Cutting the cord

Cordless tools add safety Pg. 16

Black gold Working with black iron pipe Pg. 18

Concrete facts A look at ICF construction Pg. 25

Cutting the cord

Cordless tools add safety Pg. 16

Black gold Working with black iron pipe Pg. 18

Concrete facts A look at ICF construction Pg. 25

Ron Dahl has built a business on compassion for the victims of disaster. Page 10

2022

Whether you like to read, listen or watch, Canadian Contractor has you covered.

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

Ontario Minister of Labour, Training and Skills Development, Monte McNaughton, joins The Hammer to explain the new Skilled Trades Ontario regulator. Then Gord Wornoff, Canadian Contractor contributor, weighs in with his comments and observations.

The best products in the world won’t perform properly without correct installation. Service experts from Jeld-Wen Canada, Pierre Bouffard and Don Martens, talk to Canadian Contractor editor, Patrick Flannery, about some common pitfalls in window and door installation.

Oooo...pretty pictures. Follow canadiancontractor on Instagram for photos we don’t have room for in the magazine. Plus links to other stuff we like.

Patrick Flannery pflannery@annexbusinessmedia.com

Brand Sales Manager Nav Matharu (226) 931-5095 nmatharu@annexbusinessmedia.com

Account Coordinator Barb Comer bcomer@annexbusinessmedia.com

Media Designer Svetlana Avrutin

Group Publisher Danielle Labrie 226-931-0375 dlabrie@annexbusinessmedia.com

Vice President Sales Martin McAnulty mmcanulty@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Rust-Oleum was founded on the principle of creating innovative products, and after more than 100 years, they are just getting started. A top Canadian supplier for both consumer and industrial paint and coating solutions, Rust-Oleum has grown to be a global leader in manufacturing innovative coatings that empower do-it-yourselfers and professionals alike. Their newest solution – Turbo technology, is a revolutionary application process that enhances the power of regular spray paint. The Turbo Spray System delivers the same trusted protection of traditional RustOleum paints and now gets the job done four times faster.

Turbo spray paints are an innovative solution recommended for larger projects that need to be finished quickly. Available in a 656 and 737-gram size, the cans work four times quicker than traditional spray paints— offering the speed and quality of professional spray equipment without the hassle. These large cans hold almost twice as much paint as a traditional aerosol in order to cover two times more surface area per can. How is this possible? The valve and nozzle work together

to spray more paint per second covering more surface area. It provides a spray pattern of up to 10 inches (25 centimeters) making it the perfect product for project completion.

Turbo technology works well with several of the most professionally-trusted products available from Rust-Oleum including ULTIMATE Turbo Enamel, as well as Zinsser’s Cover Stain Oil-Base Primer-Sealer and Bulls Eye 1-2-3 Water Based Primer.

ULTIMATE Turbo Enamel has a formula that offers the best corrosion protection possible, complete with long lasting high-gloss colour, and superior durability. The wide spray dries quickly to achieve a tough and attractive finish and is tack-free within four hours, allowing for quick and easy project completion. ULTIMATE Turbo can be used on structural steel, handrails, doors, storage tanks, equipment, machinery and more.

Zinsser Cover Stain Oil-Base primer-sealer is perfect for blocking stains, concealing dark colours and preventing tannin bleed. It is great for sealing exterior wood. Bulls Eye 1-2-3 is a premium water-based whole-house primersealer that can be used to seal porous surfaces

like wood, drywall, cured plaster, and even concrete and brick. With Turbo technology, users can tackle large projects faster and easier than ever and top coat in just 30 minutes. These sprays can be used on garage doors, sheds, and more – anything that’s too big to spray with a traditional aerosol and too small for a professional spray gun.

The Turbo line of spray paint is simple and straightforward to apply. This product is to be used outdoors or in a well ventilated area and sprayed between 10 and 32 degrees Celsius. Rust-Oleum’s innovative Turbo Spray System is changing the way users complete their projects, offering a unique product that provides a quick, durable, long-lasting finish four times faster than traditional spray cans. To learn more, visit Rustoleum.ca.

By Patrick Flannery Editor

Listeners to The Hammer podcast (available at canadiancontractor. com and wherever you find podcasts) can download my conversation with the Ontario Minister of Labour, Training and Skills Development, Monte McNaughton, and my follow-up discussion with Canadian Contractor contributor, Gord Wornoff. McNaughton replaced Ontario’s skilled trades regulator, the Ontario College of Trades, with a new agency called Skilled Trades Ontario in January. He joined me for a 15-minute conversation to explain the move, then Wornoff joined the podcast to comment on the Minister’s announcement and discuss skilled trades training and availability in Ontario generally. Not everyone will agree with the specifics of the new STO, and complaints rolled in immediately about the fees that had been paid in the past for certifications that are now obsolete. But one thing seems undeniable: McNaughton is giving the issue a level of attention the province has not seen in decades. That has to be a good thing. Some takeaways from the conversation...

Not a lot has changed here in terms of how Ontario trades are actually regulated and certified. Requirements, testing, timelines and apprentice/journeyman ratios are all unchanged from the OCOT regime – which itself was not substantially different from the system that preceded it. There’s no structural shift that will spur any huge surge or decline in participation. Most of the changes have to do with streamlining and simplifying the process – worthy goals, for sure, but not any kind of paradigm shift. The elimination of some fees is welcome, of course, but not a gamechanger. No trades were added or removed from the compulsary list.

” There’s no structural shift that will spur any huge surge in participation.

”

McNaughton hinted that deeper and more impactful changes could be in the works down the road. For now, I suspect the priority was to put a stake in OCOT as fast as possible and usher in a new brand and a new day. Predictions are dangerous, but I’ll go out on a limb and say we won’t see major changes to the regulatory framework any time soon. McNaughton seems to spend a lot of time listening to stakeholders and I think the message he’s getting from business owners is that simply finding workers is the pressing need. While there are certainly ample areas for improvement, as Wornoff pointed out in his comments, the appetite is probably not there for an overhaul of the system with all the confusion and uncertainty that would create in the short term. While we might all admire Germany’s apprenticeship structure, it is the end result of centuries of history that we don’t share.

One note McNaughton hits especially hard that Wornoff, a high school trades teacher, endorsed enthusiastically is the need for a full court press on advertising the benefits of a career in the trades to students. McNaughton calls for “ending the stigma.” While I’m not sure it goes as far as a “stigma,” I’d agree there is a significant perceptual gap between what parents and teachers think a job in the trades looks like and what the reality is. White collar people probably still underestimate how much money you can make if you know what you are doing. But even less understood is the potential for career growth in a whole array of different directions. Business ownership? Check. Expert sales positions with suppliers? Check. About 1,000 different government jobs? Check. Teaching and instruction? Check. Even...gulp...writing and communicating about the trades. Let’s hope McNaughton puts some public money where his mouth is and gets a serious effort going to give young people the real picture. cc

Ontario’s skilled trades regulator, the Ontario College of Trades, was disbanded by the Ministry of Labour, Training and Skills development at the start of the year. On Jan. 25, the ministry announced its replacement, Skilled Trades Ontario. The new Crown agency has the same mandate as OCOT did to issue certifications to skilled tradespeople in 144 trades, both mandatory and voluntary. The main structural change is to bring certification of training and issuing of apprentice tickets inside the one organization so apprentices and employers are not dealing with multiple departments. Fees for registration as an apprentice have been ended. Access to all administrative functions such as updating certifications, applying for tickets and applying for equivalencies will be offered through a single web portal and planned mobile app. The ministry has taken over all compliance and enforcement roles through its occupational health and safety department. The oversight board has been reduced to 11 from OCOT’s more than 20. Minister Monte McNaughton said in comments on The Hammer podcast that the focus has been to streamline and simplify the process for becoming certified in the skilled trades, while doing more to promote interest in the trades and remove barriers facing young people.

In addition to the launch of STO, the ministry has recently announced a series of funding initiatives aimed at encouraging entry into the trades. Ontario will spend

A ban on the installation of fossil-fuel-burning appliances for space and water-heating came into effect in Vancouver Jan. 1. While the ban allows the use of methane sourced from biomass reactors, the supply of renewable natural gas in B.C. is only one percent of the city’s needs, according to industry estimates. FortisBC, B.C.’s main natural gas supplier, estimates renewable natural gas would cost three times as much as the traditional kind. Therefore, the restrictions amount to a ban on natural gas heating installations in new homes under three storeys. The Urban Development Institute, in comments to The Globe and Mail, predicted builders would simply switch to electric heating designs.

In January, Vancouver voted in bylaw ammendments to address industry feedback on the restrictions. Permitted building heights were increased six inches if 14 or more inches of attic insulation are specified. Up to 25 square feet may be excluded from the permitted floor area caluculations in order to accommodate additional mechanical equipment for heating and hot water. The city has said in statements that it hopes builders and homeowners will opt for heat pumps in lieu of natural gas furnaces and water heaters. cc

$90.3 million over three years to enhance the Skilled Trades Strategy. Beginning on April 1, the Achievement Incentive program will be enhanced to include the following: Milestone payments of $1,000 to an apprenticeship sponsor for each level of in-class training completed by the apprentice (up to four levels) and an additional $1,000 certification bonus.

A new $1,000 registration payment, and additional $1,000 payments per level and certification prior to an apprentice turning 25 years of age.

A new $1,000 registration payment, and additional $1,000 payments per level and certification if an apprentice is from an underrepresented group (e.g. women, Indigenous, people of colour, people with disabilities, Francophone, newcomers). cc

Frank Bayuk has retired after 15 years with Sexton Group, according to Eric Palmer, vice-president and general manager. Bayuk joined the Sexton Group in 2007 and has been in the building materials industry for over 35 years. Over his time at Sexton Group, Bayuk worked diligently to best serve and understand the needs of B.C. members. Palmer reports Bayuk has connected with many people in his career both personally and professionally and has been a wonderful person to have onboard at Sexton Group.

“Frank built strong and durable relationships during his career at Sexton. Our members knew they could count on him to speak the truth and work hard to make them successful. I wish him the very best in retirement,” said Steve Buckle, CEO.

Taking over from Bayuk, the B.C. members will be served by Dean Toews, who joined the Sexton Group in August of 2021. Dean is an experienced manager in the area of building products with over 20 years in the industry. His roots are in sales and branch management and also include outside sales, territory management and regional management for western Canada in both drywall and insulation.

“Dean is a welcome addition to our team of professional business development managers. I am confident in Dean’s capabilities and his drive to serve our B.C. members,” says Palmer. “I know he will succeed in his new role.” cc

Shurtape Technologies has announced Vuk Trivanovic, CEO of the company’s industrial and engineered solutions groups, will expand his role and responsibilities as CEO to encompass the full scope of Shurtape’s global business, now including its Ohio-based consumer and craftsman group. This group markets DIY and home-andoffice products under the Duck, T-Rex, FrogTape, Painter’s Mate and Shurtape brands. The leadership transition comes as John Kahl, CEO of Shurtape’s consumer and craftsman group, announced his retirement at the end of last year. Kahl and Trivanovic, who earlier this year joined the board of directors of Shurtape’s parent company, STM Industries, will both continue to serve in that capacity. Trivanovic joined the company in 2015 as COO, a role that allowed him to become familiar with all aspects of Shurtape’s business and the various markets served by the company. In February, 2020, he assumed overall leadership of the industrial and ESG groups, and in that expanded role has been integral in overseeing the company’s continued

growth in those markets despite the challenges posed by the COVID-19 pandemic.

“Shurtape has thrived for generations by embracing change and by developing and promoting individuals who demonstrate outstanding leadership and vision,” said Stephen Shuford, vice-chairman of STM Industries. “Over the course of his six-year career at the company, Vuk has

Passive House Canada is reporting there are a number of provincial training grants available across Canada and it is providing assistance to organizations that are looking to increase their skills and knowledge on Passive House. Passive House is an energy-efficient building standard that can achieve the net-zero efficiencies mandated in present and upcoming building codes across the country. Course participants can qualify for government funding applied to any of PHC’s courses as well as the certification exam. Depending on circumstances and the province, students may qualify for a discount of up to 83 percent of the course cost. Passive House is aware of at least three courses that have qualified for assistance: Pathway to Designer/Consultant, Construction Training for Trades, and Master Class Series. Grant applications may take up to four weeks to process, so Passive House recommends applying early. Travel expenses may also be eligible in some provinces. The Pathway to Passive House

steadily earned the confidence and respect of the board, his co-workers, our customers, supply chain partners and local community leaders. We are all eager to lend our support as he captains the next leg of Shurtape’s continuing growth journey.”

“I am humbled and honoured to assume the role of CEO of the Shurtape group of companies and wish to thank John for his superlative leadership and selfless commitment to the business over the course of his 36-year career,” said Trivanovic. “The success of Shurtape’s consumer and craftsman business has always been rooted in its embrace of innovation and imagination, and that will never cease to be the case. My goal is simply to build upon that rich legacy by helping Shurtape continue to develop better, easier solutions for everyday household and workforce tasks.”

While Trivanovic will be based in Hickory, N.C., Shurtape’s consumer and craftsman group will maintain its operations in Avon, Ohio, where the company recently extended the lease on its facility until 2031. cc

Trades Certification online course starts March 17 for Nova Scotia and March 24 for B.C. This three-part course teaches practical Passive House Building techniques and theory. It is essential that those working on Passive House buildings can properly install components, accurately implement design details and also assess the impact that changes from planned work will have on the performance of the building. This course includes online lectures and hands-on workshop experience, incorporating actual building of Passive House elements relevant to the Canadian construction industry. A Pathway to Passive House Designer/Consultant Certification starts March 8. Passive House certification ensures organizations are expertly qualified to design high performance, highly efficient buildings to meet Canada’s national green building strategy and focuses on the following three core courses: Passive House Design and Construction, Understanding and Working with PHPP, and Exam Preparation for Designer/Consultant Exam. cc

“Questo” wants to know if he’s going to be reimbursed for the business he lost after he refused to sign on with the old Ontario College of Trades, now that the province has admitted it had problems and replaced it with Skilled Trades Ontario. Legitimate question but, well, good luck with that.

What’s in it for those licensed electricians who refused to sign with the disaster Ontario College of Trades? Will they get their licenses back? If so, who will pay for their carried damage? I lost over $3 million because the incompetence of ex-premier McGuilty. Can all we electricians in Ontario sue him now for damages? I only hope this [the creation of Skilled Trades Ontario] isn’t a manoeuver for Doug Ford’s next election. Sounds really fishy.

Are those electricians under this new apparatus free to sign their own work? We were not treated as equal under Canadian law, as we were part of the trades. Mechanics sign their work, gas feeders sign their works, maybe plumbers too (not sure on that). Why can’t we sign our works? Why do we need electrical inspectors to inspect our wallets? That’s what they have been doing, apparently. Collecting money from us. Are we second-class trades from the third world? It’s pathetic. Plus the so-called electrical contractor and master license. Another pathetic money grab. I would like to take a look at this new skills paperwork. Maybe another skills disaster 2.0.

I will call them soon. I want my Canadian electrical license back, the way it was, no restrictions. I was already a senior. If not, financial consequences will apply. And I urge anyone in this condition to do so. Time for lawsuits. McGuilty should be personally sued. Thousands of letters plus petitions were send to him and his cabinet when he set up the disgraceful College of Trades. And they were all ignored.

– Questo

“Sparky” is unimpressed with the new Skilled Trades Ontario organization and suspects more of the same as long as government is involved in regulating and subsidizing apprentices.

I have been involved in the trades for about 50 years now. I am very concerned about the latest plan. It already stinks of cash-for-life administrative jobs, red tape and government mismanagement. Of course the participants are thrilled with this new government initiative, they have just been handed a free ride on the backs of government and fees, fees, fees. Just like ESA and TSSA they have been turned into cash cows which had a safety mandate at one time but have turned it into greed. I taught electrical classes at Algonquin College and was always very disappointed when a student showed no basic knowledge of the trade after three years of their apprenticeship. Most would sheepishly say the were being used as gofers and labourers on the job site because their hourly rate was subsidised and was cheaper than the union

rate for a labourer. As for being run by a board of directors, I have been there, and by the time these hand-picked board members get their position one thing is for certain: they must play by the rules, they must do as they are told or they will be replaced. All the catchy slogans and free stuff is not going to help the trades. Keep the government, politics and high-priced executives at bay and maybe with the right leadership and a hands-on system with checks and balances to ensure the trades candidates are actually learning something it may work. To sum up, it is greed or, as they call it, good business. I am aware of contractors who take on apprentices and free school students so they have another live face on site to bill out at $100 plus per hour. They are not interested in teaching them anything, just be there and look busy. I could go on for hours. Yes, the system has been a thorn in my ass for five decades.

– Sparky

The Voices section in the magazine selects readers’ comments that are sent through emails or posted online. To be featured here, please share your opinions about the different subjects, topics and ideas discussed on canadiancontractor.ca.

21_2799_Canadian_Contractor_JAN_FEB_CN Mod: January 17, 2022 3:20 PM Print: 01/17/22 3:49:37 PM page 1 v7

Defined by his caring and compassion, this Ontario contractor is a man with heart.

By Jack Kazmierski

Ron Dahl, owner of First General Muskoka, has seen more than his fair share of disasters. Prior to running his very successful construction and renovation business, based in Huntsville, Ont., Dahl was a claims adjuster.

“After 17 years as an insurance professional,” he says, “I decided to shift gears to a more hands-on way of helping people deal with their problems.”

He made the switch from claims adjuster to contractor in 2004, and for the past 18 years he’s been helping homeowners deal with tragedies as they struggle to put the pieces of their lives back together again after a catastrophic flood, fire or other major damage to their home.

“Nobody works in the insurance industry for fun,” Dahl explains. “You work there because you like to help people. I felt that my hands were tied as I tried to help people, and I thought I could make more of a difference by actually doing the work, rebuilding the houses or renovating the basements, whatever the case may be. I felt it was more of a hands-on approach to helping the people who suffered loss.”

Changing gears from insurance to construction was easy for Dahl. “I was building houses in my spare time anyway,” he says. “My grandfather was a builder, and my father got into the business as well, so by the time I decided to make the switch, I had already built four or five houses.”

“My grandfather was a builder, and my father got into the business as well, so by the time I decided to make the switch, I had already built four or five houses.”

When dealing with customers who have just suffered a major loss, Dahl places himself in their shoes and tries to see the matter through their eyes. This allows him to sympathize and to express the kind of fellow feeling that helps the homeowner deal with the tragedy at hand.

“You have to be compassionate,” he says. “As a company, we see burned homes dozens of times a year, so we have to teach our staff to be compassionate when they speak with homeowners, rather than coming across as very matter-of-fact about the situation. This may be our 30th fire this year, and we have no skin in the game. However, this is the homeowner’s first, and they just lost everything.”

Dahl says it’s important for the homeowner to know and to feel that Dahl and his team are there to help. In fact, Dahl is willing to put his money where his principles are.

“There are certain industry practices that we don’t participate in, because it just feels dirty,” he explains. “For instance, insurance companies ask us to collect the insurance deductible upfront, before we start. But can you imagine me going to your house, you’ve just had a fire, and I say, ‘Hey, I’m Ron. I’m here to help you, but before we start, you have to give me $2,000.’ I don’t like that, and that’s something we refuse to do.”

In theory, Dahl can collect his deductible after completing the job, but that doesn’t always work out.

“Sometimes you get skinned for it,” he adds, “but who cares. I mean, the guy just lost his house. I can lose a couple thousand dollars.”

Happy customers, dedicated staff Putting the customer first, and doing so with heart, has benefited Dahl and his company. Not only does he get the joy that comes from giving, but he also gets great reviews. His customers genuinely appreciate his honesty, compassion and hard work.

“We get internal scorecards from insurers,” he says, “and we always nail it. We’re number one in our territory, for the most part, and I honestly believe that it’s just our straight communication, honesty and caring that sets us apart from our competition.”

The fact that Dahl is committed to making a difference, rather than just making money, also resonates with his staff, most of whom have been with him for many years. Employee turnover is minimal, and some employees have

been with Dahl from the day he started his company.

“I have a little mantra that we recite at the office: Always do the right thing,” Dahl says. “I know this has nothing to do with construction, but we’re pretty proud of it. We talk every day about being the best possible version of yourself today. Our people love the approach, every one of my staff is amazing, and they honestly care about people.”

Dahl’s company was recognized by the Ontario Workplace Safety and Insurance Board in 2021 with the Small Business Health and Safety Leadership Award, handed out during the WSIB’s Celebration of Health and Safety event.

Dahl received the award for his commitment to mental health, which is something he has been especially sensitive to ever since one of his close friends took his own life.

“We had been friends since high school and we were very close,” Dahl says. “I thought I knew how he was doing, but when he died by suicide, I couldn’t believe it. How did I miss the signs?”

The pain and confusion led Dahl down a path towards awareness and a need to help others find a way out of their pain and hopelessness. The company has an open door policy, and Dahl says he spends an hour everyday just talking with someone about the challenges they’re facing.

That level of compassion has been woven into the fabric that defines the level of care his employees express when dealing with customers. “If your house just burned down, you can talk to anyone in my office and you’ll know that we honestly care,” he explains. “Anyone can rebuild your house, but what sets us apart is the fact that we care, and that comes through in the customer experience.”

The commitment to mental health goes above and beyond taking care of

“I think everybody needs a safe place, hopefully it’s your home. That’s where you go to recharge at the end of the day. But if your home isn’t your safe place then your workplace better be. So I try to make a safe workplace for everybody.”

customers. In fact, it’s the cornerstone of Dahl’s approach to running his business. “I employ a lot of people with mental health problems,” he says. “And I do that on purpose.”

A few months ago, Dahl says he had a customer who was especially challenging to deal with. “We got the claim from the insurance company because the previous contractor got kicked off the job,” Dahl explains. “That’s because they couldn’t communicate with this customer. So I got the job with the warning that the homeowner suffers with extreme mental health issues.”

Dahl met up with the older gentlemen personally, engaged him in conversation, and the man soon broke down and wept because of the stress he was dealing with at the time.

“By the end of our conversation,” Dahl adds, “I had hired him. I found out that he was a drywaller, and was looking for work. So I modify his workday to help him get to the

finish line every day, and sometimes I have to move the finish line for him because he’s not having a great day.”

First General Muskoka also has a number of Millennials on their team, and Dahl says Millennials often deal with anxiety issues. “I took a course a while back on how to manage Millennials, and they do need to be treated differently than a 60-year-old person.”

He’s quick to point out that he doesn’t proactively look to recruit individuals with mental health challenges, “but if it comes up, and I see that you have a mental health issue, if you haven’t been hired yet, it doesn’t cloud my decision on whether I should hire you or not,” he adds. “If I happen to hire you and find out shortly after that you have mental health issues, I’m not going to push you out the door. I’m going to try to help you as a person.”

The WSIB recognized the fact that employees of First General Muskoka are happy to be at work, and that’s no accident. Dahl is very conscious of the fact that he wants to create a safe space for everyone who works for him.

“I think everybody needs a safe place,” he explains. “Hopefully it’s your home. That’s where you go to recharge at the end of the day. But if your home isn’t your safe place then your workplace better be. So I try to make a safe workplace for everybody.”

The WSIB award came with a monetary prize of $3,000, which Dahl says he’s pumping back into his company’s mental health program. “I’m going to free up some work time scheduled for my staff and I’m getting a company gym membership for them. We’re going to try it for a year. If you need to come in late because you’re at the gym, we’re on board. In fact, we’re going to pay for that membership.”

Focused on the welfare and wellbeing of others, Dahl is a

compassionate contractor and a caring employer. Although he has reached the point in his career where he could retire and call it quits, he has no plans to do so just yet.

“I love coming to work,” he concludes, “and I love the people around me. I’m going to keep doing this

Sticking to the letter of your contract can protect you, even when the other side is violating the terms.

A case study shows

the importance of sticking to the letter of your contract.

By Denny Chung and Buck Hughes

It is all too often during a construction project that issues will arise with respect to delays or extras. A recent case we reviewed affirms the importance of developers and contractors following their contracts to the letter in navigating these issues. If parties do not strictly follow the terms of the contract and disputes arise, courts may rely on party conduct as an interpretive guide – including precontract conduct that a party may not have fully considered when signing the contract.

In the case, a contractor claimed for extras and progress payments owing under a CCDC-2 for excavation and shoring work performed for a residential construction project. The owner counterclaimed for delay and the cost of completing the excavation work with another contractor. The subcontractor responsible for the shoring work claimed against the contractor for unpaid invoices.

While performing the excavation work, the contractor and subcontractor experienced delays and incurred extra costs as a result of unanticipated soil conditions and adverse winter weather. The contractor submitted work orders to the owners for the extras on the basis of “unknown conditions”— but did not give formal notice of “unknown conditions” as required by the contract. The owner acknowledged the contractor’s performance of extra work but did not valuate the work orders for extras.

The contractor discontinued the excavation work after completing approximately 80 percent of it because the owner had failed to make two progress payments and refused to approve further work orders for extras.

The owner issued a notice of default to the contractor for failure to complete the excavation work. The contractor refused to return without payment. The owner then purported to terminate the contract and retained a new contractor to complete the excavation work. The owner claimed for completion costs against the contractor and rejected the extras, arguing they were “baked” into the fixed-price contract and the contractor simply underbid and mismanaged the excavation work.

In deciding the issues, the court prefaced its reasons noting that none of the parties followed their contract terms fully, or at all, but each party sought to rely on particular contract terms to their benefit. This made the dispute more difficult to resolve, and, critically, it meant the court had to rely more on the parties’ conduct to determine their intentions behind the contract terms.

The court granted the contractor’s claim in contract and on a quantum meruit basis. The court observed that the contract allowed for legitimate extra work to be completed and paid, which did not turn the contract into a cost-plus contract as the owner suggested. The contractor was entitled to the extras because the soil conditions were “unknown conditions.”

Further, despite the contractor’s failure to give proper notice of the delay, the court recognized that the contractor provided supporting documentation for the extras at the request of the owner, who had acknowledged the extra work.

The court relied, in part, on the parties’ conduct during tendering and the project, which included the owner signing a proposal that specifically excluded the work upon which the extras were based. The court also found that the contractor did not cause the delay — it was caused by the unknown conditions and in part by the owner in their attempts to adjust to the unknown conditions.

However, the court went on to also allow the owner’s counterclaim for completion costs. The owner’s termination did not follow the contract termination requirements and the contractor had not fundamentally breached the contract. Nonetheless, the court found the termination was lawful in common law as the owner had a right to terminate for repudiation. The contractor’s refusal to return to work demonstrated an intention not to be bound to the contract — this amounted to repudiation. Notably, the court also commented that the contractor should not have unilaterally halted the work by leaving — they should have fulfilled their obligations and sought payment thereafter in negotiations or through a legal claim.

This case reaffirms that all parties to a construction project should strictly follow the terms of their contract if they wish to rely on those terms when a dispute arises. Failing to do so means the disputes are likely to be more complicated and expensive, and the outcome less certain.

If litigation arises, a court may rely on the conduct that the party did not intend to or think would inform their contractual terms.

For contractors, this case emphasizes the importance of strictly following the notice provisions of their contract when seeking to claim extras or anticipating a delay. Further, contractors should be aware that an owner’s failure to make payments does not necessarily mean the contractor can or should unilaterally abandon the work. Rather, the contractor should fulfill its obligations, give notice that it is doing so under protest, and seek payment at a later date, through negotiations or legal action. Failure to do so may result in a repudiation of the contract and trigger the owner’s right to terminate in contract or common law.

For owners, this case emphasizes the importance of strictly complying with their contract termination provisions. Failure to do so could result in an unlawful termination and liability for resultant damages. Owners should also make clear at the outset of a project the responsibilities and risks they wish to allocate between the contractor and themselves. cc

Join a completely Dealer-Owned company today.

Dealers share and participate equally without the influence of any external shareholders. Harness our massive buying power, comprehensive distribution, national brand recognition and marketing support.

Beside being convenient and lighter, cordless tools make jobsites safer because they eliminate trip hazards, improve air quality and reduce impact to workers’ bodies.

By Andrew Snook

It’s no secret that working in construction comes with its own set of worksite hazards. Since 2006, the construction industry has been sitting at number three on the leaderboard for the most lost time claims in Canada. According to the Association of Workers’ Compensation Boards of Canada, in 2019 lost time claims in Canada totalled 271,806. Of those, 28,111 claims were in the construction sector, behind only health care and social assistance (49,118 claims) and manufacturing (36,432 claims). To put that into perspective, the construction sector had more lost time claims in 2019 than agriculture, forestry, fishing, hunting, mining, quarrying, oil and gas extraction and wholesale trade combined (26,689 claims).

When those 271,086 claims are broken down by “event or exposure,” contact with objects and equipment account for 62,035 claims, while falls account for 55,139 claims, and exposure to harmful substances or environments account for 18,351 claims. All these types of risks are certainly prevalent in the construction sector.

Fortunately for contractors, OEMs in the power tool industry are helping reduce the number of workplace injuries on construction sites thanks to the growing popularity of cordless power tools and the latest features and technologies incorporated into the equipment.

The sheer number of power tools moving to cordless battery technologies these days will certainly assist with a reduction of workplace injuries due to trips and falls caused by extension cords that, not long ago, could be found sprawled across busy jobsites.

“From the outlet to the area where the tradesperson was working was a trip hazard the entire way because of the extension cords being tied from one to another, which caused not only trip hazards but also fraying and the potential for electrical shock,” says Brent Neilly, group marketing manager for core trades at Milwaukee Tool. “By having a cordless jobsite, you’ve now removed all of those potential trip hazards and the jobsite is a lot cleaner from the power outlet to the user.”

One type of cordless product that has taken off in popularity on jobsites is lighting equipment.

“Cordless lighting products are massively popular from handheld lighting to area lighting to complete jobsite lighting. It helps avoid those trips and falls,” Neilly says.

Once power tool manufacturers started focusing on the production of cordless products, the OEMs started to realize

that they could implement more technologies into the products that weren’t offered on AC-powered corded tools. Many of these engineering controls are designed to protect the user from injury.

“A lot of the tools coming out right now have a ton of force and a ton of torque, so when they catch or snag on something their first inclination is take the user for a ride. When making a purchasing decision, contractors should look for cordless threading tools and cordless rotary hammers that are built with some sort of auto-stopping technology,” Neilly says.

These added technologies have also allowed for the replacement of many typical handheld power tool applications with cordless applications that can lead to a better long-term quality of life for tradespeople. Features like anti-vibration technology in rotary hammers can allow the user to work longer while helping prevent white knuckle syndrome, which can lead to arthritis.

“This reduces a lot of the repetitive stress injuries from somebody working in the trades for 30 to 40 years using the same tool day in and day out,” Neilly says.

To help ensure that power tools are operating safely and reduce the risk of malfunctions on a jobsite, some OEMs have developed apps where the user can track when their tool requires any sort of annual maintenance or regular servicing.

Removing the unseen hazards

With cordless tool adoption steadily on the rise for handheld power tools, the current target in OEM’s crosshairs is the replacement of gas-powered light equipment with batterypowered tools and equipment.

“We’re getting to a point where it’s going to be a carbon-free jobsite. People are interested in having their jobsites completely emission free, removing gas generators from sites,” Neilly says. “One thing that isn’t talked about is the human sustainability element. Workers want to go home the same way they arrived. But more importantly, when they retire, we want them to have a higher standard of living and emission-free cordless products and added safety features help accomplish that.”

By switching to battery power for tools like a 14-inch concrete saw or power source instead of a generator, the user can use these tools inside a building that doesn’t expose the user to potentially harmful emissions or a lot of noise.

Another major unseen hazard that some of the latest power tools are helping tackle is dust control, which is a major concern for tradespeople across the country. Silica dust, from concrete, poses the biggest concern as prolonged exposure can lead to acute, chronic or accelerated silicosis: an incurable lung disease that causes a wide variety of health issues ranging from fatigue, extreme shortness of breath, chest pain, respiratory failure, weight loss and death.

The Canadian Centre for Occupational Health and Safety website says:

CAREX estimates that approximately 380,000 Canadians are occupationally exposed to silica; 93 percent of these workers are male. The largest occupational groups exposed to silica were construction trades labourers, heavy equipment operators, plasterers and drywallers.

The activities listed that tend to generate the greatest risk of exposure to silica dust were abrasive blasting, cutting, sawing, demolishing, drilling, grinding, jackhammering, milling, mixing, polishing, roofing, sanding and sweeping.

Fortunately, OEMs have been designing dust management systems to help reduce exposure on jobsites.

“Ensure you use a complete dust management system. It used to be that you’d drill holes and cut concrete without a whole lot of interest in what you’re drilling. Now we found there’s a lot of airborne silica, so OEMs designed solutions to reduce amount of airborne silica on site,” Neilly says.

These solutions come in the form of vacuums that are attached to tools like rotary hammers, and water-based solutions that dispel water while the user is drilling and cutting to reduce the ability for silica to become airborne.

“Look for a 99.9-percent HEPA rating to remove 99.9 percent of airborne silica,” Neilly says.

One of the biggest roadblocks to replacing light equipment on jobsites is battling user perception when it comes to battery-operated equipment.

“There’s still some perception that cordless can’t replace those corded or gas-powered units. We just need the opportunities to do head-to-heads to show power, value and savings of cordless tools” Neilly says.

Additional ways some OEMs try to keep worksites safer is through education on the use of cordless power tools.

“The actual utilization of tools starts at a grassroots level at union centres and training centres. Our field teams will go in and do Safety 101 courses with our power tools,” Neilly says.

Another way to ensure safe use of power tools is to read the manual before operation – a simple but important solution.

“The biggest thing is to read the manual. A lot of the time, the complaints we get about power tools can be alleviated by the safety benefits we put into the tools, but some people don’t know that because they haven’t read the manual,” Neilly notes. cc

Singing the praises of black iron pipe as a great finishing material.

By Steve Maxwell

As a contractor you use different kinds of raw materials all the time. Lumber, sheet goods, shingles and paint are common, but you’ve probably missed at least one excellent raw building material until now. Black iron pipe is widely available, economically priced and relatively easy to work with. I’ve used this stuff for years on my projects and it makes strong and attractive railings for stairs, landings and balconies, plus light fixtures, handles, holders and posts. Black iron pipe is one of my favourite materials and it might become yours because it looks so good and can do so many things.

Black iron (right) is different from galvanized pipe because it’s uncoated and therefore easier to weld and finish.

This stuff is actually made of steel not iron. It’s an uncoated commodity product that comes in common diameters from 1/2 to two inches and lengths up to 21 feet. The black colour comes from the manufacturing process at the mill. All black iron pipe uses the same threaded fittings as galvanized steel pipe, but the absence of zinc coating makes black iron easier to weld and finish.

Common black iron fittings include everything you’d expect when it comes to pipes: 45- and 90-degree elbows, couplers, unions, Ts, Ys, four-way fittings, valves and plugs. These fittings thread onto each other and to the pipe itself. Pipes and fittings usually come with threads already cut, though working with factory-cut threads is not the only way to go. Re-establishing threads on the ends of pipes after factory-threaded ends have been cut off is one of the more advanced techniques you can use with black iron pipe, as you’ll see.

To thread or not to thread, that is the question. The easiest way to begin working with black iron pipe is by not threading, using only standard lengths with pre-cut factorythreads. Home Hardware is one of the best places to get fittings and lengths of pre-threaded pipe from as short as a couple of inches up to eight feet long. This is where I buy most of mine. You can do a lot with off-the-shelf iron pipe and fittings, but there are three fabrication operations that you might consider adding to your repertoire if you find you like working with this stuff and want to use it more.

Black iron can create a trendy rustic look for less.

Clamping, cutting and threading

Black iron pipe is just about as soft as steel gets so it’s relatively easy to cut. I use either a hand-held metal-cutting bandsaw or when I want a crisper and more consistent cut end, a metal-cutting chopsaw. The thing about cutting pipe is that it usually leads to the need for more work. Cutting is great because it gives you exactly the length of pipe you need for a given application, but cutting pipe also removes any existing threads –threads that are one option for joining pipes and fittings. This is why more advanced users of black iron pipe often add two more skills to their capabilities: threading and welding pipe. With these skills in your lineup you can make many different things.

Pipe is round and ordinary cuts are square. That’s the challenge you’ll run into every time you try to connect the end of a pipe to the side. The solution is something called a tubing notcher. It uses a bi-metal hole saw of the same diameter as the pipe being joined to. All tubing notchers have a built-in clamp of some kind for holding the piece of pipe while the end is being shaped to a curved profile. The hole saw imparts the correct curve to the end of the pipe so it fits against the side of another pipe gap-free.

If you consider the cost of ready-made light fixtures you can make very good money building fixtures for some of your projects using black iron pipe, fittings and simple light sockets. Here are the tips you need to succeed:

Use only standard lengths of pre-threaded pipe. Short lengths up to 12 inches long are called nipples. They come as short as a couple of inches long (called a “close nipple”), and get longer in increments of one inch up to 12 inches. I find one-inch-diameter pipe is ideal for the main body of light fixtures, with a couple of exceptions to this as you’ll see coming up.

Use black rubber pigtail light bulb sockets for the electrical side of things. Standard simple black rubber light bulb sockets of the kind used for temporary construction lighting work well. You’ll find they fit nicely into the end of a 1 1/4-inch threaded fitting. The fixture in the photo above uses a 90-degree elbow that’s 1 1/4 inch on one end to hold the fixture, and one inch in diameter on the other for connecting to the main body pipe of the fixture. Use silicone caulking to secure the rubber pigtail socket into the 1 1/4-inch elbow. Do this after soldering wire extensions to the short wires coming out of the bulb socket, covering the solder joints with heat shrink tubing.

Ground the frame. This is important for safety. Be sure to connect the frame to the ground of any all-metal light fixture, whether it’s black iron or any other kind of metal. Why? If a live internal wire comes loose inside the fixture and touches the body of the metal light fixture, the entire light fixture becomes energized and can deliver a nasty shock to anyone who touches it. Grounding the metal body of the fixture provides an alternative path for stray electricity to harmlessly make it’s way to the earth in the event of wiring failure.

Use a mounting flange. You’ll find a 1 1/2-inch black iron floor flange ideal for mounting your fixture to a standard metal light box. Even the screw holes line up. You’ll need to use a bushing to reduce down to one-inch diameter pipe for the main body of the fixture, but that’s it. 1 2 3 4

For occasional threading work, a manual pipe threader is fine and costs a lot less.

When it comes to threading pipe ends, there are two options: manual or electric. Both use the same dies to cut threads on the outside ends of the pipe, it’s just that electric threading is faster and easier. Electric threaders are expensive so you might consider going manual at first. Manual threaders are nothing more than a lever arm made to hold a pipe threading die. A ratcheting head on all manual threaders allows you to keep turning the die with the handle in the most convenient position. Mechanical threaders are simple and relatively inexpensive. If you ever have enough black iron work to justify buying an electric threader, the dies you’ve used with your manual threader will work fine. Either way, always use lots of cutting oil on the pipe as the pipe is being threaded to extend the life of the dies. I like to park my pipe vice over a garbage can while threading. This keeps excess oil off my shop floor but it also captures all the metal shavings created by threading.

As you’d imagine, it takes a lot of strength to hold a round pipe steady while threading no matter how you do it. This is where a pipe vise can help. Mine is a simple, inexpensive unit I got on Amazon. It bolts to a hardwood platform that in turn gets held in the jaws of a portable workstation.

Black iron pipe welds nicely and welding is a skill that opens many creative possibilities. You don’t need to weld to make use of black iron pipe, but an electric welder of some kind can really help. I use a Lincoln gas-shielded MIG welder for my work welding pipes and it allows precise custom projects to be created, including complicated railings. Even a simple MIG welder costing less than $300 can open many possibilities for working with black pipe. Besides the pipes being easy to weld, so are the fittings.

If you can weld, you can create awesome finishes like this with black iron pipe.

They take a weld bead beautifully and I’ve never had a fitting crack because it got too hot.

Planks, sheet goods, drywall, concrete – these are all the basics from which homes are built and renovated. Add a knowledge of black iron pipe to the mix and you can boost your profits and create homes and renovations that turn heads – all because you’ve used a cool material that few have thought of in this way. cc

The Nudura line of insulation products provide solutions for maximizing energy efficiency, providing greater protection from the elements and minimizing noise, while providing a comfortable home for your family. With a full range of products to meet every insulation need, from our Integrated Series for roofs and floors to our Nudura ICF Series for your homes structure, these proven products will provide you with the home you have always dreamed of, with added benefits over traditional construction. Explore the Anatomy of a Nudura Home.

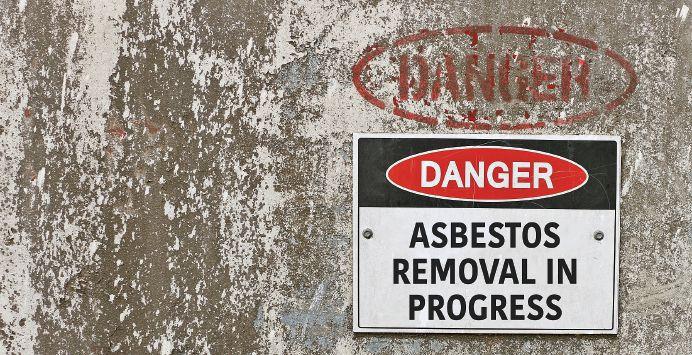

Asbestos mitigation hangs from a shaky thread

As a safety chief for a B.C. construction contractor, I’ve always been interested in the logistics of asbestos regulation, dissemination, administration and enforcement – in other words, the Prohibition of Asbestos and Products Containing Asbestos Regulation. I followed its progress from the point of writing the regulation all the way through to testing and disposal, both in the industry and in our communities.

In every instance, my interviews with safety professionals revealed a predominance of attitudes that the professionals (not just in the construction industry) are so focused on knowing the topic that they rarely zoom out to see the process itself. This also mirrors my experience in dealing with this issue over the years. After speaking with many representatives in the chain – project managers responsible to ensure environmental testing; workers responsible for working with asbestos; companies who perform the tests; and, finally, the legislators who define the regulation – I found not one individual could elaborate beyond their specific role. This implies a belief in complete trust in the system to protect everyone involved. My role in this article is to explore by whom and how this chain of trust is established, maintained and authenticated for effectiveness.

We know there are rules on the ground pertaining to safe job procedures for sampling small and large amounts of asbestos. We know there are rules around disposal and that indeed the regulation exists. But really, how much do we know and who, if anyone, is really watching the

By James Hong

dangers of inhalation of asbestos fibres

sure workers are kept safe?

work and enforcing the rules? It has always been my opinion that, with a material as toxic as asbestos, how it’s regulated, controlled and the rules enforced should be straightforward to understand. The government relies on people like you and me to carry out the ground work regardless of our individual capacity to truly understand the risks involved. Doesn’t it fall on the regulators to make sure we do understand the map without needing to become a cartographer?

Let’s start at the beginning. I contacted the government of Canada’s Toxic Substance Management department to request an interview, laying out my questions. I was rather quickly referred to a media relations liaison with Environment and Climate Change Canada. The liaison either misread or didn’t read my original request because she replied quoting my deadline date which I had not provided in any communications. And so it began. The long journey of jargon and spiralling loops of repeated

claims. “It’s not our responsibility, it’s the other guys’.”

After all the back and forth my understanding is the Department of Justice and the Ministry of Environment and Climate Change Canada write the regulation based on reasons not disclosed to me. The regulation is then communicated to all the relevant parties (manufacturing, production, suppliers and services) identified as the stakeholders. Beyond the initial distribution of the regulation communication, there is no oversight for the stakeholders. Here’s a breakdown of my interview questions and answers from ECCC.

Who writes the regulation and why?

The Department of Justice in consultation with Environment and Climate Change Canada and Health Canada write the regulation. These regulations prohibit the import, sale and use of asbestos and products containing asbestos, as well as the manufacturing

of products containing asbestos, with a limited number of exclusions.

What happens after the regulation is written and how is the regulation disseminated?

The Prohibition of Asbestos and Products Containing Asbestos Regulations were published on Oct. 17, 2018, in the Canada Gazette, Part II, and came into force on Dec. 30, 2018. Following the publication of the regulations, outreach activities are undertaken to raise awareness of the regulations and the associated requirements. The compliance promotion approach for the regulations includes maintaining a stakeholder database, preparing and delivering compliance promotion information, as well as responding to specific inquiries from stakeholders and reviewing reports and permit applications for completeness and accuracy.

Is receipt of the regulation confirmed by the stakeholders?

There is no confirmation or follow-up to confirm that all the stakeholders have received the regulation. The publication of the regulation was followed by a targeted compliance promotion campaign to inform stakeholders of the coming-into-force of the regulation and the regulatory requirements. This promotion campaign, essentially a marketing tool, was the only method used to ensure stakeholders awareness.

After the regulation is disseminated what happens with the various parties having received the regulation?

Industry is responsible for taking measures to comply with the regulation. Measures could include verifying Safety Data Sheets, consulting suppliers and product testing. An exhaustive list of measures was not available.

How is the regulation enforced after the parties receive it?

ECCC is responsible for, and committed to, administering and enforcing the Canadian Environmental Protection Act, 1999 (CEPA) and its regulations including Prohibition of Asbestos

and Products Containing Asbestos Regulations. Ensuring compliance with the regulations requires the delivery of timely and targeted information to the regulated community followed by enforcement of the regulations. This act and its regulations are enforced in accordance with the compliance and enforcement policy for CEPA, which, for the purposes of this article, are measures to compel compliance through court action, such as injunctions, prosecution, court orders upon conviction, and civil suit for recovery of costs

When there is sufficient evidence that an offence under CEPA or its regulations has occurred, ECCC enforcement officers may take appropriate action in accordance with the compliance and enforcement policy, including issuing warnings, environmental protection compliance orders or directions. When it’s appropriate, officers conduct investigations to collect evidence for the purposes of prosecution in a court of law. The decision to prosecute is at the discretion of the Public Prosecution Service of Canada.

There we have it, the governmental chain of insurances. I don’t know about you, but, for me, none of the above gives me any sure sense or confidence that we are being protected from exposure. There are so many ways to be exposed to asbestos on a job site, it’s alarming.

Nowhere in the regulation is there a list of the innumerable past products still installed in buildings today manufactured prior to the regulation or imported from other countries. Many items contain asbestos that are removed during renovations: flooring, ceiling and roofing tiles, cement and textiles, to name just a few. I can’t tell you how many times I’ve seen guys ripping out a room without wearing proper protection or even having an awareness they should be concerned.

Asbestos fibres are odourless, tasteless, indestructible fibres that can remain suspended in the air for seconds or more depending on the density of the fibres released. The fibres can be subdivided so finely that only an electron microscope will reveal them. The finest asbestos fibres are 0.00000071

inches in diameter – in comparison, a human hair might have a diameter of 0.00158 inches. These are minute numbers. To put it into perspective, an asbestos fibre can be 2,000 times smaller than a human hair. This is why it is absolutely critical to be clean shaven and fit your mask before wearing. A single facial hair in between your mask and face can allow thousands of asbestos fibres into your mask and, in turn, into your lungs. On the disposal front, even though disposal is screened as per regulations in large urban centres, there are countless small communities in Canada that rely on the honour system when it comes to disposing waste. I’ve seen it firsthand and, trust me on this, it’s not working.

In all of my articles, I continue to return to the theme that education, education and more education is the only way to effectively communicate the plethora of existing hazards that require worker and community protection. In the end, the entire responsibility for protecting workers comes down to the company. If the company is willing to overlook safety management for the sake of profit, workers remain unprotected, untrained and potentially exposed to hazards that may have short- and long-term health effects for years to come. And, might I add, without even knowing where their health conditions originated from. When safety training is not enforced as a mandate for new and continued employment, it’s the employees that are potentially in harm’s way and, at times, in extremely hazardous conditions.

I started this article wanting to talk about the logistics of asbestos regulation and ended being rather discouraged, but with a strong motivation to make a hopeful call to all workers and employers to do better, train better and keep the best interests of workers and the community in mind. Because the reality is that all we have in the end is ourselves, our families, our companies and our communities.

Be well, Be safe. cc

James Hong is an OH&S consultant for the construction industry.

By Casey Edge

During the federal election, advocates of taxing the sale of principal homes, were in the news. Globe and Mail columnist, Andrew Coyne, wrote, “As with most such proposals to take away someone’s tax break, the bigger the blowback, the better the idea.” Former Canada Mortgage and Housing Corporation CEO, Evan Siddall, also raised the issue in a recent CTV interview.

When did the absence of another government tax on private property become a “break?” A “break” implies the government has an inherent right to Canadians’ private property. A tax on personal property, especially a home, is not a government right. It is an imposition on our financial security, privacy and freedom. Taxing a principal residence ignores the fact that homeowners already pay GST, provincial sales tax for construction, property transfer tax, building permit fees, development cost charges, amenity fees, speculation tax on family cottages (in B.C.), and decades worth of property taxes. In addition, there is a capital gains tax on selling homes, other than a personal residence. Taxes on housing already generate billions of dollars for three levels of government. But it’s never enough. The real issue is governments cannot control their spending.

the start of admitting there is a supply problem. Even a recent Globe and Mail editorial admitted, “The real answer, the difficult answer, the long-term answer, is supply – everything from more rentals and more homes for purchase to a much-needed expansion of affordable housing.”

Politicians in Ontario and other provinces should pay attention to a recent remark by B.C. Housing Minister, David Eby, at a recent housing conference. “It’s fine to say that you are not interested in bringing more people into your community, but when you have thousands of people arriving in your community, through federal immigration policies and in-migration from other provinces, you need to match your official community plan with growth and with zoning.” He promised to “withhold funding for programs if a municipality refuses to work on the supply challenge.”

Now, Toronto councillor, Mike Colle, is asking the Ontario government to launch a speculation tax “as a way of slowing things down.” He should pay attention to B.C., where we continue to experience record low supply and rising prices despite a speculation tax launched several years ago. The speculation tax and B.C.’s myriad of other taxes, including the foreign buyers tax and school tax (really a land tax), have done zero to address housing affordability in Canada’s highest-priced province. If anything, these taxes contribute to housing supply shortages and higher prices, in addition to eroding Canadians’ rights and freedoms.

That said, many are starting to conclude the solution to high prices is supply. During the federal election, candidates promised to build millions of homes. Of course, they did not understand rezoning permission is first needed from municipalities. The federal government has no authority over municipalities, which report to the provinces. If the obstructions were addressed, builders would build the homes. Why spend billions of taxpayers’ money? But at least it is

So the BC government has finally admitted housing shortages are caused by obstructive municipal councils. Taxes such as the speculation tax and a tax on principal homes do nothing to address housing affordability. Rising housing prices are mostly caused by municipalities choking supply in the face of rapid population growth created by a large Millennial demographic starting families, plus a 55 percent increase in immigration by the federal government. Eby’s promise to withhold municipal funding is a step in the right direction, but we also need mandatory regional planning, deadlines on development applications and a halt to the annual rising costs of new building regulations, amenity fees and speculation taxes. And no new tax on principal homes.

It’s a lesson for the rest of the country, especially the Maritimes, Saskatchewan and Manitoba where prices are rising but still reasonably affordable relative to British Columbia. Avoid B.C.’s litany of failed tax policies and instead boost supply by holding municipalities accountable. Apparently, the B.C. government just figured that out. Now action is needed. cc

Casey Edge is executive director of the Victoria Residential Builders Association

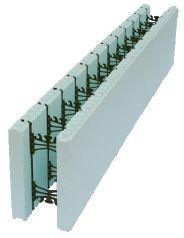

Get to know insulated concrete form construction, which is gaining popularity in residential builds across the country.

By Treena Hein

As you read this, many insulated concrete form homes are going up across Canada, in addition to many ICF multilevel residential and commercial buildings, garages and barns. This type of construction is now gaining significant momentum for the first time since its arrival in Canada in the early 1950s. And you may be surprised to learn that Ontario has the highest density of ICF adoption in the world, according to Douglas Bennion, building science and code compliance specialist at B.C.-based ICF manufacturer, Airfoam Industries. Bennion also serves on the board of directors at ICFMA, the Insulating Concrete Forms Manufacturers Association, and chairs its technical committee.

To describe this construction method, let’s start with the ICF units. They have “teeth” on the bottom and grooves on the top that fit together as they’re stacked row on row, with the two vertical panels linked together with interconnecting web materials. The hollow in between the panels is filled with steel-reinforced concrete. It’s an airtight and strong building envelope that’s fire, sound and storm-resistant.

It’s also very cost effective for contractors and clients because it saves a lot of steps and therefore increases the speed of building completion, helping to addressing the sector’s labour shortage. According the ICFMA, “ICFs combine six building steps into one easy building solution: form system, air barrier, wall structure, vapour barrier, insulation and interior/exterior finish anchorage which replaces wood studs.” Also, ICF buildings “can easily accept a variety of finish options: brick, stucco, stone or alternative products meet any design requirement. On the interior, electrical and plumbing are easily installed.” Drywall can be screwed directly to ICF walls.

In terms of the costs, the materials for ICF versus conventional building are quite similar right now due to the pandemic spike in lumber prices, and it’s expected that as ICF becomes more popular, it will become much less expensive. There’s now a myriad of companies that make the forms (and accessories, such as rigid foam window bucks), so competition should drive down prices as well.

ICF is also very energy efficient. The two layers of ICF insulation, combined with the concrete core, provide enormous savings for heating and cooling. The ICFMA outlines several reasons why ICFs are able to help achieve net-zero homes and other buildings: “ICFs maintain a stable R-Value of at least R-23, and are an inherent air and moisture barrier that does not degrade or get easily damaged. ICFs act like a thermal battery and use their stored energy to resist temperature changes outside of the structure. The combination of these properties means that the energy used to heat or cool a structure stays inside.”

Basements are insulated already in an ICF home, which also significantly boosts the building’s heat retention.

Sephton Spence first used ICF about eight years ago and has completed about 15 custom homes so far through his Toronto-based company, Kubbie Construction. Spence is also vice-president of the Afro-Canadian Contractors Association.

Right now, Spence estimates that about three per cent of homes in the Toronto area are built using ICF. “But I think that after COVID, when ICF will be presented at trade shows, it will get a lot more visibility,” he says. “At the shows, they need to let people see the efficiency rating and the comparison of heating costs to handle the forms. It must be presented well.”

Spence says the forms have changed quite a bit over the years and in several ways. (He uses more than one brand, and they’re similar in price and otherwise, but his client makes the decision.) “There’s more availability and their R factor is higher, with even higher R-value coming,” Spence explains. “The forms are a little smaller now and also easier to use. They always locked well, but now it’s a tighter seal. The meshing mechanisms are faster to use. What’s most impressive is that we can order forms for a house now with almost no wastage. With a conventionally-built home, you have a lot of waste. With ICF, we’re down to three or four percent waste now and it’s going to be nothing soon.”

Overall change in approach

In terms of overall difference in approaching the building of an ICF home versus a conventional envelope, Spence first points to the right mindset. “If you are not a strategic thinker and can’t see ahead, this type of construction is not for you,” he says. “It allows you move so many times quicker, so you have to be coordinated. Once you know what you’re doing, you’re able to pour a 3,000-square-foot home and can have it framed in a day and a half. The electrician doesn’t have to drill through studs and can work while the plumber is doing that work.”

Because of the speed, ICF home construction translates into higher profits. “Right now, the home cost is comparable, but it’s

finished three months earlier,” says Spence. “That’s huge.”

He also notes that because ICF homes are so tightly built, mould is a concern, and energy recovery or heat recovery ventilators are required. He adds that the rule of thumb is at least 10 percent glass to wall ratio, and recommends “not too much” fixed glass.

Both Spence and Rob Vandenbroek, owner of Vandenbroek Construction in Walton, Ont., note that the biggest consideration in building an ICF home is to work with experts until you know your way. “Work with an experienced architect and installer from conception,” says Vandenbroek. “You almost need to be a hybrid builder, as ICF is basically concrete and carpentry combined. I think home builders should find a qualified ICF installer and start a long relationship working together to make great homes.”

With regard to electrical installation in ICF, one OEL member (Ontario Electrical League, the voice of Ontario’s independent electric contractors) says it takes longer and requires more wire for wall installation compared to conventional buildings. It’s also hard to protect wires from damage by the wall screws. He’s found the fastest way to fasten wire to ICF wall is to use a foam gun.

Window installation

Bennion suggests that the choice of window installation method for ICF buildings is highly dependent on the local climate, building height, and exposure conditions.

Kody Horvey, owner of Up to Kode in Red Deer Alta., says that “regardless of your exterior cladding system, you still need a drainage plane with flashing, drip caps and proper water shed to manage water and allow it to exit from behind your cladding.” Horvey has done both flush and

recessed window installation into ICF buildings, but tends to do more flush outside installation because it’s faster (and more economical for the building owner). Bennion adds, “our research indicates that flush mount windows in ICF are less reliable in terms of leakage. The installation is also more complex if you want it to resist water, and therefore not necessarily less expensive.”

For more

In 2019, the BC Housing Research Centre’s Building Envelope Guide for Houses – Part 9 was released with a greatly-expanded section on ICF construction, from footings to trusses. The guide is a collaboration between industry experts, design professionals and government. It’s available for download online at bchousing.org. cc

Offered in 10 colour blends, IKO Cambridge shingles deliver an upscale appearance to enhance curb appeal. The architectural shingles feature a modern, laminated two-piece design that provides the depth, dimension and texture of genuine wood shakes, with the convenience and durability of an asphalt shingle. The shingles, which are larger than most products in their class, allow installers to cover more roof in less time with fewer bundles. Cambridge shingles are IKO True Square Advantage-sized, offering enhanced curb appeal via their 5 7/8-inch exposure and faster installation thanks to their larger dimensions. And with three bundles covering a full square, planning a project can be done with precision.

IKO Cambridge shingles are constructed with a fiberglass mat coated top and bottom with weathering asphalt, then surfaced with colourfast algae-resistant granules that help inhibit the growth of blue-green algae, which can cause unattractive black stains, streaks and discoloration. The two layers are held tightly in place with five strips of tough laminating adhesive. Cambridge shingles also feature IKO’s proprietary FastLock sealant, which creates a strong bond between installed shingles to help ensure maximum protection against wind uplift, blow-off and water penetration. They feature a limited wind-resistance warranty up to 177 kilometers per hour with standard installation and 210 kilometers per hour with high-wind application.

huntsman.com

Huntsman Building Solutions has launched new and improved pour-in-place foams. The family of foam solutions has recently been reformulated with an HFO-based technology that renders performance benefits, as well as dramatically minimizes impacts to the Earth. The improved foam products are offered in varying densities, providing thermal insulation and structural support, and are ideal for use across a wide range of construction and maritime applications. The new foams include PIP foam 50, a 0.50pound thermal insulation ideally suited for wall cavity applications and providing an R-value of R-3.4 per inch of thickness; PIP foam 80, a 0.80-pound thermal insulation also suited for wall cavity applications and providing an R-value of R-4.45 per inch of thickness; PIP foam 250CG, a 2.5-pound foam for injection, flotation, wall cavities and insulating panels and providing an R-value of R-6.5 per inch of thickness; and PIP foam 250A, a 2.5-pound foam used in insulating panels and providing an R-value of R-6.5-7.5 per inch of thickness. The composition of 250A notably

includes recycled plastic waste and renewable soy oil. It is also Class 1 (Class A) Fire Rated, Discontinuous and meets requirements for CAN/ULC S102 and S127 fire tests. The pourin-place foams may be professionally applied using highor low-pressure equipment. The products offer numerous performance benefits including superb adhesion to a wide variety of substrates and good flow characteristics, as well as a fast cycle time.

Motorized retractable screens from Phanton Screens appear at the touch of a button and disappear when you don’t need them. Suitable for indoor and outdoor living spaces, these custommade and professionally installed screens provide fresh air, shade from the sun, climate control, protection from insects or a bit of privacy. They fits openings up to 40 feet wide and can be recessed or surface mounted. Phantom Screens provides professional installation. Homeowners can choose one of the signature colours or custom match the screen’s frame to the home. Also available in custom wood grain finishes. The automated controls include sun and wind sensors and home automation integration. The screen can be controlled with

versatex.com

Builders, distributors and homeowners are rapidly re-discovering the warm appeal of wood-look porch ceilings, soffits and accent walls. In response, Versatex Building Products has expanded its Canvas Series palette of realistic colours and textures, all brought to life in maintenance-free PVC. Now Versatex has introduced three new matte-finish Canvas Series products: Natural Amber (warm and light with a slight contrast and attractive grain); Driftwood (light, neutral tan with a deeper grain texture); and Copper (saturated medium brown with a moderate woodgrain texture and a subtle contrast). Natural Amber, Driftwood and Copper join a Canvas Series range of options that includes Black Cherry, Kitami,