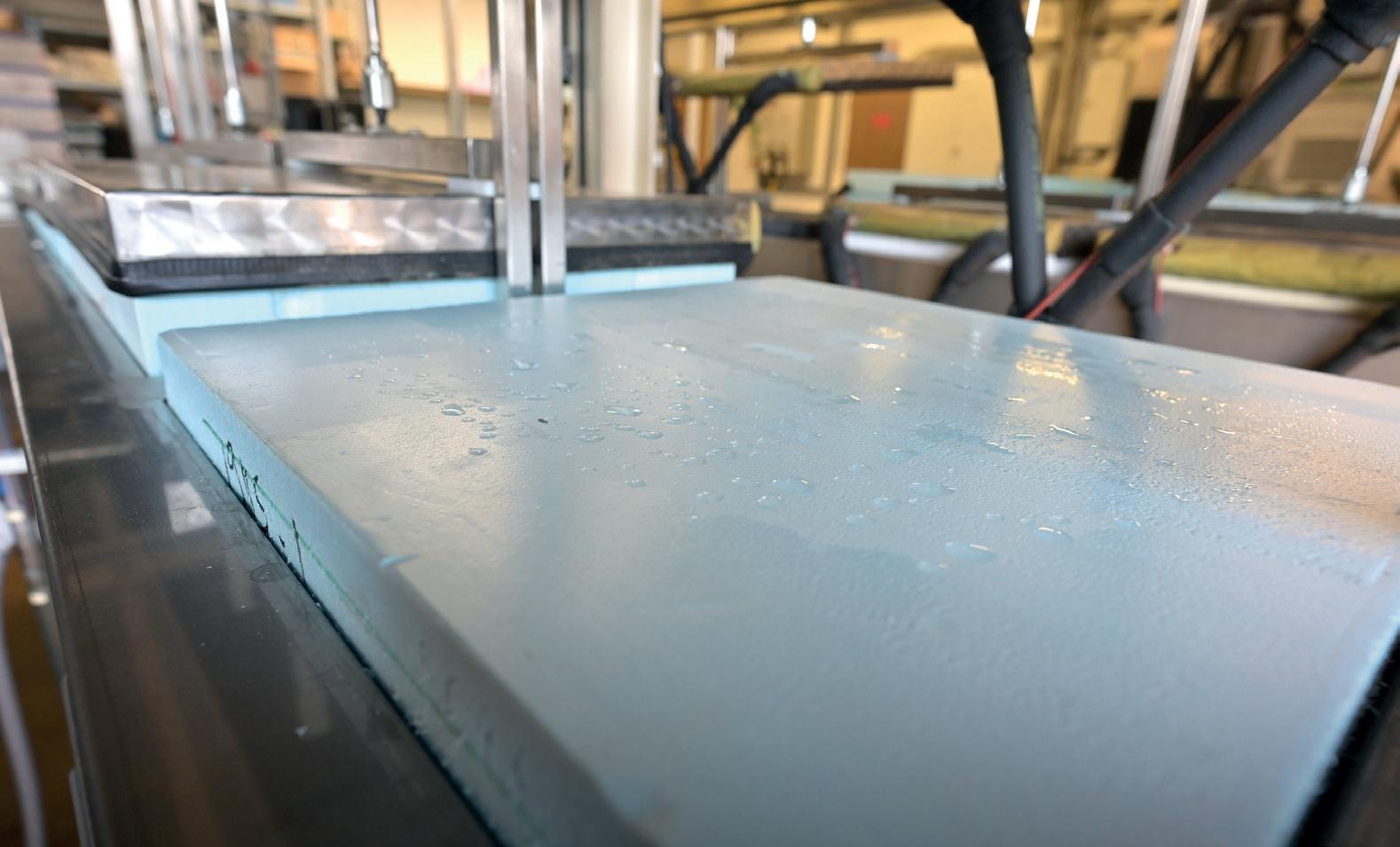

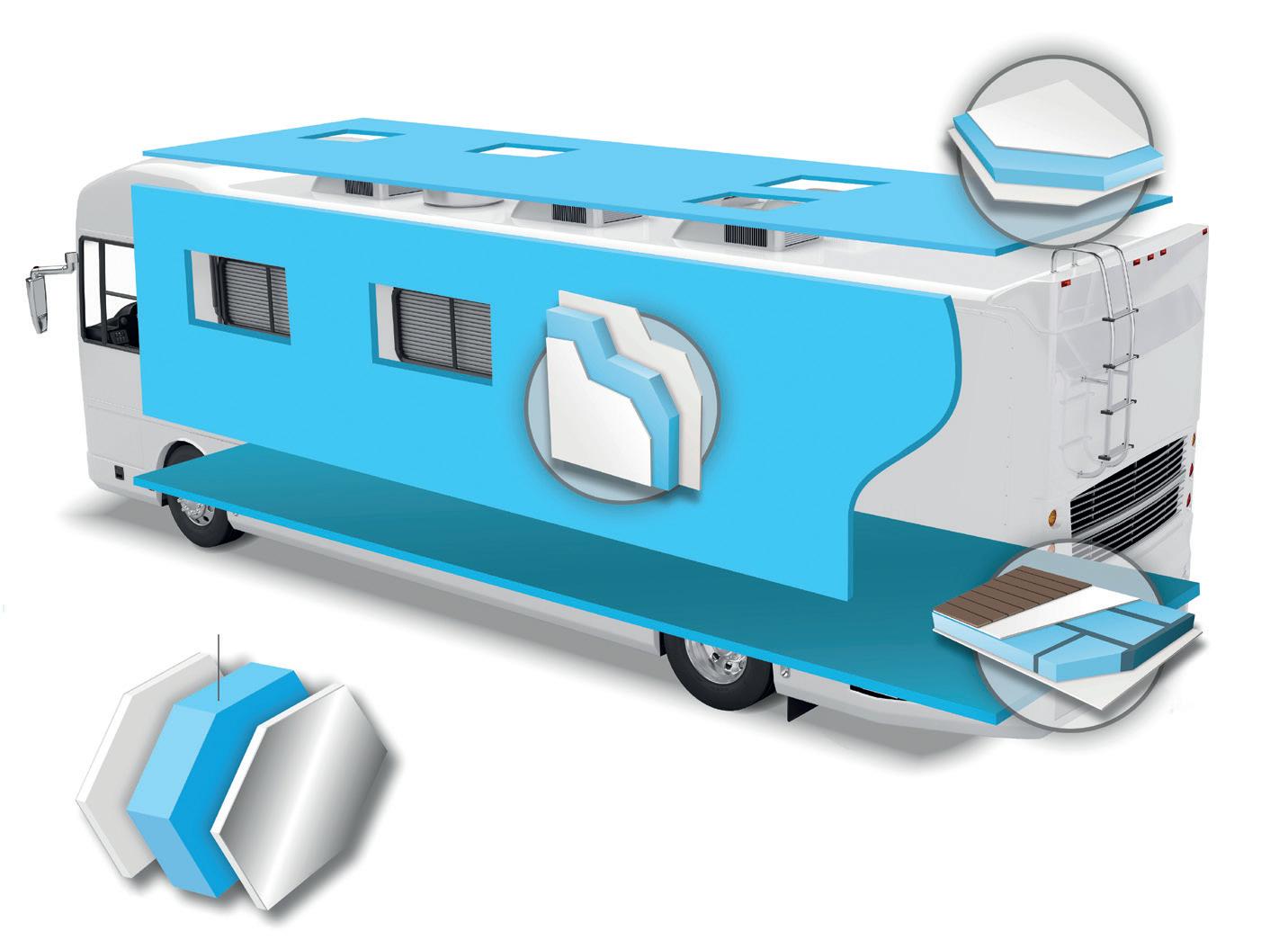

XPS thermal insulation

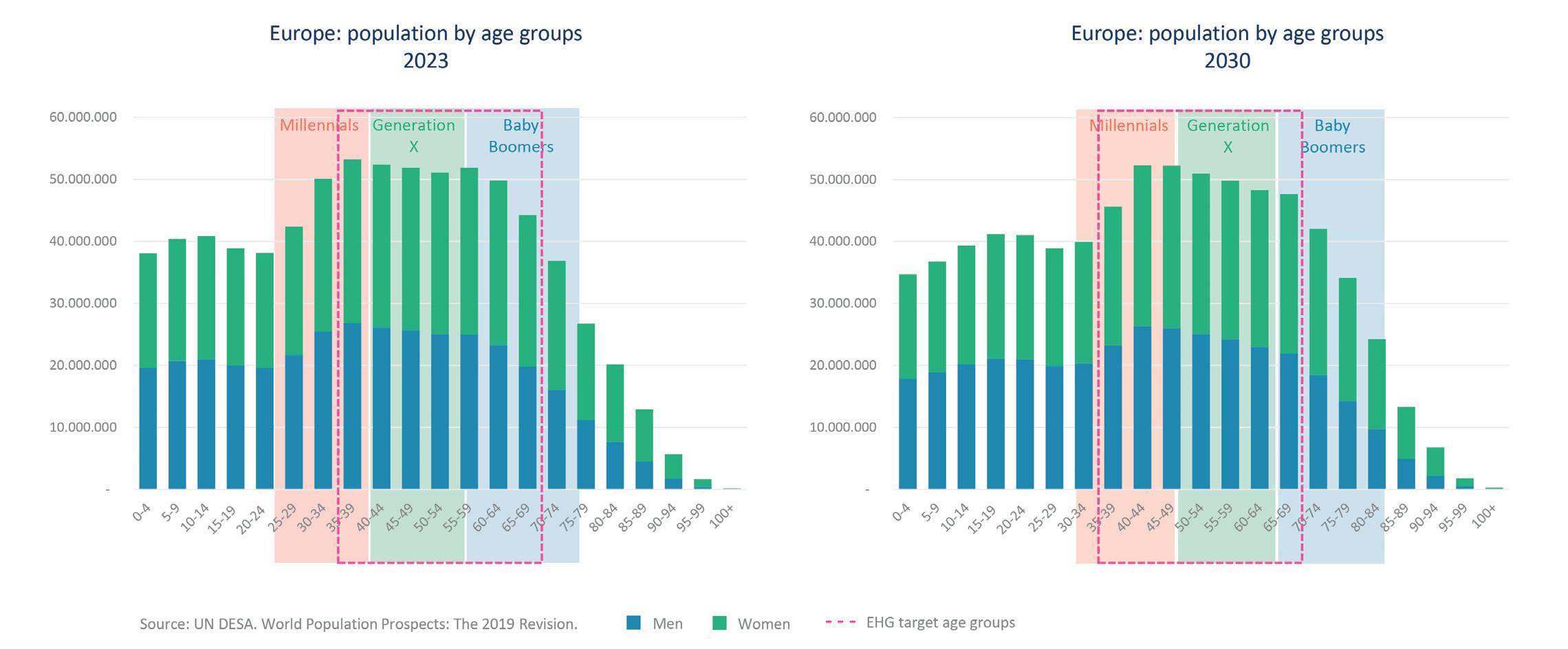

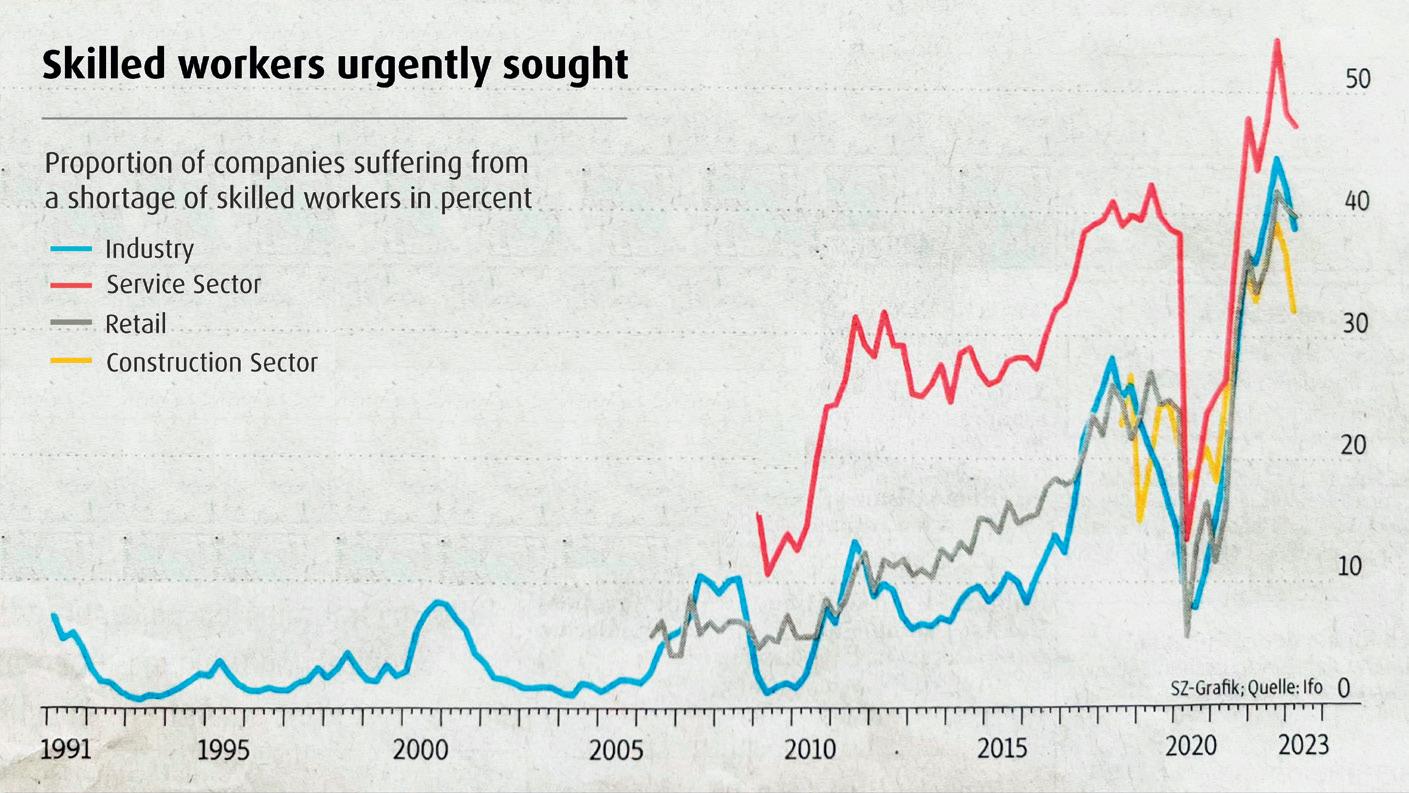

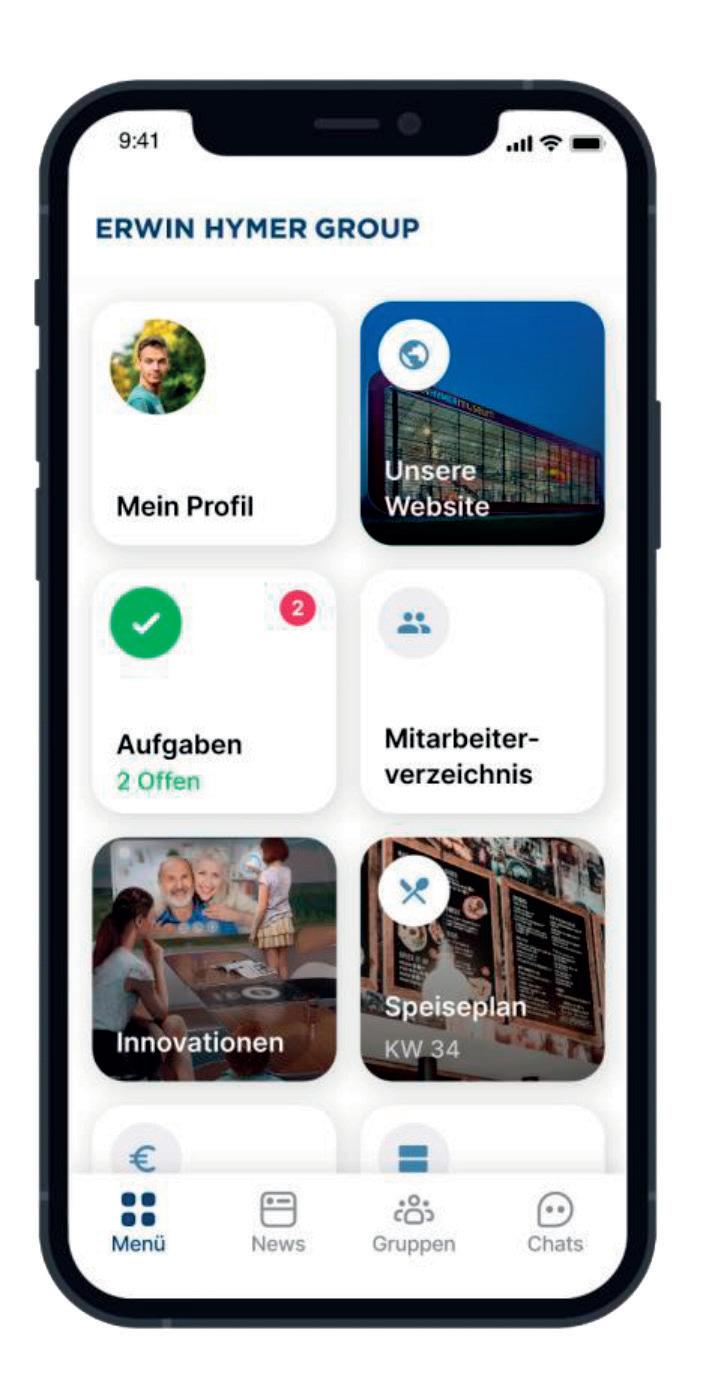

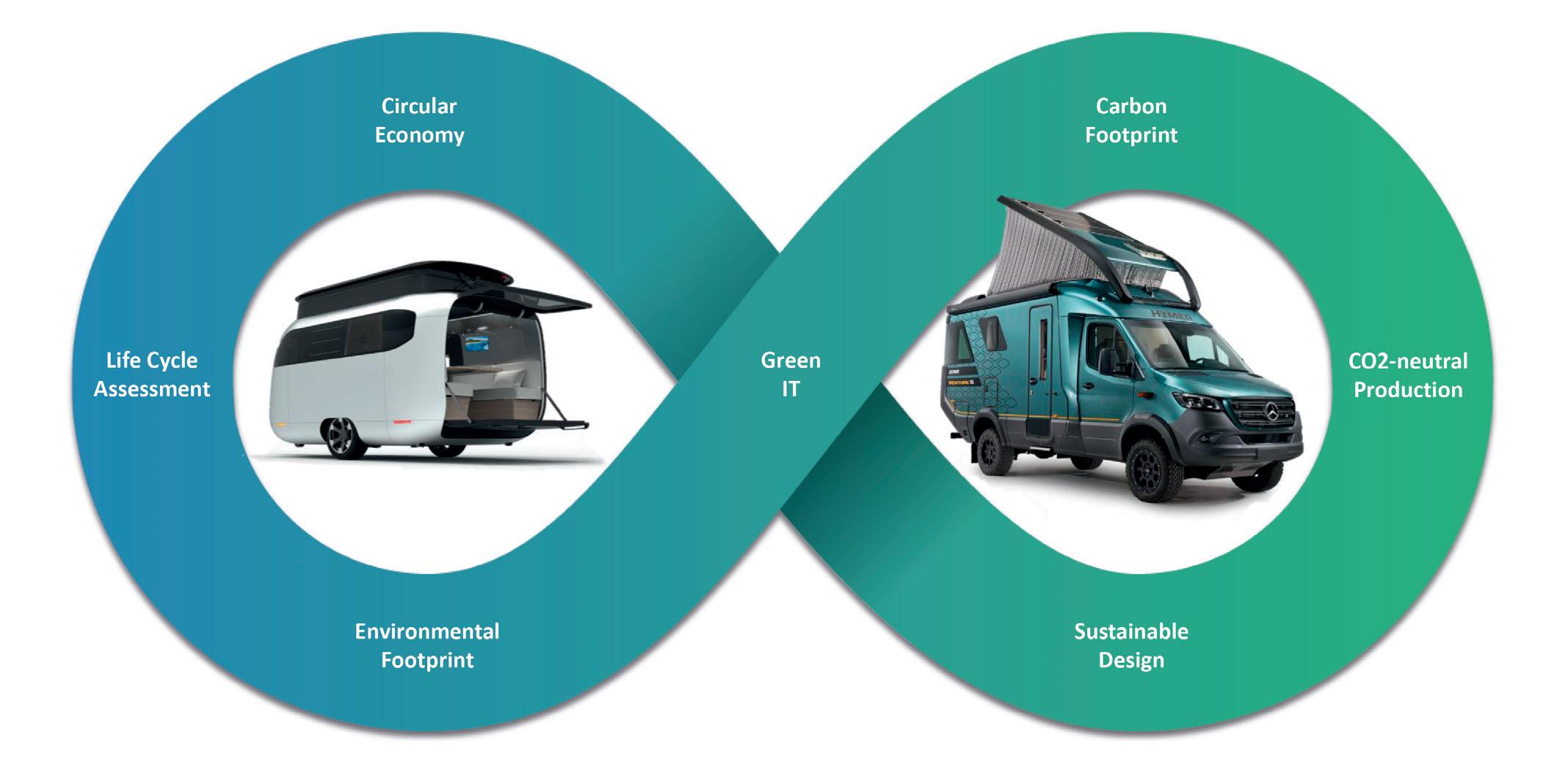

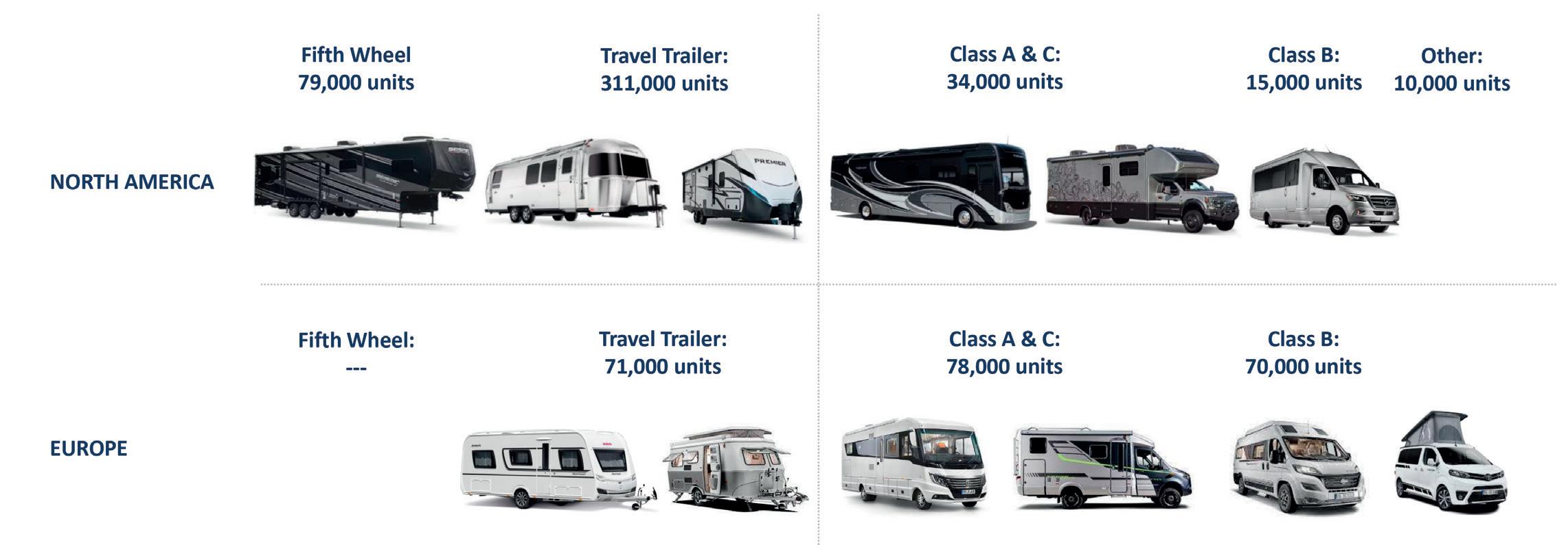

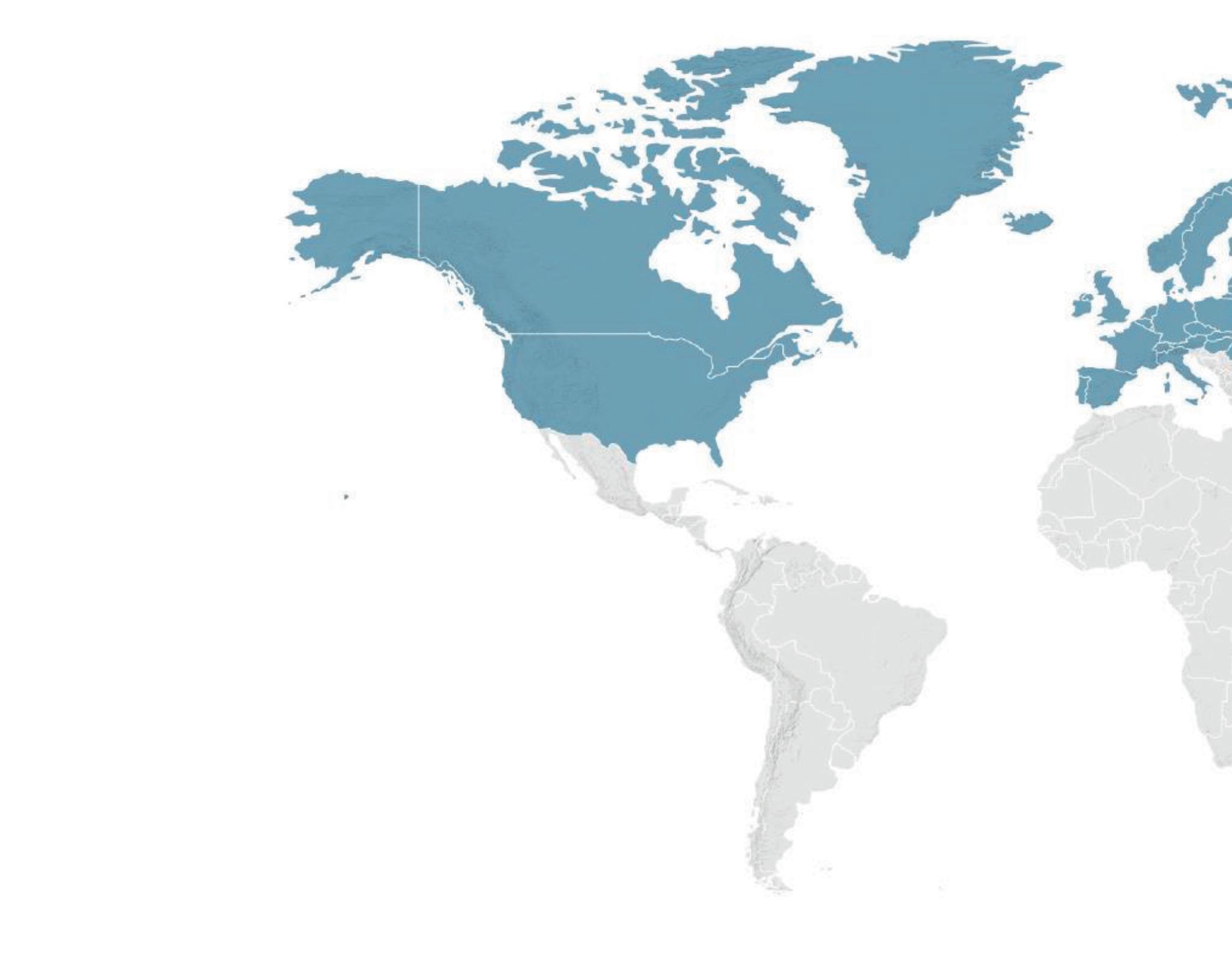

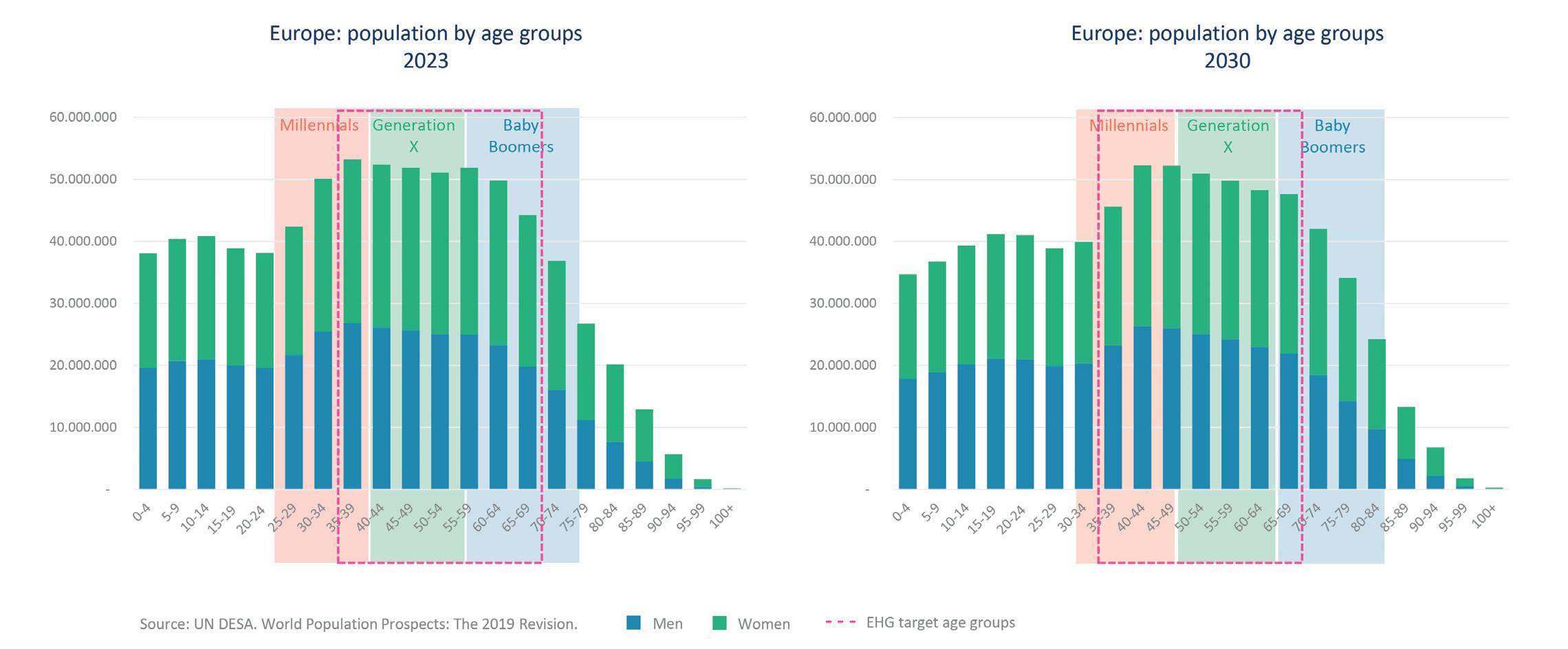

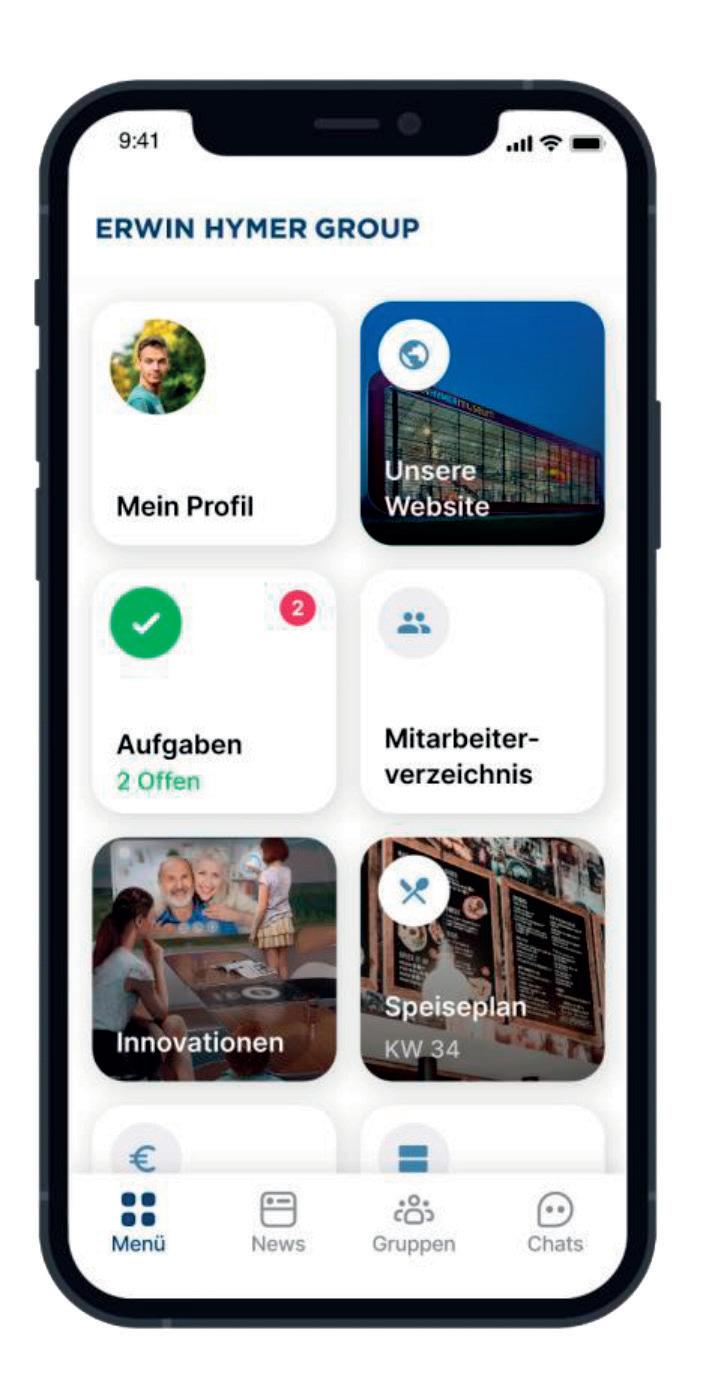

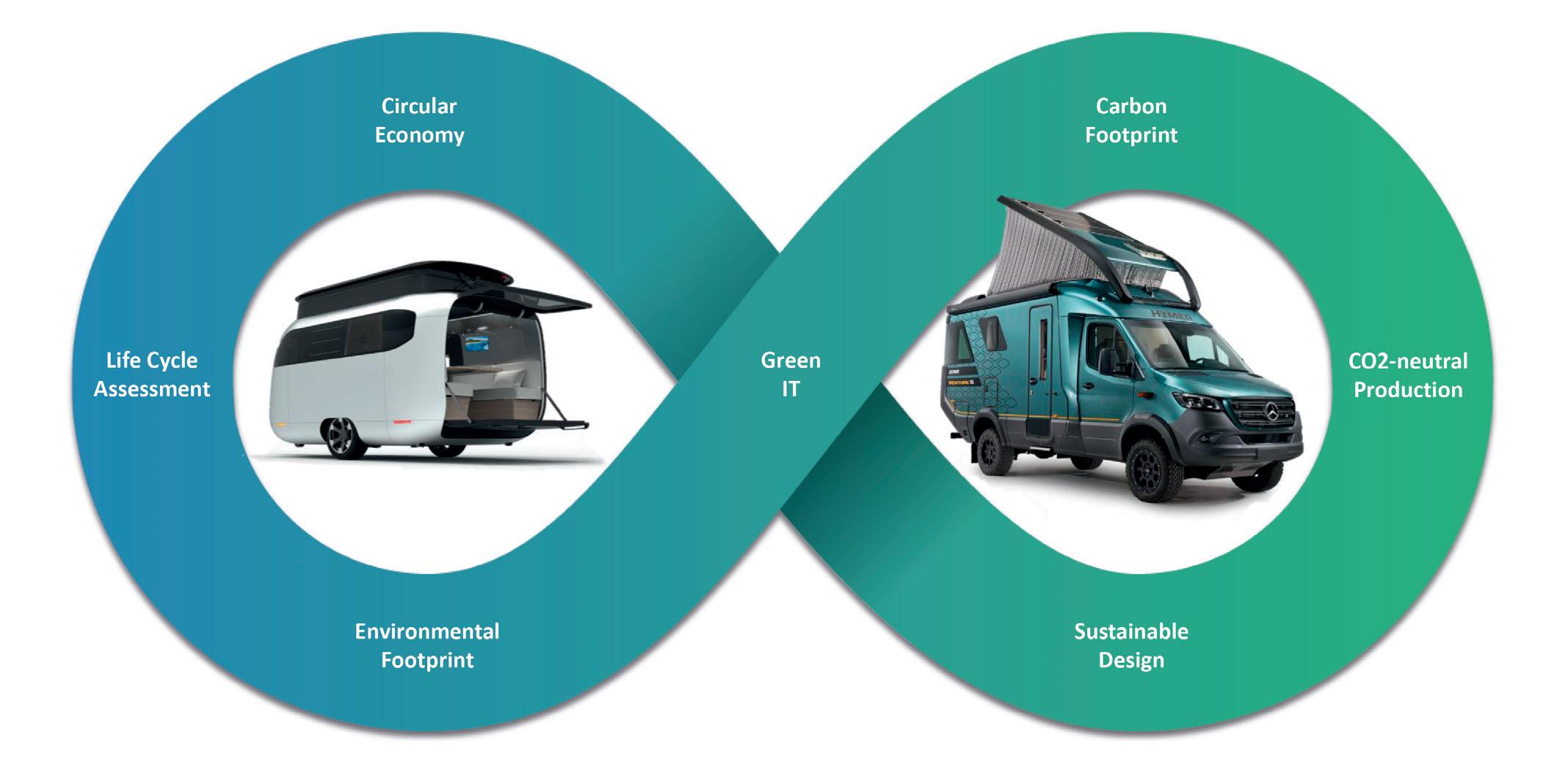

• 40 Thor and Erwin Hymer Group

Innovation, digitalization, customer-centric approach

• 50 Caravan Salon Düsseldorf

The place to be for caravanning insiders

World news

• 112 North America

3

40

Issue

2023

SEPTEMBER/OCTOBER/NOVEMBER

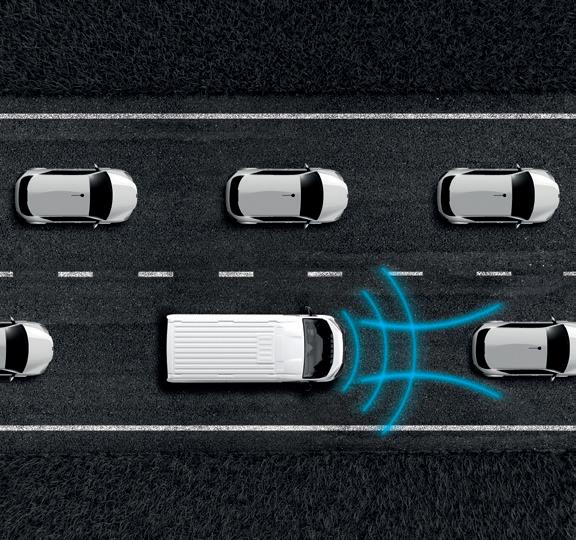

DUCATO. DISCOVER THE NEXT LEVEL.

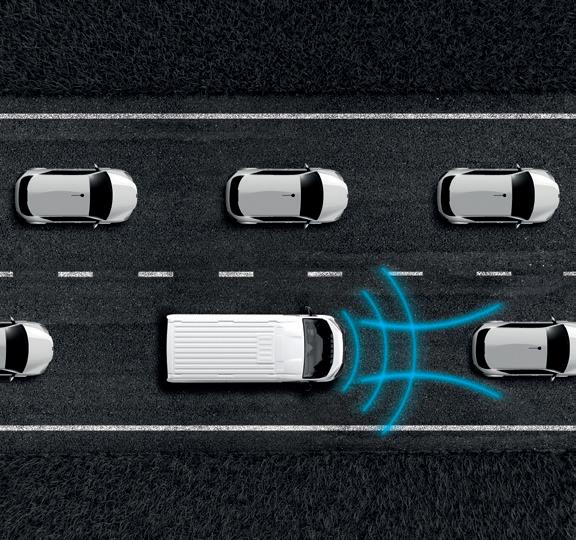

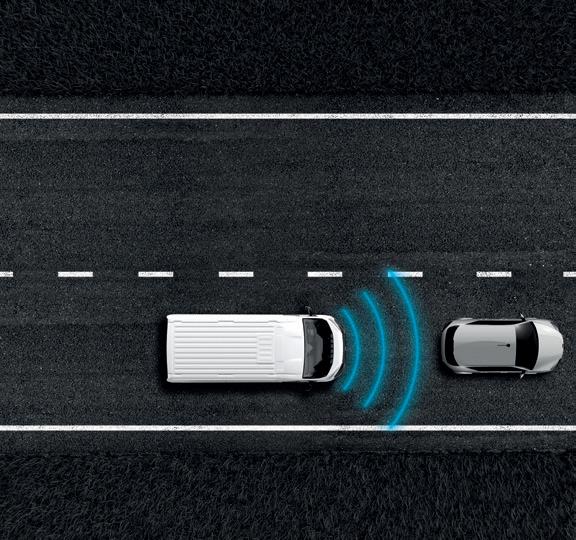

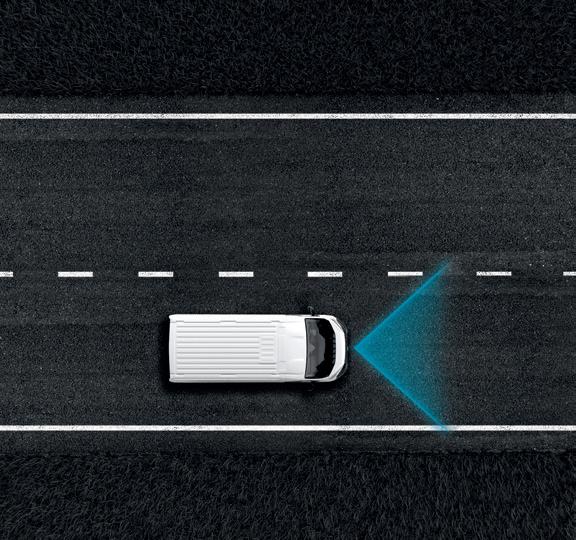

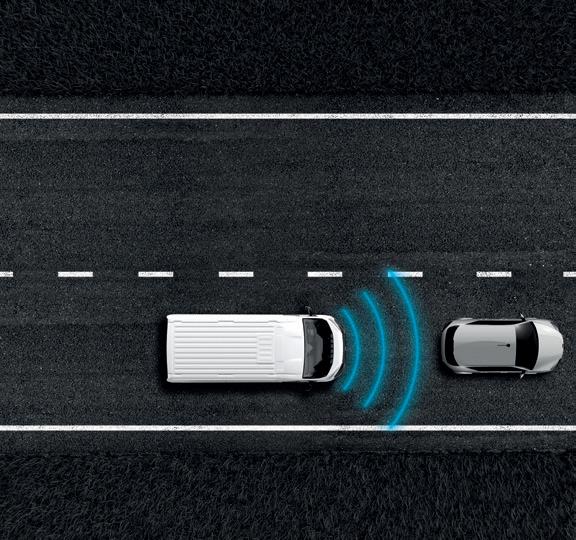

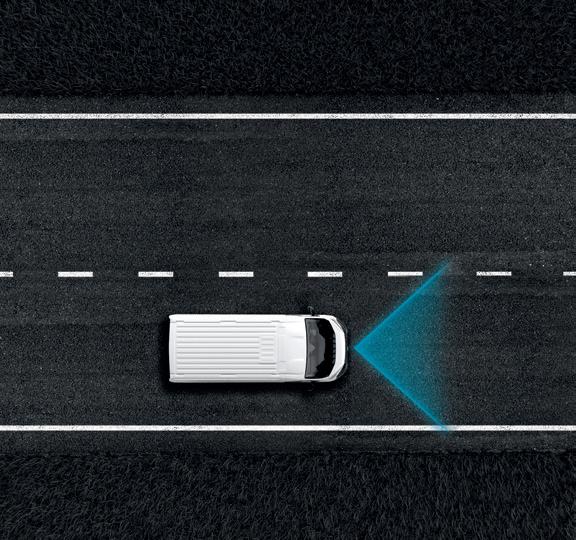

DUCATO WITH LAST GENERATION AUTONOMOUS DRIVING

LET YOURSELF BE DRIVEN

Straight to destination with Lane Centering, Traffic Jam Assists with Automatic Stop&Go and Adaptive Cruise Control. Let Ducato, with its last generation safety features, take the strain off you, reduce the risk of accidents and improve passengers’ protection. Put your holidays into the safest hands ever; choose a motorhome based on Fiat Professional Ducato.

This communication shows model-specific features and contents that can be chosen by motorhome manufacturers. Trim levels and the optional equipment may vary due to specific version, market or legal requirements. fiatcamper.com

China’s All in Caravaning (AIC) confirmed strong interest in RV lifestyle

The All in Caravaning (AIC) 2023 was held successfully from June 16th to 18th at the Beijing Beiren Etrong International Exhibition & Convention Center after a two-year hiatus. This latest edition of AIC breathed new life into China’s Recreational Vehicle (RV) camping industry, fueling its recovery and development, whilst fostering cross-industry integration.

“At long last, colleagues from the RV industry got together once again in Beijing. We felt strong public enthusiasm for RV travel along with a great innovative spirit within the industry. Trade shows continue to serve as an irreplaceable platform for face-toface communication and immersive product experiences, benefiting both exhibitors and visitors. However, the RV industry in China is currently facing challenges. In addition, the overall domestic economic downturn has led to longer buying cycles for RV users, and market demand still needs a longer recovery period. We saw a decline in professional visitor numbers compared with the previous show. But the vibrant atmosphere of the event reaffirmed the enduring aspirations and strong interest people hold for a RV vacation lifestyle. Throughout the three-day event, we welcomed 8,300 professional

Editorial

Editor in Chief: Antonio Mazzucchelli direttore@aboutcamp.eu

Art director: Federico Cavina

Editorial team: Renato Antonini

John Rawlings - Terry Owen - Enrico Bona

Steve Fennell - Paolo Galvani - Giorgio Carpi

Peter Hirtschulz - Andrea Cattaneo

Stefan Janeld - Irene Viergever

Web team: Maurizio Fontana - Gabriel Lopez

Advertising

Sales International: direzione@fuorimedia.com

Sales Italy: Giampaolo Adriano +39 338 9801370 adriano@fuorimedia.com

Web edition

Sign up

visitors. It is worth mentioning that with the lifting of international travel restrictions, we were pleased to welcome nearly 200 overseas buyers from about 20 countries and regions. I believe that China’s RV industry has a promising future ahead”, expressed Marius Berlemann, General Manager of Messe Düsseldorf (Shanghai) Co., Ltd.

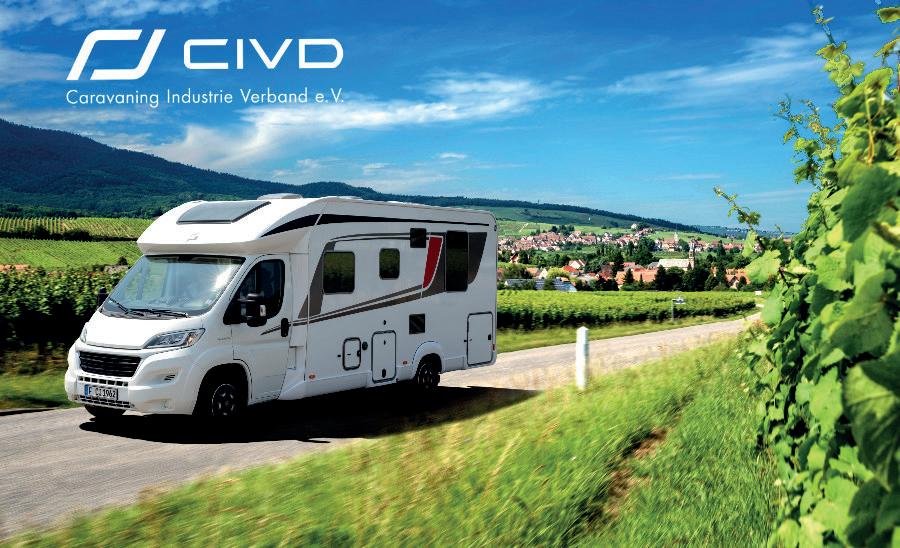

As an international caravanning trade show, AIC 2023 received the official patronage from the German Federal Ministry for Digital and Transport. The official German Pavilion, organized by German Federal Ministry for Economic Affairs and Climate Action, and supported by the German Caravanning Industry Association (CIVD), welcomed 9 producers from Germany, displaying their RV products in the 400sqm pavilion. Stefan Koschke, Director of CARAVAN SALON, the world’s largest show for motorhomes and caravans, said: “The German pavilion with participants such as Truma, Vöhringer or ALKO as well as the participation of other important European and international exhibitors at the AIC show the interest in the Chinese future market and are a unique selling point of the AIC. In addition, the mixture of business visitors and consumers, are the great strength of this event.”

Would you like to receive our fortnightly newsletter?

Aboutcamp BtoB helps professionals in the caravan/RV and leisure industry around the world keep up to date with all the latest business news and market trends in this sector. It’s the most well informed source of B2B information in the caravan industry, with a unique global perspective and an international team of correspondents delivering daily news online at www.AboutcampBtoB.eu, a bi-monthly e-newsletter, and a high quality print magazine delivered (free) in Europe, the United States, Australia, New Zealand, South Africa, Japan, China, Korea, Argentina, Brazil, Chile. The Aboutcamp BtoB magazine is published four times a year with features including exclusive interviews with senior management from the industry, reviews of the major exhibitions around the world, and reports about the latest market trends, plus in-depth profiles of OEM suppliers who specifically manufacture components for this sector. With all the recent acquisitions, new technological developments and more and more consumers buying leisure vehicles around the world, Aboutcamp BtoB is essential reading for everyone working in any business related to the caravan industry. While so many flock to the internet, and have an inbox full of emails, Aboutcamp BtoB decided to print a paper magazine so that it gets more noticed, read, appreciated and discussed; so, we wish you happy reading!

Subscribe on www.aboutcampbtob.eu

Aboutcamp BtoB is also a website updated daily with news and information dedicated to RV builders and OEM producers. The website is supported by a professional newsletter sent monthly to the professionals in the RV sector. We also strengthened our presence on LinkedIn, where we manage the business page of the magazine but also the group “Caravanning Professional” which allows us to develop direct and informal relationships with decision-makers in the RV industry.

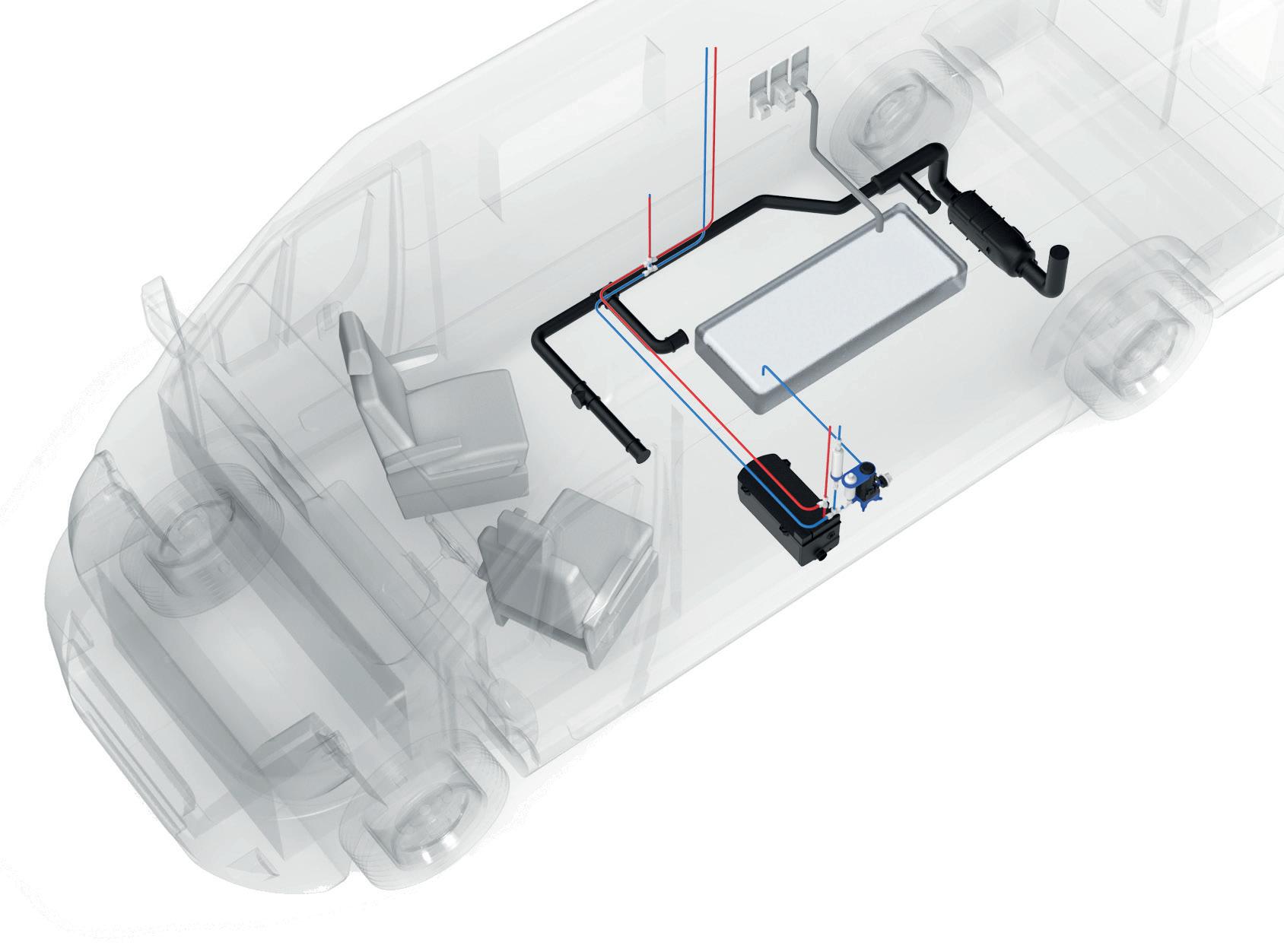

On our website is possible to read online the print edition of all Aboutcamp BtoB issues at: www.aboutcampbtob.eu/read-the-magazines

Headquarters

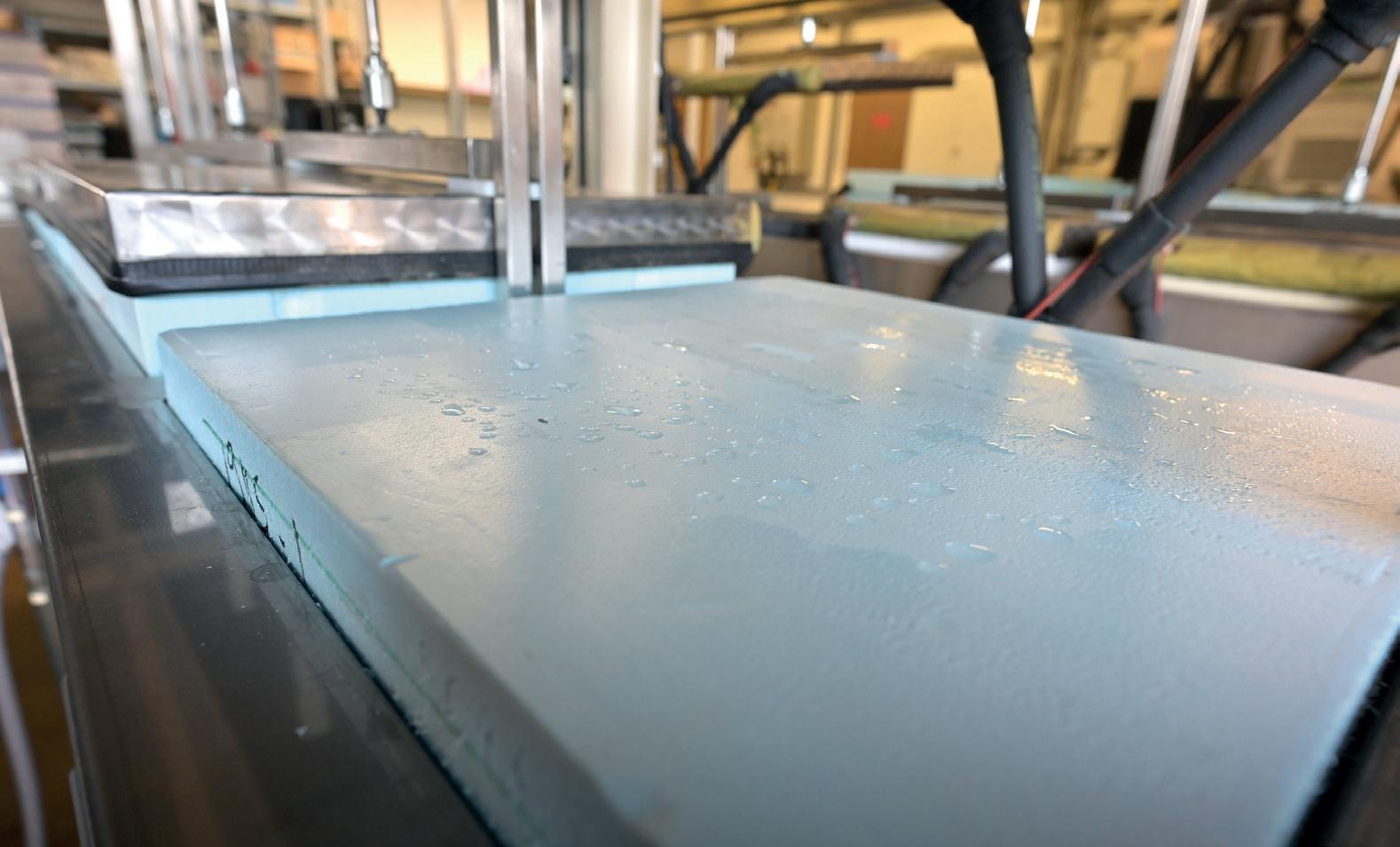

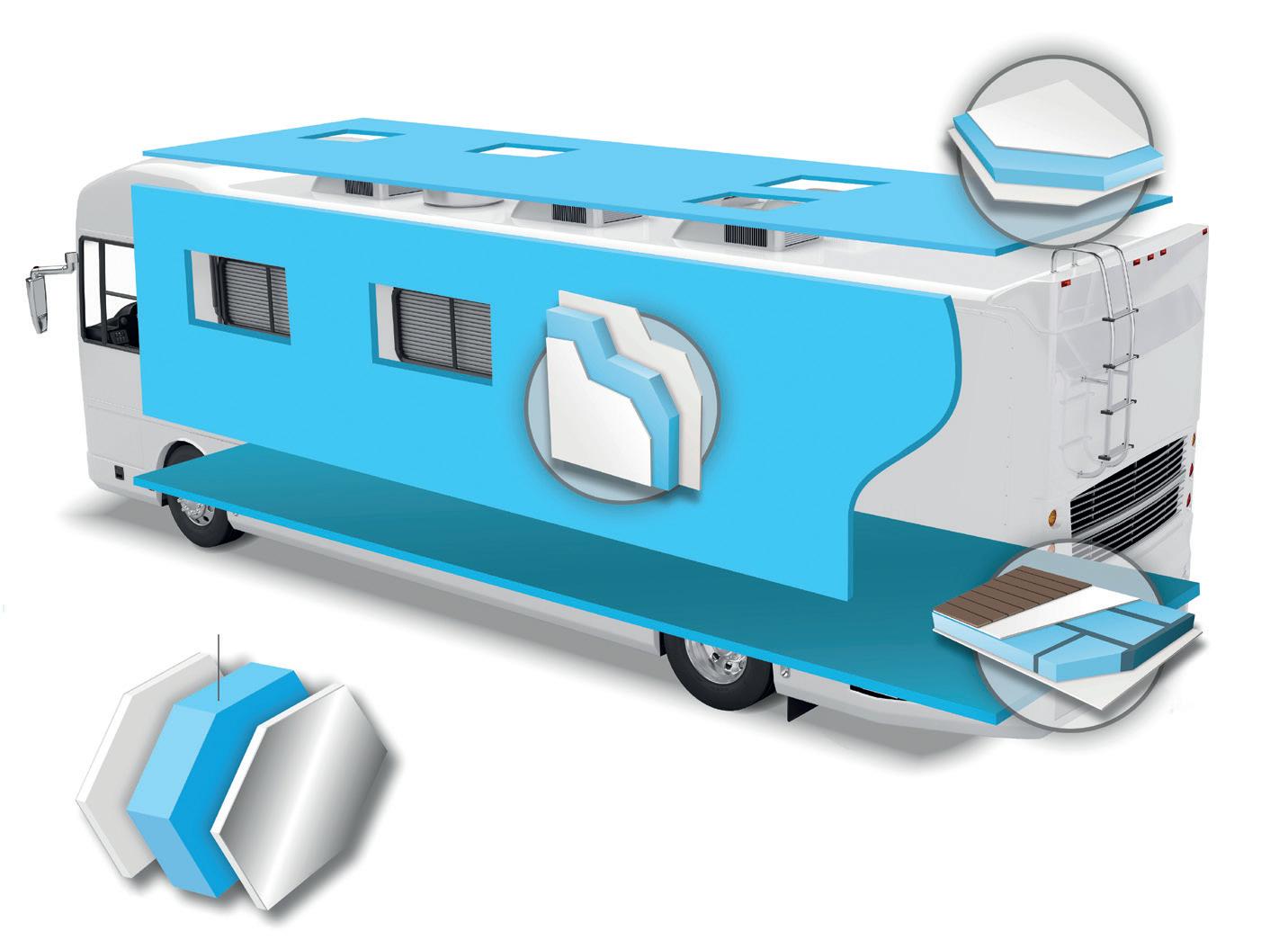

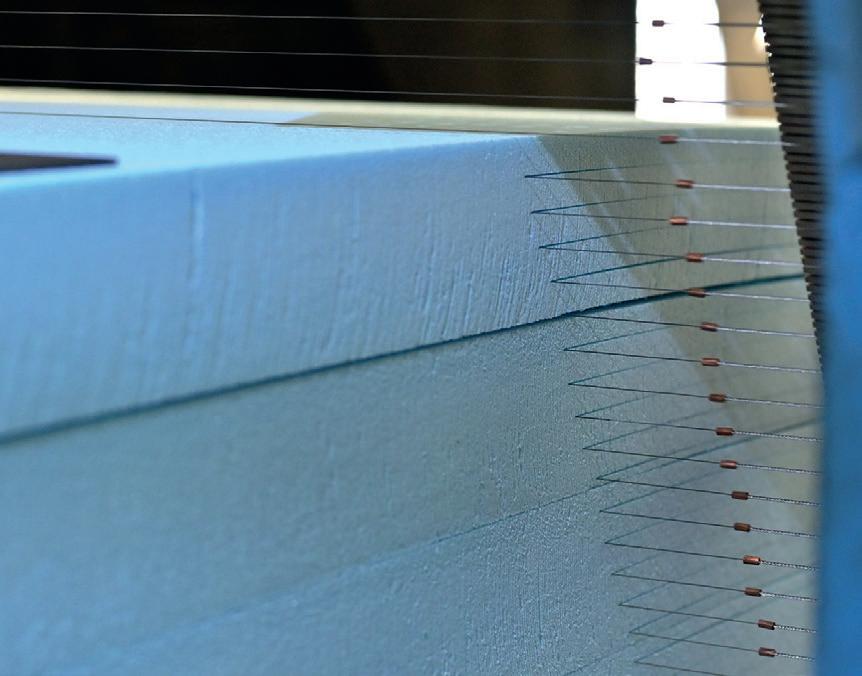

Fuori Media srl

Viale Campania 33 - 20133 Milan – Italy

Ph +39 0258437051

E-mail: redazione@aboutcamp.eu

Internet: www.aboutcampbtob.eu

Registered with the Milan Court on 22 Dec. 2016 at No.310.

Subscription ROC 26927

6

N ews

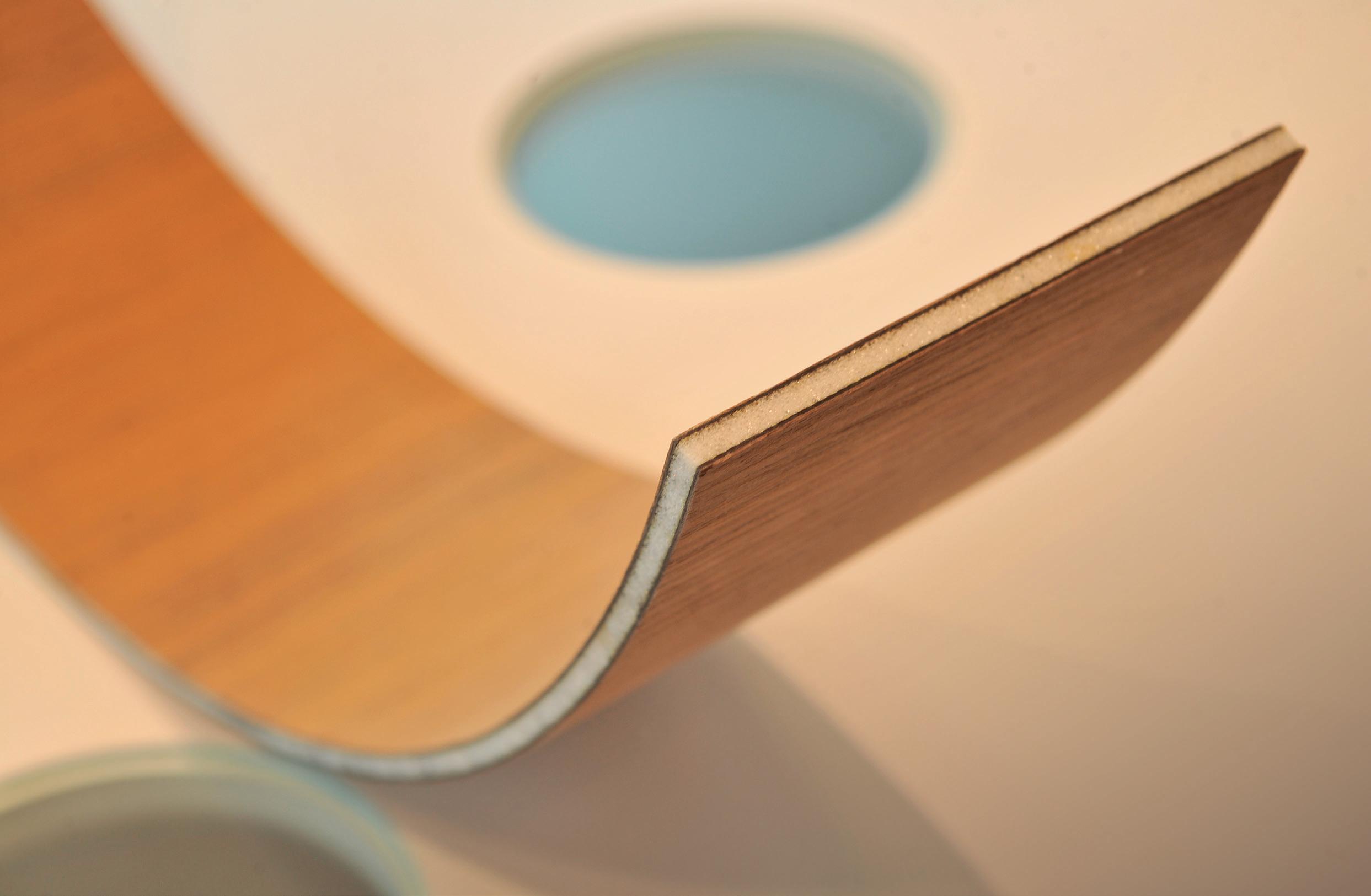

This range of products has been developed by Vetroresina SpA to obtain significant weight savings and a high flatness with the same glass fibre content and a smooth surface compared o a traditional laminate.

ADVANTAGES

.Lightness

.Good mechanical properties

.Good resistance to weather events

.High UV stability

.Good chemical resistance

.Good electrical insulation

.Good resistance to abrasion

.Easy cleaning

7 VETRO- MAT LD VETRO-LD VETRORESINA SPA Via Portuense, 10 44020 Masi San Giacomo, Ferrara - Italy Tel.+39 0532 327911 - Fax +39 0532 327110 info@vetroresina.com - www.vetroresina.com

VETRO-MAT LD VETRO-FORCE LD LAMINATI LOW DENSITY VETRO-LITE VETRO-LITE ULTRA

Lowlaminatesdensity

Three awards for the Hymer Venture S

As an exclusively equipped off-roader for two people, the Hymer Venture S promises freedom without compromise. With innovations such as the unique Instant Loft (a pneumatic pop-top roof including integrated stairway), the striking tailgate with real glass Infinity Screen that offers 180-degree panoramic views, and the exclusive sun deck, the Venture S is a motorhome in a class of its own. Thanks to the extraordinary design of the Hymer Venture S off-road van, it has received an award in the “Automobiles/Vehicles” category from the jury of the iF Design Awards. The iF Design Award has been a globally recognised hallmark for excellent design since 1954 and it is one of the most important design awards in the world. “We’re incredibly proud of this outstanding achievement and are delighted with the recognition that comes with this award,” says Christian Bauer,

President of Hymer GmbH & Co. KG. Thomas Klüber-Voss, the owner of STUDIOSYN, the studio behind the design of the Venture S, adds: “A major source of inspiration for our former Vision Ven-

ture design study was the young camper community, because their creative ideas and DIY conversions gave us fresh food for thought. When creating the Venture S, our aim was to incorporate the design and ingenuity of the con-

cept vehicle when we commenced with mass production.” In addition, Hymer has won two more awards for its Venture S: the “German Design Award” and the “Red Dot: Best of the Best Award 2023” (in the “Product Design” category), which is reserved for groundbreaking designs and is the competition’s highest distinction. The Design Zentrum Nordrhein-Westfalen e.V. awards the Red Dot Award annually as an internationally recognised quality seal for outstanding designs. The German Brand Award, initiated by the German Design Council, is considered one of the most important awards for successful brand management in Germany. Hymer received its Gold award was presented in the category “Excellence in Brand Strategy and Creation: Brand Communication – Classic Campaign” for the company’s Venture S launch campaign.

8 N ews

Thunder and Fire

CAN’s products are designed and manufactured to bring you towards your next destination.

For over 30 years, we have developed our products to meet our customers’ need for quality and customization. Every piece we create tells a story of innovation and freedom.

We thank all our partners for choosing to travel with us towards new adventures.

WWW.AIRXCEL.EU/BRANDS/CAN

Leisure vehicles make record contribution to Trigano’s €173.5m half year operating profit

Trigano’s consolidated current operating profit for the first half of 2023 reached €173.4M, representing 10.8% of sales, thanks to a record contribution from the leisure vehicle business of €173.5M, representing 11.4% of sales.

In a context still impacted by difficulties in the supply of wheelbases for motorhomes, Trigano succeeded in mastering the evolution of its

production costs and overheads, while pursuing its policy of gradual adjustment of its sales prices. The leisure vehicle production business performed particularly well, while the accessories distribution business, affected by network destocking, was slightly down.

The activity of the leisure vehicle distribution companies acquired in 2022, being marked by strong seasonality, their contribution to the half-year results is marginal with a dilutive effect on profitability rates.

The current operating income of the leisure equipment division was impacted by the under-activity of the Trailers division, which prevent the optimisation of the consumption of production resources and weighed on manufacturing costs and productivity. Taking into account a financial result of -€8.7M, affected by the transfer of two sale points imposed as part of the acquisition process of three

Bartolacci Design expands into new markets

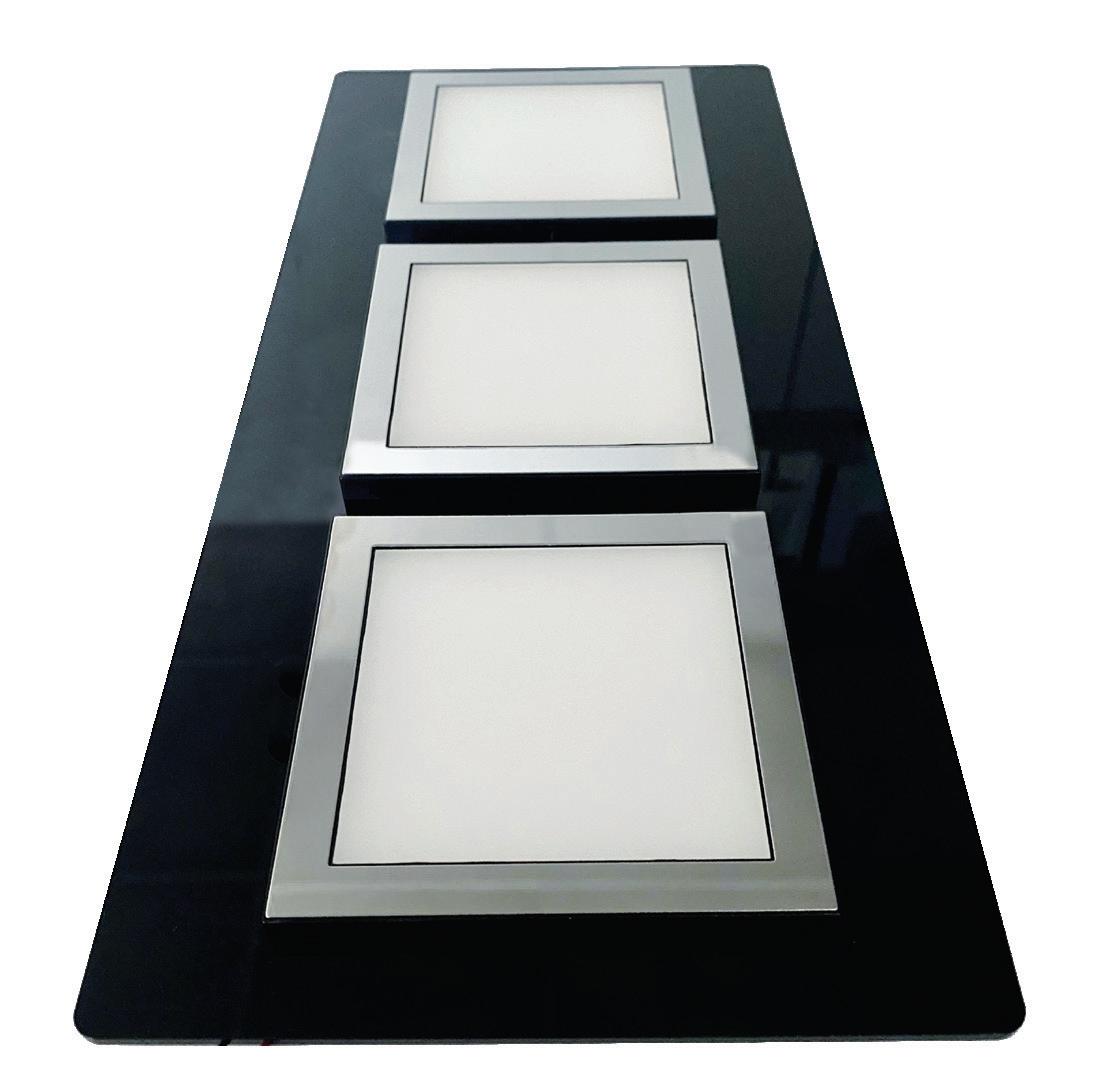

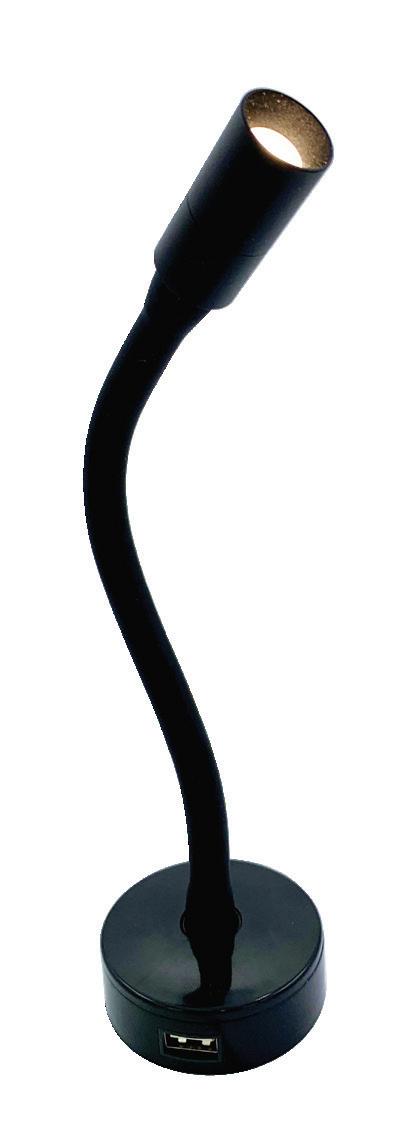

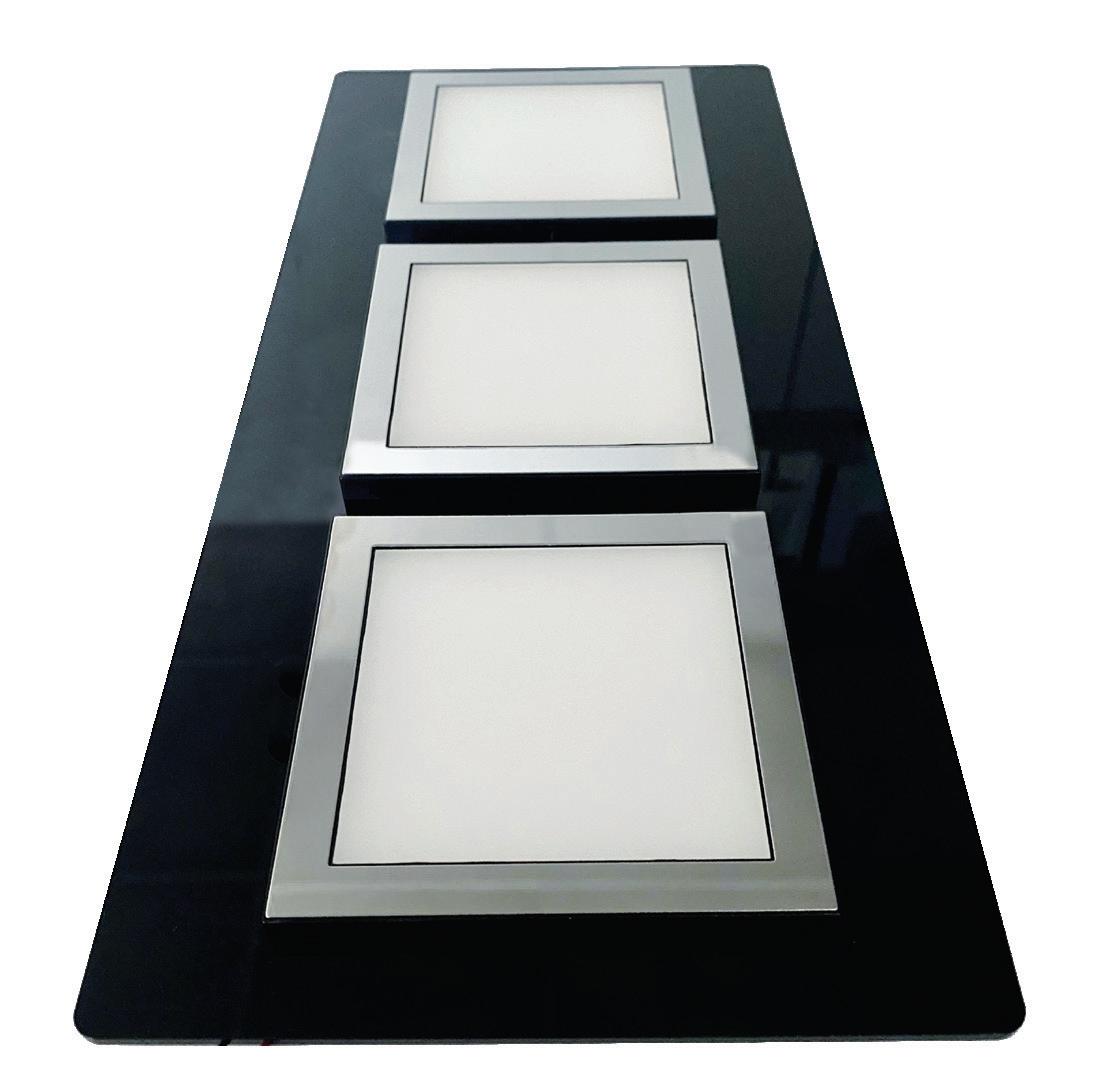

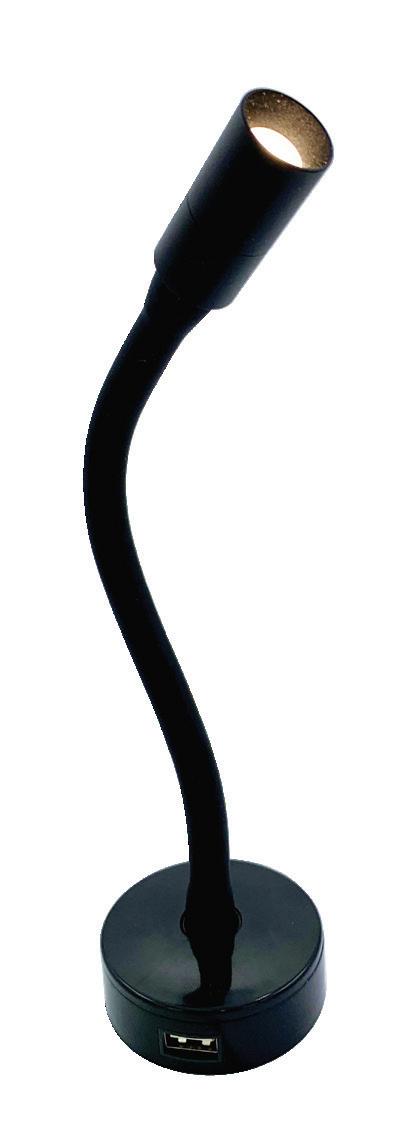

Bartolacci Design, a leading company in RV lighting, is continuing its expansion by systematically entering the Japanese market in partnership with New Japan Yacht (NJY) in Shizuoka Prefecture. NJY, a company operating in the nautical sector that has recently expanded into the RV sector, is working with Bartolacci to strengthen the company’s presence in Asia. The collaboration allows Bartolacci to utilize all of its unique features in the Japanese market, including a catalogue of lighting fixtures that can be customized or specially made for customers thanks to the company’s direct production in Italy. This feature is particularly important in a market like Japan that has different needs compared to the European market. Through the partnership with New Japan Yacht, Bartolacci Design is expanding its presence in the Asian market, starting with Japan as its first target. After Japan, Bartolacci Design is continuing its expansion by systematically entering in new markets. Now the new goal is United Kingdom and Ireland in partnership with Jason Dalton, Mobile Living Solutions, a well known company operating

in the RV market since a long time. The collaboration allows Bartolacci to utilize all of its unique features in the U.K. market, including a catalogue of lighting fixtures and methacrylate furniture components that can be customized or specially made for customers thanks to the company’s direct production in Italy. Bartolacci’s technical organization and expanded machinery park allows the company to work with various materials and create a wide range of lighting fixtures for the RV industry. With the addition of thermoforming machines and pantographs, Bartolacci is able to offer a wide range of lighting and furnishing components made from a variety of materials.

distribution groups in 2022, a corporate tax expense of €44.1M and a positive contribution of equity affiliates (€1.2M), net consolidated profit reached €121.7M (€141.3M in H1 2021/2022) and represents €6.30 per share.

Investments (excluding external growth, but including IFRS 16) amounted €49.5M (€39.0M in 2021/2022). This especially includes the activation of the rental contract for a warehouse to manage accessories sales growth in the Netherlands (€16.6M) as well as various programmes to improve productivity and working conditions.

Given the high level of its order books and the noticeable improvement in motorhomes chassis receipts observed for several weeks, Trigano should record a good increase in its sales and profitability in the second half year.

Record figures for PiNCAMP

PiNCAMP is celebrating a successful start to the 2023 season. Online bookings increased by 133% over the previous year. An overview of bookings on PiNCAMP reveals which countries are most popular with German campers this summer: the majority of bookings go to Croatia, despite currency conversion and above-average price increases. Germany is in second place, while Italy, despite the searches surpassing German tourist destinations for the first time, occupies the third position. Of all the major destinations, it is Northern European countries that experience the highest percentage growth in online bookings through PiNCAMP. The rapid increase in online bookings on PiNCAMP is due to several factors. These include the camping boom in Germany and the growing preference of German campers for online bookings. Entrepreneurs in the sector have taken note of this trend and are increasingly directing sales through online bookings.

10

N ews

Caravan and camping holidays surge in face of economic uncertainty, says report from Caravan Industry Association of Australia

Caravan and camping holidays remain Australian’s first choice for customer focused product and value for money holiday offerings, says the Caravan Industry Association of Australia (CIAA) which has released the industry’s latest holiday and accommodation data showing strong surges in trips across the country.

Numbers for the March quarter showed a strong surge in traveller numbers with people embarking on 4.5 million trips (up 24%) and 18 million nights (up 22%) spent caravanning and camping. That takes the annual rolling figure for trips to 15.5 million trips and 62.3 million nights and $11.2 billion in visitor expenditure. Far surpassing the 2019 precovid figures of 14 million trips and 59 million nights. This date also shows that caravanning and camping is the number 1 provider of nights for holidays in the country in the March quarter, this means strong support for regional and

rural economies with 90% of trips taken in regional areas.

“Growth in the industry is always great to see, but in the face of uncertain economic times, these numbers demonstrate the everlasting strength of our customer offering and our immense value for money proposition. We’re continuing to see Australian’s love affair with their country grow, spending more and more time in our beautiful regional and rural towns. That makes the growth even more encouraging, knowing that 89% of these trips are being spent in areas needing the support,” says Stuart Lamont – CIAA CEO. Australian’s love of road-tripping is evident in the demand for RV product, with approximately 800k registered RVs (30.3 caravans/campervans per

1000 people), they embody the adventurous spirit and more importantly are putting money directly into the hands of many regional small businesses.

“In a time when we haven’t seen international visitors return to our shores like we were told, it has been the caravan industry and it’s parks and holiday resorts across the country helping to provide economic relief through continued tourism dollars,” says Stuart Lamont.

11

EFOY Hybrid Power

Paris show moves to new venue

The 2023 Salon des Véhicules de Loisirs (leisure vehicles show) in Paris, France, will take place from 7th to 15th October at a new venue: the Parc Des Expositions Paris-Nord Villepinte. In 2022, the show was again a great success with more than 91,000 visitors. Divided into 4 halls on 55,000m² with 160 stands and a 100,000 m² car park for motorhome owners, the Salon des Véhicules de Loisirs is positioned more than ever as the largest showcase for RVs in France. This year’s 57th edition of the show has its share of new features and benefits from a larger surface area. A total of more than 150 exhibitors are expected. This includes the major European brands, but visitors will also be able to come and discover new brands present in preview at the show. With direct access to the Parc des Expositions de Villepinte via the RER B, the new location offers greater accessibility. The Show will also offer an unusual experience to discover the latest vehicle models. A test centre will offer visitors the opportunity to take the wheel of a motorhome or van, outside the exhibition grounds in real and normal traffic conditions.

Bailey of Bristol announces death of Stephen Howard

The UK caravan and motorhome manufacturer Bailey of Bristol has announced that Stephen Howard, whose family has owned the business since the 1970’s, has passed away. Stephen was invited to join Bailey in 1977 by his brother Patrick, who was Managing Director at that time, and together they purchased the business shortly afterwards. A fully qualified Civil Engineer by profession, Stephen became Technical Director and was part of a formidable Operations Management Team which also included Ceri Davies (Production Director) and Nigel Mattfield (Purchasing Director). Under the stewardship of the two Howard brothers the company grew to become the household name it is today and helped establish Bailey as one of the UK’s favourite leisure vehicle brand.

Stephens’ two eldest sons, first Nick and then Simon, both joined the business in the 1990s and eventually took over the running of the company. Stephen remained a company Director until very recently and continued to show a keen interest in all things Bailey. Stephen was 81.

12

EFOY fuel cell and

my-efoy.com

your freedom with the environmentally friendly and quiet power supply for on the road. Whether camping, on the boat, at an event, outdoors or on a road trip, with EFOY you are self-sufficient in any weather. Your freedom. Your p wer. Visit us at booth 13A36 and the outdoor area from CiVD

lithium battery

Enjoy

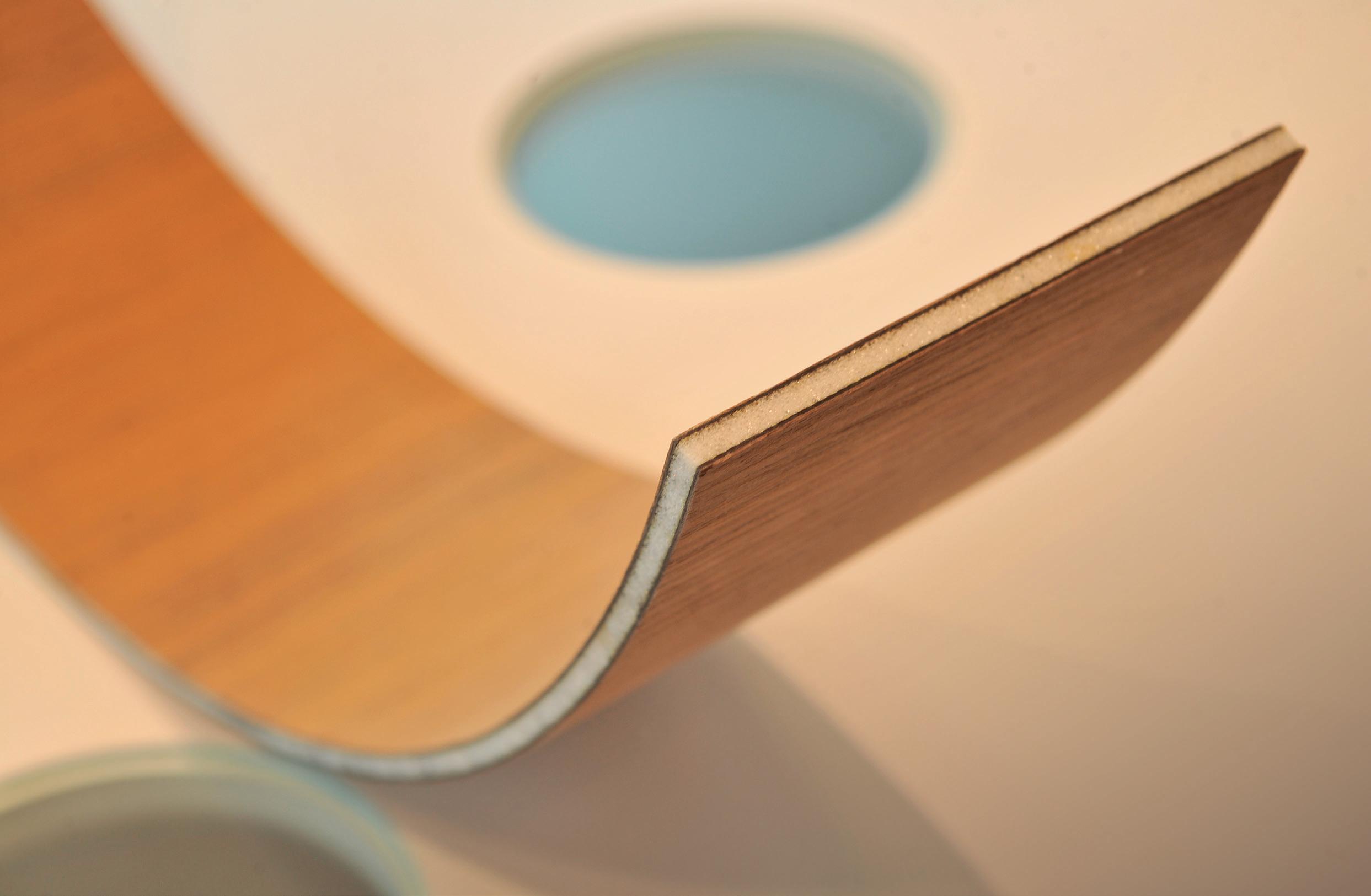

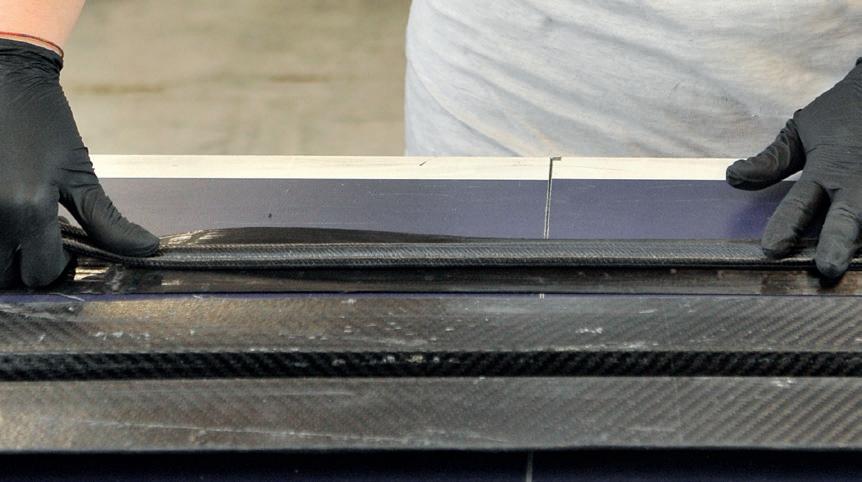

Apollo Fast-Tack Lamination Adhesives

Proven Solvent-Free Technology for the Manufacture of Your RV

With production costs a key concern for manufacturers, H.B. Fuller | Apollo’s range of fast-tack lamination adhesives allow you to cut production time and reduce costs. The adhesives give a one-to-one open to press time and extremely fast cure, allowing for a continuous production line.

Designed specifically for the manufacture of a wide range of panels, including doors, caravans and motorhomes, the adhesives provide a solvent-free solution to manufacturers, whilst still retaining the high-performance properties of traditional polyurethane adhesives.

Solvent-free

1:1 Open to Press Time

High Performance

Extremely Versatile Cure at Room Temperature

Minimise Production Costs

Minimise Task-Time

13

www.apollo.co.uk

www.hbfuller.com |

Take advantage of our Fast-Tack Lamination Adhesives. Contact us today!

Adria Home celebrates its 20th anniversary

Aboutcamp BtoB recently joined a celebration event in Slovenia for the 20th anniversary of Adria Home, part of the Trigano Group, that produces a range of modern and stylish Mobile Home and Glamping Tents. Adria Home produces between 1,500 and 1,700 housing units annually, with a strong emphasis on international markets, exporting to about 30 countries worldwide. Italy and Croatia are its main markets, followed by Austria, Germany, and Benelux. Only two percent of its product sales are in its home country of Slovenia. Adria Home has achieved impressive success over the past eight years. With annual sales of nearly €60 million and a remarkable revenue growth rate of about 20 percent per year, the company has established itself as one of the major players in the industry. During this period, it has significantly expanded its workforce from about 100 to more than 300 employees. Recognizing the importance of continuous development,

Adria Home invests about €1.5 million annually in various areas, ensuring innovation and growth. Looking ahead, the company has ambitious plans for further expansion. It is preparing to launch a substantial investment of at least €10 million in the short term, focusing on enhancing space capabilities and other aspects. This strategic move is in line with their vision of generating annual sales of up to 100 million euros and producing up to 3,000 mobile homes. Important guests at the celebration event included the Slovenian Minister of Economy, Tourism and Sports, Matjaž Han; Trigano Group President, Stéphane Gigou; Trigano Group General Manager, Michel Freich; French Ambassador to Slovenia, Florence Lévy; Andrej Kavšek, Major of Črnomelj; and the President of the Chamber of Commerce of Dolenjska

SOLERA PLUS2 ROOF

Double shell pop-up roof with integrated front spoiler

Built with thermoformed plastic material

Designed for Ducato, Jumper and Boxer campervans with H2 chassis in all lengths

Sleeping area for two people 200 x 130 cm mattress

User friendly opening system supported from gas springs

Generous internal volume with a height of 90 cm

Premium equipment including double LED lighting and two 5V USB sockets for charging electronic devices

Three windows, two of which with mosquito nets and blackout curtains

Optional 70x50 cm skylight, installation of solar panels by pre-assembled plug-in electrical connector

and Bela Krajina, Marko Gorjup. Sonja Gole, General Manager of Adria Mobil, highlighted the significance of mobile homes, glamping tents, modular houses, and floating houses as integral components of the Adria brand’s comprehensive range of leisure products and services. Reflecting on the company’s 20th anniversary, Gole emphasized the origins of Adria Mobil’s venture into mobile housing units, which began in 2001 under the leadership of Stanislav Lukšič-Luka.

14 N ews

soltherm.it

HALL 13 BOOTH A83

15

technologies for your comfort en plein air With over 40 years of experience in the caravanning sector, Teleco is proudly alongside many RV manufacturers as OEM supplier. Assistance network at European level. Internal research and development. Quality made in Europe. www.telecogroup.com Air conditioners Satellite and terrestrial receivers Lithium batteries

The best

Tom Faludy to retire

Lippert announced that Tom Faludy will retire, effective immediately, from his role as Lippert’s Vice President of Global Growth and Strategic Development. Mr. Faludy spent a total of ten years with Lippert, serving as a special advisor for many of Lippert’s emerging markets, including the RV and Marine aftermarkets as well as EMEA (Europe, Middle East & Africa).

Jason Lippert, Lippert’s President and CEO, commented, “Many of our leaders here at Lippert have been directly or indirectly influenced by Tom’s work around product innovation, aftermarket, Europe and other international business as well as a multitude of other areas over his almost 10-year tenure with the company. While at Lippert, Tom demonstrated our core values and leader qualities in everything he has done here.” Faludy began his career as Vice President and Creative Director for a full-service advertising agency then owned by one of the leading US RV manufacturers. Tom then served in managerial and directorial roles for Carefree of Colorado and Camping World, later returning to Carefree of Colorado as President. He was then promoted to a corporate officer role at The Scott Fetzer Company (Carefree’s parent company and a private subsidiary of Berkshire Hathaway), where he was the Executive Vice President responsible for 11 operating divisions and mergers and acquisitions. Faludy also began his own consultancy company, TGF Enterprises LLC, which worked with proprietors and CEOs of private and public companies to craft profitable business models and plans for sustained growth.

motorhome

According to the Spanish website, www.autocaravanas.es, data from the Spanish Association of Commerce and Industry of Caravanning (ASEICAR) says interest in outdoor caravanning tourism continues to rise despite the global automotive crisis, and concludes that Spain needs more places to accommodate motorhomes as it expects more than 225,000 of the 12 million motorhomes that will travel through Europe this summer to head to Spain.

In addition, it says that waiting lists to acquire a new motorhome have lead to 90% reservations of rental vehicles, although inflation has reduced the average trip this summer from 10 to 7 days and the price of fuel forces many to make shorter motorhome trips.

The 200,000th Volkswagen California campervan has left the production line in Hanover-Limmer, Germany

Since 2004, the camper production facility has turned the T model into the world’s most successful camper van.

Last year, 21,600 California 6.1 vehicles were delivered, a further increase of 14.9 per cent compared with the pre-coronavirus year 2019. The successor to the California 6.1 will also come from Hanover from 2024 and will be manufactured according to the same principle as the current model: the base vehicle is manufactured at the main plant in Hanover-Stöcken, where it receives the necessary cutouts for the roof, windows and connections, for example.

A brief retrospective: the VW California was launched in 1988 – initially based on the third T generation (22,000 vehicles). Until 2004, the camper van was built by the conversion company Westfalia (a further around 39,000 vehicles based on the T4), before Volkswagen Commercial Vehicles started to produce the camper in-house with the switch to the fifth-generation bus. Camper production was established on an area of 7,500 square metres in the Limmer district of Hanover. Initially, around 20 vehicles were built every day by 35 production employees. Productivity steadily increased over the years, with around 15,150 California vehicles built in 2017. Construction of the 100,000th California in Limmer was celebrated the following year.

Today, just five years later, the total has already reached 200,000 vehicles. Up to 150 vehicles are built every day by 600 employees in three shifts. Construction of the plant in Hanover-Limmer started in 2003, and production of the California was then launched in 2004. In the first year, 2,104 vehicles left the assembly line with the participation of around 35 Volkswagen Group Services employees. The location has grown continuously in size over the years and has developed further during this time. Around 31,000 vehicles will have left the production halls by the end of the year. The models T5.1 to T6.1 have been built to date.

Production of the next generation of California will begin in the summer of next year (after the factory shutdown).

16 N ews

Spain: 75% of

rental fleets are reserved for this summer

KABE Group AB: 21% increase in net sales in first quarter of 2023

The KABE Group AB, the Swedish motorhome and caravan manufacturer, achieved an increase in net sales of 21 percent to an all-time high of SEK 1,046 m, with an operating profit of SEK 78 m (+15 percent). This was the first time ever that the Group’s net sales exceeded one billion Kroner in a single quarter. It held its Annual General Meeting last month at its premises in Tenhult where it passed all proposals presented by the Board of Directors and the Nomination Committee. Delays of caravans, mobile homes and vans from the factory in Slovenia have continued to affect its ability to meet customer demand. Kabe says that thanks to the increased demand for their products outside Scandinavia, together with a stronger dealer network, Kabe is a more diversified and stable group. The increased internationalization has greatly improved the company’s opportunities to actively control the production and adapt to

each market demand. Kabe commented: “This improved business composition resulted in a lower exposure to individual markets and created conditions for higher growth and increased continuity in volatile periods. This is clearly in the quarter when the current macroeconomic situation contributed to a decrease in demand, but that the increase in sales outside of Scandinavia led to us having a wider base to meet the more challenging market situation. This has contributed to that we report a good result while adapting to them prevailing market conditions. To further strengthen our position is it is of significant importance to continue to focus on following our strategic orientation towards increased internationalization with the objective to always be one step ahead of current product development and innovation. Delivery disruptions of input materials have started to decrease during the period. We also continue with full

force to implement measures to reduce the capital tie-up. The measures have started to give effect, it will however take time to balance the stocks as we as a result of the supply disruptions have fallen out of sync with regard to deliveries of raw materials and production volumes. The stock buildup consists exclusively of products sold to retailers as well as chassis for mobile homes and vans without risk of obsolescence”.

17

German

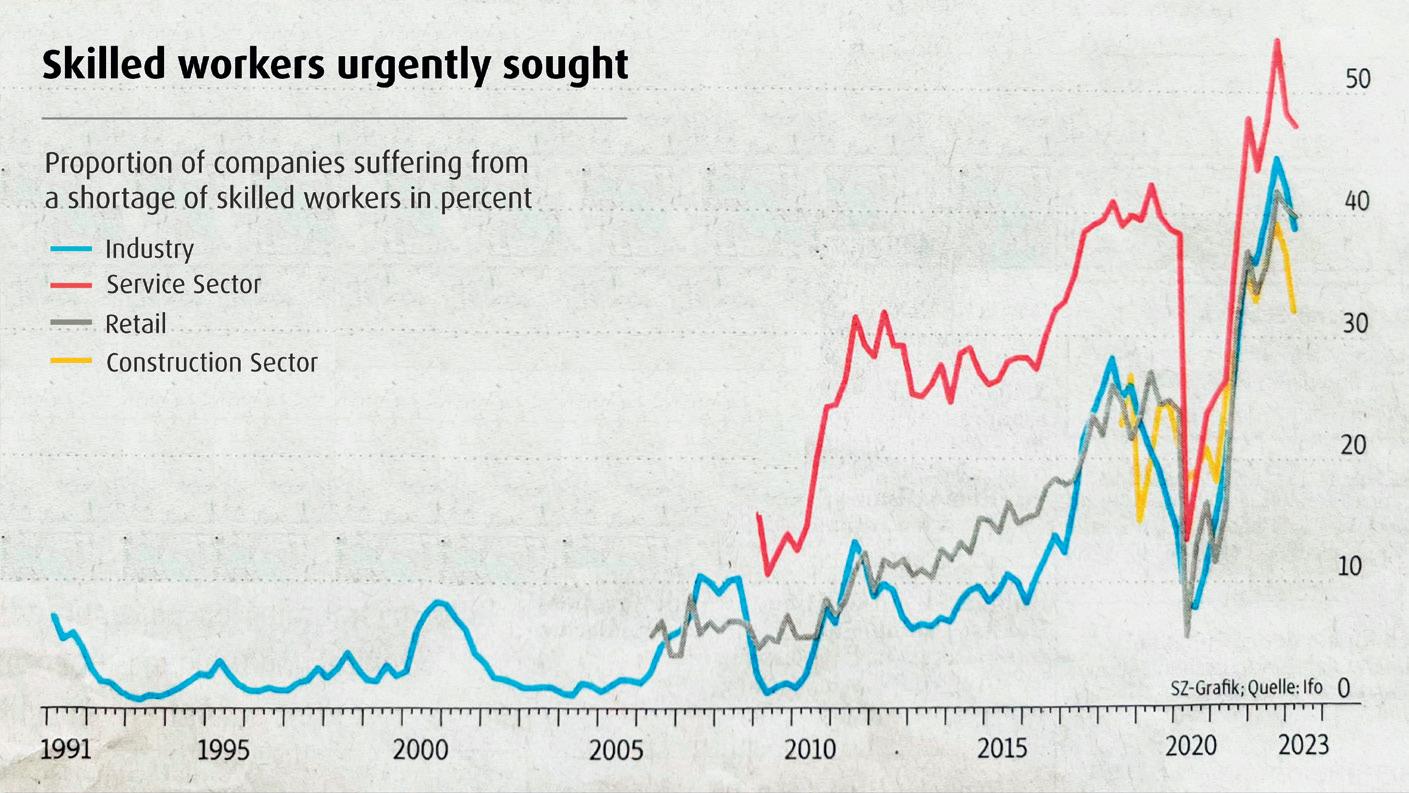

caravanning industry optimistic, despite supply chain and logistics hurdles

According to the latest press release from the Caravaning Industrie Verband (CIVD) in Germany, production and delivery of caravans and motor caravans are facing challenges due to disrupted supply chains, workforce shortages, and logistical bottlenecks. Despite these hurdles, the caravanning industry is looking forward to a hopeful future. It says that the trend of caravanning remains robustly popular in Germany and across Europe as this mode of holidaying, with its numerous benefits, is appealing to seasoned campers and newcomers alike. A surge in demand is driving the new vehicle market. German manufacturers have manufactured over 375,000 new leisure vehicles from 2020 to 2022. Manufacturer order books continue to be filled, with high demand across all segments. The industry might currently be underperforming compared to the remarkable records of previous years, but considering the difficult circumstances, the first six months have produced commendable results with a total of 54,299 new registrations (-1.6 percent) in the first half of the year – only just below the level of the previous year. The CIVD says the caravan sector has to measure up to

the good production and sales figures from 2022 and with 12,799 new registrations is 10 percent below the previous year’s level. At 41,500 units (+1.3 per cent), new registrations of motor caravans achieve the second-best result ever for the first six months of a year.

Stagnating supply chains and staff shortages continue to affect the production of manufacturers and suppliers, which is why new vehicles are being built under more difficult conditions.

New digital features and technology for the 2024 Ford Transit

Ford Pro in Europe has announced ‘significant vehicle performance and productivity-enhancing upgrades’ coming in 2024 to its Transit and E-Transit models to boost payload and improve vehicle performance, handling and efficiency.

This includes a comprehensive step-up in standard connectivity features and Ford Power-Up wireless update capability, plus new software to simplify aftermarket conversions, chassis improvements and an eight-speed automatic transmission option.

A comprehensive suite of advanced driver assistance systems for driver and cargo safety become standard for 2024 on Transit, including Pre-Collision Assist with Autonomous Emergency Braking, Lane Keeping Alert & Aid, and Intelligent Speed Assist. Driver assistance packs include a Blind Spot Information System with Cross Traffic Alert, Intelligent Adaptive Cruise Control with Lane Centering and Stop & Go, and Auto Park Assist with a 360-degree camera to provide added reassurance for drivers.

The 2024 model introduces a new eight-speed automatic transmission option for front-wheel drive Transits to improve performance, efficiency and load-hauling ability. The new transmission maximises capability with up to 4,250kg GVM and 6,000kg GTM – an increase of 700kg and 1,750kg respectively. New wheel hub and brake systems reduce weight by up to 27kg depending on vehicle configuration. The design also allows the brakes to be changed more easily, shortening servicing time by up to two hours when replacing all four discs. New 16-inch

wheels become standard across the 2024 model. A new heavy-duty Gross Axle Weight Rating pack is also now available for front-wheel drive models, raising the front axle maximum weight to 2,000kg from 1,850kg to increase conversion potential and save time and effort for operators by reducing load distribution demands. Ford Pro expects this to particularly benefit applications such as horseboxes or low loaders that require easy access to the load area and high payloads.

New features to expand the digital capabilities of its Transit and E-Transit commercial vehicle portfolio in Europe include: SYNC 4 communication and information system, supported by a standard 12-inch centrally-mounted touchscreen and 8-inch digital instrument cluster for a driver-focused, intuitive cab, with Connected Navigation for real-time traffic information to help drivers plan routes and stay on schedule Ford’s latest 5G modem, which provides superfast connectivity to Transit’s smart technologies with Ford Power-Up wireless updates for vehicle productivity improvements without a trip to the dealer; New Delivery Assist technology – available on long wheelbase panel van E-Transit and Transit models with automatic transmission; Shifting into Park stops the engine, activates the hazard warning lights and alarm, and locks any doors the driver does not use to exit the cab or access parcels; Ford Pro’s Upfit Integration System, which lets drivers control aftermarket installed equipment via digital buttons on the standard in-cab touchscreen and also links to Ford Pro software packages for remote monitoring.

18 N ews

“European Tourism: Trends & Prospects” report

The European Travel Commission (ETC) has released the “European Tourism: Trends & Prospects” report for the second quarter of 2023. The analysis shows a consolidation of the recovery of international travel to Europe, which began in the first quarter of this year, with foreign tourist arrivals reaching 95% of 2019 levels. This is a positive result considering the many challenges the industry still faces, such as inflation and uncertainty related to the Russia-Ukraine conflict, as well as staff shortages in accommodation facilities and the threat of aviation strikes and airspace closures due to the war. Nevertheless, the recovery is ongoing and confirmed in this second quarter of the year, thanks to consumer demand remaining high despite the increase in travel costs.

A quarter of the destinations already surpass pre-pandemic levels of foreign arrivals. Among these, there are Serbia (+27%), Bulgaria (+21%), Montenegro (+12%), and Turkey (+9%), all destina-

tions with good value for money. This is a clear sign that higher travel costs do not deter consumer enthusiasm but rather influence their choices towards more affordable destinations. Poland is also experiencing a particularly positive moment. From May to September 2023, airline ticket sales reached 91% of pre-pandemic levels. The data provided by the International Air Transport Association (IATA) confirms a very positive trend for this summer. Despite the generally positive context, there are also areas of concern. Firstly, there are signs that the recovery may slow down due to persistently high inflation and sluggish economic growth. Another point of reflection highlighted by the ETC study concerns the issue of overtourism. To reduce the negative impact of overcrowding in tourist sites, it is

increasingly necessary to rethink tourism strategies by offering alternative options to destinations prone to mass tourism. The goal must be to protect the environment through the development of more responsible and sustainable tourism that eases the pressure on tourist hotspots and spreads the benefits of tourism to lesser-known areas.

19 aboutcamp_issue_39_UK_VC 210x148.indd 1 11.04.23 10:20

www.dreoni.com

of BIO Habitat

Trigano has entered into exclusive negotiations with Bénéteau Group for the acquisition of BIO Habitat and its subsidiary BIO Habitat Italia. The move is part of Trigano’s strategy of development in the dynamic segment of the outdoor hospitality sector in Europe. Bénéteau’s Housing division, which includes brands such as O’hara, IRM, and Coco Sweet, is a significant player in the construction of mobile home accommodation for the outdoor hospitality sector in Europe. With 7 production sites in France and Italy and 900 employees, the division generated a turnover of €257.2 million in 2022. If the acquisition goes through, Trigano expects to benefit from synergies in purchasing, logistics, and manufacturing methods. The completion of the acquisition is expected by the end of 2023, pending information and consultation procedures with BIO Habitat’s employee representative bodies and approval from the French Competition Authority.

Emilio Vigolungo has passed away

The entrepreneurial world mourns the loss of Emilio Vigolungo, CEO of E. Vigolungo Spa, a wood industry leader for five generations. Born in 1969, he passed away Saturday, June 17, surrounded by the love of his family. Joining the company in 1997, Vigolungo initially worked in the sales department, responsible for both domestic and international markets. He later became the CEO of the company, working alongside his sister Vera and brother Stefano. The company boasts 140 employees, processes over 45,000 cubic meters of timber each season. In 2019, the family celebrated the hundredth anniversary of the company. Emilio Vigolungo leaves behind his wife and three children. The Aboutcamp BtoB team joins in mourning the loss of Emilio and extends his deepest condolences to his family.

20

Trigano has started negotiations for the acquisition

LAMILUX SUNSATION® THE WORLD’S MOST COLOUR AND GLOSS RESISTANT COMPOSITE MATERIAL

Your Benefits

+ Extreme gloss resistance, extreme colour resistance

+ Brand new look even after years in the sun

+ 90 % less effort and costs for maintenance & care

+ Higher resale value

21 LAMILUX COMPOSITES GMBH | E-Mail: composites@lamilux.de | www.lamilux.com

Dometic’s second quarter 2023 results show record-high cash flow

Dometic’s second quarter 2023 results show record-high cash flow despite challenging market conditions, plus a -2% fall in net sales. Statement from Dometic’s President and CEO, Juan Vargues: “Net sales in the quarter totaled SEK 8,329 m (8,498) with a solid EBITA margin before items affecting comparability of 14.1 percent (15.7) despite the challenging macroeconomic situation and market conditions. Our focus on cash flow continues to generate results and we delivered a record-high operating cash flow of SEK 2.3 bn, supported by reduced inventories. Organic net sales declined by 10 percent mainly due to segment Americas where RV industry production flattened out sequentially but is 50 percent below last year. OEM related organic net sales in our other segments continued to grow. Service & Aftermarket organic net sales declined by 10 percent, a clear improvement compared with previous quarters. We expect continued gradual progress over the coming quarters as retailer inventories are consumed. EBITA before items affecting comparability was SEK 1,177 m (1,330), corresponding to a margin of 14.1 percent (15.7). The de-

cline was mainly attributable to segment Americas due to significantly lower net sales. The margin for segment EMEA improved sequentially but remained below last year. As communicated previously, we are taking additional action in both Americas and EMEA to improve our financial performance and expect to see continued gradual improvement. Measures include continued rightsizing activities and selective price management activities prioritizing margin improvements over volume. The previously announced global restructuring programs are continuing at high pace, and there are 11 percent fewer FTEs (full-time equivalents) in the company than a year ago. The Igloo business continues to perform well and according to plan. Eighteen months on from the acquisition, we are entering the next phase of the integration and are establishing a dedicated global Mobile Cooling organization managing both the Dometic and Igloo brands that will benefit from common infrastructures. As expected, oper-

ating cash flow improved significantly and our inventories continued to decline. The net debt to EBITDA leverage ratio of 3.2x was flat sequentially and our financing structure is solid. While the EUR bond market remains an important longterm funding source for us, the plan is to use cash at hand to repay the bond of EUR 300 m due in September. Our focus on cash flow across the Group is strong and we are committed to achieving our net debt to EBITDA leverage ratio target of around 2.5x. Long-term trends in the Mobile Living industry are strong. Our broad and continuously enhanced product offering, combined with our global presence, means we are well positioned to benefit from these trends.”

Tecnoform USA showcases its 172,000 square-foot manufacturing facility

Tecnoform USA Inc, a new subsidiary of Tecnoform S.p.A, a manufacturer of high-quality furnishings and fixtures for the RV, marine, and residential industries, hosted a grand opening earlier this month to celebrate its new 172,000-squarefoot production facility in Grand Rapids, MI. The expansion of Tecnoform USA Inc. in North America marks a milestone in the company’s 58-year history. The move represents its strong focus on producing high-quality, lightweight furnishings and fixtures for the North American RV industry, meeting the increasing demand for lightweight parts and European designs in the U.S., and being closer to its U.S.based partnerships that include Jayco, Inc., Thor Industries, Winnebago Industries and Tiffin Motorhomes Inc. The event follows the company’s official announcement of the new facility in September 2022 after providing a capital investment of $7.3 million and receiving approval of a $750,000 Michigan Business Development Program performance-based grant with support from the Michigan Economic Development Corporation (MEDC) through the Michigan Strategic Fund. The company also accomplished its goal through the efforts and support of additional local business development agencies and the municipalities of Grand Rapids and Cascade Township. Production at the new facility is expected to start in Q4 2023 with a staff that will

eventually reach up to 130 new employees. “This is an event for us to express our deepest thanks and gratitude to all the representatives we worked with in Greater Grand Rapids, and who provided us with the opportunity to discover and expand our business operations in West Michigan,” said Renzo Kerkoc, President and CEO of Tecnoform S.p.A. and Tecnoform USA, Inc. “Through their efforts, we realized this region is the right place for Tecnoform USA and where we can continue to grow and manufacture our innovative products.” At Tecnoform’s 172,000 square foot facility, 152,000 square feet is designated for production, which will allow Tecnoform USA, Inc. to continue growing with its design and manufacturing offerings including casegoods, storage flat doors, lower flat doors, tops and worksurfaces, shaped interior drawer fronts, passage doors and vanity components for Class A, B, and C RV’s. The company also plans to move forward and grow substantially with its initiative to manufacture furnishings and fixtures for the towable market.

“We are continuing to provide our customers with consistent new approaches to elegance and high quality that we design in Italy,” explains Kerkoc. “We can now replicate the same quality here in the U.S., which will allow us to create unique Made-inthe-USA products in a very efficient way for our customers.”

22 N ews

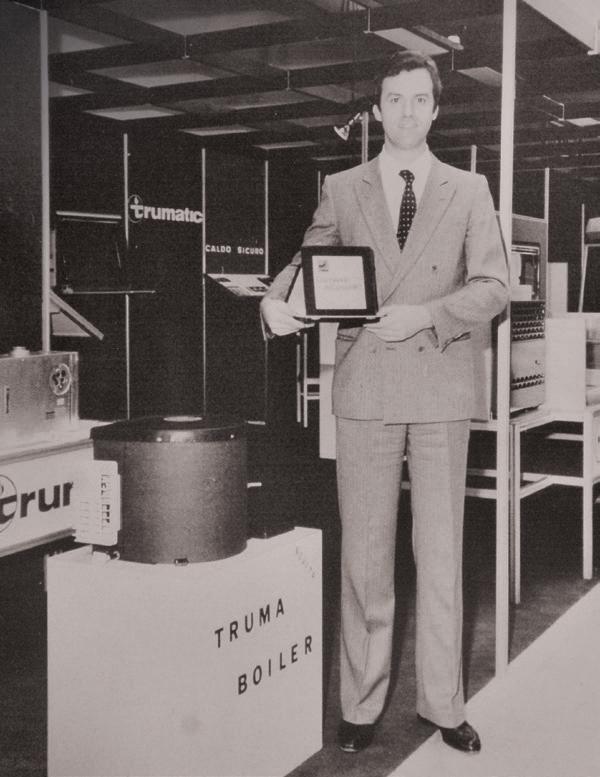

Eberspaecher celebrates 50 years in North America

Eberspaecher has celebrated a unique business anniversary: 50 years of Eberspaecher Climate Control Systems in North America. Its site in Mississauga is the oldest overseas subsidiary of the Eberspaecher Group and supplies its customers with vehicle heaters, energy storage systems, and AC systems.

Martin Peters, Managing Partner of the Eberspaecher Group, brought the congratulations on behalf of the family shareholders as well as the whole management team: “Half a century of successful operations – this is indeed a unique and outstanding performance. Happy Anniversary to our Canadian team here in Mississauga!”

And he continued: “This also demonstrates how the long-term thinking and commitment of a family-owned business can pay off.”

The German automotive supplier founded Espar products to start its North American operations in 1973 when it saw the potential of the local market for its core product: the engine-off pre-heater. While the North American winter can be harsh and long, the safety and comfort of a pre-heated vehicle or truck cabin pays off for its customers.

The company grew in leaps and bounds in the 1990 and 2000s because the US government’s interest in environmental protection increased and encouraged the use of emission reduction technologies.

“With our Airtronic D2 air heater, we were perfectly positioned for this” , explained President Climate Control Systems North America, Oleg Riabtsev the success during these years.

Located around twenty kilometers west of Toronto, the site covers a total area of almost 9,000 sqm. The central location is extremely important, underscored Oleg Riabtsev: “From here, we manage the business in Canada, the United States, and Mexico for fuel operated and electrical heaters, energy storage systems, and AC systems.”

To do so, the diverse workforce is bilingual, multicultural and many with long standing experience.

“Numerous employees have been with the company for over a decade – this honors not just us as an employer, it underlines the commitment of our dedicated people” , added Martin Peters.

Today the team with about 100 employees develops, produces, and distributes thermal management solutions specifically to meet the challenges of fleet operators in the American market.

23

The Winnebago way: in house, in control

Through the years I have visited many European motorhome factories. From those building entry level vehicles to premium. But I never saw anything like the Winnebago plant in Forest City, Iowa. They really have a different take on things

Words and photo Stefan Janeld

In Europe most factories work in a similar way. They are basically assembly plants that rely heavily on suppliers. Most manufacturers fish in the same sea of suppliers. The difference between brands within the same price range (entry level, mid-level, premium) is more or less about design and some differences in material choices and assembly techniques.

There are advantages to this approach. If suppliers can get large vol-

umes by selling to many manufacturers the cost per unit is kept low. And each manufacturer doesn’t have to carry development costs for similar products. The downside is that you need to keep to the suppliers’ timetable. If you need a new product, you have to wait until the supplier has developed it. This can take months for a simple piece and years for a technically advanced one. In short RV manufacturers are not in full control of their production.

24

F ocus on WINNEBAGO

Forest City Iowa, population 4,500. The home of Winnebago since 1958.

Extruding of aluminium profiles

I know, I should have written aluminum, since I am writing about an American company, but I couldn’t bring myself to do it. Winnebago use an aluminium framework for the walls in their A- and C-class motorhomes, so they need a lot of aluminium studs. They also use different profiles in the interior, and the design teams come up with new profiles for new solutions on a regular basis. Sometimes these profiles need to be adjusted, for one reason or another. Since Winnebago can extrude their own profiles, adjusting is a faster process than if they order from a supplier. And cheaper, because suppliers charge a lot for tooling. I am told tooling is not a big expense for Winnebago.

Finding a competitive advantage

When all manufacturers source their products from the same suppliers the drawbacks of the equipment are the same for everyone, so there is little incentive for manufacturers to make their own - because there is no competitive disadvantage! This is the reasoning of most motorhome manufacturers. At least it seems to be, but I doubt any of them would admit to it.

Winnebago has taken another route. In their Forest City facility, they make things no other motorhome manufacturer would ever dream of making themselves. This gives Winnebago a competitive advantage! Not only because they can save on production cost, many times they don’t, but because they can react faster when there is something that needs adjustment. This saves time and we all know time is money. It also gives the possibility to make custom solutions that fit better into the vehicle. This can save space and is very helpful in smaller vehicles, like vans. It is not by chance that Winnebago makes the best-selling vans in North America. Another advantage is that they can support the customers with spare parts in

a way others can only dream about since they have patterns, moulds and schematics going back decades.

Being a large factory in a small town

Forest City has a population of about 4,500 people. Winnebago is by far the largest employer here. This makes some things easier and others more difficult - like finding employees. Having a skilled workforce is crucial and, for a factory of this size, it is a challenge. Because of this they have also some plants spread out in the area, in other small towns, such as van production in Lake Mills, 20 minutes away. Winnebago also has facilities in Minnesota, Indiana and Florida.

Forest City is the main facility, where it all started, and it is huge! As I said before, I have been to many European motorhome factories. But this is the first factory where I have been driven between the different factory buildings. It is more like a small town than a factory. And as all small towns, it has its own water tower. One thing that I came to understand during my visit is that people enjoy working at Winnebago. Many I spoke with have worked there for decades. As did their parents. In many cases their children also work there. You could think this is of necessity, that they have no other options, but no. Actually, Winnebago needs them just as much as they need Winnebago, so the company treats them well.

25

The company was first called Modernistic Industries of Iowa. 1961 it was renamed to Winnebago. In 1967 the first motorhome, called Winnebago D-22, went into production. A true icon. This one is on display in the Winnebago Visitors Centre

Billets of aluminium waiting to be extruded into something useful

The size of the pistons show how much power it takes to extrude aluminium

A battery of dies ready for work

The machine heats it to 430°C (800°F) so it is malleable and then extrude it through a die

They make their own plastic mouldings

This is the largest machine for moulding plastic in the factory: it heats the plastic so it is soft and easy to shape

Cutting and folding metal

In one building they cut out intricate shapes from metal sheets using lasers. These then go to folding and become brackets and such. The metal parts that will be used where they are not seen get an E-coat to protect them from corrosion. Since the E-coat is not UV resistant the pieces that are used on the outside of the vehicle get powder coated. All in house!

Ready to have the excess trimmed. There are trim guides moulded into the piece so it is easy to manually trim the piece

There are many parts on and in a motorhome made of plastic in different shapes. Everything from larger pieces like shower cabins and dashboards to small details, some that you don’t even pay attention to. Winnebago makes most of these parts themselves. They have machines in different sizes that heats the plastic sheet and then use vacuum to shape it on a mould. The machines are large, but more impressive than the machines are the sheer number of moulds. Thousands of moulds rest on shelves in the storage area of the building. Some are very old and are not used anymore. If you have a 30-year-old Winnebago and the dashboard is cracked, you can be sure that Winnebago will make you a new one. With the original mould!

had their ends shaped

Right: behind the glass are vats of different chemicals. Here the metal pieces get a protective E-coat.

No less than five large laser cutters cuts metal sheets into pieces with great precision

Above: in a press the pieces that were cut by the laser get their final shape. The press uses two dies to make the correct bend.

26

A plastic wheel arch being moulded, it has not reached its final shape yet, the vacuum is slowly doing its job

ocus

WINNEBAGO

Moulds ready for use

F

on

Left: E-coated pieces on their way to the assembly line

Above: a laser shapes and makes holes in rods and beams, like these tubes that have

“Stitchcraft”

Winnebago don’t make their own fabrics or tan their own leather. But they do pretty much all else. In a building they call Stitchcraft there is an army of thirty seamstresses using industrial sewing machines of different types. Others quilt fabric or leather into patterns, stitch logos, cut cloth on huge machines, and make cushions. Mattresses are put into their covers by using vacuum, whilst chairs and seats are dressed.

The volume being handled in Stitchcraft is enormous. This is a few days production of mattresses waiting to get their cover.

Left: faux leather being quilted in a special sewing machine. The pattern is pre-programmed. While this is finished, another frame is prepared by an employee.

Here: this machine stitches any pattern

Left: like this emblem for a headrest

Here: in this machine layers of textile or leather are stacked. A plastic film is draped over the stack. Then the air is sucked out creating a vacuum that presses the stack tightly, so the machine can cut pre-programed pieces with precision.

Left: a finished padded panel

Below: upholstered chairs ready for delivery to the assembly line. The frames are not made in house.

27

There is a trick to fit the foam into a cushion or mattress. Vacuum is used to compress the foam.

F ocus on WINNEBAGO

Two story workflow

In most factories I have been to all production is done at ground level. But Winnebago has a way of making the flow in the factory more efficient by using a two-story layout in some of the buildings. The cabinets are made on the second floor of the assembly hall. When the prepared chassis passes under an opening in the floor, the cabinets and furniture is lowered and put on the chassis. It’s the same with the front masks, dashboards and double floor storage compartments. All are prepared on the upper level and lowered onto the chassis. In the textile facility the seamstresses get their material through a chute from the second floor.

The Forest City facility is a batch one production facility. This means they mix different models of vehicles on the assembly line, unlike some factories that make 10, 20 or even 50 of the same model. Batch one production is more demanding. Not only when it comes to delivery of material to the assembly line. Also, the workers need to be more alert - nothing they do is repetitive routine.

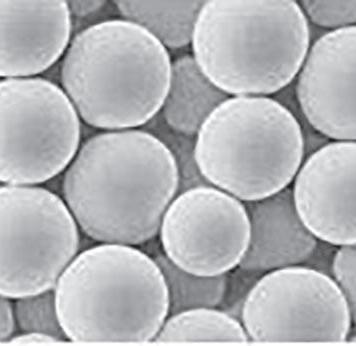

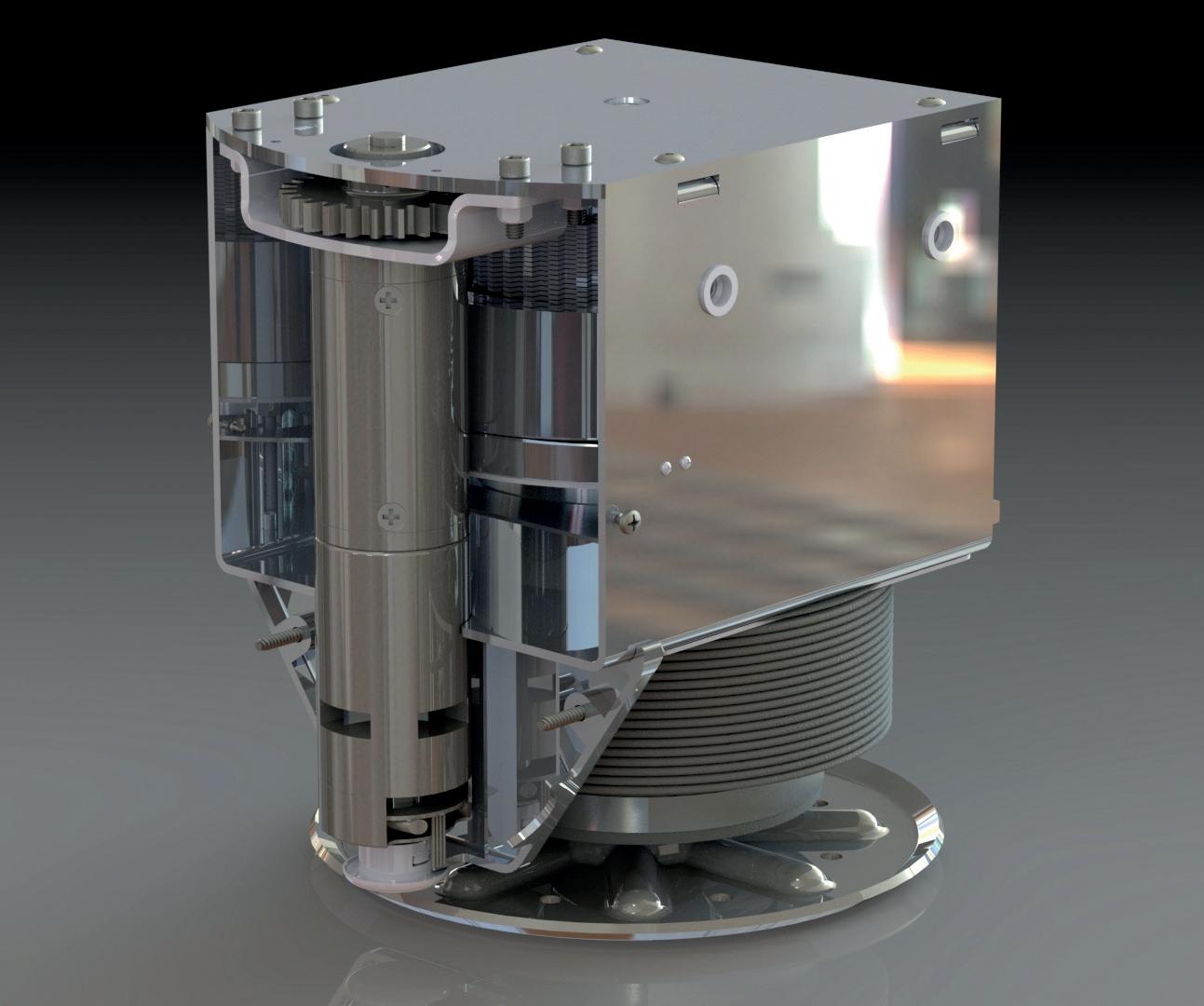

Lithionics now a part of Winnebago Industries

Lithionics now a part of Winnebago Industries

One supplier that has been very important for Winnebago lately is Lithionics, a high-tech company specialised in lithium battery technology. It’s a technique Winnebago has implemented in their vehicles with great success for some years now. In order to secure the know-how Winnebago has recently acquired Lithionics. So now you can say that also battery technology is in house, or at least in company. Lithionics is not based in Forest City, they are situated in Florida.

28

One assembly line for A-Class. Note that all vehicles are different models

One line for B-Class. Also on this line different models share the assembly line

Vans are made in a facility 20 minutes from Forest City. Here too they use batch one production

A double floor frame with storage compartments is being lowered onto the chassis of an A-Class

Cabinets lowered from the second floor onto a B-Class chassis

A glimpse into the future of motorhomes

Our contributor Stefan Janeld conducted a road test of Winnebago’s 100% electrified motorhome, the eRV2. He lived for five days in warm weather, simulating a lifestyle as if he was constantly connected to the electrical grid. During this period, he utilised various energy-consuming appliances, including the air conditioner, water heater and induction stove, whilst keeping his devices fully charged. Despite this significant energy consumption, Stefan found that, even after five days, he had not depleted even half of the battery’s energy. Stefan adhered to a driving speed below 90 km/h (55 mph), which allowed him to achieve the specified range of 170 km (107 miles) on a single charge. This road test highlights the impressive energy efficiency of the vehicle. The short range of the eRV2 was not a significant issue for Stefan, he found it manageable to drive for about an hour and then take a 20–30-minute break to top up the battery. In a motorhome, these breaks can be used productively, unlike in a personal vehicle where one would simply wait. However, on longer trips, the need for frequent recharging may become frustrating.

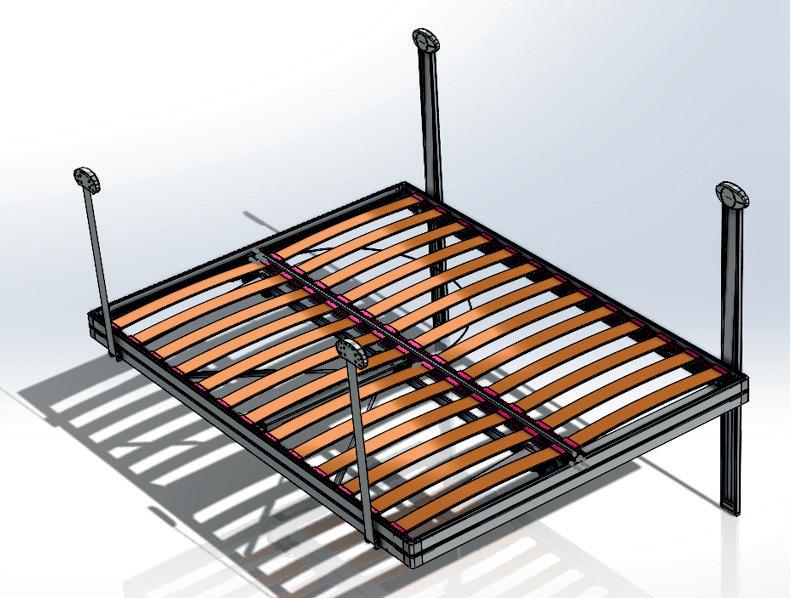

The Winnebago eRV2 is a 100% electrified motorhome, including the drivetrain and living area. The habitation battery has a whopping 15kWh of lithium power. That is the equivalent energy of thirteen 12V 95Ah AGM batteries. In real life you would need twice as many since you can’t use all the energy in AGM batteries, the way you can with lithium. The Winnebago eRV2 is based on the

Ford eTransit with a range of 170 km (107 miles), which is not a lot for a motorhome. In surveys Winnebago have found that people wish for at least 3 hours of driving between charging. However, this article is not about the drivetrain or the range. It is about the technology of the living area. - technology that offers a completely new, vastly improved, motorhome experience.

All electric house

The stove is an induction hot plate. The heater is an 1800 W electric heater. The water heater is electric. The roof air conditioner is a 48V unit. A compressor fridge keeps food and drinks fresh. All except the air conditioner is running through the inverter since the battery is a 48 V battery. The inverter stays on all the time. To

30

F ocus on WINNEBAGO ERV2

Words and photo Stefan Janeld

12 prototypes built

The vehicle I am driving is one of twelve prototypes that, since January, have been touring the USA. Journalists, dealers and potential customers have made real-world field trials and given their feedback. Now, all the feedback will be analysed in preparation for serial production.

The author

Stefan Janeld is the editor in chief of Sweden leading online motorhome magazine, www.alltomhusbilen.se and also runs The Motorhome School (www. husbilsskolan.se), an online service that advice consumers on all matters connected to motorhomes and mobile living. He has been a motorhome journalist since 2008 and has tested more than 350 motorhomes.

Chassis Ford eTransit

Motor 400 volts 67 kWh electric motor

LxWxH 598 x 202 x 284 cm

Freshwater tank 130 litres

Greywater tank 100 litres

Price Not for sale

Winnebago eRV2 is a prototype loaded with new technology and innovative ideas. The black on the side of the vehicle are fibreglass wideners, that add about 5 cm (2”) on each side. This makes the vehicle feel more roomy and gives the possibility for a transverse bed. Ford is usually considered too narrow for such a bed.

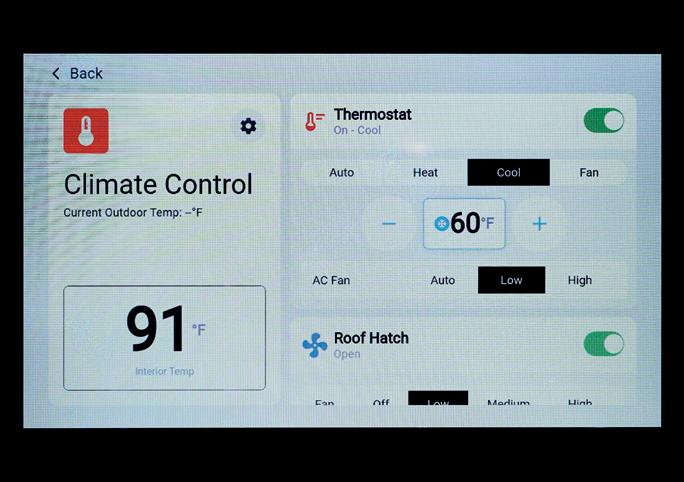

Below, clockwise: The 48-volt AC, very efficient; The electric heater is placed under the rear dinette floor; The stove is a portable induction hotplate, very practical.

use 48 volts instead of 12 volts has one really important advantage – it charges in a quarter of the time it takes to charge a 12-volt battery. So even if the battery is huge, it doesn’t take very long to recharge it. Depending on the capacity of the outlet, 45-120 minutes.

31

Four of the twelve prototypes back home at the factory in Forest City.

Model Winnebago eRV2

F ocus on WINNEBAGO ERV2

Solar panels not needed

One striking feature of the vehicle is the solar panels above the windshield. It is a clear signal that this is not a regular motorhome. In total there are 500 W of solar panels on the vehicle.

They gave a charge of 300-400 Watts during my test. This compensates for the fridge, more or less. On a normal motorhome this is a very welcome addition of energy. But in truth, the eRV2 don’t need solar panels. The 15-kWh battery is enough to boondock for at least seven days. I spent five days in warm weather. I used the air conditioner, ran the water heater, used the induction stove, and kept my devices fully charged. In short, I lived as if I was connected to the grid at all times. Still, after five days, I hadn’t used even half of the energy in the battery. I could have boondocked for ten days if it was only a matter of having electricity. I would run out of food and water before I had run out of energy.

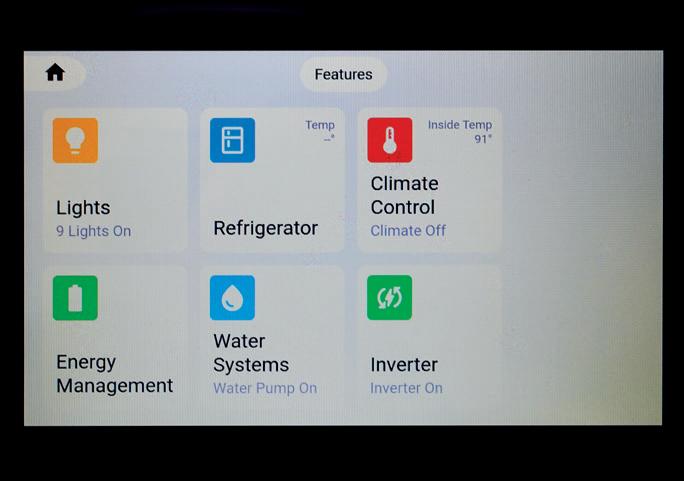

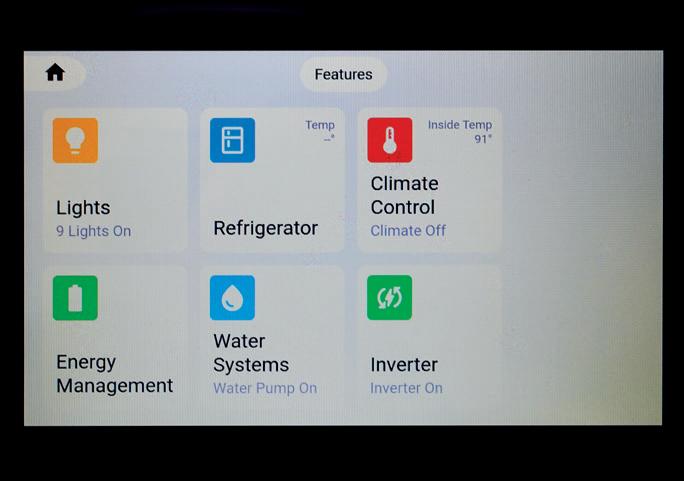

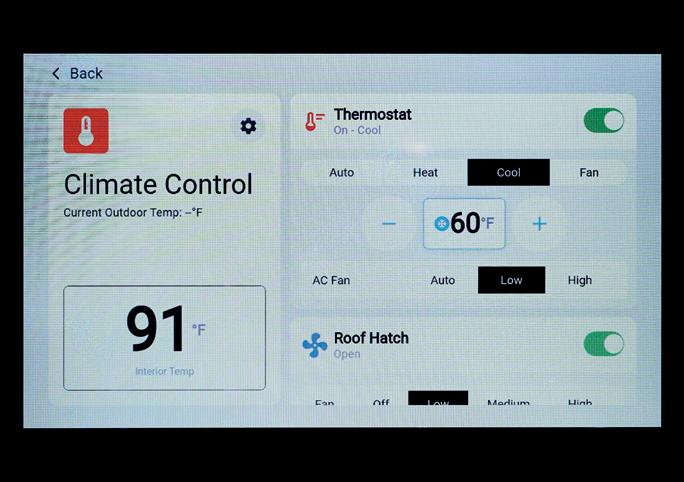

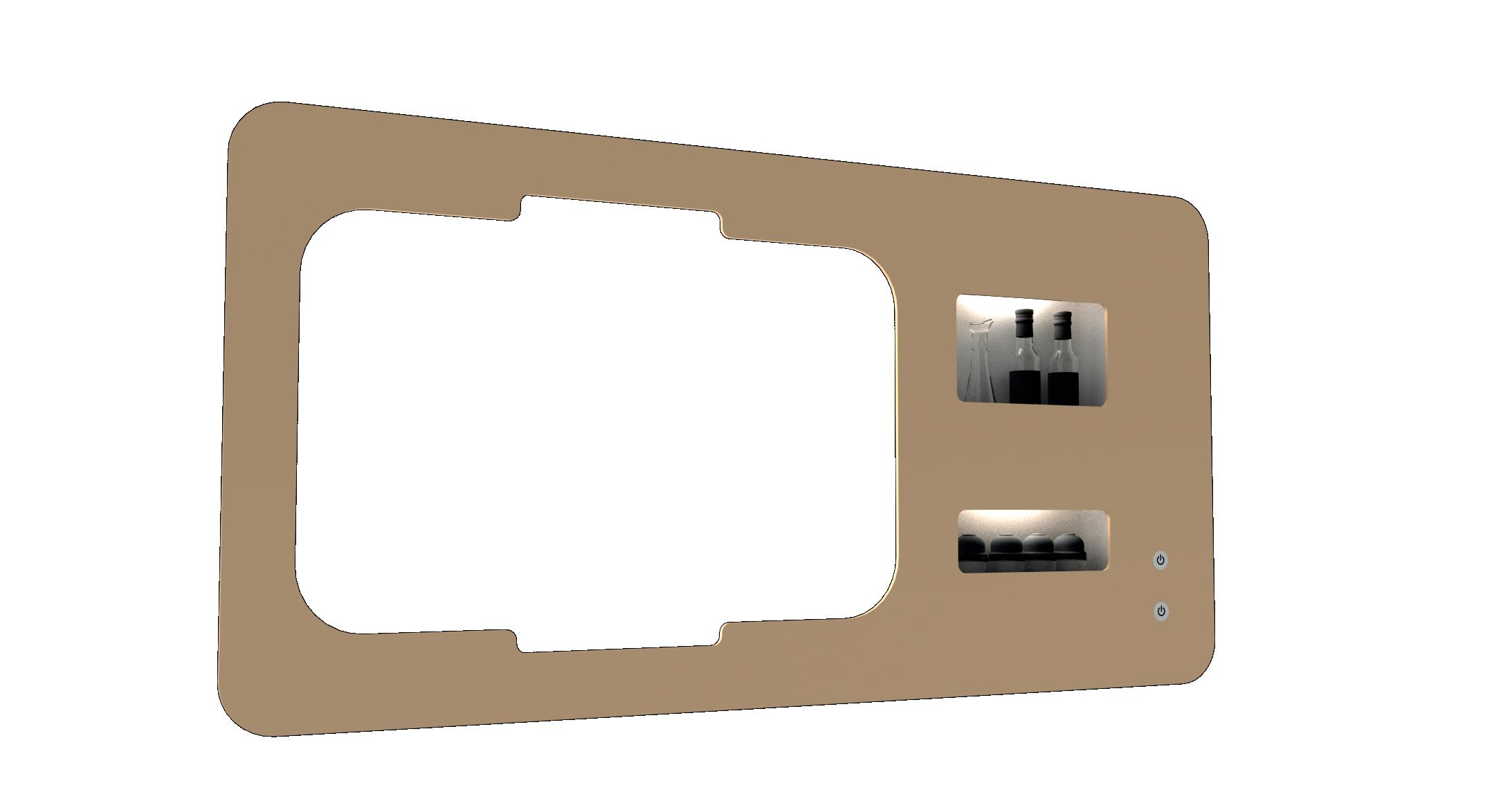

Intuitive

This is one of the most technically advanced motorhomes ever made. It is also one of the easiest motorhomes to use. The control panel is very easy to understand. All functions are intuitive. Today many manufacturers give us total control of every little detail through menus and submenus. It is easy to get lost. Not so in eRV2! You get information about tanks and energy. You can turn things on or off. That’s it! One example: I don’t turn the AC or heater on. I chose what temperature I want. If I ask for a lower temperature than it is in the motorhome, the AC activates. If the onboard temperature is lower than I have asked for, the heater starts.

Driving experience

I have driven the Transit many times. And driving the eRV2 is not much different. In ECO mode it is not very responsive. In Normal mode it is a more responsive driving experience. But if you use this responsiveness and start driving more actively, the range meter spins down like the altimeter on a crashing airplane. Keep the speed below 90 km/h (55 mph) and you get the specified range of 170 km (107 miles). The ride is a little stiffer than I am used to, but still comfortable. I suspected the tyre pressure was a little too high. But when I had it checked it

was the correct pressure. I think they recommend higher pressure in electric vehicles to reduce the resistance. But this is just me speculating.

32

The solar panels on the roof go all the way to the windshield. They do a good job, but mostly they are there for show, so people see that this is a very special vehicle.

The first view of the control panel gives an overview of tank and battery status. The second view shows six buttons, touch one and you can turn the function on or off. It is 91°F in the vehicle, I have asked for 60°F, so the AC starts; I can choose fan speed, high or low.

The living area

The floorplan is made to accommodate two people. A fold-away bed in the rear, a face-to-face dinette that can be used when the bed is folded away. Kitchen and bathroom midships. In the front of the living area is a work station/dinette. You swivel the front seats, raise the foldaway table and have a perfect workstation, turning the eRV2 into a mobile office. I kept the bed made up and used the front dinette for work, eating and relaxing. Had I had company, the bed would probably have been folded away every morning, so one of us could use the rear dinette.

Below, from left: rear dinette, behind it the bed folded away; bed ready for sleep; the “office”.

From left, clockwise:

To help you find charging stations Ford has a system called Charge Assist. But you need to know the area, because there is no map, only road names and names of places. I used a phone app called Plug Share instead. It connects to Google maps and makes life on the electric road much easier.

The biggest difference from a regular Ford Transit is the large screen and the gear dial.

With a fast charger you go to 80% charge in 20-25 minutes. A full charge, to 100%, takes 2 hours. Nobody waits for this while on the road. Better to use the outlet at the campground and charge while you sleep.

33

By having a portable induction stove stored in a drawer you gain a lot of surface area in the kitchen.

The bathroom is a shower cabin with a Porta Potti.

In my opinion

I wish manufacturers would apply this technology on all their motorhomes. Because it doesn’t have to be a fully electric motorhome to have a fully electrical living area. With a diesel engine charging the house battery when driving you would be truly autonomous. Now, to be fair. The short range was not a big issue for me. Driving for an hour or so, and then taking a break for about 2030 minutes to top up the battery, is no problem when you’re not in a hurry. In a personal vehicle you just sit and wait, whereas in a motorhome you can always find things to do. However, on long trips,

Chris Bienert

Chris Bienert is project manager for Winnebago B-Class vans and the eRV2. He is careful to point out that the development of motorhomes is not a oneman show; it is a team effort. Chris is often out camping with prototypes and

it will for sure be frustrating. I had my best boondocking experience ever in the eRV2. If this is the future for motorhomes, we all have something to look forward to. To be able to use all facilities onboard as if being connected to the grid is truly relaxing. Even with half the battery capacity it would be an amazing experience. And cheaper. This will not be a cheap van when it goes into production. But you can lower the price a little by having half the battery capacity and skipping the solar panels. Winnebago has done their part. Now we wait for the chassis manufacturers to do theirs and make chassis with better range.

finished products. He considers it a necessity and pushes his team members to do the same. This attitude has led to several new solutions. Often these are solutions that simplify handling and/ or provide a better function, but which may not give as luxurious and exclusive an impression as previous solutions.

34 Manufacture of furniture and accessories: we are proud to guarantee to our customers flexibility and a high degree of customizability. Fratelli Naldini is one of the Italian companies with the most extensive experience in the RV sector, thanks to 60 years of successful activity. Via del Chianti, 31 • 50028 Barberino Tavarnelle FI • Italy Tel: +39 055 8077928 • naldinisrl@naldinisrl.com www.fratellinaldini.com furniture care quality since 1961 Our experience at your service Production of flat and curved kitchen doors and lockers Fratelli Naldini

Srl

ocus

WINNEBAGO

F

on

ERV2

German head, Slovenian heart

With the inauguration of the Ormož plant dedicated to the production of Malibu campervans, the Carthago Group has completely reorganised its production in Slovenia, to best face the challenges of sustainable growth

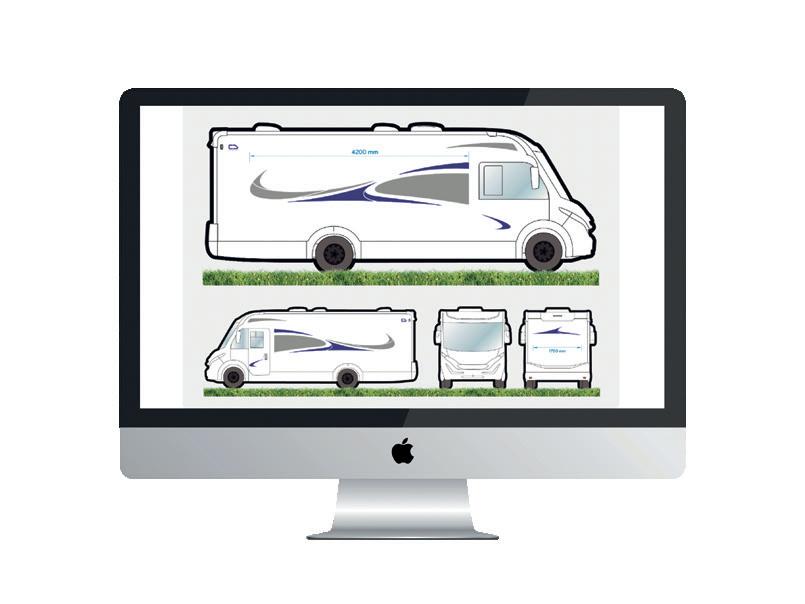

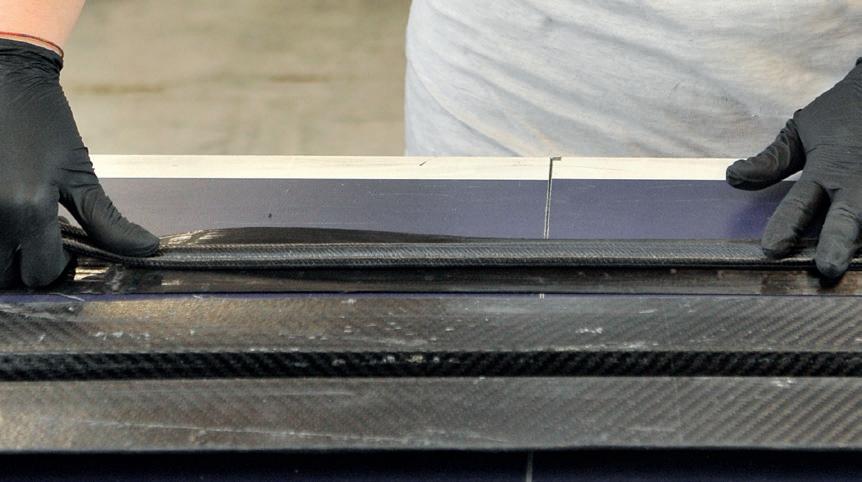

Production and logistics are two aspects that have a decisive impact on the results and development of companies that produce recreational vehicles. The Ormož facility integrates the total vehicle manufacture, including furniture, doors and walls. This helps to insulate production against ‘external’ elements, such as the difficulties encountered in recent months in the supply chain or in the supply of chassis, and the gradual shift of the market towards campervans.

A group like Carthago, which also manages the Malibu Van and Malibu Reisemobile brands, therefore had not only to find a suitable production solution for the challenges posed by the Premium segment, but also continue to invest to be able to increase its production capacity and adapt

it to the latest market demands. The last ten years have been a formative journey with the company concluding a production reorganisation which today sees three plants between Germany and Slovenia. The culmination of this journey was the inauguration, which took place in April, of the new Slovenian plant in Ormož, where the production of Malibu Vans is concentrated. Here, on a site of approximately 100,000 square metres, an ultra-modern factory was born, dedicated to campervans. With 22,000 metres occupied by the production lines, the potential is for 5,300 campervans a year, although the initial goal is to reach 3,000 vehicles a year. The opening of Ormož made it possible to free up production space in the Odranci plant, about 30 kilometres away. Now this whole site, inaugurat-

ed in 2008, has been entirely dedicated to semi-integrated and integrated motorhomes. Born with 5,000 square metres for production, Odranci now boasts around 30,000 square metres, with a capacity of around 4,000 vehicles a year.

From Carthago City to Ormož Carthago group’s investments in Slovenia parallel those in the company’s headquarters in Aulendorf, in southern Germany, between Ravensburg and Ulm. Inaugurated in 2013, the facility combines production with the administrative and customer support. Called Carthago City, the complex is truly impressive. Built on 100,000 square metres of land, it houses all the functions dedicated to design, production, administration, sales, and customer contact. In 2021, with a fur-

36 F ocus on CARTHAGO/MALIBU PLANTS

Words and photo Paolo Galvani

ther investment, Carthago built a new administrative office building, which now occupies around 5,400 square metres.

Carthago City is close to the historic places where Karl-Heinz Schuler founded the company, namely Ravensburg and neighbouring Schmalegg, just over 20 kilometres away. There the company was founded in 1979. With the latest factory in Ormož, the Carthago group has now three different plants, with the one in Carthago City focused on the production of the chic e-line, chic s-plus, and linerfor-two models. Also, from Carthago City all the numerically controlled machines in action in the Slovenian plants are programmed.

Resume growing

Immediately after the launch of campervan production in Ormož and the reorganisation of Odranci, the press were invited to visit the two Slovenian plants. The purpose was to experience first-hand how Carthago and Malibu quality is achieved and to understand the organisational complexity of a company which, after the jolts caused by the pandemic and by the shortage of components and chassis, now needs to resume its growth with impetus.

“We have planned an investment-based strategy,” Carthago CEO Markus Kern said during the welcome press conference. “We have expanded the Aulendorf site and the Odranci plant has been brought to the state of the art by completely changing its organisation. To these was added Ormož. We built it within a year, and we have been in production with the Malibu vans for a few weeks. We are also investing in IT systems to make production and administration work better. We are convinced that these measures can provide a solid basis for

our sustainable growth”. Despite production drops of between 50 and 60 per cent in the last year, mainly caused by the lack of Stellantis chassis, to which Carthago has responded by focusing more on higher value vehicles, the vision for the near future is good.

“As a Carthago group we think that the development will be positive in the medium term,” confirmed Bernd Wuschack, Managing Director responsible for sales, marketing, and customer service. “We are very popular with customers, despite everything. While on the one hand consumption is held back by a little uncertainty, on the other we are confident. Shopping habits have changed, and we cannot respond to these changes as we did in the past. Neither Carthago nor Malibu have been able to exploit the market potential of the past four years, as they were unable to meet the sharp increase in vehicle demand. Greater digitization will allow us to reach new customers. This year we will work on the CRM and by the Caravan Salon in Düsseldorf we

37