GRK Show Us

Your Deck Contest

Winning Entry from Saskatchewan Page 24

The Perfect Proportions Building to the Golden Mean Page 30

No Boiler? No Problem!

Tank-Style Heaters for Hydronics Page 39

GRK Show Us

Your Deck Contest

Winning Entry from Saskatchewan Page 24

The Perfect Proportions Building to the Golden Mean Page 30

No Boiler? No Problem!

Tank-Style Heaters for Hydronics Page 39

How drywall contractors Nick Aitchison and Brian Kitchin have built an Instagram empire Page 14

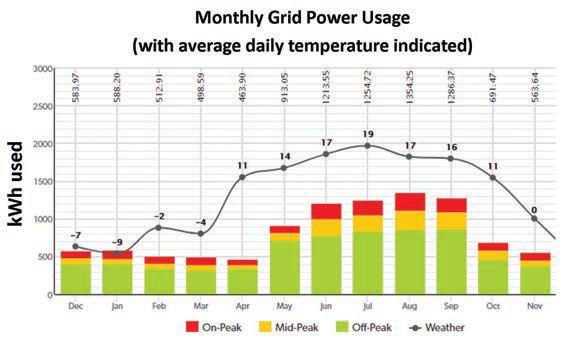

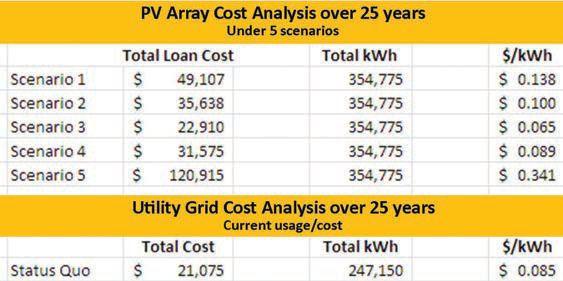

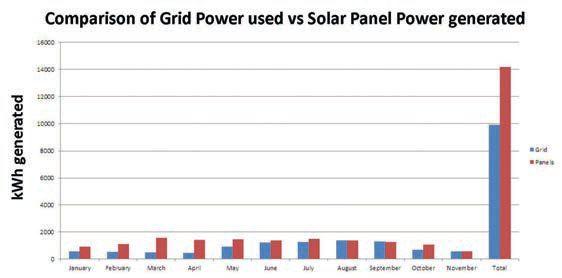

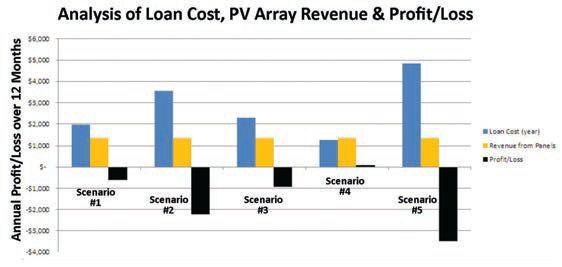

Crunching the Numbers on Solar 10

John Bleasby shows why small scale residential solar without government subsidies is costly.

COVER STORY: DRYWALL NATION 14

Instagram has brought global fame to a pair of Sudbury, Ontario drywall contractors.

Managing Income, Expenses and Cash Flow 22

An accountant outlines best practices for pro renovators and custom homebuilders.

The Winning Deck 24

Dexter Côté of Lampman, Saskatchewan is the winner of our GRK Decks Contest.

A Tribute to Harold Orr 26

The Order of Canada will be presented to this Saskatchewan-based energy-efficiency pioneer.

The Golden Mean on a Toronto Ravine 30

The mathematical genius behind a hockey-stick shaped residence in Toronto.

Steve Maxwell 37

What sets winning contractors apart from losers. Plus: Why tank-style hydronic heating makes sense.

Rob

Koci Publisher

rkoci@canadiancontractor.ca

Dr. Jordan Peterson’s 12 Rules For Life is a deserved bestseller. ”

By Rob Koci

Dr. Jordan B. Peterson is possibly the most famous Canadian on YouTube today. The U of T psychology professor with the tens of millions of views for his interviews and lectures has just written a book called 12 Rules For Life. It’s already become a deserved bestseller. We like these rules so much that, with acknowledgement to Dr. Peterson, we’ve adapted them for this industry. Here are my versions of the first six rules.

1. Stand up straight. Be proud of your profession. Implied in this one is that you are doing the kind of work for which you can be proud. If you are not, change what you are doing. You need to be proud of what you do.

2. Treat yourself like you treat your clients and your staff. If you treat them badly, and you obey this rule, you’ll stop. If you treat them well and you obey this rule, you’ll likely treat yourself better.

3. Hire subs and choose suppliers that want you to succeed. The circle of people you spend time with affects you in ways deeper than you know. Hang out with subs, suppliers and clients who know how to deal with your faults and confront them positively but also know how to bring out your best characteristics and strengthen them.

4. Compare your company’s results to your own past results, not some other company’s. There will always be a better company to make you feel like a failure and a worse company to make you feel like a hero. Both are bad.

5. Don’t let your staff do anything that will make you hate them. When you dislike your staff, you’ll resent them, treat them badly and eventually allow your company to fall into disorder. Only you know what will make you dislike them so only you will know what to stop them from doing. You’re the boss. Stop them.

6. Set your own company in perfect order before you badmouth a competitor. Trying to fix other people’s problems is a great way to avoid your own. You get to show off your virtue and avoid hard truths. If you really want to help other people, make your company perfect. They will see it and ask for your help and then you’ll be in a position to provide it.

By Steve Payne

Here are my versions of Jordan Peterson’s rules 7 through 12, adapted for contractors.

7. Do the type of work that you find meaningful, not just what people offer you. If you’re a high-end, custom homes type of firm that specializes in carriage trade finishing work, don’t be doing an IKEA kitchen just because someone has a fast cheque for you. Compromising your quality to stay busy will hurt your business.

8. Tell the truth – or, at least, don’t lie. This rule is exactly as Jordan Peterson phrases it in his book. In our industry, is there a better way to operate?

9. Assume that the person who tells you there’s a better way to do it might actually know something. In this business, everyone from subs to architects and from employees to designers will constantly challenge your authority as the GC. Give everyone a hearing. You can always say no after you hear them out with an open mind.

10. Be precise in your written contracts. Dr. Peterson writes, “Be precise in your speech.” In our industry, that’s important, too, but we need that precision in writing. A renovation contract is like a seatbelt in a car: You only need one if you think your head will be damaged if it goes through your windshield.

11. Try not to bother your crew when they are having fun. Unless it’s an issue of safety, or a major screw up, when your crew starts to really kid around with each other – let them. If you’ve hired competent, hardworking people in the first place, responsibly fun worksites are more productive than sweatshops.

12. First time in the door, pet their cats and dogs. Your mental balance, in this industry, is more important than any other attribute. If you can’t enjoy a few seconds admiring your clients’goofy pets, you are already way too tense to be taking on another project right now.

Be precise in your written contracts. ” ” Steve Payne Editor spayne@canadiancontractor.ca

April 3, 6:00 am

Busting Myths About Skylights

Part 1: But They Leak!

April 5, 6:00 am

The March to Net Zero

Episode 2: The ICF Foundation

April 10, 6:00 am

Busting Myths About Skylights

Part 2: But They Waste Energy!

April 17, 6:00 am

Busting Myths About Skylights

Part 3: But They’re Complicated!

April 19, 6:00 am

Contractor Talk

Interview with Contractor

John McLellan.

April 24, 6:00 am

Busting Myths About Skylights

Part 4: They Don’t Make You Money!

April 12, 6:00 am

All About Fasteners

Part 3: The Strength of Screws

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors

Rob Blackstien, John Bleasby, Kim Laudrum, Steve Maxwell

Art Director Mark Ryan

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@annexbusinessmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com Tel: 416-442-5600 ext. 3543

April 26, 6:00 am

Site Tips

Part 4: Straws and Scribes on Site!

May 1, 6:00 am

Busting Myths About Skylights

Part 5: But There’s No Training!

May 3, 6:00 am

The March To Net Zero

Part 3: ICF, Fittings and Mechanicals

May 10, 6:00 am

All About Fasteners

Part 4: Fastener Design

May 17, 6:00 am

Contractor Talk

Interview with Contractor

Dave Anderchek

May 24, 6:00 am

Site Tips

Part 6: We Love Zip Ties

If this is your boardroom, you’re a Pro.

Home Hardware is a nationwide supplier of quality, name brand products to Pros of all trades. Whether you are a homebuilder, a renovator, a plumber or an electrician, Home Hardware is a Pro source for everything you need on your next job.

Dedicated Pro sales staff, job site delivery, home plan services, material takeoffs, package pricing, convenient ordering options, credit services, rewards program, and exclusive e-offers are just some of the benefits we offer!

Sign up today to receive pro exclusive email offers and news. homehardware.ca/en/forms/register

Ontario is running a new rebate program costing hundreds of millions of dollars called Green On. It provides rebates to homeowners to encourage them to replace windows, upgrade insulation and do other energy-efficient renovations. Sounds like a good deal for contractors? Not so fast. Many Ontario contractors find the red tape makes the program hard to join.

35 years experience and he can’t get on the list

We are being forced to join an association so we can be trained to install windows better than the government thinks we do now? I was one of the first to install full-frame replacement windows (as opposed to retrofit) over 20 years ago. I lost many jobs because of that but the windows I installed are still in place. We are now redoing a lot of the (retrofit) jobs we lost. So I don’t know why I need to be trained (to get qualified for Green On). I have 35 years in business installing windows properly. My current crew was certified by this association over five years ago but we are required to be updated. Doesn’t make sense. I can’t get on the list until this training is completed. My company has won our local Readers Choice Award for the past 25 years.

Rick Block

Impossible for many to qualify

Re: the Green On (Ontario) window rebate program. The company entrusted with qualifying dealers and installers is not prepared to handle the number of inquiries nor the number of training requests. Not to mention the various requirements the program is imposing on dealers and installers that will make it impossible for many of them to qualify.

Martin Pitts

It’s not about energy efficiency at all!

I think we are missing the point here. It’s not the fact of improving energy efficiency or moving the economy from under the table to above board that the government is trying to achieve. It’s just their “image” of “providing” rebates to the constituents that is important. We shouldn’t try and use common sense when understanding or arguing these things.

40 Years Installing Windows - Frustrated

In February we reported on a Federal government task force that has recommended to the National Building Code folks that fire sprinklers be mandatory in new homes. Isn’t it a great thing that our politicians are keeping us safe from cradle to grave?

Fatalities from fires actually decreased from 141 in 2010 to 96 in 2014, despite the fact that Canada adds about 200,000 new homes a year or a total of about 800,000 new homes during that time period. A CMHC study also shows fire-related deaths are decreasing and that 36 per cent of fatalities take place where there are no functioning smoke alarms. BC regulations now require wired-in smoke alarms in new homes, so the homes most at risk are older homes, which is also true for seismic hazards, asbestos, antiquated wiring, etc. The fire associations/sprinkler associations have always advocated for sprinklers in new homes and the reason it hasn’t been done in the National Building Code is because the cost/benefit is not justified – the facts don’t support mandatory sprinklers in new homes. But they keep trying. In addition, new technologies like the Haven (a ceiling device that can dispense fire-retardant foam in the event of a fire) will offer improved safety for much less cost and make old expensive concepts obsolete.

Casey Edge, Victoria Residential Homebuilders Association

Just another cost to put house affordability out of reach. If we take everything to the nth degree housing will be so far out of reach. When I consider my first house it was pretty basic. It provided me shelter and housed my belongings. Today’s houses are way too complicated, cost way more than they should. Just look at kitchens and bathrooms. The two biggest rip offs in a home. Why not look at making cheaper houses that cost less to build, support basic needs, and do not cost a fortune? I feel for any young person starting out today. There is no chance they will get into home ownership. They would be lucky to afford just the sprinkler system.

Penny Sake

In the recent federal budget, Finance Minister Bill Morneau, as he did last fall, indicated the government’s intention to reduce “income sprinkling.” As most veteran contractors will know, this is essentially listing family members as contributors to a business, and having them take shares/dividends to reduce business taxes – and the owner’s income tax – even though the family members may not, in reality, work in the business. Here’s a post about that...

Do you have any specifics on how the government intends to interpret income sprinkling? Example: If a spouse does the books of a small construction business and deals with all the industry standard issues including the digital marketing and selection of who to deal with, where do they stand on the

income sprinkling? This person looks after our Homestars, Renovation Find, Get Assist, BBB and a host of other marketing initiatives that pop up every month. Surely there has to be some kind of test that the government will use to approve the work that a spouse does and contributes to the business success when issued a T4 for the past four or five years? Or do they just intend to roll the spouse’s income into the larger income of the husband on the assumption that no spouse does legitimate contributions to a business?

Bob

Your last sentence seems like a worst case – and we doubt it. Unfortunately, we don't know at this point how the Canada Revenue Agency will proceed. Ottawa has not yet indicated what tests the CRA will apply to determine how much work a family member must do in a business to qualify for legitimate tax relief as a shareholder or legitimate employee.

Theenergy-efficiency arguments for building a super-tight house with a state-of-the-art internal air management system are pretty compelling. Building this way moves the industry closer to the Net Zero Energy-ready targets laid out by governments across the country over the next few years. But do the numbers today support the next step – adding power generation in order to produce as much energy as the house consumes?

In terms of power generation to offset power use, the installation of rooftop PV solar arrays has been the popular choice. Thanks to provincial grants for installation and generous power buy-back contract programs, a vibrant solar industry was spawned over the past ten years. There was a strong financial argument – more than just the importance of doing the right thing for the environment, homeowners in some provinces could make making tidy profits from their solar installations. However, amid a glut of electrical generation in many parts of the world today from renewable sources of all kinds, there is now little incentive for governments to either subsidize new residential solar installations or to pay homeowners enormous premiums for the power they generate. So what happens now? All good conscience aside, does it make financial sense to install a PV solar array on a home today? To find out, I decided to analyze my own house, comparing my actual electricity usage over 12 months with what a PV solar array on my rooftop would generate.

My House: A brief outline

I live two hours north of Toronto in a recently-built, modern, 3,200 sq.-ft. home. The foundation and walls are ICF, right to the roof. The underside of the roof deck is insulated with spray foam. There’s low-E glass and LED lights throughout. The heating is a high efficiency forced air natural gas furnace coupled with an air conditioner, plus a natural gas water heater, cook-top and fireplace. There is also a 40 foot swimming pool that, although unheated, requires a filtration system to run 24/7 over four months. In summary, the house is extremely well insulated and energy efficient despite the luxury of the pool.

Step One: What could I expect from a PV array on my roof?

To design my hypothetical PV array system, I used software developed for the National Laboratory of the U.S. Department

By John Bleasby

of Energy called PVWatts Calculator. According to the website, PVWatts allows homeowners throughout the world to estimate the production and cost of grid-connected PV energy based on location and 12-month historic weather and sunshine patterns. The software located my house on Google Maps and allowed me to draw the perimeter of a PV array on my roof. It then indicated that an 11kWh system would fit, and calculated how much power that system would generate, based on historic data of sun and weather. I compared those figures with actual-use data available from my power utility over a full 12-month period. I did not include debt retirement, account and delivery charges levied each month — they are a constant now and in the future.

Five scenarios explored

I determined that a professionally installed 11 kWh PV array system would cost about $28,000. I don’t have that kind of cash – I would have to borrow the money. (If I had the cash, I would still

use the same interest rate, as an “investment opportunity lost” factor). I came up with five scenarios.

1. $28,000 borrowed at five per cent, amortized over the 25 year life expectancy of the system.

2. $28,000 borrowed at five per cent, amortized over 10 years.

3. The impact of a 30 per cent installation grant, similar to what Alberta introduced this past August, with a 10 year amortization.

4. The impact of a 30 per cent installation grant and a 25 year amortization.

5. A 38,000 loan to include a $10,000 storage battery for surplus power, with a 25 year amortization.

As the graph shows, given my current low usage of electricity, the PV array would generate more power than my home currently needs, every month of the year. In fact, by the end of the year, I would generate a surplus of 4,315 kWh. In dollar terms, that surplus value is $442 at current rates, not nearly enough to cover my investment and not particularly useful as energy. That's because, under net metering programs across the country, most utilities will not pay or give credit for any surplus, and essentially zero-balance the account after 12 months and start again the next year.

What should I do with my surplus power? Consume more, perhaps. I could leave my lights on, buy an electric pool heater,

switch to an electric water heater, or plug in an electric car. Frankly, none of these options suit my lifestyle.

Since posting my findings on our website in January, I’ve had feedback suggesting that installing a PV array that generates a surplus is ill-advised, that my costs estimates for a system are too low and don’t include taxes, or that my five per cent interest rate assumption is too high. I don’t believe any of these comments would alter my conclusion significantly, however. In four of five scenarios, I lose money, not even including maintenance costs.

Bear in mind my calculations are based on current costs. In order for a PV array on my home to make financial sense, one or more things would have to happen: installation grants would need to be at least 30 per cent, special financing would have to be available, grid electricity prices would have to increase steadily, and the cost of solar arrays and storage battery systems must come down. Some of these are possible, others unlikely.

As it stands today, the financial incentive for achieving full Net Zero Energy status for my home using a PV solar array simply doesn’t look very compelling going forward. Ultimately the decision might come down to the dollar-and-cents value each homeowner puts on environmental concerns. cc

“Hooked for Life”

“Fusion” is defined as “a merging of diverse, distinct, or separate elements into a unified whole.” So it is with Fusion Stone; the coming together of the beauty, strength, and maintenance free characteristics of traditional stone with the ease of installation and affordability of stone veneer.

Fusion Stone is an easy and budget-friendly way to beautifully upgrade a home, inside and out. Fusion Stone is a thin stone veneer that is easily installed with the included stainless steel clips and screws. You just screw it to the wall and it’s “Hooked for Life.”

Available in three distinct systems, all backed by a Lifetime Guarantee, Fusion Stone can be installed on both new and existing wall assemblies in any weather.

As2017 wrapped up and Built Green moved forward with year-end closing procedures, the organization surpassed a milestone of 30,000 single family projects being certified and, including the units in high density projects, the total was over 33,830. Though the organization has three programs—single family, renovations, and high density—a focus on single family projects is warranted given this remains Built Green’s flagship program and is where Built Green started. With this milestone, the cumulative impact of these single family certified homes translates into more than half a million (505,917.52) tonnes of greenhouse gas (GHG) emissions saved*.

Built Green’s programs take a holistic approach to sustainable building and include energy efficiency through Natural Resources Canada’s EnerGuide Rating System, the preservation of natural resources, pollution reduction, ventilation and air quality, and improvements to home durability. Though the impact of these programs encompasses more than energy efficiency, the GHG emissions is a metric that can be quantified.

“Given this milestone, we want to turn our attention to those builders who were with us from the beginning and have remained active. These builders, and the many others that have come since, represent the best of what Canada’s residential building industry is—people that embrace change and progress,” says chief executive officer Jenifer Christenson. “To us, they’re mavericks: those who are forward-thinking and were the earliest adopters of sustainability ahead of

BUILT GREEN HAS CERTIFIED OVER 33,830 UNITS, REPRESENTING MORE THAN HALF A MILLION TONNES OF GREENHOUSE GAS EMISSIONS SAVED."

regulation, driving innovation and an industry forward.”

It started with Jay Westman, a visionary who brought Built Green to Canada, where a group of key stakeholders adapted the program for the Canadian climate. Today, Jayman BUILT remains firmly committed to sustainable building as they continue to innovate.

“Looking back, we recognized there was a sea of change coming in the building industry’s growing size and sophistication,” says Jay Westman, chairman and CEO, Jayman BUILT. “By driving sustainable building forward through Built Green’s programs, we have contributed to changing an entire industry, which started with leadership as a company.”

Soon after, other builders joined Built Green, pushing for advanced building technologies. These include: Agius Builders Ltd., Città Group, Encore Master Builder Inc., Excel Homes, Genco Construction Ltd., Homes by Us Ltd., Landmark Homes, Limona Construction Ltd., Monarch Homes Inc., Pheasant Hill Homes Ltd., RDC Fine Homes, Sterling Homes Ltd., Verity Construction Ltd., and the Canadian Home Builders’ Association Calgary Region (now BILD Calgary Region), who opened up their office to help incubate Built Green at no cost. Over the years, the number of

builders participating has continued to grow as the demand for sustainable builds increases, driven by home buyers, industry members, and all orders of government.

Looking ahead, 2018 marks Built Green Canada’s 15th year in operation. To commemorate this and shine a light on those building more sustainably in the residential building sector, Built Green will be launching an online awards program in the coming months. The awards will complement existing award programs and will focus on advanced building technologies and innovations that are contributing to the home building industry.

Built Green Canada is an industrydriven, national non-profit organization committed to working with builders interested in responsible sustainability practices in the residential building sector. Since its inception, Built Green has worked with builders to certify their homes in Alberta, British Columbia, Saskatchewan, and in Ontario where the programs are referred to as “Green Seal.” cc

*These GHG calculations are based on the difference in energy performance between an average BUILT GREEN home and an average industry home of that same year, based on Natural Resource Canada’s HOT2000 software under the assumption of a 1,700 square foot house.

A pair of drywall contractors from Sudbury, Ontario have taken the social media world by storm – at least in our industry. Their Instagram page (@drywallnation) now has over 135,000 Instagram followers – with thousands more joining every week. We interviewed NICK AITCHISON and BRIAN KITCHIN to see how they built their online reputation.

Fiveyears ago, Sudbury, Ontario boys Brian Kitchin and Nick Aitchison were enjoying as much fame as any other topquality drywall and taping firm in North America. In other words, no fame at all.

Yes, they were already differentiating themselves from their competitors by their wide range of custom drywall finishes. Drywall Nation excels at mouldings and niches, dome and coffered ceilings, Venetian plaster and more. But not many people knew about them until they started posting videos and pictures on Instagram just four years ago.

Brian had gotten into the drywall business at 16 when a neighbour who was a drywaller offered him a job. Brian eventually went elsewhere, but the same neighbour hired Nick, who had been exposed to the trades through his builder dad. Brian and Nick first teamed up together as drywall partners eight years ago, about the exact same time that Instagram was launched (2010). The partners launched Drywall Nation in 2014. Here’s how they describe their social media journey…

When did you figure out there was a business opportunity on Instagram?

Nick: Well when it was relatively new, Instagram didn’t have the same business potential it does today. At the time, no one was posting about the drywall business. We just thought it would be a cool way to say, “This is what we did today.”

Brian: We were in that weird transitioning period when Facebook and Instagram were taking off. Instead of going to a web page and logging in, with social media people were already logged

in on their phones. So we shifted our focus from our website to Instagram, Facebook and YouTube.

Like everything else online, you’ve got followers all over the world. We see you get comments from India, New Zealand, South Africa…

Nick: Exactly! People don’t even think we’re Canadian. They’re blown away when they find out we’re from a small town in Northern Ontario!

You have a tagline that says you aren’t sponsored, so you can tell the truth.

Nick: We get endless stuff sent to us from all kinds of manufacturers but we don’t have any actual sponsorship arrangements.

Brian: We will charge for video production. But we’re not getting paid to say, “This is a good tool.” We are not paid to pump their tools. We are trying to do professional grade videos to differentiate ourselves from the competition.

You’re biggest on Instagram, but Facebook is obviously important to you, too. What’s the main difference between the two audiences?

Brian: With Instagram, you have a younger generation that is more eager to learn. They are more receptive to new methods. Facebook is an older generation. We like to joke that Facebook has a lot of retired, grumpy drywallers that like to knock everything. It doesn’t matter what you’re doing, you’re doing it

Driven by an unwavering commitment to quality, innovation and precision - Stanley® FATMAX® has established itself as the icon for industry leading tape measures. The next generation of the FATMAX® tape combines rugged construction with innovative features, such as 13’ of straighter standout*, MaxShield™ Blade coating - the longest lasting blade coating ever applied to a FATMAX® tape measure and its patented Twin-Core™ Spring Technology allows for a more compact, comfortable FATMAX® while still retaining the FATMAX® reputation for toughness and durability. More than just a tape measure - It’s a FATMAX®

wrong (laughs). You’re not as good as them. You know, cordless drywall guns are shit, you need a corded gun (laughs). That type of thing. So, yeah, Facebook is hilarious. We were thinking of doing a segment like Jimmy Kimmel’s “Mean Tweets” where we read out mean comments from grumpy drywallers. I mean we get some really hateful comments! But Facebook is still good for us, and we have a pretty strong following there.

It’s not that easy to make money on Instagram, right?

Nick: Well you’re not going to make a dime unless you’re a “somebody” on Instagram. But now that we have a following, we can show manufacturers that we can reach x-number of million people. We can expose them to a lot more people than, say, a magazine ad. (Editor’s Note: Don’t listen to him!)

Brian: The challenge in making money on Facebook and Instagram is that they’re both owned by Mark Zuckerberg - and that (expletive deleted) likes to keep all the advertising revenue for himself! But, yes, as long as you own your own content, you can make revenues off of it on YouTube. But you can get ripped off there, too. Let me give you an example. We had some success after filming our first drywall art sculpture video with Bernie Mitchell. When we filmed our second one, it went viral. We were featured on the cover of the San Francisco Globe, we were on Fox News, we were on BuzzFeed and theCHIVE. That video circulated for months and months. But we got ripped off. It got re-edited and posted on Facebook, where it ended up getting over 200 million views. If those 200 million views were on YouTube, where you can average $5,000 for one million views, we would have been sitting pretty good. I wouldn’t be surprised if it got over a billion views total. But it was getting ripped off left and right. Some people gave us the credit, others didn’t.

Drywall is a notoriously tough trade physically. Are the new power tools making it less tough?

Nick: They make it less physical, but it’s a different kind of physical. So if you look at Festool’s PLANEX (drywall sanding system with dust extraction) it’s great. However, it’s relatively new. And like we said, some drywall finishers are so stuck in their ways with pole sanders. Their grandpa did it this way, and he showed their dad, and their dad taught them. So obviously a pole sander has to be the “right” way. With new tools like the PLANEX, sometimes they think they’re going to make a mess of it, plus it costs x-amount of dollars.

What’s the biggest challenge drywallers and tapers face?

Nick: There isn’t much money in it unless you’re the kind of guy

WITH INSTAGRAM, YOU HAVE A YOUNGER GENERATION THAT IS EAGER TO LEARN BUT FACEBOOK IS AN OLDER GENERATION. WE LIKE TO JOKE THAT FACEBOOK HAS A LOT OF RETIRED, GRUMPY DRYWALLERS THAT LIKE TO KNOCK EVERYTHING.”

Comparedtostandardshingles,SureNailTechnology® sedivorpuoyhtiwehtdnob,htgnertsdnaelbuod ehtnommocdnobehtlian.aerahtiWliaNeruS,®ygolonhceT

strengthanddurabilityarebuiltintoeveryTruDefinition®Duration® seireS.elgnihsehT®liaNeruS,pirtsadereenigne-hguotnevow

fabricstripinthenailingarea,providesaneasy-to-seetarget nailingareaforafast,reliable,qualityinstallation.Theheritageof ®gninroCdnarbsnaemuoynacerushtiwliaNeruS ehtsnewO Technology®.Seethestrip,trustthegrip.

WE WANTED TO CREATE SOMEWHERE WHERE DRYWALLERS AND TAPERS

COULD GET TOGETHER AND SHOWCASE THEIR WORK ON A DAILY BASIS. BECAUSE A LOT

OF PEOPLE THINK IT’S JUST DRYWALL AND TAPE AND THEY DON’T THINK TWICE ABOUT IT. WE WANTED TO HAVE A PLACE WHERE PEOPLE COULD SAY: “THAT’S COOL. I DIDN’T KNOW THAT MACHINE EXISTED,” OR “SO THAT’S HOW THEY DO THAT.”

who wants to go out there and make yourself a success. So you have a lot of guys who work all day just to have enough money to buy beer at night and do it again tomorrow. It’s a rough and dirty trade. Brian: Yes, it’s a very undervalued and overworked and underpaid trade. You’ve got electricians and plumbers charging a premium but you’ve got drywallers charging $25 an hour. Or they have a hard time getting even that. Now, I don’t want to get too much into rates because it depends where you are working. But regardless, in North America there’s a lot of people willing to do drywall. You don’t need a college education, you don’t need a degree or a ticket. So there are a lot of guys becoming drywallers just because they can. And a small percentage of them can give the trade a bad name. There aren’t enough professional drywallers out there. We would like to see that change.

A couple of years ago, we were invited to the international drywall contractor awards in Prague, sponsored by the parent company of CertainTeed Gypsum. They really try to lift the bar for drywall professionalism at that event.

Nick: Well, that’s what we have been trying to do right from the beginning, too. We ourselves help sponsor the TrimTex Drywall Artist Contest and are going to finals later this year in Chicago. With Drywall Nation, we wanted to create somewhere where drywallers and tapers could get together and showcase their work on daily basis. Because a lot of people think it’s just drywall and tape and they don’t think twice about it. We wanted to have a place where people could say: “That’s cool. I didn’t know that machine existed,” or “So that’s how they do that.”

Brian: I think we’ve achieved what we set out to do, which was to make drywall great again (laughs). And we’ve seen that constantly in the comments on our videos. A lot of guys have said things like, “Oh man, I used to do drywall but I hated it. But seeing you guys made me want to get back into it.” So I think we’ve breathed a little more life into it. It’s not exactly a dying trade, but it’s a trade that is severely undervalued, overworked and underpaid. Our ultimate goal is to help people in the drywall trade to be proud of what they do. So they can truly state that they are in this business out of choice. cc

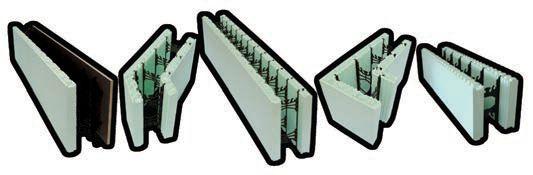

PATENTED MECHANICALLY FASTENED SYSTEM

Spring is the perfect time of the year for contractors to review how they are managing their business’s finances. Here are some tips.

By Mahyar K. Hansotia, President of Sobel

and Company, Professional Corporation

The bane of any business can be ensuring that invoices get paid, on time. Clearly establish your terms at the outset of a job, and always check the customer’s credit before accepting work. Invoicing promptly is very important but many contractors find it challenging. Fortunately, there are plenty of invoicing software options available for contractors that can automate the process, keep track of receivables and quickly contact customers with a reminder. For large or lengthy jobs, request a deposit from the customer and issue interim bills at agreed upon timelines as the project progresses. You may want to consider offering a discount as an incentive for early payment. Many payment terms are still 30 days but given today’s digital banking environment, credit card or e-transfers allow for faster collections and can ease cash-flow issues.

Many contracting businesses have larger clients. Often times, these clients will only pay when the cash flow situation suits them, leaving you in a difficult situation as you also have expenses that need to be covered. Because these clients are large, they may constitute a big component of your overall revenue and you don’t really have a choice of walking away. If you find yourself in this situation, consider selling your accounts receivable (also referred to as factoring in accounting terms). Alternatively, you can get a line of credit secured by your accounts receivable.

Gaps in inventory create inefficiencies for everyone, and it can also result in lost revenue, especially for smaller renovators and homebuilders. Contractors tend to order products at the last minute and keep a minimal amount of materials on hand, but regardless of the size of your business or inventory, a process for tracking – and good communication – is critical. It’s always worth an investment of time to review your supply management system – no matter how basic – and look for efficiencies. It’s also worth leveraging technology, whether using business-specific accounting software or even inventory-tracking apps that can be used on your smartphone. For custom orders, consider requesting

prepayment from the customer for parts and materials needed, as a way to reduce your expenses.

Contractors should be continually monitoring any discretionary costs, including advertising, promotion, office and vehicle expenses, etc. Get several quotes for fixed expense items such as insurance, bonding and maintenance.

Negotiate interest rates and bank service fees and request volume rebates from suppliers. Finance larger equipment or vehicles investments over several years to smooth out payments. How you choose to finance the equipment will also impact cash flow. Consider the tax implications of different financing methods.

Timeliness is always a best practice. Paying preferred suppliers on time will make it more likely they will help you in a pinch if you need a rush delivery or a hard to find item. Try asking for early payment discounts or extended payment terms. When applicable, review contracts to ensure holdbacks are applied. It can be easy to postpone paperwork but it’s never a good idea. Ensure long-term loan payments are made on time to avoid penalties and maintain good credit reputation. File government reports and remit sales taxes and payroll deductions on time to avoid penalties.

Like it or not, maintaining accurate and up-to-date records is critical to your business’s long term health. Retaining a qualified bookkeeper will allow you to do what you do best – focus on the business and income generation side of things. Speak to professional advisors such as an accountant or tax professional to help ensure you follow the necessary accounting and tax rules. The benefits to your business will usually outweigh the cost. cc

Sobel and Company, Professional Corporation is focused on business owners of small- to mid-sized companies, as well as large corporations, who are looking for financial acumen and strategic business expertise over and above traditional chartered professional accountant services.

Dexter Côté, a contractor in Estevan, SK, is the winner of the GRK Deck Contest

By Kim Laudrum

DexterCôté, president of Dexeco Construction Ltd., in Estevan, Sask. says he might have to erect another building on his property to store the $5,000 worth of GRK deck fasteners and the brand new Paslode nailer he just won.

Côté is the winner of Canadian Contractor’s “Show Us Your Deck Contest.” Dexeco is a contractor with a diversified client base. They do everything from bathroom tiling for homeowners to erecting pole buildings for both farmers and oilfields barons in Southwestern Manitoba and Southeastern Saskatchewan.

Dexter’s father Eldon Côté and his uncle ran a construction company from the late 1970s until early 2000s. Dexter worked for them as a carpenter. When things slowed down Eldon stopped his business and semi-retired. By 2011, “the demand was back,” says Dexter, who with his father started Dexeco Construction Ltd.

mainly to erect self-framing buildings in the oilfields.

“When I started in 2011, things were really good in the oil industry. Oil was $100 or $90 a barrel back then,” Dexter said. “Yet when the downturn came in 2015 and 2016, I was able to keep going no problem because my company was diversified. Now actually things are starting to pick up again.”

“I don’t just use GRK fasteners for decks. They are great for everything,” Côté said. “I use the RSS (rugged structural screws) screws when I’m putting rafters on a roof. For example, on a top plate on a wall, normally you would use a spike to nail the rafter to the gusset to hold it until you’ve got your hurricane straps on. But I use an RSS to screw that into the rafter through the top plate and into the roof. And then it doesn’t go anywhere. Pretty well every job where I use wood, I use those screws.”

The weather on the Prairies obviously affects how decks are built. “We get a lot of snow load on the decks out here. It’s important to structure your deck. I’ve seen guys just try to use regular screws to hold the deck up against the side of the house. That is not up to code. I usually use RSS screws in 5/16-inch diameter. Those work great. “

Côté points out the GRK structural screws are also useful for when you are building a beam to support the end of your deck. “If I’m making a three-ply beam to hold up a deck, I use those structure screws and laminate the beam together instead of using an air nailer and pounding nails through it. I want to be sure the beam will never come apart—ever. We’ve got a lot of snow and rain out here and you want to try to keep that beam real tight so no moisture gets inside there,” he said.

Why? “Because when you drill in the composite board if you use regular composite screws you’ll drill in and sometimes the fascia board will pop off or it won’t suck tight. Ever since I’ve been using the GRK composite screws they’ll suck that composite board tight. They’ve got that patented head on the screw that sucks it in, and you never have a problem.”

“I have an apprentice working with me right now,” Côté says. Dexeco has three employees, plus Eldon. “I tell my apprentice, the more you can learn the busier you can be. What you must learn is that you have to do it right. Learn how to do many things well and you’ll never not have a paycheck or a job.”

Dexter Côté built a 5,000 sq.-ft. home on his property between Lampman, the small town where he grew up, and Estevan. Why such a large home? In June 2016 his family home, where his parents were still living, burnt to the ground. He built the large home just after that to bring his parents to live with him. He also joined the volunteer fire department. The local fire chief, who inspected Dexter’s new home, noted it was built over code. Acutely aware of fire and building codes since his family’s disaster, Dexter installed a steel wall down the middle of the new house from floor to sheathing on the roof with two layers of fireproofing.

For composite decking, Côté likes the GRK composite screws.

Next door to the house is where he plans to build a second storage facility to store his new fasteners, among other things. cc

Harold

By Joseph Hough

Asgovernments around the world encourage energyefficient concepts as part of the global effort to lower carbon consumption, it’s not surprising that the Passive House concept is receiving increased media attention. However, the Passive House concept is not new. In fact, the idea goes back more than 30 years.

Credit is often given to Europe as the birthplace of the Passive House concept. It’s true that the idea came forward in 1990 as energy-efficient building laws were emerging in Europe. However, many years before, Canada had made significant contributions to home energy-efficiency research, specifically the Saskatchewan Conservation House built in Regina in 1977 with enormous contributions made by Harold Orr of Saskatoon.

Orr’s research, some stretching back to his student years at the University of Saskatchewan, has had a major impact on the Passive House movement, establishing him as a world-renowned energyefficiency pioneer. In recognition of his life’s work, the 86-year old Orr will receive the honours of Member of the Order of Canada in a ceremony later this year.

There are three main criteria for a house to be considered a Passive House. First, the house relies on very low levels of energy for heating and cooling. Second, the house functions on total “primary energy” (heating, hot water and electricity consumption) no more than 60 kWh per square meter annually. And third, the house has air leakage that does not exceed 0.6 air changes per hour. These attributes are achieved primarily through the successful blend of elements such as simple design, tripleglazed windows oriented to the south, simple heat recovery and ventilation (HRV) system, and the elimination of thermal bridging.

Orr has been on the leading edge of the home energy efficiency evolution for decades. In fact, the Passive House concept hinges on four principles Orr identified during his university studies in the early 1960’s that have allowed the concept of Passive Houses to become a practical reality.

1. Measuring where energy leakages occur in houses.

2. Minimizing the waste of energy.

3. Educating builders on how to build and retrofit houses to an acceptable energy standard.

4. Developing computer modelling software to design energyefficient homes prior to construction.

The critical first stage, measuring air leakage, became the subject of Orr’s master’s thesis. Orr recognized the need for a practical and reliable measurement methodology. Initially, he injected tracer gases such as helium and sulphur hexafluoride into houses. Using gas detectors, he would measure how quickly the air changed in the house as the gases dissipated. Although effective, this method proved impractical for widespread use because of the cost, time and labour involved — tests took nearly a week to perform, and the required equipment would cost millions in today’s dollars.

Working with the Division of Building Research at the National Research Council in Ottawa to develop a more cost- and timeeffective method to measure air leakage led Mr. Orr to develop the first blower door system. Remarkably simple, it was a piece of plywood with a fan mounted in the centre installed in the doorway entrances and a device to measure the airflow through the fan. Using this assembly to pressurize or depressurize an

entire house, a technician could move around the house and locate areas where air was leaking in or out. The result of the measurements determined the air exchange rate, measured in Pascals of pressure.

However, it was world events that triggered the further development of home energy efficiency, specifically the oil crisis of 1973. Searching for ways to dramatically reduce energy consumption, the Saskatchewan government asked the Saskatchewan Research Council to design and build a solar house appropriate for the province’s climate. The Council turned to Dave Eyre, who assembled the project team and asked Harold Orr to join the project committee as a lead engineer in building air leakage. However, the province’s solar heating ambitions were beset with issues of practicality. “We did some preliminary calculations and found that if we were to heat a conventional house with solar energy, it would require an Olympic-sized swimming pool

to store the hot water to heat it, since there is little solar energy to be gained during the cold winter months,” explains Orr. With the government insisting that solar energy be the prime heating source, a building beyond normal convention would be required. Thus, the Saskatchewan Conservation House was conceived.

“When we looked at conventional houses, we identified three major components to heat loss: the insulated portion of the building (windows, walls and ceiling), the basement, and air leakage,” recalls Orr. “Adding insulation alone only reduced the heating needs by about 30 per cent. We had to deal with the other two components: basement and air leakages.” These were handled in a straightforward manner. First, a grade-beam and pile foundation was used, thereby eliminating the basement. Second, given his expertise on air leakage, Orr agreed to personally install the project’s air barrier. The result was an air tightness level that was extraordinarily high for a home anywhere in the world at that time.

While home construction costs were modest for 1977 at

or 1”

By Ben Polley

About 15 years ago, while browsing through the architecture section of an Ottawa used book store, The Well-Tempered House, EnergyEfficient Building for Cold Climates caught my eye. Inside, it touted the presentation of “the state-of-the art, energy-efficient building” — state-of-the-art, that is, at the time of publishing; June 1980. Included were ten pages dedicated to the work of Harold Orr, then of the Natural Research Council of Saskatoon.

Orr has been recognized as a major force behind the successful Saskatchewan Conservation House demonstration project. Tracing this lineage further, Orr can also be viewed as one of the grandfathers of the contemporary and increasingly prominent Passiv Haus (Passive House) design movement that came out of Germany and that had borrowed from his work.

Ben Polley is cofounder, Evolve Builders Group Inc with offices in Guelph, Grey County and Muskoka. Evolve Builders Group Inc is a bespoke builder, designer and consultant for ultra-efficient Passive Houses and natural building methods.

Our firm, Evolve Builders Group, could also be considered one of Orr’s early descendants. We first focused on passive solar principles such as southerly orientation and super-insulation. Then, as our understanding increased, we recognized the critical importance of air tightness, which in turn led us to Passive House principles that capture these strategies and more. In doing so, and by way of Germany, we have returned to the teachings of a brilliant Canadian from Saskatoon who foretold the construction future more than 35 years ago.

approximately $60,000, the solar system added another $65,000. Orr contrasted that substantial additional capital cost with his estimate that heating the home conventionally with natural gas instead would have cost only $25 per year. The lesson learned was that by insulating the windows, walls and ceilings concurrent with insulating (or eliminating) the basement and installing an effective air barrier, the home’s energy consumption could be reduced by 90 per cent! This is the essence of the Passive House concept: homes that require minimal energy for heating or cooling.

The Saskatchewan Conservation House concept, while a

breakthrough in its own right, required further evolution in order to truly change the way home efficiency was viewed — it required education. “We needed to transfer what we had learned with the Saskatchewan Conservation House to existing houses,” says Orr. “We borrowed a house from Canada Mortgage and Housing Corporation and proceeded to retrofit it to achieve the same energy-conserving features of the Saskatchewan Conservation House. We wrapped the house in plastic; we super-insulated the house; we insulated the basement walls and basement floor. This is now what is called a ‘chainsaw retrofit.’ We get a chainsaw and cut all the fancy sprawling around the house; then we wrap the house in plastic.”

Soon after, the Canadian R2000 program was developed, bringing forward a new attainable standard for energy efficiency that would gain consumer and industry recognition. There were hopeful signs of acceptance early on. “In 1980, the Saskatoon House Builder’s Association built 13 houses to a very high level of insulation and tightness,” says Orr. “They were trying to achieve a 75 per cent reduction in energy consumption from traditional construction.”

This in turn ushered the fourth part of Orr’s evolutionary process — the required mathematical tools to assess plans so contractors could understand and achieve their energy efficiency goals prior to construction. Orr took enhancements of computer modelling developed by Dr. Rob Dumont — one that determined the furnace size and another that determined how much passive solar and other free energy might reduce heating cost — to form the basis of a computer modelling program now available free of charge through Natural Resources Canada called HOT2000.

Harold Orr remains active as a consultant and innovator on several on-going energy efficiency initiatives. In conversation, he is quick to point out that while it is wonderful that modern materials and techniques allow the construction of incredibly tight houses, the critical issue of Internal Air Quality (IAQ) must be addressed. As an analogy, he compares automobiles of the 1920’s and their leaky windows that needed no ventilation with the tightly sealed environments in today’s automobiles — no one would ever consider not having an effective ventilation system for the interior space. The same must apply to the new tight homes of today. “Build tight, but ventilate right!” he proclaims. cc

Joseph Hough is an apprentice carpenter in Vancouver with a lifelong interest in engineering, homebuilding and energy-efficiency.

The Golden Mean on a Toronto ravine

By John Bleasby

Rosedale House

Toronto, Ontario

Design: KPMB Architects, Toronto

Contractor: Severn Woods

Construction Inc., Toronto

Exterior photos: Tom Arban Photography

Interior photos: Anna Prior Photography

Construction photos: Severn Woods Construction Inc.

All panelling on the second floor is extruded terracotta, with a band of aluminium facia forming the roof parapet. The vertical fins installed in front of the glass sections are also terracotta, with a rod system running through the centre of each piece, allowing them to be fastened top and bottom.

Aclient’sprofessional background in advanced mathematical principles and personal fascination with the phenomenon known as the Golden Mean became the inspiration for a striking 10,000 sq.-ft. custom home on a ravine edge in central Toronto’s prestigious Rosedale area.

The Golden Mean is the mathematical ratio 1.618 to 1.0 often found in nature that, when used in design work, creates a pleasing, natural-looking composition. In the case of this home, the Golden Mean guided several design aspects — the objective of maintaining 1.618 width-tolength room ratios as closely as possible, for example.

The Golden Mean played a design role in other ways. The building is shaped like a hockey stick, with a pivot angle of 108° between the two wings. “That’s the interior angle of a pentagon,” the home owner explained. “The pentagon itself relates mathematically to the Golden Mean. A building using that 108° angle is de-stressed. There’s a tension in angles, in right angles for example, and there are right angles in this house, of course.

However, the big angle really speaks to you as you walk between the two wings. I believe the pentagon is central to spiritual thinking and the human soul,” he continued. “It might appear to be a big stark, modern house, but it is in fact soft, inviting and warm.” He also explained how the metal privacy screen on the street side of the house is based on the Golden Mean, a computer-generated facsimile of how nature would pack seeds

in, for example, a sunflower or arrange the leaves of an artichoke. “It crops up anywhere Nature is trying to maximize the exposure to the sun of seeds or leaves or other sort of energy gathering. It was a concept known to the Greeks in 500 BC.”

Applying the client’s Golden Mean concept to a home was new to both the architects and the contractor, Severn Woods Construction, making for an interesting dynamic in their three-way

underground garage holds five cars by dropping each one down to the basement from the double garage above, for a total parking capacity of seven cars.

Each window is 11 feet tall and weighs over 550 lbs. A spider crane was used to move each panel off the truck and move it precisely into position.

relationship. However, when building any on the edge of a ravine notes Severn Woods’ president, Tom Cumming, you must focus on issues relating to erosion, stabilization and site drainage.

The client had lived on the site since 1998 in a two and a half story house built in the mid 1930’s. After demolition, a serious water drainage issue arose that needed to be addressed immediately. Roof runoff from the home next door ran through downspouts, flowed across the driveway and emptied into the excavated area being prepared for concrete forming. There was potential for water to fill the hole, destabilize the soil, and possibly collapse the neighbor’s driveway. “We had to do something because we were going to be open for a few weeks,” said Cumming. “I came up with the shotcrete shoring idea. We set anchors and rebar back into the bank under the neighbor’s driveway combined with metal mesh on the side, just like a swimming pool.” Cumming describes

the measure as spending $50,000 to prevent a $100,000 problem.

However, that was only part of the water and soil stabilization issue. The two acre irregular-shaped lot ran down the ravine embankment. Cumming worked with conservation and ravine authorities

to develop plans that would maintain the stability of the ravine lip and control how rainwater from the home and upper lot area would drain to prevent erosion. This included the replacement of hundreds of non-native tree species with native varieties.

Five hot water-heated, forced air furnaces deal with temperature ranges throughout the three storey structure that result from the shape of the house, the amount of glass and the building’s orientation to the sun.

Note the one-inch wide linear grills on the ceiling above the window walls. Each grill is about four feet long, with a dummy grill alongside for visual continuity.

To prevent the neighbor’s drive from collapsing due to rain runoff, rebar was inserted horizontally, in combination with wire mesh, followed by a shotcrete coating.

“We made some changes to the rainwater runoff plan so we wouldn’t destabilize and super-saturate the area in the rear closest to the lip,” said Cumming. “The rainwater drains to the centre of the flat roof sections through a series of scuppers, and down through

internal drainpipes and into a 2,000 gallon cistern, which in turn is used for garden irrigation.” Cumming also obtained permission to bore a 4-inch overflow pipe through the side of the ravine so any excess water would drain further down the hill to prevent erosion at the top.

The living room feature wall of Owen Sound limestone was sandblasted to a rough finish, with an enhancer applied to bring out the colour.

The building structure is a steel frame set on a 13-inch poured concrete foundation wall. Infill framing is 2 x6 Laminate Strand Lumber (LSL) exclusively. “They’re more expensive, but they’re dead true,” said Cumming. Formed concrete structural walls rise above the foundations at opposite ends of the main wing to form first floor end caps — one wall curved and the other block-shaped to house an internal elevator. Spray foam insulates the inside of all external walls and under the roof deck; the exception is the curved exterior wall — it’s sheathed with brick and insulated on the outside.

The monochromatic exterior gains visual elegance from the mixed use of tinted glass panels, formed aluminum, iron spot brick and extruded terracotta.

The owner and his family are delighted with the successful blend of mathematics, design and structure that has influenced their home’s design. “We’re living in a piece of art.” cc

Watch for Canadian Contractor’s upcoming five-part series as publisher Rob Koci investigates the business case for skylights. Rob sits down with the world’s leading manufacturer VELUX for a deep dive on both the darker and lighter side of skylight design, manufacture and installation.

Part 1: But they leak!

Publisher Rob Koci remembers skylight installation as an invitation for callbacks

Release date:

Tuesday, April 3, 2018

Part 2: But they waste energy! Koci says your customer’s gas bills are high enough

Release date:

Tuesday April 10, 2018

Part 3: But it’s complicated! Even when skylights make sense, where do they go?

Release date:

Tuesday April 17, 2018

Part 4: But you can’t make money installing them Show Koci the money

Release date:

Tuesday, April 24, 2018

Part 5: But there’s no training! Actually, there is…

Release date:

Tuesday, May 1, 2018

Get this video series delivered right to your smart phone by going to Canadiancontractor.ca, clicking on “subscribe” and signing up for the Canadian Contractor newsletter. Or go to canadiancontractor.ca at the scheduled release date. You can also subscribe to our YouTube channel. Just search “Canadian Contractor” to find us.

Lastmonth I made videos about four contractors who had been hired to turn around serious renovation disasters left behind by bad contractors. At least one of the bad guys was simply incompetent. Another was a crook that walked off with tens of thousands of dollars of client money without doing any work. Another of the bad guys was a truly spectacular loser. He had squandered hundreds of thousands of dollars on a three quarter million dollar renovation job, forcing the homeowners to refinance their property so they could complete the project properly starting from scratch.

Now, beyond the basic facts of these shameful disasters, I don’t know anything about the bad guys. They’re long gone. But I did get to know – and pretty well –each of the four good guys who were hired to clean up the messes. The qualities they exhibit have something to teach every contractor looking to up their game. First, the good guys were all on the ball. They were simply great to work with. Here I was, bugging these busy men for details about a relatively minor video project, yet they made time for me. My emails were answered, phone calls happened as scheduled, and details got settled in good time. No excuses, just polite results.

RECENTLY I MADE VIDEOS ABOUT FOUR CONTRACTORS WHO HAD BEEN HIRED TO FIX UP THE DISASTERS LEFT BY INCOMPETENT AND CROOKED OPERATORS. INTERESTINGLY, THE FOUR HERO CONTRACTORS – WHO DIDN’T KNOW EACH OTHER – SHARED ALMOST IDENTICAL OPERATING PROCEDURES.

The good guys also understand the value of the digital world. They all have outstanding websites; they make adept use of digital communications; they have an above-average understanding of the power of video as a tool of persuasion. They’ve all invested in professionallydesigned logos. From wall to wall, they’ve built class outfits.

Commitment to proper workflow and documentation is one of the biggest differences between the good guys and the bad guys. All four of the men I dealt with understood that proper projects involve significant paperwork at the beginning and end. Where the bad guys all fired up the tools prematurely, the good guys created scope of work documents, got the jobs properly engineered and reported regularly on their progress. The good guys also collect testimonials and images after the work is

done to boost sales.

The good guys I worked with all have good hearts. When the owner of one company heard that a deadbeat contractor had left construction debris all over the yard of a homeowner before walking out, he dispatched two of his guys to pick up and haul away the trash for free. Another good guy I met spent hours reviewing materials with an owner who has extreme environmental sensitivities. One good guy orchestrated volunteer labor and materials to rebuild the home of a penniless single mother who’d lost an insurance payout to a bad guy.

One reason Canada is a better country to live in than most is because we are a more honest nation than most. International surveys prove it. Being a good guy contractor goes a long way to keeping our country something to be proud of. cc

By Steve Maxwell

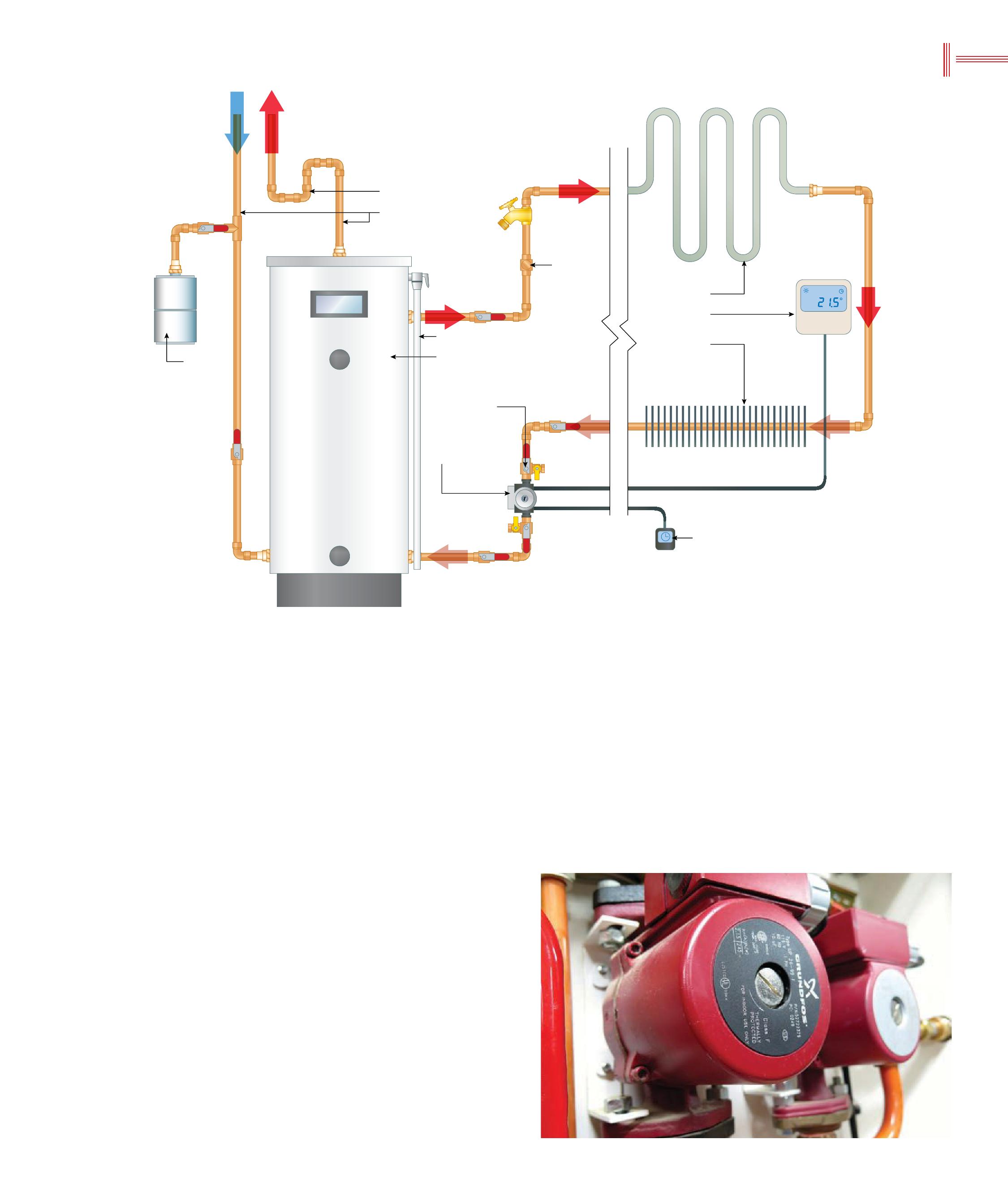

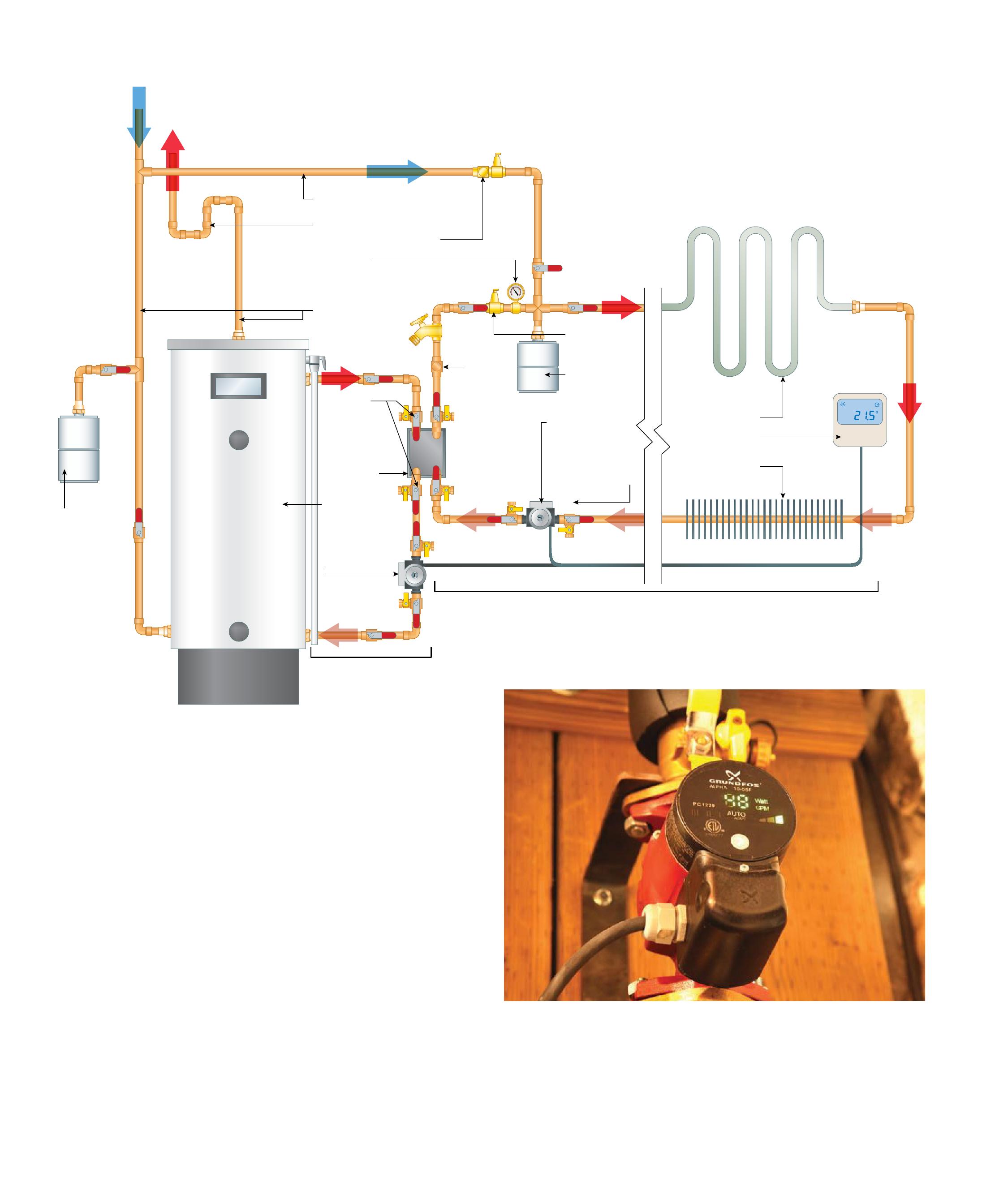

If it feels like more clients are asking you about hot water heating for homes and small commercial buildings, you’re not imagining things. Hydronic heating is comfortable, quiet, steady and doesn’t kick up airborne dust. It also makes people feel warmer at lower room temperatures. These are the reasons hydronics are gaining in popularity. What you might not realize is how tank-style propane and natural gas heaters can be an ideal heat source for every kind of hot water heating system. Simplicity, versatility, costs savings and reliability are the benefits, but you need to get past some unfounded prejudices first.

Traditionally, hot water heating systems have been fired by

some kind of boiler, and there are plenty of HVAC contractors who’ll tell you that tank-style heaters won’t work for heating. “A boiler’s the only way to go,” they say with confidence. The only problem with this opinion is that it’s wrong. The mistaken belief comes from attempts to use light duty water heaters for space heating applications in the past. The thing is, there’s nothing inherently wrong with having a tank of hot water supplying heat to warm a space. The issue comes down to whether or not a particular tank style heater is up to the job. As you’re deciding on heating systems to recommend to clients, understand that some tank-style heaters are perfectly capable of handling space heating situations. In fact, they’re actually the ideal option for several technical reasons. As you look for an HVAC contractor to work on your projects, you’ll need to know how to talk intelligently about the situation if you want the benefits of tank-style heaters for your clients.

Tank-style water heaters aren’t merely “good enough” for space heating, they actually deliver four unique benefits:

Benefit#1

Ideal Water Temperature

Boilers are often designed to put out 180ºF water in order to function properly. That’s way too hot for infloor heating and leads to lessthan-safe radiator temperatures unless you also install a mixing valve to cut back output water temperatures. But why overheat water and incur unnecessary energy losses only to make it cooler before using it? Tank style water heaters, by contrast, are quite happy taking in water of any temperature and putting out 120ºF to 140ºF without the need for a mixing valve. This temperature range is perfect for hydronic space heating.

Benefit#2

Year-Round Usefulness

A tank style water heater can act as a space heater during winter, while also providing domestic hot water year-round without any added equipment. Some boilers can do this too, but not as simply or as maintenance-free as a tank-style heater.

Benefit#3

Simplicity

Maintenance of a tank-style heater is easy enough that most property owners can do it themselves if you choose the kind of heater with the right kind of simple installation. Simply connect a hose to the outlet at the bottom of the tank, then flip a valve to flush the sediment out of the tank once a year. If the system you install includes a flat plate heat exchanger for the space heating side of things (see schematic on opposite page), flushing annually with vinegar is all that needs to happen.

Benefit#4

Compatible With Alternative Energy Sources

Tank-style water heaters are automatically and easily compatible with alternative heat energy technologies such as solar collectors or an outdoor wood boiler. Whatever alternative energy source your client has (or plans to have) it can preheat water before entering the tank, saving natural gas or propane as it does. You can’t do this with boilers.

There are a few different ways to configure a natural gas or propane tank-style heater as part of a hydronic heating system, but a dual-purpose approach for both space heating and domestic hot water makes the most sense. The main thing to understand is that you shouldn’t just allow water from these two systems to mix and leave it at that. One option is to keep domestic hot water completely separate from water that’s part of the heating system using a heat exchanger. The idea here is to prevent domestic water from getting contaminated by stale water that sits uncirculated in the heating system during the off-season. An added bonus of a heat exchanger is better heating system performance. Domestic water supplies usually run at 40 psi to 65 psi and that’s higher than ideal for hydronic heating and circ pumps. This is why the best system designs include a heat exchanger to transfer heat from the domestic hot water to the space heating water, without the two kinds of water mixing. Plate-style exchangers work best in this application, though they do need to be descaled every six months to two years by running vinegar through the exchanger with a transfer pump. This is the same maintenance required by any tankless water heater.

Another alternative is to go without a heat exchanger and install a timer and switch that automatically energizes the circulation pump on the space heating side. By circulating water through the heating system it never gets a chance to go stale. Not all jurisdictions allow this approach, and it means that your circulation pump operates at a higher-than-ideal pressure. But for small systems, an exchanger-free approach makes sense where permissible.

Regardless of your situation and plans, you need to begin by choosing a water heater that’s specifically rated for spacce heating and is large enough to handle the maximum load of both space heating and domestic hot water. Today’s modulating heaters make this decision less critical than it used to be.

Modulation is a heater’s ability to automatically dial in more or less heat output depending on the load demanded. This means your client gets just as much efficiency if they need just a little heat or all that the heater can put out. Operating the heater at lower firing rates also means less thermal stress on the tank and increases the life of the water heater. Old-style non-modulating heaters, by contrast, operated either full blast or not at all, wasting energy when little heat is demanded. Modulating heaters in the 100,000 btu/hr to 150,000 btu/hr range are ideal for wholehouse space heating plus domestic hot water production in most

Canadian situations. The best boast verified efficiencies of more than 90 per cent.

The schematic on page 42 shows an exchanger system I put in using a tank-style, 150,000 btu/hr Polaris water heater from A. O. Smith. This is a modulating unit with an efficiency rating of 95 per cent, two sets of hot and cold outlets, and an exhaust and air intake system that requires only one hole through the house wall. It’s about as easy as it gets to use this model for space heating and domestic hot water. It’s also heavy duty and easily available across Canada.

As you plan an installation, be sure your installer keeps these tips in mind for most reliable operation:

Tip#1: Install circulation pumps at the lowest part of the system. This minimizes the chance trapped air will stop pumping action.

Tip #2: Install circulation pumps so the motor is oriented horizontally. Circ pumps are meant to run this way and will last longer than if the motor is installed vertically.

Tip #3: Install flush valves if you’re using a separate heat exchanger. The question isn’t “if” an exchanger like this will need descaling, but “when.” Even though most of the crud will build up on the domestic side of the exchanger, put flush valves on the heating side of the exchanger, just in case it needs flushing some day.

Tip#4: Choose “smart” circulator pumps. These automatically control current draw and water flow and use about 75 per cent less energy than standard circ pumps. Smart pumps also include

an LED screen so you can monitor flow rate and current draw. Simpler is better, and getting multiple uses from a single appliance is always good. These are the advantages of a tankstyle water heater as part of a space heating installation. Just don’t let anyone tell you water heaters aren’t up to the job. cc

Invented 25 years ago by a guy named Cary Austin, the Cycle Stop makes water well pumps last longer by reducing ON/OFF cycles. In typical systems when water pressure drops below 30 psi, the pressure switch energizes the pump that then delivers water to the tank. As water accumulates in the tank, internal pressure rises to a preset maximum – typically 60 psi – then the pump turns OFF. Back and forth, back and forth like this. By contrast, the Cycle Stop valve maintains a constant 50 psi of water pressure output as long as water is flowing from any fixture. No more on-and-off cycles for your pump, and no more varying water pressure. The pump simply keeps running as long as the water does, delivering a perfectly steady 50 psi. I installed Cycle Stop in a water well system I put into a building in 2014 with no room for anything other than the tiniest pressure tank. The performance has been excellent and there are no electronics or fragile parts to break. Cost $200 US direct from Cary Austin www.cyclestopvalves.com, 800-652-0207.

Recip saw blades are getting way better, and the LENOX Carbide Tip family of blades is a case in point. The carbide cutting teeth are the main reason why. Unlike bi-metal recip saw blades that have been common for years, carbide holds a sharp edge longer and through more heat. The bottom line is a blade that costs less for a given volume of work done, and is easier on your arms because it cuts faster. The assortment of LENOX carbide I’ve been testing include the Demolition CT for nail-embedded wood, but the most impressive were the Laser CT made for thick steel. Every renovation contractor runs into metal thicker than nails from time to time, and this blade is made for it. Where non-carbide blades get soft and useless after they heat up, the Demolition CT blades got hot enough to smoke while I was cutting 1” galvanized steel pipe, yet with no noticeable dulling of the teeth and no tip breakage. The Laser CT blades even turned my recip saw into a surprisingly effective tool for cutting 1/4” x 4” angle iron for a mild steel fabrication project I’m working on. Available at Lowe’s, Fastenal and other industrial supply houses.

Consider pocket hole joinery for fine homebuilding details

Pocket joints offer a simple way of assembling fancy trim and millwork details, and simplicity is a big part of the attraction. The system uses different kinds of drilling jigs to create the allimportant angled holes. Results are instant, surprisingly strong and require no clamps. Special vise grip-type locking pliers hold the faces of adjoining parts in front-to-back alignment as screws draw parts together with surprising force.

Kreg is the company that made pocket screws popular and no one argues that they make the best jigs for drilling pocket holes.

For about $50 you can get their simplest jig package. For twice that you get a model that efficiently handles limited numbers of architectural details on job sites. I use a benchtop pocket hole drilling jig when I’m joining big projects in my shop.

So exactly where do pocket joints make sense for you as a contractor? They’re first-rate for building fireplace mantels, box newels for staircases and other architectural details where one face of the wood is permanently hidden. One of my favourite uses for pocket joints involves stain-grade door and window trim. The

hardest part of creating perfectly tight door and window trim joints has very little to do with cutting wood accurately, and a lot to do with the inaccuracy of the surfaces you’re working on.

Drywall is often uneven enough to throw otherwise tight corner joints out of whack as trim parts come together. Then there’s the perennial problem of window and door frame corners that aren’t quite as square as the joints that come off of your chop saw. All of these problems can be quickly and easily sidestepped by building pre-assembled trim frames, then fastening these frames to wall

surfaces as a single unit. Pocket hole joinery offers the easiest and fastest way to pre-join trim frames and they always stay tight. The trick to success is carefully measuring the size of door and window openings you’re trimming out, then precisely building trim frames to suit.

Faster, easier and more efficient options for successful building are everywhere in the contracting world. Pocket joinery may not be as flashy as other innovations, but it makes a bigger difference than meets the eye. cc

By John Bleasby

Buzz Reynolds’ clients fired his company two years ago from a $150,000 renovation job, refused to pay him $25,000 owing, and brought in a replacement contractor to finish the project. They accused Reynolds of being four weeks late with the project, and were angry when he had taken time off during construction for a family vacation even though his trades continued to work on the job. The clients had also hired some of their own trades for related work, but accused Reynolds of failing to supervise their work properly as part of his overall project management responsibilities. To pressure payment, Reynolds planned to put a lien on the house as suggested by an expensive contract lawyer. However, when the clients hinted at an out of court settlement, he withdrew the lien application. Then the clients reneged and it then was too late to issue a lien. After a series of letters back and forth that led nowhere, Reynolds made an offer to accept 50 cents on the dollar, but the clients refused. “I feel I am at war with unreasonable clients. Never in my years in business have I been unable to resolve a payment issue,” Reynolds says. “What do I do now?”

What should Reynolds do now? See the options at right.

In our Jan/Feb issue contest, renovator Chris Norton was partway through an expensive basement project for wealthy clients. All had gone well in terms of payments and change notices. Shortly before completion, the clients ask Norton to renovate the master bath on the third floor. A contract was drawn up, a $5000 deposit paid, and special-order tiles purchased to the wife’s specifications. But one week later, they cancelled and asked for their deposit back. What should Norton do?

Taking the high road was the advice suggested by almost every respondent. As annoying as it was to have a contract cancelled after custom material had been ordered, most pointed out that Norton’s relationship with the clients had been very professional to this point, and that they might be influential among their wealthy friends — important for repeat business. Smiling and moving on, trying to sell the tile on-line, storing it, or exploring the possibility of a restocking charge was the advice offered.

Our panel of experts also agreed with those who felt that antagonizing the clients by attempting to convince them to pay for the tiles would only jeopardize the on-going and future relationship. The response that best captured all of the issues involved was submitted by Eric Elford of Habidex Renovations in New Westminster, B.C.

Congratulations, Eric! You will receive a DeWalt 20V LED Tripod Light with a 6.0 Ah battery and charger kit, which has a suggested retail price of $469.

1. Hire a new lawyer and go back to court.

2. Walk away and forget it. After two years, it’s a write off.

3. Deliver three truckloads of gravel to the clients’ driveway when they are away for the weekend.

4. Something else (please explain).