Mission Statements Of Canada’s

Top Contractors page 32

Laneway

Housing Arrives In Saskatoon page 24

Box Newel Staircases

The Steve Maxwell Way page 41

Mission Statements Of Canada’s

Top Contractors page 32

Housing Arrives In Saskatoon page 24

Box Newel Staircases

The Steve Maxwell Way page 41

Montreal pro Neil Damackine on Quebec's unique business environment Page 18

Roof Pros know it takes every advantage to be successful. That’s why so many choose IKO Cambridge® or Dynasty® shingles. They’re loaded with advantages that can help improve your bottom line. They go farther with fewer shingles than most competitors’ comparable products thanks to IKO’s True Square, which means three bundles equal 100 sq. ft. of coverage. And with a multitude of colours and our complete PRO4 accessory system, IKO has the tools you need to win more sales. So see for yourself why IKO isn’t just roofing, it’s roofing elevated. To learn more call 1-855-IKO-ROOF (1-855-456-7663) or visit roofingelevated.com

COVER STORY

Canadien Contractor 18

Neil Damackine, founder of Montreal's Construction ND, talks about life as a designbuild contractor in Quebec.

Creative Eye 24

Three years ago, the city of Saskatoon approved the “laneway house” concept. Here is a photo essay of the first type built.

Mission Control 32

Does your business have a mission statement? You may not think you need one. Reading this article could change your mind.

Editorials 8

Rob and Steve talk about responsibilities and expectations.

Voices 10

The best of the recent online comments at www.canadiancontractor.ca, the most outspoken forum in our industry.

Site Notes 14

HomeStars purchased by HomeAdvisor; Drywall tariff update; Transitioning to the design-build model.

Interiors 30

An interview with John Burke, the new owner of Pro Painter magazine.

Steve Maxwell 39

Stuff Steve likes, including box newell railings and new products.

What Would You Do? 46

Send us your solutions to this month’s contractor dilemma and you could win a cool tool from DeWalt.

Volume 18, Number 2 March/April 2017 canadiancontractor.ca | Tel: 416 442 5600 80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published six times a year by Annex

PUBLICATION MAIL AGREEMENT #40065710

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, Alec Caldwell, Mike Draper, Steve Maxwell

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator

Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbizmedia.com

Rob Borthistle of Selkirk Home Hardware Building Centre knows that contractors don’t have time to waste. “Getting materials to the job site when you say you’re going to get it there is key,” he adds. Kyle Kenyon, a former employee of Rob’s who is now the owner/operator of Kenyon Construction, agrees. Selkirk HHBC supplied everything from drywall and lumber to roofing for a recent build of his.

Constant traffic and powerlines made job site deliveries particularly tricky, “but they were able to do it and get it to us on time,” Kyle says. Every Home Building Centre and Home Hardware Building Centre Owner knows that service is about more than dedicated sales staff or ease of ordering. “We treat our customers the way we’d want to be treated by our suppliers,” says Borthistle – something Kyle Kenyon knows better than anyone else.

pronews.ca

Learn to draw lines in both contract and communications. ”

Rob Koci Publisher rkoci@canadiancontractor.ca

By Rob Koci

A friend of mine was having a $300,000 reno done. He was apparently having a bad day. He texted me for urgent advice.

A raccoon had crawled into his neighbour’s attic and died. No big deal, right? Advise the neighbour to have it removed. Connect them with someone who can do this. What is the problem?

Well, the problem was that my friend was being blamed for the stench. His row house had been gutted, with the back wall completely removed and open to the world. That cavity was the entry point for the raccoon. And, when it was sealed up, its tomb.

Not only was my friend annoying his neighbour with all the dust and debris from the reno, he was now a raccoon murderer. West End Torontonians would throw themselves in front of a bus to save an animal. My friend was now a despised man.

So was the smelly carcass his fault or the fault of his contractor, my friend asked me. Who should pay for the removal and clean up?

I was reminded of a reno client I had in the early 90’s. She was widowed, single and a little infirm. After the first three weeks there, I was walking her dog, watering her lawn and feeding the cat. Halfway through, I was more worried about the health of the animals than the work we were doing. But, you know, you want to be helpful and keep the client happy, right? I was dead wrong, of course. I should have politely declined to be a pet-sitter.

But my friend’s festering problem was different. The hoarding around the house was badly installed, the tarp hanging loosely off the roof utterly inadequate to keep man or beast out. The tragic raccoon death could have been avoided with a modest effort to enclose the site properly. It was the contractor’s fault.

At my suggestion, my friend insisted the contractor pay for the removal and the contractor agreed. It really was as simple as that. My friend’s renovation continued with better hoarding and site protection. The raccoon was named, blessed, then lowered with solemnity into a funeral dumpster.

The main casualty of not drawing clear lines around your responsibilities is you. The wound you incur will bleed money. There are two places those lines are drawn: in the contract and in your communications. Make sure both are clear, unequivocal and slanted in your favour.

By Steve Payne

“The greatest casualty of not drawing clear lines around your responsibilities is you,” Rob writes across the page. “The wound you incur will bleed money.”

This might be the one time this year where Rob and I agree about something on these pages. Yes, understanding where your responsibilities begin and end (on your worksite, with your employees, towards your family and friends) will help keep you sane.

That especially includes the most difficult boundary-testers of all: your customers. (Well, tied with your kids. But they can’t fire you, usually.)

Rob and I have often chuckled about the phrase, “No good deed goes unpunished.”

When you do significant “favours” for your clients that they aren’t paying for, in extra construction, extra duties on their properties, or extra work of any kind – remember that the warm feeling you get (“I’m such a nice person!”) is an ego-trip your business cannot afford.

The reason for this is that giveaways and freebies – or insanely deeply-discounted services – are rarely understood by clients to be a product of your beautiful, selfless soul. They just assume that you must be making enough money elsewhere to do this extra stuff anyway. Which leads them to the inescapable conclusion that… they DID pay for the extras, after all! So when one of those extras falls short or must be discontinued, they can and will hate you for it. They are entitled, are they not?

I’ve experienced this many times in my work life. And, if you are honest, and not living in a fantasy world, so have you. Your beneficent gifts are met with a warm smile. Then they become standard parts of your responsibilities.

Try not to do free work, or go overboard on extra services, to fill up your own sense of what a swell person you are. Because if you overindulge in freebies to your clients, the health of your business, which feeds your family and your employees, will feel the chill. If it gets sick and dies, neither your clients, nor your workers, nor your family members are going to be singing your praises. Look after everyone better by using your head.

” Going out of business isn't going to do anyone any favours.

”

In our ongoing series of articles on Design/Build business models, John Bleasby is interviewing various contractors who have decided to move beyond simply being a builder of other designers’ or architects’ ideas. See page 16 for John’s latest work on the topic. Here is a recent comment from Waterdown, ON design-builder James Poort.

“A design to quote from, comes with a cost.” I completely agree with this [charging for quotes which require some design work as part of the process]. There is a huge difference between concepts/designs and quoting. When potential clients ask if I provide free quotes, my response is yes. But I immediately make them aware that they need to have something to quote from, and I explain that the design required to quote from comes with a cost. I find this a great way to differentiate the tire kickers from those who are serious about getting a project done.

I’m glad to see Canadian Contractor focus on design build firms. In my experience, a design build firm provides a huge benefit to the client because one firm is involved from concept to completion. This reduces the amount of “communication translation error” – meaning a discussion with the designer can include the constructor, at the same meeting. This helps everyone involved see the intent of the overall project, right from the outset.

Having the designer and constructor work side by side also helps eliminate issues throughout the project. A designer may want to achieve a certain effect that may not be possible due to structural issues (more so in renovations than new builds) and solutions are a lot easier to achieve in the planning stage than after a month or two of construction.

James Poort

In February we ran an online interview with TV contractor Kate Campbell, a “brand ambassador” for DeWalt power tools. Here is a sample of the fan mail (posts) we received.

“She never stops smiling that Julia Roberts smile…”

No question that Kate is the ‘total package.’ Having watched her on various shows over the years not only is she very qualified as a contractor but she is a joy to work with judging by the guys she works with. She never stops smiling that Julia Roberts smile and she laughs a lot. She knows how to handle being a woman working in a guy’s industry. DeWalt was brilliant in signing her up.

Gary Jones

Way back in 2012, we reported that PEX was likely to “soon” become more common than copper pipe in residential applications. As usual, there are different views on PEX versus copper, but the conversation continues online. Here is a pro-PEX viewpoint from a West Coast mechanical contractor.

“Corrosive water in Victoria and Vancouver”

Another large benefit of PEX is that here on the West Coast the water is very corrosive in cities like Victoria and Vancouver. The water suppliers have not seen fit to correct this issue which leads to widespread problems with pinholes in copper pipe as well as excess copper levels that create green staining and also leach-out from brass valves and devices. Using PEX can reduce the amount of copper in drinking water and also avoid pin holes down the road – which can cost big money for repairs and remediation.”

Wolfgang Scheuer

Contractors always complain – as they should – about municipal development fee hikes for servicing new lots. But it does seem as if, over the last two years, these fees have been going up by incredible amounts in certain jurisdictions. Here is a post on the topic from a Toronto area reader.

Great issue to address! I have been disappointed that my search for “development charges” (or “regulatory burden”) by municipality is a list that I cannot find. I claim that the cause of the alleged “affordable housing” issue stems from two issues: (a) supply-and-demand, and (b) the high cost of regulation. The development side to construction is not properly getting ahead of the issue to advance the concepts that the government has both reduced the amount of development land (i.e., “green space”) while also increasing regulatory burden upon development (to offset municipal operating and capital costs).

Andrew Sefton

The folks who promote the Red Seal program (the Canadian Council of Directors of Apprenticeship) decided almost two years ago to ask Red Seal holders to use “RSE” after their names. It means, simply, Red Seal Endorsement. The following post from an Alberta carpenter urges all Red Seal qualified trades to follow suit…

“Anyone

who argues it is not necessary is not a tradesman…”

A Red Seal should be mandatory in carpentry in Canada. Anyone who argues that it is not necessary is not a tradesman. I have heard numerous arguments that it is not required if you have the experience or time in the trade. This fable is pushed by those not willing to put the time into their craft.

I am still amazed that if I want to cut and style your hair I need to be certified but I can build you a $300,000 home with no licence, no certification, no insurance and no training.

Don’t let those that don’t see the value in training and certification hold you back. The Red Seal shows a commitment to your trade, knowledge and skill. The Red Seal is only the beginning: This is a lifetime of learning and dedication. There are always new materials, new tools, new methods and everchanging building code and municipal by-laws.

If you are intent on finishing your Red Seal and becoming a Certified Journeyman Carpenter you are entering into a trade guild that dates back centuries. Be proud of your accomplishments. Show off your projects, be proud of them and never, ever stop learning and striving to add to your skills and knowledge.

Paul Clement, RSE

This is a post from Kate, the wife of an electrical contractor who has a full-time job in the military. She was responding to a (stupid) post from a homeowner arguing that contractors don’t need to take deposits. But Kate’s letter is most interesting because it fights back against those who argue that military personnel (and police and firefighters and teachers, etc.) always have an “unfair” advantage when they moonlight as contractors. Not so. Some of these men and women are legitimate contractors in every sense of the word.

“My husband does not do ‘side jobs’ ”

I am the spouse of a small electrical contractor. My husband works full time in the Canadian military and is also a licenced, insured, electrical contractor. He does NOT do ‘side jobs.’ Everything he does is above board. This means he pays, as a legitimate contractor, thousands and thousands of dollars each month towards operating expenses. Yes, it’s not cheap to run a legitimate electrical contracting company. He pays as much as a one man, part-time operation as the ‘big guys’ do, only he makes a lot less money.

My husband does this work not only because he enjoys it. He also wants to have a trade to fall back on when he retires or is

released early from the military.

Now, on the question of deposits, If one customer does not pay him, it can ruin him. We have money for cash flow, but as you I’m sure know, copper wire is very expensive, and a simple 50A breaker cost as much as $250 each. I insist my husband receives a 50 per cent deposit if, for example, the parts are $1,000 for a $1,800 job. There is no way I want some unscrupulous person to steal money from my family.

Now for a homeowner or a business to argue that they should not have to pay a deposit, if we don’t have a working relationship established with you, there is no way we are going to do business with you. As a customer, if you are going for the lowest price only, such as hiring electricians to do side jobs without permits, then you should also expect anyone who performs illegal work for you, to possibly rip you off. But if you are dealing with a small, legitimate contractor you have never worked with before, expect to pay a reasonable deposit.

Kate

Alberta is legendary for having less red tape than Ontario and Quebec. A contractor wrote the following post saying this is NOT

DO

If so, you could be a ected by a proposed class action settlement.

The settlement is not an admission of wrongdoing, liability or fault. The settlement relates only to asphalt organic shingles. IKO/Canroof/CRC organic shingles were sold under the following brand names: Chateau, Renaissance XL, Aristocrat, Total, Armour Seal, Superplus, Armour Lock, Royal Victorian, Cathedral XL, Ultralock 25, Armour Plus 20, Armour Tite, Cambridge Ultra Shadow (laminated organic), Crowne 30. IKO/Canroof/CRC organic shingles have not been sold since 2010. The settlement does not relate to berglass shingles (some of which have been sold under the same brand names as organic shingles). The settlement is subject to court approval.

For more information about the settlement (including the proposed method for distributing settlement funds to a ected persons) and your rights in respect of the settlement (including deadlines for acting), visit www.classaction.ca/iko

a good thing. He is critical of certain firms whose names we have deleted since we cannot verify his allegations.

If you don’t like apprenticeship ratios, move to Alberta. Companies like (name withheld) have about five journeymen to about 100 apprentices and no government organization has ever done a thing. I worked at another place that had one journeyman and there were 12 of us that were apprentices, from 1st to 4th. Why it isn’t enforced at ALL here is baffling. It should be one journeyman to three apprentices maximum, not one journeyman to 10-20 because companies like (name withheld) are cheap and would rather fire a 4th year before school and hire another 2nd year and put that second year in charge of a brand new hire or two, and expect journeyman-level work.

Mike Rabbit

Editor Steve Payne did an interview with Reader’s Digest magazine recently, in which the journalist asked him if it was true that a good way for a homeowner to save money on home renovations was to do some of the work themselves – such as demolition (!) and clean up. Steve replied that a good contractor would refuse to allow a homeowner to involve themselves in this way. In this post, Alec Caldwell looks at the legal aspects...

When it comes to homeowners offering to help on a renovation jobsite, to save money, I’ve been warning about this stuff for years. There are two major reasons not to ever let a homeowner “pitch in” when you work for them.

First, if the homeowner “pitches in,” he or she risks being labelled – under the law – the “constructor.” And so your customer can become legally liable if someone gets hurt. Do they really want to be in that position? Ask them! No, they do not!

Second, if the home owner is not considered to be the “constructor” (only the Ministry of Labour/courts will decide), then you are still the “constructor.” And if someone gets injured when an untrained homeowner is “pitching in” on your jobsite then you, not the homeowner, is legally liable for the situation. Because it is your site from a health and safety standpoint, not the owner’s site. Do you want to be in this position? No, you do not.

Determining on whose shoulders the liability lies after an accident, is not fun. Why on earth would you put yourself in such a position?

A constructor (in Ontario) is anyone who undertakes, solely or with employees, all or part of the work on a construction project for an owner… and that includes the owner him/herself. Constructors have the greatest amount of responsibility. They must ensure all regulations are carried out on a project and ensure that the health and safety of any workers on the site is protected. They must also ensure all employees, sub trades or whoever is on the worksite complies with regulations. (In Ontario, see R.S.O. 1990, c. O.1, s.23(2).)

This situation opens up a can of worms and I recommend contractors don’t get involved in this type of set up. If you need to know about the Occupational Health and Safety Act in Ontario and your liabilities, call the Ministry of Labour toll free at 1-877202-0008.

Finally, make sure you comply with the new Ontario Working at Heights regulations. The deadline to comply was March 31 of this year. We at CARAHS offer the course.

Alec Caldwell, CARAHS www.carahs.org

Just to take a break from our readers’ relentless bashing of the Ontario College of Trades (OCOT), here is a post about the Electrical Safety Authority (ESA). (Note that published violations and fines levied by the ESA are often paralleled by the OCOT's own self-congratulatory press releases.) Actually, we think the ESA is a decent organization, but this electrician disagrees.

Has Ontario’s Electrical Safety Authority (ESA) become just another money grab from legitimate contractors trying to follow all the guidelines it puts out? If they require inspections for all non-ACP (ESA’s Authorized Contractor Program) contractors, they should be more available for customers to pinpoint closer inspection times than between “8 and 12” and “12 and 4.” Are they like the cable companies? Also, if we are licenced journeymen, ESA-licenced contractors, should we not have a little more leniency when it comes to inspections for basic installs or remedial tasks? When they have already been permitted? What’s the point of getting your C of Q if you still need inspections for everything you do? I’m just a frustrated contractor fed up with the ESA. Can they stop being like the Gestapo trying to nail you for everything they can find? How about a courtesy call instead of a letter fining you for bullshit?

Jeff O’Brien

By John Bleasby

HomeStars, Canada’s leading online service for connecting homeowners with contractors, was purchased Feb. 9 by Golden, CO-based HomeAdvisor, one of 150 on-line connection companies owned by publicly-traded internet giant IAC. This was just the latest move in IAC’s string of international contractor referral site acquisitions. It previously acquired Germany’s market leader My Hammer, Frances’s Travaux.com, Werkspot of the The Netherlands and Italy’s Instapro.

“The acquisition of HomeStars is the latest move in HomeAdvisor’s larger strategy to replicate the enormous success we’ve seen domestically to other markets - allowing us to build a dominant global business and brand,” said Chris Terrill, CEO of HomeAdvisor. “As digital alternatives increasingly replace word of mouth for home improvement projects, home services are poised to become the next major marketplace, and HomeAdvisor and its family of brands the de facto provider across the world.”

Canadian Contractor spoke with HomeStar’s president Nancy Peterson, who founded the firm in Toronto in 2006, about how the transaction might impact the on-line referral landscape in Canada.

How do you feel about the sale of your company to HomeAdvisor?

It’s a fantastic event in the HomeStars timeline. When I started out, I had visions of conquering North America. But the amount of investment it takes to grow a company from one market to another is absolutely massive. We’ve been growing at a nice clip and we’re still the leader in Canada. However for me, it was a matter of looking around at technology and what is going on in other markets.

help us continue to be as successful as we can be.

Will the HomeStars name remain? Yes.

Why this transaction and why now?

I felt there was a certain point at which we needed a partnership with the right fit, end of story. Technology is changing, and with the state of investment being made, you don’t want to be behind the curve. You have to be ahead of the curve. It was time to take a look at companies that weren’t directly competitive in Canada but who might be looking at Canada as a growth market, and explore which one would be the best fit for us as we moved into the next decade. I was delighted to find a partner in HomeAdvisor dedicated to this space within the service industry. When I looked at all the various options, it was a no-brainer. It’s a phenomenal partnership.

Are you staying on with HomeStars?

I’ll be staying on for the foreseeable future. I’m still young, I’ve got lots of energy, and I really want to see our team learn and grow from HomeAdvisor. They really view us as successful here in Canada and want to

Are there any changes you anticipate occurring in the near term?

It’s business-as-usual for the most part. On the other hand, HomeAdvisor has a team of experts on things like system optimization. We’ll be looking at ways to improve the product for our customers and to improve our traffic. We want to make sure that members who are currently part of the HomeStars community only get more value, and that whatever we do with our product they are absolutely thrilled with.

Will HomeStars remain independent enough to make its own decisions?

I think so, absolutely. The IAC parent company has that track record with other companies in other markets, like Holland, France, and Italy, all running independently with their own brands, their own technology, and their own revenue models. HomeAdvisor is there to make sure they can be the leader in each of these markets and to provide the resources to help that happen. cc

Drywall prices had spiked after ‘anti-dumping’ tariffs as high as 276 per cent were slapped onto US imports last September. Ottawa’s tariff reduction is significant – estimated to be about 32 per cent - but far from the price drop that contractors were hoping for.

By John Bleasby

prices shot up in Western Canada following a Canadian Border Services Agency decision on Sept. 7 to impose import tariffs on American-made drywall coming into the west. Now, after months of hearings by the Canadian International Trade Tribunal, Federal Finance Minister Bill Morneau has announced Ottawa’s compromise solution to reduce the costs of western drywall. Morneau’s statement, delivered on Feb. 27 in front of a new home under construction in fire-ravaged Fort McMurray, contains something to disappoint everyone. It is unlikely that the building industry, consumers or

CertainTeed Gypsum Canada (CTG), the original complainant concerning ‘dumping’ activity, will find total satisfaction.

The Canadian International Trade Tribunal (CITT) spent nearly three months in hearings and deliberations on the issue. While the CITT confirmed that a number of American manufacturers had, indeed, been ‘dumping’ drywall product into the west, the CITT was concerned about regional competition and the adverse effect of extreme tariffs on consumers and builders.

CITT proposed three major recommendations to Finance Canada: (1) An immediate “tariff holiday” of six months, ending in July 2017, to allow a rebalance of pricing and an opportunity for drywall purchasers to recoup losses experienced earlier; (2) A tariff reduction of 43 per cent, across the board; and (3) A program of “temporary reimbursements” to “cooperating importers” whose average dumping duties had decreased in the final determination.

Morneau only addressed the issue of tariff reduction. Even then, the amount of future duties to be imposed on U.S. gypsum board is neither clear nor a fixed number.

David Barnabe of Finance Canada explained to Canadian Contractor that under Canada’s trade remedy system, the amount of duty payable in the future will be the difference between a

“normal value” of gypsum board product established through historical records prior to the ‘dumping’ behavior, and the export price indicated on future invoices when product shipments reach Canada. Importers can avoid anti-dumping duties by pricing goods at or above the ‘normal value.’ However, if exporters resume dropping their export prices below the ‘normal value,’ a tariff will be imposed to compensate.

Finance Canada believes that as a result, the final landed price of imported gypsum board from the U.S. will be reduced by over 32 per cent from the period of provisional tariffs, an attempt “to maintain competitive conditions in the Western Canadian drywall market and reduce potential supply shortages, while ensuring a reasonable return on sales for domestic producers.” However, there can be no guarantee that resellers will pass any savings on to end users.

Morneau made no mention of any “tariff holiday,” as recommended by the CITT. However, programs to aid Fort McMurray’s rebuilding, managed through Western Economic Diversification Canada (WD) will be detailed in July this year, funded by approximately $12 million of the provisional tariffs collected since Sept. 7. Contractors elsewhere in the west impacted by the drywall hikes after signing fixed price contracts will also be compensated out of this fund, but there were no specifics. cc

Once the domain of ‘master builders,’ Design-Build is becoming the norm for a new generation of custom home builders

By John Bleasby

Contractor wrote our first article about the “new trend” to design-build in 2004. It was a cuttingedge concept at the time, but it has now become standard practice for a whole new generation of contractors.

Design-build is, of course, a single-source project delivery process that includes planning, design and construction. It’s a fully integrated service that can differentiate your company in a hyper-competitive marketplace.

Architect- and designer-furnished plans, already in place, are tough for many traditional contractors to accurately bid on. Unable to fully influence the design process means not only competing on price against other contractors, but also being unable to bring particular construction expertise to bear – including possibly costsaving measures.

Transitioning from a build-only to a design-build business model, either through partnerships or in-house investment, requires careful planning. Success depends on the size of your current operation, the capital available to invest in design services, and type of projects your company wishes to undertake in the future.

Canadian Contractor spoke to some of the country’s best-known builder personalities and residential contractors about their approach to the design-build concept. Here are their reponses.

is design-build advantageous for the client?

Paul

Gallop (Men at Work, Toronto):

“Design-build mitigates the issue of clients designing in a vacuum without an eye for costs during the planning stages, and as a result possibly designing something they can’t afford.

There is also the question of the client’s own time management. Presumably these are successful people with careers who work hard and long for their money. They don’t have the time or the skills to pursue multiple parties, deal with multiple contracts, or go searching around for the right people.”

How should a build-only contractor initiate the steps towards developing a designbuild offering?

Kate Campbell: “I would look for people with the same vision, maybe with a bit more imagination. For example, I’ve had designers into the farmhouse we just renovated to show them the way I build and the design vision I like. There needs to be a mutual understanding. By ‘googling’ designers in the area, then looking at their web sites, Facebook or Instagram pages, you can do a lot of research before you even contact anyone. Then it’s just meeting face-to-face and

seeing if you get along in terms of making decisions through a conversation. You can learn a lot about a person in the first five minutes.”

Is a design-build offering always necessary, and if so, when?

Damon Bennett: “My company will always have a design aspect to it. Designers are very important for custom homes and bigger homes. When I bid on a custom home I need design plans, and help with permits and the paperwork which I don’t have time to do. Also, I don’t bid until the design is done and the client confirms what they want. There’s no sense in the contractor doing change after change throughout the bidding process.”

What about bringing design services entirely in-house?

Paul Gallop: “I started with partnerships,

and lots of good came out of that. Some of the advantages are flexibility, not having the burden of overhead, carrying staff and worrying about not having enough work for them. However, there are many disadvantages. It’s much harder to establish control over protocols and systems. It may seem like a big scary step, but my advice is to get your own in-house design personnel before worrying about adding more carpenters. Having your own design staff will help you sell the prospects and get you out of that rut of being a build-only contractor. It’s a safe investment, a good investment, and almost a necessary investment.”

What about charging for design services? Is that feasible?

Paul and Janna Lafrance: “It’s a scary thing to do, saying to a client, ‘We charge for our designs.’ They might say, ‘But I can get a free design from these other people.’ That’s where so many small business owners who are doing design-build will lose so much time, because they’re getting your brains picked for nothing. People will take advantage of you. You have to explain why you charge.”

Kate Campbell: “People will always ask for a design or ask for your opinion. You’re doing yourself a disservice if you don’t charge for those things. By stating upfront, that this is the cost and either take-it or-leave-it, you’re standing up for yourself and giving yourself credit. You are telling them that your skills are worth something.”

Paul Gallop: “We charge for design work at initial stage, published at between $4000 and $8000. They’re going to have to pay that amount of money or more to get any kind of professional design help. We get occasional pushback on that, but not often. In a way it’s self-disqualifying if they aren’t ready to spend that kind of money for initial designs.”

Damon Bennett: “The client often thinks that the designer and the contractor are there at their whim because five hundred thousand dollars is being dangled in front of them. Initial ideas are fine, but if it’s meeting after meeting, you have to charge for your time. I offer a consulting fee. It’s expensive, three hundred dollars an hour. It’s a call we make when we feel we’re being utilized a bit too much for free.” cc

|

“... you guys got this right, the program is awesome SoftPlan is the best and I have used them all.. ” Andrew Bozeman, Montgomery, AL

2018 available now

SoftPlan remodel technologically advanced design software for kitchens | baths | additions | $985

This article was condensed from a multi-part design-build series at CanadianContractor.ca. Type 'design-build' in our search bar to see the four articles. free trial: www.softplan.com or 1-800-248-0164

That word is the same in English and French, but there are many complexities beyond language when it comes to running a residential construction firm in Quebec. Canadian Contractor spoke to Neil Damackine about how he makes his business work in this unique regulatory environment.

By John Bleasby

Montreal is a challenging place to run a residential construction business. Competition is ultra-fierce – as it is in most types of business in this very entrepreneurial province. Plus, Montreal hasn’t seen a residential construction boom in decades. Still, renovation contractor Neil Damackine has found a way to persevere in this complex environment while many others have come and gone. We recently spoke to Neil to learn what it takes to be successful in Quebec, and how he sees the future of his company, Construction ND, unfolding over the next few years.

We assume that language is the biggest challenge you face?

Actually, as far as the overall challenges of operating in Quebec go, language is not a problem. Most people are proficient in both. I’ve been very fortunate that maybe 80 per cent of the people working with me have a working proficiency in both languages. I would say my clientele is very mixed, some who are more comfortable in French, some more so in English, and others who are fluently bilingual and don’t think about which language they’re speaking.

How about marketing?

Are there online marketing using referral sites like HomeStars and TrustedPros?

There’s nothing really comparable that I know of, not exactly. We do have some companies that operate under a different premise that are not referral systems as such. Houzz, for example, is developing a presence and recognition here. Our own online marketing is really a question of keeping people in their comfort zone by showing our information in both languages and keeping it up to date.

Are there any striking differences to the home reno market in Quebec?

People here are extremely hands-on when it comes to working on their homes. They are much more likely to sub out the work and act as their own contractor.

Why is that, do you think?

We are extremely regulated here in Quebec, which tends to drive prices higher, so many homeowners want to hire directly. I’ve seen some nightmare situations as a result. The client is also left open to regulatory fines and refusal of future insurance claims because of missing documentation to back up the work. It’s shortsighted but people continue to do it anyway.

Do you find it problem for you as a fully legitimate

Let me tell you a story. I made a proposal to a customer, a professional with a million dollar home, who wanted a walkout from the basement. My submission was 70 grand. After going over my submission with a fine tooth comb for about two weeks and taking out a whole bunch of things he felt his ‘handyman’ could do, we ended up with only a five thousand dollar contract for some interior finishing. His handyman handled the rest. So, there were guys cutting concrete and paving stones for hours with no masking of the site, while guys walked in and out of the house all day long. The client ended up with asthma flare ups from the cement dust throughout his house, which also completely ruined the hardwood in his new entrance. On top of that, his handyman had been working with plumbing and a number of other things he wasn’t licenced to do. However, the handyman was cheaper than me because he had no licence, no cards, no anything.

How does that market environment impact the way you run your business?

I want to put 100 per cent of everything I do on the books. Why? Because at the end of the day, it’s not only about being

a contributing member of society: it just doesn’t pay to work and hide anything you’re doing. It’s the way I want to do business. I actually sleep better at night knowing no one is breathing down my neck and threatening to throw a bunch of fines at me. As a result, I’m also able to offer legitimate guarantees on all my labour and workmanship.

Tell us more about the regulatory stuff in Quebec. Unions here are about the same as everywhere else. As far as regulators go, licencing, safety and municipal inspectors each have their own mandates. They are concerned about conformity and they’re concerned about the paperwork surrounding that conformity. Infractions usually carry a higher cash penalty than elsewhere in the country. That, together with the labor code, has created a large specialized labor pool in Quebec. That requires a lot more management. For example, a carpenter allowed onto a renovation project may not be allowed onto a home extension project because they don’t have the right paperwork, even if they’re more qualified and proficient. Workers can get fined for doing the same job in different areas of the province. Because of the various regulatory bodies, a worker sweeping the floor on an extension can cost me more than 50 bucks an hour because it’s considered ‘construction.’ Talking to contractors across Canada about tightening administrative and regulatory issues, I’m amazed by the bureaucratic freedom they enjoy compared to me.

Your website indicates a full complement of services including engineers and architects as part of your team.

BECAUSE OF THE VARIOUS REGULATORY BODIES, A WORKER SWEEPING THE FLOOR CAN COST ME MORE THAN 50 BUCKS AN HOUR.

I describe them as ‘our people.’ Most of them have worked with me for a long, long time, either on a project-by-project basis as needed or regularly. Our focus is on renovations, not new-builds. That’s the area with the biggest demand and least amount of competition for the way we operate. We enter that arena as professionals, with insurance, paperwork, licences, and five- to ten-year warranties for certain specialized work. We go after customers who want quality work they can put on the books.

You also differentiate yourself from the competition by offering specialties like asbestos removal and, more recently, specialized protective coatings. There’s more asbestos out there than people imagine, as much in residential as in commercial, in fact. We make sure our workers are certified through appropriate courses that we provide, equipment that conforms to safety requirements, and masks that are certified and FIT tested. Surface protection – like molecular coatings for stone, glass and metal, and anti-graffiti – and decontamination processes for concrete rejuvenation, are other niches that provide us with tools to further penetrate into the renovation market. We also offer protective coatings that reduce the cost of maintaining

commercial vinyl floors by up to 80 per cent.

There’s a new type of contractor coaching that Canadian Contractor has introduced in conjuction with Renovantage. It’s called NextLevel and you were one of the first contractors to sign up. What were your objectives, and have you started seeing results?

My original objective was to become more growth focussed. The process has caused some soul-searching, questioning not only my goals but my true motivations and the roads I’m willing to go to attain them. Being a good contractor is not just about money, although no doubt NextLevel will help me reach measurable gains including wealth. In terms of operational, marketing and HR strategies, I have already had tremendous benefit from NextLevel and have been empowered by the process. Going forward, I want to maintain stable growth with increased efficiency and improved quality control.

I enjoy delegating responsibilities and cultivating an environment where people succeed. I believe creating success for others is one of the finest achievements an owner can have. Construction and renovation offers me that every single day. I see the pride my workers have when they do a job well, and I share every bit of that joy and pride watching them succeed. I also like to see the look on the client’s face when we’ve delivered a project. They’re excited. It’s changed their life, improved their lifestyle, or increased their enjoyment of life. Things like that are the big payouts. cc

Give your customers an endless supply of hot water. Imagine having all the hot water you ever need, ready within seconds. Your customers can get it from a Rinnai Tankless Water Heater. And they’ll save in operational and life cycle costs, use up to 40 percent less energy, and even save space in their home or business. Designed with durable components like high-performance heat exchangers, multiple venting options and the ability to control and monitor with the Rinnai Control-R™ WiFi module, Rinnai Tankless Water Heaters deliver dependable performance in the most demanding environments. To learn more visit rinnai.ca

Contractor: Jeff Nattress, Laneway Suites Ltd.

Designer: Crystal Bueckert,

Bldg Studio Inc.

Text By John Bleasby

Municipalities across the country are being forced to deal with issues of urban density, both to reduce the costly infrastructure associated with green field developments and to meet consumer demand. While infill housing is popular almost everywhere, innovative off-street housing is now coming to the forefront. In 2014, the City of Saskatoon formed an exploratory committee with interested community members and building professionals, which ultimately resulted in new zoning bylaws to allow laneway homes in that city.

Jeff Nattress had his ear to the ground. Only 30 years old at the time, he had wide experience in residential, commercial, and industrial construction, and was familiar with laneway development from his time spent in Melbourne, Australia where it is very popular.

Upon hearing Saskatoon had approved bylaws allowing laneway or garden homes, Nattress was first to apply, using his own North Park area property as a pilot project.

Typical to the neighborhood, the property had a bungalow at the front and garage on the rear laneway. “Along with the approvals came

Continued on next page

Laneway housing was first approved by the City of Saskatoon in 2014. A local engineer who had seen the type in Australia was first off the mark with this spectacular build.

the rules,” says Nattress. “They were quite overwhelming for the average person, but with my background in engineering, I thought I would be able to help people through the process in terms of the engineered plans.”

Nattress had a business plan in mind for the future, but needed to team up with a designer first. He contacted Crystal Bueckert of Bldg Studio Inc., a member of that Saskatoon exploratory committee. “We formed a strategic partnership. I came with sketches on a napkin and she made it look great.” The result was Saskatoon’s first off-street home, the Empress Laneway House, and from that a new company was born, Laneway Suites Ltd..

There were lessons to be learned by everyone during this pilot project. “We were guinea pigs, for sure,” says Nattress. “There was a lot of communication and cooperation between me, Crystal and the city’s development department in terms of water, sewage, and drainage for example. In Saskatoon, you can’t subdivide the property; they can only be built as a secondary residence behind the primary residence.”

Nattress acted as the contractor and brought in some specific ideas concerning how this first laneway home would be constructed. First was the foundation. The new bylaws did not permit basements and Bueckert’s design called for a two-story structure, so Nattress chose to use a series of 20 screw piles as supports for a grade beam. Each pile goes down about 14 feet, torqued into the soil. Nattress found screw piles quick to install, and economical. Most importantly they allowed construction to start in March, when frost was still in the ground.

On top of each screw pile, a cap was welded to the top after installation, a horizontal flat steel plate (6 inches x 6 ½

Continued on next page

Main Photo: SIP panels sit on top of the glulam Douglas fir beams that run the full 32 feet of the home. Flooring in the living space is wood laminate and tiles in the mudroom and bathroom. Hydronic heat is used in all living spaces and the garage below.

Opposite Lower Left: The private lower level entrance and stairway hide the hydronic heat system and water tank inside a small utility room.

Below Left: A series of screw piles are torqued 14 feet deep, each with a welded steel cap and two vertical lengths of rebar, later tied to horizontal lengths that reinforce the grade beam.

Below Centre: With the grade beam poured, the sill plate is ready to accept the SIP panels.

Below Right: SIPs shipped from the factory by truck are quickly assembled with the help of a boom truck.

inches) which had two 15 m pieces of rebar welded vertically to it and inserted into the hollow pile. Once the forms for the 32 inch by eight inch grade beam were placed around the perimeter, horizontal rebar was tied to each pile cap prior to the pour. This resulted in a very sturdy connection.

The other unique element is the construction of the home itself. Structured Insulated Panels (SIPs), prefabricated right down to window and door openings, were shipped on a truck from the manufacturer in Manitoba and assembled on the foundation beam in less than two weeks. “The idea was to make the build as simple as possible,” says Nattress. “Using SIPs saved quite few steps.”

The SIP walls are rated R22, and the roof panels R38. Nattress also points out that since there are no studs in the walls or joists in the roof structure with the SIPs, there are no thermal bridging issues. “It’s a great application for a project like this,” agrees Bueckert. “Plus, there’s no waste, and less disruption for the neighbors because the build is so fast.”

Bueckert designed a two per cent flat roof to meet the 20 foot (6 m) building height limit to maximize living space and avoiding interior slanted walls, netting 760 interior square feet on the upper floor, and 918 square feet on the ground level. The SIPs sit on Douglas fir glulam beams, 5 1/2 inches wide and 12 inches deep, running the 32 foot length of the home. On top of the SIP roof panels is galvanized sheet metal, with a waterproof membrane underneath. Using SIPs was a “no-brainer” according to Bueckert, since no air space is required between the finished ceiling and the roof deck, resulting in a very thin roof profile. cc

Canada’sone and only business magazine for professional painters, Pro Painter, built a loyal readership during its continuous run from 2002 until 2015. In 2016, ownership changes led to a hiatus in distribution. Now the magazine back with a new owner, John Burke, who worked extensively on the publication when it was owned by Dynamic Paint Products.

John, your roots with Pro Painter go back almost to its beginnings. Tell us about that.

I worked with the founder of Pro Painter, James Mumby, from the beginning. James was the owner of Dynamic Paint Products. Dynamic launched the magazine to help painters be more successful in business and to show them new and improved products. We meticulously built up the subscriber list by meeting with painters at pro shows, painters’ lunches and special events. In 2010, I took control of the magazine as VP of marketing for the firm. This role included overseeing all aspects of Pro Painter from advertising sales to editorial direction. Today, as the owner and publisher, my day to day role will continue much as it did.

The magazine took a hiatus following the sale of Dynamic Paint Products to new owners. Why do you think it’s important that Pro Painter resume publishing? Pro Painter is the only truly Canadian magazine focusing on the professional painter in Canada. We believe that the majority of the big painting contractors in Canada are subscribers to the magazine. It has a loyal following that is quite unusual among readers of trade magazines. With such strong support from the subscribers, I felt it was time to get

the magazine back into their hands.

What changes are you going to bring to the magazine?

Aside from a totally redesigned and easy to use website (www. professionalpainter. ca), I don’t plan to change much about the content of the magazine. We will continue to feature a Canadian painter for our cover story, show painters the latest new products and coatings, and generally provide business articles that help our readers to be successul. That being said, we are always looking for feedback from our readers and we will continue to provide the things that they feel are important to their businesses.

The magazine has been around since 2002. How has life changed for paint contractors in Canada since that time? The techniques and tools used by pro painters have really undergone a revolution over the past 15 years. There have been significant changes to paint chemistry, real improvements to rollers and brushes, ladders and scaffolding, and it has been hard for painters to stay on the top of the changes. Painters are too busy painting to attend every trade show and pay attention to every new product. Pro Painter makes it easier for them to stay informed.

Steve Maxwell, who writes for Canadian Contractor, is returning as editor of Pro Painter. Tell us a little bit about Steve. Steve has been with us for about five years now. He is one of Canada’s mostread home improvement journalists. He has been a columnist for the Toronto

Star, Globe and Mail and National Post newspapers, as well as Canadian Contractor, Canadian Home Workshop and Cottage Life magazines, to name a few. Steve is unique in that he actually does his own testing of products prior to writing about them. He then gives an unbiased overview in the article or feature.

You’ve been talking to manufacturers about the relaunch for a while. How excited are they?

The reception has been great! Manufacturers of products for our industry have a difficult time getting their products and stories into the hands of painters. Pro Painter offers them the ability to help painters improve their work quality, productivity and bottom line by introducing the latest products available. We have had wonderful response from our subscribers and advertisers about the relaunch. cc

For more information about Pro Painter magazine, please email John Burke at propaintermagazine@gmail.com.

AVECDESMATÉRIAUX CANADIENSETIMPORTÉS WITHDOMESTIC / IMPORTEDMATERIALS

Consistent, high quality paint is crucial to your success. We understand what it takes to formulate great paint because we are Canada's #1 Canadian owned and Canadian made paint brand. All of our products are developed in our own modern plant and fully equipped lab. Our goal is to produce the best products you can buy. Each batch is tested a minimum of three times through the production process in one of the most modern paint facilities in North America.

Contact your local Home Hardware Store for a list of MPI approved products. Proven Products for Painters!

Painters love us for our spatter resistance! See our selection of proven professional coatings at beauti-tone.ca

Available exclusively at Home Hardware and Building Centre locations.

As a contractor, you may never have created a formal mission statement. After all, you know why you’re a builder, right? Still, many of Canada’s top contractors swear by the power of a written set of values. Here are some examples.

By John Caulfield

At the beginning of 2016, Neil Damackine took some time off to re-examine his 10-year-old company, Montreal-based Construction ND, with an eye toward improving the customer experience. During this sabbatical, Damackine came up with a mission statement whose exact language he had been struggling to articulate for several years.

“I needed a way to transmit, very quickly, what it is we do,” he recalls. Damackine was also looking to convey his company’s “approachability.”

What he arrived at is simplicity itself: “Our business is renovation. Our focus is people.” His inspiration, he acknowledges, came from a speaker he heard during a provincial meeting of Business Networking International. And while he concedes Construction ND’s mission statement isn’t perfect, it succinctly gets the point across that “we’re making an impact on people’s lives every day, so everything we do has to be for the customer.”

Straddling the line between platitude and philosophy, the mission statement has become the business community’s shorthand for distilling what companies are about and aspire to. These statements are often filtered through “core values” that guide companies’ decisions and interactions.

Mission statements vary widely in length, depth, purpose and intellectual rigor. They can be self-serving, high-falutin and unrealistic. Or they can be thoughtful and dynamic. As often as not, they reveal the personality of the owner or CEO, for better or worse.

While some contractors say they do fine without them, many pros see mission statements as essential to their businesses, if for no other reason than to document what homeowners, employees, and business partners should expect from their companies, and vice versa.

“I want the client to fully understand

my mindset,” says Rose Barroso, owner and operations manager for Barroso Homes in Toronto. A good contractor mission statement, she says, “explains the manner in which you build, what you expect the client to see, and what you want the world around you to understand.”

Barroso’s mission statement, which she wrote three years ago, sets the quality bar high: “When you chose Barroso Homes you are guaranteeing quality, comfort and magnificent design,” it says. “For Barroso Homes, a custom luxury home is about the refining of the quality of life by means of modern but yet elegant designs, fine craftsmanship and innovative technology. This is what

brings about true refinement. You will unquestionably appreciate our high standards of quality and attention to detail.”

Richard St. Laurent says his decadeold company, Edmonton-based Peak Improvements, crafted its mission statement in mid 2015, after it had joined Maryland-based contractor training organization Remodelers Advantage. The company’s seven employees and managers all had input into that writing process, and the statement is now part of Peak’s marketing literature and other communications with customers. “It makes us look more professional.”

“Peak Improvements’ experienced and capable team of professionals has been redefining renovations since 2007,” the statement reads.

“Our distinctive six-stage project development and completion process builds client understanding and trust.

Personalized service, constant communication, and our fixation on details painlessly take clients from initial concept to a flawless finished project. We foster excellence while encouraging the personal and professional development of each employee. Peak Improvements is constantly adapting to our changing industry, ensuring client satisfaction, sustainable sales growth, and a fair company profit.”

Gavin Parsons, who owns Parsons Family Homes in Vernon, BC, hasn’t gotten around to writing down his mission statement,

which he says is pretty basic: “We’re in business to keep customers happy.” But as he turns over the running of this 41-year-old company to his son, Taylor, Parsons appreciates the significance of having a value system in place. “You should know why you’re in business, and it can’t just be the money.”

Ben Polley, president of Evolve Builders Group in Guelph, ON, says he formalized his company’s mission statement in 2011, primarily for the purpose of reinforcing Evolve’s intention to pursue the certified Passive House market. He and co-owner Chris Vander Hout composed the original draft, which they then circulated to Evolve’s entire staff for comment and feedback. “The entire team concurred that this resonated with them, and was proud and excited to have our already pursued direction in print,” says Polley.

“Evolve Builders Group values ideals of sustainability and the natural environment,” the statement reads.

A GOOD MISSION STATEMENT EXPLAINS THE MANNER IN WHICH YOU BUILD, WHAT YOU EXPECT THE CLIENT TO SEE, AND WHAT YOU WANT THE WORLD AROUND YOU TO UNDERSTAND.

or aid with professional development or public awareness. Evolve is committed to delivering a positive customer experience by combining these aspirations together with quality craftsmanship that is both on-time and on-budget.”

“Through continuous learning, research, innovation, valued relationships, and professional integrity, Evolve is dedicated to being a leading edge custom green builder, dominant in its field throughout its chosen service area. Evolve focuses effort on projects that explore natural materials, energy efficiency, and human health

Evolve then states its objectives, which include: “To seek work that involves special considerations of any or all of human-health, environmental preference and energy or water efficiency. To secure meaningful, consistent work at market wages and continual improvement learning opportunities for our full time employees. To maintain and strengthen leadership in natural building including but not necessarily limited to straw bale, earthen floors and plasters, clay veneers and cob ovens. To develop on-site capacity and brand awareness in emerging markets: passive certified homes, ’tinyhomes' and additional natural building methods as well as re-locateable portable classrooms.”

Avoid major revisions

The general consensus among pros

is that a mission statement should be sturdy enough to withstand market and competitive vagaries without needing major revisions. And once contractors settle on a mission statement, most are disinclined to make a lot of changes to it.

Fifteen years ago, Steve Barkhouse, president of Amsted Design-Build in Stittsville, ON sequestered his management team in a local hotel for three days of brainstorming to come up with the company’s elaborate vision and mission statements, to which they’ve made only minor tweaks since.

relate specifically how they have applied core values to their jobs. The company also provides each employee with a wallet-size card on which its statements are printed, and posts those statements and objectives in the office and at each jobsite. “We live and breathe our vision, mission, and core values,” Barkhouse says.

continuously provide the foundation and guiding principles for a company’s operations and relationships.

“We will be the most sought-after company in our industry,” the statement declares. “We will be highly respected for integrity, excellence and success. We will provide a work environment that is enjoyable and achieves a balance between work and personal time. Our mission must be to exceed the expectations of our customers, whom we define as clients, partners and fellow employees. We will accomplish this by committing to our shared values and by achieving the highest levels of customer satisfaction. In this way we will ensure that our profit, quality and growth goals are met.” Amsted’s document than lists ten “core values” that the firm will always strive to uphold. They are: integrity, empathy, excellence, progress, teamwork, respect, trust, loyalty, fulfillment and pride. Barkhouse is determined to make sure the company lives by its constitution. The vision, mission and core value statements are read aloud before every company meeting. Then employees are asked to

Michael Fobert’s mission statement for his firm Traditional Styles, Coboconk, ON, speaks entirely to the prospective customer.

“Specializing in turnkey design/ build projects,” it reads, “we are here to guide you through all the stages of construction, from ‘wish list’ to ’house warming!’ There is no such thing as a ‘small’ detail in custom home building - every detail is equally important. Building your dream is a huge and exciting endeavor that works best when there is strong teamwork, excellent communication and a shared goal: your complete satisfaction. Our team of skilled craftsmen and administrators work for you but build as if they were building their own. So whether you have a scribbled design or architect’s blueprints in hand, we’d be happy to meet with you to discuss your vision and how we can help make it a reality.”

Fobert says he has been disseminating this statement “for years – I don’t see any reason to adjust it.” But if he did, he says, he would boil his mission statement down to one word: “Honesty.”

While mission statements may be timeless, the best ones are living documents that

Rococo Homes in Spruce Grove, AB, doesn’t have a mission statement, per se. But its president, Rick Lystang, observes that its objectives in dealing with customers and trade partners revolve around three common denominators: “good work, value for dollars spent, and work meeting or exceeding expected time lines.”

He sees himself as the gatekeeper of those values. “I approve all invoices and make payment to the trades,” he says. “I monitor weekly schedules of my staff through our tracking system and regular construction team meetings, always checking that delays and variances do not happen. I do all the turnover and occupancy inspections with clients to ensure we delivered what we sold them.”

Lystang adds that the values inform his decisions about which homeowners he chooses to work with. “We interview our customers just about as much as they interview us. I have even referred some customers to a better-suited builder for their personality, price or job scope. For us, it’s about quality, not quantity, and this has served us well when it comes to being true to what type of company we are.”

Contractors say one of their bigger challenges is getting employees and installers to abide by their companies’ mission statement. That’s one reason why Parsons is a big proponent of apprenticeships, “so new hires understand exactly what’s expected of them.”

Fobert of Traditional Styles says that he and his managers “recite the importance of integrity to everyone who works for us. We have a lot of subs, and they can make me look like a bum or a rock star. It’s important to reinforce our expectations. And I can’t assume that people’s memories are good; you have to keep reminding them.”

A KIND

Some contractors are more systematic about how they monitor their mission statement’s execution in the field. Peak, for example, has “numerous system checks,” says St. Laurent, that track different milestones for its employees, who have access to a portal whose project software tells them what’s expected on a daily basis. St. Laurent explains that those expectations can include everything from working with a drywall vendor to completing a jobsite inspection.

Alair Homes in Collingwood, ON, uses what its president, Kevin Blair, calls a “sophisticated, proprietary management platform” that measures key performance indicators that are tied to its statement. This feedback system “confirms whether our values and strategic commitments are being met on a continual basis” by its employees and installers, says Blair.

Blair

“it’s built around the business, not the business’s clients.” He prefers an “ultimate strategic position” that “defines our purpose and the reason why our clients become our clients.” Blair’s ultimate strategic position is: “We are in the business of helping individuals and families eliminate the challenges they face in their living environment, to enjoy a happier, healthier and more comfortable lifestyle.”

Alair Homes’ “position” focuses on its commitment to be honest, transparent, accountable, “most respected,” trustworthy, and “pioneering.” Blair insists that its position and values are resilient to competition or changing market conditions. He also notes that his company is quick to remove any trade partner from its preferred list that doesn’t meet its “strict code of standards.”

Nearly all of the contractors interviewed vet their trade partners and customers through the prisms of their mission statements or written vision documents. “We’re trying to establish partnerships that aren’t all about making money,” says St. Laurent.

Evolve Builders’ mission statement is a kind of “litmus test” says Polley, that helps determine which prospects and partners are the best professional fits for his company. “We live our mission every day through selective hiring and selective project acceptance, followed by carefully considered project implementation and the provision of targeted in-house training.”

when the clients aren’t there. Trust is an important word for us.”

When it’s hiring staff or subs, Amsted provides them with a deck of cards showing 52 different values, and asks them to pick their top ten. That way, says Barkhouse, Amsted can gauge whether their personal values align with the company’s corporate values.

Blair thinks the term “mission statement” is antiquated because, he explains,

Having a mission statement in place can also give homeowners clearer insight into a contractor’s quality and reputation. “Ninety nine point nine percent of my business is cost-plus,” says Fobert of Traditional Styles. “Clients need to feel comfortable with us because our crews are often working in their houses

The precise wording of their mission statements notwithstanding, most contractors still prefer having wriggle room to re-steer their business models in changing tides. Barroso, the Toronto area builder, says that when her company began building Smart Homes, she altered her mission statement to include wording about innovative technology. She notes, too, that her electrician of 12 years “had to adjust to working with an Automated Tech trade.”

Damackine of Construction ND says his company is constantly changing, so its mission statement needs to change along with it. He’s thinking of adding another speciality - probably either windows, doors, or roofing - and bring its installation in-house. He is also considering adding a showroom and light manufacturing.

As he refines his mission statement, Damackine says the one thing that’s still missing is “the quality aspect,” which is tricky, he explains, because that sometimes requires extra work and costs. “By doing the best job possible, we’re focusing on the client, even if that hurts a bit.” cc

Efficiency is crucial to your success and profitability.

The patented FUSION STONE clip and screw technology was specifically designed with efficiency in mind. With this easy-to-use, rapid installation system you will complete projects faster and without the complicated, technical know-how of traditional masonry.

Our quality assurance and lifetime guarantee allow you to move quickly and confidently to your next job knowing your customer is satisfied and will stay satisfied.

Firestop Sleeves Page 44 DIABLO

Tracking Point

Saw Blades Page 45

How to build a box newel staircase railing Page 41

By Steve Maxwell

Being a contractor is probably one of the most challenging ways a person can earn a living. Few ordinary people looking in from the outside realize the skills required and risks involved. There’s no builtin pension at the end of it all, and physical danger is always around the corner. So why do you it? Even if no one asks, having the right answer is important, and I think it comes down to one word. Freedom.

Contracting is the economic equivalent of being Indiana Jones. It’s a swashbuckling occupation where you live by your wits and succeed in direct proportion to how smart you work. If you think of some way to become more efficient, to deliver more value and to negotiate better, you pocket the benefits. That’s pretty attractive to a certain kind of person – just the kind of men and women Canada needs more then ever.

Have you ever thought of the parallels between farming and contracting? The day-to-day details are different, but the motivation is similar. It’s that freedom thing again. The ability to call your own shots in a varied, physical and challenging occupation is attractive in ways that few jobs can match. Some of us will put up with a lot to capture the right kind of freedom.

Of course the freedom you enjoy as a contractor is nothing like the freedom of winning the lottery and never having to work again. But in a world where you and I have to work, and given the way the nanny state is extending further and further beyond its legitimate boundaries, life as a contractor is one of the few venues left for people who hate the 9 to 5. Being a contractor means being something of a rebel.

Understanding why you do something is often the necessary foundation for the satisfaction you feel doing it. As a contractor you will have bad days. Sometimes many in a row. You might even seriously regret your career choice from time to time. But in the end, could stepping into someone else’s corporate dream ever really compare to the freedom of being a contractor?

steve@stevemaxwell.ca

By Steve Maxwell

If you enjoy craftsmanship, consider box newel railings. They’re a classic detail and the right kind of client will love you for suggesting them. I designed and built my first box newel staircase in 2009, and it’s still rock solid. That’s one of the practical benefits of the box newel approach. It makes for very solid results because the box newels have such a wide stance on the floor. Besides, newels like these look gorgeous.

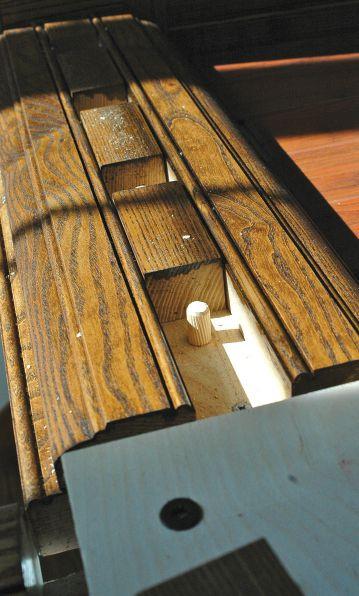

The newels I build are hollow and made of four separate stile and rail frames each. A plywood panel covered with shopcut 1/4”-thick “veneer” fastens to the back of each frame, with completed newels anchoring to a 4 1/2”-thick Baltic birch ply anchor block fastened to the floor. Spindles are shop-cut 1 3/4” x 1 3/4” hardwood with chamfered edges, and pyramid newel caps go on after bolting the ends of the hand railings from inside.

Here’s a closeup view of how I make it all happen.

Building Newel Frames & Panels: If you’re starting with rough lumber, as I normally do, cut each stile and rail 1/2” to 1” longer and 1/4” to 1/2” wider than necessary, then joint, plane and saw all components to finished dimensions. Finished stiles are 1 3/4” wide and rails are usually 3” wide in my design. All parts need to have absolutely square edges and ends. I use pocket screws to join the stiles and rails into open frames – one frame for each side of each newel box with an outer dimension of 8”x 8”.

Cutting Panel Edges: Rip the edges of newel panels to 45°, glue them to the inside face of all newel frames. Join all four frames of each newel into a single unit using glue, screws and clamps to secure butt joints.

Shop-Cut Bookmatched Veneer: I make newel panels from 1/2” Baltic birch ply with 1/4”thick shop cut “veneer” glued to one face. This allows me to create my own bookmatched grain patterns on the face of each newel. Use factory veneered ply if you’re lazy, but you can’t beat shop cut for looks.

Shop-Cut Bookmatched Veneer: Screws are best driven into predrilled holes along the inside edges of the stiles to join newel frames into a box. I complete my newels with 5/8” x 5/8” Roman ogee trim on inside edges of the frames.

Handrail, Shoe Rail and Spindles: You can buy hand rail if you prefer not to mill your own, but a great shoe rail is something you’ll have to mill yourself. Shoe rail goes on horizontal areas where spindles meet the floor. Where spindles meet stair treads they don’t need a shoe rail – they simply connect to treads with 1/2” diameter fluted dowel.

Spindle Details: I make my spindles 1 3/4” x 1 3/4” square, with routed chamfers that extend to within 5” of the top and 9” of the bottom. Both the top and bottom ends of each spindle also need to be drilled for a 1/2” dia. x 2” fluted dowel that strengthens the connection between the handrail and the shoe rail after installation.

Railing Base Design: My design has three parts for the bottom of the railing: the wide shoe rail that fastens to the subfloor, the side strips that flank the bottom ends of the spindles on each side, and spacer blocks that determine the distance between each spindle. Total height of the completed railing is 38” above finished floor and stair tread, with a space of 4” between each spindle.

Bullnose Profile Accents: I rout semicircular bullnose profiles into the outer edges of the shoe rail and the inner edges of the side strips to hide any small mismatch between these parts. Bullnose also looks great.

Anchoring Newels, Shoe Rail and Spindles: Slip a newel over one anchor block after it’s screwed to the floor, then drive screws horizontally through each side of the newel at the bottom. As long as the anchor block is firmly attached to the floor, the newel will be absolutely solid, even before railing and spindles go on.

Drill holes in the shoe rail for the 1/2” fluted dowels that secure the bottom of the spindles, then use glue and screws driven down into the bottom of the dowel holes to permanently fasten the shoe rail to the floor.

Anchoring Hand Rail: The spindles fasten to the shoe rail over fluted dowels, with spacer blocks in between. Here’s a trick: With all spindles in place on the shoe rail, temporarily clamp their top ends to a strip of wood that’s as long as the section of railing you’re working on so each spindle is plumb. Next, put dowel centres into all the holes in the tops of the spindles, then set the handrail down on them to mark the location of dowel holes underneath. Drill these holes, dry-fit the handrails over the dowels, then bore screw holes in the newels for the handrail. I use structural screws with large heads and threads for this job.

Newel Caps: My design includes a pyramid-shaped piece of solid hardwood that sits on top of a four-sided trim frame. I decided to leave these caps free to be removed, in case anyone ever needs to tighten the screws anchoring the railings.

Box newel railings aren’t something you’ll get to build every day, but now that you’ve seen how they go together maybe they’ll make it into some of your projects. Email me at steve@stevemaxwell.ca if I can help.

Firestop Sleeves

If you’ve ever tackled a multi-story commercial job, you know that those people wearing the white hard hats get pretty picky about pipe penetrations between floors. The Holdrite HYDROFLAME Pro Series telescoping sleeve system guards pipe penetrations better than anything else I’ve seen because it deals with all the issues you run into in the real world. Need to pour floors of different thicknesses? The Pro Series telescopes and locks in 1/4” increments. Need to prevent firefighting water from damaging floors below? A built-in mid-body seal grips pipes and keeps water from sneaking past. Need a system that meets fire code specs? This sleeve system includes an intumescent wrap that protects and seals the pipe penetration in the presence of sufficient heat. Afraid a forming crew might lay concrete a little too thick and hide the pipe sleeve? Removable plastic whiskers let your crew know where they need to bust through a skiff of hardened concrete to find the pipe sleeve. Price for an 8” - 12” telescoping sleeve for 1 1/4” to 2” pipe is $25 – about half the cost of labour and materials for site-built alternatives. Visit baileylineroad.com/hydroflame to see how this thing works.

MAXWELL’S PICK