Getting Ready for Growth, Part 2

Constructing a Budget

Page 24

The Dilemma

Give Heinz a 5-Point Plan

Page 30

Energy Efficiency

A House in a Hill

Page 20

Constructing a Budget

Page 24

Give Heinz a 5-Point Plan

Page 30

Energy Efficiency

A House in a Hill

Page 20

Hard work and a love of building takes Andrei Sosnovsky from Belarus to success in Vaughan, Ontario

Page 12

Canadian Contractor has hundreds of videos online for serious residential construction professionals

Sponsored by ITW Construction Products Canada

In this collection of videos, Rob Koci talks to experts from ITW Construction Products about the different uses of specialty fasteners in the Canadian renovation and custom home building industries. Topics include failure mechanisms for screws and bolts, mechanical versus chemical bonds for anchors, concrete pins and thermal bridging solutions.

Sponsored by Home Hardware

This series of videos looks at ways to build better, faster and more profitably. Rob Koci and Steve Payne present a number of construction tips sent into the magazine by Canadian contractors – and they also interview experts from around the industry. Everything on a job site from framing to interior finishing is fair game for Site Tips.

Sponsored by Various Manufacturers

Innovation is the engine that keeps profitable construction companies going. Unless you discover new and better ways to build, you risk falling behind your competitors, and your company may be challenged to compete in the new industry landscape. Buildwire is the place for contractors to see what’s new and improved.

ISSN 1498-8941 (Print) ISSN 1929-6495 (Online)

Editor

Contributing Editors

Steve Maxwell

Media Designer

Mark Ryan

Advertising Sales

Steve Payne

416-219-9949

spaynei@canadiancontractor.ca

Account Coordinator

Tracey Hanson

thanson@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz

bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Circulation email: lmalicdem@annexbusinessmedia.com Tel: 416-510-5187 Fax: 416-510-6875 or 416-442-2191

By

Rob Koci Editor/Publisher rkoci@canadiancontractor.ca

” Employing yourself in running a renovation and custom homebuilding business is assurance you’ll get your fair share of suffering and struggle

”

I had a moment not long ago when I was having so much fun that I was full. By that I mean there was no more room in me—no capacity—for any more of the great, wonderful, pleasurable feelings I was having in that moment. And before your brain starts guessing what nefarious activity I was indulging in, I’ll tell you it was while I was floating around in a rubber dingy at a local beach at the end of a very successful, sunny day of sailing with my wife.

What was notable about the moment was that, beyond the recognition of how wonderful it felt, was the thought that accompanied it: Pleasure is not enough. It was not enough to simply enjoy the pleasure of that moment and to extend it in my imagination to a string of moments like it to the end of my life. Yes, it was wonderful and fulfilling, but not fulfilling in the bigger sense.

We all know that life includes suffering and struggle, but it was the first time I understood the need for it in living a complete life. When I arrived at work the next day, the sense for the value of struggle was heightened. More importantly, I didn’t fear it. In fact, though I didn’t know in what form it would come, I was looking forward to it.

I can’t think of any pursuit with greater challenges than selfemployment, and employing yourself in running a renovation and custom homebuilding business is assurance you’ll get your fair share of suffering and struggle.

One way to overcome it is to have a plan and vision for your future. We’ve often said so in the pages of Canadian Contractor. Vision gives you the energy to solve problems by promising a brighter future if you do.

Another way is to embrace it. Recognize that the pleasure you have planned for your future as you overcome your struggles won’t be enough. It will be wonderful, that’s for sure, but I am willing to bet that sometime in the future you’ll have a similar experience when a fulfilling moment comes with a realization of some emptiness, and you understand why there are so many stories of people who successfully extract themselves from suffering and struggle only to jump right back in.

Learn from Future You, floating around in a metaphoric rubber dingy, satisfied and happy but unfulfilled. Bring that person back here, to their past, in the middle of the struggles they are overcoming, and thank your lucky stars that you have struggles and suffering to engage you, to improve you, to define you, to grow you into the person in the dingy, not just with the pleasure of a sunny sky and a good life, but with understanding and a willingness to embrace struggle and suffering without fear.

Canadian Contractor recently came across signage on the back of a truck advertising that the employees of the painting company owning the truck were all female. Men need not apply. In a conversation with the owner, Canadian Contractor learned the key reason for the marketing focus was to attract customers who preferred to have women working in their home. We asked for your comments.

What if this idea was reversed?

That’s 100 per cent discriminatory. No company is allowed to discriminate, there should be no exception made here. If this was reversed, and the add read “women need not apply” the company would be bashed in every social media realm out there. Sad but true, this is another example of how society is “ok” with advertising a negative point of view towards men. Listen to the news, look at programming on tv, the main male characters are now generally portrayed as goofy, clumsy, un-opinionated clowns or aggressive, fearful characters that offer nothing but “masculin toxicity” to the equation. Rarely treated with any respect by the children, wife, girlfriend etc. I come from a family with two sisters (one older, one younger) and have a wife and two children (a daughter and a son). I whole heartedly believe in and agree with equality. If you’re the right person for the job, the position should be yours. What’s happening out there right now has nothing to do with equality, it’s just discrimination in a different package. This company should receive the same response as any other company advertising like that. Sorry to rant, but sometimes you just have to say things like they really are. Keep up the good work

Ian

I’ve employed women and I found that, generally speaking, though people pay lip service to wanting women included in construction, in reality when women showed up the female homeowners often did not appear to like it. It just seems to be that many women prefer to have men do their renovations.

My own experiences of working with and employing women is that it makes for a more pleasant work environment with males and females on site together. Often women are more detail oriented but overall not as strong or as willing to put up with the harsh conditions.

Dave

We should not market gender

I am a female electrician. I have a master license and run my own company. When I first started the company I had people tell me I should really market the woman thing. I do get comments here and there by clients that they would trust a woman more, but I don’t believe in marketing an all-woman company. I have three male employees now and they are the best ever and I’m very proud of them and wouldn’t want anyone else. They are the best for the job: not hired just because they are female so I can market them. Can you imagine if a company marketed all males and that no women should apply?!! Equal rights, honey. I don’t even think this should be allowed. You may as well say ‘all white electric’: see how far that gets you.

Victoria Williams

Hey there,

I am a female owner of a painting company. I have been in business for 14 years and currently have seven staff including summer students, both male and female. We work in high end residential (both new builds and renos) and the commercial and institutional markets. Last year we won the Business Excellence award for businesses under 50 employees at our local Chamber of Commerce. My parents were general contractors and I have worked in the construction industry my whole life.

Early on in my company many people assumed i would only hire women. Although I do think this is a brilliant marketing idea, one that could be run with quite far, it is not the path I chose. I have had female staff, and have always had male staff. Early on in my company we were doing a lot of commercial work and only small amounts of residential re-paint. Commercial appeals to me as that is what I grew up with, but it is hard to find women who are interested in working on a commercial site over a residential re-paint.

I hire for character, then competence and chemistry. I have had many potential hires work alongside my current staff who report back to me if they are a good fit. I have chosen not to hire many due to character issues that come out immediately. I work hard on our corporate culture. Our values are clearly defined and we have a ‘no asshole’ policy. This means my staff are vetted to be upstanding all-around good people who love what they do.

If a homeowner starts to express concern over who I send; I can confidently say I have a good team. If they need all female painters, or me to be on site with my male crew for perceived safety reasons, I encourage them to call someone else.

Suzanna Geerlinks Refine Painting

A guest blog by Doug Kramer, president and CEO of IcyneneLapolla Canada, outlined some of the changes taking place in the formulations of spray polyurethane foams (SPFs) in order to reduce greenhouse gases in the atmosphere. Long-time friend of Canadian Contractor and Green Party advocate Ben Polley was pleased.

I was very happy to see this post and the attention drawn to climate implications of traditional SPFs (and XPFs, too, I will add.) I cannot fathom knowingly damaging the climate as we did with the ozone layer, so in the instances where we do use foamed plastics my company had long ago switched to HFO-blown,

Metrie®, a leading interior moulding & door provider, recently reached out to two realtors to talk about their experiences helping clients buy and sell their homes. Mark Gilmore is a realtor in Salt Lake City, Utah, while Bill Schiavone works in Oakville, Ontario.

They were asked how trim and moulding can affect potential buyers’ reactions to a home, as well as how builders and homeowners can use interior finishings to help homes sell faster and more profitably.

For Gilmore, the answer is the big picture: “They want to know about the size of the living room, the floorplan. They talk about what the entrance is like and what condition the interior finishings are in.”

Schiavone sees similar reactions. Buyers are looking more surface level: “They see the kitchens and bathrooms. They look at the flooring, trim and crown moulding.”

The data supports what both realtors are seeing on the ground. For example, a recent study found that updating or adding crown moulding in a home has an

closed-cell SPF, for the reasons you describe. In doing so we have had to sole-source while awaiting other manufacturers’ ability to also provide a similar formulation. While we have also long used Icynene’s water-blown open-celled SPF, when I last investigated, your closed cell HFO blow foam – about this time last year – it did not yet have CCMC approval for use in Canada. Can I assume from your promotion here that it is now certified?

In advance, my thanks,

Ben Polley President, Evolve Builders Guelph, Ont.

* Sponsored Editorial *

ROI of over 170%.

“We definitely see that,” says Gilmore. In fact, Mark Gilmore recently sold two nearly identical homes. The home with crown moulding sold in only three days, while the one without took more than two weeks.

“At a certain price point,” Schiavone adds, “It becomes expected. Whether it’s solid doors or updated trim, buyers notice that. They can touch it, and they can tell when the quality is there.”

When you incorporate crown moulding, wall treatments or simply upgraded moulding options, you’re not only adding value to the home, but adding value to your business as well. cc For more information or to find a distributor near you, visit Metrie.com.

The 2019 version of Canada’s biggest homebuilder and renovator Dec. 4-6 emphasizes education for builders

HomeBuilder & Renovator Expo has expanded and now, together with Construct Canada, PM Expo and World of Concrete Toronto Pavilion, provides professionals the tools needed to sharpen their skills and continue their professional development in the biggest show . All shows combined make up The Buildings Show, North America’s largest event for products, services, educational programming and professional networking for the design, construction and property management communities.

Supported by BILD, HomeBuilder & Renovator Expo, The Buildings Show offers a two and a half-day trade show and conference, Dec 4 – 6, 2019, in the North Building of the Metro Toronto Convention Centre. The Buildings Show occupies of 400,000 sq. ft. of space in both the North and South Buildings and is comprised of 30,000 attendees from 43 countries, 1,600 exhibitors and 350 seminars and workshops.

Offering engaging interactive learning and face-to-face opportunities with exhibitors and speakers to learn, lead, and empower each other to create tomorrow’s stronger built environment, HomeBuilder & Renovator Expo The Buildings Show is the ideal marketplace to meet key industry professionals, discover new innovations, and source the latest materials, products, tools and technologies.

“This year, there will be a focus on new technology, project management, best business practices, and lessons learned for renovators and builders as well as an interior design educational stream. There will something for everyone to help grow your business, increase efficiencies, or provide value added products or services to your customers.” says Teresa Baker, Director of Programming.

Seminar topics include:

• Applying Lean Project Management Techniques: From Office to On-Site

• The Retirement Bubble is Here: What Can You Do to Attract New Talent

• Stacked Townhouses: New and Old Forms of Housing Defined and Regulated

• House of the Future

• Get Organized! Best Practices for Builders and Renovators, conducted by Rob Koci of Canadian Contracor fame!

• Connected Home Roadmap: Learn from the Research

• Project Planning and Estimating for Residential Contractors and Renovators

• Code Analysis of Residential Roofing Requirements for Climate Adaptation

• Lessons Learned: Designing and Building with Wood

• Housing Supply, Affordability and Choice: Bill 108 and the Building & Land Development Industry

• Do More in Less Time: How to Integrate Technology into Your Residential Construction Firm

• Passive House Multi-Unit Residential Buildings Case Studies

• Take Your Business to the Next Level: Your Business Plan in Writing (also presented by Rob Koci)

• Significant Energy Savings with ICF Thermal Mass vs Insulated Frame Construction

For more information or to register online, visit www. thebuildingsshow.com.

This annual event is part of a growing list of architecture, design, construction events and exhibitions owned and produced by Informa Markets including GreenBuild, World of Concrete, International Surfaces Show, and International Roofing Expo. cc

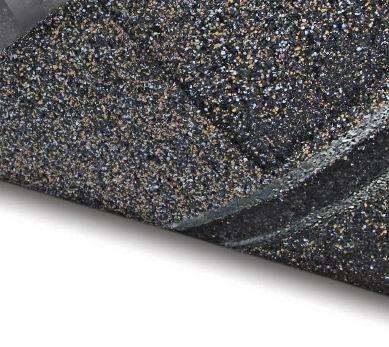

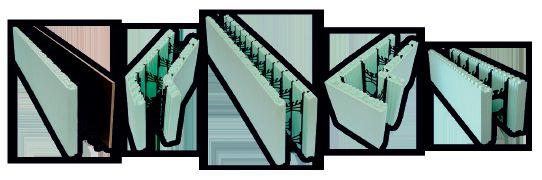

NUDURA ICFs complete the building envelope in one building step.

Building codes today demand buildings and structures be built with greater energy efficiency by utilizing continuous insulation. NUDURA insulated concrete forms allow you to complete the building envelope with one building product for a stronger and more efficient structure.

ICFs give you the opportunity to build residential, commercial, and a variety of other build projects while achieving the demands of todays building codes.

Register for a one day training course to learn more about building stronger with NUDURA ICFs on your next project.

www.nudura.com/training | 1-866-468-6299

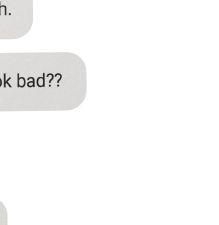

By Rob Koci

Editor’s note: The mandate of Canadian Contractor is “Make life better for renovators and custom homebuilders” and we do our best to stick to the how-to’s and “top ten tips” type stories. But then we come across a story like this one: how Andrei Sosnovsky, president of Sosna Inc. in Vaughan, Ontario, came to Canada as a young, naive dreamer from Belarus to “make a million dollars and see the world.” It doesn’t quite fit the “how to” format but this story is full of the human truth of the life of contractors so, we sat back and listened as we hope you will also.

You were a trained lawyer in Belarus. Why would you leave for something completely unknown?

I left Belarus because I was young and it was a chance to promote this Russian martial art called Sambo that I was involved in since I was 11 years old. And I thought money grew on trees in Canada. I never intended to stay. I was going to stay long enough to become a millionaire and see the world. And it was interesting, you know? I thought, why not?

What was your introduction to Canada?

I came on a one-year work visa in 1996 to teach martial arts in Timmins, Ontario. I lived at the Windsor Hotel in Timmins where I worked as a bouncer on the weekends in exchange for a tiny room on the second floor. I had 70 martial arts students to start but after a month I had only 15. They told me much later that I lost those students because I was too hard on them. My training was too difficult. I didn’t know any better. I trained the way I trained all my life but in Canada

it was a little different. They don’t want to get hurt. Some people don’t even want to sweat. It affected my salary until for three days I didn’t have anything to eat. I had no money and no food. I needed to make some money so I worked construction and I really, really liked it. I never really worked with my hands in the past. As a lawyer in Belarus I never worked with a hammer or a drill. I liked it a lot!

What was your experience encountering Canadian culture for the first time?

Total shock. I was speechless. In Timmins there was more snow that year than you had in the last 60 years. It was minus 52C that winter. And did you know that Timmins is in the Guinness Book of Records for the most liquor establishments per capita? It’s a mining town and they make lots of money and there is nothing to do there but drink. And being a bouncer at the Windsor Hotel I have seen a few interesting things and been in quite a

few situations and I was shocked. It was a cultural shock. For instance, I was not used to seeing drunk women screaming and yelling and cursing their men and hitting them and behaving obnoxious. I had never seen anything like that. In our culture, women were the gentler side. You could see men like that and even worse, but not women! And I could tell you other stories. I did not intend to stay at all. I thought, 'this place is crazy, everyone is crazy. Everybody drinks.' When I was passing through the tables a drunk woman would grab my ass and say “nice ass.” I was so mad and angry, coming from Russian culture. It was insulting.

But looking back now, I am grateful, too, because I had a lot of good stuff from that experience. I trained Indian kids at a reserve. I had many discussions with a chief of the tribe. I was invited to a sweat lodge, something that white people generally don’t get invited to. The experience I had was something I think very, very few people have—even native Canadians—with native peoples. There was a lot of good stuff and interesting stuff and stuff that taught me a lot. It was tough but I don’t regret it one bit.

How come you didn’t just go back to Belarus?

A lot of people ask me this question. I couldn’t go back home. What was I going to tell to my friends? They would ask, “Andrei, why did you come back?” What was I going to tell them? Because it’s too tough? Because I couldn’t make money there? Because I didn’t like it there? It felt like I would have been like a dog with my tail between my legs. A beat-up dog. I couldn’t stand the thought of that. That’s why I decided that I would come back to Belarus but only when it was my choice. I would come back as a winner, not as a loser. And I decided to stick it out and earn money and achieve something and then I will come back so I would not be ashamed.

Back to construction. You worked in construction so you could eat?

That’s how I ended up on construction sites and, after leaving Timmins for Toronto in '97, that’s what I did. Very soon, I was

intrigued and I wanted to learn everything I could learn. I worked for Polish renovators in Toronto. One time, me and my Russian friend took out 17 tons of brick and masonry block over a weekend from a walkout basement where we had to walk uphill to carry all this stuff by hand in plastic bins to load in a dumpster at street level The Polish guys thought, “Oh my god, who are these guys?!” We were like maniacs and I loved it. I continued to teach martial arts after work. Then in the evening this Polish guy named Caesar would come in to do plastering. It looked like art to me and he was so good at it, so I approached him to ask if I could work with him. He said, “Andrei I can’t pay you any money but sure, if you want I can teach you.” So, after my class I would return to the job site. He had a day job but he really liked taping and plastering and I would come in and he would hold my hand and he would put a putty knife in my hand and he would show me where to press and where to scrape. We would work till midnight at times. He was good to me and I learned the trade and eventually he said, “Andrei you are really helping me. I am going to start paying you.” And I got better and better and he got a better job and went to Calgary and he passed all of his clients in Toronto on to me. He had very good clients.

How did you eventually find yourself in business? Around 1999, I assembled my own computer with parts that I

bought here and there and posted my resume on the internet. Half a year later I had forgotten all about the resume but I got a call from P&C Construction and they ask me, “Are you looking for a job?” and I said, “No, but how much are you paying?” He said, "$20 per hour," and I said, "what?" because I was making around $12 or $14 at the time. I said, “Yes, I am looking for a job!”

It was commercial work. Offices, steel studs, etc. The Polish guys were sad to see me go. I was supposed to work at the IBM building offices but I was asked to go to Toyota for one day and never ended up at IBM. The foreman, a really good guy, Bob Belisle, liked me and he said, "there is no way I am giving this guy away." He was a carpenter for 47 years, a good guy that had seen it all. I worked under his supervision at Toyota. Then Toyota said why don’t you work for yourself? I asked P&C for a phone because I was being called all the time and I thought they should, so I asked, “Can you give me a phone.” I was paying for my own phone. Phones were expensive. I guess it was only $40 per month but it was still a lot of money for me. They refused. In 2001, I opened my own company. Toyota was my only client.

How did you end up in residential?

I was always attracted to residential work. Commercial work is good money but there is no feeling of fulfilment. Nobody appreciates your work. Nobody cares because it is a big corporation. As long as you get it done on time, as long as you don’t make any big surprises…as long as it is quiet, it is good. But nobody says, “Thank you.” In residential, I felt I could make something beautiful out of nothing. I could create something. So I left my assistant at Toyota and I moved on to pursuing the residential projects. I hired a designer and I hired Roman (the current Project Manager at Sosna) and another carpenter, and so on and so forth. And now we have 17, 18 employees, I guess.

When did Sosna start?

Sosna started in 2001. Initially, I did both commercial and residential work. Then there was a point I noticed I was not getting any commercial work. In commercial you have to be very good at doing the backdoor thing. Facility managers like to get kickbacks from the contractors. The bidding process is not really fair. I got a chance to look behind the curtain a little bit and did not like it at all. I can’t give these envelopes, you know, I don’t have it in me. I can’t give these bribes. It doesn’t feel good and I don’t respect myself with that. I found when I was dealing honestly I would not get a job because my price was always higher. I thought what am I going to do? I thought I would have to be the cheapest contractor or I would have to be a crook, so, I figured, you know what, I don’t want either. I don’t want to be known as the cheapest and I have no talent for being a crook.

That’s when I decided to focus on residential.

Slowly but surely, with my designer Olga, we grew on the residential side and I turned down commercial. Initially I thought I will never make money in residential but I was wrong! I am very happy I made the switch.

Talk about some of the decisions you had to make to grow and be successful.

When I started focusing on residential, I was still doing a lot of the work myself. I remember I was trying to put a screw though drywall when my phone rang. Okay, I put down the screwdriver and answer the phone and then as soon as I finish talking on the phone I pick up the screwdriver and I am trying to put the screw in again and my phone rings again. And it’s back and forth and back and forth and I realize I can’t put screws in drywall anymore because my phone is ringing off the hook. And I also notice that I am not answering the phone very well because I am thinking of something else or I have a screwdriver in my hand or I am on a ladder and I am not doing anything well. So, I decided, I will either have to put in screws or answer the phone and run the business. It was a no-brainer. I hung up my toolbelt.

Did you take a financial hit to make that decision?

I don’t remember it being extremely difficult in terms of financials. It was definitely a financial hit but I wouldn’t say it was a dramatic change.

What other moments were key to growing your company?

What helped me very much, I was actively looking to learn about how to run a business in Canada. I knew construction from my Polish guys and Bob and Caesar but, how to run a business? I was looking actively for information. CMHC had lots of good information for contractors and homeowners at that time. I was reading something, I don’t remember where, that said if the owner of a construction company has no knowledge of construction, that he was more likely to have success! This blew me away. I went to all of the courses—air quality control and building science, carpentry, everything I could do. I’ve got a Red Seal carpenter’s license and I read all the books on carpentry because that is what I thought I needed to be successful. And then I am reading this and it says to me, “It’s not true buddy! You don’t need any of this stuff!” That really blew me away. Really, wow. I was doing it all wrong. So I stopped reading construction books. I completely abandoned them and started reading books on business. I realized if I want to be successful I don’t need to know all these things. And it was true. 100 per cent. To me a whole new world opened up. I read the book, “E-Myth.” You need to work on the business, not in the business. And now you've got to find the people who do the work so you can build them. It was intriguing.

How was the transition off the tools?

At first, I was hungry for the feeling of accomplishment that I got from the tools. You know, I would do a very difficult project and

it might be the last day, and I have a difficult issue, like how to install trim around an obstacle or a bulkhead and I would work the whole day and I would find the solution and, oh my gosh it looks so beautiful and the client is so happy and you are so tired

One of Sosnovsky’s strongest commitments to the company is to define the client that is “the best fit” for his company and, perhaps more importantly, be willing to turn away those that are not.

You need to define your ideal client. We have it down to science. With the help of the Sandler sales system and my sales coach, we determined that our ideal client is a couple in their 60’s, empty nesters who have their kids grown up or are about to leave and they want to stay in their older house. We have the question on our lead sheet, “How long do you intend to stay in the house?” And when we hear, “Five years,” we disqualify them right away. It doesn’t matter what their budget is or where they are located, we recommend them to someone else. If they don’t intend to stay in the house for a long time, if it’s not their “Forever House,” Sosna is not a good fit for them. It is definitely the client who will stay in the location, enjoy our work and brag about their renovation to their friends and neighbours for years. We want to get referrals from them. We don’t want to build for people who just wants to be comfortable for a few years or who want to rent it out or sell. And our ideal client has lived in the same house for many years, too. It’s true, if someone has just moved in to a house, we might take them if they have a specific problem that we are good at solving, but only if they say, “Yes, we are planning on staying for a long time.”

Andrei Sosnovsky

and exhausted but you know your client is happy and you got money in your pocket and sit down to dinner that night and life is so good. I was hungry for this feeling—this feeling of fulfilment— that you have accomplished something, completed something to everyone’s satisfaction. That feeling was very good, but the feeling was gone because I was no longer doing construction. I felt hungry for it. Even lonely! I was doing all this business stuff and the only results was money in the bank. Yeah, it’s good but okay, move on. Only in the last few years that I started see it differently. I am building a company. Yes, I am not building walls and stuff but I am building my company. It is also a creative process and I am finding that old satisfaction again.

Now I realize that I have unique opportunity to influence people in other ways. Do I still miss that sense of accomplishment? Yes. I think sometimes if I had the option for someone else to run my company, and me just working on the tools, I would rather do that, because I loved it.

Okay, let’s keep going with teaching. Talk to contractors in the $1/2 million gross revenue range. What would you tell them?

First, never think that you know everything. Always learn from others. That would be my biggest advice. To actively seek out help. Be it a business coach, or sales coach or a NextLevel group or some sort of peer group or something where they can learn from someone that is ahead of you. That is the most important thing. If you are just trying to invent a wheel on your own, eventually you probably will if you are determined, but it is going to take you a long time and will cost you a lot of effort and it’s just not worth it. Learning from others is a lot easier. And you have to continue doing it. All the time.

And when you are delegating, first of all you need to realize what happens if, and what will you do if, and you build the scenario and then find ways and strategies to avoid problems and

prevent bad things from happening.

Running a business is like a chess game. A good chess player thinks a couple of moves ahead. He thinks what is next and what is next. The further you can see, the better player you are. And the same thing goes with construction. If you are thinking a few moves ahead, everything goes very smoothly. But if you look at only what is happening today, you can’t be successful. I see it all over the place, many contractors even my framer who is building my house. I ask him what are you going to do tomorrow? He says, we’ll see, I’ll let you know tonight. He has no plan. He has no plan. Amazing! No plan whatsoever.

And it’s important also to say this: Probably the most important aspect of all for me. That is praying to God. All we can do is our best effort but the result is in God's hands, not ours. Praying for guidance, patience and wisdom is crucial to me. I'm afraid to think about a single project that I would start without a prayer for help. There have been few occasions when God saved my health or reputation. Faith also helps put things in perspective. Knowing that this won't last forever and that there is something else more important than business helps relieve the stress that our industry is so susceptible to. cc

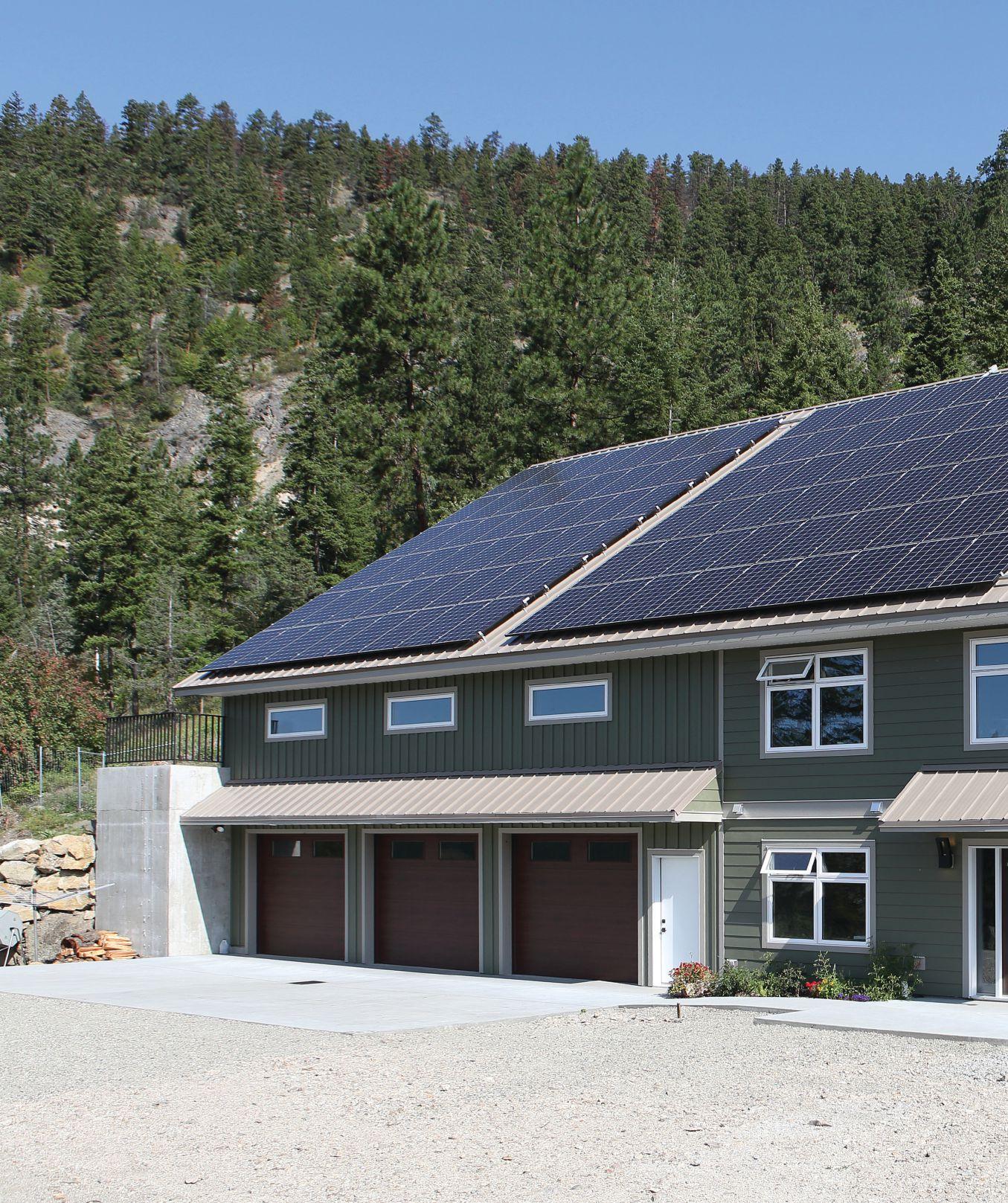

A progressive client wanted “comfortable living with minimal environmental impact.” Keith Construction and Design delivered.

Design: Keith Construction and Design, Vernon, B.C.

Construction Keith Construction and Design

Solar Array: Roost Solar

FuftHaus Earth Tubes: Trevor Butler

Photography: House: Don Weixl

LuftHaus: Trevor Butler

Solar Array: Steve Russell

After a stuttering start, the owner of this high tech, nominally Net Zero home in Vernon, B.C. he calls his “Earth Ship,” found himself looking for another builder when it became obvious the first builder chosen just “wasn’t getting a feel for it,” the “it” being incorporating into a remotely located house up the side of a mountain the most creative, progressive ideas available today in new home construction.

Ken Dahlen, owner of Keith Dahlen Construction, on the other hand, was up for the challenge. “You’ve got to look at it differently. People might say, ‘Well architecturally, what is it?’ but you have to look beyond the architectural to the concepts of, say, creating a solar roof and building the house into a hillside.”

And not incidentally, you have to be willing to work continuously with the homeowner on virtually every aspect of the technology, including the crazy ideas for which most builders have little tolerance. For instance, during the planning stage, the owner had the idea of building a reservoir uphill from the house and generating hydroelectricity through small turbines as the water flowed to the house. With untypical patience, Dahlen says, “We did a cost analysis and told him it would cost more to pump the water up to the reservoir than was worth it.” The idea was scrapped.

However, just about everything else you could think to build into an energy efficient home was included. The homeowner had “concepts” says Dahlen, and Dahlen worked with him to see them become reality. One of the first was to build the house right in to the mountain so the north, east and west walls were inside the mountain and only the south facing facade was exposed.

Dahlen and his engineers ran some numbers and showed that the homeowner could achieve 95 per cent of the climate smoothing effects he was looking for by burying only the back wall. The design was modified. The rest of the house is super-insulated, similar to Passive House construction. “The walls are double staggered 2 x 6 stud exterior walls with R 32, spray foamed the ceiling to R 60. The works,” says Dahlen.

The heating sources start with the south facing window wall that allows massive amounts of natural light and heat. Next up in a hydronic system of in-floor heat on the first floor with the heat provided by a wood stove. With the super-insulated walls, it promises to be enough to heat the home, but there was also installed an Earth Tube system (see sidebar), a series of tubes run into the hillside that are used primarily to provide cooling in the summer but also when heating the house to reduce the gradient between the temperature of the outside air being heated and the inside air temperature desired, thus reducing the amount of energy used.

One of the innovative additions to the Tesla Power Wall lies in its advanced monitoring system. The owner can see energy production, output and efficiency in real time, all the time, anywhere there is an internet connection. So far the sytem is producing exactly what was expected, says Power Wall and solar array installer Steve Russell. "The winter production will drop off, but it is pretty easy to see it. And being higher up on the mountain helps the production," he says. Though the feed-in tariff is not as generous as that in Ontario, any solar energy produced but not used and pumped into the provincial grid will give the home owner credit on his energy bill.

Unfortunately, the B.C. codes have not yet caught up with the sophistication of these new forms of heat and require what it calls, “a primary source of heat” for which none of the above systems qualify. The simplest and cheapest solution to meet code was electric baseboard. “It will likely never be used,” says Dahlen.

The most dominant and obvious feature of the house is the solar array, which suppliers about 40.26 kW of power. The owner, being very passionate about solar, required the entire house to be designed around it. Then there is the 36-degree tilt of the due-south-facing roof, which is the most efficient angle for generating energy at the home’s latitude. The steep angle also allows for snow to run off the panels easily, helping efficiency. The house was purposely designed with almost no roof obstructions: no stacks, vents, valleys or ridges to get in the way of the panels, and only one chimney. Even the installation of the panels was done in such a way that the they can be easily

This earth tube system, brand named LuftHaus in the case of this home, uses the stable temperatures underground to mitigate the fluctuations of the unstable air temperatures above ground. It is most effective in providing cooling in the summer, as the gradient between above and below ground temperatures is usually between 10° - 15°C. So, on a day where the air temperature is 30°C, the system can easily reduce the temperature to the low 20°’s. Unlike a geothermal system, the earth tubes don’t need to be more than eight feet below the surface. Outside air is pulled though the underground

repaired, replaced or upgraded.

And unlike most solar installations, the power generated by the solar panels is delivered not only to the grid, but also to a Tesla Power Wall comprising two very large lithium ion batteries that put out 13.5 Kwh and powers the home in the event of a grid outage. The home is normally run first by the solar power sent to the Power Wall, then from the municipal grid. In the event of total grid failure, the Power Wall itself, fully charged and will no supplemental energy supply from the panels, could supply the energy needs for the house for about two days.

The house also excels at water management. Toilets are lowflow and the plumbing is designed for planned installation of a greywater system that recycles water from bathtubs and showers to be used to flush toilets. Rainwater from the roof is channelled into in-ground drains which then flow into a 2,000-gallon cistern for use in irrigating gardens and landscaping. cc

tubes by the furnace, cooled, and then connected to the forced air system to cool the home.

In the winter, the reverse occurs, where the outside air is warmed as it is pulled into the house through the tubes and, though it is not enough to heat the house by itself, it provides warmer air for the furnace to heat thereby reducing the energy needed to bring the living spaces up to a comfortable temperature.

One of the attractions of earth tube systems is their low-tech nature. In some cases, the air is brought in to the home by convection and no mechanical help is required to circulate the air. Otherwise, the fan of an HRV unit or the furnace fan are enough. They system amounts to little more than buried tubes dropped in the ground during construction before the basement is backfilled.

By Rob Koci

In the last issue of Canadian Contractor, we looked at the proper structure of a Profit and Loss (P&L) statement for a renovation or custom homebuilding company. In this issue, we will discuss assembling a one-year budget.

“Begin with the end in mind,” says Stephen Covey, author of the iconic book, The 7 Habits of Highly Successful People. That’s good, simple advice and the core reason to make a budget for your company.

A budget is your vision in numbers, so making a budget assumes you have a clear vision. One of the contractors this magazine is working with (see Part 1 of “Getting ready for growth,” Canadian Contractor July/August, 2019) intends to change the makeup of his company to slowly wind down and eliminate the revenue it earns as a subtrade and migrate its focus entirely to a 100 per

cent consumer-facing design/build renovation company. His experience is a great example we can use to explain the process of building a budget.

Let’s call this company Freely Contracting and the owner, Fred. The $644,800 revenue Freely generates comes from homeowners and General Contractors (GCs) with an 80/20 split in favour of homeowners. Of the 80 per cent from homeowners, none of it is design/build, but rather exterior siding and window-and-door installation. In other words, the move from Freely Residential and Commercial to Freely Design Build (100 per cent residential) will have to give up 20 per cent of current revenue and move the other 80 per cent to a sector of the industry it does not currently serve.

So, how will that happen? What are the key moves he will have to make to

get there? How long will it take? Let’s ask these questions and a few more before we attach numbers to his budget.

The best place to start is to ask how the revenue move to 100 per cent design build will happen. Let’s look at what is involved:

Freely relies exclusively on wordof-mouth marketing. You can see in his current P&L (fig 1) his marketing expenses were $270 for the year. The company does not even have lawn signs. The website is very nicely constructed and homeowners see Freely as a potential contractor, but for exterior and interior upgrades and repairs only. There is no suggestion that Freely does

Continued on page 26

BUDGET FOR NEXT YEAR

Now we have a new vision for the company and Fred has made some decisions:

1. It will take two years to be fully transformed to a design/build company.

2. He will have a designer in place as a subtrade by the second half of the year (line d, fig 1). The cost of the designer will be reflected in the reduced GP (line g, fig 1).

3. He will spend $1250 to send his best guy for some training in business and leadership right away (line 15).

4. He will establish a marketing budget for the design/build work he aspires to right away to redesign his website, build his social media presence, create brochures and other sales materials and order a dozen lawn signs (line 10, fig 1). He will use his existing mailing list to begin to promote himself to homeowners as a design/build firm.

5. He will end the work he is doing as a subtrade by the fourth quarter of this year (line b, fig 1).

6. He will expect to win $130,000 of design/ build work (line c, fig 1), probably a few kitchen and bath renos, or a small addition.

7. He will expect a slight drop in his GP as he hires a new person to take over his job site duties and gets them up to speed (line f, fig 1) while at the same time he works less on-site and more on the business. Because the money he was making as part of COGS will drop, he’ll pay himself a little more as the business owner (line 5, fig 1).

8. He will hire a more experienced bookkeeper/accountant that can help him stay on top of his numbers (line 9).

REVENUE

design/build work. However, as a result of its excellent work and good reputation, it has a great mailing list of its past customers.

Given this, it is clear that, where marketing is concerned, Freely will be building up a plan from scratch. That means an upfront cost of…well that will depend on how fast Fred wants the transition to take place. It also means a new focus and a change of culture. That will have to be reflected in the budget. But, let’s leave that for now and look at something else.

The “design” in Design/Build

Design/Build companies need designers. Freely has a great builder in himself, but he’s no designer. It will take time to find the right designer who is willing to work behind the scenes and let Freely be the face of their design work, relatively easy where kitchen design is concerned, but whole house renovation design is something else. It won’t be necessary to bring them on payroll right away, but Fred will have to plan one day to do so.

Will it be in the first year? If so, somewhere in his one-year budget, he will have to acknowledge that increase in payroll. More likely, Fred will be using subtrade designers to do Freely Design/Build plans for at least a year before he has a designer on staff.

Design/build is by far the best model for renovators to command the margins they need to maintain a healthy bottom line. But the model is not currently Freely’s model. What will it take to redesign its processes to accommodate a design phase in the production schedule? How should the billing be structured? How much does Freely need to bill for design? However it works out, the budget will need to recognize

the design billing separate from the construction billing and Fred will need to decide when he thinks the design revenue will start to flow. If it is this year, he’ll need to add a revenue line to his budget named “Design Fees.”

Here’s another consideration. Fred’s work redesigning the company will take him away from the job site, which takes up about 60 per cent of his time now. He will have to replace himself at some point as he makes the necessary changes to the company. What will that cost? How much additional time will he need off-site to get the company pointed in the right direction? At some point in the budget, there will need to be money to hire another carpenter.

And then, there’s the guys Freely has three employees now. One of them, says Fred, is close to ready to run the jobsites without him, leaving him to sell design/build projects. That employee will be a key factor in making the changes necessary to grow. Fred needs to make sure he is on board with the changes, and wants to take on the additional responsibility that comes with the expansion into design/ build. He’ll also need some training, not only in leadership, but in the general process involved in a wide variety of renovation work. Yes, he knows exterior installations, but has he supervised a basement pour, or pulled a permit? There is a cost to getting him up to speed and it has to be reflected in the budget.

The P&L for the past year (not shown) shows total revenue of $644,800. The Gross Profit (GP) is $193,440, which is 30 per cent of Revenue. Total Expenses are 19 per cent of Revenue, which leaves an 11 per cent profit. That’s pretty

good for a renovation company. Now read through the changes he makes as illustrated in the sidebar on the previous page. You will see tha the end result of the decisions as outlined in the sidebar is clear from the budget. The company’s Net Profit (NP) will drop from $164,500 to $19,312 — from 11 per cent to three per cent. That’s a little close to the breakeven point, but the upside is that the first year of his big changes is profitable and steers his company in the right direction.

Note also, the Revenue portion of the budget has two new lines to include the expectation of future revenues for design work and design/build projects (lines c and d). Over the next few years, he’ll keep all four lines in the P&L until he is a fully functioning design/build firm and can drop the Subtrade and Non-design/build consumer work.

Of course, there are many hours of research that will have gone into making this budget. For the marketing budget to be realistic, Fred would have had to talk with a web developer, pulles prices for the printing and design of new brochures, priced out and designed lawn signs and made up a plan for increasing his social media presence. He will have asked other contractors what they charge for design and changed his sales technique to include the relationship building that is so important to turning design clients into build clients. As he sees the company growing and increasing staff, he will have started to write a Policies and Procedures manual and employee contracts for signing instead of relying on a handshake and good manners.

Growing a business is not for the faint of heart. But whatever direction you want your company to grow, the foundation is a proper budget. In the next issue, we’ll discuss your operational business plan. cc

By Paul Duffy, M.A.Sc., P. Eng.

Last issue, Duffy pointed out why the regulatory industry makes innovation so expensive. In this issue, he uses the realworld example of Slab on Grade construction to illustrate the roadblocks to innovation and how they create real world problems.

There are many factors driving the need for innovation, ranging from energy and environmental imperatives to limits on raw material resources, or simply finding more effective ways to build, reduce cost or improve affordability, etc. We have all seen the workings from researchers, policy analysts, lobbyists and the like. To continue building without new systems and technology advances is nothing short of crazy.

To illustrate the point, it really takes a couple of examples. Slab on Grade Construction

Firstly, consider slab-on-grade construction. Why do we build foundations a minimum of 4 feet below grade in Canada? The answer is simple—to get footings below the frost line. But, what if you insulate the footings so that frost does not penetrate the ground, how far down do you need to go? Well the Code does not tell you.

No big deal… you have to go down four feet, so insulate the walls and turn the basement into living space. It’s not the best solution—moisture ingress can be an issue and the view underground is less than ideal, but, creating living spaces below grade does kind of turn a lemon into lemonade, as the expression goes.

But wait, suppose you are building a home for seniors, or someone who has mobility problems. You don’t want a house with stairs. You can add an elevator, I suppose, with all the associated costs. Or, you can simply build a slab-on-grade house. But that is not described in the Code particularly well, so you will need to hire an engineer, and because the Code doesn’t help much, be prepared for delays getting a building permit because most municipalities will balk at a house that does not have a basement or at least perimeter footings that go below the “frost line”.

Not convinced that this is important to you? Slab-on-grade houses are not common in this part of the world so is it a real issue or am I just making a mountain out of a molehill? How about building a house near a lake or river… chances are you will hit the water table close to the surface of the land… do you really want to go down 4 feet to avoid frost? Do you

want to drain the lake? I have seen lots of folks try to solve the problem by moving in soil, sometimes hundreds of cubic meters of soil to raise the grade and protect their foundation. You can easily see lots of situations where tens of thousands of dollars are added to the cost of a construction project because the builder needs to place footing below the frost line. Does that sound more sensible than a slab-on-grade foundation?

Still not convinced? Maybe you simply want a basement walk-out at the rear of the home. If there was a simple solution that could save you thousands of dollars, wouldn’t you want to hear about it or at least have that option?

The interesting thing is that most of the world builds without basements. Yes, it is true that you don’t need to go down below the frost line in places like Florida or Texas so the way they build might not necessarily work in Canada. But consider the way they build in places like Sweden. Swedes often build with insulated slab-on-grade construction and they have done so for years. Here is the crazy part…their Code was based on research partly done right here in Canada! In the 1960’s, a Professor by the name of Fred DeLory at the University of Toronto did pioneering research into insulated slab-ongrade construction and his work made its way into Nordic Building Codes, but the Codes for foundation design right here in Canada never did change. It’s hard to say whether we should be proud or embarrassed.

It’s a pretty important (and ironic) gap in our Codes but is it the only area where we are lagging? Sadly, no it is not.

Next issue: Roof venting

Questions and comments on this article can be addressed to Paul Duffy and Associates Inc. cc pduffy@jpaduffy.com

CMHT37825S 25 foot tape measure

Tape measures are disposable items for every professional builder, so you’ve no-doubt owned, used and destroyed many tapes over the years. The new Craftsman 25-foot tape is about as good as tapes get and well worth considering. Big numbers on a 1 1/4”-wide white blade, a big hook with a strong magnet, and a locking button that’s easier to use than most raise the performance of this tool to pro levels. The Mylar blade coating gives the tape a stronger-than-usual feel, and though I couldn’t get the blade to stand out the full 13’ as claimed on the package, the 12’ I got is plenty. I especially like the flat back edge of the tape case. It works perfectly for taking inside measurements by extending and locking the blade. Every hardware store carries lots of tapes, but most are homeowner grade that won’t last for a pro. Despite Craftsman’s name as a brand for weekend warriors, the line is now owned by Stanley Black & Decker, so quality is better than it used to be. The CMHT37825S is a professional-grade tape that won’t disappoint. Suggested retail of $32.99, but you’ll sometimes find this tape as low as $25. cc

The smaller a drill or impact is, the better you’ll like it in your pouch. This is true as long as power and workability are there, too. That’s what I found with the new DEWALT 12 volt Xtreme sub-compact drill driver and impact driver combo.

At 1006 grams (2.2 pounds) for the impact and 1076 grams (2.4 pounds) for the drill driver on my postal scale (both with 2 amp-hour batteries that come in the combo kit), these are light tools indeed. The impact is especially easy to like. At 5”-even from front to back without a bit, this tool is short, maneuverable and exceptionally easy to slip into any ordinary pouch.

One long-standing beef of mine is the way it often takes two hands to get a cordless tool battery out of a tool or charger. Sometimes you don’t have two hands handy, right? Batteries on both the drill driver and impact pop out nicely from the tool

and charger one-handed. At 1 15/16”-thick x 2 1/2” x 3 1/2” and 220 grams, you won’t notice a second battery in your pouch. The balance point on both tools is right at the trigger, exactly where you want it for best comfort. The DCK221F2 combo kit I tested goes for $269 with charger and battery. The bare drill driver is $119 and the bare impact $129. Don’t install the belt hooks if you plan to carry the tools in your pouch. cc

The Gebaur Building Group was growing nicely, but not breaking any records. President Heinz Gebaur had built the company up from “Less than nothing,” he would often say. He recalled with some passion how tough it was for him and his wife, only a week away from losing everything, to decide to carry on with only $700 in the bank, two kids in school and the mortgage due in two weeks.

The salvation for them was a contract with a local retailer to do its window and door installations. It was tough, low margin work, but it paid the bills and put bankruptcy in the rearview mirror.

Things are different now. The service work that saved Heinz brings in only a fifth of his revenue but takes up 60 per cent of the company’s time. Worse, the bottom line contribution is poor. At the same time, he is pulling 90-hour work weeks, with 35 of those hours dedicated to it. What was once a salvation has become an anchor on his company.

On the other hand, the work has been a great lead generator. The retailer is a key supplier and will be none too happy when he cuts the cord. He has staff dedicated to the division he would have to let go. How does Heinz deal with this?

Heinz needs a five-point plan to transition out of the installs contract with his retailer. Can you help him? See some options at right.

Last issue, Gerry and Sam Grundland received some negative social media comments subsequent to the publication of their receiving an award from their local homebuilder’s association. We asked how they should handle the negative press that was shading their positive news.

Of the many responses we received, we feel Shawne Yonan, administrative supervisor at EPG in Saskatoon was the most thorough in their response: “Gerry & Sam should first call the customers that were affected and request a meeting with them.

I don’t think a lawyer needs to be involved at this point, but they should mention that restitution was made by repairs and refunds. Then they should ask that the customers withdraw their comments and negative reviews after an agreement has been made.

Gerry and Sam should suggest that, if there is no agreement, they would have to seek legal counsel. But I think the customers would agree that they should withdraw their comments. Then Sam and Gerry should go on the review site and be honest that the situations were resolved and the customers have come to a mutual agreement and have withdrawn their comments. Maybe the former clients could actually mention that the trophy was well deserved after a few bumps in the road that were resolved.”

Congratulations, Shawne. You will be receiving a DeWalt Atomic 20V MAX LithiumIon Brushless Cordless Compact Drill/Impact Combo Kit. Enjoy!

Here’s the start of a five-point plan:

1. Raise his pricing to the retailer until the retailer decides to fire him.

2. Develop a media plan to replace the leads he was getting from the installs

3. 4 and 5. What else should he do?

If you have a five-point plan for Heinz, email your entry to rkoci@canadiancontractor.ca and put “Heinz dilemma” in the subject line. Please don’t post your plan as a comment to the Dilemma post on our website

Entries close October 25th. The winner will be announced on www.canadiancontractor.ca on November 8th.

DEWALT’s new 12V MAX* XTREME Brushless Drill / Impact Driver Combo Kit + DEWALT New 20V Max Cordless Heat Gun

Retail value is $269 for the Xtreme Kit and $169 for the 20V Max Cordless Heat Gun (bare unit only)

Last year’s winner of the ITW projects contest: Stephen Cartwright

Last year, contractor Stephen Cartwright of Canadian Waterfront Services, Ltd. won $5,000 of GRK fasteners and a Paslode nail gun. Stephen sent us photos of this beautiful boathouse and boat port he built for a client at Gloucester Pool, Muskoka, Ontario. If you’ve got your own completed project that used GRK fasteners — no matter what type of construction it is — let us have a look. You, too, could win the grand prize.