Multifunction Safety Relays

Starting at $155.00 (UG6980-02PS-61-24)

With single or separately settable dual-channel models, these multifunction safety relays can be configured for a variety of applications.

• E-Stop

• Safety gate

• Two-hand control

• Safety mat / Safety edge

• Exclusive XOR contacts

• Light curtain

Download our white paper: “When to use Multi-function Safety Relays” www.go2adc.com/MFSR

Safety relay modules use monitoring logic, as well as overvoltage and short-circuit protection, in combination with redundant relays, to provide fail-safe operation. All models offer LED status indicators and DIN rail mounting.

E-stop / Safety Gate Relays

Starting at $88.00 (LG5924-02-61-24)

Emergency Stop and Safety Gate Relays with redundancy and monitoring for fail-safe operation.

• Single and dual channel operation

• Time delay models

• NEW! Viper Series (red body)

Safety Extension Relays

Starting at $95.00 (LG5929-60-100-61)

Safety relay extension modules provide additional contacts for emergency-stop relay modules and safety gate monitors.

• NEW! Viper Series (red body)

Two-Hand Safety Control Relays

Starting at $139.00 (BG5933-22-61-24)

Designed to protect people and machines in applications with dual hand buttons, typically on machinery with dangerous closing movements.

• Feedback circuit to monitor external contactors

• Overvoltage and short-circuit protection

Light Curtain Safety Relays

Starting at $115.00 (LG5925-48-900-61)

These light curtain controllers offer capabilities such as release delay, muting, stepping, broken wire detection, and protection for multiple curtains.

• Connect up to 3 light curtains

• Broken wire detection

Safety Mat & Edge Relays

Starting at $125.00 (BG5925-22-910-24)

Switch gear to detect personnel stepping onto or contacting the edge of a protected area.

• Single or dual channel operation

• Manual or automatic restart

Speed Monitoring and Motor

Standstill Relays

Starting at $279.00 (all BH5932- series)

These safety relays actuate when speed is under a preset value (using separate sensors) or provide standstill detection on 1- and 3-phase motors by monitoring remanence voltage.

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

The

Alyssa Dalton

A

Pozzalini

@ItrisAutomation

Isolation is no longer a viable security solution for ICS. Now we need risk visibility and prevention: buff.ly/2upFyix.

@GeniusSolutions

Inventor of programmable logic controller (1968) passed away Tues. Thankful for his mfg contrib. https://shar. es/1PggB8

@SkilledTradesON

Worth noting for job seekers. As many 40% of jobs created in Canada this decade alone will be in the #skilledtrades.

@RogerDHallett

This neatly sums up the message of #Industry40 RT @barterpaul Industry 4.0 “getting mass manufacturing efficiency with a batch size of 1” #CMTS2017 Michael Gardiner, #Siemens.

BY ALYSSA DALTON

The lack of women in manufacturing has been a critical topic of discussion for a number of years. This is of particular concern as attracting and retaining a skilled labour force will be an increasing concern for about 60 per cent of manufacturers over the next five years, according to Canadian Manufacturers & Exporters (CME).

L ast month, CME published an action plan that explores the opportunities to help promote and inspire women to pursue manufacturing professions. According to Untapped Potential: Attracting and engaging women in Canadian Manufacturing, there are roughly 1.7 million people employed in Canadian manufacturing today and of that, women account for only 28 per cent of those jobs or about 476,000 positions — and the gender imbalance is not improving.

“The share of manufacturing jobs held by women has remained essentially flat, fluctuating between 27 and 29 per cent, with no clear trend in any direction,” writes CME. The study finds that women make up less than 10 per cent of skilled production workers across Canada and less than one quarter of science, technology, engineering and mathematics (STEM) workers.

“ There is no larger, more relatively untapped group of talent to work in manufacturing in this country,” writes Lesley Lawrence, senior vice president, Ontario, at BDC and member of CME’s national Women in Manufacturing working group. “Many Canadians still believe that a job in manufacturing is monotonous assembly-line tasks, or work that is done in a dirty, dangerous environment. These preconceptions

bear little resemblance to the modern, innovative and technologically advanced manufacturing operations.”

The action plan suggests several ways to improve female representation in the industry, such as: exposing young women to modern manufacturing facilities for a more accurate perspective on these careers, and highlighting high-profile female role models.

Linamar recently invested $5 million to create scholarships for female students in the Western Engineering and Ivey Business School dual-degree program at Western University. The scholarships cover half the cost of tuition and provide a guaranteed paid co-op placement and full-time job offer to graduating scholarship-holders.

“ This is a great way to bring together the three things that mean a lot to me and to Linamar as a company: manufacturing, business and improved opportunities for women,” said Linamar CEO Linda Hasenfratz.

Recruiting more women into the industry is key to helping manufacturers grow. Send me an email and let me know how your company is inspiring the next generation of female workers, whether it’s a plant tour, an open house, internship opportunities, or a school visit.

As Lawrence puts it: “Our hope is that in a few years, the participation of women in manufacturing will not be a challenge, but rather a strength that powers the competitiveness and growth of Canadian manufacturers internationally.” | MA

CONNECT @AutomationMag adalton@annexweb.com AutomationMag.com

EDITORIAL ADVISORY BOARD

AL DIGGINS, President and General Manager, Excellence in Manufacturing Consortium, and Chairman and CEO, Canadian Manufacturing Network

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, founder and owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

Your resource for Canada’s industrial automation news

EDITOR

Alyssa Dalton adalton@annexweb.com

PUBLISHER

Klaus B. Pirker kpirker@annexweb.com

VICE PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbizmedia.com

ART DIRECTOR

Graham Jeffrey gjeffrey@annexweb.com

ACCOUNT CO-ORDINATOR

Debbie Smith dsmith@annexbizmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbizmedia.com

COO

Ted Markle tmarkle@annexweb.com

PRESIDENT & CEO Mike Fredericks

CONTRIBUTING WRITERS

Paul Hogendoorn, Ed Nugent, Fulvio Pozzalini, Craig Rayner, Jennifer Rideout, WSPS

Manufacturing Automation is published seven times a year by:

Annex Business Media 80 Valleybrook Drive, Toronto, ON M3B 2S9 Tel 416-510-5187 Fax 416-510-5170

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION email: lmalicdem@annexbizmedia.com Tel: 416-510-5187 Fax: 416-510-5170 Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION RATES Canada — $40.95 per year United States — $71.95 (US) per year and Foreign — $82 (US) per year Students — $20 per year

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2017 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

We acknowledge the [financial] support of the Government of Canada.

A recent report by Future Market Insights studies the performance of the global artificial intelligence (AI) systems spending market over a 10-year assessment period from 2017 to 2027.

The report, Artificial Intelligence Systems Spending Market: Global Industry Analysis (2012 - 2016) and Opportunity Assessment (2017 - 2027) , presents the value forecast of the global AI systems spending market and provides insights into the factors driving market growth as well as the factors restricting market growth. The estimates point to a revenue growth from about US$11.7 billion in 2017 to nearly US$516.2 billion by 2027, resulting in a CAGR of 46.1 per cent over the forecast period.

In 2017, the deep learning segment is estimated to be valued at US$4,758.4 million, and is expected to register a CAGR of 49.3 per cent over the forecast period, to be valued at US$262,031.6 million by the end of 2027.

In 2017, the machine learning segment is estimated to be valued at US$2,784.5 million, and is expected to exhibit a CAGR of 46.6 per cent over the forecast period, to be valued at US$127,790.1 million by the end of 2027.

Meanwhile, the hardware segment is estimated to be valued at US$4,841.1 million in 2017, and is expected to register a CAGR of 43.9 per cent over the forecast period, to be valued at US$183,734.3 million by the end of 2027.

As per the forecast of Future Market Insights, the North America artificial intelligence systems spending market is estimated to be valued at US$3,197.1 million in the year 2017 and is estimated to touch a value of US$133,620.3 million in the year 2027, exhibiting a CAGR of 45.2 per cent during the assessment period.

The Asia-Pacific (APEJ) artificial intelligence systems spending market, however, is estimated to be valued at US$2,527.1 million in the year 2017. According to the report, the market is estimated to touch a value of US$132,964.7 million in the year 2027, registering a CAGR of 48.6 per cent during the period of assessment.

Labatt to invest $460 million to boost Canadian operations

Labatt Breweries of Canada is investing $460 million between 2017 and 2020 to enhance its operations and help boost growth.

The maker of popular brands such as Labatt Blue, Budweiser and Alexander Keith’s says the figure includes $62.2 million to be put toward brewery operations this year.

Each of Labatt’s six breweries have already received at least $19 million in recent years, as it invested $546 million in capital improvements between 2011 and 2016.

The company says this investment in new technology and equipment should help increase the production of new and innovative products, as consumer tastes

develop and demand is rising for different kinds of beverages. The investments are not expected to result in new jobs or layoffs, says Labatt.

Linamar invests in scholarship to support women pursuing engineering and business

Women seeking to combine engineering and business degrees will receive a major boost at Western University, thanks to a multimillion-dollar gift from Linamar and the families that grew it from a one-lathe machine shop into a global enterprise.

Linamar, CEO Linda Hasenfratz and her husband Ed Newton, and founder Frank Hasenfratz have invested $5 million to create the Linamar Scholarships

for Women in Engineering and Business. The scholarships support up to 10 female students in the Western Engineering and Ivey Business School dual-degree program each year, providing half the cost of tuition and a guaranteed paid co-op placement and full-time job offer to graduating scholarship-holders.

children attend Western, including her two oldest daughters who are taking a similar path in completing the engineering and business dual-degree program that the newly established scholarships support.

Woodstock Firestone plant set to close next year

The incredibly versatile Model MA58H absolute encoder offers a range of configurations to fit any application – especially where your encoder needs to retain absolute position after a power outage.

The Model MA58H offers: Multi-Turn and Single-Turn Resolution

SSI and CANopen Communications

58 mm Diameter

Operating Temperature Range of -40° C to 85° C

Two flexible mounting options

IP67 Seal (IP65 on the shaft)

Available with bores up to 3/8” or 14 mm

learn

“This is a great way to bring together the three things that mean a lot to me and to Linamar as a company: manufacturing, business and improved opportunities for women,” said Linda, who explained she hopes this will encourage more women to pursue a dual degree in engineering and business at Western. “Western has world-class engineering and business faculties — it’s the perfect combination to help develop this country’s next generation of women leaders.”

She said the advanced manufacturing sector needs people who understand the technical, financial, production and business aspects of industry. The dual-degree program offered at Western, plus the guaranteed offer of employment, “puts graduates that much further ahead and gives them the ability to lead within our organization or any other. They’re ready to hit the ground running when they come in,” she said.

Linda, a Western alumna, holds a Bachelor of Science and a Master’s of Business Administration from the Ivey Business School. As well, three of her four

Bridgestone Canada has announced the closure of its Firestone Fibers and Textiles facility in Woodstock, Ont.

The closure will be conducted in phases beginning December 31, 2017, and operations will completely cease in the second half of 2018. According to a company statement, the plant will ramp down operations over an 18-month period, continuing to produce in Woodstock during the transition, while also leveraging existing assets in Kings Mountain, N.C., to meet customer demand.

“This has been an incredibly difficult decision that has come about only after extensive consideration and a thorough assessment of our business and operations,” said Bill Thompson, COO, Bridgestone Americas, the parent company of Bridgestone Canada. “There is a strong team at the Woodstock plant and we are grateful for our employees’ contributions to our business and the community. In light of increasing

global competition and difficult market conditions, however, it is no longer viable to maintain operations in Woodstock.”

The closure will affect 35 salaried employees and 135 hourly employees.

“We are committed to helping to reduce the impact of this decision on affected employees and the community,” Thompson said. “We are proud of our long-standing presence in Woodstock and our Canadian footprint, and are focused first on our employees through this transition, but also on our customers, suppliers and community partners.”

In addition to severance packages, Bridgestone says it is working with the union representing hourly employees at Woodstock to determine how to best support those affected, including exploring options such as outplacement assistance and onsite job fairs.

The plant has been in operation

since 1936 and currently produces Nylon 6 for external customers, and reinforcement materials for Bridgestone Americas Tire Operations, Firestone Industrial Products and Firestone Building Products.

Palliser opens a fourth furniture plant in Mexico

Palliser Furniture has opened a fourth plant in Mexico to handle two growing segments: theatre seating and its entry-level price point brand.

The new 65,000-square-foot plant is located in Matamoros, Mexico, adjacent to its existing cut-and-sew operation, said the Canadian furniture manufacturer, adding that it will employ up

to 180 people in various positions such as operators, technicians, engineers and management.

“We are so proud of this new facility and of the growth that we’ve been able to realize over the past few years,” said Cary Benson, president and CEO. “This is our fifth manufacturing facility in North America, allowing us to service our customers even more efficiently.”

The plant will apply modern manufacturing methods such as conveyor one-piece continuous flow production to achieve higher efficiencies and more strenuous quality control, as well as energy efficiency through the use of low-demand kilowatt equipment and LED lighting, said company representatives.

Based in Winnipeg, Man., Palliser operates a total of five manufacturing operations in Winnipeg, and Saltillo and Matamoros, Mexico.

Toyota has officially ended more than half a century of manufacturing vehicles in Australia.

The Japanese automaker shut the doors of its Altona factory on October 3, ending 54 years of production by Toyota in Australia.

A crowd of about 3,000 attended a farewell ceremony at the plant including current and former employees, suppliers, affiliate companies and officials from Toyota Motor Corporation. At the event, Toyota Australia president Dave Buttner paid tribute to employees past and present for their commitment.

“It is you, our dedicated employees, who have built Toyota into Australia’s leading car company — the biggest-selling

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

Whether it’s our industry leading range of solid state relays and contactors, or our vast range of sensors, motor controls, energy meters and voltage/current monitors, CARLO GAVAZZI has the solution for your application needs.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

brand for 20 individual years, including the past 14 in a row,” Buttner said. “It is your efforts that have helped Toyota become a byword for quality, for reliability and for trust wherever you go in Australia.”

Buttner said Toyota would continue to be the leading automotive brand in Australia, retaining approximately 1,300 local employees and the existing dealer network of more than 270 sites.

At Altona, plans included the relocation of key business units and the development of a Centre of Excellence.

“Altona will house our expanded design and engineering capabilities. Our 150-strong team are in great demand by Toyota affiliates around the globe. The Centre of Excellence will include a world-class training facility and other commercial initiatives that will enhance the company’s business and the community.”

As part of Toyota Australia’s transition to a national sales and distribution company, the consolidation of all corporate functions from Sydney to Melbourne will take effect by January 2018. As a result of the consolidation and cessation of manufacturing, the number of employees will reduce from 3,900 people to approximately 1,300.

ABB has announced the acquisition of GE Industrial Solutions, GE’s global electrification solutions business, for US$2.6 billion. The transaction will be operationally accretive in year one.

Headquartered in Atlanta, Ga., GE Industrial Solutions has about 13,500 employees around the world and has an established install base with strong roots in North America, ABB’s biggest market.

ABB says it expects to realize approximately $200 million of

annual cost synergies in year five, which will be key in bringing GE Industrial Solutions to peer performance, it says. As part of the transaction and overall value creation, ABB and GE agree to establish a long-term, strategic supply relationship for GE Industrial Solutions products and ABB products that GE sources today.

“With GE Industrial Solutions, we strengthen our Number 2 position in electrification globally and expand our access to the attractive North American market,” said ABB CEO Ulrich Spiesshofer. “Combined with the long-term strategic supply relationship with GE, this transaction creates significant value for our shareholders. Together with the GE Industrial Solutions team, we will execute our well-established plans in a disciplined way to bring this business as part of the global ABB family back to peer performance.”

GE Industrial Solutions will be integrated into ABB’s Electrification Products (EP) division, resulting in a “unique global portfolio and very comprehensive offering” for North American and global customers. Included in the acquisition is a long-term right to use the GE brand. ABB will retain the GE Industrial Solutions management team and build upon its sales force.

EP offers a portfolio of lowand medium-voltage products and solutions for a “smarter, more reliable flow of electricity from substation to socket.”

The Weidmüller Group, an industrial connectivity and automation company headquartered in Detmold, Germany, has acquired the W Interconnections group companies in Canada, the U.S. and Mexico from Rockwell Automation.

With this acquisition, Weidmüller says it will strengthen its global presence and customer proximity as an international

market leader in industrial connectivity and automation, adding that the deal supports its growth strategy in industrial connectivity, communication and digitalization, and reflects a long-term commitment to the NAFTA market.

Weidmüller will continue to operate from the current sites in Toronto, Ont., Richmond, Va., and Puebla, Mexico.

Enclosure solutions manufacturer Rittal Systems is welcoming Franklin Empire to its distribution and partner network.

With a family history dating back to the 1940s and a distribution network in Ontario and Quebec, Franklin Empire is a large

independently owned electrical distributor in Canada.

“Franklin Empire is known for their expertise in the electrical distribution industry, as well as in manufacturing and processing automation,” said Rittal Systems president Tim Rourke. “Rittal Systems is confident that partnering with Franklin will expand our reach to new areas and industries, and will be a win-win for our customers.”

“Rittal’s many years of experience both globally and locally, as well as their level of quality and innovation, will enable us to offer high value solutions to our customers. We are confident that Rittal’s extensive product line will complement offerings for our key suppliers, and offer a more holistic solution to the end customer,” said Michael Almeida, general manager of Franklin Empire.

It is with great sadness we share the news of the passing of Dick Morley Dubbed the father of the programmable logic controller, in 1968 Morley led the team to develop what is considered one of the most important inventions in manufacturing. Along with the PLC, his patents include the anti-lock braking system, the computer floppy disk and magnetic thin film, among many others. For nearly 20 years, he penned the Distorted Realities column for Manufacturing AUTOMATION Please visit www.gofundme. com/lv6bho if you would like to contribute to memorial and scholarship funds in his memory. He will be truly missed.

In response to Paul Hogendoorn’s September 2017 column: How raising minimum wage could affect manufacturers

Hi Paul, I just read your article. I appreciate your viewpoint that people working should earn more than those who choose not to and rely on our social safety nets… I really agree with that!

However, the increase to minimum wage is not going to only apply to the people earning the lower wages… if we’ve got a forklift operator who is earning $15/hour (just a hypothetical – that’s actually low for a FLT operator), this operator is not going to be happy when someone with no skills is now earning the same wage… so of

course, his wage needs to be increased. And this will continue to ripple upwards!

The problem society faces today is not that the wages are too low, it’s that costs are too high! And this wage increase will only increase costs more… we’ve already started seeing it everywhere you go!

So how do we reduce costs? Unfortunately, I truly believe it’s the greed at the top that is hurting everyone. Executives are not going to drop their salaries, or bonuses, or other expensive perks… it seems to be a game of who can make the most. They seem to believe their status is measured in dollars and cents. Raising the minimum wage will have multiple effects:

• Other wages will increase causing costs to increase – the lower income earners are no further ahead!

• Companies will begin looking

at more automation – jobs will be lost and now these low income earners are leaning on the social safety nets!

• Companies will move their manufacturing out of Ontario –more jobs lost at many levels!

As you can see, none of the effects are positive. Now combine all of this and the timing of it with the recent housing situation… people sold their homes at exaggerated values – and bought at exaggerated values. Their mortgage may come up for renewal in say 2019… but the house isn’t worth what they’ve got it mortgaged for… how do they come up with $100K to stay in their house when they don’t have a job anymore?

I know I’m predicting doom and gloom… but some very bad decisions have been made and people will pay the price!

— Diane M. | MA

Aligned with PC-based control to provide the latest in processors, flexibility and main stream Ethernet fieldbus, Advantech provides solutions to machine makers and system integrators. With the support of EtherCAT open standard protocol, users can leverage the fast cycle time for high performance synchronous motion control.

BY JENNIFER RIDEOUT

Canada, including channel alignment and content development. She can be contacted at jerideou@cisco.com.

2017 has been a remarkable year for the digital factory. Additive manufacturing and Industry 4.0 finally entered the mainstream, while the convergence of IT and operational technology (OT) gained significant traction with factory floor and IT leaders.

So the question is with the advances made in 2017, what is left for 2018? What digital trends will influence factory operations in the year ahead?

To answer this question, I enlisted the help of some friends. And it looks like 2018 is going to be another incredible year for technology on the factory floor.

IT/OT convergence will continue to be top-ofmind in 2018, as more manufacturers come around to the possibilities of an industrial IT network. Convergence is also a significant component of Industry 4.0, and will also increase as companies move from planning to implementing their Industry 4.0 projects.

The timing for this couldn’t be better — Canadian manufacturers are facing increased pricing pressure from global competitors, as well as significant personnel and operational costs. These pressures won’t go away in 2018, and through convergence, manufacturers will be able to identify efficiency opportunities that will save time and money.

This trend comes courtesy of Ben Hope, Festo Canada’s head of business development for manufacturing and Industry 4.0. When asked what digital trend he saw emerging in 2018, Ben told me the following: “2017 really saw progress on the data side of Industry 4.0. But what is the next step? If we’re taking data from our automation components, it’s likely we want to gain insights from that data; and, it’s also likely we’ll want to take actions based on those insights. We need mechatronic solutions that are agile, reconfigurable and intelligent so that they can respond and adapt to changes in production requirements. The rise of smart mechatronics will enable better manufacturing and the faster design and development of automated equipment.”

Mechatronics is a vital piece of the Industry 4.0 puzzle. Like the convergence of IT and OT mentioned above, industry-leading manufacturers will begin to leverage smart

mechatronics in 2018 as they gain more valuable insights and data from equipment.

Speaking of data, there are two pillars every manufacturer needs in 2018 if they are to realize business value from digital solutions: a robust, secure IT network and analytics. Analytics aren’t possible without a network to collect data, and without analytics, the data is meaningless. As IT networks become table stakes on the factory floor, watch for analytics to become a bigger part of your technology stack to better predict machine maintenance and reduce waste.

In addition, data suggests analytics is ripe for a boom with Canadian manufacturers. In IDC’s 2017 Forecast on Manufacturing Spend, 44 per cent of industry IT leaders saw a high business value for analytics over the next five years.

Matt Rendall, CEO of Kitchener, Ont.-based Clearpath Robotics, had this to say about digital trends in 2018: “It has never been more important for processes, machines and humans in manufacturing to work harmoniously together. Intelligent automation – like self-driving vehicles – brings together sensors, connectivity and artificial intelligence (AI) to deliver flexible manufacturing processes that react in real time to changes on the shop floor. The factory of the future will be realized with

intelligent automation.”

While AI and automation are hardly new, the technologies have progressed significantly since 2011. Advances in machine learning abilities, sensors and computing power on the factory floor have created the ideal environment for intelligent automation to break through in 2018.

For years, Canadian manufacturers have trailed global counterparts in the adoption of advanced technologies. This must end in 2018 if they hope to close the gap between themselves and industry leaders.

The challenge is that 2018 is poised to be the year of the intelligent supply chain. Companies who have been investing in advanced technologies for several years now have the network and analytics foundation to implement a data-enabled, agile and responsive supply chain that better services customers and increases production efficiency. As intelligent supply chain deployments increase in 2018, manufacturers in Canada need to catch up with competitors.

2018 will be a definitive year for Canadian manufacturers. The impact of technology on the factory floor is no longer debated: those who adopt digital solutions will thrive — those who don’t will not survive.

My thanks to Matt and Ben for their assistance with this article. | MA

National Manufacturing and Distribution Centres: Calgary, AB • Edmonton, AB • Airdrie, AB • Milton, ON Mississauga, ON • Etobicoke, ON • Perth, ON

Regional Manufacturing Facilities: Delta, BC • Calgary, AB • Winnipeg, MB • Mississauga, ON Lachine, QC • Dartmouth, NS Call toll-free: 1-800-268-3578 Learn more at eatoncanada.ca

MACHINE SAFETY

BY WSPS

Workplace Safety & Prevention Services (WSPS) is a leader in providing impactful risk management solutions. WSPS offers unparalleled health and safety expertise, insight and solutions. Learn more at wsps.ca.

Workers have three guaranteed rights under Ontario’s Occupational Health and Safety Act, including the right to refuse to perform work believed to be unsafe. But this right is often enacted as a last resort, when other means to resolve a health and safety concern have failed, says WSPS ergonomist Tanya Muller. “Refusals can occur when workers and supervisors don’t fully understand what a work refusal is and is not, when there’s a poor relationship between workers and management, or when perceived hazards are not acted on,” she explains.

All three of these situations are inconsistent with the positive culture you need to foster health, safety and organizational success, she says. “Workplaces with a vibrant health and safety culture, and good two-way communication, are often able to resolve health and safety concerns so that they don’t escalate to a refusal.”

So what are the elements of a positive safety culture?

A positive safety culture is based on leadership, trust, good communication and shared values, attitudes and beliefs.

A positive safety culture is based on leadership, trust, good communication and shared values, attitudes and beliefs, says Muller. “To ensure a good safety culture, you must first have the right building blocks in place.”

Building block #1: Create a holistic health and safety program

Some factors to include:

• Training for workers and supervisors on hazards and how to control them.

• Training on violence and harassment that promotes respect.

• Training for workers on work refusal intent and process. “A worker can refuse when he/she feels there is a specific hazard that is likely to endanger him. Group refusals, refusals with no specified hazard, and refusals based on personal relationships are not allowed.”

• A well-communicated hazard reporting procedure. “You see a hazard, you report the hazard, and the supervisor deals with the hazard. If

it’s not dealt with, the supervisor needs to explain why. When the hazard reporting procedure is working well, it helps to prevent work refusals.”

• Procedures for investigating incidents and inspecting the workplace.

• A well-functioning joint health and safety committee.

Building block #2: Ensure procedures are implemented and used

This ensures supervisors and managers are held accountable “For example, hazard reports are actioned, incidents are investigated, and workplace inspections are done.”

Building block #3: Identify hazards and obtain worker input

For example:

• Integrate health and safety into all business activities.

• Use a participatory approach to involve workers. “Ask workers for input on how tasks could be performed more safely and efficiently.”

• Take health, safety and ergonomics into consideration when purchasing or installing equipment.

Building block #4: Strong and caring leadership starts at the top and is needed from managers at every level This allows for information to be freely shared both ways between management and workers. “Instead of an ‘us versus them’ attitude, everyone works together with a common goal of producing/selling a quality product safely,” says Muller.

If you’re still seeing work refusals, there’s something wrong, she says, noting that a cultural survey by WSPS can help investigate trends and pinpoint issues.

“It could come down to bad relations with a particular supervisor, or a perception that management provides only lip service to concerns about hazards.” | MA

Realizing the production of the future today

Industry 4.0 changes the world of production and connects the virtual world to the real world of machines. We use our expertise as an operator in our own plants and as a provider of intelligent drive and control technologies to develop and continuously expand our Industry 4.0 solutions. Initial results show the advantages—among them are higher productivity, more individual production and more efficient human-machine interaction. This strong base creates new value networks and allows Industry 4.0 to become a reality in your company.

Contact us today to discuss your requirements: 1-855-REXROTH (739-7684)

Order your free Factory Automation Resource Kit: www.boschrexroth.ca/factoryautokit For expert advice call 1-855-REXROTH (739-7684) or email us at info@boschrexroth.ca

BY PAUL HOGENDOORN

Paul Hogendoorn (paulh@getfreepoint.com) is co-founder of FreePoint Technologies, “Measure. Analyze. Share.” (Don’t forget to share!) Visit www.getfreepoint.com for more information.

What is Big Data and why should you care?

The best analogy to explain the Big Data approach to capturing information is comparing the first generation of GPS navigation systems to the current technologies available. The first generation captured and used all the data known at a certain moment to chart your course to your destination. It used maps, your location and your intended location to calculate your shortest route and time using the map information and associated speed limits. The current technology uses information collected from all the other cars travelling along your suggested route and then calculates your arrival time using the speed of traffic for your entire route, or any route you choose to take. The first generation technology collected and used only the specific information relevant to that known situation and known question — where am I, where am I going, and how will I get there?

This is similar to how most data collection systems are structured on the plant floor today — how many parts am I making, am I on target, and what are my constraints?

The Big Data approach collects all the information available, regardless of whether there was a predetermined reason for collecting it. Data from every car travelling (with suitably equipped cell and GPS technology) contributes to that Big Data database, allowing you or your system to know the exact traffic patterns and determine the best route.

My wife’s car is equipped with a first generation GPS while an app on my cellphone uses data collected from every other car on the road. On summer weekends when we travel from our home in London, Ont., to our boat in Midland, Ont., I have often put the two methods to the test, just for fun. The cellphone app (the Big Data approach) gets us to the boat quicker every time and predicts our arrival time with incredible accuracy.

The idea behind Big Data is to collect and store as much event-byevent information empirically and in the most consistent format you can

— because data storage is cheap — giving you the benefit of being able to mine it later when you come up with new questions to ask. New questions such as, how did that event link to this event? How did that machine change affect quality? How did a change of consumables affect the reliability of our process?

What is IIoT and how does it fit in?

From a manufacturer’s point of view, IIoT, or the Industrial Internet of Things, represents the opportunity to start to collect Big Data from all existing processes today – without the cost or time associated with replacing or upgrading the manufacturing equipment you currently have in place. The IIoT movement has in effect commoditized technology to the point that information can be collected from any machine or process extremely easily and cost effectively, enabling the collection of Big Data without the big costs associated with upgrading or replacing more constrained and restrictive technologies typically in use on the plant floor. Existing systems can be left in place, undisrupted, providing the essential services they always have. The IIoT however, allows manufacturers to start collecting Big Data today, setting them on the Industry 4.0 course without changing a physical

The idea behind Big Data is to collect and store as much eventby-event information empirically and in the most consistent format you can.

piece of critical manufacturing equipment. The IIoT does not get you there by itself, nor does Big Data, but they are very effective first steps that can be taken now, and like the modern GPS technology, they will help you get there quicker, and with more certainty.

What is Industry 4.0 and what does it mean to my plant?

The Wikipedia definition is probably the most concise explanation: Industry 4.0 is a name for the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of Things, Cloud computing and cognitive computing. Industry 4.0 creates what has been called a Smart Factory.

$14T

The common dialogue today focuses heavily on the data collection and automation side of things. However, I believe that an equally important objective for these technologies is to connect and engage the people in our companies better, making their work more meaningful and their efforts more constructive. Information needs to have a purpose to make it valuable. Getting data out of machines is only one part of the equation and getting useful information to people — all the people, not just management — is the other. | MA

At an open house in October, Ian Almond, head of location at Siemens Canada Peterborough, discussed the company’s recent $10-million investment into the manufacturing facility.

MA: What facility upgrades did the investments go toward?

IA: Established in 1954, the Peterborough factory employs around 280 employees, and is part of the Process Instrumentation business segment of Process Automation which is a business unit in the Process Industries and Drives division. We design and manufacture measurement instruments for various process industries, such as oil and gas, chemical, food and beverage, mining, aggregates and cement. We also manage all of our own supply chain from this building. Without investing in our own location, it [becomes] very difficult for us to stay competitive. This is why from 2014 to 2016, we invested $7 million into the physical location and an [additional] $3 million over the last year. Of the $3 million, about $1.5 million went into the building infrastructure and the other $1.5 million went toward the manufacturing environment. Part of the investment was [devoted] to the factory’s new North American distribution centre, which is three times the size of the old centre previously located on the opposite side of the building. Last year a decision was made to in-source a number of products to [Peterborough] and in order to do that, we had to make some changes so we could accommodate that volume — about 22,000 unique raw materials a month now come through these doors. We’ve had to change how we manage materials in order to [stop] our costs from increasing and impacting our customers. We’ve also hired a dedicated industrial engineer for logistics. Another part of the project is the investment of two new air exchange systems that monitor air quality. [These] white stacks emit sensitive vapours and

chemicals from our manufacturing process, changing the air four to five times an hour within the building. The emissions are well below legal limits and are monitored and certified through the Ministry of Environment and Climate Change.

Meanwhile the electronics assembly area, which takes the designs of printed circuit board assemblies and turns them into physical components, received new laser markers which create barcodes directly on the circuit boards. As well, new pick-andplace machines enable the production line to place 10 parts per second. These investments have made for smarter ways of working, allowing the department to move from a three-shift operation down to a more efficient one-shift operation. At the controller flow line, the

investment [secured] a soldering machine, a board stack functional tester, a hipot tester and ergonomic workstations that can be customized for worker height and arm reach.

These are very, very significant investments and that means this location is here to stay. We are like any other manufacturer, we need to make adjustments in order to get the best out of [our] opportunities.

MA: What are your thoughts on today’s manufacturing industry?

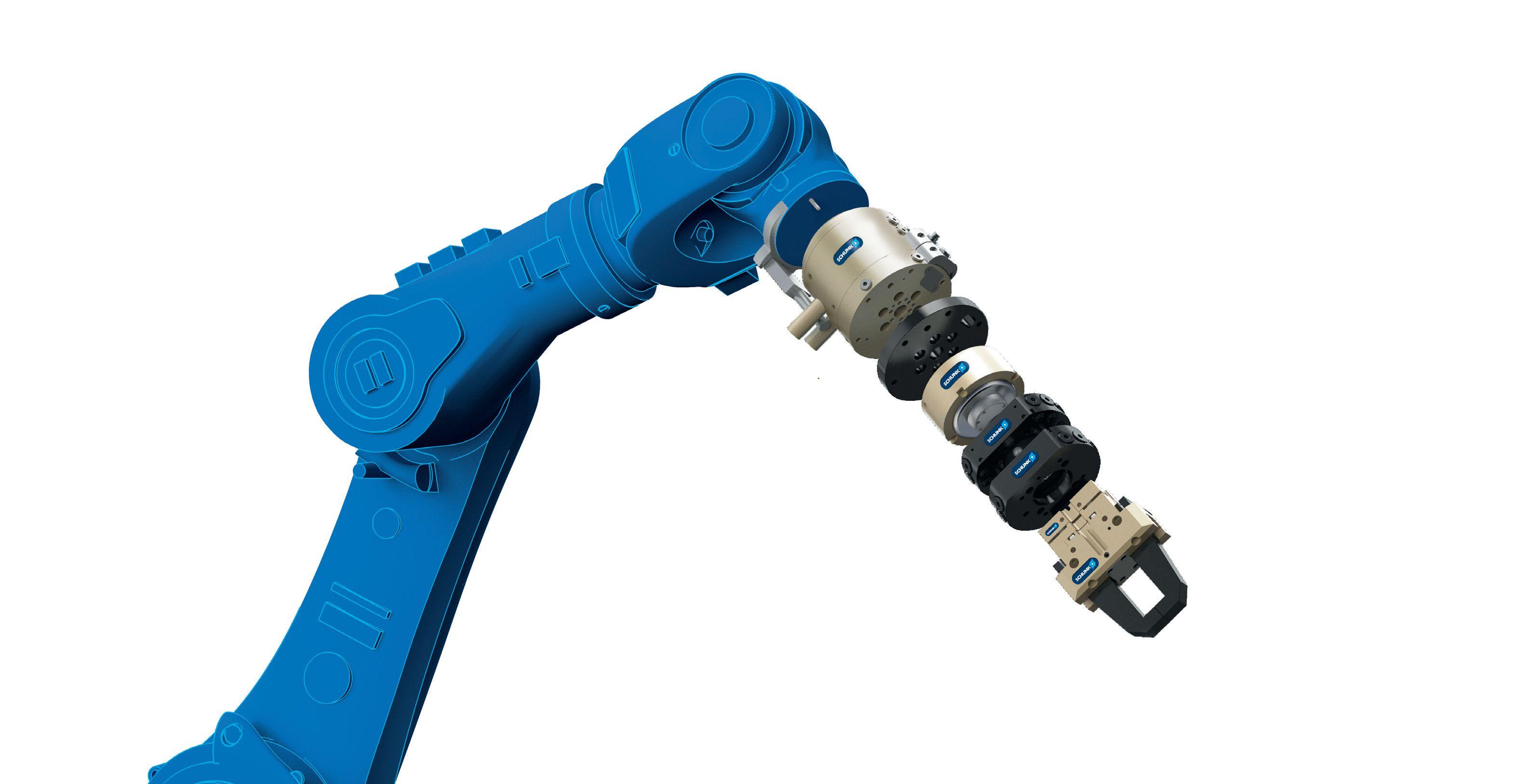

IA: One of the [most] exciting parts of business at the moment is the move toward affordable technology. [Behind me] is an image of a robotic arm shaking hands with a human hand. Embracing technology in manufacturing is not a way of

eliminating jobs — it’s a way of changing the way we work. We’d like to say we have achieved a real harmonization in our manufacturing environment and we have done that hand-in-hand with our employees. We’re moving toward a more optimal way of working and we [want to help] our employees understand that technology [can actually] support them by helping them do what they do. We spend a lot of time with our workers so we can learn about their pain points and look for ways to take those away — whether it’s by introducing new technology or by changing a process. Because they are [involved] right from the very beginning, they really embrace these [changes].

The employees of the future who are now in school are looking at ways to make use of the technology that we haven’t even begun to introduce into the facility yet, but as we do and as we continue to embrace sensible automation...we get to do that journey together. We’re doing things here that are going to excite them and attract them to the organization.

MA: What’s next for Siemens Peterborough?

IA: We don’t want to stand still. We will take the investment and will look for how we can [develop] that — not just in the building, the infrastructure or the manufacturing — but in our people. We have more ideas than money to spend on them; we have more ideas than we have people. To embrace some of those, we look to leverage [those possibilities] with government funding. Opening our doors today [provides some] insight into what we do, and as we go forward, we will look for ways to do even more. | MA

The most trusted brands, all under one roof. Phoenix Contact, TDK-Lambda, AP, SolaHD, Bel Power Solutions, SL Power, Cosel, Panasonic, Meanwell, Dantona Industries, Power-Sonic, XP Power, Traco Power, EOS Power, Altech Corp., and hundreds more.

BY ALYSSA DALTON

The Glad manufacturing facility in Orangeville, Ont., turned 50 years old this year, and it has never looked better.

“It is a unique milestone certainly in Ontario, if not Canada, for a manufacturing plant to stay operating that long,” says Peter Reynolds, plant manager at the Clorox Company of Canada’s Glad plant in Orangeville.

“I think to remain competitive, it comes from innovation you bring to the market, but it also comes from efficiency in your own operation.”

With a 110-employee workforce, the 128,000-square-foot plant produces indoor, outdoor and compostable garbage bags and Cling Wrap products, making roughly 50 different SKUs in total. About 15 per cent of what Clorox manufactures in Orangeville is exported to the United States.

A nearly 12-year veteran of the company, Reynolds has been the plant manager for the Orangeville location for the last three years and now also oversees the Brita water-filtration plant in North Etobicoke, Ont.

Other brands under The Clorox Company include Burt’s Bees natural personal care products, Pine-Sol cleaners, Fresh Step cat litter, Hidden Valley dressings and sauces, and

Clorox Healthcare and Clorox Commercial Solutions. The Orangeville and Etobicoke locations are the only Clorox plants in Canada.

The 128,000-squarefoot Orangeville plant is the only Glad facility that produces compostable garbage bags.

“I’ve worked for a couple of Canadian operations of multinationals and I think that from my vantage point, it tends to come [down to] the fact that Canadians have a very holistic view. When you’re a small plant, you need to be able to do multiple things, whether you’re a manager, a supervisor or an employee,” he says. “I think that flexibility, adaptability and being nimble [allows] you to react to changes in the market. Making business decisions quickly enables [Canadian manufacturers] to be a little bit more responsive to the market and I think that a lot of the time, that’s what separates us from our competition outside of Canada.”

The plant is essentially divided into two parts, describes Reynolds. “One part is where we extrude the film from a polyethylene resin, and in the other half of the plant we convert the film

into bags and put them into various forms of packaging.”

Nine months ago, the plant completed two major capital investment projects. One was a material re-processing system to handle all scrap for reuse internally, and the other was a robotic palletizing and conveying cell. Reynolds says a combination of factors prompted the robotic palletizing project, with safety and ergonomic concerns at the top of the list.

“With 12-hour shifts and an aging workforce, we felt like that type of manual work was better suited for automated equipment. That was the biggest driver for the project.”

Reynolds says the facility has transitioned from primarily manual packaging to close to 80 per cent automation over the past 11 years, with some departments, like the converting area, utilizing more automation than others.

“Anytime that we’ve automated, we’ve always been conscious of the efficiency side of it, and we have balanced our labour force with natural attrition,

such as retirement. As so, for the vast majority of the processes we’ve done over the last 11 years, we’ve been able to maintain a steady workforce,” he says. “[Regular investment in a plant] is vital. I think to remain competitive, it comes from innovation you bring to the market, but it also comes from efficiency in your own operation. The two of them go hand-in-hand together in order to sustain your operation and grow your business.”

A focus on sustainability

In addition to its various safety and quality awards, the facility in 2015 achieved zero-waste-to-landfill status, becoming the second Clorox location to obtain the designation. As part of its 2020 Strategy, Clorox set a goal to have 10 zero-waste-to-landfill sites, where 90 per cent of waste is either

recycled or composted with the rest of waste sent to a waste-to-energy facility.

The plant achieved the designation by working on and improving its recycling programs, which includes a composting program and training for contractors and new employees. In 2014, the diversion rate was more than 97 per cent, with less than 3 per cent of waste going to landfill, and in 2015, the plant began diverting its remaining non-recyclable material to a regional waste-to-energy facility.

“In Canada, our recycling programs are far more advanced and part of our day-to-day life. As far as recycling things, it’s basically about minimizing the amount you’re putting into landfill,” says Reynolds. “There’s a fairly rigid audit system in order to qualify and we’ve had that designation for two years. We’re proud to have played a part in helping the company reach our 2020 goal of 10 zero-waste-tolandfill sites.”

All about the people

On September 16, the plant hosted its 50th anniversary celebration. Operations were temporarily shut down and plant employees and their immediate families, local dignitaries, and Clorox executives from the U.S. head office gathered on a sunny Saturday to enjoy the festivities.

“We provided plant tours for everybody — we were touring people for about four hours — and then we were outside for a barbecue lunch, some [speeches], a cake-cutting ceremony

“The fact that we’re working at this plant today is [the result of] the hard work and success that all our retirees created over the years.”

and lots of pictures. We also had stuff for the kids, like games, toys and face painting. We had something for everybody.”

What makes the plant special is the people, says Reynolds. “It’s the people who have worked here over the years. The biggest part of our recent 50th celebration was having as many retirees return for an afternoon visit, a tour and lunch. It was great to see them all. The fact that we’re working at this plant today is [the result of] the hard work and success that all our retirees created over the years.”

Two years ago, the plant achieved zero-waste-tolandfill status, becoming the second Clorox facility to obtain the designation.

Reynolds believes that having the right people and treating them “fairly and with respect” is a fundamental element of manufacturing operation success. “That will drive a lot of engagement in your workforce and the rest takes care of itself. Once you’ve got people who truly care about the operation, and take pride in what they’re making, that’s the engagement piece.”

One way the facility is dealing with turnover due to retirement is with a more creative recruiting process.

“The biggest challenge for us is to continually improve the training, orientation and qualification of new people in the plant. We’re looking for great employees differently, from hosting job fairs to using electronic media to create a profile that people want to [join]. Our recruiting processes are very different than they were 10 years ago,” he says. “From that process, we have an excellent group of [employees] in the five-and-under-years of service category.”

With 50 years under its belt, the Orangeville plant maintains its drive to stay innovative.

“The next step is to prepare for the next wave of new products. For us it’s always about innovation. We want to lead the categories that we’re in and you have to continually provide something new, different and exciting to the consumer to do that.” | MA

BY FULVIO POZZALINI

Industry 4.0, whether it is referred to as the Smart Factory or the Industrial IoT (IIoT), has long offered more conceptual ideas than realizable solutions, at least from the perspective of outside observers. Yet for those involved in advanced automation, where factories are becoming smarter, more connected and autonomous, Industry 4.0 is an everyday reality. A new breed of smart cameras is acting as

practical solutions with tangible improvements in the monitoring, analyzing and controlling of data from anywhere on the globe.

First introduced in the 1980s, smart cameras combine lenses, sensors, processors, interfaces and software together into small, all-in-one vision systems. Besides being inexpensive, their primary advantage is having the on-board computational ability to solve a vision task independently without connection to a host PC. A compact form also makes smart cameras easy to fit in tight spaces or to retrofit into an existing process. Since they have few moving parts and do not generate high temperatures, maintenance costs are kept low. Smart camera systems are also typically provided with GUIs for developing a machine-vision inspection program with little or no programming. Smart cameras that integrate fast CPUs may even allow the use of off-the-shelf software packages designed for PC-based systems.

Until the late 2000s, smart cameras featured mainly low-end processors and were deployed for single-purpose applications, such as barcode reading, go/ no go decision making, OCR or counting. Difficulty managing sophisticated algorithms meant that complex images or operations requiring rapid analysis were well outside their scope. As processing improved however, smart cameras began to compete with PC-based systems in applications including assembly verification, 1D and 2D barcode inspection, and robotic guidance.

Processing power has long been a problem for smart cameras, prompting many customers to ask “why not incorporate larger processors?” Simply put, a larger processor and FPGA mean a much larger camera. The same goes for a larger sensor to increase image resolution. Both defeat one of the main benefits of the smart camera — its compact size. Also, a larger processor requires additional power consumption resulting in higher heat dissipation. Using a

fan isn’t an answer since it introduces the potential for mechanical failure. Fans also cause vibrations that could influence measurements. As a result, system integrators have continued to rely upon traditional PC-based cameras for high-speed, complex applications and smart cameras for low-end, single-purpose applications, or they’ve simply added more smart cameras to gain more power, which is not an efficient solution.

Meeting the needs of Industry 4.0 requires a new breed of smart cameras, one that combines multi-megapixel resolution and speeds comparable to a PC-based system, but without the size, heat and power drawbacks associated with bulky processors or sensors. Easy-to-use, open source software is a must for rapid and successful development. In addition, since network connectivity is the key factor defining a successful Industry 4.0 program, intelligent smart cameras must be built around machine vision standards such as Camera Link, GigE Vision, CoaXPress or USB3. As well, it

should feature industrial-grade IP67 housing to survive harsh chemicals, vibration, moisture, extreme temperatures, dust and other contaminants commonly found in industrial environments.

Better, faster, stronger

In Industry 4.0 settings, smart cameras must be able to connect with components and systems involved in the industrial value creation process as well as to the factory’s networks and the Internet. Ethernet networking connects smart cameras to automated devices that act on provided information, instantly leading to desired actions without any human intervention. Instead of being a reactive tool to detect defects, these smart cameras have become extraction tools that employ Big Data-style statistical and data science techniques to draw insights from images and apply them throughout the enterprise.

For example, with the use of data analytics and smart cameras, a plant manager is able to determine when a piece of equipment will fail before the maintenance crew notices there is a problem. The systems sense warning signs, use data to create maintenance timelines, and preemptively service equipment before trouble starts. Or consider the use of smart cameras to acquire images of molded plastic parts at every stage of the production process, starting at the locations of suppliers. Images of parts can be compared with thousands of others stored in the Cloud to identify correlations and trends, or they can be combined with data from sensors from other connected devices to gain insights into how each step and variable impacts the final product.

Production game-changer

Going forward, an increase in processing power, together with

software advances, will help overcome one perceived disadvantage of smart cameras — flexibility — and expand the scope of smart camera applications. Industrial, pharmaceutical, food and beverage, surveillance and other sectors are all anticipated to offer smart cameras a healthy growth rate.

Specifically for Industry 4.0, smart camera manufacturers must work to accommodate the range of industrial networking standards used in automation so that their cameras are able to communicate across all industrial protocols and with standard discrete I/O. Factory protocols can be directly integrated on some cameras today, but emerging

Cobots improve productivity and quality – and protect workers Make the most of repetitive machine-tending tasks with accurate, consistent, flexible, and cost-effective UR cobots. They’re easy to program and redeploy for almost any operation. And they keep workers safe for upstream and downstream collaborative processes.

protocols like Ethernet/IP and PROFINET may require thirdparty converters.

While current points of view differ over meeting the challenges presented by Industry 4.0, one thing everyone can agree on is that smart cameras will play a gamechanging role in its development and adoption. No other component on a production line captures more information than a smart camera — assessing products, flagging defects and collecting data that is transformed into actionable information and insights that can drive measurable performance improvements. | MA

BY ED NUGENT

In building management systems (BMS) and human machine interface (HMI), manufacturers need to seek the right architecture for supervisory systems. Costs are being further driven down from legacy systems while historically, reliability is improving and efficiency is increasing. Due to the enhanced connectivity of these systems today, improving cybersecurity has become an equally important goal.

For SCADA, one of the most important technology developments has been the trend away from serial

communications to IP-based industrial network communications. This has allowed much more flexibility in where the supervisory server is physically located relative to the PLC. Remote Terminal Units (RTUs) were geographically distributed away from the SCADA host. This was very valuable in realizing distributed control and remote monitoring, but the limited bandwidth radio communications of the time made this architecture unsuitable for many SCADA applications. Combining the advances in client-server technology and network

Supervisory Control and Data Acquisition (SCADA) systems are control systems used in various critical industrial sectors.

technology, it has – for several years now – been possible to migrate the SCADA or BMS host server out of the control room and off the shop floor and into a physically secure, environmentally controlled data centre. In the lexicon of Cloud computing, when we have the supervisory host on a dedicated machine running in a data centre we have created a Private Cloud.

Consider this example. A grocery store chain has a warehouse where they store cheese products. They purchased an air quality control system to ensure the “cave” was kept at

What is significant about these examples is that public and private Cloud architectures can both be the right choice for SCADA but one size does not fit all.

optimal conditions to maintain the quality of their cheese products. This environmental system consisted of PLCs supervised by HMI software. It was installed on a PC in the warehouse. The management team for warehouse operations was concerned that physical damage could occur to the computer, for example, a forklift accidentally running into the PC, which would cause them to lose control.

Since the PLCs used IP connections and the HMI was easily converted to a SCADA host with the HMI client, it was straightforward to move the SCADA/ HMI to the IT data centre. This data centre is located at the headquarters of the company and was installed on a dedicated server. In the process of migration, the single-user HMI station was simply converted to a multiple -user SCADA system so that the maintenance team had access to the same information that the operations team was seeing.

With virtualization technology, it is not necessary to have the dedicated machine in the data centre. This is now becoming increasingly common as supervisory vendors make the necessary adjustments to allow both the client and server to be deployed on virtual machines (VMs). The next step in the warehouse migration project was to move off the dedicated server and onto a VM. The rational for the second move was that it is possible to restore a VM from a backed up version in approximately 15 minutes. In the data centre, IT had a common process to continuously backup the VMs on a frequent basis. For this customer, this was preferable to have a redundant backup because it was a familiar process for IT to manage.

This illustrates the growing role of IT in operational

technology ( OT ) deployment. While some aspects of managing IT versus OT have different primary objectives, there are other aspects where IT best practices will benefit OT managers working in collaboration with IT, which includes developing a robust cybersecurity culture.

For IT, business risks are mainly related to the confidentiality and integrity of data processed and hosted by IT systems, which leads to intangible consequences, such as loss of know-how and loss of reputation for the enterprise. For OT systems, business risks are related to the availability, integrity, reliability and safety of the industrial control system itself. Risks include operational consequences in the physical world, such as production shutdown and financial losses, environmental damage and the inability to control the process or to obtain accurate information about its state.

Further collaboration and development of appropriate common practices and shared principles are the hallmark of top performing companies and has been enabled by the advancement of OT architectural thinking.

What about the public Cloud? While the technology is the same, the grocery store did not want to risk losing the system if access through the Internet service provider was lost. It was also concerned about an architecture requiring the use of the Internet to connect the PLCs to the SCADA host. The concerns were both from the perspective of latency and reliability. In some cases, data privacy is also a concern with having third-party hosting of the operational data. In this case, that was not a concern.

In a second example, the public Cloud is the ideal place to host the SCADA server. PcVue have worked with a service provider

who deployed SCADA software on Amazon Web Services. In this case, the architecture consists of a private Windows Server running on a VM connected via a Distributed Network Protocol (DNP3) to devices that are strategically and, in some cases, very remotely located to provide real-time views of the voltage across a network of high voltage transmission lines. The DNP3 protocol is used to connect to monitor and control electrical devices and is very heavily used in North American substation automation.

In this case, the connection was made by creating a VPN running over satellite links to some very remote locations, far from the substation. The ability of the utility to monitor the transmission line voltage in real time offers great value. The satellite connection may have latencies that aren’t appropriate for substation automation, but when compared to putting a data logger on the transmission line in the field and collecting the data a week later, it is fast enough.

The utility could access the data with the HTML browser and a connection to a public server providing Remote Desktop Services (RDS) for each user. The RDS server runs on a VM connected to the data acquisition server through another VPN.

What is significant about these examples is that public and private Cloud architectures can both be the right choice for SCADA but one size does not fit all. In 2017, a lot of

discussions focus on the Industrial Internet of Things (IIoT) and Industry 4.0. While Industry 4.0 goes beyond the scope of operations, within the OT space both concepts are driving toward Cloud-based solutions. In the past few years, the focus of discussion on IIoT is increasingly on data acquisition and Big Data analytics rather than supervisory control.

In 2014, it was difficult to find a real consensus of what IIoT is and what the architecture for it would be. Over the past three years, a common architecture has emerged — one in which field sensors are connected to gateways that move the data to a public Cloud where it is analyzed and individuals or software packages may access it with standard APIs, but not yet standard protocols. New low bandwidth networks are emerging from companies and alliances, and LTE and 5G cellular providers. What they have in common is the expectation that data rates will be slow — updating once a day or once an hour. Most are priced on the amount of data transmitted to the Cloud.

For many SCADA and BMS applications, this allows for sensor integration that was not previously possible in the past. For example, a private LoRaWan network can be constructed to integrate IIoT sensors without going to the Cloud but rather by directing the data from the gateway directly into the supervisory system.

In the parlance of the IIoT, this is known as edge computing, as in the

edge of the Cloud. The term Fog computing was coined to recognize that some data treatments and response needed to be done near the process rather than from the Cloud. In the previous examples, the control of the warehouse was essentially Fog computing even though it didn’t make use of IIoT sensor data acquisition. The second example is clearly Cloud computing.

Wikipedia defines Fog computing as “providing location services and service quality for real-time applications and streaming. It also permits a bigger heterogeneity since it is connected to end-user devices and routers. The applications can include industrial automation, transportation and networks of sensors.” To most control engineers and SCADA vendors, this sounds very familiar.

Due to the enhanced connectivity of these systems today, improving cybersecurity has become an equally important goal.

As we develop the language of IIoT and incorporate it into the supervision of industrial processes, infrastructure, buildings, utilities and other common SCADA verticals, it is clear that there is no one solution that fits all. Software vendors who supply platforms for SCADA, HMI and BMS will need to continue to be flexible and scalable in terms of supporting various architectures for deployment, including Fog and Cloud computing, and incorporating IIoT data accessible from the Cloud and private IIoT networks which collect IIoT sensor data directly from a gateway device at the edge.

The location services aspect of Fog computing is essential to delivering the exponentially increasing data in a meaningful and actionable way to users of the supervisory system. A secure contextual mobility server –which may be Fog or Cloud hosted – that utilizes location services and user profiles to deliver intelligent data to the mobile devices of operators and maintenance teams, based on the user’s job responsibilities, is essential in driving down costs and increasing the efficiency and reliability of supervisory control for smart buildings, smart grid and emerging Industry 4.0 evolutions. | MA

Ed Nugent has 24 years of experience with SCADA development and implementation and is currently the chief operating officer for PcVue Inc., www.pcvuesolutions.com, a global independent SCADA/ HMI provider. His career has spanned education, engineering and management leveraging a passion for capturing and communicating the business value of measurement and control technology.

Mettler Toledo Process Analytics has launched a new version of its multi-parameter M400 transmitter series for process analytics applications. The updated version features a combined touchscreen and tactile soft-key user interface, says Mettler Toledo, adding that the high-contrast screen permits viewing in all light conditions and the soft keys allow for operation even if protective gloves are worn. The series is compatible with analogue sensors and Mettler Toledo’s digital Intelligent Sensor Management (ISM) probes. ISM includes sensor diagnostic tools that can be displayed on the M400 and accessed remotely via asset management software. The HART communication protocol provides integration of the diagnostics into process control systems. In addition, ISM sensors can be calibrated away from the process in any convenient location, then connected to the M400 which will set itself up appropriately, says the company. A software tool supplied with the transmitter enables configuration of the M400 via PC and USB stick, which can then be shared among other M400s. www.mt.com

Beckhoff Automation has integrated HART protocol functionality in its TwinCAT automation software and I/O system hardware. PC-based control from Beckhoff integrates process-specific protocols and interfaces by offering an extended range of products for hazardous areas, says the company. Full implementation of HART functionality, both in the I/O system and in the TwinCAT engineering environment, provides “simple project planning and reliable commissioning,” it adds. TwinCAT software aims to reduce development efforts in process technology because

it facilitates the application of comprehensive HART functions directly from the engineering interface. As such, the TwinCAT FDT container enables implementation of any field device drivers (Device Type Manager), says Beckhoff, adding that an entire HART configuration can be implemented using a single software tool.

www.beckhoffautomation.com

Antaira Technologies has added the LNX-1002G-10G-SFP gigabit 10-port unmanaged switch with 10G SFP+ slots to its industrial networking infrastructure family. The LNX1002G-10G-SFP is an industrial-grade model that is Ethernet-ready to fulfill various networking applications in harsh and outdoor environments, such as manufacturing automation, security surveillance, power/ utility, water wastewater treatment plants, oil/gas/ mining, and transportation. The device, according to Antaira, supports high density Ethernet port connectivity, 10G fiber backbone and long-distance data transmission. The series has an IP30-rated metal casing design that has DIN-Rail or wall mounting support, and provides a dual redundant power input range of 12 to 48VDC with an overload current and reverse polarity prevention. Additionally, there is a built-in relay warning function to alert maintainers when power failures occur. The unit measures 54 x 99 x 142 mm and has a unit weight of 3.0 pounds. www.antaira.com

has announced the digiVIT digital variable impedance transducer, boasting a new user-friendly graphical user interface for easier setup and connectivity, and Cloud-based data access and monitoring. According to the company, the digiVIT offers an array of networking capabilities ideal for Industrial Internet of Things (IIoT) applications, and is suitable for position, vibration and proximity sensing, part sorting, process control, laboratory testing, engine dynamics testing, condition monitoring and more. Kaman describes the digiVIT as the most advanced digital signal conditioner for non-contact linear position and displacement sensing available on the market. It is a self-configuring system, it says, capable of performing with nearly any sensor as well as any conductive target. The transducer also features pushbutton calibration,

temperature compensation, and zeroing. The digiVIT offers scrolling menus for set-up and calibration, as well as Ethernet communication capabilities. In addition, it is capable of detecting when no sensors or shorted sensors are present, notes the company.

www.kamansensors.com

Omnitron Systems, a provider of fiber connectivity products, has introduced its managed and unmanaged RuggedNet industrial PoE fiber switches and OmniConverter enterprise PoE fiber switches that enable fiber optic distance extension to PoE and PoE+ powered devices. Both the RuggedNet and OmniConverter PoE fiber switches feature four or eight 10/100/1000 RJ-45 ports capable of delivering 15.4 W PoE or 30W PoE+ to all ports, and one or two fiber gigabit ports. They are classified as Power

The Measuring Division of Kaman Precision Products

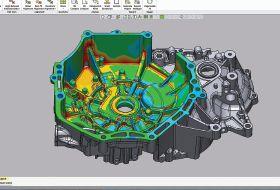

3D Systems has unveiled the latest versions of two manufacturing software solutions: GibbsCAM 12 and Geomagic Control X 2018. Announced at EMO Hannover 2017, the solutions enhance 3D Systems’ manufacturing software portfolio and strive to help customers lower their total cost of operations while maximizing software investments. GibbsCAM 12 features: a user interface designed to increase productivity by 30 per cent; an in-house library of more than 15,000 post processors for machine/control combinations; and Multi-Task Machining (MTM) programming capabilities. Meanwhile, Geomagic Control X 2018 features: a new UI that provides the “fastest path

Sourcing Equipment (PSE) and provide full PoE+ power for up to eight Powered Devices (PDs). RuggedNet industrial PoE fiber switches are standardscompliant network switches that are temperature hardened to -40 to 75 degrees C, and designed for deployments in manufacturing, transportation, energy and IoT applications. They can be wall or DIN-rail mounted, and are powered using external 100 to 240VAC power adapters.

www.omnitron-systems.com

to inspection results”; Scan Processing Automation to help users design and automate scan registration, merging, clean-up and other pre-inspection processes; and Deviation Location to analyze the size, shape and location of deviation groups.

www.3dsystems.com

Rockwell Automation says it wants to help manufacturers make better business decisions by providing easy access

to advanced analytics and operational insights available at the point of production in milliseconds – not hours. The company recently showcased its newest scalable compute offerings at IoT Solutions World Congress in Barcelona, Spain, along with other technologies, solutions and services in an effort to help manufacturers take advantage of the Industrial Internet of Things (IIoT). The new scalable offerings leverage Windows 10 from the edge to the Cloud, integrating the Windows 10 IoT Enterprise operating system with existing manufacturing equipment and software, says Rockwell Automation, adding that they can also connect a manufacturer’s on-premise infrastructure to the Microsoft Azure IoT Suite when needed. www.rockwellautomation.com

With the TERMITRAB complete product range, Phoenix Contact says it now offers the narrowest surge protective devices on the market. They are suitable for MCR applications starting from an overall width of 3.5 mm, which means the devices can protect up to 572 signals against surge voltages on just one metre of DIN rail, says the company. The integrated disconnect device promises safe behaviour in the event of an overload. It signals the status on each individual protective device mechanically without auxiliary power. Optional remote signalling modules monitor the status of up to 40 neighbouring surge protective devices by means of a photoelectric barrier. Phoenix Contact says installation is simplified as a result — no additional wiring or programming is required for the protection modules. The surge

protective devices are available with push-in connection technology as well as screw connection.