Job Costing Made Easy A Simple Method For Contractors page 32

Homebuilding Excellence

A Unique Project in Montreal page 26

Pro Methods For Wood Stain

Steve Maxwell's Masterclass page 39

Job Costing Made Easy A Simple Method For Contractors page 32

Homebuilding Excellence

A Unique Project in Montreal page 26

Pro Methods For Wood Stain

Steve Maxwell's Masterclass page 39

Oakville, Ontario contractor Mike Cochren shares some salesmanship advice from 35 years in the business

Sales Tips From A Pro 18 An interview with Oakville, Ontario builder Mike Cochren.

Creative Eye 26 A photographic tour of some supremely well-designed infill homes in Montreal

Job Costing Made Easy 32 Tracking your expenses across multiple renovation projects is made easier if you implement the system we show here.

Exterior Wood Finishes 39 Steve Maxwell explains stains and staining techniques for exterior wood in the Canadian climate.

Editorial 6

The pitfalls of selling are almost all mental - which is why we need mentors.

Voices 8

The best of the recent online comments at www.canadiancontractor.ca, the most outspoken forum in our industry.

Site Notes 12

An interview with Casey Edge, head of the Victoria Residential Builders Association. Plus: A report on a recent DeWalt power tool event in Nashville.

The Buildings Show 36

A preview of the giant construction trade show coming soon to downtown Toronto.

Dilemma Contest 46

Send us your solutions to this month’s contractor business case study and you could win a cool tool from DeWalt.

Volume 18, Number 4 September/October 2017 canadiancontractor.ca | Tel: 416 442 5600

80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published six times a year by Annex Business Media.

PUBLICATION MAIL AGREEMENT #40065710

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Alec Caldwell, Mike Draper, Steve Maxwell

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbizmedia.com

Tim Dimopoulos, Vice President tdimopoulos@annexbizmedia.com

Ted Markle, Chief Operating Officer tmarkle@annexweb.com

Mike Fredericks, President & CEO

”We could blame Willy Loman or Herb Tarlek, but it’s our own fault

”

By Steve Payne

All of us being pushed for time – and none of us having as much grey matter as we like to think we have – we all tend to form mental constructs about various jobs and professions. That way we can pigeonhole entire groups of people in easy-to-remember slots.

Computer programmers: Nerdy, socially-inept adolescents.

Government employees: Lazy, entitled clock watchers.

Doctors: Super intelligent, learned authority figures.

Architects: Artistic, creative geniuses and nutcases.

Here’s another one. Sales representatives: Pushy, aggressive manipulators.

You don’t have to agree with any of these characterizations, but many people hold to them. Especially that last one.

Maybe this is why – whether we admit it or not – selling is so much more difficult than it needs to be. Anyone who has ever knocked on a door trying to sell anything to anyone, has heard the inner voice of doubt. Of doom, actually.

“Is my tie on straight? Is my fly done up? Geez, I hope I don’t have anything stuck in my teeth!”

If you’ve never felt nervous showing up for a sales presentation to a “prospect” (an intimidating term in its own right), congratulations. You obviously have made a fortune by now. You could probably quit already.

Where does this sense of inherent unworthiness – so common in the sales profession - come from?

I think it starts with sad sack salesman figures from popular culture like Willy (Death of a Salesman) Loman and Herb (WKRP in Cincinnati) Tarlek. It’s reinforced by the sales incompetence inflicted on us in the evening when we pick up the home phone to hear some telemarketer reading –usually badly – from a prepared script.

What we all need are models of sales excellence. People who are so good at selling that they inspire others to want to do likewise. People who bring honour and class to the profession of persuading other people to sign contracts and part with their money.

Steve Payne Editor spayne@canadiancontractor.ca

In our industry, there is no hall of fame for selling, no Nobel Prize for ‘Renovation Sales Excellence.’ All we have is the continued existence of renovation and homebuilding firms into their fourth and fifth decades, headed up by builders who somehow learned to be salespeople, too.

We believe that Oakville builder Mike Cochren, on the cover of this issue, is one of those models of sales excellence.

Anyone who needs to make a sale from time to time (most of us) should turn to page 18 and see what Mike has to say about the art of persuading renovation customers to pay for real quality.

Bob Collins

Home Building Centre – Gravenhurst Gravenhurst, ON

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Experts at Home Building Centre and Home Hardware Building Centre to provide the tools, materials and services you depend on – from dedicated contractor sales staff and easier ordering through phone, fax or email to job site deliveries, credit services and package pricing. With a relationship built on trust, you know you’re building on a strong foundation.

pronews.ca

In July, an unlicensed “electrical contractor” was handed a five day jail sentence from a provincial court judge, plus a $40,000 fine from Ontario’s Electrical Safety Authority, for completing hazardous pot light work with no license and no inspection. When we reported this online we got the following complaint right away from a contractor reader. We agreed with him and amended our story.

“Please don’t call him an electrical contractor!”

The article starts: “A Brampton, ON electrical contractor felt the full force of the law…” That’s an insult to legitimate contractors everywhere that are licensed, insured and take out permits. There’s no way this guy should be referred to in this way.

Klaus

Another post on the same topic…

“Glad they stuck it to this guy!”

I love this. I am a fully licensed electrician, and I am always fixing bogus work done by hacks! I am glad they stuck it to this guy… Yes, send the message out!

Albin Wandeler

And one more post we received on this issue…

Why are there no photo IDs of tradespeople?

Re: the unlicensed “electrician” who was jailed. A while ago I asked for electricians and other compulsory tradespeople to have a license photo ID or a driver’s license incorporated with it.

But there is no need for alphabet soup regulatory agencies. Nor do the compulsory trades in the Ontario College of Trades need inspections of their work. Simply give customers the chance to identify the real contractors from the crooks. Then if they allow themselves to be defrauded that should that be their fault and nobody else’s.

Oliber

Nail guns are one of the best inventions our industry has seen in recent decades. We recently wrote about how to handle them safely – which is not difficult if you follow a few common-sense rules.

He was blinded in left eye by a nail gun

As someone who was blinded in his left eye from a nail gun, I

can personally attest to their danger, and the cavalier way many tradesmen handle them. I was 19 when the accident happened. I had received almost no training. And never once was it mentioned to me that I should wear safety glasses.

Now with 20 years as a safety specialist in construction, it is nice for me to see that things are starting (ever so slowly) to change

Samuel Livingstone

If we published in print every negative post we got about Ontario’s WSIB, we would have a magazine as thick as a phone book (remember those things?). Contractors from other provinces, please bear with us while we restrict ourselves to just two posts about the Ontario workers insurance monopoly this month…

“WSIB forced me out of business”

The WSIB had overcharged me on my last three years of business before I had to close the doors from all these government fees.

They are still hounding me for one last payment and yet they refuse to credit me the thousands they owe me from overpayment. Some BS about not being able to go back past one year of payments. They won’t hesitate to bring up an “adjustment” payment you forgot to make from five years ago, however.

We have made no claims ever in 15 years of business and never saw a rate decrease but we knew if we made one claim our rate was sure to double up. The WSIB is a scam and it will destroy other small businesses like it did mine.

To add insult to injury to contractors in Ontario, add in a tax hike, a promised $15/hour minimum wage from Kathleen Wynne and that massive increase in electrical costs. All this means that a zero-skilled-labour worker has to be charged out to customers at $30/hour for a contracting business to break even. My workers in my six years in business made more money than me. I did the calculations and I would have made more money if I was on welfare and doing cash jobs. It’s a despicable government we have here.

John Doe

And here is one of many replies to this post…

“Gouging and bullying small businesses…”

Very respectfully, I am saddened to hear of another small business closing their doors.

I am a permanently disabled worker who was nearing retirement anyway, thankfully. In my early years I also had a

small business for nearly ten years so I understand the frustration felt by all who need to deal with Ontario’s WSIB.

Let us simply start off by stating WSIB is CORRUPT and this is what has been happening.

WSIB gouges and bullies small businesses. It is a complete lie that WSIB can only go back one year when you make a request for information. You can and should request your complete file from WSIB. WSIB only works for WSIB.

Here are some facts that injured and disabled groups have that should make small business owners in Ontario equally angry.

WSIB claims that higher premiums were necessary to cover their multi-billion dollar “unfunded liability.” These are bills that WSIB might eventually have to pay: not today but years in the future.

WSIB rebates are regularly paid to multinational corporations that wipe out the expense of WSIB premiums paid into the plan by them. Small businesses are carrying the full burden of WSIB since they do not have the political influence that multinationals have.

[Many] injured and disabled workers today are completely denied any loss of earnings benefits, medical and prescriptions under the guise of [various WSIB] policies.

So what happens to these monies, since accidents victims are not getting them? These are used to pay WSIB employees much more than what they would make anywhere else. The rest is invested into funds that make money that the government can access to balance their books or other government pet projects.

In Saskatchewan, premier Brad Wall has used these so called surplus funds created through claim denials by that province’s WSB plan to balance the provincial budget.

This is fraud and thief. Premiums are paid by workers and the contract should be binding to pay beneficiaries.

Disabled workers are suing the WSIB. Join them. Small businesses and workers are all victims of this fraud on the public. Go to www.fightwcb.org for more information.

Ontario citizens deserve better government. WSIB is run by Elizabeth Witmer, the former Tory minister. The NDP in Alberta has capped the wages paid to its WSB workers and has been trying to return that province’s WCB to its founding principles.

C.

Hawkins

Our contributing editor John Bleasby wrote a series of online posts recently about the technical aspects of passive houses. In addition, in our last magazine, we carried a special supplement on Building

Envelope Technology. A couple of online posts continued the discussion.

“Plastic bag moisture-trap homes”

John, I appreciate your posts and follow them very closely. However, I would like to give my input to your post where you assert that “Homes don’t breathe: people do.”

Saying a house should ‘breathe’ is not wrong. A real breathing home has a somewhat permeable wall/roof system. This cannot be provided with any foam insulation and petroleum-based membrane products. This can only be achieved with “real green and sustainable” products like wood fibre insulation and similar products.

All of us were told as toddlers never to put plastic bags over our heads. Obviously, we wouldn’t survive, right? Why then do we want to live in a ‘plastic bag moisture trap home’ instead of a comfortable and healthy environment?

Nevertheless, a great air ventilation system is a great asset. Andreas Herrmann

Here is a post in response to Andreas. The Grenfell Tower fire in London, UK, killed more than 80 people in June of this year. Blame has been placed on the flammable exterior cladding on the 24-storey residential high-rise.

Andreas Herrmann makes good points. The Grenfell Tower insulation/cladding contained the energy equivalent of 30,000 litres of gasoline and gave off hydrogen cyanide. Other examples of costly mistakes in the pursuit of energy efficiency without due diligence include leaky condos and asbestos and urea formaldehyde insulation. In addition, if in the near future we are able to harness unlimited energy from the sun via technology (Tesla shingles, better batteries) does it matter if homes are superinsulated?

Casey Edge, Victoria Residential Builders Association

John Bleasby's posts last month also included a technical discussion of HRV systems. Here is a post from a homeowner with problems with their unit.

We have just built a house to passive house standards and have put a balanced ventilation system in. I cannot tolerate the sound that the HRV makes. The ducting in the house carries the sound of the motor through the house and also transmits sound from

one room to another. There must be a system out there that does not make such a noise? The contractor says if I don’t like the noise don’t use the HRV. But as your diagram indicates an HRV is essential to a super insulated home.

Eve

Here is John Bleasby’s reply…

Possible solutions, Part 1

Eve, I’d get your mechanical contractor in to have a look. My HRV unit is suspended on straps from the joists above, so the unit cannot reverberate against any stud walls. Is yours? Also, your unit should have variable speeds you can program from the master keyboard. Maybe yours is set for a high speed, hence the noise? Just some random thoughts. The HRV should not be so noisy as to bother you!

John

Possible solutions, Part 2

This is a topic that too many future homeowners really like to ignore, or are not aware of. I used to sell Zehnder units for passive houses, and it’s a requirement for these units to be very quiet and properly installed as to not transmit any mechanical noise into the walls. I’ve had a few customers replace their units with ours, because they ended up turning the units off due to the noise. In an airtight house, that’s really not a good idea. My advice? Pick a quiet unit to begin with, mechanically isolate it from the walls it is mounted on (i.e., hang it on extra studs that are not coupled to the drywall, or special rubber decouplers, hanging a unit by a chain can still transfer noise into the ceiling, unless you have springs in there, even then it may still transfer noise through the ducting etc.).

Also, use absorbers in your supply AND return lines: the noise can travel upstream through the ducting. Also pay attention about room to room noise

transmission. In a home run system, where all the runs go back to a sound absorbers attached to the unit, it is much harder for any noise to travel between rooms.

Lastly, sizing the unit too small can also be an issue. If you are running your unit at the max to reach the desired ventilation amount, the fan blades can be really noisy. If you oversize the unit and run it at a lower rate, they can be very quiet. Careful though, not every unit lets you set the speed in small enough increments to properly balance the ventilation of the house.

So it really pays to pay attention to the fine details. I know some of the whole house systems can get pricey, but what is much more expensive is to buy an improper system first, only to realize later that you should have gotten the proper one in the first place.

Hans Eich

Solar with storage is the future. Therefore, solar capture must be considered in the design of new buildings. It makes no sense use valuable resources on expensive insulation and mechanical systems. The average roof space can convert sunshine into electrical energy. It will provide energy for lighting, appliances, heating and electric car charging. The average home with a proper design can support 50 solar panels on a 1,000 sq ft. roof. This solar array on an average home will produce 15 megawatts per year. This same roof space in B.C. provides enough rain water catchment for a family of four. So why are we talking about over the top building codes? Design our buildings properly for clean energy and water capture. Why not? It comes from the sky for free.

Dennis Olson

The NUDURA ICF Series features our patented innovative DURAMAX Technology®, the largest standard ICF block in the industry, allowing the placement of 12 square feet of wall area in one building step. Our DURAMAX Technology® results in faster installation times, less waste and a reduced amount of seams allowing builders & contractors to save time on labour.

Register for a training class near you or visit nudura.com/icfseries to learn about our other innovative features.

An interview with Casey Edge, Victoria Residential Builders Association

Interview by John Bleasby

Ottawa has mandated that new homes in Canada must be constructed to a Net Zero Energy Ready (NZER) standard by 2030. British Columbia has responded by introducing its ‘Energy Step Code.’ This is “a voluntary compliance path within the BC Building Code that establishes progressive performance targets (or steps) that support market transformation from the current energyefficiency requirements in the BC Building Code to Net Zero Energy Ready buildings.”

Many industry groups and housing organizations have looked at BC’s Energy Step Code with envy. But not Casey Edge. The CEO of the Victoria Residential Builders Association (VRBA), Edge has been particularly outspoken and direct in expressing his views regarding the Step Code’s shortcomings. Here is an abridged version of our exclusive interview with him.

You see a strong link between regulations to make new homes more energy efficient and home affordability.

The CMHC conducted a national housing survey about six months ago and released a report. There’s absolutely no question that the number one issue for British Columbians is housing affordability. The average price of a house in BC is at least $100,000 more than the average house price in Canada. That is the dialogue. In certain niche circles, I think the dialogue is energy efficiency. However, amongst the average consumer in British Columbia it’s, ‘How am I going to be able to afford to buy a home?’

Yet Net Zero Energy is gaining a foothold in many places. Why is that?

When we hear that they’re building Net Zero homes in some regions at an affordable price point, that’s because of the land cost. They’re selling lots for $100,000, not up to $200,000 to $300,000. That $100,000 difference in land cost in BC is the cost of your Net Zero. This is a land issue. Promoting Net Zero when you’re getting your land for half the price of other jurisdictions, frankly that’s not very transparent.

What are your builder members telling you about the BC Step Code and NZE?

They’re already showing leadership through a program called BuiltGreen. And it’s market-driven. My builders tell me, “Casey, we can now build an affordable EnerGuide 80 home,” and they’re doing it. It’s above national code, it’s affordable, and it’s supported by proven practice. So we’re there, and we got there through a marketdriven program, not through regulation.

Many think the BC Energy Step Code eases the way to NZE. What in fact is happening with the implementation of the Step Code at the builder level?

Right now you have municipalities that, in a negotiation [with a builder], will say, “We want, or we need some level of energy efficiency,” when negotiating a rezoning. Usually the discussion is over density. The developer says, “I can do that because I can make the numbers work.” That’s what is happening now. However, what the Step Code does is enable 160 municipalities to determine one of five levels of energy efficiency, not as part of a negotiation in terms of affordability and density… but as a blanket, “You must build to this level.”

And this directly impacts housing affordability, in your view?

The government has created the housing affordability problem. They’re in control. In terms of the Step Code and government policy, what we’re saying is the government tells us what to build, how much we can build, where we can build through rezoning policies, how to build in terms of the building code, and how much money we have to give to the government in order to build through property transfer taxes, GST and so on. So how is the lack of affordable housing the responsibility of industry?

Where do you think the BC Step Code went wrong? I was part of the consultation for the BC Step Code along with the

other players, so I can tell you about that consultation. When the government does these consultations, they like to meet with other governments because that’s where they get their support from: other regulators. In this case, there were about 20 municipal officials and bureaucrats sitting on that consultation and only three or four representatives from builder organizations [including the VRBA].

And what was the result of these Step Code consultations?

They basically said, ‘We’re going to enable municipalities to cherry-pick any one of the five step levels. We’re going to encourage them towards a best-practices guide, to be responsible etcetera.’ However, best-practices guides are not regulations. They are advice, not regulations. And since there is a self-determination policy for municipalities in BC, which is unique in Canada, the provincial government will not override municipal authority. For example, the Minister of Municipal Affairs cannot amalgamate small municipalities without their permission.

What do you think would be a more sensible approach instead of these immediate arbitray measures?

Our position is this: Maintain a building code standard in the province that is based on cost-benefit in the most expensive province in Canada, along with proven practice. Start out at a reasonable level of energy efficiency that can be supported by affordability, education and current proven practices. Today, that might be Level Two. Then, in five year increments, and based on affordability and proven practice, you go to Level Three. Another five years, Level Four. And by 2030, which is the government’s stated goal, based on affordability and proven practice and by observing a building code standard, you get to Net Zero.

And so the BC Step Code is, in your opinion, too much too soon?

Here’s my question: When did it become fashionable to ignore the national building code in Canada? I’m not talking about tweaking, I’m talking about implementing extremely different ways of constructing a home. If the national building code standard is irrelevant to that, why do we have a national code standard at all? What does the agreement between the federal government and the provinces mean?

You have argued there are more effective ways to deal with climate leadership.

My members are currently building new homes with three air changes per hour. There’s no question that building a passive home is going to cost tens of thousands more than what is being built now with three air changes per hour. If climate leadership is the goal, and the majority of older houses have between 10 and 40 air changes per hour, why not address that?

Sounds sensible. So what is the problem?

The government is not interested in climate leadership. They’re not really interested in housing affordability. They’re interested in scoring political points. What they’ve done instead is significantly ratchet up the cost of new home ownership in the most expensive province in Canada while doing very little to address the climate issue. It’s one thing to build a super-insulated, energy-efficient home, but you also have to sell it to a consumer. And that's the part that I frankly don't think the government appreciates.

For the full version of this interview, please visit canadiancontractor.ca and type “Step Code” in the search bar. You will see that the article is in two parts, with links to the other part within the text. cc

The One Series by NUDURA is the industry’s first multi-link form offering builders and architects unmatched versatility for projects designed using ICFs. The One Series is ideal for pools, stairwells and anywhere only one side of foam is needed by combining traditional forming methods and Insulated Concrete Form technology.

Register for a training class near you or visit nudura.com/oneseries to learn more about the One Series.

Text and photos by John Bleasby

from the top matter. So when Frank Mannarino made his opening remarks at DeWalt’s ‘Tough in the South’ North American media event in Nashville, TN in mid-August to explain the direction his company is heading in the future and how it intends to get there, everyone paid close attention. Mannarino is the president of power tools and equipment for DeWalt USA, and he made it clear that the company is committed to the evolving concept of the cordless job site combined with improved tool design based on the company’s FlexVolt battery system.

DeWalt’s FlexVolt power package system was announced with much fanfare in June last year. FlexVolt’s ability to automatically change between two voltages gives users a serious advantage when it comes to efficiency by increasing the power and improving the runtime of DeWalt’s 20V MAX tools, thus eliminating the need to invest in a whole new battery system.

At the same time, FlexVolt also brings the ‘power of corded’ to the company’s lineup of 60V MAX and 120V MAX tools. The company has built their cordless line out to 130 tools today, and they aren’t stopping there. “We see ourselves at over 150 tools over the next year,” Stephen Blain, commercialization manager for Stanley Black & Decker Canada told Canadian Contractor “Where there are opportunities to take a corded tool

OPPOSITE TOP: DeWalt now offers seven models of 20V cordless nailers, covering framing, flooring and finishing applications. OPPOSITE LEFT: DeWalt’s new 60V FlexVolt cordless 2.5 gallon compressor for pneumatic tools can fire up to 1220 nails per charge. OPPOSITE RIGHT: With more attention being paid to silica dust, contractors will like DeWalt’s 24V hammer kits, with integral dust collector connected to a cordless vacuum. ABOVE: DeWalt now offers a full range of modular heavy duty storage boxes with theft-resistant piano opening and hingers.

cordless (it) gives us more opportunities to grow the system.”

From a design standpoint it is more than simply being cordless. DeWalt is equally concerned with the weight and balance of their cordless tools and precise fingertip control. After all, many of these tools are operated for hours each day, often in random and unpredictable situations. This is where research and field testing plays a major role prior to rolling out new product offerings. Blain explains, using a cordless nail gun as an example. “A nailer is tool that can be operated above or below your head, at different angles. The proper placement of the battery in the tool is therefore very important. If you put it in the wrong spot, it changes the center of gravity, which changes the overall feel of the tool. You want to avoid making the tool being either front or back end heavy. I

Imbalance will result in more strain throughout the day because the user has to compensate for the imbalance.”

To this end, DeWalt has established relationship with a number of key end users who give valuable feedback prior to product release, social media ‘influencers’ and real-life construction professionals like Canadians Kieffer Limeback (Toolaholic), Joe Canning (Canadian Carpenter) and Murray Kruger (Kruger Construction). “You develop a relationship with users like that,” explains Blain. “They’ll tell us, ‘Here are the good points, and here’s what I want to see different or what is not up to what I want.’ This is the type of information we need before the tool hits the market.”

However, it’s important to recognize

The Integrated Series from NUDURA combines building products that work in conjunction with our line of Insulated Concrete Forms or independently to provide maximum energy efficiency. Our Integrated Series offers Ceiling & Floor Technology, HYDROFOAM® Radiant Floor Insulation and our unique RetroFit Insulation Technology.

Register for a training class near you or visit nudura.com/integratedseries to learn more.

that not the entire tool world is going cordless. Corded tools have their place and always will have. However, technical developments in DeWalt’s cordless lineup have an impact on the corded line up, too. For example, Blain explains the impact of integrating brushless motors in corded tools, an element vital for the power and long battery-life demanded in cordless tools.

“A user who is grinding all day isn’t likely to move over to cordless,” Blain says. “He’s using the tool in his shop. He’s all set up for that with outlets and benches. The cord is his system. However, if we can give him the increased power and reduced maintenance offered by brushless motors, we’ve increased his productivity.”

DeWalt’s commitment to integrating all aspects of the job site goes beyond the tools of the trade.

Among the many interesting items alongside the new power tools in Nashville were a comprehensive lineup of storage boxes, from the standard toolbox right up to 18 gauge steel worksite boxes. Also of note were the company’s work van racking systems designed to make tool storage organized and retrieval easy.

DeWalt also showed off job site LED lighting systems, some with Bluetooth control, which improve worker safety. DeWalt goes even further, offering Bluetooth connectivity software systems and jobsite WiFi systems that allow larger contracting firms to manage, control, and locate tools over the largest jobsites. One soon recognizes that Frank Mannarino’s words at the Nasvhille event opening, ‘Design, Protect, Build and Connect,’ were right on the money. cc

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Paint and Colour Experts at Home Building Centres and Home Hardware Building Centres to provide the right product and colour for any project. Our Canadian made products have outstanding quality and durability. Our paints are tested by a third party, ISO certified lab to ensure consistent, high quality. With a relationship built on trust, you know you’re building a strong foundation.

Contact your local Home Hardware Store for a list of MPI approved products. Proven Products for Painters!

Painters love us for our spatter resistance! See our selection of proven professional coatings at

Very few contractors learn anything about selling before they learn to build. Mike Cochren has taken 35 years to learn the best methods to sell the services of his design-build firm in Oakville, Ontario. In this interview, he shares his secrets.

Interview by Steve Payne

One of five contracting sons of a Hamilton, ON homebuilder, Mike Cochren first incorporated Cochren Homes in 1983. Today it’s a design-build firm that does a mix of very high quality homebuilding and renovation projects in the Oakville, ON marketplace that generate some $2.5-million in annual revenues.

Mike, now 68, has learned many business lessons in his 35 years at the helm of his firm. Canadian Contractor first talked to Mike about his business at our RenoFocus event last November. He told us about his experiences helping train contractors when he was chair of the CHBA National Renovators Council. We were so impressed that knew we wanted to explore his sales philosophies further in an extended article for all of our subscribers.

Very few contractors learn to sell at all before they learn to build, which can lead to some challenging years for their firms early on. The growth curve of Cochren Homes was no exception. We thank Mike

for sharing his sales tips in this interview. As the reader will see, Mike is frank and open about the many pitfalls that can trap the less experienced builder, especially those operating with older business models where the architect is king. Hopefully, some younger contractors can benefit from this veteran builder’s wise counsel – especially when negotiating with “challenging” customers.

Can you briefly describe your business model?

We do additions, complete guts and general renovations, mostly based on referrals. About a third of our annual business is with repeat clients. We also do complete new builds as well. We have two designers and an architect we work with on a regular basis to do the design and process the permits. The majority of our projects are usually in the $125,000 to $250,000 range.

Within that price range, the jobs are big enough that we are separated from the smaller contractors who don’t have either the capability to handle that size of job, nor the management skills to handle either the complexity of the job or the planning and permitting aspects. Further, on the larger $500,000 to $1-million projects, clients tend to polarize to architects, who despite their design skills, usually design a product that far exceeds the owner’s budgets. The fallout of this is very dissatisfied clients and a substantial amount of wasted time that could be spent more productively elsewhere. We like to apply our expertise right from the ground floor, where we prequalify, based on the homeowners wish list - and what

we feel is a realistic budget. Thus the old adage: “I'd rather take a No today and stop working, than continue on and get a No next week.”

So you are a design-build contractor, essentially?

Yes, though we weren’t always that way. We started moving in that direction about ten years ago. We realized that we were wasting so much time when the architect had already done the design and established a budget – but with designs that were usually not actually complete! Also, we would sometimes start building and find that the architect was still drawing and designing stuff that they, and the client, expected you to do for the price you’d agreed on for a previous version of the project. So we prefer to do it so that we manage it from the start to the finish. If we can establish the budget and the design we can make sure that, as we go along, it’s not going to exceed that number. Now, when we hire the designer, they answer to us. Whereas with the outside architect, there would be conversations happening with the client that we would not be privy to. And this would lead to issues down the road. Ours is now a much more successful process in terms of meeting the budget and getting things done on time.

You have been the sole salesperson for your firm for 35 years. If you were hiring a replacement for that role, what special skills would they have to bring to the table?

Given the nature of our industry, a successful candidate for a salesperson would be someone with a good background either in design or fieldwork.

The key to selling in our industry is to be able to evaluate the customer’s personality, relate to the customer and properly align the budget to the scope of work. Your three drivers in selling in our business are (1) budgets (2) objectives/ scope of work and (3) timelines. But again, you’ve got to be able to assess and relate to the customer to make sure you are the right fit. What I mean is, relate to them as human beings. Different generations of customers bring different challenges. Millennials are a new challenge for many contractors. They are going on Houzz and looking at all these images online –which is great – but they are often putting icing on the cake in terms of going right to finishes when we haven’t yet established the cake!

How has your sales approach evolved over 35 years?

Well, nobody ever sat me down and taught me how to sell. So when I first started out, it was mostly about the lowest price. I think this is typical of the growth of firms in our industry. Usually a contractor starts out on the tools and then manages his way up to the point when he starts his own business. Then he needs to rapidly acquire some business acumen. Unfortunately, there is a high business mortality rate amongst contractors because ours is a highly managementoriented business. Thus as contractors grow they can easily over step their management infrastructure.

Give us your firm’s basic selling proposition.

I tell people, “We are not the cheapest on the block, nor are we the most expensive. If you get ten prices, we might be about the sixth.” And there are a number of reasons for that. One, we don’t do part jobs. We don’t go for the cheapest of

NOBODY EVER SAT ME DOWN AND TAUGHT ME HOW TO SELL.

everything; we try to improve what we do: we add value. As we say on our website: Good, better, best. We make our ‘good’ better and our ‘better’ best. My staff knows that if they come across something where they don’t think that’s the right way to do something, if it takes a few extra hours to do it the better way, then they are to do it that better way. No one at our firm is going to challenge them for spending the time to do it the right way. People appreciate that. And the second point we stress to our prospective customers is that we have a track record: we have stability. We have the proper staff to do the particular jobs we like to do. We highlight jobs that we have done for others, take them through the projects and show them the work that is in there.

Another key value-added item is the fact that we keep the number of actively running projects to approximately three at a time. I highlight this to potential clients and explain that that is about the maximum we can handle and keep the projects running smoothly and on time. We also show them the timelines from where they are now and when we can start the project, as well as the estimated production time to complete. Further, once the drawings are progressing, we will do a customer selection list and dates that we need met in order for us to meet our production times. This illustrates that a successful job is a collaborative effort and that we have the experience needed to execute professionally.

Did you have any sales mentors or people you specifically learned how to sell from?

For me, a key moment was when I was the chair of the CHBA National Renovators Council. We had our first stand-alone renovation conference in Toronto. We found a speaker, Charles

Clarke III, who spoke about “personality selling.” His technique is called BOLT Selling and basic message is that you should sell to people the way they want to be sold.

The concept categorizes people into four basic types, Bulls, Owls, Lambs and Tigers (BOLT), based on two personality traits, “emotion and aggression.” Once you can access their particular leaning, you can then illustrate to them features

of your product or proposal on which they would place the highest values. For an example, a client who is fairly low key and analytical would be categorized as an Owl. Owls are typically more interested in values like “cost per square foot” or “energy efficiency” than, say, a glamorous kitchen or party room. Thus, you would highlight to this type of client details like better insulation, better windows and high efficiency HVAC units.

YOU NEED TO UNDERSTAND THE PERSONALITY OF THE POTENTIAL CLIENT AS EARLY AS YOU CAN.

The BOLT concept is very beneficial and I highly recommend looking further into it as a helpful tool in doing presentations and addressing clients. You can thus have an easier, more successful closing ratio than just presenting in the same fashion as you have always done.

How do you deal with the highly aggressive prospect who demeans your price in almost insulting language: “You’ve GOT to be kidding me! You are TWICE the price of your competitor! We may as well end this discussion right now.”

We get often get this reaction. The younger Mike Cochren would have replied, “Well, I can go back and sharpen my pencil.” But what you really need to do is stop. Step back. Calm them down. Do not argue with them when they are emotional! This customer is a bull. They want what they want and they want to win. You have to calmly explain: “I can do this, and I can do that, and based on my experience, this is my price that includes certain value-adds that maybe you haven’t taken the time to fully consider. So let’s go back and review this item by item and I’ll explain why I’m different than the other guys. I explain that there are only three ways I can change my

price. We can delete – take something out. We can defer – not do this or that section at the same time as the rest of the job. Or we can substitute. Instead of the quartersawn oak that matches what they’ve got, for example, we will go get a prefinished one at a half the price. And you explain

how much that will drop the overall price. There are only those three ways. Now there’s a fourth way that the customer can lower the price. They can go and get a different contractor! But you don’t want to propose that. You do need to deal with price issues right away. As I said earlier, it is better to take a No today and stop working on it, than to go home, come back tomorrow, and get a No tomorrow night.

How do you handle the prospective customer who hasn’t a clue what their budget is and won’t declare it?

Normally, from the initial discussions about the scope of work, from the wish list, you will have a fairly good idea what the price is. So you just have to table a number out there. If it’s $100,000, it’s $100,000. If you get the response “Oh, that’s WAY high, WAY high!” you reply that, “Well, I did one similar to this for $85,000 but you’ve got some extras in there. So if you come down very much from $100,000, you are going to be cheating yourself out of many valuable

features. The most important thing is that you come at it from a position of strength. You have to ask yourself, “Do I really need this job? Are my groceries next week really going to depend on this? Or is it just one of ten potential jobs and you’re going to close four? So you want to leave it on a positive note, but be honest: “Look, I think your expectations are way beyond what you’re going to be able to do if you want a reputable contractor that’s going to do a proper job. You don’t want to dirty down your project to save a few dollars. You don’t want to spend 10 per cent less but get 30 per cent less value. Your home is worth $850,000 (or whatever it is). You shouldn’t put a $15,000 kitchen in it, because that’s not the right fit. You don’t buy a Jaguar and then put the cheapest tires available at the discount store.

I shy away from them unless there’s a really good reason for me to be involved. Usually in a competitive bid situation, the client will have a set of drawings. And if they’ve gone out and obtained a set of drawings they’ve already become biased by the price put on the work by the person who produced the drawings. Of all the times in my career I’ve been involved in competitive bids, I’ve won about 10 per cent of them. Yes, historically I have gone out and bought the work just to keep my guys busy. But they’ve pretty well all turned out to be bottom-line disasters. So all being perfect, I would rather stick to my knitting. We have had great success with our method. People say, “Mike, we had a good experience. It was fun. And we knew all the time where we were. And we’re coming back.” cc

Continued on next page

Architect: L. McComber ltée, Montreal (Olivier Lord, David Grenier, Laurent McComber)

Construction: Nicora, Montreal

(Nicolas Rasselet)

By John Bleasby

Photography: Raphaël Thibodeau

The culturally rich Villeray neighbourhood in north central Montreal is a village-like blend of small commercial enterprises alongside the city’s distinctive two and three storey “plexes” built in the 1930’s, many with spiral front staircases, back alleys, clotheslines and sheds, interspersed with the occasional older fully detached home. Three years ago, architect Laurent McComber was commissioned to design a replacement for a 60-year old single family house located on a 75-foot wide lot that had been successfully subdivided into three 25 foot lots. The first phase consisted of two semidetached homes for resale, with the third designed and built later as the developer’s personal residence.

While such “gentle intensification” of Canada’s urban centres is slowly gaining acceptance, it faces challenges in many jurisdictions, contributing to an on-going national housing affordability and availability debate. McComber‘s experience is that rezoning is especially difficult in wealthier Montreal neighbourhoods where resistance to change is more organized. Happily, in the case of this Villeray project, McComber says that approval was “unexpectedly easy,” suggesting that because the neighbourhood was only beginning to become “gentrified” in 2014, local authorities were more open.

At the municipality’s request, the development was aligned with the front facades of other houses on the street, bringing it much closer to the street than the original home’s 27 metre setback. As a result, private

Continued on next page

gardens were created in the rear and partially belowgrade garage parking made possible at the front, somewhat of a rarity in this area of Montreal. The only other condition set out by the city of any note was for the facade to be 80 per cent masonry, in keeping with existing structures nearby. That excluded openings, says McComber, explaining why the garage door is natural wood.

The client asked McComber for a building with simple ideas and a vibrant facade, resulting in a modern design featuring a pattern of oblique protruding bricks that create a scale-like texture. The brick base is warmed by the tongue-and-groove cedar arranged vertically in a saw tooth layout.

While the poured concrete foundation and 2 x 6 stud framing is not unusual, what is interesting was the decision to create thermal breaks inside the building rather than on the outside. Three-quarter inch, foil-faced foam sheathing board was placed over top of the typical fibreglass batt insulation installed between the studs. The exterior layup of the building therefore consists simply of OSB, house wrap and the brick facade.

Surprisingly, the three new homes are heated exclusively with electric baseboard heaters, with minisplit air-conditioners on the second floors for cooling, a nod to the high level of insulation overall. The resultant absence of ducting eliminates any need for wall or ceiling bulkheads, high on this client’s wish-list. However, McComber also notes that the additional cost to install ducting caused his cost-conscious developer client to look for alternatives. “Electric baseboard heaters are very inexpensive to buy and easy to install,” he says. There is of course a HRV-heat system to ensure air changes and circulation, as required by the Quebec building code.

The flat roofs on all three homes have drains that run internally, not through external eaves and downspouts. This leaves the roof edge completely clean on all sides. The roof deck itself is covered with a two-ply, modified bitumen elastomeric membrane from Soprema that has become, in McComber's words, “almost a standard” for commercial and residential flat roofs in Quebec. He favours the two-ply layup of this product over single

PREVIOUS PAGE: The new triple townhome project was brought forward to 5.21 metres from the street, in line with other buildings in the neighbourhood. The municipality requested that 80 per cent of the facade, not including openings, be masonry in keeping with the area.

ABOVE: Moving the building forward created private rear gardens bathed in southern light for each new home. Extensive use of cedar arranged in a sawtooth pattern, warms the exterior.

OPPOSITE TOP RIGHT: The clean modern lines of the kitchen cabinetry and quartz countertops are warmed by the extensive use of ash, both on the floors and as accents at room entries. Aluminum clad, double glaze, lowE glass was used throughout.

OPPOSITE BOTTOM LEFT: Striking trim accents on the stair railing match the open stair treads. Light pours down from the skylight above.

OPPOSITE BOTTOM RIGHT: An open office space overlooks one of the two main level living spaces. The warmth added by tongue and groove ash on the balustrade, ceilings and floors is obvious. Note the mini-split air conditioner unit on the second level.

‘bump-out’ allowed for the glass wall and the rear deck. Two new lower level walkouts on each side

layer membranes such as TPO.

There are three levels of living space. On the lower level, partially below grade, the garage shares space with a playroom, bedroom, bathroom and utility room. The main level has two living rooms, each with potential for its own formal or casual atmosphere, a large open kitchen and dining area, and a powder room. Two more bedrooms, a master bath, and an office area that overlooks the lower level complete the third level.

Cleverly, McComber was able to diffuse natural light streaming from the rooftop skylight by reflection off white angular surfaces incorporated into the roof trusses and down to the living spaces below. This successfully deals with a problem common with semi-detached townhomes that often lack natural light in the central sections due to only front and rear windows. cc

TOP: Traditional 2x6 frame construction over a poured concrete basement foundation wall was covered in OSB, housewrap and then the brick facade.

MIDDLE: The design called for three-quarter-inch foil faced foam board on the interior, which was laid over top of fibreglass batts installed between the studs in order to create thermal breaks.

interesting

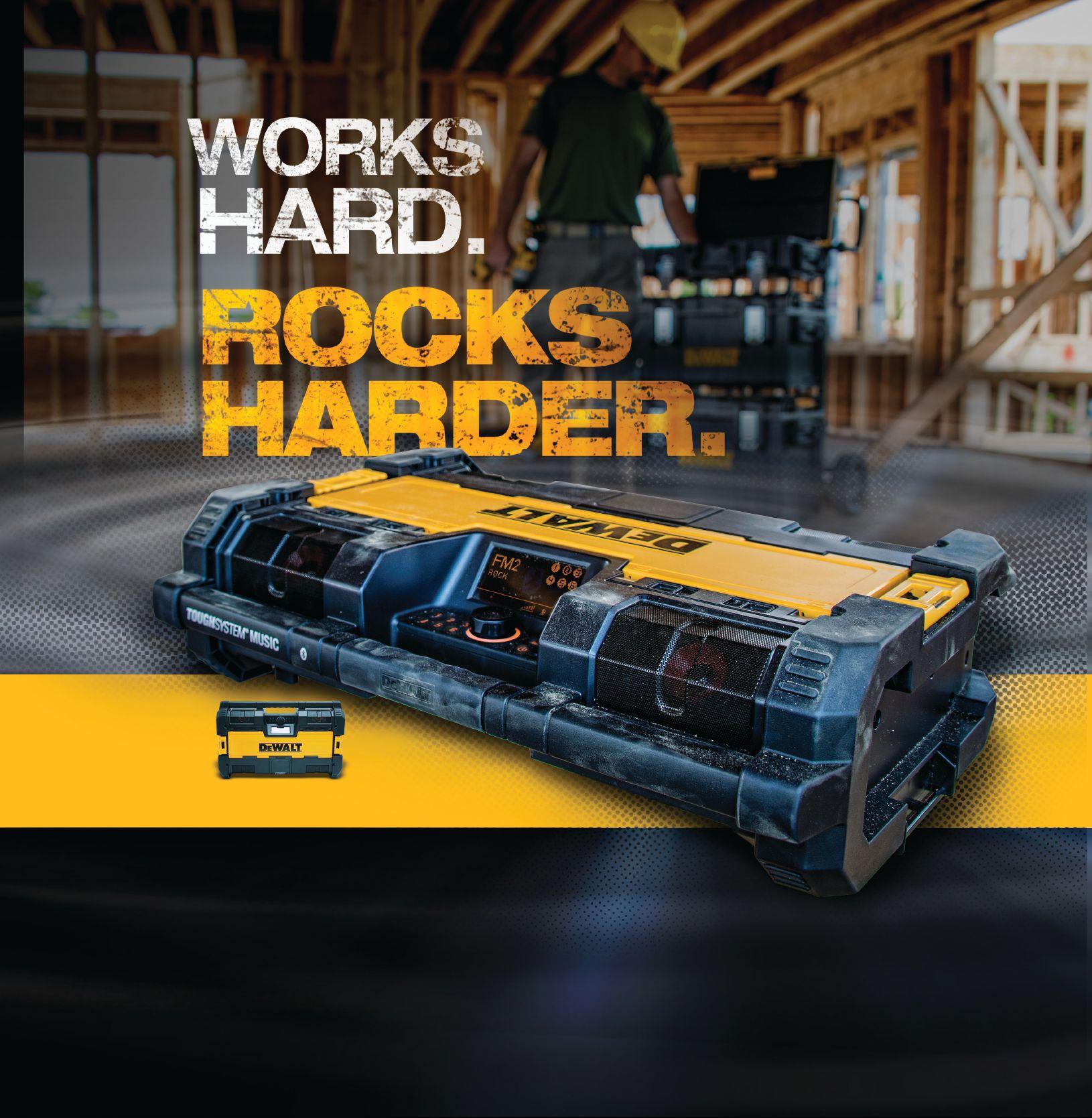

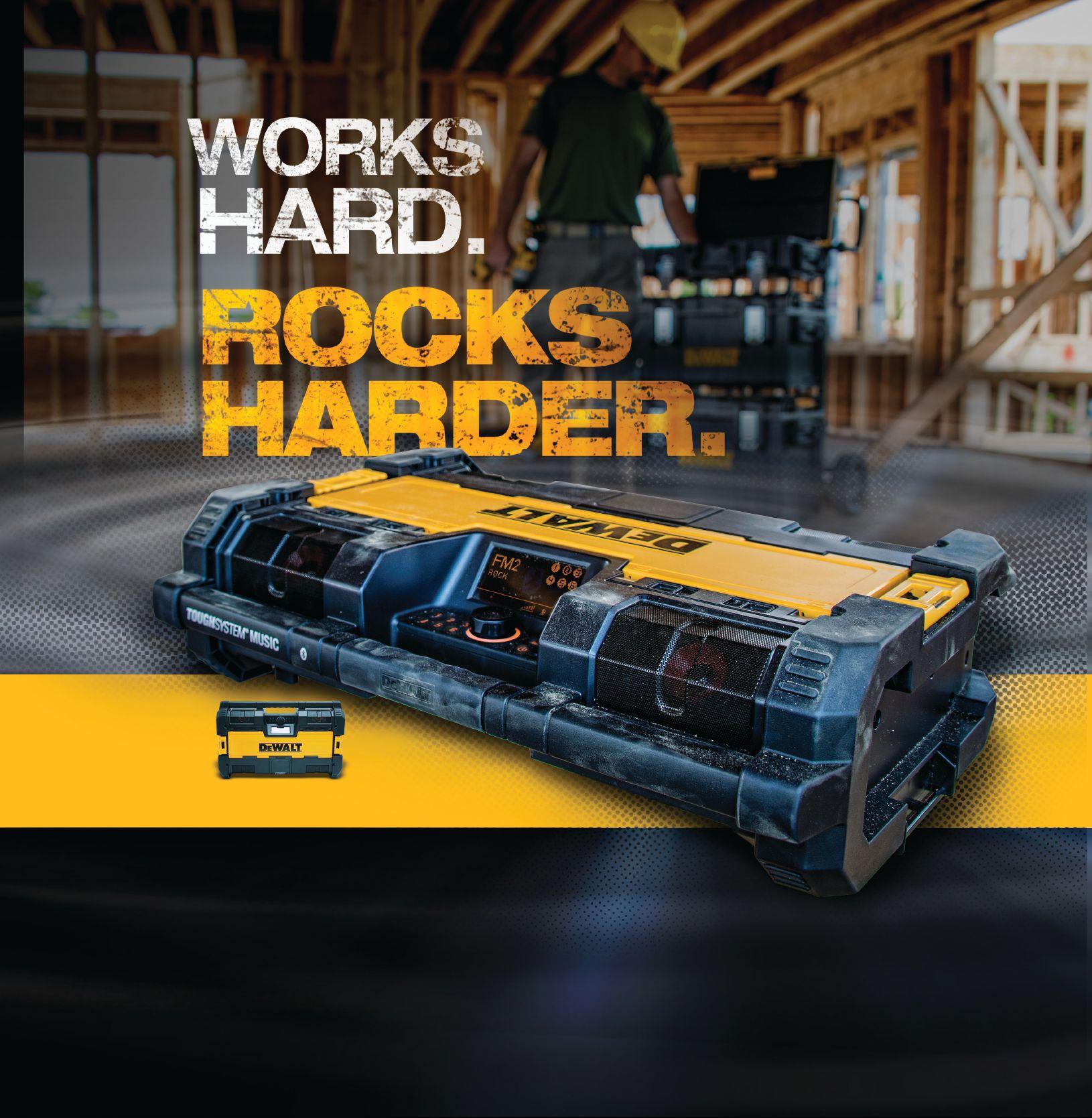

ToughSystem® Music + Charger is the song blasting, battery charging, IP54-rated jobsite sound system that brings concert quality sound to your worksite. Integrates with the ToughSystem® storage product family and features 5-speakers with 360° quality sound distribution and Bluetooth® connectivity up to 100 ft. The water & dust resistant storage compartment with built-in USB charger allows you to secure and charge your mobile devices on site. There’s even a built-in charger for DEWALT® 12V MAX* & 20V MAX** batteries (not included) Sound & Performance so good, you won’t be able to turn this charger down.

Here is a no-nonsense primer on the most important number crunching you will ever do. If you don’t have an accurate job cost system already in place, read this and get started today!

By Steve Ryan

You probably understand very clearly that your contracting business, like any other, must sell its products for more than it costs to make them. Tracking those costs is imperative.

For contractors, job cost tracking can get complicated. This is because renovators and custom homebuilders almost never produce the same product twice. Yet the complexity of residential contracting job costing needs to be

Continued on next page

tackled. And a good system can simplify the process. This article will show you the basic elements of such a system.

Not having a job costing system at all will cost you dearly! You can only sell at a profit reliably if you have an accurate and flexible method for tracking your production costs for each job. This is so critical to the success of your contracting business, that we will repeat it one more time:

Even for highly successful builders, overall net profits will typically be in the range of 5-10 per cent of sales. How easy do you think it is to let your spending on a project get ahead on you by that much, resulting in zero profit or even losing money? Without an accurate, timely method for tracking costs on each job, you never really know if you are doing work at a profit.

If you think otherwise, try this exercise. On your next grocery shopping trip, try to keep a running total (in your head) of the cumulative bill as you place items in the shopping cart. Before you check out, write

down what you think your total bill will be. What are the odds that your guess will be within 5 per cent of your actual grocery bill? Now, if you had two or three separate shopping carts on the go, to be paid for separately at the end, how would you do on your estimates then? How about five carts? Ten? Most of us wouldn’t want to bet our businesses on our ability to guesstimate this stuff. But if we will woefully fail at this exercise on a few hundred dollars’ worth of groceries, why do we think we can run our businesses, involving hundreds of thousands of dollars of job costs, on multiple projects – many concurrent – without a decent job costing system?

Without accurate, up-to-date cost reports you aren’t managing for profit, you are just hoping for it.

If you recognize the risk in this and want to avoid it, you must be able to add up the costs for each job independently. If you are not tracking costs to individual jobs, you need to start. If you are doing that already, well done! But there may be one or two ways to improve your approach or to make it consume less of your time and effort.

Before we go there though, it would help to touch on a few basic principles.

1. Make your computer do the tracking and sorting

Too many contractors spend time and effort trying to classify invoices, receipts and payroll costs after the fact. By feeding information into your accounting system properly, your computer can do most of that for you.

2. Allocate where costs belong at the time of purchase

One of the most common frustrations we hear from contractors is the time they spend going through stacks of invoices to allocate them to specific jobs. Yet, far from being a major demand on their time and attention, this activity should scarcely involve them at all. When we say allocate costs at the time of purchase, what we mean is simply to have the specific projects(s) identified on the invoice, receipt or time report as soon as the cost is incurred!

3. Let common sense prevail

The quality of your management decisions improves with how accurately and how completely you can calculate job costs, so if you can identify what spending is devoted to each job, then you should make the effort to do so. However, not everything you pay for is easily charged precisely to the job it was used on, so don’t tie yourself in knots trying.

For example, you probably can’t say how many of your rent dollars were due to each project you carried out. So rent may not be recorded as a cost specific to any job.

4. Consistency is important.

You can decide which types of costs you allocate to individual jobs but the logic you use should be consistent in all the work you do. For example, some contractors track workers compensation costs to each job. (Yes, it can be done, and no it’s not that complicated.) Once you decide to do that, though, it needs to be your uniform approach. You shouldn’t track it for one job, and not for another.

5. You don’t need a 100 per cent solution.

We will shortly look at ways you can improve the quality of your cost tracking while reducing the effort it requires from you. These steps won’t eliminate that pressure entirely, but every transaction that flows accurately through your accounts without your intervention frees up time that you can redirect to more valuable work. So don’t wait to find the magic solution to every situation. Get started on a system you can work with and that you can improve over time.

Up to this point we have focused on theory and accounting practice, so let’s shift to some practical pointers on how your business can monitor job costs better, while letting you step back from the job of shuffling numbers.

1. Use a simple numerical code to identify each job.

If you identify jobs by the client name or address it is too easy for different people to record that in slightly different ways. For example, one person might enter Tom Smith, where another might

enter Thomas Smith or T. Smith or… well, you get the point. Remember, we want the computer to do the sorting and tabulation. Computers aren’t very clever at matching “similar” descriptions. They need you to be precise. When you give jobs a code, there is usually only one way to enter it. Job number 217 can really only be entered one way.

2. Treat that code as a “purchase order number.”

Most of your suppliers and sub-trades will use an invoicing system that allows for them to enter a “P.O. number.” Tell them you need that P.O. number on all their invoices. When an invoice includes that number, your bookkeeper will need no help from you to identify which job to code it to. If you have authorized your staff to make purchases or call in sub trades, train them to provide the job number (P.O number) with everything they order. Most suppliers can set up your charge account to demand a P.O number whenever someone makes a purchase. In other words, they are already set up to help you manage this discipline.

3. Split up your purchases to be specific to each job.

It might sound fussy or complicated, but when you buy for more than one job at a time, run separate transactions for each job. Yes, it can complicate life at the check-out or with your telephone order, but if you don’t do it now, you will only have to do it later, when you are buried in other paper work and your facts are not as clear. A little effort now saves a lot of effort and distraction later.

4. If you sub-divide projects, use the same coding system

Some contractors split their spending into sub-groups. For example, if you need to separate your costs by the stage of the build (demolition, foundation, framing, etc.) you can adapt your job code to capture those sub-groups as

"Job costing is not difficult, once you develop a consistent sytem."

well by using an extension to your job code. In our example, our “P.O. number” for demolition work might be 1234A, for foundation work 1234B, for framing 1234C. It is wise to have a standard list so the suffix “A” always refers to demolition, “B” always refers to foundation work, etc. Use whatever classification and coding makes sense to you, but make sure your definitions are consistent from job to job and over time. Remember, computers need you to be precise.

5. Have field staff report their hours specific to the jobs they work on.

If an employee’s hours are devoted to specific projects, then record their time that way. Your payroll system can then capture those wages as specific job costs. Use the same coding system. In our example, labourers who were working on Tom Smith’s house would make out a time report that stated hours spent on job number 1234. The time they spent on demolition would be reported as job number 1234A, for foundation work 1234B, etc. Believe it or not, employees can adapt to it without much difficulty or confusion.

Now let’s recap, because the point here is to make your life easier, not harder.

1. You have to track your job costs specifically to each individual project you do.

2. If you can identify a cost as devoted to a specific job, then do it.

3. Use consistent rules so that the same kinds of costs get counted against each job.

4. Capture information at the time of purchase so it is easily classified in your

accounting system.

5. Use a simple coding system so that when costs get loaded into your computer, it has a reliable, unambiguous way to sort and summarize those costs the way you need.

1. That you must build in extra levels of detail. If you need or want to subdivide jobs, you can adapt your job code for the purpose. It’s up to you.

2. That you must change what you are doing and use what is described here. If you already have the capability of reporting your job costs specific to each project and it works for you, stick with it.

To sum up, if you and your bookkeeper are spending time and effort trying to sort invoices, time cards, cash register tapes, etc. days or weeks after the orders were placed, then give yourself a break. Classify spending at the front end. Get the people who place the order, make the purchase, or do the work to provide the information. When you do that, your computer can tabulate the information that you need to make management decisions. And that is the job you should be doing, rather than shuffling paperwork.

Steve Ryan is the principal of MMI Business Training for Builders. He is a veteran of both corporate and construction business management roles. Steve is a TARION-certified training provider for the general management and finance education that is now required of new home builders in Ontario. He has an MBA from the Ivey School of Business at Western University, London. Reach Steve at steveryan@mmiproservices.com. cc

Join CANADIAN CONTRACTOR next month at the largest construction show in Canada. The Buildings Show gathers together almost all types of professional builder – from the small renovator doing basements and decks to commercial builders of high rises, airports and stadiums.

TheBuildings Show is the leader in sourcing, networking and education for the North American design, architecture, construction and real estate communities. The show is home to Construct Canada, HomeBuilder & Renovator Expo, IIDEXCanada, PM Expo and World of Concrete Pavilion, and together they create the largest North American exposition for the entire industry. The Toronto Real Estate Forum also happens concurrently.

More than 30,500 trade professionals attend the show annually to discover new innovations across the building industry and source the latest materials, products, tools and technologies from more than 1,600 Canadian and international exhibitors.

Through the show’s comprehensive seminar program, attendees can choose from more than 350 seminars, panels, keynotes and roundtables led by a roster of over 500 industry experts. In addition, there are tours, awards, association meetings… and of course social opportunities and parties. This year, construction topics include best practices, leadership, building codes and regulations, sustainability, new approaches to construction, technology and design trends in housing, healthcare, education, retail, workplaces, accessibility, hospitality and wellness.

The Buildings Show takes place at the Metro Toronto Convention Centre from November 29 – December 1, 2017. IIDEXCanada runs from November 29 – 30, 2017. cc

“Hooked

for Life”

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole”. So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer. Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips & screws. You just screw it to the wall and it’s “Hooked for Life”.

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

INDUSTRY-LEADING WALKABILITY

The unique embossed pattern allows for better traction and grip

Our portfolio of roofing underlayments provide choices to meet your needs

The bottom layer is designed to grip to the roof deck when unrolling, ensuring it lays flat

DuPont™ Tyvek® Protec™ engineered synthetic roofing underlayments offer you and your crew a high-performance product and greater confidence on the job. With its industry-leading walkable surface, DuPont™ Tyvek® Protec™ is ideal for slopes 2:12 or higher and performs under dry, wet, hot, cold and dirty conditions. An ideal combination of protection and performance for you and your customer.

Tough. Tested. Proven. | That’s DuPont™ Tyvek® Building Envelope Solutions. For installation instructions and safety guidelines visit www.tyvek.com/protec

Accepts and holds chalk marks for more visible lines and a better finished product

By Steve Maxwell

Different cultures express craftsmanship differently, and it can be surprising how good some trade workers get with tasks we never see here in Canada. The trowel skills of black South African masons is a case in point.

My wife and I traveled to South Africa back in 2008 to pick up our adopted daughter Ellie. We travelled to the city of Durban, and it wasn’t long before I was wandering around home building sites with my camera. This led me to a contractor named Dave Scates. He’d been building in the same Durban neighbourhood for a quarter century. No job was ever more than 5 miles from his home. Ten minutes after shaking hands, Dave was driving me around in his truck, proudly showing me a handful of residential projects he had on the go.

There are no tract homes in Durban. Each house is unique and built using traditional masonry techniques that came originally from Britain. All walls – both exterior and interior – are built with clay brick, several courses thick and plastered to create a smooth surface inside and out.

Until the mid-1990s, it was illegal for any black man to use a trowel professionally. Building work was reserved for whites, some of whom traveled down from Europe for work. All that changed when laws demanding racial segregation under apartheid were dismantled. This opened the floodgates of labour onto the construction market, causing wages to drop by at least 90%. They’ve been down there ever since. These days you never see a white person involved in construction. The entire home building workforce is black. Contractors like Dave Scates are white, and so are electricians, plumbers and specialized trades. That said, the black workforce brings something surprising to their work.

For cultural and historical reasons no one understands fully, black trade workers in South Africa are exceptionally good at using trowels. Perhaps it’s a throw-back to the days when all traditional African homes were made of mud and straw. I don’t know, but the precise, handguided results speaks for itself. It’s beautiful and detailed in a way that goes way beyond what you can accomplish with forms or precast components. The hand-troweled cap of the food court separation wall you see here is what I mean. It was even more impressive in real life than it is in this picture. Results like this are done entirely with handguided work. No forms, no guides.

We tend to get narrow minded after a while when we think of manual skills. I don’t know about you, but I love the idea that somewhere out there are people who can do amazing things with trowels, even though it’ll never matter much in Canada. Do you know what I mean?

steve@stevemaxwell.ca

How to choose and apply finishes you won’t regret

By Steve Maxwell

You don’t have to be a contractor for very long before harsh experience teaches you what’s important. As essential as it is to work productively, to bid profitably and to manage subs wisely, the ability to avoid bad products and materials is also a make-or-break skill. If you put your trust in something and it fails on one of your projects, it can cost thousands of dollars of profits and many hours of time as you make things right. Few manufacturer warranties ever come close to making up for disasters like this, either. Nowhere is this danger more present than with outdoor wood finishes. Choosing and applying products is often like leaping into the dark, and that’s why I decided to shine some light on the subject beginning back in 1990. This is the year I started testing specific outdoor wood finishes in the real world and keeping records. I prepared sample boards, coated them in outdoor products I believed might last well, then put the samples outside for full exposure to the sun, rain and snow over a period of years. This approach takes patience, but the results are gold. Eventually you get a sense of what works and what doesn’t. I don’t claim to know all the outdoor wood finishing products that perform well today, but I do know specific formulations that are worth trusting. Some of these are clear, others tinted and some opaque. I’m also always adding new products to the program, too. Sometimes I might have half a dozen test boards in the sun, sometimes only one.

Why go to all this trouble? More than most building details, outdoor wood finishes have a huge blow-up potential. There are a couple of reasons why. First, they’re usually applied over a large area. It’s more than enough work staining that deck or all that wood siding in the first place, but when results go bad, it’s 3x more work stripping and getting back to square one to start again. Wrestling with this kind of large scale freebie work when you should be doing something that brings in the bacon is a recipe for a bad day.

Superdeck makes an opaque elastomeric coating that has done well so far in test samples I set outdoors in 2014, so when I heard about this company’s Cool Feel technology I added it to my testing program. Their Deck & Dock Solid Coating is a super thick, opaque product, but it’s also formulated to get less hot in the sun than other products of similar colour. You can feel the difference with your hand, but my main interest is reliability and finish life. All else being equal, a wood surface with smaller swings in temperature from day to night should last longer because there’s less expansion and contraction to stress the finish. Time will tell, but Deck & Dock Solid Coating is the kind of modern outdoor finish we’re seeing more and more often these days. It’s very thick, completely water washable and there’s almost no odour.

The second reason to be careful with outdoor wood finishes is trust. Every product looks great on store shelves, and labels always inspire so much confidence. But the truth is, many outdoor wood finishes fail quickly even if you apply them perfectly. It’s a shame to ruin new wood like this. And as I’ve discovered, name brands are no guarantee. Some of the worst products I’ve seen have the biggest names and retailers behind them. There are great products out there but there are also imposters. Some kind of testing was the only way I could begin separating sheep from goats.

In a nutshell, this is what I’ve discovered: All else being equal, the more opaque the finishing product the longer potential service life it has. A short coating life isn’t necessarily bad if it’s coupled with an easy recoating regime. For instance, it’s not unusual for outdoor oils to require a fresh coat each year. But since oils don’t peel, it doesn’t take long to prep for that recoat.

Client education is key because even when done correctly, many outdoor wood finishes demand more ongoing maintenance than some people feel is reasonable. Certain clients are fine with the low maintenance weathered look of a one-time wood treatment. Other clients get irritated as soon as their furniture-grade outdoor finish gets its first scratch. Recommend accordingly.

Of all the outdoor wood finishing tasks, finishing a deck is the most common situation you’ll face. It also involves the highest risk because decks are so large and get so much foot traffic. Since I get lots of questions about which deck finish to use and how to fix existing deck finishes gone bad, I keep a web page updated with all the latest information from my testing. You’ll find everything I’ve learned since 1990 at baileylineroad.com/how-to-stain-deckproperly.

Limiting the risk of costly call-backs is an important part of turning a reliable profit. Learning to avoid outdoor wood disasters may be one of the most important skills you develop.

We’ve all heard it before: “Preparation is the key to a long lasting outdoor finish.” But what does this mean? It all comes down to maximizing the ability of wood to hold onto a finish. New wood often fails to allow finishing products to soak in because of surface burnishing from the planing mill and pressure treatment chemicals. Old grey wood allows absorption, but surface fibers are weak and they can let go from the underlying board, letting the finishing treatment peel, too. The best approach I’ve found is to pressure wash outdoor wood as an initial step, then let the wood dry completely before sanding with an 80-grit disk in a 6” random orbit sander. Pressure washing removes all dirt and sawdust and begins to break down surface burnishing. A quick sanding knocks off any loose fibers and opens wood pores so a finish can get a good grip. I know of no other surface prep regime that’s as fast and effective as pressure washing followed by a quick 80-grit sanding.

If you’ve got an especially picky client who thinks they like wood, consider gently steering them towards composites or plastic wood substitutes for deck surfaces. Though these never look quite as good as a fresh, top notch wood finish, synthetics keep on looking good with nothing other than regular cleaning. They offer much lower risk for you.

Fifteen years ago the first cordless impact drivers hit the Canadian building scene, and though designs have gotten better in many ways since then, loud tool noise has been a problem for a long time. Classic impacts use a mechanical drive that’s annoying enough that I use hearing protection for long work sessions. The new Milwaukee M18 Surge is different. It’s noticeably quieter because it uses a hydraulic oil drive that also delivers less vibration. Refinement, less noise and greater controllability are the two reasons I find this tool to be the nicest impact driver I’ve ever used. The tool is different enough that Milwaukee calls it a hex hydraulic driver to differentiate it from old style impact drivers. There are three torque settings on the 2760-20 for driving deck screws and a fourth setting for driving self tapping screws in metal. It’s fast at first during the drilling phase, then torque drops off automatically so the threads don’t strip out. Overall length of the tool head is 1/2” shorter than the current Milwaukee impacts, so the 2760-20 is also easier to use and pop into your pouch. Cheapest Canadian street price is $220 for the bare tool. That’s $30 more than Milwaukee’s conventional impact but the benefits are worth it in my book.

MAXWELL’S PICK

Using outdoor wood on your projects can be risky because too few clients understand the ongoing maintenance demands of most wood finishes. When outdoor wood begins to peel or flake faster than clients expect, you get the call back. Low maintenance of outdoor wood is what attracted me to a made in Canada product called Eco Wood Treatment more than 10 years ago. I’ve been using it on my own projects since then. It’s a powder you mix with water and apply to new lumber as an odourless, non-toxic liquid. I usually use a pump-up sprayer for application. A few hours after it goes on, Eco Wood begins to create an even, weathered appearance by chemical reaction. Full results take months to appear, but you only ever have to apply it once. Not every client is okay with a weathered look, but for those who do like it, the “weathering” is even and much nicer looking than the natural stuff. The company has just come out with additional colours, but I haven’t had enough time to see how they last long term. You’ll find Eco Wood Treatment at Home Depot and online at ecowoodtreatment.com. Cost for a pouch of powder to make one gallon of solution is $25.

Doug and Al Harvey are the top two employees at Dick Zimmerman Renovations. What should they do, now that Dick seems to be losing the plot?

Do they stay or do they go? Brothers Doug and Al Harvey have often talked about starting up their own contracting business. But Dick Zimmerman has been a good boss for almost 10 years now. Doug is the site supervisor/project manager and Al is the lead carpenter. The three men have always operated as partners, if not in terms of dollars (Dick is the sole owner) then at least in terms of decision making. They even have a profitsharing plan.

Yes, Dick has paid the brothers well. He’s given each of them a company truck, started matching their RRSP contributions, and has more or less let them run the business. Lately, however, much has changed. Dick seems to have lost a step. He doesn’t show up on sites as often. And he’s not chasing down new business, leaving the brothers out of work for a few weeks each year, particularly in the winter. Lately, they’ve heard Dick exchanging harsh words on the phone with his wife, Pat, who does the books. Are the Zimmermans having problems at home?

The brothers really like Dick, but he’s in his mid 60s now and the Harvey boys worry that their future may be less secure than they thought.

What should Doug and Al do now? See the options at right.

In last issue’s contest, Howie and Brian, two of contractor Ian Dobson’s framing crew, were punching it out after Howie had made lewd comments about Brian’s wife. This was not the first time Howie had yanked Brian’s chain. He was just that kind of guy. Dobson arrived on the scene to find both men with blood on their faces yelling at each other. What should Dobson do now?