Small Business

Tax Changes

What Contractors Need to Know Page 8

Yukon House

Photo Essay

Creative Eye

Flies North Page 22

Small Business

Tax Changes

What Contractors Need to Know Page 8

Yukon House

Photo Essay

Creative Eye

Flies North Page 22

How tools editor Steve Maxwell built his own limestone farmhouse on Manitoulin Island Page 12

Special Insert

Kitchen and Bath

Ideas, Products and Techniques

Centrespread

Show Us Your Deck! 10

You could win a year’s supply of incredible wood screws from GRK Fasteners if you enter this ‘Show Us Your Deck’ contest. A sneak peek at some of the early entries.

Our tools editor Steve Maxwell had a dream about living in a stone house amid natural beauty. So with $200 in his pocket, at the age of 22, he pitched a tent on Manitoulin Island, Ontario… and started gathering rocks.

Homebuilding in the Yukon 22 Residential building in the Yukon presents challenges. We look at some of them in this ultramodern new build near Whitehorse.

Editor

spayne@canadiancontractor.ca

By Steve Payne

At a time when the general public was least engaged with the political news coming out of Ottawa, deep in mid-summer, Finance Minister Bill Morneau's department announced that it was about to introduce small business tax "reform." A 75-day consultation period would follow.

Labelling their real targets as "tax cheats," the Liberals were proposing a major rewriting of the tax rules for professional corporations. There were four major parts to their plan. One, the distribution of income to family members, as a method of sheltering profits from the taxman, would be severely curtailed. Two, businesses that attempted to shelter profits by making investments in, say real estate or equities, within the company structure, would see that behaviour punished as well. Entrepreneurs who attempted to issue dividends to convert business income to lower-taxed capital gains income would find that method severely taxed. And finally, the "enhanced capital gains deduction" that was designed to help families pass their businesses onto the next generation - especially important to farmers - would be under the Liberals' axe.

The negative reaction to all of this from contractors was predictable. During the 75-day consultation period, our industry was well-represented by the folks at the Canadian Federation of Independent Business (CFIB) and the major contractor associations. Rocked by the negative publicity, Morneau's bureaucrats have already backtracked on some of their originally-announced intentions. But until we see the final legislation, it's important for contractors to remain vigilant - and vocal.

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Steve Maxwell

Art Director Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

ISSN 1498-8941 (Print) ISSN 1929-6495 (Online)

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Ted Markle, Chief Operating Officer tmarkle@annexweb.com

Mike Fredericks, President & CEO

Circulation email: lmalicdem@annexbusinessmedia.com Tel: 416-442-5600 ext 3547

Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription

Annex

Bob Collins

Home Building Centre – Gravenhurst Gravenhurst, ON

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Experts at Home Building Centre and Home Hardware Building Centre to provide the tools, materials and services you depend on – from dedicated contractor sales staff and easier ordering through phone, fax or email to job site deliveries, credit services and package pricing. With a relationship built on trust, you know you’re building on a strong foundation.

pronews.ca

On Oct. 26, the City of Hamilton (Ontario) announced the sentencing of Mr. Jason Dennis, “an individual with a lengthy history of operating as an unlicensed roofing contractor in Hamilton.” Dennis was given ten days in jail and two years’ probation for breaching his previous probation for working as a contractor without a license. It was his eighth licensing offence. This particular conviction stemmed from an incident with a Hamilton homeowner who hired Dennis in 2013. “The roof was replaced; however, there were significant deficiencies and the homeowner was required to re-do the roof with a licenced contractor, effectively paying twice,” the city reported. “In addition, Mr. Dennis failed to complete other work agreed to in the contract.” The judge in the case could have been more severe, the city said: “Due to Mr. Dennis’ lengthy history of licensing offences with the City of Hamilton, City prosecutors requested 30 days in jail at the sentence hearing – the maximum that would have been permitted under the legislation.”

Here are some posts from our online readers.

“Glad to see”

I am glad to see those pirates and charlatans brought to account. It is difficult enough for us legitimate professionals to operate our businesses and make an honest living without being smeared by these rotten eggs.

Noel Murphy

“Where was the restitution?”

Ridiculous. Obviously he should have had to pay his clients restitution, at the very least. As a roofing contractor this is my clients’ worst nightmare. The cost of taking care of their homes is already high, without having to get it done twice. So why not hold him financially responsible, also?

Roberta

“Likely a man with few options”

As much as any decent professional would view this as appalling behaviour, it should be understood that this person needs to make a living the same as anyone else. While his skill and ethical approach are not acceptable, it’s not as if he can resort to factory work any longer as we are outsourcing or automating these jobs more and more every day.

The people Mr. Dennis has harmed in doing bad work are likely the same people who have chosen cheaply made foreign goods; and who hire the cheapest bid for any work they are

unable or unwilling to do themselves.

Mr. Dennis is likely a man with few options. Until Canadians realize that a domestic economy is a fully integrated system, the Mr. Dennises of this country will continue burning people out of necessity.

As much as I disagree with the approach, I must admire the persistence of the Mr. Dennises, who seem to be deterred by nothing.

Chris Langman

Many contractors across Canada are as outraged about the Federal Liberals’ small business tax reform as are doctors, accountants, architects, farmers and other small business operators. Self-incorporated individuals in these and other professions would see their taxes go up substantially if Ottawa closes off widely used and currently legal method of sheltering tax within private corporations. Following a consultation period in Ottawa, Federal Finance Minister Bill Morneau took a hammering in the daily media regarding his own family fortune inherited from his family's benefits consulting firm and his own family trust. The Liberals branding small businesspeople as tax cheats didn't help, either. While the proposals are now being watered down, we received dozens of posts from our readers, including this one...

As a small business owner I wish to express my outrage on this attack on small businesses. I will give you an example of how my company would have been affected if these proposed new rules were in place 11 years ago. At that time we purchased two small companies using retained earnings accumulated over many years. We had decided to add to our company because at that time we had one client representing 80 per cent of our business. If that client had left we would have been out of business.

As it happened, the 2007 recession came about right after we made the purchase. It did significant damage to our company and then, in 2011, that large customer did leave us. If we had not purchased those companies with those retained earnings all those years ago we would have gone out of business for sure.

Today we have approximately 25 employees and business is always difficult. But if this attack on small business had occurred all those years ago – and we were not allowed to use those retained earnings that we had accumulated over the years – we would not be here today.

Brian Barney

FederalFinance Minister Bill Morneau

has faced a lot of fury from Canadian small business owners over the past three months, as Justin Trudeau’s government conducted consultations with affected groups on pending legislation to “reform” (translation: increase) taxes paid by selfincorporated small businesses.

Opponents of the plan to reduce the ways in which small businesses can shelter their profits from taxes include renovation contractors and custom homebuilders, farmers, doctors, architects, accountants and other individuals who work for themselves.

While the draft legislation is not yet complete, Morneau’s department has revealed its plans to remove tax-sheltering methods commonly used by Canadian small businesses in at least four areas. They are:

Income Sprinkling. The government wants to effectively increase small business taxes by curtail the practice of attributing income to family members who may or may not actually work in the business.

Passive Investments. The government wants to wring more taxes out of

businesses which decide to use profits for other investments – possibly unrelated to the main business – within the company structure.

The government wants to stop companies from converting profits to capital gains, via dividends, and therefore paying the lower capital gains rate on profits instead of the higher corporate business tax.

Enhanced Capital Gains Deduction (ECGD). The government said it would attack the ECGD, which has been historically important for businesses –especially farms – to be passed onto the next generation.

Associations and business groups made presentations to the Finance Department about these announced plans before public hearings ended at the beginning of October. Opposition to Morneau’s plan from our industry was led by the Coalition for Small Business Tax Fairness, which

included the Canadian Home Builders’ Association, the Canadian Construction Association, the Mechanical Contractors Association of Canada and the Canadian Institute of Plumbing & Heating.

Morneau’s plans were heavily criticized by many commentators as being severely punitive to Canadians who have to run all of the risks of owning small businesses while enjoying few of the benefits of being an employee, such as pensions, paid sick and vacation days, consistent and predictable income, employment insurance, etc. Tax sheltering methods are a way for professional corporations to mitigate their much higher risks, critics said.

Following the pushback in the media from vocal critics – as well as personal criticism aimed at Finance Minister Morneau for his own personal use of tax shelters related to his inherited family business – the government has begun to water down some of these planned tax measures. The Liberals have also announced a cut to the federal small business tax rate from its current 10.5 per cent to 10 per cent in January, followed by a further cut to 9 per cent in 2019.

THE WORDING OF THE FINAL LEGISLATION REMAINS TO BE SEEN

“Hooked for Life”

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole”. So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer.

Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips & screws. You just screw it to the wall and it’s “Hooked for Life”.

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

No matter what the building structure, DuPont™ Tyvek® Building Envelope Solutions offer an ideal balance of properties to help effectively seal the building envelope. Tyvek® building products provide a wide selection of air, water and thermal management options for helping to protect single family homes, commercial structures and multi-family buildings ranging from duplexes to high-rise apartments. With more than 35 years of experience working with architects, builders, engineers and installers, the DuPont™ Tyvek® team of specialists and certified installers is committed to working with you to protect your next generation of construction projects.

Tough. Tested. Proven. | That’s DuPont™ Tyvek® Building Envelope Solutions. construction.tyvek.ca

There is still time to enter the GRK Fasteners deck contest. Here are some of our finalists. Enter now to possibly win a one year supply of GRK Fasteners!

Dexeco Construction Ltd., Estevan, Saskatchewan

“I used GRK Fastners for everything on this deck, from attaching the deck posts to the concrete piles, to the ledger board attachment to the house, the composite fascia boards, rim boards and even the railing posts.”

- Dexter Cote

Renovation to Perfection Lanark, Ontario

“This deck is all cedar with my custom railing design, using an invisible fastening system on the deck boards. All the screws and nails are stainless steel. I used GRK stainless stell #8 x 2” trim screws on the steps, border boards and railing. My client is very happy with the result”

-Martin Lavoska

All you have to do is go to canadiancontractor.ca, type in “Deck Contest” in the search bar, and follow the instructions. You will see the link to send us some pics of the deck you want to enter (it must be built using GRK fasteners somewhere in the project) and why you think it should win.

Winner will receive a ONE YEAR SUPPLY of GRK Fasteners! Contest closes for entries on Dec. 22, 2017!

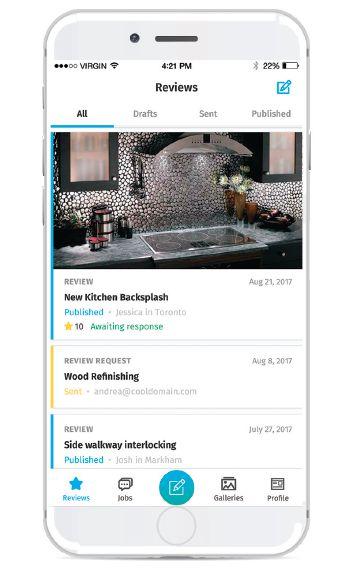

Here are some tricks of the trade to help you reach more homeowners on HomeStars.

Build your brand

Today your best business card is your HomeStars profile page. It features your skills, photos and reviews

Add reviews

Homeowners look for reviews when searching on HomeStars. Adding reviews to your page builds your reputation and customer loyalty.

Get found online

Homeowners are always searching for your skills. On HomeStars you can be seen by more qualified leads.

Be with the best

HomeStars is the go-to home repair and renovation site in Canada. With 600,000 qualified homeowners visiting every month making 50,000 service requests per month, this is the place to grow your business.

HomeStars is ready to work for you.

Get started today with HomeStars and connect with qualified homeowners looking to hire service professionals.

Do business anywhere

Through HomeStars you can close jobs, respond to reviews and ultimately build your brand while on the go.

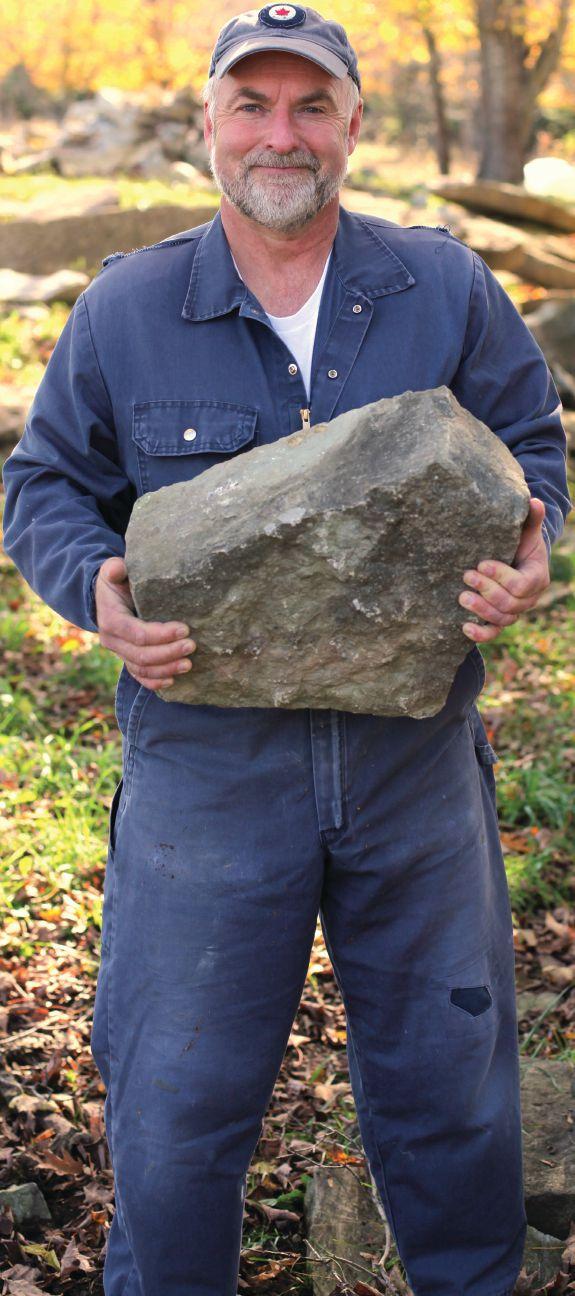

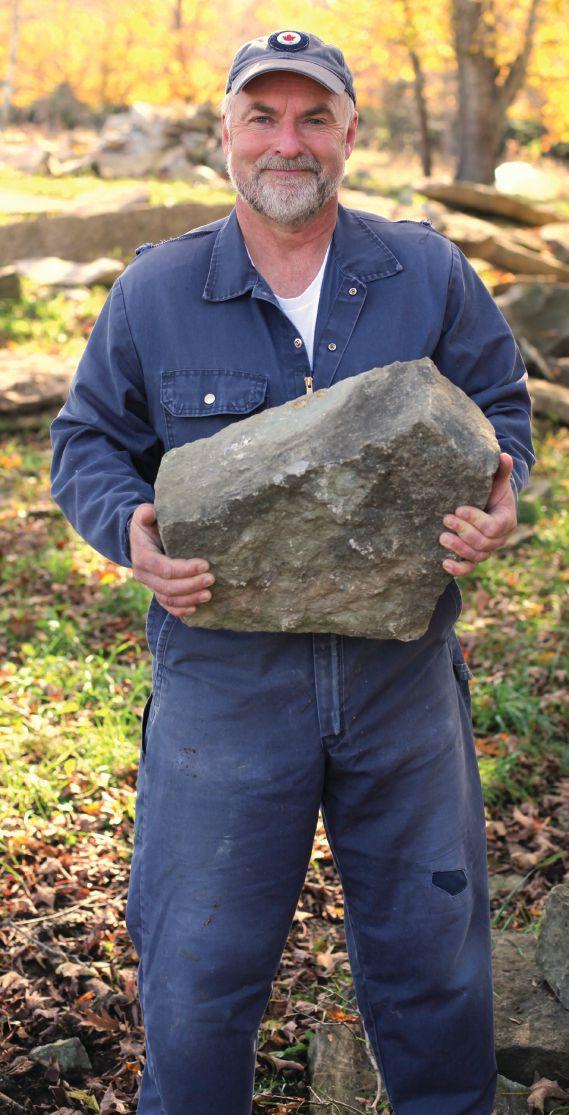

30 years ago, while many of his big city classmates were taking jobs with prestigious corporations, our tools editor Steve Maxwell, then 22, bought a chunk of wild farmland on Manitoulin Island and lived out of a tent. He wanted to build a stone house and raise a family there. Here’s how he made his dream come true.

Steve Maxwell has been Canadian Contractor tools editor since 2002, but he does more than just test tools and write about them from his shop on Manitoulin Island, Ontario. Steve is also a carpenter, cabinetmaker and stonemason

with an audience of a million people in print and online. Back in 1986, Steve moved from the suburbs of Toronto to a 90-acre piece of farmland and forest in a quiet corner of Ontario. He and his wife, Mary, are now at the tail end of raising five kids in the stone house they built themselves on their Manitoulin homestead. Normally

the journalist asking the questions in our pages, Steve agreed to be on the other side of the interview this time and tell us about his homesteading experiences.

Steve, you’ve recently started writing about your homesteading journey on Manitoulin Island (see excerpt from

Steve’s Bailey Line Road Chronicles, page 18). At first, you were tempted to give up?

For Mary and I, buying that 90-acre piece of Manitoulin Island was a dream that came true after four years of searching across Ontario for the right area that was also inexpensive. But after investing all my money on this piece of land, the enormity of the project ahead of me discouraged me like nothing else had before or since. This was an emotional thing, but emotions are often deceiving. There were two things that kept me going in the beginning. First, I kept reminding myself that from a logical point of view, it was a good idea. Just because I was cold and lonely and poor didn’t mean my initial idea was bad. I needed some place to live, and it might as well be a big and beautiful place. The second thing that kept me going was the most powerful. I shortened my mental timeline. Instead of thinking of the years of work ahead of me, I shortened my area of focus to just one day: “What do I need to do to make the best use of this one day?” I wouldn’t let myself think beyond this short perspective.

A few weeks of “one-day living” during my first summer on Manitoulin helped kill the monster of despair.

You actually started your dream house by gathering rocks from your property. Yet the only experience you’d had in stone building was from books?

I had a vivid dream once when I was about 10 years old. I dreamed I was building something from stone using mortar and a trowel. This was a strange dream since I’d never seen anyone working with stone in my life. At the time I didn’t even know people did that sort of thing. A few years later I remember finding an old cold chisel and hammer. I used it to break stones and old bricks and concrete blocks – anything masonry I could find. Looking back now I must have been a pretty weird kid to amuse myself for hours breaking stone and shaping it. The thing that got me going with serious stonework was a book my dad gave me for Christmas 1985. Manitoulin is a limestone island and he gave me the book the first Christmas after I bought my

ALL I EVER WANTED WAS TO ENJOY GOOD WORK ON MY OWN TERMS, ON MY OWN PIECE OF LAND.

Tackle Framing, Flooring and Finishing jobs both large and small with the features of a pneumatic tool and the convenience of cordless. Our compact and lightweight cordless nailers & staplers offer features like tool-free depth adjustment and micro nose for precision nail placement. Brushless motor technology and advanced Lithium-Ion battery packs give you maximum runtime. Cordless Confidence - Guaranteed Tough.

property. It got me started, but only in the most basic of ways. I struggled for many years since traditional stone working is almost a completely dead trade. You can’t buy the tools easily and there’s almost no one that knows how to do it. The learning curve is very long.

In my case, building with stone started by collecting stone on and around my property. I’d drive my old tractor and wagon onto an area of flat bedrock, then gather whatever rock looked good for building. Trouble was, I didn’t know what a good building stone looked like at first. I spent one summer gathering rocks like this by hand – probably 100 tons or so –only to discover that almost none of them were useful for building. It was a complete waste of time, but I still wanted to work with stone. I have ancestors who were stonemasons, so that must be part of it. Some things run deep.

The internet has changed everything. You used to write about home improvements for big newspapers like the Toronto Star, National Post and Ottawa Citizen. Now you reach a million people on the internet.

In addition to building, I love to teach through writing, photos and video. I started this work in 1988 by reaching out to the editor of Canadian Workshop magazine. She gave me the go-ahead to write my first article, and things evolved from there. The internet has taken a lot of money out of the print publishing industry over the last 10 years, but this same change has also allowed me to connect with my audience directly online. I still have a print audience, but more and more I’m acting as my own publisher creating articles, video courses, and stories for an online audience. My online audience

generates about 500,000 page views per month in all venues and my newsletter subscriber list has doubled in the last year. I’m thankful that people find my content worthwhile.

Your technical videos are, in fact, a family production, we hear?

My wife, Mary, and I have five children, and our oldest has decided to make his home on our property here on Manitoulin Island in a house we built together. I’ve taught Robert everything I know about earning money remotely on the internet, and this includes videos we make together. Right now we’re working on a series of training videos for technicians who repair barbecues, as well as videos for online courses I create and sell to my audience. We also work together on building projects as they come up.

Thirty-one years ago, Steve Maxwell moved from the suburbs of Toronto to a 90-acre piece of farmland and forest on Manitoulin Island, Ontario. He was 22 and lived in a tent, dreaming of building a homestead and raising a family there. After many years of satisfying toil, Steve and his wife Mary fulfilled that vision, raising five children in the stone-built farmhouse they made from local materials, pried out of the earth and shaped by hand. Steve is writing about all this and more in his book: The Bailey Line Road Chronicles. We have excerpted one chapter here. To read more please visit baileylineroad.com/blr-chronicles.

Aspirations can be strange things. That’s because when you begin to experience the reality of what you’ve been dreaming of, it’s often quite different from what you imagined. And this difference

– the difference between theory and practice – can be discouraging and scary if you don’t expect it.

The biggest theorymeets-practice event of my life so far happened on May 16, 1986. That was the day I woke up alone in a tent on Manitoulin Island, 500 km from my boyhood home. I was a homesick 22 year-old with only a few hundred dollars in the bank. I also happened to be completely drowning in regret of the worst

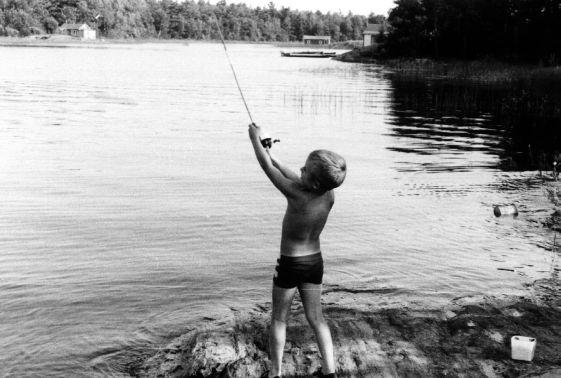

Steve’s great uncle Ken Evans during his years as a Georgian Bay lighthouse keeper

kind – the regret that used to be enthusiasm. All I could think of as I woke up in my tent on that bright morning in May was that I’d made a massive mistake. I’d blown all my money on a foolish dream and a useless piece of land in the middle of nowhere.

I grew up in the suburbs of Toronto in the 1960s and 70s, but I never was a city guy. The lack of natural beauty always left me empty. I’m sure my attraction to the country and addiction to beauty also had something to do with fond memories I’d gained at the family cottage on the shores of Georgian Bay. It was a log place built in 1923 by a bachelor great uncle of mine named Ken Evans.

Uncle Ken came back from the First World War looking for a quiet place to live, and found it on four acres along the water in a spot called Pointe-au-Baril, Ontario. He was freshly returned from the horrors of Paschendale, Ypres and the Dardanelles. He had experienced poison gas, a shrapnel wound and crawling over the decaying bodies of German soldiers as his company advanced through the mud. He came home completely opposed to killing, never ate meat again and wouldn't even kill mosquitoes. Uncle Ken died eight years before I was born in 1963, but his cabin dream somehow settled into my soul anyway.

For a city boy, Uncle Ken’s cottage was magic of a most powerful kind. Fishing whenever I wanted; unsupervised use of a Red Ryder BB gun that was my dad’s when he was a boy; a woodshed full of Uncle Ken’s tools; and nothing to think about all summer long except bacon and eggs in the morning, swimming

I IMMEDIATELY THREW MYSELF INTO WASTE-OF-TIME, NONPRIORITY FOLLIES

I’D BLOWN ALL MY MONEY ON A FOOLISH DREAM AND A USELESS PIECE OF LAND.”

and fishing all day, with fairly regular roast beef dinners at night. It was a magic land and I wanted to return. I wanted to build a place like Uncle Ken.

The weather was bright on that first morning on Manitoulin. The air had an intoxicating smell I’ve only ever found during the island’s spring, bluebirds and loons and deer were all around me, yet it all seemed so insane. I was a young idiot and I’d thrown my life away, dragging my girlfriend, Mary, into the folly. While our city friends were taking swanky overseas trips for their new careers, I’d just spent all my savings and then some on a chunk of property in the middle of nowhere, without any buildings, no water well, and nothing but tumbledown fences and forest surrounding me.

I immediately threw myself into waste-of-time, non-priority follies on the land. They included: trying to break heavy sod and start a garden with nothing more than a shovel and seed packages, even though I had nothing resembling a proper shelter to live in; attempting to resurrect a fleet of 60 year old discarded farm machinery in preparation for my life doing some unidentified but profitable agricultural pursuit; trying to save money by digging a basement hole for a 34’ x 44’ foundation for the home I’d build in hard clay soil using nothing more than a shovel; fixing tumbled-down pasture fences when the only animal I owned was an ill-tempered golden retriever named King. I wasn’t getting much accomplished and I was almost completely broke.

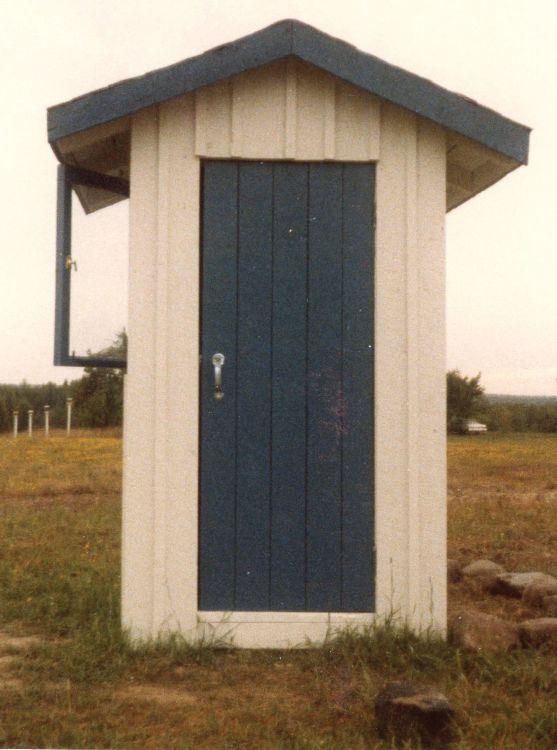

Most of the insights in my life happen in a moment, and a heavy thunderstorm one night triggered an insight that snapped me out of my treadmill of misdirected work. As I made my way in the deluge from my tent to the poplar log that passed for a latrine seat I’d set up over a crack in the limestone bedrock, I knew what I really needed. There I was, sitting on a log with my pants down, in complete darkness while a torrential downpour soaked me to the skin…

“Tomorrow I’ll start to build an outhouse,” I vowed. It was the first sensible thing I’d done since arriving on the property some months earlier, but in true greenhorn fashion, I built it in an especially difficult way. I had the conviction that I should build it with reclaimed lumber. I consulted my new neighbour, a spry 76-year old local icon named Ivan, if he knew where I could find any.

“Ches Bailey over on the Blind Line has a pile of old lumber in one of his pastures,” Ivan told me. “It’s cedar, but full of nails.” Ches lived about 5 miles away and was apparently Ivan’s cousin (as most people in the township seemed to be). Ivan grabbed the receiver of his rotary dial, party line telephone and about an hour later Mary and I were knocking on the door of the Baileys.

Ches and his wife Floris lived in the tiniest house I’ve ever seen. It looked like an over-grown playhouse – about 40 per cent smaller than a typical house. They were in the middle of a meal of boiled potatoes and wieners when we arrived.

“Would you like some?” Floris asked through her thick glasses. She’d never met me before, but that’s the kind of hospitality I’d see again and again on Manitoulin. “No thank you, we just ate. But you go ahead and finish.”

Mary and I sat there watching this sweet couple in their 70s quietly eating hot dog wieners without buns, boiled potatoes and sipping mugs of hot water as they probably had every night for 40 years since they got married back in 1946. I’d never seen people sit down and enjoy hot water as a beverage before, but it’s not unusual among the old timers here.There was almost no conversation during dinner, and it seemed quite likely their meals were always like this. It was the kind of situation where you definitely wanted to chew with your mouth closed.

After dinner we ambled out into the pasture to see the pile of old, half-rotten boards that confirmed that Ivan’s rural database of local details had done the job. He had somehow known about and remembered a pile of old lumber sitting in the middle of a run-down pasture, completely out of sight and 300 yards from any road. His description of cedar with lots of old nails was accurate, too. Fifteen dollars lighter in my wallet, we were soon loading a couple of hundred board feet of lumber into the truck to bring this horde of “old gold” back to our property.

It was the kind of wood I’d never build with now because some of it was too old and sections were punky and needed to be cut out and thrown away. But for a frugal, inexperienced guy with $200 in the bank and memories of sitting on a latrine log in the middle of a pitch-black nighttime thunder storm, the prospect of an outhouse made me feel like a king even if it meant working with old wood.

Mary and I started work at 8 am on nail day and it was about 9 pm on a June evening by the time we’d finished de-nailing the last boards. Shadows were getting long and we didn’t have the

energy to light a campfire and cook. The box of crackers and peanut butter we launched into tasted like a Christmas feast. The canteen of well water filled from Ivan’s kitchen sink was as good as a bottle of excellent wine.

Have you ever noticed how satisfaction eludes people, even people who have more material goods and comforts than a king did a hundred years ago? Maybe the reason is because so few people drive themselves to get tired enough, hungry enough and thirsty enough to truly enjoy simple food and drink. Three thousand years ago a wise man named King Solomon got it right:

“There is nothing better for people than to eat and drink, and to find enjoyment in their work. I also perceive that this ability to find enjoyment comes from God.”

As any experienced builder knows, holes in the ground seem simple enough, but they can be tricky. The unlined hole under my outhouse performed perfectly during its first summer, and this success lulled me into a sense of complacency. But arriving back on Manitoulin for a fresh season of work in the

spring of 1987, I was surprised to find my trusty outhouse was now leaning perilously to the side. The clay soil underneath that had been so firm and trustworthy as I dug it out the previous summer was now a soupy porridge of collapsed dirt, spring run-off and “substances” of the kind you’d expect to find in any experienced outhouse hole. The soil was collapsing into the unlined crater, and without intervention the entire outhouse would go down.

I flirted with the hope that the hole might not get bigger, but that was foolish optimism. It might be fine if the summer was dry, but another winter and the outhouse would fall on its side or worse. After unspeakable hours removing the porridge one shovelful at a time (I got it all out, I really did), about 4 feet down I reached the smooth limestone bedrock that I knew would make the perfect foundation for a circular stone structure to keep the soil from collapsing inwards. This structure was the first of about 500 tons of stonework I’d lay over the years.

It was like diving for pearls except in reverse. I’d grab a few rocks and a small bucket of mortar, lower these down into the hole, then dive down with my legs and waist on the wooden floor of the outhouse and the top half of my body below ground level. Ten minutes of working upside down would use up my supply of stone and mortar, then I’d return to the surface for more.

The thing about a young city guy moving to the country is that it attracts the attention of everyone in the area. I was the first person to build anything new on my dead-end road since 1953, so my neighbour Weldon would come around to see what was going on every now and then. On this particular visit, he arrived to find his city neighbor head down in his outhouse hole, legs flailing around up above the ground. Weldon didn’t say anything when I came up for more supplies. Laughing at myself was all I could do to try to persuade this man that the new guy down the road wasn’t a complete lunatic.

To read more of Steve’s Bailey Line Road Chronicles, please go to www.baileylineroad.com/blr-chronicles.

Architect: Kobayashi + Zedda Architects Ltd. (Lauren Holmes NWTAA, Lead Architect)

Contractor: 360 Design Build (Nicolas Rasselet)

By John Bleasby

Building in the Yukon presents obvious climate challenges. ‘Warm season’ lasts only three and half months, from mid-May to early September, with daily highs averaging +14°C, mitigated somewhat by up to 20 hours of daylight. In winter, average highs plunge to -5°C and often reach -23°C at night, combined with less than six hours of daylight. Architects Jack Kobayashi and Antonio Zedda have tackled Yukon’s climate for nearly 20 years, winning numerous awards including the Canada Council’s prestigious Prix de Rome in 2006.

Both men graduated from the University of Manitoba School of Architecture and, finding themselves settled in Whitehorse around the same time, formed a design partnership in the late 1990s. Not long after, they decided to strike out in a unique way. In contrast to builders who incorporate design into their contracting businesses, Kobayshi + Zedda chose to add building to their design practice.

“We found ourselves leading design projects with hardened contractors and very hands-on clients with years of practical experience in the construction industry,” recalls Kobayashi. “By the year 2000, we realized that if we were going to lead the design process in Whitehorse in earnest, we would have to gain experience and respect quickly. The quickest route was to actually work as contractors. Like an independent recording artist, we essentially had to create our own ‘label’ and produce our own buildings.”

Continued on next page

The residence consists of two simple forms that intersect at an angle, clad with a combination of tongue and groove fir, Prodema wood, and metal. The entire upper floor is slightly rotated to capture panoramic mountain views.

The open main living and dining space is spanned with 24’ sloped trusses that range in depth from 3’ 9” to 4’9”.

Exterior insulation under the exterior strapping is 3 inches thick. The home is so well insulated and tight that air intake management is needed to balance the large kitchen fume hood, HRV, clothes dryer and bathroom exhaust to avoid negative pressure developing during heating season.

While the majority of KZA’s buildings are commercial or institutional, the firm undertakes custom residential work from time to time. The Woodland House shown here was, in fact, designed for a previous commercial client. The relationship inspired the home’s most striking feature: massive canopy housing the main living space overhanging a car port below, a design element originally conceived for the client’s car dealership.

Another challenge in the Yukon: topography. The Woodland House site is a very steep, two hectare country residential lot just outside Whitehorse, with significant scatterings of bedrock and boulders below a thin layer of sand, gravel, sand and silt. Burying the power line from the street was painstaking.

Hidden rocks impacting the foundation work resulted in the home’s site location being adjusted twice while still capturing the panoramic mountain views. Even so, the space below the ground floor level remains a 5-ft. heated crawl space, since the bedrock restricted further excavation.

As might be expected in the Yukon, insulation values are high throughout. The underside of the overhanging living space is spray foamed to an R40 level. An ICF foundation wall rises just a few feet above grade, giving way to more traditional 2 x 6 frame construction. The frame walls are insulated with three inches of Roxul on the exterior plus another five and a half inches between the studs, for a total value of R36. The carport floor is an R20 poured concrete slab. Windows throughout are triple glazed, argon-filled, double low-e, mounted in fibreglass frames to an R8 insulation level.

A radiant in-floor heating system using Warmboard under the hardwood floors was chosen for all levels of the three-bedroom, 3,800 square foot home.

A fireplace divides the main living and dining space. East-facing windows allow spectacular views of the distant mountain. Due to relatively low summertime temperatures, no mechanical air cooling system is required.

Kobayashi says that the system’s easy installation made it particularly appealing. “This product provides factory finished OSB deck sheets with a pre-patterned water loop complete with aluminum vapour barrier. That reduced installation time and ensured appropriate coverage of radiant loop.” The heat source is locally-generated electricity, thus meeting the client’s aversion to fossil fuels.

The exterior cladding is a combination of tongue and groove fir, Prodema wood cladding, and metal. “Some of the metal cladding is factory finished. The remainder is Corten corrugated cladding, delivered in a silvered state but which quickly transitions to a rusty finish, a look evoking that of many local, dilapidated mining structures that dot the area,” says Kobayashi.

The 3,680 square foot home features guest bedrooms and bathrooms, a gym, open living and dining space, a kitchen, breakfast nook, office, a library which encircles an acoustically isolated home theatre, and an east-facing master bedroom with a walk-in closet and ensuite.

Designed for framers and other construction professionals looking for a tape measure to withstand the harshest job sites and extreme use, the DEWALT XP Tape Measure features a tougher blade coating, tougher case, and tougher hook connection. The blade features 9" of heavy-duty thermoplastic coating at the beginning of the blade to provide more blade protection and reduce blade breakage near the hook. The 1-¼” wide high-carbon steel blade provides up to 13’ of straighter blade standout for increased reach and efficiency. The impact-resistant PC/ABS and rubber case is engineered to survive drops up to 60 feet. Integrated lock protection guards the lock button when dropped. Built-in lanyard slot offers an additional security option. This tape measure features DEWALT’s toughest hook connection reinforced to reduce blade breakage. The extra-large end hook grabs construction material from all four sides making grabbing objects while taking measurements easy. The reinforced housing on the DEWALT XP Tape Measure also has a newly redesigned screw-less belt clip, making it easy to attach, secure, and remove. Approximate retail price: $46.

By Nancy Peterson

Haveyou ever considered ditching your office? You spend the majority of your time driving from one jobsite to the next, so why not take advantage of modern technology and turn your truck into a mobile office? Odds are, if you own one of 38.6 million mobile devices in Canada and own a business, you are already headed in that direction.

Real estate is expensive, whether you own or rent. Warehousing of materials may be non-negotiable for you, but modern technology is making it easier to manage both staff and inventory from afar. With everyone, including individuals, using cloud technology to store and share content across regional “borders,” it has never been easier (or less expensive) to embrace the power of digital technology. And the best part? Your online activity can be shared across devices, meaning whatever activity you engage in on the jobsite is automatically shared to your laptop, other devices and employees.

How do you do this, you might ask? One word: apps. Apps, or applications, can help you manage everything from time tracking, to payroll, to invoicing, and even managing online reviews using just your smartphone. According to IT World Canada, Canadian mobile app use grew by an average rate of 74 per cent in 2016, far exceeding the global average of 11 per cent. An Intuit survey also showed that more than half (56 per cent) of successful small business owners use up to five different mobile apps regularly to keep their organizations running – and some 19 per cent of respondents were fully reliant on a mobile device to keep operations moving.

This year has been a year of mobile tech innovation in Canada and the emerging digital ecosystem is becoming more accessible than ever before to small and medium-sized business owners.

Tools of the Trade mHelpDesk is a fantastic resource for busy pros. It provides powerful mobile tools designed specifically for field service

professionals, including automated tools for workflow management, scheduling, GPS tracking, staff communications and even payment processing.

Speaking of payments, there are many options now to process mobile payments on the jobsite, including giving your clients the option to pay upon completion of the job with a credit card. Mobile payment companies like Square offer free readers that use the earphone jack in your smartphone to accept credit, and now even debit cards, for a small percentage of the transaction. Other apps, like Inventory Control by WASP Technologies, and time tracking tool, Toggl, can give you a great snapshot of inventory and staffing needs on the fly.

Even managing your online reputation, which in the past involved creating a digital presence for your company online, is now easier than ever.

Did you go to the trouble of developing a website for your company only to find that it doesn’t look great on smaller screens? When potential customers look up your company on their smartphone, make sure that they can read your website, as well as see your job photos and read your reviews.

With the HomeStars for Business app, all you need is your phone to build up your online reputation by requesting reviews from your happy customers right from the jobsite. Plus, you can earn new business by receiving quote requests and managing your branding, exposure, and business leads, all from your smartphone. You can even share your reviews in a unique banner on Facebook and Twitter. The days of “I’ll get to that once I’m back at the office” are slowly becoming a thing of the past!

Getting the most from your business, while leveraging some fantastic new technologies that streamline the online user experience, is the way of the future. You may never look at your office the same way again.

Nancy Peterson is the founder and CEO of HomeStars, an ANGI Homeservices company.

In 1987 I bought the biggest, baddest worm drive circular saw on the planet. It was corded, of course, and until now nothing cordless could touch it for power. The new DSC577 framers’ saw changes that. DEWALT calls this tool a “worm drive style” saw because that’s what it looks like. Although the motor is located next to the blade (with no worm gear drive, just like sidewinders), the look and feel is more like a worm drive because the battery sits between the handle and the blade. It’s one of those saws you can push as fast as you want without noticeably taxing the motor. Like most worm drives, the blade is on the left, just where us right-handers want it. The DCS577 is part of DEWALT’s FLEXVOLT line, so you can use this saw’s 60 volt battery in tools made for both 60V and 20V tools. The 9.0 amp-hour pack I used during my tests gives the tool a ton of working life spinning a standard 7 1/4” blade. The magnesium shoe swivels effortlessly for bevel angle and depth of cut, and the blade guard moves out of the way more easily on its own than I’ve seen on other saws, even for 45º cuts. The wide-mouthed rafter hook is another reason this saw is easy to like. Canadian street price is approx. $529 with charger and 9.0 amp hour battery; approx. $329 bare tool.

This isn’t a new product but you’ve probably never used it the way I most often do. I’ve found no better option for reviving the look of previously stained and sealed woodwork that’s worn and scratch. Imagine you’re doing a renovation and the client can’t afford new cabinets or trim. You’ll be a genius to them when they see how much nicer and newer their old woodwork looks after you colour the damage areas with a coat or two of Polyshades. The difference is dramatic and it doesn’t take long. Besides being a stain, it’s thick enough that you can control how much colouring happens on damaged areas. Daub some on with a brush, then wipe it off more or less vigorously with a rag. If you can’t find a perfect colour match, go for a version of Polyshades that’s slightly darker than the original stain. Don’t worry about keeping it off surrounding areas that still have a layer of urethane or lacquer. It’ll wipe right off while soaking into bare wood. Polyshades is supposed to act as it’s own sealer, but it doesn’t create much of a protective surface film. If the budget allows, go over the whole area with a fresh coat of urethane and the results will look great.

Phil

Wilmer decided to close his custom staircase and railing business.

Long-time millworker Pat Roulstone was given one week’s notice, and a verbal explanation. “I’m plain tired, Patty,” Wilmer said. “I want to retire and relax.” Wilmer offered Roulstone no promises of severance pay after his 17 years’ service. “I’ll be selling off my machines and stuff. I’ll see what I can give you then.”

Roulstone was devastated. He had a family to feed. Luckily, after four stressful weeks, Roulstone found work with a large kitchen cabinet manufacturer in a nearby town. They were delighted to have such an experienced man working with them. Three weeks in, his new boss – the owner of the firm – came up and told him he’d just hired a new shop supervisor for that part of the floor.

It was Phil Wilmer!

Wilmer, grinning from ear to ear, slapped Roulstone on the back. He seemed to think it was amusing: “Hey, Patty! Just like old times, eh?”

Pat Roulstone is understandably furious that the former employer who left him high and dry is now his new supervisor. He is having trouble controlling his emotions.

What should Pat do now? See the options at right.

In our last issue’s contest, renovator Dick Zimmerman seems to be losing his business drive and perhaps reaching the point when retirement is close at hand. That unsettles employees Doug and Al Harvey, brothers who are concerned about their future. Yet over the years, Dick has always treated the Harvey brothers well, training and rewarding them in many tangible ways. We asked, should the Harvey brothers stick it out – and try to work through the transition –or should they look for new jobs with longer potential futures. Loyalty to a good boss came through loud and clear in virtually every entry we received. From many great answers, we chose as our winner the solution submitted by James Larusic, owner and operator of Sid’s Electrical Maintenance in Sydney, N.S. Like many, James felt Zimmerman had been a good boss over the years and deserved an open discussion about taking over the business. However, a cautious approach to the buyout should be taken. “Be careful what you wish for,” says James. “Even though they [the brothers] work very well together now, things can change dramatically when family members try to work together in their own business.”

Congratulations, James! You will receive a DeWalt FLEXVOLT 60V MAX 2.5 Gallon Cordless Air Compressor (DCC2560), including a 6.0Ah FLEXVOLT Battery with fast charger (retail value approx. $449). Visit www.canadiancontractor.ca for a more detailed look at the winning entry.

1. Talk to the company owner/boss to explain the situation and ask for a transfer across the shop floor.

2. Talk to a lawyer and see if some action can be taken now that Wilmer is working and earning money.

3. Look for a new job.

4. Just deal with it and let bygones be bygones.

5. Something else.

HOW TO ENTER

Email your answer to John Bleasby (jbleasby@canadiancontractor.ca)

Your suggested solution can be any of the above ideas, a combination, or your own solution entirely. The best contractor-submitted answer, as judged by the editors, will

a DeWalt Express Folding Workbench (retail approx. $129) and a DeWalt 60V Max FlexVolt Blower (retail approx. $369)

Deadline for entries is December 21, 2107. The winner will be announced on-line December 22.