Why True Zero Energy Housing Is So Difficult To Achieve

Page 14

Buying Tools & Material Online: Save Time and Save Money

Page 18

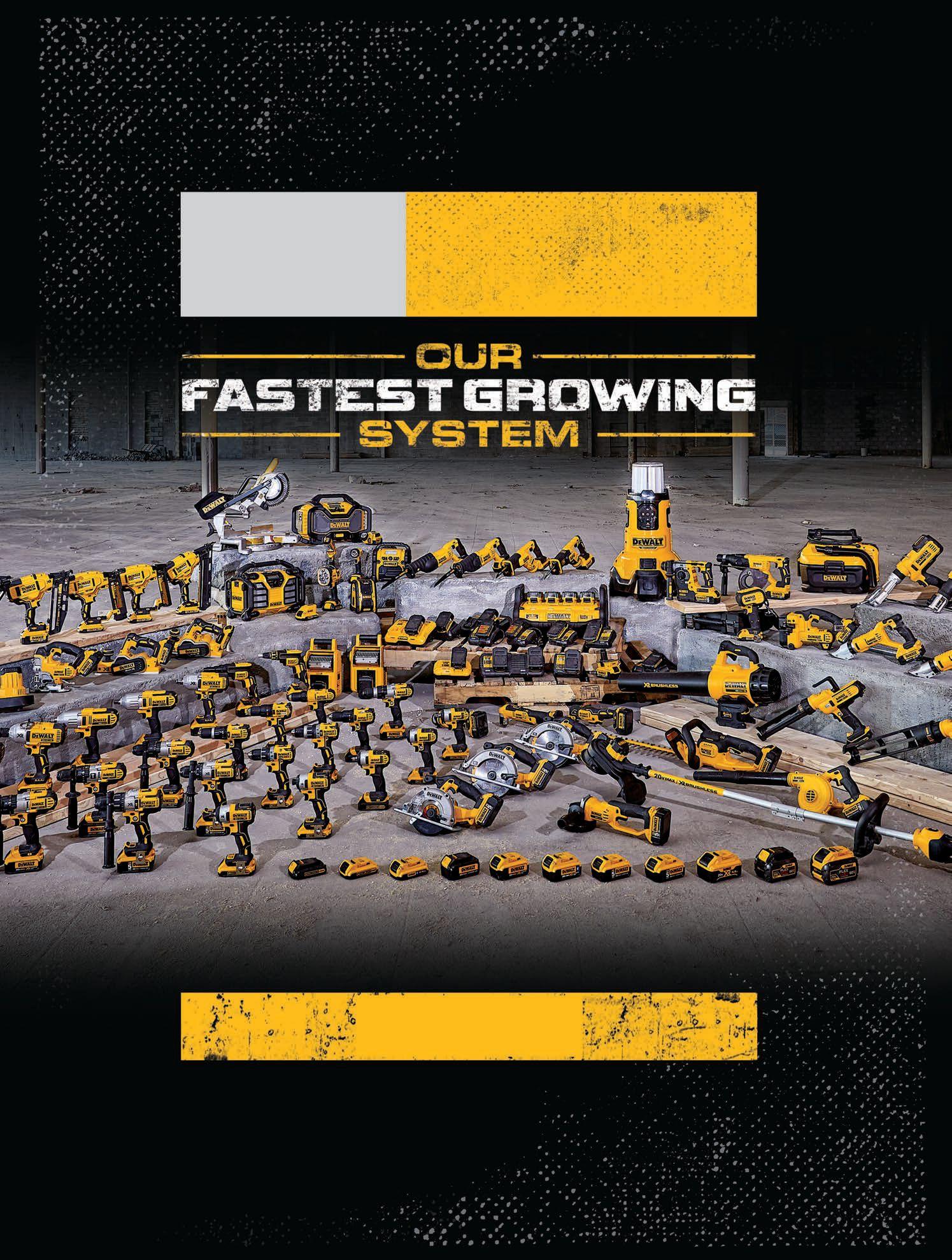

Cordless Power Tools So Good That The Amish Are Using Them

Page 40

Why True Zero Energy Housing Is So Difficult To Achieve

Page 14

Buying Tools & Material Online: Save Time and Save Money

Page 18

Cordless Power Tools So Good That The Amish Are Using Them

Page 40

How an Edmonton vice principal became one of her city's leading home builders and renovators

Page 22

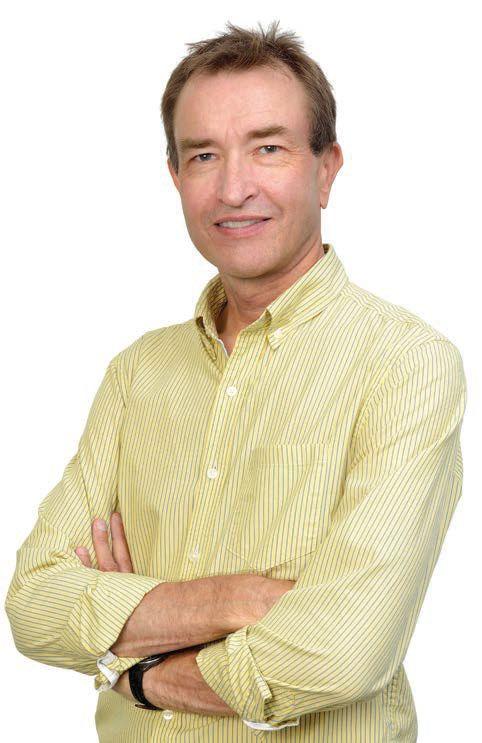

Housing 14 Energy-efficiency expert Paul Duffy explains the difference between Near Zero, Net Zero and Zero Energy.

Online 18 Three cool places to buy paint supplies, power tools and building supplies on your phone.

STORY: MARIE SOPROVICH 22

Edmonton’s Marie Soprovich never set out to be the owner of a large residential contracting firm. But fate and courage have changed her life.

Surf’s Up 32

John Bleasby takes us on a photographic tour of the CHBA’s Best Custom Home Under 2,500 sq.ft., a stunning build on the west side of Vancouver. Steve Maxwell’s Stuff We Like 39 Are you operating at your optimum RPM? Mennonite contractors and cordless power tools. Standby power generators.

Rob Koci Publisher rkoci@canadiancontractor.ca

” If you don’t have a vision for your future, how can you expect anyone to back you?

”

By Rob Koci

Recently, I had the opportunity to interview most of the staff of a midsized renovation company. They loved their jobs, were fiercely loyal to the owner and were hoping to grow with the company for their entire careers. They were a staff any of you would kill for.

They had reason to be that good. Fiercely loyal himself, the owner was apt to teach and loved nothing more than to see the staff prosper personally and professionally. He was a great boss.

But I was worried. The owner had no vision for the company. Why? “If I ever planned to be somewhere in the future it was guaranteed to never happen,” he said.“And where I am today, which is a pretty good place, I never planned. So what good would a vision do me?”

We all know too well the capricious truth he expressed.

In grade one, I decided I was going to play professional football. But I stopped growing in my teens at 5’-7,” 150 lbs. So much for that dream.

Next, I imagined myself a novelist. But a couple of years later, I was peeling 100-foot power cords out of six inches of cold March mud making $7 per hour as a framer.

In midlife, I saw myself running a multi-million dollar renovation company, and here I am, publisher of a magazine.

Things don’t work out as you envisage a lot of the time. As the famous quote says, ”Life is what happens while you are making other plans.”

I asked those employees I was interviewing at the renovation firm where they saw themselves in five or ten years. Almost all of them expected to be better off, with more money, a better position and having to do less physical work. Those were their dreams, anyway.

“Do you think you can fulfill those dreams at this company?” I asked. They shrugged their shoulders. They had no idea. They could invest their present in the company, but they had no way of investing their future there because the owner hadn’t even considered what that future might be.

It doesn’t have to be this way. Today, when it matters most, your employees need to know where your company is going.

Because when you tell your people about your vision for your company, it’s not boasting and it’s not wishful thinking. It’s so your staff can make the decision to invest their careers – or much of them – in you.

You owe them – and yourself – that much.

By Steve Payne

As I write this, the world’s most famous guitar manufacturer, Gibson is filing for bankruptcy.

And yesterday, we had a long talk with one of the most successful pro renovators in the country about his business woes. No, he’s not going to declare bankruptcy, but he just had to lend his firm a large sum of money. Money that he’d socked away for retirement and didn’t think he’d need to use to boost up his cash flow.

Gibson guitars got itself into trouble by diversifying too far away from its core business into something called Gibson Brands Inc. It lost focus. Our friend (we’ll call him Jerry) got his business into trouble by losing focus, too.

Jerry’s problem was (and is) perfectionism. Contractors walk a fine line between production and perfection. Produce too fast and your quality slides; try to be too perfect and your gross margin crashes.

That’s what happened to Jerry. His gross margin collapsed. Once enjoying a healthy 35 per cent gross margin, Jerry noticed that he’d slid all the way down to 15 per cent “just like that.”

It’s never “just like that,” of course.

In Jerry’s case, a number of errors compounded to put him in the position of working for free, once his overheads were factored in. First of all, he decided to use his line of credit too liberally. Cushioned by this false sense of security, Jerry let his job costing slide and didn’t notice that his subtrade prices had crept up. And his guys were working way too slow. Finally, reporting from the field was so poor that client requests that should have been change orders were being done for free.

Luckily, Jerry and his wife have the money to refloat his boat. The company is a good one, with a stellar reputation and loyal, repeat clients. But Jerry’s got religion. Of all of the changes that he is implementing, his Price Book is the one that he’s counting on the most. Now, once a year, all of his regular subs will be asked to quote chapter and verse pricing for standard work they do for Jerry – by the hour, board foot, square foot, by the piece, etc. There has to be a really good reason to deviate from that pricing, and Jerry needs to know about it in advance.

Gibson guitars will likely rebound from Chapter 11; their brand is that good. Jerry will be fine, too. How about you? Do you need a Price Book?

” His gross margin dropped to 15 per cent Steve Payne

spayne@canadiancontractor.ca

www.canadiancontractor.ca has everything you need to build better and build a better business…

Sponsored by ITW/GRK/Tapcon

Most contractors don’t give a second thought as to how common building material fasteners actually work. There’s a lot of science involved – and it can actually make you a much better contractor if you take a few minutes to study it. Our All About Fasteners video series will, over time, cover every type of common fastener, from concrete anchors, to concrete pins and specialty screws... and more.

Sponsored by VELUX

Once upon a time, contractors would shudder when the homeowner client said they wanted skylights installed. There are a number of myths about skylights that still exist today and they include: They leak; They waste energy; They are complicated; You can’t make money installing them; There’s no training. Rob Koci dispels each of these skylight myths with Mark Taylor and Russell Ibbotson from VELUX.

Sponsored by NUDURA

Whether you are ready for it or not, governments and municipalities across Canada are pushing “Net Zero” building requirements into contractors’ daily lives, commencing in 2030 –with changes to building codes beginning already. What does this mean to you, the contractor? Well, for one, now would be a good time to learn to build with Insulated Concrete Forms (ICF’s). In this video series, Rob Koci discusses The Road to Net Zero with Gary Meine of NUDURA.

ISSN 1498-8941 (Print)

Editor

Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Kim Laudrum, Steve Maxwell

Art Director Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Ted Markle, Chief Operating Officer tmarkle@annexbusinessmedia.com

Mike Fredericks, President & CEO

Circulation email: lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875 or 416-442-2191

Annex

If this is your boardroom, you’re a Pro.

Home Hardware is a nationwide supplier of quality, name brand products to Pros of all trades. Whether you are a homebuilder, a renovator, a plumber or an electrician, Home Hardware is a Pro source for everything you need on your next job.

Dedicated Pro sales staff, job site delivery, home plan services, material takeoffs, package pricing, convenient ordering options, credit services, rewards program, and exclusive e-offers are just some of the benefits we offer!

Sign up today to receive pro exclusive email offers and news. homehardware.ca/en/forms/register

In April, we reported that one of the largest construction projects in Canada, Toronto’s Crosstown LRT, had been shut down for a day because of workers allegedly smoking pot. We got a lot of online posts echoing the warnings of the Ontario General Contractors Association, who had told an Ontario government hearing last year that legalizing pot was going to significantly increase construction injuries and fatalities.

“Put Justin and Kathleen on a worksite as labourers and have the machine operators stoned”

I think we should put Justin, Kathleen and the rest of their members on a work site as labourers, and have the machine operators stoned. Or better yet have them run a jobsite, with time and financial responsibility, with stoned workers working for them. They would change the legalized marijuana laws the same day.

Joe

Locksmith's reputation being destroyed by pot

Glad to see Canadian Contractor tackling this wrestle between “legal” and “right” when it comes to marijuana. I had a locksmith show up stinking of pot. His work was beyond sloppy and he blamed everything under the sun for the reasons why. It was like dealing with an unmotivated 30 year-old pre-teen. There’s no doubt in my mind his addiction was robbing him of clarity and ultimately will destroy his reputation and business in the not too distant future.

Neil Damackine

Contractor Al Barnes recently posted under a (really) old article we wrote about Mike Holmes. He makes some good points.

The elements of a quality basement reno

One of the things that bothers me about Mike Holmes is that he never chastises homeowners for trying to do projects for less money because that’s all they have.

As a contractor, I have given hundreds of estimates where I was not awarded the job because the client said it was too much. Then I would find out that they had it done by someone else for half my price – and were not satisfied with the workmanship or finish.

I have done many basements. My average 800 to 1,000 sq.ft.

basement finishing job usually costs in the area of $40,000. This includes: fully finished spaces (with framing, insulation and vapor barrier), finished ceiling (drywall or suspended), multiple separations, hallways, doors and hardware, bathroom rough-in (only), full-code electrical with dedicated circuits and average lighting fixtures, a sub-floor and finished floor (be it wood, laminate and/or carpeting), and multiple paint colors with contrasting trim. This is all done correctly with all new materials.

For every contractor like myself who wouldn’t do this project for $20,000, there are ten who would. And those are the ones who give the industry a bad name.

That said, when three or four contractors estimate the job at around $40,000 and the potential customer says they want it done for $20,000 (“It’s all we have and we want it done right away!”) who is really at fault when the job is botched and they need to call Mike Holmes.

As much as I believe it should be done right, is the onus completely on the contractors who will do it for $20,000 because that’s all that the client is willing to pay? Personally, I always tell clients like this to wait until they have saved enough to do it right .

Al Barnes

The Ontario Residential Tenancies Act says that a property owner can ask a tenant to move out if the property is going to undergo substantial renovations. But under the Act, the tenants are supposed to have first right of refusal to move back into the renovated unit without a substantial rate increase. Where the tenants are denied that right, the word “Renovictions” has been coined. The Ontario Liberals say they may toughen up the legislation to wipe out Renovictions. Here is a post about that.

While tenants’ rights should not be violated, and they should not be tricked or swindled out of their homes, the property owner’s right to save or improve their investment (and livelihood) should be upheld. The tenants should be given ample opportunity to find a temporary home while renovations happen. But they should also be prepared to pay accordingly for modernization and upgrades if they want to return. You can’t cry about living in a slum and having to pay a reasonable amount for an upgraded home. Kicking people out unfairly is not acceptable. But neither is living in luxury for a pauper’s wage.

Terry

In March, John Bleasby wrote a post about refugees to Canada and the potential to hire them into the trades.

And then we have Quebec! Please let me know how I can legally take advantage of a skilled immigrant labor pool in this province. It is tremendously difficult, if not impossible, for a skilled immigrant to find legal employment in the Quebec construction industry without language skills and connections, etc. The bottom line is that they end up being employed in the black market by unscrupulous “contractors” who undercut those of us trying to operate within the law. Thus making it impossible to make a decent living without also participating in this practice.

“La Belle Province”?

“b— s—!”

Tim, Montreal

“Safety profession is a ‘make work’ project!”

Safety is a personal responsibility. Your supervisor cannot climb a ladder for you. If an Ontarian were to read the current rules or discuss them with a Ministry of Labour inspector, they would realize that it is impossible and potentially illegal to climb a ladder in order to affix a “D-ring” to a building.

The make-work project that is Canada’s “safety profession” does only two things. First, it creates more government jobs –making a Hoover Dam out of rules and red tape. And second, it impedes the ability of competent construction professionals to carry out basic, albeit risky, tasks.

It should also be mentioned that the bizarre convolution of safety rules provides plenty of regulatory loopholes for the insurance industry (a major donor to Ontario’s political parties) and the WSIB to renege on their policy holders when accidents do happen.

Chris Langman

It’staken a bit of time for Ontario’s justice system to nail two separate cases of malfeasance by Toronto-area contractors. Charges were laid back in 2015 and 2016 under the province’s Consumer Protection Act against Adam Gardin, of Garcon Building Group, and Michael Last of TLG Contracting Inc., resulting from the rip-off of homeowners and trades for amounts totaling hundreds of thousands of dollars. There are finally some developments.

Gardin pled guilty to 11 charges this past March. Among the charges laid under Ontario’s Consumer Protection Act, Gardin agreed that he “engaged in an unfair practice.” Eight families had sued Gardin back in June 2015 claiming he had taken a total of over a million dollars of dollars in deposits for various home improvement projects before walking away from the barely-begun work. Gardin is scheduled to be sentenced in August, a sentence that may include jail time.

Last was arrested in late 2016 for alleged frauds on homeowners totalling over $260,000 as far back as 2015. Detective Paul Mackrell of the Toronto Police Services Financial Fraud Department told Canadian Contractor that Last pleaded guilty to all charges this past February and was ordered to pay restitution to those who were bilked.

Adam Gardin and Garcon

As recently as 2014, Gardin’s company Garcon had been a topranked firm on HomeStars. In fact, Garcon had been a HomeStars “Best Of” winner in 2010 and 2011. However, the fall from grace came quickly and publicly. In January 2015, Gardin was the subject of a protest by his subtrades and employees in front of his Toronto residence for allegedly failing to pay them while abandoning some 20 of his current renovation and homebuilding projects.

By way of defence, Gardin told the few media outlets that could find him that he was personally broke. It was estimated that in 2014, Garcon had total debts in excess of $1 million. Gardin told Global News at the time: “It’s not like I have a wad of money. If I was a thief, if I was defrauding somebody, I’d be on the next plane

to Vegas.” Ironically, it was reported that Gardin had gambling debts of approximately $100,000 incurred at casinos much closer to home in Niagara Falls and Windsor.

Gardin later expressed remorse for his actions in an email to the Toronto Star. “I truly wish that I had not caused so many people to suffer. While I realize my words do not help solve anything, I hope that you will at least understand that I did not intentionally create this mess.”

Despite his claims of financial distress, Canadian Contractor has recently learned that Gardin, an American citizen now living in Michigan, has since purchased a number of properties in the Detroit area.

Meanwhile, Michael Last and his TLG Contracting outfit had been the subject of several complaints posted on-line on HomeStars. One such complaint spoke of a 50 per cent deposit being taken at the time of the contract signing.

“On October 16, 2015 we signed the contract with TLG Contracting Ltd.,” the review says. “We were never provided an executed copy of the agreement. The first payment (deposit) of $35,736.25 was made on Oct. 22. The contract that was executed shows that an additional $35,736.25 would be given to TLG Contracting Ltd on Nov. 2, 2015. As we felt very uncomfortable about giving 50 per cent upfront prior to any work being done it was agreed by all parties that the draw schedule would be bumped. Work was to commence on Nov. 2, 2015. Initial delays on the side of TLG Contracting Ltd cause a one week delay on start date. Many issues with delays and poor scheduling transpired between November and December 15, 2015 which was to be the second draw. Although milestones were not met we were convinced that the second draw should be given otherwise TLG would be losing money.”

Work delays continued into the next year, the review alleges, along with requests for more payments and even a request for a personal loan for a vacation property down payment.

The original charges laid against TLG in 2016 named Michael

Last and his alleged business partner Kirsten Henderson. Recently, Henderson’s lawyer contacted Canadian Contractor claiming that Henderson never had any business ties to Last or TLG Contracting Inc. Indeed, Henderson’s name does not appear on any of TLG’s corporate registration documents. Detective Mackrell confirmed to Canadian Contractor that fraud charges against Henderson were dropped earlier this year.

John Bleasby

As of March 1, Trademark Renovations of Calgary began accepting Bitcoin and Ethereum as a method of payment for both renovation and custom build projects. The firm claims to be the first general contractor in Canada to allow customers to pay for their services unsing cryptocurrency.

Trademark is a multi award-winning luxury renovations contractor providing upscale full home renovations, roomspecific renovations such as kitchen, basement developments, and home additions as well as custom home builds.

Trademark Renovations owner Blair Foisy said: “I am excited to bring Bitcoin and Ethereum as new payment options to our customers. We believe that blockchain technology and cryptocurrencies will become an important part of everyday transactions for consumers and are happy to be able to offer this new payment alternative for our services to the Calgary public.”

“Trademark has always been on the leading edge of innovation in the construction industry and now they are the first renovation and custom build contractor to embrace the growing popularity of blockchain technology,” said a company press release. “Companies such as Microsoft, Samsung, IBM, Expedia, Kodak, Dell, Tesla and even some banks and governments have already implemented this new technology trend.”

“The decision to start accepting Bitcoin and Ethereum is also indicative that they and other established cryptocurrencies have now developed into more broadly accepted forms of settlement,” Foisy said.

Mirror, mirror on the wall, who’s the greenest province of them all? After a series of recent announcements, it might well be Alberta: Canada’s oil rich and historically most-conservative province.

Last August, Alberta announced a $36 million installation

and rebate program for homeowners and. In early April, Alberta announced the extension of a consumer rebate program that gives Albertans instant savings of up to $15 per item for in-store purchases of easy-to-install, energy-efficient products like programmable thermostats, low-flow showerheads, smart power bars, LED light fixtures, and LED yard lights with motion sensors.

“Our government continues to make it easier and more affordable for Albertans to embrace energy efficiency,” said Shannon Phillips, Minister of Environment and Parks and Minister responsible for the Climate Change Office. “Our popular programs are putting money back into households, supporting local jobs and reducing millions of tonnes of emissions – that’s a win for Alberta families, a win for the economy and a win for the environment.”

The Instant Savings campaign is one of a series of recent energy efficiency announcements, part of the Residential Retail Products Program being funded by $26 million from Alberta’s Climate Leadership Plan over the next three years, aided by $25 million from the federal government’s Low Carbon Economy Leadership Fund. Last year, Albertans received over $24 million in instant rebates by purchasing over 9.5 million energy-efficient products such as programmable thermostats, and energy-efficient washing machines, refrigerators and light bulbs.

This small product rebates pale in comparison, however, to the proposed legislation announced in early April. If passed, the An Act to Enable Clean Energy Improvements would give Alberta municipalities the option to establish a Property Assessed Clean Energy (PACE) program, an initiative that would allow home and business owners to make their spaces more energy-efficient without putting any money down.

Typically, PACE programs pay for 100 per cent of a project’s costs. The home or building owner repays this amount over the next several years as an annual assessment added to the

property tax bill. PACE financing may stay with the building upon sale — the next owner picks up the tab — and is easy to share with tenants.

The province says it believes that the energy savings resulting from the energy-efficient upgrades or renewable energy systems such as solar panels, high-insulation windows and highefficiency heating and cooling systems could be greater than the annual repayment.

The big attraction for governments like Alberta, of course, is that PACE costs the province nothing. It’s an easy-financing plan for municipalities to offer if they choose. It provides great optics, but there is no money at stake. PACE programs were implemented in California ten years ago and have since expanded to most regions in the United States, generating a reported $6 billion in economic activity.

Alberta’s PACE offering certainly has the support of one of the province’s biggest builder associations, BILD Alberta (Building Industry and Land Development Association). “BILD Alberta is pleased to support the PACE program and the opportunity for Albertans to access energy efficiency upgrades with less financial burden,” said Wendy Jabusch, chair of BILD Alberta. “PACE will allow BILD Alberta renovator, developer, builder and supplier members increased ability to offer consumers efficient and renewable energy choices in a more affordable way.”

Retrofitting older buildings to meet higher energy standards though the PACE program is also supported by the Alberta Construction Association. “The ACA feels strongly that PACE programs offer a financially viable way to retrofit older buildings, or for new buildings, to meet future environmental standards. It also offers a method for investment which does not create costs to the taxpayer,” said Paul Verhesen, past president, Alberta Construction Association. cc

John Bleasby

“Hooked for Life”

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole.” So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer.

Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips and screws. You just screw it to the wall and it’s “Hooked for Life.”

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

By Paul Duffy, M.A.Sc., P. Eng.

Haveyou ever wondered why there is so much talk about “Near Zero” or “Net Zero” energy housing versus Zero Energy Houses? After all, we have zero energy land vehicles (they are called bicycles), zero energy water vehicles (they are called sailboats) and zero energy aircraft (they are called gliders). When you really think about it though, even if you have “zero energy” applications like these, some energy input is needed—either human power or some renewable source like wind and solar.

Now, I could go into a long-winded explanation of the laws of thermodynamics in an explanation of why this is so, but that is not really what I wanted to focus this article on. Let it simply be said that we will need to consume at least some energy to make buildings comfortable. The only other option is that you put up with some amount of discomfort—a house that is somewhat too hot in summer or too cold in winter—not necessarily unlivable but outside the normal comfort ranges we expect when mechanical systems temper the indoor air.

If you reframe the question, however, it may be possible to heat and cool a house with the renewable energy that is available on site. Imagine, if you can, a house that could be heated and/or cooled with only the solar energy that is generated from the roof of the building. Such a building is not a “zero energy consuming building,” but it might be thought of as “net zero” or, at the very least, “near zero” energy consumption because the energy captured on the roof offsets the need for heating and cooling.

Now let’s consider the host of factors that affect the captured solar energy that is available for any given building. The amount of energy available will be affected by:

• Latitude of the site

• Slope of the roof

• Weather

• Season of the year

• Shading of the roof

• Orientation of the building

• Time of Day

To have enough energy available consistently, it is likely necessary to oversize the energy collection system such that it overproduces power when conditions are optimal, and so some power is stored to be available to fill in the gaps when available power is sub-optimal (e.g. overnight.)

Storage of energy, via batteries, is expensive so builders usually look for other options. Where allowed, the most economical option is to back-feed power into the electrical utility grid selling the power to the electrical utility. This illustrates the “Net Zero” concept: If energy sold to the utility equals the energy purchased from the utility, the net of those transactions is zero. In future, utilities will increasingly become the vehicle that facilitates such transactions, rather than being energy suppliers only, as they were originally set up.

The prospect of energy independence holds a lot of appeal. So how does this affect the way you build houses?

Firstly, the amount of energy available on the roof is much

smaller than we are used to having as our “peak” energy used in our buildings so it is necessary to take aggressive steps to conserve energy.

Secondly, certain measures are going to be much more effective at minimizing energy use versus others. So it is necessary to clearly understand what to prioritize and what to minimize, and in what order, to get the desired r esult.

Finally, you have to realize that “net zero energy” means different things to different people. Some use net zero energy use (e.g. 0 kWh net energy use) as the target. Others use net zero energy cost as the target (e.g. $0 energy use—usually utilities buy back energy at rates that are much lower than the rates at which they sell them so net zero cost might actually mean you sell a lot more power than you buy to get to net zero cost.)

In most cases, people are promoting concepts of “net zero ready” or “near net zero,” providing a very efficient building but not adding the cost of solar collectors on the roof because solar panels are not cost-effective at present. Whether you realize it or not, the market is very confusing partly because people are promoting near “net zero” concepts where the finished house still consumes a significant amount of energy.

Assuming you want to move along the path to net zero housing, where do you begin?

1. Start with a focus on air tightness. The debate over how tight is too tight is over: the world has moved on! Air leakage is undesirable because it leads to increased energy consumption, it compromises the performance of air permeable insulation, and it can lead to concealed condensation which leads to rot, corrosion, mold, and other health and durability problems.

2. Increase insulation levels. However, be smart about it. Focus on poorly insulated areas: thermal bridges, poorly insulated basement walls, uninsulated slabs on grade. It also makes sense to use continuous insulation—an exterior layer of spray foam or insulating sheathing versus heavier framing with larger cavities for insulation.

3. Use high quality windows. Today’s wall systems are insulated to RSI 3.6 or more. Windows typically one tenth of that value. It makes most sense to improve the thermal performance of the weakest links... and typically that means improving the windows and doors.

4. Avoid running mechanical systems and ductwork through unheated spaces. Even if you bury ducts in a mountain of insulation, the pressure of fan power can cause even minor defects in ductwork to leak a lot of air!

5. Use heat recovery on ventilation air. If you go to so much trouble to keep the heat in, it makes no sense to exhaust heated air to the exterior without recovering at least some heat.

You will notice that I have largely avoided the whole topic of mechanical systems, not because they are not important but because system choices are highly dependent on some very basic assumptions—assumptions that vary greatly across the country. Huge regional variations exist.

In some parts of the country, fossil fuels like natural gas are plentiful and cheap so a low energy house naturally includes the lowest cost fuel. But fossil fuels are typically non-renewable so it becomes difficult to convince some customers we should be using them as our primary heating fuel.

In other parts of the country, there have been conscious policy decisions to only use electricity in the specifications for net zero housing because it is readily available and because it is the only fuel that can be generated locally. Electricity as a heating fuel is costly however—costly enough that it usually makes sense to incorporate air source or even ground source heat pumps into the design to minimize peak load requirements.

Regardless of fuel type, provincial codes are tending to require high efficiency equipment because this has been a relatively simple change to mandate and it results in significant greenhouse gas reductions. The only downside is that Code requirements

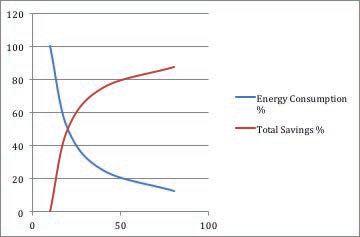

Part of the reason that zero energy consumption is difficult to achieve is that insulation additions follow a pattern of “diminishing returns.” Initially, adding insulation is very effective. But as you add more insulation, there is less energy to be saved, and it takes significantly higher R-values to have an impact on the energy use that remains. The pattern is graphically illustrated in Figure 1 above.

If you start with a base case of a building insulated to R-10 throughout, and then add insulation, initially the savings from adding insulation are very significant, but as you approach higher and higher R-values, the savings begin to level off. Worse yet, you never do reach zero energy consumption. Consequently it is impossible to reach Zero Energy Consumption by adding insulation alone.

requiring high levels of energy efficiency leave relatively small gains available in terms of moving to higher efficiency heating and cooling equipment. Current industry practices already tend to be at the high efficiency end of the spectrum.

When you talk to builders of net zero or near net zero housing, they inevitably want to talk about their wall assemblies and similar innovations, so it is always topical to discuss trends.

Thirty years ago, in the aftermath of the “energy crisis”, builders of super energy efficient houses were experimenting with double walls, fat walls and similar concepts - and that trend has returned. Radically thicker walls, with multiple layers of framing and lots of insulation, are one way to improve performance. The trouble is, this is almost a “brute force” approach—if you are prepared to live with radical changes to your construction process, sequencing problems, detailing issues and a total re-engineering of the houses you build, this might work for you. But for many or perhaps most builders, this is not the preferred approach. It is simply too radical a departure from the way they are used to building to be their preferred method. A growing trend is the so-called hybrid wall. This approach uses layers of different insulation types to increase R-value, air seal, control vapour flows, and fulfil other functions in the wall. Consider a wall comprised of conventional 2x6 framing, with a 3” layer of medium density, closed cell spray foam on the interior of the sheathing and a lower cost insulation filling the rest of the cavity. You can add insulating sheathing or even more closed cell spray foam for a wall assembly with a thermal performance of R-40 or more. There are some cautions with this approach. Do not skimp on the amount of medium density closed cell spray foam you use in the cavity. Medium density foam will effectively become a vapour barrier at thicknesses over 1-½ “, so if you are not careful you could end up with condensation on the interior of the foam. Using more foam (at least 3” thick) tends to avoid this problem in most parts of the country because the interior surface of the foam is closer to the interior, and therefore warmer so it avoids the cold temperatures that cause condensation. There is an added hidden benefit to this approach—the spray foam in the cavity adds structural rigidity to the wall, resisting high winds with added racking strength. Looking to promote a more durable, highly efficient home? This might be the approach that works for you!

Finally, if you follow the technical magazines, there has been a lot of talk about the so-called “perfect wall.” This is a wall with all of the insulation on the exterior of the framing running “continuously” over the studs. Proponents argue that,

if you have enough insulation on the exterior, you don’t need insulation in the cavity, and that whole concern about concealed condensation goes away. The Structural Insulated Panel (or SIP) manufacturers have been arguing in favour of this approach for years. Without framing to interrupt the insulating layer, thermal bridges are eliminated and a higher effective insulation level can be achieved in the same space. More recently, foam sheathing manufacturers and spray foam manufacturers have gotten into the act with wall assemblies predicated on high levels of continuous insulation applied outboard of the stud cavity space.

This trend is being helped along by ever more stringent codes requiring not only high insulation levels but also:

• At least some continuous insulation on the exterior

• Continuous air barriers

• Water resistive barriers

• More sophisticated vapour/condensation control schemes.

Foam sheathing and spray foam manufacturers are actively pursuing schemes to combine these features into their wall system solutions. In commercial buildings, particularly, the trend is to have one material perform several features. If you have to add more insulation, best to do it in a way that combines multiple features into the one product solution.

Manufacturers of insulating sheathing are promoting use of their materials with sealed joints, auxiliary flashings, transition membranes and other accessories that air seal, limit water ingress, and redirect rain back to the exterior as part of their insulation solutions.

Spray foam manufacturers are pursuing similar schemes using medium density closed cell spray foam in combination with transition membranes and flashings. The key difference is that, because foam adheres to the exterior sheathing bridging gaps and sealing around brick ties, penetrations and other elements, the amount of additional work required to provide a continuous air barrier, vapour barrier, water resistive barrier, as well as continuous insulation is greatly reduced. It is not uncommon to see savings of 10 to 20 per cent in installed cost versus other approaches.

Clearly, the path to net zero is very challenging, but savvy builders are re-engineering their homes and using innovative approaches to build better, more durable, as well as, highly energy-efficient homes. Even houses built as recently as five to ten years ago did not have access to the array of innovations coming on the market today. cc

Paul Duffy is an independent Building Science, Engineering and Management Consultant. He may be reached at jpaduffy@ gmail.com.

By Steve Maxwell

Faster,

easier, cheaper and more varied shopping choices are the reasons online shopping has revolutionized consumer buying. These same advantages are also why more and more tradespeople are shopping for materials and professional supplies on the web. Online shopping is a trend that’s here to stay and as the buying options get more sophisticated, it’s helping tradespeople make more money by being more efficient.

Amazon is the king of online shopping for consumer goods, but it’s also grown into one of the hottest places to buy pro tools these days. And it’s not just because Amazon is fast and simple. Extensive user reviews get the word out on the best tools in each category, making it easy to buy intelligently. And it doesn’t hurt that Amazon prices are about as cheap as you can get.

“I never thought online sales of tools would take off, since people want to touch and try their tools first,”says Karl Bach, owner of Prestige Custom Homes in Mississauga, ON. “But I recently made some purchases on Amazon for the only reason that the price was a lot lower than the big box stores. I think places like these will start seeing major competition from online retailers. You try to support local stores to keep jobs, but the prices online can be much lower.”

“Our success in selling tools with Amazon.ca has grown year over year and it’s proving to be a great advantage for us in the world of e-commerce,” says Robert Eddy, e-commerce manager with Stanley Black + Decker Canada. “We offer a great selection of most of our brands which include Black + Decker, DEWALT, Porter Cable, BOSTITCH, and more. We expect to add more variety and see growth continue in the years to come. Pros are using Amazon to save time by having tools delivered right to the jobsite.

The interesting thing is, online shopping doesn’t necessarily need to eliminate local jobs. In fact, the online option can work directly with the most local of materials and supplies for the trades. Something called RenoRun (www.renorun.ca) is a case in point. It’s the mission of Canadian entrepreneur Eamonn O’Rourke and it’s taking off fast. Think of it like the Amazon of building materials. Actually, it’s much faster than Amazon even though it deals with stuff you can’t always tape up in a box.

Download the RenoRun phone app, choose whatever building

materials you need from the 50,000 options on the drop-down menus, then hit the button. You get your stuff in two hours or less if you’re in any of the service areas covered. Cost for delivery is never any more than $65 and it saves you the hassle and expense of pulling someone off the job to go get supplies you need to keep working.

“We started developing RenoRun in 2015,” explains O’Rourke, “and we launched our first location in Montreal in March 2017. Toronto came online in October 2018 and we’re currently looking at Calgary and Vancouver for our next Canadian locations. We’ll be extending the service to include several US cities later this year.”

Will Gonell is owner of Gonell Homes, an award-winning custom home and restoration contractor in the Greater Toronto Area. He’s also been a very satisfied RenoRun user since day one. “I always structure my jobs only with subs”, explains Will, “so the only people who could drive out to get materials are either me or my supervisor. Our time is too valuable for that, so when I saw an Instagram post about RenoRun back in the fall of 2017, I called them up. The owner came out personally to see me. That’s been the kind of high quality experience they’ve delivered throughout. The drivers are great and I have a lot of respect for RenoRun’s support side. I’m always calling them. The service has saved me tons of money and tons of time, and I’ve never had them take two

hours to get to me. Even when I sent them to do a custom run in a nearby city, they got to me in less than two hours.”

Paul Sharples is a 31 year-old finish carpenter and painter from London, Ontario and he recently bought from an online supplier called Paint Supplies Direct (www. paintsuppliesdirect. ca). “I saw a couple of posts on social media that this company had shared and I decided to look at their website,” says Paul. “I never used to be a large online shopper as I enjoy the social aspect of shopping in local stores and businesses. But with kids and full-time work, my time has become limited. So for that reason I’ve started to venture into the online world and have found it extremely convenient. I'm able to do all of my shopping and ordering after business hours from home and still have the product within an extremely reasonable timeline.”

When Toronto inventor Norman Breakey created the paint roller in 1940, it took some painters years before they gave up their brushes for painting big, flat surfaces. These days there isn’t a professional painter anywhere who’d even dream that brushes are always better than a roller. It’s the same with online shopping. The internet is changing the world because it empowers individuals to do things faster, more easily and more directly. The building trades is one of hundreds of sectors being streamlined by online shopping that delivers better goods at cheaper prices and it’s hard to argue with that. cc

Driving to buy stuff is a lot more expensive than it looks. According to the Canadian Automobile Association’s online driving cost calculator (www.caa. ca/car_costs), the total cost of running a late model half-ton is 69 cents per kilometre including fuel and all other costs. Take that 30 km round trip detour to pick up supplies (easy to do), and

that’s more than $20 in direct “delivery” costs, not including the money you’re not earning while driving a truck instead of pushing a roller or managing your team. You’re essentially operating a courier service when you pick supplies up on your own, and if you count the costs honestly you’ll find that you are the most costly delivery option out there.

2 HOUR RE-COAT

You know what it takes to be successful. It starts with you and we can help. Beauti-Tone’s Natura Paint and Primer in One helps improve indoor air quality. Natura paint is virtually odourless and is 100% acrylic. That means better quality, better adhesion, better scrub, excellent chemical and stain resistance too. Available in Eggshell, Pearl and Primer Sealer. Get the job done right with Beauti-Tone’s Natura paint.

MPI #44 Beauti-Tone’s Natura Eggshell

MPI #43 Beauti-Tone’s Natura Pearl

MPI #149 Beauti-Tone’s Natura Primer Sealer

Painters love us for our spatter resistance! See our selection of proven professional coatings at beauti-tone.ca

Edmonton native Marie Soprovich never set out to be the owner of a large residential contracting firm. But fate and courage have changed her life.

INTERVIEW BY JOHN BLEASBY

I CAME INTO THE LEADERSHIP POSITION VERY WOUNDED… THE UNCERTAINTY OF WHERE WE WERE GOING AS A COMPANY WAS ON MY SHOULDERS."

MarieSoprovich could have walked away from her husband’s mid-sized renovation company, Edmonton-based Aquarian Renovations. Everyone would have understood if she had closed the company down or sold it when Doug was diagnosed with cancer. She had a career as a school vice principal and all the security that the position offered. But Marie didn’t walk away. Instead, Marie chose to re-shape the company to take advantage of the skills acquired during her career in education, both out of respect for what Doug had built over the years and as a personal challenge to give her strength for the future.

Leadership transitions can be difficult at the best of times. However, Marie’s situation was particularly difficult. Although she and Doug shared a creative background and often talked about the business at home, the home renovation industry was a world away from the secure culture of the public school system.

Now, six years later, Aquarian thrives as both a renovator and new home builder, handling multiple projects at a time. I met with Marie while she was visiting Toronto and learned about the power of personal commitment.

How much time did you have to transition into the leadership role?

Doug was diagnosed with stage four lung cancer in December 2011. He passed away in November 2012. So he had a few months to talk about things, to teach me, tell me how to do things, how to manage things.

How was the company structured at that time?

Aquarian is a design-build company. Doug did estimating and architectural design work. He had spent a lot of time setting up systems in terms of architectural technologists and estimators. Our total staff ranged from 18 to 24 people over the years.

You had the choice to simply close it down or sell, but you didn’t.

That was floated out as an option. I could not do that. I knew how hard Doug and I worked to build the company, the amazing team we had pulled together, the reputation we had built, the awardwinning work we had done. And I thought, “Everyone deserves the chance to try.” I needed to try, because if I didn’t try, I would have given up on Doug’s legacy.

That was an incredibly hard decision for you, but also difficult for the team at Aquarian.

At the time, we were moving the office out of our basement at home into new offices. The staff knew me, but I had left for work when they showed up and they were gone when I came home. Doug and I talked about the business every day — a lot of the HR things, what projects we were working on, the clients, or my input on how he might handle a difficult conversation he might be expecting. Nevertheless, I came into the leadership position very wounded, not only because I had lost my husband but because I had also lost my career. The uncertainty of where we were going as a company was on both my shoulders and on the staff’s who were running things during the interim.

Your background in education would have given you a sense for process and order. How did you approach the company structure to fit your leadership skills? Where did you find support?

It was a matter of taking what Doug had done, quite an organized company, and restructuring to determine who needed to be in what position. We had a good team in place at that time. And I had a brother-in-law and sister-in-law who worked in the

GET MORE DONE™** with 100+ PRODUCTS in the DEWALT 20V MAX* line. All tools come with upgraded features, superior ergonomics and use Lithium-Ion batteries. For extreme performance, step up to the XR® series and get advanced electronics, extended runtime and faster application speeds.

Aquarian Renovations is a design-build contractor for new build homes as well as renovations of older ones, like the early 20th century farmhouse pictured below.

company. But there were so many things I didn’t know. I needed to live it through it day by day, figure it out, keep moving forward. Another brother-in law in the building industry really helped me understand budgeting and looking at the bigger picture of staff and employees, wages, salaries, what we could afford, the move into our new building. With that kind of support around me, being able to sit in the captain’s chair and listen, I found my strength as a leader.

Were you able to keep the team together for the most part?

We lost some very key people who went to start their own company, and that was a challenge at the time. I really had hoped that they would take this on as something that would allow them to grow, but that’s what happens. Good people left and took others with them. But that was an opportunity to rebuild with the people I hired, people who came to work with me, under my leadership.

Doug would have been on site much of the time. That’s obviously not you. How did you structure your processes to take this into account?

It’s been really refined since I took over from Doug. At the front of the company, I have two designer coordinators. They handle intake calls, screen the calls, talk with clients, and set up appointments for initial site visits. Two go out for a visit — an

estimator and a design coordinator — meet the client to capture the scope of the work, get an idea of the budget and bring that back. We then put together a ballpark package, get that information to the clients, then follow up. I conduct meetings every week with my production team so I know what’s happening on the job sites and how we’re using our manpower over the next few weeks. I also have meetings with the design coordinators, check how many calls we’ve had this week, this month, where we are with follow-up. After that, what I really what I do is business development.

Your career has given you organizational skills and your educational background also means you are very articulate. But what personal steps did you take in terms of the business development you speak of?

I totally immersed myself. I knew I had to. One of the first things was to connect with the Chamber of Commerce. I needed to know what business people looked like. I came from the

education world where there was lots of support and I knew the infrastructure. Take that away and all of a sudden it’s, “OK, where is the new playing field? Who are the people I need to know?” I got involved with another group called Synergy Business Network that meets once a month to listen to speakers. I also took my late husband’s spot on the Renovation Council to learn about the issues that renovators are facing, what we need to talk to city counsellors about, new bylaws coming out, and how we can help each other. I’m co-chairing that committee right now. And I joined the Women’s Presidents Organization (WPO) which is another support group with an international community where we can talk and learn from each other.

Are there other ways your previous background has been an asset for Aquarian?

I’m an educator! I strongly believe that the more we invest in ourselves and our personal growth, the better we get in every place. I’ve offered my staff the opportunity to take a course called The Pursuit of Excellence. Many of them have and I pay for it. We also help put our trades through NAIT (Northern Alberta Institute of Technology) courses, hold their spaces and pay their tuition. I’ve probably put four or five journeyman carpenters through that. If there’s other courses like account training, they can approach me, or I might ask them if it will help them and if they would like to take it.

What has been the most difficult challenge that you have faced since take leadership of Aquarian?

Believing I could do it! It’s huge! But right now, I’ve got a few years under my belt and I’m loving what I’m doing. cc

TV personality and building expert

Damon Bennett is giving away $5,000 worth of GRK fasteners AND a brand new Paslode nailer, to the builder of the best GRK project he can find. It's all part of our

Show Us Your GRK Project

Go to Canadiancontractor.ca, search ITW contest, then send three photos of your best project where you used GRK fasteners.

Explain why your GRK project is the best ever.

Damon will pick the winner for a Canadian Contractor Stuff We Like feature in the Nov/Dec 2018 issue.

After all, Ottawa helped create the problem in the first place, back in the 1970s

By Casey Edge

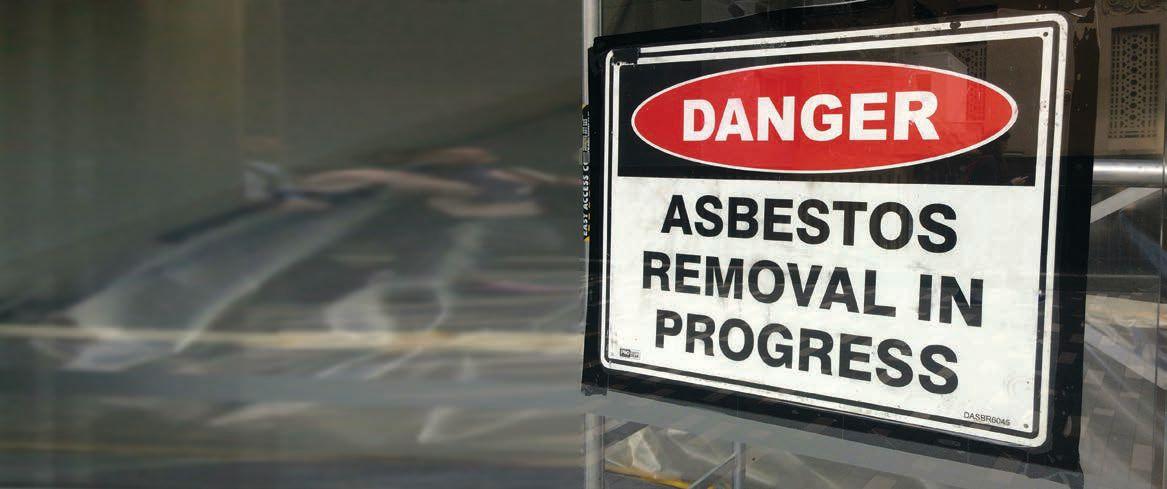

Fewhousing issues have been so widely ignored by Canada’s political parties as asbestos in homes. This is particularly poignant considering the federal government originally promoted and subsidized the use and installation of asbestos as part of energy efficiency programs.

Let’s review the history of asbestos insulation in this country. In the 1970s and 80s, the federal government’s Canadian Home Insulation Program (CHIP) offered grants for installation of insulation such as Zonolite in consumers’ homes. In 1984, the Federal Government established The Asbestos Institute to promote the use of asbestos.

Consumers and contractors relied on the government to ensure these products were safe, which in hindsight, was not the case. In fact, today, asbestos is in the process of being removed from building codes. Asbestos remediation by contractors is highly regulated. Why is there no oversight for homeowners?

Asbestos can be found in stucco, drywall, roof shingles, window putty, vinyl and linoleum floor tiles, electrical wires, insulation and more. However, safe remediation and removal is required in order not to create new health hazards. Provincial regulators such as WorkSafeBC have established very stringent and expensive regulations for renovations, demolitions, and handling of building materials that may contain asbestos, especially in older homes. These regulations include employee training, hiring consultants, testing materials, and hazardous materials management procedures costing thousands of dollars. Unfortunately, some consumers may try to avoid these costs by undertaking their own remediation, over which there is little regulation. According to BC’s Ministry of Environment, “The

management of waste asbestos, including transportation and disposal, from residential buildings is within the ministry’s jurisdiction, but the decision to remove and the removal process is not.” Government officials are quick to pounce on contractors not abiding by regulatory details, yet there is zero interest in a homeowner exposing his family to asbestos.

We have written to Canada’s elected representatives: Liberals, Conservatives, NDP, and the Green Party. None has expressed any interest in helping to mitigate asbestos in home renovations. Perhaps the Green Party might be interested if asbestos was transferred via a pipeline in B.C. rather than sitting in thousands of Canadian homes?

The time is long overdue for the Canadian government to take responsibility and offer a tax credit program to assist with the costs of a health and safety problem which they helped to create and fund. Provincial governments should also take some responsibility in addressing the significant costs of their regulations.

History has demonstrated again and again that elected officials and bureaucrats must be wary about pushing energy efficiency over health and safety and proven practice in our building code. The unintended consequences Canadians have witnessed and experienced include asbestos, urea formaldehyde and leaky condos. When governments err, they have an obligation to step up and assist Canadian homeowners. cc

Casey Edge is the Executive Director of the Victoria Residential Builders Association, an independent organization tackling national, provincial and municipal housing issues on behalf of Canadians.

Under 2,500 sq. ft. Mackenzie Heights, Vancouver, BC

Contractor:

Roadhouse Homes Ltd., Langley, BC

Architect: Go Design

Collaborative Studio, Vancouver, BC

Exterior project photos: Ema Peter Photography

Construction photos:

Roadhouse Homes Ltd.

By John Bleasby

One of the challenges of this home was blending four different types of cladding, each with different thicknesses: acrylic stucco, Equitone TE 80 (an architectural fibre cement paneling material from Austria) and AL13 metal panelling. The exterior wood treatment is CedaPRO red cedar marine plywood.

Wood framing was installed around the moment arms: steel posts and beams required due to the seismic activity in the area. The lower level concrete was left exposed and parged. Frost levels are only 18 inches in Vancouver.

who enjoy their summers surfing off Vancouver Island’s

Tofino beaches still wanted a city home in Vancouver that honoured their love for the outdoors. “From the earliest stages of the design concept, they really wanted to incorporate that surfer mentality into the design,” explained Langley, BC contractor Dale Roadhouse of Roadhouse Homes.

The result is an open concept spreading over three levels, highlighted by earthy tones and material choices. Skylights feed vertical light shafts that flood the upper and main levels, vertical grain spruce is used generously as a ceiling finish, and glass balustrades on the main staircase allow the eye to move easily across the living spaces.

This year, the Canadian Home Builders’ Association (CHBA) has recognized this project – known by the nickname Surf’s Up – as their award program’s top custom home under 2,500 square feet. Roadhouse says he was proud to win the award “because it was a challenging build, but overall what I am most passionate about is that my clients had a great experience.”

Located on an above-average sized corner lot in the Vancouver suburb of Mackenzie Heights, the project’s modern design is part of the new-build trend popping up in even the most mature residential areas of the city. However, in contrast to many of their neighbors, the owners chose not to build the biggest allowable home. In fact, they weren’t even certain how to proceed at the

The feeling of openness is enhanced by generous ceiling heights throughout the home: 8-ft. in the basement and second floor bedroom levels, and over 9.5-ft. on the main floor.

Vertical grain spruce is used on several living area ceilings and carried outdoor as roof soffit trim.

AS THE CONCEPT STARTED TO EVOLVE INTO PRELIMINARY PLANS, I KNEW THIS HOUSE WAS GOING TO BE A CHALLENGE, AND I WAS REALLY EXCITED ABOUT THAT.”

Originally designed as a two car garage, the size was increased to a triple to allow a worthwhile number of PV panels to be installed on the roof.

THROUGH THE CONCEPTUAL STAGE, I HAD A LOT OF INPUT INTO THE NUMBER AND SIZES OF WINDOWS, AND THEREFORE WAS ABLE TO BE CAREFUL ABOUT HOW THE WINDOWS WOULD IMPACT THE HEATING AND VENTILATION.”

beginning. “The clients couldn’t decide whether to renovate or build new,” said Roadhouse. In fact, Roadhouse says as many as 80 per cent of his new build clients start out as undecided. “I walked through that process with them. We went through the pros and cons of each. I put choices in front of them to help them make the right decision for their family.”

One of the parameters set out by the clients, reflective of their

passion for nature, was ecological consciousness. Roadhouse suggested building with EnerGuide standards in mind. “They wanted the home to be ecologically sensitive and had already decided to use mechanical components that were efficient. It was an easy transition to EnerGuide.” Triple pane windows with casings of vinyl and wood, LED lighting almost everywhere, a 2.7 KwH PV solar array on the garage connected to a net metering system, spray foam insulation on exterior walls and under roof decks — these features are becoming more common across Canada. However, unique to Vancouver were a couple of other features.

One was ecological. There are often water use restrictions during Vancouver’s dry summers. The clients chose a rainwater harvesting system consisting of downspouts and an underground cistern. This services not only a year-round, drip irrigation system for the garden, but the rainwater is also used as grey water for toilets inside the home.

The other challenge was structural. An open concept home with clerestory windows (high level glazing) in an area of seismic activity required a complex steel system of moment frames. “I’ve done moment frames before but never this many,” said Roadhouse. The issue went beyond the layout of the steel beams

themselves. “The number of beam and steel packages made it very difficult to route the mechanical components,” he explained. “I spent a lot of time with my mechanical trade contractors planning routes and locations before we built, locating the flush beams and drop beams, to determine how we would run the mechanical components through the structure. We had a really good understanding of how things were going to run before we broke ground.”

A relatively temperate climate, and clients who spend so much time in Tofino during the summer, eliminated the need for air conditioning. “We just don’t have that super heat like in Central Canada. I’d say only half my projects have air conditioning,” said Roadhouse.

That temperate climate also reduced the need for extensive thermal breaks on exterior walls. Although the home is framed with 2x6 studs with foam insulation that meets the City of Vancouver’s R22 code requirement, Roadhouse has observed that most builders are meeting code simply with 2x8’s and fibreglass batts — no exterior insulation. However, the West Coast’s heavy rainfall does require more attention to flashing and end dams on the tops and bottoms of windows than in most areas in the country.

Roadhouse has been building homes under his own name for seven years after more than three decades in the industry. “I started out as a young guy slogging it out on site, working my way up over the years,” he explained. “One of the things that sets me apart today is that I’m a small builder with a large builder mentality. I came from a large builder and brought with me the processes and systems that make the project go smoothly for both my clients and my construction team.” cc

Different contractors work at different intensities. But like any engine, there is a sweet spot for the most efficient output. Have you thought about yours?

By Steve Maxwell

I’vebeen around long enough to see more than a few contractors come and go in the building business, and one of the biggest factors of success is what I call “personal RPM.” Think engine speed and revolutions per minute and you’ll know where I’m coming from.

Many ill-fated contractors turn over too slowly, like my 1953 International tractor. It chugs along at a pleasant and laid-back 1,650 RPM at full-tilt. That’s fine for a tractor built 65 years ago, but way too slow for a contractor looking to make the grade today. What does slow RPM look like in the world of contracting? Too much pointless talk, too much irrelevant thinking and too long at coffee. Even the walking pace of low RPM people tells the tale. Taking twice as long as it should walking to and from the truck a dozen times a day adds up. Eventually low RPM catches up in the form of low profitability.

By contrast, some contractors rev too high, burning out and missing too many important details. It’s not that these high RPM people necessarily get a lot done, either. Having too many balls in the air usually means you’ll drop some. Rev too high for too long and missed details will cause your reputation to fall. Burned out health and relationships will put you on the sidelines.

Most of the best contractors I know spin at a nice, steady 2,500

SOME CONTRACTORS REV TOO SLOWLY, LIKE MY 1953 INTERNATIONAL TRACTOR. BUT OTHERS REV TOO HIGH, BURNING OUT AND MISSING TOO MANY IMPORTANT DETAILS.

to 3,000 RPM, so to speak. They’re still far enough from the red line that they won’t blow a connecting rod or bend a valve, but they always seem to operate with a sane but persistent level of high output urgency. They remind me of a big bore V-twin motorcycle engine on the open road as you drive for hours at speed. The output is high, the engine is hot, but it just keeps on putting out hour after hour.

Free market capitalism has done more than any other economic system to pull people out of poverty and into affluence worldwide, but capitalism isn’t sentimental. It doesn’t care how nice you are or how much you need your business to succeed. The bottom line is efficiently doing enough of what the market pays for. And from what I’ve seen, the “enough” part has a lot to do with consistently hitting the right personal RPM. cc

How the Amish embrace today’s best cordless tool technology

By Steve Maxwell

tools have been at the leading edge of the building scene for decades, but not everyone who embraces cordless tools are leading edge people. Take the Amish for instance. Although they dress in plain, 18th century clothing, choose not to own motor vehicles, reject anything with rubber tires, and don’t connect to the electrical grid, the Amish I know have happily used professional-grade cordless tools ever since they became available in the mid1980s. These tools are a big part of the Amish building scene.

Over the last five years Amish families have begun to move to my quiet corner of Manitoulin Island, Ontario and I’m glad to see them. One thing I’ve learned is how modern cordless tools fit into the Amish way of living. I was surprised by this until I came to understand why.

When I first learned that an Amish couple – David and Miriam Kuepfer – had moved to a farm a few miles from my place, I decided to give them a handsaw as a house-warming present. I never thought for a moment that they’d use power tools, but I’d learn differently soon enough. The saw I handed David was

The Amish are Bible-believing Christians who trace their roots back to Jacob Ammann in the late 1600s. They’re among the few people in the world who take a cautious view of technology because of the possible negative side effects specific technologies can have on faith, family and community.

While it’s natural to think that the horse-drawn lifestyle of the Amish is all about being environmentally green, that’s not the main motivation. The Amish decide together as a community to come to a consensus about the modern conveniences they allow or reject. While Amish households generally do have a land line telephone, for instance, it’s not in the house. The Amish way is to put the phone in a little building some distance from the house.

Why? The same reason they choose not to connect to the grid though they still use electricity. One way to make use of a technology without over-using it is to make it less convenient. Wasting aimless hours on the phone is less enticing if that phone is in a little dark building 50 yards from the house. The Amish understand that while we humans create and shape technology, technology inevitably returns the favour by shaping us, too. The Amish are people who choose technology based on more than just how well it works. And cordless tools are on their side of the line.

a nice, new Irwin model – the kind with those super-sharp, hard-point teeth. When I arrived at their farm that day it was like I’d stepped back in time. When David and his wife Miriam came out of the house to meet me, they spoke English with an old German accent and wore simple, handmade clothes that showed a lot of skill in the making.

The Amish greatly value humility and that’s the main reason they don’t allow personal photos to be taken. While I was taking photographs for this story, David made sure to be well out of the way.

I learned later that David works at carpentry and building probably as much as he works with the cattle and horses he keeps on his farm. A few visits later I also noticed the well-worn DEWALT cordless tools he had. Eventually I came to understand that it was not electricity the Amish rejected, but rather easy access to vast quantities of electricity. This is the kind of thing that only the grid can provide, and I have to admit that it does change the way people spend their time and interact with each other.

“My dad bought his first cordless tools when I was still in grade school in the mid-1980s,” explained David. “Dad’s first tool was a 7.2 volt drill – one of the first cordless tools available. From there we’ve basically stayed with DEWALT the whole time. We upgraded to 12 volt tools, then 36 volts when we did a lot of metal work on horse-drawn farm equipment. When I married in 2007, I bought an 18 volt drill, circ saw, recip saw, angle grinder and an

The Amish don’t use much electric power, but they always produce the electricity they need using technology that’s not connected to the grid. David and Miriam don’t yet have solar or wind power, so charging the batteries in their lives happens with a simple home-made 12-volt system cobbled together from an old automotive alternator. A 5hp Honda utility engine drives a V-belt connected to the alternator as it sits bolted to a wooden base. This is the setup they use to charge the 12 volt automotive battery they use to power the running lights on their horsedrawn road buggy and to power an inverter for charging cordless tool batteries.

impact driver. After 11 years of hard use, the only repair I had to do was change a bearing in the circ saw. We did burn out a drill, but only after a lot of hard work in steel. Those DEWALT XRP tools held up really well.” These days David is using 20 volt and 60 volt DEWALT FLEXVOLT equipment, including a cordless table saw – the first he’s ever owned.

David is a productive carpenter. He

builds sheds, furniture, repairs barns and does any other jobs involving wood and metal. He works mostly with lumber he cuts on his own sawmill from the forest that’s part of his 300 acre farm. Lately David’s been building a bedroom set for sale and working on a kitchen renovation, complete with site-built cabinets made entirely with the cordless tools he depends on to earn his living. cc

If you do anything more than casual sanding, you know that there’s quite a difference in the quality, effectiveness and working life of sandpapers. The good stuff not only lasts longer, but it smooths wood better, too. I’ve used 3M Ultra Flexible Sanding Sheets for four years now and it does two things very well. First, this stuff lasts a long time and delivers excellent results in all the usual situations. That’s a given with any pro-grade sandpaper. But second, the backing of this stuff is flexible. It isn’t paper at all but a kind of stretchy synthetic material. The bottom line is a much better ability to conform to curved shapes and a much greater ability to stay nicely on your fingers when you use this stuff by hand. It’s easy to like and doesn’t even cost more than regular, paper-backed pro-grade sandpapers. You can use it wet or dry, too. If you can’t find Ultra Flexible at your local hardware store it’s easy to buy on Amazon.ca. At $8 for a package of four with free delivery, it’s a great value.

The only thing better than having a set of booster cables for starting dead vehicles is not needing another vehicle to boost from at all. That’s the thinking behind the new breed of portable battery boosters becoming available from different manufacturers. The trouble is, by many accounts most of these things are junk. They won’t hold a charge in storage and cold weather kills them. The NOCO GB70 is different. In my experience it does the job in all temperatures and delivers a solid boost that’s beyond what most contractors will ever need. Although I haven’t tested the claimed limits of boosting diesels up to 6.0L and gas engines as large as 8.0L, the GB70 boosts my 5.0L truck reliably. There’s also a built-in light (with variable intensity output and strobe settings) plus USB ports for charging phones. You can charge the GB70 with a USB cable or directly from a vehicle battery. NOCO makes smaller units than the GB70, but bigger is usually better in my experience, even if it does cost more. I bought mine at Canadian Tire for $250 – the best deal I could find. MAXWELL’S

Everything you need to know to protect your clients against power outtages

By Steve Maxwell

More and more property owners are deciding to get proactive about electrical power supply at homes, cottages and small businesses, and that’s why standby generators are gaining in popularity. Declining reliability of the electrical grid is one motivation, but so is price. The cost of standby generators has plummeted over the last 10 years, and reliability has skyrocketed. Although you’ll almost certainly sub out the installation of a

THE PROMISE OF UNINTERRUPTED POWER IS THE ATTRACTION OF STANDBY GENERATORS. FUELLED BY NATURAL GAS OR PROPANE, THESE THINGS CAN RUN FOR DAYS WITHOUT ANY ATTENTION FROM THE HOMEOWNER.”

standby system, you should be informed enough to suggest the technology when it makes sense for a client and answer questions as they come up.

Standby generators are large, stationary permanently-installed generator units that work together with switching gear. The moment power goes down on the grid, a standby generator system starts itself up while also disconnecting the household panel and circuitry from the grid. In most systems power from the standby is delivered to a secondary panel for distribution to pre-determined essential circuits. Since the engine is housed in an insulated cabinet, standby generators operate very quietly. Engine oil change and maintenance is typically required every two years or 100 hours of operation, whichever comes first.

Standbys typically come in sizes from 7,500 to 20,000 watts. An average home without electric heat can be powered by a unit 10,000 watts or larger. If you’ve got a client interested in reliable backup power, encourage them to use fuel-burning sources of heat, not electric resistance heating. Cost for an 8,000 watt unit is $2,500. A 20,000 watt unit is typically $6,000. Installation costs run an additional 40 to 60 per cent of the price of the generator. Most standby models run on propane or natural gas, eliminating problems caused by stale gasoline or diesel fuel. You can pour a concrete pad to support a standby, or you can lay and level some heavy paving slabs of the kind used to support outdoor oil tanks.

Connecting a standby generator requires two things. The first is piping to deliver natural gas or propane to the outdoor generator unit. Explain to your clients that supplies of natural gas

or propane will keep running in the event of an electrical power failure, so it’s simpler and more reliable than generators that run on liquid fuel.

The second connection required is the power cables from the standby generator to the building’s electrical panel. Most systems require the installation of a second panel with a built-in transfer switch inside the building to accept this power feed and distribute it to difference circuits while also automatically disconnecting from the grid. Some connection cables include smaller control wires bundled together with large power feed conductors, while others use separate control wires. These control wires create a path for the generator to communicate back and forth to the panel and transfer switch.

Not all home-generated power created by portable units is safe to use with sensitive electronics, but modern stationary standbys are different. They’re made to safely power everything found in a typical home, including computers and entertainment equipment. Any generator output that’s less than 5 per cent total harmonic distortion (THD) is fine to use with electronics and smart appliances.

So next time you have a client who seems sensitive about power outages, you’ll know how to explain the details of a solution that more and more Canadians are using. cc

By John Bleasby

Jeremy Pudney’s new clients, the Howards, know what they’re talking about when it comes to the nuts and bolts of home renovation. The enthusiastic young couple can discuss in detail all the required elements involved in the gutting and rebuilding of their newly-acquired 1920’s semi-detached. The bad news is that they want to be involved in almost every aspect of the job. It’s not that they can’t handle the tools – they can – it’s that they’re so keen they are actually causing problems. For example, last weekend they laid down new hardwood on the main floor when the new interior walls and ductwork hadn’t yet been installed. “We saw the exact flooring we wanted on sale and couldn’t wait!” an excited Sue Howard explained. A few weeks earlier, the couple installed new stair treads before Jeremy’s concrete guys could pour a new floor in the basement. Jeremy’s guys are constantly having to protect their work from damage. Now the HVAC team has arrived and the Howards have their own ideas of where the ducts should run. Jeremy doesn’t want to hurt their feelings, but their well-meaning interference is really slowing the job down.

What should Jeremy do now? See the options at right.