Northern exposure: Trevor Trainor Pg. 12

Time for builder software? Pg. 16

Best practices in Net-Zero design Pg. 22

Northern exposure: Trevor Trainor Pg. 12

Time for builder software? Pg. 16

Best practices in Net-Zero design Pg. 22

The advancements shaping construction technology. Page 10

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

Robert Bronk of the Ontario Construction Secretariat joins The Hammer to discuss his organization’s research into the state of the skilled trades supply and what might be done to improve it.

There’s a lot to consider when going green - carbon emissions, involved cost, timelines and more. Check out Canadian Contractor’s Going Green webinar recording to hear from a panel of industry experts on hot topics like passive homes, net-zero renovation programs and more.

Oooo...pretty pictures. Follow canadiancontractor on Instagram for photos we don’t have room for in the magazine. Plus links to other stuff we like.

ISSN 1498-8941 (Print) ISSN 1929-6495 (Online)

Editor Kaitlin Secord (416) 435 1779 ksecord@annexbusinessmedia.com

Brand Sales Manager Nav Matharu (226) 931-5095 nmatharu@annexbusinessmedia.com

Account Coordinator Barb Comer bcomer@annexbusinessmedia.com

Audience Development Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com

Media Designer Lisa Zambri

Group Publisher Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

As the days have flown by, I’ve found myself caught in a whirlwind of experiences that have made me even more curious about construction. As we quickly approach 2024, I look back at how much I have learned over the last six months with Canadian Contractor and how much there is left to explore.

In September, I attended Procore’s Groundbreak 2023 in Chicago and what an adventure! Hearing about the evolution of the construction industry over the border got me thinking about the transformation it has taken here in Canada as well. From legislation passed to ensure clean, safe washrooms for all on-site employees to the ever-evolving world of tech tools to help make jobs more seamless, it seems that with a little more time to adapt and adopt, the construction industry may be just fine.

Another prevailing theme at this year’s Groundbreak was the next generation, and how, as an industry, construction needs to work to not only find but keep future tradespeople interested in their careers. One way to do this is with technology.

In Canadian Contractor’s October edition, we hear about some of the innovative technology already swirling around the trades. In our focus section, Gord Wornoff spoke with nidus3D about their project on North America’s first residentially-permitted, multi-unit, 3D printed home in Windsor-Essex, Ont. Nidus3D talks with Gord about challenges faced coming into a pre-established project, the prospect of technologies like their 3D printer in aiding Canada’s housing crisis and what the evolution towards tech could mean for the future of construction as a whole.

We circle back to more tech talk with the Ryan Report, where Steve Ryan talks builder software and choosing what is right for your needs.

Our profile for this edition is with Trevor Trainor, president of Bawating Building Science. Trevor and I spoke about his career in building sciences, the importance of them and what’s next for Bawating as they continue their work with Dillon Consulting and Nunavut Housing Corporation to develop and monitor residential retrofit strategies throughout Nunavut. Trevor noted that the future of construction and renovations does not have to be bleak, all it takes is a shift in perspective.

This edition is also holds some insight for our renovation experts. Maxime Duzyk writes on the role of contractors when it comes to mitigating radon build-up, and Mike Anderson talks best practices in Net-Zero home design.

Richard Lyall encourages the industry to rethink urban growth by considering mid-rise housing and reframing the way policymakers look at densification of current low-rise neighbourhoods.

We round off the edition with some how-tos, including James Hong’s guide to site inspections. You can also read more about my time at Groundbreak 2023 in our CON the move section.

As always, I invite you to pitch me your ideas, send me your latest news and accomplishments, or connect with me just to have a conversation. You can reach me at ksecord@annexbusinessmedia.com.

Until next time, happy reading! cc

By Kaitlin Secord Editor ”

”It feels like just yesterday we were ringing in the New Year and setting resolutions, and now we’re approaching another one. It’s astonishing just how much I have learned in my six months as editor for Canadian Contractor and how much there is left to explore.

The Government of Canada has announced an additional $73 million in funding under the Opportunities Fund for Persons with Disabilities (OF) to support 31 projects that organizations

across Canada will launch this year. This funding is in addition to $118 million announced in June 2023 to support 60 projects, which brings the government’s total investment under the OF 2022 call for proposals to approximately $191 million. The OF aims to bring together employers and employees with disabilities, to increase the participation of workingaged persons with disabilities in the workforce. The objective of the program is to assist persons with disabilities to prepare for, obtain and keep employment, advance in their careers, or become self-employed. Minister of Diversity, Inclusion and Persons with Disabilities, Kamal Khera, made this announcement at the YMCA Cape Breton in Sydney, Nova Scotia, who received $1.19 million in funding under the OF to assist persons with disabilities who face barriers to employment in Cape Breton and the Antigonish County. The organization will connect individuals who selfidentify as persons with disabilities to subsidized employment and self-employment opportunities, supporting them through skills training, digital literacy and skills development that are required for positions in the region. Program participants will also have access to an entire host of services including, employment support, career counselling, and referral services to external agencies assisting in areas such as mental health and addictions disorders. cc

The British Columbia Construction Association (BCCA) has now issued $10 million in financial incentives to small and medium-sized construction industry employers through its Apprenticeship Services project.

The project provides employers with cash incentives to hire and register first-year apprentices in up to 39 Red Seal trades. Funded by the Government of Canada’s Canadian Apprenticeship Strategy’s Apprenticeship Service initiative, it has become the most far-reaching construction trade apprenticeship drive ever undertaken in British Columbia. Since launching in Sept. 2022, the project has issued financial incentives to employers for the hiring and registering of 1,329 apprentices. Continuing to improve diversity

within B.C.’s construction industry remains a critical goal of this project. An additional $5,000 is issued if the apprentice self-identifies as part of an equity deserving group, as part of an effort to redress underrepresentation in the trades. Employers can register up to two first-year apprentices before March 31, 2024 to earn up to $20,000 in cash incentives. Apprentices hail from across B.C., and to date 51 per cent of project apprentices have declared themselves to be a member of an equity deserving group. While the project has registered apprentices in 35 different Red Seal trades, almost $6 million in funding has gone to B.C. employers registering first-year carpenters, construction electricians and plumbers. All participating employers must adhere to BCCA’s Builders Code, which sets a standard code of conduct for workers on construction sites. To date, 1,059 employers have signed theBuilder’s Code pledge through the BCCA Apprenticeship Services project. This culture shifting commitment is helping to build a construction workforce where all employees are ensured safe and productive worksites free of hazing, bullying and harassment, thereby giving all workers the best opportunity to reach their full potential. cc

By Kaitlin Secord

is the name of the game when it comes to the world of construction. Whether digital or cultural, the need to enhance and advance as an industry is vital to its survival.

Fourty-one per cent of the industry’s current workforce will be retired by 2030, and its up-and-coming faces are shifting focus to tech-centred operations.

Procore’s Groundbreak 2023, held in Chicago from Sept. 19 to 21, was centred around this evolution, along with themes of mental health, diversity, equity, inclusion and belonging, A.I. and the value of roundtripping data to enhance learning opportunities.

Around 4,000 attendees from over 20 countries gathered to discuss new ideas, common challenges and to be inspired by keynotes from Michael Steep, Laila Ali and Michael Phelps.

During the opening day keynote, Procore unveiled new digital and cultural innovations that aim to help construction professionals attract and retain top talent, improve safety outcomes, and meet growing demand.

Some of these new updates focus on key areas like enabling payments and leveraging artificial intelligence to drive efficiencies.

The expo hall features a demo pavilion, innovation lab, and culture lounge, along with more than 100 companies showcasing their concepts, products, and services. At the demo pavilion and the innovation lab, attendees had the opprotunity to chat with Procore experts about products and give feedback and suggestions to further the practical devleopment of Procore’s technology. The culture lounge is where Groundbreaker’s from

across the world met to explore the indsutry through its members. The space features a stringwall where attendees were encourages to connect their attributes together, to demostrate shared expereinces from far and wide.

A focus on people and cultural transformation is equally as important to drive change and position construction as an industry of choice.

The three-day conference featured more than 80 breakout sessions intended to help industry professionals become better leaders, team members and builders.

Sessions included enhancing job site safety, streamlining deliverables, improving communication, collaboration and connectivity as well as outlining how Procore can be used to enhance productivity across businesses.

A session, titled “Best Practices for Creating Community for Women in Construction”, focused on what

companies – big or small – can do to build networks for support for women. Another panel discussion, “A Balancing Act: Overcoming the Challenges of Recruiting and Keeping Women in Construction,” heard from women in the industry, who spoke about their mutual challenges, opportunities from remote work and flexible schedules as well as ways to recruit and retain women onsite.

Sasha Reed, Procore’s senior director of business development, noted in an interview with Canadian Contractor, that supporting women and young people coming into the industry is vital. Procore. org, an avenue for education for the construction industry, hosts an advocacy group called Women in Construction.

Reed explains the purpose of this group is to “create a safe space for women to network with peers, and strengthen each other and how they are working not only within their organizations but how women are

finding themselves in the industry as a whole.”

Reed notes that a focus of the advocacy group has been how to better support women of colour entering the jobsite.

“It’s about understanding barriers of entry for these women and how do we help them either network or to navigate and negotiate those barriers. Some of those conversations point us to our Culture Academy, where we can actually speak to women and other monitories that we are hearing from on the topics that matter to them,” said Reed. “It’s not about us telling them what to do, it’s about showing them they are supported.”

Reed went on to explain that while supporting women and other minorities is crucial, it is equally as important to maintain a consistent conversation at the leadership level within the industry about core business problems and how are they being solved.

“The biggest problems are getting

enough people in the right roles. What can become a part of that conversation then is well, what does the makeup your organization look like? If you’re looking statistically at the different groups of individuals from different communities that are in the workforce, ready to work and your workforce is a monoculture or you’re very swayed towards a singular group, that is when you need to start asking ‘well, if we’re really looking at solving a business problem around capacity, are we employing the right people?’”

Reed also noted that as the industry diversifies, it is important to look at the

communities you are serving and what they look like.

The many pathways to organizational success was an overarching theme at Groundbreak, with Procore’s Groundbreaker awards highlighting the companies across the construction sector blazing these new trails forward.

This year’s ceremony saw B.C.’s ETRO Construction taking home an award in the category of excellence in workforce deployment. ETRO were honoured for the management of their company’s growth since their founding in 2015 from eight to currently over 100 employees. cc

By Gordon Wornoff

We had to start with this design versus what our printer could do and figure out how to execute that design.

Nidus3D in Kingston, Ontario is a trailblazer responding to the housing crisis. They’re 3D printing Canada’s first buildings using innovative technology to confront the country’s shrinking housing supply.

Ian Arthur, president and co-founder of nidus3d, spoke about his company and their story.

Tell us about your project with Habitat for Humanity WindsorEssex. Is it North America’s first multi-unit 3D printed home?

Yes. It was also the first residentiallypermitted 3D building in Canada. The Canadian Mortgage and Housing Corporation contacted Habitat for Humanity Canada to investigate construction 3D printing technology. Habitat Canada worked with Habitat Windsor and the University of Windsor, who were doing a lot of work around 3D construction printing themselves.

Habitat for Humanity Windsor had originally contracted another company, but their technology wasn’t there yet. I got a cold call from Fiona Coughlin, the

executive director and CEO of Habitat Windsor, saying, “I hear you guys have this printer, are you able to come print?”

The time frame was very ambitious, and we hadn’t planned on printing that soon. But when an opportunity for a partnership like that knocks, you move mountains to make it happen. Our first project took a little longer than we thought, but we got there.

The major challenge was that we inherited a design that was already in place and permitted. We had to start here v.s. what our printer could do.

Our crew had gone through the process of using the printer setup in a warehouse but not in the field, so of course there were adjustments made. We moved the printer partway through the project and had two printer locations.

On a bigger scale, there have been some challenges stemming from the innate conservatism we have here in Canada. We tend to look South and

let new technologies develop down there. When you are deploying new technology up here and are ahead of the curve, it can be difficult to get buyin from others at the table.

You had a huge debut with this project. Please tell us about bursting on the scene with the newest tech?

We started this company to prove that 3D construction printing is a scalable and deployable technology with a strong business case behind it. We’ve had an extremely production-orientated approach to 3D printing with an ambition of rapidly scaling execution.

Our Habitat build in Leamington was the first single story multi-unit project. Our next project on Wolfe Island was the first two-storey 3D printed building in North America. We also think it might be the first two-storey building that was printed out of concrete in the world, with everyone else using mortar up until this point. We went and executed another three-storey building in Kingston.

In our first year, we didn’t want to

limit it to one home. We aimed for three to four projects, all of them increasingly more complex than the last.

We want to see other companies use this tech. We could get 100 of these printers working and still not make a dent in Canada’s housing shortfall.

When we talk about other disruptive technologies, I consider how they emerge on the scene, dazzle shareholders with their growth, but fall flat with unintended consequences. Are you worried this technology will hurt workers or put family businesses under? I think there are a couple things at play here. I don’t think we have a choice but to introduce new technologies to the construction sector. We used to dig holes with shovels and now we use excavators, and there’s still tons of holes to dig.

We have an incredible shortfall of skilled tradespeople with a massive amount about to retire. We’re not graduating enough young people into the trades to replace them, let alone meet the increase in demand we’re going to experience in the future.

We need 1.5 million new homes in Ontario and four million homes across Canada in the next decade and we have no viable path to achieve that number with our current building approach.

Our economic recovery from COVID is heavily dependent on immigration and growing the economy through new

Canadians, and they’re going to need places to live, increasing demand for housing even further.

I believe that 3D construction printing is one of the first technologies in a long time that could play a significant role in addressing these problems.

Look at the process problems we have in construction. We’ve complicated the build process to an incredible level. We build homes with hundreds of types of materials, thousands of different components, and tens of thousands of process steps. And it has not managed to achieve price equivalency with wood frame construction, in large part due to the labour costs required.

With 3D printing, we’re using fewer materials to accomplish more of the build. And that is why I think it’s transformative. I think we will absolutely see 3D printers perfect concrete work and move on to other types of printable materials that will work for housing. I think we’ll see insulation extruded by the machine rather than be a secondary subtrade that comes on site. I think it’ll expand, but will never accomplish 100 per cent of the build.

And so, we can’t say that 3D construction printing is going to be the one thing that solves all our housing problems. It’s not. But it’s a key transformative feature in contending with our housing crisis.

What are some key characteristics of your products and in what direction is nidus3D headed?

Our buildings are cost equivalent to other forms of masonry construction right now, like cement block or brick. But there’s huge potential for the prices to come down and be competitive with wood-frame construction. Once we design a home, we can execute that home again and again. This is where we really start to see this technology shine. Our soft costs are spread out over more and more buildings.

We’re aiming to print one storey per day by next summer. The speed of delivery will be phenomenal.

We can print through eight months of the year - about the same as a regular house framing crew. We can print through light rain but must pause during torrential downpours.

We use an accelerated concrete mix, so the lower layers are solid and set by the time we are printing the new layers with new weight above.

We have about 20 employees and our recent profile has helped us gain a lot of valuable and interesting people. We have some young people who sought us out, we have engineers and other technicians who are in their mid-career, and we have some skilled tradespeople who are closer to the end of their career and have some trouble with some of the physicality that traditional construction requires. This is an opportunity for them to use their skills and share their vast accumulated knowledge with us.

The most exciting thing is how infinitely scalable this technology is. We’re in the process of scaling to neighbourhood-sized projects. I’m not saying it all has to be cookie-cutter but this is the scale we’re moving towards.

Our next project is 60 units across four buildings. And we’re looking at doing one to three dozen prints per location in the coming season. So, a 60-home subdivision would be our capacity next summer with the equipment we have. But, if we get the right contract, we just order more printers, train more people, and keep putting up houses as needed. cc

By Kaitlin Secord

Apassion for science and building led Bawating Building Science president, Trevor Trainor, into the world of Indigenous housing issues and tasked him with the mission of how to improve them.

After 10 years in automotive assembly ergonomics, Trainor began his journey into building sciences. Deciding to pursue his passion for building, he began building himself a cottage and started up a residential construction company.

After six years, he came to realize there was more to it – high performance homes. Intrigued, Trainor enrolled himself at the University of Waterloo in their Master of Applied Sciences program, with a specialized focus on building sciences. During his time in the program, he worked alongside Dr. John Straube.

“Dr. Straube is one of the true experts in the industry. I started working for his firm, Building Science Labs, where I was surrounded by other experts in the field who taught me more about building science and helped to accelerate my education,” said Trainor.

Upon graduation, Trainor joined the Building Science Labs team and worked there for eight years, continually learning from his peers.

After his time at Building Science Labs, Trainor founded Bawating Building Science, his own consulting firm, after a joint venture fell through.

“I was ready to pursue my passion and focus my expertise full-time on Indigenous housing issues.”

Trainor said the goal with Bawating is to “provide exceptional building science services for Indigenous communities across Turtle Island (North

America) and to make a significant contribution to solving the Indigenous housing crisis.”

Overcrowding and poor housing issues are major issues in Indigenous communities across Canada. According to a 2018 Canadian Housing Survey, Indigenous people were nearly three times more likely to report dissatisfaction with their dwelling’s energy efficiency, with 20.1 per cent reporting dissatisfaction with their dwelling’s ability to maintain a comfortable temperature in summer and 17.7 per cent in the winter.

In 2021, one in six Indigenous people lived in crowded housing. Statistics Canada also reported that Indigenous people were almost three times more likely to live in a dwelling in need of major repairs (16.4 per cent) in 2021 than the non-Indigenous population (5.7 per cent).

These issues and trends led Trainor, a member of the Thessalon First Nation, to look toward finding solutions to these problems.

Bawating Building Science focuses on projects related to building enclosures. This focus includes providing services related to design, analysis, testing and research of building enclosure systems as well as forensic investigation related to building moisture issues.

For Trainor, education about these issues is equally as important as fixing them.

“We also develop and deliver educational programming for other industry professionals on related topics.

We collaborate regularly with other consulting firms such as Building Enclosure Labs Inc., Building Knowledge Canada, and Construction Instruction.”

Bawating is currently working on a project with Dillon Consulting and Nunavut Housing Corporation to develop and monitor residential retrofit strategies.

“There are significant problems related to mold and the rot and decay of unvented roof systems throughout Nunavut. Our remediation project involved developing and analyzing two strategies to retrofit these roof systems,” said Trainor.

The analysis has included an extensive hygrothermal modeling study to determine the most effective retrofit approaches.

“In the pilot phase of the retrofit work, the team has instrumented the roof systems with temperature, relative humidity and moisture content sensors during the construction process, and have remotely monitored the thermal and moisture performance of the retrofitted roofs.”

For Trainor, his hope is that this data will be used to further inform future retrofit and new roof designs in Nunavut, along with other regions in the Inuit Nunangat.

In his pursuit of improving Indigenous housing conditions, Trainor said that he is guided by what he sees as three crucial priorities for sustainable building design and construction: safety, and durability.

“Only once we have addressed the issues of fire susceptibility, poor indoor air quality, mold growth and premature deterioration of our buildings, can we then address energy efficiency,” said Trainor.

As trends in the construction industry continue to shift, Trainor’s hope is that housing health and durability stay in focus.

“I see emerging trends like modular housing, energy neutral buildings and embodied carbon accounting. While these are important and interesting areas of study, my focus is on building enclosure design for the far North, where extreme climates and over-crowded conditions are resulting in mold, poor indoor air quality and rapid decay of the buildings.”

Trainor believes that collaboration is key for effectively addressing these efforts. Building science walks the line between design and construction, something he says is important to its development. Working with other industry professionals has allowed Trainor to adopt a “work smarter, not harder” philosophy, which keeps him motivated and eager to do meaningful work.

For Trainor, success is a long game that can be hard to capture but is incredibly meaningful when achieved.

“Measuring the success of our projects is a difficult task,” he said. “Customer satisfaction is certainly one measure but to truly evaluate our contribution to the development of healthy, durable, and efficient housing is something that occurs in the long-term.”

BUT MORE

While the demand for building is growing, so is the need for build science expertise.

“There is no better time than now to get into building science. The demand to help restore our existing building stock or creating the next generation of buildings is high,” said Trainor.

The avenues in building science consulting are endless, including design review, energy modeling, field review, forensics, and research. Exposure is key, Trainor recommends those interested in building sciences explore their options.

“Compared to other industries, construction is slow to change. While there are definitely groups working on the leading edge, others can be slow to adapt and adopt.”

Learning and education is an ongoing process at Bawating Building Science, with Trainor leveraging every opportunity their team has for exposure in the industry into a chance of growing

their knowledge base.

“We are always reviewing information related to the latest developments in building materials, approaches to design, construction techniques and analysis to understand how these developments can apply to our work in Indigenous housing,” said Trainor. “ The learning never stops.”

For Trainor, the future of Bawating Building Science is clear: to continue to make significant contributions to solving the Indigenous housing crisis.

This goal is about more than just getting shovels in the ground for Trainor. Bawating’s vision also includes contributing to building science expertise and teaching building science

principles to others in the Indigenous housing space, as well as training the next generation of Indigenous housing professionals.

In their first two years of operation, Bawating has been actively involved in achieving these goals, and Trainor looks forward to the future of what they will achieve.

“I’m pleased with the work we have done so far, but we are just getting started.” cc

Join a completely Dealer-Owned company today.

Dealers share and participate equally without the influence of any external shareholders. Harness our massive buying power, comprehensive distribution, national brand recognition and marketing support.

The case for mid-rise housing in Canada.

By Richard Lyall

Theway I see it, we have two choices if we’re serious about closing the gap between the number of homes needed and built in Canada.

Communities and cities can either build outward which will result in urban sprawl. Or we can build upward and promote more density by allowing more mid-rise homes to be built in existing neighbourhoods.

Admittedly, high-density developments are not always welcome. But they are a way to put a significant dent in the housing supply and affordability crisis. Mid-rise buildings allow more people to live in less space, make more efficient use of land and transportation and result in less environmental destruction. In my view, there should be no debate about the need to increase density.

The stark and deeply troubling fact is that we face an acute shortage of housing supply and must improve the density of housing in our cities. We need millions more units.

Increasing density is not the sole solution but it is a start. Densification of existing neighbourhoods can be accomplished by tearing down older buildings and replacing them with mid-rise residential structures with more units or converting underused properties into housing.

It is distressing that we are still arguing over the merits of densification as any advanced jurisdiction on the

planet has embraced it as a way of building the homes we need. Other cities around the world have had success building mid-rise housing on a large scale.

A recent report called Making Room for Growth examined the prospect of Canadian cities growing inward and upward through densification and how much housing stock is occurring in existing urban areas.

The report, done by Josef Filipowicz and Steve Lafleur, both senior fellows at the Fraser Institute, an independent, non-partisan Canadian public policy think-tank, found that despite a housing shortage in many cities, 26 per cent of urban neighbourhoods, or one in four, actually lost more dwellings between 2016 and 2021 than were added.

Our urban neighbourhoods had a cumulative net loss of 33,723 dwellings over the study period. Toronto fared especially poorly, reporting a five-year net loss of 7,195 housing units.

The authors noted that the city of Toronto faces a net loss of housing units partly because gaps are being left by apartments that have been razed or multiple units are being converted into single-family homes.

Alarmingly, what growth is being seen in new housing units across Canadian cities is largely happening in very small pockets. As study co-author Lafleur noted in a press release, to more meaningfully tackle the housing shortage policymakers will have to look at ways to create more housing units of

all types across urban areas.

To its credit, Toronto has started moving in the right direction. Council recently adopted a new policy allowing as-of-right permissions for single-family homes to be converted into mulit-plexes in all low-rise residential areas. The change will allow more density in lowrise neighbourhoods city-wide while ensuring they largely maintain their built form.

The move could transform up to 70 per cent of Toronto’s yellowbelt areas where only one single or detached family home per lot was permitted. This is certainly a good start. However, the city has a long way to go. In The Danforth area, for instance, the city has limited the height of buildings along much of the street. RESCON has proposed that the city amend its threestorey limit to eight storeys on minor arterials and to 15 storeys on major arterials.

According to the Canada Mortgage and Housing Corporation, we need to build 5.8 million housing units between 2022 and 2030 to restore affordability to the housing market.

The task is huge, and that is why immediate action is necessary. Permitting more housing density in our cities is one way to make inroads. The necessity of higher density should not be up for debate. It is a given. cc

Richard Lyall is president of the RESCON. Ontario. Contact him at media@rescon.com.

Follow Wayne Gretzky’s motto and head to where the puck is going to be

By Steve Ryan

If you are contemplating builder software for your company, you probably agree that the subject is too complex to handle in a short article. We aren’t going to provide the magic code for how to choose the right product. Perhaps the best we can do is clear up some of the mystery around what you should expect from software and what it takes to realize its promise.

Let’s start with just what software should do for you. You certainly need a better reason than “Everyone says I should do this”. That, in turn, leads to a blunt statement: If you are one who feels record keeping gets in the way of business, you can stop reading now. Builder software is a better way to collect and share information. That’s all it does. It doesn’t create information or make decisions for you or do any of the building.

Perhaps the least recognized benefit your software can offer is to drive consistency. By bringing structure to what information is gathered and how it is stored or shared, builder software ensures that critical steps are followed, reported, and verified.

By making that information immediately available to the people who need it, software helps everyone make better, more timely decisions.

By keeping track of what got done, software enables the people who do build things to do their jobs without

conflict, in the right sequence, with the right materials on hand.

There is a blessing and a curse here. The blessing is that it makes it hard to overlook or avoid critical steps and it allows you to prove that those tasks are done. The curse is that it compels you to do things the way the software creators set things up. (I had a software provider suggest we should simply not pay provincial sales tax because their product couldn’t handle it.)

That sets up your first challenge: deciding on whose software to use. It needs to reflect the way you do business and how you run projects.

Your next challenge is to ensure it can handle everything you need it to do now and in the future. A lot of different disciplines enter the picture and I’m not so sure a single product or provider can be lights-out good at all of them. As a sampling you might want to try:

• Tracking the selling process

• Scoping and estimating

• Project cost control

• Project scheduling

• Ordering/ delivery / inventory

• Time reporting

• Change management

• Customer updates / project portal

The list goes on, and you will probably agree it’s diverse.

So, faced with the dual challenge of selecting an unfamiliar product that mirrors your way of doing things, and making sure it can perform all the

functions you might ask of it, what are you supposed to do?

There may be hope for us coming out of the ICI construction sector. Large scale builders around the world are making it clear that any software, from initial design through to building maintenance, must interface with other software products or they won’t use it. That means rather than trying to find the one product that does it all, they can use the software that does the best job for them in each functional area. They can move data across different functions using the most suitable software option for any or all of those other functions. More than this, when one thing turns out to be less than perfect, they can transition to something else without disrupting every function in the business.

Many of the products aimed at residential construction started out with the ambition to be your one and only software solution. Some have gone so far as to make it impossible to so much as download data into Excel. If you are shopping or doing your research on builder software, keep your eye on where this industry is going. Find someone who can advise you on IT and look for products that are open to information exchange. The question of what software to take on becomes less imposing when you aren’t looking for that single all-in-one solution. It can also be reassuring to know you can make a course correction without turning the company on its head. cc

By James Hong

Construction site safety inspections are part of a standard set of protocols to evaluate and safeguard a work site prior to work start. Many times, I’ve seen this step misinterpreted by performing the site safety check on the first or first few days while work has already started. Doing so defeats the purpose of the protocol and puts workers at risk of injury and the project at risk of delays which are always costly.

To properly perform a pre-production safety check, all documents, plans, drawings, and specifications are needed to fully assess the site. The best way to achieve this goal is through BIM, which includes software that is populated by each step of the building construction plan, from conception to completion.

Once these documents are assembled, check for safety regulations, standards, and applicable codes for your project.

Using the gathered materials, do a preliminary paper safety check by identifying potential hazards and safety risks.

The site inspection visit should include all stakeholders.

There are seven critical areas to cover to perform a complete and thorough inspection: site access and egress, structural integrity, work areas, utilities and services, safety signage and markings required, emergency preparedness, and environmental factors.

You should assign a safety team member the sole responsibility of taking notes and performing paper checklist duty. Take photos and video; this step will save you from doing a second pre-production safety check or making errors on the first pre-production safety check.

Once your inspection is complete, schedule a debriefing meeting with the relevant parties. Inform and assign responsibilities and make clear who the reporting contacts are with contact information.

Once site work starts, a new safety inspection is required whenever a new division crew starts, a problem arises, or an initial inspection alert is triggered by an event. There are a myriad number of areas to watch over. Do not make the mistake of completing a pre-production site safety check and thinking you are done.

Obscured areas can present hidden hazards such as electrical wiring and improper storage. Housekeeping always plays a big role in keeping sites safe. Check for clutter, material storage and debree.

Make sure you have the proper safety signage at the site. Check for missing or damaged signs and replace them to protect workers from failing to follow safety measures.

Check that workers are wearing proper PPE and that they know where to find company required PPE provisions.

Keep an eye out for ergonomically safe material handling and correct workers if necessary. Make sure your workforce is trained and look for signs of inappropriate working habits. Ensuring workforce training should be done before any project is even pre-inspected.

Your daily check-ins are good opportunities to distribute and collect maintenance inspection records for equipment and machinery. This includes records for temporary structures and scaffolding as well as any structure modifications.

And finally, always encourage open communication between the crew, supervisors, and management. This will empower workers to speak up about potential and existing hazards. Be safe. Be well. cc

James Hong is an independent writer & journalist.

23_006951_Canadian_Contractor_OCT_CN Mod: August 30, 2023 9:31 AM Print: 09/19/23 12:21:21 PM page 1 v7 ORDER BY 6 PM FOR

Whatis a contractor’s or builder’s role when it comes to mitigating radon build up?

Across Canada, all homes have some concentration of radon gas within them. The amount differs based on the amount of uranium present in underlying rock and soil, but even houses that are right next to each other can have different concentrations of radon present within them, typically in the basement or ground floor.

Radon is a pervasive issue in Canada as numerous households are exposed to high levels of the gas released from the soil. This radioactive gas is odourless, tasteless, and colourless, making it difficult to detect, and can infiltrate homes and enclosed spaces through various openings such as cracks in foundation floors and walls, construction joints, and gaps around service pipes, among others. Shockingly, it is the primary cause of lung cancer in non-smokers, silently claiming the lives of 3,300 Canadians annually, more

By Maxime Duzyk

than those killed in car accidents, house fires, and carbon monoxide incidents combined.

Due to their airtightness features, Canadian homes are particularly susceptible to trapping radon gas, leading to potentially hazardous levels that can damage the DNA in lung tissue with prolonged exposure. According to Health Canada, about 16 per cent of lung cancer fatalities are attributed to radon exposure within homes. Despite this, the frequency of radon testing among homeowners remains low. In fact, a recent study conducted by Health Canada indicates that merely 6 per cent of Canadians have conducted a radon test in their residences.

To protect Canadians from radon buildup, the contractor and builder communities need to consider building code measures that will control radon entry, especially as government incentives to protect against radon accumulation increase. With increased public interest in protecting homes from

radon, contractors and builders need to have plans and products in mind to tackle this issue. This article will explore active and passive radon mitigation systems, and the surprising role that certain closed-cell spray foam insulation (ccSPF) products can play in creating a radon barrier in residential homes.

Regarding radon mitigation, there exist two fundamental approaches: passive barriers, which consist of a collection of pipes and a stack riser that leads to the roof without a mechanical fan, and active devices, which comprise a passive barrier system along with a mechanical fan.

However, it is essential that all radon control measures include a depressurization zone (gravel) situated below the plane of airtightness. Once these components are in place and connected to the occupied space, the next step is to implement either a

passive or active method to extract the soil gas from beneath the slab and release it into the atmosphere. In the non-powered passive approach, depressurization is created through natural convection forces, such as a stack effect or positive pressure zone. The stack extends through the building shell and releases ideally above the roof or the rim joist. As warmer air from the vent stack rises, it naturally depressurizes below the slab. To preserve the momentum of the stack effect, the section of the stack that runs through the attic should be insulated, and a hardwired receptacle must also be installed to allow for future conversion to an active system.

Sometimes, a passive system cannot move enough radon out of a home, and a powered, active approach is necessary. This is not too different, as it just involves an electric fan installed in the same type of venting system which actively draws air up through the stack.

In both active and passive methods, it is crucial to have a continuous air-soil gas control layer and permeable material to establish a depressurization zone.

To accurately measure radon levels in a home, testing must be conducted after construction and under normal living conditions. Unfortunately, there are currently no reliable or affordable methods to predict if a home will have high radon levels prior to construction. Therefore, it is necessary to enforce code requirements that regulate the entry of radon in all residential buildings.

To control soil gas ingress during new construction and renovations, various measures can be taken. These include applying soil gas barriers to ground contact floors, foundation walls, and roofs, installing a gas collection layer (such as clear stone or gas mat) under all ground contact floors, setting

up a piping system to extract soil gas from beneath the floors, sealing seams, cracks, penetrations, and all openings in ground contact floors, walls, and roofs, and conducting post-construction radon level testing.

If the indoor radon concentrations are found to be above Health Canada’s action level, the piping system can be connected to an extraction fan to control radon entry and safely vent the accumulated radon outdoors.

Obtaining a perfect air barrier/soil gas barrier is virtually impossible using conventional construction methods such as sheeting and taping.

Insulation (ccSPF) as a cost-effective solution

Air leakage is the primary pathway for soil gas intrusion, which occurs through joints, cracks, and penetrations in buildings. Therefore, it is crucial to ensure that these areas are well

sealed, and that the soil gas barrier is continuous. Spray foam insulation, when applied correctly by authorised and certified professionals, can expand into crevices, and adhere to building elements, making it an effective option for creating a continuous soil gas barrier. This method can be used underslab, on foundation walls, and on roofs. Additionally, spray foam insulation can help to minimize construction defects that may be present in taped or caulked radon barrier systems.

Although spray foam insulation is not a new product or invention, recent developments have led to the creation of hydrofluoroolefin (HFO) based closed-cell spray foam insulation products that have been tested for radon diffusion and have proven to be highly effective in reducing radon levels.

Typically, an air barrier material is used for radon protection since radon primarily travels through the air. However, some air barrier materials may allow radon diffusion. For this reason, ccSPF products have been tested in accordance with K124/02/95 (method C of ISO/TS 11665-13) for radon diffusion. At only one inch in thickness, some HFO ccSPF products have been found to perform 35 times better than a 6-mil (0.15 mm) polyethylene sheet for radon protection.

R-10 rating, which meets most code requirements for slab insulation. In many regions, 1.5 inches of ccSPF is adequate to address the requirements for a subfloor vapor retarder. Additionally, using under slab insulation has numerous benefits such as being hydronic heating ready, preventing cold concrete floors, saving energy through the thermal mass effect, reducing floor cracking, and preventing condensation which can lead to mold growth.

Why does ccSPF work so well as a radon control layer?

“As awareness of the dangers of radon, and the presence of government grants to combat it grow, there will be more opportunity for contractors and builders to take on radon mitigation projects.”

• To start, it’s seamless. The ccSPF ensures a smooth and uninterrupted surface coverage. The reliability of the polyethylene barrier’s continuity is dependent on the installation’s precision and the tape’s durability. The use of caulking or mastics to supplement the barrier, as well as concerns over termination edge failures and material compatibility, can be eliminated.

the tested tape must be used in conjunction with 6-mil (0.15 mm) polyethylene. In commercial construction, ccSPF is a frequently used insulating air barrier system that has undergone an air barrier system test and an additional durability test procedure, which confirmed its compliance with air barrier system test standards after being exposed to the Canadian climate for a full year.

When aiming for continuity between the insulation on the walls, rim joist, and sub-slab, spray foam insulation can be applied directly onto the prepared gravel substrate, which should have a minimum thickness of 1.5 inches. This area is a crucial one for air leakage and thermal bypass. The application rate may vary depending on the job’s complexity, but typically, installing both the air and vapor control layer and insulation in a 1000 square feet basement (wall, rim joist, and under slab) can be done in half a day. This production rate is much faster compared to installing 0.15 mm polyethylene sheet, which requires seaming and detailing all penetrations, followed by insulating and seaming the insulation boards.

To account for the unevenness of the gravel bed, typically 1.5 inches of ccSPF is used. Initially, less than an inch is applied in the first pass to level out the substrate. Then, a final application of one inch is applied on top of the preliminary layer. This approach utilizes ccSPF for its barrier properties, while also acting as insulation.

A slab that has been insulated with 1.5 inches of ccSPF has in average an

• ccSPF is also water resistant. ccSPF has a slow water absorption rate and if it does become wet, it will eventually dry out and remain resistant to fungi. It also serves as a vapor retardant when it reaches a thickness of 1.25 inches and has received approval from the Federal Emergency Management Agency (FEMA) for use as insulation in flood zones.

• The requirements for an air barrier are exceeded by ccSPF. To comply with ASTM E23 or CAN/ULC S742, which is the standard test method for determining air leakage rate of air barrier assemblies, air barrier solutions need to be tested as systems. For this requirement,

In terms of ccSPF’s seal and selfflashing capability, each penetration is entirely sealed, and the joint is insulated, resulting in no thermal shocking. The concrete and penetrations become part of the thermal envelope, which eliminates thermal expansion for the pipe and makes the concrete-topipe seal permanent. The concrete is thermally protected and no longer prone to shrinkage, which often results in cracks. Additionally, the sump pump lid is also sealed.

Adding ccSPF as a radon control layer on the existing slab and a new second slab can complete basement retrofits for radon mitigation. To ensure effective radon mitigation, the radon vent stack must penetrate both slabs and terminate

within the permeable fill layer.

Existing floor penetrations can be sealed and insulated by directly applying 1.5 inches of ccSPF to the existing concrete floor. This is also an opportune time to install hydronic heating. If the load-bearing wall needs to be isolated, it’s recommended to wrap plywood with commercial-grade air barrier material and install them before pouring the second concrete floor.

For a crawlspace, ccSPF can be applied directly onto the original floor slab or over the gravel. The spray foam will adhere fully to both surfaces. Retrofit applications can also be done over the original floor slab in a full basement, using a total of 1.5 inches of ccSPF, reinforced with rebar, with a hydronic heating system installed, and concrete applied.

As the Canadian Government pushes for more recognition of and testing for radon accumulation in residential

homes, there are a few incentives and grants that have appeared across Canada. As awareness of the dangers of radon, and the presence of government grants to combat it grow, there will be more opportunity for contractors and builders to take on radon mitigation projects. As a contractor or builder, don’t miss out on what is likely to become a pressing issue in the years to come, and be prepared with the right products and procedures to combat radon buildup.

There are multiple spray foam insulation products on the market, so how can you know which most effectively resist radon buildup within a home? As a contractor or builder, you know that ccSPF is an effective measure for combatting radon buildup, when properly installed. It’s best to look for spray foam insulation that has radon diffusion testing or has been evaluated by the Canadian Construction Materials Centre (CCMC) as suitable for radon control. The

CCMC operates under the National Research Council of Canada (NRC), and objectively evaluates the performance of various materials and products on the market to ensure they comply with regulations.

Selecting a spray foam insulation that has been rigorously examined by a team of unbiased experts is the best way to choose a product that will effectively mitigate radon buildup, while also contributing to an excellent building envelope that can be implemented into new builds and retrofits alike. cc

Maxime Duzyk is the global director of building science and engineering with Huntsman Building Solutions. He holds a background in architecture and has been in the spray foam insulation business for the last 13 years. Maxime is involved with different building envelope committees and associations in North America like CSC, SFC, SPFA, CCMC and ULC Standards.

By Mike Anderson

TheCanadian housing market is on the verge of a building boom.

Surges in population, combined with a restricted housing supply are creating the conditions for a vibrant building market. However, in addition to meeting this demand, builders are increasingly tasked with ensuring that these new homes comply with more stringent building codes as well as the industry’s climate targets. This is an ambitious task, as it not only requires builders to adopt new materials and building strategies, but also new supply chains and the effective retrofitting of older properties.

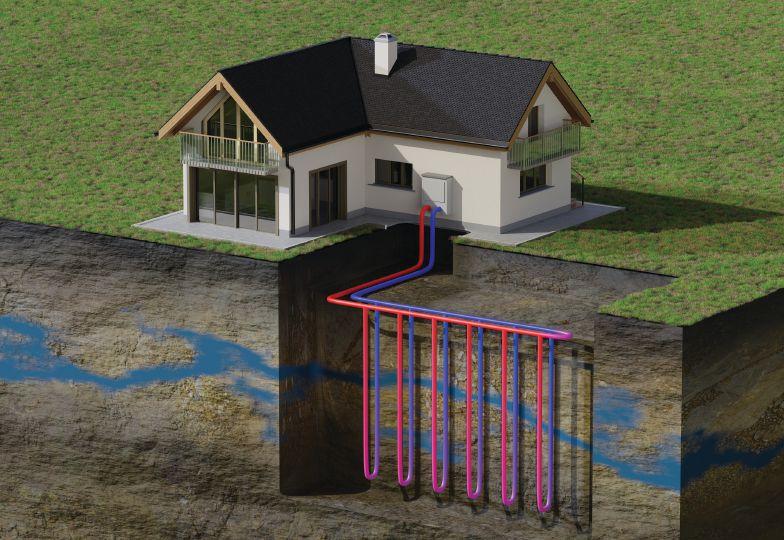

The Canadian construction industry is uniquely poised to assert itself as a leader in high-performance construction for cold climates. The present housing situation is ripe for the opportunity to use novel approaches and model a greener future for all. Net Zero building is one of the dominant approaches in sustainable construction right now and will undoubtedly become more widespread in the near future as it brings together a reduction in energy consumption and renewable power generation.

Build strong bones

When it comes to building Net Zero homes, size matters. The more surface area and outside/inside corners your building has, the more opportunity there is for heat loss during the winter. Net Zero building is all about maximizing heat retention, and a

compact build is the most effective way to achieve this.

Assemblies can make or break a home’s efficiency, so it is essential to ensure that they are airtight and wellinsulated. Thermal bridging poses a risk of condensation, as well as heat loss in winter and heat gain in summer. Continuous insulation is effective at reducing and eliminating thermal bridging, making it a must for any Passive or Net Zero home. It is important to conduct a pre-drywall blower door test to verify airtightness and identify any potential issues before closing up and finishing the home.

While it is always important to tailor the design of your project to the opportunities and constraints of the site itself, it has an especially significant impact on construction of Net Zero homes. These buildings have

a uniquely symbiotic relationship with their surrounding environment, using the natural features of their particular climates to their advantage.

For example, consider the impact of the vegetation surrounding a given site. Coniferous trees can provide cooling shade all year round, whereas deciduous trees provide shade during warmer months and allow more sunlight to come in during colder months. Being strategic about positioning the building in relation to the pre-existing vegetation can have a noticeable impact on energy consumption and heat retention.

Understanding the location’s climate and orienting the build to maximize (or minimize) heat and light from the sun can provide both environmental and aesthetic benefits to the home. Similarly, opting for strategically sized, wellplaced windows can provide natural temperature regulation all year round.

Establishing the infrastructure for

solar PV from the beginning is also a crucial step in optimizing performance and planning for Net Zero. Either rooftop or ground-mounted solar PV (depending on location) requires planning the location and size of the solar system as part of the design and build. Even if solar PV will not be installed as part of the initial build, creating the infrastructure for an upgrade is crucial to ensuring improved efficiency down the road.

Don’t cut corners

Achieving Passive House levels of airtightness is another key aspect of Net Zero home design. Passive Houses dramatically reduces the need for mechanical heating and cooling, instead creating a comfortable living environment through the strategic use of windows, insulation, and other structural features.

Generally, it is suggested to work with a high-performance envelope specialist to achieve optimal results, as Passive House construction requires extensive technical expertise. The primary principle behind this approach is to maximize heat retention through high-performance windows, doors, and assemblies, orienting for passive solar heating, and using high efficiency mechanical systems to keep energy costs low and comfort high.

Achieving this balance requires close attention to the unique orientation, climate, geometry, and construction assemblies of the build. Minimizing or eliminating exterior venting fans, installing a highefficiency heat recovery ventilator, avoiding single or double hung windows and opting instead for triple pane, casement, awning, or tilt and turn windows are all helpful best-practices in Net Zero design.

Make the most out of your investment

Once you have upgraded the building envelope, it’s essential to adopt mechanical heating and cooling

systems that capitalize on the efficiency of its architecture.

For primary heating and cooling, high efficiency heat pumps should be your go-to-option. These all-electric systems are both inexpensive and efficient, minimizing energy costs for the consumer while maintaining a higher standard of comfort. Domestic

“These buildings have a uniquely symbiotic relationship with their surrounding environment, using the natural features of their particular climates to their advantage.”

hot water is the next largest demand for energy in a home after heating and cooling and especially in larger households with higher demand, a hybrid heat pump water system is typically the most convenient and costeffective option.

These practices are not hard-andfast rules, but flexible guidelines that should be adopted and adapted based on the particular logistics of your site, project, and client. Deviating from these practices, however, may have dramatic impacts on both construction costs and the size of the home’s solar array, so conducting due diligence by having an experienced consultant model the project and various scenarios beforehand is important. They can optimize your design based on your particular budget and the needs and constraints of the project, allowing you to consistently achieve your building goals. cc

Mike Anderson, MArch, BSc is the CEO and Design Leader of Passive Design Solutions, a Canadian design firm specializing in Net-Zero ready building design. In addition to building singlefamily homes, the team has worked closely with a number of non-profit and community housing groups to design low-income community housing projects that achieve exceptional netzero performance. Mike has worked on over 300 Net Zero Ready projects throughout North America over 10 years, establishing him as one of the nation’s foremost passive house experts.

What caught our interest

MILWAUKEE M18 ROTARY LASERS

milwaukeetool.ca

Milwaukee Tool launched three new M18 rotary lasers and two new accessories.

The M18 Red exterior rotary laser features manual masking shutters and a one-button setup.

The M18 Red dual-slope rotary laser is designed to help with levelling, aligning, and squaring applications. It is 1/16-in. accurate at 100 feet.

The M18 Green interior rotary laser features Center-Find for long-range alignment. It is precise at 1/16-in. at 100 feet.

MIRKA DE 1125 L mirka.com

Mirka’s newest addition to their dust extractor range is the DE 1125 L. The L-class extractor features antistatic capabilities, a 1200w motor, a 25 litre container capacity and is suitable for wet and dry use. It also features auto-start and Push & Clean filter cleaning functions.

HELLY HENSEN HI-VIS WOMEN’S CSA WORKWEAR hellyhansen.com

Helly Hansen has released three new products to their women’s workwear lineup – a winter jacket, bib and softshell jacket. The Alta line of garments all feature HELLY TECH® Performance waterproof, windproof and breathable fabric.

The winter jacket features 120g insulation in the body and 100g insulation in the sleeves, as well as two hand pockets and a Napoleon pocket. The bib features a front fly and boot hem adjustment straps. The softshell jacket features an ID card loop, articulated sleeves and adjustable hems.

HEARLOK® SOYA HP

huntsmanbuildingsolutions.com

Huntsman Building Solutions have released a new closedcell spray foam solution, Heatlok® Soya HP. The solution was designed to have the best R-value of any HFO product on the market, with an LTTR value at 50mm of 2.06 RSI (R 11.68). The product leverages Honeywell’s latest Solstice® Liquid Blowing Agent technology, which is noted as the most environmentally conscious produced to date, with zero-ozone depletion potential, and a global warming potential less than 1. Heatlok® Soya HP is made in Canada and is suitable for roofs, walls and sub-slabs.

ROLL-A-SHADE® SOLAR ZIPSHADE rollashade.com

Roll-A-Shade’s latest exterior shade system, Solar ZipShade, uses solar power to power and control the screen. It contains a solar cell on the front of the head box that provides energy for its operations. The absence of wiring for the motor was intended to make installation simpler, eliminating the need for electrical work.

FESTOOL CORDLESS SAWS festool.com

Festool has released two new cordless saws – the CSC SYS 50 cordless table saw and the RSC 18 cordless reciprocating saw. The CSC SYS 50 cordless table saw is designed to produces parallel cuts of up to 11 inches, a cross-cut width of up to 17 3/4 inches, and bevel cuts of -10 to 47 degrees. The battery-powered saw features a 2x18V dual-battery system as well as a rip fence, a miter gauge, and a sliding table. The RSC 18 cordless reciprocating saw features a brushless EC-TEC motor combined, switch-activated pendulum stroke and vibration control.

Stirling, a passionate and skillful custom homebuilder, has a lot on his plate. While on the jobsite, he is responsible for managing a team of tradespeople, ensuring projects stay on schedule and within budget while also acting as a liaison to clients. He was also tasked with taking over leadership of the company when its owner and founder, Frank, decided to retire.

Frank oversaw the company for decades and built it from the ground up with hands-on leadership. Upon his retirement, he passed the reins to Stirling, recognizing his dedication to the company and the importance of maintaining its reputation.

The transition of power has not been smooth, however, as the two have different visions for the future of the company. Stirling wants to transition the company to modern tech and tools, whereas Frank is adamant that keeping things traditional is best.

During the period of transition, the two have struggled. Frank questions Stirling’s decisions to adopt new methodologies and technologies, while Stirling feels Frank’s approach will limit the company.

Stirling is feeling defeated and is unsure of how to resolve their conflict while respecting Frank’s years of dedication to growing the company to what it is.

Parker’s client, Rosemary, wants to change her design in the middle of a major basement renovation. The changes would alter the timeline, budget and would require additional labour and permits. The pivot in design also involves work that Parker’s company does not specialize in. What should he tell Rosemary?

At the end of the day what matters is that the customer is satisfied and receives a service that she is happy with even if it means that Parker is not the one who completes the job. If she has been re-inspired and no longer wants the previous design, then Parker needs to let her know what the costs to date are because he acted in faith to get her to that point. She would also owe for the work up-to-date.

If Parker feels he can’t meet the demands/pricing and level of services she requires within the timeline he can advise what the cost would be for the changes and allow her to either accept his new quote or obtain additional quotes. The client wants the changes so would need to compensate for the expenses accordingly, a marginal increase is not fair of her, and she should not expect Parker to accept the changes and additional costs without proper compensation.

If the client is not happy with updated pricing based on her changes, then Parker can agree to walk away from the contract, receive payment for work to date and allow her to find another business to do the work. The client may have a change of heart after discussing the changes, costs and timeline impacts or she may decide to move forward with her new vision with another outfit or work with Parker to make fewer changes or increase her budget. Because the client wants these changes, she needs to take responsibility and accountability for the extra expenses.

1. Stirling should keep Frank in the dark – he handed over ownership of the company, so he doesn’t need to be involved in business decisions.

2. Stirling should assert himself as the company’s new lead decisionmaker and communicate with Frank that he can provide opinions but not make final decisions.

3. Bring in an external mediator to help the two figure out the best course of action that satisfies both of their interests, as well as the company’s.

4. Stirling should give leadership back to Frank – it was his company after all.

5. Something else.

If you have a solution to Stirling’s dilemma, email your entry to ksecord@annexbusinessmedia.com and put “Old school, new school dilemma” in the subject line. Include your email information in your response. Please don’t post your response in the comments section on our website.

Entries close January 15, 2023. The winner will be announced in the March 2024 issue.