Pick Up Truck Reviews What’s New in the 2017 Models page 34

The Porsche Of Power Tools?

A Visit to Festool’s HQ in Germany page 44

Spray Foam Myths Busted Why Maxwell Likes This Stuff page 49

Pick Up Truck Reviews What’s New in the 2017 Models page 34

The Porsche Of Power Tools?

A Visit to Festool’s HQ in Germany page 44

Spray Foam Myths Busted Why Maxwell Likes This Stuff page 49

How Canadian carpenter KIEFER LIMEBACK got himself a cult following on Instagram

As a professional contractor, being under pressure is nothing new to you. That’s why using products that help you to get the job done faster is a must. DRIcore SMARTWALL® simplifies basement finishing by providing a product that is 5x faster compared to conventional construction methods.

FEATURES:

•INTEGRATED VERTICAL & HORIZONTAL WIRING CHANNELS

•ACCESSORY PANELS CONTAIN ELECTRICAL BOXES.

•MICRO BEVELED EDGES - NO TAPING REQUIRED

•TONGUE & GROOVE INTERLOCKING SYSTEM

•HIGH DENSITY GRAPHITE INFUSED EPS INSULATION

•OSB FRAMING MEMBERS

•1/2" PRIMED DRYWALL WITH VAPOUR BARRIER SMARTWALL®

One of the many conveniences of the SMARTWALL® system is the patented “Micro Bevel” edge detail, which eliminates the traditional taping stage of finishing the drywall surface. The micro bevel requires much less filler to achieve a finished surface, resulting in far less sanding and therefore less dust created.

The SMARTWALL® ChallengeWatch Adam take on traditional building methods with DRIcore SMARTWALL®. Which method is faster? Watch to find out!

Unlike the multi-step process of conventional construction methods, DRIcore SMARTWALL® combines framing, insulation, drywall and a vapour barrier in one fast step. SMARTWALL® panels lock together using a tongue & groove system.

Kyle Kenyon

Kyle Kenyon

Kenyon Construction

Kenyon Construction

Rob Borthistle of Selkirk Home Hardware Building Centre knows that contractors don’t have time to waste. “Getting materials to the job site when you say you’re going to get it there is key,” he adds. Kyle Kenyon, a former employee of Rob’s who is now the owner/operator of Kenyon Construction, agrees. Selkirk HHBC supplied everything from drywall and lumber to roofing for a recent build of his.

Rob Borthistle of Selkirk Home Hardware Building Centre knows that contractors don’t have time to waste. “Getting materials to the job site when you say you’re going to get it there is key,” he adds. Kyle Kenyon, a former employee of Rob’s who is now the owner/operator of Kenyon Construction, agrees. Selkirk HHBC supplied everything from drywall and lumber to roofing for a recent build of his.

Constant traffic and powerlines made job site deliveries particularly tricky, “but they were able to do it and get it to us on time,” Kyle says. Every Home Building Centre and Home Hardware Building Centre Owner knows that service is about more than dedicated sales staff or ease of ordering. “We treat our customers the way we’d want to be treated by our suppliers,” says Borthistle – something Kyle Kenyon knows better than anyone else.

Constant traffic and powerlines made job site deliveries particularly tricky, “but they were able to do it and get it to us on time,” Kyle says. Every Home Building Centre and Home Hardware Building Centre Owner knows that service is about more than dedicated sales staff or ease of ordering. “We treat our customers the way we’d want to be treated by our suppliers,” says Borthistle – something Kyle Kenyon knows better than anyone else.

pronews.ca

pronews.ca

At NUDURA, size does matter. NUDURA standard forms feature DURAMAX Technology™, the largest standard ICF block in the industry, allowing the placement of 12 square feet of wall area in one building step. Our DURAMAX Technology™ results in faster installation times, less waste and a reduced amount of seams. Building Has Evolved™ at NUDURA, allowing builders & contractors to save time on labour, which is money, with the biggest block on the market.

Learn about our innovation and how NUDURA can reduce your labour costs at a NUDURA Training Academy installation course, nudura.com/trainingacademy.

Online 10

How to put the Canadian Contractor icon on your phone, for one touch access to our breaking news.

Editorials 12

Rob and Steve discuss various ways to deal with harsh criticism.

Voices 14

The best of the recent contractor posts at canadiancontractor.ca.

Site Notes 18

High school students in Barrie, ON build commercial-quality log cabins. Plus: Canadian drywall prices after the new tariff.

Pro Interiors 41

A look at an award-winning restoration of a heritage home in Westmount, QC.

Maxwell’s Stuff We Like 49

Our tools editor Steve Maxwell busts some die-hard spray foam myths.

What Would You Do? 58

Send us your solution to this month’s contractor dilemma and you could win a cool tool from DeWALT.

Instructions for Android

• Google Canadian Contractor on your mobile device

• Open the link to canadiancontractor.ca

• When the page opens, tap the menu button on the lower left corner of your screen

• Select “add shortcut”

• Go back to your device’s screen and locate the Canadian Contractor icon (It may appear on one of your later pages.)

Go to canadiancontractor.ca and type “icon” in the search bar at the top right. The link to the video will pop up.

| Tel: 416 442 5600 | 80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published 6 times a year by Annex Business Media.

• Press and hold the icon, and drag it forward page-by-page to the desired page on your device

• Go to canadiancontractor.ca using Safari or your favourite browser

• When in portrait mode, click on the square icon with the “up” arrow that appears at the bottom of the screen

• Chose “add to home screen”

• Click “add”

• The icon should appear on your Iphone or Ipad home screen

Now with one click, you can go directly to the latest news!

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Alec Caldwell, Mike Draper, Steve Maxwell, Jil McIntosh

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbizmedia.com

M2Tech gypsum board is engineered for enhanced moisture and mold resistance, and promotes healthy indoor air quality.

• Handles and finishes the same as standard paper-faced gypsum board.

• Numerous fire-rated assembly designs for safety and performance.

Hear Is What Matters: The noise-reducing gypsum and sound-dampening viscoelastic polymer of SilentFX® QuickCut™, combine to deliver superior acoustic performance without complex techniques.

• Score and Snap for faster installation

• Lower labour costs

• Superior acoustic performance

• Provide STC ratings of 50 and up

Learn more about reducing noise with SilentFX QuickCut at certainteed.com/gypsum/acoustics.

CertainTeed has a complete system of finishing products, specially developed to meet the demands of drywall professionals.

• Professional-grade performance.

• Minimizes callbacks and improves profitability.

I felt my guts had turned to liquid. ” ”

Rob Koci Publisher

rkoci@canadiancontractor.ca

By Rob Koci

Ever had a renovation client who by the end of a project even though you did everything right clearly hated your guts?

Many of us push back – at least inside our heads – and hate them in return. We write them off.

The first time anyone really stuck it to me like that was when I was in Grade 8.

I really liked my geography teacher and I was sure he thought I was spectacular, too. Right from the first class of the year, he and I made a terrific comedy duo. He would give me the straight lines and I would have hilarious rejoinders for them that would leave the class in stitches. It was a fun class. He never led me to believe he thought otherwise.

At the end of the last class of the year, he asked me to stay behind so we could talk. I beamed as I marched to the front. This was my moment. He wanted to thank me personally for being such an asset to his class. The rest of the students filed out and we were alone.

“Robert,” he began as I took a seat. “I wanted to let you know that, if you are assigned to any of my classes next year, I will do everything in my power to transfer you out. I have never had a student like you. You are arrogant, ignorant and insulting. You made my class a misery. I will never have you in my class again.”

I was crushed. My guts were liquid. How could I be so blind?

All summer, I obsessed over his criticism. Was I really that big a loser? (I was 16, for God’s sake!) It was a seminal moment in my growth into adulthood and taught me a life lesson that has remained with me for 45 years.

Back at school that fall, I tried out for the football team. My geography teacher was the coach. I kept my mouth shut and worked my butt off. I did everything he demanded of me, and more. I played both ways: running back and safety. I was possessed of a missionary zeal, but not for football. If it killed me, I was going to prove this man wrong about me.

At the end of our last practice before opening game, he called the team together to announce his choice for team captain.

The “C” my mother sewed on my sweater that evening was all I needed to know that, in the middle of the hurt and confusion of the summer, I had made my first real adult choice.

By Steve Payne

You’ve poured your heart and soul into a renovation project and you’re ready for your final cheque from the client. Maybe it’s your 10 per cent holdback. Maybe it’s some other sum. Regardless, that cheque represents a large chunk of your profit.

Whether there was an official deficiency list or not, you’ve fixed all the minor imperfections in the project. You feel proud. You did nice work, on time, on budget. That final cheque will feel good. You phone the client to see when you can pick it up.

“We are not very happy campers over here,” says your client on the phone. Their tone is nasty flat. “You did sloppy work. You didn’t deliver what you promised us.” Then, the massive blow to your solar plexus: “We think we need to shake hands right now and call it even. We are not going to pay you another nickel!”

Before you can reply, they are off the phone. Now you want to punch your fist through the windshield of your truck. You are being stiffed for ten grand.

What are your options? Call them back and scream at them? Sue them? Lien their property? All of the above? What should you do?

This scenario plays itself out time and time again – not just in renovation contracting but in many industries. (I remember a paint company in Quebec faxing us, back in another era, that they weren’t going to pay us for some advertising because they had just fired the VP of marketing who had signed our contract for it.)

What are your options when faced with this kind of customer bullying?

Taken at face value your client is a deadbeat with no ethics. But in 1981, in the groundbreaking book Getting To Yes: How to Negotiate Agreement Without Giving In, authors Roger Fisher and William L. Ury highlighted a vital business truth: Sometimes customers will insult you in a hostile way simply as a tactic. The insult (“We are not going to pay you another nickel!”) is deliberately intended to knock you totally off balance in the hopes that you will make a ridiculous concession. Don’t be fooled. In business, you can expect to catch flak from time to time. Take a deep breath, refuse to be drawn in, and respond calmly and assertively. You can get paid fully if you recognize their tactic as simply that. Don’t take all business insults at face value.

”

Don't take all business insults at face value.

In our last issue, we invited contractors to send us their personal ‘Rule of 3.’ (We first read about this “get things done” technique in The Productivity Project, a 2016 bestselling book by Ottawa-based time management guru Chris Bailey.) A Rule of 3 is a method whereby you focus on the three most important things you have to get done every day. Yes, you will have a To Do list in the hundreds of items. But try to pick the three MOST vital tasks for the day. It works. Try it! Here are some of the Rule of 3 lists that we received from renovators and homebuilders.

“One hundred per cent effort or don’t bother!”

Give your clients, employees and yourself 100 per cent effort every day or don’t bother. No one deserves something half thought-out. Listen to complaints/suggestions.

Ensure you are continually training and educating yourself and your crew/design staff, etc. on new methods of installation, new products and new techniques. Ask yourself: ‘Is this the best we can do?’ and ‘Would I be happy if this was done in my house?’

Enjoy your work! And help your employees enjoy their work! Yes, there are some parts of the job you won’t like. But you need to be able to enjoy the process as well as the people you work with. This way, you will take more pride in what you do and you will produce a better product.

Jordan Godwin

“A clear vision for the day”

Leave home before traffic builds up with a clear vision for the day. Someone will soon try to change that vision But only you can decide what it is.

Try to visit each of your jobsites for meetings with crew chiefs and client updates. This will allow you to put out bad fires, stoke the good ones and keep the wheels turning.

Reach out to new leads. These should be scrutinized and prioritized by existing clients, referrals and in-house leads.

Neil Damackine

“An hour of billing and estimating”

Make sure all tools and supplies are ready to go before you leave home.

Check voicemail and return all messages.

Do an hour of billing and estimating at the end of the day.

Jesse Burkett

“Hydrate, exercise, gratitude”

Start your day early with a glass of water.

Do enough exercise to work up a sweat every day.

Remain positive and thankful, always.

Brian Chadwick

This contractor only needs nine words!

Get to work.

Get the job done.

Get paid.

Ming Wang

How about two words?

Show up!

Maeghi

Safety, attitude, self-care

Here are my three vital tasks on a seemingly never ending list of daily tasks:

Play safe.

Keep a positive attitude.

Take care of yourself. Only by doing this will you be able to take care of others.

Michael De Jong

“Each day most contractors are doing one of three things…”

The are building (marketing, calling, following up). They are managing (doing site visits, scheduling, paperwork). Or they are blaming (making excuses why they aren’t doing one of the first two).

Ben Kuypers

Start with thanks, end with receipts

Thank a client for their business!

Reply to all emails from the day. No matter how many!

Review all receipts from the day for the current projects you are working on.

Derek Pallister

It all comes down to paying attention

Stop – be attentive.

Look with all of one’s senses – a blind person can often see more clearly than one having sight.

Listen to all noise, silence and movements with all of one’s senses – a deaf man can often listen more clearly than one having hearing.

John Meloche

There’s no doubt about it: Some contractors have trouble working smoothly with architects – and vice versa. Recently, we received a thoughtful post from an architectural technologist, who says his own profession can help contractors to work more efficiently.

Don’t overlook architectural technologists

I just want to take a moment to comment on your article regarding the contractor-architect relationship. I am educated as an Architectural Technologist and used to work for architects in the Toronto area until the recession of the 1990s when you could not buy a job and so I had to come home and work in the mechanical and electrical trades with my father.

This was an environment that I was used to and one in which I had worked since I was 9 years old. I also had a good background in carpentry and drafting as a result of my high school technical education. This experience coupled with my architectural experience gave me the presence of mind to work as a troubleshooter in my many different jobs working for architects.

There are many good architects out in the industry. There is also the other end of the scale – as there is with many things. At the time when I was working in this field, new architects were only taught one semester of producing working drawing documents. We architectural technologists and technicians, on the other hand, study this field for three years and two years respectively. (In the USA, technologists are referred to architectural engineers which I think is a more fitting title to our education and experience.)

An architect’s education is very good in the concepts of design that deal with form, harmony and aesthetics, as well as the history of architecture. But it does, in my experience, lack something in the area of building science and constructionrelated documents. The answer to this situation is the architectural technologist or technician that performs this task

My point is that you do not need a architect to do house drawings, although today you must have other accreditations due to liabilities of the design work and the structural conditions of the design. Many technologists and technicians are employed by architects for this very purpose. Further, many technologists work independently on their own or perhaps as a separate contractor to an architect because they have a better understanding of building components and their interaction in a structure.

When this relationship is able to work then you have the ultimate respect that is needed in the industry to promote a good relationship. Rather than just referring to these key personnel as “staffers,” it is worthwhile doing some research on the educational background of architectural technologists and technicians. The extent of their training is impressive.

Lyle McGill

Last issue we printed an online post from contractor Bill McCance, Mayne Island, BC. He urged contractors to switch to Insulated Concrete Forms from traditional stick-frame construction. Alberta. contractor Jeff Rempel posted the following reply to Bill.

Excellent points about ICFs, Bill. I hope builders in Fort McMurray heed this wisdom. As a builder in High River, Alberta, where floods devastated several thousand homes in 2013, I can say with absolute certainty that ICF is a standout product. We have built with ICF foundations exclusively for over a decade. Every one of the over 50 flooded ICF foundations passed engineering after the flood, and over half of those were under water for three weeks or more. We ‘gutted’ and remediated dozens of basements, both ICF and conventional concrete and frame. ICFs were faster and more efficient to clean out and rebuild. Perhaps most importantly, they statistically outperformed conventional basements in terms of indoor air quality after being professionally remediated. Conventional homes often needed to be cleaned multiple times over months as the mold kept coming back if it wasn’t done thoroughly the first time.

We’ve been cost-neutral building with ICF for several years now, providing a significantly better product for the same price as our competitors. Good for builders, good for clients, good for communities.

Jeff Rempel

This app has become his

We use a phone app called “abouttime.” Every project is entered into the system as well as tasks. The guys punch in and out the same as if they worked in an office or factory. All of the info is automatically sent back to my computer so that I can look at it daily. There is a ton more capabilities with this app than we will ever use but in my business it has become a lifeline.

Richart

We need permanent safety harness anchors! Permanent safety harness anchor installation should be mandatory on all roof renews and new home construction. Without it, exterior contractors often have nothing to hook onto and have to use a ridge anchor which is screwed into the ridge of the roof, requiring patching at end of use.

Terry Emerson

Forget about bread boards! Wood shop students at Patrick Fogarty Catholic Secondary School in Orillia, Ontario are manufacturing full-size log cabins

By John Bleasby

Idon’t wish to re-live my angst-filled high school years, but if I could go back in time, I sure would like to take Brett Carron’s shop class. In my day, shop was all about bread boards, table lamps and tiled trivets for teapots. Carron’s classes are way more fun than that. Heck, his students actually build full-sized log and timber frame cabins!

Carron joined the faculty of Patrick Fogarty Catholic Secondary School in Orillia, ON 14 years ago, his first full-time teaching position after several years of furniture building, cabinetry and house framing. Flexibility within the province’s

high school shop curriculum allows schools to customize programs to fit a teacher’s individual skills and background, making for a better educational experience.

“If a teacher is teaching to their strengths and is comfortable and confident, the learning is that much more enriched,” says Carron. The result is that students all around the Orillia area are drawn to Carron’s log and timber frame construction option.

Matching Carron’s background to both the program and the culture of the local area has been critical to the success of this initiative. “When we started the log timber frame construction

program, we wanted to make a pathway for students into the construction trades,” Carron explains. “We knew that in Muskoka we have these types of builds. We also knew students love the romanticism involved in the log cabin pioneer set up. We wanted to draw them in and create a pathway to employment after graduation.”

The result is that about seven years ago students choosing Carron’s ‘specialist major in construction’ option started building full-size log and timber frame buildings, right on school property. There were multiple benefits. First was the build itself.

Head Start Construction, Severn, ON re-assembled this kit on a cliff overlooking Lake Simcoe.

“They’re learning not only about large timber construction but also about power tools, foundation layouts, wall systems, and the specific electrical layouts that go with a log home,” Carron says. “It lends itself to all aspects of the trades.” It’s also highly motivating for students to be part of something that will likely stand for decades.

But where do these buildings go? That’s the second part of Carron’s strategy: partnering with local builders and contractors. The students build the timber or log buildings as kits and builders buy the kits for re-assembly on client lots.

“Our first build was a 16’ by 22’ log cabin, with a 6-foot pressure-treated front porch and overhanging porch at the loft door,” recalls Carron.

Although built without a specific buyer, that project quickly attracted the attention of the community. Today, Carron’s students build timber frame and log kits to order for builders like Peter Head, owner of Head Start Construction Company in Severn, Ontario, recouping material and tool costs only. The workmanship is first rate. “Even my structural engineer was pretty impressed with the work the kids have done,” says Head. “Brett’s got a top notch program.”

Carron has managed to not only find a meaningful aftermarket for the kits produced by the students but, more importantly, he’s developing a skilled and safety-trained future workforce for the industry that includes WHMIS and Working at Heights certification.

“I hear from a number of past students,” says Carron. “In fact, a former student came by a few days ago. He’s framing houses in Barrie now and asked for the names of my three best guys.”

Carron has a suggestion for contractors on the lookout for the next generation of talented tradespeople: “Ask your local high school shop teacher about students with a strong work ethic who are interested in the trades. And express your interest to the school’s co-op department. Schools are looking for these placement opportunities. It’s a golden opportunity.” cc

CERTAINTEED FIBER CEMENT

SIDING CLASS ACTION Legal Notice

If you are resident in Canada and own a home, residence, building, or other structure located in Canada on which CertainTeed WeatherBoards Fiber Cement Siding (the “Siding”) was installed on or before July 1, 2016, your rights could be affected by a proposed national class action settlement with CertainTeed Corporation (“CertainTeed”).

The CertainTeed Action Class action lawsuits were commenced in Alberta and British Columbia against CertainTeed alleging that the Siding is defective and subject to cracking, bowing, buckling warping, delamination and shrinkage. The actions were certified as class proceedings on September 21, 2016 in BC and on October 3, 2016 in Alberta.

The Settlement Although CertainTeed denies liability, it has reached a national settlement with the plaintiffs (the “Settlement”). The Settlement is subject to approval of the Court in Alberta and British Columbia. CertainTeed will pay CAD $7.25 million (the “Gross Settlement Amount”) for the benefit of the Settlement Class Members (defined below) in exchange for a full release of claims against it and its related entities (this may affect your rights under the warranties provided by CertainTeed).

If the Settlement is approved, the Class Lawyers will ask the Courts to approve the deduction of certain amounts (collectively, the “Court Approved Expenses”) from the Gross Settlement Amount, including costs incurred to distribute this notice and process opt-out requests, comments and objections (see below), a counsel fee of up to 18% of the recovered amounts, plus applicable taxes and disbursements.

Who Are The Settlement Class Members? You are a Settlement Class Member if you own a home, residence, building, or other structure that had Siding installed on or before July 1, 2016.

All Settlement Class Members are affected by this notice.

Settlement Approval Hearings A hearing to consider approval of the Settlement, a counsel fee of up to 18% of the recovered amounts, plus applicable taxes and Court Approved Expenses will be heard on January 31, 2017 at 2:00 p.m. at the Court

of Queen’s Bench of Alberta in Edmonton and on February 17, 2017 at 10:00 a.m. at the Supreme Court of British Columbia in Vancouver. Anyone can attend the hearings, but if you wish to speak to the Court, please advise one of the Class Lawyers.

If you wish to provide written comment on or objection to the Settlement, you must do so by delivering same to the Class Lawyers by December 30, 2016. Comments or objections will be provided to the Court for consideration in whether to approve or reject the Settlement.

Participating in the Settlement If you fall within the Settlement Class and wish to participate in the Settlement, you do not need to do anything at this time.

Opting Out of the Class Proceedings The deadline to opt out of the Settlement is December 30, 2016 By opting out, you are choosing not to take part in the Settlement.

Settlement Class Members who opt out will not be bound by the Settlement or the releases in the Settlement, but will also not be entitled to share in any of the proceeds that may become available as part of the Settlement.

Consequences of Not Opting Out Settlement Class Members who do not opt out will be bound by the Settlement and the releases in it, and will be entitled to share in any of the proceeds that may become available to Settlement Class Members as part of the Settlement.

FOR MORE INFORMATION on the status of the approval hearing, how to opt out of the Settlement, comment or object to the Settlement, or to view the Settlement, visit www.CertainTeedSettlement.ca which will be periodically updated with information on the Settlement approval process.

The CLASS LAWYERS are James H. MacMaster and Chelsea D. Hermanson of Branch MacMaster LLP and can be reached at:

• Email: chermanson@branmac.com

• Telephone: (604) 654-2999

Fax: (604) 684-3429

Mail: 1410 – 777 Hornby Street Vancouver, BC V6Z 1S4

This Notice is approved by the Alberta Court of Queen’s Bench and the Supreme Court of British Columbia.

By John Bleasby

in Western Canada have been hit hard by drywall price increases since the Sept. 6 imposition of a provisional tariff on drywall shipped into Canada at points west of Manitoba.

The tariff, ranging from 125 per cent to 275 per cent, was imposed by the Canadian Border Services Agency (CBSA). It was a response to CertainTeed Gypsum Canada’s complaint that U.S. manufacturers were ‘dumping’ drywall into Western Canada “at prices materially lower than those at which they are sold in the U.S.,” thus harming CertainTeed’s plants in Vancouver, Calgary and Winnipeg.

margins are slim for all of us these days, so new home construction and the renovation industry are impacted. Ultimately this creates more consumer cost for home construction and for renovation projects thus making homeownership and improvements more difficult for all of us.”

In a press release, Matthew Walker, general manager of CertainTeed Gypsum Canada said, “Dumping creates material injury to domestic manufacturers in the form of [market] share loss and price and margin suppression. Faced with increasing injury from dumping, we had to terminate Western Canadian employees, reduce investment in our manufacturing plants, mine operations and business, and put in jeopardy the continued viability of our plants.”

Reaction from homebuilders was swift and harsh. Bob de Wit, CEO of the Greater Vancouver Home Builders’ Association, told local media that he was worried the new duties would not only drive suppliers and installers out of business, but make housing even more unaffordable in all areas of Western Canada. Fort McMurray in particular has been identified as one community that will be hard hit by the higher cost of drywall, given the massive re-building program following devastating fires this spring. Many contractors took their complaints public on Canadian Contractor’s website. “As CHBA (Canadian Home Builders’ Association) members, we have all been encouraged to write our MP and let the government know of the hardships that are created by a sudden and extreme tariff,” wrote one Edmonton renovation contractor. “Bigger builders (or their drywall subcontractors) with projects underway are the ones who will be hit the hardest. I know

Drywall is re-priced each week, according to a national chain store manager who spoke to Canadian Contactor. “It’s just like lumber,” he explained. “We’ve had variations as much as 20 per cent over the past few months.”

To track the effect of the tariff, Canadian Contractor pricechecked drywall at select Home Depot outlets from Vancouver, BC to Saint John, NB. Before the tariff was imposed, customers in Western Canada were purchasing U.S.-branded drywall at prices only slightly less than the average price of drywall across all of Canada. However, once the tariff started impacting supply lines, prices in Western Canada soared. Surveys of Home Depot outlets in Calgary and Vancouver suggest an 80 per cent price increase for a standard 4x8 (1/2”) sheet of drywall since September.

Our research also reveals that the average price in the U.S. of that same sheet of drywall was 54 per cent higher (after currency conversion) than the average Canadian price in September. However, increases to the Canadian average price have caused that gap to all but disappear.

The new tariffs are deemed preliminary and are subject to investigations and public review ahead of the final Canadian Trade Tribunal ruling scheduled for January 2017. cc

For updates on this story, please visit canadiancontractor.ca and type 'Drywall' in the search bar.

HK & HKC - Miter saw precision, in the size of a sidewinder. Yes, it’s that good.

IIf you have a smartphone, you have a chance to become a global internet celebrity of some sort – if you have something really interesting to share.

Mild-mannered Ajax, ON carpenter Kiefer Limeback, 28, certainly does. He has built a sizeable cult following on Instagram (@Toolaholic) simply by posting spur-of-the-moment tool reviews.

Kiefer and his videographer brother, Kyle, 26, are of the perfect generation to understand the nuances of today’s social media. Yet they are both experienced enough as carpenters to be acknowledged craftsmen and tool nerds. In the parlance of modern marketing, the Limebacks are what are called ‘influencers,’ confirmed by their 71,000 loyal Instagram followers. Canadian Contractor recently caught up with Kiefer to quiz him about his burgeoning internet fame.

Let’s start at the start. Where would that be?

You know, the standard question is: ‘Were your parents involved in the trades?’ The short answer is ‘No.’ Our Dad has always been handy but he has a computer background. The story goes that he gave me a hammer at a young age and I just followed him around when he was building stuff at home.

That

led you towards course choices at high school?

It wasn’t a straight path. I started to do side jobs during high school, and by the time I left I was remodelling kitchens, tiling and so on. But my high school (W.A. Porter Collegiate, Scarborough, ON) didn’t have a shop class so I transferred to a technical school (Bendale Business and Technical Institute) where I took as many shop classes as I could. Then I went into a co-op program and did framing. It was like a pre-

apprenticeship: when I graduated I had a running start at a real apprenticeship.

What trade did you choose?

After high school I did more framing. But I loved the outdoors. So I started my own thing: landscaping, building decks for clients, lots of fencing, interlock. It grew to where I owned two trucks, three trailers, tons of equipment, and had a bunch of labourers.

It was overwhelming. I wanted to stay relatively small and actually be the one doing the work. I was also losing a lot of days to bad weather. So I went into remodelling and that’s what really pushed me to where I am today. We got bigger and bigger jobs, did millwork installation and cabinetry, started working with other contractors, meeting guys on site, networking. Now everything is just word of mouth, one job leads to the next. It’s been like that for the last four years.

Ajax, Ontario carpenter Kyle Limeback used to go without new shoes or clothes to fund his power tool addiction. And now he's become a tool review cult figure on Instagram.

INTERVIEW BY JOHN BLEASBY

Did your brother Kyle follow the same path?

He’s been alongside me from when we did landscaping, my sidekick for the whole ride. These days, Kyle is the guy filming the reviews. He’s also who I go to for a second opinion on tools.

You were already pretty busy as a contractor. Why did you start reviewing tools online?

I’ve always been known by friends and other contractors as a tool freak. If something new came out, I had to have it. That was my thing: I didn’t buy shoes, didn’t buy clothes. I would go to the ends of the earth to get a tool that was new or super-unique.

People knew that and were always asking me about tools and how they were working out, and I’d be talking,

sometimes hours on end. When Instagram was released on Android, I started posting pictures, saying, “Check out my new driver, or this new reciprocating saw.” People started asking me, “How does that work for you, how is it performing?” Those conversations got longer and longer. And I thought, “Hey! I could be one of those tool reviewers I’d seen on the internet!” I was doing the same thing anyway, so it just evolved and snowballed.

Your Instagram posts indicate a strong technical understanding of how tools are put together. Where does that come from?

In my youth I was always pulling stuff apart, fixing things, pulling engines apart, trying to figure out how stuff works, and I’m still doing that today.

People call me a tinkerer. Every tool I ever had I’ve pulled apart to see what’s going on inside. It’s how I improve my understanding of tool quality and what separates one company from the next.

It’s a crowded tool review community online, especially on YouTube. Yet you’ve chosen Instagram’s very simple format and have an army of followers. Are you surprised?

It’s a bit of luck, for sure. However, my posts have a spur-of-the-moment realism. I feel that connects better. I joined the tool review scene because I was sick of reviews clearly in favour of a certain tool and rarely talking negatively, that was more of a commercial. And I understand that side completely. They all want to get paid. No one wants to ruin their

I attend all of Atlas Machinery’s events on an appearance level. They’re known for having the new tools before anyone else. They have extremely well established relationships with all the big brands.

relationship with manufacturers. But at the same time, I felt the quality of the reviews was suffering. The other thing that really resonated with me was that many tool reviewers are not in the trades. I am, and I wanted to bring that level of honesty to my reviews. I post from my phone; there’s no film crew, I’m not getting paid. I’m doing this because I love helping people. We’re on site, this is really happening, and we’re reviewing a tool as we use it.

So the attraction of using Instagram is the ability to be totally spontaneous?

I post news about tools even in the middle of an actual job. I don’t have to go home and edit anything. It’s real time. It’s natural. It’s like a diary. I pride myself on that. A reviewer has a choice; either go home, edit, and add sound, or just shoot in one take, which is what I do on Instagram. It’s all on my cell phone. If I make a mistake, I make a mistake.

You are starting to work with YouTube now. What’s the reasoning?

We’re trying to bridge the gap between

information about construction and information about tools, showing what I am doing on site as an actual tradesperson, things like system tricks and processes. I’m showing how these new tools improve our workflow, showing tools being used in real job site situations. That brings another level of realism.

You’ll continue with both, Instagram for spontaneity and YouTube for in-depth analysis? Exactly. And this is going to take a tremendous amount of time, of course. It’s another job on its own.

And then there’s all the feedback you get. You actually encourage feedback and interactive discussion.

That’s the other half of the whole Instagram thing. We’ve got hundreds of people commenting back to us, and we want that. There’s two reasons: I want to help people as much as possible, and I want them to ask questions, not sit in the dark wondering if this tool or that tool is the right one for them. I feel Instagram is the best platform for this type of discussion.

Your weekly open forum on Instagram is unique.

Every Sunday night, people can send me a construction or tool-related question. Last week I had about 120 questions and had to answer them all in about two or three hours. I leave the questions and my answers up so people can scroll through them to see the questions and whether I answered them successfully.

Given the time and trouble you and Kyle go to, how will you be able to resist the temptation to accept money from manufacturers?

It would mean giving up everything we believe in: completely unbiased tool reviews. There might be other ways to monetize what we do, but it can’t affect the review side of things. However, a little money would help justify putting more time into the reviews and helping more people.

Many of the tool manufacturers are huge fans of your work. Do they support your efforts in any way at all?

I get pre-release tools from manufacturers

now, so many of the things you see are not available to the public yet. But that doesn’t compromize me in any way. The companies appreciate honest reviews because it allows them to improve.

Does that lead to technical discussions with the manufacturers themselves?

One hundred per cent! Sometimes it’s good, and sometimes it’s not so good. I remember having a serious issue with one tool I was sent, and really broke it down in my review. The manufacturer was disappointed but understood and said, “Don’t worry, generation two will be better.”And they went back to the drawing board.

What are your long term goals in terms of where you are taking this?

I want to influence tool development. By doing the reviews and asking questions, I’m trying to take on the hard-to-solve problems. Maybe some of my ideas will result in the creation of a new product. cc

BOLTR (“Bored Of Lame Tool Reviews”) is a Canadian YouTube Channel that has hundreds of thousands of views for some of its power tool teardowns. Humour? Top marks! The accuracy of its criticisms? Fail!

Scrolling through the near-endless number of online tool reviews, one sees every possible variation imaginable. Choose from high production values with soundtracks and eye-popping visual effects, to Aussie accents so thick that subtitles are provided, to down-home hillbilly friendliness. Choose your language: English, Portuguese or maybe Mandarin. For the most part, the format is the same: a bench filled with saws or hammer drills, and a guy giving his two-cents worth on one or all.

And then there’s AvE (pronounced ‘Ah-Vee’). We don’t know AvE’s real name and can only guess his exact age. His YouTube channel is called BOLTR (Bored of Lame Tool Reviews). With a title that provocative, I had to check it out.

A reviewer has a choice: either go home, edit, and add sound, or just shoot in one take, which is what I do on Instagram. If I make a mistake, I make a mistake.

I’m suspicious that AvE actually works with tools professionally, but he sure has a lot to say about them. His teardown of a DeWalt grinder, for example, was spread over two 30-minute segments, extremely long by on-line review standards.

AvE has a massive following, in some cases over 750,000 views. His shtick is to pull a tool apart and examine every little component. Furthermore, he does this with a cynicism and condescension that, quite frankly, I found disturbing. In one particular review, he begins with the conceit that the manufacturer is obviously cutting corners. He laboriously picks at gears, speculates on the chemical make-up of mechanical lubricants and even tries to melt the tool casing with a soldering iron. We hear him exclaim, “This is really odd!” and “I’ve never seen that!” and “I’m really surprised!”

Me, I’m saying to myself, “Is this ever going to end?” and “Is he ever going to actually use this grinder?” and “Who the hell does he think he is?” AvE reminds me of the know-it-all in biology class, determined to prove he could design amphibians better than Mother Nature. I also wonder if anyone other than micro-particle engineers are still paying attention.

Watching Part B of the review, another 30 minutes, and admittedly snoozing my way through, AvE suddenly begins talking about his adventures while naked in a family sauna in Finland. Sorry AvE: you’re boring, lame, and a bit on the wrong side of acceptable. John Bleasby

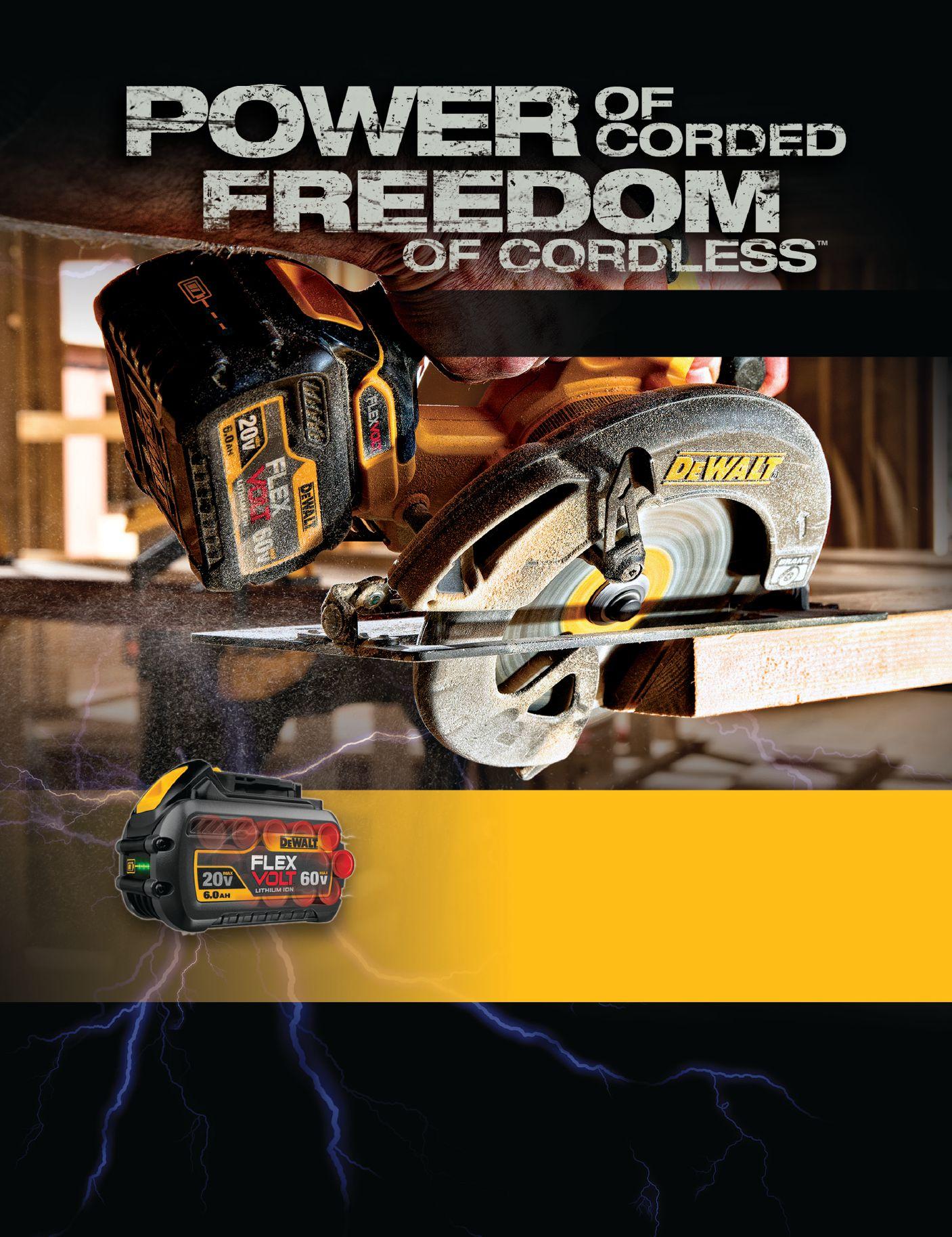

COMPATIBLE

Compatible with all our 20V MAX* tools

WORLD’S FIRST BATTERY PACK THAT AUTOMATICALLY CHANGES VOLTAGE WHEN YOU CHANGE TOOLS.

The FLEXVOLT™ battery's ability to automatically change between two voltages gives users a serious advantage when it comes to efficiency. It's the battery that not only powers, but improves the runtime** of our DEWALT® 20V MAX* tools, so you don't have to invest in a whole new system. It's the battery that brings the power of corded to a new lineup of 60V MAX* and 120V MAX* DEWALT® tools so you can finally work on a fully cordless jobsite. Built Guaranteed Tough®, Built by DEWALT®.

EXPANDABLE

Brings power to a whole new lineup of tools

POWERFUL

Combine two 60V MAX* batteries for revolutionary cordless freedom

Rayleen Hill

Architecture + Design

Trevor MacLean

Specialized Construction Ltd.

By John Bleasby

Photos by Rayleen Hill

Hawthorne is a winding residential street, only steps from downtown Dartmouth across the harbour from Halifax. Several houses here were originally built for dock workers and mariners prior to 1914, thus are designated heritage properties. Although modest in size and style, some of these houses back onto nearby Findlay Community Centre Park, a significant public green space, making the neighborhood very desirable. Many homes have been either tastefully restored or maintained to showcase their original charm.

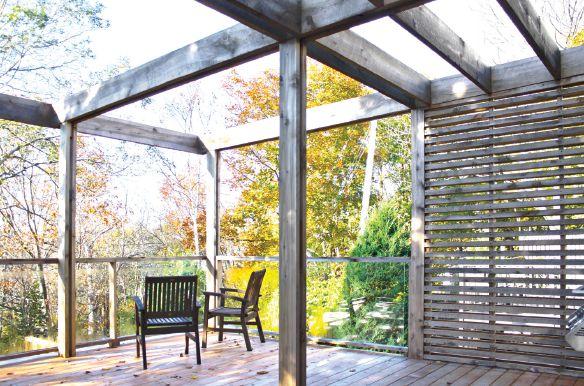

The owners of this previously untouched side-hall residence approached Dartmouth architect Rayleen Hill in 2014 with a number of improvements in mind. They wanted a new, street-level garage on an unused, 15-foot wide strip of property at the side; an open main-level floor plan that would include a modern kitchen; a new main level washroom, mud room and laundry; and a large outdoor living at the rear. All this was to be achieved in a package that was to be, in Hill’s words, “cutting-edge energy efficient.”

“Most of the house was in good condition,” says Hill, “but the kitchen was a hodgepodge of appliances and

Continued on next page

This renovation of a heritage property in Dartmouth was given Honourable Mention by the Nova Scotia Association of Architects.

cabinetry with no flow. The confined and cut-up layout made this little house feel dark and drab.” Hill gutted the 625 square foot main level and selected bold colours both for walls and kitchen cabinets. “By opening up the plan and allowing the kitchen, dining and living areas to all flow as one large openconcept space, the house feels much larger, brighter and functions more effectively for the three-member family.”

Trevor MacLean of Specialized Construction Ltd. agreed that the 2x6 frame house was essentially sound. However, he noted that some structural engineering was required to deal with minor water damage around the original stone foundation, and to strengthen the main floor due to the increased weight of the two-inch cement topcoat needed for new radiant floor heating.

The unused 15 feet of property on one side is unusual for the street, given the pre-existing mutual driveway on the other side that continues down a gentle slope to the rear of the house. However, adding the garage became the catalyst for an entirely new, yet pleasingly traditional exterior look. The low profile of the garage with its dark, horizontally-laid siding suggests European modernism, while the cedar shingles replacing the 60’s-era asbestos siding, and the bold colour choice for the front door, lend an East Coast authenticity .

The new garage is built on a concrete slab. However, the back wall of the garage and its foundation wall at the rear also serve as walls for the new 450 square foot of added space for the new main floor bathroom, and mud room/pantry/ laundry behind, plus the identically-sized new utility room constructed below at basement level.

The house was reinsulated with spray foam, and the main floor rewired and almost entirely re-drywalled. Windows throughout

Top: “The design exemplifies a commitment to energy efficiency, without compromising style and character,” says architect Rayleen Hill.

Left: A slight cantilever on the deck gives it a lighter feel than it would otherwise. Stairs down to grade level, railings and privacy screens are untreated hemlock. Note the solar collectors on the south-facing roof.

Bottom: The mutual driveway slopes to the rear, allowing single car parking under the deck. Note the original stone foundation exposed at grade.

were replaced and strategically located.

“The large windows above the kitchen countertop are shaded in the summer time by a pergola over the deck that doubles as a brise-soleil for the windows,” Hill says. During the cold winter months, the lower sun angle dips below the pergola allowing the sun to penetrate and warm the interior.

The new 400 square foot rear deck is an oasis of pastoral serenity, maximizing the view of the trees and public green space beyond. There is enough space underneath, accessible via the mutual driveway, to permit single car parking and storage for outdoor tools.

To meet the clients’ objectives of energy efficiency, a German-made Walltherm wood-burning, hot water heating system was selected. The wood furnace component of the system was installed in the main living area and the hot water storage and controls installed below in the newly built utility room. The Walltherm system provides radiant heating for the new hardwood floors on the main level and radiator heat on the upper floor. “It’s is the first natural downdraft hydronic wood gasification stove,” Hill explains. “It’s is not just a wood stove; it’s a hydronic wood stove which also provides space heating and domestic hot water.” The system has an HHV fuel consumption efficiency of 84 per cent.

Roof-mounted solar collectors can produce heat for the system when the wood stove is not required. They can also provide sufficient electricity to power the home year-round, thereby lowering the owners’ total energy consumption to 26 per cent of the original.

The project was given Honourable Mention recognition by the Nova Scotia Association of Architects in 2014 for exemplifying an open concept home committed to energy efficiency without compromising historic style and character. cc

Above: Views from the rear deck off the main level seem endless as they look through the canopy of trees towards the park.

Opposite Page Lower Left: Bright cabinetry, bold wall colours and new windows add brightness to what was previously a dark little house.

Opposite Page Lower Right: “We use two angle irons to turn the corner on the siding. Half the angle is behind the siding and the other half sticks out,“ explains Hill. “This happens on both sides. Then we caulk the seam. It looks like there is just one angle without vertical trim pieces at the corners.”

From the super heavy duties to the nimble gas misers, the 2017 model year has the perfect pick up for your mood

By Jil McIntosh

With trucks as popular as they are, automakers aren’t standing still. Several models undergo everything from a mild refresh to a complete makeover for 2017.

For those who need ultimate workhorses, Ford completely updates its Super Duty, while General Motors puts a new Duramax diesel into its HD models. Nissan adds a redesigned half-ton Titan following last year’s release of its large Titan XD, while Honda’s new Ridgeline handles light-duty needs. Here’s what the truck manufacturers have to offer.

Ford puts a new engine and transmission in its F-150, unveils an all-new Super Duty, and reintroduces its high-performance Raptor.

The new F-150 engine is a turbocharged 3.5-litre EcoBoost V6 engine making 375 horsepower and 470 lb.-ft. of torque, compared to 365/420 in last year’s version. Carried over from 2016 are a 2.7-litre EcoBoost V6, naturally-aspirated 3.5litre V6, and 5.0-litre V8.

A new ten-speed automatic is added to some models, in addition to a six-speed transmission. Depending on the model, maximum towing capacity is 12,200 lbs.

Like the F-150, the all-new Super Duty gains an aluminum body underpinned by a high-strength steel frame. Choices are Regular Cab, SuperCab and Crew Cab, with two wheelbases and box lengths.

The Super Duty comes as the three-quarter-ton F-250; one-ton F-350 with single or dual wheels; and 1.5-ton F-450. Engine choices are a 6.2-litre V8 engine producing 430 lb.-ft. of torque, or a 6.7litre Power Stroke V8 diesel making 925 lb.-ft. Maximum towing is 21,000 lbs., while payload hits 7,630 lbs.

New available Super Duty technologies include adaptive cruise control with trailer brake support, forward collision warning, blind spot monitoring including when a trailer is attached, speed-sensitive adaptive steering, and a moveable rearview camera for mounting on a trailer.

The Raptor returns with a high-output 3.5-litre EcoBoost engine that’s more powerful than the V8 it replaces, with 510 lb.-ft. of torque, along with a ten-speed transmission and new 4WD system that can be dialled in for specific driving conditions.

General Motors makes a few changes to its Chevrolet Silverado and GMC Sierra, including a new 6.6-litre V8 Duramax diesel engine in its heavy-duty models.

On the 1500 models, capless fuel fill is standard, and low-speed emergency braking is added to the optional driver alert package. Maximum towing on the 1500 Crew Cab rises by 500 lbs. to 12,500 lbs., matching the Double Cab’s maximum rating.

The Silverado and Sierra 1500 models come in Regular, Double, and Crew Cab, in 2WD or 4WD, and with three available box lengths. Engine choices are a 4.3-litre V6, 5.3-litre V8, or 6.2-litre V8, all of which switch to four-cylinder operation under light load for improved fuel economy. A six- or eight-speed automatic is available depending on engine.

A limited number of 5.3-litre models are available with

eAssist, a mild hybrid system that adds gasoline-free power on acceleration and keeps the engine in fuel-saving mode longer. The battery charges through regenerative braking and doesn’t require plugging in.

The new 6.6-litre Duramax diesel available in the 2500HD and 3500HD improves on the previous 6.6-litre with 445 horsepower and 910 lb.-ft. of torque. Also available is the carried-over 6.0-litre gasoline V8, making 380 lb.-ft. of torque.

Although the Silverado and Sierra are mechanical twins, they differ slightly in their trim levels. The Silverado 1500 comes in six trims, including a base Work Truck trim on all cabs and configurations, and rising to the High Country 4WD Crew Cab. The Sierra comes in four trims, topped by the luxury Denali.

Although not designed as a work truck, Honda’s Ridgeline may fill the bill for lighter-duty needs. It’s redesigned for 2017 with a more truck-like appearance and new driveline.

It uses a 3.5-litre V6 engine making 280 horsepower and 262 lb.ft. of torque. The engine automatically switches to three cylinders under light load, and combined city/highway fuel economy is 11.3 L/100 km.

Unlike other trucks, the SUV-based Ridgeline uses an allwheel-drive system that’s primarily front-wheel biased and sends power to the rear wheels as needed. Maximum towing is 5,000 lbs., while payload tops out at 1,570 lbs.

The unique dual-action tailgate drops down conventionally, or can be opened sideways like a door for easier load access. The bed is made of a non-corroding composite material and includes a locking trunk under the box, with drain plugs for washing it out or using it as a cooler.

The interior also features considerable storage space, and the folding rear seats are on metal legs so items can be stored under them while passengers are seated. Those who only need a lighter-duty truck and are looking at options such as the Chevrolet Colorado, GMC Canyon, Nissan Frontier or Toyota Tacoma might want to consider the Ridgeline as well.

In 2016, Nissan introduced its large Titan XD, intended to span the gap between half- and three-quarter-ton trucks. For 2017, the company adds the Titan Crew Cab V8 half-ton. Single cab and King Cab models will be added later, along with a V6 engine.

For 2017, Nissan adds a new factory warranty that covers all trucks bumper-to-bumper for 5 years/160,000 km.

The new Titan half-ton uses a 5.6-litre V8 that makes 390 horsepower and 394 lb.-ft. of torque, up from the 317/385 produced by the last-generation 5.6-litre, and mated to a seven-speed automatic transmission. It shares its cab with the Titan XD but rides on a different chassis and is 373 mm (14.7) shorter overall. Available in 2WD or 4WD, the Titan half-ton tops out at a maximum 9,390-lb. towing capacity. It comes in five trim levels,

all of which include a 5-foot-5 bed, locking tailgate, folding 60/40 rear seats, and mobile phone app integration. Waterproof, locking in-bed storage boxes are available.

The larger XD continues into 2017, as a Crew Cab with a 6-foot5 bed, and in 2WD or 4WD configuration. It’s available with the 5.6-litre V8 gasoline engine that’s upped to 401 lb.-ft. of torque for the XD, or with a 5.0-litre V8 Cummins turbodiesel that makes 310 horsepower and 555 lb.-ft. of torque.

The XD’s towing capacity reaches a maximum of 12,038 lbs., which may seem like a head-scratcher given that some competitors’ half-tons are rated for more. The key is in how easily it handles heavy loads. Those who pull consistently at half-ton full capacity, but who don’t want to move up to heavy-duty, should give it consideration.

Ram remains the only half-ton pickup available with a diesel engine, although buyers now have a second choice with Nissan’s slightly larger Titan XD. The 2017 Ram carries over with only minor changes, including a new cabin air filter, and automatic climate control added to more models.

The three-quarter-ton Ram 2500 adds two trim lines: the Power Wagon, with trim-specific styling and interior, and a 4x4 Off-Road Package with Bilstein shocks, limited-slip differential, and hill descent control.

The Ram 1500 is available in Regular Cab, Quad Cab, and Crew Cab, while the 2500 and 3500 come in Regular, Crew, or the oversized Mega Cab. Two bed lengths are offered.

Engines in the 1500 are a 3.6-litre gasoline V6; 3.0-litre

EcoDiesel V6 producing 420 lb.-ft. of torque; and 5.7-litre Hemi V8 making 410 lb.-ft. of torque. Six- or eight-speed automatic transmissions are available, depending on the engine. Towing capacity rates as high as 10,640 lbs.

The 2500 and 3500 models offer the 5.7-litre V8, plus a 6.4litre Hemi V8. The diesel option is an inline six-cylinder 6.7-litre Cummins, rated as high as 900 lb.-ft. of torque in the 3500, and which can be ordered with a manual transmission. Towing capacity for the 3500 is a maximum of 31,210 lbs.

The 1500 offers an optional four-corner air suspension, which can be lowered for accessibility or raised for rough terrain, but its weight affects the maximum payload. Ram’s available RamBox bed-side storage system provides locking storage for tools and other items.

Toyota’s full-size Tundra carries over unchanged for the 2017 model year, including the off-road-ready Tundra TRD Pro package added last year.

The Tundra comes only as a half-ton, in Regular, Double Cab or CrewMax configuration, with three bed lengths depending on the cab or trim, and in 2WD or 4WD.

A 4.6-litre V8, producing 310 horsepower and 327 lb.-ft. of torque, is available in specific Double Cab 4x4 models. All others use a 5.7-litre V8 making 381 horsepower and 401 lb.-ft. of torque. Both engines use a six-speed automatic transmission. All models come standard with a backup camera, front tow hooks, manual headlight levelling system and phone connectivity. Trucks equipped with the 5.7-litre include a heavy-duty tow hitch

receiver. Towing capacity goes as high as 10,196 lbs. in 4x4, and up to 10,500 lbs. for 4x2 trucks, while payload reaches 1,770 lbs.

Numerous options and packages are available for the Tundra, including blind spot monitoring, a power-sliding rear window that completely opens vertically like a door window, factory spray-in bedliner, and the luxury 1794 Edition.

The Tundra TRD Pro, available in Double or CrewMax configuration, uses the 5.7-litre V8 and has a towing capacity of 9,800 lbs. It includes a factory-installed trailer brake controller, 4- and 7-pin connectors, transmission cooler, and heavy-duty hitch receiver, along with an off-road suspension kit, skid plate, dual exhaust, and TRD-themed styling cues.

The exquisite restoration of the Blinderman Residence in Westmount, Quebec wins EVOQ Architecture a prestigious award from the Canadian Association of Heritage Professionals (CAHP)

EVOQ Architecture has won two prestigious architecture awards from the Canadian Association of Heritage Professionals (CAHP). One is for EVOQ’s work on the Blinderman Residence, Westmount, Quebec. The other is for its work on The Wellington Building, a Federal Government building in Ottawa.

The Blinderman Residence received an Award of Excellence in the category of Conservation: Small & Lovely. The Committee and the Jury thought the submission was “excellent, and appreciated the sensitive minimal intervention.” The residence is the former home of renowned architect Percy Nobbs. The project was designed and managed by Julia Gersovitz, Rosanne Moss and Giovanni Diodati.

The Wellington Building received an Award of Excellence in the category of Conservation: Architecture. The Committee and Jury thought “the project complexities were very well explained, and appreciated the high quality of the design work.” The Wellington Building is a Federal Government building in the Parliamentary Precinct of Ottawa, Ontario. EVOQ was the Heritage Conservation Architect, responsible for all aspects of the historic elements in the complex, including the exterior envelope, ornamental entrance canopy and the interior heritage spaces. The rehabilitation, restoration and preservation of these elements were designed and managed by Julia Gersovitz, Eric Stein and Neil McNulty. The prime consultant was NORR Limited.

The awards were presented at the National Trust Conference in Hamilton, Ontario on October 21, 2016. “We are extremely honoured to be recognized with these awards. The two projects showcase the range of our expertise and talents, which we apply with equal passion to monumental institutional buildings and

smaller, architectural gems,” said Julia Gersovitz, EVOQ Director.

EVOQ is an award-winning architecture firm recognized for quality interventions and site sensitive design solutions. It has over 100 employees, based in Montreal,

Toronto, Ottawa and Iqaluit. The firm’s portfolio includes a number of highprofile buildings including the West Block of Parliament in Ottawa, the heritage conservation of Union Station in Toronto and the Canadian High Arctic Research Station (CHARS) in Nunavut. cc

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Paint and Colour Experts at Home Building Centres and Home Hardware Building Centres to provide the right product and colour for any project. Our Canadian made products have outstanding quality and durability. Our paints are tested by a third party, ISO certified lab to ensure consistent, high quality. With a relationship built on trust, you know you’re building a strong foundation.

Contact your local Home Hardware Store for a list of MPI approved products. Proven Products for Painters!

Painters love us for our spatter resistance! See our selection of proven professional coatings at beauti-tone.ca

Available exclusively at Home Hardware and Building Centre locations.

Festool’s HKC 55 Carpentry

Saw is an interesting tool, combining the precision and angular adjustments of a miter saw (in combination with its guide rail or crosscut rail) with the portability of a standard circular saw.

Editor STEVE PAYNE travelled to Germany last month to tour three of Festool’s factories alongside power tool journalists from around the world. Here is his report.

The Porsche headline came to mind as I waited for my flight back to Toronto at the Stuttgart airport. I had been in Germany all week, in late September, a guest of Festool, who had invited some 20 North American and European tool journalists to tour their factories and see demonstrations of their newest products. Stuttgart is famous for, among other manufacturers, Porsche. There is a Porsche

museum in town and it’s promoted heavily at the airport. The Porsche brand is one we all know well. It’s high performance, uncompromising, and expensive as hell. Porsche’s slogan, “There is no substitute,” is about as arrogant a motto as you can find. And it’s not even necessarily true. Porsche’s southern German manufacturing neighbour, Festool, does not have anywhere near the worldwide

renown of the performance car giant. Except in our niche of an industry. Among contractors, especially in Europe where Festool better known, Festool is indeed a bit like Porsche. Except the Festool slogan, “Tools for the toughest demands” is toned way down in the arrogance department. And given the type of new product torture testing I got to see on the Festool tour, it’s undoubtedly true.

You won’t find Festool products lining the shelves of your local big box home improvement store in Canada. Just beginning its penetration of the North American market, Festool is available at precious few retail outlets. The company seems to like it that way, at least for now. It’s a specialty brand with a special distribution.

“We are not a power tool company,” we were told by a Festool official on the first day of presentations at the Festool headquarters in Wendlingen, about half

an hour east of Stuttgart. I wrote that down with a “?” after it, because I thought it was, honestly, nuts. Of course Festool is a power tool company! But then the explanation came. Festool doesn’t see itself as a power tool company in the same sense as the world’s biggest power tool brands – who seem to have a tool in every possible category. Festool only has tools in select categories of construction – with a strong emphasis on wood shop tools. It’s a company for craftsmen.

The firm was founded in Germany

1. In late September, journalists from North America and Europe got an inside look at Festool’s power tool operations. Here they are at Festool’s dust extractor factory at Illertissen.

2. The Festool head office in Wendlingen, near Stuttgart, is a hub of research and development for the firm. It’s one of the firm’s three major facilities in southern Germany.

3. Festool technician shows us how the firm’s new cordless drywall screwdriver (Festool Duradrive DWC 18-4500) uses “intelligent electronics” to control a start/stop function that prevents the user from having to continuously press the on/off button.

4. A hands-on demonstration of Festool’s new HKC 55 carpenter’s saw. It’s brand new in Canada and several of our readers have won this powerful unit through our contests.

in 1925 by a man called Gottlieb Stoll, under the name Fezer & Stoll. Herr Stoll did very well with his first invention: a portable chainsaw. He quickly built a powerful family business which was sort of obsessive-compulsive about checking in with the users of these tools to see which minor (or major) tweaks the operators wanted.

Festool is still family-owned, marking it out from the world’s largest power tool consortiums, which are almost all publiclytraded. During our tours of the three major

Festool facilities in Germany (Wendlingen, Illertisseen and Neidlingen), we were told that family members often showed up at management and technical meetings, allowing major decisions at Festool to be made on a dime, rather than through the more bureaucratic process that larger firms might have to cope with.

Festool’s manufacturing is still largely done in Germany. “Whoever enters the production halls of Festool immediately feels a special spirit, passion and feeling which shows how the employees identify with the products they manufacture,” Festool says in one of its promotional documents. Well, that is great PR, but

many firms like to tout the dedication of their employees. Still, I noticed that almost every single car in the parking lot at the three factories we visited had Festool logos emblazoned on the rear panels. “It’s a sort of status symbol,” someone told me. Then I heard that they were actually company cars - a benefit that North American firms have almost entirely shied away from by now. They seem to treat their people right. Festool is a status brand, no doubt. If you want to get a sense of the ferocious loyalty that the purchasers of their products exhibit, go online to the Festool Users Group (FOG). On this forum, carpenters and renovators from around North America

5. Festool is famous for its dust extractors which it manufactures at its CleanTec division in Illertissen. Like most Festool products, each model is put through a variety of torture tests, such as this water spray chamber.

6. In a world of outsourcing to Asian factories, Festool continues to employ a large, skilled workforce in Germany. While performance is intense and strictly measured, morale appears really high. And the firm enjoys a very low turnover of staff.

7. Assembling a dust extractor at Festool’s Illertissen factory. Each work station is precisely designed for ergonomic and efficient minimization of hand and arm movements.

8.There was almost four day’s worth of product information to be gathered at this Festool media event. Still there was lots of time to compare notes with other media.

9. Festool’s new construction site light is not only powerful in terms of lighting intensity, but it is also rugged, lightweight and it has a versatile and stable support structure.

compare notes - in great technical detail - about their favourite Festool products. Devotees of other, equally worthy power tool brands have a little fun with these guys, too, accusing them of“drinking the Green KoolAid.”

German-engineered premium brands are not, of course, eternally top end. To return to cars again, just look at the ways in which BMW has grabbed a share of the North American middle class market by (frankly) cheapening some of their models for greater market share.

Given what I saw on this Festool tour, that will be not be how this particular company grows its sales. cc

to work.

Our windows are crafted for style and engineered for performance. Let’s work together to give homeowners the best of both worlds.

Low-E glass for enhanced performance.

There is a reason JELD-WEN is the go-to brand for so many experienced professionals.

Attractive window shapes for architectural symmetry.

Thanksto media exposure of the health risks of mold and mildew, more and more homeowners want contractors who are renovating their basements to use modern products that can help protect against moisture.

This is why specialized building materials like DRIcore’s SMARTWALL and DRIcore’s Subfloor system have become so popular among contractors. Installed correctly, these DRIcore products can be an important part of keeping a basement renovation dry, warm and mold- and mildew-free.

Unfortunately, from time to time the general public will also be exposed to myths about the best types of materials to use in basement renovations.

One of these myths is that “inorganic materials” are somehow better at preventing the growth of mold and mildew in basements than “organic” materials.

One particular version of this myth says that using “inorganic” steel studs and magnesium oxide wallboard in place of traditional “organic” materials like wood studs and gypsum wallboard is a good idea. Mold can’t grow on such materials, right?

Wrong, unfortunately.

In fact, mold can thrive on almost any substance if moisture is present. Just look at the 100 per cent ‘inorganic” surfaces (ceramics, steel, aluminum, glass, etc.) on the interior of any typical household shower enclosure.

Unless moisture is quickly removed from this location (through sufficient bathroom venting), such a space is quickly going to show signs of mold and mildew – even with frequent cleaning. Every homeowner knows this. It is moisture itself, not the substrate it grows on, which is the problem.

Likewise, mold can grow within magnesium oxide walls in a basement renovation if moisture is present. It can grow on steel studs. Mold can grow within any “inorganic” basement wall or floor structure.

Therefore, mold prevention is not simply a question of finding “moldproof” substances to build with. There really aren’t any. The risks of mold can be reduced, rather, by installing an integrated wall and floor system that is designed to minimize or remove the accumulation of moisture in the first place. Just like that well-ventilated shower enclosure.

DRIcore’s SMARTWALL panels, 23.5 inches wide by 96 inches high, do precisely that. They are a proven method to reduce moisture accumulation that can plague traditional stud-frame, fibre insulation and poly vapor barrier construction methods.

SMARTWALL does not rely on “inorganic” materials in its structure (largely consisting of EPS foam factory-bonded to 1/2 inch drywall) –because it is carefully designed to allow water vapour to move freely through its semi-permeable vapour barrier system, where it can dry out.

In a traditionally-built basement wall, water vapour can run down the inside of traditional poly vapour barriers, or accumulate inside fiber insulation. Steel studs and/or “inorganic” wallboard materials won’t solve that moisture-flow issue. SMARTWALL, on the other hand, is designed to deal with that moisture.

On basement floors, DRIcore’s Subfloor product consists of 2-foot by 2-foot tongue-and-grooved engineered tiles. High-density plastic feet on the underside of the tiles create an airspace that allows air to circulate, evaporating moisture.

No “inorganic” flooring material is a magic bullet against mold. The solution to mold is to deal with the underlying moisture issue. DRIcore has become a market-leader in such basement building solutions by fully understanding where mold and mildew come from.

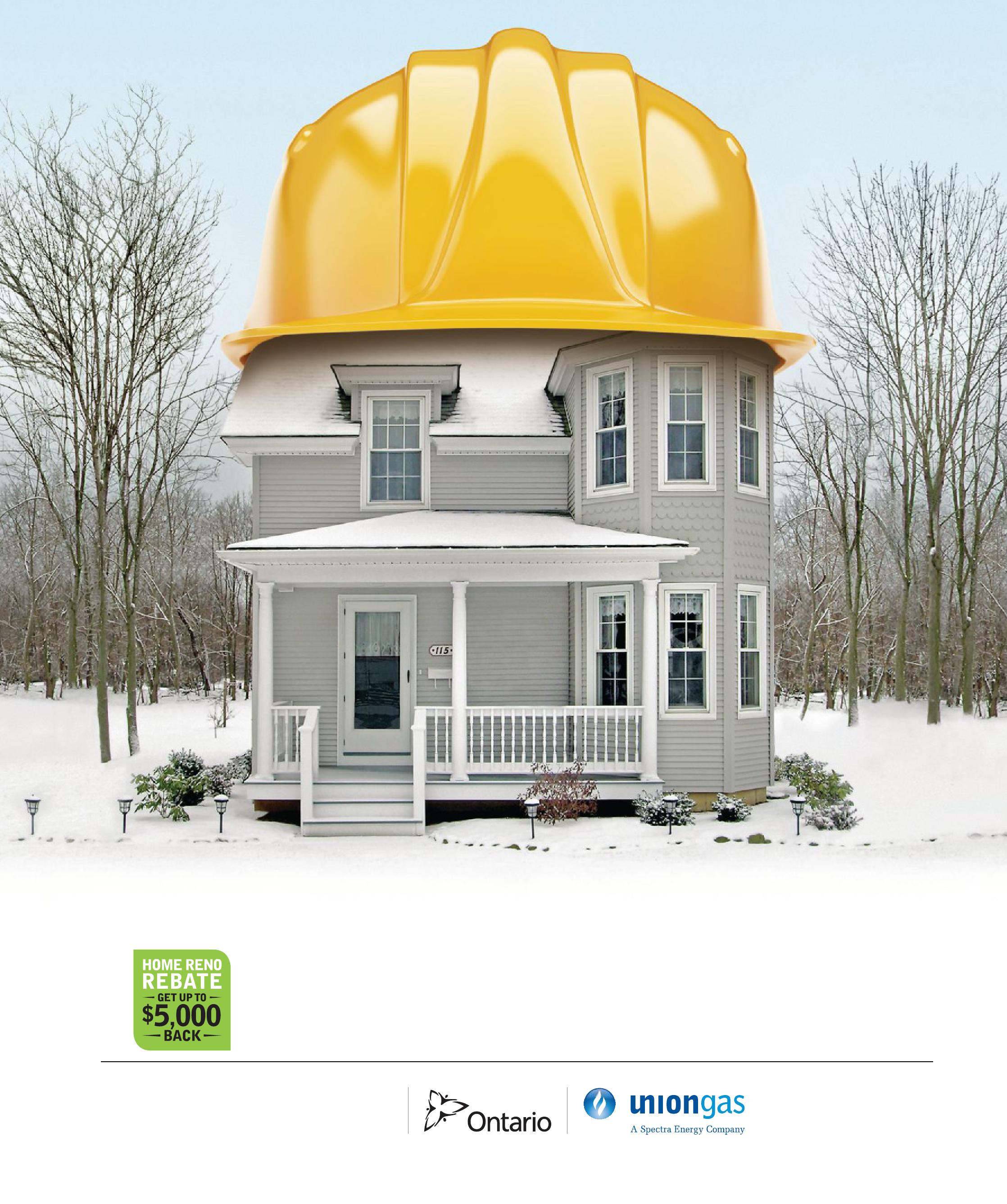

Why this type of insulation makes so much sense

52

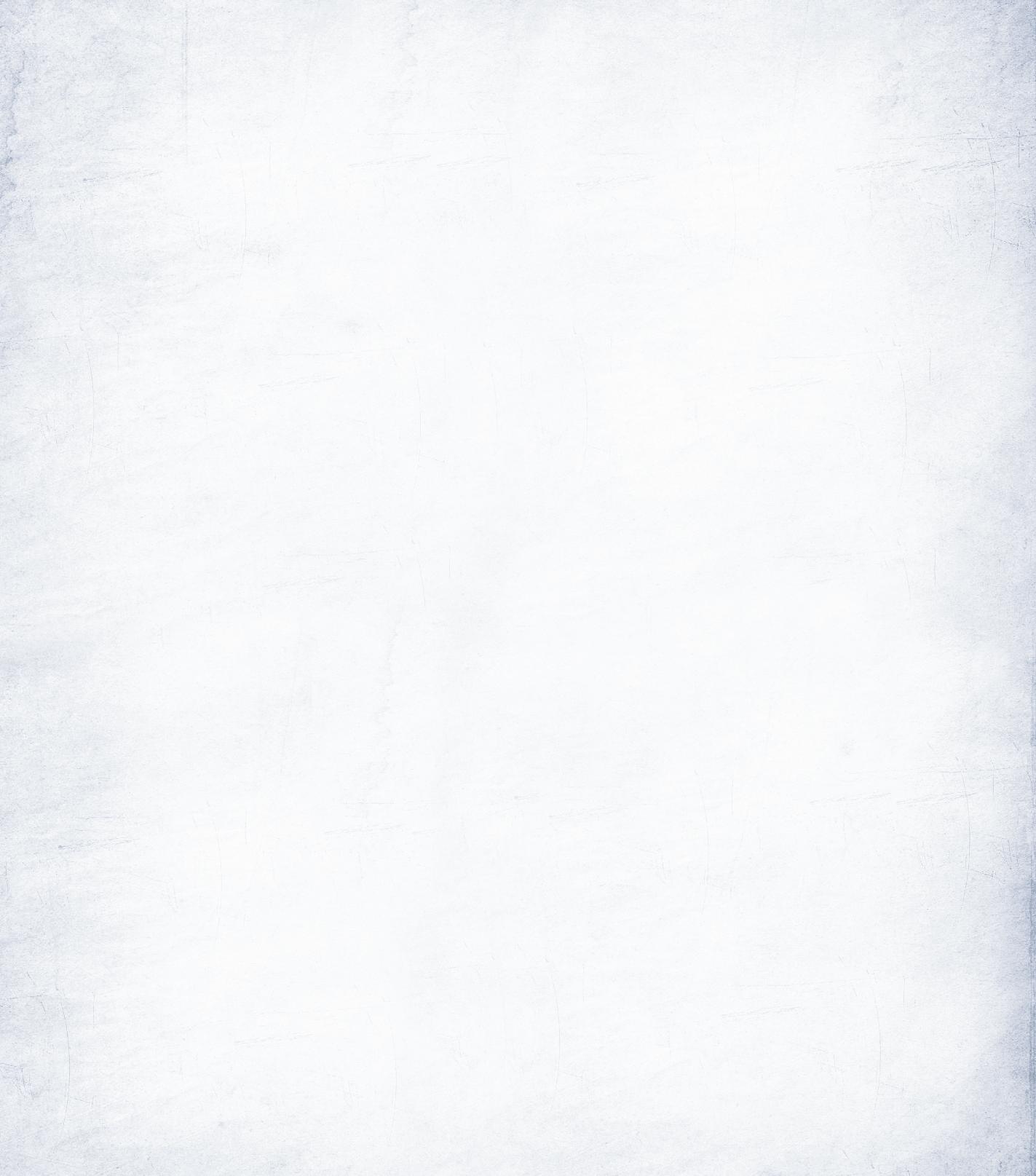

Our mobile app’s SiteHub screen lets you view real-time clock-ins, job costs, field notes and more for any job site, at a glance.

The app is compatible with all iOS and Android devices.

You can see a list of who is currently clocked in at any job site.

For remote sites, you can also see weather updates and get instant directions to the site.

Track and manage your crews. Monitor their activities in the field for better budgeting and oversight, and nip overtime in the bud. Make informed business decisions on the go with our app and cloud-based software.

• Leave the pain and hassle of paper time cards

• Workers use our app to clock in and out on their own device

• Photo ID verification & GPS tracking enable better oversight

• Get real-time visibility on overtime and compliance

• Easily transfer time tracking data to your accounting package

By Steve Maxwell

I recently received an email from an electrician named Ken on the east coast and it got me thinking. He’s been in the trade for 25 years and during that time he’s noticed how training has degenerated. When Ken began, apprentices shadowed journeymen, learning all there was to know. But these days, Ken observes, new tradespeople are simply “thrown under the bus.”

“Quality has taken a back seat to quantity,” Ken told me. “Jobs are thrown together and look good only on the surface. Behind the scenes there are accidents waiting to happen! I recently left a company after a number of years because of this reason and the fact the boss was using someone with no certifications to run jobs and look after apprentices.”

I hear similar stories from people in the trades all the time. What can be done?

First of all, I think we can give up on the idea that government can improve the state of the trades in Canada. There’s very little in the world that government does well, especially when it involves the operations of private businesses. I agree with philosopher Henry David Thoreau, who famously wrote in his 1849 pamphlet Civil Disobedience: “That government is best which governs least.”

Second, we need to ask a question: Do enough people in the world of building care about the state of workmanship to make a difference? If people like Ken are right, the root of the problem stems from the kind of greed that leads to cutting corners on training and project management. It’s more profitable in the short term to require a 20-year-old to bumble along on his own than it is to let an experienced tradesperson show that young person how it’s done. Doing the right things for the trades can only happen if a critical mass of contractors care enough to make a difference in

their own area of influence.

Once upon a time, a long time ago, the world had no formal training for the trades. The highly successful apprenticeship system of yesteryear developed slowly, over centuries, in response to real needs. Government was not involved. The driving influence was the practical people who knew how to make good things happen with their hands and knew how to pass this knowledge on to young people.

Well, if tradespeople of the past could build an apprenticeship system from scratch, why can’t we recreate it? Maybe we can. Except for one thing that worries me. Could it be that government has placed such a burden of cost and regulation on the building trades that it’s necessary to cut corners and “be greedy” just to stay alive?

steve@stevemaxwell.ca

By Steve Maxwell

How to address the three most common objections to this type of insulation

Good contractors steer their clients toward quality materials. This task requires diplomacy and tact and so it isn’t always easy, but it pays off. The better the projects you’re allowed to build, the happier your clients will be in the end. And happy clients are your ticket to future jobs that you don’t have to work as hard to find.

Quality builds require the best materials. It’s just as simple as that. This applies to everything from foundations to roofs. Spray foam is one specific case in point. It’s an example of how a safe, proven building technology can boost your reputation, despite being seen by some as a tougher, more costly option. Here are the three most common objections to spray foam, with logical reasons why fact should prevail over fear.