pay so much for wire and

Get affordable pricing with no gimmicks or hidden charges

A ordable Cut-to-Length cables with NO hidden fees

Bulk or Cut to Length shipped same day!

Have you ever noticed the other guys’ 30¢/foot cable tripling in cost at checkout?

The reason is some suppliers add cutting charges, other fees and in ated shipping cost, which ends up being not such a good deal after all.

No worries, we’ve got you covered with these AutomationDirect advantages:

•UL certified re-spooling facility - Ensures that our cut-to-length cables maintain the UL certifications

•Low price per foot, starting at 19¢ (Q7120-1)

•Low minimum cut lengths

•Free shipping on orders over $49*

•Same-day shipping (order by 6:00pm ET)*

•Fast and easy online, phone or fax* ordering

•Standard 30-day return policy* (yes, even custom cut cable)

Types of cables available:

• Flexible portable cord

• RS-485 & RS-422/RS-232 cable

• Flexible Control cable

• Power Machine Tray cable

• Variable Frequency Drive (VFD)

• DLO, RHH, RHW-2 heavy-duty flexible power cable

• Instrumentation cable

• Continuous Flexing Control

• Continuous Flexing Tray Rated Control

• Continuous Flexing Motor Supply

• Continuous Flexing Industrial Ethernet Cable

• Continuous Flexing Profinet

• Continuous Flexing Profibus-DP

• Sensor/Actuator

• Control and Signal

• Thermocouple & RTD Extension

Bulk Electrical Hook-up / Building Wire

AutomationDirect also has a large selection of quality MTW, THHN and TFFN electrical wire that meets all NFPA and NEC requirements, at unbeatable prices with FREE shipping (on orders over $49). So, if you haven’t looked at us for your wiring needs, you’re probably paying too much!

• MTW Machine Tool Wire

Primarily used in control cabinets, machine tool or appliance wiring applications. Available in various AWG sizes and colors and in 500 or 2500 ft. reels. Starting at $26.00 (500 ft.)

• TFFN Fixture Wire

Primarily used as fixture wire as specified by the National Electrical Code (NEC). Available in various AWG sizes and colors and in 500 or 2500 ft. reels. Starting at $30.50 (500 ft.)

• THHN General Purpose Building Wire

Use for conduit or cable tray, services, feeders, and branch circuits, including new construction or 600 volt rewiring needs. Available in various colors and AWG sizes and in 500 or 2500 ft. reels. Starting at $52.00 (500 ft.)

Research, price, buy at: www.automationdirect.com/multi-conductor-cable www.automationdirect.com/wire

shipping

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

The

Andy

Establishing

Raven Telemetry employs an AI-based platform to connect operators on the plant floor with senior managers

By Kristina Urquhart

Build a Dream guides young women to careers in manufacturing, automation and STEM while advocating for workplace diversity

By Kristina Urquhart

Industrial automation experts round up their predictions on what technologies may impact factories this year

Compiled by Kristina Urquhart

Collaboration, out-of-box thinking key to success in a highperformance Lean manufacturing environment By Jacob

Stoller

@WatchGuard

In a recent guest column for @ AutomationMag, @XORRO_ outlines four danger zones in the industrial space that #hackers are targeting and how #ITpros can secure them. bit.

ly/3atF7H8

@NanoLockSec

“The most important machines and systems on earth are at risk of attack.” In a new piece @ AutomationMag, our CTO Nitzan Daube shares thoughts on how we can bolster #cybersecurity to protect our critical infrastructures from cyberattacks. bit.ly/2Gh8PBj

@getfreepoint

FreePoint Founder Paul Hogendoorn discusses the challenge of launching new projects: bit.

ly/367G9p3 #Manufacturing

@JoshuaHodgson3

Good news from Ontario: #Toyota invests $2.1M in #automotive engineering at U of Waterloo bit.ly/2Rc8hmt via @AutomationMag

BY KRISTINA URQUHART

It’s the beginning of another new year and while 2020 is getting off to a slow start, orders-wise (see the Canadian manufacturing outlook according to IHS Markit on p. 5), there is much to look forward to this coming decade. If the recent conferences I’ve attended are any indication, more small and medium-sized manufacturers are exploring what automation and digitization can do for them.

The industrial automation market is teeming with solutions to help you digitize your operations, increase production efficiency and reduce waste. There is so much out there, in fact, that if you’re looking to automate processes this year, whether for the first time or to make upgrades, the decision-making might be a bit overwhelming.

Our annual trends roundup is here to help you wade through which strategies and systems are worth looking into. On p. 15, automation experts from three research firms and industry associations delve into which technologies are most relevant in 2020 and beyond (find a bonus one by searching “top 5 trends” on automationmag.com).

Choosing which automation system is right for your operation depends on what your business strategy is and what you expect your return on investment to be. Perhaps your goal is to introduce flexibility, or reduce production bottlenecks, or increase safety measures, or expand your workforce. Or maybe it’s to streamline your warehousing and distribution.

Logistics automation is going to be one of the biggest opportunities for companies this decade. Consulting firm Westernacher estimates that at least 10 per cent of manufacturers in the United States are already using complex,

automated warehouse systems. And in its report “Automation in logistics,” research outlet McKinsey expects warehousing to see significant impact from a number of new technologies, including optical recognition, automated guided vehicles (AGVs), pick-and-place robots and multi-shuttle systems. On p. 11, I chat with Andy Battler, director of operations of the new AGV division at JMP Solutions, to learn more about how this market is emerging in Canada. No matter what type of automation you are considering, it won’t replace your human workforce. In fact, cultivating highly skilled employees is more important than ever, with all of this new automation requiring operators and service technicians. With precious few available to fill those new roles, industry experts are urging manufacturers to look to their existing workforce with an eye on retraining. (For more on that, read trend #1 for 2020 from Eric Cosman, president of the International Society of Automation, on p. 17.)

B ut there’s also the untapped workforce to consider. According to Canadian Manufacturers & Exporters, women make up just 28 per cent of the manufacturing workforce in Canada. Build a Dream, an Ontario-based organization and subject of this month’s cover story, is grooming a generation of young women to explore careers in the skilled trades, engineering, emergency response and entrepreneurship. Founder Nour Hachem-Fawaz and her team are doing wonderful work to bring that untapped workforce to light, and I’m pleased to share their progress on p. 12. Questions, concerns, goals for 2020 – send them my way. And from all of us at Manufacturing AUTOMATION, all the best for a prosperous new year. | MA

@AutomationMag @mfgautomationmag /company/automation-mag kurquhart@annexbusinessmedia.com

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Your resource for Canada’s industrial automation news

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 416-442-5600

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com Tel: 416-510-6757

VICE-PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

MEDIA DESIGNER - TEAM LEAD

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-510-5180

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PRESIDENT & CEO

Mike Fredericks

CONTRIBUTING WRITERS

Jeff Burnstein, Eric Cosman, Paul Hogendoorn, Ian (Hyam) Nicacio, Craig Resnick, Jacob Stoller Manufacturing Automation is published seven times a year by:

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: ugrzyb@annexbusinessmedia.com

Tel: 416-510-5180

Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $43.00 per year

United States — $98.00 (CAN) per year

Foreign — $112.00 (CAN) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2020 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Canadian manufacturers experienced a setback in December 2019 from their previously reported three months’ recovery in manufacturing growth, according to the latest Manufacturing Purchasing Managers Index (PMI), compiled by research firm IHS Markit.

There was a near stagnation of production volumes and a renewed downturn in order books during the latest survey period.

Manufacturers also indicated more cautious staff hiring strategies and efforts to tighten inventory management, which partly reflected concerns about the near-term business outlook. The latest survey signalled the lowest degree of confidence about yearahead prospects for production growth since February 2016.

“Weakness in the investment goods category linked to softer capital spending at home and abroad remained a key factor behind the subdued manufacturing trend,” says Tim Moore, economics associate director at IHS Markit, in a statement. “Consumer goods producers once again fared better than elsewhere in the industrial sector, but even this outperforming area reported a growth slowdown at the end of 2019.”

At 50.4 in December, down from 51.4 in the previous month, the headline seasonally adjusted IHS Markit Canada PMI signalled the weakest overall manufacturing performance since August 2019. The latest reading was only fractionally above the 50.0 nochange mark.

Survey respondents noted that subdued demand across the automotive and energy sectors was a factor weighing on manufacturing order books in December. Some firms also commented on the need to initiate discounting strategies to stimulate customer demand.

Export sales also dropped at the

end of the year, with manufacturers often citing difficulties winning new work in U.S. markets.

On a more positive note, there were a number of reports that demand from China had improved.

Employment levels increased at the weakest pace for four months in December. Softer rises in payroll numbers were partly linked to cost cutting and concerns about the demand outlook.

Manufacturers named to Canada’s Top 100 Employers

Several industrial companies have landed on Mediacorp Canada’s list of the country’s Top 100 Employers for 2020.

The company reviewed the organizational policies of

approximately 100,000 companies through its job-search engine, eluta.ca, and invited about 10,000 employers to submit applications to the 2020 contest, which is in its 20th year.

Employers are graded on eight criteria: physical workplace; work atmosphere and social; health, financial and family benefits; vacation and time off; employee communications; performance

management; training and skills development; and community involvement.

The list of manufacturing and industrial companies named as Canada’s Top 100 Employers includes: 3M Canada, ArcelorMittal Dofasco, BASF Canada Inc., Cisco Systems Canada Co., Danone Canada, Ford Motor Company of Canada Ltd., GSK/GlaxoSmithKline Inc., K+S Potash Canada GP, Kellogg Canada Inc., Labatt Brewing Company Ltd., Laurentide Controls, L’Oreal Canada Inc., Mars Inc., PepsiCo Canada, Procter & Gamble Inc., Rio Tinto, Salesforce, Samsung Electronics Canada Inc., Schneider Electric Canada Inc., Toyota Motor Manufacturing Canada Inc., and West Fraser Timber Co. Ltd.

Anthony Meehan, publisher at Mediacorp, credits improvements in workplace culture to a number of factors. “Technology and globalization have changed the nature of employment and have accelerated the pace at which organizations rise and fall – you need to attract talented employees more than ever to make sure your organization is the one driving change, not the one being driven out by new competitors,” he says.

A new centre in Oshawa is providing skills retraining and employment services for auto parts workers affected by the assembly line closure at the local General Motors plant.

The “action centre” is funded by the Ontario government and independent parts suppliers (IPS) in the area. The centre is open to union members affected by the assembly line closure, including security officers at Securitas and IPS workers at Lear Corporation Whitby, Robinson Solutions, Marek Hospitality, Syncreon, Auto Warehousing Canada, Inteva Products, Oakley Industries

and CEVA Logistics.

The investment includes more than $780,000 through Ontario’s Rapid Re-employment and Training Service, which provides coordinated community response in labour adjustment situations.

The assembly line stopped Dec. 18, 2019, a little more than a year after GM announced it would close the plant, citing market changes and a need to double down on electric vehicle investment.

The plant had been in operation since 1953, and an estimated 2,600 unionized workers have been affected. About 300 will continue work in a section of the plant after GM spends $170 million to transform it into a parts operation.

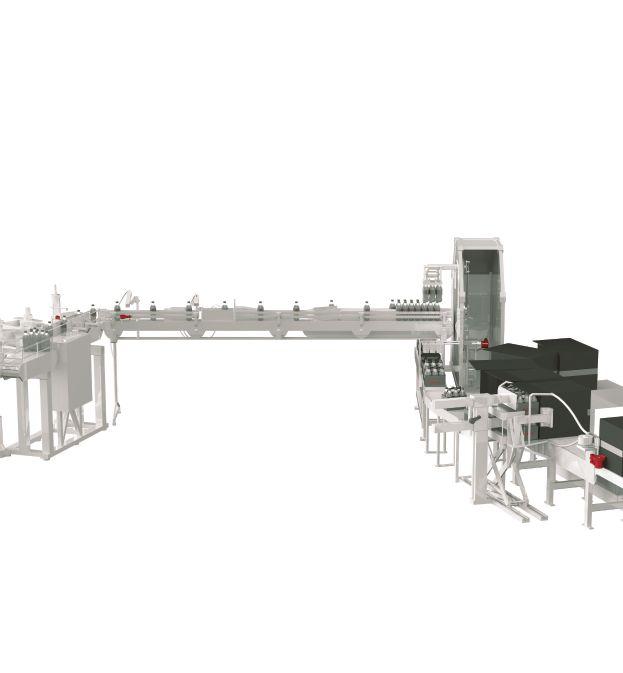

The former Bosch Packaging Technology is now known as Syntegon Technology following the successful sale of the company on January 2, 2020.

Syntegon Technology’s business focus is on intelligent and sustainable technologies for the pharmaceutical and food industries. The company employs 6,100 people at more than 30 locations worldwide and posted 1.3 billion euros in sales in 2019.

The former Bosch Packaging

Technology’s headquarters remain as Syntegon’s in Waiblingen, Germany.

Bosch initially announced the plan to sell its packaging machinery division in 2018, and revealed it would become a newly incorporated entity managed by equity firm CVC Capital Partners in July 2019.

Syntegon developed a new corporate brand over the past few months. The name Syntegon stands for synergy, technology and focus on the future.

The company says that its new corporate colour, green, underscores the importance of sustainability and health. The square in the newly designed logo symbolizes a package as well as packaging technology’s ability to protect products.

“We are building on 150 years of experience and the 64,000 machines deployed by our customers, and pursuing new avenues of business,” says Dr. Stefan König, chairman of the executive board, in a statement.

Syntegon Technology offers material testing, machine applications and packaging.

Manufacturer fined $225K for worker fatality

A manufacturer of pre-finished hardwood flooring in Toronto has been fined $225,000 in Ontario

court after a worker died by getting trapped in a wood-drying kiln at its manufacturing facility.

Satin Finish Hardwood Flooring, Limited (now known as Prodtor Inc.) also received a 25-per-cent victim fine surcharge as required by the Provincial Offences Act. The surcharge is credited to a special provincial government fund to assist victims of crime.

The company’s factory included three large wood-drying kilns made of sheet metal and capable of holding large quantities of wood while it is dried with high heat from a gas-fired appliance.

The kilns are equipped with large hanger-style doors that open to load and unload wood. There are two “man doors” on each kiln, one at the front and one at the rear of each kiln, through which workers enter or exit. The inside of the kilns has no source of either natural or artificial lighting.

A Ministry of Labour, Training and Skills Development investigation found that on December 13, 2017, two workers were asked to fix a malfunctioning damper on kiln #3.

One of the workers had ascended to the roof of the kiln to free up a frozen damper, and the other went into the kiln’s control room. The co-worker descended to the ground level and could not locate the other worker.

The co-worker and a supervisor proceeded to kiln #3 and opened the front man door. They found the worker lying on the floor unresponsive with vital signs absent. At the time, the kiln was operating at a temperature of 149 degrees Fahrenheit or 65 degrees Celsius, with very high humidity. Emergency services were called and attended but were unable to save the worker.

There was a door lock assembly designed to be used to open the front man door either from inside or outside the kiln. In the closed-door position, the lock assembly had a latch that locked the door closed. The lock assembly was functional from outside the kiln, allowing workers to

enter the kiln. However, on the inside there was a push bar (also known as an “anti-panic system”) used to release the door latch from inside the kiln.

The door could not be opened from the inside. Corrosion was observed under the push bar and cracks seen in the body of the man door on the kiln-facing side.

After disassembling the door lock, the investigating engineer noted that an internal component known as a “push pin” was corroded and seized, which prevented the door from being opened with the push bar from inside the kiln once the door was latched in the closed position. The engineer concluded that this was the direct cause of the fatal event, as the worker was unable to open the latched man door and leave the operating kiln.

The manufacturer’s instructions for the door lock assembly outlines routine maintenance on the door lock assembly, including checking for corrosion of metal parts. The defendant did not have a preventative maintenance schedule at the workplace for the door assembly.

The ministry’s engineering consultant concluded that maintenance would have prevented malfunctioning of the door lock assembly.

Universal Robots offers cobots to lease

Collaborative robot manufacturer Universal Robots (UR) has launched a cobot leasing program in collaboration with DLL, a global vendor finance company.

Under the program, manufacturers of any size and with any capital equipment budget will be able to automate without major upfront costs.

“We’re levelling the playing field by enabling all manufacturers to immediately put cobots to work without an upfront capital

investment,” says Klaus Vestergaard, CFO at Universal Robots, in a statement. “The partnership makes it easy to upgrade existing cobots, add additional units or test cobots for the first time – and equips end-users to maximize productivity, quality and profitability, without increasing costs or cash outlay.”

As needs change, customers will have the option to schedule payments to fit fluctuations in cash flow, upgrade to new equipment or add cobots at any time during the contract term.

At the end of the finance term, customers will have the option to buy the equipment for a fraction of the original cost, upgrade to newer technology, extend the finance term or return the equipment.

“The market we operate in is evolving rapidly. Through this partnership we can now offer financial solutions for a wide variety of automation equipment,” says Neal Garnett, president of the construction, transportation and industrial global business unit at DLL. “Manufacturers can build the operations they need to compete and thrive, while people work on strategic tasks.”

UR’s distributor network will work directly with DLL in each country to provide new payment and leasing options for interested customers.

Wajax Corporation has acquired all shares in industrial repair company NorthPoint Technical Services ULC, headquartered in Calgary, Alberta.

The shares were acquired from an affiliate of Denver, Colorado-based Lion Equity Partners for an aggregate purchase price of $18 million.

According to Wajax Corporation, the acquisition of NorthPoint is expected to provide meaningful growth in the corporation’s engineered repair services (ERS) business, which includes Montreal, Quebec–based Groupe Delom Inc., acquired by Wajax Corporation in October 2018.

NorthPoint was formed in 2018 as a national electro-mechanical services provider and serves a broad range of resource and industrial customers.

Specializing in the repair of rotating industrial equipment, including motors, generators, gearboxes, switchgear, transformers, pumps, fans and turbines, NorthPoint operates nine branches across Canada, employs approximately 177 people, and sees revenues of approximately $49.2 million.

ABB Canada has appointed Eric Deschenes as country managing director and head of the electrification business. Prior to joining ABB in 2017 as executive vice-president of the electrification business, Deschenes was most recently North American vice-president of mining, minerals and metals segment at Schneider Electric, where he worked for 15 years in various positions.

Toyota Motor North America (TMNA) has named Frank Voss as president of Toyota Motor Manufacturing Canada (TMMC). Former president Fred Volf, who had worked for the company for 32 years, retired Jan. 1. Voss was most recently the vice-president, administration and corporate secretary at Toyota Motor Manufacturing, Kentucky Inc. With over 30 years of automotive manufacturing experience, Voss will be responsible for all production and administrative functions at the manufacturing facility.

Steven Wyatt has been named as the new president of the International Federation of Robotics (IFR) by its executive board. Wyatt succeeds Junji Tsuda, who served in the rotating post since December 2017. Wyatt is currently global head of portfolio and digital for ABB’s robotics and discrete automation business. Prior to joining ABB in 2010, he worked in a series of executive marketing and sales roles within the plastics industry globally.

INDUSTRY WATCH

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies seven years ago with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at paul.hogendoorn@ getfreepoint.com or getfreepoint.com.

Deadlines can keep you awake at night. Baselines can help you sleep.

Last month, I found myself staring at the ceiling tiles in a sleep lab, listening for a voice to give me a few instructions and tell me what to do. As with many people my age, or people in stressful, mentally demanding jobs, falling asleep at night is not as easy as it once was. In fact, sleeping problems permeate all sectors in our society, from old to young. It is often related to too much mental activity, sometimes to not enough physical activity, and sometimes to too much of one kind of mental activity (perhaps video gaming, for instance). I fit into the first two groups, and, realizing that sleep is critical to my health, I decided to take sleep more seriously.

After a few consultations with my doctor about stress, reducing caffeine intact and putting a more rigid daily schedule in place (establishing what I refer to as a “glide path” – a period where I am very selective with what activities or communications I will engage in), I found myself staying overnight at a sleep clinic for a battery of tests. The series of instructions that came to me over a small speaker in the room went something like this: “Holding your head still, look up and then down, and do that 10 times”; “Look to your left, then to your right, and repeat that ten times”; “Hold your breath and count to 10”; “Take 10 big breaths through your nose only and then 10 through your mouth only”; and on it went until the last of the instructions: “Make three snoring noises.”

As I lay there staring at the ceiling, while listening for the next instruction, it occurred to me that what they were doing was exactly what I have been encouraging manufacturing companies to do for the last few years, and that is to establish a baseline to be able to know what “normal” looks like. They were going to be monitoring my eye movement, my breathing and other normal sleep activities, so that they could look for anomalies and abnormalities while I slept. But, they wouldn’t be able to do that without knowing what “normal” looked like, and knowing in an

empirical and objective way. With the help of small sensors glued to different parts of my face, and the small series of breathing and eye movement instructions, they established a baseline of “normal” for me, and that is important because every patient is unique.

The key to being able to know where you are, and if you are moving forward or backwards, is having an accurate baseline against which you can measure.

The same is true for manufacturers. Every company is different, with different rhythms, cadences and processes. As much as we try to establish a standard of “normal” across a wide variety of industries or factories, what is normal for one is not normal for others. The key to being able to know where you are, and if you are moving forward or backwards, is having an accurate baseline against which you can measure. It should be granular, empirical and relevant. Granular means it should be recorded minute by minute, or perhaps hour by hour, not day to day or month to month. Empirical means it should be measured automatically, without interpretation. And relevant means it needs to be associated with only value-adding functions and activities – the actual activities and processes that make the company money minute by minute, or hour by hour.

On the plant floor, it is not difficult to know where to put the sensors. Every value-adding activity likely has a simple actuation that is easy to monitor; a press cycle, a spindle on, an arc present,

a pressure present, a through-beam interrupted. Simply monitoring that condition on every machine would be like putting a Fitbit on every machine, letting you know, minute by minute, or hour by hour, which of your critical processes are healthy, and which ones are not. The goal is not to know every vital statistic or parameter of the machine or the process, but just to know if it is healthy or unhealthy. And to know that, if it’s healthy or unhealthy, all you need is to know what normal looks like, and that’s why you need to establish your baseline. Measuring for even just 30 days (granularly and empirically) is enough to establish a solid baseline, which you can then use to discern a machine or process’s health in real time. Keep in mind that broader goals and metrics, such as productivity or profitability, are only general indications of the state of your company’s overall health. If one or several critical processes started to falter, it would take a long period of time before it affected the general overall metric that you were limited to watching. Knowing in advance that things were changing, giving you the opportunity to address them and correct them before they affected the company’s overall health metric, would be an incredibly valuable insight to have. And, my guess is, it would help you sleep better at night, too! | MA

BY IAN (HYAM) NICACIO

Canadian manufacturing companies are adopting digital technologies as they aim to transform their businesses. However, in the race to achieve operational excellence and boost profit margins, companies must not forget the basic principle: employee wellbeing and safety is essential to any successful operation.

With 951 fatalities and 251,625 workplace injuries reported in Canada in 2017, the need to foster a culture of employee safety in the Canadian workplace is evident.

Keeping employees safe on the job should be the highest priority for any organization. It’s the right thing to do and can also improve your bottom line, because a safe manufacturing operation is also a productive one. If the right steps are taken, it can be a source of savings for companies by limiting production downtime, reducing worker time off for injuries and avoiding ministry reviews.

The key is to track and use meaningful data to enhance workplace safety.

Tip 1: Capture and analyze data effectively

Some of the common health and safety data organizations collect are the number of incidents, type and frequency of accidents, injuries and ill health.

In addition to tracking injury categories such as “date” and “injury severity,” companies should also consider tracking specific categories such as “time of day,” “shift,” “supervisor name,” and “body part” – with further detailed drop-down options such as “left shoulder” and “right eye.”

M any organizations don’t capture specific data points, and ultimately fail to fully realize the potential of the information at their disposal. Often, the reason

for this is these data points are stored in different systems, exist in “silos” and aren’t used for insights or analytics. Many health and safety managers also feel their collection and analysis is either too time consuming or expensive – all of which are myths.

Tip 2: Keep it simple

Any organization can effectively track and collect data but if the acquired data is complicated, people will choose to ignore the information however valuable it may be.

It’s essential for safety leaders to be comfortable with analytics so they can communicate meaningful data that highlights trends and patterns in company injuries and helps organizations focus efforts where needed. Examples of trends that data can uncover include employee complacency, lack of equipment and carelessness.

Good recordkeeping makes it easier for employers to evaluate the effectiveness of their health and safety programs and can be as simple as an Excel spreadsheet. Additionally, good records may provide evidence to help an employer act before an injury occurs, accurately track injuries over time and respond to worker compensation claims. As an example, at 3M we noted shoulder discomfort at our computer station in a plant so we installed an adjustable desk before it became an injury.

To avoid the hassle of paperwork, organizations could consider using apps to help document and track workplace injuries, frequency of accidents, etc. This is what 3M did in Canada – transition 24 checklist binders into an app. The outcome: safety managers found it easier to document and analyze problems given the app’s simplicity and adaptability.

Tip 3: Create processes that

are easily implemented

Regardless of what industry you operate in, employees expect a top-down approach when it comes to instilling processes that improve efficiencies, add value and are simple for them to use. Through data-driven insights, companies can create guidelines for taking action that drive operational change, whether it’s about handling new equipment or providing workers with additional training. It also creates the foundation to develop effective safety measures, as there is a better understanding of health and safety hazards in a facility.

Tip 4: Use data to create cultural change

Dissecting data for insights and new processes will not be successful if it doesn’t transform an organization’s attitude towards workplace safety. Organizations must take steps to deliver easy-to-digest

information that can advocate, sensitize and instil key safety values in their workplace culture. Additionally, anticipating and addressing safety concerns ultimately increases trust in leadership when these types of cultural changes are implemented.

Tip 5: Always use the right equipment for the job

Never compromise on the quality of equipment or try to improvise a tool to do a job, as that could prove costly and dangerous. Assess your work processes to identify operational gaps and ensure you get the right equipment to fill those gaps. Employees must receive adequate training to use the equipment.

A s organizations transform their business operations digitally, it is equally important they prioritize the digital transformation of their workplace safety if they really wish to improve their bottom lines. | MA

BY KRISTINA URQUHART

Improving profitability through top-line growth or cost reduction is the priority for any manufacturer, and most collect shopfloor data in pursuit of that goal.

With the advent of artificial intelligence, there has been a glut of applications promising to help manufacturers to analyze data, and then provide insights over time.

Where many of today’s solutions – whether manual or automated – get stuck, says Martin Cloake, chief executive officer of Ottawa-based Raven Telemetry, is in seeing sustained change once production inefficiencies are identified.

“ The biggest opportunity is to eliminate the things that are keeping operators from producing, and it is the support staff whose actions have the biggest impact on changing productivity – the lead hands, supervisors and maintenance technicians,” Cloake says.

Since having a dedicated supervisor or maintenance staff per operator is not feasible, Cloake says support workers often tackle what they can, where they can.

“Effectively, you have supervisors looking for problems. They’re looking for where the biggest issue is and then solving it, but it’s like playing Whack-a-Mole,” he says. “You don’t know which problem is coming up.”

Reports and dashboard analytics may show that actions taken by support staff have had a positive impact, but that’s not what leads to lasting change, Cloake says. “Changes in

behaviour [are] the only thing that will help manufacturers improve.”

Changing behaviour

Cloake co-founded Raven Telemetry with chief technology officer Braden Stenning and president Andrew Blanchard in 2013 to help manufacturers act on their data. They call their artificial intelligence–based platform “augmented management”– it uses tablet computers installed at each process or machine to collect data that is used to guide plant workers to seize opportunities for increased profits.

The tablets interpret online and offline data on metrics such as process health, cycle times and costs, obtained from PLCs, relays, sensors, ERPs and other sources in the plant. Through a simple, user-friendly interface, the system asks operators questions pertaining to their process – initially to learn how the process works, and thereafter only when abnormalities occur.

“We minimize how many questions we ask to operators – and as the system learns, it asks less and less questions and is able to fill in the gaps,” says Cloake.

Using all of this information, the system establishes a detailed picture of the production line. “If you don’t have a true account of what is happening and what has happened, any other step in your process is pointless,” Cloake says. “The challenge here is that the data from the machines and the data from operators is an extremely messy dataset, and there is a real fine line between taking data

and producing nonsense, and taking data and actually getting to the truth.”

As Raven’s technology learns what “normal” for each process looks like, it draws insights over time. For example, it will be able to tell if a particular process is being performed at different rates between operators, or if shift changes take longer at certain times of the day. Cloake says that one of the biggest costs for manufacturers is when an operator is waiting for maintenance to arrive to fix something, thereby stalling production. As a way to guide action, the Raven system will send an alert to maintenance when a process needs immediate attention. But it also gives feedback – it will later notify supervisors whether that maintenance visit had an effect on performance.

Guiding users to taking the correct action is Raven’s sweet spot, and not just for operators. The system benefits continuous improvement teams by overlaying the financial impacts for each production opportunity, and by then identifying which will offer the biggest ROI.

Beavers Dental, a dental-drill plant in Morrisburg, Ontario, saw its OEE move from the high 70s to the low 90s after implementing Raven’s technology, which led to increased output. Before Raven, management had been collecting data and using performance boards on the shop floor to track progress. But with 150 machines and 30 operators per shift, waiting times for support staff had been increasing.

Raven’s system changed how support staff prioritized and responded to situations by pinpointing the root of the problem through real-time operator feedback. The technology also brought gains on the continuous improvement side, identifying variability in regular procedures, including a cleaning process.

“ Based on the data, Beavers brought together a team – a combination of engineers and operations – had a kaizen event and came up with a better approach,” Clarke shares. “We have found that guiding clients to minimize controllable losses is a much more effective way to drive gains than to focus on the metrics.” | MA

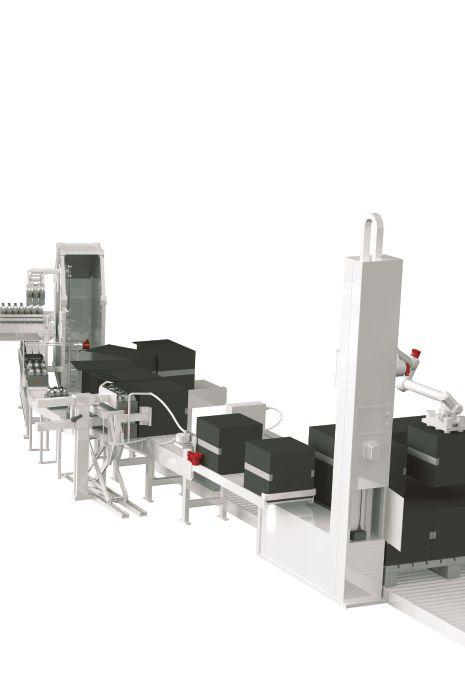

ANDY BATTLER, director of operations, AGV at JMP Solutions, explains why material movement is the next frontier in automation

MA: What automated guided vehicle (AGV) solutions does JMP offer?

AB: We are experts in multiple AGV platforms, so we can help our customers identify the right technology, and the right OEM to provide the technology. Then we will integrate those vehicles or software solutions into existing factories.

There are different technologies out there – there are self-driving, or autonomous, vehicles that don’t need any sort of infrastructure. And there are guided vehicles, which require either laser guidance or inertial guidance – so magnets on the floor or magnetic tape. We can work with our customers to identify what the right solution is, because there are obviously different price points for different levels of flexibility and complexity.

MA: In what applications might one type be better than the other?

AB: I wouldn’t say that self-driving or autonomous is right for every situation. Typical autonomous vehicles are autonomous mobile robots (AMR) or self-driving vehicles (SDV). Those are unit carriers, so they have a mobile platform. You build an appliance on it, or some sort of lift where we can pick up parts, and then move them to other parts, or to other places. You can’t pick from the floor and you can’t pick from racking. You have to pick from a stand, or some other fixture, so there are definitely situations where you would use guided vehicles versus

autonomous ones. There’s still a pretty clear gap there. Autonomous vehicles are meant for rapidly changing environments; they provide flexibility so that you’re not restricted to a specific path.

MA: What are the benefits of AGVs? Why should manufacturers consider them?

AB: AGVs solve a lot of problems for manufacturers. One of them is resourcing. A number of our customers simply cannot resource enough. AGVs are a way to provide flexibility within the manufacturing environment where typically you would install conveyors or move material from one point in your process to another point – any process that is fixed.

We’re not looking to automate the factory so that people don’t have jobs. Our goal is to help manufacturers increase their competitiveness by implementing technology and different solutions.

MA: What should a manufacturer consider when they’re evaluating whether an AGV is right for their facility?

AB: The company has to be forward thinking in order to go towards an AGV solution.

The company has to consider their existing automation. Are they a fairly technology-driven company? Are they looking for more advanced solutions to increase their competitiveness?

When we’re talking to customers to decide what type of technology they should use, it’s application-specific. If they’re delivering a single part to a single point, that’s a great opportunity for a self-driving vehicle. If they find that they require the flexibility to change their traffic patterns regularly, then that’s great opportunity for self-driving vehicles as well. If they need higher speeds and constant routes, that’s a great opportunity for guided.

MA: How have you seen the manufacturing landscape change over the past few years as a result of AGV implementation?

AB: I don’t mean to minimalize it, but AGVs are really just another evolutionary step in the greater automation or manufacturing evolution. It’s no different than PLCs in the ’60s, ’70s and ’80s, or robotics in the ’90s and the ’00s. AGVs are the next natural step. Material movement in a factory or a manufacturing facility is bound to be automated. | MA

knowledge. Better safety. CMSE® – Certified Machinery Safety

CMSE® – The leading international qualification for machinery safety. With TÜV certificate!

Become a CMSE® – Certified Machinery Safety Expert!

CMSE® is a globally recognized qualification enabling a 360° approach to Machinery Safety.

PILZ has developed with TÜV a four-day training which provides an overall view of the subject of machinery safety and gives to attendees the understanding of safety regulations and standards in reference to existing machinery, as well as to the design and construction of new machinery. The training provides guidance on how to implement the legal and statutory requirements pertaining to machinery.

Our training sessions for Q1 and Q2 2020 Langley, BC - May 26-29

Mississauga, ON - March 3-6 - June 2-5

Don’t hesitate to contact us if you would like to have the full schedule for 2020: canada@cmse.com

BY KRISTINA URQUHART

When Elizabeth Moses, a machinist at Windsor Mold, arrived at St. Clair College in 2016 to the general machinist apprenticeship program, she was looking for a mentor who would help her to navigate the industry – one she had been disheartened about entering as a young female.

In high school, Moses discovered she liked to work with her hands after signing up for a woodworking course. A teacher recognized her aptitude for building and encouraged her to join the school’s FIRST Robotics team. Over the next three years, Moses learned about opportunities in manufacturing automation and determined that she would pursue a career in the trades.

“A lot of people didn’t believe I would be successful as a young woman,” she

says. “The only person who was really encouraging was my teacher. And because of that reason – because he believed in me – I wanted to do it.”

Moses now speaks to high schoolers as an ambassador for Build a Dream, a Windsor, Ontario–based non-profit that brings industry and educators together to inform female students and their parents about career pathways in traditionally male-dominated fields such as skilled trades, STEM, emergency response and entrepreneurship.

“ When I saw young women, I wanted to make sure they heard the message: yes, I believe in you. Yes, you should believe in yourself. And yes, you are more than capable of doing this job,” Moses says. “The support that I didn’t have – I wanted to give it to them. Through Build a Dream, I was able to do that.”

Addressing the skills gap

Moses, who graduated with her certificate of apprenticeship in 2019, steps away from Windsor Mold’s factory

With the “We Can Do It” campaign, Canadian Manufacturers & Exporters is campaigning for companies to hire 100,000 more women into manufacturing by 2023.

floor several times a year to travel across Ontario on behalf of Build a Dream and promote the skilled trades at career information events. She met Nour Hachem-Fawaz, Build a Dream’s founder, when she was recruited into St. Clair College’s general machinist apprenticeship program, which HachemFawaz was heading up at the time.

“[Elizabeth] is continuously trying to encourage more youth to go on this pathway,” says Hachem-Fawaz. “If we really want to get more women into the skilled trades, and if we really want to encourage youth to consider this pathway, we need to have a youth leader [like her] to represent the trade.”

Build a Dream’s mission is two-fold: attracting more women to industry will bridge the skills shortage by tapping into a talent pipeline that is historically underused, and it will boost diversity and inclusion. In addition to the career expos, Build a Dream runs camps and workshops for both the classroom and workplace that aim to increase self-esteem and encourage teamwork while introducing young women to new technologies.

“Build a Dream starts the journey early,” says Hachem-Fawaz. “If young women are making career-informed decisions, then they can lead their lives into high-paying jobs that are in demand and have security.”

Hachem-Fawaz began her career helping women on the path to job security while working at Women’s Enterprise Skills Training of Windsor (WEST), a non-profit committed to equipping women – particularly marginalized women and youth, who face more barriers in the workplace – with the training and employment tools they need to enter the workforce.

In 2012, recognizing an underrepresentation of women in the trades sector, WEST conducted more than 500 interviews and surveys to uncover what factors influence the career decisions of female students. “What we found was that young women still felt that certain jobs were very male-dominated, and they based their career decisions on where they saw themselves as females,” says Hachem-Fawaz. “Gender was a huge factor.”

Parents ranked highly on the list of influences, as did teachers and support staff. If a student’s parent worked in the trades or emergency response, she had a higher likelihood of entering those industries herself.

Build a Dream is born

That early research into the role of parents in their daughters’ career choices was the foundation of Build a Dream, which started as a one-off information event on STEM and trades roles at St. Clair College, presented by WEST, the University of Windsor, Workforce WindsorEssex and several local school boards.

The ability for parents to hear directly from industry and female leaders made the event a success, says Hachem-Fawaz. “Ultimately, when we talked to parents, what they really wanted was that security – that if their daughter went into a field a) there would be opportunity, b) she’d be accepted, and c) that it would lead to financial success for their child.”

Hachem-Fawaz registered Build a Dream as a non-profit in 2017, and began holding events across Southern Ontario. The organization now hosts career information sessions in 10 Ontario cities, with over 10,000 attendees annually and more than 200 exhibiting companies. There are plans to expand the brand into Alberta this year.

“ We’re just one of the many touch points young women need,” says Hachem-Fawaz. “[We] take the intimidating factors out and build their confidence, so that once they get to that significant decision – whether it’s going to post-secondary, going into an apprenticeship or going straight into industry – they feel confident enough that they have the knowledge and the skill to pursue this opportunity.”

With the Windsor-Essex region located in

Southern Ontario’s manufacturing corridor, Build a Dream is well connected to industry and sees partners such as Linamar, Windsor Mold, CenterLine, Reko, and Laval Tool and Mold at its area events.

The organization has pledged its commitment to increasing female representation in the workplace as part of the Canadian Manufacturers & Exporters “We Can Do It” campaign promoting the Women in Manufacturing program, which advocates for industry to hire 100,000 more women by 2023. (Women currently comprise 28 per cent of the manufacturing workforce in Canada.)

At every Build a Dream event, a FIRST Robotics team showcases an automated

application to demonstrate how STEM education is used in practice, and to help young women visualize themselves in tech-centric roles.

Hachem-Fawaz has been working with FIRST Robotics since 2015, when she judged one of the organization’s Windsor-area competitions. She noticed that while female students were indeed represented on the participating teams, they were only filling the marketing or business roles instead of the STEM-related ones.

So in 2017, along with long-time FIRST Robotics volunteer SheriLynn Koscielski, Hachem-Fawaz launched Windsor’s first all-girls robotics team with a roster of female

During a diversity consultation, “we will never, ever tell a company, ‘Change your qualifications. Or, change the way you assess,’” says Nour Hachem-Fawaz, founder and president of Build a Dream and the Workforce Innovators Network (see p. 14). “What we say is, ‘Change the lens that you look through for assessing.’ Or we encourage a different approach in trying to recruit certain candidates.”

True transformation usually requires the help of a dedicated diversity or HR officer, but here Hachem-Fawaz shares some quick tips on how to increase inclusivity on the shop floor.

1. Consider the language of your company policies.

One client asked Hachem-Fawaz if they should implement a policy for women who needed to start their shift late because of daycare drop-off hours. “You need to have a family policy,” she says. “Childcare is not a women’s issue – it’s a family barrier, because both men and women will put their child in daycare.”

2. Review your public-facing assets. Hachem-Fawaz says she often hears from women that have trouble picturing themselves in STEM or trades roles. Start by auditing the images on your website. “If they’re all [pictures of] men, and then I look at the management team and it’s all men, and I look at your board of directors and it’s all men, then I’m automatically not

going to see myself reflected in your industry,” she explains. “So [as a female candidate] I’m likely not going to apply.”

3. Evaluate your recruitment methods. If you’ve used the same network for years to recruit for jobs, it’s time to get out of your comfort zone, Hachem-Fawaz says. “If you’re asking the shop floor, which is predominantly men, to recommend people, you’re likely not going to get a female recommendation.” Try a recruitment agency, or post on industry groups on LinkedIn – and review that job posting for inclusive language.

4. Build industry partnerships. Take stock of all of your partners – and if you don’t have any, start thinking about recruitment agencies, colleges with vocational training, universities with engineering programs, or government-funded programs for women in career apprenticeship.

5. Forgive yourself, and learn along the way.

Hachem-Fawaz says that in most cases, companies are not exclusive to women on purpose. “It’s an unconscious gender bias. You don’t know what you don’t know,” she says. When Build a Dream works with corporate clients on creating diversity policies, management is usually keen to understand how they can improve workplace culture and in turn operational performance by diversifying their workforce. “They’re very sincere in wanting that support, so that they can begin to transform therein.”

mentors. “I [thought] that’s what it’s really going to take to get more women to see themselves in the actual building and designing of the robot,” she says. The team, called the Builda-Dream Amazon Warriors, has since enjoyed considerable success – they advanced to the FIRST Robotics World Championships the following year and continue to compete.

O ther initiatives in the Windsor-Essex region are popping up to draw more women into manufacturing. In late 2019, Automate Canada, the industrial automation arm of The Canadian Association of Mold Makers (CAMM), announced a partnership with WETech Alliance, the region’s entrepreneurship accelerator, to launch the Innovation Catalyst Cohort. For the next four years, the program will bring women working in industrial automation together for six-month stints to solve real-life business challenges.

The innovation program is supported by the Windsor-Essex Economic Development Corporation, which in August 2019 received $692,000 from the federal government to assist female entrepreneurs in scaling their businesses in “emerging technology sectors” (such as automation and automotive), in an effort to boost the number of women-owned SMEs in Canada up from 16 per cent.

Hachem-Fawaz’s mother was one such entrepreneur, who re-entered the workforce to sell automotive parts to the aftermarket after 18 years of caring for her children. “When my mom first went into the workforce, she had never finished high school,” says Hachem-Fawaz. “I saw how she persevered through all her challenges, and then entered an industry that was very male-dominated.”

Seeing her mother’s story reflected

in the women she has encountered throughout her career is what HachemFawaz says drives her work with Build a Dream.

“I made it my commitment and purpose to really break down those barriers for women, because I feel that financial independence not only builds economies and builds families, but allows women to have the power of choice,” she says. “To have power in your own choices for your future is so key to living a successful, prosperous, healthy life.”

Diversity and inclusion: the bigger picture

In 2014, while working at Women’s Enterprise Skills Training of Windsor, Hachem-Fawaz helped to secure a government grant for a program at St. Clair College that would train women as industrial mechanics and millwrights for work placements that could lead to permanent roles.

She started working at the college full time to manage the training program and, while soliciting companies to participate, found manufacturers were interested in the program because it would provide them fully trained apprentices at no cost. Several told her they would hire more women, as long as they had the correct skills and training for the job. In practice, Hachem-Fawaz found that wasn’t always the case.

After coordinating training for 25 women, who spent 18 weeks on the shop floor with college instructors to prepare for a 12-week paid placement, Hachem-Fawaz approached the same employers. “And then some of the excuses started coming up,” she says. Some said they didn’t have female washroom facilities, expressing trepidation about how a female on the shop floor might affect existing policies and

procedures.

“ They started asking some really tough questions, but they were questions that I think are very important for us to address because they’re not the only ones thinking about it,” she says. “‘What if she goes on maternity leave?’ Or, you know, ‘Childcare doesn’t start till 8:30; my shift starts at seven.’ How do I overcome these barriers in getting more women into industry?”

The challenge, Hachem-Fawaz found, was that small- and medium-sized companies often don’t have a human resources department to handle such policy changes. “For them to say, ‘Okay, I’m going to drop everything I’m doing and now focus on diversity and inclusion while trying to meet my bottom line’ is going to be very difficult,” she says.

As a result, she became a de facto diversity officer, working with the companies participating in the placement program to appropriately onboard their new female employees and to develop diversity and inclusion plans for future hires.

Now, with Build a Dream, HachemFawaz is continuing the diversity work. In October 2019, the organization launched the Workforce Innovators Network, a platform offering speakers, workshops and business consultations to assist companies in creating inclusive practices for talent management.

“ We really wanted to – through a grassroots initiative – address the underlying barriers facing women in work, and how we define women in the workplace,” says Hachem-Fawaz of Build a Dream’s expansion. “If you’re saying you want to tap into the other 50 per cent [of the talent pipeline], your approach must change of how you traditionally do recruitment or advancement in your own industry.”

Some of that legwork should be the responsibility of government agencies, she says, through the funding of awareness campaigns on both of the issues that drive Build a Dream: attracting more women to industry, and helping companies to diversify their workforce.

“We’re beginning to see a shift,” she says. “[D&I] needs to be embedded into companies’ organizational culture, from recruitment, to HR, to retention.

“Advancing women in the industry is going to really be key to growing.” | MA

Industrial automation experts round up

COMPILED BY KRISTINA URQUHART

It’s a new decade, and a good time to start thinking about moving on from any legacy systems that may be lingering in your plant. Digital transformation across factory hardware, software and other systems is at the forefront of our automation experts’ predictions for 2020, as are the skills gap, supply chain management and security. To compare them to prior years’ predictions, check out our digital archive at automationmag.com/digital.

Craig Resnick, vice-president at ARC Advisory Group, supports both automation supplier and financial clients. He has more than 30 years of hands-on experience in marketing, business development and strategic planning. Resnick graduated from Northeastern University with an MBA and BS in Electrical Engineering.

The edge of industrial internet-enabled architectures is becoming increasingly important, largely due to their often-critical role in determining the success of digital transformation strategies. Solution architects now rely on the edge not only for cloud integration, but also as a solution to address manufacturers’ concerns in areas such as latency, security, cost containment and isolation for production environments. Edge computing applications –particularly high-value analytics and artificial intelligence (AI) delivered via machine learning (ML) – allow data to be processed near its source. Recognition of the rising importance of the edge will be reflected in the spike of investments targeted at this space.

IT and OT suppliers alike are introducing new Industrial IoT edge hardware, software and solution offerings – what we call “Industrial IoT Edge 2.0.” This will place greater emphasis on turnkey solutions that address specific outcome-oriented use cases, shifting away from a simple “run the operations” mentality to use of real-time data analytics to rethink competitive fundamentals.

2.

While manufacturers ramp up to meet demand for the growing “smart product” market, they are facing challenges developing and manufacturing new and more complex products and systems. These require tight integration between the computational (virtual) and the physical (continuous) worlds. To meet these complexity and integration requirements, there will be more cyber-physical systems deployed using advanced simulation platforms that validate product and design in the physical world.

Cyber-physical systems are an engineered system or mechanism that is controlled or monitored by computer-based algorithms and is tightly integrated with both the Internet and its users. In cyber-physical systems, physical and software components are deeply intertwined and get much of their intelligence from the use of AI and ML. Factory production lines will depend on cyber-physical systems to self-monitor, optimize and run autonomously. In the future, cyber-physical systems will rely less on human control and more on the AIenabled core processors.

3.

Advances in hardware, software, networking and security, along with increasing global competition and cybersecurity risks, will accelerate the development of open process automation systems, driven by the collaboration of users, such as ExxonMobil, Georgia-Pacific, Linde and others. These companies are members of the Open Process Automation Forum (OPAF), established by The Open Group for identifying standards to be used for technology and systems. The goal of this collaboration is to accelerate creation of a standards-based,

open, interoperable and secure automation architecture that addresses both technical and commercial challenges of current systems. A recently developed test bed for use by the collaboration partners will act as the foundation for testing the performance and operation of individual components and standards. The results from the test bed will be shared with all collaboration partners and create a foundation for the development for future solutions.

4.

Digital transformation is pivoting from “digitization” to “digitalization technologies.” Digitization focuses on technology and infrastructure, and involves creating digital versions of previously analog data, such as replacing paper-based work orders with digital work orders. It involves replacing legacy analog technology with digital technology, such as the transition from analog field instrumentation and control systems to digital.

However, digitalization involves using digital data and technologies to improve business or work processes. For example, using data from a digital work order to improve maintenance work processes and execution, or using digital twins to improve asset information and/ or engineering processes. Digitalization uses digital technologies and data to improve the way people work, collaborate and get things done within a plant, across a company or the value chain by using, for example, augmented reality (AR) for assembly and maintenance, and virtual reality (VR) for training and simulation. Successful digital transformation does involve both digitization and digitalization.

5. Applying engineering to industrial cybersecurity

Industrial systems share many of the same vulnerabilities and are subject to the same threats. However, the consequences may be very different and, in some cases, more severe. This makes cybersecurity an imperative for the asset owner, who ultimately must bear the consequences of an adverse event. The threat is ongoing and evolves constantly, so cybersecurity should not be viewed as a one-time “project” with a defined beginning and end. Since there is no such thing as being fully secure, the preferred approach should be ongoing, similar to the approach used for safety, quality and other performance-based programs. Similarly, it is not sufficient to focus on specific elements. Instead, asset identification and management, patch management, threat assessment, and so on are all parts of a broader response that must address all phases of the life cycle.

“Collaborative applications are encouraging more small and mediumsized companies to automate – companies that have never automated before.”

Jeff Burnstein is president of A3, the parent group of the Robotic Industries Association (RIA), AIA – Advancing Vision + Imaging, and the Motion Control and Motors Association (MCMA). Together, these trade groups represent some 1,250 global companies involved in robotics, vision, motion control and motors and related automation technologies. Burnstein joined RIA in 1983 and has held a variety of senior positions, culminating in his promotion to president in 2007.

1. Increased use of AMRs in manufacturing and logistics

Autonomous mobile robots (AMRs) are the latest innovation that have been transforming traditional robot tasks through increased flexibility and diversified applications, including their ability to navigate in an uncontrolled environment with a higher level of understanding. As e-commerce expands, there’s a greater need for rapid fulfillment. It’s hard for companies such as Amazon and Walmart to hire enough people to ensure consumers get their products on time, especially during the holiday season. The growing demand can’t be met without automating. AMRs also keep the supply chain moving faster in manufacturing facilities, and are playing an increasing role in retail environments for tasks like shelf scanning and floor cleaning. The RIA is developing a new standard to address all aspects related to the safety of people around AMRs. The R15.08 American National Standard for Industrial Mobile Robots and Robot Systems – Safety Requirements, will be released in 2020.

2. Expanded use of machine vision

Traditionally, machine vision was thought of as primarily a technology for tasks like inspection and identification. However, vision now plays an expanding role in all fields, enabling all sorts of interesting new applications. Embedded vision is bringing a whole new range of capabilities to existing products, combining both image capture and

image processing into one device. Embedded systems are lightweight, consume lower amounts of energy, feature lean designs, and create opportunities for new functionality, making them perfect for integration with existing systems, as well as products such as mobile phones and computers. Vision also is enabling advances in driverless cars, drones, and even in shopping, with the advent of stores like Amazon Go.

3. New applications for robotics enabled by AI Solutions leveraging the power of artificial intelligence (AI) are already paying off in automation and manufacturing. We expect to see many advances in the year ahead, especially related to robotics. Machine learning software can help robotic systems adapt to their work environments, rather than designing every aspect of the environment and processes to suit the limitations of the machines. These advances will enhance both productivity and safety, and lead to more applications involving true collaboration between humans and robots. With more and more connected systems featuring advanced sensor technology, AI can identify patterns in the data that are associated with breakdowns and other mechanical issues. This data will drive predictive applications, where AI can detect patterns that indicate a robot needs maintenance soon. It can automatically alert engineers to take necessary steps towards repairing a machine before it breaks down, saving companies costly downtime. We also see machine learning being used by robots to teach themselves how to perform tasks more successfully.

4. Grasping advances

End effectors are the ultimate touch point for every product or part that goes out the door. Hardware and software advances enable safer, closer human-robot collaboration, ease of use, and flexibility for handling a wide variety of shapes and sizes. To date, the challenge has been developing gripping solutions that are fast, don’t require lots of training, and can be used on any product, even ones the robot hasn’t seen before. This will lead to the use of robots in areas where they’ve rarely been used, such as food processing or mobile manipulation in warehouses.

5. Growth of collaborative robot applications

Collaborative robot applications are gaining in popularity, and are often the entry point for new robotics users. Collaborative applications are encouraging more smalland medium-sized companies to automate – companies that have never automated before and see these specialized applications as an opportunity. From small job shops to major aerospace companies, new uses for collaborative robots are popping up. These robots hold the promise of being easy-touse, quick to set up and deploy, low cost, and safe for people to work around (meaning less floor space is needed and reduced investment in systems integration and safeguarding). According to the International Federation of Robotics (IFR), collaborative robots make up just three per cent of the current installed robot base around the world, but are likely the fastest-growing segment of new robot sales.

Eric C. Cosman is the 2020 president of the International Society of Automation (ISA), which was founded 75 years ago. He is a retired engineering solutions architect with The Dow Chemical Company in Michigan. His responsibilities included system architecture definition and design, technology management and integration planning for manufacturing systems globally.

Much has been said and written about the “greying” of the workforce and the challenges faced by industry as members of the baby boomer generation retire. We are approaching the peak years of this trend, and while the challenge is real, so is the opportunity.

Senior members of the automation profession should take every opportunity to establish mentoring relationships with their younger colleagues. This preserves valuable experience and expertise, and it offers the baby boomer generation a chance to give back and stay engaged. More attention must be given to tools, techniques and processes for effective knowledge transfer while respecting the fact that younger professionals can bring different perspectives to solving common problems. Every organization should have a strategy for adapting and optimizing their environments to leverage one of their most critical assets – their people.

2.

While digital transformation has been cited for years as an emerging trend, this time, we’re not referring to the technology itself as much as we’re referring to our ability to use it wisely. The term “digital transformation” has become so pervasive in recent years that it has become something of a meme. As is so often the case with memes, interpretation and definition are dependent on context. In the case of automation, it generally refers to the application of digital technologies to increase the value of industrial processes. Unfortunately, new technologies often emerge much faster than the level of understanding of how to best apply them. Asset owners are faced with significant challenges in determining the current state of their processes and equipment, but also in understanding how to select the technologies that have the highest potential for increasing value with minimal cost and disruption. Automation professionals must supplement their focus on what technologies are available with increased emphasis on understanding current processes and determining the best choices for each situation. Many asset owners do not have the resources or expertise to do this for themselves, which increases dependence on expert consultants.

Automation professionals have experienced a shift: from a world where data collection was costly and time consuming, to one where the sheer amount of freely available data is almost impossible to deal with. Data has gone from being expensive to being essentially free, and the new challenge is selecting the data that can significantly improve operational efficiency and value. In many cases, the approach has shifted from using process analysis and first principles

models to more empirical methods. Beginning with the use of tools such as neural networks, this has evolved to increased use of analytical tools to develop empirical models for process improvement. Again, the trend on the horizon isn’t necessarily the development of new technology; it’s the application and optimization of the technology we’ve already developed.

Automation systems were originally custom-built for a particular purpose, using specialized tools and technologies. These have now been replaced with complex systems that are assembled using commercial offthe-shelf technologies in areas ranging from operating systems and databases to hardware and networking platforms. Much of the complexity of these systems is introduced in the system integration phase of a project. The result? Asset owners own and operate systems made up of products and technology that they may not fully understand. While it is unrealistic for them to have security, operating system, and network experts in their operating facilities, it is essential for them to understand what components are used in their solutions, how and by whom they were developed, the requirements and constraints used in the design process, and how components were assembled into complete systems. They must understand the solution life cycle from conception and development through integration, installation, operation and maintenance. This requires close partnerships with suppliers and integrators that include clear definition of responsibility and accountability for all parties.

Industry standards have long provided a means of defining the essential requirements and operational characteristics of various technologies. They are often of most interest to suppliers, who wish to develop their products to meet the broadest set of requirements. Unfortunately, defining how a technology must operate and the performance to be achieved is not enough. While standards are often the basis for describing what is referred to as “commonly accepted engineering practice,” they must be supported with practical examples, guidelines and practices that allow integrators and asset owners to apply the technology. Standards development organizations must expand their offerings to include practical guidance aimed at these stakeholders, which in turn leads to broader acceptance and adoption of the standards | MA

BY JACOB STOLLER

Oil and gas doesn’t appear to have much in common with the manufacture of medical equipment, but Edmonton-based LJ Welding Automation, which has roots in Alberta’s energy sector, had just the expertise that GE Healthcare needed to help streamline two key processes in its Florence, South Carolina plant.

The initial project involved the handling and welding of 5.5-tonne aluminum helium vessels that are a core component of magnetic resonance imaging (MRI) machines. The success of this led to a second project involving the design and construction of a universal rounding fixture – a 28-axis forming device that corrects minor deformities in vessels that routinely occur during shipping and handling.

LJ had begun to diversify when its current owners acquired the company in 2006. Because oil and gas is “one of the more technologically advanced businesses,” notes engineer and LJ co-owner Ryan Holt, the company’s specialty – delivering automated material handling and welding solutions for pipes and vessels – has proven to be remarkably versatile.

“ Whether you’re welding a vessel for oil and gas or a helium vessel for an MRI scanner, the same principles apply,” says Holt.

GE Healthcare is a global leader in Lean production methods and applies automation according to Lean principles. Accordingly, instead of asking, “How can we automate tasks done by humans to reduce headcount?” the GE Healthcare production team was asking, “How can automation help us make this a better process?”

In keeping with this vision, the creation of automation solutions at GE Healthcare is collaborative – input is received from all stakeholders, including the operators on the shop floor. “This wasn’t about delivering a shiny product,” says Holt. “These people wanted to own the technology and make it work, and that sets them apart.”

What the GE Healthcare production

team was looking for was a way to create a Lean condition called single-piece flow, where the vessel flows linearly through the welding process uninterrupted, and then, once the welding is complete, exits the process at the opposite end of the work area, triggering the next vessel to be loaded. When flow is achieved, the resulting improvements in speed, quality, safety and cost are often dramatic.

The previous process was executed in two stages. First, the vessel was placed by a crane on rollers, exposing two seam areas, which were welded manually. Then, the vessel was repositioned by crane to give access to a second area where welders completed the remaining two seams.

This extra handling of the vessel

“Instead of asking, ‘How can we automate tasks done by humans to reduce headcount?’ the GE Healthcare production team was asking, ‘How can automation help us make this a better process?’”

between steps was, from a Lean perspective, a barrier to one-piece flow, and the GE production team was looking for a way to eliminate the extra positioning of the vessel.

After a rigorous vendor selection process, GE settled on LJ, working in partnership with gas supplier Praxair. Although there were concerns about working with a Canadian vendor 3,000 kilometres away, LJ’s communication skills won the team over.