The Ryan Report License to build Pg. 15

Creative Eye Reviving history Pg. 16

FOCUS: Outdoor living Pg. 22

The Ryan Report License to build Pg. 15

Creative Eye Reviving history Pg. 16

FOCUS: Outdoor living Pg. 22

Saskatoon homebuilders looking to become a household name Page 12

THERE’S MORE WAYS TO HELP YOU GET MORE DONE. Tool, Truck and Large Equipment Rentals. Pro Xtra Loyalty Rewards. Grow your business as a Local Pro with Pro Xtra. Shop Online with a Pro Business Account. Express or Scheduled Jobsite Delivery. Download our Mobile App for on-the-go convenience.

See all the ways at homedepot.ca/wepowerpros

STORY From the ground up 12 Bella Vista is on the path to becoming a household name in the Saskatoon area.

Creative Eye: Reviving history 16 MacMinn Contracting transformed an old house that was falling apart into a modern award-winning masterpiece.

A recipe for success 22 Land-Con co-owner, Ofner Winkler, takes a few moments to reflect on his company’s drive to award-winning success.

Creating a great outdoors 26 Steve Maxwell shares three project ideas that can liven up your client’s outdoor living space.

Outdoor living showcase 28 Meet the surging demand for upgraded outdoor spaces with these top products.

Responses to our last Dilemma produced a slew of good advice on how to deal with fluctuating material costs.

The Ryan Report 15 Licensing can bring the professionalism and trust that the industry needs right now. The Dilemma 30 Adam is the latest victim of Murphy’s Law. Where does he go from here?

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Canadian Contractor is proud to offer our new job search site dedicated to careers in Canada’s construction trades. Post a job or find a job at canadianjobsite.ca or by clicking Job Board on the Contractor home page.

In the latest episode of The Hammer, Sephton Spence of the Afro-Canadian Contractors Association explains the formation of this new organization dedicated to advancing the interests of people of colour in Canada’s construction industry.

Join Canadian Contractor associate editor, Sukanya Ray Ghosh, for this inspiring series of video interviews with amazing women from the trades.

Follow @CanConMag or look us up on Facebook to add Canadian Contractor to your daily diet of online interaction. New! Check us out on Instagram at canadiancontractor.

Account

ISSN 1498-8941 (Print)

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

To celebrate International Women’s Day, eight of Canada’s leading construction media brands teamed up to deliver an exclusive virtual event. You can view the content ondemand, and stay on top of news throughout the year, at women-in-construction.ca.

SPONSOR

GOLD SPONSORS

SPONSORS

SPONSOR

By now we’ve all heard about the incident where a drywall installer team in Milton, Ont., hired a stripper to come party with them on the job site. The photos went viral, the drywallers have been fired and a maelstrom of opprobrium has washed through the media against their behaviour. A lot of the criticism has been accurate and deserved. Some has overreached. And some of the reaction has exposed some attitudes that are not helpful.

I think it pretty much goes without saying that having parties of any kind on a jobsite is unprofessional and risky behaviour that no responsible employer in our business would countenance. Certainly, bringing in outside “talent” with no business on the site is the wrong thing to do.

But the larger issue is whether this incident reveals a culture of misogyny that would tend to exclude women from the profession. Some of the commentary seems to suggest that there is something misogynistic about hiring a dancer at all. Maybe. Such evaluations of social justice are above my pay grade. I would point out that the practice is entirely legal. I’d also point out that the dancer no doubt makes quite a bit more money than she can make at Tim Horton’s. Maybe her opinion of whether her trade is misogynistic or not is the most important one here, and it’s the one we aren’t hearing.

That said, it’s beyond doubt that most women would not be comfortable working in an environment where parties with exotic dancers were part of the end-of-day unwind. Even if the parties themselves were not happening, the whole atmosphere of leering objectification and sexualization would be, and is, highly unfair and unwelcome. Boys, leave your libidos at home. You’re here to do a job and your employer needs women to help with that job.

That last point is where this incident has scared out some old-school attitudes that are apparently still swirling around. I saw a comment on social media that women should not be working in construction anyway since it is physically demanding and they aren’t up to it. Wow. I want to point out why it’s wrong. Statistics deals in groups. What statistics tells us is that if you selected a man and a woman at random out of a group of all people, the man would likely be physically stronger than the woman. This is a true statement, but not applicable to the question at hand.

It is always a mistake to apply these rules to individual cases. Some women are stronger than some men. And, crucially, the selection process for construction trades is not random. If a woman is presenting herself as a candidate for a construction job, it’s likely that she knows she can do it. Saying to her “I know women are too weak for this work” makes the logical and mathematical error of applying a group rule to an individual case. You could very well be turning away a valuable worker. Plus, I’ll just add that it is statistically true that women have more endurance than men. What is more valuable on your jobsite, a person who can lift an extra 50 pounds or a person who can keep working at a high level for an extra hour?

Your answer to the above is probably, “Neither. I need people who can use their brains.” In which case you’ll certainly be looking for women to join your workforce and making all efforts to discourage the kind of jobsite culture that led to that unfortunate scene in Milton. cc

” Boys, leave your libidos at home.

By Patrick Flannery Editor ”

In our last issue, The Dilemma challenged you to come up with solutions to Justin’s problem of setting prices in today’s world of wildly fluctuating material costs. You rose to that challenge...and then some. Here’s some of the great advice and ideas that came in response to Justin’s Dilemma.

Emile Rocher suggests that Justin should break each quote into two categories.

Justin should break each quote into two categories. Supplies which are unlikely to be affected by price changes based on firm quotes from suppliers and minor items where price variations will not substantially affect his profit margins. Then “big ticket” items for which suppliers cannot guarantee prices. He should go through his regular estimating process making his best assessment of what the big ticket item prices will be, allowing for reasonable increases, and quote the jobs with specific allowances for each big ticket item at cost then working in his usual profit margins. The customer is liable for any direct cost overruns, but not expected to pay for added margins on added costs. This way there is some sharing of the risk but the customer also gets the benefit of a credit if the cost comes in under budget.

– Emile Rocher

Adding a materials surcharge based on market price of materials could be the answer, says Nico TeWinkel

Remember the “fuel surcharges” about a decade ago when oil prices skyrocketed? Booking a cruise, riding a ferry and even having packages delivered would come with extra charges depending on the current price of their fuel. I suggest that Justin, and contractors in general who are caught in a similar situation, consider adding a materials surcharge that depends on the market price of the materials required for the job. In general, I would quote for the job based on current prices to give the client the best possible idea of what the full project will likely cost them. However, I would also add a very clear clause to indicate that the quoted price is based on current market prices of the materials required for the job. I would then add a clause that states something along the lines of, “If materials prices increase by more than five percent of current market prices, the contract price will increase for each one percent materials price increase.” It might be necessary, for simplicity’s sake, to base the calculations only on the price of a few key materials for the quoted-on project, such as

plywood or framing lumber. Whatever the quoted materials cost is based on, those base prices should be included in the quote. You might also include a similar decrease option in the quote, to be completely fair to the client. The other option is to quote as above, but quote labour and materials separately with a “materials price fluctuation” clause stating that materials will be charged to the customer at the price it is when the project begins. In any case, make sure you also explain why: “Due to rapidly changing materials prices caused by our current pandemic, we are unable to provide fixed quotes on materials costs. We are doing our best to quote fairly, based on current and expected market trends, but unfortunately we cannot guarantee that our estimates will be accurate by the time the project begins.”

– Nico TeWinkel

Joel Cohen offers a 30-day price guarantee, while adding a provision to review prices before project commencement. The dilemma is one that all reputable contractors are facing during these trying times. Unfortunately, the costs for materials are changing almost on a daily basis, making estimating very difficult. When we prepare our quotes, the price is guaranteed for 30 days and subject to review prior to commencement of the project. Our experience has taught us that most clients are very aware of the cost fluctuations and are in agreement with the review. As a rule, our estimates always show the individual trade pricing, so the review is a simple process. We require a deposit to secure the dates for the project, however, if we cannot agree on the revised pricing, a full refund of the deposit is made.

– Joel A. Cohen

Jackie Stezik manages the pricing problem by adding a page with the quotations that explains the situation to customers. We’ve all been dealing with Justin’s dilemma since the pandemic started but particularly in the last six months. We found a way to deal with it that not only protects us from high price increases but satisfies the client by letting them know they won’t be charged more than necessary if we don’t

have to. We include a page with our quotations that helps explain this. It reads like this:

“The global pandemic of 2020 has changed the renovation industry dramatically. As of October 2020, we have seen dramatic increases in building material costs. Many of our supplies have increased in price by as much as 100 percent. For this quotation, we have priced your project at today’s rates based upon our expected rates of building materials. Our hope is that when the pandemic settles down in 2021, so will the prices of materials. As a result, if you decide to work with us on your projects, we will guarantee our labour costs at the rate quoted in this proposal but the materials costs will have to be revisited at the time your project is to commence. If the materials costs have come down, you will receive a credit. If the materials cost have increased, there may be an increase in your final price.”

We have found our clients find this to be very fair as we are offering them a reduction in the cost if material prices return to normal. The clients who have booked us for their projects told us that they understood what the pandemic has done to the construction industry and felt we handled the situation professionally and extremely fairly.

– Jackie Stezik

John Perri has used his industry experience to create a threepronged approach that keeps everyone happy.

Early on in 2020, I knew I was going to have to adapt to the new normal that is COVID-19. I knew that supply chains were going to be affected. But I have built relationships with my suppliers over my 39 years in the construction industry.

Problem One: Hard costs for materials. I was able to get products ordered at today’s prices. I knew what my hard costs for all the materials were going to be. Problem solved.

Problem Two: The unknown here was when all the product would arrive. So, I had conversations with my clients and explained that their products could arrive at undetermined times. I had a clause put into my contract with the clients approval to wait until 100 percent of the construction materials arrived. Problem solved.

Problem Three: The clients agreed to provide enough funds at time of signing the contract to cover the cost of all materials. That way, I wasn’t spending my money. Something I have always been averse to. Problem solved. Every project started a little further down the line but once each one started, things progressed smoothly without interruption. It worked so well in fact that I plan to make this my company’s new normal.

– John Perri

Transparency is the key

A transparent pricing process has helped Michael Flatt.

This was my normal practice pre-COVID as material issues are nothing new. We have had much worse in my over 40 years in the business. As per the term used in the last issue, transparency is the key. On an ongoing basis, and especially before any major bid, I contact my subcontractors, labour and material suppliers and ask how long each will guarantee their pricing. If necessary, in the material aspect, they allow me to prepay for what I need and often will hold it until I need it or will supply it from new inventory at the time. I can thus lock in material costs for up to six months. My quotes are valid for the length of those guarantees subject to signed approval and a paid deposit, which covers all material costs plus any other normal charges. Subcontractors and suppliers are immediately paid from these deposits and the balance held in our trust account until work begins. My quotes include the actual allowance for subtrades and materials at the time, so alternatively the client can sign an agreement but not pay for all the materials upfront. They would then pay on an ongoing basis with an upcharge for any material price increases that I could demonstrate. My pricing is thus competitive at all times, no assumptions need be made and the client either becomes responsible for price increases if necessary or not. Their choice.

– Michael Flatt 21_0741_CN_Contractor_MAY_JUN_CN Mod: March 18, 2021 12:50 PM Print: 04/21/21 9:54:40 AM page 1 v7

The federal government released its 2021 budget on April 19. Here are some highlights of special interest to the home-building industry. Budget 2021 proposes to provide $4.4 billion on a cash basis to the Canada Mortgage and Housing Corporation to help homeowners complete deep home retrofits through interest-free loans worth up to $40,000. Loans would be available to homeowners and landlords who undertake retrofits identified through an authorized EnerGuide energy assessment. In combination with available grants announced in the Fall Economic Statement, this would help eligible participants make deeper, more costly retrofits that have the biggest impact in reducing a home’s environmental footprint and energy bills. Some homes in certain regions of Quebec have had serious and costly structural problems as a result of the presence of the mineral pyrrhotite in their foundations. In response, the government of Quebec has provided significant financial support to affected homeowners to replace foundations and undertake other necessary repairs. To help more homeowners dealing with the consequences of pyrrhotite, the government of Canada provided $30 million over three years in Budget 2016. Quebec recently announced an additional $25.7 million in its 2021 budget. Budget 2021 proposes to extend the CEWS wage subsidy until Sept. 25. It also proposes to gradually decrease the subsidy rate, beginning July 4, in order to ensure an orderly phase-out of the program as vaccinations are completed and the economy reopens. It proposes to extend the rent subsidy and Lockdown Support until Sept. 25. It also proposes to gradually decrease the rate of the rent subsidy, beginning July 4. The government recently extended the application deadline for Canada Emergency Business Account to

A proposed ASTM International standard will help engineers to better understand how various climates affect water vapour transmission of water-resistive barriers and air barriers in building envelopes. ASTM’s performance of buildings committee (E06) is developing the proposed standard. ASTM International member Danko Davidovic says that the proposed

June 30. The government proposes to provide up to 12 additional weeks of Canada Recovery Benefit to a maximum of 50 weeks. Budget 2021 proposes to introduce the new Canada Recovery Hiring Program for eligible employers that continue to experience qualifying declines in revenues relative to before the pandemic. The proposed subsidy would offset a portion of the extra costs employers take on as they reopen, either by increasing wages or hours worked, or hiring more staff. The budget also proposes many longterm changes to EI.

Budget 2021 proposes to provide up to $101.4 million over five years to Innovation, Science and Economic Development Canada for the Small Business and Entrepreneurship Development Program. To provide affordable financing, increase data and strengthen capacity within the entrepreneurship ecosystem, Budget 2021 proposes to provide up to $146.9 million over four years to strengthen the Women Entrepreneurship Strategy. Budget 2021 proposes to provide up to an additional $51.7 million over four years, starting in 2021-22, to ISEDC and the regional development agencies for the Black Entrepreneurship Program. Budget 2021 proposes to provide $960 million over three years to Employment and Social Development Canada for a new Sectoral Workforce Solutions Program. Budget 2021 announces that the government will engage with stakeholders to examine what barriers exist to the creation of employee ownership trusts in Canada, and how workers and owners of private businesses in Canada could benefit from the use of employee ownership trusts. cc

standard (WK51917) will explain how WRB/AB function in various wall and roof assemblies.

“The proposed standard is focused on factors affecting WRB/AB performance, best practices to test, and ways to easily report water vapour transmission characteristics,” says Davidovic, a senior building scientist at Huber Engineered Woods. “The standard will be easy to follow and reflect the current best building science practices regarding how water vapour transmission properties of WRB/AB impact moisture transport through wall and roof assemblies.”

Davidovic notes the following potential uses for the proposed standard. Manufacturers will find the

proposed standard to be a resource to educate themselves about real-life performance of WRB/AB products. Regulatory agencies will be able to improve water vapour transmission property requirements for WRB/AB materials and systems in current building codes. Architects, designers, and engineering professionals will be able to better calibrate the design requirements and specify WRB/AB water vapour transmission properties in their design documents. Educators will be able to use the proposed standard as a supplemental educational tool in engineering curriculums for building envelopes, as well as in industry training programs on the best WRB/AB products for a particular project. cc

In response to feedback from various industry partners, the Western Retail Lumber Association has prepared the following update on the current situation facing the building materials industry. The strong housing and R&R market has placed a high demand on all building materials and the industry continues to be caught in a cycle of catch-up as demand continues to outpace supply. Mills and manufacturers have been struggling with surges in demand all while juggling closures, labour shortages, raw material shortages and transportation issues. Price increases and delays have extended to product lines beyond lumber resulting from raw material shortages, increased transportation costs and continued labour shortages. Resins have been greatly impacted and it will take time to recover. Plastic packaging has also been impacted in some cases creating additional delays. Transportation continues to be a concern. Insulation is experiencing raw material shortages as well from resins to glass, impacting the ability for production to keep up with the demand. Drywall demand continues to outpace supply and trucking issues are extending lead times here as well. Steel products have seen increases in the range of 50 percent and there is a good chance there will be more on the way. A shortage in global zinc supply in 2020 created shortages in the product. Roofing products such as shingles and accessories are also in high demand and tight supply. WRLA urges industry members to reach out with questions and suggestions. cc

After a year of the pandemic, Canadian homeowners are more likely to plan renovations than buy and sell their current property or purchase an investment home, despite an active housing market, a Scotiabank poll revealed. Six in 10 Canadian homeowners are planning to renovate in the next two years, with backyards, kitchens and bathrooms topping the list. Among Canadian homeowners planning renovations, one in four are looking to start in the next six months. One in four Canadians who are currently renting (24 percent) plan to buy a home in the next two years. About half of Canadians (49 percent) planning to purchase an additional property will pay for the down payment with their savings. Regionally, plans for renovations are highest in the prairie provinces, with 70 percent in Manitoba and Saskatchewan and 62 percent in Alberta. Top three renovation spaces for Canadians: backyards (33 percent), bathrooms (30 percent) and kitchens

March 2021 marked the third consecutive month of recordsetting numbers as building permits rose 5.7 percent to $10.9 billion, reflecting a booming residential sector. The residential sector climbed 15.9 percent, clearing the $8 billion mark for the first time in March. Multi-family dwellings jumped 24.5 percent compared with February to an unprecedented $4.3 billion. This gain resulted largely from permits being issued for residential towers in the Ontario cities of Toronto, Burlington, and Vaughan. Singlefamily homes also reached new heights, increasing 7.6 percent to $3.8 billion. Oshawa, Ont., was responsible for just over one-third of this growth. Three consecutive monthly highs led to a record-setting first quarter, up 12.7 percent to $31.2 billion compared with the fourth quarter of 2020. Gains were reported in all components. On a constant dollar basis, the first quarter of 2021 posted the largest value since the start of the series in 2011 ($23.3 billion), beating out the previous record of $22.3 billion in the second quarter of 2019. The first three months of 2021 were the highest posted in the residential sector (plus15 percent). Single-family homes (plus 22.8 percent) showed stronger quarterly growth than multi-family dwellings (plus 8.3 percent) and both reached new heights by breaking previous records set in the fourth quarter of 2020. Commercial permits decreased 14.6 percent to $1.5 billion, about 25 percent lower than the average monthly value reported in 2019. After declining slightly in the first two months of 2020, commercial permits took a large hit at the start of the pandemic, and have since averaged around the $1.5 billion mark observed in March. cc

(28 percent). In a recent survey by HomeStars, almost three quarters (74 percent) of Canadian homeowners said they are planning to improve their homes in 2021. The national survey found that the most popular projects this year will be outdoor work including landscaping and decks, with 54 percent of homeowners planning to improve their outdoor space. In second place came bathroom renovations at 32 percent, followed by kitchens at 23 percent. Basement renovations and appliance repair/replace round out the top five at 17 and 12 percent, respectively. Twenty-nine percent cited the reason for renovating was to enjoy their outdoor space now that they are spending more time at home. Fourteen percent of homeowners said since they weren’t spending on vacations, they would invest the money in home renovations and repairs. Only six percent planned to spend money on improving their work-from-home and homeschooling space. When asked why they were planning on renovating, 50 percent mentioned they were renovating their home to ensure they could age more comfortably, not surprising considering 79 percent of respondents said they were planning on aging at home. cc

things,” Jeremy recalls.

Shortly afterwards, friends and family started inquiring about getting work done at their properties. And in 2009, Bella Vista Development Corp. was born. Headquartered in Saskatoon, the company services a two-hour radius around the city.

“We started with smaller renovations and grew to larger projects and eventually custom homes,” Sheena says.

“We were doing a lot of kitchen renovations,” Jeremy adds.

But to be successful in the kitchen business you need to have a kitchen cabinet line, Jeremy explains.

“So we started dealing a Canadian-manufactured cabinetry product line. We have been repping that product for eight years, focused on kitchen renovations. We stayed out of the homebuilding business for a while,” Jeremy says. “But as the market shifted and demand increased, we ended up building a house for a family friend. That led to us to designing and building houses.”

In addition to custom-builds, the company now focuses on larger, more complex renovations, as well as its signature mid- to high-end kitchens.

Bella Vista is looking to become a household name in Saskatoon.

By Andrew Snook

WhenSheena and Jeremy Sinclair tried their hands in the renovation market for the first time, they had no idea they were taking their first steps to becoming professional homebuilders. While looking for a new home for Sheena’s grandparents in Swift Current, Sask., they found a place in the right location but required significant work. Between Jeremy’s experience in the construction sector and Sheena’s design background, the couple felt they were up for the challenge.

“We ended up doing a three-month renovation of the home and moved them into it. It turned out rather fabulous and I seemed to excel at the project management side of

“Our renovation focus is now on major renovations, we’re not tackling smaller projects anymore,” Sheena says. “We’re doing custom home buildings and additions, as well as kitchens. We have a kitchen designer on staff. It’s been a good fit.”

The company typically employs up to eight full-time staff, although they needed to reduce staff temporarily, like many other companies, when the COVID-19 pandemic first hit.

“We geared down last year because of COVID, but we’re ramping up again,” Sheena says. “Sales are going back to pre-pandemic levels.”

their dream home set

While the challenges related to sales are lessening, issues around obtaining building materials is a constant challenge.

“Quotes from suppliers are coming in effective immediately then only good for three days, compared to a few weeks or a month. One supplier gave us a quote valid for only 24 hours,” Sheena says. “To have a client change something, then have to go back to the supplier to get re-quoted, and then get that extra step of approval is difficult in that short turnaround.”

On one project the couple is managing they’ve had to change the flooring three times, because the first two floorings ended up not being available, locked up in a port in another part of the world.

“Most of the things we’re purchasing aren’t made here in Canada, which, in my opinion, is not the greatest idea for Canadians to continue to be doing – importing things from all over the world,” Jeremy says. “We try to focus on buying more local product, but they also have their issues with product supply as well.”

Jeremy says the biggest challenge related to the pandemic has been the constant changing regulations and the unknown end date for when COVID-19 will be under control.

“People can’t go to work if they have a cold. Then you have to figure out how many people are allowed in a house at one time. Then we’re cutting back the number of workers in a house and constantly managing schedules,” he says. “We’ve got a tight-knit group of subtrades, so we’re accustomed to being around each other. Then we have to police things, making sure they understand they have to wear masks and that they have to hand sanitizer and socially distance.”

In addition to managing the constantly changing schedules, there’s the worry about what people are doing in their free time.

“Working in other people’s houses during a pandemic, going in and out of them all the time, is a slippery slope. I don’t know where my apprentice electrician was the night before [for example], so there’s a little bit of stress,” Jeremy says.

One benefit of the pandemic is that people are stuck in their homes, many of whom have additional savings due to not being able to go on vacations, which means more homeowners looking to renovate.

“People are sick of looking at the same things,” Sheena says.

“The increase in sales is a challenge. Not a negative challenge, but still a challenge. Since most people want everything now,” Jeremy adds.

Taking on more projects can be difficult, given

and

Saskatchewan’s short building season.

“In Saskatchewan, we only have five good months of the year for working,” Jeremy says. “Trying to pile on more projects in that smaller period of time can be a challenge.”

Although retaining staff has generally not been a huge challenge for the company, it is something the couple regularly thinks about.

“Once you find those people and demand goes up, you need to keep them happy where they are, so they enjoy coming to work and enjoy the projects they’re working on. Training is a big investment,” Sheena says. “There’s no

one-size-fits-all for employee retention. The biggest thing is communication.”

Before the pandemic, Sheena and Jeremy regularly enjoyed celebrating milestones and other achievements with their staff. But, like many other things, they had to change their routine to adapt to life with the threat of COVID-19.

“We won a Saskatoon and Region Home Builders’ Association home award this year. We were a finalist in three categories and won Best New Home Design. Normally there’s a gala, but it was cancelled. So, we celebrated in the office with just our staff,” Sheena says. “The association sent over a package with champagne. It felt really good to get together after so long.”

The Saskatoon and Region Home Builders’ Association award may not be the final piece of hardware the company collects this year.

“We have a national awards competition coming up and we’re a finalist there as well,” Sheena says, referring to the Canadian Home Builders’ Association Awards.

The project up for the national award, which also won the Saskatoon and Region Home Builders’ Association Award, was one of the company’s most challenging projects.

“It started out as a referral from another house we built. The family wanted us to change the carpets and redo a couple of bathrooms. But when we looked at things after the demolition, we found evidence of mould. Then we did more demolition and found more mould, which led to tearing down their house. That process was super challenging. The family had no plan to tear down their house,” Jeremy recalls.

The house sat on a prime area of Saskatoon with a nice view of the South Saskatchewan River.

“It wasn’t on the water, it was on the other side of the

street. But we designed the house with as many views of the river as possible, and they didn’t have a home to live in, so we had to do it rather quickly. We designed a beautiful three-storey home where you have multiple views of the city,” Jeremy says. “Planning the new build was challenging because it was designed under such tight timelines with homeowners that hadn’t been thinking of a giant wish list for a year in advance. It’s something that we’re very proud of.”

The biggest challenge of running the company has been balancing it with raising a family.

“We have two kids. People think business owners work independently and come and go as they wish, but we’re at the beck and call of our customers. Weekends count, we’re obligated to them. It’s someone’s home. So, trying to raise a family through that, and losing your business partner for parts of those years is probably the biggest hurdle [when Sheena was taking some time off and working from home for a few months after their children were born],” Jeremy says.

In the future, Sheena and Jeremy hope to continue to grow their brand and become a household name in Saskatoon and through the region.

“We want a slower, steady pace of growth, to manage it effectively while maintaining our customer service,” Sheena says. cc

By Steve Ryan

In our last column we made the argument that residential construction, more than most industries, needs standards for who may participate as a contractor. With purchases as large as home improvements or new homes, there is too great a risk that a family’s financial future can be ruined by engaging a contractor who is not up to the job. “I think I can” hardly stands as qualification to be a contractor, but in most parts of Canada, that is all it takes.

There is a valid counter point that when that much money is involved, a great deal of research should naturally follow. It is probably true that many consumers set themselves up for failure because they don’t do their homework. One might reasonably think that the principle of “buyer beware” should prevail as it does in other areas of the economy.

For this industry to take that approach is self-destructive though. Other professions learned that lesson so long ago that we may overlook the fact that they too had to take consumer protection into their own hands. Today, it seems preposterous that anyone could simply claim to be a doctor, lawyer or accountant. But that is because those professions recognized it was unrealistic to expect buyers to adequately judge qualifications for themselves. The principle of “buyer beware” doesn’t work in those professions, and it’s time to recognize that it doesn’t work for residential construction either for many of the same reasons.

The prime directive should be to improve the quality of information consumers use to make their decisions. That is what licensing accomplishes when implemented correctly. “If your service provider is licensed, you can be confident they have the capabilities and the ethics to protect your interests.”

Unfortunately, it is that last word – “correctly” – that trips us up. Where contractor licensing does exist, it is often a municipal requirement. You may work in one of those municipalities. How well does your license prove your capability? Yeah, I thought so. Do you think the average consumer is even aware of that licensing requirement? Yeah, I thought not.

Done correctly, licensing does two things. It filters out the least competent, and makes obvious to buyers who complies with minimum standards of professionalism. It makes very clear, very public statements to that effect so that consumers

actively seek out licensed providers as the best way to protect their own interests. In short, licensing makes it easier for consumers to make informed decisions by consolidating many of their most crucial questions into one: “Is this business licensed?”

The regulators often look at it differently. They feel the greatest attribute of licensing is that it eliminates the rogues and fast talkers. I disagree. Policing to take out offenders just isn’t that effective. Once again, if you are in an area that has contractor licensing, how easy is it for other contractors to function without one. Yeah, I thought so.

Licensing people see their primary purpose as enforcement. But that isn’t actually achieved very effectively. The practical objective should be to provide consumers with a simple straightforward tool to do the research they need but are unable to do for themselves. We don’t need legislated licensing to achieve that.

The industry should be capable of elevating professional standards itself and communicating them to consumers. The challenge for you is to accept standards that may not land just where you think they should. We all need the humility to commit to a common front.

The call to action for all contractors is to find your voice and get engaged. Take this specific question to your local home builder’s association. If you’re not a member, make it a condition of joining. Some associations, like the Saskatoon and Region Home Builder’s Association and the Greater Toronto chapter of RenoMark have clearly articulated standards and training requirements. By committing members and enforcing standards of professionalism, they can make the pledge to consumers “when you work with our members, the questions most crucial to your welfare have already been answered.”

Ultimately, it comes back to that frustrating fact that customers often don’t know how to do their own research. Well-defined professional standards offer the buying public a concise and practical way to get it done. They can only do that if professional contractors make it happen. cc

Steve Ryan is the founder of MMI Professional Services. MMI is committed to the success of contractors by helping them develop the business and management skills they need. For information on ways to run a better building business contact the writer at steveryan@mmiproservices.com.

MacMinn Contracting revamped a historic house into a modern masterpiece.

By Gordon Wornoff

After 30 years working in Toronto, Alan MacMinn returned to his hometown of Victoria, B.C., rebranded his contracting business, and took a solid first step with his banner build, “Ross Bay.”

His efforts led to four awards this past November from the Victoria Residential Builders Association in the

2020 Construction Achievements and Renovations of Excellence awards of Vancouver Island.

MacMinn Contracting’s debut in Victoria earned “Best Residential Renovation or Restoration,” “Best Interior – Residential under 2,500 square feet,” “Best Heritage Project,” and “Best Contemporary Bathroom.”

Alan MacMinn discusses what it takes to uproot your business, relocate across the country, and maintain the same standard of quality.

You ran Redux Renovations in Toronto for 17 years, winning multiple awards for your work. Your first build in Victoria gets

four awards. How did you pull that off?

I didn’t move here for retirement, not quite yet. In order to establish myself as a builder and a renovator, I needed to pick a project that potential clients could look at. They can always go to my website and see photos, but it’s better if people can come and kick the tires – to get more of a feel of what I can do.

So I picked the house. But I also needed a place to live in. It was kind of a twofer. A project house or “show home” and a place for my wife and I to live.

I found this house that was nearly falling apart. An Edwardian near the water in the Fairfield area, built in 1911.The house had a lot of things

going for it – location probably being number one. Secondly, I’m experienced working on homes of this vintage. The housing stock back east is mostly turn -of-the-century when you’re working in downtown Toronto. These kinds of structures are normal for me. I wasn’t intimidated by what I might find. I just assumed I might find some crazy stuff.

Did you uncover any trouble?

There were a few oddities, but nothing major. It was balloon-framed. There was no subfloor on the second floor. It was just the finished fir flooring. I ripped it up and said, “Wait they’re missing a subfloor here.” It was weird. They had put their finished floor across the joists and then built their partition walls on top of the finished floor. It is a strange methodology, but maybe it was more common out here. I never saw it back east.

Can you please describe some of the features and what went

The fireplace is original to the home although I had to rebuild the firebox. We salvaged the original tile surround which is that iridescent green. This fireplace originally burned coal, so I sourced a replica coal-burning basket from Georgia. I saved the original decorative Victorian cast-iron surround.

For the fire source, I’ve got an open flame gas burner that vents up the existing chimney – no glass in front. I avoided the more common, direct vent setup, because it’s sealed behind glass and looks like the fireplace channel on TV. I want a little snap, crackle, and pop. I want a little smell, a little visual. It may not be as efficient as a directvent, but you’re looking at the closest simulation to an authentic fireplace without all the mess and work of firewood. And to me, in an urban context, the fireplace is all about ambience.

The patio was designed by

James Darnell of Land Story Design Associates. We installed a large contemporary concrete surround that separates the patio from the garden behind. We decided against any cladding, any stone. It includes a fireplace and a water feature. I chose to feature the gas burner without any adornment, so all you see is flames shooting out of the flame bar. No piles of coloured glass or pebbles or lava or other media. The rim of the water feature is at perfect seating height and it’s got a nice width to it.

I wanted a connection between indoor and outdoor here, so I decided to blow the entire back wall out. We put in a 16-by-nine-foot commercial

grandiose shower. It’s a four-by-eightfoot shower, curbless, and gently slopes to a linear drain. It’s got heated floors, large format tiles that creep up the wall for continuity. There’re no clips on the glass whatsoever. We installed the glass first and ran them up to the ceiling joists. Then we drywalled up to the glass and ran a bead of silicone. The shower head is flush mounted. It’s very minimal in an intentional way. Even the LED lighting is recessed into the ceiling. I had to

get that right. I’m so sick of pot lights. So my electrician and I experimented with different LED strips and the oneinch flush-mounted housing channels. We set them up for testing and I would come by at night to see if they cast enough light.

grade curtain wall into the rear of the house. It took eight installers to put it in. I didn’t want a deck because that disconnects you from the yard. From the hallway or the kitchen inside, you can easily see the lovely patio and garden out back.

It was a very deliberate effort to be boldly contemporary in the ensuite bathroom and the kitchen. The rest of the house features original wainscotting and scroll work and railing systems – there is a fealty to the historic. I had the exterior wood siding custom milled. This bathroom has no trim on the windows; it’s meant to be a completely different space. In the ensuite, we went all-in on a

You have a very modern style. Clean lines, glass and concrete, white finishes. Beautiful. What are some of your pet peeves in residential design?

I remember in the golden days of flipping in Toronto, suddenly my plumber announces, “I bought a house, I’m gonna flip it.” The people get great plumbing, sorry about the finishes. People think they can do it but ignore the details which are so important. Good design is a fine line. I have some strong ideas on a lot of things. I picked up a lot of my skills and knowledge through osmosis while working. I worked for years in the film

industry before I became a contractor. I worked in the art department, mostly in set design. I’ve created whole worlds in a past life. I was wellsuited for getting the details right and recreating the intricacies required.

One thing I see that bothers me are heritage homes with front-porch additions that were not part of the original architect’s vision of the façade. I think it’s important how the home looks from the outside.

Façades are important to me. The front of the home, it faces the street, it’s what presents. So, I’m very particular about how you present to the street. If you are going to replace the windows of a house, don’t pick and choose, replace them all. You can’t do a $300 000 renovation and still have a few brown aluminum windows while the rest are white.

How did it feel, starting fresh in a new city, knowing what you left behind?

Brutal. I just cry about it all the time. I had the best framer in the city, hands down. He is a super nice guy and reasonable. He always answered his phone, just the greatest guy. And my assistant, I just spoke to him the other day, was the most valuable, most amazing number two.

And then my list of subs – three or four deep for each trade in my rolodex. I just had to pick up the phone and it’s done.

And that’s another thing – in Toronto you’ve got a wealth of personnel available compared to here. Here it is so tough. So, so tough finding good people. I’m new and that’s part of it. There’s also a much more laid-back attitude out here. The market seems much less competitive than back east and prices are high as a result.

I miss my guys. I miss the working environment that I built up over the years. I kind of left at the top of my game out there and now I have to deal with the fallout from that.

What’s the plan to get back in the game?

I’m starting over, from the bottom up. Part of the “Ross Bay” build has been to join the local building association, build a super great place, win some awards, and bring up my profile. So it’s really a market strategy.

After the awards I sent out letters to all the designers and architects, just sort of saying, “Hi, here I am if you can

ever use me.” If I can get one or two nibbles out of that, that will be all I can expect.

The phone is ringing. I’m featured in a local lifestyle magazine. The quality of life is great out here. Things are working out. cc

Land-Con Luxury Landscapes creates winning projects every year.

By Gordon Wornoff

Each year, Landscape Ontario hosts an Awards of Excellence Gala to recognize exceptional and extraordinary landscape design and construction. With more than 2000 members, the competition is fierce and the awards prestigious.

Land-Con Luxury Landscapes from Concord, Ont., was victorious in earning the coveted Casey Van Maris Award for unique and innovative design in landscaping.

Their residential project, “Bold and Bubbly,” incorporates a pool, fire feature, 300lb. steel screens, and an outdoor TV wall with a pergola over it. Land-Con remains on a winning streak, every year earning a few more awards for their inventive, bold, and flawless backyard revivals.

Co-founder Ofer Winkler offers his story and insight after decades in the GTA landscape industry.

in York Region. I grew too fast, and it was very stressful. It got to the point where I got fed up and sold it. Then I built up an irrigation business and I sold that as well.

After those experiences, were you hesitant to partner with Jeremy Lerner for Land-Con?

I knew it was going to work. I had zero doubts. At that point Jeremy and I had known each other for about 20 years. I was excited to have a partner. It’s in my nature to trust people. I had just started having kids, and when they were babies it was really hard.

You had 1,000 clients and 25 employees in your mid-20s in Thornhill, Ont. Now you are the co-founder of a thriving luxury landscaping company. Did starting young help catapult your career?

I finished high school but I don’t have any post-secondary – no college, no university. I never had the patience to sit in the class; I love being outdoors and that’s where it all started.

It always felt natural for me to run a business. Looking back, when you are young and in business, you make mistakes. I had a maintenance business, one of the biggest

He’s a hard worker, we have a very similar background, and we both have experience in business, in the industry. Before Jeremy, I had three different partnerships with people that didn’t work out. All three of them, looking back, it was not a good idea. They didn’t have the same work ethic as me. Nine to five, you can’t do that in business, unfortunately. Seven a.m. to 10 p.m. – that’s the life we live.

What is your strategy for attracting clients?

Spending on marketing and advertising is big. Now it’s all digital, but 20 to 25 years ago, it was all about flyers, mailings, and we even had faxes we would send out. Fax advertising [laughs]. I have tried every type of advertising and marketing technique and route you can think of. I’ve done cold calls. Walking around neighbourhoods, business parks, knocking on doors. When you’re starting out, you have to try everything.

“Bold and Bubbly,” incorporates a pool, fire feature, 300-pound steel screens, and an outdoor TV wall with a pergola over it.

You offer a five-year warranty on all your work, which is transferable even if a client sells their home. What motivates that? Marketing? Loyalty to your customers? We want to give the client that secure feeling. We want people to trust us. We’re not afraid to give it out because we know our work is going to be good for that many years. We were just talking the other day about offering a ten-year warranty. Why not? I know our stuff lasts. If you’re selling a Ferrari you can give a ten-year warranty on the engine because you know nothing is going to go wrong.

How has tech changed the landscaping business?

Back in the day, we did designs on a napkin with a pen. “Okay, you’ll get a 20-by-20-foot patio, we’ll spread some boulders in there.” Bam, contract on the spot. Now, it’s very involved. We have designers go out to the

house, and the client has pictures from Pinterest, Google images, Houzz -- there’s a world of pictures out there. We give them 3D renderings, identical to real life. There’re all these websites that specifically target home renovations and improvements. We have a presence on all those sites. Everything in our industry is evolving like crazy now.

You used to have like three choices of stone. Now you have hundreds. You have access to natural stone from every country, every continent in the world -- China, India, Europe, US, obviously Canada, Africa and Australia. Every colour, any stone, any type of natural boulder you can think of – it’s all here now.

And then you have the man-made stone which has evolved from the simple rectangle brick look to any colour you can think of, any colour mix, any size. You can get slabs four by four feet, any thickness, for any application. And they make it all to look just like natural stone – all the ripples,

imperfections, – hundreds of colours and textures. It’s endless.

LED lighting is in everything now. Before you could only put three outdoor lights on a circuit.

And there’s constantly new innovations for stairs, for walls, for retaining walls, for pavers, railings, for waterfalls, composite materials for decks. It’s all becoming huge, it’s booming.

Artificial grass is becoming big. Even that looks more natural – it’s not that shiny green any more, now they put a little yellow in it to make it look natural. Different thicknesses, different heights, too.

We love to use as many elements as possible. Granite countertops in the outdoor kitchens. Composite, steel, wood, glass, aluminum, wrought iron, natural stone, manmade stone. And then all your varieties of plants on top of that.

Generally speaking, what is the most expensive feature clients want?

It’s often the cabana which accompanies the pool. The cabana has a washroom inside, it has a TV inside, it has heating. It’s like a mini-house. A cabana can get very expensive. You need footings, a permit – you need structural engineered drawings.

Best part of the job?

The name we have built for ourselves and our reputation makes life easier in so many ways. The respect we get now really helps. We can just make a quick phone call and get things done because of our relationship with dealers and manufacturers and subcontractors. When you are smaller and nobody knows who you are, you don’t get that respect and you are not a high priority for people.

What are some lows you’ve experienced on the job?

I’ve had very, very few customers like this, but some just squeeze the life out of you. They take advantage, you have a hard time collecting, they try to scare you. It’s a real downer to deal with these people every day. They’re in your life for awhile, right? These projects are not a day or two. They last weeks, unfortunately. Once it dragged on for months, that was very difficult.

And, of course, like anybody, you have those very long days, you are super stressed, it seems like nothing’s going right, there’s fires to put out everywhere. That’s our job: to make sure the client is happy. Along the way, there’s always breakdowns and material shortages – now more than ever during this COVID time.

The pandemic has accelerated demand so completely, business has snowballed. We’ve had to expand very quickly to keep up. That comes with a lot of challenges. Materials, whether it’s stone, pools, barbecues, all of it, you’re waiting months and months for anything. Sometimes they tell you two months and when that time comes they tell you it’s another month. It’s very hard to plan. We understand, manufacturers have new protocols in place, less stuff is getting produced, more demand. We thank God every day that we’re working. So many industries are being shut down completely.

Do you remember any key moments in your career where everything clicked for you?

Doing things the right way is the best lesson. Not cutting corners is huge. Sometimes, you rush. You try to do things quicker but that never works. You always have to find the problem before the customer sees it. Never wait to see if the client catches it. That’s business and maturity coming together. Take pride in your work.

You know, I can’t say I’ve actually had time to think back and reflect like I’m doing right now. We’ve got big goals for this company. It’s literally just, “go, go, go,” year after year. Looking at the awards we’ve won, I’m reminded of all these things we used to look at, these dreams, and all those thoughts in the back of your mind that say you’ll never get to there. But then you find yourself there and you don’t even have time to look back and say, “Whoa. How the hell did this even happen?” And I’m not even talking about that long ago. We’ve grown really fast as a company.

Last month we opened a second location in Aurora. We’ve already got our Concord location and one in Aurora. This second one will be a retail store and showroom selling outdoor furniture, hot tubs, and with offices for our staff as well. We’ve had so many people give us such positive feedback, it’s been a blessing. cc

Three practical options for helping clients enjoy more time outdoors.

By Steve Maxwell

This summer promises to involve more outdoor time than usual for Canadians, and that’s why you’ll probably be asked to take on different kinds of projects this building season. Increased outdoor living is something people have been doing more of for a year now, and this summer and autumn will be at least as extreme. The new normal, at least for the time being, is a lot more home time and a lot more resources put into making that home and yard special. Here are three outdoor living options to consider talking to clients about.

While decks are a popular outdoor upgrade for Canadians, ordinary designs fall short in one big way. The usefulness of a deck is greatly limited because it provides no shelter. Strange as it sounds, adding a verandah-style roof over a deck boosts the outdoor living value a lot. That’s because a covered deck becomes a transition zone, a place where the virtues of fresh air and sunshine are still present, but tempered to make them more sustainably enjoyable. Besides allowing comfortable enjoyment of fresh air even when it’s rainy or way too hot and sunny, covered verandah’s make life much easier on windows and doors because of the shelter they afford. Deck finishes last longer, outdoor furniture resists fading better, and the household enjoys more space for storing outdoor gear from the weather.

Modifying a garage is the fastest, easiest and cheapest option for increasing outdoor living space in a home. With that big garage door open fully the space becomes much more outdoorsy, though standard concrete floors remain a problem. Bare concrete is neither inviting nor beautiful. It’s also hard on the feet if you stand on concrete for a long time and this is where basement-style OSB subfloor panels can

make a big difference. Typically made in twoby-two-foot shapes, subfloor panels fit together with tongue and groove edges and they take paint quite well if your client is looking for something other than the chipboard look.

The best modified garages can still be used to store cars if your client wants that, but a few things can make things better. If you’re working with a double garage, consider preparing one side for leisure and leaving the other side for vehicle storage. Some of the nicest enhanced garages I’ve seen have indoor/outdoor carpet on subfloor tiles with a hot tub and lounge chairs nearby. Put a fridge out there and some fairy lights and your clients will have a great space to enjoy leisure time during the day or night.

Paving brick, flagstone and textured concrete are the three main options for civilizing a backyard outdoor living space, and the freedom from mud and dust is one big benefit. The thing to understand is that best hardscaping these days is permeable. The ability to let water flow through and into the soil is a big thing because more and more urban areas often have trouble dealing with the sudden spike in storm sewer water flow. Most paved surfaces are not absorbent enough, and if too high a percentage of area is paved it can and does overwhelm storm sewer systems. This is why urban municipalities often enact bylaws preventing the paving of surfaces using conventional paving products. This doesn’t mean that backyards can’t be made to handle more traffic in all weather.

An entire sector of the paving products industry is now devoted to making durable but permeable surfaces that let water simply flow right through. The thing is, many municipal clerks don’t understand the improvements and have blanket bylaws against any kind of paving of lawns and backyards. Don’t take no for an answer because permeable hardscape products are an up-and-coming thing with many effective products to choose from.

Our world might be different than usual for the time being, but that doesn’t mean there aren’t many opportunities to build great things profitably. cc

Who would have thought that supplies of pressure treated lumber would become so low that money simply can’t buy the stuff in many areas of Canada. And while you could just go ahead and build outdoor projects in the usual way using whatever non-PT wood you can lay your hands on, that wouldn’t be fair to clients because the results they pay for won’t last nearly as long as they should. A better approach (and one that will win the respect of clients if you explain it to them) involves using good design and whatever rot-resistant wood you can find. Minimizing wood-to-wood contact is always a good idea because wood needs to remain wet to rot. Spacer strips, double floor joists, spaced deck board ends, cedar and composite lumber are all options for building well in a PT-free world. Outdoor wood structures were often built well without pressure-treated lumber years ago, and this can happen again.

When clients start talking about outdoor projects, their minds and hearts often turn to ideas of “natural”. This usually means lots of exposed wood, typically finished in some way that lets the grain show through. This is precisely when you need to become something of a diplomat. Very few homeowners understand how much work is required to keep that nice bright, new lumber looking better than barn board. Explain the need to sand and strip back to bare wood every few years before applying another coat or two of stain and you may get their attention. Talk about all the new low-maintenance building materials that make life a lot easier. Composite lumber, factory-finished metal siding and synthetic trim and molding substitutes are the main ones. Why does it make sense for you to steer clients away from their own ideas sometimes? Even though it’s illogical, clients often blame their contractor when a project becomes a burden over time, even when you have nothing to do with the natural forces of decay.

STAIN IT ONCE

ecowoodtreatment.com

Ecowood Treatment is a water-based wood finishing product that you only apply once. It changes the colour of the wood permanently. It’s a non-toxic wood stain that gives all wood a high-end aged look with just one application and no need to ever re-stain and no maintenance needed. The product is environmentally safe, non-toxic and lasts a very long time. It can be applied to decks, fences and siding. Ecowood Treatment creates a silvery patina for a high-end, aged, weathered look. It can be used for exterior or interior applications. It mixes completely with water – no inert particles are added. Recognized by the U.S. Green Building Council for LEED points. Ecowood Treatment is designed to not wear off, fade or peel. Unlike other sealers and stains, Ecowood Treatment migrates and covers the exposed wood as cracking occurs. The wood’s natural beauty is enhanced. Ecowood Treatment is a powder composed of natural substances from minerals. It contains no solvents and leaves no harmful residue in water or soil. It is safe to use on retaining walls or any structure that penetrates into the soil or into the water, containing only 100 percent organic compounds. cc

GARAGE LIVEABLE

dricore.com

COVID restrictions on indoor gathering has many homeowners converting their garages into living space. But what about that cold, hard concrete floor? Dricore subfloor is designed with a high-density plastic membrane containing a patented air-gap pattern to ensure that moisture emitted from concrete floors can naturally evaporate. Even small water leaks will not reach the floor covering. The secondary layer of oriented strand board provides a solid foundation that can support any type of finished floor and furniture. The panels elevate finished floors to create a thermal break from the cold concrete. Tongue and groove design makes the installation fast and easy. A 500-square-foot room can be completed in an afternoon. The raised subfloor panel design creates positive airflow beneath the finished floor to help protect against mould and mildew growth. Compatible with all types of finished flooring, Dricore panels can be used with laminate, luxury vinyl tile, engineered hardwood, carpet and tile. Strong enough to support gym equipment and large furniture, Dricore subfloors are rated to support up to 6,642 pounds per square foot. cc

trexrainescape.com

As our homes have become offices, classrooms and fitness facilities, space has become a precious commodity. The area beneath an elevated deck can offer an ideal solution. With the addition of an under-deck drainage system, this space can become usable for a multitude of purposes. Using a network of troughs and downspouts, an under-deck drainage system captures and diverts water away from a deck, not only preserving the studwork, but also making the area under the deck useable for storage or as additional living space. Once protected, the dry space beneath a deck can be used like any room inside a house. There are two main types of drainage systems – those that install above or below the joists of the substructure. For maximum protection, opt for an above-the-joist system, such as Trex RainEscape. The main advantage to this type of system is that it protects the entire foundation and the area beneath the deck. Systems that install below the joists leave wood and metal exposed to the elements and are more susceptible to water damage and corrosion. This type of system can also trap moisture in the core supports of the substructure, which can lead to rotting

Some call TrapEase 3 the ultimate composite deck screws. They create a perfect colour match with several specific composites. They are designed to create a clean, finished look without pre-drilling in all three types of synthetic decking: composite, PVC, and capstock. TrapEase 3 screws feature anti-fade head paint, the new anti-strip Torx TTAP drive system and a lifetime corrosion warranty. The Torx TTAP drive system features a stability button which delivers superior stick-fit and wobble-free installation that eliminates fastener strip-out. Individual bits are now available. The FastenMaster Spotter installation guide reduces installation time by consistently placing the fasteners and gapping the deck boards. TrapEase 3 screws are approved for use with over a dozen popular composite deck board brands. cc

and deterioration. Trex RainEscape is easy and efficient to install – whether during a new deck build or when replacing existing deck boards. The entire system includes just five SKUs and installation requires three basic tools: scissors or a utility knife, a staple gun hammer and a caulk gun. Each trough is clearly labeled with staple markers to expedite the process, which takes no more than a few hours to complete. And, the system is backed by a 20-year warranty from Trex. This minor upgrade can have a major impact on customer satisfaction and your bottom line – especially during a season as busy as this one promises to be. cc

Adam is a small independent contractor just starting out in the business. He’s got a truck, his tools, a helper, and not much else. He’s able to pick up enough work in his rural area through word-of-mouth to pay the bills, but he’s living job to job. The hours are long, money is tight and the strain has been too much for his long-time girlfriend. She’s moved out and taken their daughter with her. Juggling co-parenting and dealing with all the rest of the fallout from the separation has proven a significant distraction and expense. Then disaster strikes. His helper totals the truck, gets hurt and can’t work. The insurance company says he shouldn’t have been driving it and refuses to pay. Adam is looking at a long, expensive legal battle. He’s going to incur additional expenses to rent or buy a new truck. And he doesn’t have his worker and doesn’t know where he’ll find another. Then there’s the worker’s compensation claim. Adam is a man on the edge. He doesn’t have a lot of other skills and construction is his passion...

Justin’s dilemma over rapidly fluctuating supply prices brought in several innovative strategy suggestions. But Paul Leach of Iron Cabin wins for combining price protections, flexibility for both the contractor and the client, and legal protections.

In Justin’s situation, communication with the client is the most important aspect of his business’ success, as incorrect communication could result not only in him losing the job but in him being sued for misrepresentation, fraud or failure to provide goods and services, which affects his reputation and his livelihood. I suggest that Justin take some extra time to ensure that this does not happen by sitting with the client and explaining the current circumstance as it relates to supply and demand. Armed with statistics and figures from the past year’s industry suppliers (lumber, drywall, concrete, etc.), he can easily show the economic shift in pricing and justify the fact that he is unable to provide a static quote on the project, as he is at the mercy of the fluctuating market. He can then ensure that the client’s satisfaction is paramount by making modifications to his regular business model to involve the client more thoroughly in the process. This, ideally, would mean that Justin would provide a base quote to the client, informed by the current prices in the economy. He could suggest an additional 15 percent contingency to cover possible increase in materials costs due to the market but, prior to making any purchases that go over that 15 percent threshold, he will consult with the client so that they can sign off on it. Not only does this absolve Justin of any accusations of overcharging, misrepresentation or fraudulent business practices but it involves the client as a partner in the project, which is beneficial to both parties and encourages transparency and trust in the transaction. At that stage, the client may opt to go with a less expensive material or product, keeping their costs lower and keeping Justin working. To further protect himself, Justin would get a lawyer to draft a standard contract with this information included, as well as the inclusion of a “kill fee,” where, if the client decided that the project was too expensive to continue, it could be terminated (or put on hold), and a reasonable fee would be paid to Justin to bridge the downtime between that client and the next. If the client isn’t amenable and feels that they can get a better deal elsewhere, it is in Justin’s best interests to let it go, rather than trying to compete when, most likely, the job done by contractors who quote less will be sub-standard in both, the work and the materials.

1. Suck it up. Find a lender wherever he can and go into debt to keep things going. Hard work will turn things around in time.

2. Take a job with a larger contractor and give up his dream of owning his own business...at least for now.

3. Skip town, leave it all behind and try to start anew in a faraway place. Like maybe somewhere in the Caribbean.

4. Go back to school to learn some new trade or get a degree. Obviously he’s not cut out for this business.

5. Something else?

HOW TO ENTER

If you have a solution to Adam’s dilemma, email your entry to pflannery@annexbusinessmedia.com and put “Adam’s dilemma” in the subject line. Please don’t post your response to the comments on the Dilemma post on our website.

Entries close June 7. The winner will be announced in our July/August issue.

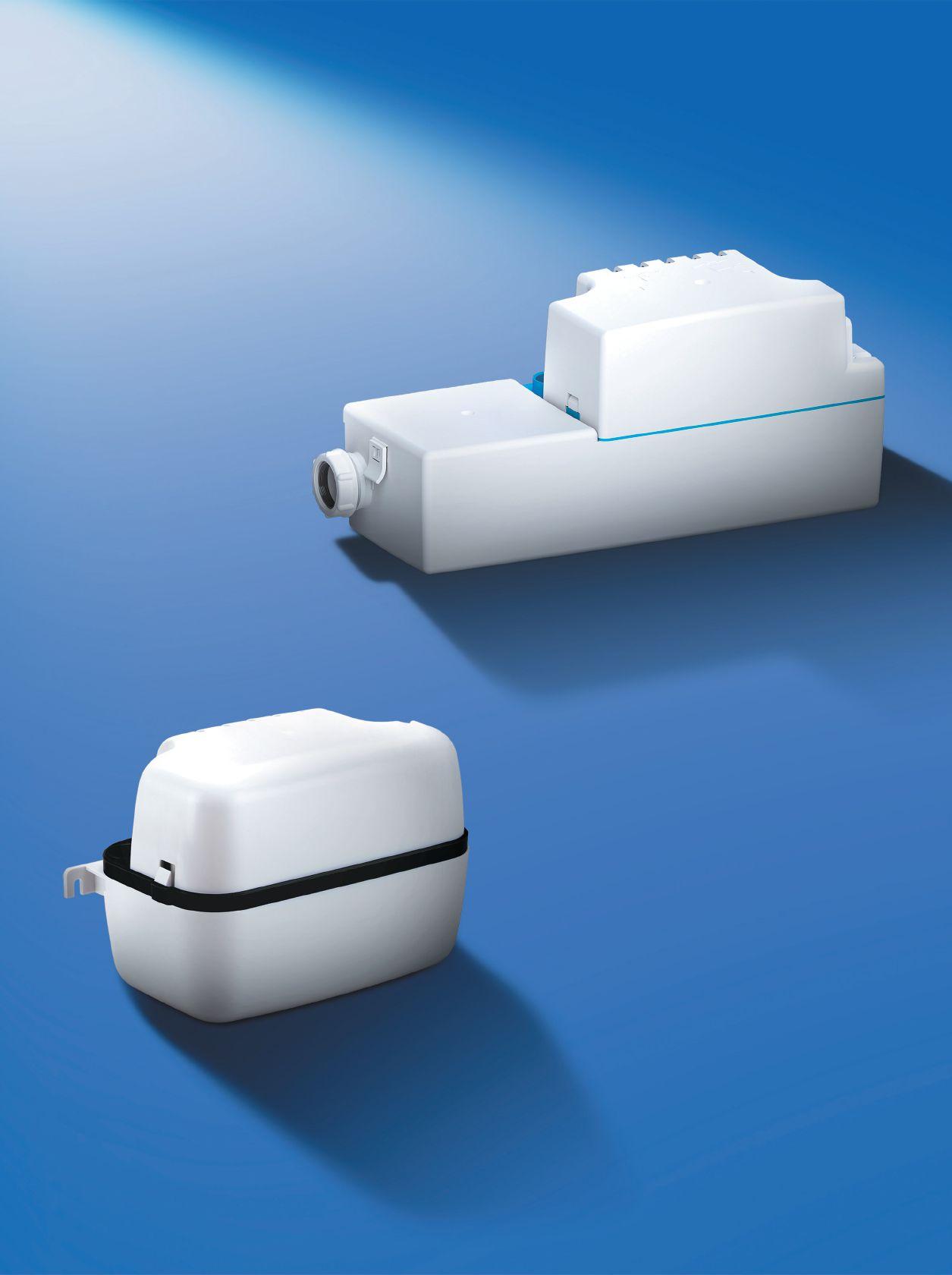

Residential and commercial condensate pumps with multiple inlets will discharge up to 15 Ft vertically.

Standard 3-year warranty. Comes with ready to install connections to an alarm system or shut-off switch

Equipped with 20 feet of vinyl tubing, PVC discharge adapter and neutralizing granules*.

Low profile commercial model with built-in neutralizer can handle up to 500,000 BTU/hour*.

*