STAYING CLOSE TO THE WORK

Avi Gilbertson keeps the focus on craftsmanship at Gilbertson Fine Homes

By Patrick Flannery

Editor

” It’s pretty clear that Ontario municipalities, with some prominent exceptions, don’t feel they can afford to bring development charges down. And they are probably right. ”

A CHARGED DEBATE

Amajor feature of the spring Ontario association conferences this year has been a steady drumbeat of complaint about municipal development charges. It’s certainly the position of RESCON and the Ontario Homebuilders Association that these charges are far too high and escalating out of control while not delivering the intended infrastructure benefits. They blame development charges for driving the price of new housing up to a point where it is unaffordable and builders won’t build because buyers can’t buy. Ontario premier Doug Ford appeared aligned with this message in his speech at a RESCON meeting, bemoaning the high fees and taxes afflicting builders and praising the efforts of places like Vaughan and Brampton to cut back DCs.

Let’s turn to the mayor of Ajax, Ont., Shaun Collier, for another perspective. He was one of five mayors on a panel at the Durham Homebuilders’ Central Ontario Summit. Durham region is an area of Ontario bordering Toronto to the east.

“I heard the comment this morning that we don’t understand DCs or they have no use for us, which is completely wrong,” Collier said in a blunt tone. “We absolutely do. But what’s happening is, DCs we collected 10 years ago, when we go to build a road or a sewer or any type of infrastructure today, is only maybe a quarter of what it actually cost me. Guess what? DCs are going up. Because we have to start looking at the long term, how to pay for the growth. There are some major capital investments coming. So just a bit of a heads up. We do know what they are. We do know how they work, and that is one of the big challenges going forward.”

DCs are going up? Needle scratch.

Collier’s comments dovetailed nicely with an anecdote Steven Del Duca, the mayor of Vaughan, Ont., told at RESCON. Del Duca has cut development charges nearly in half in Vaughan, though they were some of the highest in the country when he started. He told a story about a meeting he was in for York region (a regional authority comprising several towns near Toronto).

“I moved a motion in new business that we have regional staff report back to council [...] on strategies such that we can consider a reduction in residential development charges.” Del Duca related. “I didn’t pick a number, didn’t say we had to do it. I just wanted a report back. I just wanted to empower the elected officials, the 22 of us in that chamber, with enough information to make an informed choice, given the gravity of the housing affordability crisis that we all face.”

Del Duca’s motion didn’t go well. “Every single other member of regional council who spoke that day – other mayors that we all know well, all dear friends and colleagues of mine – went on to speak after I made that request in such strong terms, in such critical terms, against the simple concept of a staff report,” Del Duca remembered. “Another mayor, a very dear friend of mine, used the term fools three times in a five-minute intervention to describe the very concept of even considering a reduction in residential development charts.”

It’s pretty clear that Ontario municipalities, with some prominent exceptions, don’t feel they can afford to bring development charges down. And they are probably right. Over the last three decades, Ontario municipalities have had to shoulder a frankly incredible burden of expenses. It may be time to revisit those funding models in order to get the progress we need on homebuilding.

Digital channels connecting you to critical information

Whether you like to read, listen or watch, Canadian Contractor has you covered.

DIGITAL EDITION ARCHIVES

Flip through the digital versions of your favourite past issues of Canadian Contractor. All available in the digital edition archives at canadiancontractor.ca.

THE HAMMER

High-profile wildfires doing substantial property damage to urban areas in B.C. and Alberta have spurred NRCan to look at creating Canadian building standards for wildfire resistance. It seems likely that some day soon we may see new codes requiring resistant windows, doors and other components in wildfire-prone areas. Robin Urquhart of RDH Building Science has worked on rebuilding communities destroyed by wildfires and joins The Hammer to share his deep knowledge of this topic.

COVER STORY

Looking for a longer read in your inbox? Each month, Canadian Contractor delivers a full version of one of our features straight to your email. Kick back on the dock or the deck and take in an engaging reader profile, an informative technical article or an inspiring project review – right there in front of you.

ONLY THE GOOD NEWS

Sometimes we all just need a break from the chaos in today’s headlines. Canadian Contractor is here for you with a monthly special version of our e-newsletter focused on the happy events in our industry: someone gets a new job, a company makes a nice donation, a reader wins an award, etcetera. It’s a lighter, uplifting read, delivered free to the inbox of our digital subscribers.

Editor Patrick Flannery pflannery@annexbusinessmedia.com

Brand Sales Manager Nav Matharu (226) 931-5095 nmatharu@annexbusinessmedia.com

Account Coordinator Barb Comer bcomer@annexbusinessmedia.com

Audience Development Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com

Media Designer Jaime Ratcliffe

Group Publisher Danielle Labrie (226) 931-0375 dlabrie@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Tariff turmoil

The first quarter of 2025 saw significant economic chaos as U.S. president Donald Trump threatened, imposed and withdrew a number of different tariff policies on a number of different sectors and countries. In his April 2 “Liberation Day” announcement, he did not impose the across-the-board 25 percent tariffs on Canadian imports he had previously threatened, so Canada did not apply the additional $125 billion in retaliatory tariffs to American imports it had promised in response. He did apply tariffs to some automotive imports, triggering Canadian reciprocal tariffs on imports of U.S. vehicles.

The so-called “fentanyl tariffs” of 25 percent (10 percent for energy and potash) announced back in February still apply on all Canadian imports not registered under the Canada U.S. Mexico trade agreement. Separate American 25-percent tariffs on steel and aluminum imports also remain. So the $30 billion package of Canadian retaliatory tariffs on American imports also remains in place, affecting this list of construction products:

• Plastic floor, wall or ceiling coverings;

• Self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics;

• Baths, shower-baths, sinks and wash-basins;

• Lavatory seats and covers;

• Doors, windows and their frames and thresholds for doors;

• Most pre-cut wood products, including veneer, flooring, particle board, fibreboard, plywood, wood doors and

windows, shutters, post and beams, shingles and shakes, flooring panels, glulam and engineered timber;

• Power, pneumatic, hydraulic and manual hand tools of just about all kinds;

• Table, floor, wall, window, ceiling or roof fans, with a selfcontained electric motor of an output not exceeding 125W;

• Chandeliers and other electric ceiling or wall lighting fittings.

U.S. stock markets dropped 17 percent in the days following the April 2 announcement and bounced part way back when Trump announced a 90-day “pause” on April 9. Today, the markets sit about eight percent below where they were at the start of the year. Economists now predict a general recession in both the U.S. and Canada and Canadian Contractor readers are reporting difficult sales conditions.

MMI evaluates Liberal housing plan

The University of Ottawa housing think tank, Missing Middle Initiative, has evaluated the new federal government’s housing policy released in the April election in an article titled “10 Thoughts on the Liberal Housing Plan.” The full article can be found at missingmiddleinitative.ca. From the article:

There are over a dozen commitments in the Liberal housing plan, which can be broken down into a few categories:

• Creation of a new crown corporation called Build Canada Homes (BCH);

• Innovation policy to help increase productivity and lower costs in the homebuilding sector;

• Tax reforms and a cut to development charges to lower costs and attract investment into homebuilding;

• Regulatory reforms.

The Liberals clearly want the Build Canada Homes promise to receive the most attention, as it is listed first and in the most detail. It seems to have worked; the bulk of the media attention on the plan has centred around that promise. However, we believe that the tax reform pieces, rather than Build Canada Homes, will have the largest impact on homebuilding.”

Most of the housing policy is of more interest to developers and tract builders. Innovation funding from the BCH is going to be channeled to prefabricated home builders. Promises to reduce development fees are related to multi-family builds. The GST rebate will only be offered to first-time homebuyers (something the MMI criticizes).

Thousands of Quebec construction workers to get cheques

The Quebec Superior Court has ordered thousands of Quebec workers and contractors be compensated for time and expenses lost during an illegal strike launched by two of the province’s largest trade unions in 2011. FTQConstruction and Inter were ordered to reimburse Quebec workers for time lost on Oct. 25 of that year. Parties have until April 15, 2026, to file their claims online. Successful claimants will get direct Interac transfers of up to $500, less fees. Lawyers who brought the class-action suit estimate between 60,000 and 80,000 workers may be eligibile.

Alberta building houses faster

According to a provincial government release, Alberta is the only province in Canada meeting its targets for homebuilding. Year-end data from the Canada Mortgage and Housing Corporation (CMHC) indicates a recordbreaking one for homebuilding in the province. Alberta led the country in housing starts per capita in 2024.

According to the latest National Rent Report from Rentals.ca and Urbanation, Alberta was the province that experienced the largest yearover-year decline in asking rents in 2024. Calgary saw the biggest drop in rental prices in the entire country, with Calgary’s apartment rents decreasing by 7.2 percent. Outside of the larger cities, Alberta communities made up six out of the top 10 most affordable small- and mid-size rental markets in Canada, including Lloydminster and Fort McMurray.

Alberta’s government says it supports builders and encourages new residential housing construction by cutting red tape, incentivizing housing construction and supporting innovative strategies that speed up the home building process. Over the past year, some of the province’s work on this has included launching the Stop Housing Delays online portal, making provincial land available for housing, exempting designated affordable housing from property taxes, supporting home ownership through alternative financing options and taking action to ensure Alberta receives its fair share of federal funding for housing and that the funding meets provincial priorities.

In 2024, Alberta saw 46,632 new homes under construction, breaking historic records. Alberta led the country in housing starts per capita for 2024. Provincewide, housing starts for 2024 compared with 2023 were 46,632 compared with 35,223 (up 32 percent).

Saskatchewan backs off energyefficiency standards

The government of Saskatchewan has moved energy efficiency requirements in new Part 9 buildings back to Tier 1 of the National Energy Building Code. This level requires the dwelling to be equally energy efficient to a reference model design. Saskatchewan initially mandated Tier 2 (five percent better than the reference) when it adopted the NECB in 2024 and announced at that time plans to move Saskatchewan housing to Tier 3 (10 percent better) by the start of this year.

The Saskatchewan Ministry of Government Relations is saying the move is aimed at improving housing affordability. The Construction Association of Saskatchewan is supporting the change.

“All provinces are dealing with the challenges of growth, including affordable housing for all residents, and removing red tape allows us to harmonize our standards and support Canadian industries,” government relations minister, Eric Schmalz, said. “While Saskatchewan is one of the most affordable places to live in Canada, we understand there is more work to be done, and we have heard from industry that this decision will help maintain housing affordability in the province.”

“Let’s be clear – our industry will continue to build safe, durable, and energy efficient structures because we take pride in our work and the communities we serve,” Construction Association of Saskatchewan treasurer, Dan Yungwirth, said. “This change allows us to prioritize affordability while still achieving exceptional outcomes.”

“Eliminating red tape is always a good thing when it comes to affordability,” Construction Association of Saskatchewan president and CEO, Shannon Friesen, said. “We trust the expertise of Saskatchewan’s construction professionals who have a deep understanding of our province’s unique climate and building needs. With less red tape, our industry can continue to deliver exceptional, high-quality infrastructure that meets the needs of our communities.”

B.C. court rules contracts must include a completion date

A provincial court in B.C. has ruled in Fan v. Northern Tropic Homes that the British Columbia Business Practices and Consumer Protection Act requires home renovation contractors to include a project completion date in contracts with clients. Failure to do so entitles the client to cancel the contract at any time within one year of its signing, with a full refund and no deductions.

The defendant in the case was a B.C. company contracted to build a sunroom in late 2021. Ten months later, no work had begun on the project and no building permit had been issued. The defendant cited rising costs and supply chain issues related to COVID and asked for additional payment to complete the work. The homeowner then cancelled the contract and asked for the deposit back. The defendant refused, citing planning and design work already done and parts already fabricated. So the homeowner sued and the court found in their favour because the contract had not included a completion date.

The defendant argued in the case that asking for a completion date in construction contracts is unreasonable due to the uncertainties inherent in the business. The court rejected this argument on the grounds that the Act does not specify how far out the completion date may be, nor does it prevent contractors from including clauses allowing for the date to be adjusted or work suspended contingent on circumstances.

STAYING CLOSE TO THE WORK

Avi Gilbertson keeps the focus on craftsmanship and client trust.

By Patrick Flannery

AviGilbertson’s motivations come from being close to the work and the clients he serves. He has the basic craftsman’s love of the project itself. He understands that there are a lot of ways to approach this business and has made a specific choice to stay small and stay focused on the kinds of work he likes to do. “One of the afflictions on the construction market right now is management,” he explains. “You don’t really get a carpentry company any more. A carpentry company now would subcontract to a general contractor. Everybody’s really specialized for these

bigger projects, which I understand. But the core value of what I’m about is appealing to somebody who owns their home. You want to renovate it, you want to build a new home or you want to do an addition. You want to have some meat and potatoes things done to your house, a project. Do you really need a construction manager, a project manager, a project coordinator? I really want to provide a more personalized service.”

That means Gilbertson is happy to get down with every aspect of the job with his clients, from shopping and selecting finishes through developing

plans though executing the job. “I want to be the one doing. I want to set it up for myself to come into your home and make a difference, make it all visible. You’re going to come to the work site and you’re going to see me there pretty much every day.” Gilbertson has two employees but is very much on the tools himself.

Gilbertson Fine Homes is a renovator and custom homebuilder located in Nanaimo, B.C., serving Vancouver Island from Qualicum Beach to Lake Cowichan. GFH is a Net Zero builder and a member of Built Green and the

Vancouver Island Canadian Home Builders’ Association.

Gilbertson learned the trade on B.C.’s Sunshine Coast in Sechelt, working for family friends and old-school builders who emphasized the fundamentals. It was a great start, but he was hungry for larger challenges and Sechelt was a small market. Across the Strait of Georgia, the lights of Nanaimo beckoned from Vancouver Island. He had done some subcontracting for construction companies over there and was finally presented with an opportunity from Creative Concepts Construction to manage a large project in Ucluelet, B.C.. Gilbertson calls it his “golden ticket” opportunity. Instead of completing little renovations here and there, he was suddenly handed management of a multimillion-dollar project. He felt like he’d been handed what he had been seeking, going from managing two or three workers to having control over a full site with 12 to 15 employees on the job. “It went pretty damn well for all that I was kind of thrown to the wolves and had a learning curve,” Gilbertson remembers. “It was problem solving every day, dealing with the weather out there – everything. That was really the big ‘I can do this.’” Gilbertson worked for three and a half years for Creative Concepts before starting to think about the next opportunity.

“My job is to take my hand, stick it in your pocket, and spend your money.”

establishing trust with his clients and only taking projects that can proceed on that basis. “On thing I tell my clients is that my job is to take my hand, stick it in your pocket and spend your money,” he says. Maybe not a slogan you put on a sales brochure, but it establishes parameters in the relationship that are more likely to result in a happy outcome for both parties. Gilbertson has arrived at this approach after seeing contractors bid low to get the contract, then have to squeeze every penny along the way to achieve a specification that may not have been realistic. “I hate doing the hard sell mid-project,” he explains. He prefers to walk away from clients with unreasonable expectations at the outset and has done so many times. But he makes sure the trust goes both ways. If he’s going over budget on some unforeseen aspect of the project, Gilbertson will sometimes eat some cost in order to keep things on track. “I’m here for the passion,” he says.

Part of establishing that trust with clients has been organization and transparency. Gilbertson tracks his costs with a custom spreadsheet his office manager, Jennifer, developed. The spreadsheet not only records what has been spent, but updates projected costs on a bi-weekly basis. He’s

That came from a friend who was gaining rank in a building company of his fathers and needed a project manager. Gilbertson took the role and appreciated the chance to learn how another company operated. He liked the culture, liked his co-workers, but the skyrocketing cost of property and impending recession on the island was reducing the amount of work his employer could get. “Probably not a great time to make that kind of change,” Gilbertson reflects ruefully. He was spending more time on the tools than anticipated and was becoming concerned that he wasn’t advancing his career. Ron, being a very motivational employer, encouraged Gilbertson to strike out on his own.

So about two years ago Gilbertson left his employment with a newborn son in the house and started putting together his own company. The work before he could even take his first contract was enormous – getting his builder’s license, getting insured, building a website, making sales. That effort took about four months. Then it was time to hit the ground running with any jobs he could land. “The first couple jobs were…I describe them as ironing,” Gilbertson says. Small renovations and repairs well below the kind of creative custom homebuilding he aspired to. But he applied careful management and professionalism to them anyway. “I really take a lot of pride in my process,” he says. Having seen how multiple different builders approach construction, Gilbertson feels he’s come away with a solid understanding of what works, what doesn’t and what he’d like to try to do differently. He says he’s found out that managing a project is a lot different from managing a business.

For one thing, Gilbertson has learned to prioritize

found it makes his cost-plus contracts much easier for clients to understand and agree to. But he’s happy he put in the time and effort to develop his own system rather than pay for one of the off-the-shelf software products. He estimates he spent $4,000 developing his own tool, but now that the work is done, he is not spending $500 - $1,000 per month for a platform that has far more features than he needs. Keeping it simple is very important to him. “Jesus was a carpenter,” he says. “It’s an old trade. We’re not building skyscrapers. Once I get into planning a project, I can pretty much visualize the entire thing in my mind. Software definitely helps but actually knowing and being in touch with a project just outweighs software.”

Unsurprisingly for someone so focused on the craft, Gilbertson is is not enthusiastic about the process of promoting the business. “With the amount of effort I have to spend marketing myself I’d way rather be building your house,” he grumbles. “We’re all out here like peacocks trying to flash our feathers. You’ve got to have a flashy website, all the company trucks. I’d rather just be your neighbour. You’ve seen me – yeah, that guy down the road who does renovations. You want to change up your bathroom, give him a call. That’s not the world we live in anymore.” Yet Gilbertson maintains a slick website with a blog and professional photography and a social media presence. He does it all with a little help from friends. A socialsavvy friend from back in his days with Creative Concepts, Melissa Kruper of Everlign Social, helped refine the website his

The beautiful B.C. coast is the perfect backdrop for a jobsite.

Carpentry is an old trade and Gilbertson appreciates the simplicity.

nanny had built and launch accounts on Facebook, Instagram and LinkedIn. Adam Price, Audio Lens Creative, is a friend and photographer who produces great images like the ones in this article. One thing Gilbertson is looking forward to a bit more is doing more writing on his blog and hoping to pull in other local builders to share their thoughts on important local issues. “I definitely have a few perspectives,” Gilbertson admits, “and, if you’ve talked to anybody who knows me well enough to sit down and have a coffee, they’ll tell you I’ve got some strong opinions on the market.”

One of those opinions is that the cost to build homes in Nanaimo is too high, but that the region justifies the cost of living there. He has a story about him and another local builder having a conversation about a friend in Kentucky. They have a large farmhouse, indoor riding ring and a marvelous shop, with about 70 acres of beautiful farmland and pasture. The place cost about $400,000 USD. Gilbertson and his friend were marvelling at the low price and kicking around the idea of moving there. “Sounds great,” Gilbertson remembers. “Then, we kind of looked at each other and his friend despairingly says “Yet, we’ll never leave.” And we don’t. We hear about these places that are more affordable, but we don’t leave. There’s something special about where we live and people are willing to pay the price to be here.”

As long as that’s true, Avi Gilbertson and Gilbertson Fine Homes should find a bright future in beautiful B.C.

INSPIRATION ALLEY

Three Canadian contractors take us inside their awardwinning interiors.

By Patrick Flannery and Gordon Wornoff

On the fireplace beach wall, we used large porcelain slabs to clad that. I really love that veining look. And then I used that same material in the back splash for the rest of the kitchen. The flooring is porcelain floor with tile from Julian Tile. It’s strategically selected because it looks like hardwood, but it’s tile, so it’s super durable. Never have to worry about dogs scratching it or kids or anyone else. This property’s got hydronic heating everywhere, so it’s all toasty warm on your feet.

We used fir on the slats. There’s wood vertical slats in the foyer and in the great room feature wall that were stained on site. And along with that little kind of a seat there at the bottom of the fireplace, that’s also fir that was stained on site. [Designing the fireplace] took me a lot of time until I was happy with it. A lot of sketching and drawing and playing with colours, but it was worth it. I was hemming and hawing about the tile for the fireplace. I almost went with Dekton, but Dekton is costly and I found a porcelain slab at Julian that looked pretty similar to what I was looking at. So I decided to change courses and went with the porcelain.

MID-CENTURY MODERN

by Vicky’s Homes, Edmonton

Vicky Kujundzic, owner of Vicky’s Homes, takes us through her Mid-Century Modern renovation, a finalist for the 2025 national Canadian Home Builders’ Association’s Best Whole Home Renovation Over $800,00 award.

The great room was eight feet tall and had a little higher portion in the middle. So we completely ripped off the roof and the side walls and we raked it up. We went from eight feet to about 16 feet there.

We added some floating countertop stairs so we can have chairs where you can watch kids that are playing in the pool. I have my laptop set up there. That’s where I spend a lot of time. It’s kind of like a tropical view – it makes me feel good when I’m working. I love it. So I sit there a lot. My kids have breakfast there. If you zoom in closely, you’ll see there’s a phone charger there on the wall. Those are some cool phone chargers. So when guests are over, they can always just pop in their phones and charge them because a day never goes by without someone asking me, “Oh, do you have an extra phone charger for me to charge my phone?”

That’s one sole piece of glass [on the opposite wall.] It almost could not be done. It maxed out what they could bring in. I was first told no, that couldn’t come in one piece. Then I had to push back: please, I need one piece. Nerval did that.

This originally was just a room that had a circular fireplace in the middle of it, so I’m not sure what the other family used it for, maybe just congregating around a fireplace in the middle. But my family loves watching movies, so we moved that and changed it into a family movie room and a games room. So we play cards and games on that round table there and there’s also a wet bar.

The dining room was opposite where it was higher towards the front and it came really low. Maybe it was even seven feet at the very back, where the beautiful view is. It was the lowest ceiling. So we completely flipped that upside down. The roof and the walls were completely taken down. So we built the walls and we used spray foam. We put in the curtainwall of windows there. That’s from Durabuilt. You can see there’s no header in between the top portion of the windows and the bottom. Usually you’ll see a header that’s drywalled and breaks up the upper and lower windows. Well, this is all windows, so that was specially engineered for that space. So they cost a pretty penny, but it’s quite beautiful.

The original home had exposed beams. We wanted to carry through that exposed wood beam look throughout the great room and the dining room, so we brought that back into the space as well just to add a bit of warmth and to fit that mid-century modern vibe.

MID-CENTURY MODERN

by Vicky’s Homes, Edmonton

Those are lovely swing chairs where you can sit and have a drink at the bar. The whole pool room was just gross and rusted out, and we had to rip out the whole pool liner. It was all falling apart and crumbling and mould. So we had to redo the pool, reinforce it, put steel wall panels throughout the pool, fix all the cracking and put new liners in. We needed a whole new furnace and HRV system in there. Originally the house had ducts in the floor that pushed the air up through the floor and it was all rusted and had dirt from the earth in there. It was all falling apart and wasn’t very healthy. So we just terminated all those. The heat runs in the floor…we created hydronic heating lines instead. We have a high-velocity furnace in there and a couple HRVs – like big, massive HRVs. And we did an addition in the front of the house where we created the tiki bar. And there’s also a hot tub out there. And we created a counter by the hot tub so guests can sit outside the hot tub and still communicate and interact with people in the hot tub. And we added a bathroom as well. That space did not have a bathroom, so we have a full shower and everything in there and a little bit of a change room. We also foamed the walls and ceiling and everything. And added all those pot lights, all those pot lights are new. Pretty much everything is new in there. The beams are original to the house, we just painted them. They’re just glulam beams. Every beam has lighting and different colors.

Those are really cool cabinets. We wanted something different, something that wasn’t so boring as a regular closet door. So we went and worked with Town and Country on this. Alana is our our designer there. We love her very much. She’s very talented. It’s a shape of a sun, right? Which I love. So that sun could have been proud or it could have been recessed. The technology is really improved on what they can do with cabinetry these days. We wanted a nice little feature so this sun design was selected as something cool, and having some fluted doors there just kind of jived with our theme.

The kitchen is completely different from what was there before. I wanted to be able to work in the kitchen to where I could see the kids in the pool and also enjoy the view on the on the other end. So orienting the kitchen that direction allows me to see kids and entertain with guests who are in the great room and have the beautiful view as well of the trees and forest behind. So it was a winwin. The bar fridge and the wine fridge were strategically put there because when we’re entertaining I don’t really like to constantly serve people and ask people if they’d like a drink so everyone knows, please help yourself. So they’re strategically put there kind of out in the open so people can help themselves. That countertop is Dekton so you can put boiling pots of water on it. You can cut on it. You can put the knife right on it. You’ll damage your knife and not the countertop. So it’s a super-durable product. But the back splashes you’ll see there are porcelain slab, which actually looks very similar to that Dekton piece. So we matched products and I don’t think anyone notices that it’s actually a different material. I like the subtle black. It’s not a black in your face. It’s kind of a gunmetal colour.

So there’s a spiral staircase and above the spiral staircase is an office space they had. So we blew out that back wall of the office and created a master bedroom upstairs because this house was only a onebedroom house on the main floor. We needed more bedrooms because there’s three kids. So we created a master bedroom and suite and a mini office upstairs. By extending the master bedroom, we created a covered deck at the back that has electric screens. It also is roughed in for soffit heaters as well and outdoor televisions too. We used decking because it looks warm and cozy like the inside of the house. We kind of wanted to bring the inside out.

I gave [our finisher] a sketch [of the slats] and he made it happen. Fir fluting. Those are original stairs, we didn’t touch them. They’re grandfathered. If we removed them, we’d lose it being grandfathered. So that’s the original stair. It still squeaks and all but we love it. You can’t [replicate that] now, it’s not allowed, it’s against code. It’s too tight of a spiral. And they’re quite dangerous, actually, because it gets quite narrow in the inside portion. So that’s not allowed. But I love that feature. There’s no other way we can get a staircase to go up there that would follow code anyway. So we had to make it grandfathered. We love it. I wish we could do them in houses we build these days.

The interesting thing with this one is that we designed the whole main level and the upper level as one project. This was in COVID and prices were changing. So they decided we were going to focus our efforts on the main level because costs were getting kind of crazy and they wanted to do some significant work. They wanted to update all the installation throughout the home and make sure it was much more comfortable, change some windows and the patio door. They didn’t want to sacrifice how far they would take a particular, you know, level of the project. So they opted to phase it. The way we always approach design is we will let people know that it’s always best to come with a holistic approach where we detail out the entire building so we can understand what are you wanting to accomplish in the future. And in this case, it ended up working out because although they phased the upper level, we did it as part of the overall concept. We relocated their laundry room and we changed it around, I believe there’s a bedroom that we converted into a bathroom in the upper level for the ensuite. So we were able to do all the plumbing and some of the HVAC ahead of time while we had the ceiling open and we were doing the structural work on the main level.

NOT A COOKIE CUTTER ANY MORE

by CCR Rebuild Remodel, London, Ont.

Peder Madsen, owner of CCR Build + Remodel, spoke to Canadian Contractor contributor, Gord Wornoff, about “Not a Cookie Cutter Any More,” his London, Ont., renovation project that is a finalist for a 2025 national CHBA Best Whole Home Renovation $200 – 300,000.

Oddly enough, we we actually closed off some space. There was an access to a powder room and it just seemed kind of funny coming right off the kitchen. So we closed that powder room location and we flipped it over to the other side, closer to the patio door going outside. There was a door to the backyard right next to the powder room. So that got closed off and became a pantry for the kitchen. So, oddly enough, we actually removed some window that was in the door. But I think just a nice use of materials here really brightens up the space. We also added a lot of lighting. You’ll notice a lot of those pot lights are centered right on the cabinet. You can see with the way the light splashes down the millwork. We do a lot of thinking and planning on how lighting is going to impact the space. Sometimes you see these lights that just kind of come down in a strip in the middle of a room. And really, what that’s going to do is make the room, in my opinion, feel smaller because you’re just going to brighten up the space right in the middle and create these shadows on the outside. So what we opt to do is push those pot lights to the outside and really brighten up the outside of the room, which then makes the room feel bigger. And, in this case, you’ve spent all this money on this beautiful millwork. It’s crazy if you’re not going to put the pot lights in the right space to highlight it evenly and as much of it as possible.

We will always recommend to bring in an interior designer on our projects because there’s a lot to think about when you want to be picking hardware, flooring, cabinetry, stain, countertops, plumbing fixtures, paint, trim, mouldings, you name it. The particular designer we work with here, she does a great job putting these packages together with a lot of renderings. We nailed it. It looks just like what the renderings look like. And the homeowner really just trusted the process. They met with our designer. They said, “You know what? You know exactly what we’re after. And we don’t even know exactly what we’re after, so just show us some things.” And she showed them basically this. And they just, they fell in love with it right off the bat. And then we were set a task to execute.

NOT A COOKIE CUTTER ANY MORE

by CCR Rebuild Remodel, London, Ont.

Our design team in house is quite, quite capable. She finished top of her class in the interior design program. We’ve been interviewing co-op placements to fill another spot that’s opened up. With design, they have decorating, they have architectural technologists on the other side, and then they have interior design in the middle. The designer who did this, she went through the architectural technology program and she just has a knack for interiors and picking all these things. So she actually does more of our blueprints and our permitting plans and working with engineers and HVAC designers and doing detailing on how these projects come together. I look at it as they are the efficiency team and kind of part of the sales team and they’re part of the production team. Erin will create beautiful rendering packages so she can showcase what’s possible so homeowners will feel more comfortable. You know, it’s not like test driving a car. You can run out for a weekend and try a bunch of different models. Your house looks like what it looks like and we have to try to explain what it could look like and then shock you with a bit of a price. So you’re going to have to see something to get more comfortable with the investment. Erin does a great job with this on the sales side of it. But then from an efficiency standpoint she does really good job detailing how to build so when she hands it off to production they can do an amazing job budgeting it and scheduling it all well ahead of actually getting into the space.

What about this millwork, this two-tone kitchen? We do a lot of those and honestly, they’re all different. Every kitchen is different. We really try to feel out the client. I would say it’s going more modern. We see a lot of dark. Ssometimes it’s black and then white oak. And sometimes we’ve had green, dark greens and different other walnuts and all that type of stuff. We do quite a few that are all solid white with maybe a blue island. But really what it is is trying to figure out what’s going to look great in the space. What is the client really hoping for? Is it transitional, modern, traditional? Scandinavian is –you see a lot of this white oak type of stuff – but if it’s a whole bunch of white oak it just gets heavy, depending how you’re doing it. So mix it up with another colour. In this case, the white really brightens this space.

If we look at like the old kitchen versus the new one, it’s so much lighter. I believe we made the window over the sink a little bit larger. Light makes it seem bigger. I’ve always been really passionate about highly optimized housing. Once you experience that then you’re going to be telling all your friends, “I can’t believe how comfortable my house is now.” They actually brought it up to us. So there was an easy sell with them.

ONE

I think this is just a special space where you’re not having to put wallpaper on a big old wall like a lot of powder rooms. I think it’s the perfect space, depending on the style of the reno, to put, something really fun and creative. And I’m trying to remember what was there but it was like squirrels and little woodland creatures. You go in there and it just feels like a such a cool, unique space. The powder room, to be honest, is the is the most important bathroom, in my opinion, in the whole house. That’s what your guests come to see. I would put more money per square foot in in a powder room than my own master ensuite.

We do everything fully custom for the client and we’ll do things that…well, we just put a kitchen in that was golden oak. Like, I’m shocked. But the homeowner really wanted that. I asked the production team, “Hey, how’d it go?” and they said, “Well, it looks like it did before we started.” So to the homeowner, that was timeless. They just wanted to replace the cabinets. I guess where I’m going with this is that we work with people who have more Asian influence, more traditional, American influence, more of the Scandinavian influence, a lot of Shaker. But then there’s also a lot of just flat slab millwork. It’s really all over the place. I feel like, if you are going to build a house 15 years later you might want to change your style. But if you wanted to go sell it, you want it timeless because someone else is going to come in there and be like, “Oh, look at these amazing cabinets!” As long as they’re durable and they’re not having wear that looks obnoxious. We’ve been doing so many different styles over the years that we’re at a point where maybe we might get trendy with Shaker. Good quality is timeless and that’s really what we push for.

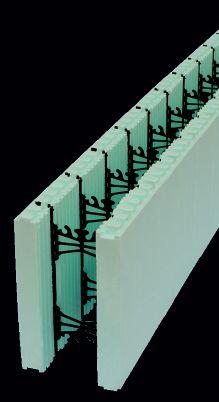

Nudura® ICFs offer the most user-friendly system on the market with a single source for a leak-free wall assembly. Get ICF forms, bracing, waterproofing, sealants, flashings and window/door bucks all in one place. Backed by the best warranty in the industry, Nudura also provides fast, local jobsite support and access to North America’s largest Authorized Distributor network. 866.468.6299 | nudura.com

These are definitely my favorite customers because they gave me a vision of what they wanted and then they said, “Create that for me.” And so I did a lot of research, looking in the magazines, looking at what they’re doing in these high-end New York lofts and I found a picture very similar to what this island is. And I thought it looked so good in terms of distinguishing your work area and your eating area, but it made them compliment each other. It’s because of how they were wrapped together. It didn’t feel like one stopped and one started. It feels like they flowed together. She said she wanted a modern kitchen. She wanted lots of space to entertain. She wanted an open concept. Wanted to keep the fireplace as a focal point and then really utilize the space better. So she gave me those parameters but I had a lot of leeway in terms of what materials we were going to choose, what options for the countertop material, the design of the fireplace, a lot of that. And then we went back and forth and we settled on each individual item with her but being able to create that initial look, I think, helped set the tone for her and me picking out everything.

I think the choice of a walnut and that more earth-tone brown really helped set this off to be a little bit more cozy versus some of the paler woods. What we really wanted to bring in is a little bit of nature. There is a lot of good lighting. I find that the lighting is often overlooked other than the decorative lights. But on this one here, we had under-cabinet lighting. We had kick lighting. We had pot lights and we had decorative lighting. So lots of different options. It sort of gives that nice, bright look and you can actually feature some of the nice wood that we had in there.

They liked that large living space with the spiral staircase. She liked having her office up there, but the kitchen for her felt very closed in. She had lots of storage in it but she just felt like it wasn’t connected to the rest of the main living area. That’s something she really wanted to be able to do, is to cook, to prep food and yet still be able to have a conversation with somebody at a seating area right or across the room.

FIRST CLASS FINESSE

by Lyle Woodward, Strongwood Construction, Medicine Hat, Atla.

Lyle Woodward of Strongwood Construction spoke to Gord Wornoff about “First Class Finesse” – a finalist for the 2025 CHBA Best Whole Home Renovation $300,001$500,000 award. The project is in Medicine Hat.

She said, “I want something that I can put my plants on, you know, my display things. But I want to let all the light in from that side.” And she suggested that I just put a storage shelf and make it look good. And so I took that idea but did some research and how could I incorporate it into the design of the kitchen so that it looked like it belonged, versus just another piece of furniture that was put there.

In almost every conversation I have on a job, I’ll always mention that my crystal ball is being fixed. I don’t have it in front of me. So I would love to say that these trends are going to last for 10, 20, 30 years but you really have no idea. I do my best to follow European trends because typically it’s from Europe to the east coast to the west coast and then the prairies. We’re the last to get it. And so [it’s good] being able to see what’s coming down the pipeline. If floating shelves, for example, are not being used anymore then I can now say, well, let’s go to something different. Let’s see what other people are doing here in terms of that timeless design. It’s something that is probably white cabinets. It’s the backsplash. I call it geometric monochromatic. So we’re not pulling out crazy colours but we’re giving it that nice texture. So a white herringbone with white grout. We’ve got lots of texture there but that pattern has been around forever.

A lot of people, when they see this say that must have been really expensive because it’s walnut. The only actually true walnut is the table. Everything else is a vinyl wrap. That’s MDF with vinyl. It’s called super real walnut and, even up close, you really can’t tell the difference. We love the product because it’s very easy to clean. It’s much less expensive. We can do virtually anything with it in terms of creating these shapes. It’s on three-quarter MDF panel, so warping, twisting and cracking we don’t have to worry about. It’s a material that I think is very much for the modern household where we don’t want to do a lot of maintenance.

FIRST CLASS FINESSE

by Lyle Woodward, Strongwood Construction, Medicine Hat, Atla.

I’ve got a fantastic team. We’ve got on staff a journeyman carpenter and an electrician. We typically sub those out, though. But I’ve got a cabinet maker, a tile setter, a journeyman carpenter –someone to fill as many niches as we can so that we have control over the final product. I think there’s a little bit more care and attention to detail when you know you’re working directly for your boss versus working for a contractor who is working for the customer.

The fireplace on the main floor is exactly what it looks like in the basement. They just continued that all the way up and through the ceiling up to the roof. So we demolished it piece by piece, brought it all down, and then we had to keep the basement fireplace still functional – which was an open air gas fireplace that we eventually converted to electric. And then try to get ours in with piping and, yeah, it was interesting. So it was a lot of work to get all the pieces put together but I think it’s a really nice focal point of that whole main area. Something we were really worried about was actually how the roof was being held up. We had an engineer come in and sort of confirm that, but no, we were good to go. We were concerned that once we took out that middle wall and took out all the brick of the fireplace, was the girder truss going to sink on us? It was a nice surprise that it didn’t, it’s going strong. The amount of brick that we had to remove was pretty incredible.

I actually brought in a full time designer. We had worked together on a few projects, and then I brought her on staff, and she worked for us for two or two or three years. So I was able to learn a lot from her.

I was able to learn how the colours work together, how materials work together. Her favourite design was a mid-century modern type of home. But she was able to put together some out-there ideas so that gave me the confidence that when she left to take over the design side of things.

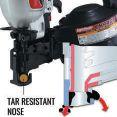

THE PROS CAN ALWAYS COUNT ON MAX TOOLS

EQUIPPED WITH A TAR RESISTANT NOSE

Tar resistant nose is designed to resist tar 8X longer than conventional tools. When necessary, the SuperRoofer®’s contact foot is easy to remove, clean and is also inexpensive to replace.

What caught our interest

STUFF WE LIKE

CALMING KITCHENS

nobilianorthamerica.com

Nobilia North America says biophilic-inspired interiors that make us feel safe, calm, and comfortable continue to perform strongly in homeowner and renter markets. It points to ASID’s 2025 Trends Outlook report that calls outdoor integration a trend redefining the future of interior spaces, helping residents foster a closer connection to nature. Natural and sustainable elements such as ecofriendly, recycled materials and earth-coloured finishes are hot trends in residential and multifamily housing designs, appealing to societal trends prioritizing health and wellness. In response to these preferences, Nobilia has introduced two solid earthy shades (Premium Honed Olive, Sky and Black) to Senso, its lacquer front line and two vertically grained wood decors (Como Oak and Milano Walnut) to Structura, its popular melamine range. Senso and Structura finishes are applied to Nobilia’s German-engineered cabinets designed for use in kitchen, bathroom and living spaces. A PEFC-certified manufacturer, Nobilia makes each cabinet using a high proportion of recycled material and wood sourced from sustainable forestry. Olive, a serene green and Sky, a soft blue, are newly available for Senso lacquer fronts, coated with Nobilia’s anti-fingerprint technology which reduces smudges and the need for constant maintenance. Como Oak reproduction adds a fashionable eye-catching elegant natural look to the Structura range while the new Milano Walnut reproduction offers a distinct modern flair to any space.

Drawing inspiration from Scandinavian design, the new Iver bathroom suite from Moen boasts warm minimalism made to compliment any modern space. Defined by its classic geometric forms, Iver offers a thoughtfully curated esthetic that is sure to draw the eye of contemporary enthusiasts. Central to Iver are the bathroom faucets, available in single-handle, two-handle centreset and widespread platforms. The high-end bath fixtures’ stacked elements and sleek lines intersect with precision to present modern appeal, while the softened corners convey a more approachable look. The flat, rectangular-shaped handles allow for easy water adjustment and with an aerated flow, everyday bathroom tasks like brushing teeth and washing hands are effortlessly completed with optimal efficiency. The suite is available in a variety of finishes, including Chrome, Lifeshine Brushed Nickel, Matte Black and Lifeshine Bronzed Gold, offering options to compliment any design preference. To further elevate the contemporary styling, matching bath and shower trim kits, along with bathroom accessories such as a robe hook, towel bars, a towel ring, a paper holder and lighting are available. Each piece is thoughtfully designed to create a cohesive, welcoming, yet refined look throughout the bath. The bath faucets also meet EPA WaterSense criteria, with various Eco-Performance showering options available to ensure sustainability remains a priority without sacrificing performance. The M-Core universal valve system allows for functionality updates without changing the valve behind the wall.

SCANDINAVIAN COOL moen.ca

BULLETPROOF TOPS wilsonart.com

From the beauty of natural stones and woodgrains to the soft elegance of textileinspired patterns and the clean sophistication of solid colors, Wilsonart has drawn from nature’s most awe-inspiring elements to introduce 16 new surface designs to the Wilsonart Thinscape Composite Tops collection. The new designs offer a fusion of durability, performance and the beauty of the natural world to homeowners, designers and architects seeking to elevate their spaces with long-lasting, versatile surfaces. Thinscape features a sleek, European-inspired profile that pairs well with modern spaces by combining beautiful esthetics with innovative engineering and everyday durability. Performance is not sacrificed in the countertop’s ½-inch thick, ultra-thin and stylish profile; instead, it offers exceptional performance with resistance to impact, scratches and moisture. It’s easy to clean, stain resistant and will never require sealing, and is available with a colour-coordinated core and an edge that’s easy to fabricate with common woodworking tools. Because Thinscape can be used for different elements within a single project, it creates consistency in both design and performance. The new introductions are ideal for surfaces such as countertops, bath vanities, tabletops, bar tops, reception areas and kitchen/break rooms. Thinscape comes in a variety of textures including stoneinspired, wood-inspired, textile and solid. They meet rigorous emissions standards, earning UL GreenGuard Gold certification for low chemical emissions, ensuring improved indoor air quality. The collection also features the International Living Future Institute (ILFI) Declare label, including the declaration status of “Red List Approved,” making it a sustainable solution.

MIX THAT STUCCO

indco.com

Indco has introduced the M-2000 series turntable-style tabletop mixer that rotates a one- to five-gallon pail while mixing with a stationary paddle that scrapes the side and bottom providing a radial and axial action. With a ½-horsepower single-phase motor and a mixing angle that adjusts from zero to 15 degrees, these heavy-duty pail mixers are ideal for high-viscosity materials. The zinc-plated carbon steel paddle is quickly removable for cleaning and inspection. All units ship fully assembled.

PASS THE AIR, STOP THE SOUND

New solutions promise a better indoor environment.

By Vick Yau

Goodindoor air quality requires robust airflow within the home. Adequate home ventilation ensures a consistent supply of fresh air while diluting stale air, which accumulates pollutants over time. According to the U.S. Environmental Protection Agency (EPA), people spend about 90 percent of their time indoors where air quality can be two to five times more polluted than outdoor air. Alarmingly, the average person receives 72 percent of their chemical exposure in the home. These pollutants may stem from occupant activity or contaminants inherent in the products and materials present within the building. Common contaminants include carbon dioxide, volatile organic compounds (VOCs), particulates, mould, toxins, odors and gases.

Building envelopes have also become more airtight. Leaky building envelopes can no longer be relied upon for adequate air exchange, placing more emphasis on ventilation design. An airtight envelope coupled with a lack of adequate ventilation can worsen IAQ and negatively impact health.

In addition to improved air quality, increased air circulation better manages temperatures throughout the home and prevents pressure imbalances between rooms when doors are closed. The overall impact is a healthier, more comfortable living environment and lower heating/cooling costs with less wear and tear on the mechanical systems.

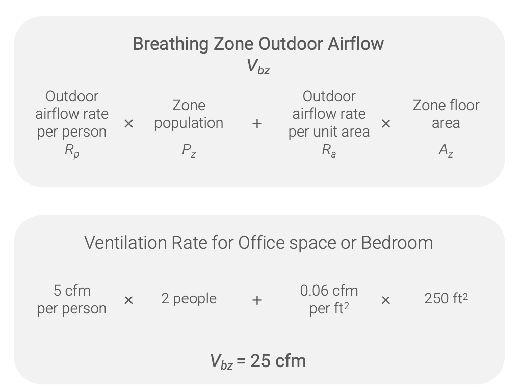

Understanding ventilation rate calculations

The American Society of Heating, Refrigerating and AirConditioning Engineers (ASHRAE) standard 62.1 specifies minimum ventilation rates and other measures intended to provide indoor air quality that’s acceptable to human occupants and that minimizes adverse health effects.

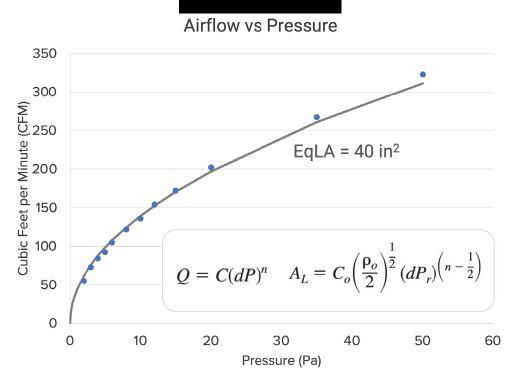

The American Society for Testing and Materials (ASTM) International E779 standard is another essential tool. It is useful for home construction and code compliance as it determines the air leakage rate of building envelopes. It can also be adapted to characterize the performance of individual ventilation components including grilles, louvers, cutaways, and other solutions. The test method involves pressurizing a source room and measuring airflow and pressure drops through the test sample at different fan speeds. The resulting airflow, measured in cubic feet per minute versus pressure, determines the equivalent leakage area for ventilation components.

Understanding sound transmission

Every ventilation opening transmits sound. Sound waves travel through gaps and cracks with little energy loss. The ASTM E90 and E413 standards are used to determine Sound Transmission Class (STC) ratings. The test method requires two reverberant rooms separated by the test sample. White noise is played across a broad frequency in the source room, and sound level measurements are taken in both rooms. Transmission loss is the reduction in sound levels from source to receiver room and it is plotted over frequency. The STC rating for a composite wall, comprised of several elements, is often limited by its weakest element – frequently, the door and door seals. A door comprising only 25 percent of the surface can reduce overall STC by 45 percent.

Primary

residential ventilation strategies

Residential ventilation strategies include passive and mechanical approaches. Passive ventilation relies on the home’s natural air pressure differences to allow air to infiltrate through planned penetrations such as transfers and door undercuts. The limitation is that these systems lack control. Mechanical ventilation uses fans to drive air through

To measure air leakage, data points are plotted at different fan speeds.

ducts. It is controlled and consistent, but requires energy use and maintenance.

Transfers

Transfers, common in commercial buildings, are gaining use in home applications, especially in residential structures designed to be more airtight. As the name suggests, transfers

An equation is applied to generate the leakage by surface area.

exchange air between adjacent spaces. With a t-bar or dropped ceiling, the plenum – the space between the dropped ceiling and structural ceiling – is used to house the transfer. While effective in transfering air, not all residential structurers offer plenum areas for the physical transfer. In addition, without any attenuation, sound easily transmits to the adjacent space, an acoustic effect known as “cross-talk.” A telltale sign of poor sound privacy is the obvious presence

25_003448_Canadian_Contractor_JUN_CN Mod: April 22, 2025 10:44 AM Print: 04/22/25 page 1 v2.5

of light within the transfer space. The acoustic impacts are a significant downside to transfers.

Door grilles

Door grilles are also most common in commercial spaces but can appear in residential homes. They’re primarily used in mechanical and utility rooms with furnaces, water heaters and laundry appliances, as well as spaces requiring make-up air for exhaust fans.

While effective in creating passive airflow, grilles are typically located near the floor where the hard surface reflects the sounds of appliances in mechanical and laundry rooms into living spaces. The approach is also esthetically brutal – the cutting of a square or rectangular hole in the door. Door grilles also have the distinct downside of transferring sound to adjacent living areas, decreasing sound privacy.

Door undercuts

Creating undercuts at the bottom of interior doors is perhaps the oldest and least refined solution to creating airflow. While a simple, quick fix, undercuts offer poor acoustics and compromised esthetics. Undercuts make doors look poorly fit, allow light penetration and do not hide flooring transitions.

The acoustic impact of door grilles and undercuts is significant, as STC ratings decline dramatically when door material is removed. For instance, a fully sealed solid-core door with no undercut has a 29 STC. A 1/2-inch undercut drops that to 18 STC and a 12-by-12-inch grille takes it all the way down to 14.

Mechanical systems

Managing airflow within the home can also be accomplished using fans and ducts. Unlike passive airflow solutions, mechanical systems require energy,

have an ongoing operational cost, create noise and can eventually suffer breakdowns. But in the airtight homes built to today’s higher energy-efficiency standards (Net Zero, Passive House), mechanical ventilation is a must. These systems cost money up front and opportunities to limit the amount of mechanical equipment installed are welcome to builders. Better internal airflow and pressure equalization helps builders to downsize the mechanical system and ducting and achieve higher levels of home energy efficiency with less rework of walls, ceilings and floors.

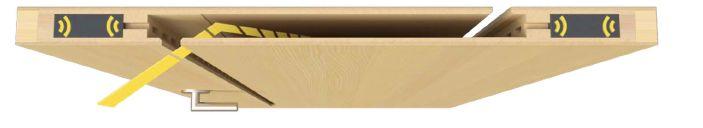

Innovative new designs

A newer approach has been introduced for air transfer that addresses the typical compromises between passive airflow, esthetics and acoustics. The patented door design on this page creates a passive airflow channel within the door itself using vertical slots on both faces. Air passively balances throughout the home, potentially reducing mechanical ventilation requirements. And the doors can be easily hung in existing homes that have indoor air quality concerns. The internal baffles significantly improve acoustic performance. This door design has been tested to a 26 STC, despite being hollow. The vertical slots offer a clean, modern look – much superior to undercuts and louvers.

Conclusion

A thoughtful approach to indoor air quality is becoming more and more important in the design of indoor spaces. Designers, builders, and homeowners alike must weigh their priorities, but improving each element supports better indoor environmental quality, creating homes that are not only healthier but also more comfortable and refined.

Vick Yau is the cofounder of VanAir Design, a Burnaby, B.C.,-based manufacturer of interior doors featuring a patented, built-in passive air transfer system.

This door design allows air pressure to equalize through the closed door while still blocking sound.

The air channel in the door actually enhances the look of the door, unlike grilles and louvers.

PEACEFUL LIVING IN COMPACT SPACES

Minimize noise transfer between rooms with QuietZone® Acoustic Insulation from Owens Corning.

JUST DO IT

IT’S TIME FOR ACTION

by Richard Lyall

Withthe election over, Ontario governments must fully turn their attention to tackling the critical housing supply and affordability crisis. The Ontario residential construction industry is in dire straits due to a combination of complicating factors. The political brain trust have fully grasped this fact and announced measures to build more homes. Now they must act.

For starters, I’d like to see them announce they are cutting red tape, unlocking land, slashing unfair costs on new housing like sales taxes, levies and development charges, and speeding up the development approvals and permitting systems so that the new homes can be built faster.

Having represented the residential construction industry in Ontario for the better part of 34 years, I believe the ratio of housing costs to incomes must also revert to 4:1 from the current ratio of 9:1. We must ensure that the dream of an affordable home is again within reach for every family. Bringing down the cost of housing is essential to our economic well-being. Two recent reports on population change and interprovincial migration indicate that young people are fleeing every province but Alberta in droves. In 2024, 8,094 left Ontario while Alberta gained 18,413. Lack of effective action to address housing affordability is one of the big reasons they are leaving. For the other provinces, the exodus means fewer workers and new home purchases and

reduced economic development, not to mention the loss of talent.

A report released by the Missing Middle Initiative (MMI) has highlighted the need to increase the rate of homebuilding in the Greater Toronto Area significantly, particularly when it comes to ground-oriented housing and larger, family-sized units within multiresidential developments. The report, commissioned by the Building Industry and Land Development Association and the Ontario Home Builders’ Association (OHBA), estimates the GTA will need 30,000 new ground-oriented homes and 20,000 new apartment units built each year in order to keep up with the demographic shifts. It’s a tall order indeed. But the costs of doing nothing are troublesome.

In a LinkedIn post recently, Murtaza Haider, a professor of data science and real estate management at Toronto Metropolitan University, noted that average household incomes have not kept pace with the increase in housing prices and the fundamental challenge is a lack of adequate supply. He wrote that an earlier report done for the MacDonald Laurier Institute highlighted that the rate of housing construction relative to population declined by nearly half from the 1970s to the early 2000s. To address the current crisis, he stated that Canada must build far more homes annually than it has over the past decade. Raising the annual construction rate to 350,000 homes, including a mix of low-rise housing and not just high-rises, is essential to tackling the affordability

crisis.

Sadly, another report done for the OHBA found that 11 of 26 municipalities analyzed in Ontario were “completely unattainable” for middle-class households. Meanwhile, young people in Ontario are spending more than 40 percent of their monthly income on housing in many areas. This can not be allowed to continue. The housing crisis must be at the top of the to-do list for politicians. We are at a breaking point. The stratospheric rise in home values has priced many families out of the market. Home prices have doubled across Ontario over the past two decades, yet real wages have only increased by 16 percent. In 2005, there were only three of 26 markets in southern Ontario where a middle-class homebuyer of a single-family home would have to pay 25 percent or more of his or her pre-tax income on mortgage payments. Today, this is the case in all 26 markets.

Nationally, in March, actual housing starts were down 12.5 percent yearover-year in centres with a population of 10,000 or greater. There were 14,924 housing starts recorded in March, compared to 17,052 in March 2024, according to Canada Mortgage and Housing Corporation. In Toronto, meanwhile, housing starts in March declined 65 percent over the same month in 2024. The condo market has been hard hit, particularly in the Greater Toronto and Hamilton Area. A recent survey by Urbanation reported that only 533 condos were sold in the first quarter of this year – their slowest point in more than 30 years, with a 62-percent year-over-year decline.

An Ipsos poll conducted last year indicated that 45 percent of Canadians don’t believe they’ll ever be able to afford a home, regardless of interest rate cuts. Data like this shows the urgency of the situation.

Richard Lyall is president of the Residential Construction Council of Ontario (RESCON). He has represented the building industry in Ontario since 1991. Contact him at media@rescon.com

RESULTS!

Crafted with ALIGN® Composite Cladding—these successful projects are a showcase of stunning work.

The results are in! And wow, did our first ALIGN ® Composite Cladding contest deliver! With so many standout entries, these three earned the spotlight with projects that are a showcase of bold design, expert execution and undeniable curb appeal. ALIGN ® brings the look, performance and ease of installation pros rely on—and homeowners love for years to come.

1ST PLACE: ERIKA GARAND, ARCHITECT

Modern rustic. Stunning views. ALIGN® Board & Batten in Iron Ore makes a bold first impression—and a lasting one.

“THE

1001 Corporate Drive | Burlington, ON L7L 5V5 gentek.ca | Make us a part of your home.

RUNNER-UP: H.E. CARPENTRY

Clean lines. Farmhouse charm. Snow White ALIGN® proves timeless never goes out of style.

RUNNER-UP: O’MALLEY HOMES

Big texture. Bold color. Hudson Slate ALIGN ® transforms this home with striking contrast.

Ready to create a winning look of your own? To learn more about the benefits and features of ALIGN, check out our website or scan the QR code. gentek.ca/align

H.E. CARPENTRY O’MALLEY HOMES

PAIN AVERSION

Alex’s employee, Dan, tore some tendons in his shoulder in a fall on a jobsite. He needed surgery followed by six weeks of recovery and physiotherapy before he was able to return even in a reduced capacity. Alex has had him doing paperwork, running errands and light jobs around the sites in accordance with a back-to-work plan arranged with his provincial worker’s compensation board. That plan included a date where Dan was expected to be able to return to full job duties. That date went by a week ago, but Dan is still not at full speed.

He’s complaining that the shoulder still hurts, even though the doctor says it’s fully healed. The WCB case worker is saying manageable levels of pain are not a reason to not work and they won’t restart benefits for this injury. The physiotherapist says the shoulder needs to be used in order to restore it to full function. Alex suspects the real problem is that Dan was traumatized by the injury and is now afraid to hurt the shoulder again.

Alex knows it is illegal to simply let Dan go because of his injury. Plus, he was a good worker and he needs him back on the job.

Q1 Winner: David Tucker, Tucker Homes

Vince was pondering whom to vote for in the Ontario election and David Tucker won our Q1 contest with this erudite advice. However, it looks like Vince didn’t listen, as the Ford government was been returned with an historic third straight majority. No matter, David won the draw and takes home a DEWALT 20V Drill with New Tabless Battery Technology!

Ford has no problem centralizing government power for things like bike lanes and municipal council size for Toronto, but shies away from reforming planning and development charges and claims it’s difficult and makes municipalities the scapegoat, rightfully so. However, municipalities are a product of the province and reform is possible if the governing party had a back bone and wasn’t afraid of NIMBY politics within their own ridings. Ontario’s own statistics prove that our province is a failure on housing and we need the Ford government to own that so it can be fixed. So, I’d tell Vince to vote for the party with the best policies that will impact his business. The platforms and results from last seven years shows it is anyone but the PC’s, but I would actually rank the Green party as the best on housing policy.

What should Alex do?

1. Make a permanent position for Dan where he doesn’t have to test the shoulder. Even though he doesn’t really need someone in that role.

2. Complain to the WCB that Dan has not completed his back-to-work plan. If they find a worker is not cooperating with a plan, they will eventually authorize the employer to let them go.

3. Offer Dan some incentive to push himself harder.

4. Pay for additional physiotherapy for Dan.

5. Give Dan a stern talking-to telling him that he’s all better now and there’s no room for wimps in this company.

6. Just wait. Dan will get there.

7. Something else?

HOW

TO ENTER

Email your answer to Alex’s Dilemma to pflannery@annexbusinessmedia.com by June 30 to be entered for a chance to win!

Entries close June 30. The winner will be announced online in July.

YOU COULD WIN

The 20V MAX GRABO Lifter has a lift-load capacity of up to 265 lbs. The lifter utilizes a powerful electric vacuum pump to lift a wide range of heavy construction materials. Retail price: $449.99.

DEWALT 20V Grabo Lifter Kit

TIME TO SHINE

JWC8500 HYBRID WINDOW FEATURES:

26% LOWER PROFILE FRAME FOR EXPANDED VIEWS

UP TO 22% BETTER ENERGY EFFICIENCY

DURABLE VINYL AND ALUMINUM CONSTRUCTION, RESISTING WEATHER AND DAMAGE

ALUMINUM-CLAD EXTERIOR, OFFERED IN AN ATTRACTIVE SELECTION OF COLOURS

Welcome in the beauty and brightness of spring with JELD-WEN®’s newest addition to the JWC8500 window series. This innovative window offers exceptional energy efficiency, a low-profile design and remarkably robust frame. This intentional engineering gives you cool, comfortable, and quiet interior spaces, expansive views and long-lasting performance. Our newest JWC8500 hybrid option exceeds performance, in all regions of Canada, offering an aluminum-clad exterior finish with an exquisite selection of colours to choose from.