Truckin‘

Our 2020 truck roundup

Page 26

in the

Succession planning with the Upshalls

Page 14

Creative Eye

Winning in the 'Peg Page 18

Decked Out

Avoiding deck and fence nightmares Page 22

Our 2020 truck roundup

Page 26

Succession planning with the Upshalls

Page 14

Winning in the 'Peg Page 18

Avoiding deck and fence nightmares Page 22

Last November, contractor Ben Crocker of D.F. Crocker Ltd., St. Thomas, Ont., won $5,000 of GRK fasteners and a Paslode Impulse nail gun. Ben won because he sent us the above photos of a splendid project he built, The Willemse House, which made extensive use of GRK fasteners.

That’s how easy it is to enter the 2020 GRK Projects Contest. If you’ve built something with GRK products in it – no matter what type of construction it is – let us have a look. When we pick the winner, it could be you. And that means not only these great prizes but a feature story in Canadian Contractor magazine in our November/December 2020 issue.

Go to CanadianContractor ca. In the search bar, look for 2020 GRK Project Contest and click on the link. You will see that you can submit up to 3 photos and a description of the project, and how you used GRK fasteners to built it.

GOOD LUCK! Entries close September 30, 2020

The Choreograph® shower wall and accessory collection is tough enough to handle the rigours of the job site – and look good doing it. The Serica ® material walls can be trimmed on-site for custom cuts, and the joint system helps with installation and hides silicone for easy cleaning. KOHLER.com/Choreograph

Under virtually any circumstances, we're pretty sure it's disrespectful to dance on a grave. However, in the case of the Ontario College of Trades (OCOT), we'll make an exception – especially in light of its reticence to openly discuss its current status when we reached out to the agency.

Contractors, if and when this cash grab of an agency finally sheds its mortal coil – something that was supposed to occur in early 2019 but has still yet to officially happen – we welcome you to do a jig of joy.

Since OCOT first appeared from the hellfire of the netherworld in 2011, many of the agency's transgressions and totalitarian-like techniques have been well-documented in these pages and on our website.

In brandishing virtual pitchforks and torches, Contractor Nation was certainly not shy about voicing its hatred, either.

The stream of vitriol from our readers describing OCOT as a bundle of red tape that's sole purpose was to separate contractors from their wallets is time-honoured and well known. There's little reason to revisit it. But you know what? We can't resist...

"OCOT added absolutely nothing for those who were paying fees to them;"..."nothing more than a cash cow;"..."I think OCOT’s demise should be expedited by cobras and red ants." [Editor's note: bonus points for descriptive imagery.]..."Let it die painfully. It was just a cash grab and did nothing for the trades."

Some argue that the red tape is merely a necessary cost to ensure the province's trades are being appropriately regulated and enforced. Still, what kind of job would you have in which you were so lowly regarded that your boss was constantly watching over your shoulder and providing a punitive wrap on the knuckles each time he determined you had erred?

Um, no thank you. Personally, I choose to engage in activities that do not strip me of my self-respect.

We called OCOT to see how its "winding down" was going, considering it was about a year behind schedule. When we spoke with its communications manager and asked about its status, we were told "we don't have a comment on that."

In fairness, we did receive an email (three days later!) that was pure government-speak (read: it had a lot of big words, but didn't say much), and that didn't exactly shed any light on our questions. They wrote: "We continue to enforce the Ontario College of Trades and Apprenticeship Act, 2009 (OCTAA) but our focus has continued to shift to compliance assistance for members and non-members.”

What does that mean? Does OCOT still have agents, and if so, are they still actively patrolling work sites? These are valid questions that contractors need answers to, and anything short of an upfront and clear response is disrespectful. Actually, it goes beyond disrespect.

Imagine calling up the police, asking them what their powers are, and having them refuse to answer. You know where that happens? In an Orwellian society overseen by Big Brother.

It's starting to get quite clear why contractors can't wait for OCOT to take a dirt nap.

And when it finally happens, don't forget to get out your dancing shoes. Just make sure they've got a Footwear Safety symbol on them; you don't want to get fined, do you? cc

” It's disrespectful to dance on a grave.

By Rob Blackstien Editor ”

Canadian Contractor has hundreds of videos online for serious residential construction professionals

Sponsored by Home Hardware

This series of videos looks at ways to build better, faster and more profitably. Canadian Contractor presents a number of construction tips sent into the magazine by Canadian contractors – and they also interview experts from around the industry. Everything on a job site from framing to interior finishing is fair game for Site Tips.

Canadian Contractor Contributing Editor Steve Maxwell shows you how to avoid the most common deck disaster.

Sponsored by Various Manufacturers

Innovation is the engine that keeps profitable construction companies going. Unless you discover new and better ways to build, you risk falling behind your competitors, and your company may be challenged to compete in the new industry landscape. Buildwire is the place for contractors to see what’s new and improved.

(Print)

Editor Rob Blackstien rob.blackstien@rogers.com

Contributing Editor Steve Maxwell

Media Designer Mark Ryan

Publisher Steve Payne 416-219-9949 spayne@canadiancontractor.ca

Account Coordinator Barb Vowles bvowles@annexbusinessmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-510-5182

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com Scott Jamieson, COO sjamieson@annexbusinessmedia.com Circulation email:bolechnowicz@annexbusinessmedia.com

We've sure had our share of readers spouting off about the Ontario Workplace Safety & Insurance Board, but it's actually been a couple of years since our last good rant.

Despicable them

They are 100 per cent not there for the employees. They are there for themselves. Period. They are in the business of denying claims. They pocket just under $1 Billion each year — profit… how do you suppose they manage that? They are a monopoly being forced upon us. It’s despicable.

Dean Kadikoff had a fantastic WSIB rant back in 2013. Now, Mike Muschik has his own thoughts on the situation.

I am terrified

I am terrified by what I see happening to Canada with anti free speech laws and banning some books. Canada is seriously at communist doorsteps (and) unless the Canadian people wake up, Canada will become a communist country. I am 52 years old and the changes I have seen in Canada since 2015 are very disturbing.

Mike Muschik

In response to an article we wrote about a contractor facing murder charges after one of his disgruntled clients went missing, we asked Contractor Nation how they deal with such instances (the disgruntled clients part, not the murder part).

Holding my head high

Not that for sure. I try to do what I can to make them happy enough so I can walk away holding my head up. Sometimes takes a bit of magic though.

Marten

Write it all down

Well, as a contractor you have to live up to your end of the deal. Everything should be on paper, the material that you’ll be using, what all will be done, and the length of time that in should take.

Probably the best thing to do with big jobs is have two witnesses to be present and everyone signs the contract.

Clint Molesky

Several years ago, we wrote an article about a new idea called “Straightforward Pricing,” which involved shifting from hourly rates to a price list with different tiers. Many contractors piped in over the years, but the thread had been dormant for three and a half years… until recently.

I

I really don’t like the prices mentioned above in the example of “Straightforward Pricing.” In my line of work, I’m able to give the customer a quote for the job, rather than an hourly rate. I realize that is not always possible depending on what’s being done.

Mike

This is not a new idea

New idea? This method has been used since the early ’90s, however in the U.S. Canadian contractors are always a bit behind on some of the methods that are being used. Pretty much any contractor that is part of a Best Practices Group uses this method of pricing their customer as it shows complete transparency as to what the job will be before starting any work.

While there are those few who get accused of price gouging, rest assured that the majority of companies using this method are held to a high standard and operate very successful businesses. The problem is really not in the pricing methods, it is the way that many companies operate. Most of them do not have any type of operational systems or proper processes and no fault to them, they just simply have never been shown. We all pretty much started the same way, tradesman in a truck and now we are “Businessmen.” No formal education as to what it takes to run a successful company, no understanding of accounting methods or financials, but boy can we build or service stuff.

Lots of those newbies fly by the seat of their pants thinking they are making money when in fact they are praying for profit at the end of the year when they hand over their shoebox accounting to their guy and cross their fingers. Straightforward pricing has all of the costs associated with what it takes to run your particular organization without guesswork. It is based on knowing what your break even numbers are as it applies to the

business operations, how many billable hours are required and at what rate.

Calculating what is your overhead cost per Billable Hours. No one ever thinks of these items. It is relevant even if you’re a solo individual, we all have overheads. Once you learn that, it is actually shocking to see what must be calculated as your billable rate. If anyone wants a calculator to figuring that out please feel free to reach out and I’ll send what we use here in our company. I always recommend two books to read – The first is E-Myth by Michael Gerber — currently there are 17 different business verticals in his library, and the second book is The Power of Positive Pricing by Matt Michel.

I encourage you to obtain these books as it will help people understand what is required to have a opportunity to succeed. While there are those who have done well, there are far too many failures and that is not cool especially when you are trying to support yourself and family and not fair as well to the employees you hire if you go out of business. SMS me at (250) 258-8889 if you want any info.

Thank you for allowing me an opportunity to share. I am a contractor/provider just like all of you.

Joe Gerolami

We recently ran a guest article from Skills Ontario that aimed to debunk the myths of skilled trades. Questo took issue with it, suggesting the biggest myth regarding the industry was overlooked.

Maggots on decaying corpses

Dear Skills Ontario CEO Ian Howcroft, REALITY CHECK, SHOULD BE THE FIRST ONE. You forget the biggest reality of all or was it intended to be concealed?

The bogus agencies and bogus licenses/bogus permits on the trades people to operate their businesses.

So you know that for sure, but rather not say it, right? Convenient isn’t it?

The biggest reality in the skills trades in Ontario is: Too many non for profit organizations acting as salesman of trades licenses. Can be compared with maggots on decaying corpses. They love to be in control of someone’s legal trade license, making that look like it's not legit. Make trades people looking like criminals to operate.

You either buy our so called license or face demise. The MTCU license is the one (that has) international value. All others are nothing but legalized robbery, extortion, coercion, cunning.

It’s a shameful collection services.

It’s a fundamental human rights violation. Free to operate on his/her carries without any form of extortion barriers.

No matter if legislation was passed to obtain the coercive license in exchange for a payment. It became unlawful from the start. Unless it was on the free voluntary vote for the benefit of the trades, whatever skills direction. When and where did these votes take place?

The Ontario trades people became specific targets, for extortion (discrimination on a specific trade’s skills for extortion).

That’s the reality.

Furthermore, coercive licenses are direct intimidation, a threat, unlawful, posed as real. Can be viewed as fraud or criminal intent to obtain funds with unnecessary oversight. Using none for profit organizations as the scape goat (SCAMS).

And after you have all these bogus licenses, you still have to apply for permits.

What should the point be in the trades?

Take your so called licenses, from ESA/ECRA, (LEC) TSAA, OCOT and all others, go to Europe and other countries. Show these licenses to apply for your job carrier? See if you obtain any credit for them to work? All these licenses will be thrown into the trashcan, so much value, huh?

If you show the MTCU certificate and license then you can work. Can you see the difference?

When all the garbage coercive licenses and permits to operate are thrown into the garbage can where they belong, then Ontario may indeed have a big flow on the trades people.

The dignity they all deserve.

Questo

Contribute to our ultimate playlist

Hey Contractor Nation, here’s your chance to help form history as we work on the ultimate Canadian Contractor musical playlist.

Here’s the deal: we’d like you to ask your site super to poll his or her workers and find out what are their favourite songs to listen to on the worksite. You can supply as many songs as you like (the more, the better!), but if you’re submitting more than one song, please rank them from No. 1 to whatever, in order of preference. Ideally, you will include the full song name and the artist.

Email rob.blackstien@rogers.com to submit your lists.

Careers in trades, technology are a viable first option for young people

Thefollowing press release is from Skills Ontario… Outdated misconceptions about working in the skilled trades and technology fields are a significant obstacle Ontario must overcome to address a serious labour shortage that is projected to worsen over the next decade.

Over the past 30 years, Skills Ontario has developed a growing portfolio of programs and initiatives – such as hosting Canada’s largest skilled trades and technologies competition – to help students of all ages and backgrounds understand that they can find fulfilling career paths in the skilled trades and technologies. We also provide them, their parents, and their educators information on informative, skill-building programs and work-experience opportunities that can help them pursue these positions.

“Jobs in the trades and technologies sector offer high pay, good benefits, flexibility, rewarding work, variety and unlimited opportunity,” says Skills Ontario CEO Ian Howcroft. “We need to set the record straight about these positions so that they are viewed as a first option for those preparing to enter the workforce.”

There continue to be misperceptions and inaccurate generalizations about working in the skilled trades and technologies in some circles. Among them:

Myth 1: The skilled trades are primarily for people who can’t make it into university or have limited education.

Reality: Careers in skilled trades and technology require critical thinking skills and a solid education. Most positions demand a combination of hands-on work and specialty training, which may include post-secondary education and learning on the job through apprenticeships.

Myth 2: Jobs in the trades are dirty and physically demanding.

Reality: It’s true that many positions in the trades have some element of hands-on work, but technological innovations in recent years have radically transformed how many tasks are performed, making them cleaner and less physically intensive.

Myth 3: Once you take up a trade, you’ll be stuck doing the same job the rest of your career.

Reality: There are abundant opportunities to move up the ladder in the skilled trades and technology fields. Apprenticeship training, additional certification courses and other professional development activities open the door to new responsibilities and career options. Many decide to start their own business and hire other tradespeople.

Myth 4: These jobs aren’t suited to women.

Reality: There are many opportunities for women in the skilled trades and technology fields, offering high pay, advancement and challenging opportunities. Skills Ontario and its partners have been encouraging more young women to explore these positions through initiatives such as Young Women’s Career Exploration Events throughout the year, plus a Young Women’s Conference every year at the Skills Ontario Competition. We need to do more to introduce these opportunities to girls and young women and facilitate them moving forward.

Myth 5: You can’t earn a good living in the trades. Reality: Skilled professionals in Ontario make highly competitive salaries, including opportunities to earn while learning through apprenticeships. Because there is a severe shortage of skilled trade and tech workers across the province, there are plenty of job opportunities in many sectors that pay very well! cc

DISCLAIMER: Not evidence-based or rooted in any sort of statistical measurement of actual show size. But we promise it’s going to be really, really big. Please address all complaints about this ad to our editor, Pat Flannery, who would be happy to buy you a beer at the Oktoberfest party at the show on Oct. 20. This is the fine print, why are you still reading this? Really, go register at canadianrentalmart.com so you don’t miss out on Canada’s Big Ass (sorry, “largest”) rental show. See you there!

To exhibit contact Danielle Labrie | Associate Publisher dlabrie@annexbusinessmedia.com

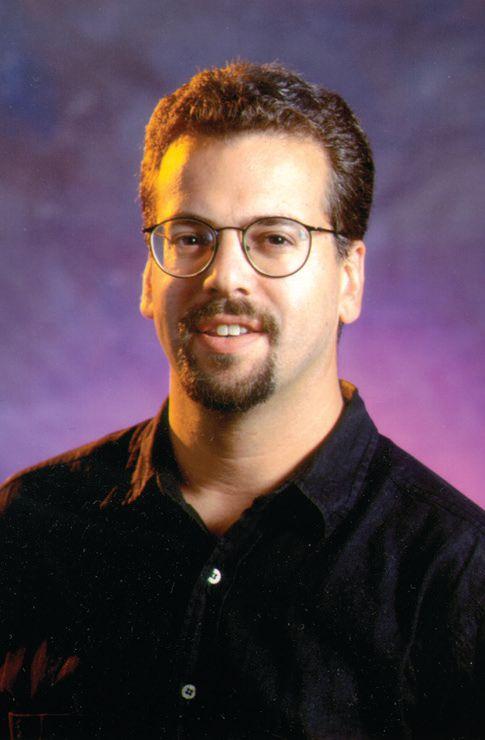

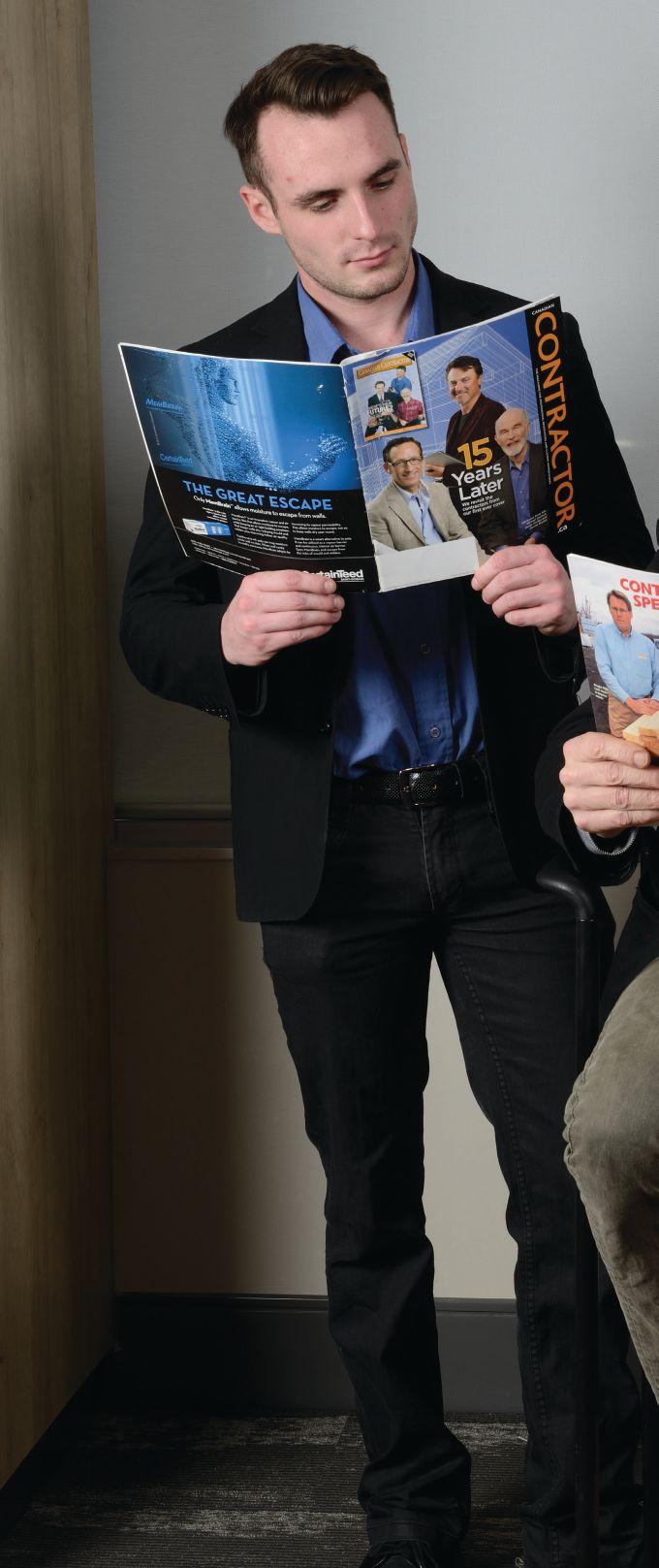

By Steve Payne

Canadian Contractor recently sat down with Michael Upshall and his son, Michael Upshall Jr. of Caledon, Ont.-based custom homebuilder Probuilt Design + Build, to talk about the business and its succession plans. Michael Sr. is a 40-year industry veteran who is currently grooming his son, Michael Jr. to one day take over. For the last seven years, Michael Jr. has been learning the business (junior site supervision and drafting) and is currently studying architectural technology at Fanshawe College.

Michael Upshall Sr. (sitting) of Caledon, Ont.-based Probuilt Design + Build was the cover boy on the premiere issue of Canadian Contractor. The article asked 'What's your future?' Twenty years later, we can answer that as he's back with his son and heir apparent, Michael Upshall Jr. (left).

Canadian Contractor: Mike Jr., it's probably both a blessing and a curse to have your father in your chosen business. You have that person there who's going to invest in you, but one of the things with children is their parents don't get too many things right. Has there been any tensions in separating the business relationship from the parental relationship?

Michael Upshall Jr.: You nailed it right on the head when you said a blessing and a curse all at the same time. A blessing because I always know that he's always looking out for my best interests no matter what. But a curse at the same time because he's looking to push me much harder than pretty much anyone else within our company. But when you say tensions, for the most part, we get along pretty well. Even when we're not working, we're always talking about work. It's mainly both of our passions, big time.

CC: Mike Jr., you're going into your final year of college. Did you take architectural technology with a view that you knew your father was a builder?

Jr.: Since I was about 13 or 14, I've been helping my father. One of the things that my dad has always pushed is that everything starts with design and that (almost) nothing can ever happen within the industry without design. That is the baseline. Once you can get your design down, then you're able to move forward from there. So if I have my design (education) I'd be able to push myself throughout other areas in the industry too, while getting a better understanding of the building aspect. (I'm) mainly focusing on getting my Part 9 (house building envelope) one day and being able to bring that into our company as well through the design aspects of things.

CC: Mike Sr., you were on first ever issue's cover in 2000. How have things changed in 20 years?

Sr.: At the time when we did this cover, I was just growing the business and understanding that I had to learn to become a businessman. Over time, I found out about this design-build concept which allowed us to get more control over our business, meaning that through the design process we could control things like budgets and control levels of designs and things like that. Over the years, it's proven to be the way to go because you're able to have more control and also your competition is a lot more professional we find. You're not going up against Chuck and his truck, I like to say. But the one aspect that I wanted to stress, especially about bringing Michael on board, is being a true design-build firm means that you actually have your design in-house not subcontracted out, which a lot of firms do. Which we did, which isn't a bad thing. It's just you don't have as much control that way if it's not right in your office doing the designs. So I'm really happy that Michael decided to take the architecture

HE'S LOOKING TO PUSH ME MUCH HARDER THAN PRETTY MUCH ANYONE ELSE WITHIN OUR COMPANY."

and that he's going to be getting his license to practice low-rise residential and then we'll have that base covered. The whole thing though is this is a really tough business to be in. It's a bugger of a business because of many different reasons. One of the main ones is that it's unregulated and the ramifications that go along with that, and I'm trying to teach Michael the ins and outs of what that means and what the future is.

CC: Mike Jr., growing up you would have heard your father talking about business. Were there misgivings about the fact that you were going to do something probably at a higher risk or was that actually something that juiced you up more to do it?

Jr.: My dad's kind of always taught me high-risk, high-reward, as well as always being able to take the high road. Never look to really take the easy way out. And I know that he's always the kind of person that has really looked at trying to take the high road and he really pushes me to try to do the same. Because at the end of the day, if you do take that high road, then the rewards, it can really help you out there as well too, right?

CC: In our November/December issue we interviewed Andrei Sosnovsky, a Toronto builder. He came from Belarus, part of the former Soviet Union, as a lawyer. He came here and learned drywall and he worked in the trades for about five years. It was only when he said that he decided to stop building entirely and stop doing drywall and stop doing anything on the tools at all, that he started to learn... He decided that he would no longer pick up a hammer even once and he was simply going to work on the business instead of thinking like a trades person. So I know Michael's talked about that, that you need to make a decision that you're going to be in business. You yourself, how do you feel about just running it as a business?

Jr.: Right now I'm really focused on mainly being on the tools and learning the ins and outs of the industry. But at the same time my dad has kind of been grooming me for the business pretty much from quite the young age. Almost every single day throughout driving in the car or wherever we're going we're always talking about sales, marketing, what's our next target, low hanging

fruit. Pretty much anything to do with business and he's been trying to groom me towards actually getting into that. And that is something that I really do enjoy as well. And I find it super interesting. But at this very moment, I'm really focusing on being on the tools, production and getting things done in that aspect while he focused on the business. But still while grooming me towards eventually being able to fill those boots.

CC: Michael, I just want to ask you about the lead carpenter system as financial responsibility. We did an interview with you in 2015 when you said the people that you had, the lead carpenters, had full budget ability to make decisions on the fly and always check with you. David Litwiller in Calgary said it was something that he'd also done because he was getting older and he just didn't want to work the 80-to-90 hour weeks anymore and he was forced to give his people on the site budget responsibility because he couldn't do it anymore. How has that evolved over the last few years?

Sr.: It's difficult to control costs in this industry. There's a technical word called "slippage," meaning your projects are slipping and you're losing money and there needs to be checks and balances to ensure you're making money, because we receive lots of money up front before it's being spent. As you're going along you need to know where you're at and there's different ways to do that.

We've learned to become business people in this industry. I came up as a master carpenter on the tools and then after a while I found out, oh boy, there's more to just being a carpenter -- that there's lots of other hats to wear. All of a sudden I realized I'm an entrepreneur, I'm a frigging businessmen now, I've got to figure this out. I've got to do things (differently), because I like to do things properly and wanted to be a professional. I learned all of the aspects of business as most have all the same moving parts. It's just a little bit different for this industry.

I think the hardest part is because we're dealing with very personal issues with respect to our clients... we're dealing with their nests, we're dealing with their homes. There's not a lot of industries where you're dealing very personally with people like that on a very close level. It's for a long time usually, especially if it's a sizable renovation project -- minimum four to six months for a design and then anywhere from six months to a year and a half for the project itself. So in dealing with a client right from initial consultation to meeting them, to handing them the keys once the paint's dried on the last paint stroke, there's a whole bunch of processes that go in there and we had to learn that.

Now that Michael's coming onboard and I'm pretty excited because we now have the design aspect of the whole picture. That was the one thing that was kind of missing from an in-house perspective. So (after) bringing him in and teaching him, I'm going to slowly step back as time goes by. It's important that he learns.

BY

Because in running projects, large or small ones, they're all the same with respect to the business processes. Michael now is learning all of that and then some, I actually want to get it to the point where he's going to be able to take this business to the next level. The hard part is going to be the same problem that we've always had in this industry — it's unregulated and it's hard for us to make our margins. We have to do business a certain way to survive and make money in this industry. It's not easy.

CC: So Mike Jr., how old are you?

Jr.: 21.

CC: Don't read a newspaper I assume?

Jr.: I read the newspaper on my phone.

CC: iPhone generation. Everything is completely doable through your phone. In marketing Probuilt as a firm, how do you see your role in making sure that the marketing aspect of the business reflects your generation?

Jr.: One of the things that I'm really understanding now, especially being introduced to the business side, is that you really have to try to push your social media marketing, especially. Just due to the fact that the old way of the marketing is kind of going like the Dodo Bird. It's there for sure, but even for people to recognize and know your business really, you almost have to have some sort of a social media presence, whether it's Instagram, Facebook, Twitter, LinkedIn, all of them together even. And just for people to know your name, know who you are, you kind of have to be on top of those sort of things. And whether that's in-house, which we're kind of doing right now, but we outsource it as well from time to time, but the marketing, it's really important to go through social media marketing. One of the biggest issues I see is, for the most part from my generation, it sounds terrible to say, but a lot of these people are feeling very privileged and feel like they almost need to be given something. Say somebody goes to school, four years, gets a degree, comes out of school, they're expecting this top-of-the-line job or expecting to get into something and be paid all this money and nobody's really looking to work and nobody's really wanting to work. I'm hearing this and I've kind of been raised throughout the entire way that if you want something, you got to go get it. You can't just sit back and, "okay, I got a degree, I did a little bit of work here and now I can go in there and I can just make all this money." No, now is the time to really get your hands dirty. Now is the time where you really start learning and it's time to get your experience and that's pretty much how you work your way up. It's start from the bottom and then maybe eventually you'll be able to make the big bucks. cc

See the complete interview at CanadianContractor.ca.

By Steve Maxwell

Every year in Canada, nearly a quarter of a million new homes are built, but only a few of them ever win awards. What does it take to build a winner? When Foxridge Homes completed the detached, two-storey home at 687 Bridge Lake Drive in Winnipeg’s south end, it had already planned to enter the project in the annual Manitoba Home Builders’ Association Fall Parade of Homes contest. Foxridge production manager Barry Hedgecock and his team earned another gold medal when this project won last fall, bringing Hedgecock's career total to eight golds (along

with numerous silvers). Join Canadian Contractor for an exclusive interview with Hedgecock as he explains what went into this project and some of the reasons it bagged him more hardware.

Q: What’s the story behind the project?

A: Often when we’re designing a home, we look for specific detail or requirement as a launching point to begin the design. It can be a look, a feel, an exterior detail or an interior detail that we have seen or created, and that starts our process. This design really

approximately 2,700 square feet on two above-ground levels. Add a developed walk-out basement of 888 square feet and this leaves a total of 3,600 sq. ft. of living space. We broke ground on April 8, 2019 and completed the home on August 29.

Q: Why do you figure this home won gold? In a country where hundreds of thousands of homes are built each year, what does it take to win?

A: The Bridge Lake Drive project started out as a show home and is now currently for sale. One of the side benefits of winning gold is the marketing panache it provides. Any builder can do the same by bringing together all the elements of a winning entry. I think the house itself is really a great family home. Even though the floor plan is large and has three levels, it feels warm and comfortable the minute you walk in the front door. All of the details, both subtle and bold, really tie together to give the home a great feel. If you are a cook, you will love this kitchen. If you want to entertain, the open concept is well thought out. And if you want a great place to watch the Jets and Bombers, or enjoy a game of pool, the walkout basement is fantastic. Great design is a big part of winning.

fell in our laps as the 687 Bridge Lake Drive design was originally built by the Vancouver division of Foxridge Homes on the west coast. We here in Manitoba were impressed with the overall idea and layout, but felt we wanted to add our own spin on the plan. Over a period of two weeks we adjusted our elevations and floor plans to meet our design intent. We’re so fortunate to have a strong drafting team that was able to put on paper what we had in our heads. After this we needed four weeks to get to the point where we could put a shovel in the ground. The house is

Q: Are there any particular products or unique techniques that stood out on this project?

A: Being a custom builder, we tend to use higher end materials than typical production homes would use. Steel beams and open-web joists were incorporated into our structural design, plus energy efficiency details. Builders in other parts of Canada are usually surprised that our heavy clay soils here in Winnipeg require 25-foot deep piles under the foundation walls for support.

Without that, houses shift and can create structural issues over time. Our homes also incorporate high efficiency multi-stage furnaces, air conditioners and HRVs, all running from WiFi compatible thermostats, and often tied into integrated Crestron Home automation systems. We spend a great deal of time on the kitchen and millwork components in our homes, too. Even the slightest details like a shaker wainscoting wall we have at the front entrance helps to add to the overall look and feel.

Q: Has the home been tested for energy efficiency?

A: Yes, the project was tested by Prairie House Performance Inc. and scored very well with an airtightness of 0.68 air changes per hour (ACH) @ 50 pascals of pressure. This house is so tight that it’s eligible for both the CMHC rebate and the Manitoba Hydro New Homes Program rebate.

Q: What’s the story behind Foxridge as a company?

A: Foxridge has been a long-standing brand within the Qualico family of companies, but in 2016 it underwent new branding in the Manitoba market. The original parent company was called Quality Construction, founded in Winnipeg in 1951 by Dr. David Friesen and Katherine Friesen. After beginning with the construction of six homes, this company grew to be one of the most successful integrated real estate companies in Canada. Qualico now operates in Metro Vancouver, Saskatoon, Regina, plus Austin and Dallas-Fort Worth in Texas. Current company activities include land acquisition, single-family and multi-family house construction, commercial development, leasing, property management and building material sales.

Q: How many people work at Foxridge and what are their roles?

A: Foxridge Homes currently employees only two full-time people directly, but shares management, administrative, marketing and

sales resources with Kensington Homes, our corporate partner. Currently, upwards of 10 people are actively involved in Foxridge at any given time to create homes such as the Bridge Lake Drive project. Our team is strong and committed, and it's only for their efforts that Foxridge Homes won this award.

Q: As production manager, what is your role like, and how long have you been doing it?

A: I’ve been involved in custom home building and design since 1997, largely in the design and building of custom homes and multi-family structures. In my current role I’m fortunate to be involved in design, scheduling and product/material selection, but in the end I am only effective because of the team that surrounds me. With our new show homes about to break ground this spring, we will have 21 homes under construction here at Foxridge this season. My role is fast paced but also rewarding. Truth be told, this is a great business to be in, especially when you’re supported by a company like Qualico. At times I have to pinch myself.

Q: What’s one of the most important things you’d like other contractors to know about the Bridge Lake project?

A: I think our main focus has been, and will always be, the attention we put into our homes. From structural components to finishing details, we try to ensure each home has the quality that any homeowner would be proud and excited to own. We’ve

designed and built homes that are 4,000 square feet and as small as 1,600 square feet and they all have to feel like they would be a great place to live in. This is part of the recipe for an awardwinning project regardless of the size.

Q: Were there any particular technical challenges on this project?

A: Any time you’re building on a walkout, your grading and elevation is really important to get right. We measure twice and dig once as they say! That Manitoba gumbo soil also presents special challenges, of course, but we’re used to that. While this particular plot of land didn’t provide too many issues, we often have to work with our engineer and trades to account for varying soil conditions throughout the province. It would not be uncommon to hit bedrock at 12 feet in parts of Manitoba and when that happens, you work with professionals that can help you through the revised structural change that may need to take place.

Q: What are some main technical details of this build?

A: We use laminated strand lumber (LSL) studs in all our homes for tall walls and anywhere we have cabinets and tiled showers. The LSL ensures the walls are stable and have little or no deflection or crowning. This is definitely worth the extra trouble in high stakes locations. It pays off later in fewer call-backs and easier finishing, too.

Foundation walls are 8” poured concrete, 9’ tall, with all walls sitting on 25’+/-deep concrete reinforced piles installed on

average every eight to 10 feet along walls. These piles replace a typical footing that is commonly used in other areas of the country. Without pilings like these, homes sitting on Winnipeg gumbo never stop moving. Almost all homes built in Winnipeg these days rest on piles that extend down below the area of active soils and frost conditions. That’s because this clay expands a lot when it gets wet, and shrinks a lot when it gets dry. It’s like having to go down 25 feet to get below the “frost line,” except that frost doesn’t go that far down, even in Winnipeg.

Q: What are the smart technologies installed in this home?

A: Don Estabrook from Inspire Audio designs and installs Crestron home control and automation systems in the homes we build, including the Bridge Lake project. The system can be controlled with a smartphone, one of the dedicated touch panels in the house, key pads or handheld remotes. There’s a 10” touch screen in the kitchen and a 7” in the ensuite bathroom. Enterprise-grade networking and a WiFi booster provide total wireless coverage over the entire property. The five-camera security system allows monitoring of the property from anywhere in the world, with an intruder alarm and smoke alarm on every floor. The surround sound system in the great room and the basement can also be controlled remotely. Automated lighting is installed in the main living area and exterior.

Estabrook offered his take on working with Foxridge.

"In addition to all the details that go into the planning and design phase," he explains, "being on a Foxridge job is a little different than most builds. The culture and communication creates an awesome atmosphere to be working in. The constant communication of what’s going on and where things are at is top notch. The culture of looking after the details and ensuring things are done right is key. This has created unparalleled cooperation between all the trades, and it shows.” cc

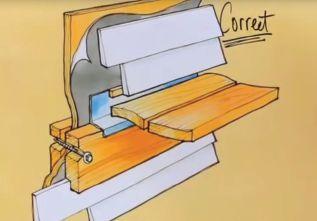

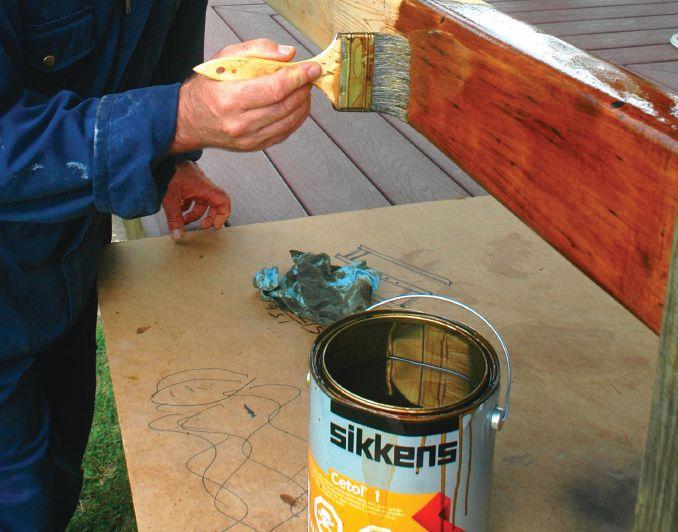

Three steps prevent profit-sapping outdoor wood finishing disasters

By Steve Maxwell

Depending on when during the life cycle of a project you see a particular client call in on your cell, it can fill you with joy, indifference or panic. A call early on is probably good news because you’re getting the job. A call in the middle of the project is usually fine because there are mundane details to discuss. But a call from a client whose fence or deck you built and finished last season could be very bad news indeed. It may well be the start of the fence and deck finish nightmare. No wonder your stomach tightens as you say “hello.”

The fence-and-deck nightmare happens when a client becomes dissatisfied with the stain or sealer you applied, asking you to “do it again.” Three short words, but they sure can do a number on your profit for that job. You can almost eliminate this risk with three key steps taken before the project begins.

Step No. 1: Know your finishes

Finishing outdoor wood so it looks good and lasts long is more

difficult than it seems, in part because so many outdoor wood finishing products fail too soon. I know because I’ve been running

Once you explain to clients how much work it can be to maintain a high-end deck or fence finish, many project owners are happy to opt for something simpler and less formal. Ecowood Treatment is my favourite low-key outdoor wood finish because it’s so efficient. Mix up the Ecowood powder with water in a pump-up weed sprayer, then spray the solution onto new, uncoated outdoor wood. Beginning in a few minutes and continuing for months, Ecowood Treatment gives the surface an even, grey weathered appearance. Better than natural weathering that can be ratty and uneven, you can cover a lot of wood in a short time, with no chance ever of peeling or finish failure.

an outdoor wood finishing trial on different stains since 1990. Sometimes even reliable outdoor wood finishes can still fail prematurely if the surface prep isn’t done right or if application conditions are wrong. That’s why you should never let hope get the better of you and try some new-to-you finish on a client’s deck or fence. Just because “you feel good about it” or your brother-inlaw used it is not sufficient. Aim to find several finishing regimes you can trust, then stick to them. If a client insists on you using something you’re not familiar with, have them sign a waiver releasing you from responsibility for the results. Chances are you’ll be glad you did. Visit baileylineroad.com/deck-stain for detailed, up-to-date results from my outdoor wood finish trial.

Step No. 2: Educate your client

Even the best outdoor wood finishes in the world involve compromises of some sort. They’re far from perfect, and you need to explain this to your clients so unreasonable expectations don’t develop. This is especially important when dealing with picky first-timers. You know the kind I mean. It’s amazing how demanding homeowners can be when they’ve never before faced the reality of having to finish and refinish outdoor wood every two or three years. Educate them about reality before they call you expecting some kind of impossible outdoor wood finishing performance. Make up samples of your outdoor finishing repertoire, then bring them with you when meeting clients.

Step No. 3: Budget for prep

There is almost no outdoor wood finish on the planet that performs optimally without surface preparation. Even new wood needs to have mill glaze removed to prevent or delay finish peeling. Assuming your wood has a moisture content less than 16 per cent (that's a must, so check it with a moisture meter on a

fresh-cut end), then pressure washing followed by sanding with a 60- or 80-grit abrasive does the most to optimize the absorption of finish into the wood. And the better the absorption, the longer the finish will last, all else being equal. The problem with prep is that it takes time. You can easily spend more time preparing outdoor wood than actually applying a finishing product. If your client won’t agree to a fence or deck price that covers the cost of prep time, then either get them to do the finish application themselves or walk away. A missed project is always better than a nightmare project.

There are good profits to be made building fences, decks and outdoor structures, but only if you can avoid the surprise of finishes gone bad. Get your finishing system finalized and you probably won’t get one of those dreaded calls from a client you said goodbye to last spring.

By Steve Ryan

Weall have our list of regulatory obstacles and fees for which we see little or no corresponding benefit. This won’t be an essay to try to convince you otherwise. We will, however, argue against being too assertive in sharing your views with clients or prospective customers.

You do want your customers to understand the burdens you must overcome on their behalf, but how constructive will it be if they become resentful or angry about it all? If, for example, your project is delayed over building permits, you need the client to recognize where the delay is coming from. You certainly need them to recognize the cost. You also need them to see value in your efforts to move things along. But how will it help you if your conversation takes the tone that this is extortion by people in authority? Sure, you may sidestep the blame for time and expense but don’t expect that to forge a tighter bond between you. If a customer feels victimized it will more likely spill over into all aspects of their project.

Think about how these obstacles appear to your customer. It’s natural enough for them to feel frustration with a process that seems more cumbersome and expensive than it should be. We can share the pain, even as we work to overcome the hurdles. From that perspective you have an opportunity to impress with how deftly you manage the process. But nobody, including you, will look good if the whole thing is presented as pointless or incompetent. To a client who resents what’s happening you might seem more like a “bag-man” than a steady hand at the tiller.

I suspect that one reason cash deals are so pervasive in the home improvement field is that even contractors who strive to operate legitimately don’t convince the client of why that benefits them. If you project the notion that doing things legally is feeding

a government cash grab, you might also project a moral argument for bypassing that process and opting for a cash deal.

We’re not suggesting that you can make customers happy about the time and expense imposed by regulatory demands. You will do yourself and them a favour though if you can explain why these things matter. Not every fee is a cynical attempt to pick your pocket and not every license or regulatory requirement is an arbitrary attempt to block your path. Most were put in place to protect either workers or consumers so make the effort to understand their intentions. Whether or not they are administered properly is a separate issue and you have to set that aside. The client needs to hear of the challenges you face to operate legitimately. It’s more critical though for them to hear why it matters to them that their project is executed legitimately.

There are enough rogue operators spreading the message that regulations are unreasonable and can be safely ignored. Don’t make their job easier by echoing that opinion. Whatever your feelings about red tape and bureaucracy, the risk of ignoring it will lie with the homeowner. Learn how to explain those risks to your client. After all, what is a better message to give your client: (a) That you grudgingly pass along costs the regulators have dumped on you; or (b) That you are determined to comply with regulations because it protects your clients from risk.

Your actions can be identical in either case. The only difference between them is the attitude you project. cc

MMI Professional Services is committed to the success of contractors by helping them develop the business and management skills they need. For information on ways to run a better building business contact the writer at steveryan@ mmiproservices.com

Mounted on a wall in my workshop is a wire basket that holds ear muffs, safety glasses and all the different tape measures I own. There are probably 10 different tapes there and I know that a tape is above average when I naturally grab for that one instead of others. I’ve been using two different Irwin CommandLock tapes for a month and both keep ending up in my hand, especially the 16-footer.

All models in this group have what you’d expect in a pro-grade tape – comfortable shape, effective rubber over-wrap, easy-to-use blade lock, a decent belt clip, 14-foot reach – plus one other thing. Irwin calls it a “touch-button finger brake” and it’s easy to like.

Push the spring-loaded middle of the bottom of the tape case and it holds the blade extended as long as you keep that finger brake pressed. Release the brake and the tape slides into the case again. This is easier than using the locking button when you just want to hold the tape open briefly, and it means the tape blade never has to slam into the case when retracting. Just ease in the

Sometimes a marginal building practice becomes so commonplace that no one ever questions it any more. Basement crack repair is one of those practices. Couldn’t we do better than the fill-and-hope method? Isn’t there some way to impart decent tensile strength to a repair that potentially has to resist big forces?

DRICORE’s Pro Concrete Repair system is a unique answer to questions like these, and it’s an effective method for sealing out ground water and radon gas where present.

The three-step application process begins by sealing the crack in the area then installing temporary plastic injection ports into the crack. The second step is to inject expanding polyurethane into these injection ports. These direct the placement of the expanding polyurethane filler beyond the surface and deep within the crack.

Remove the injection ports, grind the surface of the repair zone flat, then apply a coat of epoxy to the face of the wall. Press a piece of pre-trimmed carbon fibre fabric into place over top, then

end of the tape using the finger brake and you can easily come in for a smooth landing.

One especially nice feature of the 16-foot model is the width of the case from front to back. It measures an even 3” which makes it easier to mentally add the case width when taking inside measurements by extending and locking the blade. Prices for tapes in the CommandLock line, depending on model, range from $23 to $31 at Canadian Tire. cc

saturate the carbon fibre material with more epoxy, troweled on. Tensile strength is what carbon fibre is all about, and it increases the reliability of repairs a lot.

Check out my video on this product’s performance at BaileyLineRoad.com/basement-crack-repair. Available at Home Depot (online only at the moment and only in Canada), the Pro Concrete Repair system is part of a complete basement finishing program that includes DRICORE subfloor panels and SMARTWALL rigid insulated basement wall panels. cc

After an influx of new products hit the truck market in 2019, this model year is more of a transition period for many brands

By Mario Cywinski

CanadianContractor looks at what is new, updated, and available in the pick-up truck and van market for 2020.

Once exclusive to heavy duty pick-up trucks and a selection of full-size vans, trucks brands are now adding diesel engines to light duty trucks. While FCA added one to the Ram 1500 a few years ago, it is now introducing a new version on its 2020 truck; similarly, General Motors is adding a diesel option to its Chevrolet Silverado and GMC Sierra, while Ford added a diesel to the F-150 in 2019.

Safety and technology also takes centre stage for 2020, as many brands are adding features not usually seen on pick-up trucks and vans in the past. These include cameras to improve sightlines around the vehicle, automatic emergency braking, adaptive cruise control, and options to help with towing.

For 2020, a new player is added to the mix, as the Jeep Gladiator makes its debut in the mid-size segment. Heavy Duty models also see updates for 2020, as both Ford (Super Duty) and General Motors (Chevrolet Silverado HD and GMC Sierra HD) are all-new. Nissan has updated its Titan and Titan XD.

Ford has updated the Super Duty for 2020, with engine, capability, design and technology changes. A new engine is added to the line-up, as a 7.3 litre V-8 gasoline engine with 430 horsepower and 475 foot/pounds of torque make its debut. The 6.7L Power Stroke diesel engine gets an update and now offers 475hp and 1,050 ft/

lbs of torque. The standard engine continues to be a 6.2L gasoline engine. A new 10 speed heavy duty automatic transmission is included in the Super Duty and features drive modes that include normal, tow/haul, eco, slippery, and deep sand and snow.

The updated diesel engine allows the Super Duty to now offer gooseneck towing of 16,783 kilograms, fifth-wheel towing of 14,742kg, and conventional towing of 10,977kg. Maximum towing numbers are increased for all Super Duty models for 2020 (F-250, F-350 and F-450).

Ford has optimized the front end of the Super Duty to help with cooling, including a new front bumper and air dam. The rear tailgate, taillights, and rear bumper are all updated. LED headlights are also updated, as are DRLS on higher trims.

Technology and safety changes also occur, as Pro Trailer Backup Assist is now offered and allows the truck’s Trailer Reverse Guidance to be compatible with fifth-wheel and gooseneck trailers. Automatic emergency braking, lane-keeping alert, and blind spot monitoring are now standard on XLT trim and above. Other standard features now include FordPass Connect with 4G LTE modem, available wireless charging, and Ford Telematics.

A new Tremor off-road package is also added to the line-up for 2020, featuring an upgraded suspension, running boards, 35-inch tires, and Trail Control (described as cruise control for off-road driving by Ford).

For 2020, the full-size Transit van gets a new 3.5L V-6 gasoline

engine (replacing the 3.7L engine), while joining the 3.5L EcoBoost gas engine with 310 hp and 400 ft/lbs of torque and now with automatic start/stop function. Both engines are mated to a new 10-speed automatic transmission. An all-wheel drive system is also added as an option for 2020.

Safety is enhanced for 2020, with new standard automatic emergency braking (with pedestrian detection), forward collision warning, post-collision braking, lane keeping system, and automatic high beams. New available safety options include adaptive cruise control, front and rear camera, and a speed limiting device.

Minor changes occur to the exterior of Transit, including available HID headlamps with LED DRLs, unique grille designs for different models, and an available power sliding door for cargo and passenger vans. Interior is updated with subtle changes and improvements, and the inclusion of available swivel front seats. FordPass Connect model with Wi-Fi hotspot (for up to 10 devices) is now standard.

Canada’s top selling pick-up truck, Ford F-150, goes into 2020 with only minor package and colour changes. All-new in 2019, the mid-size Ranger carries over into 2020 with minor changes. Ford Transit Connect mid-size van is also available for 2020, albeit minus its diesel engine.

Chevrolet Silverado

After being all-new for 2019 model year, the 2020 model gets a new 3.0L turbocharged inline-six diesel engine that offers 277hp and

460 ft/lbs of torque, with maximum towing for four-wheel-drive models of 4,218kg and maximum payload of 848.2kg. A 10-speed automatic transmission is now available on 5.3L V-8 models. Silverado will also receive available 15 camera views and adaptive cruise control with camera.

Chevrolet Colorado

Carrying over into 2020, Chevrolet has announced an all-new Colorado to come for the 2021 model year. It will offer updated lower fascia, front skid plates, and centre bars, new logos, embossed tailgate, and unique looks for each trim. The ZR2 model will feature a lettered Chevrolet front fascia.

GMC Sierra HD

As both the GMC Sierra HD and the Chevrolet Silverado HD are all-new for 2020 and share many changes, we will focus on the GMC model to avoid repetition. The Sierra HD features an allnew design that makes it taller, longer, larger and with a longer wheelbase. Redesigned lighting is prominent as headlights, taillights, fog lights, roof marker lights and DRLs are all available in LED. Additionally, the grille is larger and hood scoops are more functional.

In the back, cargo bed volume is improved, 12 corner tie-downs are included, a 120v power outlet is available, cargo bed steps are new (in addition to the current corner steps), and the MultiPro tailgate, which debuted on the Sierra in 2019, is available on HD models

Technology is also front and centre, as GMC’s ProGrade Trailering system is now available on HD models, as is an available 15 camera views. Additional technologies include an automatic electric parking brake, park grade hold assist, and tow/

haul mode that stays on for the next time the vehicle is turned on (up to four hours).

Power wise, Sierra HD now offers a 10-speed automatic transmission on its 6.6L turbocharged diesel engine that outputs 445hp and 910 ft/lbs of torque.

An AT4 off-road version is also added for 2020.

General Motors also offers two full-size vans, GMC Savana and Chevrolet Express. GMC Sierra models also receive the 3.0L diesel engine as all-new for 2020. GMC Canyon sees the addition of AT4 off-road variant for 2020. A max towing capacity of 13,607 kg is expected.

All-new for 2020, the Jeep Gladiator is the newest member of the mid-size pick-up truck market. It brings Jeep’s off-road pedigree, so when it is driven off the main road -- something that many contractors, job site workers, and others do on a daily basis -- it doesn’t miss a beat. It has a wheelbase of 3,487 millimetres, a five-foot cargo box (1,531 millimetres with the tailgate closed), and towing capacity of 1,814kg to 3,469kg (depending on how its equipped).

Power for the Gladiator comes from the Pentastar 3.6L V-6 with 285 hp and 260 ft/lbs of torque mated to an eight-speed automatic transmission or a six-speed manual transmission. A 3.0L diesel engine will also be available and offer 260 hp and 442 ft/lbs of torque, mated to an eight-speed automatic transmission as standard.

The vehicle is available with trailer sway control, the cargo

box offers standard cargo lights, dampened tailgate, tie-down loops, and optional spray-in bedliner and roll-up tonneau cover.

Three sizes of FCA’s uConnect system are available, a standard five-inch screen, a seven-inch, and an 8.4-inch model. The instrument cluster comes with a standard 3.5-inch screen or an optional seven-inch.

Gladiator is available in Sport, Overland and Rubicon models.

All-new for 2019, the Sprinter sees minor changes to packages and available equipment for the 2020 model year. All crew vans now come standard with wood floor with six d-rings; rear window defroster, storage compartment with net in rear doors, and windows in rear doors; satellite radio now available on all models; and all cargo models now offer a full window package.

Sprinter comes outfitted with a V-6 diesel engine that provides 325 ft/lbs of torque and 188 hp mated to a seven-speed automatic transmission, a four-cylinder gas engine provides 258 ft/lbs of torque and 188hp and is mated to a nine-speed automatic transmission.

Four body types are available (cargo, crew, passenger and cab chassis), two roof heights (standard and high), three wheelbases (144”, 170” and 170” EXT), three rear wheel types (single, super single, or dual), and standard rear-wheel drive and available 4×4.

Mercedes-Benz Canada also offers a smaller mid-size van, Metris. The Metris is available in both cargo and passenger variants. In addition to new colour, wheel and equipment options, the Metris receives a new instrument cluster design as standard for 2020.

For 2020, Nissan has updated the exterior styling of the Titan, which it dubs the Powerful Warrior design. The new design now offers a unique grille for each of its three trim levels, PRO-4X and Platinum grades now offer standard new headlights, LED DRLs, and available LED fog lights. The bed now has all-LED lighting with four light sources, also the rear of the Titan now has LED lighting. The exterior changes also include an updated front bumper, fog lights, badging and wheel designs.

On the interior, Titan now offers an available nine-inch touchscreen (an eight-inch screen is standard) as part of its integrated command centre, which also includes Apple CarPlay, Android Auto, and a Wi-Fi router (subscription required). A seveninch driver information display is also included. With a new NissanConnect on the 2020 Titan, it now has over-the-air software updates.

For 2020, Nissan has also updated its 5.6L V-8 engine, which now offers 400 hp and 413 ft/lbs of torque, and is mated to a new nine-speed automatic transmission. Nissan Safety Shield 360 technology is now standard on all Titan models. It offers: automatic emergency braking (with pedestrian detection), blind spot monitoring, rear cross traffic alert, lane departure warning, automatic high beams rear emergency braking.

The larger Titan XD model shares the updates of the smaller Titan. It will now be offered in a crew cab body with a 6.5’ bed and four-wheel-drive as the only configuration available in SV, PRO4X, and Platinum Reserve trims.

Nissan offers two cargo van options. NV full-size cargo van now has navigation package standard on SV models. While the mid-size NV200 van has a new seven-inch colour touchscreen display unit on S and SV trims with NissanConnect with Apple CarPlay and Android Auto, with satellite radio and Bluetooth, iPod Interface, and USB inputs. A mid-size pick-up, the Frontier is also still available.

Added for 2020 is a Night Edition model that offers monochromatic design with black wheels (22” on Laramie, 20” on Big Horn), black badging, and a variety of colour options. The Rebel model offers a Black Appearance package with black wheels, black skid plate, and a black interior (red is optional). It now has a safety package with adaptive cruise control, automatic emergency braking, lane departure warning, and automatic high beams.

For 2020, the HD models also get a new Night Edition, with similar options. Ram also adds lane keeping and adaptive steering as available equipment on all trims. Additionally, trailer tire pressure monitoring and blind spot monitoring (including coverage for trailer) are added, as is an auxiliary camera system that can have two cameras added. Crew cab with eight-foot bed now comes standard with an 187L fuel tank. Colour and wheel changes also occur.

Other models

Ram also offers two van models, ProMaster and ProMaster City, and both carryover into 2020 with minimal changes.

Tacoma

The mid-size Tacoma see incremental changes for 2020, with all models now offering Toyota Connected Services Audio with seven- or eight-inch touchscreen, and Apple CarPlay and Android Auto. Some models get multi terrain view monitor and birds eye view monitor; TRD Pro models get new colours and features; while other trim levels get equipment updates.

Tacoma is available with a 3.5L V-6 engine with 278hp and 265 ft/lbs of torque, mated to a six-speed automatic transmission, with a six-speed manual transmission available on several TRD models. Access cab and double cab are available in 4x4 configuration.

Toyota Safety Sense P is standard on all Tacoma models. It offers adaptive cruise control, lane departure warning, automatic high beams, and automatic emergency braking (with pedestrian detection).

All 4x2 and four-cylinder models are discontinued for 2020. cc

Introduced as an all-new model in 2019, for 2020 a diesel engine is added to the lineup. The 3.0L EcoDiesel V-6 engine offers 260 hp and 480 ft/lbs of torque, and has a towing capacity of 5,697 kilograms (12,560lbs). It joins the 3.6L eTorque Pentastar V-6 with 305hp and 269 ft/lbs of torque; and the 5.7L HEMI V-8 (with or without eTorque) outputting 395hp and 410 ft/lbs of torque.

Mario Cywinski is the Editor of Machinery and Equipment MRO magazine. He is a member of the Automobile Journalists Association of Canada (AJAC), a judge for Canadian Truck King Challenge, and has over 15 years of automobile industry experience. He can be reached at mcywinski@mromagazine.com.

Walter Meza owns a thriving design-build contracting business that has grown to 20 employees with several million dollars in sales annually.

Among his employees are Ziggy, his long-time designer, and Mandy, his site supervisor. Both have been working for Walter for around 15 years, and — having met in the workplace — have been married for around 10 years.

However, the couple has recently separated and with divorce looming, things have gotten extremely tense around the workplace with Ziggy and Mandy sniping at each other. Productivity is slipping and it's creating a general sense of discomfort for the rest of the staff, not to mention that the firm's professionalism is in danger (the couple recently had a heated exchange that was clearly audible while Walter was meeting with a very important supplier).

Walter has been patient, but it's become obvious something needs to be done. Ziggy is a very talented designer, and one of the firm's first hires (not to mention he's one of Walter's oldest friends), however, he can be replaced much easier than Mandy. Walter and her have never been close, but she's a top notch site super, and is well liked and respected by both his crew and customers. Losing her could really hurt and it would take some time to find a suitable replacement.

Neither wants to leave the firm. In fact, individually, each of them has come to Walter to pitch that they keep their jobs as they need the income more than ever now that they live separately.

Here's my take on this situation. The doctor knows that he can hold Karl for ransom with the money. The doc will always be able to find something wrong, being cheap will almost guarantee it. I get it in that you want the money and work but trusting your gut always wins, been there, done that. It's best to either price it high and hope for the best or walk away from it.

This should not damage his wife's reputation with the doc. If it does, the doc is not much of a guy to work for. She could get work elsewhere if she loses her job. Karl will have to explain this to his wife in a way she understands. Better to not work and have no money then to work, buy material and still not get any money.

Marten Burghgraef

Dutch Touch Construction Ltd.

Well played Marten! For your thoughtful response, you've won a pair of DEWALT products: a 20V cordless router and a 20V cordless quarter sheet sander (combined value of $498). Enjoy!

1. Work them both extremely hard and see who breaks first and resigns.

2. Walter should sit them down and tell them they have to cool it or they'll both lose their jobs.

3. He should fire Ziggy, citing his recent work suffering, but risk losing one of his best friends.

4. Fire Mandy, but risk losing some of the crew.

5. Do something else.

If you have a five-point plan for Walter, email your entry to rob.blackstien@rogers.com and put “Walter dilemma” in the subject line. Please don’t post your plan as a comment to the Dilemma post on our website.

Entries close May 1, 2020. The winner will be announced on www.canadiancontractor.ca on May 22, 2020

DEWALT new 60V MAX* 1-3/4-In. SDS MAX Combination Hammer (DCH614) Retail: $899

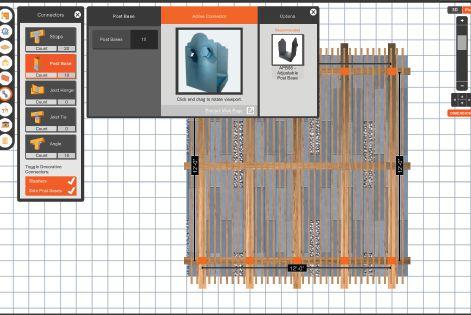

Help deliver a dream outdoor structure with Deck Planner Software™ and Pergola Planner Software™ from Simpson Strong-Tie. Easily design a strong and beautiful deck, pergola or other popular structure in just minutes using prebuilt templates or custom dimensions. Work in 2D or 3D environments and select wood species or additional features from a full library of options. Then just print out the plan view and materials list and start building. Your clients, and your business, will thank you.

To learn more about our free downloadable software, visit our website at go.strongtie.com/pergolaplannersoftware or call (800) 999-5099.

Compared to standard shingles, SureNail® Technology provides you with 2x the bond strength, and up to double the common bond in the nail area. With SureNail® Technology, strength and durability are built into every TruDefinition® Duration® Series shingle. The SureNail® strip, a tough-engineered woven fabric strip in the nailing area, provides an easy-to-see target nailing area for a fast, reliable, quality installation. The heritage of the Owens Corning brand means you can be sure with SureNail® Technology. See the strip, trust the grip®.