The Master of Outdoor Living

Stunning Build on Saanich Inlet

Paul Lafrance on backyard retreats Page 10 Emergency Backup Power

A post-and-beam project for the ages Page 18

Steve Maxwell on generators Page 23

The Master of Outdoor Living

Paul Lafrance on backyard retreats Page 10 Emergency Backup Power

A post-and-beam project for the ages Page 18

Steve Maxwell on generators Page 23

An interview with CASEY EDGE, executive director, Victoria Residential Builders Association Page 12

Canadian Contractor has hundreds of videos online for serious residential construction professionals

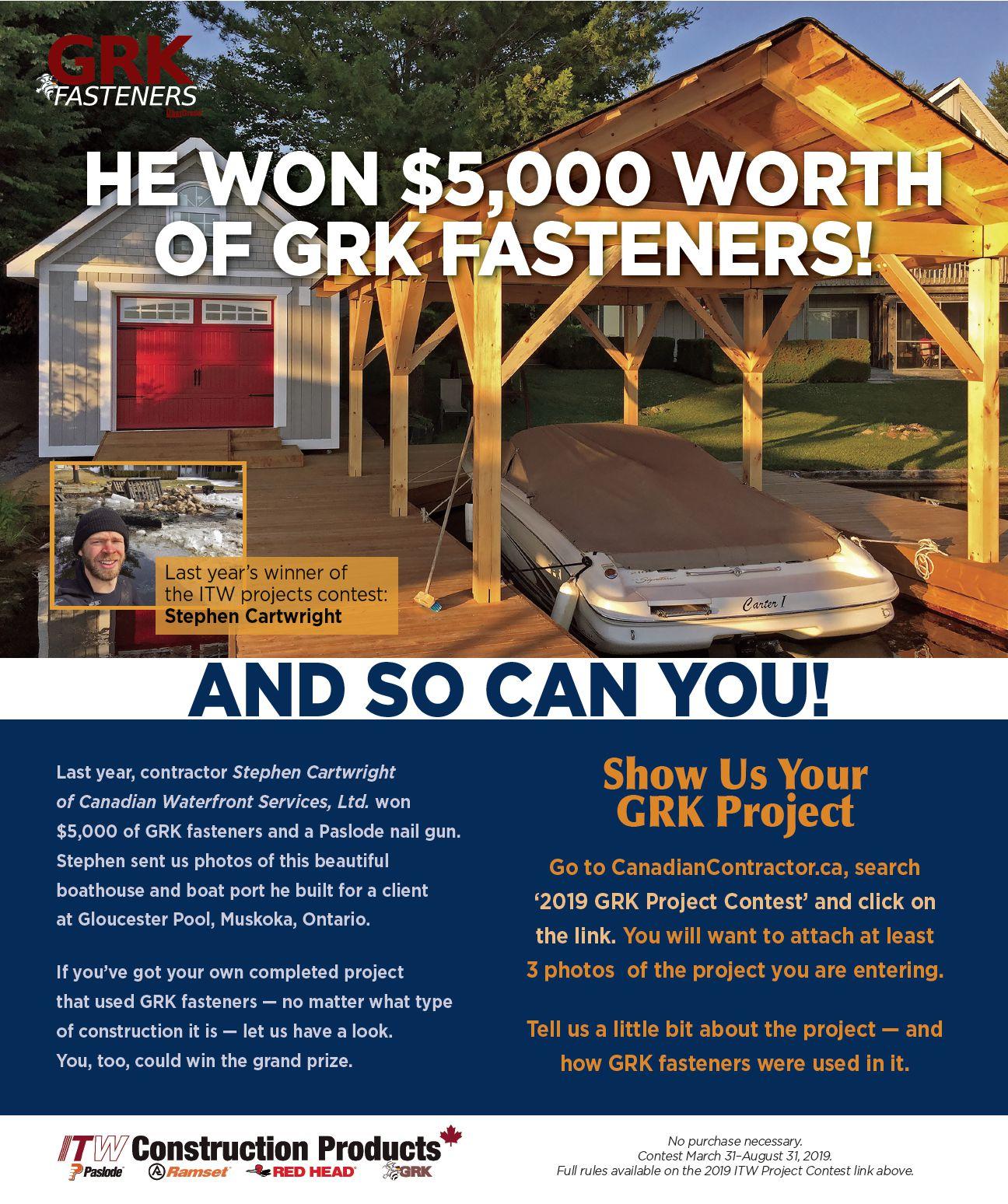

Sponsored by ITW Construction Products Canada

In this collection of videos, Rob Koci talks to experts from ITW Construction Products about the different uses of specialty fasteners in the Canadian renovation and custom home building industries. Topics include failure mechanisms for screws and bolts, mechanical versus chemical bonds for anchors, concrete pins and thermal bridging solutions.

Sponsored by Home Hardware

This series of videos looks at ways to build better, faster and more profitably. Rob Koci and Steve Payne present a number of construction tips sent into the magazine by Canadian contractors – and they also interview experts from around the industry. Everything on a job site from framing to interior finishing is fair game for Site Tips.

Sponsored by Various Manufacturers

Innovation is the engine that keeps profitable construction companies going. Unless you discover new and better ways to build, you risk falling behind your competitors, and your company may be challenged to compete in the new industry landscape. Buildwire is the place for contractors to see what’s new and improved.

ISSN 1498-8941 (Print)

Editor

Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Kim Laudrum, Steve Maxwell

Media Designer Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

Tim Dimopoulos, Vice President tdimopoulos@annexbusinessmedia.com

Mike Fredericks, President & CEO

Circulation

lmalicdem@annexbusinessmedia.com

or

Steve Payne Editor

spayne@canadiancontractor.ca

” State the problem, solve the problem, set the price.

”

By Steve Payne

Nothinghappens in business until someone sells something to someone. Selling home improvements is not different. You can be the greatest builder since the time they put up the Parthenon – but if you suck at sales, you may as well get a job at Timmies.

This is why, at least once a year, we devote a feature article to selling in our industry, This issue, I thought I would focus on one simple strategy passed onto me 20 years ago by the owner of a building materials wholesaler in Ontario (who shall remain anonymous).

“Everyone complicates sales far too much,” he told me once at a trade show. “We have a really simple three-part strategy for selling. We like to say: State the problem. Solve the problem. Set the price.”

I asked him to explain. This is what he told me.

State the problem. Great salespeople, the true masters of their industries, quickly uncover the problems that their clients are really dealing with. Poorly trained, cheap labour can be a problem. Substandard materials can be another. Unguaranteed work is a problem. Undefined schedules and endless delays are yet more problems. Ask your prospective clients what they are most afraid of, leery of, or irritated by. State the problem.

Solve the problem. You need to explain to the client how your specific processes and people will keep these problems from rearing their ugly heads . (“We have long striven to be the cleanest, most meticulous kitchen renovators in this city. We aren’t dustless, nobody is. But we really try to keep things clean.”)

Set the price. Never, ever quote a price on a project until you have utterly established, without a shadow of a doubt,that your prospective client’s problems are best tackled with your specific solutions. That what they most want, you will provide. Then quote the price.

If you don’t define the problem, present yourself as a unique solution for it, then set the price, you will forever be a “Me Too” contractor. What a horrible place to be.

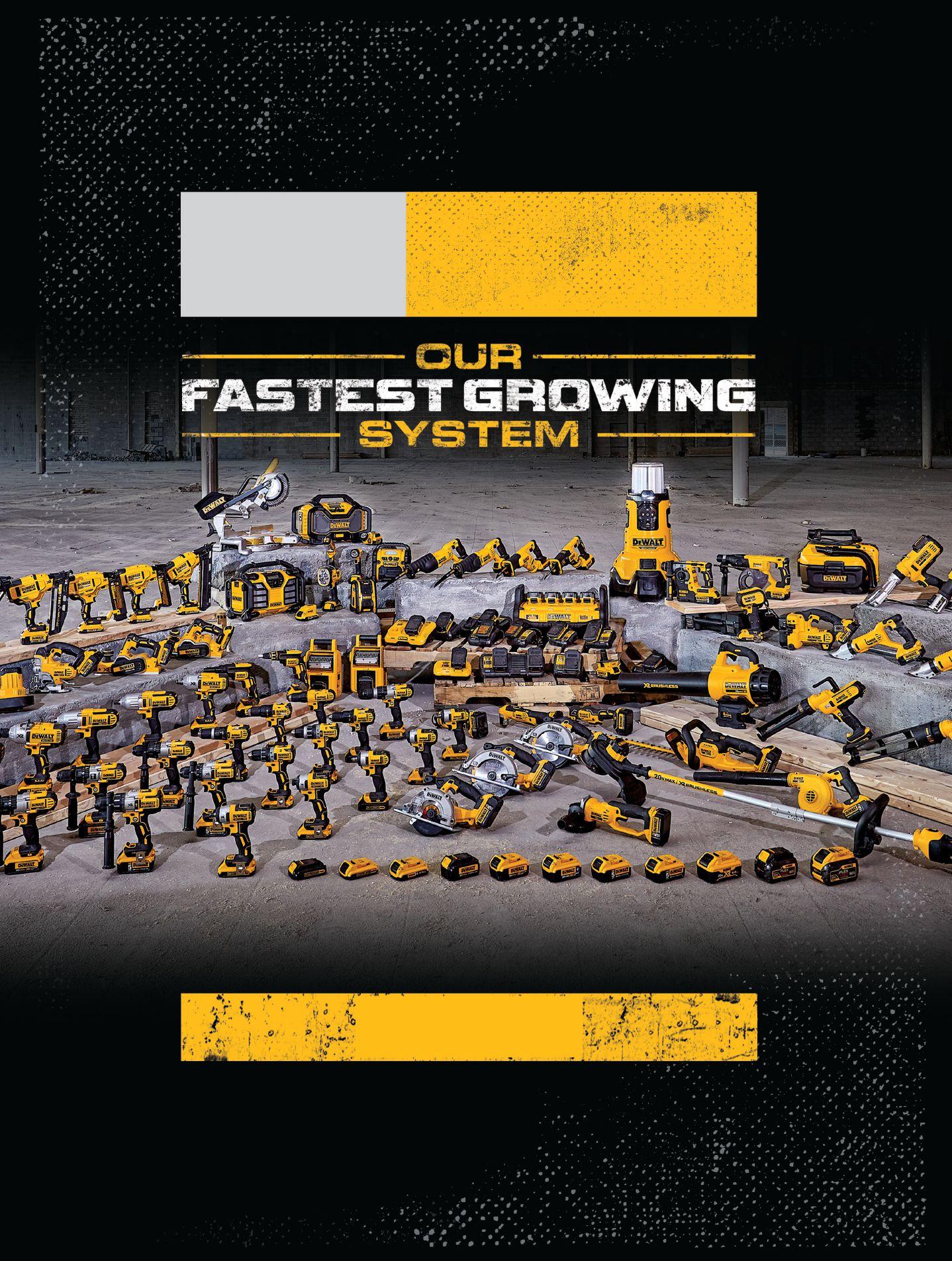

GET MORE DONE™** with 200+ PRODUCTS in the DEWALT 20V MAX* line. All tools come with upgraded features, superior ergonomics and use Lithium-Ion batteries. For extreme performance, step up to the XR® series and get advanced electronics, extended runtime and faster application speeds.

It will soon be six months since Doug Ford’s Ontario government announced that the Ontario College of Trades would be “wound down” (with no timetable for that, nor any definition of what “wound down” means). The natives are restless. Many contractors who hated the organization (the majority of those who have communicated with us about OCOT over the years) are getting impatient to know when the wind down begins. Others are filled with vitriol for Ford’s regime for attempting to reduce red tape in our industry. For example...

Doug Ford knee high in s**t?

I sincerely hope that Ontario premier Doug Ford and/or his loved ones never have a home burn to the ground, due to a “Jack of all trades” contractor practicing skills he or she does not have. I also wait in anticipation for a snapshot of Mr. Ford, knee high in waste because the same person – working for the same contractor – also wears the plumber’s hat. I wonder if then, Mr Ford will finally have enough s**t on his hands.

Brad Lawrence

Increasingly, we are getting posts from consumers who feel vicitimized by contractors’ liens.

$102,000 lien is just an attempt at “legal theft”

Our contractor seems to make his living suing owners. He treated us horribly, did not build as per contract or plan, kept giving us change orders and refused to build unless we paid them. This was a fixed price contract. He kept doing work not approved by us and he kept charging us. Then he put a false $102,000 lien on our house when we were paid up to date as per the contract. Now $20,000 later we are just waiting for a quantity survey, the rough copy of which states all the mistakes and how we should be credited for them, how there should be no lien. This company has an amazingly false website; they did not honour their contract. All we have from July 07, 2017 to now (Feb 25, 2019) is a barely framed house on a foundation, a roof, exterior doors and a basement floor. HVAC and plumbing is roughed in. That’s it. We had paid the contractor almost $90,000 for all the work complete, so how do they get off putting a $102,000 lien on our house?

This company has over 30 registered court cases against them.

I talked to one client briefly as she stated she lost $25,000 to them last September. But she was just happy to get rid of them and hired someone else. They have ruined our life. Our house is now full of mold as its been sitting all winter after they abandoned the build five months ago. It’s taken us this long for us to save the money to prove the contract. This is not fair, there is very little help for the consumer…

We had no invoice, no warning at all about this lien. We have no clue what the $102,000 lien is for. How fair is that? They do not talk to you. Our lawyer has four binders of horrible texts, emails and bullying from our builder. They are big and rich so they don’t care. I believe this is some kind of legal theft. Anyone thinking of hiring a contractor, please check the justice system and how many times they have registered in the courts against customers. I really wish we had. We wish the law would change. There are bad contractors that use the lien system to make money. I believe we fell into that trap.

Della Mackie

A lawyer, Gino DiCiocco, replied to Della, citing ways to defend agains a a contractor’s lien from a Quebec point of view. Note: lien law varies by province, please check your provincial statutes to see if this information applies to your own jurisdiction.

Below are some ideas and defense for Della Mackie, in random order.

1) (In Quebec) lien law requires the total value of the work to have been approved by the owner. Therefore, unless your contractor has a mutually signed formal document(s) showing a total of $192,000 (i.e., $90,000 paid, plus lien of $102,000 for unpaid contract balance), the lien cannot stand.

2) Some jurisdictions permit the owner to formally request a detailed statement and itemization of the liened amount, which would provide you a “clue [of] what the $102,000 lien is for.” I’d have your lawyer make a formal request.

3) Your lawyer could try to dismiss the lien for “willful exaggeration” by the lienor. If proven, some jurisdictions permit fines and recovery of damages against the person who filed the lien, in addition to the company itself.

4) Construction costs to correct or repair for mold caused by the contractor’s negligence failure to protect the work could be a deduction to any amounts proven to be properly owed to them in the lien.

5) In the interim, you can “bond off” the lien through a surety (at a very nominal cost) which can be renewed annually.

6) This would permit you to continue construction on your home at little risk — while the lien just sits there, until the contractor files a lawsuit to foreclose on its lien, which would ultimately be shown to be invalid in court.

Gino Di Ciocco

In February, we posted about B.C.’s intention to license those who do asbestos abatement. Here is a post about that.

Residential asbestos hysteria is about creating jobs

Very interesting. I worked at Cassiar Asbestos Corporation for quite a while in the 1980s. I still get tested periodically with no answers as to whether I will ever be affected or not. My reason for responding is that everybody makes a really big deal about the problems with coming into contact with asbestos in houses, etc. But this level of exposure may or may not cause problems. I really think it is more about creating jobs – a lot of jobs. But what about the asbestos mines like Cassiar blowing that killer stuff all over the north? In winter, the snow always had a green sheen on it from the blowing asbestos. That mine shut down in 1992 but has been subject to blowing winds ever since. Why have governments never addressed that?

Sterling Stump

In our March 8 E-News, we ran a list of the HomeStars Best Of Award winners. It didn't take long for a debate to begin about which awards were most important for Canadian contractors.

Our company, Tego Design Center, has been operating in Ottawa for over 30 years. We have won the Consumer Choice award 23 years in a row and we have won a number of other design awards. Further, we are members of Renomark and the NKBA as well as the local homebuilders association. How come I have never heard of HomeStars before this article? An award of this type only has value if it surveys all the competitors IMHO.

Mike Aubrey

Tego Design Centre, Ottawa

Nothing but a social media popularity contest

The Consumer Choice Award is essentially a social media popularity contest. Businesses are told to reach out

for nominations from whomever they want. One doesn’t even have to have been a customer to submit a vote or answere their questionnaire. Consumer Choice also does not invite negative reviews, meaning there is zero attempt to maintain accountability. I think HomeStars has done a great job of identifying this weakness by making the winners completely based on reviews from actual customers. My intention, however, is definitely not to discredit your award. Consistency is by far the greatest accomplishment for a business, in my opinion. Your business has displayed this in spades by winning this award 23 years in a row. All the best!

Sean

Thanks for the feedback, Mike! First off, congratulations on all your success in the industry so far. Based on your credentials, it’s clear that you understand the importance of building a rock solid reputation for your business. This is exactly why HomeStars is such a valuable tool for home service professionals like yourselfwe’ve taken the tried and true word-of-mouth referral process and transformed it into an online review-based platform that connects ready-to-hire homeowners with qualified pros in their area. As a result, a Best of Award, in conjunction with company reviews, is a valuable indicator to homeowners who use the platform to make safe hiring decisions.

Just for your reference, HomeStars was founded in Toronto in 2006 and was acquired by Denver-based HomeAdvisor in 2017. It is now an ANGI Homeservices company, part of a global network of home improvement marketplaces in Europe, the UK and the US, including Angie's List. If you'd like to learn more about HomeStars and how you could qualify to win a Best Of Award next year, please don't hesitate to reach out to us at 1-877-488-0312.

Shir Magen VP Marketing, HomeStars

Toronto

I THINK THE ASBESTOS HYSTERIA IS MORE ABOUT CREATING JOBS – A LOT OF JOBS!

Wise words on selling backyard projects from Canada’s master of outdoor living space

Interview by John Bleasby

How does an outdoor living space expert keep busy through the Canadian winter?

I’m kind of a rebel by instinct so when it comes to the winter telling me what to do, well, let's just say I don't back down. It has been a rough winter but we do find ways to build, particularly on larger projects. However, I do spend a lot of money on tarps and propane heaters.

Renovating interior spaces seems to be top of mind for homeowners. What’s your argument for investing in outdoor living spaces?

I take a bit of a philosophical approach. This is the busiest culture in the history of humanity. People are desperate to escape. Once people realize that the backyard can be a retreat that feels like taking a weekend vacation, that's huge!

Is there a backyard that’s too small for a retreat?

That little backyard space of grass is prime real estate. It's always my favourite. The transformation is dramatic. It's fantastically rewarding; not just the emotional impact, but also the return on investment has been, in some cases, astronomical.

Is the return on investment always there?

It’s there with the right products. If I say it’s going to cost $50,000, they might say, “What are you talking about?” But if I say they could buy a cabin in the woods for $100,000, they’ll say it’s a bargain. But you have to travel there and you have to maintain it. This can change people's mindsets when they look at their backyard. They don’t ask me to build a deck — they ask me to build a retreat, an escape, something that is going to have a psychological impact.

You talk about the “right products.” Give us some examples. Nobody has time to maintain anything anymore – it’s stressful and time consuming. There are so many new products on the market that didn't exist before, products created because of the demand for low maintenance. The days of rotted decks, corroded BBQs, and vinyl chairs that stick to your backside are gone. Now exterior furniture looks like interior furniture. The barbecue is

now an outdoor kitchen with cabinets that look like cabinets in the kitchen. These products are made for the outdoors. People are catching on that they can have the haven they need to de-stress, right in their own backyard.

In addition to his numerous appearances on television (HGTV’s Decked Out, Disaster Decks, Deck Wars), Paul is a designer and builder of breakthrough outdoor living spaces through his company Paul Lafrance Design.

”

Casey Edge represents the interests of Victoria, B.C. homebuilders to various levels of government and to the public. “Housing has become both a cash machine and a political tool,” he laments. “Our goal is to have changes made.”

Interview by John Bleasby

ARE UNREASONABLE.”

Casey Edge has been Executive Director of the Victoria Home Builders Association (VRBA) for some 20 years. Recently, Casey has become a frequent columnist in Canadian Contractor, writing in a no-holds-barred manner about the issues facing contractors across the country. His background in journalism and public relations is clearly serving his members well. We recently interviewed Casey about industry and regulatory issues that are affecting his members the most.

Is your media outreach a reflection of you personally or of your organization’s position concerning industry matters?

I don’t rant about stuff for the sake of ranting. There has to be some really good reasons. And it’s going to come from meetings with my board and particularly my builders council. Our builders are going through significant challenges and costs that are unreasonable. When confronted with an unreasonable situation then, yes, you will hear from me. But it's not just about speaking out. Engaging the media is really part of our goal to educate the public. You can't educate the public unless you engage the media. And the media is only going to be engaged if you've done your research and you have something credible to say.

How do you see the role of your association and its relationship with members?

I've been doing this job for over 20 years, and over that time I've distilled, I think, the value that our members see by belonging to our association. Directing their real world challenges is number one. You can say that I am outspoken about some of issues, but you cannot run an association entirely on speaking out.

Explain what you mean by bringing value to membership in the VRBA.

We have a lot of partnerships and relationships with organizations in our community. For example, we partner with the B.C. Construction Association on education courses and their benefits program. We promote courses on advanced building envelopes. For years we have promoted the Built Green Canada program, which is based on education, affordability, certification and proven practice. We also provide free fixed-price and costplus contract templates for our builders that are fair and balanced both for them and consumers. A couple of years ago we started

offering an online expression-of-interest service for consumers so they can send their new home and renovation projects directly to our builders. Builders get jobs through membership in our association! That's real-world value.

What are the major issues you are addressing on behalf of your members?

Housing has become both a cash machine and a political tool. Our goal basically is to have changes made that affect the housing industry to prevent it from continually being that cash machine and political tool. Politicians will keep you in meetings for as long as you want to keep attending — it’s not the way that I believe you effectively create change.

Cash machine, political tool — those are strong words. Explain what you mean.

Every level of government has decided that housing is a gravy train. For example, GST and land transfer taxes didn't exist 40 years ago. Development fees and charges should be based on the cost of providing inspections, not the cost of construction. All this has created multi-million-dollar surpluses for municipalities.

That obviously affects housing affordability.

It's claimed the housing industry hasn't done its job by providing affordable housing. But the market is entirely governmentcontrolled! Governments tell us where and what to build through zoning and permits, how to build through the building code, and how much revenue they require through all the fees and taxes.

K2 Stone; Casey Edge (VRBA executive director); Russ Barry, Interactive Construction; Ellie Sercombe, Limona Group; Lisa Dunsmuir, Step One Design; Jenny Martin, Jenny Martin Design (VRBA president). Not pictured: Todd Halaburda, New West Developments (past president); Derek Ballman (suppliers and trade council chair).

They've created greenbelts for urban containment zones that have choked development, and they have handed development decisions to community groups opposed to higher density.

What is the concern with greenbelts?

There’s no question greenbelts are important parts of creating liveable, sustainable and balanced communities. However, they are often created from aerial photography — there needs to be on-the-ground verification of their agricultural or environmental assets. Second, greenbelts significantly limit land for housing. As a result, higher density must be regionally mandated within the urban containment zones, just as the greenbelts were mandated. The problem is that provinces have left density decisions to municipal councils and community associations, which is resulting in conflicts over development, obstruction, and ultimately higher housing costs for homebuyers.

Are you saying the problem of affordability is a governmental problem?

Yes. They created the problem in the first place. If builders could build anything anywhere, there would be no affordability issue. Of course they can't, so government must accept the logical conclusion that regulatory restrictions on supply, more regulations, more taxes and more fees are not the solution.

POLITICIANS WILL KEEP YOU IN MEETINGS FOR AS LONG AS YOU WANT TO KEEP ATTENDING.”

Some suggest that government should be putting money back into the industry in some manner, perhaps through incentive programs, rather than loading the costs on the backs of new houses and their purchasers? Do you agree?

Absolutely. If the government is going to continue collecting the money, I would rather see that money put into retrofit programs for older homes, especially if the government believes greenhouse gases are a significant problem that needs to be addressed. Rather than passing the Step Code, as has been done in B.C., when there is already a perfectly good Built Green program, government should create major retrofit or renovation programs to address the exponentially higher number of greenhouse gases coming from older homes. The CMHC has demonstrated that air changes per hour could be reduced from 40 down to seven. Even a small investment can significantly reduce air changes in a leaky home. That's low-hanging fruit.

Are there other benefits you see coming from incentive programs?

Retrofit programs have proven to be very popular with Canadians in the past. They employ Canadians in every community across the country. They also encourage homeowners to get receipts, which addresses the underground economy.

You said earlier that housing has become a political tool. What do you mean?

The currency of politics is votes. For example, some municipalities in B.C. are adopting the Step Code to knock off one or two air changes per hour while adding tens of thousands of dollars to the cost of each house.

Then the politicians can turn to the voting public and say, “Look what great guys we are!”

Exactly. When I say housing is being used as a political tool through the building code and through other activities, that’s what I mean. They don’t want to raise taxes on existing homeowners — they tax the homes where nobody lives yet. They won’t offend anyone. Instead, they go after the builders and developers. Governments everywhere are using the housing industry in a similar way. What builders are experiencing here in the West is exactly what builders across Canada are going through as well.

Do you feel the industry itself bears any responsibility, for example by being slow to adapt to new construction methods?

The builders I talk with are very interested in presentations on new techniques, and efficient ways of building and selling homes that will work in the real world. I think what builders are doing right now is just trying to find out how they can adapt to the regulations put in place by people who do not build and sell houses for a living. I believe, however, if you empower builders to come up with and entertain new ideas, they will do that.

Do you believe regulators are trying to do too much, too quickly?

When the government imposes higher energy efficiency without mandatory education, that’s putting the cart before the horse. The order should be: education first, then regulatory change. The fact is, there’s very little mandatory education, particularly building envelope education. Even then, it’s not as if you can look at new regulations and come up with a list of the problems in a day, a week, or a month. It takes a lot of time. Changes to the code should be incremental. Take the B.C. Step Code as an example. It’s a Leap Code—it’s not incremental. In fact, it might actually fast-track building envelope failure by imposing higher levels of energy efficiency on currently approved materials, causing

them to deteriorate more quickly because they were not designed for the purpose. It’s like a Honda Civic — it was designed for certain driving conditions, certainly not for a NASCAR track. The brakes, the engine, the suspension were not designed to drive consistently at 200 miles per hour. It might achieve that speed over a short period, but everything’s going to deteriorate a lot faster under those conditions.

Can you explain, and maybe give an example?

Here in B.C., there were recent changes to the building code that, among other things, addressed insulation, air tightness, vapor barriers, etc. Subsequently, some building envelope experts have suggested there may be a risk of creating two virtual vapor barriers. One comes from the increased thickness of exterior rigid foam insulation. The other is the poly used on the interior side of a standard 2x6 stud wall. Increasing the exterior’s vapor impermeabilty could trap moisture in the wall, resulting in accelerated structural deterioration. It’s only one example, but I believe it highlights the complexity of building more energyefficient homes and the potential for unintended consequences. It reinforces what the Canadian Commission on Building and Fire Codes called the “confusion within the industry regarding vapor barriers and air barriers.”

I WOULD

What needs to be done in order to turn the process around, in your opinion?

Consultants and regulators should be the minority listening to a majority of builders, and then doing what the industry recommends. Right now, it’s the opposite — government officials, consultants and regulators, and only a few contractors, are deliberating over a previously-set government agenda. In order to have an effective home building industry and change the way things are done, first you have to understand the building business model. But if you create multiple rules ahead of the building business model, which is the practice today, moving forward is going to be really difficult. Our goal as an association is to post wins, not meet politicians. Just because you've met with politicians does not mean you are meeting your goals. Wins means achieving policy changes that meet the demands of real life industry players. Some of our advocacy has resulted in policy changes. And it's not like we're stopping here — we're always trying to improve. cc

What keeps you up at night? Is it the howling wind, or worry over what it might be doing to your reputation? Wake up to peace of mind with IKO’s Dynasty Shingle featuring ArmourZone™. You’ll sleep better knowing your roofing jobs are covered by a 210 km/h (130 mph) Limited Wind Warranty1. The ArmourZone is an oversized 1-1/4” wide nailing area reinforced by a tear-resistant, woven band inserted into and extending beyond the common bond. It makes nail placement easy and helps prevent pull through in high winds. So go ahead. Elevate your game with IKO Dynasty Shingles. You’ll sleep easier, and your customers will too. To learn more, 1-855-IKO-ROOF (1-855-456-7663) or visit roofingelevated.com

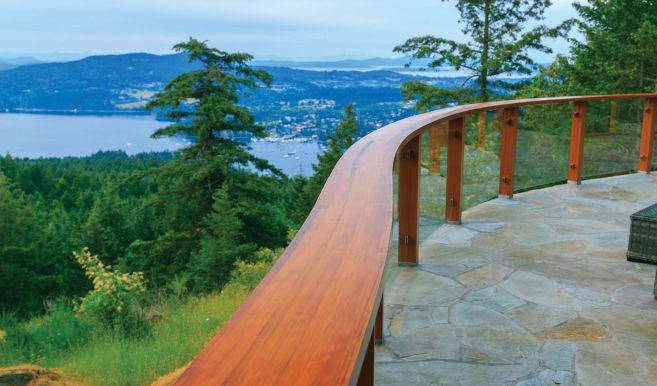

A curvaceous Vancouver Island beauty overlooking Saanich Inlet

By John Bleasby

Contractor

R. Parsons Construction Ltd., Victoria, B.C.

Architect Bo Helliwell, Blue Sky Architecture, West Vancouver

PHOTOS THIS PAGE: HEATH MOFFATT

Fromevery angle, Bo Helliwell’s design for the Arbutus House is spectacular. Overlooking Saanich Inlet on Vancouver Island, the design and execution of this open-concept, 2,840 square foot, gently curving home of glass and wood represents all that is possible in a West Coast residence.

The site itself lies on a rock outcrop at the end of a onekilometre forested driveway, perched 880 feet over the water on a private 30 acre property. It was a labor of love for the client from the outset. “He’s a real hands-on guy and owned some

heavy equipment, an excavator and so on,” said Bo Helliwell of Blue Sky Architecture. “He worked on it for a few years, building the driveway up through the forest and running the electrical services. It was a really big job."

The name Arbutus relates to the hardwood tree native to Vancouver Island. "It’s very beautiful, specific to this area, and only grows at certain elevations,” explained Helliwell. “A big part of the siting of the house included taking advantage of those trees on the approach from the driveway with the least amount of damage to the property.”

The site itself was also fortunate in many ways with respect to the province’s seismic design considerations. “The rock had been glaciated, ground and rounded, but it was solid,” said Helliwell. “We had a topographic survey done, determined the most naturally level platform, and then blasted the top off the outcrop and levelled the broken rock. It’s basically a slab-on-grade house built on top of that broken rock.” Although unseen to the eye, all seismic requirements were therefore accommodated by the foundation connections, occasional solid-paneled walls and the roof design. Helliwell said that the curved building itself is also stronger than a straight line design.

For Rob Parsons, owner of R. Parsons Construction of Victoria B.C., the Arbutus House was his fourth successful collaboration with Helliwell. Parsons established his business in Canada several decades ago after years of previous experience in his native New Zealand.

The quality workmanship of what Helliwell calls “a hybrid post

and beam” structure is a salute to Parsons and his team of skilled carpenters. Parsons’ boat-building experience as a young man is evident throughout, but perhaps nowhere more so than in the sweeping 60-foot patio handrail, made from 1x2-inch cedar strips, laminated directly on top of the posts.

First class materials always make a difference. Parsons commented on the quality of the heavy Douglas fir beams supplied by the client, owner of a wood mill at the north end of Vancouver Island. The beautiful 2x10-inch cedar exterior cladding boards, also client-supplied, were so high in quality that Parsons regarded them as “furniture grade.” Parsons further enhanced the visual impact of the siding by milling each board with an alternating upper and lower tongue and groove, and then devising a clever attachment system involving Galvalum metal strips overtop of plywood sheathing. This allowed for the beautiful grain to flow around the mitered corners.

The north-facing walls facing the inlet are almost entirely floor-to-ceiling windows from one end of the building to the other. Many glass sections open to provide access to the full length patio overlooking the water below. Yet, the Arbutus House incorporates several Passive Home concepts, in keeping with Blue Sky’s sustainable outlook. Large roof overhangs on the south side, in combination with the shade provided by the forest, reduce summertime overheating. These overhangs also protect the building from the heavy rains experienced in the fall and early winter. A separate guest house incorporating a large two-bay garage and workshop follows the gentle arch of the overall plan to the side of the main building.

Those in Central and Eastern Canada might understandably drool at the extensive use of glass. In fact, the mild climate of the Saanich area — rarely below freezing in winter or above the midtwenties in summer — means less dependence on mechanical systems. In-floor heating suffices in winter. Opening clerestory windows along the top of the south-facing wall provide sufficient all-season, natural ventilation in place of an HRV, while also negating the need for air conditioning in the summer.

Of course, the building meets or exceeds the National Building Code R-value requirements in the walls where fiberglass batts were used — albeit without accommodation for thermal breaks — and on the roof. There, rigid foam was installed above the plywood deck, the so-called “warm deck” approach. Two layers of torch-on roofing were then applied, the first screwed through the foam and into the deck with long screws and washers.

Not surprisingly, the Arbutus House has been recognized by the homebuilding industry and regional wood councils alike for its highly successful combination of design, materials, and workmanship, including a Gold for “Best Single Family Detached Home” at the 2017 the CHBA Vancouver Island CARE Awards. cc

By Steve Maxwell

ooner or later, in more ways than one, staying sane in this life involves mastering mental gymnastics. I think this is especially true for contractors. You’re involved in a tricky industry with lots of moving parts. If you’re a professional who values quality, there’s also a chance you battle with perfectionism. I used to, but more than 25 years ago I discovered a trick for turning the negative effects of perfectionism into something positive and productive.

Wikipedia defines perfectionism as a personality trait characterized by striving for flawlessness and setting high performance standards, accompanied by critical self-evaluation and concerns regarding others’ evaluations. On the surface, this doesn’t sound too bad, does it? After all, if you want to run a successful contracting business, you need to set high standards, right? You certainly need to be concerned about what your clients think about your work if you want future business. It’s also perfectly reasonable to expect high standards from yourself and the trades you hire. The problem with all this is the unspoken reality that nothing is ever good enough for the perfectionist. That’s the part that drives perfectionists (and the people around them) crazy.

The way to harness the power of perfectionism without it making you batty comes down to a small but crucial mental flip-flop. Master this flip flop and it’ll convert damaging perfectionism

into something I call the “pursuit of excellence.” Just don’t be fooled. The pursuit of excellence looks and sounds like perfectionism on the surface, but it has one feature that makes all the difference.

The problem with perfectionism is that nothing can ever be absolutely perfect in this world. That’s why perfectionism is a game no one can win. In Disney’s classic 1967 movie The Jungle Book, Baloo the bear offers some powerful anti-perfectionist philosophy in

while I’m working. This is identical to perfectionism and it’s necessary for high quality results and improving skills. Nothing good ever happens without effort, and nothing great ever happens without high standards. The thing is, at some point, you need to adopt a certain measure of surrender. You need to do that mental flip-flop I mentioned. If you remember that absolute perfection is impossible, it’ll help you kick into “satisfied mode.” This is the fundamental

PERFECTIONISM WILL BE YOUR RUIN AS A CONTRACTOR. BETTER TO PURSUE EXCELLENCE.

the song “The Bare Necessities.”

And don't spend your time lookin' around

For something you want that can't be found...

Absolute perfection simply does not exist in this dirty old world of ours, and the root of the distress of the perfectionist is believing the lie that perfection is possible. It’s not. Rejecting this lie is the first step towards relief, but there’s something even more important.

The thing that delivered me from perfectionism is the understanding that I need to have two states of mind whenever I’m working on any task. The first state involves striving for the best results I can possibly get

feature of the pursuit of excellence. Try your guts out within the time, budget, conditions and skills you’ve got, then flip-flop into a perspective of surrender as you approach completion.

Without this mental flip-flop, all perfectionists do one of two things. Either they go crazy, or they abandon the pursuit of excellence altogether because it’s too painful to do anything else. Both outcomes are negative and unnecessary. If you’re a hard-core perfectionist, you’ll find the “flip-flop of sanity” difficult at first. Keep applying this mental discipline to your life and it’ll become your new and healthy habit. Trust me, if you’re a perfectionist, the results are definitely worth the trouble. cc

How to help your clients choose an economical emergency generator. And three legal ways to hook it up.

By Steve Maxwell

generator cost and greater concern about the reliability of grid power are the two main reasons more property owners than ever are interested in electric generator backup. The thing is, most of your clients only know that they want this sort of protection, not how backup power works nor how to choose equipment wisely. This is especially true when it comes to one of the most popular backup options – the large portable generator. Learn how to sell this option to clients and you’ll expand the scope of your projects and look good in the process. Besides, the best backup power installations depend on features that should be built in right from the start of major projects.

Generators come as small, big, quiet, not-so-quiet and permanently installed versions. And of all these choices, large portable generators are the one category that’s consistently popular with home and small business owners. Defined as

putting out 8,000 watts of power or more, large portables deliver plenty of juice and they can be used for more than just electrical backup. Your clients can use the generator at the lake or for building projects beyond the grid. Value is perhaps the most attractive feature for these models. Large portables deliver the most electrical power output for a given price and have become

very economical in recent years. See the sidebar on Generator Costs below. You’ll be pleasantly surprised by the numbers. It’s one thing to own a generator, but another thing to legally connect that generator to items in a building. Electrical authorities everywhere forbid direct connection of a generator to an electrical panel unless that system is physically prevented from back feeding generator power into the grid. The issue is line worker safety and the threat posed if power accidentally comes back into the main service lines from a generator connected to the supposedly “dead” side of the power grid. Laws are in place to protect workers from this potentially dangerous connection and it

I bought my first generator in 1988 for $3,500 (in today’s money, $6,700). It was a nice red 3,500 watt Japanese model. Nothing fancy, just a good, brand-name portable with no wheels. Fastforward 30 years and you can buy Chinese-made generators that are much larger than that – for a lot less money. Are they any good? Some are great and some are junk. It all depends on the brand you choose. In my own field trials, I’ve found Champion generators to be the best in their class in performance and price. You can get a 12,000 watt portable Champion for about $2,000. That’s almost 3.5 times more power at less than 30 per cent of the cost of that first generator I bought. Champion also has the best parts and service program I’ve seen from any brand. They’ve got technicians standing by to give detailed phone and video guidance on how to fix things yourself if you’re so inclined. Low price and good performance are the big reasons generators are becoming almost as popular these days as lawnmowers.

You can guide clients towards a simple system for allowing a portable generator to power a home or business, but that doesn’t mean their system will keep on working when it’s needed. This is why it makes sense for property owners to choose and install essential equipment so it can accept power from any small portable generator that can’t use a hard-wired interface. Typical water well pumps, for instance, use 240 volts but this means the pump can’t be powered by a small 120 volt-only generator if that becomes necessary. Better to recommend a 120 volt pump that’s also wired with a plug end and not hard-wired into the building. Same goes for essential heating controls and ventilation equipment. The ability to revert back to powering essential items with any generator using extension cords is a worthwhile “plan B” in case the large generator or power connection system fails.

means there are only three options for legally making emergency generator connections in homes and businesses.

Today’s multi-outlet generator extension cords mean this option isn’t as troublesome as it used to be because only one extension cord needs to come indoors. That said, extension cords still leave a lot to be desired. They’re what most clients end up using unless they’re taught about generator connection alternatives, and it’s worth steering them to something more convenient than cords. Besides the hassle of connecting items with multiple extension cords, it’s almost impossible to make full use of the power of a large portable using extension cords only. There are only so many things you can plug into cords.

Imagine an extended, cylindrical meter base with a port for accepting a proprietary cable that connects to a generator. This is how a meter base generator connection system works. It’s the simplest to install in an existing building without doing extensive electrical work.

GenerLink is the best example of meter base generator connection hardware right now. When power goes out, plug one end of the connection cable into the meter base and the other end into the generator. Fire up the engine and that’s it. The GenerLnk automatically disconnects generator power from the grid, while

also allowing generator power to flow into the main electrical panel and to the various circuits. Besides connecting and firing up the generator, part of the meter base connection regime happens down at your electrical panel. You’ll need to switch off the breaker serving high-load, non-essentials such as the electric water heater, baseboard heaters or clothes dryer.

GenerLink keeps on delivering generator power to the house as long as the generator is running and even after grid power is restored. The generator needs to be shut off for grid power to switch back ON. There are only two drawbacks with GenerLink. It’s a fairly expensive unit ($1,100 to $1,500 in Canada with cable depending on the model), and not all jurisdictions allow GenerLinks to be installed. Check with your local municipality to see if it’s legal in your area.

The best time to install one of these is when major electrical work is already being done on a building. Transfer switches provide an opportunity to connect a generator cable to your electrical system, and connect either the generator or the grid to the building circuits, but not both at the same time. Transfer switches typically work with a small, secondary panel. Essential circuits are connected to this panel during installation, and this panel is the only one that gets energized when the manual switch is flipped during and outage. The connection between the grid and panel is cut when the transfer switch is moved to generator mode, then re-established when the switch is pushed back to grid mode.

As a contractor, the public sees you as an expert in all things related to building, so it’s natural they’ll turn to you for basic advice on generators. The better you know the subject the better you’ll build your reputation as an expert. cc

Here’s what your clients need to do to keep a portable generator working well:

Burn stored gas in a vehicle after six months. Gasoline bought in winter starts engines more easily in cold weather than gas bought in summer.

A portable generator can sit for months without running. Add gas preservative to the tank, then let the preserved gas work through the engine for a while running before storage. Faster starting is what this delivers.

Generators need fresh oil after every 50 to 100 hours of operation. Warn property owners that they need to have motor oil stored as well as fuel for long-term outages.

Generators aren’t supposed to be exposed to wet or snowy weather, but that’s usually the kind of weather they’re needed in. There are generator covers made specifically to protect generators and help them last longer. They fit properly and are easy to store with the generator so they are ready to use when needed. An open carport (never a garage) or open verandah on a workshop can also shelter the unit from nasty weather.

One contractor I know does both residential and commercial work but he tells me he much prefers commercial because there’s far less indecision from clients. One small but annoying source of indecision is paint colours, and that’s where something called the Nix Mini Color Sensor (nixsensor.com) can help. It’s a tiny, wireless device that lets your smartphone “see” existing colours and offer intelligent colour recommendations. Charge the Nix Mini with a USB cord, download the app, then pair the thing with your phone wirelessly. Any time you want to record an existing colour as a basis for an exact match or pleasing contrast, just place the Nix Mini eye-side-down, then hit the scan button on your phone. In a second or two the colour is scanned and recorded, with specific paint suggestions automatically generated. You can share these colours to any phone, you can choose from all major paint colour codes, and see their corresponding paint chips and

I was finishing some acacia wood in my shop recently and it got me using a wood finish again that I have a love-hate relationship with. I discovered Tried and True Varnish Oil about five years ago, and I love it because it creates one of the most beautiful effects I’ve ever seen on hardwoods, especially dark hardwoods. This oil also yields a very durable and water-resistant finish that’s easily renewed. It even stands up well on kitchen tables that see hard use with multiple damp wipings each day. Unlike urethane or lacquer, you simply apply more varnish oil when the wood is starting to look dry or scratched after a couple of years use. Clients love this stuff because of its beauty and repairability, but I have to tell you that it’s more of a pain to use than typical clear film forming finishes or wipe-on poly. The problem is drying time. You really do need to allow three or four days between coats for best results. The product is fairly thick, too. Flood the wood with the oil, wait an hour or so, then wipe the surface dry. Four or five coats do the trick. I buy mine from Lee Valley Tools, and at $45 for 946 ml, price is another reason to hate this stuff. But like most love-hate relationships, I keep coming back for more.

paint availability online. Look further into the app and you’ll find colour suggestions including monochromatic, complementary, analogous, split complementary, triadic and more. The Nix Mini costs $100 and makes more sense for a contractor than the more expensive Nix Pro Color Sensor.

Want adventure with purpose? Travel the world and use your skills to empower others!

Canadian Contractor and World Vision are providing the opportunity of a lifetime. Experience SkillTrain – Canadian trades professionals training young Rwandans. Experts in carpentry, plumbing, welding, electricity and masonry are needed.

WINTER 2019 • RWANDA, AFRICA • LIFE-LONG IMPACT

Be a part of the action and change a community for good. Are you part of this team?

E-mail skilltrain@worldvision.ca to learn more.

A Canadian-made solution to preventing ice dams from forming on your clients’ rooftops

By Steve Maxwell

ManyCanadian roofs form at least small amounts of ice during winter, but large and damaging levels of ice are a different matter. This kind of build up is always the product of too much heat escaping through the roof. When snow melts on the main part of a too-warm roof and this melt water runs down and hits the sub-zero eaves, the water freezes – forming an ice dam. If they get large enough, ice dams trap water and trigger leaks. Exremely large ones can even break the eaves.

The ideal way to prevent ice dams is by making the roof surface colder by adding more attic insulation or by boosting attic ventilation. The thing is, it’s not always possible to do this kind of root-cause fix. This is where rooftop heating cables come in. They melt drainage channels through rooftop ice so that water doesn’t get trapped behind ice dams.

Back in the fall of 2017 I had a project that needed a roof de-icing system, but I wasn’t crazy about installing the usual sort of exposed, zig-zag cables needed. Besides looking less-thanideal, rooftop cables are open to physical damage because there’s nothing to protect them. That’s why I decided to install a unique, hidden Canadian system called Edge Cutter (heatline.ca; 800-5844944). Edge Cutter uses self-regulating heating cable encapsulated in an aluminum extrusion that runs all along the eaves. An Edge Cutter roof looks no different than a conventional, unheated roof. Edge Cutter is the brainchild of Ontario inventor Lorne Heise. His aluminum extrusion is 5-1/2” wide and fits underneath the shingles at the eaves. The edge of the extrusion turns downwards at the bottom and is made to accept a single electrical cable that conducts heat upwards to where ice needs to be melted.

The amount of cable required is roughly 1/2 to 2/3 less than conventional systems because it travels in a straight line (no zigzagging). The cable also economizes on electricity by delivering more or less heat along its length depending on temperature at that spot. If there’s an area with lots of ice, the cable heats with full power in that location. If there’s another area that’s warm from the sun at the same time, electricity use throttles back automatically in that area.

Installing Edge Cutter on an existing roof with fiberglass shingles was trickier than with a new installation because of the nails holding the shingles down at the edge of the eaves. In the end I used a recip saw to slice through those nails I couldn’t pull up and out from underneath the slightly raised shingles. You slip the extrusion in place under the shingles and above the aluminum drip edge, then house the cable in a groove in the edge of the extrusion, capped and held in place with a separate aluminum strip. Finish up by running blobs of construction adhesive to the drip edge, to anchor the Edge Cutter extrusion and stop it working downhill over time.

Can warming just the bottom 5-inches of a roof really stop the formation of ice that normally extends higher than this? I had my doubts, but yes, surprisingly enough, the system is working fine on the roof over the last two years. It doesn’t get warm enough to completely eliminate ice, but the ice is weak and porous enough to be a non-issue. cc

Dennis Sherwood has new responsibilities. He’s been elevated to supervisor of his framing and carpentry crew after a veteran of the firm retired. The promotion should be good news but it’s not working out. To keep team numbers steady, the company owner brought in Jerry, an apprentice fresh out of college. Jerry is giving Dennis trouble — he thinks he knows everything and is not shy about it. “That’s not the way we learned it in school,” he often says to Dennis, while the other guys shake their heads and smile to themselves. Dennis is worried that Jerry’s constant push-back will begin to erode his newly-minted authority — he’s supposed to be in charge now, not taking lessons from some kid. Dennis has asked his boss for advice but he didn’t like the answer. “The kid might have some good points,” his boss told Dennis.“Maybe you should listen to him and pick up some new ideas.” Dennis is finding the situation increasingly uncomfortable.

What should Dennis do? See the options at right.

In our January/February contest, we described contractor Andy Roy’s attempt to set up a year-end bonus system for his employees. Points would be awarded to each employee for meeting deadlines, staying under budget and satisfying clients. But his staff soon started finger-pointing at each other, claiming there were too many aspects of these criteria that were out of their control. What should Andy do?

Virtually every respondent felt that Andy should live up to his bonus payouts for the past year, but rethink his plan going forward. Many entries suggested a more simplified bonus plan, one that involved employee input into its creation. Of many excellent entries, we decided the best response came to us from Bob Zimmerman of Glacier Drywall Systems, Calgary.

Bob suggested a bonus reward system based on corporate goals set out at the start of the year. As he explained, the system must “be measurable to remove bias, and to the greatest degree possible, the worker or supervisor must have control” over the areas measured. Progress towards those key corporate milestones and the associated financial rewards should be discussed quarterly, not annually. Employee feedback, expressed with confidentiality if necessary, should also be part of the program.

Congratulations, Bob. You will receive a DEWALT DCN662D1 20V Cordless XR Brushless Straight Finish Nailer (retail value $499). With its brushless motor, this unit drives 16 GA finish nails from 1-1/4" to 2-1/2" in length.

1. Speak firmly to the apprentice, in private, and ask him to show some respect.

2. Ask the boss to transfer the apprentice to another crew.

3. Do what the boss suggests: Maybe Dennis can learn from the kid.

4. Something else. Please explain in 300 words or less

Email your answer to John Bleasby (jbleasby@canadiancontractor.ca). Please do not post your proposal on our website

Entries close May 2, 2019. The winner will be announced May 7 on our website. The best contractorsubmitted entry, as judged by our panel, will

a DEWALT 20V MAX Tool Connect AllPurpose Light. This LED emits 5,000 lumens of natural white light, with Bluetooth connectivity for tracking and setting control through the free mobile TOOL CONNECT app.

The Highline® toilet series packs Kohler’s powerful AquaPiston® flushing engine beneath the hood. The 3 to 2 ratio between valve intake and outlet harnesses the natural force of gravity to deliver a high-octane flush for virtually plug-free performance. A concealed trapway simplifies cleaning.

KOHLER.ca