8th Annual Salary Survey

How Do Your Profits and Take Home Compare? page 20

Insulated Concrete Forms

The Pros and Cons of Modular Foundations page 34

Introducing Pro Interiors

Our New Section Especially for Painters page 41

8th Annual Salary Survey

How Do Your Profits and Take Home Compare? page 20

The Pros and Cons of Modular Foundations page 34

Our New Section Especially for Painters page 41

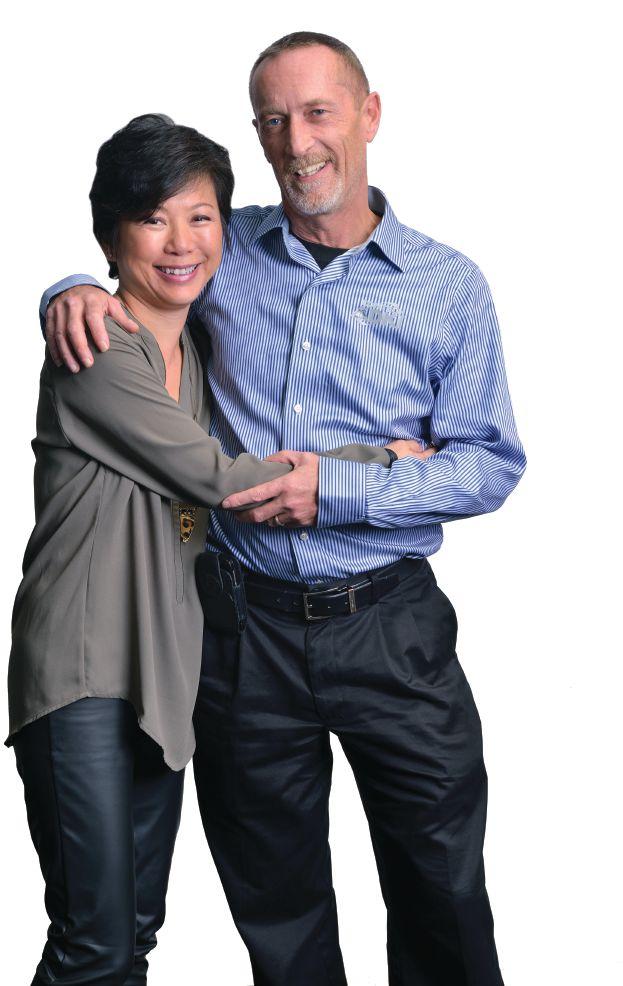

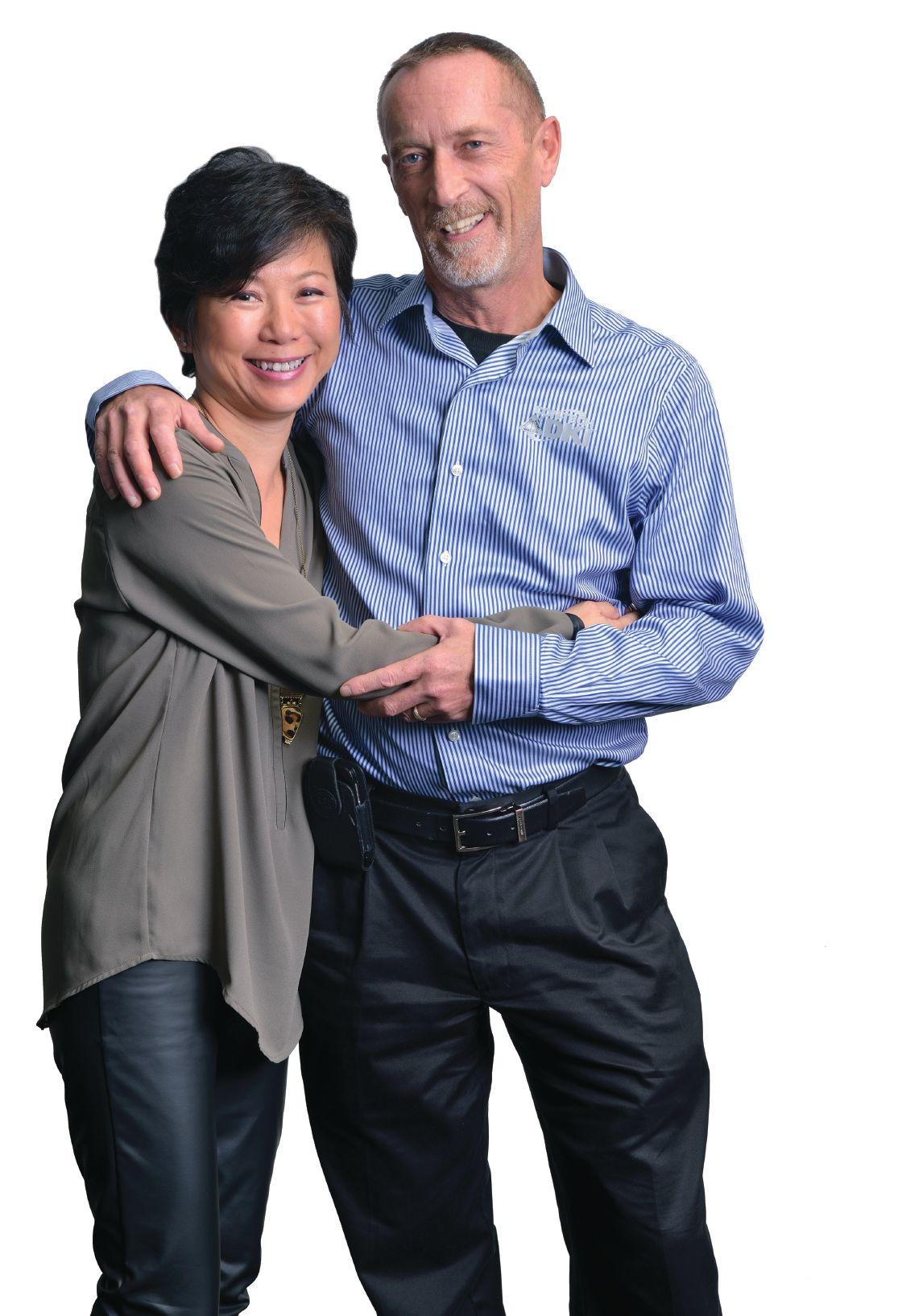

Jeanne and David McGregor, Con-Tech

Restorations, talk about how they make it work

Kyle Kenyon

Kyle Kenyon

Kenyon Construction

Kenyon Construction

Rob Borthistle of Selkirk Home Hardware Building Centre knows that contractors don’t have time to waste. “Getting materials to the job site when you say you’re going to get it there is key,” he adds. Kyle Kenyon, a former employee of Rob’s who is now the owner/operator of Kenyon Construction, agrees. Selkirk HHBC supplied everything from drywall and lumber to roofing for a recent build of his.

Rob Borthistle of Selkirk Home Hardware Building Centre knows that contractors don’t have time to waste. “Getting materials to the job site when you say you’re going to get it there is key,” he adds. Kyle Kenyon, a former employee of Rob’s who is now the owner/operator of Kenyon Construction, agrees. Selkirk HHBC supplied everything from drywall and lumber to roofing for a recent build of his.

Constant traffic and powerlines made job site deliveries particularly tricky, “but they were able to do it and get it to us on time,” Kyle says. Every Home Building Centre and Home Hardware Building Centre Owner knows that service is about more than dedicated sales staff or ease of ordering. “We treat our customers the way we’d want to be treated by our suppliers,” says Borthistle – something Kyle Kenyon knows better than anyone else.

Constant traffic and powerlines made job site deliveries particularly tricky, “but they were able to do it and get it to us on time,” Kyle says. Every Home Building Centre and Home Hardware Building Centre Owner knows that service is about more than dedicated sales staff or ease of ordering. “We treat our customers the way we’d want to be treated by our suppliers,” says Borthistle – something Kyle Kenyon knows better than anyone else.

pronews.ca

pronews.ca

An interview with Jeanne and David McGregor, Con-Tech Restorations, Toronto.

Our 8th Annual Salary Survey 20 We were always told it was rude to ask people how much they make. Nevertheless, over 400 contractors told us –in some detail – plus many other items from their operating statements and balance sheets.

A look at the many excellent reasons to use ICFs in place of poured concrete foundations –or even above grade.

Introducing a new section of Canadian Contractor written especially for painters and decorators, whether residential, commercial or industrial. This issue: Church painting as a calling, Kansas City-style.

Online 8

How to put the Canadian Contractor icon on your phone, for one touch access to our breaking news.

Editorials 10

Rob on his recent road trips all over North America; Steve on why Getting Real is the only way to go when trying to sell anything to anyone.

Voices 12

The best of the recent contractor posts on our website including… Why did you guys exclude BuildTools? Will Lowe’s mess up RONA? Are IKEA kitchens that bad? Why aren’t we getting more ex-military on the tools?

Creative Eye: Chalet on Champlain 30

A look at a recent build of an ultracontemporary three-storey vacation property on Lake Champlain, Quebec.

Stuff We Like 49

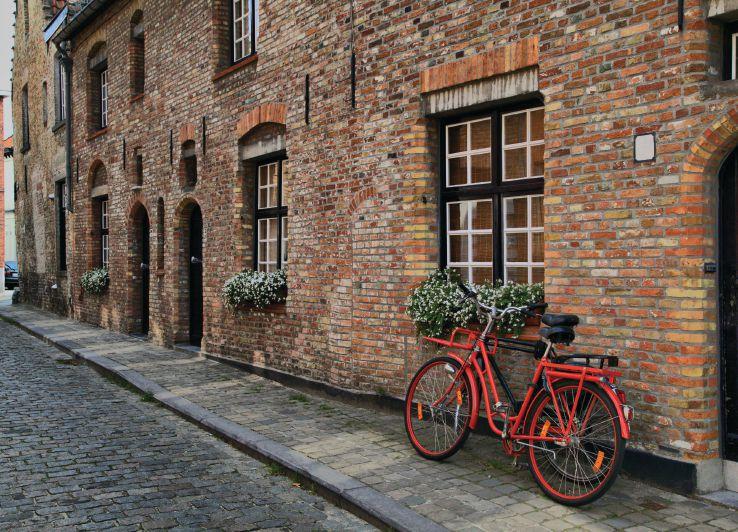

Maxwell rediscovers his love of brick.

What Would You Do? 58

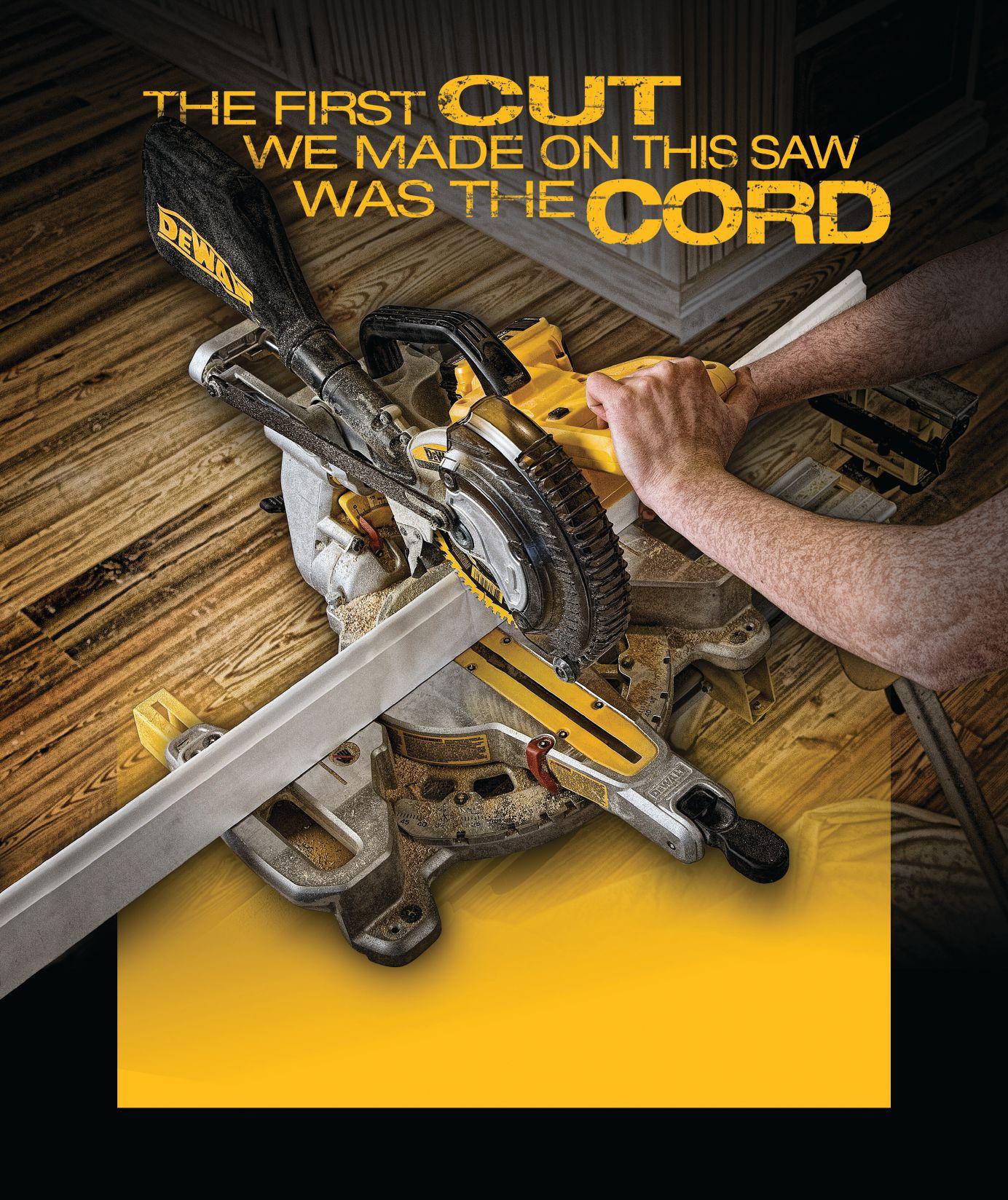

Solve this contractor’s dilemma and you could win an awesome new DeWALT cordless impact wrench.

INSTRUCTIONS

• Google Canadian Contractor on your mobile device

• Open the link to canadiancontractor.ca

• When the page opens, tap the menu button on the lower left corner of your screen

• Select “add shortcut”

• Go back to your device’s screen and locate the Canadian Contractor icon (it may appear on one of your later pages).

Go to canadiancontractor.ca and type “icon” in the search bar at the top right. The link to the video will pop up.

| Tel: 416 442 5600 | 80 Valleybrook Drive, North York, ON, M3B 2S9

Canadian Contractor, established in 2000, is published 6 times a year by Annex Business Media.

• Press and hold the icon, and drag it forward page-by-page to the desired page on your device

• Go to canadiancontractor.ca using Safari or your favourite browser

• When in portrait mode, click on the square icon with the “up” arrow that appears at the bottom of the screen

• Chose “add to home screen”

• Click “add”

• The icon should appear on your iPhone or iPad home screen

Now with one click, you can go directly to the latest news!

Editor Steve Payne spayne@canadiancontractor.ca

Contributing Editors Rob Blackstien, John Bleasby, John Caulfield, Mike Draper, Kim Laudrum, Steve Maxwell

Art Director Lisa Zambri

Publisher Rob Koci rkoci@canadiancontractor.ca

Account Coordinator Tracey Hanson thanson@@annexbizmedia.com

Circulation Manager Beata Olechnowicz bolechnowicz@annexbizmedia.com

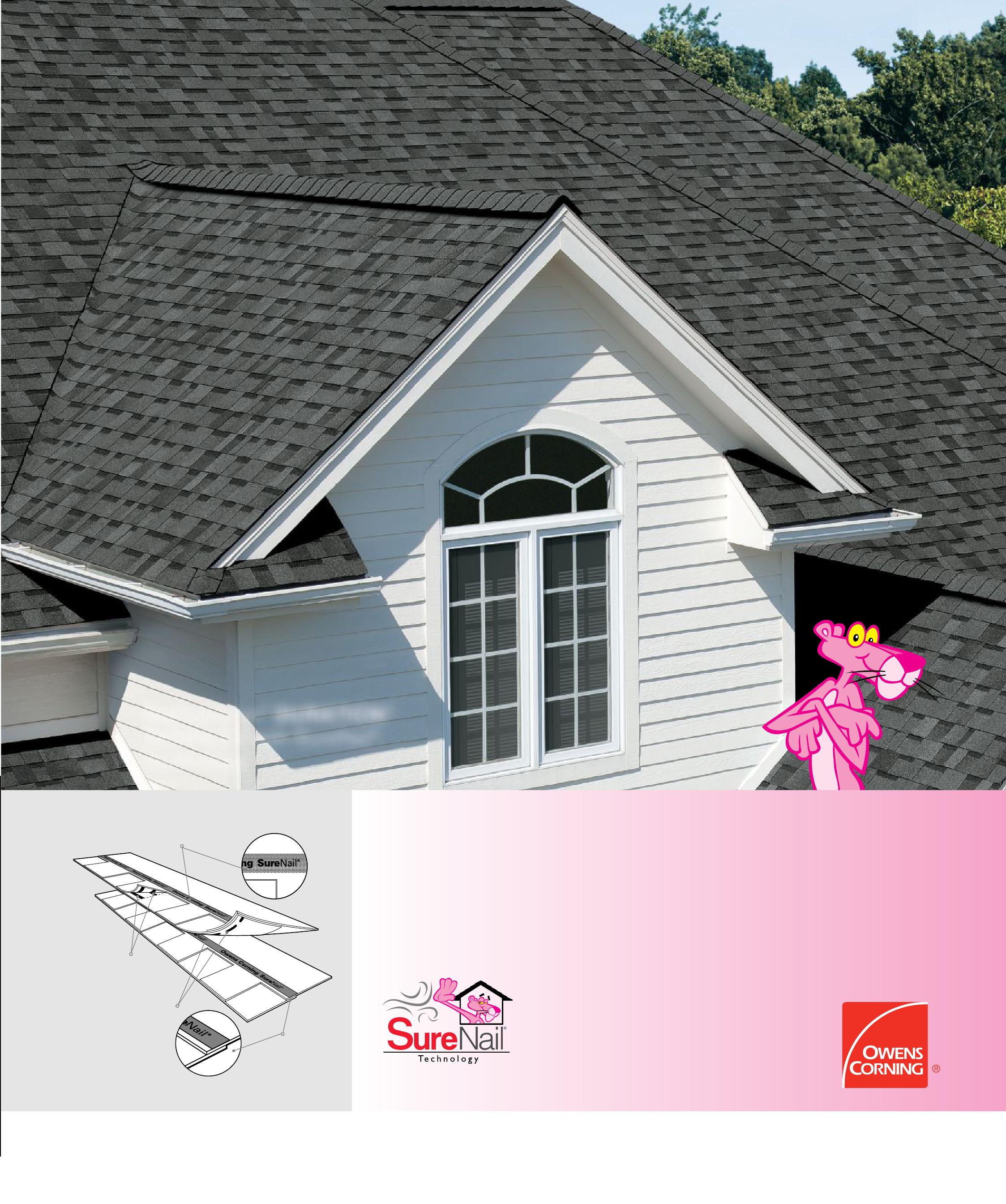

It’s easy to see why TruDefinition® Duration® shingles are easy to sell. Not only do they have magnificent curb appeal, they have outstanding performance characteristics thanks to SureNail® Technology. These shingles have exceptional wind resistance that delivers a wind warranty of 209 km/hr* with only 4 nails. Plus, the highly visible woven engineered reinforcing fabric in the nailing line makes it easy for you to show homeowners why this shingle is different. And, more importantly, it makes it easy for your crews to install. Choose TruDefinition® Duration® Shingles from a recognized brand leader in the building industry for over 70 years, Owens Corning.

Try to find some time to get off your own jobsites and talk to some new people.”

Rob

Koci Publisher

By Rob Koci

I am writing this from Phoenix, Arizona after a long day of seminars in which some 60-plus builders from the U.S. and (mostly) Canada associated with the Alair Homes franchise received what I considered some of the best training on the renovation and custom home building business I’ve heard in a long time.

Last week, I spent a couple of days in Edmonton at the Home Hardware PRO Contractor Show, part of a six-city road show that Home puts on every year as a thank you to its contractor customers. It was another great opportunity for me to talk to scores of contractors about their businesses – and what they wanted to see in our pages.

Next week, I’ll be heading to Baltimore to chat with Victoria Downing, president of Remodelers Advantage. Long-time readers of Canadian Contractor will know Victoria and Remodelers Advantage from the RenoSummits we hosted in the past and the quality business advice Victoria has provided for the last 10 years in this magazine – and online.

When I get home, I’ll have a nice chat with Mike Draper of Renovantage, one of our sponsors of last year’s RenoFocus and a partner in our efforts to bring some powerful, one-on-one coaching to our readers (more on this soon; make sure you are subscribed to our e-newsletters to catch up with Renovantage’s latest programs).

Add all that to the International Builders Show (IBS) I attended in Las Vegas this past January, an important paint industry show Steve Payne attended in Orlando a few weeks ago and an upcoming conference John Bleasby will soon attend in Baltimore, and it’s no doubt we are going to be able to put together some terrific future issues for you.

Where have you been in the last year? What have you done to get your nose off the grindstone and your eyes looking up at the prize that you so dreamed of when you started in this business? Who have you been talking with outside your company to keep you loose and motivated? Try to find some time to get off your own jobsites and talk to some new people in the industry, in new places. It’s where great ideas come from.

Anyone who runs their own contracting business – as most of you do – knows the difference between the corporate world and the reality faced by you, your crews and your trades. No amount of business school jargon is going to get you off the hook if you build or price things sloppily. Professional renovation and home building businesses are no places for glib salesmen or smooth talkers. Our industry has them. But they get found out.

This is because our industry still operates on an artisan basis, the same way people earned their livelihoods 500 years ago: You make something. If it’s good and you didn’t ask too much money, you might be asked to do it again.

In this way, we can all be proud that our industry conducts business in a way that minimizes slogans and brand names and maximizes actual performance and getting things done.

The mega-corporations in the world of banking or telecommunications or the hospitality industry are obviously quite different. Generally, they don’t give a crap about you and your options are strictly limited. You can buy from them or someone almost identical to them. Good luck with that. Yet they pose, in their marketing, as your friends.

Examples of this type of folksy, down-home BS are all around us these days. “Roam Like Home” from Rogers, for example. Or “Banking Can Be This Comfortable” from TD Canada Trust. Or “We’ll Leave the Light on for You,” from that awful chain of U.S. motels.

But look what these big firms all want. They want what you, the self-employed contractor, already have. You have real personal relationships with your customers. You are working with them collaboratively to change the very core of their lives – their homes. You know the names of their kids. You probably (or you had better!) know precisely what they can and cannot afford

By Steve Payne Steve Payne Editor spayne@canadiancontractor.ca

Canadian contractors, you are running much more authentic businesses than the banks or the telecoms or the hotel chains. Be proud of it.

”Our industry still operates on an artisan basis.

”

In our Nov/Dec print issue, we ran an analysis by Greg Peterson of Renovantage.com, who examined four leading residential construction software systems. His report was based on evaluations by a committee of his organization’s contractor members. After we printed Greg’s report, Ben Polley (Evolve Builders, Guelph) emailed Greg to say that, in his own firm’s view, BuildTools was the best system – though it did not make the Renovantage final four. Here is that correspondence… republished by permission of both Ben and Greg.

“Dismayed… at your summary dismissal of BuildTools”

Hello Greg: Thank you for your insightful and detailed comparison of four different construction management systems. Our own integration of one such similar system has in my view become the necessary tool for our firm to streamline our geographically dispersed projects and teams while providing us with a solid basis on which to deploy systems that will see us able to deliver work ever more cost effectively.

When we researched products about two years ago, we assessed many of the same capabilities as did you. I am, however, rather dismayed at a seeming disconnect between that which you stated as being among the most important issues facing custom contractors and builders – timely owner decisions and selections – and your summary dismissal of one product (BuildTools) that has tools to address this while keeping one that doesn’t do so at all (Corecon). That this dismissal was further based on the reply of just one of your own clients is a dubious manner in which to conduct such a published comparison in my view.

As you may have guessed, BuildTools was the product selected. This however is not intended as a defense and rationalization of our own choice. Rather, from an editorial perspective I would just like to note that you might in the future consider consistency between your own argument and your subsequent comparison. Separately I would for the future respectfully suggest also adding a couple of other categories for consideration.

In our own review, we assessed the provider’s commitment to Canada and perhaps more importantly, our own anecdotal assessment of the company’s stability and viability (little could affect a contractor more than to have their selected platform suddenly disappear as others discussed in this publication have already done, to say nothing of the capacity to keep up changing technological needs and opportunities).

On these counts none had viewed Canada as having any

distinction from their American markets, except BuildTools who for a couple of years running showed at Toronto’s Construct Canada trade show. While a small gesture it, however, proved correctly indicative of what I hoped for – they have been responsive to adjusting nomenclature, system fields and tax calculations to better suit Canadian verbiage and HST requirements.

With respect to viability, it appeared to us that BuildTools was of a magnitude several times larger than Co-Construct. BuilderTrend itself appeared larger yet but had a rather rudimentary selections capability (at that time) while we did not compare Corecon because of the aforementioned lack in selection management. I do not recall comparing UDA (instead we included Procore & Sage until eliminating it because of cost and lack of web platform at that time).

Lastly, while only a current user could know what this might look like from any provider, we have come to learn that support – for set up, training, and maximizing potential – is another valuable comparator. I cannot speak for the users of other systems, however with respect to BuildTools, we have always found its support team to be timely in response (if not immediate), knowledgeable and infinitely patient. Your disoriented user must not have taken much advantage of this free and unlimited help.

On the count that BuildTools system is difficult, I would actually concur that an inconsistency in features’ presentation and language sometimes makes initial training more cumbersome than I would prefer (and needs to be). Our own original assessment had predicted this to be so but it did not scare us off as the trade-off was a system that was more ambitious or offered yet more capabilities and/or cost-effectiveness than the others. To our pleasant surprise they have even been responsive to our requests to make some system changes and improvements based on our feedback.

In short, I thank you for comparison. Exposure to such systems will be to the benefit of all readers. I would be happy to be included if you need constructive feedback inclusive of BuildTools in the future (on the assumption that we haven’t changed platforms by that time).

Ben Polley, Evolve Builders Group, Guelph, ON

Greg Peterson replies:

“Our evaluation was done with input from all of our members.”

Ben, the evaluation of the software programs was undertaken originally for the benefit of Renovantage members. The first thing we did was work with our group to develop a specification of the functionality that was required. BuildTools certainly passed the initial screen. When we initiated phase two of our research, one of

With endless design options, helping homeowners find the ideal features to get the most value out of their renovation budget is easier than ever.

Stylish grilles for increased curb appeal.

There is a reason JELD-WEN is the go-to brand for so many experienced professionals. Visit jeld-wen.ca to

Attractive window shapes for architectural symmetry.

our members expressed his dissatisfaction with BuildTools, which his company had been using for a number of years. Specifically, he and his project managers found aspects the project management component to be cumbersome to use. We looked at the specifics of his concerns and compared them to the other programs. Our conclusion at the time was that his concerns were well-founded and that the four other programs selected for detailed review were easier to use. Since one of our objectives was to get all of our members on a standard platform, we dropped BuildTools from further evaluation as we were unlikely to be successful getting everyone on BuildTools over the reasonable concerns of one of our members. Most of our members were on manual systems and they listened carefully to input from other contractors as to the pros and cons of each system. Our evaluation was done with input from all of our members. The decision to not pursue BuildTools was one that was made with careful consideration based on a number of factors.

Greg Peterson, President, Renovantage

We have had a number of online comments about the Swedish giant’s ready-to-assemble kitchens versus real, custom cabinets. Unscientifically, the posts are about two-thirds against the Swedish firm’s kitchens but here is one in favour…

“IKEA kitchens in million dollar homes… with clients proud of the results.”

We have installed several hundred IKEA kitchens over the last 10 years and have had no complaints about quality, style or functionality. We now have many repeat customers who have moved and want another IKEA kitchen. We only work by referral and are kept very busy. Contrary to what one reader posted, custom kitchens are not “twice as good as an IKEA kitchen at three to four times the cost;” a lot has to do with the planning and installation. Our IKEA kitchens have been installed in million dollar homes and our clients are quite proud of the results.

Roland Skeries

Contractor Damon Bennett spoke out on our website (and in other media) about the need to get more ex-military personnel into our industry – not only for them, but for all of us.

“No problem, no fuss, no drama.”

Well, as a veteran myself, I can say that us ex-military guys do

work well in a group because that’s what we were trained to do. Got a job to do, work together and get it done. No problem, no fuss, no drama. The fact that you’re working with other vets means that there’s someone who has some of the same background as you, even if they were born on the other side of the country (or even in another country). So you get a connection quicker with your co-workers, something beyond just the construction side of things. And as some of us did join the military at an early age: We can put our X number of years in and still be young enough to do the labour. Good idea, Damon.

Roger Smallman

Online we wondered why Canada’s National Building Code costs several hundred bucks – even for a PDF version. (Seriously?) The government seem to have a much better idea across the pond: Building codes should be free. Always!

“Downloadable for free from the Scottish Government…”

I am an architect in Scotland. The Scottish Building Standards for Domestic + Non-Domestic Buildings are downloadable for free from the Scottish Government portal and have been since 2009. Hard copies are charged for. I don’t know that cost as I use the free download straight into my computer, available for instant reference and print out. The attitude is that these standards are mandatory for the health and safety of the building users and the public at large and, as such, they should be available to all involved in the industry for reference and implementation at low or no cost to ensure those aims of the legislation are achieved. Hope this may be of assistance to those preparing their arguments for easy access to Canada’s National Building Code.

Robin Clunie

While the following sounds like a paid ad for Mercedes Sprinter vans, we can only assure you it is not! We should clarify that Chevrolet Express vans are available in 4WD and AWD formats although Ford has switched (since 2014) to a RWD-only format for its Transit vans in North America…

“Finally, freedom to roam where I need to go.”

After having a Chevrolet Express van for work in the city where

Continued on page 18

Thanks to a wide variety of package options, PowerSelect makes deciding which cordless tools to select easier than ever. Whether you need a new cordless tool to use with your existing batteries and charger—or you need a complete set with tool and accessories—PowerSelect simplifies getting the right tools and accessories for your job requirements.

festoolcanada.com

Continued from page 14

low underground parking lots won’t allow tall vehicles, I had the chance to change to a Ford Transit with 6 foot interior cab height a few months ago because I live in a rural area now. Unfortunately, it was unable to climb slight slopes, slippery grass lawns, steep hills and driveways covered in a layer of muck as only one wheel drives. So I was stuck many times and had to be pulled out. On one job, I was required to park along a roadway and walk all the tools and supplies 200-300 feet up the inaccessible driveway to renovate the home. Enough of that: I was able to get into a Mercedes Benz 2500 4x4 van. I can now drive any and all of the worst, steepest, slippery driveways. This van is nicely equipped with a bulkhead wall which keeps the heat in the cab and the dust in the rear. It has covered walls to which I have attached the shelving system I had in the Express. There are tie down systems all along the floor and walls to strap down any goods which might tip over while driving. I put on the rear view camera which really helps avoid rocks, trees and lumber obstacles at job sites – and it’s good for the trailer hitching. The vehicle also has the Bluetooth phone feature for hands-free operation – great for making calls during the work day. Finally, freedom to roam where I need to go. I suspect many van manufacturers will need to have a 4x4 version available as the old one wheel drive cannot be good in many snow, mud and mountain terrains in North America.

Bill McCance, Mayne Island, BC

Alec Caldwell wrote a post online about the sorry state of portable toilets on home building and renovation sites. Our frequent poster, Questo, below, wrote this post reminding us that – on some high-rise construction sites – things can get a heck of a lot worse.

“The smell of pot, shit, urine and cigarettes.”

Thanks, Alec, for your article on Porta Potties. I worked on high-rise building construction as a journeyman electrician, laying out PVC flex tube for electrical, telephones and other needs on a floor-by-floor basis. The last building I worked was at Front and Jarvis, Toronto, the “Chinese towers.” Two Italian electricians and I quit working when we got up to the 14th floor because of the issues with sanitation. In the heat, the smell of pot, shit, urine and cigarettes was horrible. Our company manager just told us we could handle it. When one of us asked to come down to the ground floor to use the portables there –less hot, and more to choose from – we were met with name calling. It reached the point where we had to do what we had to do: We quit. This sort of (policy) for (restricting access to) portable toilets should

be prohibited under the Ontario Health and Safety Act. We had tried (to make that happen) in 2002, but nobody cared – it fell on deaf hears including the unions, too. We argued that a small trailer with 10 or more washrooms in satisfactory condition – and daily inspections –should be provided at ground level. In my view, as far as the Ontario government goes on this issue, ignorance was bliss on its part, back then, and maybe it remains so now.

Questo

Shutting down your business in Ontario will not shut down your invoices from the WSIB if it thinks you owe money, as this contractor found out.

“Find out who is responsible – and fire them on the spot!”

I am an ex-contractor because I can’t afford to keep the doors open. Now that I have shut down my business, WSIB continues to harass me with bills that are a guess. None of the bills are accurate and it insists that I pay them, costing me more money. WSIB needs be scrutinized to find out who is responsible for these kinds of actions –and fire them on the spot.

David Hirscheld

It has been almost two years since Alec Caldwell wrote his post about an Ontario Ministry of Transport blitz on contractors’ vehicle, calling them “vultures.” (Don’t hold back, Alec, tell us what you really think!) A new MTO blitz seems to be in effect…

“They are hitting trailers owned by small businesses.”

In London, ON, they are pulling trailers over and trying to find anything they can because of the death of a woman by a tractor trailer tire. They are hitting small trailers owned by small businesses. The officers are abusive and rude. In my opinion, the OPP and the court house are working together to make money. They make sure that, when they fine you, the officer will show up at the trial. You don’t stand a chance to win. The trials are unfair and onesided – as I discovered: the officer in my case avoided the truth by playing dumdum. The court rooms are so packed, they are starting some trials at 5 p.m. The doors automatically lock in the court house at that time and you are trapped inside.

T. Roberts

We are looking for 32 contractors from across Canada who want: FREE • Travel to Toronto • Hotel • Food • Entry to Construct Canada AND Contractors who can share their business and product challenges.

“ Whether it was being involved in discussions or just listening to the other contractors and being involved working, writing, and talking about our challenges and triumphs, it showed how professional we are in our industry. Great all round! ” - Steve Barkhouse, Amsted Construction, Ottawa, ON

RenoFocus is a series of focus-group sessions behind closed doors in which manufacturers and suppliers gather market information from successful contractors.

Do you have what it takes to be a RenoFocus contractor? Go to www.renofocus.ca to fill out the application.

Our annual online survey shows you the gross revenues, take-home paycheques and net profits of Canadian contractors who responded to our online survey in January and February – 403 of you.

By Steve Payne

Wedid our first survey of our readers’ financial results in the first quarter of 2009 – asking questions about the previous year. Ah yes, 2008. That was the year the bottom fell out of the American housing market, thanks to the subprime mortgage crisis, and Canada’s builders and tradespeople felt the slowdown, too. Since that recession, Canada’s renovation and homebuilding industries have been in a near-constant boom for eight years. But in the past year, our contractor readers in the oil-and gas-regions of the country are anecdotally reporting a slowdown. The following charts summarize the responses of 403 of our 31,000+ subscribers to questions based on their 2015 business years. They include numbers from renovators (38 per cent), subtrades (29 per cent), ICI contractors (11 per cent), service and repair contractors (10 per cent), custom home builders (10 per cent) and ‘others’ (2 per cent).

For the second year in a row, exactly 4 out of 10 owner respondents were billing a million bucks a year or more

40 per cent of respondents, exactly, billed at least $1 million in work last year. And 17 per cent of owner/ operators billed at least $3 million. Interestingly, that statistic is also identical to last year’s survey. We estimate the median (half of respondents above, half below) gross sales is roughly $750,000 per owner/firm.

What were your estimated gross sales in 2015?

- $2,000,000

- $3,000,000

- $4,000,000

Over $4,000,000

The median compensation of our owner respondents was approximately $75,000

This chart shows the owner’s compensation (before taxes and deductions) – excluding any profit kept in the company (or paid to shareholders or partners, etc.). The company profit portion is shown in the next chart. We calculate the median compensation of our owner/operators at around $75,000 (since we ask respondents to answer within brackets, this is an estimate). 68 per cent of respondents were making less than $100,000 – but a healthy one third (32 per cent) were hitting six figures. This is up from 25 per cent last year. The remaining 26 per cent of respondents earned under $50,000.

What was your estimated personal salary last year, not including company profits that you did not take as compensation?

$100,000 - $150,000 22%

$50,000 - $100,000 42% $150,000 - $200,000 4%

The median net profit of our respondents was just under $60,000

This chart shows the net profit (before taxes) of each owner’s business after he or she deducts their personal salary and other overheads from gross profits. This money can stay in the bank for cash flow, be invested in the business or elsewhere, be distributed to partners and/or shareholders as dividends… or it can be used to increase the owner’s compensation (not always a prudent move). The median net profit of our respondents was approximately $60,000 – bearing in mind that a median owner’s salary of $75,000 has already been deducted (previous chart).

What net

(loss) did your firm earn last year, not including

compensation?

68 per cent of owners reported more sales in 2015 than they achieved in 2014

Over two-thirds of owner respondents (68 per cent) reported that they made more sales in 2015 than they did in 2014. This is up from 64 per cent of owners who reported revenue increases last year, and 56 per cent of owners who reported revenue increases two years ago.

What percentage increase or decrease in gross sales did you experience last year?

Gross margins in the 20 per cent and 30 per cent ranges continue to dominate the industry for jobs up to $100,000

This chart shows you the average gross margins for different sizes of jobs, as reported to us by various types of contractor. As you can see, the most common gross margin for jobs under $10,000 is 30 per cent, but with a wide range of other selections. For jobs between $10,000 and $100,000, 20 per cent gross margins are reported the most – again with a wide range. For jobs over $100,000, 10 per cent gross margins (or less!) make up 43 per cent of the responses. The handful of respondents who checked off “zero per cent” gross margins are hopefully headed for better future estimates.

When estimating jobs in the following ranges, how much is your gross margin?

The bulk of the reported mark-ups are still in the 1.2 to 1.3 range, as they have consistently been in recent years

Each year we ask the “same” question two different ways: how much are you building into your quotes to allow you to make a decent profit? We ask the question in terms of gross margin (previous chart), defined as the percentage profit on a job, before deducting overheads. And then we ask the question in terms of how much you're marking-up your costs, when quoting a job, in terms of a multiplier. As we all know, a 1.1 mark up gives you only a 9 per cent gross margin. A 1.2 mark up gives you only a 17 per cent gross margin. A 1.3 mark up gives you 23 per cent margin, and so on. Easy, right? If so, we always wonder why with the gross margins as reported in our previous chart, the mark-ups on this particular chart aren’t slightly higher. We will keep wondering.

74 per cent of respondents reported “zero” cash work, compared to 71 per cent the year prior

We probably should reword the question “how often are you breaking the law?” but then hardly anyone would answer it. In this question we don’t imply (even though most people understand it that way) that by “cash” work we are referring to illegal, off-the-books projects. But we think people get what we are asking. And the cash-work numbers are dropping – from 71 per cent of contractors headed for Tax Compliance Heaven in 2014 (zero cash work) to 74 per cent Upstanding Citizens in 2015. We hate to think government enforcement officers are finally having an effect on dampening down the underground – but there you go. More likely, even more people are fibbing than usual. Choose your own world view. We like ours.

When estimating projects in the following ranges, how much mark-up do you apply?

What percentage of your work comes from cash jobs?

Know what’s going on in the field at a glance.

With a tap of the screen, view vital data from any of your job sites. Our cloudbased time tracking system provides all the information you need to make informed business decisions on the go: see who’s clocked in, their activities, weather updates and more at a glance on any browser-based device.

Manage your workforce from anywhere.

• Track and manage individuals or crews across multiple job sites

• Easily monitor job costing and overtime to stay on budget

• Get simple access in the field or office on a permission-only basis

• Easily transfer data to your accounting program, saving payroll processing time

Competitive pressure is once again the number one reason contractors cite for not making enough money

A few things have changed since last year in this “chart of irritants.” Competitive pressure, our perennial number one reason for not making more money, was mentioned by more than half of all respondents this year (52 per cent), up from 47 per cent last year. And the plague of cost overruns, however caused, has leapt up the chart from fifth place (20 per cent) last year, to second place, 36 per cent, this year. Estimating errors are also up, from 29 per cent last year to 35 per cent this year.

Marketing always seems to be the biggest challenge for contractors – especially in this complex digital world, so once again this year, you named it as the biggest source of headaches

The big difference between this year’s numbers and last year’s is the giant leap in marketing’s rating –from 2.10 “difficulty” last year to 2.43 this year. Administration is also up significantly –from 1.81 last year to 2.04 this year.

In your experience, which of the following are the main reasons why you are not making sufficient profit?

Please rank, on a scale of 1 (little difficulty) to 5 (a lot of difficulty), each of the following aspects of running your contracting business.

Word of mouth remains the leading “marketing” method for our survey respondent contractors, followed by “jobsite advertising”

It was surprising to us to see referral-based web services such as HomeStars and Trusted Pros so far down this list of marketing methods for contractors. We think some contractors are missing a great opportunity.

There’s no escaping it, it’s a digital world

Yet 81 per cent of our contractor respondents are able to keep their online activity – for business anyway – down to less than two hours a day. These numbers were increasing every year, but this year they have sort of flattened. (Last year only 76 per cent of respondents were keeping their online down to two hours or less.)

How much time do you spend online, for business purposes, daily?

Facebook is back in front in our Social Media Sweepstakes, narrowly beating out last year’s winner, LinkedIn

Twitter, though everone wants to talk about it, is up only 4 points to 25 per cent of all respondents.

Which of the following social media types do you use for your business?

“SoftPlan continues to work great for us. Our estimates are as tight as they can get. Well under ½ of a percent variance from budget. ” Dave Tucker, Sedgewick Homes North Carolina, USA

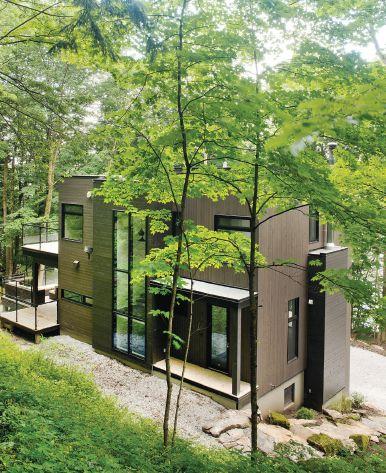

Champlain Chalet Philipsburg Bird Sanctuary, Quebec

Architect:

Eric Joseph Tremblay, BOOM TOWN, Montreal

Contractor:

Constructions Réal Messier, Bedford, QC

By John Bleasby

Montreal architect Eric Joseph Tremblay designed this stunning weekend hideaway, 100 km southeast of Montreal, for clients who were “looking for an exceptional place,’’ he explained. The breathtaking hillside setting is part of a 1.8 acre property bordering Lac Champlain, right in the middle of the Phillipsburg Bird Sanctuary. “It was love at first sight,” Tremblay said.

Although spectacular, the setting had its challenges. The site consisted of two flat sections of ground separated by a 23 degree, 10 metre cliff followed by a gentle slope down to the lake. There were drainage issues associated with the soft soil of the hillside. A rock underlay had to be dynamited in order to prepare the foundation.

In keeping with the client’s wish for privacy while serving as a lookout to nature and the nearby lake, Tremblay developed a contemporary three-storey design built on to the side of the cliff that almost disappears into the trees. By minimizing any tree removal, both Tremblay and his clients were able to retain the view of Lac Champlain yet enjoy complete privacy. “The oblique trunks of cedars and maples form a veil between the living areas and the lake.”

The 4-bedroom, 4,700 sq. ft. house succeeds in one of Tremblay’s primary design goals:

Continued on page 32

THIS MAGNIFICENT THREE-STOREY CHALET ON LAC CHAMPLAIN, QUEBEC, BEAUTIFULLY NESTLES INTO ITS CLIFFSIDE SETTING

blending the building with its location as seamlessly as possible. “I always try to abolish any boundary between interior and exterior spaces.” Fragmenting the building’s sectional elements to minimize the impact of this large house also gives a visual break that allows views of the lake from street level.

An interesting variation is the somewhat unconventional upside-down layout of the house. The bedrooms are on the entrance level, above the living room and billiard rooms found one and two levels below, respectively. Each of the lower levels has a large walkout entertainment area, while the master bedroom has a private terrace, the sunniest place in the house.

Tremblay chose steel and conventional wood construction on a concrete foundation wall for the building envelope. Mineral wool insulation (R20) in the 2x6 framing was supplemented with expanded polystyrene foam (R4) on the exterior. Some solar gain is realized via the orientation of the home, allowing the concrete floor’s thermal mass to retain heat as sunlight pours through the large window openings. The windows are metal-framed double glaze with Low-E argon gas. Heated floors were used both for the polished and waxed concrete on the lower level and for the wood on the living and bedroom levels. A bi-layer membrane was laid under the cedar roof decks, with access ports for any drainage maintenance requirements.

Every room offers a view, either of the lake or of the abundant nature cliffside. Zinc-coloured windows frames match the roof trims and facia, with added continuity between the interior and exterior resulting from the matching of B.C. cedar siding with interior walls and exterior slate patio with the concrete floors. Material choices for the

interior include concrete, steel, glass, wood and natural stone. An interior/exterior blend with the surrounding hillside is further enhanced by the use of light, natural colours and wide openings.

These elemental and design decisions were in keeping with both the clients’ vision and Tremblay’s objectives. “It was very important to use natural materials in order to root the project in a context. We wanted the project born of the land,” he explains. “Nature and architecture enhance each other “ cc

Among the many types of modular construction getting the ‘Lego’ label, Insulated Concrete Forms are probably the least experimental. After all, they’ve been around almost 50 years. Here’s why ICFs make sense.

By John Bleasby

True story. We were building our new house, ready to move from plans on paper to pricing out the real thing. Our architect suggested we consider building with ICFs – Insulated Concrete Forms.

I had always imagined a house built with frame construction atop a concrete foundation wall and had little knowledge of ICF. Our architect lent us a DVD from an ICF manufacturer. We watched and we were intrigued.

But the contractor we intended to use (we’ll call him ‘Fred’) was not. While admitting to having no direct experience with an ICF build, he said he had heard rumours ranging from structural concerns to pest infestation and mildew problems. And our locally-owned building supply dealer was equally reluctant. “We sell ICFs,” he said. “But we don’t push them.”

Mike Holmes has probably helped to create suspicion of ICFs. At least, he did in 2012 when, in his syndicated newspaper column he wrote: “When it comes to ICFs… many things can go

The thickness of the concrete and the EP foam can vary depending on the application and the desired level of insulation, but in most cases it's 2 inches of EP on either side of 6 inches of concrete. The ICF blocks come in factory-formed shapes that fit together like Lego. There are long rectangular blocks for wall sections obviously, but many manufacturers also offer angled, shaped and stepped pieces to suit virtually every shape required.

wrong… I like sticking to what I know. And I know that a cinder block home studded and spray foamed is 100 per cent thermal broken.”

But as I made plans to begin building, I took some of this ICF negativity with a grain of salt and kept researching.

What exactly is ICF construction? Quite simply it’s concrete reinforced with rebar, sandwiched between two layers of EP (Expanded Polystyrene) foam. The ICF blocks themselves look like over-sized Lego pieces, with a plastic web separating the two layers of foam. Stacked and lined up, they create their own concrete form, replacing the traditional solid concrete, block, or wood framed wall, while simultaneously providing high levels of insulation on both sides of the concrete. Manufacturers offer a variety of thicknesses, heights and specialty pieces that results in a building of any shape that is tight and extremely energy efficient.

ICF technology may be a departure from traditional methods, but as Gary Brown of Toronto-based ICF manufacturer Amvic explains, “It can no longer be categorized as simply new or innovative. ICF is now part of the building code of Canada.”

Like my contractor colleague ‘Fred,’ many contractors have an instinctive reluctance to try new ideas after years of doing things a certain way. Consequently, a number of misconceptions and concerns need to be addressed before a builder is comfortable making the leap from traditional concrete and frame construction to the ICF process. Cost is always near the top of the list. “They want to make sure that as they go through the learning curve they can deliver both value to the customer and

remain profitable,” explains Greg Doren of Advantage ICF.

“There is an unfortunate myth out there that the costs of ICF in percentage terms are very high compared to traditional construction,” says Scott Carpenter of Nudura. “(Such numbers are) in fact unfounded and do not reflect reality.”

While there is an initial ICF price premium, when one fully understands the potential savings offered by ICF in various areas of the build, that premium starts to shrink. The ICF story is about much more than energy savings.

Barrie, ON builder Brian LaForge joined the ICF revolution eight years ago. Then 30, he was young enough to consider new ideas openly, yet experienced enough after 10 years of hands-on construction to recognize what worked and what didn’t. His company, Living Spaces, was the perfect candidate for ICFs: a small builder with perhaps half a dozen custom projects each year. I met Brian after cutting ‘Fred’ loose and embarking on my own odyssey of discovery as the contractor for my new house.

“I did my own research, looked on the Internet, and contacted the manufacturers,” Brian recalls. Finally, he enrolled in a training course offered by one of the leading ICF manufacturers. He was on his way.

Today Brian works almost exclusively with ICF. “I would rather search out an ICF build than any other type of construction.” The reasons are not only structural, they’re economic. For example, new builders can rent the recommended bracing equipment from most ICF product suppliers thus minimizing start-up costs, then purchase later as their commitment to ICF grows.

More importantly for Brian there’s the issue of keeping his regular crew working and enhancing his bottom line. “As a general contractor with employees, the longer I can keep everything in-house throughout the build, the more profitable I become, and the steadier the work is for my guys. If I sub-out footings plus a concrete or masonry block wall to other trades, not only are my guys not working, I’m paying a premium to someone else who’s then making a profit off me.”

ICF can also simplify the building process. An ICF wall does not require a vapour or sound barrier, and is ready for drywall without any additional strapping or framing. Below grade, this saves both money and time while also increasing the useable living area, since interior framing and insulation to code is not required. Nudura’s Carpenter estimates that foundation cost differences are a wash, after allowing for local variations in concrete and lumber pricing, compared to a traditionally-constructed building with interior studding, insulation, vapour barrier included. Above grade, the premium is between 5 and 8 per cent. LaForge’s estimates concur.

Learning this, ‘going ICF to the roof’ became viable for me, and Brian was hired to build to the entire shell, from footings right up. All the previously mentioned insulation, vapour barrier and wall finishing benefits were extended above grade, plus. For example, in a traditional frame house, achieving the latest code insulation values and eliminating cold conduction through wood sill plates and studs is normally done by adding polystyrene foam on the building exterior under the siding. With ICF, it’s not only integrated into the wall structure, but floor joists can be mounted to a ledger plate inside the ICF wall itself. In a cold climate like Canada’s,

the reduction or elimination of cold conduction means a more comfortable living space near walls, doors and full length windows. ICF also gives owners the quietness and security that can only come from a concrete building.

Nevertheless, it’s not hard to be scared off ICF construction if you put your faith in the Internet. Time spent online will uncover myriad horror stories. Most relate to the consequences of incorrect assembly and bracing of the blocks, and the concrete pour. When concrete starts filling the space inside the ICF blocks, the pressure build-up is considerable. All sorts of things can happen. Blow-outs, leaks, and wall alignment problems are the most catastrophic.

A lot rides on the skill of the ICF builder and his training course. Brian explains: “You learn about proper bracing, how to strap, how to ensure your corners and butt joints are secure so they don’t blow out. Then you go out on site with another contractor pouring a wall, so you learn with some on-site experience.” This is clearly not a job for a DIY’er or untrained beginner!

Brian was totally hands-on when it came to my pour. He’s worked with concrete for years. “You have to understand how concrete flows, the consistency and speed of the pour coming out of the truck, the specifications of the mix.”

To get the concrete to settle correctly as it fills the ICF, internal vibration is required. “You have to know the exact time to start vibrating and, most importantly, when to stop vibrating,” continues Brian. “If you over-vibrate the concrete will lose all its air and become too condensed in one area. As you keep compacting, it wants to sink and expand. That’s when you will get a blowout.”

I did my own research, looked on the Internet, and contacted the manufacturers, Brian recalls. ” ”

As my own contractor, being on-site from the moment the first backhoe smacked the ground allowed me to observe, learn, and plan the comings and goings of the various trades that needed to be brought in during construction. I also watched as ICF Internet myths began to fall away.

“ICF takes up internal floor space.”

Not true. My ICF walls are 8 inches thick, including insulation. That’s actually less than a concrete foundation wall after internal framing and insulation, and the same as walls above grade using stick construction assuming polystyrene is added on the exterior in order to meet code.

“ICF walls are not straight.”

Without correct bracing during the pour, disasters can occur. However my walls are rod-straight, and drywall went up on interior walls with minimal fairing and cleanup. That’s because Brian was trained and knew what he was doing.

“Mess up the concrete pour and you’re really in trouble.”

Unless the contractor has experience with

concrete, they’re better off calling in a specialist to assist with the pour.

“Styrofoam is not ecologically friendly.”

Fervent eco-enthusiasts can find fault with almost every building technique. In fact, the EP foam (Expanded Polystyrene) used in ICF does not off-gas, plus on-site waste is minimal compared to wood framing.

“Drilling or coring service penetrations through concrete and rebar is difficult and timeconsuming.”

With planning before the pour, penetrations are simply a matter of installing sleeves through the foam and back-foaming before the pour.

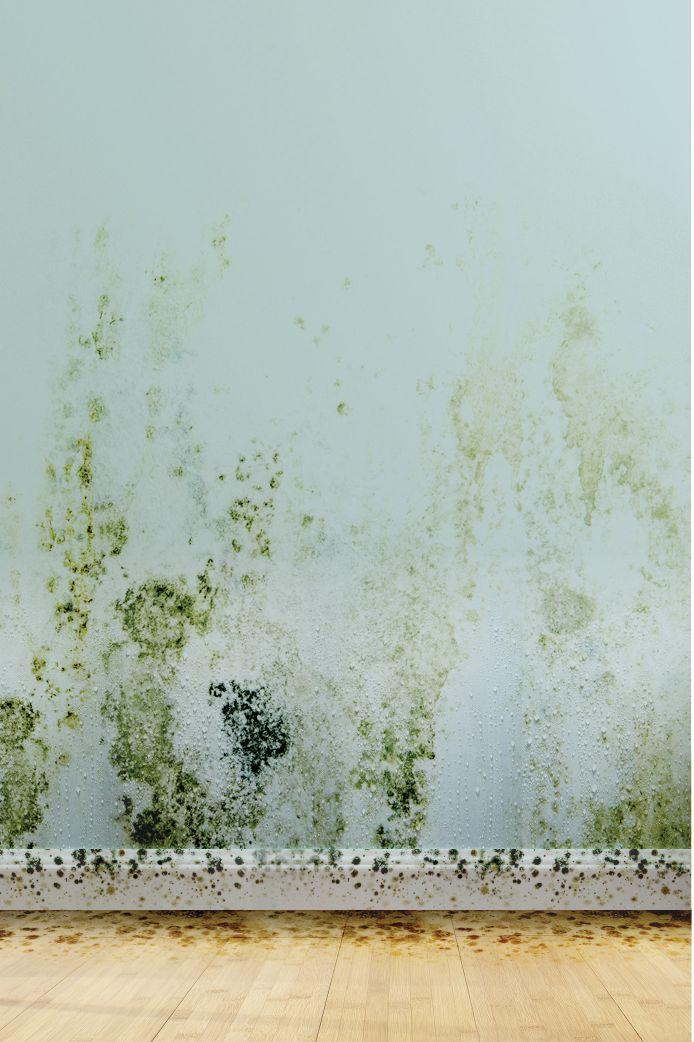

“ICF buildings have mildew problems.”

In fact, the opposite is true. However, recent code amendments have resulted in tighter buildings across the country no matter the construction type. That’s why suitably-sized HRV’s are mandatory in most jurisdictions.

Evolving building codes focused on energy-efficiency will drive more builder interest towards ICF, and the discovery of its further advantages, although it may be still some time before volume production builders embrace the product. Yet, as Carpenter puts it, “We have to make more energy-efficient structures, just as car manufacturers have to make more fuel efficient vehicles.”

Now 18 months after moving in, I’m not only a satisfied owner, I am a champion of ICF construction. In fact, I wonder why someone would choose any other method. cc

Slash noise in one quick cut: Specially formulated noise-reducing drywall with viscoelastic polymer lets you slash sound transmission without complex techniques.

• Score and Snap for faster installation

• Lower labour costs

• Superior acoustic performance

Be Certain™ with CertainTeed Gypsum.

Visit certainteed.com/gypsum/acoustics to learn more.

Jeanne and David McGregor have been married to each other and to their property restoration company, Scarborough, ON-based Con-Tech DKI, for 25 years. Not every couple can handle a 24/7 personal/business relationship. We wanted to know how they make it work.

Interview by John Bleasby

What motivated two newlyweds to risk working together in business?

DAVID: I started the business in 1990, the same year we were married. Jeanne started in 1991. She had joined a bank two years earlier, but I convinced her to come because we needed administrative help. We both took risks. I took the risk of including her in my business and she took the risk of leaving the bank to come with us.

JEANNE: There were only three of us at the start, David and his two partners. There were no systems or programs to run estimating and other aspects, so we had to do everything by hand. David’s two finger typing wasn’t very fast! It was really a matter of David having someone he could trust so he could be in the field and not worry about anything else.

How would you describe your division of responsibilities?

DAVID: She does it all!

JEANNE: David does the project management and I do the administration.

Is there a good cop, and a bad cop?

JEANNE: I’m the bad cop. I have to create processes that have to be very tight and that can cross over to David on the production side. Our industry is regulated

by our clients, the insurance companies. They want to close out the files as quickly as possible because for them, time is money.

Do your employees see your relationship as a couple at work?

DAVID: It’s not something we can avoid.

JEANNE: But we don’t air our dirty laundry in front of the employees!

You save that for the car ride home?

DAVID: We don’t ride together. I might be off on the job somewhere and won’t get home until later.

Is there time of the day that you agree to switch off the business talk?

DAVID: I would like to, but it doesn’t work out that way. Sometimes it just goes on and on.

JEANNE: Emergency restoration is 24/7, 365 days a year, so we’re always checking our Blackberries. People will call at odd hours. And as a female I need to vent, I just need to talk!

It’s said “If you can laugh together, you can work together.” Any comments?

DAVID: Yeah, we can have some laughs sometimes, but we can get into some

heated debates too. I’m more casual, laid back. Jeanne is more by the book. She pushes me around, that’s what it is! (Laughter)

JEANNE: We’re kind of polar opposites. I’m an executor and David is a procrastinator. We can have very different and opposing viewpoints, but we work well together when both of these sides come through.

Are you able to take breaks together and get away from the business?

DAVID: Yes. We’re able to because we have good people. We’re not paranoid about what happens if we leave. But the Blackberries are always with us. Always!

Do you think you individually and the company would have been as successful if you were not married?

DAVID: I think our marriage tempers emotions in a way that might have driven us apart if we weren’t married.

JEANNE: With all the challenges we’ve had over the years, I think it’s made us stronger as a couple. I really wanted to make this successful. In a more traditional setting I don’t know if I would have pushed and challenged myself as hard. cc

To Don and Alex Wendt, second- and third-generation church painters in Kansas City, truly professional painting isn’t just a job – it’s a calling.

By Steve Maxwell

If you haven’t been into a church for a while, you might consider going for professional reasons. There’s a lot more painting skill behind traditional churches than you might realize, and it’s definitely worth looking at. Alex Wendt, his father Don and long-time friend and painting colleague Cliff Foth are the three men behind Ecclesiastical Studios & Sons, Kansas City, Mo. It’s a third generation firm.

“About 80 per cent of the painting we do is entire interior church restorations,” says Alex. “The rest of our church work consists of statuary and altar restorations. I like restoring these old churches because you can be as creative as you want doing a variety of things – decorative and architectural painting, plaster repair, stenciling, gold gilding and trompe l’oeil painting. Every day is different.”

Restoring old church interiors blends the skills of a classical artist with that of a modern commercial painter. Church spaces

Alex Wendt (left) is a perfect example of a man who learned his trade the old-fashioned way. He’s been following his dad, Don Wendt (right), on jobs since he was three years old. Alex and Don continue the church painting tradition first brought to the family by Don’s uncle.

are often large and tall, and this makes for challenges of scale.

At the same time, church painting also involves brushes small enough to colour the eyeball on a statue of a saint. What could be a wider range of scale than that?

“We always use the very best quality products we can find because materials are only a small fraction of the bid,” says Alex. “Cost of materials is no object with these projects. The majority of our job cost is labour, so we don’t focus on materials cost at all. We’ve heard that some contractors nickel and dime their clients

on every little expense, including the use of cheaper materials. We don’t buy in to this philosophy. Why would we want to trust all our hard work on materials that are lacking in quality and performance? We definitely don’t want call backs because a stenciled ceiling or gold gilding has started to fail.

Looking at the finished projects done by the Ecclesiastical team, you’ve got to wonder about the complication of church congregations choosing colours, patterns and painting styles. After all, it’s hard enough for most married couples to agree

Don Wendt (left) and son Alex (right) are second and third generation church painters. They specialize in all areas of interior churches, travelling up to 500 miles from home for jobs.

All types of painting tools and techniques are used for restoring old churches. Everything from rollers and sprayers to the finest bristle brushes and air brushes.

on two or three paint colours for their home. How much more complicated would it be with a whole congregation fundraising together and trying to agree on the dozens of paint choices that go into a church job? But sometimes when things get too complicated, it actually forces them to become simpler. That’s the case here.

“We like to have complete control over the designs and colours used in each of our projects,” says Alex. “But we sometimes have to work with the priest or church committee on some things like

liturgical rules or designations. Having three generations worth of experience means we have acquired a good deal of knowledge on these historical structures.”

The oldest church that Ecclesiastical has ever painted is St. Joseph Catholic Church in Leavenworth, Kansas. It was 150 years old back in 2007 when it took on the job. The team rarely does new churches, and this means it often has to travel far from home for work. “The distances vary from job to job, but they all require a lot of travel time,” says Alex. “There are only so many churches

Painting church interiors means painting everything. Here Alex is refurbishing a stations of the cross element. Church restoration involves everything from painting massive walls and ceilings to intricate repainting of religious statues. Painting the interior of large churches is a big job, but the threeman crew completes most projects in just 15 to 30 weeks.

close to home that need to be restored. On the jobs that are 500 plus miles away, we usually stay until the work is complete. My favourite part of this business is the restoration phase and seeing the transformation first hand. My least favourite part is being away from home for long periods of time.”

Word of mouth brings most of the work to Alex and Don, but active marketing is part of the mix, too. This includes direct mailings and cold calls. They’ll be trying social media ads soon.

“When we meet with a potential client, we always stress certain things,” says Alex. “First, we never sub anything out. We do all work ourselves all the time. If we can’t do the work, we won’t bid on the job. We also only do one project at a time. This way each client gets our full attention. It helps that we own our scaffolding and rigging, too. We’re comfortable using it and there’s never any delay because subbed-out rigging didn’t happen as it was supposed to. All bids are complete, with no charges added later.”

What’s the most surprising thing about the business side of painting churches? “You’d be amazed at all the legal red tape we have to go through just to get the project,” says Alex. “You need an attorney just to decode the contract, all the insurances you need

to carry, and the sheer volume of paperwork takes a lot of time. It’s not like the old days were you could seal the deal on a hand shake and good faith.

“The thing that impresses me most about our work is the chance to see how these churches were built. Even when you’ve seen as many as I have,” says Alex, “you’ve got to be amazed how these wonderful creations went up, all without computers or heavy equipment. You gotta love these magnificent places.” cc

Horizon® Symmetry™ Collection Decking from Fiberon® features a rich color palette inspired by natural elements and pigments -- and preferred by homeowners over other leading boards. Low-gloss formulation and micro-texturing on top and bottom creates a reversible, matte-surface board with subtle, fluid grain patterns. There’s exclusive PermaTech® surface protection for exceptional stain and fade resistance, and a 25-year warranty for added peace of mind.

How do you top Horizon Symmetry Decking? With Fiberon Symmetry Railing.

Another industry game-changer, Symmetry Railing features an exclusive 12-ft. span, sturdy aluminum sub-channel, hidden hardware, easier installation, and three decorator colors.

Learn more at fiberondecking.com Need samples? Contact your dealer today.

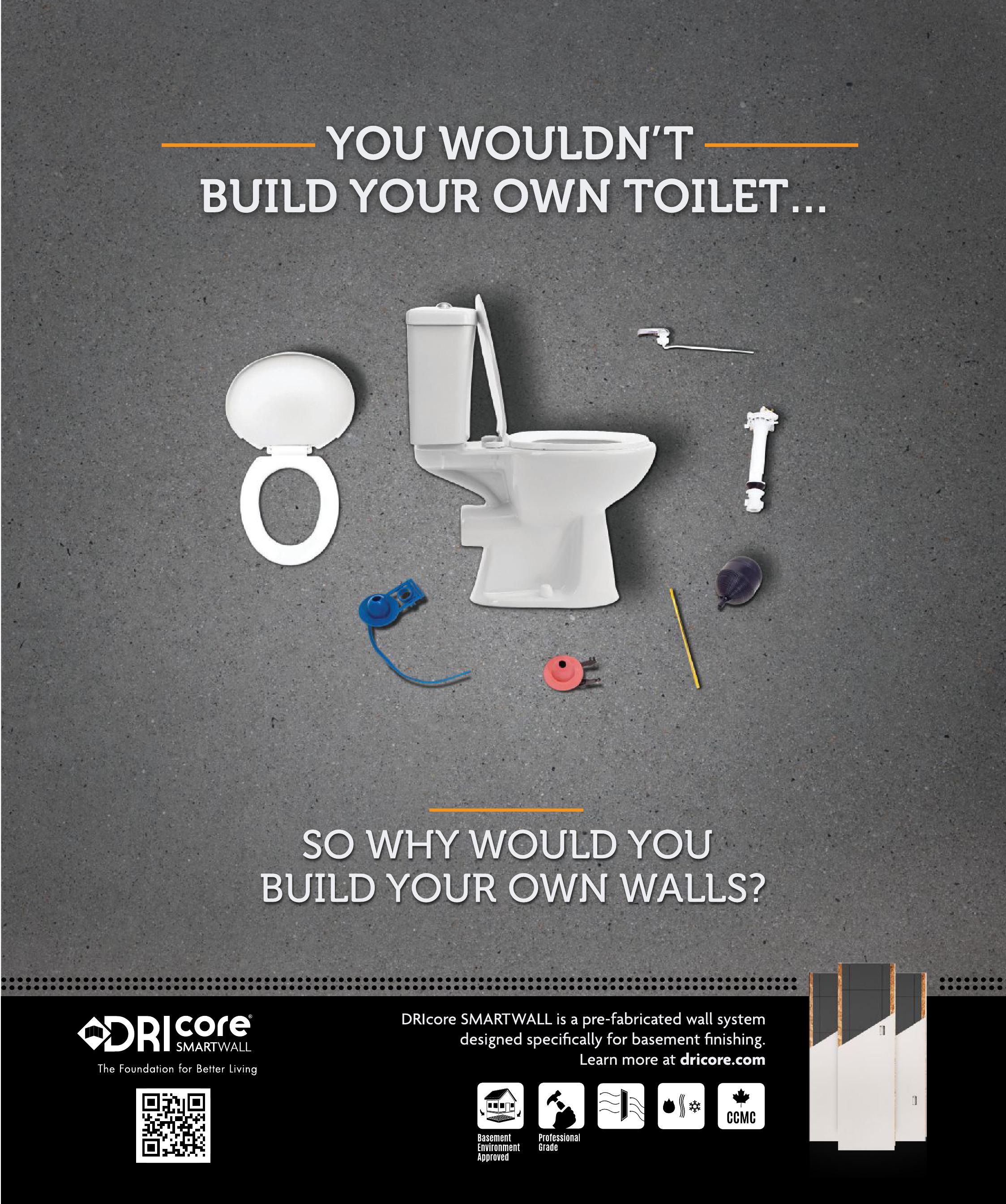

Experts from the Canada Mortgage and Housing Authority (CMHC) predict that we are entering a boom period for basement renovations. The trend is being driven by homeowners’ need for more living space. It’s a terrific opportunity for contractors that have developed good systems for basement finishing using state-of-the-art techniques.

But while the business opportunities in basement renovation work are large, so are the risks. The biggest risk of all concerns moisture. How are you going to make sure that moisture – and its inevitable consequence, mold – doesn’t wreck your client’s dream renovation and your reputation?

As “building envelope” science has progressed over the years, traditional methods of finishing basement walls and floors have come under attack.

The traditional way to renovate a basement is, of course, to use good old-fashioned stud framing, fibre insulation and a poly vapour barrier –just like you would above grade. Nothing wrong with that, right? “It’s the way we’ve always done it,” most contractors will say.

In some cases this method will work. If the contractor has a lot of expertise, specific technical knowledge and the right site conditions – plus a bit of luck – a basement finished the old-fashioned way can work out just fine. But there is a lottery factor at play.

Why? Because moisture – in the form of water vapour – is often on the move through concrete basement walls. In the summer, vapour will tend to move from the outside in, through the concrete and through the batt insulation, until it finally stops at the plastic vapour barrier with nowhere to go. There, especially if the AC is going full blast, the water vapour can condense into water droplets on the back of the vapour barrier. It can begin to pool at the bottom of that wall and begin to rot and mold the wood studs and batt insulation.

Imagine stuffing a wet, used bath towel into a plastic bag – and waiting to see what happens. This can be precisely what you are doing if you

finish a client’s basement with this type of traditional structure. Engineered wall and subfloor systems for residential basement renovations aim to defeat moisture problems like this before they can even start. The leading products in this category, DRIcore SMARTWALL panels and the DRIcore Subfloor system, allow contractors to build with proven moisture-protection technology.

DRIcore SMARTWALL panels are prefabricated, non-loadbearing wall panels that are 23.5 inches wide and 96 inches high with a tongue-andgroove system to interlock the panels together. Vertical and horizontal channels allow for electrical conduit. The panels are insulated with EPS foam (polystyrene) which fills the void entirely, factory-bonded to 1/2-inch drywall. SMARTWALL is designed to allow moisture to move freely back and forth by the way of its semi-permeable vapour barrier. Your walls are allowed to breathe and dry. No more wet bath towel in a plastic bag effect!

On basement floors without a moisture barrier, similar water vapour problems can occur. To prevent this, DRIcore’s Subfloor product is the correct material to use with DRIcore SMARTWALL. This subfloor is comprised of 2-foot by 2-foot tongue-and-grooved engineered tiles. Bonded to the underside of each tile is a high-density plastic layer with “feet” that provide an airspace under the subfloor to allow air to circulate to help dissipate moisture that might collect. DRIcore Subfloor tiles can be covered with floor finishes that range from laminate and hardwood, to ceramic and stone, to vinyl and carpet.

At the beginning of this article, we looked at the reason that basement renovations are experiencing such a boom. It’s about living space. Living space, moisture and mold problems do not go well together. In order to protect your client’s health and your own reputation, consider asking some tough questions about traditionally-framed walls below grade.

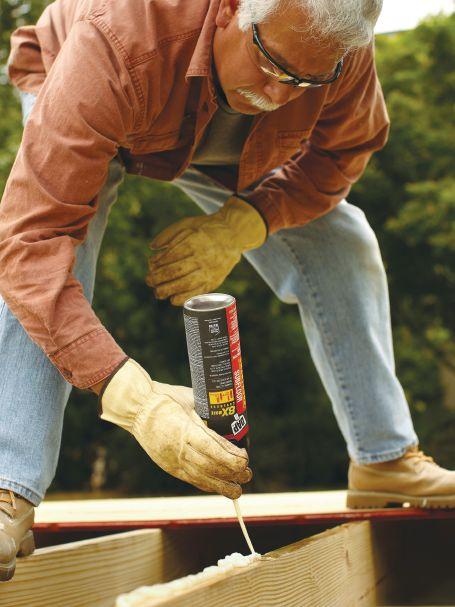

DAP

Smartbond Adhesive

Page 56

Five reasons Canada needs more brick, block and stone

Page 52

STANLEY Inspection Camera

Page 56

Give your customers the power to do more, wait less, and simply live better.

For innovative water heating solutions that enhance the way people live, look no further than Rinnai. In addition to providing an endless supply of hot water, energy savings, space-saving design and environmental benefits, Rinnai Tankless Water Heaters now boast another key product benefit your customers are sure to appreciate: Hot Water Faster!

With the smart recirculation technology of our NEW Ultra Series RUR Model Condensing Tankless Water Heaters, Rinnai delivers:

Faster hot water provided by an integrated recirculation pump, internal bypass line inside the unit, thermal bypass valve and digital timer controller inside the box

Less time waiting, less water wasted

Easy installation and maintenance with Concentric Polypropylene or PVC/CPVC venting providing the most venting flexibility in a single application of any manufacturer, recirculation with or without a dedicated line and included isolation valves

Energy Factor of up to .95 and meets ENERGY STAR® Qualifications

Longer product lifespan up to twice as long compared to traditional tank water heaters* *Based

By Steve Maxwell

Last September I took a trip to Ann Arbor, Michigan. I’d heard good things about this small midwestern city, but I wasn’t prepared for the spectacular brickwork there. It’s some of the nicest I’ve seen. In fact, Ann Arbor is rich with great masonry buildings, big and small. Masonry is part of the charm of the place and this got me thinking.

The world has changed a lot since the beautiful, old buildings of Ann Arbor went up. There are many more cheap and dirty building materials to tempt clients these days, and too many people are giving in to this temptation. Like all cheap-and-dirty

propositions, the promise involves the same lie: getting something for nothing.

The something-for-nothing lie behind cheap building materials is the kind of thing your clients need you to save them from. Once the building is up, it’s too late to learn from mistakes. The crappy crackprone siding is on, the bathroom’s got an exhaust fan that sounds like a lawn mower low on crankcase oil, and the window caulking is as durable as Cheez Whiz. History has just inherited another second-rate building.

Great buildings, neighbourhoods, communities and regions are never built with quick-anddirty materials. Even the “starter” bungalow my grandfather bought in 1950 had brick on all four walls, real hardwood flooring everywhere, and an enameled cast iron kitchen sink that still looked great 45 years later when Grandpa died in 1995.

“But my clients won’t pay for the good stuff,” you say? Maybe, but perhaps you’ve bought into a lie yourself. Have you ever really tried to sell your clients on quality? Have you tried to save them from their own cheapskate inclinations by explaining the lie behind it all? Masonry offers one area in which building quality can be enhanced in a way that clients understand. A reminder about the benefits of masonry is what you’ll find in this month’s Stuff We Like section on page 52. As you read it, keep something in mind.

A hundred and fifty years ago, the people of Ann Arbor, Niagara-on-the-Lake, Victoria, Quebec City and every other old, great place in the world were much poorer than we are today. Tradesmen back then had tools we’d laugh at now. Building products were harder to come by. Life had far fewer luxuries. Yet despite all the reasons to cut corners, all those now-gone contractors of yesteryear often enjoyed the luxury of working with better materials than we do today. With the exception of energy efficiency (which we’re clearly better at), why do so many old buildings look, feel and age better than run of the mill buildings today? Aren’t we supposed to be better off than our grandfathers? Maybe our world needs to understand that just because something can be built more cheaply doesn’t mean it should. And could it be that the best people to preach this message are building professionals just like you?

steve@stevemaxwell.ca

By Steve Maxwell

Whenever I go to Europe, I feel jealous. It’s all those solid houses. They use so much more masonry across the Atlantic than we do here, even in regions that get colder and hotter than Canada. Masonry makes for substantial, sound-resistant and long-lasting results. Even partition walls in Europe are often made of solid masonry. While there certainly are situations in which non-masonry building materials make the most sense, here are five reasons I keep thinking we should be using more masonry.

Rebar and fiber used together is the best way to reduce cracking of concrete structural slabs, but this only works if the rebar is actually completely surrounded by concrete. That’s where rebar chairs come in. One of the most common lies contractors tell themselves is that we’ll pull that rebar up during the pour. Right, while you’re standing on it? Better get some chairs. And if that rebar is supporting hydronic heating lines, chairs mean more consistent pipe levels and more even heating.

Why is there a difference in “masonry consciousness” between Canada and other parts of the world? One reason is our building heritage. A hundred years ago the place where my house sits was virgin wilderness. A pioneer family named Taylor spent their entire lives dealing with a vast over-abundance of wood on their land. This is the same story across much of Canada, and our once-upon-a-time abundance of wood is why we have a heavily wood-based building culture today. But times change and the building business is following.

Twenty nine years ago I built my first masonry exterior walls, and they still look brand new today. That’s because three decades is nothing compared with the working life of properly built masonry. Not many other exterior wall materials can compete with good brick, decorative block or stone. A poured concrete foundation is still the industry standard for strength and durability. Natural stone is the king of building materials and always will be.

The great places of the world are all made with great materials. But we live in a time when the prominence of quick-and-dirty consumer goods is on the rise. Ultimately this trend is fueled by the fact that people like low prices way too much. But isn’t it also true that no diligent contractor gets in the business to satisfy an urge to work with cheap materials in a race to the bottom? You probably feel an attraction to craftsmanship and the chance to build something that people will admire a century from now. I know I do and classy permanence is one reason I like masonry.

Whether or not you believe that destructive weather events really are on the rise, some people want a home that can stand up to anything. That’s why disasterresistant housing is a trending feature for more and more clients. Part of this is demographic. As the population ages, physical security and solidity become more valued. Insulated concrete forms are one example. Built properly, a disaster-resistant ICF home can withstand the kind of severe weather events that regularly destroy non-masonry structures. In fact, this happens all the time. The ICF home to the right fared a lot better than other kinds of houses (and even cars) in a hurricane.

Sometimes the top of ICFs remain visible in the finished project, so you need to protect the foam in some way. This happens when an ICF foundation wall ends at a garage door, for instance. One of the best options is some 2 1/2-inch wide track for steel studs. Many ICF systems use foam that’s also 2 1/2 inches thick, so the track slips down over the exposed edge perfectly, protecting it while making it look great. The steel cap here is actually two caps, one on top of the other for extra protection. After eight years of traffic, it still looks great.

Not every client can afford masony. But then again not everyone understands that $4/sq.ft. siding isn't necessarily the bargain it seems compared with $16 to $18 per sq.ft. exterior brick. But the fact is, even for people who look at homes as investments only, masonry still makes sense. It costs more up front, but this translates into more when it comes time to sell. In fact, a brick wall will continue to look new for longer than other materials, so the long-term payoff is actually higher. Some jurisdictions in Canada are catching on to this idea too, exploring local building codes that require masonry exteriors.

Every time you build or renovate, you’re on the hook for the continued performance of your work. There’s a time limit on this, of course, but at any given moment you’re vulnerable to call backs on dozens – maybe even hundreds – of projects. All else being equal, the proven reliability of properly installed masonry translates to less financial vulnerability to worry about.

Every time you build something you either add to your reputation or subtract from it. Masonry’s reputation for quality not only benefits your clients, but it looks good on you, too. Communities are starting to appreciate this fact as well. The simple truth is that once a home or commercial building is done, it exerts a permanent influence on the flavour of a place. Some building authorities are even mandating against cheap-and-dirty building materials in favour of masonry. That’s a good thing in my book. Visit places like Niagaraon-the-Lake, Victoria or Quebec City. Beautiful masonry is one reason people travel to these cities from around the world.

Next time you’re pouring concrete, make it easier for your crew to vibrate it properly. The current boost-in battery technology means that cordless concrete vibrators make sense for small and medium-size jobs. Much handier to use than corded vibrators, convenience means it’s more likely vibration of poured concrete will actually happen like it’s supposed to. You'll still need to use a corded vibrator for large pours, but cordless has its place when finesse is required. ICFs are an especially good place for a cordless vibrator.

There’s only one construction power tool that’s remained unchanged since it was invented in 1885. That’s when 29-year-old William Holden unveiled the air hammer. Designed to create a more rapid version of hand-driven hammer blows that propel masonry chisels, air hammers sold new today are virtually identical to the ones Mr. Holden designed. Nothing compares with their effectiveness for applying textured patterns to concrete and stone. Air hammers also make traditional stoneworking a lot more efficient. That's how I use these tools.

In the last 20 years, diamond masonry blade technology has improved in two ways. First, the blades cost at least 75 per cent less now. And second, today’s diamond blades cut much faster. The best 14-inch masonry blades I use today cut almost twice as fast as the first one I bought for a whopping $600 back in 1992. These days you can get more-than-decent 14-inch diamond blades for less than $200 each. Dry or wet cut? Most blades are designed to work fine either way, but water injected into the cut is always better when you can get it. Besides making your blade last longer, water eliminates the mushroom clouds of dust kicked up by dry cutting.

Construction adhesive in caulking tubes has done a lot to make subfloors quiet, but it’s also a pain to use. Because it's thick, goopy and especially hard to gun in winter, my love-hate relationship with caulking tube adhesives prompted me to take a look at DAP Smartbond Subfloor. It’s an aerosol replacement for ordinary subfloor glue, and it impressed me in three ways during my tests. First, a single can goes a long way. The label says it replaces eight contractor-size caulking tubes, but even if you’re sloppy and only get half that yield, Smartbond still works out to 50 per cent less money for a given area of subfloor. Second, Smartbond is polyurethane based, so it works fine on wet or frozen wood. It looks just like polyurethane spray foam sealant when it comes out, then settles down into a semi-liquid, expanding a little to fill gaps as it cures. And finally, Smartbond goes down much more quickly than tube adhesives, even if you’re using a cordless caulking gun. It costs $25 for a 20 oz can, cleans up with acetone and comes in heavy duty and landscape versions. Each can includes a tight fitting plug if you don’t use the whole thing.

Every contractor could use an inspection camera from time to time, but that doesn’t mean you can justify the cost of owning an expensive one. At $149, the Stanley STHT77363 offers the best combination of performance and low price I’ve seen. The simple, no-nonsense design uses four AA batteries to power the 1 3/4 inches x 1 3/8 inches screen. You don’t need to be a computer geek to understand the simple four-button control, either: ON/OFF; image orientation; screen brightness adjustment and adjustment of headlight brightness on the end of the 36-inch flexible wand. The camera does a great job even in complete darkness. Hooks, a magnet and a mirror are included in the kit and can all be fitted to the end of the wand to retrieve objects or inspect more closely. A remote video output port lets you watch the footage on a separate screen. All in all this is an impressive, economically priced tool with a two-year warranty.

You know what it takes to be successful. It starts with elevating your game, and we’ve raised ours to give professional roofing contractors, like you, an even greater advantage.