Canada’s Top Grower 2024

From the micro and standard LP categories, meet two of the guys helping shape this industry P.10

Left to right: Gerrit Richards, Living Cannabis, Patrick Pagé, Great White North Growers.

AD LUCEM LAW CORPORATION is an international legal and consulting practise based in Vancouver, British Columbia. True to its meaning “to or towards light,” AD LUCEM LAW CORP. brings clarity and resolution to legal challenges in emerging and regulated industries.

AD LUCEM LAW CORPORATION has been instrumental in supporting policy reform, constitutional challenges, and business development since its inception in 2013, earning founder Robert W.E. Laurie recognition as a skillful lawyer, valued industry consultant, and requested public speaker.

COLUMNS

06 | Cultivation

Scaling West Coast greenhouse production with Pure Sunfarms BY ROB BALDWIN

20 | Vantage Point

Finding new growth opportunities for Canadian cannabis BY DENIS GERTLER

DEPARTMENTS

the Editor

| Under the Lights

with Wade Forrest, master grower, Glasshouse Botanics

Sacred Roots

Meet three B.C. producers you may not have known were Indigenous owned BY ALY K. BENSON

COVER STORY

Top Grower Award, Micro Category

Gerrit Richards of Living Cannabis in B.C. unlocks Top Grower status using the trusted organic method BY HALEY NAGASAKI

COVER STORY

Top Grower Award, Standard Category

Patrick Pagé joins the ranks of Quebec growers with award winning cannabis through taste and persistence BY HALEY NAGASAKI

2024 Market Trends

Take a look back over the year from the perspective of both LPs and retailers BY JOE NAVARRO

Kyra Horvath and Laine Keyes of Pineapple Buds in Oliver, B.C.

From

By Haley Nagasaki

Congratulations, Canada’s Two Top Growers!

Welcome to the wonderful world of cultivation. This Winter issue features several pro growers from the Canadian cannabis industry, including our Top Grower spotlights Gerrit Richards and Patrick Pagé, Rob Baldwin author of our cultivation column, Q&A subject Wade Forrest, and the LPs featured in the stories by Aly K. Benson and Joe Navarro.

This season we bring you the winners of our fifth annual Top Grower Award. To celebrate, Top Grower sponsor CANNA provided two branded BMX bikes (on top of their usual swag) and I couldn’t think of two more deserving lads. Congratulations Patrick and Gerrit!

Thank you Top Grower sponsor Biofloral, for supporting this contest and for providing an essential service to the domestic market – outfitting so many of our cultivators with top shelf supplies and guidance.

I’d also like to thank our panel of judges. OG grower David Kjolberg has scored the contest candidates since its inception. Thank you to three-time returning judge and award-winning master grower Stacie Hollingworth, two-time judge and expert of the highest integrity, Av Singh, and first year judge and winner of our 2022 award, Alexandre Gauthier. I’m happy to close 2024 with a focus on the heart of this industry, the growers. To toast and take a closer look at how it is we all got here.

This year we highlight one standard and one micro-LP winner. Two men representing the Eastern and Western conferences, equally: an Anglophone from Quebec and a B.C. boy from Alberta. There’s a parallel between the two profiles, including how they got their start in cannabis, trimming at Aurora facilities, and meeting and working alongside their dedicated partners. They are the women who nominated them for this award, Beth Talbot and Mehgan Race Widdison, growers who go above and beyond in performance and attention to detail. If it wasn’t for them, we wouldn’t have gotten to hear these tales of dedication to soil biology and the evolution of a refined pallet, respectively.

Two men representing the Eastern and Western conferences, equally: an Anglophone from Quebec and a B.C. boy from Alberta.

I’m always inspired when I speak to young talent who have moved into serious leadership roles and are helping others along the way. This industry should be proud of the legacy knowledge it retained and the networks forged among growers of all ages and stages in their career development. To the folks who learn the ropes of a corporate environment even if it goes against their nature. It is a powerful thing, integrating a skill you didn’t know you were made for and then putting your own spin

on it. Something perhaps I explored during my time as editor of Grow Opportunity magazine.

This is the 12th and final magazine I’ll be putting out for this beloved brand as I carry on the road of my own story.

There is room for B2B storytelling in this space, and the people are still here to read longform human interest pieces despite constant inundation with bites of information. Thank you to the many folks of varying expertise I’ve spoken to and called upon over the last few years, to my colleagues at Annex Business Media for taking a chance on me, and above all, thank you to the sweet cannabis plant in all her otherworldly glory.

Thank you for inspiring in all of us the creative avenues that are the spice of this life – the titillations made bold enough to follow, and for fostering an interest in gardening that for some like me, provide a powerful bridge to stewardship of the natural world. To be frank, I’m still not entirely sure of my grasp on the nuts and bolts of cannabis as an industry, but I can be sure of my place in it.

Finally, Denis Gertler writes about potential growth opportunities in the sector using the blue ocean strategy analogy, supported by this Socrates quote: “The secret of change is to focus all of your energy not on fighting the old, but on building the new.” While likened to business possibilities in cannabis, I just think they’re sound words to live by.

Winter 2024 Vol. 8 No. 4 growopportunity.ca

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Services Administrator Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Haley Nagasaki hnagasaki@annexbusinessmedia.com 519-410-0600

PUBLISHER

Adam Szpakowski aszpakowski@annexbusinessmedia.com 289-221-6605

NATIONAL ADVERTISING MANAGER Nashelle Barsky nbarsky@annexbusinessmedia.com 905-431-8892

ACCOUNT COORDINATOR Kathryn Nyenhuis knyenhuis@annexbusinessmedia.com 416-510-6753

MEDIA DESIGNER

Jaime Ratcliffe

AUDIENCE DEVELOPMENT MANAGER Shawn Arul sarul@annexbusinessmedia.com

GROUP PUBLISHER Paul Grossinger pgrossinger@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

MAILING ADDRESS

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES 1 year subscription (4 issues: Spring, Summer, Fall, Winter): 1 year offers: Canada $26.01 + Tax USA $47.94 CDN FGN $54.57 CDN GST # 867172652RT0001

ANNEX PRIVACY OFFICE privacy@annexbusinessmedia.com Tel: 800.668.2374

ISSN: 2561-3987 (Print) ISSN: 2561-3995 (Digital) PM 40065710

Occasionally, Grow Opportunity will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

By Rob Baldwin Cultivation

How to scale greenhouse production on the West Coast

Istarted at this location in 2008 working for Village Farms International growing produce. Prior to that I worked at some other greenhouses, so I’ve been in the greenhouse industry since 2000. I studied a greenhouse management course. At the time, greenhouses were expanding rapidly in the late 90s and early 2000s; the vegetable industry really picked up here in Delta, British Columbia. Today at Pure Sunfarms, we’re currently cultivating in 1.65 million squarefeet of greenhouse space.

The real advantage of growing in a greenhouse in B.C. is that even though it appears that it’s raining here all the time, the absolute humidity is actually very low. You can see that from the types of plants we have – like pine trees and spruce – that are drought tolerant. Generally, the air is very dry in B.C. We can keep the rain out and use the dry air to make the greenhouse air optimal for the plants. The fact that it rains a lot here is a benefit because we’re able to collect all that rainwater to feed the plants. We collect the runoff from plants so we’re not losing the fertilizers into the environment – they’re just going back into our plants.

The other benefit to growing in a greenhouse is that a lot of the wind that comes off the ocean in the summertime has a cooling effect, so the coastal climate doesn’t have as many extremes. The supplemental light we use is for the winter, especially in flower when the plants require

more energy. Once you get to May, it’s not really worth it to run the lights, because you’ll get enough sunny days in between the cloudy days.

The importance of continued experimentation

Understanding what quality you’re trying to achieve is critical. The team is very important, as is learning through experimentation. We’re not solely using mechanics to make the climate inside. We depend on the air outside a lot. We don’t have air conditioners in the greenhouse; we’re trying to use the energy from the sun as well as the air outside and the physics of the greenhouse to make the climate inside. There’s also a local climate benefit. The wind coming off the ocean tends to blow the clouds away quickly, so we have a lot more sunlight hours in this area.

We’re constantly experimenting. Sometimes I run mini experiments because I want to see the limitations. I have to understand the limitations and the problems, and what caused

them – pushing the boundaries of what’s possible to make continuous improvements. That gives us the parameters we need to be within. From those learnings, scaling up is easily done.

Research, development and innovation

We innovate in other ways as well. We have research partnerships with Simon Fraser University (SFU) and Langara College, and a lot of those experiments, they run them, and our teams direct them.

The experiments help with innovation and problem solving. With SFU, the kinds of innovation we collaborate on are more plant-related: disease management, IPM, and water sterilization. Unlike gardening, in farming you’re often battling bacteria, fungi, viroids and viruses, so you have to build a way that you’re protected from that into your system. With Langara, the work we do is more on the secondary side, like figuring out procedures and optimizing our product and manufacturing processes.

When thinking about AI as a tool for innovation, I’m interested in reaction time; the reaction time to the changing environment outside. This high-tech greenhouse is fully controlled by a climate system. Our expertise is setting the optimal parameters, which are constantly adjusted, especially when transitioning seasons. So, in using AI, I’m most interested in speeding up reaction times to maintain the optimal climate.

As far as choosing new cultivars, we have a system. What I learned during my time in produce is how to best run our climate and our system; the cultivar has to work within that system. We don’t try to change the system to make the cultivar work in it. Overall, we’re phenohunting in the greenhouse, trialing as many different cultivars as possible, and then we look at how it fits in our system, all the way to processing. It has to work in our climate, and it’s got to meet the consumer’s quality expectations.

We’re fortunate that we have an in-house lab that we can use to test all aspects of what we do, including trialing new products. I think this year we’ve already grown 1,000 different cultivars. Each pheno is different, and we have this ability to quickly assess them through trial. That’s something I’ve never been able to accomplish in produce previously. At the end of the day to achieve brand loyalty, we need consistent great quality. And that’s our job, from farm to shelf, starting with cultivation.

VP of cultivation and operations, Rob Baldwin grows high quality plants with a passionate team of growers. He is responsible for all aspects of Pure Sunfarms’ cultivation and greenhouse operations, and continues to showcase world-class growing capabilities.

Pure Sunfarms grows in 1.65 million square-feet of greenhouse space in Delta, B.C.

Indigenous Roots: Honouring quiet representation

By Aly K. Benson

Brand commitment is finally normalizing in the cannabis industry, meaning niches are trending, and consumers are looking for brands that connect with their individuality. One particular area within the cannabis space that is also gaining recognition surrounds the representation of Indigenous peoples and their businesses. First Nations, Métis and Inuit involvement began at a low point when the Cannabis Act was initiated, leaving many to criticize the lack of council sought to discuss the avenues of legalization.

Years later, communications about sovereign land rights, financial aid programs, the Red Market, band-led businesses and Indigenous brands finally began breaking the barriers. As a result, many have witnessed the success of indigenous-led brands. But what qualifies a cannabis business as Indigenous? Is it something we can genuinely quantify?

Beyond branding in British Columbia

Currently, the BCLDB website features a list of precisely five LPs under the B.C. Indigenous Cannabis Product (BCICP) program, where cultivators and processes must have at least 51 per cent Indigenous ownership of facilities in British Columbia. This leaves to question how many are Indigenous-run but have not applied or qualified for this program. And what about retail locations? Grow teams? Or sales and marketing firms? All of those who contribute to economic growth, product preparation and jobs funnelling into the industry. Where can these operations be found featured in a comprehensive list?

So, I ask: how can we recognize and celebrate those who may employ the majority of Indigenous peoples? Or those who may not own 51 per cent of their brands but initiate internal practices that reflect traditional practices? And what about the licensed producers whose leadership and employees proudly own their indigeneity, even though their identity may not be predominantly present in their B2C branding?

Follow the insights given by a mix of three LPs that represent indigeneity differently –some you might not know are owned by First Nations or Métis peoples.

The beginning of recognition

Allowing space for Indigenous voices to be heard, amplifying representation and pushing for inclusive policies is the beginning point to better the industry for the workers within the cannabis community. One perspective not spoken of too popularly is that of

non-indigenous individuals or those lacking stereotypical identifiers;an instance of an identity crisis known too well by many biracial First Nations and Métis peoples.

It is important to be clear: not involving one’s indigeneity does not diminish or reduce one’s heritage nor require the explanation of a person, leadership or brand’s background to the public – we don’t owe anyone the justification of where we come from and why we do or do not include personal identity, especially around branding. But those who share this badge of honour can inspire others to take their own route in brand identity.

Alannah Davis, Métis CEO of Dabble Cannabis Co. in Cowachin Valley (processing & cultivation), addressed this, stating that one of the biggest challenges is embracing and representing Indigenous heritage authentically. This involves balancing limited personal experience with a genuine desire to learn and honour family histories.

Alannah and Brody Davis at their family operation, Dabble Cannabis Company, on Vancouver Island.

Aly K. Benson (AKB) is a biracial Cree writer and strategist currently residing on the ancestral lands of the Syilx/Okanagan peoples.

“You shouldn't have to have heritage at the forefront in order to be seen as an Indigenous brand.” - Laine Keyes

Organic Visionaries: Growing cannabis the living soil way

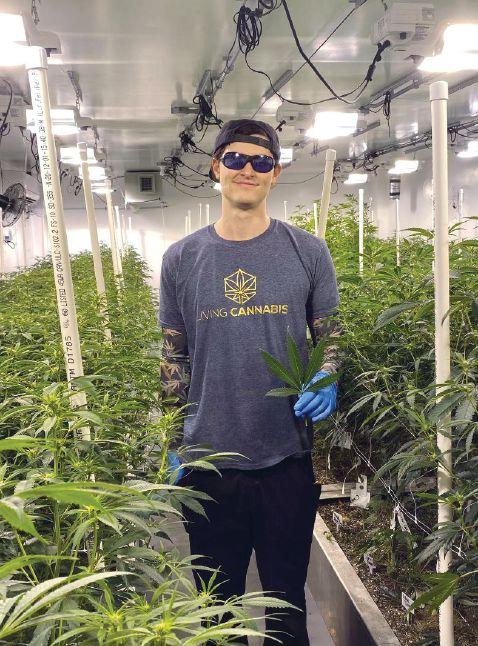

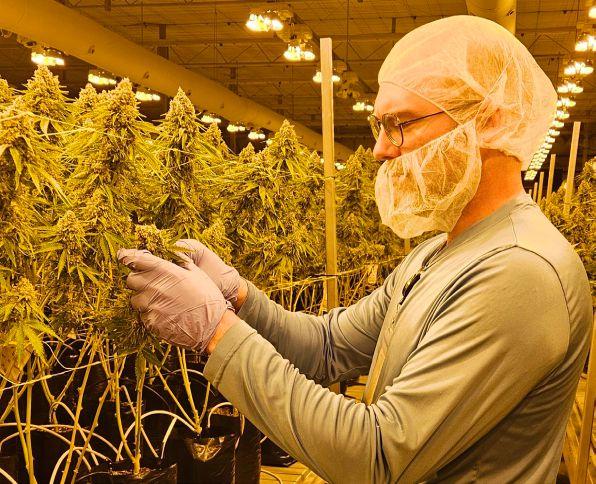

Micro category Top Grower winner Gerrit Richards brings passion and precision to micro cultivator Living Cannabis, wielding the alchemy of living soil and a commitment to clean burning products

By Haley Nagasaki

Gerrit Richards relates the living soil approach to growing and consuming cannabis as an alchemical progression from “water to fire,” where the same permanent beds have been tended since 2019 means the diverse microbiome requires only water to unlock its soil nutrients for healthy plant uptake. The fire, of course, comes later.

Backing up, born in Calgary and raised between the ages of six and 11 on a 40ft sailboat touching 32 countries and covering 45,000kms, Richards had an unconventional childhood that challenged social norms and profoundly broadened his horizons. Since age three, he has been an insulin-dependent Type 1 diabetic who found relief using cannabis for the management of secondary symptoms such

as nausea, appetite, stress and overall mental health.

Richards began growing in 2014 which spurred a deeper scientific interest in plant production and biology, specifically psychoactive plants. Then he went on to complete a Bachelor of Applied Science in Horticulture at the Olds College in Alberta, and pre-legalization worked at Aurora Cannabis in Cremona, Alta.– the first medically licensed facility in the province.

After his first year at Olds, Richards immediately broke into the industry, working weekends while he was in school. He began in the medical side of things and later transitioned to the rec market.

While the micro cultivator Living Cannabis was founded in 2019, Richards worked at the original build of Candre Cannabis, a 45,000 square foot mul-

tiple-tiered facility where he spent just under five years doing IPM and genetic development, eventually taking on the role of master grower before moving on to the Okanagan micro in early 2023.

Partner Beth Talbot also began in the legacy market, and later met Richards at Aurora as trimmers “harvesting into each other’s bins,” she says. Talbot moved onto Sundial and Candre, until the pair made the jump to the North Okanagan-based Living Cannabis facility, where she currently works alongside Richards wearing many hats including cultivation tasks, quality assurance, social media management and B2B sales.

Richards’ knack for organic growing is rooted in the principles of permaculture and the pursuit of efficiency after having experienced the waste associated with

large scale facilities growing beneath single-use production systems. Having witnessed the closure of facilities due to factors such as overhead, Richards says he saw the writing on the wall. “These systems aren’t really sustainable from an economic, operational or environmental standpoint,” and has aligned himself with what he believes is as a more positive future for the industry with less supply chain dependency and waste.

The founders of Living Cannabis had the foresight in 2019 to use living soil, however until Richards, they lacked the direction from an appropriate operator to produce consistent quality product using a system that worked for their operation.

Since Richards and Talbot came on in early 2023, relocating from their home

province of Alberta to the interior of British Columbia with a couple cats and dogs, the producer’s yield has increased substantially, their lots are consistent and they produce clean flowers that do not require microbial remediation or irradiation. They’re also committed to continue developing their own in-house genetic bank, which was already in the works when they arrived, however Richards and Talbot are now actively trialing new phenotypes to bring to market.

The organic method

Living Cannabis bootstrapped its build and completed its licensing process inhouse. The team works with just under their allotted 200m 2 canopy spread between three flowering rooms, a veg room

and a mothers/genetics room. “We are optimistic about the proposed changes to increase the micro canopy license from 200m 2 to 800m2,” says Richards, “but for now are just focused on the day-to-day.”

He states that with the right operator, he believes the organic methods could be scaled. And with the confidence and the right knowledge, the living soil method is actually quite an easy and low maintenance system to steer. “I water one-to-two times per week as needed,” he says, without ever adjusting the pH. “The soil and plant genetics do most of the hard work, we minerally amend periodically and just do our best to guide plant expression to its full potential.”

The grow team duo are training themselves to work using a different mentality than say a hydroponic grower, “because you’re dealing with nutrients that aren’t immediately available, and you actually have to be working on balancing the soil minerally and microbially.” Genetics also plays into the question of consistency and yield. “We’ve seen massive variability in our system,” says Richards. “The seeds are like siblings. So, we take advantage of the diversity within our seedbank and then find the ones that express the best and have the most desirable characteristics.”

Having the same soil since 2019 means the beds become increasingly microbially rich as the composting organic matter performs nutrient cycling. The high nutrient and moisture holding soil is supplemented with amendments: kelp, humic and fulvic acids, teas, enzymes, as well as cover crops that promote soil biology, root health and nutrient availability.

Interestingly, the mycorrhizal fungi and other amendments help with the observability of soil life under the microscope. Richards learned from soil biologist Elaine Ingham Soil Food Web School where he trained in soil microscopy to identify and study microorganisms in the food web, having since incorporated this training into the regenerative agricultural practices he employs at work.

“We think in terms of availability,” says

NSFW cultivar, grown in organic living soil, nears harvest at micro-LP Living Cannabis in the Okanagan, B.C.

PHOTO: BETH TALBOT

Richards. “The big thing is the base nutrients are always all there, but we’re trying to make sure they’re available at the right times, and that primarily occurs through soil biology.”

Aside from beneficial predatory insects for IPM, the medium is also teaming with beneficial fungi, bacteria and nematodes. “I fundamentally believe that living soil helps plants express fuller genetic potential and produces a very nice, clean burning product that resonates with consumers.”

Spreading the word

Living Cannabis spent the last year selling B2B for a company exporting cannabis to Australia. Domestically their product is available in B.C. and on occasion, Ontario. They’re also focusing on supplying nearby processors and brands, such as Pistol and

Paris and Dealr, to expand the supply of products nationally.

In terms of marketing, Talbot says they’ve largely shifted their efforts towards B2B, “because it’s easier for us to sell our product without having to focus on the retail side as much.” They also work with other processors to get their cannabis to market. “A lot of our marketing is consumer targeted in the sense of education about living soil,” she says. “It’s also targeted at business entities who are looking to get organic or eco-conscious cannabis produced using living soil methodologies.”

Talbot finds the old school legacy mentality puts a high emphasis on living soil; they appreciate it. For the novel consumer, she finds it’s more of an ongoing education process as they may not consider the way the plant is produced. Richards adds that all of the desirable secondary

metabolite production in cannabis (terpenes, cannabinoids, flavonoids, esters) evolved over millions of years out of soil systems and are inherently linked and synergized by microbiological processes.

Overall, the team is pleased with their current trajectory and the headway gained in the last two years –growing out cultivars like NSFW with its heavy nose, as well as some old school Blueberry crosses. Richards and Talbot are proud of their low impact cultivation style that negates the labour of filling pots, or the environmental impact of disposing rockwool or coco.

Richards says he’s grateful for the differentiation in their business practices, and for the mutual growth shared with Talbot over the past seven years, “working side by side for various employers,” he says, now happy to continue that ongoing journey at Living Cannabis in B.C.

The cultivation team at Living Cannabis, Gerrit Richards and Beth Talbot, moved from Alberta to the interior of B.C. to take on their new roles in early 2023.

A finer taste for cannabis

Top Grower Award winner

Patrick Pagé talks coming of age in Montreal and desiring the finer flavours of cannabis

By Haley Nagasaki

For Patrick Pagé, the measure of success in the cannabis industry isn’t the trophies or awards for best flower, it’s the tremendous impact of mentorship. Guiding others to run successful facilities, as he himself was guided, Pagé believes is the most meaningful recognition he could receive.

He likens this process to his previous experience working in high-end kitchens. Aside from the obvious similarities between the restaurant industry and regulated cannabis such as strict SOPs, cleanliness and a fast-paced environment, it’s the legacy of the star chefs he sees as the strongest parallel.

“It’s 'who am I going to train to run the next successful cultivation team, and maintain the high-quality standards that follow?' If you want more from the industry, go get mentored by the top dogs, and carry on the tradition.”

Early on

Hailing from Huntingdon, Quebec, Pagé moved to the city at age 17 where he was introduced to some of the finer flavours in the legacy game. He recalls trying “EXO’S” for the first time, upstaging the M39 and outdoor grown he was used to. When he would return home, his friends knew he had the best cannabis: “always super flavourful, super potent,” he says. “It just sort of stuck; I wanted more.”

The weed coming out of Montreal at the time was a real influence for Pagé. “I can’t put a name, or any one person or grower per se because it was all very

black market. But there was a lot of really flavourful, really nice cannabis going around Montreal, and I wanted to be a part of it.”

Cannabis was already a permanent fixture in his life, mainly recreationally, as well as for sports recovery and for unwinding. Pagé found the plant beneficial and he self-medicated for focus, for slowing down a busy mind. “It helped me dial in,” he says. There was a discrepancy between his passion for cannabis and only growing a few plants in the backyard. So in 2017, with a baby on the way, Pagé had just bought a house with his then wife and decided

to transition from working in the kitchen to a trimming position at Aurora Cannabis in Pointe Claire, QC. “Cooking was amazing, and I loved the lifestyle that came with. There’s a certain beauty to the chaos that I really enjoy,” says Pagé. “But cooking didn’t seem like something that was going to pay the bills or take me to where I wanted to go.”

He started at Aurora in the spring of 2018 and worked for a year until he met best friend, Alexandre Gauthier. First impressions of the industry took a more political standpoint, which was the pivotal moment in Pagé’s career where his desire to grow a

Guiding others to run successful facilities, as he himself was guided, is the most meaningful recognition he could receive. “If you want more from the industry, go get mentored by the top dogs and carry on the tradition.” – Patrick Pagé

From Montreal's Island, Pagé is leading the expansion at GWNG.

craft product became the forefront of his focus. He wanted to grow better than what was available. “It was a motivating factor to be more than just a 9-5 trimmer,” he says. Gauthier moved to New Brunswick to work at Tidal Health Solutions, “and I followed him out there,” says Pagé. He was the irrigation specialist for about eight months, at which point he moved back to Montreal to be closer to his daughter.

November 2019, Pagé went to work for Mitch and Rich Clément at MTL Cannabis and came on as the alternate master grower working beneath Denis Clément, the youngest of the three brothers. “Eight months into working there I became the master grower.”

Pagé stayed on until November 2022, helping grow the canopy at MTL from 3,600 square-feet to 30,000, speaking to his skill in scaling premium cannabis production.

Montreal mentorship

Pagé credits his progress to the “people who took the time to mentor me and support my career.” Alexandre Gauthier, the Clément brothers, Mick, Vincent Gagné and many others. During his time at MTL he learned how “running an LP isn’t that different from running a kitchen. You need a strong team,” says Pagé.

Like running a Michelin-starred kitchen, growing quality weed requires precision, the right people in your corner and a continuous focus on the fundamentals. “Alex and I always used to joke about the rugby team analogy,” he says. “It needs to be the same with a cannabis company. Either you’re going with this genetic, or we’re going into Phase 2 – whatever it is – you need to know that they’ve got your back and that they can run with you.”

By that time, he had taken on more of a desk job at MTL. “I had trained mul-

tiple successors (partner Mehgan Race Widdison, Michel Goulet & others) to run the day-to-day. To run the grow,” says Pagé. “It was at a point where it wasn’t really necessary for me to be there anymore; I’d done my job and it was time to go look for a new challenge,” he says, leaving behind something meaningful: “Not just the weed but the people who know how to grow it right.”

GWNG

The new challenge came in the form of Great White North Growers (GWNG). Pagé had an impromptu meeting with them and learned that their latest project saw them reviving cultivation dreams with single-tier bench-style growing and hopes of a second phase. “I met co-owners Peter Schissler and George Goulakos at an Origine Nature industry party,” says Pagé, “and we just hit it off.”

At Great White North Growers, the second Phase 2 flower room is now complete. Here their prized Amnesia Haze sativa-dominant flower is nearing harvest.

The result was the sativadominant Amnesia Haze flower with 6% terpenes, incapable of meeting the growing market demand therefore instigating their Phase 2 expansion.

When the Montreal Island-based LP started in 2019, they’d been sold on the idea of aeroponic towers. Then they implemented a bench style but eventually slowed growing and switched focus to processing until they met Pagé who brought their cultivation back online. “They had 25 partners that they were packaging for when I came on board,” he says.

After coming on near the end of 2022, Pagé helped grow a roster of rooms under double-ended HPS and some LEDs, and establish a core team of three trained growers, using a logical, data-driven approach to business and cultivation. Fueled by CANNA products. “I love the CANNA Coco Flex; I love the CANNA A&B,” says Pagé.

The result was the sativa-dominant Amnesia Haze flower with six per cent terpenes, incapable of meeting the growing market demand therefore instigating their Phase 2 expansion.

“Out of the 15-20 seeds we popped, we found the right genetic and that ended up being the Amnesia Haze we’re putting on the market now,” says Pagé. “We opened up about 2,000 square-feet of canopy all in Phase 1. We were also planning to open Phase 2 so we started building the rooms, we got the license, and we have the first room up and running now, with a second coming soon. We’ll build three more, in a perfect world, by the end of next year... I can’t grow enough of the Amnesia. I’d love to phenohunt, but we cannot spare the flowering space at the moment.”

GWNG also works with some local micros: Microcannabi has a 1:1 called Molten Core, and another called Grease Monkey. XOPRO is an LP out of Montreal suburb, Châteauguay, growing a nice Time Wreck. “And the Clém+Co. guys are the people making aeroponic towers work, they have one called Apricot Cream and Cheese that I swear tastes like apricot and cheese,” he says.

“At the end of the day, legacy isn’t just what you grow – it’s who you grow with,” says Pagé. “The goal isn’t just to grow good weed, it’s to build this industry into something we can all be proud of.”

“At the end of the day, legacy isn't just what you grow — it's who you grow with. The goal isn't just to grow good weed, it's to build the industry into something we can all be proud of.”

– Patrick Pagé

RIGHT: Patrick Pagé has been the master grower at GWNG for two years, helping bring cultivation back online and launch their Phase 2.

Standing out in a crowded market

2024 trends from retail to cultivation demonstrate a gradual move away from high THC, but still an overly saturated marketplace overall

By Joe Navarro

This year, 2024, marked the sixth anniversary of cannabis legalization in Canada.

The cannabis industry has evolved rapidly over this time. After initial distribution challenges were overcome, the Canadian adult use market has steadily grown, buoyed by an increasing number of licensed retail stores across Canada.

With Canadian adult use sales decreasing from a year ago, through August 2024, licensed producers and brands are adapting to serving the evolving cannabis consumer. Fresh contenders are steadily entering the market, driving up the number of listings with regulated distributors, intensifying pricing pressure and setting the stage for fierce competition.

As markets mature, sales growth slows and industries are often faced with a shakeout period. Subject to slow growth, focus shifts to expense reductions, cost savings and cash flow. Bankruptcies and industry consolidation are natural symptoms of a challenging and crowded market.

Ontario (-5%) and British Columbia (-12%) lead the way with year over year sales drops, while Alberta (+5%) and Quebec (+11%) tallied increasing sales over a

year ago. With different provincial mandates and regulations, the provinces and territories have varying approaches to cannabis and public safety.

While leaders in Canadian cultivation, Quebec has taken the most cautious approach to regulating cannabis. This is exemplified by requiring consumers be 21 year of age or older, limiting edibles to 5mg per discrete unit, and opting out of the extracts category by restricting the sale of products with greater than 30 per cent THC content. The sales mix breakdown by product category has dried flower reporting at 35%, pre-rolls at 35%, concentrates and extracts at 4.8%, edibles at 4.8% and vapes at just over 16% of sales. Notably, 2024 has seen continued growth in both the pre-roll and infused pre-roll categories.

Princess Buds

Erika Bustos, owner of Princess Buds – a retailer in Stouffville, Ont., shared: “our customers are becoming more educated on cannabis overall. They now frequently ask about terpenes and the terpene percentage, but high THC does seem to still reign.”

2024 has revealed the rise of the more discerning consumer, as customers are becoming educated, expecting more from products. From packaging dates to exotic genetics, and high THC cultivars, consumers are seeking products that meet their desired effects and in their preferred product format.

“For new products, there are all-in one vapes, some are live resin while others are distillate based. Some people don’t care… with a higher THC content vape, customers

Rob Dawe is the head grower at Boreal Cultivation. The only LP in The Northwest Territories was founded by a group of long-time friends and epitomizes the virtue of small business and hearty community.

Joe Navarro is an Ontario-based cannabis journalist and content creator focused on the Canadian marketplace.

are often expecting them to last longer or in the very least get them higher,” says Bustos. “As a female business owner, I understand the importance of offering a welcoming environment where customers are comfortable to ask questions.”

“People are always looking for new products… the same thing but different. Sampling really helps us to decide if something is a good product and worth bringing into the store. If it’s a quality product and consistent, then we want to talk about it and share it with customers,” she says.

The cannabis sales game has always been built on marketing, hype, and chasing the next big thing. Successful retailers have cultivated an on-going dialogue with their customers, offering up the new drops of the week and serving up education that their regulars value. Most critically, seem to want consumers want quality cannabis and a consistent experience.

A taste of the North

Boreal Cultivation, The Northwest Territories’ only LP, was founded by a group of longtime friends and epitomizes the virtue of small business and community. “When legalization happened, it seemed like the North was a dumping ground for subpar product… so it was really important for us to grow some good weed. That’s everything to us. Ultimately, the most important thing,” says co-founder Jordan Harker.

“We are most proud of our breeding and genetics, as we’ve found a couple winners. In the Artic, our things is to find that unique smoke for the people. The best way to do that, is to create it,” he preaches. “Our main focus was supplying locally grown flower to the North…it’s a small market and the population is quite low, so we also have to supply other markets. Ontario has been buying anything that we can grow.”

“Shouting out the growers on the label, I think is a nice touch. To recognize all of the hard work that they put in growing the flower, that the people are enjoying,” says Harker. “It only seemed right to put their name on the bag.”

With early success, Boreal is planning to increase volume while maintaining their craft approach and authenticity unique to the North.

New in concentrates from 1 Above

In 2019, cannabis 2.0 products consisting of edibles, concentrates and extracts were rolled out. The concentrates category has been steadily growing, but it is one of the remaining areas where the legacy market remains competitive.

1 Above is a new Canadian brand launching a 73u live rosin, a 2 gram “hash hole” infused pre-roll and an all-in-one rosin based vape. Chas Sibbett, founder of 1 Above, is excited about the continued evolution of the concentrates market. “We are doing a hand rolled hash hole joint. That’s going to be a two-gram joint with 1.6 grams of flower and 0.4 grams of rosin. The rosin would be in a snake right down the middle of the joint, so that when you burn it,

it creates that hash hole effect. It is almost like a cigar. They smoke really smooth and have the best flavour ever,” he says.

“We are bringing to market the Juice Bar Live Rosin all-in-one vape. It is a half gram of decarbed rosin in a really high-end device. It has a glass cart with a ceramic heating element, opposed to the standard plastic with a cotton wicking heating element,” shares Sibbett. “They have been dialed specifically for rosin, so the temperature is relatively low and keeps the flavour high.”

With dabbable concentrates, proper temperature control, along with handling and storage throughout the supply chain, are all crucial to ensure that the product is delivered into the consumers’ hands as intended. “It is enlightening to show people the difference between rosin that has been kept in the fridge for six months and rosin that hasn’t been kept in the fridge for six weeks and seeing how rapid that degradation can be,” says Sibbett.

Programs such as BC’s Direct Delivery and Ontario’s FlowThrough were designed to better address these issues and get fresher product from the LPs to retail faster and more frequently. Looking ahead, the cannabis industry will also continue to evolve with stakeholders petitioning for the allowance of consumption lounges and increased opportunities for cannabis tourism, which to date remains a largely untapped market in Canada.

Harvesting with Italian pruners from Castellari

Say goodbye to tired hands and wrists with our range of professional hand pruners designed to prevent kickback

Contact us for a quote

Vantage Point

By Denis Gertler

How a Blue Ocean Strategy could grow opportunities in cannabis

This fall I appeared on a panel at the Grow Up Conference in Edmonton to discuss the state of the cannabis industry and offer some thoughts about its future. My assessment: with the exception of medical exports, which are growing rapidly, and perhaps cannabis health products finding new channels, Canada’s cannabis economy seems to have hit a wall.

Recreational markets have stagnated for some time, retail prices remain low while cannabis equities are still trading at a fraction of their peak values reached in early 2018. Since legalization, the Canadian Cannabis Survey has shown that recreational users of the legal product amount to a niche market, albeit at 20-25 per cent of the population a fairly large one. The domestic medical market remains small and continues to shrink. At 184,000 registered users in 2023, it’s 26 per cent smaller than in 2022. Retail coverage appears to be saturated while operating costs have risen sharply in major urban centres across Canada.

Walking about the conference I heard the familiar complaints about regulatory restrictions, high taxes and lax enforcement of illegal businesses but little about tapping new growth sources. Granted, 3 per cent overall annual growth to 2029 is forecast (Statista), but I wonder if that’s due to the surge in medical exports and provincial wholesale revenues.

So which way forward?

One approach to consider is Blue Ocean Strategy, an analytical framework that has helped many businesses achieve high growth. In their landmark 2004 Harvard Business Review article, authors W. Chan Kim and Renée Mauborgne presented the framework as a new way to innovate by discovering new value for consumers. Their thesis is that the business universe is com-

prised of two spaces, one red and one blue. Red oceans host most existing businesses with readily defined boundaries, characteristics and rules. The game is competition for market share. As the market becomes increasingly crowded, products become commodified, supply outstrips demand and rampant competition begats bloody, red oceans.

On the other hand, blue oceans spring up from markets not yet in existence. As the authors state: “In blue oceans, demand is created rather than fought over.” This is done in two ways: either by creating a completely new industry, as with online auctions (eBay), or by changing the boundaries of existing industries, which is what Henry Ford did in introducing the Model T. The auto industry had existed since the late 1800s, but despite 500+ manufacturers it had few customers. Only the wealthy could afford motor carriages which required skilled craftsmen at least a month to build. Ford’s genius was to expand the boundaries of that industry by adapting the assembly

line from the meat packing industry to offer vastly cheaper products that could be built in days. Assembly lines and unskilled workers assembled cars at much lower cost, using interchangeable parts. Ford also deduced that he could pay his workers higher wages so that they, along with the general public could now afford cars, thereby unlocking great value and creating a huge new market.

In classic blue ocean scenarios, markets ripe for value creation are characterized by oversupply, product commoditization, reduced brand distinctiveness, margin compression, price wars, regulatory complexity and shrinking profits. Does this sound familiar, cannabis colleagues?

What might a Blue Ocean Strategy look like in our industry?

In my previous column I described how hemp beverages took U.S. cannabis businesses by surprise to achieve exponential growth. New value was tapped by identifying demand from different customers, using familiar distribution channels (super-

PHOTO: ADOBE STOCK

Denis Gertler is a regulatory consultant, board member and former government regulator.

The blue ocean concept means creating market opportunities rather than overfishing a crowded red ocean.

markets and liquor stores) where most people shop, bypassing dispensaries. Lowdose hemp sellers turned the prevailing logic of cannabis on its head to focus on low-potency products for users who prefer these to high-THC. Hemp businesses created distinctive brands that speak directly to the intended buyer. The product is manufactured from a widely supplied ingredient that can cross state boundaries and be readily made by contract producers. Gaps in the U.S. Farm Bill paved the way, but the success of this market is not just a regulatory artifact. Are there other blue oceans hiding in plain sight? One possibility I’ve touted is bespoke cannabis based on the premium wine model. Devoted outdoor craft producers are already approaching this model. Aided by the expansion of farmgate in several provinces these cultivators are focused on terroir and regenerative agriculture,

using living soil and natural pest control. Consistency is less important here than in CPG-oriented or medical cannabis, because seasonal variation can be leveraged and even celebrated as it is in winemaking. Energy costs are much lower than indoor and greenhouse growing, and there’s benefit to be gained from the moderate THC levels and more distinctive terpenes often associated with outdoor cultivation.

The idea is not to churn out high volumes of weed but to focus on quality to achieve greater margins. Unique terroirs and extensions into tourism could be used to build brands and attract new customers. Creating regional appellation schemes to map terroir and establish standards would differentiate products and provide options at different price points. This could also shift government’s perspective, from seeing cannabis as a harmful substance to be overmanaged, to

welcoming it as a business with local support and a broader constituency.

A few factors are constraining the development of this business model: a lack of capital; a need for consumer education; marketing and branding that focuses on enlisting new customers as well as pitching to enthusiasts. There are regulatory gaps and hurdles. But Canada’s domestic wine industry had similar issues not long ago.

The Vintners Quality Alliance (VQA) system was developed at the behest of winery owners who worked together to lobby politicians. Climate change and calls for a cannabis tourism strategy are aligning to create more favourable conditions for this model.

These scenarios may not produce entirely competition-free blue oceans, but they do focus on creating new value and new markets. The obstacles are surmountable.

MARIJUANA GARDEN SAVER

MarijuanaGardenSaver is the go-to field guide for growers who need to quickly identify and fix problems and restore plant health. It covers the pests, diseases, nutrient deficiencies and environmental stresses that impact a cannabis garden, threatening a successful harvest.

Q&A with Wade Forrest: Exploring the rigors of EU-GMP certification

Wade Forrest has spent 3.5 years as the operations manager and master grower at Glasshouse Botanics in Pembroke, Ont. Previous work at Biobest Canada, Aphria and Zenabis, coupled with his science-based education from Acadia University, has prepared him for commercial cannabis cultivation within the rigors of EU-GMP. The following questions were crafted specifically for Forrest by threetime Top Grower Award judge, Stacie Hollingworth of Safari Flower.

GO: What are the challenges when transitioning into growing GMP flower for international medical markets, and has it impacted your growing style or technique?

WF: There are several challenges that we have had to work to overcome. From the insistent availability of pesticides from country to country within the EU, to the stricter and varying PHI period for pesticide applications. The extreme level of supplier control, which includes supplier qualification, lot number tracking, etc. Every regulation and requirement that has come our way via EU-GMP certification has made cultivation just a bit more challenging! We’ve had to adapt in many ways to ensure we’re meeting all requirements and maintaining yield and quality.

GO: What were the significant challenges faced when joining a team that was already operational?

WF: The challenge was as you would expect, learning to conform to a different spin on the same rules and regulations. Learning the skillset and know-

ledge base on the staff and gaining the trust so that necessary changes that had to be made were met with acceptance as opposed to reluctancy.

Glasshouse Botanics is the third LP

I’ve worked at with Aphria and Zenabis being the others, all of which have/ had EU-GMP in their sights, so the push here for EU-GMP was nothing new to me. Thankfully (for me), GHB was at an earlier stage in the EU-GMP push, so I was looked at to help guide not only the cultivation and operational side of conforming to EU-GMP standards, but also a subject matter expert on how EU-GMP restrictions intersect with cultivation practices. It’s been an interesting and enlightening journey thus far!

GO: What benefits and challenges do you find working with an LP that was established with a strong QA mindset?

WF: The clear benefit of a strong QA

mindset is that we’re always able to satisfy even the strictest auditors from all over the world. This has been proven again and again. The challenge that presents itself is in the legwork needed to ensure any necessary change is completely and thoroughly researched, risk assessed and presented to satisfy all aspects of the Change Control process.

Kudos to the QA team here at GHB who have been able to bridge the gap in their mindset towards quality with the success and progression of our operation, where even though they ask the tough questions and expect complete answers, they understand that we’re working with live assets that will at time present challenges to us that require immediate action. The whole team works tirelessly to ensure that we’re able to do what is necessary for plant health and product quality, but in a manner that checks all the boxes for EU-GMP.

The clear benefit of a strong QA mindset is that we’re always able to satisfy even the strictest auditors from all over the world.

PHOTO: NICHELLE

Wade Forrest grows in a peat-based medium for the mom, veg and flower stages of cultivation.

Wade Forrest is the operations manager and master grower at Glasshouse Botanics in Whitewater Region, near Pembroke, Ont.

One less thing to worry about.

EASY-TO-USE | CLEAN & QUALITY INPUTS

TRACEABILITY OF ALL PRODUCTS | TECHNICAL GROWING SUPPORT

CANNA is the pioneer and global market leader of plant nutrients and growing mediums for the cultivation of fast growing crops. All CANNA products are manufactured from the highest quality materials, as a known partner of the Green Market. We understand the importance of clean, consistent, traceable inputs, as well as keeping it simple!