GROWING UP?

Grow with the pros

CosMic Plants

Beamsville, Ontario

CosMic Plants, a premier Phalaenopsis grower in Ontario, initiated their first HPS to LED replacement in 2022 with the installation of Philips LED toplighting. Due to an almost 40% energy savings coupled with flexibility afforded by the dimmable LEDs, they continue to expand their LED install. “One of the things that drew us to Philips brand and Signify is the fact that it’s a large, strong, reputable company. We wanted to partner with a company that we know can stand behind their product.”

Creative season

Canada’s independent garden centres have come up with innovative ways to keep busy during the quieter months of the retail cycle.

Beyond blooms

Growing up?

Where

HESIC Q & A

Exploring

BY ANNE KADWELL AND STUART SERVICE

BY J LYNN FRASER

modular hydroponic farms. Photo courtesy Growcer.

Innovation, resilience and the road ahead

As we prepare to gather for the Canadian Greenhouse Conference in Niagara Falls, I’ve been reflecting on this year’s theme of ‘cultivating resilience.’

There’s no doubt that the Canadian greenhouse industry has weathered a number of severe storms in recent times: COVID-19, policy shifts, supply change disruptions, U.S. tariffs and increasing economic uncertainty. Through it all, however, the industry keeps finding ways to adapt, innovate and ultimately weather the storms that keep coming at it. This resiliency is a product of the sector’s commitment to coming together at events like this month’s CGC to share knowledge, resources and innovations that inspire solutions. I think, during this month of Thanksgiving, we should take a moment to offer our gratitude to the individuals, organizations and business who continue to organize, host, sponsor, attend and ultimately support events in the Canadian greenhouse industry that provide a springboard for growth.

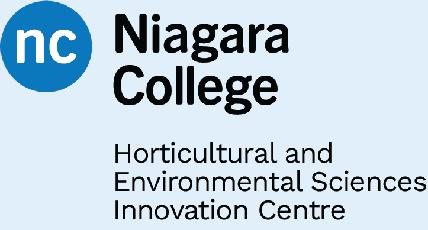

Niagara College’s Horticultural and Environmental Sciences Innovation Centre (HESIC). I recently had a tour of HESIC’s new research greenhouse and sat down with the researchers to discuss how this incredibly cool facility with help growers reduce risk and strengthen resilience. Read more on Page 28.

On the topic of resilience, that of Canada’s independent garden centres is put to the test every time the colder months start to settle in. Our friends at the Canadian Nursery and Landscape Association (CNLA) explore the creative and practical ways that these businesses are successfully navigating the tricky shoulder season on Page 8.

When it comes to equipping growers with the know-how to manage tricky situations, Dr. Mohyuddin Mirza is in a class all his own and this month, takes a dive into climate control for smaller greenhouse operations. On Page 22, he gets into a case study where a grower lost control of the climate when growing several

‘Resiliency is a product of the sector’s commitment to coming together.’

The themes of innovation and resiliency run through this issue of Greenhouse Canada as we look at the potential for vertical farming and traditional greenhouse production to collaborate. Starting on Page 14, read up on how across Canada, growers and entrepreneurs are finding novel and efficient ways to grow up. Montreal’s Lufa Farms is literally raising the roof on what greenhouses are capable of.

You’ll see our themes also play out in our Q and A with Ashley Paling and Scott Golem from

different crops in one operation and how he advised a course correction.

Capping off this edition of Greenhouse Canada is another thought-provoking piece from our longtime Inside View columnist Gary Jones who takes the time to reflect on how growers may be feeling societal pressures to find ways to disconnect from natural gas and the challenges and possibilities associated with that.

As always, keep in touch with any thoughts and ideas about Greenhouse Canada; we love to hear from you!

OGVG digital campaign earns marketing award

The Ontario Greenhouse Vegetable Growers (OGVG) has received the Marketing Excellence Award from Produce Business magazine for its ‘Greenhouse Goodness’ digital campaign.

According to a recent OGVG press release, the campaign utilized seasonal landing pages and a mix of digital and print media. A central component was the Greenhouse Goodness microsite, which provided information on greenhouse-grown vegetable benefits, recipes, children’s activities, educational posters, and influencer spotlights. Social media platforms, including Facebook and Instagram, were also used.

“Our growers work tirelessly to bring fresh, nutritious greenhouse vegetables to tables across North America,” said Richard Lee, OGVG Executive Director in the release.

“Greenhouse Goodness was designed not only to highlight the quality of our produce but to inspire healthier eating by making greenhouse grown vegetables part of everyday meals.”

Campaign metrics included 279,841 unique visitors to seasonal landing pages and 323,885 total page sessions. There were 977,537 tracked events, with an average of three interactions per session.

(Source: Ontario Greenhouse Vegetable Growers)

NATURE FRESH EXPANDS INTO LEAFY GREENS WITH REVOL PARTNERSHIP

Nature Fresh Farms has announced a new partnership that expands the company’s portfolio of greenhouse-grown produce into leafy greens.

The Leamingtonbased grower shared news of the partnership with Revol Greens, a Minnesotaheadquartered grower of leafy greens with a network of state-ofthe-art greenhouses throughout the U.S., in an August blog post.

“This partnership

with Revol Greens aligns perfectly with our strategic growth plans and reinforces our commitment to advancing sustainable agriculture solutions,” said Patrick Criteser, CEO at Nature Fresh Farms in the post.

“The leafy greens segment offers tremendous potential for innovation and consumer value creation through controlled environment agriculture, and we’re excited to bring our

Alberta agtech unveils pressurized greenhouse

Rimaco Greens Inc., an Alberta-based AgTech firm, announced the launch of a fully sealed, pressurized greenhouse system. According to a recent release, this patent-pending solution is a ‘first-of its-kind.’

“We’ve applied advanced energy optimization techniques from the oil industry to farming,” said Ricardo Solano, co-founder of Rimaco Greens. “Our system doesn’t use traditional air conditioning or air exchanges. Instead, it controls temperature and humidity using thermal energy storage at scale with tightly integrated flows of air and water.”

(Source: Rimaco Greens Inc.)

proven approach to this important market category.”

Through this partnership, Nature Fresh will offer organic and conventional packaged salads produced using Revol’s specialized growing expertise and facilities. Nature Fresh will contribute its brand recognition and market reach.

“Nature Fresh Farms brings exceptional brand recognition and market reach that

perfectly complements Revol Greens’ growing capabilities,” said Dirk Aleven, Revol Greens’ president.

“This exclusive partnership creates a compelling value proposition for consumers seeking premium, sustainably grown leafy greens while positioning both companies for accelerated growth in the expanding CEA market.”

(Source: Nature Fresh Farms)

BY THE NUMBERS

Source: ‘Gross domestic product, income and expenditure, second quarter 2025,’ Statistics Canada.

0.4 %

The rate by which real gross domestic product (GDP) declined in the second quarter of 2025

Exports declined 7.5% in the second quarter of 2025

International imports declined 1.3% in the second quarter

BLACK BEAR® PROFESSIONAL MIXES

Featuring biochar, an eco-friendly alternative to perlite that optimizes aeration

Made from 100% renewable forest by-products, Black Bear® biochar has captured organic carbon, preventing it from entering the atmosphere. We blend this proprietary ingredient with Canadian sphagnum peat moss that’s made using responsible peatland management practices and principles. The result? A premium, grower-trusted mix that’s rooted in good.

Scan to sign up for our Grower Trial Program and experience the difference.

OFF-SEASON IS ON

Fewer independent garden centres shrug during the shoulder season

BY ANNE KADWELL AND STUART SERVICE, CANADIAN NURSERY

LANDSCAPE ASSOCIATION

For many independent garden centres across Canada, the months between September and March present a unique challenge: how to keep customers engaged when the gardening season slows and temperatures dip. Owners and operators have found creative ways to draw traffic, often transforming their stores into community hubs during the colder months. From seasonal markets to family traditions, these initiatives help bridge the gap between the shoulder season and spring’s return.

At Shelmerdine Second Nature in Manitoba, Matt Bell described a multi-layered approach that keeps momentum going throughout the fall and early winter.

“In the Fall, we hold a Fall Market with more than 60 vendor booths set up in our parking lot,”

ABOVE

Bell said. “This is a great opportunity for people who haven’t been introduced to our garden centre to come out, as well as a space for the community to gather over the weekend.”

MAINTAINING MOMENTUM

Before switching over to their full holiday transformation, the home and garden centre hosts a six-week kids’ fair complete with small rides. Later, countless families return for “holiday photos taken with Santa and Mrs. Claus here at Shelmerdine.”

Looking ahead, Bell noted that new winter activities are on the horizon: “Yoga in the Garden, Music in the Garden, and personal or VIP shopping experiences are going to be making an appearance in 2026.”

An enticing retail display at Shelmerdine Second Nature, a home and garden store located in Headingley, Manitoba. The garden centre has established itself as a destination for consumers even in the off-season as it expanded its product lines and hosts numerous events year-round.

ABOVE

Staff at Grow and Gather in British Columbia have witnessed customers’ children grow up pond-side over the years. The koi pond is a popular attraction for customers and the local community. Although not a direct sales generator, the display is an opportunity for the garden centre to demonstrate pond equipment and answer questions about koi care.

Food and drink also play a role in drawing customers. Sunshine Greenhouse’s Chinos Bistro, located in Steinbach, Manitoba and run by Dorinda Penner, has proven that a cosy café atmosphere encourages repeat visits.

“Our bistro has a consistent traffic flow and patio season helps bring traffic to the yard,” she said, adding that pumpkin-

flavoured lattes and gelato are a big factor in increasing September traffic. “Customers grab a drink or gelato and want to stroll into the greenhouse when it’s cool outside.”

In British Columbia, Grow and Gather in Maple Ridge has found that its koi pond provides a surprising year-round draw.

ABOVE

Workshops span both horticultural topics, like growing herbs indoors, and lifestyle activities such as jewellery making and yoga at TERRA Greenhouses’ five locations.

“We were fortunate that our koi pond, along with several other water features, were existing elements when we purchased Trice Farms more than 14 years ago,” said co-owner Renata Trivieri. “While many of the features have been rebuilt, and the pond has had improvements made to it, it remains a big draw to our regular customers.”

ABOVE

At Shelmerdine Second Nature in Manitoba, fall and winter programming ranges from a Fall Market and a six-week kids’ fair to family photos with Mr. and Mrs. Claus. Debuting in 2026 are new initiatives like yoga, live music, and VIP shopping experiences to keep customers engaged through the colder months.

SECRET GARDEN

She added that staff have watched customers’ children grow up pond-side over the years, and that students from a nearby high school regularly stop by to ask if they can feed the fish. The feature functions like a “secret garden” Trivieri said, surprising even longtime customers who stumble across it. The pond is stocked with more than 40 koi, many of which were rescued or donated by the community, and has become a touchpoint for conversation, education, and repeat visits. The pond also allows for demonstrations of some of the garden centre’s more advanced pond equipment, and a living example to help answer customer questions about koi health and care.

“While the feature doesn’t directly create sales, it does create interest and causes folks to drop in just for a wander.”

Continued on page 36

ThinkPlants® connects breeders, rooting stations, and suppliers to give growers access to innovative genetics and a dependable supply of URC, bareroot, seed, and liners. With transparency at every step, we’re committed to supporting your success.

Learn More at ThinkPlants.com

Hemerocallis Blazing Skye™

SunMagic Vintage Orange

HGC Ice N’ Roses Red Peach Pearls Hydrangea BloomChampion® Fresh White

Coreopsis SOLANNA™ Bright Touch

Heliopsis Sole Giatto

Achillea Desert Eve™ Terracotta

Growing up?

Exploring the potential collaboration of greenhouses and vertical farms

BY J LYNN FRASER

A vertical farm (VF) is a type of controlled environment agriculture. A VF, at its most basic, involves a crop that is grown in vertical stacks. This growing approach uses limited space in comparison to traditional greenhouses, which makes them suitable for urban environments or growing in areas with limited space (Mottech, 2022).

What is typically listed as advantages for VFs are their controlled humidity, climate, energy, and nutrients; it is said to require limited to no pesticide use; there is efficient use of water (they may use close to 95 per cent less water than traditional greenhouses); they are able to grow specific crops year-round as they are usually found indoors in a

MAIN

controlled space (Mottech, 2022); and that limited space means a smaller environmental footprint with high production (Funk, 2023).

Despite appearances, vertical farms and traditional greenhouses are not two solitudes. They can collaborate and accommodate each other.

MULTI-LAYERED APPROACH

“Vertical farming [can be classified] into two types: one with multilayer horizontal growing surfaces and one with growing surfaces vertically arranged,” said Dr. Youbin Zheng, of the University of Guelph’s School of Environmental Studies. “If potted ornamentals are grown in multilayer

Kale thrives inside a modular vertical farm developed by Ottawa-based company, Growcer. INSET

Montreal’s Lufa Farms’ first rooftop greenhouse, opened in 2011, in the borough of Ahuntsic.

RIGHT

A closer look at the rootzone of some leafy greens inside one of Growcer’s hydroponic modular farms. These units employ deep water culture hydroponics where plants sit on floating rafts with the roots in water.

systems, the same crops can be grown as a conventional system, and the same type of truck delivery can be used.

“For vertical farming, the same set of staff can be trained to grow and manage crops differently,” he adds. “We can simply divide vertical farming into two types. Both can be premanufactured off-site or set up on site.”

When considering VF use on the same premises as traditional greenhouses the disadvantages traditional growers should be aware of are the high initial costs; specialized equipment such as hydroponics and grow lights that can be “energy intensive” and expensive (Mottech, 2022). Depending on how the VF is configured it may not be as sustainable as a traditional greenhouse (Mottech, 2022). Additionally, VFs

require a “delicate balance” that makes crops vulnerable to changes in their controlled environment (Funk, 2023).

HOW TO GROW AN URBAN FARM

Vertical farming [can be classified] into two types: one with multilayer horizontal growing surfaces and one with growing surfaces vertically arranged.

An important advantage of VFs is their adaptability to different spaces. They can be found in skyscrapers and warehouses, and other spaces usually not associated with farming such as urban environments (Funk, 2023). This is a critical characteristic in their usefulness as it is estimated that by 2050 “80 per cent of the world’s population will live in urban areas” (Funk, 2023). In present day, and in the future, many of these urban areas are/will be considered “food deserts” where there is an inability of some urban communities to access fresh fruits and vegetables (Funk, 2023). Vertical farms supply a solution to this problem — they can be a “food oasis” in an urban environment (Funk, 2023). In urban environments produce from VFs do not need extended shipping, thus reducing emissions, or warehousing, and are fresh (even harvested the night before) when consumers receive them (Funk, 2023).

ABOVE

There are a few but critical ingredients for successful collaborations of VFs with greenhouses. They involve having the right technology combined with the right partnership (Funk, 2023). According to Emily Peloquin, Public Relations for Montreal’s Lufa Farms, you need a strong foundation, literally and figuratively, to develop a vertical farm in an urban environment.

When Lufa Farms, founded by CEO Mohamed Hage and his team fifteen years ago in Montreal, was looking for buildings suitable for their vision they looked to buildings built in the 1960s and 1970s. These building choices “were not random, they were heavy structures, stable buildings.” Lufa Farms put its first, and all of its subsequent greenhouses, now six in total, on top of buildings in Montreal. It is important to do extensive homework to establish an urban greenhouse. According to Peloquin, Lufa Farms looked at Google Maps to find candidates for its plans. They then interviewed building owners.

Lufa Farms’ 127,000 square-foot hydroponic greenhouse atop the Marché Central Walmart Supercentre opened earlier this year.

DISCOVER HOW I MADE IT

Every time we expanded or renovated a greenhouse, we didn’t just build; we optimized. Even if something worked well, we’d ask, ‘How can we do it better?’

• Water: Vertical systems can dramatically reduce water use (often >70% savings) and reduce water risk in drought-affected regions;1

• Yield: Vertical systems can massively increase output per unit footprint — attractive in urban or high-land-cost locations;1

• Energy & Operating expenses: Energy is the dominant Opex; efficiency choices and local electricity costs largely determine long-term profitability.2

• Capital expenses and ROI: Expect substantial up-front investment; ROI is achievable but sensitive to scale, automation level, crop selection and market pricing.3

• Market forecast: Canada’s verticalfarming market revenue was estimated at close to $900 million in 2024 and is forecast to grow rapidly to more than $3 billion by 2030.4

Sources:

1. Han, D. (2020). Water Demand for Vertical Farming: Advantages and Challenges (Major Project, Master of Land and Water Systems). University of British Columbia, Faculty of Land and Food Systems.

2. Canadian Manufacturing. (2024, March 14). CubicFarm releases data showing its vertical farms use 54-to-62% less energy. Canadian Manufacturing.

3. Alberta Agriculture, Forestry, and Rural Economic Development. (2021, April). Vertical Farming Case Study: Economic Assessment of Current Vertical Farming Systems Being Marketed in Alberta and Canada. Government of Alberta

4. Grand View Research. 2024. Canada Vertical Farming Market Size & Outlook, 2024-2030. San Francisco: Grand View Research.

Next, they looked at prospective buildings’ blueprints to assess, for example, water sources, energy consumption, and access points. Another issue of concern for Lufa Farms was “administrative” such as how the building was zoned.

“Municipalities [in Montreal] have been extremely enthusiastic,” Peloquin notes. Montreal, she points out, has “more urban agriculture than anywhere else in the world.” In contrast, she comments, “Toronto was an absolute headache” in regards to a proposed project.

SUSTAINABILITY MINDSET

In Montreal the municipality of Ahuntsic, where Lufa Farms’s first project was established in 2011, was “ahead of the curve in a sustainability mindset” Peloquin

ABOVE

Growcer co-founders, Corey Ellis and Alida Burke outside one of their modular units.

observes. This forward thinking is found throughout Quebec where there is support for entrepreneurs, investors, stakeholders, and clients (customers) who are working to improve food security in the province. In the Ahuntsic neighbourhood of Montreal the Lufa Farms’s greenhouse, the “world’s first commercial rooftop greenhouse” according to their website, measures 31,000 square feet and uses both vertical and horizontal growing systems such as troughs for vining plants and nutrient film techniques for microgreens (website). The Ahuntsic greenhouse is capable of creating compost, recirculating rainwater, and can test crops such as growing bananas.

Lufa Farms’s operations are profitable, innovative, efficient, and sustainable. They

use renewable energy and sustainable lighting such as LEDS. They work with 300 businesses, local and otherwise, to offer a variety of complementary goods to what they grow through processes that include physical delivery and use online systems to process deliveries and a blog among other functions. Their market research keeps them informed about the lifestyle of their clients and their budgets. Lufa Farms calls their community “Lufavores” (website). Both the head and the heart come together in Lufa Farms. In addition to its commercial efforts, Lufa Farms has a foundation to help mitigate food insecurity.

Sky Greens Vertical Farming System, established in 2009, uses “rotating tiers of growing troughs mounted on a A-shape

aluminium frame.” This VF approach can be placed on top of a structure, while the lower level can be used for other activities or “income streams.” In this system “The tallest model is nine metres tall and has 38 shelves holding eight trays each. In each tray, three-to-six plants can be grown. This brings the total production capacity per nine-metre tower to 912-1824 plants.”

BUY FOR LIFE

Growcer, founded in 2015, offers another example of what VFs can achieve. Co-founder Corey Ellis (Alida Burke is also a Co-founder) notes that the conditions their VFs are used in vary across Canada. The company helps clients “develop indoor modular hydroponic farms” and “support you every step of the way - from seed to strategy.” According to Growcer’s website the company, while still working with communities in the North, now partners with more than 85 growers throughout Canada that includes “farmers, retailers, schools, nonprofits, and non-remote communities.” These include Nipissing First Nation, Durham College, a dairy farm in Quebec, and Yellowknife Co-op.

On greenhouse crops, provides effective, convenient and flexible suppression of Phytophthora blight and Pythium root rots.

BioCult is a living microbial inoculant consisting of a diverse team of

control is an issue as is powdery mildew.” Growcer helps clients with financial support for their modular units and with practicalities like permits.

To be successful Ellis advises doing “leg work throughout” and “talking to others, not just vendors” while doing the initial research when considering VFs. The result will be “reducing common mistakes and increasing your learning curve”. Use VF as a “tool to complement what you already know” and “not to spread yourself too thin.” Running VF as a separate business with a separate location involves “different synergies,” which could produce problems. Ellis cautions that VFs are not a “silver bullet”, and that VFs are not a “plug-in and forget” project. Ellis acknowledges that the economics of a particular area affect the success of VFs. He suggests implementing a direct-to-consumer pre-pay system to provide guaranteed cash flow, starting small, and “validating the market that you think exists.”

In the current economic environment “buying local is here to stay,” Ellis notes. The consensus “is that clients want to buy in Canada” and that “demand is outstripping supply.” Once a customer tastes the quality of crops from VF a customer will “buy for life.”

SOURCES

Funk, B., 2023, Eden Green Technology, What Is vertical farming?, https://www.edengreen.com/blogcollection/what-is-vertical-farming

• Growcer, https://www.thegrowcer.ca/ our-story

• Lufa Farms, https://montreal.lufa.com/ en/#/

• Mottech, 2022, Understanding the pros and cons of vertical farming, https:// mottech.com/news/understanding-thepros-and-cons-of-vertical-farming/#

• Sky Greens Singapore Collaboration, 2022, Canada: Livestock operation finds new niche in vertical farming, Vertical Farm Daily, https://www. verticalfarmdaily.com/article/9396852/ canada-livestock-operation-finds-newniche-in-vertical-farming/

• Sky Greens Vertical Farming System, https://skygreenscanada.com/

THAT WORKS FOR YOU.

Sollum’s advanced dynamic lighting solution delivers measurable results.

By adapting in real time to crop stage and conditions, growers achieve higher yields and quality, and reduced energy use.

It’s about increasing productivity, season after season.

This article discusses following points:

• Multiple crops are grown in smaller greenhouses and the biggest issue is lack of optimum climate control.

SMALL SPACE, big climate demands

Crop production challenges in smaller greenhouse operations

BY DR. MOHYUDDIN MIRZA

BELOW

Smaller greenhouses serve a variety of important purposes but they come with some big climate management challenges.

• High or low temperatures, high and low relative humidities affect the crop performance.

• CO2 levels can reach below ambient and thus affect yields.

• Insect and diseases can significantly affect the crops.

• Strategies to manage such greenhouses.

I deal with many greenhouse crop growers whose operations can be considered “small” in size. Varying anywhere from 3,000 sq.-ft. to 40,000 sq.-ft., these operations serve a variety of purposes, incluuding growing vegetable seedlings for their market gardens and full tomato, cucumber, pepper and other crops to supply the demands of a market garden. Recently, I visited a greenhouse growing eggplants, beans and many herbs like arugula, basil and other leafy crops.

Growing multiple crops in the same greenhouse can present many challenges, especially as it relates to climate control and pests. Consequently, yields can be lower when compared to good commercial crops. Let me take you through a one-acre, plastic greenhouse growing cucumbers, tomatoes, peppers, eggplants, beans and herbs.

BALANCING CLIMATE

Climate control is the number one challenge in such greenhouses. Different crops require different temperatures, both day and night. Growers who struggle to achieve the desired 24-hour temperature and can lose control over wether or not a plant is vegetative or generative and maintaining a balanced growth.

In this case, the grower had peppers, eggplants and beans in addition to cucumbers and tomatoes. The cucumber crop was under a big stress. The day temperature was going above 35ºC and relative humidity was 35 per cent. This resulted in a very high vapour deficit or moisture deficit. The symptoms on leaves appeared to be much like magnesium deficiency, however, it is “transpiration stress.” This happens when the leaf temperature is close to air temperature and roots cannot meet the transpiration water loss.

The importance of transpiration from leaves and fruit skin must be understood properly. Just like in economics, there’s a balance between water demand (driven by transpiration) and water supply (provided by irrigation). In a greenhouse where multiple crops are grown, each crop will likely require different day and night temperatures, which means the demand for water for each crop will be different. If the irrigation system is not computer controlled and adjusting to each’s crops needs, all plants will get the same amount of water and nutrients.

In Canadian climates, we have challenges of both low relative humidity, like in the prairies, and high humidity in coastal climates. Both humidification and dehumidification systems are required. In this context, we need understand the

LEFT

A little bit of shade goes a long way to controlling temperatures in the greenhouse

relationship between temperature and relative humidity. Simply put, warm air can hold more moisture than cold air. When the temperature rises but no extra moisture is added, relative humidity decreases. Conversely, when the temperature drops, relative humidity increases — because cooler air has a lower capacity to hold water vapour.

In smaller greenhouses the relative humidity is a big challenge. It could be very dry where relative humidity drops below 30 per cent and temperature rises to 30ºC and above. That is evident in Images 1, 2 and 3. The grower attempted to ventilate more by opening the doors to bring the temperature down, but the relative humidity also drops resulting in symptoms that look like sun scalding. The photosynthetic area of leaves is significantly reduced and thus much less food is available to the plant for its needs. There was very limited new growth visible, lots of new cucumbers aborted and few existing fruits in poor condition.

Warm air can hold more moisture than cold air

PEST PRESSURES

Besides climate-related leaf symptoms there was an abundance of pests and diseases. Spider mites forming webs on eggplants, quite a few aphids on peppers, whiteflies on peppers and spider mites also on beans. It was clear biological controls were not working.

Tomatoes are also affected under such conditions by showing smaller, darkgreen leaves, clusters are or poor quality, blotchy ripening of fruit and in many cases of severed blossom end rot.

Images 4, 5 and 6 depict problems in three different greenhouses. Image 4 is an example of very high relative humidity whereby adventitious roots are developing on stems. Botrytis grey mold

can easily target these plants if night temperature dips to dew point. Image 5 shows where very intense heat “toasted” the top parts of plant and there was also accidental dosing of high fertilizer rates. The EC in the root zone was very high.

Image 6 is an example of a tomato crop where grower used “garden” fertilizer which were labelled for tomatoes.

One can see poor flower and fruit set and thin, spindly

growth. An interesting observation that this tomato grower was using same day and night temperatures on his thermostat. The grower believed that by using warmer night temperature, the crop can grow fast and will get large fruit.

I was able to convince him to use cooler night temperatures without going into too much details of photosynthesis and respiration.

STRATEGIES TO IMPROVE CLIMATE

• For better temperature management, shade the roof with shading compounds. Reducing the amount of light coming into the greenhouse helps to reduce the temperature. Sometimes the thinking is that more light equates to better production, however, light contributes to heat as well. Only about five per cent is used for photosynthesis, the rest is used for heat.

The importance of transpiration from leaves and fruit skin must be understood properly.

I remember a time when greenhouse roofs were shaded with hydrated lime or flour slurry, so the practice of applying shading compounds is an old one but effective nonetheless. With the arrival of inside screens, growers are in a better position to achieve desired light reduction.

• If possible, install misting or fogging systems. Fogging systems may require more investment but simple misting systems are relatively economical. I have seen many smaller growers using a fan to blow water across the greenhouse and also wetting the floor frequently during hot periods.

• Dehumidification may be achieved by controlling venting.

• Pests must be monitored regularly especially knowing the fact that eggplants can be a magnet for spider mites and white flies. Diseases like botrytis, powdery mildew and fusarium must be monitored.

I found lots of good information in Greenhouse Canada. Have copies handy at the lunch table so that staff could take advantage of this valuable knowledge resource.

Dr. Mohyuddin Mirza is an industry consultant in Alberta and can be reached at drmirzaconsultants@gmail.com

RISK-FREE INNOVATION

Q & A: HESIC researchers talk new greenhouse at Niagara College and opportunities for industry

BY GREENHOUSE CANADA

Greenhouse Canada recently had the opportunity to tour Niagara College’s Horticultural and Environmental Sciences Innovation Centre (HESIC)’s new greenhouse research facility.

We sat down with Research Lead Ashley Paling and HESIC Research Facilities Manager, Scott Golem, to learn how this brand new facility is designed to help growers reduce risk, strengthen resilience, and drive innovation across Canada’s greenhouse sector.

What follows is a snapshot of our conversation, condensed and edited for clarity.

1Can you describe the new facility? What are some of the key design features and technologies that have been incorporated?

Scott Golem: The new HESIC research greenhouse at Niagara College is designed with flexibility and industry relevance in mind. It features

five individually controlled research bays, each approximately 130 square metres, equipped with independent systems for temperature, humidity, CO2, irrigation, and lighting. Some bays use spectrum-adjustable LED lighting, while one bay remains outfitted with high-pressure sodium (HPS) lighting to reflect the realities of many commercial greenhouses still using legacy systems. Each bay allows us to replicate commercial-scale conditions on a research scale, so the results from our trials are directly applicable to real-world production.

The facility supports a wide range of growing systems. One bay is focused on hydroponics and includes ebb and flood tables capable of running up to four different nutrient trials simultaneously, as well as two nutrient film technique (NFT) systems. We’ve also integrated Phenospex DroughtSpotter scales to run drought stress trials. Another bay is dedicated to high-wire crops such

Two Varieties, One Goal Resilient, High-Performing Tomatoes

Meet Ferguson RZ and Camiletto RZ , two reliable tomato varieties from Rijk Zwaan, both equipped with Rugose Defense for added protection against ToBRFV. Ferguson RZ is a red beef tomato offering consistent fruit weight, strong yield potential, and balanced vigour. Camiletto RZ is a specialty red plum tomato with high yields, excellent shelf life, and a labour-friendly, vigorous plant that delivers firm, flavourful fruit. Contact us to discover how these resilient varieties can elevate your tomato program!

For more information, contact: Rijk Zwaan Canada | David Janik, Fruit Crop Specialist | d.janik@rijkzwaan.com RZH Canada Ltd. | Max Saad, Director of Sales | max@rzhcanada.ca

Seminova / Agrocentre Fertibec Inc. | (450) 454 5155

Terralink Horticulture Inc. | (604) 864-9044 www.rijkzwaanusa.com

Ferguson RZ

Camiletto RZ

as peppers, cucumbers, and tomatoes. We’re in the process of licensing one bay for cannabis production under Health Canada regulations, which will allow us to conduct specialized cannabis trials in a compliant environment.

The remaining bays are equipped with expanded metal mesh benches, providing a flexible setup suitable for a variety of crops including floriculture, leafy greens, herbs, and vegetables, making them ideal for multi-purpose trials and quick adaptations based on industry needs.

Beyond the greenhouse bays, we’ve incorporated a vertical grow room with approximately 35 square-metres of production space spread across six rack levels in two separate systems.

This setup supports research into vertical farming and controlled environment agriculture. Supporting all of this is our analytical lab and postharvest labs, which will enable us to conduct inhouse quality assessments, including tests for colour, texture, flavour, yield, and nutritional content, across a wide range of horticultural crops.

2Howdoes this facility differ from other research greenhouses in Canada in terms of equipment, environmental control, or capabilities?

Ashley Paling: Canada already has a great ecosystem of research centres, specifically in Ontario, so we’re really honoured to see ourselves as a valuable addition to that existing network. Where we’re unique at HESIC is how we’re structured to serve businesses and ultimately growers.

As a newly designated Technology Access Centre (TAC), our mandate is to help businesses validate and develop their horticultural innovations and technologies, moving those products towards commercialization. HESIC provides access to leading-edge technology, equipment, and expertise, which we make accessible to clients of all sizes, from small- and medium-size enterprises to larger businesses and also commercial growers.

A few things set us apart:

• Accessibility and responsiveness: Because of our scale, we can move quickly to design custom projects and adapt to industry needs.

• No intellectual property restrictions:

Five individually controlled research bays

• Each 130m² in size (6m gutter height, 8m width)

• Hoogendoorn IIVO systems

• Bays with spectrum adjustable LED and HPS lights

CONVIRON GEN 2000 growth chamber

• 5m² growing space

• Tissue Culture kit

• Short height and tall height kit

Vertical Grow Room

• 44m² total, 35m² of growing space

• Hoogendoorn controls for room with HVAC for cooling/temperature control

• Philips LED lights

Equipment of note

• Phenospex Traitfinder and DroughtSpotter scales

• Hoogendoorn Aquabalance

• A variety of LICOR, Apogee, Thermo Fisher Scientific, and other relevant pieces of equipment

• Two laboratories: analytical and postharvest with relevant instruments to plant growth and postharvest quality analysis

The new HESIC research facility is equipped with:

We don’t keep any intellectual property (IP) related to the project work we do. Results and any IP generated belong to our clients, making collaboration straightforward.

• Student engagement: Our projects involve students who work alongside clients and our research team. It brings fresh perspectives, builds the next generation of talent, and provides clients with motivated hands on the ground.

• Range of systems under one roof: From vertical farming and hydroponics to conventional greenhouse production, we can test innovations across different controlled environment models in one location.

• Third-party validation: We specialize in validation and development of new innovations in controlled environment agriculture.

• Dedicated research team: Our team of experts is completed focused on conducting research projects in the horticultural space with clients. We see our role as being an agile, industry-focused service provider who complements the work of other research centres in Canada.

RIGHT

Ashley Paling, research lead at HESIC and part-time instructor with Niagara College points out some of the features inside the new research facitlity’s vertical farm.

3You’ve mentioned some of new technologies and tools at the facility. Can you explain how these instruments will give growers insights they wouldn’t typically have access to in their own operations?

SG: One of the most exciting things in my mind is the Phenospex TraitFinder. It is basically a plant phenotyping camera. It works on multi-spectral wavelengths to take pictures of plants. It 3D models each plant as it grows and it allows us to see things like nutrient deficiencies or early senescence before it shows up for human eyes to see. [It’s] a very strong tool for when we look at performance of different soil amendments, fertilizers, and different types of media, along with other ways of growing, where we can really start to see what’s happening inside the plant. Another really impressive one is the Phenospex

HORTICULTURAL

AUTOMATION SOLUTIONS

DroughtSpotter scales. These allow us to precision irrigate individual plants to do drought stress tolerance tests. We can incorporate this into projects to see the impact of innovations. We can really start to see the capabilities with these pieces of equipment; how do we maximize water and fertilizer efficiency without being detrimental to the plant.

Another one we have is the

Hoogendoorn Aquabalance, which is a scale for growing in highwire rockwool slabs. It allows [for] precision irrigation to, again, save on irrigation water and fertilizer, and ensures healthy growth with efficient resource use. We incorporate the use of this into projects, to see how an innovation is impacting irrigation. We also have an analytical lab and a postharvest lab which have a wide range

LEFT

A trial assessing disease resistence in different pepper varieties is currently underway in one of the research bays at the new HESIC greenhouse at Niagara College’s campus in Niagara-on-theLake.

of capabilities. We have equipment to measure the impact of client innovations on everything from plant size, biodensity, nutrient analysis, pigment content, and sugar content, in addition to a wide variety of genomics equipment. Whatever clients are looking for or whatever new products they would like us to evaluate, we probably have the ability to run those tests, tailor a project to their needs and give very accurate results.

4With

vertical and hybrid production models included under one roof, how do you see crossover opportunities between traditional greenhouse production and vertical farming research?

AP: We tried to aim for having as much adaptability and flexibility as possible in one centre. Our main goal [was] to make sure that we can serve as many clients and their research needs as possible, so we incorporated as many different growing systems as we were able to into the design. Our area of focus as a TAC is specifically in controlled environment agriculture research and in working with clients to evaluate their innovations in that space, which includes both traditional production and vertical growing.

Something we’ve seen in agriculture, horticulture and greenhouse spaces is a trend of field crops moving indoors because of weather patterns and land usage over the years. A great example of that is peppers, tomatoes, and cucumbers: a majority of those are grown in Ontario greenhouses right now, and that wasn’t always the case. We’ve also seen within the last 10-15 years, [a] trend of more crops transitioning from greenhouse growing to specifically vertical growing environments. This is a more recent technology and it’s still an evolving field, which means there’s lots of opportunity to work with clients on research projects.

Something important to consider is that vertical grow facility rentals come at a very high cost, so having this space available for clients to test out new ideas means that we can take away that risk

Greefa grading machines are a perfect balance between fruit-friendliness, efficiency and ease of use, with different models available to cover a wide range of fruits and vegetables.

FEATURES: controlled temperature, humidity, lighting and CO² in various growing environments, five individually contained bays, dedicated horticulture and postharvest laboratories, and vertical grow room.

Niagara College’s Horticultural and Environmental Sciences Innovation Centre is actively seeking technology, innovation and product validation and development projects to fill this new specialized research greenhouse and plant growth facility.

We collaborate with industry across the horticulture chain on:

Greenhouse and Controlled Environment Agriculture Trials

Product Collaboration and Development

Technology and Innovation Evaluations

Genomic Services

MEET WITH US. WORK WITH US. Contact us today to learn more:

David DiPietro, Manager, Business Development

ddipietro@niagaracollege.ca ncinnovation.ca

There’s definitely some broad themes I think our facility is flexible enough to be able to address.

of that initial investment for them. In addition, many clients may have innovations in the vertical grow space but may never have their own facilities and need a space where their products can be evaluated. We have that pre-existing infrastructure to take the risk out of innovation and just focus on their product, its performance and the actual questions that they want answered.

5What kind of applied research projects will growers/industry be able to follow or participate in?

SG:We focus on applied research that has direct relevance to the horticultural industry and commercial operations. Projects might include:

• Variety trials for vegetables and specialty crops;

• Cannabis-related trials with our soon-to-be licensed cannabis bay, vertical grow room, and labs;

• Technology evaluations, such as new lighting systems, substrates, or automation tools;

• Soil and nutrient studies, including amendments like composts, biofertilizers, rock dusts, and fertilizers;

• Pest management strategies and products, including biocontrols, pesticides, and other integrated pest management strategies for specific crops;

• Crop quality testing, from fruit texture and nutrition, quality and sweetness, to shelf life;

• Sustainability initiatives, such as waste reuse or circular economy projects.

Because of our TAC designation, we’re committed to working directly with clients to answer practical questions, test innovations and reduce risk around adopting new practices.

6What role will industry stakeholders play in setting research priorities for the greenhouse?

AP: Clients are at the centre of our research program. We build projects in response to their needs, whether that means testing a new input or innovation, validating a product, or helping troubleshoot production challenges. Our advisory connections, industry consultations, and direct partnerships ensure that we’re not just doing research for research’s sake, but tackling real-world challenges that matter to clients, growers and the industry today. We can help with connections for acquiring funding

LEFT

Paling (left) and Scott Golem show off the ebb and flood tables in one of the new greenhouse bays at the new HESIC research facility.

to help offset the costs of our services, Intellectual Property Ontario (IPON), expertise on trial design and interpretation, and delivering industry applicable results.

7Looking ahead, what do you see as the biggest challenges and opportunities for Canadian greenhouse growers that this facility could help address?

AP: It’s important to focus on current challenges, but it’s also crucial to look ahead [at] what’s coming down the pipeline. We can’t see every single

challenge that’s coming our way, but there are some trends and common themes in the industry that I think we can help clients with:

• Sustainability and resource use: Evaluating innovations with the goal to reduce inputs, recycle waste streams, and maintain profitability under tighter environmental standards.

• Crop diversification and innovation: Innovations that address pathogen resistance, climate and temperature adaptation, expanding beyond

LEFT

Rear shot of the new HESIC facility where there are five self-contained research bays where the team can carry out industry-focused trials.

traditional crops into high-value or specialty crops that can make operations more resilient.

• Risk reduction: Providing an independent space where clients can work with us to validate and further develop products and practices before scaling up in their own operations or moving to commercialization.

There’s definitely some broad themes I think our facility is flexible enough to be able to address,[and] we can take that risk out of asking questions and really focus on providing the answers.

For more information on HESIC and Niagara College, or to connect with the HESIC team about possible collaboration, visit ncinnovation.ca, or contact our Manager of Business Development, David DiPietro at ddipietro@niagaracollege.ca.

TOP LEFT

A hit at Sunshine Greenhouses in Manitoba is the sandbox area near the front entrance of the greenhouse, where the kids can play while the parents shop.

BOTTOM LEFT

Chinos Bistro is open year-round at Sunshine Greenhouses, allowing customers to wander the greenhouse with a latte in hand.

At Gardenworks locations across the province, Leanne Johnson mixes retail strategy and event programming. Their “impressive bulb selection for fall planting” sets the stage for autumn, while the “Art of Autumn Event” offers contests, seminars, and terrarium workshops to engage customers. The holiday season is another highlight, featuring mingle and shop events, pet photos with Santa, and holiday workshops.

For TERRA Greenhouses, variety is key. John Hawley from TERRA Hamilton explained that merchandise diversification has been central: “Currently, we are telling a fashion, toy, artificial, and very strong sustainable, local fragrance and food story through our newly acquired Kind Matter brand.”

To maintain customer engagement in the depths of winter, TERRA Hamilton hosts markets from mid-January until just before Easter. Some of TERRA’s five locations run a winter market with over 40 local vendors each Saturday, “making the store a weekly destination and keeping us top-of-mind until Spring transitions.”

TERRA’s senior retail operations manager, Phil DiFlorio, added that affordability and variety are equally important.

GETTING IN THE SPIRIT

“With most customers being price conscious, we have been running daily door crashers year-round to entice people to buy and, more importantly, come out and visit one of our locations.” He added that their workshops span both horticultural topics, like growing herbs indoors, and lifestyle activities such as jewellery making and yoga.

On the East Coast, Cedarcrest Gardens

Preventing injuries between people and machines in your greenhouse: Your safety checklist

Greenhouses are busy, fastpaced environments. With carts, conveyors, forklifts, and workers all moving around in tight spaces, the risk of someone getting struck by equipment or materials is high. These types of injuries are called struck-by injuries and they are one of the leading causes of serious workplace incidents in Ontario’s greenhouse sector.

“Greenhouse operations rely on mobile equipment like tote carts, scissor lifts, tractors, and pallet wrappers,” says Joshua Paine, Machine and Robotic Safety Consultant with Workplace Safety & Prevention Services (WSPS). “But when people and machines share space, there’s always a risk. That’s why it’s so important to have strong safety controls in place.”Struckby injuries can lead to lost time, costly claims, and long-term harm to your workers. As an employer, you’re responsible for identifying hazards, implementing controls, and ensuring your team is trained to work safely around equipment.

6

tips for your greenhouse to prevent struck by injuries

Whether you’re growing vegetables, flowers, or cannabis, these six tips can help you protect your workers and your business:

1. Identify your workplace hazards

Before you can train your workers on how to safely work around moving equipment, you have to understand what the specific hazards in your workplace. Start by reviewing the tasks your workers perform and identifying where they might come into contact with equipment or materials. “Look closely at each step of the job to pinpoint where injuries could happen,” says Joshua. Once you’ve identified these risk areas, put controls in place to prevent incidents, such as reorganizing the flow of traffic or adding barriers.

2. Make training clear by overcoming language barriers

Workers need to fully understand safety training for it to be effective. Providing health and safety information and training in the language of the workers is the best way to ensure they fully understand what’s being taught and can protect themselves from hazards. Communicate effectively without words and utilize visuals, such as photos and videos, to demonstrate safe practices. Another effective way to overcome language barriers is through demonstration: show workers how to perform a task safely, then observe them doing the job to ensure they understand the instructions.

3. Keep materials secure and walkways clear

Loose carts, bins, and containers can quickly become hazards. Secure all items properly to prevent them from falling and injuring a worker. When filling bins or carts, keep the weight manageable to avoid strain when pushing or pulling. Designate proper storage areas and keep pathways free of clutter so your team can move around safely. This

not only prevents injuries but also improves workflow and efficiency.

4. Always use machine guards

Machine guarding is essential to preventing struck by injuries. “Make sure adequate machine guarding is in place to prevent access to hazardous motion and workers are trained to recognize the hazards and report them,” recommends Joshua

5. Separate people from equipment

Space is often tight in greenhouses, but it’s important to separate pedestrian walkways from areas with mobile equipment. Consider one-way traffic flows, mirrors at blind corners, and physical barriers where possible.

6. Stay ahead with maintenance

Regular inspections of carts, conveyors, shelving, and machinery help catch issues before they become dangerous. Schedule preventative maintenance and keep records to ensure everything stays in a safe working condition.

Have questions or need help identifying hazards? WSPS is here to help WSPS offers expert consulting, training and resources to help greenhouse employers meet legal requirements and create safer workplaces. Let’s work together to make sure every worker goes home safe. Visit WSPS.ca to learn more.

ABOVE

“We want people to come in at Villeneuve and have a moment in the nature looking through beautiful environments,” said Martin Breault from Pépinière Villeneuve in Québec, which offers customers a more than five-kilometre trail system, a petting zoo, and is a draw for bird-watching enthusiasts.

has built a strong reputation for blending seasonal experiences with community events. Heather Saunders outlined a packed calendar: “In October, we are having a fall festival and are inviting some food trucks to come and set up for the day. In November, we offer workshops to make our 12” outdoor winter planters. We are always fully booked with a waiting list.” Their Christmas open house adds festive spirit with “specials, draws, treats, hot apple cider and sometimes entertainment,” while “Pet Pics with Santa” has become a charitable tradition, raising funds for a local animal rescue. Even in midwinter, Cedarcrest hosts more than 30 vendors with a weekly farmers’ market.

From koi ponds and bistros to fall markets, holiday traditions, and winter workshops, garden centres like Shelmerdine, Sunshine Greenhouses, Grow and Gather, Gardenworks, TERRA, and Cedarcrest are drawing visitors year-round. These initiatives keep traffic steady, strengthen community ties, and position garden centres as destinations even when gardens lie dormant.

Priva Connext Philips GrowWise smart spectrum helioSENSE

Priva offers integrated greenhouse lighting control within its automation and climate systems, helping growers optimize plant growth and energy efficiency. Solutions like Priva Connext use PAR sensors to measure light levels, enabling modulating LED control that adjusts to natural light and cropspecific needs. Integrated with energy management, these systems reduce costs and allow remote monitoring and control via platforms like Priva Operator, making sustainable, efficient lighting simple for growers. (priva.com)

PLANT EMPOWERMENT: THE BASIC PRINCIPLES

Automatically optimize LED lighting to save energy or boost crop growth up to six per cent. Philips GrowWise smart spectrum is an innovative algorithm designed to automatically optimize horticultural LED lighting based on real-time sunlight irradiation in just a few clicks. Signify empowers growers to achieve energy savings or boost crop growth by automatically replacing less efficient spectra by more energyefficient ones. ( lighting.philips.ca)

PlantEmpowerment:TheBasic

Principles details how an integrated approach based on physics and plant physiology leads to a balanced growing method for protected crops resulting in healthy resilient plants, high yield and quality, low energy costs and economic greenhouse concepts.

PlantEmpowerment:TheBasic

Principles details how an integrated approach based on physics and plant physiology leads to a balanced growing method for protected crops resulting in healthy resilient plants, high yield and quality, low energy costs and economic greenhouse concepts.

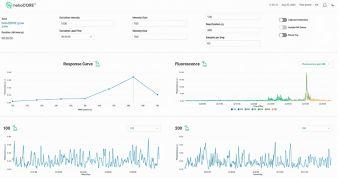

$197.95 | Item #9082903508

Heliospectra continues to develop its smart lighting platform, helioCORE, by introducing helioSENSE — a proprietary biofeedback sensor based on chlorophyll fluorescence. With helioSENSE, the plant determines the optimal and maximum light level, which can be used as a setting for light control. HelioCORE™ also features a DLI calculator that incorporates weather forecasts, local PAR sensor data, energy prices and peak prediction programs, helping Class A and Class A-eligible growers to achieve significant energy savings. ( heliospectra.com)

Verjure Arize L3000

The new Verjure Arize L3000 by Acuity Brands redefines greenhouse lighting with unmatched power, efficiency, and durability. Delivering up to 4,300 µmol/s at 3.5+ µmol/J, it’s more compact, lighter, and built for maximum uniformity with our new glass optic. Featuring an independently controllable Far Red channel, robust 6kV surge protection, and the highest ambient temperature rating in its class, the L3000 ensures long-term performance. Serviceable, sustainable, engineered and built in North America with toptier components, it’s the grow light built to last. For more information or a light study, contact Hort Americas Canada at 1-844-255-9197 or canada@hortamericas.com. ( hortamericas.ca)

OCTOBER

VERTICAL

Oct. 7 to 9

Amsterdam, NL

CANADIAN GREENHOUSE

Oct. 8 to 9 Niagara Falls, ON

INTERNATIONAL

Oct. 13 to 16

Bloomington, MN GLOBAL

Oct. 16 to 18 Anaheim, CA

IGCA CONGRESS

Oct. 19 to 25

Cape Town, ZA

PEST MANAGEMENT CONFERENCE

Oct. 24 to 26

Hamilton, ON

NOVEMBER

FRUITNET TOMATO CONGRESS

Nov. 11 to 12

Málaga, ES

GREEN INDUSTRY SHOW & CONFERENCE

Nov. 13 to 14

Red Deer, AB

HORTEAST CONFERENCE & TRADESHOW

Nov. 24 to 26

Dartmouth, NS

DECEMBER

FLOWERS CANADA (ONTARIO) AGM

Dec. 3

St. Catharines, ON

INSIDE VIEW

GARY JONES | greenhousewolf@gmail.com

Muck or money?

Anyone running a greenhouse these days will probably feel the societal pressures to ‘decarbonise’ and find ways to disconnect from natural gas. It’s a tough proposition though, because unlike other sectors that see carbon dioxide as a polluting waste product, greenhouses actually want it as a valuable input to increase crop performance. Nonetheless, greenhouses, researchers, and supply companies around the world are working on possible alternatives. Here’s just a couple of interesting ones…

Norrbotten in northern Sweden has access to 100 per cent renewable energy, and some of Europe’s lowest electricity prices, making it very attractive to energy intensive industries such as tech data centres and greenhouses. “But it’s not just about cheap power,” says Matz Engman, Senior Advisor of ‘Invest in Norrbotten’. “It’s about how you use it. We’re promoting industrial symbiosis—using waste heat from steel plants, data centres, and fertiliser production to heat greenhouses at a fraction of the cost.”1 This benefit is also backed up with a stable climate and abundant clean water supplies in Norrbotten. Of course, there are other historical examples of greenhouses using waste heat. Unfortunately, while having cheap electricity and waste heat from other sectors to use in greenhouses is great, it doesn’t solve the issue of supplying CO2

However, cheap electricity can also open doors for other opportunities. An electrolyzer can be used to produce hydrogen, converting electrical energy into hydrogen via water electrolysis. “Not all of the energy is converted into hydrogen gas; some is lost as heat. And

allows the region to have some of the cheapest electricity in the country. Location is also a key aspect: the stability offered in Norrbotten is not just ecological but also geopolitical. “In a world with energy crises, war, and political uncertainty, we offer predictability”1 Matz adds. “Several municipalities have already zoned land for greenhouse development,” Matz says. “We have sites next to major industrial hubs like the new green steel plant near Luleå, where waste heat could be a game-changer.”1

Norrbotten also offers strong support for research and education. “We have technical universities, an agricultural university, and active R&D within the food sector,” Matz says. “We work in a triple-helix model, industry, academia, and public institutions collaborating to drive innovation.”1

WHAT ABOUT HERE?

In Canada, we have many of the benefits listed above: cheap, clean electricity (particularly in B.C. with all its hydro power), geopolitical stability, land protected for agricultural use (particularly the Agriculture Land Reserve in B.C.), and an extensive support system from universities engaged in research, development and application of new agri-tech. There is also support from government to build domestic food security, although we’d always like to see this increased and some of the red tape removed. We have a lot going for us.

“As they say in Yorkshire, ‘One man’s muck is another man’s brass.’”

that heat can be put to good use in horticulture.”2 “For many sectors, residual heat below 100°C is a waste product,” says Bart van Meurs, of Division Q, a Dutch company. ”For horticulture, though, it’s a raw material. That means greenhouse horticulture can play a role in, say, the hydrogen transition.”2 Installing an electrolyzer at a greenhouse enables hydrogen production on site. If combined with solar PV systems, that’s an ideal scenario to produce green hydrogen. Division Q hopes to have a system operational by 2026.

MORE THAN A TECHNICAL SOLUTION

But it’s not just about access to novel energy supplies. Places like Norrbotten are made more attractive because government policies enhance the technical possibilities, in this case, zoning of utilities that

From the stories mentioned here though, we’re missing some possibilities: Note what was said: “We have sites next to major industrial hubs like the new green steel plant [near Luleå], where waste heat could be a game-changer.”1

It’s not easy to move a greenhouse, of course, but maybe we would do well to explore options to change development policies/tax breaks to help locate near potential industrial partners to reap the benefits of sharing each other’s waste. As they say in Yorkshire, ‘one man’s muck, is another man’s brass [money]’.

1. “The green industrial transformation offers waste heat to fraction of a cost”, HortiDaily, 19 Aug 2025.

2. “Producing tomatoes, cucumbers, and… hydrogen?”

HortiDaily, 18 Aug 2025.

Gary Jones has worked in many aspects of the horticulture industry in BC, the UK, and elsewhere, and welcomes comments at greenhousewolf@gmail.com.