Think rental

Renting vs. owning Pg. 16

Creative Eye The daring makeover Pg. 20

The Ryan Report The pandemic explained Pg. 26

Think rental

Renting vs. owning Pg. 16

Creative Eye The daring makeover Pg. 20

The Ryan Report The pandemic explained Pg. 26

Roger Hardy on what it takes to stay successful in the industry, Page 12

Industry veteran Roger Hardy has now seen it all in renovation and custom home construction.

In pursuit of passion 12

Roger Hardy’s story of following his dreams and carving a place for himself in the construction industry.

Creative Eye: The daring makeover 20 How Coulson Design gave an awardwinning French Country makeover to it’s LaSalle, Ont., project.

5 Has COVID-19 brought inflation back into the Canadian economy?

Today’s Builder 10 Stephanie Rota discusses the truth about budgets.

The Ryan Report 26

Steve Ryan discusses the lockdown and its impact on the industry.

18 How radon could be silently killing Canadians.

The seal of approval 24 RenoMark and similar programs could help contractors further their professional growth. The Dilemma 26 Kyle faces a PR disaster through no fault of his own.

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

In the latest episode of The Hammer, Canadian Contractor editor Patrick Flannery talks to Liz Kovach of the Western Retail Lumber Association about the wood shortages facing the industry. Visit canadiancontractor.ca for episodes, or subscribe on your favourite podcasting service to listen in.

Triple-paned windows are going to become the norm in Canada. Tune into Patrick Flannery’s discussion with Jeff Pigeon and Paul Commisso from Jeld-Wen to find out more.

Follow @CanConMag or look us up on Facebook to add Canadian Contractor to your daily diet of online interaction.

ISSN 1498-8941 (Print)

ISSN 1929-6495 (Online)

Editor Patrick Flannery 226-931-0545 pflannery@annexbusinessmedia.com

Associate Editor Sukanya Ray Ghosh 647-203-7031 srayghosh@annexbusinessmedia.com

National Account Manager Amanda McCracken 226-931-5095 amccracken@annexbusinessmedia.com

Media Designer Mark Ryan

Publisher Danielle Labrie 226-931-0375 dlabrie@annexbusinessmedia.com

Account Coordinator Barb Vowles bvowles@annexbusinessmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-510-5182

Martin McAnulty, Vice President Sales mmcanulty@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Circulation email:bolechnowicz@annexbusinessmedia.com Tel:

or

Some of us are old enough to remember when inflation was the monster under the bed of the economy. When annual rates were in the double digits in the late ‘70s and early ‘80s, it was looking for a while there like our economy had entirely lost the ability to produce goods and services at prices people could afford. With interest rates also incredibly high (I think my father was paying around 20 percent on his first mortgage), and wages rising but nowhere near fast enough to keep up, there was a real chance for a sharp decline in lifestyles. A lot of that was due to oil prices driven up by price-fixing cartels and protectionist trade policies that discouraged cheaply made foreign products from entering the country.

As trade policy liberalized through the ‘80s and early ‘90s, and central bankers learned to control inflation by manipulating interest rates, inflation first came under control then, apparently, almost vanished altogether. For almost 30 years now we’ve seen inflation rates under three percent in good times and in bad. The dragon that economists assured us was an inviolable principle of the business cycle appeared to have been slain by two white knights: expanded oil production in North America and globalized trade creating an endless supply of cheap manufacturing and labour.

The persistence of low inflation even under conditions that should have generated higher rates has puzzled many economists. Interest rates have been lower than at any time in history for a couple decades now, and they appear to have had the expected effect on consumer spending and debt, yet a continued glut of supply for most products has kept prices reasonable relative to overall growth. The productivity surge from the information revolution coupled with steady immigration has supressed wage growth and kept the brakes on prices. Only real estate seems to have reacted in a predictable way to decades of economic growth with a sustained boom in prices that puzzles economists even more than the low overall inflation rates. Maybe that’s because you can’t get real estate anywhere except the country in which it resides.

It seems possible to me that the COVID pandemic has shaken some of this loose. Everyone I talk to has more orders coming in than they can fill. Part of that is the sheer volume of demand, but part is also the slower pace at which we can get things done both because of supply chain disruptions, health measures on the jobsite and the pandemic making it even harder than usual to add staff. And we know what has happened to the price of materials, especially lumber (check out The Hammer podcast episode #5 for my conversation with Liz Kovach of the Western Retail Lumber Association about this). As our costs grow and we need to take on less work while still not worrying about losing market share, the only sensible approach would be charge more. This industry has never been subject to offshore competition, but its suppliers are. If there’s a long-term chill in our ability to source supplies globally, those cost increases could be permanent.

That’s the view from our industry, but it’s common in a number of other sectors, too. Look out for the return of inflation. cc

” COVID may have changed the conditions that kept this old bugbear away.

By Patrick Flannery Editor ”

Kim Menard appreciates Jacob Stoller’s thoughts on Lean construction, and adds a few.

This is a great article. Time wastage can be a significant cost to a project not just in terms of production, but also in achieving optimum value of the work, which in turn affects profit. Engaging workers is essential to having a strong productive team. Project drawings/documents are reviewed in close detail during the design phase to look at more efficient and cost-effective ways of achieving the desired outcome without high cost or loss of quality. Long delivery items are flagged and set as priority to ensure delivery meets schedule. No job ever runs perfectly but we have the tools to influence the outcome with good planning.

– Kim Menard

No reason not to agree to milestones

Ben Polley chimes in on the milestones debate.

On the basis of the prospective clients’ limited comments alone, I cannot understand why a contractor would not be able to commit to milestones, or some other similar structure, such as percent complete, so long as these are reasonably representative of when the renovator incurs costs and risk. I don’t know the regulations nor administration of worker’s compensation in Quebec, but in Ontario, contractors can request a WSIB clearance form (indicating that we are up-todate and in good standing) for our clients at no charge at any point in a project. If the renovators use industry-standard Canadian Construction Documents Committee contracts, there are also easy-to-use forms that the contractor may use to verify for the owner that all vendors and trades have been paid. This does need to be notarized at each milestone, so it incurs an administrative and legal cost. So long as this cost is also built into the contract price, then this shouldn’t be an impediment.

– Ben Polley

Spray foam contractors rush to help

Noreen and Bob in Calgary shared photos of their lovely new storage barn, completely destroyed by a spray foam contractor who clearly did not know what they were doing. Their story brought out the best in the spray foam industry. According to Ehren Klein of Pinnacle West Spray Foam Insulation and Coatings, the Spray Foam Canada private Facebook page has been inundated with offers to fix their problem.

I wanted to touch base regarding the recent article written by Patrick Flannery. This is an unfortunate event for the entire spray foam industry. Due to the nature of the materials being manufactured onsite, the material that was sold to this contractor was not for code-approved jobs…yet the contractor used this material regardless of the law. This article has

been circulated around on a Facebook page call Spray Foam Canada: a page for the Canadian professional applicators community regarding industry news and happenings. There have been over 80 responses so far from spray foam contractors and suppliers from Vancouver to Winnipeg that have been stepping up to offer material and labour to make this job right for the home owner in Calgary, Alta. This is amazing and I feel that a follow up story could be positive for the spray foam contractors industry in Canada. Just the fact that this industry and contractors have come together so quickly to respond to this “disaster.” The common thread is their livelihood and we all need to work as a team to make things right to protect and positively grow our industry. Articles such as this, that highlight one “disaster” out of the thousands of positive projects across Canada, really put a black mark on the industry and shed an unbalanced dark light on the product and superior performance it offers when applied correctly.

– Ehren Klein

Don’t vent through the soffit

A 22-year veteran says bathroom fans should never be vented through the soffit, though the Ontario code allows it.

I disagree with venting moist bathroom air into the soffit. I have seen the results when the damp air is up-drafted into the attic. I have been a renovating contractor for 27 years, specializing in upscale bathrooms, (design and build). I have been a Certified Property Inspector for 22 years, now retired. Ventilation is critical in every building, especially in residential dwellings, where the health and well being of the residents should be of primary concern.

– Noel Murphy

Is there a skilled trades shortage or not? Depends what you call a “skilled tradesperson.” Just about everyone in government and unions agrees there is a shortage. But some economists have tried to argue there is not. David’s note below may explain the discrepancy.

I worked as a construction and maintenance electrician for thirty years, laid off all the time. There was never a shortage of electricians in Ontario, never. Most all tradesman are laid off at one time or another; that’s why they call us journeymen. Made $40 an hour back in 1999. Been offered $20 in the last few years. Hiring agencies now make things worse; middle men taking wages and benefits from hardworking people. I feel bad for the future of the trades. And yes, the wages are very low and benefits few and far between. Joe the Plumber is very correct in his plight, I know from experience.

– David

Benjamin Moore has revealed its Colour of the Year 2021 as Aegean Teal 2136-40 – an intriguing bluegreen that creates natural harmony and invites us to reflect and reset.

Rooted in the elegant, hand-spun textures of the home, the Colour Trends 2021 palette comforts as it uplifts. In an intimate look at the home, Colour Trends 2021 begins in the kitchen, exploring how this intersection of craft, nourishment and community breathes colour and design inspiration into the rest of the living space.

The Colour Trends 2021 palette and the Colour of the Year reflect this grounded sensibility with warm, sunbaked hues that play to the senses.

“Amid uncertainty, people

yearn for stability. The colours we surround ourselves with can have a powerful impact on our emotions and wellbeing,” said

The Saskatchewan Party got re-elected this October. The re-elected government has promised to make it more affordable to renovate homes by introducing the Saskatchewan Home Renovation Tax Credit. The Saskatchewan Home Renovation Tax Credit will allow Saskatchewan homeowners to claim a non-refundable 10.5 percent provincial tax credit on eligible home renovation expenses undertaken on their primary residence between Oct. 1 and Dec. 31, 2022. Saskatchewan homeowners taking full advantage of the program will be able to claim $20,000 in home renovation expenses on their 2021 and 2022 income tax returns for a maximum non-refundable tax credit of $2,100. Eligible goods or services can be claimed for the tax credit during the period in which the costs were incurred. Eligible renovations to a property must be of an enduring nature that are integral to the dwelling, including expenditures for the cost of labour and professional services, building materials, fixtures, and equipment rentals and permits. The Western Retail Lumber Association stated that it was thrilled for its members at the election outcome as this means that the Home Renovation Tax Credit announced on Sept. 30 is now effective.

“From the beginning of the pandemic, WRLA has been advocating for home renovation and eco-retrofit tax credits as a strategic way to support economic recovery. We are very pleased that the government listened to our requests and took our proposals into consideration,” said Liz Kovach, president of WRLA. cc

Andrea Magno, Benjamin Moore director of colour marketing and development. “Aegean Teal 2136-40 and the corresponding Colour Trends 2021 palette express a welcoming, lived-in quality that celebrates the connections and real moments that take place within the home.”

Chosen for their modernity as much as their time-tested appeal, the 12 hues in the Colour Trends 2021 palette include: Aegean Teal 2136-40, Atrium White OC-145, Muslin OC-12, Foggy Morning 2106-70, Rosy Peach 2089-20, Beacon Hill Damask HC-2, Potters Clay CC-360, Chestertown Buff HC-9, Amazon Soil 2115-30, Gray Cashmere 2138-60, Kingsport Gray HC-86 and Silhouette AF-655.cc

The Canadian Construction Association was pleased to hear commitments by the federal government to invest in infrastructure and skilled training, secure jobs and support small and medium sized businesses. The extension of the Canada Emergency Wage Subsidy until next summer and the expansion of liquidity supports such as the Canada Emergency Business Account and the Business Credit Availability Program will help small and medium-sized businesses in Canada’s construction sector contribute to employment, job creation and economic growth. Additional measures, including reskilling displaced workers and supporting education and accreditation, were also welcome announcements. CCA also strongly supports the government’s objective to keep building stronger communities by investing in all types of infrastructure, including public transit, energy efficient retrofits, clean energy, rural broadband and water/irrigation infrastructure. However, the government does not seem to have a clear plan on how these investments will be rolled out. Now is not the time to compromise urgently needed economic recovery by entangling infrastructure investment with unrelated policy goals. CCA members – 70 percent of which are small and medium-sized, family-run businesses – have been asking for a clear, balanced, fair and flexible infrastructure stimulus plan. CCA has been pressing the federal government to remain focused on getting tenders out, reducing red tape, and working with all levels of government to continue supporting important infrastructure projects in all regions of Canada. cc

The Ontario government is investing an additional $75 million over the next two years to help apprentices pay for living expenses during their in-class training and ensure they receive a high-quality education in a safe classroom environment. The $75-million investment includes several benefits. The Grant for Apprentice Learning, is a $5.8 million commitment to support those ineligible for Employment Insurance while attending in-class training, including a boost of $1.3 million this year and next year. The Apprentice Development Benefit, is a $24 million commitment to increase the maximum benefit rates for EI-eligible apprentices attending full-time in-class training, including a boost of $4 million this year and next year. The In-Class Enhancement Fund, is a $211.9 million commitment to support training providers so they can deliver higher-quality training, including a boost of $11.8 million this year and $22.3 million next year. The Apprenticeship Capital Grant is a $24-million commitment to training providers to upgrade their facilities with state-of-the-art and modern equipment, including an additional $10 million next year. $5.1 million for training delivery agents, and an additional $500,000 for pre-apprenticeship training service providers, will be available to assist them with implementing COVID-19 health and safety measures during the pandemic. Also included is $4.7 million as part of a multi-year $19.4 million investment in the development of a client-facing digital system to support the skilled trades and apprenticeship system in Ontario. The portal will provide skilled trades and apprenticeship clients with secure and convenient access to online information and services and will bring Ontario in line with digital delivery channels in other provinces. $2.5 million this year and $7.5 million

next year have been allotted to launch the new non-repayable Tools Grant. The government has also appointed a five-member Skilled Trades Panel to provide advice and recommendations to the Minister of Labour, Training and Skills Development on developing a new approach to training and certification. Michael Sherrard, Jason Ottey, Shaun Scott, Melanie Winter and Melissa Young are on the panel. “With my colleagues on the panel, I

look forward to listening to interested stakeholders and contributing to a solution that serves apprentices, journeypeople and anyone who may consider a career in the skilled trades,” said Sherrard, panel chair.

Ian Howcroft, CEO of Skills Ontario noted, “We are proud to play a key role in the promotion and encouragement of the skilled trades and technologies in order to build a strong future skilled workforce.” cc

The CT 48 E AC HEPA puts jobsite dust in its place.

• Helps to control large amounts of dust like silica, drywall or wood dust.

• HEPA Filtration

• AutoClean Function

• High volume capacity for big jobs with high dust volume.

• Tapered 36-32 mm hose ensures optimal airflow.

• 3-piece cleaning accessory kit

• Ready to work – included reducer allows for connection to all Festool products with both a 36mm & 27mm port.

By Stephanie Rota

Mostmajor financial decisions centre around a budget. They are first driven by our wants and needs, but the fiscally disciplined will drive their decisionmaking with a budget. I have yet to work with a client who didn’t have a budget, although I have worked with clients who withheld their true budget. “Why do this?” I’ve wondered.

The obvious reason is the client doesn’t want you to know how much money they have to spend so they can keep the pressure on you to deliver the lowest price. But this doesn’t usually work out the way the client thinks it will.

Any custom project is a huge financial undertaking and the builder/client relationship should be based upon trust. Arguably, this is the foundation for any great relationship, right? So, in order to successfully leverage this working relationship, let’s talk about some reasons why client transparency with their budgets yields the best outcome for both renovations and new builds.

If the shoe fits, wear it

A true budget number will guide project owners in the search to find the right contractor to partner with. There are all types of different contractors and our specialities range in scale and scope. Some builders have very large operations and maybe can’t give a smaller project the time and attention the client would like. Or maybe the project has complexities requiring a certain builder that’s positioned well to handle those intricacies. Clients need to match their projected spend with the services being offered. When they are coy about the true budget, we lose the chance to say, “Hey, we’re not really right for this project.” That’s something a homeowner should want to hear right off the bat, if it’s true, and most of us are not shy about saying it.

Sometimes clients can overthink a situation and overanalyze, leaving them unable to move forward. We know clients are cagey about budgets out of fear of being ripped

off or overcharged. What they often don’t understand is that opening up about their budget can be the best way to avoid this. When they are honest about their budget the builder can share ideas for areas to allocate funds that will maximize the items that are most important. We can help guide and re-direct funds away from items that are less important to spend money on. Transparency is key to helping our customers achieve the house of their dreams.

Not revealing the true budget can stop clients from ending up with the product they actually want. Yes, some clients think every project goes over budget anyways, so they start out with a smaller number to end up where they want to be. But planning for how much money will be spent starts from the beginning. Due to current market conditions, it appears that homeowners are generally moving in and out of houses less these days. So their large renovation project or new build could possibly be their forever home. Making decisions today that will impact them in the future needs to be factored into the budget. Once it’s built, it’s done. It would be crying shame to invest all that time and money only for them to regret things they wish they had included.

So, there are at least three ways that concealing the true budget number can derail a job. When we sense that a client is avoiding giving us this information, we should look for ways to gently communicate these pitfalls and encourage them to open up the lines of communication. Building the trust required to do this can be challenging, but it’s a skill we’ve all had to develop. Professional quoting practices and transparency about costs and margins from our end can only help. At the end of the day, a relationship of mistrust between a contractor and a client is rarely going to work well. As a builder, I can say the happiest clients with the best projects were the ones who were honest from the outset. They found the right balance between making logical decisions and making emotional ones. cc

Stephanie Rota is co-owner of Carmelin Design + Build in Toronto.

As a self-made man in the industry, Roger Hardy’s journey has been a memorable one. His passion for the construction business has allowed him to achieve all his dreams.

Roger Hardy’s journey of building dreams, both his and that of others’.

By Sukanya Ray Ghosh

On the bank of Lake Ontario in the picturesque town of Cobourg, Roger Hardy has set up shop. His company, Quality Construction and Renovations has been creating dream projects for clients for many years now.

Hardy’s journey in the construction industry goes way back to his teenage years. When he was 14 years old, Hardy started working for contractors, doing renovations and whatever they wanted him to do. He had the opportunity to dabble in the industry throughout his school life since then, doing summer jobs. At the age of 18, he went to the west of the country to work in construction.

Hardy originally wanted to be a photographer, so he tried his hand at it. However, he realized quite early on that there was not a lot of money in it. So, when his family asked if he would like to go into the restaurant business with them, he did. Hardy decided to go back to school when he was 26, earning his diploma in Business Administration. Although he thought that he would remain in the restaurant business, he soon realized that his true passion was in construction. Without any further delay, he went back to the construction industry and has never looked back since then.

Hardy worked hard in the construction business for a few years to understand the industry and gain the necessary experience. He eventually decided that with his work

experience and his business background, he was ready to venture out on his own as a contractor. This was in 1986.

However, he had to face ups and downs along the way.

“The first contract that I had was to trim out subdivision homes. Unfortunately, the subdivision went bankrupt. I worked for eight weeks. It was all strictly labour. And I didn’t get paid. I was quite disillusioned with being self-employed, as a result,” recalls Hardy.

But he persevered. In the first year, Hardy was able to make $5,000. He began to develop a reputation for being a hard worker, someone who cared about what he was doing and cared about what the customer wanted. “I started to find a little bit of success,” he says.

He has continued to work hard and has been successfully running his company for 35 years now.

During his early years, before he had opened up his independent business, Hardy bought a house for $10,000 which was about to be condemned and torn down. “This happened while I was going to school. I had a newborn at home. I held down three part-time jobs. And in the meantime, I renovated the house that I bought. I gained a lot of experience renovating it. I built two additions on it. It helped later on,” he recalls.

As time progressed, Hardy expanded his company and at one time had 10 employees working with him. But he realized that he was sacrificing quality for quantity and wasn’t making a lot of extra profit. So, he scaled back his operations again to having three to four employees on an average.

Following a dream

In high school, Hardy had studied architecture as a subject. He always had a dream to design, build and sell unique homes. Having spent 10 years as a contractor, encouragement to pursue his dream came from home. “My wife convinced me to purchase a property, design a home, build it and sell it. I had tremendous success with it,” says Hardy.

This was all the encouragement he needed. For around 25 years now, Hardy has continued to design, build and sell his homes, depending on the market conditions. This is in addition to his regular construction and renovation projects. The most recent home that he has designed and built brought in almost a million dollars.

Over the years, Hardy has also worked with a lot of welloff clients on home projects with budgets exceeding 1.5 million dollars. He has also worked in close quarters with a lot of architects over the years, including Moriyama and Teshima Architects in Toronto. Not shying away from the opportunity of gaining varied experience, Hardy has even taken up large-scale renovation projects.

“I’ve done work encompassing almost the whole

gamut of the building industry. This has helped me learn considerably along the way. I made mistakes but I always made sure that I made right my mistakes. I always made sure that when I completed the job, the customer was always 100% satisfied,” notes Hardy.

Hardy’s journey in the industry has always been strongly linked to the economy. For a long time, he focussed on building new homes. When the market changed, he did a lot of renovations as well as new homes. He often bought old homes, renovated them and rented them out or sold them.

“I had to learn to be flexible and adapt to the times. I’ve also always tried to maintain that business is based on people. If you treat people well, if you show that you care, and you work hard, you can build a successful company. Profit is not my number one motivation. I have just wanted to earn a comfortable living,” explains Hardy.

Having built and renovated so many homes through the years, some projects have been more memorable for Hardy. One such project that he found quite interesting was a home he built for his clients Mr. and Mrs. Barnicke. The architect who designed it was Peter Burton. The house had a large 7,000 square feet of living space.

The project that gave Hardy the most satisfaction was a million-dollar-home that he designed, built and sold. To this day, every time he looks at the project, he feels happy with how it turned out. The reason he holds it most dear to his heart is because 99 percent of the home was Hardy’s design and inputs for the finish. Hardy and his wife even planned on moving into it. He had created the home with this idea.

Hardy has a good eye for ergonomics – the required understanding of what works in terms of the flow of a house. He also has a keen eye for interior design. He pours his thought process in combing these factors to achieve the desired results with his homes. His homes are often sold before they are 100 percent complete. So, the client comes along and requests for some changes. But for the most part, these homes turn out to be what he envisioned them as.

Apart from homes, Hardy quite enjoyed building a winery. “It was really fun and exciting to work on that project. And it lasted for quite a long time – seven months,” he says.

Hardy always took up a lot of jobs that other contractors didn’t want to tackle. He liked to challenge himself with projects that were complicated and with clients that other contractors did not want to work for. Although he has worked with challenging clients, he has always been able to manage the projects successfully.

Among the many challenging jobs, one stands out to him as the toughest project Hardy ever had to complete. Early on in his career, he worked on commercial and retail projects as well. During this time, he once contracted a job in a mall to build a high-end fashion store. Hardy had four employees at that time and he hired five subcontractors to finish the job.

He narrates: “This was a nice warm job in the middle of winter. All these guys said they knew what they were doing. But they didn’t. Eight weeks into the job, the company I was contracting to said that we weren’t moving fast enough. I added up all the numbers and realized I would lose my shirt over it. So, I fired the five guys. And I myself worked from 6 a.m. until midnight, seven days a week, for the next three weeks to get the job done. For all that hard work, I was able to make only $800.”

The lesson that Hardy learnt from this experience was that he had to be careful when trusting people. However, his hard work allowed him to maintain his integrity and come out of the situation with his head held high.

A challenge of the current times for everyone has been the pandemic. Its effects have been felt by Hardy as well. Quality Construction and Renovation shut down for two months and then started up with small renovation projects.

The real challenge, however, has been the supply chain

disruptions – being able to acquire the materials in a costeffective manner. There has been a shortage of pressuretreated lumber. Ordering doors and windows has taken twice as long. Hardy has had to plan and order materials much further in advance. Managing the timelines and the staff has also been challenging.

Something that has always worried Hardy since he started his company is whether his employees are satisfied and happy. He cares about his employees being satisfied with the workmanship and having good value.

To the next generation of young people starting out in the construction industry, Hardy would like to tell that they should learn to make their lunch, don’t take much time off and to remember that success is a long steady climb.

“As a self-made man my career has been just that! Good value and respect for all the people I work with. Growing a business is the same as growing as a person where we need constant evaluation of what we are and where we want to be,” he says.

Hardy has been relatively accomplished at his craft and his business. Giving back to the community and people feels extremely gratifying as part of this process. He recalls having a client who was suffering from bipolar disorder. He often drove her to the hospital a few times a week while working on her project. The project turned out spectacular and the family were ecstatic about it. Today, Hardy sits on the board of the Canadian Mental Health Association –Haliburton, Kawartha, Pine Ridge branch.

“We all have to learn to be tolerant, flexible, understanding, and compassionate. We have to try not to judge and not to be too self-absorbed. I’ve tried to learn to be humble and appreciative,” says Hardy.

This year the association branch raised $18,500 through Hardy’s annual golf tournament fund raising event. He feels as proud of this achievement as he does of his career. cc

Rental companies today are offering newer equipment that is in top condition and additional services such as preventative maintenance and parts support, all managed by them.

By Michael Frey

If you’re working in construction today, you’re likely under more pressure than ever to improve productivity and efficiency while reducing costs. This was true before a global pandemic slowed down or halted work in almost every sector. As the world starts to adjust to a new normal we are starting to see work ramping up again, but these pressures remain. So, what does this mean for contractors looking to grow their business while managing financial risk?

Looking at equipment differently and considering renting versus owning is a good first step. Incorporating rental machines into daily operations is a way to respond to shifting market demands, economic uncertainty, and increased competition. Whether it’s a compact machine for a quick landscaping job; a replacement for a unit that’s in the shop; or a more specialized piece of equipment needed to bid on a larger job; rental equipment can help contractors quickly scale operations to demand.

The biggest concern is being confident you can get

the right equipment for the job, when you need it, at an affordable price.

Renting vs. buying - know your options

There is no one-size-fits-all solution when it comes to construction equipment. The benefits and challenges of renting versus owning often depend on the specific need for the job. But there are also other factors that should be considered before making a decision: cash flow; the condition of your current fleet; and short/long term equipment needs are just a few examples.

The primary concern when looking at rental options is equipment availability and ensuring the costs fall in line with your budget. Ownership might mean you have the equipment when and where you need it, but transporting, maintaining, repairing, and storing the equipment makes it one of your biggest assets and your highest expenses. Additionally, the constant wear and tear on equipment

means it can quickly lose resale or trade-in value. Once you consider the impact of large down payments, financing, varying project demands and workload, you might consider incorporating rental machines into your fleet mix.

With the wide variety of equipment that’s readily available, many companies can better balance equipment availability and costs through rental. In such a competitive market, rental companies have stepped up in recent years, offering newer equipment that is in top condition and additional services such as preventative maintenance and parts support – all managed by the rental company. An added benefit is that contractors can focus on the job at hand, rather than worrying about having to deal with potential breakdowns and equipment failures.

When deciding between renting or purchasing, make sure you understand your return on investment. Finding your rental equipment’s ROI involves knowing the cost to rent the machine, how long you’ll need the equipment, and its frequency of use. On a new piece of equipment, you should look at the total cost of ownership. For example, if your revenue on a $100,000 machine is $25,000 after maintenance and ownership costs, the ROI is 25 percent – meaning it will take four years to pay for itself. Other factors to consider (your equipment dealer can help you with these) are maintenance, depreciation, the machine’s profitability and its resale value.

If you decide to purchase equipment, ensure you sufficiently research the specific machine. Some makes and models hold their value better than others, and some brands offer re-build options and maintenance plans to help you make the most of your investment, including access to technology and data analytics. Short-term and long-term contracts, rent-to-own, and other financing options such as leasing allow for even greater flexibility, especially when finances are tight. There may also be beneficial tax incentives when purchasing equipment, as well as the added benefit of adding an asset to your books.

The right equipment partner can help you plan for your equipment requirements to meet the demands of your business and advise when ownership or rental makes more sense. They can offer a wide variety of solutions, from ordering parts and attachments; on-site fuelling, service and maintenance plans; to delivery and pickup in the field. The right rental partner is not limited to small equipment and tooling but can cover your large equipment needs as well. Now contractors of all sizes can compete for jobs that may have previously been out of reach due to lack of equipment availability and the high cost of purchasing a new machine.

Rental equipment can provide contractors with assurance of reliable equipment and greater control over operations, eliminating uncontrolled costs and managing regular upkeep needed to maintain the quality of the machine. Knowing your overall equipment costs can help make budgeting and estimating more accurate, while guaranteed uptime means your project will be on-time and on-budget.

Making a decision regarding renting versus depends on factors such as the specific need for the job, cash flow, the condition of your current fleet, and short/long term equipment needs, among other things.

Construction companies are looking to technology as a means to keep costs low, production high, and jobsites safe. There is a growing demand for technology that monitors rental equipment usage, helps train operators remotely, increases safety and tracks stolen or lost machinery. When you are dealing with an experienced rental partner you are not just accessing the best equipment for the job, but the latest, most technologically advanced machines that include GPS, connectivity, grade control, telematics and machine monitoring.

Technology is helping to monitor, manage, and maintain equipment, and these machines are producing a great deal of data. Our ability to understand what the data is telling us from a maintenance and performance perspective is the most important piece of the puzzle for both owned and rented equipment. Parts, maintenance, and scheduled service are tied to analytics from this data and can be managed to prevent downtime and identify productivity problems before they become costly issues.

With brand-new, next-generation, emission-compliant machines available to rent, contractors can also test new technologies without the financial commitment of ownership. Most will quickly discover that technology is getting jobs done faster, more efficiently, and with greater accuracy.

The recent growth of the rental industry is providing substantial opportunities for manufacturers, dealers, rental companies and contractors. The idea of rental as a quick fix for unexpected needs is transforming. Rental is becoming an integral part of a much longer-term equipment strategy.

Giving companies the flexibility to access the right equipment, at the right time and the right price will continue to help contractors manage the challenges they face today to keep costs low and productivity high. The right rental partner can not only provide the best equipment but help integrate technology into your operations to meet your specific business needs, maximising operational productivity and performance. cc

Michael Frey is the rental operations manager at Finning Canada.

The quest for energy-efficient homes could be killing Canadians.

By Jack Kazmierski

The Law of Unintended Consequences applies to everything from economic policies to social change and even the design and construction of Canadian homes. A good example is the way in which a tighter building envelope can result in unwanted mold, or even a much deadlier unintended consequence: radon exposure.

According to Health Canada, long-term exposure to radon is the number-one cause of lung cancer for non-smokers. “Research has shown that energy efficiency can increase indoor radon levels,” Kelley Bush, manager of Radon Education and Awareness at Health Canada told Canadian Contractor. “Research has found that a more recent construction year, greater square footage, fewer storeys, greater ceiling height and reduced window openings are all associated with increased radon in the home.”

Radon is everywhere. While it’s true that parts of Canada have higher levels of radon than others, all buildings have some radon in them and none should be assumed to be radon-free. “The reason for this,” Bush explains, “is that radon comes from the breakdown of uranium in the ground. And because there’s uranium everywhere in the Earth’s crust, it means that radon gas will seep into all buildings everywhere, unless it’s a home that’s built on stilts, a boat house or a tree house.”

While radon maps offer an overview of where radon levels may be higher across Canada, Bush warns against relying on them. “Even in areas where we know radon is very high, you can go into a neighbourhood, test all the houses and it’ll vary by house,” she explains. “So really, the only way to know for sure is to test.”

The complexity of the radon problem is further compounded by the fact that it’s impossible to tell whether a building will have elevated levels of radon before it’s actually constructed.

“You have to test after you build the house and you move into it,” Bush adds. “The amount of uranium in the area that you’re living in is a significant contributor, but how the house was built; the ventilation system; how many doors

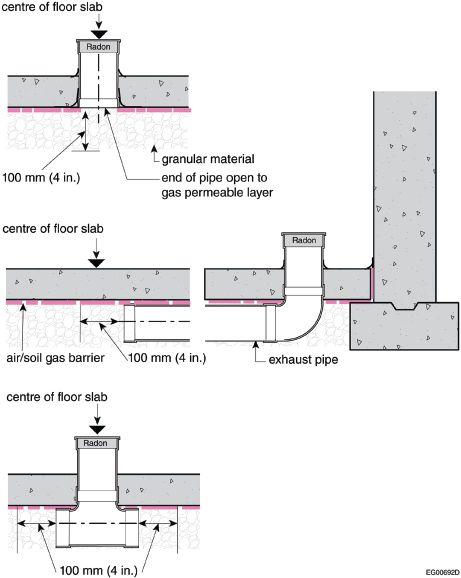

Acceptable configurations for the extraction opening in a depressurization system.

and windows you open throughout the day throughout the month and throughout the year; all affect the amount of radon that is drawn from the ground into the house itself.”

Without knowing which homes will have higher radon levels and which ones won’t, Canadian homebuilders must abide by local building codes in order to mitigate radon issues, should they surface in the future.

The National Building Code of Canada first addressed the radon issue in 2010 and again in 2015, with most provinces and municipalities now adopting recommendations in their Building Codes. Specific requirements for radon are spelled out in subsection 9.13.4 of the NBC, and according to Grace Zhou, senior research officer at the Construction Research Centre at the National Research Council of Canada, Alberta, Saskatchewan, Manitoba, Nova Scotia, P.E.I., Nunavut, Northwest Territories and Yukon have adopted NBC 9.13.4. without variations; B.C., Ontario and Quebec have significant technical variations; Newfoundland and Labrador delegates adoption to cities; and New Brunswick has not adopted the 2015 NBC.

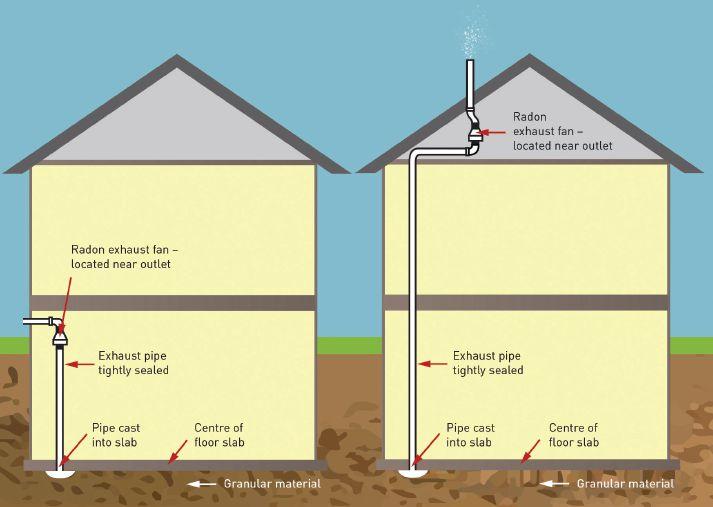

The key to effective radon mitigation is an active soil

depressurization system. “The current building code requires a minimum four inches of gravel above the soil, and below the concrete slab,” Zhou explains. “On top of that should be a continuous air barrier system. Minimum requirements would be six-millimetre poly, taped and sealed at all the joints, walls and any penetrating points. If the walls are in contact with the soil, an air barrier system is required there as well.”

With new construction, a four-inch PVC pipe that goes from underneath the slab at ground level to the roofline is required in order to draw the radon from under the home to the outside (retrofitted homes can be vented from a nearby wall). “This is basically a rough-in,” explains Ulrik Seward, chief building official and managing chief of approvals, City of Calgary. “The length of pipe is capped off and labeled in case the building owner wants to install a future radon extraction system.”

Seward says that when it comes to radon, Calgary takes the requirements from subsection 9.13.4 of the NBC very seriously. “The pipe is clearly labeled near the cap and if applicable every 1.8 meters, and at every change in direction, to indicate that it is intended only for the removal of radon,” he adds.

The good news is that energy-efficient homes don’t necessarily have to be radon death traps. “If the walls that are in contact with the soil and the basement floor slab are very well sealed and insulated by materials with low radon permeability, then those energy-saving measures would actually help to reduce the amount of radon coming indoors,” explains Zhou. “However, if radon finds its way into [an airtight] home, and the home is not equipped with mechanical ventilation, then it will be more difficult for radon to escape. So there’s no absolute yes or no. Some energy efficient features will reduce radon gas, and others may make the radon problem worse.”

It’s this sense of uncertainty that has Casey Edge, CEO of the Victoria Residential Builders Association, sounding the alarm about how dangerous it can be for us to continue pushing the energy-efficiency envelope without fully understanding the full consequences, as well as ignoring the need for builder training and education.

Edge explains how the B.C. government initiated a “step code,” which enables municipalities to establish their own energy efficiency levels, and to do so in leaps and bounds without first considering the consequences of each step.

“I’m not opposed to energy efficiency,” Edge says. “But if you’re going to increase energy efficiency in the building

code, each step should be required, and there should be several year increments between each step to make sure that we understand the unintended consequences of changing the Code. We’ll get to where we want to go in terms of building more energy-efficient homes, but it’ll be done responsibly and with consumer protection in mind.” cc 20_2014_CN Contractor_NOV_DEC Mod: September 17, 2020 11:53 AM Print: 10/22/20 12:06:49 PM page 1 v7

Drew Coulson has designed and built an award-winning project nearly every year for the past 15 years...from his local Windsor-Essex Homebuilder’s Association. On June 20 Coulson claimed his first national top prize at the Canadian Home Builder’s Association National Awards for Housing Excellence.

In the “Whole Home Renovations from $500,001 - $1 million” category, Coulson Design Build hooked the win for its “French Country Makeover” in LaSalle, Ont.

Coulson says, “I’m constantly trying to improve, I’m competitive in nature. I just want to be better than everybody else. I know I’m not making the NHL anymore. I don’t think this attitude is harmful to anyone, it just makes everything better and sometimes more headaches for me.”

Q. How did the French Country Makeover come about?

A. The clients reached out to us about a year prior. We worked through the design phase, meeting often and designing a Prairie style/Frank Lloyd Wright initially. Then

Creating a perfect blend of the old and the new

By Gordon Wornoff

they wanted to go more modern with bigger overhangs and a higher pitch roof. We transferred those ideas into more of a French Country because that was their passion in the end.

The owners and I worked well together which made it easy to troubleshoot the design part of it and control budgeting. They had a growing family and were interested in open concept spaces, so we blew out the walls and ceiling to have a soaring feel inside the home. We landed with a French Country look on the outside and a rustic-chic on the inside.

Q. It’s a very big renovation. What did you have to start with?

A. It was beyond belief. It looked like an old school on the outside, with a flat roof. It had a very sixties vibe inside: the mahogany panelling, blue suede walls, red shag carpeting, linoleum floors, aluminum windows, orange bricks, and a mustard-coloured aluminum band that ran the length of the entire property. A lot of old and dated construction that

needed to be freshened up, but it was well-built. It had the bones there to develop the desired end result.

Q. What were some of the main challenges on the build?

A. The existing footprint was tricky because there was so much of a footprint. The home was almost bigger than they needed. Also, the roof system – it was a very highpitched roof – so we designed a three-tier roof system to vault the hips. The spans were quite long, so we built using engineered girder beams, and laminated trusses. Going from 10 feet off the ground to 40 feet off the ground was not the easiest.

Salvaging the existing structure was also demanding. The roof was very old, two inches thick, cutting membrane after membrane. A lot of old dirty material to work through. Creating that old charm isn’t always that easy or costeffective. We finessed a lot of floor-to-ceiling tiles. The tilers sourced more affordable materials so they could spend more time creating custom designs, using a variety of patterns, or smaller, quartz tiles. Each room is quite unique in that regard.

Q. Sounds nice. What are some materials and design features you are proud of on this build?

A. The interior core of the home is a soaring hip roof with shiplap and beams all sprayed white, giving it that rusticchic look. We carried some of this look into the office and included tall windows in there. As we move away from the open concept, softer colours and earthy tones change the feel of the other rooms.

We sourced wood flooring from out east and had it

shipped from one port to another. It had a lighter tone so it tied in well with the vaulted ceilings. Our stone was locally sourced. We did a cedar shake feature in the living room. We only use West Coast cedar because it’s just so much better.

We helped promote Delta faucets in this house, which was great because the homeowner was looking for savings wherever possible.

The custom front entry door was a heavyweight. It’s a big wrought iron and steel door that was injected with insulation and fabricated in the States. That was interesting to square up with our Ontario Building Code.

Q. How is your relationship with your local building officials?

A. It’s great. I thrive on continuing my education with building officials. They are an asset to discuss new technologies, and newer, better ways of doing things. Essex County has great inspectors that will talk with you and go through that education together. If you want those better tricks of the trade then that’s what you gotta do: fill your brain with good deeds. But not everybody wants to do that. Most guys just want to go out there, build a house, collect the cheque, see you later. I don’t mind the other stuff.

Q. What is your company like?

A. There’s six of us full time. Our in-house employees are fantastic and our sub-contractors are the ones that make us look good. We’re a small family business; I’ve got my brother working with me, my nephew and my best friend and it’s been like that for many years. It’s a small, trustworthy business, where we’re loyal to our trades and vice versa for 15-20 years.

We do about 20 projects a year. We build homes that are

8,000 square feet, and we build homes that are 1,000 square feet. If they want our quality, we’ll build it. The same quality, the same passion, has to go into every project whether they’re large makeovers or custom homes. That keeps it interesting. Construction can be somewhat repetitive. People here complain about the weather 24/7, but we work 12 months a year, we don’t take time off, and I don’t lay guys off. Never have, never want to.

Q. How did you get started in the business?

A. I went to school for architecture but didn’t finish my degree. I worked for a firm for three years in Windsor and then three years in the States. I took on two freelance jobs and offered both clients the option of building. They said “Yes,” and I said, “Uh-oh.” So, I was stuck in a pickle and I met with the boss and he gave me his blessing. He said, “Hey, I think you’re cut out for it and you can make it work.” I left the firm within the week.

I worked at my first lumber yard when I was 15. And you get that smell on you, you know? The smell of the wood, of the trim, and all the building equipment, so I kind of knew. I worked all through high school for a construction company doing forms and framing and general labour work. You name it.

Q. Does winning building prizes gain you clients? Did you know this renovation was a prize-winner as you worked on it?

A. I met with a client last week and they mentioned the awards. They said, “I want to have my home built by an award-winning builder.” And that was great to hear. I go into every home like it has to be better than the other guys. It’s like a competition. At the end of the day, you want

this to be the best renovation you’ve ever done. I do think of the awards category for every home and I want that, rather than just slapping things up and trying to cash in on the economy. I think that’s wrong. But if we build and make it look stellar and compete against each other for these coveted awards, it makes us all better. I’m not saying I’m better than the rest – there’s a lot of great builders out there.

Moving forward, I’m going to keep doing the same thing. This area can be very judgemental and very small, and some people don’t want to see you do well. It’s a weird smalltown mentality.

I’ve built up that reputation over the years. We don’t skimp on stuff, we strive for quality, time is never our strong suit, our pricing is very competitive, and we’re very fair. I have a strong passion for making good products.

Q. What’s next for Coulson Design?

A. I love building with wood and constructing a five or six story wood building is kind of intriguing to me. I’ve had an opportunity to talk with people about this in a preliminary way, and I’d love to do it tomorrow, but it’s not the case. The money’s not there yet.

We’re converting a small church in Amherstburg into an Airbnb right now – this area is hurting for accommodations. I bought it with a partner friend of mine. It’s a historic little white church that’s been a staple here for 100 years. It’s a balloon frame. We’re preserving the exterior and dividing the interior into eight squares and uniquely designing each room. It’s been about a year and a half, but it feels like forever. We keep adding more, more, more, breaking the bank a little, but I have to do it right. cc

By Sukanya Ray Ghosh

Akeygoal that every contractor would like to achieve with every project is 100 percent customer satisfaction. Certification programs have been created to assure customers they have selected the right person to do the job, but questions persist as to whether contractors see the benefits. As with just about everything in this industry, there are a range of opinions.

A question that comes to mind is are these programs really required? Steve Barkhouse, president of Amstead Design-Build, notes that having programs (like RenoMark, Tarion, etc.) are an improvement, a step in the right direction.

“More than 50 percent of the renovation work that is done in Ontario is underground, that’s proven. And I think that if you talk to the average person, they find it exceptionally difficult to distinguish between professional renovators and non-professional renovators. Part of that is education. But I think if there was a certification program, educating the public could be one of their mandates,” he says.

The RenoMark way

RenoMark is a certification program that recognizes members of the Canadian Home Builders’ Association who conform to the RenoMark Code of Conduct. The program was started in 2001 in the GTA by the Building Industry and Land Development Association. Eventually, the program was launched throughout Canada.

A RenoMark renovator himself and heavily involved in the program, Jack Torossian of Golden Bee Homes narrates what led to the conception of the program.

“We felt as professional renovators, we have to find other professional renovators and bring them together. We wanted to come together with the understanding that we were against the cash under the table. Everything needs to be written down. We felt that the clients are hurting because of the bad renovators out there,” he says.

Torossian says that they knew that there were a lot of good renovators and custom home builders out there. The BILD members felt that it was necessary to bring the good renovators together as they cared about the industry, the standards, the ethics and customer satisfaction.

Personally, Torossian notes that although he didn’t know where the program was headed at that time, he knew it was the right path and believed in its message. The RenoMark requirements were straightforward and simple to follow. Provide a written contract. Give a minimum one-year warranty. Have liability insurance of minimum $2 million.

Carry applicable licenses and permits, even when you’re using subcontractors (the subcontractors should be licensed and insured). Respond to homeowners’ calls and emails within 24 hours or two business days. Push the renovators and custom builders to have access to education and training and professional development on a yearly basis. All these requirements are part of the RenoMark Code of Conduct that the program members need to follow diligently.

In keeping with one of the RenoMark codes, a pilot education and training program was recently launched to further the professional development of the members. The program is endorsed by the Canadian Home Builders’ Association. The first batch of around 25 renovators and custom home builders will have to pass exams on all the course topics. At present, there are around 1,200 RenoMark renovators across Canada. The idea behind the program is to ensure that all the RenoMark renovators and custom home builders will eventually go through the training, pass the exams, adapt to the program every year and carry on with all educational programs that RenoMark comes up with.

Commenting on its inception, Torossian says that when he first became the chairman of RenoMark two years ago, he pushed hard to have the educational program in place. He felt that there was some disconnect between some clients and renovators.

“We started meeting these educated clients, who had done several renovations. They asked us smart questions that we sometimes couldn’t answer. We felt like there was a lack of education and knowledge. This pilot educational program is designed to cover that part. We participated in a four-week education program recently. Some of the courses included the code of conduct, customer service, the risks, insurances and documentation,” explains Torossian.

Torossian further notes that it is especially important for renovators and custom home builders to have protocols in place to ensure professional success. It is not possible to have a good system in place without proper documentation, insurance and exemplary customer service. Staying at the top of the game, he says, is like maintaining a machine that needs to be regularly oiled with knowledge. This can bring peace of mind to the renovators themselves since they are doing the right thing every time.

Torossian notes that education supports renovators with valuable information. And RenoMark has been providing

Every year, RenoMark recognizes the efforts of its members through awards and honours. Here are two such award-winning projects.

this support for years by educating members on building codes. RenoMark gives them the necessary platform to understand how other renovators are doing business. They get to ask questions and even volunteer their time to share their experiences.

Just registration is not enough to become a proper RenoMark renovator, according to Torossian. The purpose of the program is to ensure that members remain active and try to improve day in and day out.

“When the renovators are involved, they are able to become educated, informed professionals. They are aware of what is going on even before things hit the ground. They know the next steps they need to take. They will stop seeing competitors as just competitors,” says Torossian. He adds that they will be able to ask questions and get the right answers from their peers without talking about their numbers.

The success of programs like RenoMark often depends on how well they are executed. Jon Eakes, a building science educator who appeared as TV’s Mr. Chips in 1978 and 1979, comments, “The concept,” he says, “is good. Get a brand name that gives consumers confidence in hiring unknown companies. The weak point is all too often the actual quality of work being done is not well monitored and there is the very difficult political problem of controlling or un-listing members who are not up to the standard.”

He adds that such groups that put their names on contractor members need to be clear to the consumer as to just what that label means does not mean. Will the brand mark association mediate disputes? Step in to finish jobs left unfinished by bankrupt members? Is it a warranty program? What are the criteria for membership? What is the monitoring of members over time? Is there membership

training, and does such training reach down to the workers or do they only train one member of the whole organization?

RenoMark, says Torossian, recently had an executive board meeting to ensure that such checks are in place. The Canadian Home Builders’ Association is taking over the operations of RenoMark to implement it coast to coast. CHBA plans to implement all the rules and regulations as per the guidelines for each province. The association intends to create a format that every RenoMark renovator has to fill in. It will be used to track, for example, whether they have their worker’s compensation account in place, whether they have their other insurance in place, and so on. On a yearly basis, each renovator will have to submit all the documents, the contract samples and other items to the CHBA. And whoever is not complying will be given a specified time to send the documents in or they will be out of RenoMark. They will not remain as members any more.

This system will be implemented in due course. Torossian notes that at present the system is being tested before being rolled out. He himself has taken part in it by sending in his documentation. If the renovator is well organized, he says, it will take merely minutes to attach the documents and send them in.

Barkhouse, who was involved in the original creation of the RenoMark, notes that the program is meant to give a sense of comfort to clients and assure them that a sort of policing mechanism is in place for that brand.

“We’re a fragmented industry that has no credentials. So, being involved in such programs would give them a certification that they could put up on the wall and advertise. And that would hopefully bring them additional work because people would recognize that they professional and insured. RenoMark, to a certain degree, has been able to achieve that,” he says. cc

By Steve Ryan

Ascase counts rise, we may be facing a return of more restrictive infection control measures for coronavirus and the COVID 19 illness it causes. We are already pretty exhausted by what we’ve been through but perhaps by better understanding the reasoning behind those precautions we can be less frustrated and more effective in executing as we face evolving demands.

What follows is not to offer medical advice or to suggest you stray from the public health guidance in your area. These notes are intended only to help clarify the objectives some of that guidance is aiming for.

First, let’s consider why COVID 19 stands out so starkly from other infection risks. It poses a danger for a number of reasons, but the uncommon feature that makes this virus so hard to contain is that it is a stealthy invader. Other deadly viruses exist but with most of them a person becomes contagious around the time they start to show symptoms. That allows for precautions almost as soon as the patient becomes a risk to others. With COVID 19, most victims are contagious for several days before they notice symptoms. Infections can spread from someone who might never know they were a carrier.

Instinctively we understand that cleaning and sanitizing is an essential part of infection control. But that provides a limited defense against COVID 19 where the primary route of infection is in the air we breath. We cannot control this virus as long as we share the same air, and that demands behaviour changes that really clash with how we need to live.

While the public health initiative is broader and more complex, each precaution we are asked to follow has a specific objective in containing the virus.

Give it fewer targets – stop people from interacting. The lockdown jammed the brakes on our society to prevent interactions as much as possible. Why was that? On March 20 there were just over 1,000 confirmed cases of COVID 19 in Canada. It only took until March 23 for that to double to 2,100. At that rate of compounded growth it would have taken just six weeks for everyone in Canada to become exposed. With runaway infection rates and a poor understanding of what interactions cause new infections, our crisis response was to restrict interactions of all types.

Give it distance – if you must interact, make it hard for

the virus to transmit. Social distancing incorporates what we learned along the way about how the virus transmits. The primary route is via the air we exhale. We also learned that the critical concentration for the virus to be infectious in our breath dissipates beyond about two metres. Social distancing acknowledges that since some interactions have to happen, we should maintain a gap that the infection is unlikely to bridge. Perhaps it’s more important to realize that where people get closer, the virus spreads more easily. That, in turn, threatens to re-ignite infection rates that only a lockdown can contain.

Find it early – identify who is contagious and restrict their interactions. Testing is sometimes misunderstood as an infection control tool. The point is not to provide a negative result so you can relax. Testing protects the community when it identifies a positive individual. That alerts them to isolate and prevent the many ongoing contacts they might otherwise carry on with. Contact tracing is an essential companion to testing. Each positive result includes the likelihood that person has been contagious for several days. Any close contact they had in that time could now be contagious and spreading the virus without knowing it.

Presume you are a risk to others. Because none of us can be sure if we are carrying the virus, we owe it to those around us to behave as though we might. For most of us, PPE means wearing a mask and, once again, the public health objective is poorly understood. Those who think a mask is to protect themselves might reasonably feel entitled to take that risk. However, the more critical function for masks is to limit the spread of our own breath (the primary route of transmission, remember).

By understanding the reasons and the limitations of each mitigation strategy, perhaps we can feel less frustrated by them. Recognize that each one has a stand-alone purpose. In other words, to really contribute to the control of COVID 19, we need to follow each one for its own reasons. Doing more of one will not compensate for overlooking another. cc

Steve Ryan is the founder of MMI Professional Services. MMI is committed to the success of contractors by helping them develop the business and management skills they need . For information on ways to run a better building business contact the writer at steveryan@mmiproservices. com.

Randers Tegl clay bricks have been developed through the experience of many generations working with clay. The company runs brick-work production through Denmark. The Ultima range of soft-moulded bricks have an exclusive format: Ultima has the length of two ordinary bricks and a height of just 38 millimeters. The long format creates a unique and distinctive expression. Interior walls made of clay bricks help create a pleasant indoor climate, as they store heat and cool air. In winter, the walls offer warmth, while on a hot summer day they have a cooling effect. Houses made entirely out of brickwork require less energy for heating. An interior wall made of bricks does not deteriorate as quickly as other materials. It has higher durability and reduces the risk of cracks. Brick is a clean natural material that doesn’t impact on the environment. Bricks are fired at temperatures so high that organic materials are eradicated.

rothoblaas.com

Rothoblaas, a specialist in solutions for wooden structures, has introduced Vertilock and Terralock fasteners designed specifically for the installation of wooden planks in decks and facades without the requirement of a drill. They are available in plastic or galvanized steel. Vertilock and Terralock are invisible after installation so they do not interfere with the esthetic appearance of the surface. They are screwed underneath the wooden planks, connecting to a substructure. The fasteners are available in metallic colours as well as black and brown, so as to reduce visibility even further. The micro-ventilation underneath the wood planks provided by Vertilock and Terralock prevents the accumulation of water, which extends the durability of the boards. The fasteners come in boxes of 50 or 100 units in black, grey and brown. Sizes are 60 by 20 by eight millimeters or 180 by 20 by eight millimeters.

A house made entirely of bricks is an investment, and it pays off in the short term and long run. Bricks can easily absorb humidity, as they have a surface which is more open to diffusion than other materials. Brick is a heavy material, which offers the best noise absorption between the individual rooms. Noise coming from outside is likewise insulated, thanks to thick walls.

Festool USA’s new Limited Edition installation kit delivers an efficient solution for organizing and transporting the hand tools that installers depend on at the jobsite. The tools in the new kit are positioned inside labeled, easy-to-read organizer trays to ensure tools remain easily accessible. The installation kit, situated in the latest generation of Festool systainer organizers, comes equipped with a see-through lid and is stackable with other Festool systainers for efficient tool transportation. The new kits are packed with five categories of tools in a range of fixed and adjustable sizes. The components of the installation kit include an adjustable wrench, ratcheting combination wrenches, screwdrivers, nut drivers and a hex key set with a holder. The tools are available in either Imperial or metric.

Ridgid has added versatility to its line of press tools with the introduction of the RP 350: an advanced, long-running press tool that’s built for demanding jobsites. Engineered to be five percent lighter and almost three inches shorter than its predecessor, the RP 350 eliminates scheduled service intervals for less downtime and features a brushless motor, 360-degree swivel head and an advanced LED interface and lighting. Weighing only eight pounds with the battery, the RP 350 features an advanced brushless motor for maximizing tool longevity, efficiency and durability. The tool’s 360-degree swivel and bright LED light lets users not only access tight spaces but see them more clearly in low-light applications. Ideal for making connections on residential, commercial and industrial jobs, the RP 350 is compatible with the full line of Ridgid jaws and rings, including ½ to four-inch ProPress for copper and stainless steel, ½ to two-inch PureFlow for PEX, and ½ to two-inch MegaPress for carbon steel. It also offers excellent versatility, pairing with the Ridgid Press Booster for 2 ½ -inch, three-inch and four-inch carbon steel, the StrutSlayr strut shear head and the Press Snap soil pipe cutter. The tool’s 18-volt battery platform includes a car charger for on-the-go battery charging. The unit also pairs with the Ridgid Link app to track tool usage, service needs, battery life and last-known location.

Kyle has a problem. His normally reliable roofing subcontractor messed up big time and has left him with a public mess. Apparently, the fellow was in a pinch for labour on their last job and sent in some workers who didn’t know what they were doing. These people accepted a mixed load of shingles and installed them without noticing the colour difference. Now the client’s roof is a patchwork of different tones and looks terrible. The client was so mad they took photos and posted them all over social media, naming Kyle’s company as the culprit. Kyle is in a small town and he knows word is getting around. This is sure to impact business. The subcontractor is going to fix the job, but the public relations damage is done and appears to be getting worse.

The story of Terry and his nasty boss, Sam, attracted many calls for better communication.

Ann Borque of Bourque Renovations in Petrolia, Ont., wins the DeWalt 20V Coil Roof Nailer for this thoughtful reply that includes some personal details.

First, a comment: I wish all the Sams could read this too. It is unfortunately in our human nature to be so quick to pick up on one thing done wrong when the majority of the job was done right!

Although my husband is not verbally abusive like Sam, he gets very frustrated and impatient when tasks are not completed exactly to his expectation. He himself works to very high standards and doesn’t understand why everyone else doesn’t do things exactly as he would do. For 30 years as a business owner (and regularly reminded by me), he has worked on trying to be mindful of praising employees for their positive attributes besides only criticizing them when their work falls short.

Regarding Terry: Giving it back to Sam with both barrels or beginning an internal whisper campaign will only add fuel to the fire and there will be no winners. Terry should ask Sam if they can have a private meeting. Terry should begin on a positive note by expressing his gratitude for the guidance and opportunities offered by Sam, and also say he hopes he is equally pleased with how well Terry has learned and contributed positively to the company.

Then in a pleasant and respectful way, he should tell Sam how he feels when he goes off on his rants. Streams of verbal abuse achieve nothing except to garner resentment from employees, dislike of the job and thoughts of working elsewhere. Terry can impress that he is always open to constructive criticism and positive lessons, but that he is neither lazy nor stupid and does not feel he deserves such derogatory labels.

Terry should set his boundaries and be clear that his wife and family are off limits, and that Sam has no right to criticize any member of his family. When on holiday, everyone deserves a mental break from work and should not be expected to be on call.

Terry can try to end their talk on a positive note and reiterate how much he feels he has grown with the company and in the trade.

If after all this Sam goes off on another rant then Terry should start looking elsewhere for a boss who will appreciate him. He sounds like a person who would be a valuable employee for any company.

1. Make it clear to everyone who is really at fault here with social posts of his own. Explain what happened, name the subcontractor and deflect the blame to its proper location.

2. Ignore the bad press. Answer any questions about the job privately and keep everything on the high road.

3. Sue the client for their defamatory statements, seeking a settlement that involves taking down the offending posts.

4. Buy ads. Launch a month-long sales drive to attract new business to make up for any loss of market share. Mention his ironclad warranty on all roof work and materials.

5. Something else?

HOW TO ENTER

If you have a solution to Kyle’s dilemma, email your entry to pflannery@annexbusinessmedia.com and put “Kyle dilemma” in the subject line. Please don’t post your response to the Dilemma post on our website.

Entries close Nov. 30. The winner will be announced in the Jan/Feb issue.

T4 I-F GAS POWERED

Faster and safer, industry approved, leading thermal efficiency fastening system. 4X faster than traditional stick pin installation method.

RAMSET T4 I-F WILL FASTEN INTO

RA-27

FULLY AUTOMATIC

Stands up to the toughest use for interior and exterior applications on commercial jobsites.

is a breakthrough product which can be used to prime over existing stains left by mould, mildew, moss, fungi and any other odour causing bacteria*. *This product contains an mildewcide to prevent any growth on the paint film only. The Mould Stop Primer is ideal for non-porous interior and exterior surfaces such as drywall, concrete, masonry, painted metal and non-porous wood.

www.rustoleum.ca/zinsser