Reclaimed Wood

The Aura

Of Antiquity page 24

Infill Housing

Creative Eye

In Calgary page 34

Steve Maxwell Energy

Saving Tactics page 49

Reclaimed Wood

The Aura

Of Antiquity page 24

Infill Housing

Creative Eye

In Calgary page 34

Steve Maxwell Energy

Saving Tactics page 49

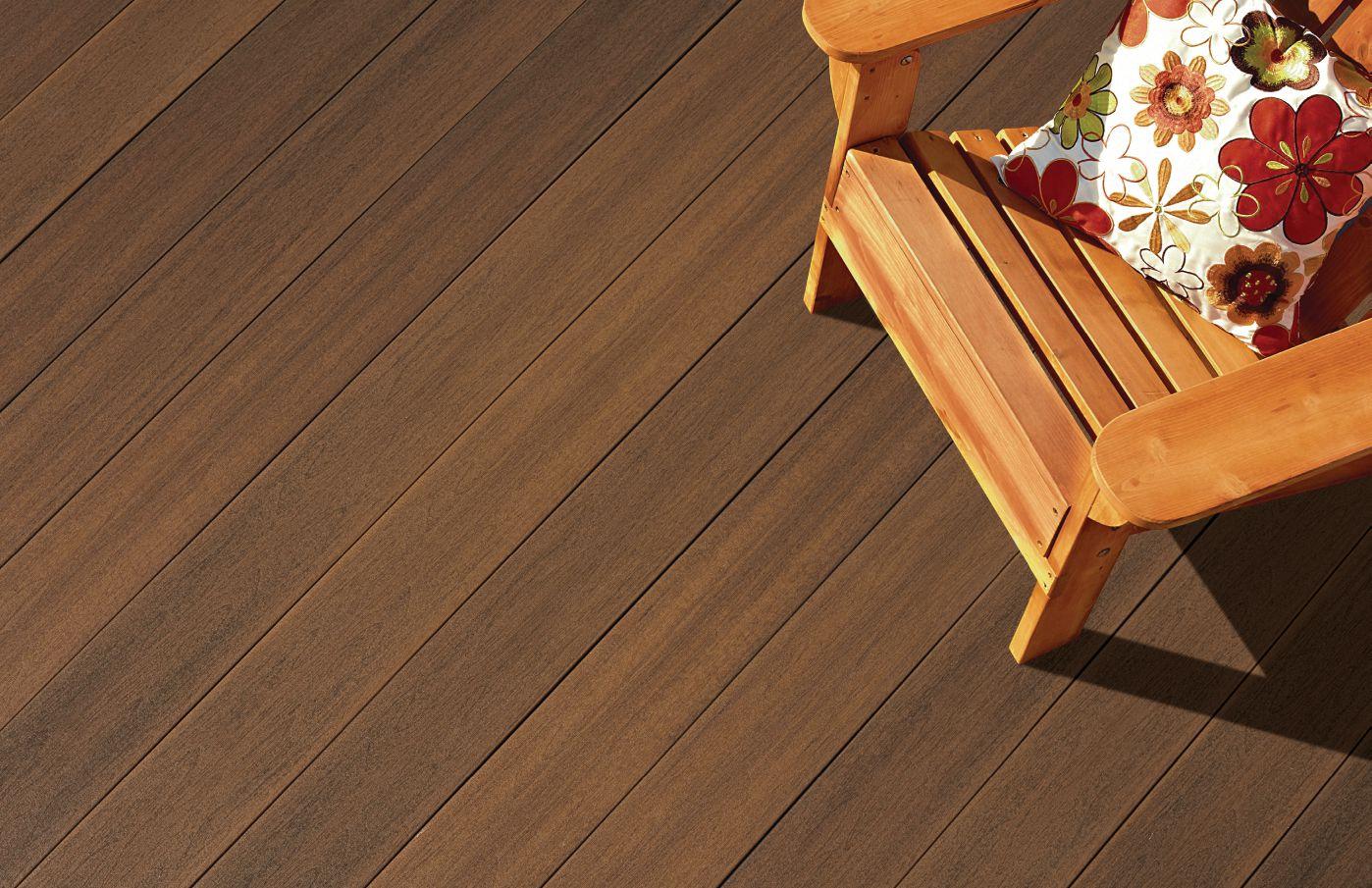

Brendan Charters and Jim Cunningham of Eurodale Developments are thinking and building big

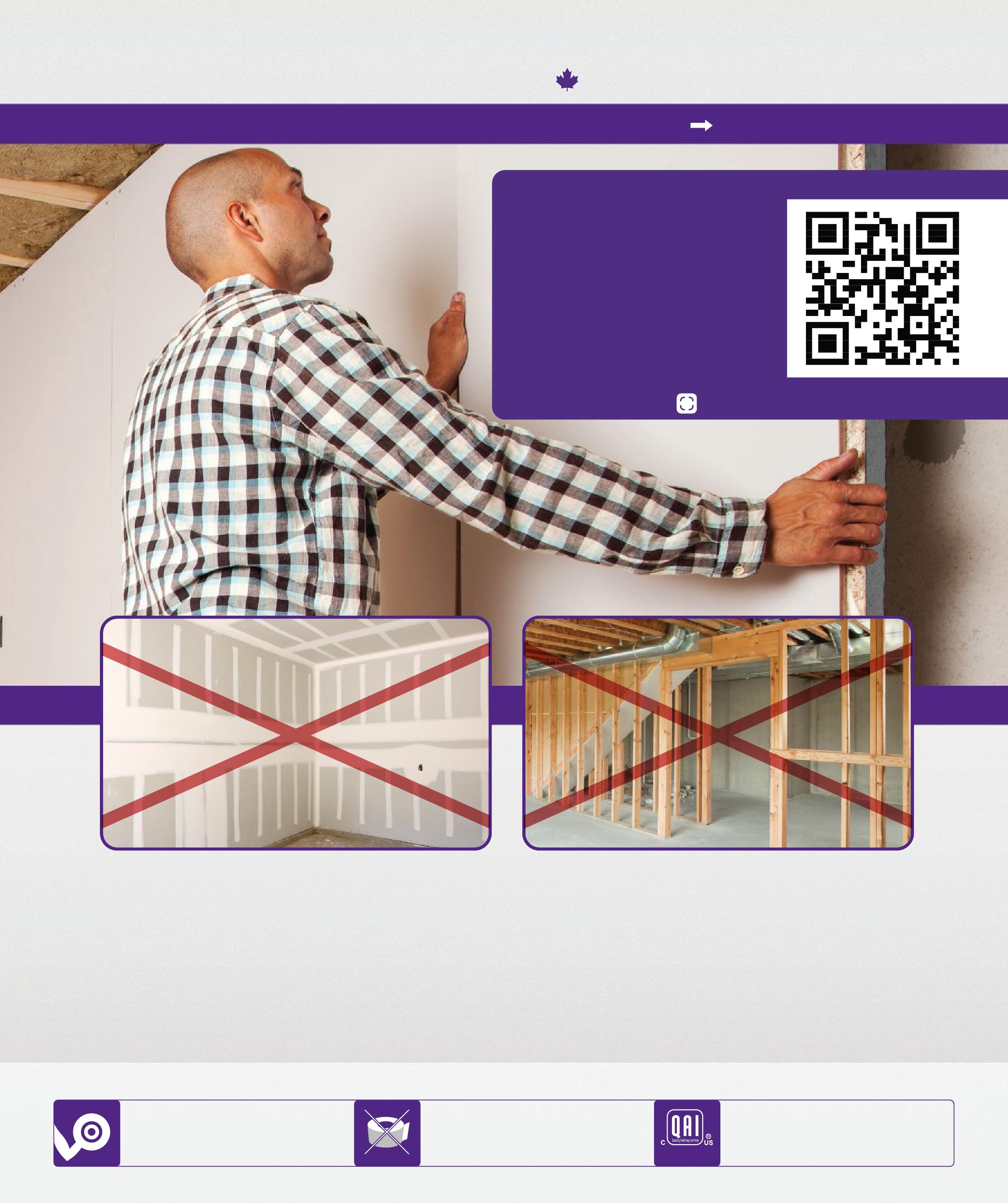

As a professional contractor, being under pressure is nothing new to you. That’s why using products that help you to get the job done faster is a must. DRIcore SMARTWALL® simplifies basement finishing by providing a product that is 5x faster compared to conventional construction methods.

FEATURES:

•INTEGRATED VERTICAL & HORIZONTAL WIRING CHANNELS

•ACCESSORY PANELS CONTAIN ELECTRICAL BOXES.

•MICRO BEVELED EDGES - NO TAPING REQUIRED

•TONGUE & GROOVE INTERLOCKING SYSTEM

•HIGH DENSITY GRAPHITE INFUSED EPS INSULATION

•OSB FRAMING MEMBERS

•1/2" PRIMED DRYWALL WITH VAPOUR BARRIER SMARTWALL

One of the many conveniences of the SMARTWALL® system is the patented “Micro Bevel” edge detail, which eliminates the traditional taping stage of finishing the drywall surface. The micro bevel requires much less filler to achieve a finished surface, resulting in far less sanding and therefore less dust created.

The SMARTWALL® ChallengeWatch Adam take on traditional building methods with DRIcore SMARTWALL®. Which method is faster? Watch to find out!

Unlike the multi-step process of conventional construction methods, DRIcore SMARTWALL® combines framing, insulation, drywall and a vapour barrier in one fast step. SMARTWALL® panels lock together using a tongue & groove system.

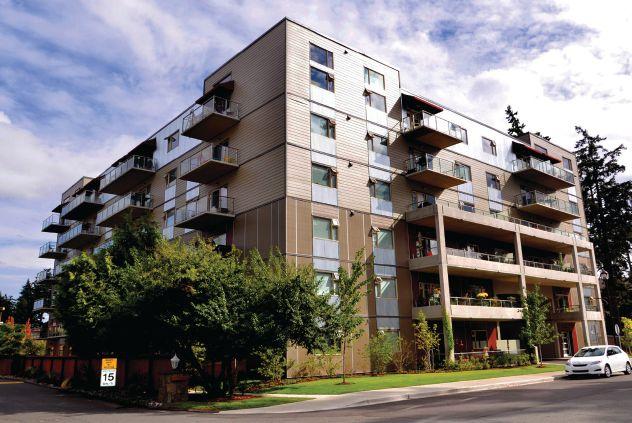

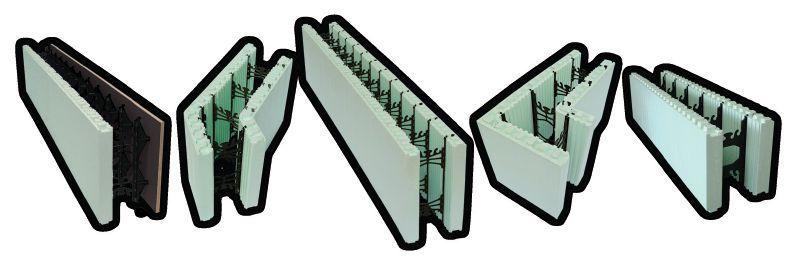

At NUDURA, size does matter. NUDURA standard forms feature DURAMAX Technology , the largest standard ICF block in the industry, allowing the placement of 12 square feet of wall area in one building step. Our DURAMAX Technology results in faster installation times, less waste and a reduced amount of seams. Building Has Evolved™ at NUDURA, allowing builders & contractors to save time on labour, which is money, with the biggest block on the market.

Learn about our innovation and how NUDURA can reduce your labour costs at a NUDURA Training Academy installation course, nudura.com/trainingacademy.

If you are thinking about going into business with a partner, first read this cautionary article by a veteran entrepreneur and CEO. Historic Warmth 24

What you need to know about working with reclaimed wood from rivers, barns and century homes.

Scaling it Up 30

An interview with up-market contractors Brendan Charters and Jim Cunningham, Eurodale Developments.

Stairways to Heaven 40

An interview with Dean Jones, Creative Design Stairs & Railing, Orillia, ON. Wanted: Young Bricklayers 42

Not many kids these days think of masonry as a good career option. Organizations like MasonryWorx are trying to change all that. The Man Who Sculpts Drywall 44 Canadian contractor Bernie Mitchell has become (sort of) world famous for his magnificent drywall art.

Bob Collins

Home Building Centre – Gravenhurst Gravenhurst, ON

When your reputation is built on quality, you depend on relationships built on trust. That’s why you can trust the Experts at Home Building Centre and Home Hardware Building Centre to provide the tools, materials and services you depend on – from dedicated contractor sales staff and easier ordering through phone, fax or email to job site deliveries, credit services and package pricing. With a relationship built on trust, you know you’re building on a strong foundation.

pronews.ca

Online 10

How to put the Canadian Contractor icon on your phone, for one touch access to our breaking news.

Editorial 13

What every contractor can learn from Warren Buffett, merely the third richest businessman in the world.

Voices 14

The best of the recent contractor posts at canadiancontractor.ca, including thoughts on after-work beer and (not at the same time) training your kids to be contractors.

Contractor Law 22

Guest column from veteran litigation lawyer Jay Ralston.

Creative Eye: A Matched Pair 34

We look closely at a design-build project in Calgary’s Altadore neighborhood that exemplifies split-lot brilliance.

Maxwell’s Stuff We Like 49

Steve Maxwell explains four tactics that can help you become a more energyefficient builder.

What Would You Do? 58

Send us your solution to this month’s contractor dilemma and you could win a DeWALT TOUGH storage system as well as a DeWALT TOUGH music system.

Building Wraps

Drainable HouseWraps

Flashings & Fasteners

Construction Tape

Get the facts about superior performance that proves as strong in the lab as it does in the field.

More pros than ever are making TYPAR® Building Wraps their go-to choice. That’s because our products don’t just surpass high standards in lab testing, but prove their real performance on the job under true, tough conditions. From superior tear strength, to the ideal balance of breathability and water holdout, to a lifetime warranty—the facts back TYPAR. Find our Top 10 Reasons, expert FAQs and more at typar.com.

INSTRUCTIONS

• Google Canadian Contractor on your mobile device

• Open the link to canadiancontractor.ca

• When the page opens, tap the menu button on the lower left corner of your screen

• Select “add shortcut”

• Go back to your device’s screen and locate the Canadian Contractor icon (It may appear on one of your later pages.)

Go to canadiancontractor.ca and type “icon” in the search bar at the top right. The link to the video will pop up.

canadiancontractor.ca | Tel: 416 442 5600 | 80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published 6 times a year by Annex Business Media.

• Press and hold the icon, and drag it forward page-by-page to the desired page on your device

• Go to canadiancontractor.ca using Safari or your favourite browser

• When in portrait mode, click on the square icon with the “up” arrow that appears at the bottom of the screen

• Chose “add to home screen”

• Click “add”

• The icon should appear on your Iphone or Ipad home screen

Now with one click, you can go directly to the latest news!

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, John Caulfield, Mike Draper, Treena Hein, Steve Maxwell

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbizmedia.com

by: Jim Caruk Master Contractor, HGTV Host and Editor-in-Chief of Renovation Contractor Magazine Save up to 20%* on your heating and cooling costs with AttiCat® Blown-In Insulation System.

• It’s never been easier to top up your attic and start saving* today.

• An easy, Do-It-Yourself system, that is safe, quick and reliable with virtually no mess or settling.

• Save time and money*. Insulate your attic for under $349, in as little as 2 hours.† Visit your local building materials retail store to learn more and start saving* today. 1-800-GET-PINK ® or visit owenscorning.ca

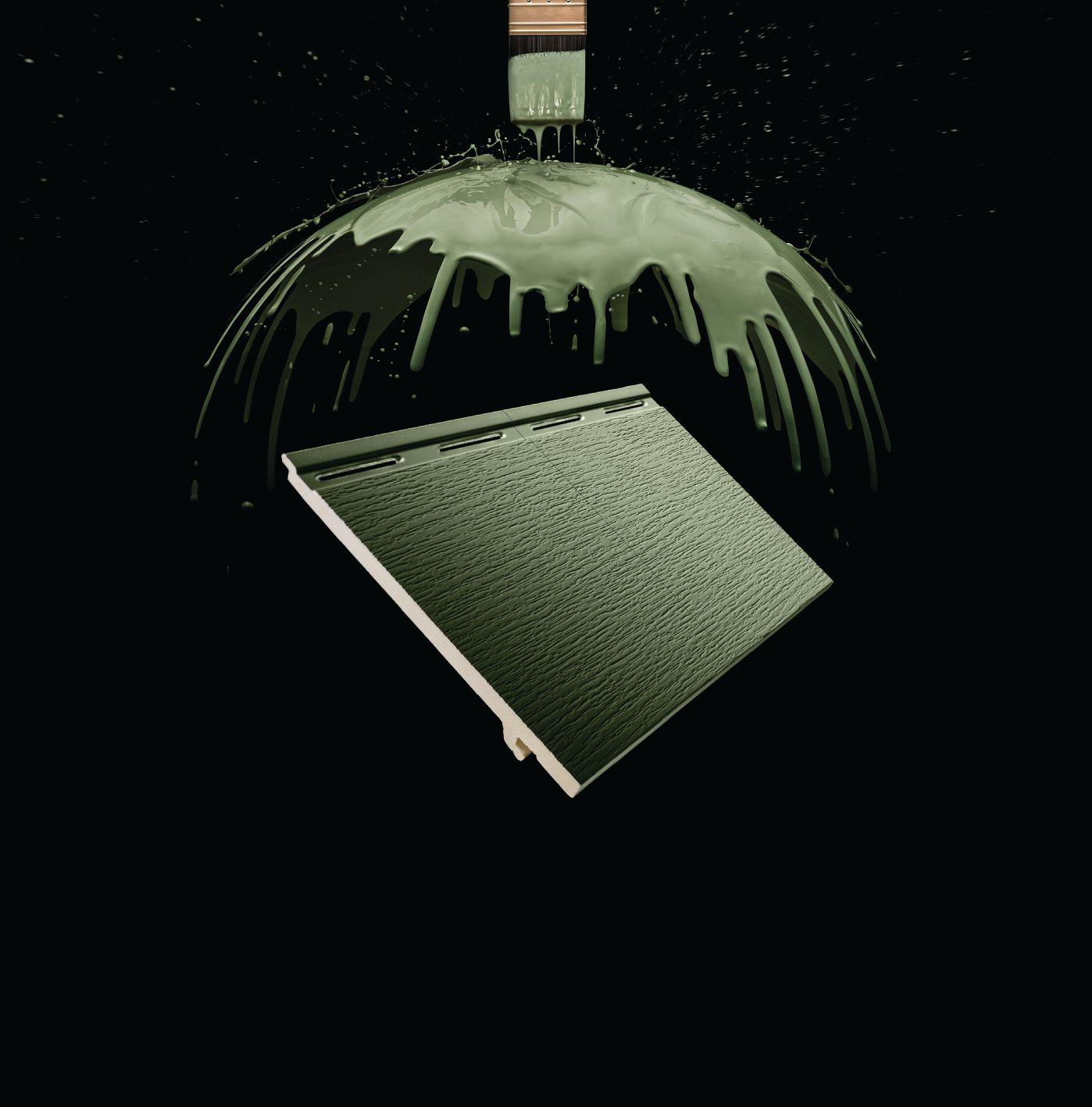

Celect and painting: Don’t even think about it.

Celect® Cellular Composite Siding is engineered to be the most aesthetically pleasing and maintenance-defying exterior on the block. That means no painting and no caulking. Celect’s advanced cellular material and fade-resistant Kynar Aquatec® coating work together to protect homes from the impact of the sun and the punishing effects of time. Plus, the patented interlocking joints that produce its virtually seamless looks inspire effortless admiration while blocking out moisture and all varieties of weather. Just a few of the things that make Celect perfectly superior to fiber cement, engineered wood and the rest of the siding crowd.

Find out everything siding can do at celect.royalbuildingproducts.com.

By Steve Payne

The worlds of Bay Street and renovation contracting are almost diametrically opposed. Stock prices fluctuate minute by minute and the investment industry – as opposed to its customers –makes vast amounts of money whether the TSE is up or down. In fact, the more turbulent the prices, the greater the frequency of trades – and the more money brokers earn. The medium- or longterm viability of the actual company issuing the stock seems to matter less – to vast numbers of “investors” – than whatever momentum a particular equity is exhibiting this week.

Renovation contracting is a different world, of course. Hardly any residential builders are publicly-traded and reputations can't be measured by share prices. The reputation of your contracting firm is based on how you perform for your clients, not how your stock is trending. The value of your business is based largely on what your clients think of you – and whether they are interested in hiring you again.

It's instructive to spend a little bit of time reading about one of the richest men on the planet: Warren Buffett, legendary American investor, aka “The Sage of Omaha.” Buffett made his fortune largely (if not exclusively) by playing a long-term “value investing” game. Early training by Wall Street icon Ben Graham taught him the difference between speculating (day trading) and investing (which is about the long term). The long view has worked for Buffett. His net worth is currently about $US 67-billion. So let me ask you. If you looked at the performance and reputation of your own contracting firm as a stock – and you calculated how your fortunes are likely to change over time –would you buy stock in your own firm, if you were an outsider? And having bought the stock, would you hold it for decades?

“It takes 20 years to build a reputation and five minutes to ruin it. If you think about that, you’ll do things differently,” Buffett once said. That's a worthy mission statement for any contractor.

”And having bought it, would you hold onto it long term?

”

In our last issue, we featured Toronto area contractors Jeanne and David McGregor, Con-Tech Restorations, as our cover story. The theme was: Making It Work, in terms of married contractors learning to work together 24 hours a day.

“Wow, honey, they wrote an article about us!”

I read your husband and wife contractors story in your last issue. I said to my wife, “Wow, honey, they wrote an article about us with a few minor changes and stand-in actors!” LOL. My wife and I dated from the age of 13 and we took over the 25-year-old family business in 1995. So this year it is 21 years on our own and 46 years as a business. I feel the same way as David (in the article) because he listened and learned, as did I, and placed his wife Jeanne in control, as did I. Life is great when you learn to listen. Yes, yes dear! I’m coming!

Donald Brian Baker

Online, we asked contractors to weigh in on five potentially troublesome employee behaviours – including tool ‘borrowing.’

“Have a clear, written policy.”

It is extremely important that you have a written policy manual that covers all of these situations and gives your employees a clear understanding about what is acceptable and what is not. Once you have a clear, written policy you simply follow the guidelines. For most of your examples, our employee would be immediately terminated as these behaviors are clearly indicated in our manual. Now, on your 4th example, borrowing tools. Our employees know they can borrow tools – all they have to do is ask. If the tool is not required over the weekend they are able to use the tool. But if it is just taken – no request made – then we would issue a very stern warning if not a possible termination.

Allan

We knew we were opening a can of worms when we asked readers, online, about having a beer on a jobsite after the day’s work is done. Yes, we know that drinking on a job site is illegal at any time. No, we don’t recommend it from a safety point of view during work hours. And drinking and driving risks lives under any circumstances. Here are some responses…

“Our employees understand what is at stake.”

We have a no drugs or alcohol, no smoking or foul language policy on the job site – or the job is FREE. This policy also applies in or on company property. Our employees understand what is at stake, and in ten years we have never yet lost money because of this. We need our crews to look and act professional on every site, regardless of whether the client is around or not.

Anonymous

“I never saw a drunk guy on site.”

I would allow a beer or two at the end of the work day. Back in the ’70s, I used to work with Italian tradesmen. Their culture was even a half a liter of red wine on the morning break, but I never saw a drunk guy on site nor witnessed any accident related to it. Everything is all about responsibility.

Andreas

“Builds camaraderie and opens up discussion.”

Life used to be easy and enjoyable. Nowadays with too many lawyers, the constant cloud of liability and too much government, most of the enjoyment has been sucked out of our existence. While I do not support drinking at the work place during regular hours, I do feel that there is a benefit to having a cold beer at the end of the day on Friday (as long as it is just that – one or two cold beers and not a drink fest). It builds camaraderie and opens up discussion. It is team building. As long as I am an employer, a beer fridge will be maintained and a Friday cold one will be the standard.

Old School

Our frequent contributor Mark Mitchell opened up this discussion, saying the Ontario College of Trades is now preventing a father from teaching his kids a trade.

“Excessive regulation.”

There are two huge obstacles in Ontario to attracting young people to the trades and/or construction work. One is frost, which limits and dictates when work can start or proceed, which usually means construction workers face layoffs in winter, and long hours in the summer. Not what young people are looking for. The other is excessive regulation and government control. Allowing agencies like the Ontario College of Trades to prevent a father from teaching his children the family trade, and preventing anyone from being a helper for a few months without being a signed-up apprentice, will limit opportunities in all trades. Those

KAPEX KS 120 EB Miter Saw

The most advanced sliding compound miter saw available, the Kapex is engineered to be light weight and compact. It’s the perfect saw for the workshop or the jobsite. The Kapex features fully-adjustable dual-line lasers that accurately define the cut area. Loaded with a host of time-saving features and a rail forward design that prevents head play, you’ll spend more time working and less time on cleanup with our unmatched dust extraction.

that oppose this kind of government control over their lives (like me) will completely give up passing on their skills to the next generation.

Mark Mitchell

He taught all four of his kids

I taught all my children (two sons, two daughters) in the trades just like my father trained me at a very young age (12-15). My children are now mainly in the electrical trades but also in the building trades as well. They all have a good basic knowledge of how to swing a hammer and turn a screwdriver – this has not hurt them in any way. Having my own company, I have hired young people on a RAP program as well as young apprentices at the age of 16. It’s scary: a lot of these kids don’t have practical knowledge or construction common sense so I ask myself: how can we change this? I don’t think changes come from over-legislating by governments that prohibits young people from trying or being taught the trades at a young age. Schools used to teach shop and woodworking at a grade 7-9 level, ages from 12-15. I think we should be putting more money in the budget for these kind of programs rather than buying more computers for computer labs.

Peter G. Vohr

“Got my sons roofing with me at 12”

I’ll probably get hung out to dry on this one, but I started getting my two sons roofing with me at 12 (not steady). I kept them away from the edge and taught them all about the trade. By the time they were 18 they were better roofers than most roofers twice their age, knew the value of hard work and we had quality father-son time. Today, one has a successful roofing company and owns a couple of houses. The other is in construction, does well and has three houses, too. I say, keep the left-wing idealogues in their office cubicles and let the rest of us do what is natural, normal and healthy.

Joseph

Many people who go for a job interview think the deck is stacked against them being chosen. But ask any entrepreneur: The toughest thing to do is to find a good employee!

Here are some posts about that…

“There simply isn’t the pool of prospective employees.”

Two years ago when I posted an ad for staff I would get anywhere between 20-30 responses within a couple of days. Fast forward to

2016… now we typically get a mere handful. I got three responses to the last ad and we are paying better than most, providing full benefits, vehicle, etc. There simply isn’t the pool of prospective employees out there. One of those three is from the UK and is trying to get a visa but without success so far. The other two are local and I’ve hired one of them and may well hire the other one if given the option… but he has several employers to choose from.

Historically, this region of BC has relied heavily on foreign workers on one- or two-year visas to fill positions at the nearby ski resort. Now that those visas are far harder to come by and regulations for hiring foreign workers are tougher, the resort employers are offering even more perks and money which is further reducing the pool we have to pick from. Right now I am forced to slow growth and on some occasions say no or defer work because we simply don’t have the resources to continue to grow. On the positive side, it makes it easier to say no to the projects we really wouldn’t want anyway.

Related to this is the cost of renting, owing to high property values. Many apartments are beyond the reach of many employees and landlords can be so picky. One of my new staff is going to stay with me simply because he could not find anywhere else to live.

Barry

As a local deck builder, here in Ontario it is very tough to find workers that would like to learn a job and then actually work. I find the challenge is unrealistic expectations, and possibly on both sides (employee-employer). I try to encourage that it is a rewarding job and it can support a lifestyle. We have lots of work and have to turn down jobs because we cannot grow enough to match the work output.

Derek

Several months ago, Alec Caldwell alleged that the WSIB was on a “claims denial binge.” The giant Ontario bureaucracy wrote to us to argue it just isn’t so. Tell that to E. Hawkins, below, who sent us his proposal to reform WSIB – including every employer in the province joining it!

WSIB has become a self-serving, money-making business for the provincial government. They have gone after the businesses who are the least able to pay: small businesses. Another shortsighted

Put our to work. EXPERTISE

Our windows are crafted for style and engineered for performance. Let’s work together to give homeowners the best of both worlds.

Low-E glass for enhanced performance.

There is a reason JELD-WEN is the go-to brand for so many experienced professionals.

Visit jeld-wen.ca to explore our endless selection of top-performing windows and doors.

decision by a government that is more interested in listening to their corporate buddies than doing what is best for Ontario. Independent contractors are the least able to pass on these costs to customers. Small businesses are the real job creators in any economy. Shame.

Approximately 30 to 35 per cent of Ontario workers do not have WSIB coverage and many of these jobs have less risk of physical injuries than labourers and sub-contractors. All employers should be required to be part of WSIB and all premiums paid by small businesses need to be lower, especially when one considers the challenges faced by private contractors. Retail, banks and insurance companies should be forced to pay into the plan. This would then reduce the level of premiums needed from other businesses.

That said, WSIB hasn’t been paying for injuries and disabilities anyway, in many cases. Perhaps WSIB will pay for short-term injuries but they haven’t been paying for the permanently disabled.

Here are some Fast Facts from the Injured Workers and Poverty Survey 2010:

.

• Before injury, 89 per cent were employed full time; after injury 9 per cent

• Nearly one in five lost their homes after injury

• Nearly one quarter had moved in with family or friends at some point after their injuries

• One in five injured workers could no longer afford a car

• Food bank use rose from 5 to 77 people after work injury

• 20 per cent reported an overnight hospital stay in the last 12 months (most because of the work injury) compared with 7 per cent for the general population of Canadians

• Over half had not been able to afford medications in the past 12 months

• 57 per cent of injured workers in the study were unemployed. For more information: www.http://www.injuredworkersonline.org

So where are employer premiums going? One only needs to look at Ontario’s "sunshine list" where there are hundreds of WSIB workers making well in excess of $100,000 plus bonuses while WSIB denies and limits benefits to injured and disabled workers who are being forced into years of appeals. Management has introduced illegal policies that have cut benefits and services to the permanently disabled. Injured and disabled workers are not receiving the benefits promised at 85 per cent of wages and health care coverage. Thousands have been forced onto welfare and some have committed suicide.

Where else are these premiums going? Rebates in the form of experience ratings. Businesses are fined after workers have been injured and killed, then WSIB turns around and provides certain big businesses with huge rebates that are well in excess of these fines. This effectively results in these businesses receiving a refund for the premiums paid into WSIB. Who are these big businesses? I do not know but I can only guess they are supportive of this government.

WSIB was supposed to be an independent, non-adversarial body that gathered information for the administration of social benefits to injured and disabled workers – much like EI is for the unemployed where legitimate benefits are to be paid in full. The WSIB system is supposed to be fair and unbiased for the benefit of all. This has not been the case for many years.

WSIB should not be paying huge fees for doctors and clinics to rubber stamp benefit denials while ignoring medical specialists' reports. All law abiding citizens need to let WSIB and the government know that this will not be tolerated anymore. WSIB has paid for and created many of these clinics across the province which override medical reports from treating specialists in their determination to deny legitimate claimants.

Visit any injured worker Facebook site to hear some of the horror stories of your fellow Canadians. Injured workers are forced by WSIB, under the threat of having their benefits cut, to go to these “clinics” for an evaluation of their injuries.

This includes cases where workers have just had surgery to repair their injuries and where WSIB has been advised by their specialists that these injured workers are medically unfit for any work.

On these websites are disabled workers who claim to have been to WSIB’s clinics where physiotherapists have permanently disabled them. How? Physiotherapists, testing for Range of Motion (RAM). Imagine your surgeon advising you to not use your arm, leg or back after surgery but a physiotherapist forcing these injuries past their safe zone and ripping out the work of the surgeons.

Check out some of the Facebook sites of disabled workers talking among themselves: Occupy WSIB, Injured Workers Fighting WSIB, WSIB/WCB Needs To Change, and more.

The reason employers' premiums are as high as they are has nothing to do with disabled workers since WSIB is on a claims denial binge. Normal age-related conditions are also being used to deny benefit claims. Canadians would be shocked to learn that many strategies being used by WSIB are both illegal and a Charter violation.

E. Hawkins

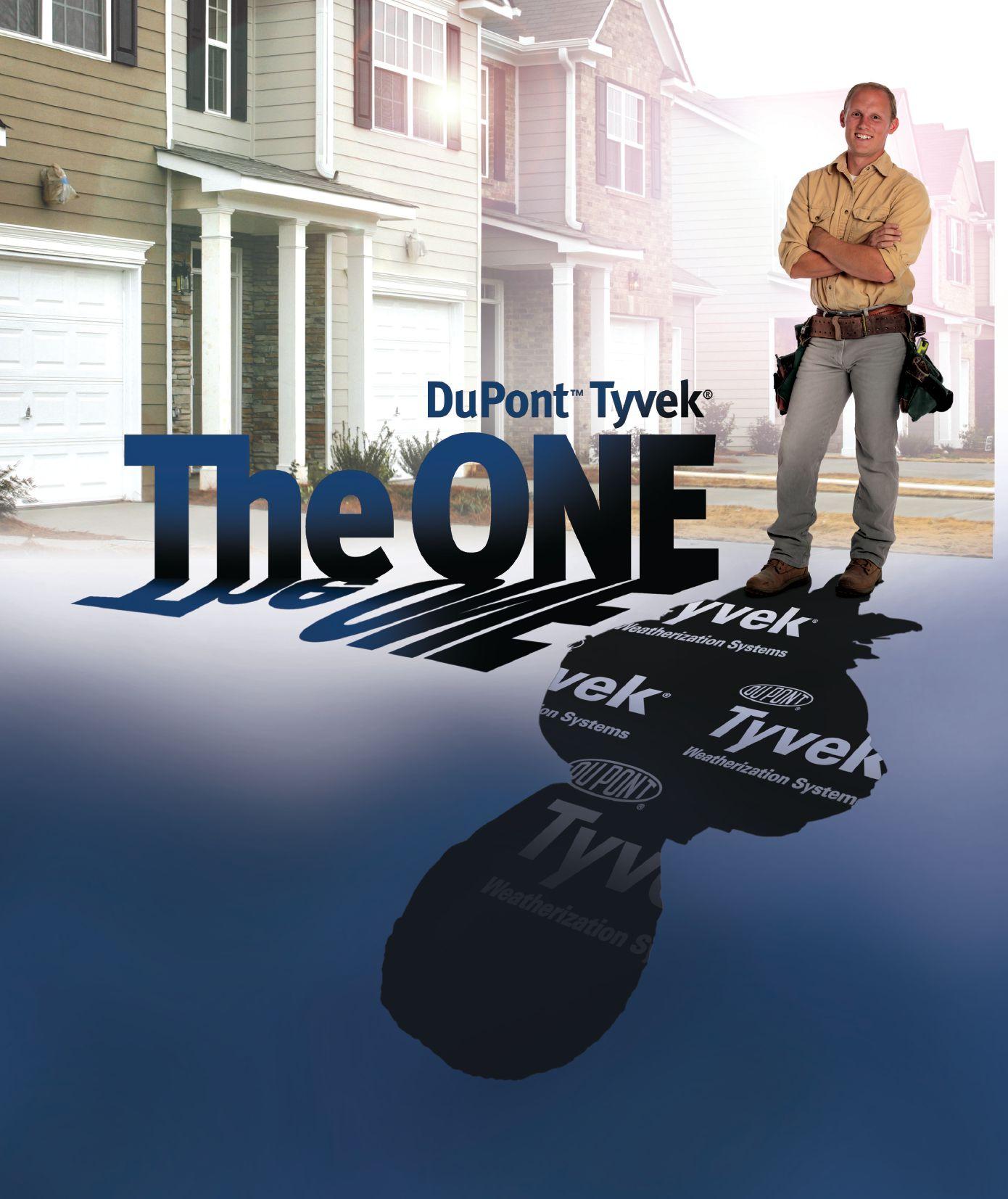

For more than thirty years, DuPont™ Tyvek® has set the performance standard and today it protects millions of homes in North America.

Our weather barriers are made using a unique process that fuses polyethylene fibers into a strong uniform web structure that provides superior air and water hold-out while letting moisture escape. Whether you’re building a new home, or residing or remodeling an existing one, insist on DuPont™ Tyvek® for superior weather protection.

The difference is DuPont™ Tyvek®

“It is never a question of if the partnership will run into trouble, it is a question of when.”

By T. Paul Thomas

Overthe years, former mentors and business associates send me great stories that I use during my lectures at Northern Arizona University. Marsha Morgan was my very first manager out of college and to this day we are great friends (which is a column for the future about the importance of maintaining relationships, staying in contact and networking in business). Marsha emailed me several great short business stories and this one is my favorite.

It is early on a weekday morning and Karen is stepping out of the shower as Bill is stepping into it in order to get ready for the business day. As Bill turns on the water, Karen hears the doorbell. She wraps a towel around herself and runs to the front door only to discover their neighbor Jason standing there. Jason holds out five $100 bills and says, “I’ll give you $500 if you drop your towel.” Karen thinks for a few seconds and decides to accept the offer. She drops the towel and immediately Jason hands her the five bills and walks away.

Karen returns to the bathroom and tells Bill it was just the neighbor, to which he responds, “Did Jason give you the $500 he promised to repay me today?”

The business lesson here is that if you have a partner, it is critical that they know everything that is going on or bad things may happen in the business. Which takes me to my topic for this article. I received an email from someone

interested in buying an existing business, wondering whether he should buy the business with a partner or go it alone.

As a general rule, I do everything humanly possible to talk anyone out of starting or buying a business with a partner. It is never a question of if the partnership will run into trouble, it is a question of when. Every partnership will eventually run into trouble. Someone will complain about unfair division of responsibilities, someone is working harder or longer hours, someone is taking more vacation or not working weekends. Sure, having a solid and well thought out Partnership Agreement will help, but in my 30 years of business, I’ve never seen a partnership live on happily ever after.

However, sometimes you don’t have a choice. So if you feel the need to ignore my advice, only get a partner if the following apply: you need help with the purchase price (consider a loan because they go away once paid off); the other partner(s) have a skill or expertise you don’t have and it is critical to the business; they share the same business drive and passion and you can easily split roles and responsibilities. Never, never, never start a business and then communicate that you and your partner are co-owners and will function as co-presidents. That is a recipe for disaster. Having very clear roles and responsibilities and boundaries is important for the partnership and for the

sanity of the employees.

Should you consider partnering with a spouse or significant other? Personally, I think it is a mistake. It is important to have balance in your life and if you and your significant other are working together you will never get away from the business. My wife, Jill, and I partnered on a business and it worked just fine but it was because we had clear and separate roles and responsibilities. We had been married for 25 years at the time so we were going into the business with a strong foundation.

Most everyone dreams of owning his or her own business and if you can do it without a partner, all the better. If you need a partner, go into it with your eyes wide open. A business partnership is just like a marriage, but without the fun stuff. And by all means, make sure you are communicating constantly so there are no surprises. cc

T. Paul Thomas teaches business and entrepreneurship at Northern Arizona University, serves as CEO of the Northern Arizona Leadership Alliance (NALA) and is the chief entrepreneur of the NACET Accelerator. Prior to joining NAU in 2013, Paul spent 25 years as a serial CEO and president. He can be reached at thomas.tpaul@gmail.com.

If you are thinking of litigating to get a deadbeat client to pay up, read this first

By Jay Ralston

“Lawyers are like nuclear warheads; they have theirs, I have mine. Once you use them, everything gets messed up.”

- Danny Devito in Other People’s Money

I remember watching this movie and hearing Danny Devito deliver those lines (although he used a more colorful word than “messed up”). I was a young associate lawyer embarking on a litigation career, learning from one of Ontario’s most experienced and respected construction lien litigators. I laughed uproariously: the line was funny. As far as I was concerned, he wasn’t talking about me or the career I was just beginning. After all, I have ethics. I have morals. I simply want to get my clients a just and fair result.

Twenty five years later I am saddened to say that often – much too often – the Danny Devito quote appears to be true. A construction project goes awry. On the one hand, the homeowner refuses to pay another cent to the contractor because the project has soared past the original estimate. On the other, the contractor must get paid, and is in fact already owed many thousands of dollars. They’ve done good work and haven’t over-billed; they billed exactly as was initially agreed upon. The homeowners knew the eight foot entrance doors were an extra. They knew that adding those pot lights and upgrading the fixtures was going to increase the cost. They’ve paid all of the invoices up until now without complaint. How can they now take such an unreasonable position? This scenario, or those like it, is a

mainstay of many construction litigation lawyers. I hear the potential client (the contractor) telling me they just want to be paid for what they have done, nothing more. After all, truth is on their side.

How disheartening it is for that contractor when I tell them what I tell every potential litigant at our first meeting: “Despite what you may have been told, trials are not a search for truth. Trials end with a judge deciding what they believe to be true on the basis of the admissible evidence that was presented to them during the trial.”

Litigation is expensive. From the time the client walks into the lawyer’s office for the first meeting through the completion of a trial, a matter that may take only four or five days of actual trial time, legal fees can easily cost each party well in excess of $75,000. That number can reach $100,000 once you add in the costs of experts, out-ofpocket expenses and taxes. And although our legal system might suggest that the loser pays the winner’s “costs,” the costs payable after a trial almost never equal those actually incurred. In fact, it’s not uncommon that the winner recovers only about one half of their legal fees. It’s easy to see why it is extremely important to avoid litigation if possible. The question therefore becomes: “What could the contractor have done differently in these circumstances?”

The best way to avoid a court battle is to call your lawyer for legal advice before you contract with a customer. Ask your lawyer to help create a standard form contract that

you can use not only for the particular job, but for future jobs as well.

In addition, create a standard process for documenting changes and for approval of those changes by the customer during the construction process. And very importantly, follow that process.

Communicate often and fully with the customer. Remember: your customer is not in the construction industry, so don’t assume they have any knowledge of construction. Explain things to them in everyday language.

Litigation can almost always be avoided if steps are taken at the outset of any project to ensure that both parties fully understand what work is going to be done and how it will be billed. A small investment in legal advice at the beginning may help you avoid using the “nuclear warhead” and experiencing the cost of the fallout from litigation.

At the end of the day there is always the possibility you’ll end up in litigation. However, if you have followed your legal advice, you should at least have persuasive and admissible evidence to put before the judge to convince them you are right. cc

A principal partner of Barrie, ON-based legal firm Murray Ralston with over 20 years of construction law experience, Jay Ralston is also a director of the Ontario Trial Lawyers Association (OTLA).

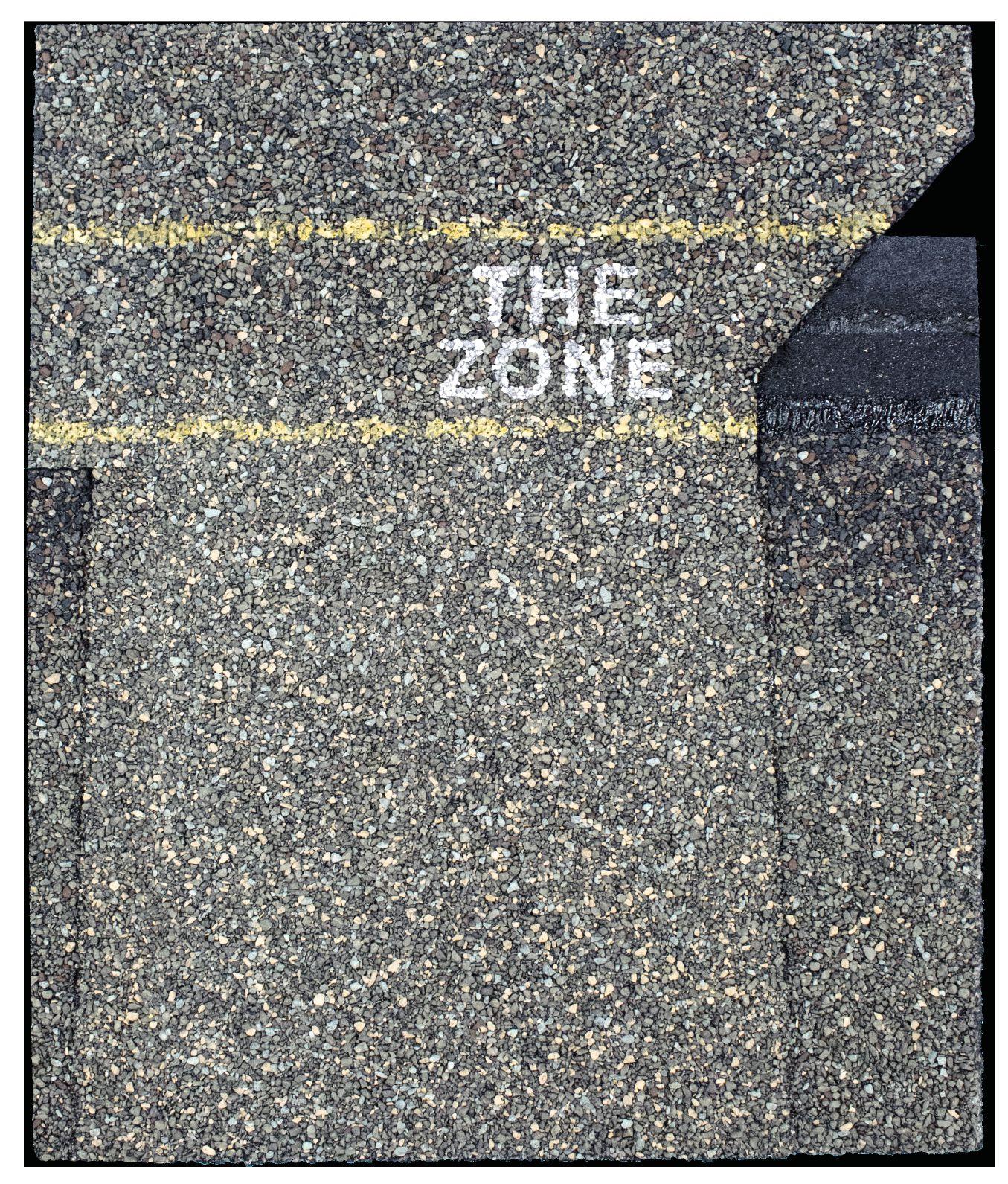

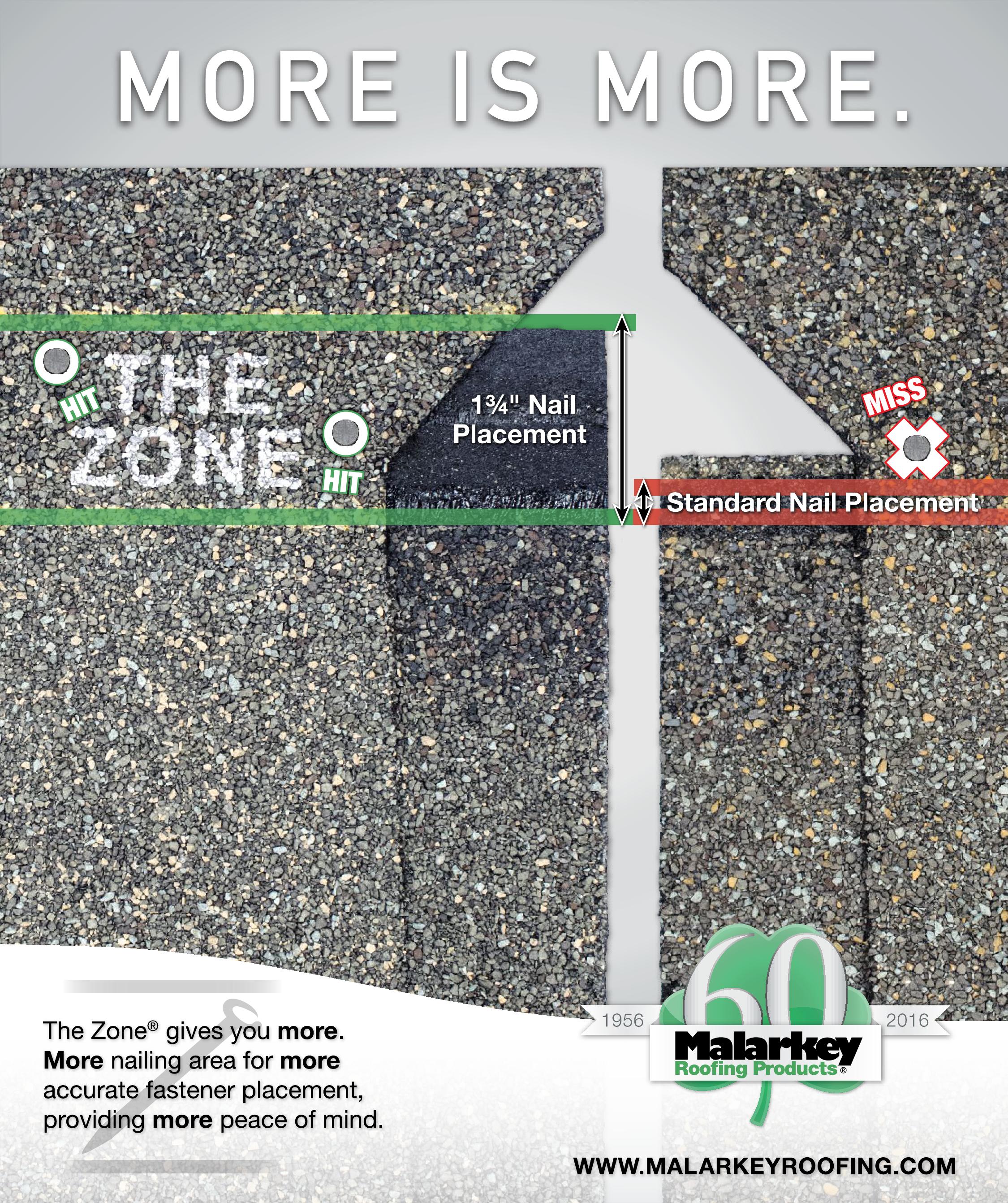

You know what it takes to be successful. It starts with elevating your game, and we’ve raised ours to give professional roofing contractors, like you, an even greater advantage.

Our architectural shingles are heavier and larger than most competitors’ comparable products. They combine with our professional-grade PRO4 engineered roofing component system to offer incredible performance. And it’s all available when and where you need it, thanks to one of the nation’s largest manufacturing footprints. Because, like you, we believe in going above and beyond.

So go ahead. Take it to the next level.

By Treena Hein

Reclaimed pine flooring from Logs End, Ottawa, was a good fit for this project by Cornelius Grey Construction, Manotick, ON, a firm which has a strong environmentally-conscious focus. They built this structure (Red Castle), a passive house, in 2014.

PHOTO: CORNELIUS GREY CONSTRUCTION

It’s not hard to understand why more contractors are using reclaimed wood in more projects these days. For those customers who can afford it, reclaimed wood provides a unique dimension of warmth and history in both modern renovation projects and brand new houses, and can really make a home stand apart. People also love sharing the story of the wood’s origin, and appreciate its environmentally-friendly nature. Canadian Contractor spoke to some providers of reclaimed wood in Ontario – and some contractors who use it – to find out about current design trends and usage differences that you should be aware of compared to conventional materials.

LogsEnd in Ottawa has logged the Ottawa River and its tributaries for historic timber since 1997. Most of these logs are between one and two centuries old, from the square timber era when countless logs were sent to Europe for shipbuilding during the Napoleonic wars and to bring immigrants across the Atlantic to a new land. Some timbers got snagged on river bottoms and missed the boat, but are still available for the taking. LogsEnd scuba

divers carefully secure each log by hand – no dragging them along the bottom and no going into sensitive waterway areas. LogsEnd vice president of sales Rob Black points to studies finding historic log salvaging to be environmentally beneficial as it apparently increases the nutrient content of the water. In addition, removal has been found to be positive because some tree species apparently emit substances harmful to fish, and the shifting of logs in riverbeds can contribute to erosion and sediment relocation.

People want this historic wood, Black says, because of a general or specific historic connection. “I’ve had clients whose grandparents were involved in the lumber drive and are fascinated by the history in the wood,” he explains. “One of the many things I always take pride in when seeing our products installed is knowing that all of the work that went in to cutting down that tree, bringing it through the bush and loading into the river wasn’t in vain! I’ve often heard from clients that they chose our flooring or wall paneling because they love that we’re not cutting down a tree to produce our products.”

LogsEnd verifies every order with a certificate of authenticity. Number 1 pine, red oak, white oak, ash, hickory, maple, walnut and birch is available, with select yellow birch being the most popular hardwood. Black says it has a quiet elegance, with unique swirling grain patterns that capture light differently throughout the day. Their Number 2 materials with more knots provide a more rustic feel. The company supplies over a hundred different contractors each year, and Black says this is growing. “Part of that is because the customer demand for reclaimed material is growing,” he notes. “But I also think, reclaimed or not, quality is a major focus for contractors. LogsEnd has invested hundreds of thousands of dollars into our manufacturing facility to bring the level of quality to an incredibly high level. Contractors are looking for a consistent experience with their suppliers and we strive to provide that.” LogsEnd wood is generally used in flooring, wall and ceiling

coverings, mantles and benches in homes as well as commercial locations like restaurants (mostly wide-plank flooring).

Compared to normal wood, Black says their watersalvaged historic wood is stronger and more durable, surpassing anything available today. “The reclaimed wood we work with is typically old growth and generally 25 per cent more dense than today’s new growth and faster-growing stands,” he states. “Also, from spending that much time in the water, the sap and resin in the wood has leached out of the material, causing our product to be more stable. We’re able to have wider planks and longer lengths with less risk of movement in the wood.” LogsEnd sorts for grade, species and colour, and can mill to custom sizes and lengths with tongue and groove as desired. “We also now offer engineered reclaimed wood flooring, which can be used in areas where humidity levels are not monitored and areas with radiant heating,” Black says. “It can be installed directly onto concrete.”

Cornelius Grey Construction (which is currently re-branding as ‘The Conscious Builder), located in Manotick near Ottawa, has been a LogsEnd customer for over 18 months. Owner Casey Grey says they have only used the reclaimed wood as flooring so far, and that it’s a good fit for his company because he only takes on environmentally-friendly and high-performance projects. He says clients are attracted to it because of its rustic feel, and because they see its beauty and potential when they come to his firm’s home office to do project planning. “We are always recommending reclaimed wood as one of the products available,” he says.

Their experience using reclaimed wood is the same as for any other wood, except that Grey says the reclaimed pine is harder than regular pine. “I recommend it because it’s the same wood that customers want, but it’s from a tree that’s already been cut down,” he says. “It’s more expensive, because site-finished is more expensive than pre-finished flooring because there’s more labour involved, but also reclaimed wood is just more expensive than other raw materials. We’ve just started doing cost comparisons.”

Another huge arena of reclaimed wood is barn board and wood pieces reclaimed from historic homes. Bill Van Veen, owner of Century Wood Products in East Garafraxa, Ontario has been in the business for about 20 years, purchasing and milling materials from demolition companies. He began by shipping reclaimed wood to

Europe, because at that time, Canadian interest just wasn’t there. Now local consumers are his largest market. Van Veen says the majority of reclaimed wood in Eastern Canada comes from rural barn demolitions. Residential materials are primarily ‘architectural salvage’ – items like doors, windows, trim and so on.

Van Veen believes the appeal of reclaimed wood from barns and historic homes is in its uniqueness – the natural-aged colour and the cracks, holes and other distresses from former use. This look, he notes, obviously also has the benefit of hiding new wear and tear. As with reclaimed underwater wood, the price of reclaimed materials from barns and home is usually higher than that of new wood because of the labour involved. “It begins with the demolition company, which will grind up the wood if they are not being paid for the extra effort to separate and salvage,” Van Veen notes. The extra labour continues with the washing, de-nailing, cutting to lengths, drying and so on.

Century Wood Products sees greatest demand in flooring for homes. This is closely followed by materials for wall and ceiling treatments in homes and retail outlets, including beams (original hand hewn or re-sawn) for mantles and more. He says some installers may have to resist the urge to cut out imperfections and

marks rather than display them, as they are used to new materials without flaws. “Otherwise,” he says, “it is similar to installing new wood.”

Gerrit Duits, owner of Du-it Carpentry in Creemore, ON, sources from Century Wood Products and has been using reclaimed barn and century home wood in projects since 2007. “It’s mostly used for flooring and staircases, with some on ceilings with barn beams,” he says. “We’ve also done wine cellars and built-in bookcases. Mostly pine and elm.” He says historic wood is more intuitive to work with and calls for more prep time, but otherwise is the same as working with new wood. “We like working with it,” Duits explains. “There’s a pleasure in it, to see the character of the wood and to see that come out. And the durability is very good.” He adds, “You don’t have to worry about scratching and marking it, because it already has these marks.” The flooring is about $7 per square foot to buy rough, and then there’s prep work, installation and finishing, so it ends up costing customers $12 to $14 per square foot. “There’s about 20 per cent waste with the wood,” Duits adds, “because large cracks and such sometimes need cutting out.”

Allan Bousfield is also busy reclaiming and selling barn lumber and century home wood through his company Historic Lumber near Milton, ON. He’s been at it for 40 years, and notes that for decades nobody cared about historic wood. “Then a few people wanted some of the character of old homes in their houses,” he says. “Then came the ‘environmental generation’, and the last four to five years, it’s been extremely busy. Gray barn board, old floor joists and barn beams are very popular.”

Bousfield has developed his own techniques over the years to achieve colours and texture that are unique, but that also ‘save history’ as he describes it. “We remove nails and are careful with the material,” he says. “We keep material from one barn together so a customer can come and buy the same colour tone, texture, size and so on for their project.” About 60 per cent of his customers are homeowners and 40 per cent are contractors with half from the GTA and the rest from further afield in the province. “We have contractors who are told by their clients to get grey board for a wall, but when they come here and see the colours and selection, they will send the homeowner to make the choices,” Bousfield says. “We also have a lot of homeowners who want to do their own projects.”

In spite of constant land development, the number of barns and century homes being demolished in Ontario is dwindling. “The material has become more costly as time goes on, not just because it’s rarer,” Bousfield explains. “It takes time to remove material correctly, and there is a lot of cleanup involved afterwards. People want the mess cleaned up, and labour is costly.” cc

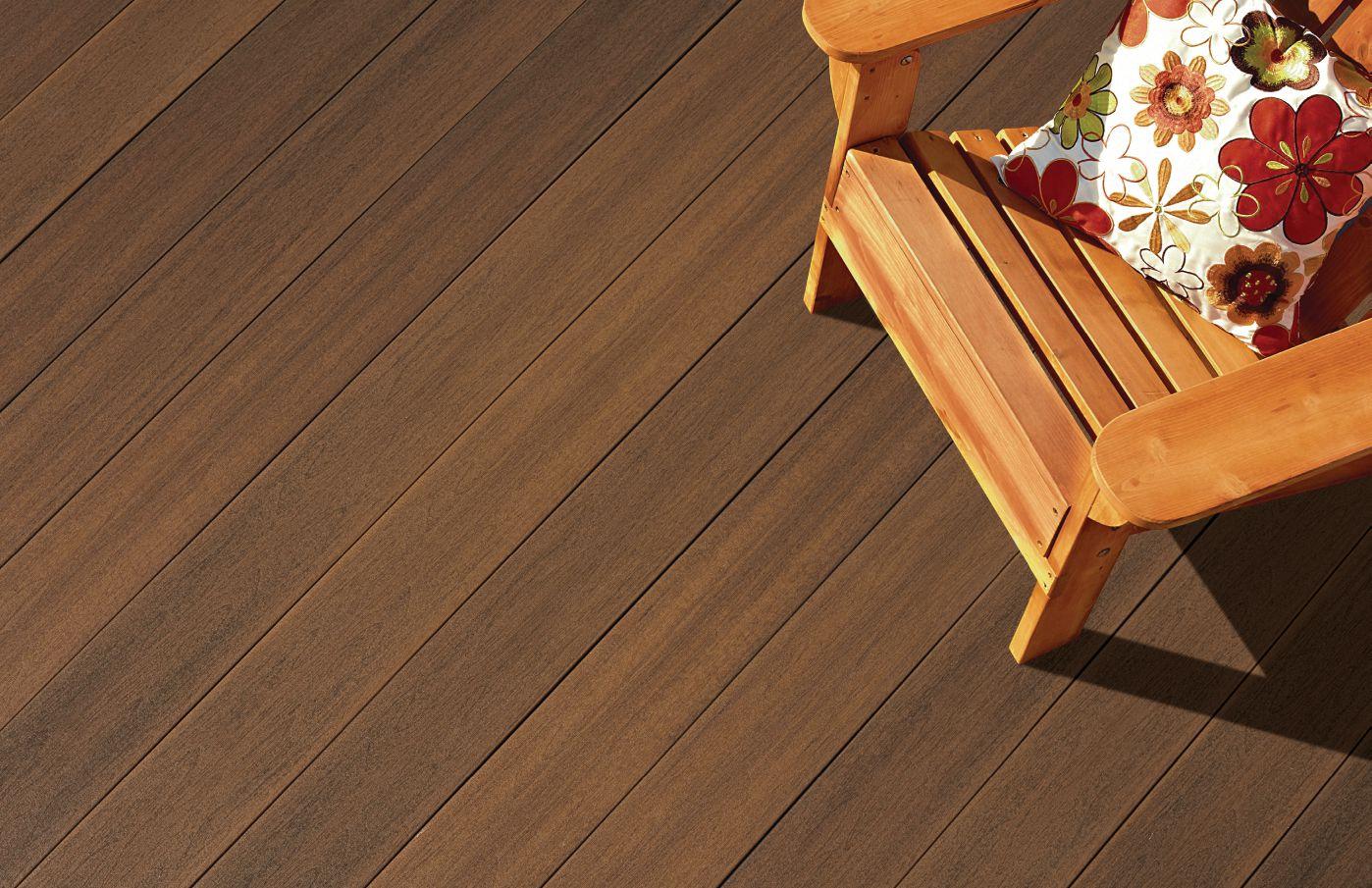

Horizon® Symmetry™ Collection Decking from Fiberon® features a rich color palette inspired by natural elements and pigments -- and preferred by homeowners over other leading boards. Low-gloss formulation and micro-texturing on top and bottom creates a reversible, matte-surface board with subtle, fluid grain patterns. There’s exclusive PermaTech® surface protection for exceptional stain and fade resistance, and a 25-year warranty for added peace of mind.

How do you top Horizon Symmetry Decking? With Fiberon Symmetry Railing.

Another industry game-changer, Symmetry Railing features an exclusive 12-ft. span, sturdy aluminum sub-channel, hidden hardware, easier installation, and three decorator colors.

Learn more at fiberondecking.com Need samples? Contact your dealer today.

Early on, Brendan Charters and Jim Cunningham of Toronto design-build firm Eurodale Developments Inc. decided that they had zero interest in being low-end builders. Their website declares their ambition: “We

are driven to alter the landscape of the business. We strive to shed the cloak of negativity commonly looming over the building industry.”

Interview

by Rob Blackstien

Eurodale Developments has been building and remodeling homes in the Greater Toronto Area since 2003. Headed by development manager Brendan Charters and production manager Jim Cunningham, the company’s work has earned it plenty of recognition, including three BILD Renovator of the Year awards since 2010. Canadian Contractor asked Brendan and Jim to tell us how they think different.

How did you two get into the building and remodelling game?

JC: It started in Ottawa. As a graduate of architecture, I was working at a design-build firm. Brendan and I worked together right out of school. He joined the sales force of the company we worked for at the time in 2001. We were running a design-build company out of Ottawa and for somebody else, and we decided that we’d run our own business.

Your website says you are “Driven to alter the landscape of the business, Eurodale strives to shed the cloak of negativity commonly looming over the building industry.” What do you do differently?

BC: Our industry by and large has typically had to deal with reality TV shows and other forms of media. They love to sensationalize the renovation horror stories or the construction horror stories that give good headlines and get the public’s attention. Our big intention here is to operate at a level of professionalism that is common in other industries, but not so common in ours. The way we have decided to try to do that is really to deliver on what we say we’re going to do. It’s not rocket science and it’s not some special prescriptive, but really just being able to deliver for a homeowner the type of product and the experience that is enjoyable and trusting. And that isn’t the stress endeavour that the TV shows sensationalize it to be.

JC: The way we treat each one of our relationships with our clients

is: it’s a marriage. There are certain elements that have to go into a marriage - you have to take care in the relationship, you have to understand each person’s needs - all those elements come into play when we’re dealing with a client. We don’t treat it as a job where you just go in and get out. We understand that there’s a relationship and it’s very important to us.

And you’ve got to have enough intimacy in the relationship, right?

JC: 100 per cent! That’s what I’m known for [laughs]. That’s why they call me ‘Thunder.’

How come you guys are playing Barry White at the jobsite?

JC/BC: [Laughing]

BC: Scrap all that stuff I said about professionalism [laugh].

I’ve read that you focus your clients’ attention on looking at the house as a system and how it provides not only shelter but is healthy to live in. What does this mean to you and what are some of the considerations to make that happen?

BC: Especially when it comes to additions and renovations, it’s increasingly important. We do so many projects in Toronto that are attaching to or changing older homes. [For example] suppose you have an old solid masonry home and you’re building a wood frame addition onto it… You’re going to build this super tight addition onto a house, onto an old, leaky brick house on the front half and so the heating system is going to be unbalanced, the cooling system is going to be unbalanced. So we need to design the entire system to account for that. I often use the reference that if you’re building this super tight addition to the back of the house and you have the old, original uninsulated house at the front, it’s like going outside with a Canada Goose down jacket on, but leaving the zipper open. Because the front of the house just leaks energy like crazy and in

the back in the addition, you’ve got this super, hyper-insulated, really tight envelope on it. So as a result you need to balance the heating and cooling systems accordingly. You always have to look at the full house as a system.

JC: There’s no systematic approach on how to attack each one of these houses - they’re all differently completely. So like Brendan was saying, when looking at an existing house and a new addition, there’s so many elements that come into play, not just heating, it’s from our composition of floor packages -- everything has to relate to each other and work together.

You’re building a new head office for your firm in the Lawrence-Caledonia area of Toronto. It’s three storeys and very modernistic. Tell us about this project.

JC: The approach on the building is it’s a onestop shop for our clients to come in and meet the kitchen company, the designer, the architect, the builder - all within one building to avoid them having to go all over the city.

BC: We branded it as ‘The Building Block.’ Clients will be able to come in and not only design their addition, renovation or custom home but also work through their interior design, their kitchen manufacturing, the design of their actual millwork - all within one space.

JC: The key thing with our building is that it’s going to have a lot of our ingenuities and techniques for how we apply these insulations and all those elements to our clients’ homes so they can physically see it within our own building.

BC: Enbridge partnered with us and they brought in all the building science specialists, everything from building envelope, heating and cooling to green roof technologies and all these experts gave us advice on things that they thought we should do differently. cc

One of Eurodale's most interesting clients is... itself. Here, it is building a multi-storey office/showroom in midtown Toronto that it brands as The Building Block. When up and running, it will house not only Eurodale, but a kitchen firm, designer and architect.

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole.” So it is with Fusion Stone: the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer. Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips and screws. You just screw it to the wall and it’s “Hooked for Life.” Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

“SoftPlan continues to work great for us. Our estimates are as tight as they can get. Well under ½ of a percent variance from budget. ” Dave Tucker, Sedgewick Homes North Carolina, USA

Although sharing similar floor layouts, the individuality of each half of this Calgary split lot project is apparent from the street. Ontario oak barn board and a distinctively angled roof profile mark the b85 house (left). A more industrial look is prominent on the b90 house (right), with its corrugated metal/cedar plank sheathing and flat roof.

DEVELOPMENT & CONSTRUCTION: BEYOND HOMES

By Jon Bleasby

photos by Jared Sych

Urban infill is all the rage as downtown land costs in cities like Calgary soar. Developer/designer couple Majida and Alkarim Devani demolished an older home in the established Altadore neighborhood, severed the property into a pair of 25’ by 125’ lots, and created this speculative design/build home project in 2015.

The couple have done this before, blending Alkarim’s experience as a developer with Majida’s talent as an architect and designer. Although Calgary has no issues with infills per se, it gets a little tricky when it comes to the actual design of the house, Majida says: “They’re very particular about height restrictions and context, but are open to what is going on.”

At first glance, we see a pair of almost identical twin homes. Yet like most siblings, there are as many differences as similarities, starting with the exteriors. Alkarim faced a small challenge when it came to sourcing the barn board exterior for b85. “We had to fly to Ontario to find the board. There are mostly pine barns in Alberta, whereas the old barns in the east were often built with oak: harder and more durable.” In contrast, corrugated metal and cedar was chosen for the exterior cladding for b90. “We apply a natural Sikkens product on the cedar so there’s no maintenance. We generally never stain; we let it grey and weather.” The curb appeal is heightened by the lack of street side parking. As is typical with

Continued on next page

smaller urban lots, there is a rear laneway with a detached garage.

The houses again defy their southfacing exteriors with similar-yet-different interior ambiences. House b85, with its rustic barn board cladding, has a very clean, bright main floor palate, highlighted with unique features such as exposed copper piping and striking ceramic tiling in the second floor master bathroom.

In contrast, b90 carries the warmth of its exterior cedar onto the walls and ceilings of the main living space using 2 x 8 cedar beams, while leaving the second floor master and bath simple and clean.

To contrast with their exterior styles, the home with the more rustic exterior has a clean, minimalist kitchen and main floor design (this page), whereas the more industrial sibling has many natural wood features and detailing (opposite page). Both have open stair treads made from Parallam beams, although each is stained differently.

Parallam beams were chosen for the stair treads and fireplace mantels of both homes, being doubly cost efficient and attractive when sanded and sealed. “It’s important to bring some texturing into a cool, modern interior. It warms the space aesthetically,” explains Majida. Basement layouts of each house are identical, with a guest suite, full bathroom, and large multi-functional entertainment area with wet bar.

Both frame structures are insulated with WallBAR, a recycled material blown between the studs. “We like it from a green perspective. It has a consistency similar to paper maché, and is both formaldehydefree and mold-resistant,” Alkarim says. WallBAR's high insulation qualities also deliver above-minimum code in the walls and R50 in the attic spaces.

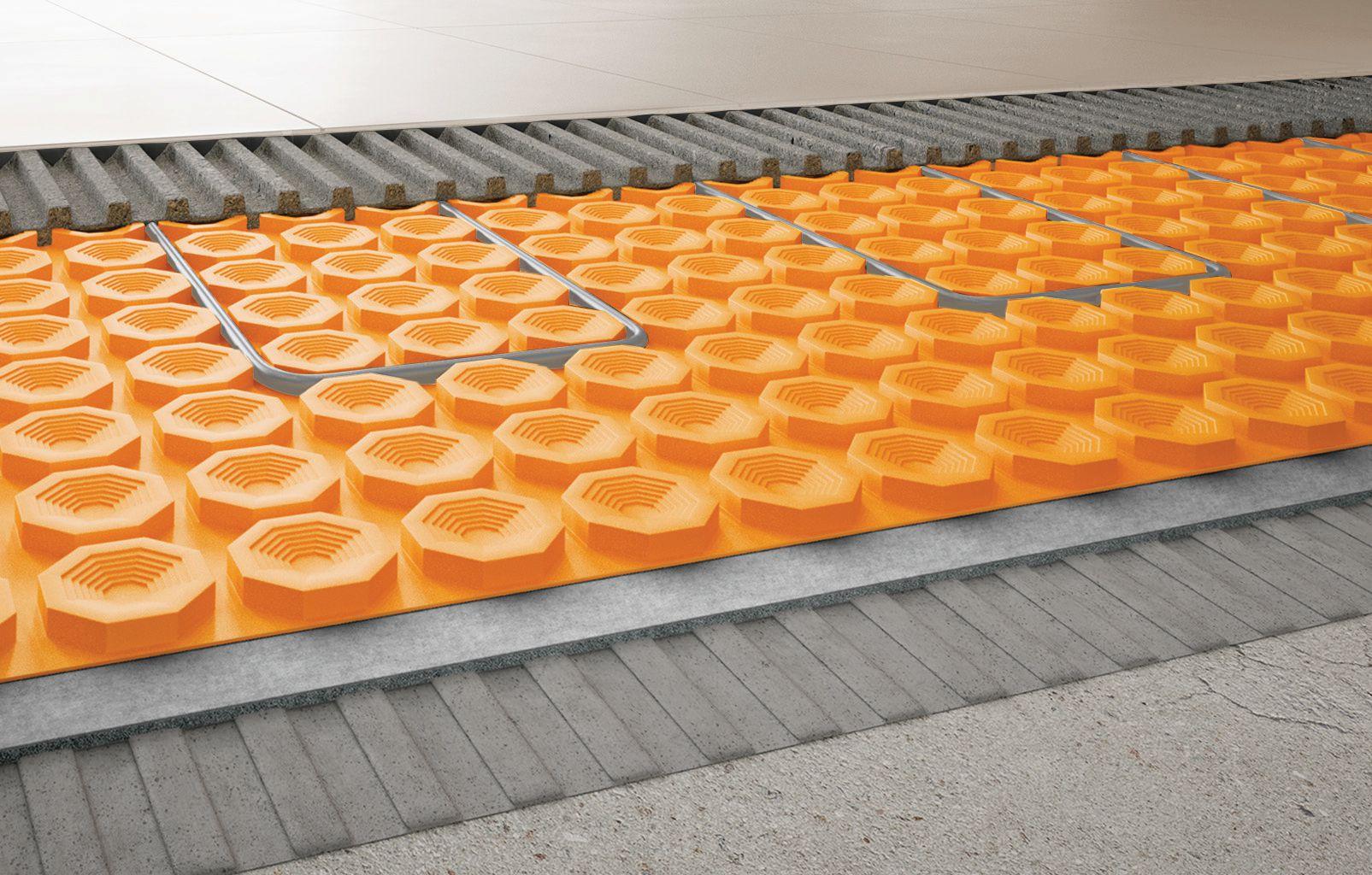

Despite being speculative projects built to tight budgets, eco-awareness was not set aside. Heating is via a 96 per cent high-efficiency, forced air, natural gas furnace for the main and second floors, and in-floor hot water for the basement, along with LED lighting, ‘smart’ thermostats, and instant hot water systems. Windows are double-glazed, metal-clad with vinyl on the interior side.

“Altadore is in an interesting phase right now,” observes Majida. “Older bungalows are being torn down and a number of modern houses are replacing them. Project b85 + b90 fits in well given the materials chosen and different rooflines. It was fun building two houses so similar yet with different heights, colours, exterior textures, and window treatments.” cc

House b90’s rustic interior look continues into the master bathroom (opposite page), notably with wrap-around wood detailing at the tub and vanity. The vaulted and angled roof line of near-twin b85 creates a spacious feel and allows large amounts of natural light to flow into the master bedroom. The copper tube light bars and patterned wall tiles brighten the monochromatic tiles and counters.

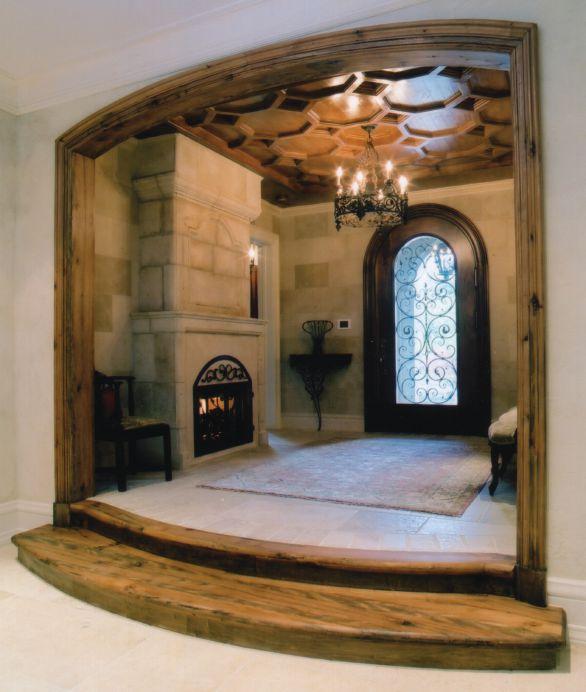

Dean Jones, owner of Creative Design Stairs & Railing, Orillia, Ontario, is proud to be a leader in of the most geometrically complex trades of all.

By John Bleasby

From the time his family relocated to Florida when he was three years old, Dean Jones has bounced between the southern USA and his birthplace in Simcoe County, near Moonstone north of Barrie. He runs his business, Creative Design Stairs & Railing, from a modern 10,000 square foot facility in Orillia with a staff of seven that includes his daughter, son and son-in-law.

Why staircases?

My dad was a builder. I’ve been swinging a hammer since I was six years old. I’d done a lot of cabinetry, trim, anything that had a challenge. The more complicated the job, the more fun for me. When I was about 20, I was with flipping through the Yellow Pages looking for a job. Nothing caught my eye until the letter ‘S.’ I saw an ad for a company that made staircases and gave them a call. They put me on part-time. I’ve been making stairs for more than 30 years now.

Do you custom work or do you do high volume work for developers?

We don’t do cookie cutter development work. They’ve asked me but I turned them down. I don’t want my eggs all in one basket. If I have one builder doing 300 homes and another doing 500, it would take up all my capacity.

Do you work with architects?

Architects come to me because the stairwells are often a challenge for them with calculations like headroom, widths, code issues. They run their designs through me to make sure that they’re going to work. I have a three dimensional vision of how it will look when it’s finished.

What geographical area can you serve?

I like to say I’d rather go three hours north than one hour south! When we get offers from Toronto, we don’t know if it will take us one hour or four hours to get down there.

How do you select your new hires?

I prefer those with no carpentry experience at all. Some people say they’ve got experience, and I’ve hired those guys. But it’s hard to break

in someone who thinks they already know it all, especially when it comes to safety.

How have designs and style changed over the years?

We’re seeing more modern designs using steel structural stringers, more open risers, central mono stringers, and steel and glass for railings. Staircases are often the centrepiece of a home. The sky’s the limit. If someone brings us a photograph from a magazine, we can make it. We like to take our time and use the best materials. We take pride in our work and our customers appreciate our quality.

There must be very sophisticated mathematics when it comes to curved and complicated staircases.

I have my formulas. I could show you on a calculator but I’d lose you in five seconds. I’ve seen CAD-CAM systems, but everything is rough. I had to teach myself. Sometimes I would wake up in the middle of the night and say, “I know how to do that now!”

You’ve grown to a staff of seven and a 10,000 square foot facility. Where do you see your business going from here?

I leased my building for several years. Now I own it, so I want to work on the showroom and display more styles and finished samples. I also want to put in some engineered racking for wood storage in the shop. In terms of keeping busy, there’s lots of building and renovations around here and up in Muskoka. Word of mouth is strong. cc

Installing a smart thermostat is one of the easiest ways to save on energy costs. Smart thermostats “adapt” to homeowners’ schedules through sensors and Wi-Fi technology, automatically delivering comfort when people are home and savings when they’re not. With the Enbridge Smart Thermostats Program , your customers can receive a $100 bill credit applied to their Enbridge account. Once they have purchased and installed a qualifying thermostat, they simply need to apply for the bill credit before December 31, 2016.*

If you DO NOT sell Nest or ecobee products, find out if your smart thermostat qualifies for the program by emailing smartthermostats@enbridge.com.

Not many kids these days think of masonry as a good career option. Organizations like MasonryWorx would like to change that.

By John Bleasby

Where will the next generation of bricklayers come from? All across North America, growth of the home building and renovation industry is being undermined by the ongoing shortage of skilled trade workers. The situation is magnified during an economic downturn; younger members of the work force are let go as companies downsize in favour of the experienced ones, but when the demand picks up again those young workers have moved on, leaving a vacuum.

In the U.S., over 90 per cent of builders surveyed feel labour shortages prevent them from expanding their businesses. In Canada, the situation is very similar. In fact, Rosemary Sparks, a Construction Sector Council spokesperson, has suggested that by 2020 almost 25 per cent of the industry’s skilled workers who were on the job in 2010 will have retired. Furthermore, skilled labour shortages vary from trade to trade, and are influenced by shifts in regional economics. For example, recent reports indicate that skilled construction workers are now leaving recession-gripped Alberta for better prospects in faster-growing B.C.

The impact of geography, age, and skill sets is not lost on Bob Sanders, president of MasonryWorx, a member-funded, Ontariobased organisation. MasonryWorx’s efforts span both the product supply side and the labour market to promote the increased use of masonry in commercial and residential construction. Masonry demand continues to grow, but skilled labour supply is an issue.

Masonry is also somewhat regionally specific. “In Ontario and Quebec, masonry is typically the first choice among building materials, simply due to its historic use for decades,” Sanders told Canadian Contractor. “Heading west or east from there, one sees less masonry for a variety of reasons, including design styles and availability of alternate local products.”

Even so, decorative masonry, (i.e., non-load bearing stone or brick) remains a popular material choice across the country for external cladding and detailing, plus interior features such as fireplaces and walls. The factors go beyond aesthetics and include longevity, eco-

friendliness and safety. Masonry has a compelling story to tell, and as a result there is a steady demand for those trained to lay it up.

One of the challenges is attracting younger people to the trades as a career choice. Sanders has few illusions, especially about the appeal of masonry to the millennial generation and the physicality of the work. “Today’s generation does not look on the trades as an attractive career choice, and masonry itself is not one of the trades young people necessarily consider versus being an electrician, a wood framer, or a plumber,” he explains. “Yet, if you speak to anybody in the field today, you’ll find masonry is an extremely rewarding long-term career.”

The suggestion that the industry faces a clash of heightened expectations in a culture dominated by highly advanced technology is confirmed by a recent Statistics Canada poll: 42 per cent of those aged 13 to 24 said they would be unlikely to consider a career in the skilled trades, whereas 67 per cent identified university as their first choice for post-secondary education. “Yet the kids graduating are struggling to find work, even with post-secondary education. The trades seem to be, in some cases, a fallback proposition,” Sanders points out.

That masonry suffers from a talent shortage like any other trade means Sanders has his work cut out. “We’re no different; the framers could use more framers, the electricians could use more electricians, and we could use more masons.” However, he points to two areas of continued optimism for masonry in particular.

One is the training offered by unions such as LiUNA (Labourers International Union of North America) with their Red Seal accredited apprenticeship programs. Another avenue for training is the nonunion courses offered at several community colleges, including Conestoga College in Kitchener, Ontario.

Graduates have a choice to ‘go union’ or not after course graduation and apprenticeship. “There are advantages to both;

it depends on the individual person,” explains Sanders. “However, both union and non-union companies want to attract employees, so they have to be wage and benefit competitive.” Furthermore, graduates with entrepreneurial spirit have the potential to head out and start a masonry company of their own after a few years working alongside experienced masons.

Secondly, there have been important product advances over recent years, innovations that offset some evolutionary changes from traditional building techniques and preferences. For example, while concrete block foundations and walls are not as

If you speak to anybody in the field today, you’ll find masonry is an

common as before, new manufactured veneers, cultured stones, non-mortared stone panels, and decorative products mean a new generation of masons can enjoy exciting creative possibilities.

“Maybe yesterday they were using using a trowel, but today masons are using a trowel, a glue gun, and a drill,” says Sanders.

There will always be traditional masonry. Furthermore, new product developments and sophisticated training programs offer young people career prospects with a solid future. However, MasonryWorx and other similar groups

are aware that a lot of work still needs to be done to convince the next generation that a trades career might provide a better employment option than working in an office.

At a recent forum in the United States, John Courson, president and CEO of the Home

Builders Institute recognised that while the trades perception problem is obvious, the solutions require more than the industry simply complaining to itself about it. Courson suggested that the issue needs the attention and engagement of the general media and government officials at various levels. Otherwise, the industry will fail to appeal to an entire generation. cc

From small drafts to room renovations, our full spray foam insulation assortment will exceed your project needs. (800) 325-6180 • touch-n-foam.ca

Thanks to the power of social media and YouTube, Canadian contractor Bernie Mitchell, who lives near Peterborough, Ontario, is getting enquiries from around the world about his unique drywall art.

Interview by John Bleasby

How did you get into the drywall business?

I hitchhiked out West just a couple of days after finishing high school in 1976; there was more employment opportunity out there. I started drywalling that same summer in Northern Alberta.

Your website shows a very high level of finishing on walls, archways and fireplaces. Has that always been a specialty?

People think of me as someone who thinks outside the box. What you see are my creations and my designs. For example, I started to double-up the drywall around some fireplaces and make my own step-able reliefs. That’s how it developed. I just took it further and further.

You must have a creative background beyond drywall?

I did leather carvings when I was a teenager: belts, wallets, that sort of thing. And some pictoral carvings – some quite large, maybe 20 inches by 20 inches. It’s the same effect, just taken to drywall.

Your scenes are very dramatic. What is the creative process? I’ve always done what the client wants. We pick a subject together. As we go through it, I like them to be involved. And the location is key. I’m pretty limited where I can do these. There always has to be an indirect light. For example, natural light going towards sculpture head-on has a negative effect. Since people know that I do these sculptures, they usually have me into the home during the pre-wiring stage so we can make special arrangements for the lighting we need.

Your YouTube videos show you using every day tools to shape your designs.

It’s pretty basic: a 4 inch drywall knife, a kitchen spoon and of course a little bit of a water mist on top. It’s a really forgiving material. When I did leather work, you made a mark and there was no going back. When you’re working with drywall mud, I can scribe it up, I can sand it, I can do multiple layers for texture. I can use a brush, a plastic bag for sweeping hair on a wolf, or even use some of my old leather modelling tools.

Do you have a secret mud recipe?

Years ago when I was first doing this, I didn’t have access to setting compounds; I wasn’t even aware of them. Everything was done with just drywall mud. It would shrink in the shallowest areas and crack. As those voids showed themselves, I’d have to wait and then fill the cracks up with additional product. Now I use a 90 setting compound with the pre-mix drywall mud.

You’ve had incredible interest expressed in your work recently.

I’m kind of surprised by all this. I’ve had inquiries from all over North America, Europe, even Abu Dhabi. It’s unbelievable. I’m really just a drywall guy, although I’m coming around to the fact that I am a bit of an artist. But it can be quite stressful. I maybe need to go in other directions and do more of my own ideas. Otherwise it might take the enjoyment out of what I’m doing. cc

Is

there an easier way to do the hardest thing you’ve ever done?

Imagine if reaching new customers was easier than you ever thought possible. What if you could find the right balance between growing your business and running it more efficiently?

Picture a solution that lets you reach customers from coast to coast or across the border. One that helps you more efficiently manage your inventory, fulfill your orders or expand your business online.

With Canada’s leading integrated freight, package, and supply chain solutions provider, it’s possible.

Learn how we can help your business at purolator.com/smallbusiness

Thanksto media exposure of the health risks of mold and mildew, more and more homeowners want contractors who are renovating their basements to use modern products that can help protect against moisture.

This is why specialized building materials like DRIcore’s SMARTWALL and DRIcore’s Subfloor system have become so popular among contractors. Installed correctly, these DRIcore products can be an important part of keeping a basement renovation dry, warm and mold- and mildew-free.

Unfortunately, from time to time the general public will also be exposed to myths about the best types of materials to use in basement renovations.

One of these myths is that “inorganic materials” are somehow better at preventing the growth of mold and mildew in basements than “organic” materials.

One particular version of this myth says that using “inorganic” steel studs and magnesium oxide wallboard in place of traditional “organic” materials like wood studs and gypsum wallboard is a good idea. Mold can’t grow on such materials, right?

Wrong, unfortunately.

In fact, mold can thrive on almost any substance if moisture is present. Just look at the 100 per cent ‘inorganic” surfaces (ceramics, steel, aluminum, glass, etc.) on the interior of any typical household shower enclosure.

Unless moisture is quickly removed from this location (through sufficient bathroom venting), such a space is quickly going to show signs of mold and mildew – even with frequent cleaning. Every homeowner knows this. It is moisture itself, not the substrate it grows on, which is the problem.

Likewise, mold can grow within magnesium oxide walls in a basement renovation if moisture is present. It can grow on steel studs. Mold can grow within any “inorganic” basement wall or floor structure.

Therefore, mold prevention is not simply a question of finding “moldproof” substances to build with. There really aren’t any. The risks of mold can be reduced, rather, by installing an integrated wall and floor system that is designed to minimize or remove the accumulation of moisture in the first place. Just like that well-ventilated shower enclosure.

DRIcore’s SMARTWALL panels, 23.5 inches wide by 96 inches high, do precisely that. They are a proven method to reduce moisture accumulation that can plague traditional stud-frame, fibre insulation and poly vapor barrier construction methods.

SMARTWALL does not rely on “inorganic” materials in its structure (largely consisting of EPS foam factory-bonded to 1/2 inch drywall) –because it is carefully designed to allow water vapour to move freely through its semi-permeable vapour barrier system, where it can dry out.

In a traditionally-built basement wall, water vapour can run down the inside of traditional poly vapour barriers, or accumulate inside fiber insulation. Steel studs and/or “inorganic” wallboard materials won’t solve that moisture-flow issue. SMARTWALL, on the other hand, is designed to deal with that moisture.

On basement floors, DRIcore’s Subfloor product consists of 2-foot by 2-foot tongue-and-grooved engineered tiles. High-density plastic feet on the underside of the tiles create an airspace that allows air to circulate, evaporating moisture.

No “inorganic” flooring material is a magic bullet against mold. The solution to mold is to deal with the underlying moisture issue. DRIcore has become a market-leader in such basement building solutions by fully understanding where mold and mildew come from.

“I know exactly where my business is headed.”

“Before I started RENOVANTAGE coaching, I worked as hard as I could and hoped that everything would work out OK. Not anymore! Thanks to RENOVANTAGE, I now know three months in advance how many dollars I will produce and my cash flow position. It feels great to be in control of my business!”

• Insufficient profits? • Too many hours? • Not enough time? • Too much pressure? • Not enough sales?

RENOVANTAGE is the leading Canadian training organization for self-employed renovators and homebuilders. We have many coaching options available to suit your budget and availability. Call our Master Contractor Coach Mike Draper, at 416-840-6566, ext 227, for a complimentary discussion about your own business issues and opportunities.

CHAMPION

6250 Generator Page 56

STANLEY Inspection Camera Page 56

Four ways to boost the energy ratings of your future builds Page 52

By Steve Maxwell

Every young contractor I’ve ever met figured he was as tough as new rebar. Strength, independence, a big truck and a cowboy attitude serve these young bucks well for years. But eventually, without realizing exactly when, the glitter of the young, solo contractor lifestyle begins to rust. Our vital, independent mover-and-shaker eventually grows weary of constantly getting dirty, tired and bruised. Business independence is a great thing, but not if it blinds our contractor to how handy it can be to have trusted people on board to keep the business rolling while he takes a vacation or when the flu strikes.

If our young contractor never does anything to change the natural trajectory of the business started when he was 23 and immortal, he finds himself doing the same thing on the far side of middle age. Bags of cement are heavier. Piles of lumber grow mysteriously larger. Mondays take on a new dread. Our onceyoung contractor, now on the downhill side of 40, is living what he thought was his dream, yet feeling more like an overworked employee on a nightmare treadmill. Occasionally he wonders if he wouldn’t have been better off with an office career and a pension. Not that he ever considered it an option at the time, but

it’s too late now.

The root problem here is that even though our solo contractor hires subs, he’s never grown a succession plan to build capable leadership to take control of things at the top. Had he built a true “business,” our contractor would have managed his affairs with the aim that some day the operation would run itself. Everyone involved could be replaced, including that “irreplaceable” young swashbuckler who never thought past his ambition, strength and boundless energy.

If our young contractor turns out to be smart enough to balance braun with brains, by the time he’s in his 50s he sits at the top of an organization he has built. It may not be a large organization, but it no longer requires his constant attention, exertion and youthful vigour. The business runs on auto-pilot, at least for short bursts and in most ways. And while it’s good to feel the vibrancy of being a young, rebar-tough contractor, the day always comes when it’s more than good to have someone else a little less rusty on your side. steve@stevemaxwell.ca

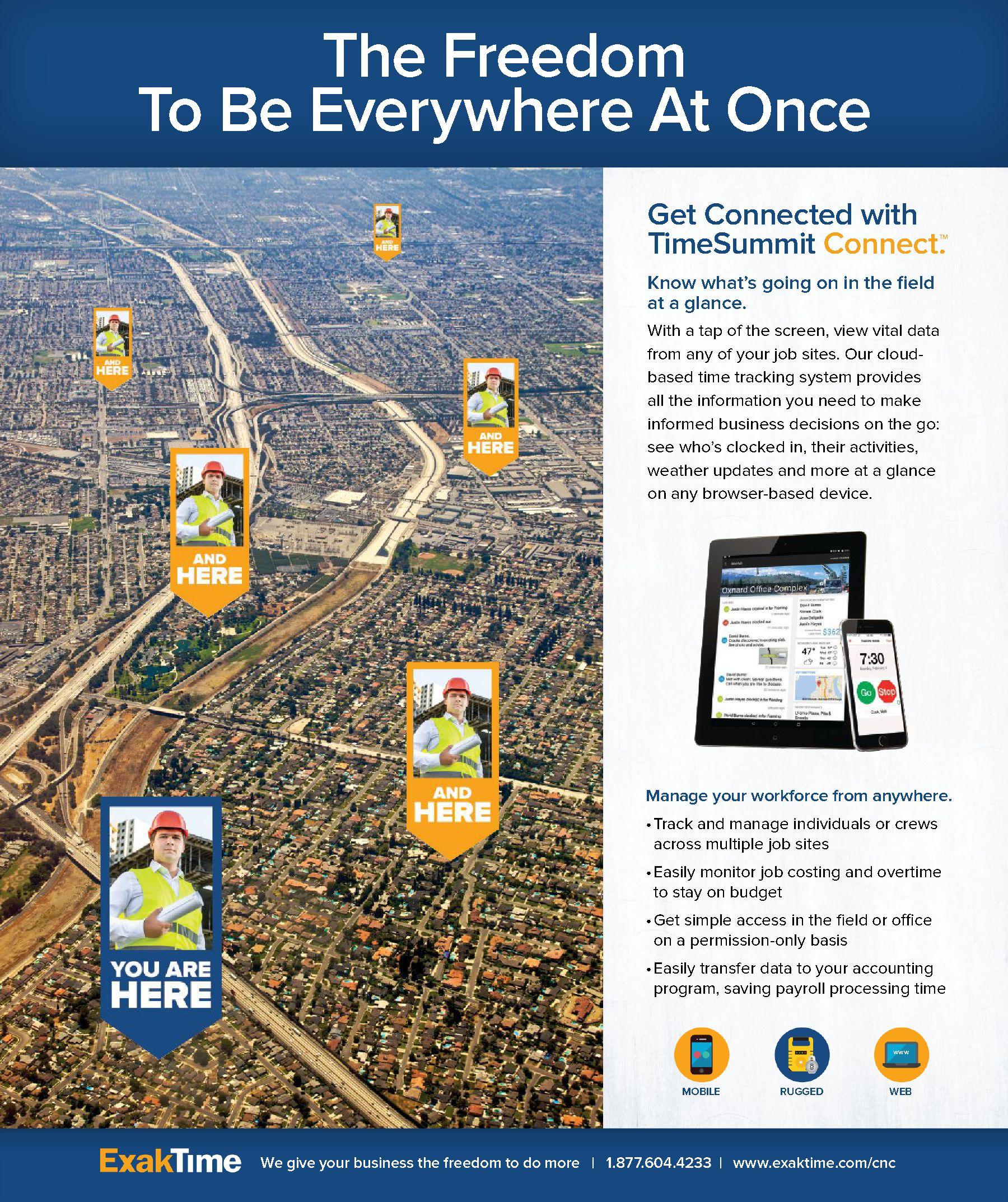

How to profit from the coming transparency in energy performance

By Steve Maxwell