Heritage Homestead

Transformation

Creative Eye

Basement MoldBusting Strategies Five Steps

Resurfacing With Composite Decking Why Your Clients

Heritage Homestead

Transformation

Creative Eye

Basement MoldBusting Strategies Five Steps

Resurfacing With Composite Decking Why Your Clients

What keeps you up at night? Is it the howling wind, or worry over what it might be doing to your reputation?

Wake up to peace of mind with IKO’s new Dynasty Shingle with ArmourZone . You’ll sleep better knowing your roofing jobs are covered by a 210 km/h (130 mph) Limited Wind Warranty1. The ArmourZone is an oversized 1-1/4” wide nailing area reinforced by a tear-resistant, woven band inserted into and extending beyond the common bond. It makes nail placement easy and helps prevent pull through in high winds. So go ahead. Elevate your game with new IKO Dynasty Shingles with ArmourZone. You’ll sleep easier, and your customers will too. To learn more, 1-855-IKO-ROOF (1-855-456-7663) or visit roofingelevated.com

Rob Koci Publisher rkoci@canadiancontractor.ca

” ” For some insane reason they think: ‘I can have that!’

By Rob Koci

Ihave always marveled at those who get up early, work late, work hard and claim to enjoy every minute of their lives. I know one contractor who does exactly that. He is courageous, smart and successful. He loves what he does. One step at a time, he is finding his stairway to heaven.

That doesn’t mean he’s never been scared to death. He tells the story of the day he sat in his kitchen with his wife and realized they were barely a week away from not paying their mortgage and with no prospects for work on the horizon. Every once in a while, he remembers that day when a job falls through, or a client won’t pay. With seven years of success between today and that day, he stills feels the sting of it. It drives him on.

But now most of his days are happy, and filled with possibilities. It’s the life we all want to live, but what’s the trick? How can we have that, too?

Something has to happen to people before they can live that kind of life.

First, they have to see something most others can’t see. They see a possible future. And when they see it, they see themselves in it, with their families, still working hard, and with people around them who are happy for their success.

But then something else happens. A penny drops, and they add to their vision a sense of purpose and passion. For some insane reason they think, “I can have that!” And they are off: a vision in their minds and the passion in their hearts for an achievable, desirable future.

When you see people like this, you know there is no stopping them. No setback is so intolerable for them that they can’t get up and face the world again. The vision and passion are now bigger than anything that might get in their way.

Vision and passion are the answer, working together in common cause within you. And there is no power on earth that can manufacturer those ingredients for you. You have to find them yourself, for yourself. There is simply no other stairway to heaven.

By Steve Payne

Don’t blame the whole idea of “Fake News” on Donald Trump – or social media itself. It’s always been with us.

“Early in life I had noticed that no event is ever correctly reported in a newspaper,” said George Orwell some 70 years ago.

When it comes to our industry, the blatantly incorrect news comes thick and fast from – among other sources – the big construction unions, government regulatory bodies and (well, obviously) politicians themselves.

I’ve been writing for Canadian Contractor for almost two decades. I was a slow learner, but eventually I cottoned on to the most important tool a reporter has at their disposal: an ability to ask, “Says who?” Most public sector unions routinely issue statements about our industry that are so soaked with self-interest that they are laughable.

Let’s start with the reforms to the trades in Ontario recently announced by the new PC government (see page 12). Most of the public sector unions are doing everything they can in the mainstream media, every hour of the day, to portray Doug Ford’s government as deeply evil. Yet few selfemployed contractors will agree. Most of our readers are cheering the news that the Ontario College of Trades will be “wound down” sometime next year. And young kids who are clamoring for a chance to get into our industry will now have a fighting chance at a career in Ontario, thanks to the Ford government pledging to adjust apprenticeship ratios to 1:1.

Meanwhile, at the Federal level, the Liberals have seriously jacked up the price of everything from drywall to rebar thanks to unnecessary, punitive tariffs. The Trudeau government is introducing a multi-billiondollar tax grab dressed up as a “tax on pollution” that even some environmentalists admit will not impact global “climate change” in any measurable way. And, of course, the Liberals have made little progress on their much vaunted “affordable housing” strategy. Read Casey Edge’s column on page 30 to see what B.C. premier John Horgan is doing to make things even worse in that province.

Thank you for reading Canadian Contractor and supporting a forum that always asks, when it comes to conventional wisdom, “Says who?”

spayne@canadiancontractor.ca

” No event is ever correctly reported in a

Canadian Contractor has hundreds of videos online for serious residential construction professionals…

Sponsored by VELUX

In this collection of videos, Rob Koci talks about how contractors can make money installing skylights. Popular misconceptions about skylights are corrected by Mark Taylor and Russell Ibbotson from VELUX. After watching these videos, you will be able to educate your own customers about why a skylight might work well for them.

Sponsored by Home Hardware

This series of videos looks at ways to build better, faster and more profitably. Rob Koci and Steve Payne present a number of construction tips sent into the magazine by Canadian contractors – and they also interview experts from around the industry. Everything on a job site from framing to interior finishing is fair game for Site Tips.

Sponsored by Various Manufacturers

Innovation is the engine that keeps profitable construction companies going. Unless you are finding new and better ways to build, you will eventually fall behind your competitors and your company will begin to find the landscape too difficult to compete in. Buildwire is the place to have a sneak peek at great new products - and techniques - entering our industry.

ISSN 1498-8941 (Print)

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Kim Laudrum, Steve Maxwell

Art Director Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Mike Fredericks, President & CEO

Circulation

If this is your boardroom, you’re a Pro.

Home Hardware is a nationwide supplier of quality, name brand products to Pros of all trades. Whether you are a homebuilder, a renovator, a plumber or an electrician, Home Hardware is a Pro source for everything you need on your next job.

Dedicated Pro sales staff, job site delivery, home plan services, material takeoffs, package pricing, convenient ordering options, credit services, rewards program, and exclusive e-offers are just some of the benefits we offer!

Sign up today to receive pro exclusive email offers and news. homehardware.ca/en/forms/register

In September, Ontario’s newly-elected PC government announced that it intended to “wind down” the Ontario College of Trades (OCOT) next year. It also announced that it would move the province’s apprentice-to-journeyperson ratio to 1:1 (see page 12 for the full story). Most of the comments we received online were very supportive of these moves. For example…

Electrician of 43 years’ service hopes OCOT is truly done Hopefully, premier Doug Ford does rid us of the scourge known as OCOT. They effectively do nothing for the skilled tradespeople of Ontario other than to extort outrageously inflated fees from the pockets of hardworking trades. As an electrician of 43 years service I watched my license fee go from $60.00 every three years to $135.60 annually immediately upon the inception of OCOT. I’m not a math wizard but that’s roughly a 600 per cent increase. Any common sense person can tell when a government agency “is peeing on your shoe and telling you it’s raining” just because they know they can get away with it.

Edgey

He wants to see the ESA evaluated next I am glad that the Ontario government is reducing the red tape and getting rid of the Ontario College of Trades. I would like to see the ESA evaluated as well, and also CSA. I see many organizations misusing the word “safety.”

1:1 apprentice ratio is a good idea to make apprenticeship more easily accessible. In my trade, the required practical experience is 9,000 hours. That is a torture. This should be reduced to 6,000 hours and the school time increased.

Today, many employers are asking for multiple trades, and the excessive time makes it difficult. Could we also clean up mistakes in the Certificate of Qualification exams? Also adding a practical part to the exam would help.

Al

“Blue collar workers” can’t be “professional” without the OCOT

So now the regulatory oversight of the trades in Ontario will move back to the Ministry of Colleges and Universities, which is taxpayer-funded and government run, eh? Great to see my taxes go up. Why doesn’t the PC government shut down the other colleges, like the Ontario College of Physicians and Surgeons, The Ontario College of Teachers, The Ontario College of Social Workers. The Ontario College of Pharmacists, etc.? I guess blue collar workers will always be under the thumb… never professional.

Garrett Reid

Got your trades education at school? Breaking into a union is the hard part. We have had many posts from recent trade program graduates trying to get their first apprenticeship. Here is one of many replies.

Network, network, network!

My advice would be to network. Just like any job, it helps to know someone. Same for the unions. I had been looking for an apprentice opportunity for a year and a half. I’m in the door now, but it took me pouring through my network of friends and family to find degrees of connection to electricians, introduce myself, chat with them and build rapport. I manufactured relationships - as you have to do in every other job. They also don’t care if you went to school, because they will teach you what you need to know during your apprenticeship. A lot of people feel entitled to jobs because they are educated, and a lot of people don’t know that the union (my local) receives 1,200 apprentice applications per year. They bring in people who they have a character reference for. People they know. Don’t take it personally, just do what you can to be known.

Guy

What do you do if a client demands to see receipts for your purchased items? A contractor asked for our advice when the customer suddenly changed the rules on his Time and Materials agreement…

They want to see his receipts for materials before paying him

I need some advice. I am an HVAC contractor. I have one particular customer who, every previous time they have asked me to fix something for them, I have had to quote them the price of the parts. I have always done that, then I have put markups on the parts, and they have always agreed on the prices. Now they say they don’t want to pay me unless I give them all of the receipts for all the parts I have replaced in the past! What should I do? Thanks for your advice!

Richard

Tell them you can’t do it, version 1

Richard, here’s a suggestion on how to handle such enquiries. I’ve informed clients that I buy in bulk for many items and also in job lots. Job lots could be many items together – so it’s next to impossible to show them an individual cost. Bulk buys

are grouped with other items so, again, hard to show them a cost. Unless this client is a big part of your business, I would consider dropping them. If you quoted the job it should not matter what you paid for anything – but if it’s a T&M job break down the bill to the last couple cents: parts-labour-insurancestruck cost-overhead cost management cost–the list can go on and on.

Harry Veenstra

Tell them you can’t do it, version 2

Why would you show or tell your customer the wholesale value of a part you buy from a manufacturer or wholesaler? If they had to buy it they would be paying list price. The price that you put on your invoice to the customer, if they have accepted it, is the only price that they should be concerned with. Tell them to check their records, or send them copies of your previous invoices. Everyone is entitled to put a markup on items they are selling. You should never have told them what you pay for an item. It’s on you. You should have told them you can’t work for them.

Tom DalBarco

Painter agreed a price with a “homeowner,” who now tells him another contractor will pay him I did a written estimate for exterior painting: eaves, siding, windows and doors. Three-quarters of the way through the job, the homeowner introduced me to a contractor performing other work on the house and informed me that this person would be writing the cheque.

Now, the contractor said that I was under his WSIB and I didn’t need a clearance certificate. Now I am in a battle because I want to get paid – but the only way I can is if accept this contractor’s cheque. I want to stay WSIB exempt but now it looks like I am being forced into this. WTF!

Now, I don’t even know now if this house belongs to the person who hired me. I didn’t get my estimate signed by the

“homeowner” because I’ve always done business by the handshake method. I do have texts from him telling me this is his house. And I’ve sent texts back to tell him that I need to be paid by him, as the homeowner, and not by his contractor –putting my WSIB exemption in jeopardy.

Any suggestions?

Anonymous

One potential solution

I would advise the “homeowner” that you are contracting with them and that they should pay you. If they don’t pay you, I would then ask them to put in writing why they are not. Going forward, bear in mind a verbal agreement isn’t worth the paper it is written on. Texts do help you but without them you would be quite vulnerable. I would ensure that going forward you always get your quotation signed, signifying who you are working for and ensure that you take a form of ID from the person signing it.

Finsbury

In our last issue, tools editor Steve Maxwell began a 10-part series to help contractors with the “psychological” (and, yes, spiritual) aspects of contracting. His second instalment is on page 39 of this issue. If you missed the first column, type “Inner Life” in the search bar at www.canadiancontractor.ca.

Keep swinging Steve Maxwell!

Hey people! Just liking the “Inner Life of a Contractor” article in your September issue! I’m sure you will be getting the not-sopositive feedback as well! Keep swinging Steve Maxwell! Love it!

Anthony Goosen

“Hooked for Life”

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole.” So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer.

Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips and screws. You just screw it to the wall and it’s “Hooked for Life.”

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

Being a contractor can take its toll on you. Shortly after celebrity chef Anthony Bourdain committed suicide earlier this year, we wrote about the definite similarities between being a chef in a high-pressure kitchen and working in the renovation business. We got a number of supportive posts on this life-or-death topic, including this one, below. Thanks Simon.

Read this if you’re struggling

Reasons To Stay Alive by Matt Haig is a good read – everyone knows someone who is severely depressed. This well-written first hand account can help those who are afflicted, and those who love them to be able to relate to them.

Simon Kuhl

Editor’s Note: The post below has about six major issues in it and, typical of many consumer complaints about liens, there is no description of why the contractor felt the need to go that route in the first place. To find and comment on this post online, please go to www.canadiancontractor.ca and type “liened” in the search bar.

She feels her contractor is bullying her

We are stuck with a horrible lying contractor we hired to build our house. They took a $49,000 deposit on July 7, 2017 but did not apply for permits until 5 months later – we did not get permits until February 2018. It is now the end of September and we have been bullied by and stressed out so bad by these guys. They do not care about the plans or the contract; they bill us for whatever they feel like, then they stop working. We are not even at lock up 14 months after they took our deposit. I informed them that the contract expires Oct. 5. They abandoned the build on Sept. 10, did not finish to lock up, but wanted the lock up amount of $43,000 –then put a $102,000 lien on our house with no explanation. Our lawyer, after only a few appointments, just sent us a $5,700 bill. He is a good lawyer and that is the rate – but it was still a shock. He knows we are getting screwed but contractors also know it is so expensive to fight them so they take advantage and do what they want. They threw a high lien on our place mainly to bully us, as they have been doing all along. So, in short, we are screwed if we can’t afford the lawyer. We are giving the lawyer every penny to fight them, because it is so wrong, but we are running out of money and still do not have a house. And we are paying high interest costs for the construction loan.

Is there no help out there, other then the high-priced courts, to stop these crooks? They prey on people like us and try to take everything we have worked so hard for. No one will not sit down and talk or negotiate anything with us. They hired other contractors to build our house: I met the company owner three times and I met the project manager three times. But the project manager was never on our site. I know because I was there, staying in my trailer. How do we get this unfair lien off our house without it costing us $50,000?

Della Mackie

Anyone interested in another story about an Old Alberta Homestead, please turn to page 32…

How to fix “dirt smell” in a 1930s farmhouse

We have an old family homestead in central Alberta. Circa 1930s or 1940s. No heat, unless we use the fireplace or the old wood stove. The floor is wood, the basement floor is dirt, the walls are concrete block, probably, and are cracking – typical for this area. What we are trying to do is to keep the dirt smell from rising into the house: it’s not wet but it’s not pleasant. There are four window holes that have been boarded up which we are going to put windows in.

Here’s the thing. In the past, the family put fiberglass insulation into the ceiling joists of the basement and then put vapor barrier over that. Well, of course, the squirrels burrowed into it and made their home there. They had gotten into the basement through those unfinished windows. And there was mildew and moisture where the insulation met the vapor barrier. So we tore it all out. Now we have the problem of no insulation in the ceiling of the basement.

Some people say put poly on the walls and insulate the walls. Some people say put poly on the dirt and put blocks around it to hold it down – or use silicone. Some people say run vapor barrier through the joists back and forth similar to insulating mobile homes, then put insulation into the joists and then strap the insulation to the joists. We’re just confused as to what to do.

Remember there is no heat and no one goes out here in winter. We need an economical, quick way to insulate this basement. There is no furnace. Please help us keep the cold from the basement rising and the stink from the dirt. Thank you so much.

T. Lowry

Editor's Note: To find and reply to this post, please go to our website and type "dirt" in the search bar.

Owens C orning Building Scientists continually research and develop smar ter ways to build better homes, creating complete building and insulation solutions that lead the industr y in per formance, durabilit y and safet y. These for ward-think ing designs are not only proven to per form, but they also deliver me aningful benefi ts your homebuyer s will be willing to pay for. Let us show you how to Tur n B uilding Scienc e into B

your O wens C orning Area Sales M anager to connect you with the O wens C orning Building Science Team, or call us today at

For more info and insights from building industr y exper ts, check out our online community at ww w.hi

“OCOT was a red tape monster” says Ontario Skilled Trades Alliance

Independent contractors in Ontario were quick to applaud the Oct. 24 announcement from the province’s new PC government that it would “wind down” the Ontario College of Trades some time next year.

The OCOT closure announcement was part of the unveiling of the Making Ontario Open for Business Act in the legislature. As part of the changes to the regulation of skilled trades in Ontario, apprenticeship-to-journeyperson ratios will be lowered to 1:1.

Most public sector unions – and the Liberals and the NDP – slammed the most controversial part of the Act: freezing the province’s minimum wage at $14, rather than increase it to $15 in January as legislated by the previous Liberal government.

The Ontario Skilled Trades Alliance (OTSA), representing companies that employ over 400,000 skilled tradespeople across Ontario, had been advocating against OCOT ever since it was established seven years ago. “After years of calling for action to reduce barriers and red tape created by the Ontario College of Trades, we’re pleased this government is moving to address the concerns of so many employers and workers across the province,” said Patrick McManus, chair of OSTA. “These are the kinds of changes that make it possible for more employers to hire and train the next generation of skilled trades workers, and do it right away.”

“Liberals had handcuffed us”

Independently-owned contracting firms contacted by Canadian Contractor were highly supportive of the changes that will see apprenticeship ratios reduced and OCOT removed from the landscape.

“Small business owners want to grow. We want to succeed,” said Lindsay Haley, president of Precision Contracting in Brockville, ON. “The Liberal government had done nothing but put handcuffs on many small businesses, resulting in a total lack of growth and opportunity. The 1:1 apprenticeship to journeyman ratio is a huge help, both for creating jobs for graduates and to provide an increase in production. It increases the chances for young apprentices to work in their field of choice.” Haley said he hoped that this was just the start of a continued “clean up” of restrictive business regulations.

Hanna Taylor, president of family-owned Hotwire Electric,

THE ONTARIO COLLEGE OF TRADES WAS ESTABLISHED BY THE LIBERAL GOVERNMENT TO “PROMOTE THE TRADES,” WHILE FINING AND PUBLICLY DISPLAYING THE NAMES OF THOSE TRADES WHO REFUSED TO PAY ITS FEES.

Toronto, had suffered a forced, card-based unionization three years ago that was enabled by Liberal government legislation. Like Haley, she applauded the Ford government announcement. “The 1:1 ratio is a great movement towards business and apprentices by allowing apprentices to be registered faster in small businesses, and allowing them to progress faster through the process to get their license,” Taylor said. “We are all committed at Hotwire to ensure the timely and professional development of all our electrical apprentices (309a) and seek the best methods to train and develop them.”

Richard Speare, a contractor as well as a carpentry instructor at Georgian College’s Barrie, ON campus, said his students will benefit. “This is so overdue,” Speare said. “There is no reason ratios needed to be as they have been. This move will help many small companies contribute to training by taking on more apprentices. OCOT added absolutely nothing for those who were paying fees to them”

As overwhelming as the support for the new measures seems to be, there were notable voices of opposition. One Canadian Contractor reader who asked for anonymity expressed concerns over safety. “If you were to flood every construction site with a 1:1 ratio tomorrow, it would be chaos. I personally would be afraid to go to work.” All the same, Ontario is hardly unique in going to a 1:1 ratio. Most other provinces have had 1:1 ratios in place for years.

“The College of Trades was a red tape monster,” Patrick McManus of the OSTA said. “It provided no real benefit. There were duplicated enforcement services, and it created added administrative burdens for business. We had already been struggling for the last decade to find people to fill the roles in the existing operating environment. All we could foresee was the situation where we needed more bodies on a jobsite to do the same amount of work.”

For the OSTA, the future without OCOT is brimming with opportunity. “We think the biggest issue facing the trades now is the Skills Gap,” said McManus. “That’s really where the discussion around the trades table needs to be. We really want to participate in that because I think we have valuable input regarding where jobs are needed, the types of skills we need to train for, what regions of the province need which tradespeople.”

That sentiment is echoed by Michael Gallardo, executive director of Merit Open Shop Contractors Association of Ontario. “We now need to modernize the apprenticeship system to promote the trades as careers as a plan A, not a plan B,” he told Canadian Contractor. “Cutting the red tape will mean less bureaucracy, making it easier for people to find work. We want to be a part of the solution. It is important that the government receive input from all stakeholders. The open shop construction sector is the backbone of many, many communities throughout Ontario.”

Union versus non-union “irrelevant”

Gallardo and McManus also agree that the union, non-union question is irrelevant. “We want to make sure all workers are given an opportunity to work and bid on all projects in Ontario,” Gallardo said. “This is an issue of fairness for all people.” McManus concurs. “The 1:1 ratio is really going to open up more jobs, bolster union construction, and increase membership in the unions themselves.”

OSTA’s McManus concludes by suggesting that a new coordinated effort by all industry stakeholders is vital. “This whole process of creating interest in the skilled trades over the last few years has been so disjointed,” he said. “Everyone has been working so independently. There really hasn’t been an organizing body to bring everybody together so we can all be rowing the boat in the same direction. We need to share our ideas and initiatives, and make sure we are not duplicating and triplicating. If we all came together we could do a much better job.”

- John Bleasby

Your customers ALL want more daylight and fresh air in their kitchens and bathrooms. Skylights are the answer!

Humans crave fresh air and light. The beauty of skylights is in their ability to deliver both in the two rooms with the highest traffic and the most impact on comfort and wellbeing: the kitchen and the bathroom. And they always do it as well or better than windows. Here’s why.

In urban areas, building codes limit the amount of window that can face close neighbours. (In many jurisdictions only seven percent of a wall can be glass where the neighbour is less than four feet away. Check your local building code.) That’s great for privacy, but it becomes difficult to bring light into the center of the house where bathrooms are located. Skylights on roofs are not usually counted in this formula, which makes installing skylights in second floor bathrooms not just possible, but limited only by the size of the room.

Kitchens and bathrooms put a bigger premium on wall space than any other room in the home. Every inch of wall is precious. Kitchen and bathroom cabinets, fixtures, appliances all need wall space, which reduces dramatically the amount of window that can be designed into them. But skylights? They take no wall space at all! Where there is a ceiling with direct access to the attic, there is a place for them. Does your customer want the kitchen or bathroom flooded with light? No problem. Place as many skylights as they like. Does your window,

pass-through or doorway design take away cabinetry space? Get that wall space back without losing light or fresh air by including skylights.

Environmental Skylights make sense on a lot of levels, but it’s when considering their environmental impact that they really come into their own.

Start with home comfort and livability. Skylights deliver two times the amount of daylight as a wall window. It has been proven in studies over and over again: daylight and fresh air promote health and well-being. For over 75 years, VELUX has been a worldwide pioneer in the skylight category and now engineers hundreds

of skylight options for any home installation.

For instance: Sun Tunnels make an affordable solution for tight retrofits. The Cabrio Balcony Roof Window can instantly turn a tiny attic into a beautiful, comfortable space. Cabrio is also a cost effective solution to a dormer. Skylights in high cathedral ceilings can be remotely managed with a programmable remote control.

There was a time when skylights were thought to reduce energy efficiency. On the contrary, the solar gain from flat glass skylights can be better than windows.Adding solar powered blinds helps to increase energy efficiency and allow homeowners to control their environment with the touch of a button.

Solar Powered Venting Skylights (see previous page)

With all the practical advantages they bring, skylights also bring a certain sophistication to your business. When you have a solid knowledge of their uses and understand how they can enhance a home, they also enhance your reputation in the marketplace. When you bring your designers, purchasers and site supervisors up to speed on all aspects of skylight installation, performance metrics and lifestyle improvements, you will do what all builders must do if they are to succeed; separate yourself from the crowd. For more information on how to grow your business with VELUX register at vipmembers.ca

The Solar Powered Skylight features a solar panel that captures available daylight and uses it to recharge a highly efficient, fully concealed battery powered operator and control system. This operator is the power source that opens and closes the skylight, negating the need for electrical wiring. It also closes in case of inclement weather.

Electric Venting Skylights (see above)

The Electric Venting Skylight is the perfect daylighting solution for overhead applications, particularly in kitchens. It allows for abundant natural light, and with the touch of a button, opens to let in fresh air. If the homeowner forgets to close it, a rain sensor will shut the skylight during inclement weather.

Sun Tunnel Skylights (left)

The Sun Tunnel Skylights automatically bring natural light into even the darkest and most isolated spaces through a specially designed tunnel that passes from roof to ceiling. The attractive ceiling diffuser blends into the ceiling, spreading a soft and restful light throughout the room. For contractors, the Sun Tunnel is a quick and easy installation with no structural changes required.

The Endeavour Centre in Peterborough, Ontario is sending their sustainable building course graduates to all corners of the world

By John Bleasby

George from Ghana, Nicole from Nicaragua, Diederich from Holland, Justin from Minnesota — each with diverse backgrounds and future ambitions. They join Maya and Genevieve from Ottawa and Justin from Toronto with a shared objective — hands-on experience with sustainable, natural building materials and techniques. Along the way, they’ll also learn how to manage the design and build process of a real-life project. Returning home to develop their future career paths, they may well be among tomorrow’s influencers of residential design.

Each May, students from all over the world arrive at the Endeavour Centre, a private learning facility in Peterborough, Ontario. They’re drawn to Endeavour’s learn-while-you-build project, a summer-long course that has really put the facility on the map. “We thrive on working with the most promising and innovative sustainable building materials and technology,” the Endeavour website explains. “From simple natural materials to effective high-tech mechanical systems, our exploration of what’s available, possible, practical and affordable is our raisons d’être.” It’s a unique outlook, but reveals only a part of the independent streak that runs through the organization.

Chris Magwood, one of Endeavour Centre’s co-founders, had previously been teaching sustainable building at Fleming College in Peterborough for several years. “We had been looking at expanding that one course but decided it would probably work better outside the institution,” Magwood tells me when we first talk during the winter. “It simply takes longer to initiate those types of programs inside a college environment. We thought we could be quick and nimble and start our own thing.” In response, Magwood along his wife, Jen, and three associates came up with the idea of the Endeavour Centre. Today, it offers more than 25 courses and workshops in design and building science that run almost year-round.

That initial conversation with Magwood arouses my curiosity. So

Endeavour Centre Students, Summer 2018. Back

THIS SUMMER, STUDENTS CAME ALL THE WAY TO PETERBOROUGH FROM AS FAR AWAY AS AFRICA AND CENTRAL AMERICA

TO GET THE ENDEAVOUR CENTRE’S HANDS-ON, DESIGN-BUILD

does the Zero House, an Endeavour Centre project that made a dramatic statement at the Expo for Design, Innovation & Technology (EDIT) held in Toronto in the fall of 2017. Built in collaboration with Ryerson University in Toronto, the Zero House was a pre-fabricated, 1,000 square foot, two-storey NZE home constructed by Endeavour students earlier that summer at the Centre’s campus, then reassembled at the Expo.

I decide to visit Peterborough in May at the start of their summer-long sustainable building course, and spend two days shadowing seven students ranging in age from 21 to 56 years. Each has paid several thousand dollars to be part of the 2018 project — transforming an unsightly concrete block garage behind a large, older home near the city’s downtown into a modern, energy-efficient rental apartment. Surprisingly, only one student is a carpenter by trade, but never mind — that’s neither a prerequisite nor a concern to Magwood and the way the course operates.

Students paying to work? It’s just another aspect of the Centre’s uniqueness — financial autonomy. The Endeavour Centre earns its way almost exclusively through tuition fees plus the management fees charged to the project’s property owners. “In Canada, paying (entirely) for your education is a little bit outside people's expectations,” Magwood says. “But people who come from outside the country think it’s a really affordable education, a bargain, in fact. I think that's one reason why we attract so many international people.”

The Endeavour Centre doesn’t run on government grants or subsidies, either. “There really aren't any government programs that cover what we do,” Magwood tells me. “We don’t like being beholden to granters. What we do is outside the box, and grants tend to define you. We have to be able to change, be flexible and explore new things. That often doesn't mesh very well with grants.”

Magwood explains that working hands-on from start to

finish on actual projects is the key to students understanding the full arc of the process. They’ll learn to use a number of materials and strategies for sustainable building. They’ll learn how to assess existing building conditions and formulate sustainable solutions such as rammed earth, natural insulation, wood framing and natural plasters, all in real-life situations. Air tightness and avoiding thermal bridges are also high on the list, as well as the selection and installation of natural finishes and low carbon heating systems.

Shane McInnis is Magwood’s right hand man supervising this summer’s project.

A Red Seal carpenter and Endeavour Centre alumni who joined the Endeavour Centre

faculty three years ago, McInnis teaches at Georgian College in Toronto during the off-season. He likes the direction Magwood has set and Endeavour’s ability to adapt the curriculum on the fly. “If we notice a gap or need in the students’ learning, or a learning outcome that needs to be addressed, we can make those changes.”

The term “sustainable” in the building industry has been subject to a certain amount of marketing abuse. For clarity, I ask McInnis how Endeavour defines it. “The way we define sustainability is to actually set goals for the project,” he explains.

If it’s wood and it needs cutting, Maya is there to contribute her passion for tools

“Those goals should be measurable and need to take into account the combined carbon, the indoor air quality for occupants, responsible waste management — how much is diverted away from the landfill — and energy efficiency. These goals are set at the start, based on the specifics of that project. It’s more than simply using non-VOC paints, for example, or quoting some certification.” McInnis is quick to add, however, that project goals must relate to budgetary objectives, too, not just idealism. Endeavour alumni later becoming industry influencers in the goal. Chris Magwood’s passion for sustainable building practices has played a key role in the professional development of one of the country’s leading eco-friendly builders. Ben Polley, co-founder of Evolve Builders in Guelph, Ontario, met Magwood in the days before the Endeavour Centre. “Chris had started as a straw bale subcontractor with two other building partners,” he tells me. “When I was looking to do something similar, they effectively took me under their wing. They first taught me what they knew about straw bale building, and then helped me on my way by providing leads in areas they couldn’t have easily serviced.”

Who can say how or where Endeavour’s class of 2018 will impact the world of construction. I return in late September to ask the students to comment on the personal impact the course has made on them. George is a 30 year old Ghanese, and the executive director of Roots Without Borders, a foundation

STUDENTS PAY THE FULL COST OF THE PRIVATE EDUCATION AT THE ENDEAVOUR CENTRE, WHICH DOES NOT RELY ON GOVERNMENT FUNDING

GEORGE FROM GHANA BROUGHT SOME OF HIS OWN MATERIALS WITH HIM TO

PETERBOROUGH – AND THE ENDEAVOUR CENTRE WORKED WITH HIM ON FINDING NEW WAYS TO BUILD WITH THEM

supporting environmental programs in Ghana and Canada. Although he’s not a carpenter by trade, he tells me about his background in agri-education, and how he and his Canadian wife have built a school incorporating a 20-acre farm that supplements the student fees. He exudes enthusiasm. “This program is one of the greatest I've seen so far. This sustainable building idea is a big new chapter for me in my life — the materials, the concept, and the actual building itself. I really believe that sustainable building is something that is going to protect this planet, which is very, very important.” George brought materials from Ghana, experimenting withn how to adapt them back home based on what he has learned here in Canada. In December, he will host Magwood on a two-week exploratory trip to determine if a sustainable training programme can be set up in Ghana, perhaps with government support.

For Nicole, a Canadian living in Nicaragua, returning with an understanding of how to adapt cheap, abundant and indigenous materials into a sustainable building process was a goal shared with George. She and her partner are developing an eco-lodge.

It’s no easy task. “Nicaragua is the second poorest country in the Western Hemisphere,” Nicole tells me. “Clay is one of their biggest resources. There's bamboo, there’s palm leaves — it’s an entirely different environment, a jungle.” Justin, Maya and Genevieve came to the Endeavour Centre from other angles entirely. Justin is an architecture grad from Toronto who will return with his passion reignited, ready to blend it with an improved understanding of sustainable processes. Genevieve works with her father’s design firm in Ottawa as a draftsperson. She’ll incorporate her new understanding of sustainable options into presentations to clients who are interested in an earth-friendly approach to their new homes. Maya, the youngest of the group, is a creative mind with a background in industrial design and a love for working with tools and her hands. “I just started school at Carleton University in Ottawa, and wrote an internship report on this program. It's really going to be part of my career in industrial design.” Justin from Minnesota, the only bona fide carpenter in the group, may or may not return to the States. He’s considering moving to Canada and setting up shop, perhaps to offer sustainable methods to homeowners. And Diederich will return to Holland to continue his personal voyage of philosophic discovery and development. He can’t say where his summer’s experience will take him. “I have no idea what I will do with this knowledge I have gained, but I will come up with something.” cc

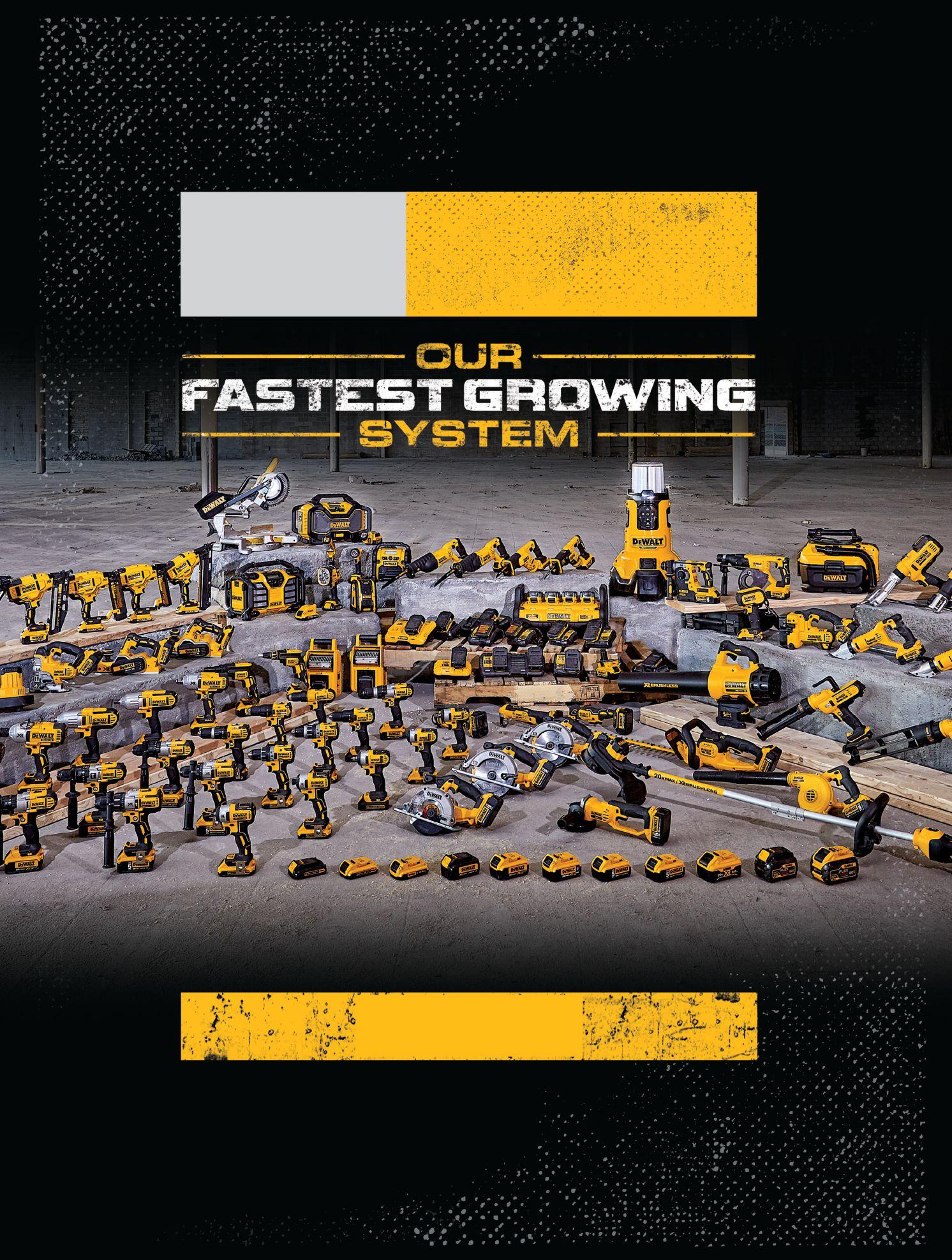

GET MORE DONE™** with 180+ PRODUCTS in the DEWALT 20V MAX* line. All tools come with upgraded features, superior ergonomics and use Lithium-Ion batteries. For extreme performance, step up to the XR® series and get advanced electronics, extended runtime and faster application speeds.

Full disclosure: In my real life, I drive a Subaru Impreza. 180 HP, four-wheel drive, small enough for my five-foot tall wife to call it “her size.” A week’s worth of our laundry approximates its payload. Even when I was working 90 hours a week as a framer, I didn’t own a truck. My ride was a blue, bashed-up GMC van, centuries old, filled with mud-encrusted power cords and worm drive saws. So these will be the least competent truck reviews you have ever read. But was I ever enthusiastic to get my hands on these beauties! In this issue I’ve paired the Nissan Titan and the Chevrolent Silverado as they are a close match on sticker price.

Even when he was a framer, Rob Koci never owned a pickup truck. He pulled up to jobsites in a demolition derby GMC van with glimmers of blue underneath a half-inch of mud and filth. Which is why his recent test-drives of the Nissan Titan and Chevrolet Silverado gave him quite a thrill.

By Rob Koci

Walking up to Nissan’s light-duty workhorse, keys in hand, I was mostly impressed with how short my 5’ 7” frame feels against this behemoth. My rockclimbing skills helped when I pulled myself up into the cab. First thought: “This is where real contractors live!” Second thought: “I am not a real contractor.”

The Titan has taken some criticism for being a rougher ride than its North American rivals but my first impression out of the parking lot was more Cadillac than dune buggy. It was a soft, rolling ride, with a hint of luxury. The bluetooth hooked up easily and the sound was

butter smooth. The steering wheel, simple but elegant dash and the bucket seats were clearly made for comfort. The contrast from the trucks I drove in the 70s and 80s couldn’t be more dramatic.

Of particular note was the wide console between the bucket seats that long ago replaced the bench seats that were standard in my trucking days. It was desk-sized with enough room to easily spread out a laptop and a bunch of paperwork, with decent storage space underneath. This truck said comfort, capacity and commerce in equal measure. Clearly, the days when trucks were for driving out to Lookout Point with a sixpack on the floor and your sweetheart

snuggled close under your arm are long gone. Geez, I am old.

A few nitpicks: Even a senior citizen like me will find it annoying that the Titan’s bluetooth shuts off when I turned off the truck. I would have preferred for it to wait until my phone call was over. And why can’t Nissan give you the option of turning on the backup camera any time you want it? Wouldn’t it be useful to check what’s behind you before you shift into reverse? And the constant warning bells, lights and whistles backing up, driving into underground parking lots, turning corners and just driving down the highway mostly scared the shit out of me. Maybe that was the idea. Consequently, I drove the thing all week like an 80-year old.

Reviewing the cargo area, kudos for the soft-drop tailgate, the excellent cleat rails with well thought-out cleat design and the rail slides along the bottom of the cargo area. I wish I could have thrown a few different payloads in there because I

just know it would have handled them like a boss.

After testing the Titan for a week, the Silverado ride was a different experience: neither Cadillac nor dune buggy but sports car. It needed the same climbing skills to mount, but ran like a road hugger, with a tighter suspension and responsiveness. I felt like I could throw it around more and have a little more fun with it. Match that with a very cool red and black detailing on my model and I had a machine that let the blood run a little hotter. It is still a work vehicle but the Silverado wants to play, too.

From the driver’s seat, the cab was similar to the Titan, but with a few more plug-ins: two USBs, two lighter plugs and even an AC plug. Another office on wheels with plenty of comfort. Of note, the

steering wheel was smaller and added to the sporty feel.

The lined cargo box got a little work this time. (I had an 18-horse boat engine to transport across town.) The bucket didn’t have the highly-engineered cleats of the Titan or the rail slides along the bottom, but it did light up like the Vegas strip, something any contractor will appreciate at this time of the year.

The second surprise was how much the thing liked me! Pressing the start button lit up the analog-looking dials on the dash, needles swinging in unison like high-kicking showgirls, lights flashing, everything in front of me looking thrilled to see me. The Silverado reminded me that, while many contractors buy a truck on payload capacity, horsepower and fuel economy, a little entertainment in a hard work day never hurt anyone. And the Silverado entertains.

Next issue: Ford F150 and Dodge Durango

The German-engineered power tools firm, still growing its presence in North America, hosted a significant Canadian contingent at its recent Festool Connect event in Las Vegas, Oct. 27

By Rob Koci

Everyone who thinks of Stuttgart and “German engineering” thinks of Mercedes Benz. But another elite brand began in that city in southwest Germany in 1927: Festo, the brainchild of Albert Fezer and Gottlieb Stoll.

Today, Festo known as one of the most important industrial control and automation firms in Europe. Festool, it’s portable power tool brand, was spun

off into a separate firm in 2000. Today, Festool enjoys a cultlike following among European fine woodworkers. In recent years, Festool has begun to increase its share of the North American market – including in the homebuilding and renovation industry.

Part of the growing interest in Festool involves the company’s annual Festool Connect event where contractors, traditional media, social media influencers and tool experts from across North America are invited to try out some of the latest updates on its tools and accessories.

Canadian Contractor attended the first-ever West Coast staging of Festool Connect last month, in Las Vegas. The event included a live presentation by This Old House stars Tom Silva and Kevin O’Connor celebrating the 40th anniversary of this groundbreaking PBS show.

Bryan Boutin, owner of BJB Woodshop in Edmonton AB, (@bjbwoodshop, 11,000 followers) was one of many to win an all-expenses paid trip to Festool Connect this year through a This Old House viewer contest. “I was fed up with having to buy a new chop saw every year. Someone told me to buy the Festool KAPEX KS 120 saw. With that and with what the dust extraction system can do, I never looked back.”

High standards are a Festool hallmark. Festool’s Surface Control Light is probably the best example of Festool’s commitment to the drywall contractor.

Carpenter Kiefer Limeback (@Toolaholic, 211,000 followers) from Toronto, and Murray Kruger (@Krugerconstruction, 198,000 followers) from Saskatoon have helped to introduce Festool to Canadian contractors.

Murray Kruger: “We use a lot of Festool. Last year was my first year at Festool Connect. I love that you can get hands-on updates and good advice right away. But Festool is good with that. I had a problem with my dust extractor this year. I made a call and had my answer just like that.”

Look at the ingenuity that Festool has added to its vacuum system. This “End Man” suctions on to the wall to provide a stabilizing hook for long mounting brackets, ledger boards and installations where two hands are better than one.

Festool’s Planex drywall sander (centre) and dust extractor (right) could be the soul-saving tool for every renovation contractor who has finish drywall in a home still occupied by the owner. A sander hooked up to a high efficiency HEPA vac system, the Planex delivers your high-end results dustfree.

Festool helped the iconic TV show This Old House to celebrate its 40th anniversary with a presentation by Tom Silva, one of the show’s original hosts. Silva walked the audience through the progress of the show, its impact on home building in America and the renovations he is doing to some of the original houses the show remodeled 40 years ago.

We had many fine entries in our 2nd Annual ITW/ GRK PROJECT CONTEST. This beautiful boathouse and boat port in Muskoka, Ontario, took first prize. Congratulations to the contractor, Canadian Waterfront Services, Ltd.

GRK has a number of specialty fasteners for contractors, so perhaps it’s fitting that a specialty contractor has won this year’s ITW/GRK Project Contest.

Canadian Waterfront Services, Ltd. specializes in boathouses, steel shore work, landscaping and full concept cottage construction. The firm, owned by brothers Stephen and Andrew Cartwright,

operates from its HQ and workshop in Hillsale, Ontario equidistant from Barrie, Orillia, Georgian Bay and Muskoka.

The project the firm submitted to our judges is this post-and-beam boathouse and boat port at Gloucester Pool, Muskoka. It was a challenging project requiring helical piles to be driven down to bedrock 22 feet below the waterline.

Stephen Cartwright

“We used GRK fasteners in almost every aspect of this project,” said Stephen Cartwright. “The floor joists were laminated with GRKs; the hand-cut trusses were secured with them. All of the posts and beams are held together with custom aluminum knife plates (T-REX brand from Connecticut Post & Beam) that

were fastened with GRKs… The structural design of these fasteners allowed us a lot of creativity. We literally use GRKs on a daily basis.”

Because of the job site’s location on a waterway administered by the Federal Government, there were a number of rules and regulations over and above local municipal codes, Cartwright explained. The rules are there to protect fish, turtles and other species.

“Because of fish and turtle spawning concerns, you can only work in the water during specific calendar dates to avoid contaminating the habitat,” he said. “We had to do the demolition of the old structure during the winter, so that the debris could go on the ice surface and be cleaned up. We had to get all the foundation work done before March and you can’t work in the

water again until July.”

Even hammering on the structure between those dates can create vibrations in the water that can be harmful to the fish. “You’ve got to adhere strictly to the schedule and meet all your timelines,” Cartwright said.

Canadian Waterfront Services has six employees. It’s been a busy yearand the project was complex. The firm does boathouses that range from $80,000 to $500,000 - in additional to full-scale cottage construction. “Other than subbing out our electrical, plumbing and HVAC, we do try to keep everything in house as much as possible,” Cartwright said.

Canadian Waterfront Services is a certified installer of Almita Helical Screw Piles and also a dealer of Nydock Floating Docks, a Huntsville, Ontario firm.

Linden, AB

Justin Stewart of Ridgetech Builders sent us these cool construction photos of a recent project. “We are trusting GRK fasteners with our reputation and the safety of all who walk up these offfice stairs and use this railing/ baluster assembly,” Stewart said. “We are relying on the combination of our quality craftsmanship and joinery and our GRK fasteners holding up under rigorous use for years to come.”

Calgary, AB

Ken Schultz of Gateway Outdoor Living, Calgary, sent in this fun project that he did in Winnipeg for a friend he’s known since Grade 7. “Another buddy (who I've known even longer) was able to work with us as well. The three of us graduated from high school 40 years ago, so it was a reunion of sorts. The design called for laminated columns consisting of six 2x10’s. We used GRK R4 screws to fasten these boards together.”

Salmon Arm, B.C.

These photos are from a community-driven project called Haney Heritage Village in Salmon Arm, B.C. “We were the project manager and provided the carpentry for the structure,” Exel’s Rick Semenzin said.

“GRK fasteners were used in many of the buildings’ structural connections and for all of the timbers and decking.”

Whether it’s Trudeau’s carbon tax rebate, tariffs on building materials or rebates to stimulate renovation and construction, politicians always have one goal: your money

By Casey Edge

wizards, sorceresses and illusionists are creating a House of Horrors. Trudeau, the Great Illusionist, recently made a carbon tax rebate magically appear while promising to return approximately 90 per cent of the anticipated $2.3 billion revenue to Canadians. However, the audience must be careful. Is this is not just another case of “climate change” smoke and mirrors?

Trudeau also recently imposed tariffs on steel after the Astonishing Trump made tariffs suddenly appear on imports to the U.S., thus making U.S. steel the most expensive in the world.

And as John Bleasby recently discussed online (canadiancontractor.ca, type ‘tariffs’ in the search bar), Ottawa is collecting millions of dollars in tariffs on homebuilding materials: everything from rebar to drywall. These tariffs are adding to the cost of housing in both Canada and the United States. They serve no useful purpose except to pad the coffers of political wizards, sorceresses and illusionists.

Almost 30 years ago, Ottawa the Omnipotent first launched a New Housing Rebate program (at that time it applied to the Federal Sales Tax, later versions applied to GST/HST). Today, Ottawa’s New Housing Rebate program has vanished before our eyes through the magic of inflation.

When introduced in 1990, the full rebate was applicable to about 90 per cent of new homes in Victoria. However, today a search on www.realtor.ca reveals that no single detached homes now qualify for the rebate — it disappears at a home price of $450,000. In fact, according to the Canadian Real Estate Association, the average home price in Canada is $475,591. Therefore the rebate’s cap is actually less than the average price. When introduced, Ottawa the Omnipotent said the rebate would be indexed to inflation. We kept our eyes on the index-toinflation pea, but it, too, disappeared.

Now the collective handwringing concerning the lack of housing affordability by wizards, sorceresses and illusionists at every political level is wearing thin with the audience. Meanwhile, Trudeau the Great Illusionist’s affordable housing

strategy doesn’t really kick-in until sometime down the road, provided he is elected again. Now you see it, now you don’t!

Even that strategy does not address market housing affordability for the large generation of millennials trying to start families. The potion of rising interest rates and the new mortgage stress tests will make buying a home that much harder to achieve. What Canadians don’t realize is that mortgages have become the latest trick from which political illusionists pull endless streams of dollars.

B.C. premier John Horgan collects $2 billion annually from the Property Transfer Tax, creating a House of Horrors for purchasers. It may, in fact, be charged several times over during the development of a single new home, yet it deceives the audience into thinking they pay it only once. Speculation Taxes and School Taxes are being added to Premiere Horgan’s bag of tricks, neither of which have anything to do with speculation or schools.

As well, common sleights-of-hand by municipal illusionists are merely taxes that generate million dollar surpluses — based on value of construction rather than a simple fee for service, as required.

Trudeau the Great Illusionist’s magical appearance of a carbon tax rebate while the GST housing rebate languishes reveals what is really behind the curtain, and it’s not housing affordability. A recent study by the C.D. Howe Institute reveals that regulations, taxes and fees add $644,000 the cost of a single family home in Vancouver, $264,000 in Victoria, $168,000 in Greater Toronto, and $152,000 in Calgary.

Canada’s political wizards, sorceresses and illusionists will continue to collect billions in taxes, tariffs and fees from housing until the audience realizes that they are not only paying income taxes, but also unsustainable government costs that, amazingly, almost double over the life of their mortgages.

Ottawa the Omnipotent’s offer of a carbon tax rebate is small comfort, since it, too, will likely disappear right before our eyes. Poof! cc

Casey Edge is CEO of the Victoria Residential Builders Association and a passionate advocate for the home building industry in Canada.

A young couple updates the family farmhouse in Alberta without sacrificing its history

By John Bleasby

Aquarian Renovations, Edmonton

The exterior of the original 1930s farmhouse remains essentially the same. However, new rigid insulation and stucco have been added.

Memories of the family farm were a magnet for Steven Kohle, drawing him back home to the village of Bon Accord, Alberta, 40 km north of Edmonton. Kohle’s great-grandfather William Reed and Reed’s “Uncle Mac” had arrived there in 1907 from Illinois on a train car loaded with oxen and supplies. A small house was built on their property in 1910, and a

second larger house was added next to it in 1935. “My grandpa bought the farm in 1953 when my mom was two,” Kohle said. His mother still lives in the original house today.

Kohle recalls that all his cousins have lived in one of the two houses at some point. It’s not surprising, therefore, that honoring the heritage of the family

homestead was important. However, he had twin goals — to retain as much atmosphere of the 1935 house as possible while bringing it up to more modern standards for his young family. Kohle turned to Aquarian Renovations of Edmonton to design and execute this challenging project.

The restoration of an older prairie farmhouse can be fraught with unforeseen challenges for any experienced designbuild contractor. However, Marie Soprovich, president of Aquarian, and

her team of designers, engineers and carpenters already had a list of successful restorations behind them. They knew to expect the unexpected. “We always know that there will be surprises, but we had an idea from our site meetings of what we were getting into,” explained Aquarian site supervisor Colin Whittaker. “Still, as you start peeling back the layers, things come forward that you really don’t expect. However, we have sections our contracts that cover unforeseen circumstances, and we handle those through change orders.”

The Kohle family were calling for a more open and updated interior for the living spaces. However, that meant first investigating the state of the underpinnings to see what the building was capable of supporting. “The foundation walls were in poor shape,” said Whittaker. “It was the old farm setup where forms were filled with the rocks and large boulders found when excavating the basement, and then mixed in with concrete.”

Some of the concrete had softened,

particularly around windows, due to water ingress. New 2x8 pressure-treated frost walls were designed and installed, resting on 12-inch centres. “We had to install hangers on each stud, top and bottom, to prevent lateral pressure from pushing them into the house if the basement foundation were to ever fail.” New top and bottom plates plus lateral supports were also added.

Above the foundation, the exterior wall structure was in pretty good shape. Typical of older homes, the walls

The wood flooring is laid to emphasize the room’s length and to draw the eye to the original wood stove and brick chimney, features in the open plan living and dining space.

were constructed in 2x4 balloon-frame style, i.e., vertical studs running from foundation to roofline. However, tripleganged 18-inch LVL main floor ceiling beams were needed to correct severe sagging. The only other modification needed was to allow for new larger windows and doors, and to accept the new structural beams. New window trims were installed with efforts made to retain the style of the originals. The interior lathe and plaster walls were stripped completely. But before any drywall was installed, asbestos-based vermiculite insulation had to be removed from the walls and attic.

As part of the dual heritage/ modernization concept, Whittaker explained how spray foam was added throughout the house so that the Kohle’s

plan to heat with wood was practical. “The entire house was spray foamed with the exception of the attic — the vaulted areas there have 5-inches of spray foam, and the flat portions are insulated with blown-in insulation. The walls were filled with roughly 4-inches of foam. The 2x8 basement frost walls were filled with about 4 to 5-inches of foam.”

The original plumbing and electrical services were removed and replaced in order to be code-compliant. All lights are now LED, including many re-wired original fixtures. The main staircase to the second floor was refinished, and all original interior doors, hardware and heating grills were saved and restored. The result is an open concept on both floors with plenty of 1930’s charm and warmth retained.

Two years earlier and prior to Aquarian’s involvement, a new replacement stucco exterior had been applied on top of rigid foam insulation, establishing important thermal breaks. The color of the exterior has changed, and of course the trees have matured over the past 85 years. Most importantly, however, the farmhouse has the authentic appearance, combined with the energyefficiency gains and openness that Steven Kohle was seeking.

Marie Soprovich is very proud of what Whittaker and his fellow Aquarians achieved throughout the six-month project. “It's an amazing team of people in this company,” she said. “They make jobs like this super fun. It's also great working with clients who have vision and ideas of the possibilities. It's a joy!” cc

By Steve Maxwell

Mostof the sane and successful contractors I know have one thing in common. They take craftsmanship seriously. Craftsmanship is the extent to which a person aims towards perfection in any venture involving hands-on workmanship. It’s a product of skill, knowledge, experience and effort, and while craftsmanship pays off for the client, it also seems to pay off for the craftsman. At least that’s what I’ve noticed. Why else would the most satisfied contractors I see all pursue craftsmanship seriously? Why is it that the failing, frazzled and frustrated contractors I see seem to have no idea what craftsmanship is and where the impulse to aim for it comes from?

The craftsmanship I’m talking about here – the kind that sustains the craftsman on the inside – is possible given any budget and any time constraints. It’s not about having the best materials to work with, an open-ended schedule nor an amazing client. These things are usually out of your control as a contractor and hardly ever happen in the real world anyway. You can’t count on them. No, in my experience, the craftsmanship that sustains comes from a belief that human beings were made for a better world than we find ourselves in. We’re not just an accidental collection of molecules on a ball of rock hurtling through space. There is such a thing as absolute right and wrong, and there is such a thing as good work and bad work.

When I build things with craftsmanship in mind, I’m aiming to bring one tiny part of the world I’m in charge of into better alignment with the perfect world of beauty and permanence. In 30 years of working professionally with my hands, I’ve found nothing more inwardly sustaining than this one goal – to work towards the kind of world I wish I lived in. If all this sounds wispy and sensitive, I agree. But isn’t it also true that many times in life it’s the little things that

door on your truck and sit for a minute while the engine warms before you head home, you can take pride and satisfaction knowing that the work you did that day is as good as you could make it.

In one way every craftsmanship decision you make will be unique because no two building circumstances are exactly alike. But in another way, every craftsmanship decision is the same because they all come down to the same choice: “Will I do what’s easier here and

THE CRAFTSMANSHIP I’M TALKING ABOUT HERE IS POSSIBLE GIVEN ANY BUDGET AND ANY TIME CONSTRAINTS.”

matter most – especially the little things in your mind and heart? These are the places where the battle for joy and sanity are won or lost. Sure, you’ve got jobs to complete and deadlines to meet. You often have to struggle with bad situations, challenging clients and marginal labour. Subs can be difficult to deal with and Canadian winters don’t make any of this easier. Cash doesn’t always flow as quickly as it should, and the government red tape machine is spewing out business-killing directives full blast. All the more reason to aim for excellence to the extent that your circumstances allow it. Don’t do it primarily for the client (as much as they’ll appreciate it), do it for yourself. When you walk away from the tools at the end of the day, close the

now, or what moves this project a little closer to the ideal of beauty, durability and efficiency?” The reason your answer to this question matters is because it takes more than profits to be a good and balanced contractor. Money and success are vital, but sustained success and inner satisfaction as a contractor takes something else, too. I believe it takes a craftsman’s heart. If you have no idea what I’m talking about here, then perhaps you should find another line of work. Working as a contractor without some inner drive to do good work is a miserable way to make a living. And when I look around and see contractors that are financially successful, in high demand and deep-down happy, I see people who pursue the craftsmanship that sustains. cc

Five building strategies that combat musty basements and bad indoor air

By Steve Maxwell

a finished basement I know that’s both typical and dangerous. It’s in a small town recreational building near where I live in rural Canada, and this basement hosts a number of different groups and functions year round. Other than the very slight musty smell of the place, I didn’t think much about indoor air quality in this basement until something happened to my son.

Within minutes of walking downstairs after several weeks of hot and humid summer weather, his eyes began running, he became congested, his throat itched and so did his ears. No amount of kleenex could keep up. I’d always been fine in this place, as I was that day, but as word got around in the crowd about my son’s sudden allergy symptoms, half a dozen people piped up.

“That always happens when I come down here.”

“My throat tightens every time I walk down those stairs.”

“Coming into this basement always makes my hay fever worse.”

This basement has always been visibly dry, it’s bright and it looks good. The only outward sign that something is wrong is that faint musty odour. The thing is, basement mustiness is always just the tip of the iceberg. It invariably means there’s some kind of

hidden mold growth somewhere – enough to send signals to your nose – and it’s happening in many finished Canadian residential basements because of the way they’re built. The crazy thing is, basements are still being finished today in ways that virtually guarantee hidden mold growth and poor indoor air quality over time. By finishing basements following the five mold-busting strategies you’ll get here you’ll minimize the chance of mold growth and boost indoor air quality.

No matter how well you follow the other four strategies, mold will always win in the presence of sufficient moisture. That’s why you must never finish a basement space that’s anything less than 100 per cent dry, 100 per cent of the time. This is obvious to you, but not necessarily to your clients. In fact, it’s not just liquid moisture that will ruin a basement and air

quality, but invisible moisture vapour, too. You can have a basement that has looked dry for decades, yet you can still have a moisture problem. How do you know? Polyethylene vapour barrier plastic is your best detection tool.

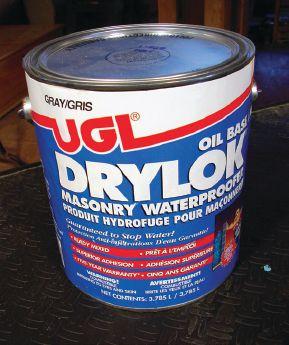

Cut 24” x 24” pieces of polyethylene vapour barrier, then tape them to the walls and concrete floor in several places. Leave them for a few days, and look for moisture building up on the inside face. What you see under the plastic is what will happen inside any walls you put up. If you do see droplets of moisture (and it’s not unusual), show your client, then remove the plastic, paint the bare masonry with a waterproof paint such as Drylok or Xypex, then test again. Only when a basement passes all moisture tests can it be safely finished.

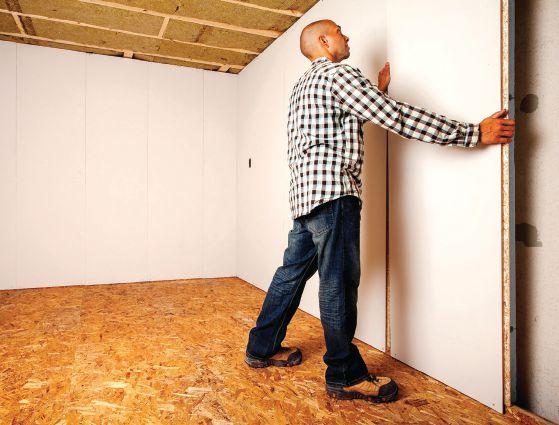

When it comes to basements (and many other areas of life), designing things with multiple layers of safety is always the best idea. If your basement really was 100 per cent dry, 100 per cent of the time, then there’d be no danger using wood or paperbased drywall for finishing. But what if 100 per cent dry actually turns out to be only 95 per cent of the time? A little bit of moisture can feed a lot of mold, but it has a harder time growing without organic matter to feed on. That’s why it makes sense to keep wood and paper building materials out of the basement, or at least well away from potentially moist masonry surfaces. This is where the still-common practice of using wooden wall studs in basements is especially foolish. Better to use metal studs or no studs at all. A growing number of foam-based, stud-free building materials for basements go a long way to eliminating organics in hidden places.

Moisture can invade a basement from two directions. It can travel in through masonry basement walls and floors in the form of liquid or vapour, but it can also come from humid outdoor air coming inside the basement. If this air is allowed to make it’s way into wall cavities, it can cause droplets of water to appear out of nowhere within the wall itself. Hidden mold is then guaranteed. What does this have to do with basement insulation? Quite a bit. All insulation products can be roughly divided into two groups: insulation that air can move through such as batts and loose fill; and insulation that air can’t move through such as rigid, high-permeability foam. The best basement insulation doesn’t allow air to move through it at all, nor does it absorb moisture in the event of a liquid leak. This is why stud-free, non-organic basement wall systems have a big advantage over studs.

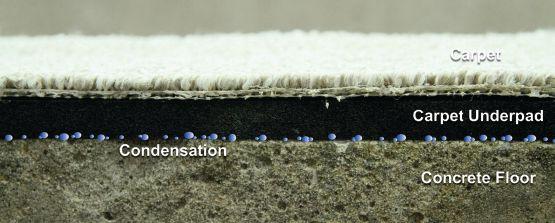

None of your clients like to walk on a hard concrete basement floor, and that’s why installing carpet and underlay are such popular basement strategies. Trouble is, they can also be very powerful mold breeding grounds, especially during hot, humid

Impervious insulation is always an excellent idea for basement walls, but it’s absolutely essential where the floor joists of the level above meets outside walls along the edges of a basement ceiling. Most Canadian homes have fiber-based insulation in this place, partially covered by a feeble and pointless layer of polyethylene vapour barrier. But this barrier can never work because it can’t be properly sealed around all those joists. This is why the only mold-resistant way to seal and insulate the rim joist area in your basement is with spray foam. You need at least 3” there to prevent hidden condensation.

summer weather. If warm, outside air is allowed to make it’s way into the basement, it will settle on the floor and sneak into the carpet and underlay. Since the concrete floor underneath is always cool, it will cool down the air to the point where it can’t hold all the water it used to at higher temperatures. The result is tiny droplets of condensed water forming within the pile of the carpet and the underlay. Mold loves to grow in conditions like these, and in time the carpet may smell like a wet dog. There’s nothing wrong with installing carpet and underlay on a basement floor, but only do it on top of a raised subfloor. This eliminates any chance that warm, humid air reaches the cool concrete. A non-organic interface between the subfloor and concrete floor is essential.

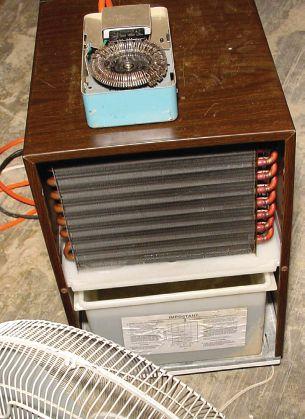

If your client believes that ventilation is the best cure for basement dampness and moisture problems, you’ve got some

Working on an old, previously-finished basement you’re refinishing? It’s virtually guaranteed that mold will be revealed when you tear into those old walls and floors. Follow these six mold-safe demolition features and you’ll stay safe and eliminate mold spores that could otherwise grow back:

1. Seal off the basement from the rest of the house before demolition begins.

2. Buy and wear a HEPA-rated respirator before you begin demolition work. You don’t know when you’ll encounter mold before you find it.

3. Remove all building material back to foundation walls and move gutted material out from the basement to the outdoors as soon as it comes off, going right into the dumpster.

4. Allow two weeks for the bare basement to dry out before you

education to do. Ventilation can actually be a source of damaging levels of basement moisture during some seasons. When it’s warm and humid outside, outdoor air transports moisture inside. As this outdoor air cools in the basement, it can’t hold as much moisture as it did. It’s not unusual for outdoor air at, say, 75 per cent relative humidity to skyrocket to 90 per cent or even 100 per cent relative humidity when it cools in a basement. Go ahead and open basement windows when outdoor temperatures are cooler than basement temperatures. That’s a good idea and will lower basement humidity levels in most cases. Just never open basement windows when it’s warmer outside than it is inside. The only way to lower basement humidity levels under these conditions is with a dehumidifier or air conditioner running behind closed windows.

If you look at newly-finished basements these days, most violate some or all the mold-busting strategies you’ve learned about here. So don’t let popularity guide you in the details of how you finish basements. What’s commonly done today will be considered completely inadequate tomorrow. After all, people get tired of grabbing a box of kleenex every time they go downstairs. cc

rebuild walls or floors. Ventilate well if outdoor temps are lower than basement temperature. Use a dehumidifier if it’s warmer outside than it is inside.

5. Use basement drying time to inspect for existing mold. Kill it with a registered, non-toxic fungicide.

6. Use a fogger or spray equipment to get mold control products into all infested areas.

I’m not sure how many work boots I’ve worn out in my life so far, but the boots I have on my feet these days are the best I’ve worn. Comfortable, light weight, easy to put on and take off, after using them for a month I can’t fault these boots in any way. Normally I’m not a fan of products that ride the coat-tails of already-famous brands, but I’ll forgive the CAT branding in this case. The more I wear these things the more I like them. Besides comfort, there are two things that work on a design level. First, this style is high enough to provide protection, but not so high as to be a pain. After all I’m not working around poisonous snakes. Second (and this is especially handy), the top two pairs of eyelets are actually hooks, not holes. This lets you open up the boot fully and easily and is the biggest reason you can simply slip these things on and off