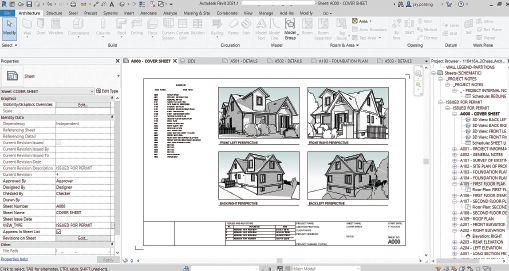

Design software

What caught our interest Pg. 24

A step further 2021 Ford F-150 Pg. 20

Design software

What caught our interest Pg. 24

A step further 2021 Ford F-150 Pg. 20

Tidman Construction looks to its roots on Vancouver Island. Page 12

Lean construction

Smart waste reduction Pg. 16

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the Digital Edition Archives at canadiancontractor.ca.

Canadian Contractor editor Patrick Flannery talks to top experts about the big issues facing Canada’s renovation and custom home contractors on our monthly podcast. Visit canadiancontractor.ca for episodes, or subscribe on your favourite podcasting service.

Canadian Contractor’s video library holds hundreds of helpful tips, insightful interviews and revealing profiles with prominent professionals. Tune in today!

Follow @CanConMag or look us up on Facebook to add Canadian Contractor to your daily diet of online interaction.

Editor Patrick Flannery PFlannery@annexbusinessmedia.com

Associate Editor Sukanya Ray Ghosh SRayGhosh@annexbusinessmedia.com

National Account Manager Amanda McCracken 226-931-5095 AMcCracken@annexbusinessmedia.com

Media Designer Svetlana Avrutin

Publisher Danielle Labrie 226-931-0375 DLabrie@annexbusinessmedia.com

Account Coordinator Barb Vowles bvowles@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com

Tel: 416-510-5182

Martin McAnulty, Vice President Sales mmcanulty@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Circulation

email:bolechnowicz@annexbusinessmedia.com Tel: 416-510-5187 Fax: 416-510-6875 or 416-442-2191

Mail:

Getting into a new industry sector, as I am with this one, always has some challenges but also some advantages. One of the advantages is you get to bring a fresh perspective informed by some of the other places you’ve been. I’ve done this a few times now, so I think I can bring an idea or two that might not be just the same as what everyone has been thinking and talking about here for the last 20 years. The challenge is to get those ideas across without being out-of-touch or really making people mad.

As I’ve read through the back issues of this magazine and dig around in the web archive, I’ve been struck by the amount of vitriol directed at the various worker’s compensation organizations across the country. To hear many of our readers (and some of our writers and even editorials) talk, you’d think WCB boards are essentially criminal enterprises run by Soviet-style government kleptocrats designed only to steal money, drive entrepreneurs out of business and ruin people’s lives.

I can only imagine the rage that must ensue when you’ve suffered an injury and can’t work to make money, but your compensation claim is denied on the basis of some niggling fine-print technicality. Or when an employee’s spurious or clearly non-work-related claim is approved. Like any bureaucratic office, WCBs can be maddeningly slow, complicated and inflexible to deal with. And like any insurance program, it’s often hard to see value from the premiums you pay. All of the above are valid criticisms of WCBs and call for reform of these systems to make them work better for employers and workers. But in the process of pursuing reform, we should be careful not to veer off into some of the wilder accusations. Doing so only makes us seem unhinged, and lessens the chances that voices from this industry will be heeded.

The specific example here is the complaint that WCBs are a “money grab.” I don’t know how many comments and articles I’ve read making the case that WCBs are motivated by a desire to collect as much money as possible. Folks, the people running provincial WCBs don’t get to keep the money they collect. They are government workers on salaries that get paid the same whether Board revenues go up or down. Yes, some WCB boards took in more than they delivered for about a 10-year period at the start of the 2000s. That’s because they rung up “unfunded liabilities” in the previous decades by keeping premiums too low and paying out too generously. That was bad management but we should be happy today that they have righted the ship and stabilized the system going forward. In any event, a naked profit motive is hardly what has been driving WCBs, since no one gets to keep such a profit.

Some might not care whether WCBs get their houses in order and continue to exist. Worker’s compensation had its origins in the early 20th century as a demand from private enterprise. It was corporations that demanded protection from lawsuits from injured workers, so the Ontario government outlawed suing employers over injuries sustained on the job and set up a quasi-judicial parallel system to adjudicate those claims and compensate workers. If WCB premiums make you mad, imagine your workers being able to take you to court for injuries and lost time.

There’s lots of reasons to hate WCBs and I’m here to share all your complaints. But they’ll be a heck of a lot more effective if we stay grounded. cc

” People running provincial WCBs don’t get to keep the money they collect.

By Patrick Flannery Editor ”

Leona wants to know how to find out if contractors doing asbestos removal are doing it right. Justin says don’t assume they are. Leona, we think your best bet is to call WorkSafeBC and get their advice.

My new neighbour has done asbestos removal in his apartment which is next to mine. He said he has a certificate for asbestos removal. I am wondering what the regulations are for this kind of job. I am also worried that asbestos is floating around the building due to what he has done. He did not post anything to let people know he was doing this. Do I call the city or WorkSafe with my concerns? I live in Vancouver.

– Leona

Yeah, I know a few people that are “certified” in some way, too. If there was asbestos removal completed in the apartment next to yours, you should have noticed activity of some sort as there is a process that actual professionals would follow. The type of material and how friable the fibres are [dictates] the removal method and measures which must be taken to safeguard the area. I would definitely look into this further with your landlord and authorities in your area. His actions may be a tempest in a tea pot or something that requires a thorough clean up by actual professionals.

– Justin

We contacted Casey Edge, the executive director of Victoria Residential Builders Association for further information. Here is what he had to say...

WorkSafeBC is the authority governing asbestos removal and unsafe work practices. Keep in mind the WorkSafeBC regulations don’t cover homeowners, just contractors. But the homeowner must dispose of the asbestos appropriately. And if the homeowner is hiring trades directly, they would be responsible as an employer. Another agency that may be involved is the city if there is a renovation taking place. There should be a permit and they will be concerned about asbestos removal and disposal.We have advocated for a renovation tax credit to incentivize homeowners to use professionals for asbestos removal.

– Casey

Alec Caldwell’s six-year-old column about the Ontario Ministry of Transportation continues to attract comment, most of it negative to the MTO. But at least one reader thinks we should have some respect for the work MTO officers do. As a commercial driver you are responsible for the safety of your commercial vehicle and trailer. That’s why the officers are out there: to protect the people that travel on highways. Too often there have been accidents (some resulting in death)

of innocent travellers and all because the commercial drivers (small or large) have become complacent. The funny thing is, you complain, but would you complain when a loved one is injured or killed because of a complacent driver?

– Phil

Rejection of project milestones

terrifies homeowner

Some contractors don’t like project milestones and we get that. But Reni wants to know what the alternative is. How can contractors and project owners share the risk?

Hello, I live in Quebec and have the following problem: I want to do a larger renovation and extension project on my house with the total cost of the project well into six-digit numbers. Two contractors (both of whom are licensed and in good standing, as far as I could check) refused to do the work because I insist on having the clause in the contract where payment is tied to project milestones and conditional upon their proving that they have discharged all payments and workers’ compensation. They are offended. Obviously, I am terrified of the possibility of a lien being placed on my property and my life savings being put at risk. What can I do to satisfy the needs of both parties and get started with my renovation? Thanks.

– Reni

Compensation boards creating skilled trades shortage

Our love for worker’s compensation boards continues to overflow…

I am a Red Seal plumber and gasfitter and I refuse to work in my trades any more because WCB denies all of my workplace injuries. I have made nine claims and been denied coverage nine times. If there is a trades shortage, then I believe it is caused by the WCB. If we are not permitted to recover from workplace injuries, then journeymen will quit their trade at an early age. Just as I have done at the age of 35. Ten years of constant agony was finally enough for me. I will not return to the trades until I see a big change in WCB’s policy. I am now back at school training towards a sustainable career. Thanks, WCB. The trades deserve what they get!

– Joe

The Voices section in the magazine selects readers’ comments that are sent through emails or posted online. To be featured here, please share your opinions about the different subjects, topics and ideas discussed on canadiancontractor.ca.

T A P C O N C O N C R E T E F A S T E N E R S

R e d u c i n g o v e r - t o r q u i n g a n d

e l i m i n a t i n g h e a d s n a p p i n g

. . . w h e n u s e d w i t h o u r u n i q u e

C o n d r i v e P r o I n s t a l l a t i o n K i t .

Sherwin-Williams has released its annual call on what interior design colours will be hot for the next year. The forecast can be an important planning tool for designers and renovators deciding what to stock for the year ahead. The paint manufacturer describes the theme of the year as “Rhythm of Color”: Rhythm is the secret to how the natural world stays in step. The same sense of balance applies to our personal sense of nature through how we live – and how we design. Fast and slow. Quiet and expressive. Virtual and physical. See it take shape in 40 trend colors, presented in four palettes designed to bring your own rendition of rhythm to beautiful life. cc

PALETTE #1 is Sanctuary:

Nature’s ability to cultivate wellness and calm is more welcome than ever. The nurturing hues of this palette, including warm neutrals and natural tones, forge the connection between the modern built environment and the living world.

PALETTE #2 is Encounter:

Layers of local character –rooted in culture and artisan craft – create an authentic sense of place. The rich but muted hues in this palette convey that heritage quality and the value of simple, meaningful experiences.

To continue to help reduce the financial burden on businesses during the COVID-19 pandemic, the Workplace Safety and Insurance Board has announced any repayment of deferred WSIB premiums will not begin before January 2021. More information on the repayment schedule for deferred amounts, along with 2021 premium rate information, will be provided in the fall. Any employer participating in the financial relief package will have to report deferred amounts by October 31, 2020. Regular monthly and quarterly reporting and payment schedules will resume in September 2020 for all businesses. Also, WSIB has determined that costs associated with COVID-19 related claims will not be allocated at an employer or class level. Instead, they will be allocated on a Schedule-wide basis and there will be no change in premium rates for 2020. Next steps for reporting and payment are as follows. Schedule 1 businesses are encouraged to start reporting deferred amounts now, ahead of the October 31 due date. They can report deferred premiums by using WSIB’s online services; emailing WSIB at employeraccounts@wsib.on.ca with each outstanding period clearly defined; or complete the premium remittance form for the corresponding reporting period and mail to P.O. Box 4115 Station A Toronto M5W 2V3. Regular monthly and quarterly reporting and payment schedules will resume in September 2020 for all businesses. cc

PALETTE #3 is Continuum:

The optimism and imagination of mid-century modernists inspired designs that reached high into the sky and deep into the sea. This palette of white, charcoal and pops of color celebrates that spirit as it bounds fearlessly into the future.

PALETTE #4 is Tapestry: Exuberance meets restraint in today’s more curated take on maximalism. The vibrancy of this palette –including lavish pinks and greens – finds inspiration in classicism, but with just a touch of cutting edge.

The Ministry of Labour, Training and Skills Development and Ministry of Education have announced the appointment of three advisors to a new committee that will advise the Ontario government on system improvements and other measures that will better enable and encourage youth to pursue the skilled trades. Jennifer Green, director of competitions and young women’s initiatives at Skills Ontario, is among the new advisors who will be providing their expertise, time and talent to serve Ontarians. Green is an industrial mechanic millwright by trade with firsthand knowledge of the apprenticeship and broader education system and an extensive background of developing programs that lead to skilled trades careers.

This panel of advisors, including Adam Melnick and Andrew Pariser, consists of industry leaders that will work with youth, educators, business, parents and other key partners and will advise the Minister of Labour, Training and Skills Development on how to make the skilled trades a viable choice for young people. Green is among the advisors who will work to introduce students from grade one to secondary school to the skilled trades in order to ensure that Ontario’s youth are aware of and encouraged to pursue the opportunities in these career paths. cc

The Canadian Home Builders’ Association has announced the first Net Zero Energy home renovation labelled under its recently launched Net Zero Energy Renovation Labelling Program pilot. The house, renovated by RenoMark member Solar Homes of Calgary, Alta., was originally built in 1985 and now has achieved a net-zero energy rating. Net Zero Energy homes produce at least as much energy as they consume on an annual basis. While there have been almost 400 NZE homes built and labelled in Canada under CHBA’s program since 2016, achieving net-zero energy through renovations is a new frontier with many additional challenges.

“Homes built to code today are much more efficient than they were in the past. For that reason, retrofitting older homes is what is necessary to make substantial improvements to residential sector greenhouse gas emissions in Canada. CHBA’s pilot for our Net Zero Energy Renovation Labelling Program supports continued improvement in the performance of Canada’s existing housing stock, which is where we need to focus to address climate change when it comes to housing – and of course that comes with the many benefits of net-zero housing, like lower energy bills and greater comfort for homeowners,” said CHBA CEO, Kevin Lee.

Solar Homes president Peter Darlington and his team are excited about being the first to achieve this milestone under CHBA’s recently launched pilot program. The renovation focused on retrofitting the exterior of the home, which minimizes disruption to occupants and results in an extremely comfortable home. In addition to decreasing the home’s energy bills – estimated to be around $2,500 lower than before – the renovation has resulted in completely netting out the home’s GHGs emissions, which was previously 14 tonnes per year. The accomplishment is more meaningful because Darlington is the homeowner. As such, he will be able to monitor the decrease in energy bills and enjoy the improvements to the home’s comfort. The Solar Homes team has been using this experience to grow its business and is sharing details of the project to help other renovators who are interested in applying its approach. cc

Trump announced on Aug. 6 that the U.S. plans to put a 10 percent tariff on Canadian aluminum ingots entering the U.S., effective Aug. 16. In response, Ottawa is threatening $3.6 billion in retaliatory tariffs on American aluminum goods entering Canada. Many building materials are on the list of products the feds are considering for tariffs,

including aluminum bars, rods and profiles; aluminum wire; aluminum plates, sheets and strip; aluminum tube or pipe fittings; aluminum doors, windows and their frames and thresholds for doors; aluminum nails, tacks, staples, screws, bolts, nuts, screw hooks, rivets, cotters, cotter-pins, washers and similar articles; frame lugs, bottom bracket shells, forks, fork tubing sets, fork bearing assemblies, hydraulic shock absorbing cylinders, spring shock absorbers, rear pivots, cable stops, cable guides and back, chain and seat stays; and prefabricated buildings. Here is an analysis from Augustine Lo, an export attorney:

The presidential proclamation affects only imports of unwrought, unalloyed aluminum from Canada, which are primary products made from raw bauxite that are used to fabricate downstream aluminum products. While seemingly narrow, this class of goods actually constitutes the largest share of Canadian aluminum exports to the United States. Assuming this 10 percent tariff proceeds, it could significantly impact the aluminum market, from competing U.S. producers of primary aluminum, to producers of secondary aluminum from recycled goods that could compete with imported primary aluminum, and to downstream users of aluminum across all industries. This re-imposition of tariffs is happening despite the recent entry into force of the U.S.-Mexico-Canada Agreement (“USMCA”) in July 2020, thus demonstrating the apparently intractable nature of the cross-border aluminum dispute. In early 2018, after a year-long investigation under Section 232 of the Trade Expansion Act of 1962, the Trump administration determined that aluminum imports from around the world threatened to impair U.S. national security. In March 2018, the Trump administration imposed a 10 percent tariff on various aluminum imports, sourced from anywhere in the world. Initially, Canadian aluminum products, along with Mexican products, were exempt. Then, in June 2018, Canadian and Mexican aluminum products were added back onto the tariff list, which prompted Canadian and Mexican retaliatory tariffs on U.S. products. Despite this tit-for-tat mutual imposition of tariffs, the three countries nevertheless signed the new USMCA in November 2018 to replace NAFTA. To facilitate USMCA’s ratification by their national legislatures, the three countries declared a tariff truce in May 2019. The Trump administration once again exempted Canadian and Mexican aluminum from the Section 232 tariffs, while Canada and Mexico rescinded their retaliatory tariffs against U.S. products. The Trump administration also agreed not to re-impose Section 232 tariffs unless there was a surge of Canadian and Mexican imports beyond historic levels, and negotiations to address that surge are unsuccessful. This truce paved the way for the USMCA’s entry into force on July 1.

As in 2018, these measures will do more to hurt Americans than Canadians, both in the form of increased prices to their manufacturers for aluminum and restricted access to the Canadian market. Glass Canada, a trade magazine for the commercial glazing industry, explained this in its August 2018 cover story, available at glasscanadamag.com. cc

Trade school is no longer Plan B.

By Stephanie Rota

Notso long ago there was a stigma attached to trade school, or “vocational school” as it was also known. Arguably, it was considered a Plan B or a direction that high school kids were pushed into. These were kids that perhaps didn’t excel in an academic environment of standardized testing. In their lack of real choices, they were similar to the generation of European immigrants in the 1940s and 1950s who found themselves reluctantly in construction and trade work because it was one of the few industries where opportunities existed. When they could not find employment in larger companies due to language barriers and prejudices, they had to create their own jobs and their own work. It was essentially forced entrepreneurship. That generation of hardworking people learned skilled trades and hustled to find work. Those that excelled reaped huge financial benefits and most others made a good living to provide for their families. But even then, the stigma persisted and nothing could rival the coveted office job.

Fast forward several decades and we find ourselves re-evaluating the merits of working with your hands and of being your own boss. Technology and automation continue to change the office landscape and lots of traditional office jobs no longer exist. But what does exist, and what can’t be whipped out by technology, are skilled trades.

The key drivers of this shift in value and appreciation for skilled trade work can be summarized in four points.

Keeping things really current, COVID-19 has forced people to work from home. Which in turn has forced people to assess their current living spaces. No time like the present to tackle that long-overdue renovation or addition to the house. Proof of this demand is evident in the 30 percent price spike in lumber. So as demand for residential construction projects has gone up, the supply of skilled labour has remained stable or even declined. Basic economics tells us the price to supply said skilled labour must go up!

2. Initiatives by the provincial government

The Ford government in Ontario, to its credit, has recognized the importance of supporting skilled trades. It’s committed $3.5 million dollars in new funding to support the trades. Ford has said, “We need the younger people coming up, going on site and getting some practical training. I hear all the time from industry leaders that we need more young people pursuing careers in the trades.”

3. The role of Instagram

Lots of the trades we work with have their own Instagram accounts. And rightly so – their work lends itself perfectly to this visual platform. No words necessary, just pictures. Photos of their workmanship, videos detailing how it’s done. Today, you don’t have to be Mike Homes with your own TV show to show off what you can do.

4. Cultural values

Without using the “M”-word, I do see a generation of young people in search of an unconventional career path. They want to carve out their own identity as opposed to being a cog in the wheel, in a rat race to retirement. They want to have more flexibility to set their own schedules. Being self-employed in the trades seems to fit these criteria. It can offer a true sense of purpose and satisfaction.

While I did go to business school for an MBA, I didn’t intentionally pursue the traditional path of academia. At one time, a graduate degree would have been a fast track to a host of high-paying management positions but that’s no longer the case today. The value of my degree doesn’t lie in my employment success but rather in the value of knowledge. But knowledge can be learned and obtained in many different forms. We have broadened our view today of what professional success entails. I love running a contracting company and I have the utmost respect and appreciation for all the tradespeople we work with. I know the future for our industry is changing and the opportunities within it are limitless. cc

Stephanie Rota is co-owner of Carmelin Design + Build in Toronto. PHOTO:

With over 60 years of leadership in structural engineering, Simpson Strong-Tie is now proud to offer smart solutions for mass timber. From our rigorously tested connectors and fasteners that provide design flexibility, to a nationwide supply network that delivers exactly what you need, when you need it — our products and expertise ensure that your mass timber projects are built faster, easier and stronger than ever.

To learn more, visit go.strongtie.com/masstimber or call (800) 999-5099.

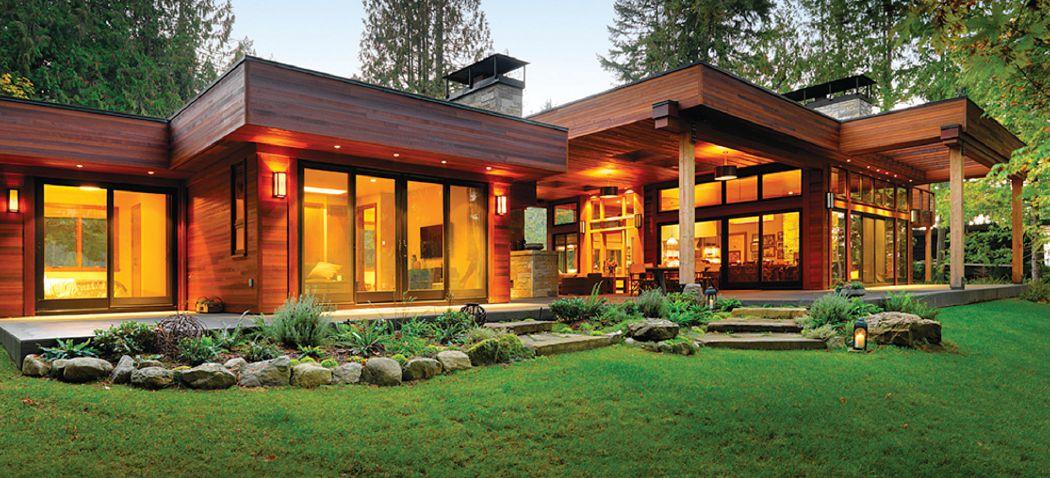

Tidman Construction is carrying forward its legacy of building quality homes and lifelong relationships.

By Sukanya Ray Ghosh

For more than 70 years, Tidman Construction, now a third-generation family business, has been building custom homes on Vancouver Island. The story of its journey starts from Halifax, where Roy Tidman started building custom homes in the early 1940s. In 1946, Roy built a sailboat and set sail with his family to their new home in Victoria,

B.C. Within a couple of years, in 1948, Roy established Tidman Construction, continuing his legacy of custom home building. When Roy’s sons Ron and John took over the reins in the 1980s after he retired, the company’s reputation of building quality homes and forging long-lasting relationships had been firmly established.

John Tidman, Ron Tidman, Andrew Tidman and Denise Tidman. Denise, Andrew’s cousin and Ron’s youngest daughter, is the EO of two retirement residence facilities that Tidman built and operates in Sidney, B.C.

Today, the responsibility for carrying the legacy of Tidman Construction forward rests on the shoulders of John’s son Andrew Tidman. Although the succession was never planned, Andrew’s roots in the building industry were quite firm. Having grown up watching his father design homes for clients, he wanted to be an architect. In his early 20s, Andrew even worked for an architectural firm in Victoria for five years.

“I originally wanted to be an architect when I was younger and that is what I had set out to do. But through a series of family events, I became a part of Tidman Construction,” he says.

During a particularly busy construction period for the company, John asked his son if he could come in

The first two generations at the helm of Tidman Construction – Ron Tidman, John Tidman and Roy Tidman in 1992.

and help out part time. Fast forward to today, and Andrew Tidman couldn’t be happier and grateful for how the chain of events put him on this path.

In his early years at Tidman Construction, Andrew started off with home design work. Having worked in an architectural firm, he had a background in that. He also worked quite a lot in customer service. At that time the company was tasked with building a retirement community in Mill Bay called Arbutus Ridge. Tidman Construction went on to become the exclusive builder of all the homes and the village centre there.

“My role was to do some home design work for that project and also act as a customer service representative,” notes Andrew. It was a natural progression from there.

“I remained in that role of customer service representative for around 10 years. And then, I ended up becoming the project manager of the entire retirement community project. Of course, I had foremen and superintendents under me. The reason

Roy Tidman, founder of Tidman Construction, specifically focussed his attention on building custom homes.

for taking charge was that my father John Tidman was starting to phase himself into retirement slowly. So, I assumed more responsibilities and more roles.” About seven or eight years ago, Andrew’s father and uncle moved toward retirement. “There was never anything discussed or said formally, he remembers. “I just assumed the responsibilities. Everything happened organically. One thing led to another. There was never any big master plan.”

Back to the beginning

Andrew’s grandfather had started out building custom homes for singlefamily living. During his time in the company, that is what Tidman Construction did. In the late ‘70s, early ‘80s, when John and Ron took over the company, they started to take on larger projects – some commercial and industrial work, as well as multi-family condominium-type developments.

However, Andrew’s interest has always been in working with custom home clients and creating higher-end custom homes.

“I have sort of steered it back to the roots of what my grandfather started, and just really created our specialty in focusing on exceptional quality, highend custom homes,” he says.

Whether it is building custom homes or doing home renovations, Tidman Construction is often called upon before the homeowner has any kind of vision.

“We are contacted to help them create a vision. I spend a lot of time with renovation clients and custom home clients helping them with the design, choosing materials and discussing finishes,” says Andrew.

Once the clients have decided to select Tidman, they go through the entire journey together.

“I like things to be unique. I also do not believe in a cookie-cutter type of design. I don’t feel we have any one particular kind of style of construction or design. I certainly feed off of what our client’s tastes are and then guide them in that direction,” says Andrew.

The secret ingredients

Tidman Construction has been on the path of success since its very beginning. Focusing on what they do best has definitely helped, believes Andrew.

“What has worked well for us I think is just focusing on what we do well and not trying to venture into things that are outside what our specialty is.”

The other ingredient to the company’s success is the relationships it has built with its clients.

“I feel that the personal time that we spend with our clients makes us unique. I’ve had numerous clients that have conveyed to me how they found

Each Tidman-built home is different. Designed according to clients’ tastes, no cookie-cutter formula is followed.

that to be such a difference. If they had ever been involved in a building experience elsewhere, they noted the difference in the personal time spent with them and our attention to detail,” says Andrew.

This is a big reason for Andrew not wanting to expand the company too much. Growing too big would take that away.

“We have deliberately stayed a certain size so that I can primarily be spending personal time with clients, helping them through the process. Building a home should be an enjoyable process for them. I spend time with them with the hope to make that journey enjoyable for them,” he says.

Currently, Tidman functions with six key people; everything else is subbed out to subcontractors.

“I think everybody we have here is multi-talented. Every one brings a great buffet of skills to the team. I think that’s another thing that sets us apart,” notes Andrew.

In this close-knit business, the team has also become a family. Additionally, the relationships built with Tidman’s clients has expanded this “family” further. “We have gone on to have continued wonderful relationships with them. To this day, there’s still people I visit all the time,” notes Andrew.

The legacy of the company is so strong that Andrew’s son Max can often identify a Tidman-built home when he spots one.

“For a part of the 70s into the 80s, we did a lot of our own design work. My father has a drafting background. So, there was some sort of signature

look to a lot of the homes that we built at that time. I believe it would be the attention to architectural detail that makes them stand out,’ says Andrew.

Having built its reputation over the years, Tidman Construction is very well known in its community. Existing clients have helped bring new clients through the door through word of mouth, instead of marketing. In numerous occasions, clients that have multiple residences have kept coming back to Tidman.

Tidman Construction is headquartered in Brentwood Bay, B.C., a village of about 15,000 people in the municipality of Central Saanich on Vancouver Island.

Challenges and challenging times Tidman Construction, like the rest of the world, has been hit with the

challenges brought about by COVID19. Although the construction industry has not really slowed down during this period, Andrew, like most other business owners, does worry a little.

“I personally feel that there’s going to be an impact even though the construction industry is busy here right now. Western Canada, in general, has a fairly booming construction industry. I might be dead wrong but my gut instinct says that there’s going to be a lag of time. And then, things will eventually slow down. To what degree, I don’t know,” he says.

While the custom home building part of the business did not see any downtime during the pandemic, the story has been different on the renovation side of things.

“I would say, the one area where we did have to do things differently was renovations. Obviously, renovation clients live in their homes. So, we stopped immediately any renovation work that we were doing for people and didn’t go into their houses once the pandemic hit. When everything started reopening in July, all our renovation clients hit the restart button at the exact same time. That proved to be challenging for us. Normally, we would stagger the scheduling of renovations,” explains Andrew.

Tidman managed to overcome this challenge due to the patience, understanding and accommodating nature of its clients.

Since the pandemic hit, Tidman has increased safety protocols. The company schedules the construction process to ensure that only a limited number of people are on any site. Meetings and appointments at the office are scheduled ahead of time. Andrew and his team also worked from home for a while, except for team members that had to be present physically on jobsites.

Supply chain disruptions have had an impact on Tidman’s work. “It has definitely lengthened some construction time frames, which would have under previous circumstances been executed much faster and more succinctly, too. It has created not only a delayed process but a random process which is obviously tough to schedule.”

Challenges are part of any business. When Andrew was younger, he did worry about a lot of things that every other business owner worries about – especially about having enough work and doing a good job for people. However, lately, nothing keeps him up at night any more.

“What experience has taught me is that things eventually have a funny way of working out. I believe if

you just do a good job for people and communicate well and deliver what you say you’re going to deliver, for the most part you will have a wonderful experience with those clients. For the most part, we have worked with wonderful people that have gone on to become friends. I find that the most rewarding. It’s what I liked about custom home building in the first place,” says Andrew. cc

•

•

• 3-piece

• Ready

The Lean approach not only boosts the bottom line, but engages workers, builds solid relationships with trades, and delivers better value to customers.

By Jacob Stoller

No builder would deny that controlling costs is a key, if not the key, to profitability. Few are aware, however, of just how much waste is costing them. Lean construction, a variation on Toyota’s revolutionary production system, gives builders a comprehensive strategy for uncovering and eradicating that waste.

“Lean is the relentless pursuit, identification, measurement and reduction of waste of all kinds in products, processes and plans, anywhere you can find it,” says says Scott Sedam, president of TrueNorth Development in Northville, Mi., who teaches Lean construction to groups in the U.S. and Canada.

Contrary to what many believe, Lean is not just about saving a buck – it’s about delivering better value for the customer’s dollar in an environment where costs keep rising.

“We strongly understand that we have to show value in everything that we do, from a $10 million house all the way down to the $100,000 reno,” says Bob Deeks, president of Whistler, B.C.-based RDC Fine Homes, which practices Lean methods.

Much of Lean is common sense. “We already had a really strong focus on process and getting things done in the right sequence,” says Deeks.”When we discovered the Lean language 18 months ago, we realized right away that we had been on our Lean journey for four years.”

Lean provided the framework for collaboration. “One of the things that first engaged us with Lean was that the language is a very effective tool,” says Deeks. “It provides structure for engaging the team and doing things better.”

Lean practices are mostly about organization and quality control. But they are also about little things, like the owner showing up early to sweep up the jobsite.

There are many kinds of waste in construction, but the most common is unnecessary delay. Lean calls this “waiting” because the work in progress, the home under construction, “waits” for the productive work to continue. Scheduling problems, rework, change orders and poor communication are typical contributors.

A common mistake is to play the blame game. “People who understand Lean realize that waste isn’t about dumb people doing doing dumb things,” says Sedam. “The source is how the company is managed and the systems and processes under which people work.”

Lean provides a frame of reference for countermeasures that range from ensuring that workers have the right tools and training to devoting more resources to planning and scheduling. The best builders, Sedam says, have their schedules ironed out months before construction begins, with all trades in agreement on timing and expectations.

“Don’t call a trade on Tuesday and say, ‘Be there Wednesday.’ That’s ridiculous,” says Sedam. “If you want to attract the best trades and keep them, scheduling is job one.”

Plans are key here. Sedam notes that when builders bring drawings into his workshops, it is common to find 75 or more errors or significant improvement opportunities. “If you’ve got lousy plans, it’s very hard to say on schedule, because there are constant phone calls and changes to mistakes you’ve made,” he says.

RDC uses Last Planner, a production system promoted by the membership-based Lean Construction Institute, on all its projects. Last Planner provides a framework for setting targets and expectations in consultation with all trades

and suppliers, beginning with the required completion date and working backwards to the start. This makes schedule performance highly predictable. Deeks reports that the results have been extraordinary.

Predictable scheduling also means fewer deliveries for suppliers and trips to the building sites for trades. “We have cold hard data showing the typical building materials dealer makes an average of six to seven trips per house more than if everything was right from plans to takeoffs to schedule,” says Sedam. Eliminating these wasted trips, he notes, makes the supplier’s business more profitable, building loyalty and increasing the odds that they will come to bat for you when you need them.

Lean teaches us that relationships with suppliers are essential to controlling overall costs. Builders, therefore, should avoid the common mistake of relentlessly shopping for the lowest price. “The only thing that buying on bid price alone guarantees is that you will never operate by lowest total cost,” says Sedam.

The Lean jobsite

Visitors to an RDC site office will notice a large whiteboard showing daily and weekly goals, milestones and other progress indicators. “This is more what you would expect to see with a large commercial project,” says Deeks. The point is that with Lean, all employees have ownership of the

project goals. And transparency is essential.

The jobsites themselves are uncharacteristically tidy for a homebuilder. RDC creates order through a variation on Lean process called “5S,” in this case, an acronym for “sweep, standardize, sort, safety, schedule.” Orderly sites not only look better, but are safer and create a less errorprone work environment, which translates to less re-work.

“We’ve worked very hard to create a culture where you clean as you go,” says Deeks.

Instilling a culture requires constant mentoring from senior management. Consquently, Deeks and his senior managers spend a lot of time on job sites.

“It’s super disruptive for me to get to a site at eight in the morning,” he says. “I have two young kids who need to be off at school. But it really brings a very different energy to the site when the owner shows up at five to eight and picks up a broom and helps them clean the site.”

Worker buy-in is also key to a safety culture. “We have a safety committee that meets once a month,” says Deeks, “and we’re always looking for ideas. I think the transformational cultural changes have been the result of the guys bringing their ideas forward.”

Lean is a significant investment, but Deeks feels that it is well worth it. “When I retire, I want my business to keep going,” he says. “But we can only do that if I create a really strong foundation and strong culture that will carry on.” cc

Pro contractor video talk online all through October with Canadian Contractor editor Patrick Flannery and top experts in business and technology. New episodes drop each Tuesday.

• Using loyalty program perks to build your business

• Understanding the neuroscience of selling

• Canadian manufacturing excellence

• Performance applications for tough climates

Using the right technology and hiring tech-savvy workers is essential for surviving in a competitive market.

By Kris Troppmann

Even in times of uncertainty, demands on the construction industry continue to grow. Since the COVID-19 pandemic began, most construction projects have been allowed to proceed on some level, while other industries have come to a halt. In order to survive in an already competitive market, it has forced many companies to catapult themselves into new, more efficient ways of working.

There is a lot of discussion around the future of construction and where the industry is headed, and the recent pandemic has only intensified this. In the short term a surplus of workers is anticipated, as some projects are deferred, but BuildForce Canada predicts that in the next decade, the industry will only be able to fill a portion of the positions needed, leaving over 80,000 unfilled jobs in the

sector. According to the Canadian Construction Association, Canada is also due to lose nearly a quarter-million construction workers in the next decade due to retirement.

So how do companies attract new workers and encourage Millennials to pursue careers in construction?

Skilled workforce

With so many workers set to leave the industry in the coming years, contractors face extreme pressure to ramp up hiring and attract a younger generation. Technology is providing an opportunity to fill that gap. Companies embracing this new way of doing business are seeing the benefits, not just by saving time and money but in growing a workforce of Millennials.

Because this generation has grown up with technology, it’s a golden opportunity. They understand how technology works and its capacity to get the job done faster, eliminating time-consuming manual processes. Drones, machine control, automation, safety technology and AI – companies that are embracing these new technologies and committed to training

will be a much more attractive option to the next generation of workers that may be considering a career in the industry.

Our education system has in the past, typically promoted a university education over technical certifications and undervalued trade schools, on-the-job training and apprenticeship opportunities, resulting in a shortage of skilled labour. Companies need to shift their thinking and discover new ways to tap into the younger generation. This includes revising training, apprenticeship and recruitment strategies to align with new technologies and changes in the industry. Also turning to tools like social media and influencers to connect with Millennials and revising job postings to focus more on technology and the new skills required for careers in construction.

The future of construction is connectivity Technology is fast becoming an indispensable part of each and every function in the construction industry and is now one of the key drivers of profitability. From keeping track of maintenance schedules, records, inventory and parts to site surveying and the maintenance and ongoing management of equipment, technology can successfully improve the efficiency, speed and accuracy of any construction operation. Earthworks, once done manually, can now be done semi-autonomously with extreme accuracy. With 3D GPS systems, the design is loaded into the machine so that with the push of a button the operator can see the terrain and know exactly where to grade, even on slopes and more complex job sites. Even site surveying, which once took days when done manually, can now be completed in hours or just minutes using drones to fly over the site. There is a growing awareness that those same technology tools that are helping companies keep costs down, operate more effectively and gain an advantage over the competition, can also help make the industry more attractive to the younger generation. For example, telematics and remote monitoring technologies that appeal to Millennials can also help prohibit bad habits like speeding, excessive idling and overloading, which leads to increased safety on the jobsite, reduced wearand-tear on the machine and increased efficiencies. Global Navigation Satellite System and machine control allows inexperienced operators to effectively operate equipment with a minimum level of instruction. It can also facilitate twoway teaching. Less experienced operators can teach more experienced operators how to use the technology to be more efficient, allowing the more experienced operators time to train new operators on the nuances of general machine operation.

New developments in safety and fatigue technologies are playing a role in increased jobsite safety. Smart cameras are now mounted on equipment to detect dangerous hazards and improve visibility, increasing awareness and safety on site. Mounted inside the cab, they work by monitoring eyeclosure duration and head poses, sending immediate alarms to operators and site-managers. There are also wearables which work by alerting operators and workers of proximity to potential dangers. All contribute to improved safety in

Companies that are embracing new technologies and are committed to training will be a much more attractive option to the next generation of workers.

the industry and provide assurance that the companies are invested in their employees’ well-being.

As a result of technological advancements, construction is much less of a physically demanding job than it has been in the past. Advancements in machine control and increased use of semi-autonomous machines on construction sites are allowing for operators of all abilities, experience and skills to quickly learn to operate equipment safely and efficiently and be more productive. These machines also feature options like touchscreens in spacious, comfortable, climatecontrolled, quiet cabs with large windows to enhance visibility, outfitted with Bluetooth and the latest technology. This is proof that both the trade and the equipment have evolved with advancements in the industry.

Apart from making the industry a more attractive proposition, investing in technology can also improve the efficiency, speed and accuracy of construction operations. Increasingly, government tenders, large contractors and large projects are demanding the use of certain technologies as a requirement to win jobs. Which means contractors not using the technology are no longer able to compete. All these advancements have resulted in projects being built faster and with fewer risks involved, but with a large portion of the workforce set to retire in the upcoming years, more needs to be done to stem the labour shortage. Strides have been made in terms of promoting gender diversity and recruiting women to construction but they are still dramatically under-represented. Rethinking recruitment strategies and efforts could help attract not only a younger generation but also a more diverse workforce. The industry is changing and technology has helped to level the playing field. The time has come for companies to invest in new ways to attract the next generation of workers to construction. Offering challenging and fulfilling jobs will create opportunities for this generation to experience longterm, well-paid and rewarding careers in the industry which could eventually bridge the labour gap. cc

Kris Troppmann is the regional technology manager at Finning Canada.

Our look at how Ford keeps adding on with the all-new 2021 F-150 pick-up.

By Mario Cywinski

In what seems like ages ago, in January, Ford Motor Company held a drive event for its all-new Super Duty pick-up truck in sunny Arizona. Much has changed since that time, and as a result Ford held a virtual launch event for its most important vehicle, the all-new 2021 F-150 pick-up.

Actor Denis Leary hosted the event, held at the former Willow Run plant in Michigan, which is significant for being where Ford built the B-24 Liberator bomber plane during the Second World War in a mile-long assembly line. Ford representatives and select Ford customers also helped launch the vehicle.

The Ford F-Series has been the top-selling pick-up truck in Canada for 54 years, and more recently the top-selling

vehicle period for many years in both Canada and the U.S. While some would take it easy when being on top, Ford chooses to do the opposite. Ford introduced the EcoBoost turbocharged engine to the line-up when V-8 powered trucks were the norm. More recently, Ford introduced an aluminum body on the F-150 at a time when steel was thought to be the only option.

“Since 1948, our hardworking F-Series customers have trusted Ford to help them get the job done,” said Jim Farley, COO of Ford. “F-150 is our flagship. It’s 100 per cent assembled in America, and we hold ourselves to the highest standard to make sure our customers can get the job done and continue to make a difference in their communities.”

All-new interior and exterior

PowerBoost hybrid model

Clamp pockets on tailgate

Tailgate work surface

Max recline seats

11 grilles options

13 wheel options

12-inch digital gauge cluster

12-inch landscape centre display

SYNC 4

More driver assistance technology

Lockable rear under seat storage

Interior work surface

Pro trailer backup assist

Trailer reverse guidance

Trailer light check

need for a generator to be placed in the bed of the truck. The integrated on-board generator is available in three levels. A 2.4 kilowatt system with two 120V 20A outlets (with a run time of 85 hours on a full tank) is standard on the PowerBoost; a 7.2 kilowatt system with four 120V 20A outlets and a NEMA L6-20 240V 30A outlet (can run for 32 hours on a full tank) is available on PowerBoost; and a 2.0kW system with two 120V 20A outlets is available on 2.7L and 3.5L EcoBoost and 5.0L V-8 models.

In addition to the new PowerBoost powertrain, five other engine options are available: a 3.3L V-6, 2.7L EcoBoost V-6, 3.5L EcoBoost V-6, 3.0L Power Stroke V-6 diesel, and 5.0L V-8. All models are mated to a 10-speed automatic transmission.

Now the 2021 model is taking things a step further, with the F-150 being available with a hybrid powertrain for the first time. Playing off the EcoBoost name, the new hybrid model is named PowerBoost, and combines the 3.5 litre EcoBoost engine (mated to a 10-speed automatic transmission) with a 47 horsepower (35 kilowatt) electric motor, and a 1.5 kilowatthour lithium-ion battery. The new hybrid model is capable of going an estimated 1,100 kilometres on one tank of fuel, and can tow at least 12,000 pounds (when properly equipped). The hybrid model is available on all trims, XL to Limited. PowerBoost also comes with Pro Power Onboard, which turns the truck into a mobile generator, eliminating the

With the truck being redesigned inside and out, the front end sees a new front fascia, choice of 11 grilles, three headlight options (halogen, LED, LED with bending), 13 wheel options, and the addition of active grill shutters and an active air dam. Ford says that every panel on the truck has been redesigned.

Many F-150 owners use their trucks to tow trailers, therefore Ford has introduced new trailer-friendly features, such as trailer theft alert, which sends a message to a mobile device when the trailer is being unhooked and the truck is locked; a trailer light check, which can check if the trailer lights are working through the FordPass app; and trailer reverse guidance, that shows various views along with steering wheel graphics of the trailer by using five cameras. Pro trailer backup assist is also available.

The redesigned F-150’s front end now features a new front fascia.

Technology is top of mind for many today and a plethora of new additions to F-150 for 2021, highlight this. Overthe-air updates allow for many updates to be done in the background while larger updates can be scheduled when the owner wants, reducing the amount of downtime needed for updating the vehicle. The new SYNC system can connect Apple CarPlay, Android Auto, and AppLink apps wirelessly. Two centre-stack screen sizes are available for 2021: a standard eight-inch and available 12-inch. An available 12-inch digital gauge cluster is also added.

“We see it as our duty to deliver not just what our customers want and need, but what they might have never thought possible,” said Craig Schmatz, Ford F-150 chief engineer. “The F-150 will be tougher than ever, and with fully connected over-the-air updates, it opens up a much wider range of potential enhancements – from predictive maintenance to feature upgrades.”

Catering to customer needs

Ford has spent a lot of time speaking with its customers about how they use their trucks. As a result, Ford has incorporated some unique features into the new truck. On the inside of the truck you can find lockable fold-flat rear under-seat storage with dividers; available front seats that fold flat 180 degrees; and an available flat surface in the centre between the seats as the shifter folds down; and a flat cover that folds over the centre. On the outside, zone lighting allows for individual exterior lights to be turned on or off and clamp pockets are built into the tailgate, as is a new work surface that includes a ruler, pencil holder, mobile phone holder and cup holder. The side of the tailgate now has cleats for tying down long items.

Ten new driver-assist technologies were added for 2021, including Active Drive Assist, that allows hands-free driving on Canadian and U.S. divided highways by having a camera facing the driver and making sure they are focusing on the road. Intersection Assist detects oncoming traffic while the driver is doing a left turn and will apply brakes if needed. Active Park Assist 2 is also new. Ford has made more safety features standard on all models from XL up.

The 2021 F-150 comes with a new work surface that includes a ruler, pencil holder, mobile phone holder and a cup holder.

With all the changes to the Ford F-150 for 2021, the company is poised to continue to be the number one selling pick-up truck for years to come. New F-150 models will be available in the fall. cc

Mario Cywinski is the editor of Machinery and Equipment MRO magazine, a member of the Automobile Journalists Association of Canada, and a judge for Canadian Truck King Challenge.

By Casey Edge

As governments prepare a wave of taxes and fees on new housing to pay for COVID-19 debt, homebuilders should arm themselves with studies showing how these costs undermine housing affordability.

A recent Fraser Institute study reveals housing in Canada’s largest cities became less affordable while U.S. housing became more affordable despite similarly rising populations and incomes. Canada’s “more rapid increase in shelter costs” was identified as contributing to the gap.

The burden of regulations on housing across Canada were outlined in a 2018 study by the C.D. Howe Institute called “Through the Roof: The High Cost of Barriers to Building New Housing in Canadian Municipalities.” Zoning regulations and development charges added $168,000 to the price of single-family homes in Greater Toronto and $644,000 in Vancouver. This was also true in Victoria at $264,000, while Calgary jumped by $152,000 and OttawaGatineau by $112,000.

The cost of rezoning restrictions was revealed in an Australian study called “The Effect of Zoning on House Prices,” which describes how obstruction increased prices by 73 percent in Sydney, 69 percent in Melbourne, 42 percent in Brisbane and 54 percent in Perth.

Reducing regulations and boosting supply would assist Canada’s housing affordability. This is supported by a study called “The Effect of New Market-Rate Housing Construction on the Low-Income Housing Market” by economist Evan Mast.

Mast says housing is an ecosystem of migration chains impacting all price points. For example, for every two market-rate homes constructed, approximately one affordable home is created. A new high-end apartment building with 100 homes results in 30 or 40 affordable homes. Encouraging market supply at all price points, which produces more migration chains, significantly assists affordability. However, these housing migration chains are not understood by governments trying to solve the affordability problem through more regulation and taxes. If governments knew how to achieve affordability, this would have been accomplished long ago.

For decades, governments have been telling builders where and what to build (zoning); when to build (permits); how to build (building code); and how much money they want from the project (land transfer tax, GST, fees, amenities). What is their explanation for today’s lack of affordability?

There is no explanation other than housing has been

turned into a politicized cash machine for multiple levels of government. For example, the federal government appears to be considering a new tax on the sale of Canadians’ primary residences, estimated to net the federal government about six billion dollars annually. The first heads-up was Ottawa adding the principal residence declaration to income tax returns. Now CMHC is funding a $250,000 study on home equity “solutions” at the University of British Columbia, whose researchers previously described homeowners as “lottery winners.”

Lottery winners? Homeowners pay amortized loans, GST, land transfer taxes, permit fees, amenities and annual property taxes, among other things. The lottery winners are multiple governments generating massive revenues from fees and taxes, such as land transfers and building permits based on the rising value of housing, not on the government services provided.

Canada’s Liberal government denies planning a tax on home sales, but the huge pandemic debt and their history of broken promises indicate otherwise. For example, the 1993 Liberal election campaign called “Axe the Tax” claimed they would do away with the GST. Not only did they renege on that promise when elected, they have refused to index to inflation the GST New Home Rebate in the interests of housing affordability.

Canada’s federal debt is expected to be more than one trillion dollars this year, not including provincial debt and municipal shortfalls. To manage this, Ottawa and other levels of government, will likely again turn to their favourite cash cow – new housing. Be prepared for a post-COVID-19 wave of taxes and fees. cc

Casey Edge is executive director of the Victoria Residential Home Builders Association.

Autodesk.ca

If you are a contractor who specializes in residential renovation and custom homes two things are true: you buy a lot of coffee and you need your design software to keep up. Clients, financers and even vendors expect to see more from your designs – 3D renderings, live pricing and quantity estimates, 2D floorplans – and all of this done quick and cheap. Individually, there are pieces of software you can purchase which will meet each of these expectations but managing and learning them all will slow you down. Where contractors can gain efficiencies is by using a piece of software that can do all these things in one place. For this reason, Revit has been used in the industry by architects and engineers. Revit LT is made for the business challenges of residential designers and builders, at the price of a coffee a day (Tim Horton’s not Starbucks). Having Revit LT in-house also allows you to use any Revit files that you may get from architects or engineers. But you may not offer in-house design and you simply receive PDF files from a designer.

3D rendering was, in the past, a costly service. It was not uncommon to pay $10,000+ per image. The cost made it only viable for large developments and developers. However, due to hardware and software improvements, the price has dropped drastically and, in many cases, you can get an image for a few hundred dollars.

Professional 3D rendering studios tend to use very complicated software that may take months to learn and years to master. The industry standard in architectural visualization is Autodesk 3D Studio Max. However, if you are inclined to do 3D modelling and rendering yourself, the best option is SketchUp. You can learn the basics in only a few hours. Although SketchUp does not offer any photo-realistic rendering options, the 3D model you create can be exported and given to a rendering company or can import it into another software.

This is where the industry standard Bluebeam Revu comes in. Consider it a PDF editor and mini-CAD. It can be used for estimation, measuring and marking up right off a PDF. The image shows how Bluebeam can be used to measure for baseboard, giving both cut and total lengths. Pricing for Bluebeam would be like adding a donut to the coffee. Many graduates come out of school with experience using both Revit and Bluebeam. Next time you meet with a client, you can show them their project in 3D with a live price estimate; they will probably forget about the coffee and donuts.

friendly program. Previously, Lumion rendering used to be quite difficult. Setting up and completing a render would take days. Today, it can be done in hours. You can even make last minute changes before a meeting and update your renders in minutes. Lumion will take time to understand how to set up lighting and different materials such as glass, brick or water. But it has fewer advanced settings, and its default set-up will provide good results.

If you want to venture into the world of rendering, things can get even more complicated. The industry standard for 3D rendering is Vray. Again, this is a software you can spend years mastering. In contrast, Lumion is a more DIY-

Contractors interested in working with a professional studio have the option of going to RealSpace. RealSpace works with almost every format of plans or 3D models. The company has noted that the most popular design software that helps streamline the 3D rendering process are Autodesk Revit, Sketchup, or Solidworks. Just about anything can be imported, including AutoCAD plans, PDFs, or images. For the DIY people, RealSpace highly recommends giving Sketchup a try as it could be a lot of fun to experiment with. If the user enjoys it, it could be an excellent tool for designing their next project.

sketchup.com

SketchUp is a 3D building design software that behaves more like a pencil than a piece of complicated CAD. SketchUp gets out of the designer’s way so they can draw whatever they can imagine, efficiently. Throughout the design-build process, SketchUp helps the user analyze problems and keep construction moving forward. SketchUp makes it easy to create 3D models and deliver them as colourful, accessible documents that tell the full story. It also helps get project stakeholders aligned. SketchUp’s AR and VR apps make it possible to host real-time, multi-user collaboration

sessions for remote attendees. The software allows its users to take decision makers through projects at scale, or immerse them in a 1:1 environment to gather feedback and quickly resolve mission-critical issues. Spending time redrawing plans can be avoided. A single 3D model can be turn into a 2D drawing in a flash with LayOut. The user can draw plans, elevations, sections, build details, model views… any detail they need to start the build. SketchUp is designed to be quite accurate, so users can be sure that anyone working on the project will have the information they need to get the job done. Another great advantage: when the model changes, so do the construction documents. Simple.

The new high-quality preview feature in Lumion 10 lets users see the highest possible quality preview of their projects before they render. They can experience how the effects in photo, movie or panorama mode will impact the final result, empowering confidence and saving time when making changes to lighting, shadows, materials and camera positions. Lumion 10.3 comes with a significant improvement to the “high-quality preview” feature by incorporating “hyperlight” lighting into the preview, enhancing the beauty of real-time view.When surfaces contain relief and detail, the materials and the entire design come to life. With the addition of “displacement mapping” to 167 materials in Lumion 10, the viewer will be able to feel the grain of the designer’s/architect’s chosen wood, the rough surface of bricks, the bumpy texture of gravel. In Lumion 10.3, it is now possible to import your own displacement maps into Lumion’s built-in or custom materials. With this feature, the act of seeing your architectural visualizations becomes the experience of feeling them, heightening emotion while drawing viewers into your designed building or space. The new displacement

map import feature requires that the user download or make their own displacement maps for Lumion’s builtin or customized materials. For the best performance, it is advisable to import 2K and 4K (maximum) textures only. With Lumion LiveSync, architectural rendering workflows will never be the same again. 3D modeling changes are immediately reflected in Lumion’s living environments. The user can explore how design decisions will impact the look and feel of their design in its real-life context. Lumion LiveSync uplifts the whole 3D modeling experience. It’s now available for AutoCAD users too. Lumion LiveSync is also available for SketchUp, Revit, ArchiCAD, Rhino and Vectorworks.

Terry loves his job and respects his boss, but doesn’t like him very much. His boss, Sam, brought him into their small 10-person company as a carpenter four years ago. Terry was new to the trade and Sam gave him guidance and opportunities that Terry acknowledges really helped him grow into his craft. With that help, and Terry’s hard work and intelligence, he has risen to be site supervisor as the team has more than doubled in size. Terry never saw himself as any kind of manager and is grateful for the chance Sam has given him.

But Sam is not an easy guy to work for. He’s short-tempered and demanding, going into extended abusive rants when frustrated. Any mistake or failure to do things exactly as he prefers attracts a stream of unfair verbal abuse, frequently calling employees lazy and stupid. He demands total commitment and perfection from his employees, expecting them to be available on short notice and at odd hours, while staying just inside the letter of the labour laws. Terry has been on the wrong side of several of these attacks over the years, as has everyone else at the company. He knows that Sam’s high standards and harsh methods have pushed him to become better at his job, but his patience is wearing thin.

The final straw comes when Terry misses an email while on holiday and doesn’t show up for a meeting held first thing in the morning on his first day back. Sam sends a lengthy tirade over email, calling Terry a bad worker and suggesting his wife is controlling him by making him concentrate on the family on vacation and not check his emails. Terry feels he can ignore slurs directed at himself, but expanding the attacks to his family is beyond the pale.

Bryan’s dilemma involved a mistaken load of wood that the delivery driver wouldn’t take back. David Weenan of David Weenan Design Build wins for his solution that combines the use of modern technology and creating a situation where you either get to keep the boards legally or don’t have to haul them yourself. David writes: Bryan only has a dilemma if he is short sighted. What to do is simple: get a newspaper, snap a picture of the newspaper on top of the load of incorrect materials in the driveway. Send it to your sales rep. Tell him to come and pick up the load as (after the third attempt of trying to sort it out) you will not be held liable for any loss or damage. This earns the respect of your sales rep in many ways and will result in you reaping the rewards that they will afford you knowing they are dealing with a stand-up guy for years to come. Simple.

There’s a great end to this story. David asked that we donate his DeWalt 20V Max roof nailer prize to the George Brown School of Apprenticeship and Applied Trades in Toronto. Instructors at the program were thrilled, and David has done his bit to promote skilled trades training in Ontario!

1. Break his long silence and give it back to Sam with both barrels. If he gets fired, he gets fired.

2. Quit. And talk to a lawyer about his options.

3. Suck it up again. The job is good, the pay is good, and Sam’s words are just words.

4. Say nothing, but begin an internal whisper campaign to see who wants to leave the company and start on their own.

5. Something else?

If you have a solution to Terry’s dilemma, email your entry to pflannery@annexbusinessmedia.com and put “Terry dilemma” in the subject line. Please don’t post your response to the Dilemma post on our website.

Entries close Oct. 12. The winner will be announced in the Nov/Dec issue.